Page 1

DR® ALL-TERRAIN® FIELD and BRUSH MOWER

Safety & Operating Instructions

Please read through these Operating Instructions and the Engine Manufacturer’s Owner's Manual to

become familiar with the basic features of the DR

before operating it.

®

ALL-TERRAIN® FIELD and BRUSH MOWER

Page 2

Page 3

And congratulations on your purchase of a new DR

®

FIELD and BRUSH MOWER!

We have done our utmost to ensure that your DR

®

FIELD and BRUSH MOWER will be one of the most

trouble-free and satisfying pieces of equipment you

have ever owned. Please let us know of any questions

or problems you may have. We want to answer or

correct them as quickly as possible. (When you do call

or write, please have your serial number and/or order

number handy—it will speed things up!) We also hope

to hear from you on how much you like your new

helper.

And, please tell your friends about your new DR

®

FIELD and BRUSH MOWER! Having DR® Owners

spread the word about our products and our way of

doing business is the best advertising we can have, and

the best way to help us provide even better service in

the years to come.

Thanks once again!

for all of us at...

COUNTRY HOME PRODUCTS

®

Page 4

We Want You to be Totally Satisfied

The DR® FIELD and BRUSH MOWER is designed to provide year after year of trouble-free

performance. To ensure that you are totally satisfied with this important purchase, we offer the

following three-part Assurance of Satisfaction:

1. THE DR® FIELD and BRUSH MOWER is GUARANTEED FOR ONE FULL YEAR against

defects in materials and workmanship in consumer use. If you believe that a part is defective,

please write or call us immediately. We will do our best to remedy the problem, including

repairing or replacing defective parts as quickly as possible. In rental and commercial use the

machine is guaranteed for 90 days. The engine is guaranteed separately by the manufacturer:

Kawasaki Engine: Two years in consumer use, two years in commercial use.

Tecumseh Engine: Two years in consumer use, one year in commercial use.

Briggs & Stratton 10.5 HP Engines: Two years in consumer use, one year in commercial use.

Briggs & Stratton 8.0 HP Engines: Two years in consumer use, 90 days in commercial use.

2. IF WITHIN THE FIRST 30 DAYS of actual hands-on use you have questions or you are less

than 100% satisfied with your DR® FIELD and BRUSH MOWER, please write or call us at 1800-DR-OWNER (376-9637). We'll do everything possible to answer your questions or make

things right—even if it means that you return your DR® FIELD and BRUSH MOWER for a full

refund of its purchase price, shipping costs included. (Refund on shipping is for standard

method, and applies to the contiguous United States and Canada only.)

3. We operate, for our Owners, a 7-Day-a-Week Customer Service Department with well-trained

and friendly folks whose sole job it is to ensure that you get any help you need...parts that need

to be replaced...or questions answered courteously and as promptly as possible.

For future reference when dealing with your warranty, save the packing list from the outside of

the DR® FIELD and BRUSH MOWER box and keep it in a safe place. Also, please fill out the

information below.

Name Purchased Under: _____________________________________________

Order Number: __________________ Serial Number: ____________________

Date Purchased: _____/_____/_____

Page 5

Table of Contents

SAFETY INFORMATION............................................................................................................. ...................................3

D

RESS APPROPRIATELY....................................................................................................................................................3

P

REPARATION...................................................................................................................................................................3

O

PERATING THE MACHINE SAFELY ..................................................................................................................................3

ARNING TO ALL CALIFORNIA AND OTHER USERS.........................................................................................................4

W

BEFORE STARTING........................................................................................................................................................5

C

HECK THE OIL AND ADD GAS.........................................................................................................................................5

C

HECK THE TIRE PRESSURE..............................................................................................................................................5

CONTROLS & FEATURES.............................................................................................................................................6

OPERATING INSTRUCTIONS.......................................................................................................................................7

B

EFORE STARTING THE ENGINE........................................................................................................................................7

S

TARTING THE ENGINE .....................................................................................................................................................7

E

NGAGING THE WHEEL DRIVE.........................................................................................................................................7

E

NGAGING THE BLADE .....................................................................................................................................................7

S

TOPPING THE BLADE.......................................................................................................................................................8

S

TOPPING THE ENGINE......................................................................................................................................................8

OCKING THE WHEEL DIFFERENTIAL...............................................................................................................................9

L

S

LOPES .............................................................................................................................................................................9

I

F THE MACHINE GETS HUNG UP......................................................................................................................................10

C

UTTING BRUSH & SAPLINGS ........................................................................................................................................10

R

EVERSE.........................................................................................................................................................................10

UTTING IN WET & HEAVY GROWTH ............................................................................................................................10

C

ENGINE MAINTENANCE............................................SEE ENGINE MANUFACTURER'S OWNER'S MANUAL

GENERAL MAINTENANCE.........................................................................................................................................11

L

UBRICATION.................................................................................................................................................................11

B

ATTERY ........................................................................................................................................................................13

B

ELTS.............................................................................................................................................................................14

LADE ............................................................................................................................................................................17

B

D

IFFERENTIAL ................................................................................................................................................................18

D

RIVE CHAIN..................................................................................................................................................................19

W

HEEL CLUTCH .............................................................................................................................................................20

B

LADE ENGAGEMENT CABLE .........................................................................................................................................21

T

RANSMISSION ...............................................................................................................................................................21

O REMOVE THE WHEELS ..............................................................................................................................................21

T

END OF SEASON & STORAGE....................................................................................................................................22

TROUBLESHOOTING ...................................................................................................................................................23

PARTS LIST.....................................................................................................................................................................25

MAIN FRAME ASSEMBLY...........................................................................................................................................27

WHEEL/AXLE ASSEMBLY..........................................................................................................................................28

HANDLEBAR ASSEMBLY............................................................................................................................................29

BRUSH MOWER DECK ASSEMBLY..........................................................................................................................30

WIRING DIAGRAMS..................................................................................................................................................... 31

DAILY CHECK LIST FOR THE DR

®

FIELD AND BRUSH MOWER.............................................BACK COVER

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 1

Page 6

2 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 7

Safety Information

We want you to enjoy years of productive use from your DR® FIELD and BRUSH MOWER. We

don't want you to get injured, so please take a few moments to read the following guidelines for

safely operating your new machine.

Dress Appropriately

· Wear safety glasses while mowing to protect your eyes from thrown objects.

· Wear shoes with non-slip treads when using your DR

have safety shoes, we recommend that you wear them. Do not use the machine while barefoot or

wearing open sandals.

· Wear long pants while mowing, and avoid loose clothing or jewelry, which might get caught in

brush or on the mower's moving parts.

· Use ear muffs or ear plugs to protect your valuable hearing.

· We recommend wearing gloves while mowing.

Preparation

· Read these Safety & Operating Instructions as well as the engine manufacturer's owner's manual

before you use the DR® FIELD and BRUSH MOWER. Become familiar with the controls,

engine and service recommendations to ensure the best performance from your machine.

®

FIELD and BRUSH MOWER. If you

· Inspect the area you'll be working in for hidden objects such as large rocks, logs, rope, wire,

garden tools, etc., and remove these obstacles before mowing. Mowing over such obstacles

could damage the machine and cause injury.

· Mow only during the daylight hours.

· Fill the gasoline tank outdoors with the engine off. Don't handle gasoline if you or anyone

nearby is smoking, or if you're near anything that could cause it to ignite or explode.

Operating the Machine Safely

· Keep bystanders at least 100 feet away from your work area at all times. Objects can be thrown

far from the mower and at great speeds. To be safe, do not operate the machine near small

children or pets, and never allow children to operate the mower. Disengage the blade and stop

the engine when another person approaches.

· Be sure all blade and wheel controls are DISENGAGED before attempting to start the engine.

Engage and disengage the blade a few times to get used to it before mowing.

· NEVER remove the shields from the mower, or alter the deck in any way.

· Keep your hands and feet away from the blade, belts, chains, blade pulleys, and concealed areas

while the engine is running. NEVER reach under the deck or grab hold of the deck deflector

when the engine is running.

· ALWAYS shut off the engine and remove the spark plug wire prior to making any adjustments

to the machine. If you have to stop to remove grass or debris from the underside of the deck,

always disconnect the spark plug wire first.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 3

Page 8

· The exhaust area on the engine becomes very hot. Allow the engine to cool before doing

maintenance or making adjustments.

· Keep combustible substances away from the engine when it is hot.

· When operating over uneven terrain and slopes, use EXTREME CAUTION and make sure

you're on firm footing at all times.

· Use extra caution when mowing in wet, slippery conditions.

· ALWAYS OPERATE THE MOWER FROM BEHIND. Never pass or stand on the discharge

(right) side or in front of machine when the engine is running.

· DO NOT, under any conditions, remove, cut, bend, weld or otherwise alter standard parts on

your DR® FIELD and BRUSH MOWER. This includes all shields and guards. Unauthorized

modifications can make the equipment unsafe and may void your warranty.

· While using the DR

When in doubt about the equipment or your surroundings, stop the machine and take the time to

look things over. Make sure that you have 100% control of the mower at all times.

®

FIELD and BRUSH MOWER, don't hurry or take things for granted.

· Some state and local regulations require the use of a spark arrester on gas powered

engines. Contact your local fire marshal or forest service for specific information

pertaining to your area. If you are required to use a spark arrester, please contact one of

our Customer Service Representatives TOLL FREE 1(800)DR-OWNER (376-9637) for

assistance in obtaining and installing one.

Warning to All California and Other Users

Under California law, and the laws of some other states, you are not permitted to operate an internal

combustion engine using hydrocarbon fuels without an engine spark arrester. All DR® FIELD and

BRUSH MOWERS shipped to California and Washington state are provided with spark arresters.

Failure of the owner/operator to maintain this equipment in compliance with state regulations is a

misdemeanor under California law and may be in violation of other state and/or federal regulations.

Contact your local fire marshal or forest service for specific information in your area.

4 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 9

Before Starting

Your DR® FIELD and BRUSH MOWER is shipped completely assembled. Just CHECK THE OIL

LEVEL AND ADD GAS, and you're ready to go!

Supplies Needed:

· SAE30 HD (High Detergent) oil (if needed)

· fresh unleaded gas

Check the Oil and Add Gas

1. Place the machine on a level surface and check the oil level. Add SAE30 HD (high detergent)

oil if needed.

Note: The dipstick on the Briggs & Stratton and Tecumseh models needs to be screwed in

completely to get an accurate oil level reading.

The dipstick on the Kawasaki model should not be screwed in to get an accurate oil level

reading.

2. Fill the gas tank with clean, unleaded gasoline.

Note: See your Engine Manufacturer's Owner's Manual for more detailed fuel and oil

recommendations.

3. Open the fuel shut-off valve.

· On Briggs and Stratton models, the red fuel shut-off valve is on the fuel line near the bottom

of the gas tank (Figure 1). Turn the valve 90 degrees to open.

· On Tecumseh and Kawasaki models, the red fuel shut-off valve is on the fuel line near the

corner of the black chain drive box (Figure 2). Turn the valve 90 degrees to open.

Figure 1

Figure 2

Check the Tire Pressure

There should be 14 psi in each tire.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 5

Page 10

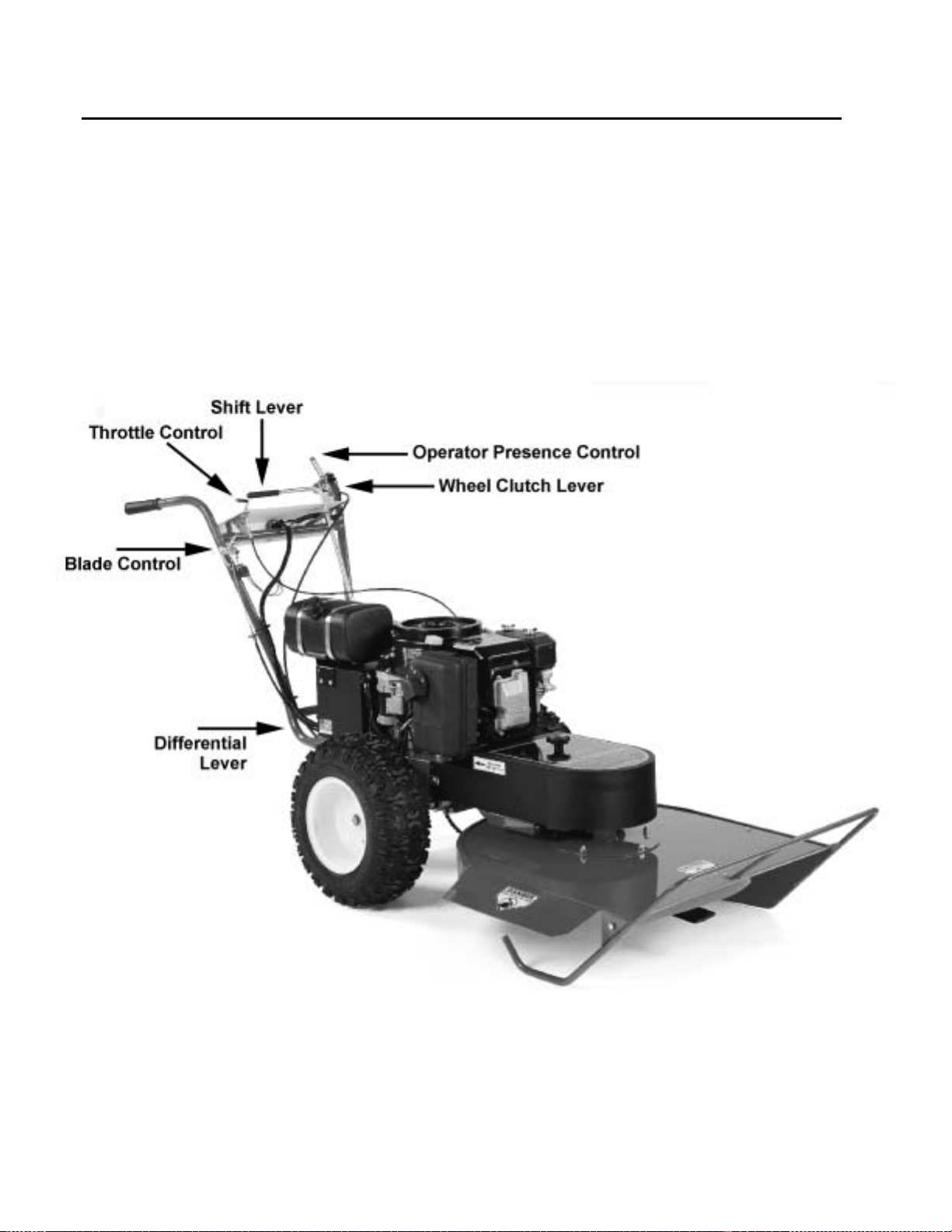

Controls & Features

Note: Kawasaki Model shown.

Figure 3

6 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 11

Operating Instructions

Before Starting the Engine

1. Check the oil level every time you use the machine.

2. Check the gas level.

3. Open the fuel shut-off valve.

Starting the Engine

Electric-Starting

1. Move the throttle to the CHOKE position (to the RUN position if the engine is already warm).

2. Turn the key to START and hold it until the engine starts.

3. Release the key, it will snap to the RUN position.

4. Move the throttle to the RUN position.

Manual-Starting (ATM10S Briggs & Stratton Model only)

1. Move the throttle to the CHOKE position (to the RUN position if the engine is already warm).

2. Turn the key to START.

3. Pull the recoil rope slowly until you feel resistance, then pull with a rapid stroke to start the

engine.

4. Move the throttle to the RUN position.

Engaging the Wheel Drive

The DR® FIELD and BRUSH MOWER has a four-speed forward transmission and single-speed

reverse. Forward speeds range from 1.4 mph in first gear to 4.3 mph in fourth gear. Use the lower

gears for mowing in thick, woody vegetation and the higher gears for wide-open areas and lighter

vegetation, or as "travel gears." Reverse is ideal for maneuvering in tight spots.

Note: Always release the wheel clutch lever when shifting gears.

1. Move the shift lever to the desired gear.

2. Gently squeeze the wheel clutch lever to engage a gear.

Engaging the Blade

1. Hold down the operator presence lever.

2. Engage the blade control lever.

Note: If you engage the blade control lever before holding down the operator presence

lever the engine will shut off.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 7

Page 12

Stopping the Blade

Push the blade control lever forward to OFF.

Note: Releasing the operator presence lever while the blade is engaged will cause the

engine to shut off.

Stopping the Engine

1. Push the blade control lever forward to OFF.

2. Move the shift lever to N (neutral).

3. Move the throttle control to IDLE.

4. Turn the key to OFF and remove it for safety.

8 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 13

Tips for Best Performance

Locking the Wheel Differential

In rough or wet terrain, or on moderate

slopes, you can lock the wheel differential,

so both wheels turn together with improved

traction.

To lock the wheel differential, move the

lever between the lower handlebars to the

right (Figure 4).

Note: When mowing with the wheel

differential locked you may find it more

difficult to turn and maneuver.

Slopes

· We do not recommend using the DR

FIELD and BRUSH MOWER continuously on slopes greater than 25 degrees. Doing so could

deprive the engine of oil and cause it to overheat.

®

Figure 4

· When moving across moderate slopes, in

ditches, etc., locking the differential will

improve traction (Figure 6).

· Note that the mowing deck pivots from side

to side (12 degrees in either direction),

which helps avoid scalping, and keeps the

weight balanced over the drive wheels when

operating on uneven terrain (Figure 5).

· Please read the safety information beginning

on page 1.

Figure 5 Figure 6

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 9

Page 14

If the machine gets hung up...

· Disengage the blade. Do not try to free

the machine from stumps or debris while

the blade is engaged.

· Try putting the machine in reverse and

backing away from the obstacle.

· Try pushing down on the handlebars to lift

the mowing deck over the obstacle

(Figure 7).

· If you need to leave the operating position,

first put the machine in "N" (neutral), turn

the engine off and disconnect the spark

plug wire.

Caution: DO NOT touch the exhaust

areas when reaching for the spark plug—they are very hot.

Cutting Brush & Saplings

· When cutting woody material, small

saplings, etc., allow the machine to ride

up and over material slowly. Adjust

your forward speed to varying conditions

(Figure 8).

Figure 7

· After cutting brush, etc., you may want

to mow over it again to remove any

remaining branches. It works best to

mow from the trunk end toward the top

as brush lies on the ground.

Reverse

Figure 8

· Be very careful of your footing when

operating the machine in reverse. Know

what's behind you and take your time.

· The blade will engage in reverse, however, we don't recommend continuous mowing in reverse.

Mow in the forward gears, using reverse for maneuvering.

· If you find it difficult to shift into reverse, lightly "feather" the clutch lever as you pull the shift

lever into reverse, then quickly release the clutch lever.

Cutting in Wet & Heavy Growth

· Be very careful of your footing when mowing in wet conditions. Avoid steep slopes and other

slippery areas.

· Use a lower, slower speed.

10 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 15

General Maintenance

For Engine Maintenance, Please Refer to the Engine

Manufacturer's Owner's Manual.

IMPORTANT: Because of the demanding conditions the DR® ALL-TERRAIN™ FIELD

and BRUSH MOWER is used in, air filters and oil should be changed more frequently

than is recommended in your Engine Manufacturer's Owner's Manual. Please follow

these recommendations:

Paper Air Filter: Should be replaced every 25 hours of operation.

Oil: Should be drained and replaced every 25 hours of operation.

Regular maintenance ensures the best performance from your machine. Follow these

instructions as well as the recommendations in the Engine Manufacturer's Owner's Manual

to keep your DR® FIELD and BRUSH MOWER in top condition. Use the daily checklist on

the back cover of this manual whenever you operate your mower.

!

WARNING: Some of the following procedures require access to the underside of the

machine. Before you tip the machine on its side with the discharge chute facing up, you must

drain the oil and gas, and remove the air filters.

Lubrication

Your DR® FIELD & BRUSH MOWER is greased at the factory. You do not need to lubricate it for

the first 25 hours of use.

Tools Needed:

· flexible hose grease gun

· Lithium grease

· FLUID FILM

!

WARNING: Always remove the spark

plug wire before servicing your machine.

®

or WD-40® lubricant

Grease Fittings

1. There are three grease fittings below the

black belt guard that need maintenance:

· The mower pivot tube (Figure 9)

should have 1-2 pumps of grease every

25 operating hours.

· The belt idler arm (Figure 9) should

have 1-2 pumps of grease every 25

operating hours.

Figure 9

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 11

Page 16

· The mower spindle (Figure 10) should

have 3-4 pumps every 100 operating

hours.

Note: Over greasing will cause grease

to leak out of the seals onto the mower

drive belt. Unless instructed otherwise,

pump only until you feel slight

resistance (1-2 pumps).

Figure 10

2. The following areas should be lubricated with FLUID FILM® or comparable lubricant every 10 to

20 operating hours—more often if the machine is operated in extremely dusty conditions:

· The differential fork at both ends (Figure 11).

· The axle above the hub where the spring is (Figure 11).

· The drive chain and the chain adjuster slide plate (Figure 12).

Figure 11

Figure 12

12 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 17

Battery

Electric-Starting Models

Proper care can lengthen the life of a battery. Follow these recommendations to ensure your

battery's best performance and long life:

· Do not allow the battery charge to get too low. If the machine is not used, the battery should be

charged every 4 – 6 weeks.

· Store an unused battery in a dry area that does not freeze.

· Do not charge an already charged battery. In theory, our battery can not be overcharged with a

trickle charger; however, when a battery is fully charged and the charger is still on, it generates

heat that could be harmful to the battery. A fully charged battery will read 12V-13.2V with a

voltmeter.

· Do not continue to crank your engine with a low battery.

Charging the Battery

If the battery loses its charge, you'll need to use a trickle charger (like the DR® Battery Charger) to

recharge it. The charger should have an output of 12 volts at no more than 6-8 amps.

· At 1 amp the battery may need to be charged for as much as 48 hours.

· At 2 amps the battery may need to be charged for as much as 24 hours.

· At 6-8 amps the battery will be charged in 2 to 3 hours.

Caution: At 6-8 amps a battery can overcharge.

Note: Using the recoil starter (ATM10E Briggs & Stratton model only) and then running the engine

will not recharge a dead battery.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 13

Page 18

Belts

To Remove the Blade Belt

Tools Needed:

· 1/2" socket with extension

· 1/2" wrench

· vise grip pliers

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. Remove the black belt guard: Unscrew

the black knob, lift the cover and pull up

and back to remove it.

2. Using a 1/2" wrench or socket, remove

the lock nut on the anti-rotation strap

and pull the strap away from the post

(Figure 13).

3. Rotate the clutch counterclockwise to

release the tension on the blade clutch

spring.

4. Remove the blade clutch spring (Figure

14). Remove the extension spring

(Figure 16). You can use vise grip

pliers to remove the spring or make a

simple wire pull as illustrated in Figures

15 & 16.

Figure 13

Caution: The extension spring (Figure

16) has considerable tension.

Figure 14

Figure 15

Figure 16

14 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 19

5. Remove the 5/16" x 2" cap screw from the

pivot tube (Figure 17).

6. Push the deck back to create slack on the

belt. Then pull the belt forward and drop

it down off the blade clutch pulley.

7. Twist the other end of the belt and drop it

off the 3" engine pulley (Figure 18).

8. Remove the belt.

To Replace the Blade Belt

Tools Needed:

· 1/2" socket with extension

· 1/2" wrench

· vise grip pliers

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. Keep the mower deck back and mount

the new belt over the two pulleys

(Figures 17 & 18).

2. Pull the mower deck forward.

3. Push the pivot washer back toward the

engine (it should be between the cap

screw and the frame).

4. Replace the 5/16" x 2" cap screw on the

pivot tube (Figure 17). Tighten until you

see 3-4 threads outside of the nut—do not

over tighten.

Note: If you can't get the cap screw

through the pivot tube, you can use a

piece of wood to push the deck forward

so the holes line up (Figure 19).

5. Replace the extension spring (Figure 16).

6. Replace the blade clutch spring

(Figure 14).

7. Replace the anti-rotation strap

(Figure 13).

Figure 17

Figure 18

Note: Only turn the nut on the antirotation strap until one or two threads

show—it is not meant to be tightened

down.

8. Replace the black belt guard and screw

Figure 19

the black knob into place.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 15

Page 20

To Remove the Drive Belt

Tools Needed:

· 7/16" socket

· 1/2" socket

· 5/8" wrench

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. Drain the oil and gas and remove the air

filters.

2. Remove the black belt guard. Unscrew

the black knob, lift the cover and pull

back and up to remove it.

3. Remove the blade belt. (Follow the

instructions on page 14.)

4. Turn the machine onto its left side, with

the discharge chute facing up.

5. With a 7/16" socket, remove the two belt

retainers from the 6" transmission pulley.

There is one on the rear of the pulley and

one on the side (Figure 20). Be careful not

to lose the retainers or washers.

6. With a 1/2" socket, loosen the two lock

nuts that hold the belt guide (2-3 turns,

don't remove them) and pull the belt guide

back (Figure 21).

7. Push the 2-1/4" clutch idler pulley to the

outside of the frame and start guiding the

belt off the 6" transmission pulley. Using a

5/8" wrench (on the Kawasaki use a 14mm

wrench), rotate the crankshaft bolt on the

engine clockwise (counterclockwise on the

Briggs & Stratton manual-starting engine)

while continuing to guide the belt off

(Figure 22).

Figure 20

Figure 21

Figure 22

16 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 21

To Replace the Drive Belt

Tools Needed:

· 7/16" socket

· 1/2" socket

· 5/8" wrench

!

WARNING: Always remove the spark plug wire before servicing your machine.

1. Mount the new belt over the 6" transmission pulley (Figure 22).

2. Place the belt in the belt guide and slide the belt guide forward, making sure it is under the flat

washers. Position the belt with a 1/16" to 1/8" space between the pulley and the belt guide.

Tighten the belt guide (Figure 21).

3. Replace the two belt retainers and washers on the 6" transmission pulley (Figure 20).

4. Reinstall the blade belt. (See the instructions on page 15.)

5. Turn the machine upright.

Note: You may need to adjust the wheel clutch cable after replacing the belt. See the instructions

on page 20.

Blade

To Replace the Blade

Tools Needed:

· 15/16" wrench or socket

· air wrench if available

· rag or gloves to handle the blade

!

WARNING: Always remove the spark

plug wire before servicing your machine.

Note: You may need a length of pipe to fit

over the wrench for more leverage when

removing the blade nut.

1. Block the blade with a piece of wood

between the blade and the skid on the

chute side of the deck (Figure 23).

2. Remove the blade lock nut (right-hand,

regular thread) and washer.

Caution: Be careful not to get cut when

pushing or pulling the wrench next to the

blade.

3. Remove the blade.

Figure 23

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 17

Page 22

4. Mount the new blade, washer and lock

nut.

Note: Be sure the blade is seated

completely over the small ridge in the

spindle hub before tightening the lock

nut (Figure 24).

Differential

Figure 24

It is important to keep the differential parts lubricated. See page 12 for maintenance instructions.

To Adjust the Differential

If the differential locks while in the disengaged position, follow the instructions below to adjust it.

Tools Needed:

· (2) 1/2" deep well wrenches or sockets

· screwdriver

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. Loosen the bolt in Figure 25 about 1/2

turn.

2. With a screwdriver, push the shift

support toward the axle as far as it will

go and tighten the bolt (Figure 25).

3. Engage and disengage the differential

lever a few times, then check the

clearance between the hub sleeve and the

hub bell. There should be 1/8" clearance

when the lever is disengaged (Figure

26).

4. If needed, adjust the nut in Figure 26 and

repeat steps 3 and 4 to get the proper

measurement.

Figure 25

Figure 26

18 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 23

Drive Chain

To Adjust the Drive Chain

This adjustment should be done after the 1st , 3rd, 5th and 10th hours of use, then every

subsequent ten hours of use, to remove any slack or looseness from the chain.

Tools Needed:

• (2) 1/2" wrenches

!

WARNING: Always remove the

spark plug wire before servicing your

machine.

1. Loosen the outer nut on the chain

adjustment bolt so you can access the

inner nut (Figure 27).

2. Tighten the inner nut by hand or with a

1/2" wrench until it is snug against the

frame (Figure 27).

3. With the machine in Neutral, roll it back

and forth several times to remove any

play in the chain, then recheck the

adjustment. When you push in the center

of the chain it should not move more than

1/2".

4. When the adjustment is correct, with two 1/2" wrenches, hold the inner nut in place and tighten

the outer nut firmly against it.

5. Check and tighten the innermost nut on the adjustment bolt (look under the machine, it's the nut

that sits against the chain adjuster bracket). This nut must be tight against the bracket.

Figure 27

IMPORTANT!: DO NOT try to adjust the chain adjustment bolt—only the three nuts.

To Replace the Drive Chain

Tools & Supplies Needed:

· Chain: Part #131081

· 7/16" wrench

· flat-head screwdriver

· pliers

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. Remove the lock nuts from the access

door and remove it (Figure 28).

Note: On the Kawasaki and Tecumseh

engines you'll need to move the fuel line and

clamps off the studs before removing the

access door.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 19

Figure 28

Page 24

2. Loosen (don't remove) the chain drive

adjustment bolt See instructions on Page

19. This will take tension off the chain

and make it easier to remove.

3. Remove the master chain link (Figure 29).

First remove the lock clip (A) with a flathead screwdriver and pliers. You'll need

to lift one side and rotate the clip to get it

off the master link. Next remove the side

plate (B). Then remove the master chain

link.

4. Slowly feed the chain out.

Figure 29

5. Mount the new chain.

6. Add the master chain link.

7. Replace the access door and tighten the lock nuts.

8. Readjust the chain drive adjustment bolt (page 19, Figure 27).

Wheel Clutch

When properly adjusted, tension on the wheel clutch lever should increase when the lever is about

parallel to (almost touching) the handlebar

grip.

Tools Needed:

· 7/16" wrench

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. Find the wheel clutch adjustment cap

screw on the right side of the frame near

the oil drain plug (Figure 30).

2. Loosen the cap screw 1/2 to 1 turn. Slide

it back in the slot to tighten the clutch

lever then tighten the cap screw.

Figure 30

20 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 25

Blade Engagement Cable

If the blade won't cut, or seems to slip in

heavy material, check the blade engagement

cable. Remove the black belt guard and

measure the length of the blade clutch spring

(the spring that attaches the cable to the

blade clutch) (Figure 31). When the blade is

engaged (lever pulled back) the spring

should measure 3-1/2" to 3-3/4".

Note: Do not adjust the spring longer than

3-3/4".

Tools Needed:

· 1/2" open-end wrench

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. On the right handlebar there is a bracket

with two nuts (one on each side) for

adjusting the blade engagement cable

(Figure 32). Loosen the nuts and push

the threaded cable housing down about

1/8" at a time into the bracket. Check the

spring measurement again and adjust as

needed.

2. Retighten the nuts.

Figure 31

Transmission

The transmission is maintenance-free and

does not need additional lubrication.

Figure 32

To Remove the Wheels

Tools Needed:

· flat head screwdriver

!

WARNING: Always remove the spark

plug wire before servicing your machine.

1. Block the machine so the wheel to be

removed is off the ground.

2. Rotate the tire so the key slot is facing

upwards.

3. Use the screwdriver to remove the U-

shaped lock ring (Figure 33), remove the

washer and slide the wheel off.

Note: Be careful not to lose the key.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 21

Figure 33

Page 26

End of Season & Storage

!

WARNING: Always remove the spark plug wire before servicing your machine.

Please refer to the Engine Manufacturer's Owner's Manual for engine-specific procedures.

· Change the oil.

· Remove the spark plug and pour about 1 ounce of motor oil into the cylinder hole. Replace the

plug and pull the recoil starter rope until you feel strong resistance. This will coat the piston and

seat the valves to prevent moisture buildup.

· Clean/replace the air filters.

· Clean dirt and debris from the cylinder head cooling fins, blower housing, debris screen and

muffler area of the engine.

· If your engine has a fuel filter, replace it.

· If your DR

using a gas stabilizer. This will prevent the carburetor from gumming up. If there is dirt or

moisture in the gas, remove it by draining the tank. Completely fill the tank with fresh, unleaded

gas and add the appropriate amount of stabilizer or gasoline additive. Run the engine for a short

time to allow the additive to circulate. Close the gas shut-off valve to prevent carburetor

overflow and leakage.

®

FIELD and BRUSH MOWER will be idle for more than 30 days, we recommend

· Store the battery in a dry area that does not freeze. If the machine is not used over a long period,

the battery should be charged every three months. See page 13.

· Remove any wrapped weeds from the blade bearing housing. Clean grass and debris from the

top and underneath the mower deck with a stiff brush.

· Check the blade for nicks and wear. Remove the blade and sharpen, or have it professionally

sharpened if needed.

22 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 27

Troubleshooting

!

WARNING: Always disengage the blade, turn off the engine and remove the spark plug

wire before servicing your machine.

Please refer to the Engine Manufacturer's Owner's Manual for specific engine maintenance

and troubleshooting information.

Belts

The belt frays or rolls over the pulley

Blade

The cut material is not being properly discharged out

of the right side of the machine

Heavier growth gets hung up under machine and

does not discharge

The blade is not cutting or is loose

Differential

Differential locks when not in engaged position

Engine

Recoil will not pull out or is difficult to pull. (Briggs &

Stratton Engine, Models ATM1 0 S and AT M1 0E only )

Engine won't start

Þ A pulley groove may be nicked. Check the belt

for wear and hard spots. File off any nicks on the

pulley.

Þ The belt may be stretched. Replace it.

Þ The discharge may be blocked. Disengage the

blade, turn off the engine, disconnect the spark

plug and check for debris.

Þ Try removing the baffle under the front of the

mowing deck.

Þ The blade may not be seated properly. Loosen

the blade nut, reset the blade and tighten the nut.

Þ Follow the adjustment instructions on page 18.

Þ Check that the blade lever is in the disengaged

position.

Þ The recoil may be broken or jammed. Try to turn

the engine pulley by hand, with the spark plug

wire off. If it turns, the recoil is broken or

jammed.

Þ Check for adequate, fresh fuel.

Þ Check that the fuel valve is turned on.

Þ Check the fuel filter to see if it is clear. Remove

the line from the engine side of the filter. If gas

flows freely, it’s OK.

Þ Check the throttle adjustment and travel.

Þ Is the blade engagement lever down

(disengaged)? It should be.

Þ Check the spark plug.

Þ Tecumseh and Kawasaki engines have a 10 amp

fuse on the wiring harness. Check the fuse and

replace if needed.

Electric-Starting Mod els :

Þ Check the wire connections—especially the

ground connection, the large green wire coming

from the battery where it connects to the engine.

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 23

Page 28

Engine won't start (continued)

Engine lacks power

Engine skips, pops, misses, shakes

Engine smokes

Transmission

Machine is hard to get into reverse

Wheels

Wheels are slipping

Wheels pulling left or right

Þ Check the wire connections to the solenoid.

Disconnect the green battery ground wire fir st to

avoid sparks. Check to be sure that all of the

connections are tight. Reconnect the battery

ground wire.

Þ Check the ground connection on the solenoid

(ATM10E, 125) where it’s bolted to the frame.

Using a wrench or socket, spin the bolts and

tighten them to ensure a good connection to the

frame.

Þ Check the throttle travel and adjustment.

Þ Clean or replace the air filter if needed.

Þ Check the spark plug and replace if needed.

Þ Add clean, fresh, unleaded gas.

Þ Check the oil level and adjust as needed.

Þ Check the spark plug and replace if needed.

Þ Clean or replace the air filter if needed.

Þ Check the vent holes in the fuel cap — clean

them if they’re clogged.

Þ Replace gas with fresh, unleaded fuel.

Þ Check the oil level and adjust as needed.

Þ You may be operating the machine on too great

an incline.

Þ Check the air filter and clean or replace if

needed.

Þ You may be using the wrong oil—too light for the

temperature. Refer to your Engine

Manufacturer's Owner’s Manual for detailed

information.

Þ Clean the cooling fins if they’re dirty.

Þ If you find it difficult to shift into reverse, lightly

pull the clutch lever as you pull the shift lever into

reverse then quickly release the clutch lever.

Þ Try engaging the wheel differential.

Þ Check the tire pressure. There should be 14 psi

in each tire.

For technical assistance call Toll-Free 1(800)DR-OWNER (376-9637).

24 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 29

Parts List

Please refer to the schematic drawings starting on page 27.

Note: Not all parts listed appear on the drawings.

Ref# Part# Description

1 100831 10.5 HP IC B&S Electric-Start

Engine

2 100841 10.5 HP IC B&S Manual-Start

Engine

3 124511 Battery Clamp

4 101341 Battery Pad

5 100861 12.5 HP OHV TEC Engine

6 100851 14.0 HP OHV KAW Engine

9 100971 Main Frame

10 124521 Handlebar Assembly, Manual

10 125071 Handlebar Assembly, Electric

11 101261 Shift Lever

12 101401 3" Blade Drive Pulley

13 100731 Brush Deck, 26" (shell only)

14 101001 Belt Guard

15 100471 Upper Bearing

16 101011 Chain Guard

17 100481 Air Tip Blade 26"

17 100491 Brush Blade 26"

18 101511 Spindle Shaft

19 100411 Spindle Housing Assembly

20 101771 Blade Washer

21 101411 Idler Pulley

22 100231 Clutch Idler Arm

23 101731 Drive Belt 1/2" x 30"

24 101721 Blade Belt 5/8" x 56"

25 101571 Steel Spacer

26 101311 Blade Lock Nut 5/8"-11

27 127471 5/16" x 3-1/4" Chain adjuster

bolt

28 101461 Bolt, HHCS, 5/16" x 1-1/4"

29 101251 Operator Presence Lever

30 101651 Momentary Switch BLACK

31 101661 Momentary Switch RED

32 100551 Belt Guard Bracket

33 100241 Shift Rod Arm

34 101241 Blade Control Lever

35 101441 Tie Rod

36 100201 Chain Adjuster

37 101051 Belt Guide

38 100561 Cable Adjustment Bracket

39 100221 Blade Idler Arm

40 101171 Spindle Hub

41 100621 Blade Engage Cable

42 101201 Knob, Belt Guard

43 100981 Grip, Mower Engagement Lever

Ref# Part# Description

44 100641 Cap, Mower Engagement Lever

45 101801 Nylon Washer 1" x .505" x .125"

46 101861 Positive Wire, KAW, 23" Red

47 101561 Spacer .75" x 1" x 1.7"

48 101891 Grease Fitting 1/4"-28

49 135971 Flexible Conduit, Split - 7/16" X

30"

50 101551 Solenoid - Briggs electric,

Tecumseh

51 106361 Key, 1/4" x 1/4" x 2-1/4"

52 100601 Bushing 1/2" OD x 3/8" ID

53 100611 Idler Arm Bushing

54 101791 Flat Washer 1/2" ID

55 101621 Extension Spring 5"

56 100961 Shift Fork

57 101061 Shift Fork Guide

58 101271 Shift Lever, Differential

59 101371 Shift Lever Plate

60 101191 Key 3/16" x 2", SQ.

61 100581 Blade Clutch Brake

62 101741 Washer 1-1/2" x .640" x 1/4"

63 101751 Washer 1-1/2" x .765" x 1/4"

64 130491 Differential w/Sprocket - 54

tooth

65 101501 Machine Screw 3/8"-16 x 1-1/2"

66 100591 Bushing .375" OD x .265" ID

67 101471 Bolt, HHCS, 5/16" x 2-1/4"

68 100441 Wire Harness B&S – Electric-

Start

69 100451 Wire Harness KAW

70 100461 Wire Harness TEC

71 100431 Wire Harness B&S Manual-Start

72 101871 Green Safety Switch Wire 15"

73 101841 Green Negative Wire 23"

74 101831 Green Negative Wire 16"

75 101851 Red Positive Wire 20"

77 101821 Red/Black Alternator Wire 12"

79 100761 Access Door

80 101021 Stone Guard

81 101431 Stone Guard Rod

82 100671 Belt Guard Clip

83 101671 Spring Link Switch

84 100211 Anti-wrap

85 100721 Deck Baffle

86 100571 Deck Support Bracket (Brush

Deck)

87 101521 Pivot Shim

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 25

Page 30

Ref# Part# Description

88 101631 Anti-Rotation Strap

90 131081 Drive Chain, #41, w/Link & 1/2,

54 Tooth Sprocket

91 110601 Master Link #41

91 110591 1/2 Link #41

92 136851 Label, Pulley Cover, ATM

93 101811 Split Lock Washer 1/4"

94 101451 Bolt, HHCS, 1/4" x 1-1/2"

95 101681 6 Qt. Fuel Tank

96 100631 Fuel Cap - Tecumseh/Kawasaki

97 100941 Fuel Filter

98 101301 Fuel Tank Mount

99 123451 Fuel Line

100 101711 Shut-Off Valve

101 100661 Fuel Line Clamp

102 101321 Lock Nut 5/16"-24

103 101761 Washer 1.25" OD

104 101601 Blade Clutch Spring 2-3/4"

105 100771 E Clip

106 100501 Carriage Bolt 5/16"-18 x 1/2"

107 101701 Transmission 4 Speed w/

Sprocket

107 127111 Sprocket Only

108 109421 Clutch Cable Assembly

109 108921 Bearing Flange, 2" Hole

110 108931 Ball Bearing 3/4" Bore

111 110281 Handle, Brake/Clutch

112 112461 Nylon Washer, .39 ID x 1 OD

113 110921 Cotter Pin 1/16" x 3/4"

114 131111 Tire/Wheel, TERR, 18"

115 106381 Key 3/16" SQ x 1-1/2"

116 129781 Steel Shim Set

117 112371 Flat Washer 3/16"

118 112381 Flat Washer 1/4"

119 110251 Handle Grip

110491 Key, Woodruff 3/16" x 3/4"

121 110241 Handle Grip

123 110691 Nut 5/16"-18"

124 110781 Nut 5/16"-24"

125 110681 Nut 10-32

126 109581 Clevis

127 110871 Clevis Pin 1/4" x 5/8"

128 110731 Nylon Lock Nut 1/4"

129 110751 Nylon Lock Nut 3/8" - 16

130 110761 Nylon Lock Nut 5/16" - 18

131 111281 Rod End

132 110971 Roll Pin, 3/16" x 1-3/4"

133 110961 Roll Pin 3/16" x 1"

134 111441 Bolt, HHCS, 1/2" x 2"

135 114701 Bolt, HHCS, 1/4" - 20 x 1/2"

Ref# Part# Description

136 111501 Bolt, HHCS, 1/4" - 28 x 3/4"

138 111491 Bolt, HHCS, 1/4" x 1"

139 111511 Bolt, HHCS, 3/8" x 1-1/2"

140 111571 Bolt, HHCS, 5/16" x 1-3/4"

141 111581 Bolt, HHCS, 5/16" x 1"

142 111591 Bolt, HHCS, 5/16" x 2-1/2"

143 111421 Bolt, HHCS, 5/16" x 3/4"

144 112391 Flat Washer 3/8"

145 111741 Screw 8-32 x 1/2"

146 111701 Washer 3/8"

147 110221 Shift Handle Grip

148 112111 Throttle Control

149 108791 Shift Arm, Transmission

150 113071 Idler Pulley 2-1/4"

151 126971 Fender Washer 1/4" x 1"

152 111261 Wheel Lock Ring

153 110881 Clevis Pin 3/16" x 1-3/4"

154 109751 Cotter Pin 1/16" x 1/2"

155 111191 Transmission Pulley 6"

156 111241 Snap Ring

157 110461 Drive Chain Idler, 10 tooth

158 112051 Electric-Start Key Switch

159 111341 Cap Screw 7/16" x 3/4"

160 112481 Star Lock Washer 1/4"

161 111871 Spacer 1/4" x 1"

163 111731 Screw 5/16" x 1/2"

164 112431 Split Lock Washer 5/16"

165 109481 Round Cap 1"

166 104831 Battery, 12 volt

167 112441 Nylon Washer 1/2" ID x 3/4" OD

168 115611 Clip

169 120891 Switch Spring 1-1/8" long

170 120631 Bushing 1/4"

171 120901 Compression Spring 1"

172 121661 Nylon Washer 1/4" ID, .20 Thick

173 114651 Full Thread Cap Screw 3/8" x 3"

174 118731 Lock Nut 10-24

175 120101 Pan Head Screw 10-24

176 119831 Cap Screw 1/4" x 3/4"

177 104871 Lower Bearing

178 107071 Bolt, HHCS, 3/8" -16 x 1", w/Nut

179 107051 Bolt, HHCS, 5/16" -18 x 3/4",

Gr5

180 111471 Bolt, HHCS, 1/4" x 1 1/4"

181 112061 Manual-Start Key Switch

182 111681 Set Screw 1/4" - 20 x 1/4"

184 101291 Differential Lock Spring

185 112431 5/16" Split Lock Washer

186 129621 Spacer

26 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 31

Main Frame Assembly

Please Note: The circled numbers match the first column of numbers on the parts list.

Figure 34

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 27

Page 32

Wheel/Axle Assembly

Please Note: The circled numbers match the first column of numbers on the parts list.

Figure 35

28 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 33

Handlebar A ssembly

Please Note: The circled numbers match the first column of numbers on the parts list.

Figure 36

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 29

Page 34

Brush Mower Deck Assembly

Please Note: The circled numbers match the first column of numbers on the parts list.

Figure 37

30 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 35

Wiring Diagrams

Electric-starting models only

Kawasaki 14.0 HP

Fig\

Tecumseh 12.5 HP

ure 38

DR® FIELD and BRUSH MOWER Safety & Operating Instructions 31

Page 36

Wiring Diagrams (cont.)

Electric-starting models only

Figure 39

Briggs & Stratton 10.5 HP

32 DR® FIELD and BRUSH MOWER Safety & Operating Instructions

Page 37

Notes

Page 38

Notes

Page 39

Page 40

Daily Check List for the DR® FIELD and BRUSH MOWER

4 OIL: With the machine on a level surface, remove the oil fill cap and

check the oil level. Fill the reservoir according to the dipstick with

SAE30 motor oil.

4 GAS: Fill the gas tank with clean, fresh unleaded gasoline, making

sure the gas valve on the bottom of the tank is open. Always close the

gas valve when storing your machine.

4 ENGINE: It is very important to keep the engine clean. Remove

grass and other debris from the engine cooling fins and debris guard.

A dirty engine retains heat and can cause damage to the internal engine

parts.

4 BELTS: Check the belts for wear, proper alignment and tension.

4 BLADE: Check the blade for tightness, nicks and wear. Remove any

wrapped weeds and grass from the blade bearing housing to prevent

buildup.

COUNTRY HOME PRODUCTS

Meigs Road, P.O. Box 25, Vergennes, Vermont 05491

®

©1999 CHP, Inc. 138341

TOLL-FREE 1(800)DR-OWNER (376-9637)

CODE# 30162X

Loading...

Loading...