Page 1

CHIPPER/SHREDDER

Operating & Assembly Instruction Manual

Model: Tractor Attachment Chipper/Shredder TPH-184CHP

This manual contains information concerning proper and improper operating procedures,

warnings, maintenance, troubleshooting, assembly, and tips. Everyone who operates this

machine should read these instructions and be thoroughly familiar with them.

P/N 911-0287

10/23/06

Page 2

SECTION I – SAFETY

This symbol points out important safety instructions, which if not followed,

could endanger the personal safety and/or property of yourself and others. Read and

follow all instructions in this manual before attempting to operate your shredder/chipper.

Failure to comply with these instructions may result in personal injury. When you see

this symbol - heed its warning.

THIS MACHINE IS CAPABLE OF INFLICTING SERIOUS INJURY

IF

OPERATED IMPROPERLY -- READ WARNINGS & CAUTION LABELS.

INTENDED USE

Never use your shredder/chipper for any other purpose than shredding and chipping limbs

or other lawn and garden debris. It is designed for this use and any other use many cause

serious injury.

DANGER: Rotating cutting blade.

Keep hands and feet out of inlet and discharge opening while machine is running.

DANGER: This machine can CRUSH, GRIND, CUT, and SEVER parts of your body if they

enter the inlet or discharge area of your shredder/chipper.

DANGER: Your shredder/chipper was built to be operated according to the rules for safe

operation in this manual. As with any type of power equipment, carelessness or error on

the part of the operator can result in serious injury. If you violate any of these rules, you

may cause serious injury to yourself or others.

2

Page 3

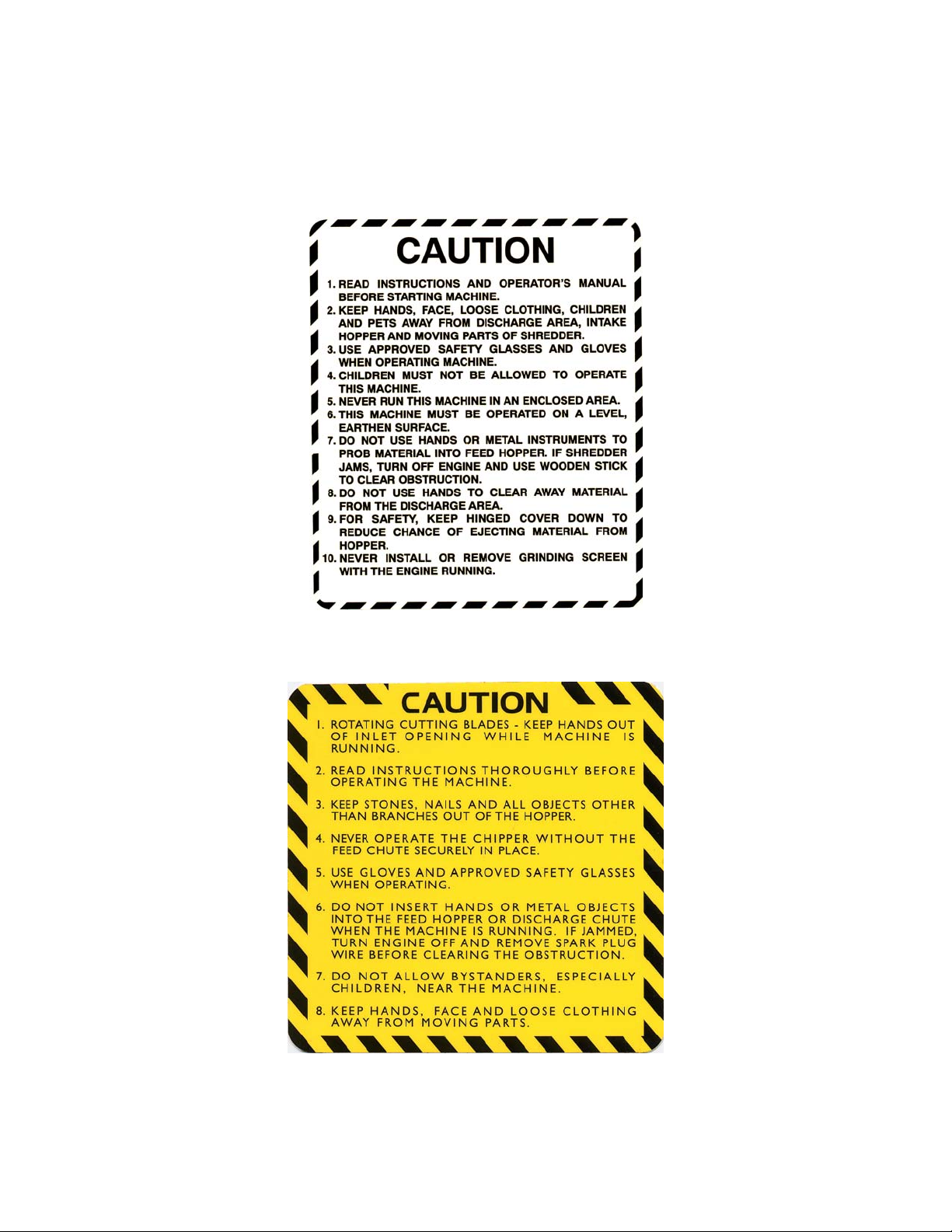

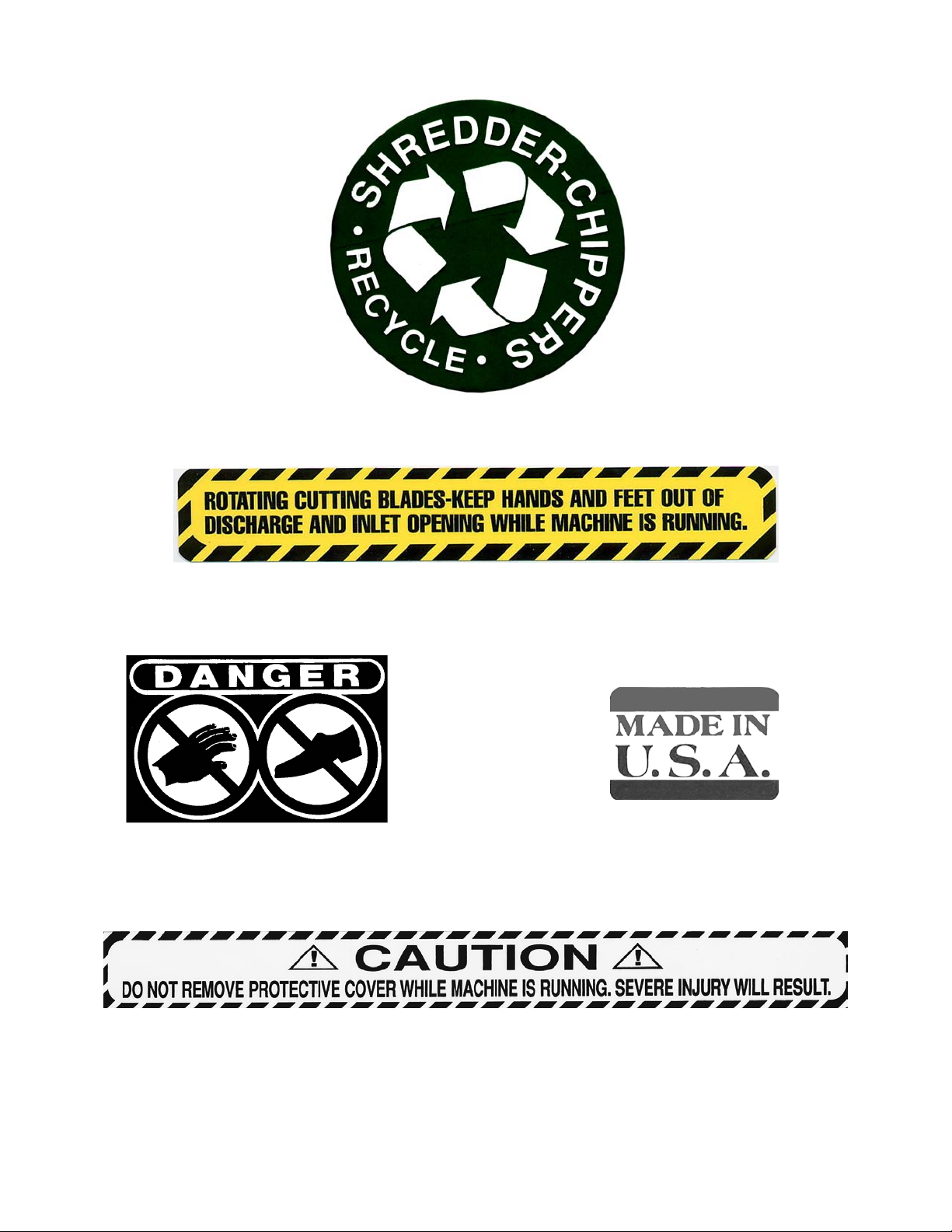

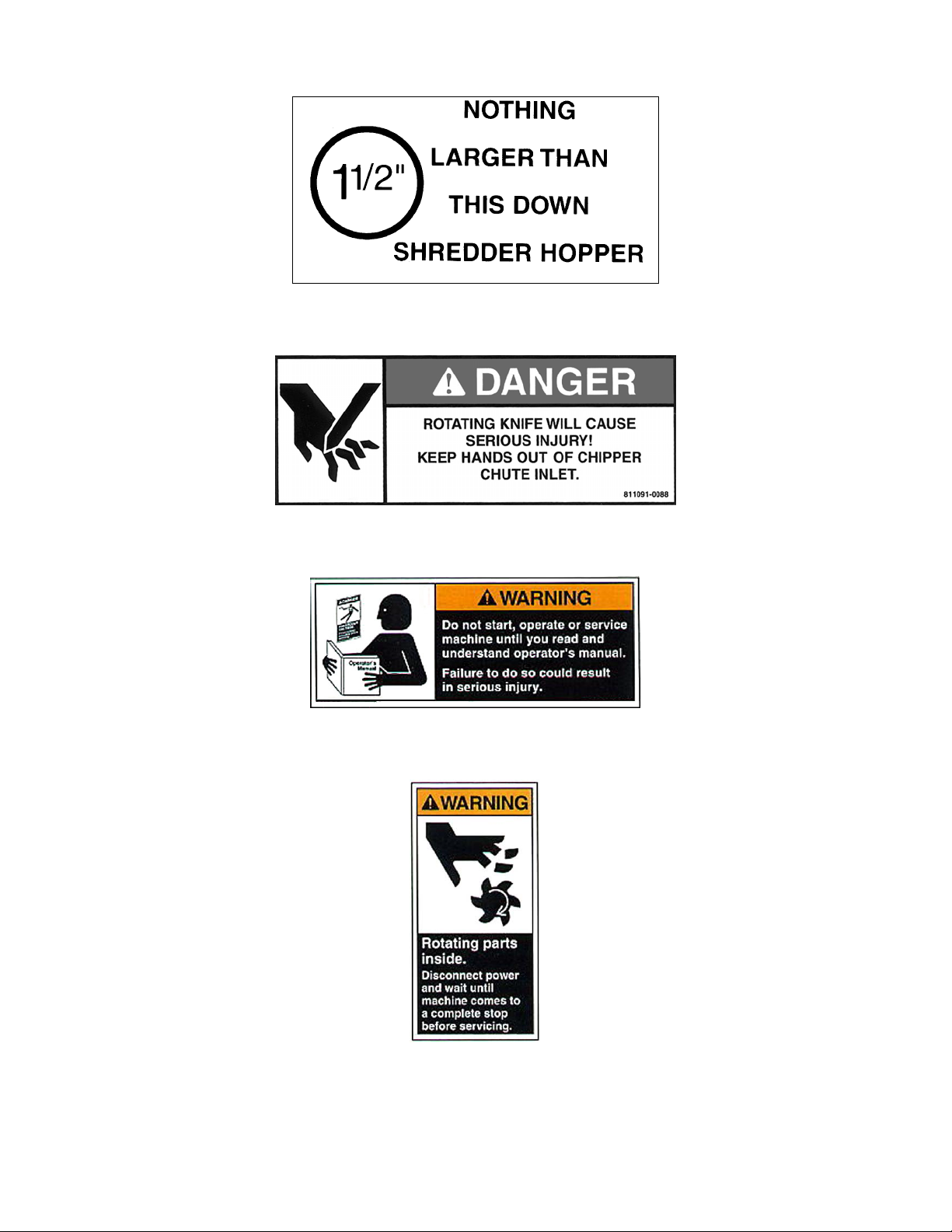

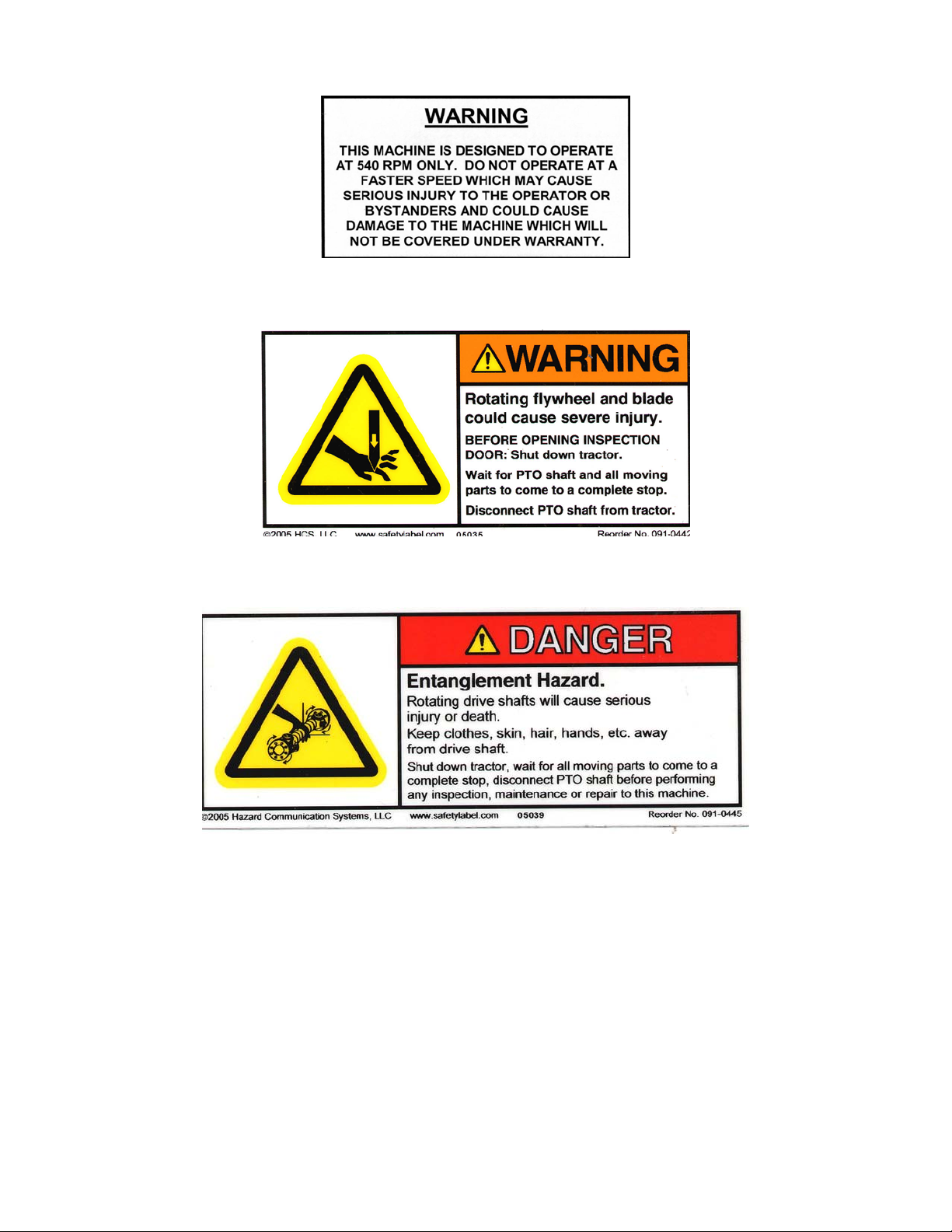

MAKE CERTAIN THAT ALL SAFETY LABELS ON THIS EQUIPMENT ARE KEPT

CLEAN AND IN GOOD CONDITION. IF YOU NEED REPLACEMENT LABELS,

ORDER BY PART NUMBER.

080-0962

080-0967

3

Page 4

091-0057

091-0044

091-0055

091-0062

091-0059

4

Page 5

091-0064

091-0088

091-0380

091-0381

5

Page 6

091-0385

091-0442

091-0445

6

Page 7

SAFE OPERATION PRACTICES

TRAINING

• Read this owner’s manual carefully in its entirety before attempting to assemble this machine. Read, understand,

and follow all instructions on the machine before operation. Be completely familiar with the controls and the

proper use of the machine before operating it. Keep this manual in a safe place for future and regular reference

and for ordering replacement parts.

• Know how to stop the unit and disengage the controls quickly.

• Never allow children to operate the unit. Never allow adults to operate the equipment without proper instruction.

Only responsible individuals who are familiar with these rules of safe operation should be allowed to use your unit.

• Keep the area of operation clear of all persons, particularly small children and pets. Stop the engine when they

are in the vicinity of the unit. Keep work area clean and clear of branches or obstacles, which could cause you to

stumble or fall.

• Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their

property, and themselves.

• Your shredder/chipper is a powerful tool, not a plaything. Exercise extreme caution at all times. Your unit has

been designed to shred and chip. Do not use it for any other purpose.

• If situations occur which are not covered in this manual, use care and good judgment. Contact your place of

purchase for additional assistance.

PREPARATION

• Thoroughly inspect the area where the equipment is to be used and remove all foreign objects.

• Do not operate the machine without wearing adequate outer garments and safety goggles. Always wear safety

glasses or goggles during operation and while performing any adjustment or repair, to protect eyes from foreign

objects that may be thrown from the machine. Be sure your glasses or goggles fit properly.

• Avoid loose-fitting clothes and use protective footwear that will improve footing on slippery surfaces. Shirt and

slacks that cover the arms and legs and steel-toed shoes are recommended. Secure hair above shoulders. Do

not wear loose clothes or jewelry that can be caught in moving parts. Never operate a unit in bare feet, sandals or

sneakers. Wear gloves when feeding material into the shredder hopper or chipper chute. Be sure your gloves fit

properly and do not have loose cuffs or drawstring.

• Never attempt to make any adjustments without shutting off the tractor and disengaging the P.T.O. drive shaft.

OPERATION

• Never place your hands, feet, or any part of your body in the shredder hopper, chipper chute, discharge opening,

or near or under any moving part while the shredder/chipper is running. Keep clear of the discharge opening at all

times. If it becomes necessary to push material into the shredder hopper or chipper chute, use a small diameter

stick, NOT YOUR HANDS.

• Keep your face and body back from the shredder hopper and chipper chute to avoid accidental bounce back of

any material.

• The shredder/chipper is designed to be run with the weight of the unit on the ground. Shredding or chipping with

the unit while it is off the ground can result in injury to yourself or others, or damage to the machine which may not

be covered under warranty.

• The machine should only be operated on a level surface. Never operate your unit on a slippery, wet, muddy, or

icy surface.

• Exercise caution to avoid slipping or falling.

• Stay alert for hidden hazards or traffic. Do not carry passengers.

• If the cutting mechanism strikes a foreign object or if your machine should start making an unusual noise or

vibration, immediately stop the tractor and wait for all moving parts to come to a complete stop. After the machine

has come to a complete stop proceed as follows:

• Inspect for any damage.

7

Page 8

• Repair or replace any damaged parts before restarting and operating the machine.

• If the machine should start to vibrate abnormally, immediately stop the tractor and wait for all moving parts to come

to a complete stop and inspect for the cause. Vibration is generally a warning sign of trouble.

• Disengage the P.T.O. drive shaft when leaving the operating position.

• Disengage the P.T.O. when moving the shredder/chipper.

• Stop the tractor and disconnect the P.T.O. drive shaft when making any repairs, adjustments and inspections.

• Take all possible precautions as recommended by the manufacturer when leaving the machine unattended. Stop

the tractor and remove the key if so equipped.

• Before cleaning, repairing, or inspecting, shut off the tractor and make certain the flywheel and all moving parts

have come to a complete stop.

• Never run this machine in an enclosed area as the exhaust from the tractor engine contains carbon monoxide,

which is an odorless, tasteless, and deadly poisonous gas.

• Keep all guards and safety devices in place and operating properly. Do not operate the machine if all safety

guards are not in place.

• Do not use the unit with the shredder hopper or chipper hopper removed.

• Keep children and pets away.

• Tragic accidents can occur if the operator is not alert to the presence of small children.

• Keep children out of the work area and under the watchful eye of a responsible adult other

than the operator.

• Be alert and turn the unit off if a child enters the area.

• Never allow children to operate the shredder/chipper.

• Do not overload or attempt to shred or chip material beyond manufacturers recommendation. Personal injury or

damage to the machine could result.

• Never operate the machine at high transport speeds or on hard or slippery surfaces.

• Never allow bystanders near the unit while running.

• Only use accessories approved for this machine by the manufacturer. Read, understand, and follow all the

instructions provided with the approved accessory.

• Only operate unit in good daylight. Do not operate unit at night or in dark areas where your vision may be

impaired.

• Use extreme caution when reversing or pulling the machine towards you.

• This machine is designed to operate at 540 RPM only. Do not operate at a faster speed which may cause serious

injury to the operator or bystanders and could cause damage to the machine which will not be covered under

warranty.

• Never pick up or transport the machine while the P.T.O. drive shaft is engaged.

• Do not operate while under the use of alcohol, drugs, or medication. A clear mind is essential for safety.

• Do not allow anyone who is not alert to operate this machine.

• When feeding material into this equipment, be extremely careful that pieces of metal, rocks, or other foreign

objects are not included. Personal injury or damage to the machine could result.

• Keep area of discharge clear of people, animals, buildings, glass or anything else that will obstruct clear

discharge, cause injury or damage. Wind can also change discharge direction, so be aware.

• Do not allow an accumulation of processed material to build up in the discharge area as this will prevent proper

discharge and can result in kickback from the shredder hopper or chipper chute.

8

Page 9

MAINTENANCE AND STORAGE

• Keep machine, attachments and accessories in safe working condition.

• Check hardware at frequent intervals for proper tightness. Never operate your shredder/chipper in poor

mechanical condition or when in need of repair. Be sure all safety guards and shields are in proper position.

These safety devices are for your protection.

• Always refer to the operator’s manual for important details if the machine is to be stored for an extended period.

• Follow the manufacturer’s recommendations for safe loading, unloading and storage of machine.

• If it is necessary for any reason to unclog the feed intake or discharge openings or to inspect or repair the machine

where a moving part can come in contact with your body or clothing, shut the tractor off and allow all moving parts

to come to a complete stop before attempting to unclog, inspect or repair.

• Check the knife mounting screws at frequent intervals for proper tightness. Also visually inspect the knife for wear

or damage. Replace the knife with parts that meet original equipment specifications.

• Knives should be checked for sharpness and the bolts attaching them to the flywheel for tightness every 8-10

hours of operation.

• Check the gap between the knife and wear plate every time you sharpen or replace the knife, or every 8-10 hours

of operation.

• Never tamper with safety devices. Check their proper operation regularly.

• Inspect the belt each time you use the unit. Look for damage, worn areas or tears. Do not use the unit if this

condition exists.

• This machine is designed to operate at 540 RPM only. Do not operate at a faster speed that may cause serious

injury to the operator or bystanders and could cause damage to the machine that will not be covered under

warranty.

9

Page 10

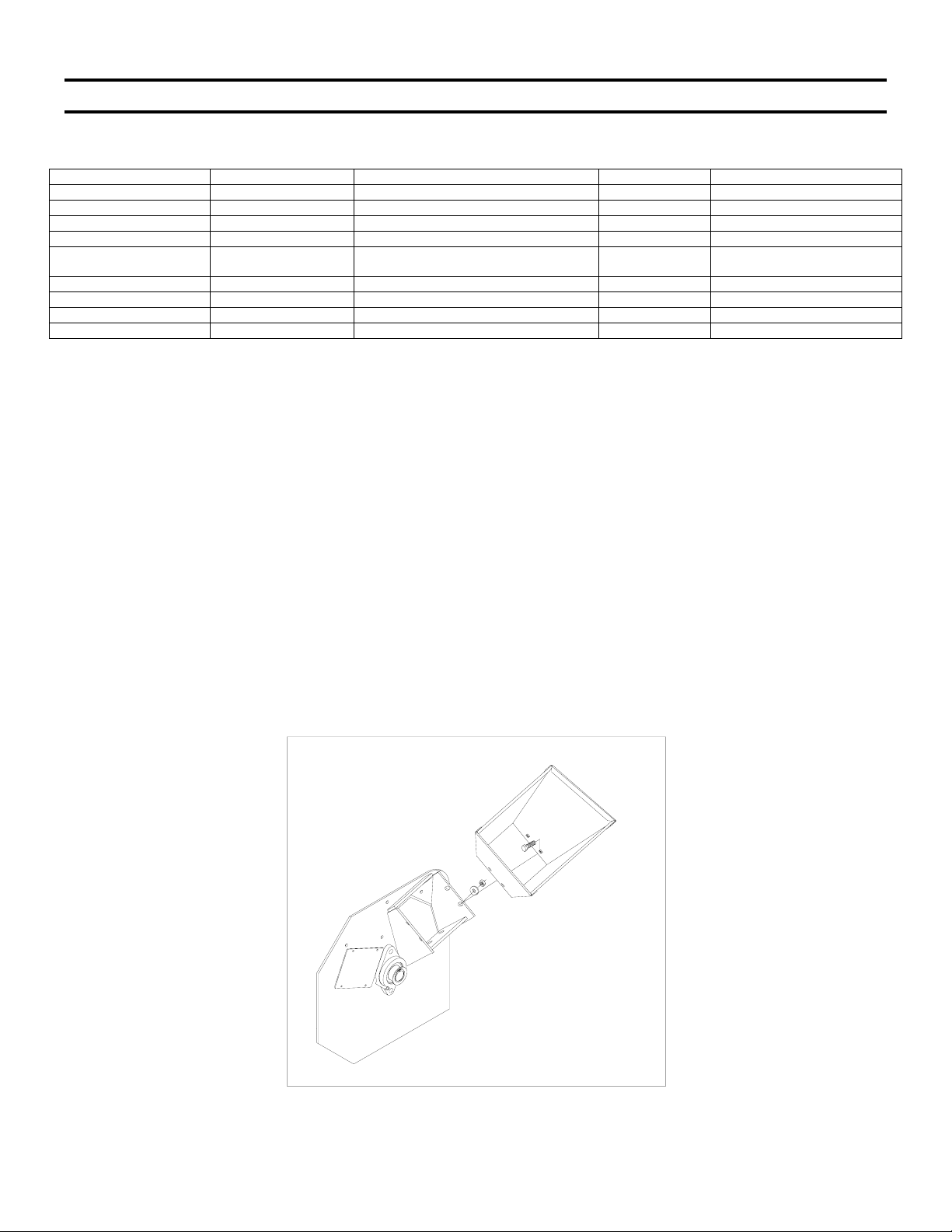

SECTION II - ASSEMBLY & INSTALLATION

PACKAGE CONTENTS

SKID POLY BAG BOLT BAG PART # WHERE USED

SHREDDER/CHIPPER OWNER’S MANUAL 1 EA – ¼” X ¼” X 1 ½” KEY 080-0080 PTO SHAFT

CHIPPER HOPPER WARRANTY CARD 4 EA – 5/16-18 X ¾” CARRIAGE BOLT 090-0462 CHIPPER HOPPER

SHREDDER HOPPER SAFETY GLASSES 4 EA – 5/16 FLAT WASHERS 090-0233 CHIPPER HOPPER

P.T.O. DRIVE SHAFT BOLT BAG 8 EA – 5/16-18 NYLOCK NUT 090-0460 4 EA – CHIPPER HOPPER

TOOLS REQUIRED FOR ASSEMBLY & INSTALLATION

• ½” Wrench or socket

ASSEMBLY

STEP I – UNPACKING AND CHECKING CONTENTS

• Remove the all items from the crate.

• After unpacking the crate, compare the contents with the list above.

• If any parts are missing, contact your place of purchase.

• Assembly should be done on a clean, level surface.

STEP II – ASSEMBLING THE CHIPPER HOPPER

• Assemble chipper hopper to the basic machine using four each 5/16”-18 x ¾” carriage bolts, 5/16”-18 nylock nuts

4 EA – SHREDDER HOPPER

POLYBAG 2 EA – 3/8-16 X 3/8” SET SCREWS 080-0056 PTO SHAFT

2 EA – 5/16-18 X 1 ¼” HHCS 090-0089 SHREDDER HOPPER

2 EA – 5/16-18 X 1 ½” HHCS 090-0090 SHREDDER HOPPER

4 EA – ANTI-VIBRATION MOUNTS 500-0068 SHREDDER HOPPER

and 5/16” flatwashers from the bolt bag. Put head of bolt inside hopper with threads sticking out. Tighten all

hardware with a ½” wrench.

10

Page 11

STEP III – ATTACHING THE SHREDDER HOPPER

• To attach the shredder hopper, push the four vibration dampeners (item #28) up into the mount holes on the

hopper.

• With the vibration dampeners in the hopper mount holes from step 1, place the hopper on top of the unit. NOTE:

the slanted side of the hopper faces the discharge end of the shredder/chipper. Align the holes in the side plates

with the vibration dampeners.

• Push the four bolts up through the side plates and thread them into each vibration dampener until one or two

threads appear. Put the locknuts in place on top of the bolts coming up through the vibration dampeners. Hold the

locknut with a wrench and tighten the bolt until two threads are completely through the nut. DO NOT OVER

TIGHTEN AS THIS WILL DAMAGE THE VIBRATION DAMPENER AND POSSIBLY LEAD TO FURTHER

DAMAGE TO YOUR MACHINE.

11

Page 12

INSTALLATION

• Many tractors permit direct mounting to the lower support pins on the frame of the shredder/chipper. If the lower

hitch arms on your tractor do not have enough inward adjustment to attach to the lower support pins, a pair of pin

extensions may be required to allow proper mounting of the shredder/chipper to the tractor.

• The P.T.O. drive shaft provided with this machine is sized to fit a standard category 1 P.T.O. (1 3/8” x 6 spline).

• The P.T.O. shaft on the tractor that is to use this shredder/chipper must rotate clockwise

P.T.O. from the rear of the tractor. If the P.T.O. rotates counterclockwise, you must have your tractor modified by

installing a gear box to reverse the direction of rotation.

• Depending on the mounting dimensions of the tractor, it may be necessary to have your dealer or yourself modify

the length of the P.T.O. drive shaft that is included with this shredder/chipper. Instructions follow for this

procedure.

• This machine is designed to operate at 540 RPM only. Do not operate at a faster speed that may cause serious

injury to the operator or bystanders and could cause damage to the machine that will not be covered under

warranty.

when viewing the

P.T.O. DRIVE SHAFT MODIFICATION

The P.T.O. drive shaft included with this shredder/chipper may be too long for your tractor. To shorten the driveshaft

proceed as follows.

• Remove the guard.

• Cut the shaft tubes to the required length.

12

Page 13

Round off all edges.

• Shorten the guard tubes to the same length.

• Grease the shaft tubes and reassemble.

REFER TO THE BROCHURE THAT COMES WITH THE P.T.O. DRIVE SHAFT FOR

ADDITIONAL DRIVE SHAFT INFORMATION.

14

Page 14

SECTION III - OPERATION

THIS TRACTOR SHREDDER/CHIPPER ATTACHMENT HAS BEEN DESIGNED TO OPERATE

ON CATEGORY 1 TRACTORS.

THIS MACHINE IS DESIGNED TO OPERATE AT 540 RPM ONLY!

DO NOT OPERATE AT A FASTER SPEED. THIS CAN CAUSE SERIOUS INJURY TO THE

OPERATOR OR BYSTANDERS AND COULD CAUSE DAMAGE TO THE MACHINE THAT

WILL NOT BE COVERED UNDER WARRANTY.

THE SHREDDER/CHIPPER IS DESIGNED TO BE RUN WITH THE WEIGHT OF THE UNIT ON

THE GROUND. SHREDDING OR CHIPPING WITH THE UNIT OFF THE GROUND CAN

RESULT IN INJURY TO YOURSELF OR OTHERS.

Operation Notes

• To activate the shredder/chipper, engage the P.T.O. with the tractor running at idle. Gradually increase

engine speed until you achieve a P.T.O. speed of 540 RPM.

• Proper rotor speed is 2200 RPM +/- 200 RPM.

• When viewed from the operator zone, the rotor and flywheel turn in a clockwise direction. This rotation pulls

branches into the shredder/chipper.

• Always wear protective gloves and safety glasses during operation of the shredder/chipper.

• If it becomes necessary to push material into the chipper hopper, only use a wood stick, never your hands or

anything steel.

• Never assume you know where the knife is. You don’t know where it is. Always keep hands out of all feed

hoppers.

• Keep area of discharge clear of people, animals, buildings, glass or anything else that will obstruct clear

discharge, cause injury or damage.

• If the cutting mechanism strikes a foreign object or if your machine should start making an unusual noise or

vibration, immediately stop the tractor and wait for all moving parts to come to a complete stop. After the

machine has come to a complete stop proceed as follows:

• Inspect for any damage.

• Repair or replace any damaged parts before restarting and operating the machine.

• If the machine should start to vibrate abnormally, immediately stop the tractor and wait for all moving parts to

come to a complete stop and inspect for the cause. Vibration is generally a warning sign of trouble.

• Disengage the P.T.O. drive shaft when leaving the operating position.

• Disengage the P.T.O. when moving the shredder/chipper.

• When feeding material into this equipment, be extremely careful that pieces of metal, rocks, or other foreign

objects are not included. Personal injury or damage to the machine could result.

• Adjust the baffle plate to direct the discharge material down and away from the shredder/chipper. The

discharge end of the machine has three holes for different discharge direction.

• If you shred or chip without any type of screen in place, be certain the baffle plate is held away from the rotor

with one of the screen and baffle rods. Failure to do this will allow the baffle plate to swing backward into the

grinding chamber and become damaged by the rotation of the rotor and hammers.

15

Page 15

SECTION IV – SHREDDING & CHIPPING

THIS SHREDDER/CHIPPER WAS DESIGNED FOR SHREDDING LEAFY GARDEN OR

ORGANIC MATERIAL AND CHIPPING LIMBS OR BRANCHES. NEVER USE THIS MACHINE

FOR ANY OTHER PURPOSE AS IT COULD CAUSE SERIOUS INJURY.

CONTACT WITH INTERNAL ROTATING HAMMERS WILL CAUSE SERIOUS PERSONAL

INJURY. DO NOT PUT HANDS, FACE, FEET OR CLOTHING INTO THE SHREDDER HOPPER,

CHIPPER CHUTE, DISCHARGE OPENING OR NEAR THE DISCHARGE AREA AT ANY TIME.

MAINTENANCE AND SERVICE SHOULD ONLY BE PERFORMED AFTER THE TRACTOR

ENGINE IS OFF, THE P.T.O. DRIVE SHAFT IS DISCONNECTED, AND ALL MOVING PARTS

HAVE COME TO A COMPLETE STOP. USE ONLY A WOODEN STICK TO CLEAR JAMMED

MATERIAL AFTER ALL MOVING PARTS HAVE STOPPED COMPLETELY.

SAFETY FIRST

• Always wear protective gloves and safety glasses during operation of the shredder/chipper.

• Never allow your hands or any part of your body or clothing inside the feed hoppers or

discharge area of the shredder/chipper.

• Keep all protective guards and warning labels on the machine and in good working

condition.

• Always stand clear of the discharge area when the shredder/chipper is running.

• Keep your face and body back from the feed hoppers to avoid being struck by any material

that may bounce back.

• Keep proper balance and footing while operating the shredder/chipper.

• If it becomes necessary to push material into the feed hoppers, only use a wood stick, never

your hands or anything steel.

• Never assume you know where the chipper knife is. You do not know where it is.

• Keep area of discharge clear of people, animals, buildings, glass or anything else that will

obstruct clear discharge, cause injury or damage. Wind can also change discharge

direction, so be aware.

• Always keep hands out of the feed hoppers.

• Never operate the shredder/chipper without the chipper hopper in place.

• Do not transport the shredder/chipper with the P.T.O. engaged.

PROCESSING MATERIAL

• Your shredder/chipper can process dry or green material.

• Green material will process quicker and easier than dry material.

• Soft wood processes easier the hard wood.

• Your operator experience will teach you how different materials shred and chip.

• Your operator experience will teach you how fast you can process different materials.

• Most materials process well with the standard screen.

16

Page 16

• When chipping branches, sometimes a tail will be left at the end of a branch. To avoid this,

rotate the branch as it is fed into the chute.

• Rotating the branch as you feed it into the machine will improve chipping performance.

• Optional screens are available for both greater and less reduction of the material being

processed through the shredder hopper.

USING THE SHREDDER HOPPER

• The shredder hopper is located on the top of the unit and is the opening into which all materials to be shredded

should be fed. Most organic materials can be shredded. A flex guard, or blowback shield is secured to the

hopper. Material must be pushed past this flap using a wooden stick in order to enter the main chipper-shredder

chamber where revolving steel hammers do the shredding. The blowback shield is an important feature. It

prevents kickback of materials! Do not use your machine unless the blowback shield is securely fastened

in place.

• Due to the wide variety of materials that can be shredded, and their very different physical characteristics, only

feed limited quantities of any material into the hopper at first. The amount and length of material can be increased

if you find that the material is being processed without any difficulty. Your judgment and operator experience is

very important. Be sure not to overload the machine by feeding too much material into the hopper at one time. If

you hear the RPM’s decreasing, stop feeding material into the machine at once. Do not resume feeding the

machine until it has returned to full speed.

• The maximum diameter of material that can be shredded is 1 ½”. Any larger material should be fed through the

chipper-hopper. Material larger than 1 ½” can cause serious damage to any of the internal parts of the chippershredder chamber. The unit should be inspected after every use for bent hammers, missing spacers, damage to

the screen or any other obvious problems. If damage occurs, the rotor assembly can become unbalanced causing

excessive vibration. If used in this state, damage can occur. Do not use the machine if vibration is present.

Vibration is generally a warning sign of trouble.

• Several small branches can be fed into the shredder-hopper at once providing their combined diameter is less

than 1 1/2”. Branches longer than three feet should be cut to make them more manageable. Green materials

should be allowed to dry, or processed in small batches with dry materials to avoid winding around the rotor

assembly.

MATERIALS BEST SUITED FOR SHREDDING

• Leaves

• Roots

• Grass clippings

• Straw

• Hay

• Small branches

• Flowers

• Soil

• Garden debris

• Hedge clippings

• Kitchen Waste

• Manure

• Corn Stalks

• Palm frond tops

• Potato vines

• Tomato vines

• Paper

NOTE - The hammers within the chipper-shredder chamber can tug suddenly at material

being fed into the shredder-hopper. Do not hold on tightly to branches and vines, and don’t

feed material straight down into the hopper with your arm pointing downward toward the

opening. Instead, keep your arms parallel to the ground and several inches above the top

edge of the hopper.

17

Page 17

USING THE CHIPPER HOPPER

• This chipper-hopper is mounted on the side of the machine and is designed to chip the larger, heavier materials

that the shredder-hopper isn’t designed to handle. Branches fed into the chute are turned into “chips” by the

revolving chipper knife mounted on a flywheel. The chipper-hopper can chip branches and vines ranging in size

from 1” to 4 ½” in diameter. Cut your materials into manageable lengths before feeding them into the chipper.

Note: The chipper hopper must be securely bolted to the side of your equipment before using the

machine!

• The chipper is designed to draw the complete limbs in through the chipping area. Do not force material into the

chipper. If the machine does not self-feed, the chipper knives need replaced or sharpened or the gap between the

knives and the wear plate needs adjusting.

• Extremely hard knots will not process very well. Short stubs that have not self-fed through the chipper can be

pushed through with the next branch to be chipped. DO NOT THROW REMAINING STUBS OR UNCHIPPABLE

KNOTS INTO THE SHREDDER-HOPPER. DAMAGE WILL RESULT.

• Cut chipping material into manageable lengths of no more than five or six feet long before chipping them.

• Overloading the shredder/chipper will cause the rotor speed to decrease. If you hear the RPM’s decreasing, stop

feeding material into the machine until the machine has returned to full speed.

• Normally the branches will feed themselves into the chipper-hopper if trimmed to an appropriate size. Once the

self-feeding starts, release the branch quickly to avoid ripping from your hands.

MATERIALS BEST SUITED FOR CHIPPING.

• Branches, vines or stalks from 1 ½” to 4 ½” in diameter.

18

Page 18

USE COMMON SENSE WHEN USING YOUR SHREDDER/CHIPPER.

• LEARN TO RECOGNIZE THE CHANGE IN THE SOUND OF YOUR MACHINE

WHEN IT IS OVERLOADED.

• BECOME FAMILIAR WITH SUCCESSFUL OPERATING CONDITIONS AND

AVOID THOSE THAT CAN OVERLOAD AND DAMAGE THE MACHINE.

• IF THE MACHINE BECOMES JAMMED BY OVERLOADING OR ANY OTHER CAUSE,

STOP THE MACHINE IMMEDIATELY.

• IF YOU JAM THE MACHINE AND DO NOT DISENGAGE THE P.T.O., IT CAN DAMAGE

THE MACHINE. THIS DAMAGE CAN BE COSTLY AND IT MAY NOT BE COVERED

UNDER WARRANTY. FOR THIS REASON, IT IS IMPORTANT THAT YOU

IMMEDIATELY DISENGAGE THE P.T.O. IF THE MACHINE BECOMES JAMMED.

• ONLY YOUR OPERATOR EXPERIENCE WILL TELL YOU HOW FAST TO FEED

MATERIAL TO BE PROCESSED.

• CHECK TO SEE THAT THE FLYWHEEL WILL TURN FREELY BEFORE YOU START

THE SHREDDER/CHIPPER.

• VISUALLY CHECK CHIPPER KNIFE FOR DAMAGE EACH TIME YOU USE YOUR

SHREDDER/CHIPPER.

• CHECK KNIFE CONDITION, WEAR PLATE CONDITION, GAP SETTING AND THE

NUTS AND BOLTS THAT HOLD THE KNIFE IN PLACE FOR TIGHTNESS EVERY

8-10 HOURS OF OPERATION.

• DO NOT ALLOW PROCESSED MATERIAL TO BUILD UP WITHIN 3” OF DISCHARGE

CHUTE OPENING. MOVE SHREDDER/CHIPPER OR PILE AS NEEDED. FAILURE TO

DO THIS COULD RESULT IN UNNECESSARY JAMMING OF THE MACHINE.

• TO MOVE PILE OF PROCESSED MATERIAL, USE SPADE, RAKE, OR LONG HANDLE

TOOL. NEVER

USE YOUR HANDS OR FEET!

19

Page 19

SECTION V - MAINTENANCE AND STORAGE

IMPORTANT: The knife should be checked for sharpness and the bolts attaching them to the flywheel for

tightness every 8-10 hours of operation.

IMPORTANT: Every time you perform maintenance or any kind of service or check on the knife, be sure to

check the gap between the knife and wear plate for proper setting.

If the cutting mechanism strikes any foreign object or if your machine should start making an unusual

noise or is vibrating, stop the engine and disconnect the P.T.O shaft before you:

a. Inspect and examine for damage.

1. When not in use, your shredder/chipper should be stored out of the reach of children.

2. After every 8 hours of operation, lubricate the chipper side and drive side bearings. To do this, wipe all dirt, etc.,

3. When the steel chipping knife needs replacing or sharpening, refer to the section on removal, sharpening and re-

4. Care must be exercised when sharpening the knife to maintain the correct bevel and a straight edge. Refer to

b. Repair o replace any damaged parts before restarting and operating the machine.

from the grease fittings with a clean cloth, then apply no more than 3 shots of quality general-purpose grease with

a hand-pumped grease gun. Over lubrication can also damage bearings. Also, check the bearing collar set

screws regularly to be sure they are tight. If they are loose, reset them with Loctite 243, obtainable at any

hardware store.

installation.

sharpening directions. When you install a knife, the clearance between the knife and wear plate must be checked

and set. This clearance or gap should be set to 1/16” (see figure 1).

FLYWHEEL

CHIPPER KNIFE

WEAR PLATE

1/16" GAP

Figure 1

5. To adjust this clearance, loosen the three ¼” nuts and bolts holding the wear plate in place. The wear plate can

be slid up or down (in or out) to achieve the correct gap setting. Tighten the nuts and bolts when the wear plate is

in the correct position. Be certain the flywheel rotates without hitting anything before starting the chipper.

6. If the gap between the wear plate and the knife is not set correctly, you will have excessive vibration when

chipping and the blade will seem to be dull. This should be checked every 8-10 hours of operation.

7. If at any time it becomes necessary to disassemble the chipper for repairs, the chipper disk must be re-installed in

exactly the same position on the rotor shaft.

20

Page 20

REMOVAL, SHARPENING AND RE-INSTALLATION OF CHIPPER KNIFE

HOW TO REMOVE THE KNIFE

• Stop the tractor engine and disengage the P.T.O. driveshaft.

• Open the access cover on the chipper basic machine.

• Rotate the chipper disk until the three countersunk screws attaching the knife to the flywheel are visible

through the access door.

• Clean out the heads of the allen screws with an awl or sharp tool.

• Insert a 3/16” allen wrench into the heads of the screws.

• While applying pressure with the allen wrench, apply heat from a propane torch to the screws to break loose

the Loctite on the screws.

• Remove the heat once the screws have loosened.

• Remove all three allen screws in this manner.

KNIFE SHARPENING

• You should never attempt to sharpen the chipper knife freehand.

• It is extremely important that the 45-degree angle be maintained consistently for proper performance.

• The chipper knife should be taken to a machine shop for proper sharpening.

• Excessive heat generated during the sharpening process will damage knives and weaken the metal. Be sure

the knife is not overheated.

KNIFE INFORMATION

• The chipper knife should be checked routinely for sharpness.

• Using a dull knife will decrease performance and cause excessive vibration that will cause damage to the

shredder/chipper.

• How many times a knife can be sharpened is determined by how much material needs to be taken off to

sharpen or to compensate for dents or gouges.

• A new chipper knife has 5/16” measurement between the short side bevel edge and the knife mounting holes.

See figure 2.

SHORT SIDE BEVEL EDGE

NEW KNIFE

Figure 2

KNIFE MOUNT HOLE

21

Page 21

• The knife should never be sharpened to the extent that more than 3/32” is taken off this measurement.

• Once this measurement is below 7/32” (see figure 3) the knife should be replaced.

• If you are unable to remove dents or gouges with these guidelines, replace the knife.

SHORT SIDE BEVEL EDGE

SHARPENED KNIFE

Figure 3

KNIFE INSTALLATION

• Clean chipper disk where knife is going to be attached.

• Visually inspect the chipper disk slot and knife mounting area and be sure they are clean and that the knife will

be able to mount flush against the chipper disk.

• Visually inspect and clean the knife.

• Apply Loctite 243 to the screws that hold the knife in place.

• Hand tighten the knife to the chipper disk. If you are installing a new knife, use the new hardware that comes

with the knife when attaching it to the chipper disk.

• Tighten the center bolt.

• Tighten the outer bolt.

• Tighten the inner bolt.

• Double-check all three for tightness one more time.

WEAR PLATE

• The wear plate should have a square edge and be free of dents or gouges.

• The wear plate can be sharpened by hand, but as with the knife, do not overheat during the sharpening

process. This will change the characteristics of the steel and it should be replaced.

• Check the gap between the knife and wear plate every time any adjustments are done to either piece, or every

8-10 hours of operation.

22

Page 22

AFTER ANY BLADE OR WEAR PLATE MAINTENANCE OR ADJUSTMENT, ROTATE THE

CHIPPER DISK BY HAND. WATCH AND LISTEN CAREFULLY FOR ANY UNUSUAL NOISES,

CLICKING OR VIBRATION. IF ANY OF THESE ARE DETECTED, INSPECT THE MACHINE

FOR DAMAGE, REPAIR OR REPLACE ANY DAMAGED PARTS AND CHECK FOR ANY

LOOSE PARTS AND RETIGHTEN.

KNIVES MUST BE CHECKED AND MAINTAINED!

KNIVES MUST BE SHARP!

BE SURE TO REINSTALL THE KNIFE CORRECTLY AND DOUBLE CHECK FOR

TIGHTNESS!

HAMMERS

When the hard steel hammers of the rotor assembly become dull or round on the cutting edge, they

may be rotated or reversed. These hammers have four cutting edges that may be used before

replacement is necessary. To reverse the hammers proceed as follows.

• Remove belt guard.

• Remove round cover plate from behind belt guard.

• Remove shredder hopper.

• Remove the top plate.

• Turn rotor assembly until hammer rod is facing up.

• Turn hammer rod until small end of groove pin is facing up.

• Drive the groove pin from the hammer rod with a punch.

• Remove hammer rod through access hole on side of machine.

• Reverse hammers and reinstall with spacers on hammer rod.

• Replace old groove pin with new groove pin.

NOTE: Be sure the hammers and spacers are reinstalled in exactly the order in which they were removed.

Refer to the rotor assembly drawing for the correct order.

23

Page 23

TROUBLESHOOTING

Symptom Problem Correction

Belt burns.

Rotor won’t turn.

Shredding & chipping action

seems too slow or rotor stalling.

When chipping, branch seems to

vibrate excessively & “hammers”

hands.

Machine has excessive vibration. Rotor is out of balance. Check rotor carefully to see if hammers or

Chipper knives move over and

are striking chipper side plate.

Products build-up in shredding

chamber.

Rotor is jammed or stopped. A. Immediately stop engine.

B. Disconnect drive shaft.

C. Remove screen & clean out shredder

chamber.

D. Turn rotor by hand to be sure it turns freely.

E. Check belt tension.

Engine speed is too slow.

Belts are slipping.

Knives are dull.

Gap between blade & wear plate is

too large.

Taper lock bushing is loose.

Set screws in rotor shaft bearings

are loose or missing.

Excessive wear on hammers. Replace or reverse hammers.

Make sure P.T.O. is at 540 RPM.

Check for loose or missing belts & tighten.

Remove blade & sharpen - be sure to maintain

same bevel of 45 degrees.

Adjust gap as per instructions.

spacers are missing.

Replace any damaged or broken hammers.

If key in taper lock bearing is too deep, file key

to seat properly.

Reset the proper blade gap & tighten set

screws.

24

Page 24

Page 25

PARTS LIST

ITEM # PART # QTY DESCRIPTION

1 090-0462 4 5/16-18 X 3/4" CARRIAGE BOLT

2 913-0380 1 CHIPPER HOPPER KIT

3 911-0034 1 SHREDDER HOPPER BLOW BACK GUARD

4 090-0012 3 1/4-20 X 3/4" HHCS

5 911-0049 1 BLOW BACK GUARD MOUNT BAR

6 090-0470 3 1/4-20 NYLOCK NUT

7 911-0028 1 SHREDDER HOPPER WELDMENT

8 090-0460 20 5/16-18 NYLOCK NUT

9 500-0068 4 VIBRATION DAMPENER

10 090-0089 2 5/16-18 X 1-1/4" HHCS

11 090-0090 2 5/16-18 X 1-1/2" HHCS

12 911-0302 1 UPPER SUPPORT WELDMENT

13 090-0370 1 1/2-13 X 3" HHCS

14 911-0296 1 CENTER BRACE

15 090-0110 4 3/8-16 X 1" HHCS

16 090-0461 4 3/8 NYLOCK LOCKNUT

17 090-0050 1 1/2-13 GRIPCO LOCKNUT

18 911-0294 2 LEG

19 090-0088 16 5/16-18 X 1" HHCS

20 911-0295 2 TPH MOUNT BRACKET

21 911-0300 1 BELT GUARD WELDMENT

22 911-0293 1 FRAME WELDMENT

23 911-0150 1 BASIC MACHINE

26

Page 26

Page 27

PARTS LIST

40 900-0040 1 COVER PLATE

41 913-0302 1 SPRING MOUNT BRACKET

42 090-0411 1 1/4-20 X 2-1/2" EYE BOLT

43 030-0329 1 SPRING

44 030-0181 1 BELT

45 030-0180 1 3 GROOVE 3.65" SHEAVE

46 030-0167 1 1-7/16" TAPER LOCK BUSHING

47 020-0001 2 3/8-16 X 5/8" SET SCREWS

48 030-0179 1 3 GROOVE 14" SHEAVE

49 030-0489 1 1" TAPER LOCK BUSHING

50 2 1/2-13 X 1/2" SET SCREWS

51 911-0206 4 MOUNT BAR

52 911-0297 1 LOWER SHAFT

53 030-0055 2 1" BEARING

54 090-0113 2 3/8-16 X 1-3/4" HHCS

55 911-0298 1 IDLER ARM

56 900-0092 2 SPACER

57 090-0461 2 3/8-16 NYLOCK NUT

58 909-0016 1 IDLER SHEAVE

59 911-0054 1 SCREEN

60 911-0033 1 BAFFLE

61 911-0036 2 BAFFLE ROD

62 911-0050 2 3/8-16 X 15" HHCS

28

Page 28

Page 29

Page 30

911-0150 BASIC MACHINE

ITEM # PART # QTY. DESCRIPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

911-0064 1 ROTOR ASSY W/HAMMERS

911-0152 1 CHIPPER SIDE PLATE WLDMNT

911-0268 1 CHIPPER CHUTE PLATE WELDMENT

913-0326 1 WEAR PLATE

030-0279 1 1 3/16" 2 BOLT BEARING

911-0151 1 DRIVE SIDE PLATE

030-0166 1 4 BOLT BEARING 1 7/16" BORE

911-0003 1 SCROLL WELDMENT

911-0026 1 TOP PLATE

911-0267 1 CHIPPER DISK – COMPLETE WITH KNIFE

030-0500 1 CHIPPER KNIFE

030-0167 1 1610 x 1 7/16" ID TAPER LOCK BUSHING

090-0162 4 #10-32 X 3/8 SELF TAPPING SCREW

030-0117 1 RETAINING RING - 1 3/16"

030-0171 2 1 7/16" RETAINING RING

090-0024 1 1.565 OD X 1.192 ID X .050 THK

090-0233 2 5/16"USS FLATWASHER PLTD

090-0111 2 3/8-16 X 1-1/4 HHCS

090-0016 7 3/8-16 X 1 1/2 HHCS GR5 - BLACK

090-0049 12 3/8-16 GRIPCO LOCKNUT GR B PLT

090-0245 3 1/4 SAE FLATWASHER - BLACK

090-0257 3 1/4-20 X 1" SOCKET FLAT HD CAP

090-0470 3 1/4-20 NYLOK LOCKNUT PLTD

090-0463 4 1/2-13 X 1 1/2 HHCS GR5 - BLACK

090-0351 4 1/2 SPLIT LOCKWASHER PLTD

090-0050 4 1/2-13 GRIPCO LOCKNUT GR B PLT

090-0413 3 5/16-18 X 1" FLAT HD SOCKET CAP

090-0066 4 5/16-18 X 3/4 HHCS GR 5 PLTD

090-0048 4 5/16-18 GRIPCO NUT

911-0050 3 3/8-16 X 15"LG HHCS PLTD (TIE ROD)

913-0210 1 ACCESS COVER

911-0064 ROTOR ASSEMBLY

ITEM # PART # QTY. DESCRIPTION

1

2

3

4

5

6

7

911-0135 1 ROTOR WELDMENT

900-0100-4 4 HAMMER ROD

500-0008 48 HAMMER

500-0010 12 SPACER-5/16"

500-0011 24 SPACER-7/8"

500-0012 18 SPACER-5/8"

030-0153 4 13/64" DIA X 1 1/2" LG DRIVE PIN

31

Page 31

COUNTRY HOME PRODUCTS

Megis Road, P.O. Box 25, Vergennes, Vermont 05491

1(800) DR-OWNER (376-9637)

32

Loading...

Loading...