Page 1

DR

SAFETY & OPERATING INSTRUCTIONS

®

R225, R300 and R390 ENGINES

Read and understand this manual and all instructions before operating the DR R225, R300 and R390 ENGINES.

Original Language

DR Power Equipment

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Website: www.DRpower.com

Page 2

Table of Contents

I: Safety Precautions .............................................................................................................................................................................. 3

II: Parts Description .............................................................................................................................................................................. 4

III: Pre-Operation Inspection ................................................................................................................................................................ 5

IV. Starting the Engine .......................................................................................................................................................................... 8

V. Stopping the Engine ......................................................................................................................................................................... 11

VI. Exhaust Control System ................................................................................................................................................................... 13

VII: Maintenance ................................................................................................................................................................................... 14

VIII. Transport and Storage .................................................................................................................................................................. 17

IX: Troubleshooting ............................................................................................................................................................................... 18

X. Specifications .................................................................................................................................................................................... 22

XI. Electrical Diagrams .......................................................................................................................................................................... 23

Conventions used in this manual

This indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

This information is important in the proper use of your machine. Failure to follow this instruction could result in damage to

your machine or property.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time without notice or

obligation to the purchaser. The descriptions and specifications contained in this manual were in effect at printing.

Equipment described within this manual may be optional. Some illustrations may not be applicable to your Engine.

2 DR

®

R225, R300 and R390 Engines

Page 3

I: Safety Precautions

There is a possibility of voiding the warranty and personal or equipment damage if instructions are not followed.

Please pay special attention to the following:

1. Operate the engine according to the recommendations in your owner's manual. Do not overload, overrun the engine or

run it with low load and at low speed for a long period of time.

2. Use regulated 87 octane brand of gas. The fuel should be fully deposited and filtrated before use. Keep the fuel filler clean

to prevent contamination.

3. Change the oil periodically as described in the “Maintenance” section of this manual.

4. Periodically check the installation, connection and the tightness of the mounting hardware. Tighten when necessary.

5. Periodically clean the air filter; change it as indicated in the “Maintenance” section.

6. This gasoline engine is air-cooled, so clean the cooling fins, recoil cover and air intake to allow the engine cool normally.

7. The operator should be familiar with the working principle and structure of this gasoline engine, knowing how to make an

emergency stop when needed. Do not allow anyone without training to operate the engine. Perform periodical

maintenance per the “Maintenance” section. Fix all operation problems immediately. Do not run the engine if it is not

operating properly.

8. Only operate the engine in a well-ventilated place, keep it at least one meter away from building walls or other equipment,

keep engine away from inflammables such as gasoline, matches and so on to avoid possibility of fire.

9. Refuel in a well-ventilated area with the engine stopped, do not smoke and do not allow flames or sparks in the refueling

area.

10. Do not overfill the fuel tank to avoid fuel spilling out. If there is spilled fuel around, be sure to clean it thoroughly before

starting.

11. Do not run the engine inside buildings or enclosure areas.

12. The exhaust muffler is very hot during running the engine and even after the engine stops. Never touch it, or you may get

burns. Do not transport or store the engine until it has cooled down entirely.

13. Safe warning label:

Please carefully read warning labels before operating. DR Power Equipment is not responsible if a person is hurt, or

equipment becomes damaged due to disregarding warning labels.

CONTACT US AT www.DRpower.com 3

Page 4

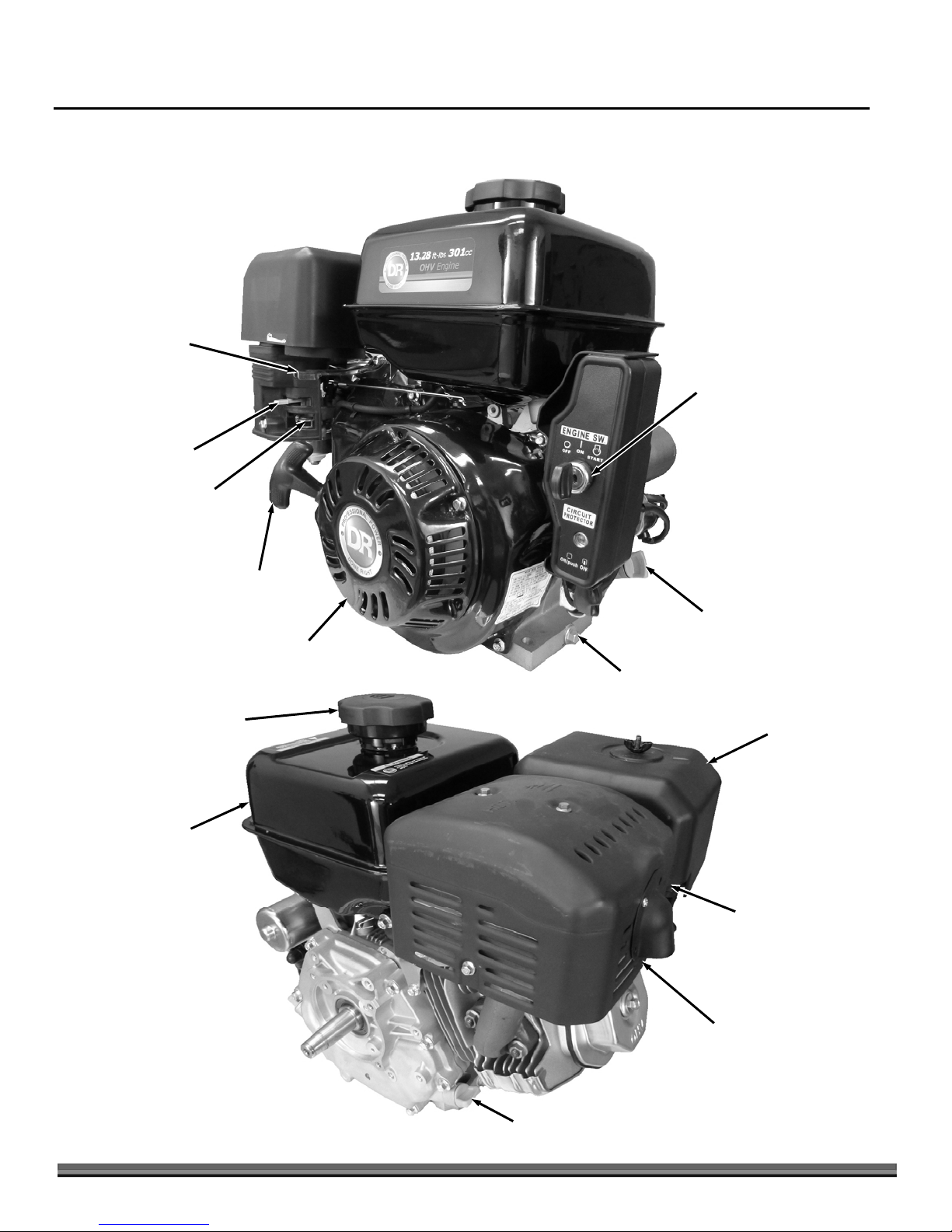

II: Parts Description

Air

r

Throttle

Lever

Choke Lever

Fuel Shutoff

Engine Switch

Fuel Tank Cap

Fuel Tank

Starter

Handle

Oil Dipstick

Recoil Starter

Oil Drain

Plug

Cleane

Spark

Plug

4 DR

®

R225, R300 and R390 Engines

Muffler

Oil Plug

Page 5

III: Pre-Operation Inspection

1. ENGINE OIL

Use 4-stroke engine oil, API service classification SJ class or equivalent. Check the API service label on the oil container to be sure

it includes the letters SJ class or equivalent.

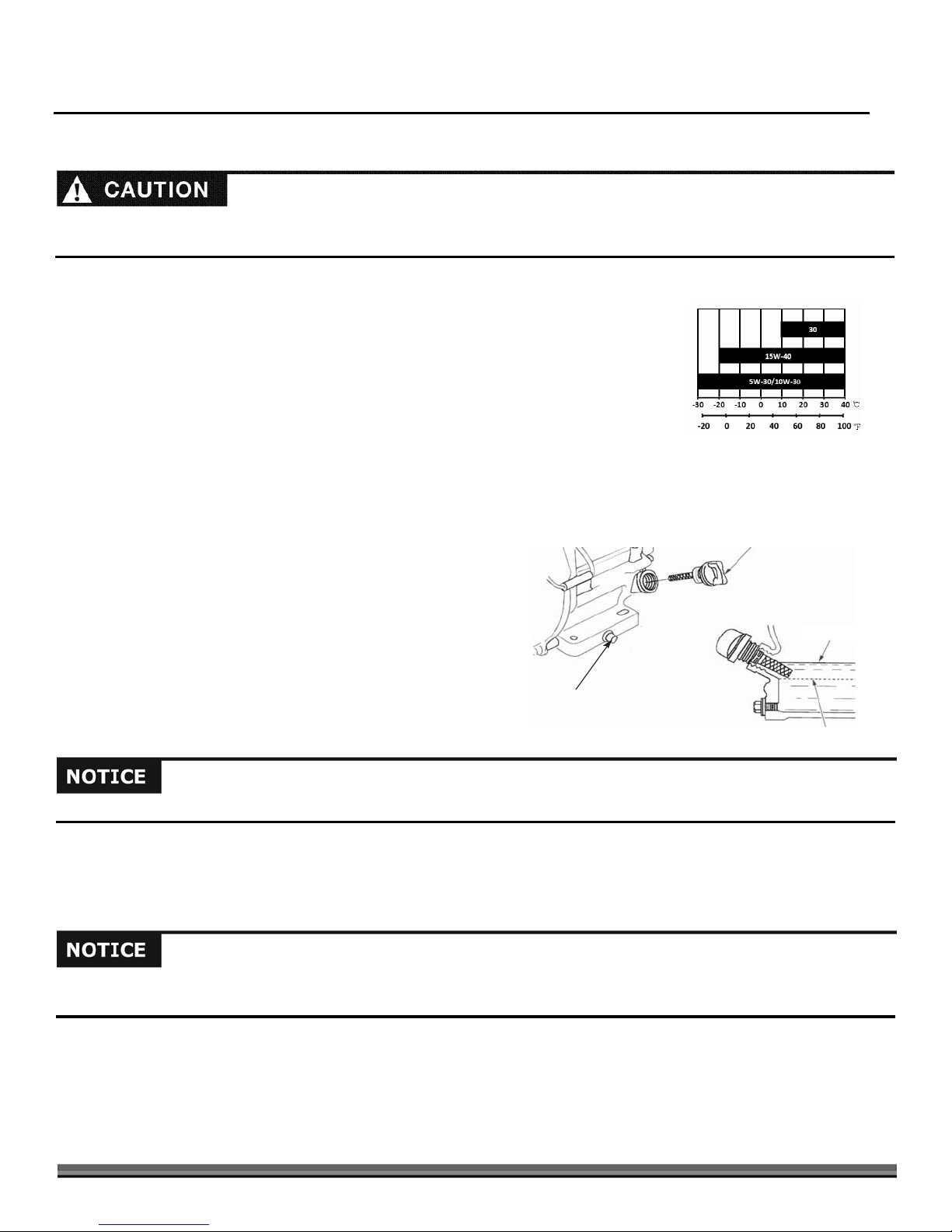

SAE 10W-30 is recommended for general use. Other viscosities shown in the chart may be used

when the average temperature in your area is within the indicated range.

Oil level check

1. Remove the dipstick and clean it with a rag.

2. Reinsert the dipstick into the oil filling hole without screwing it in. Pull the dipstick out and

check oil level.

3. If the oil level is too low, add the recommended engine oil up to the oil filling neck.

4. Reinstall the dipstick.

R225 Oil Capacity = .5 qt/16 oz (0.5L)

R300 and R390 Oil Capacity = 1.16 qt/37 oz (1.1L)

Drain Plug

SAE Viscosity Grades

Environment Temperature

Oil Dipstick

Oil Upper Level

Oil Lower Level

Running the engine with insufficient engine oil may damage the engine severely and would not be covered under warranty.

2. AIR CLEANER

Remove the air cleaner cover and check the air filter to make sure it is clean and not damaged. Clean or replace it as necessary

(see the “Maintenance” section for maintenance of the air filter).

Never run the engine without the air filter and cover installed or damage to the engine could result. Damage to the engine

by not having the air filter and cover installed is not covered under warranty.

CONTACT US AT www.DRpower.com 5

Page 6

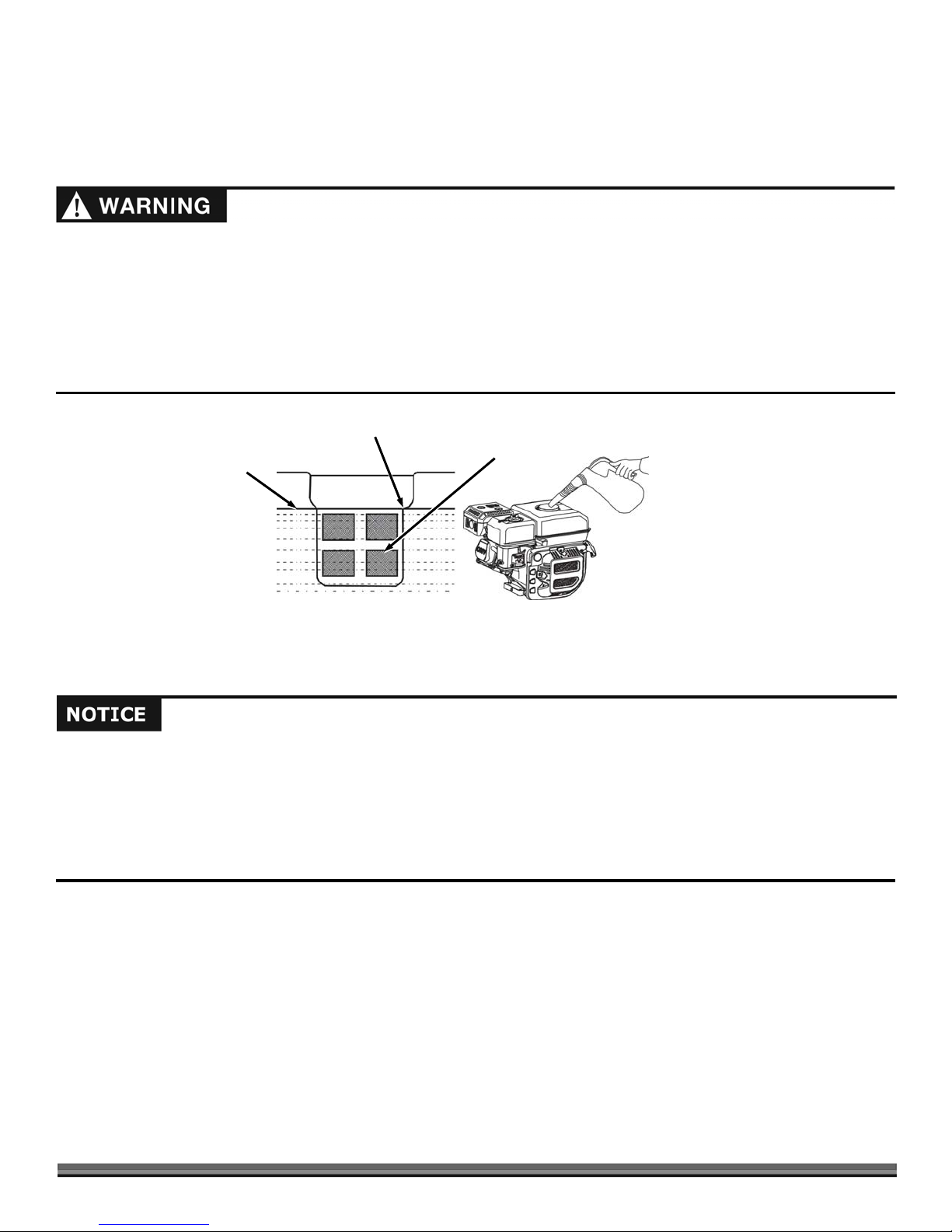

3. FUEL RECOMMENDATION

1. Remove the fuel tank cap and check the fuel level.

2. If the level is too low, refuel the tank to the recommended level. Remember to never fill fuel over the fuel filler shoulder.

Gasoline is extremely flammable and is explosive under certain conditions.

Only add fuel in a well-ventilation area with the engine stopped. Do not smoke and do not allow flames or sparks in the area

where gasoline is stored or where the fuel tank is refueled.

Do not overfill the fuel tank (there should be no fuel in the filling neck). After refueling, make sure the fuel tank cap is installed

securely.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor may ignite. If any fuel is spilled, make sure the area

cleaned up and is dry before starting the engine.

Avoid repeated or prolonged contact with skin or breathing of fuel vapor. Keep out of reach of children.

Fuel Filler Shoulder

Maximum

Fuel Level

Fuel Filler

R225 Fuel Tank Capacity = .9 gal/3.6 qt (3.4L)

R300 and R390 Fuel Tank Capacity = 1.72 gal/6.9 qt (6.5L)

Fuel may damage paint and plastic. Be careful not to spill fuel when refueling. Any damage due to fuel spilling is not covered

under warranty.

It is normal to hear a "light knocking" sound when the engine is overloaded. Do not be concerned if this occurs. If "knocking"

or sounds occur at a steady speed under normal load, change the brand of gasoline; if the sounds continue, consult your

dealer for help.

If you continue to run the engine with a "Knocking" sound during normal operation, it will damage the engine.

Continuing to use the engine with "Knocking" sounds from misusing will void the engine warranty.

6 DR

®

R225, R300 and R390 Engines

Page 7

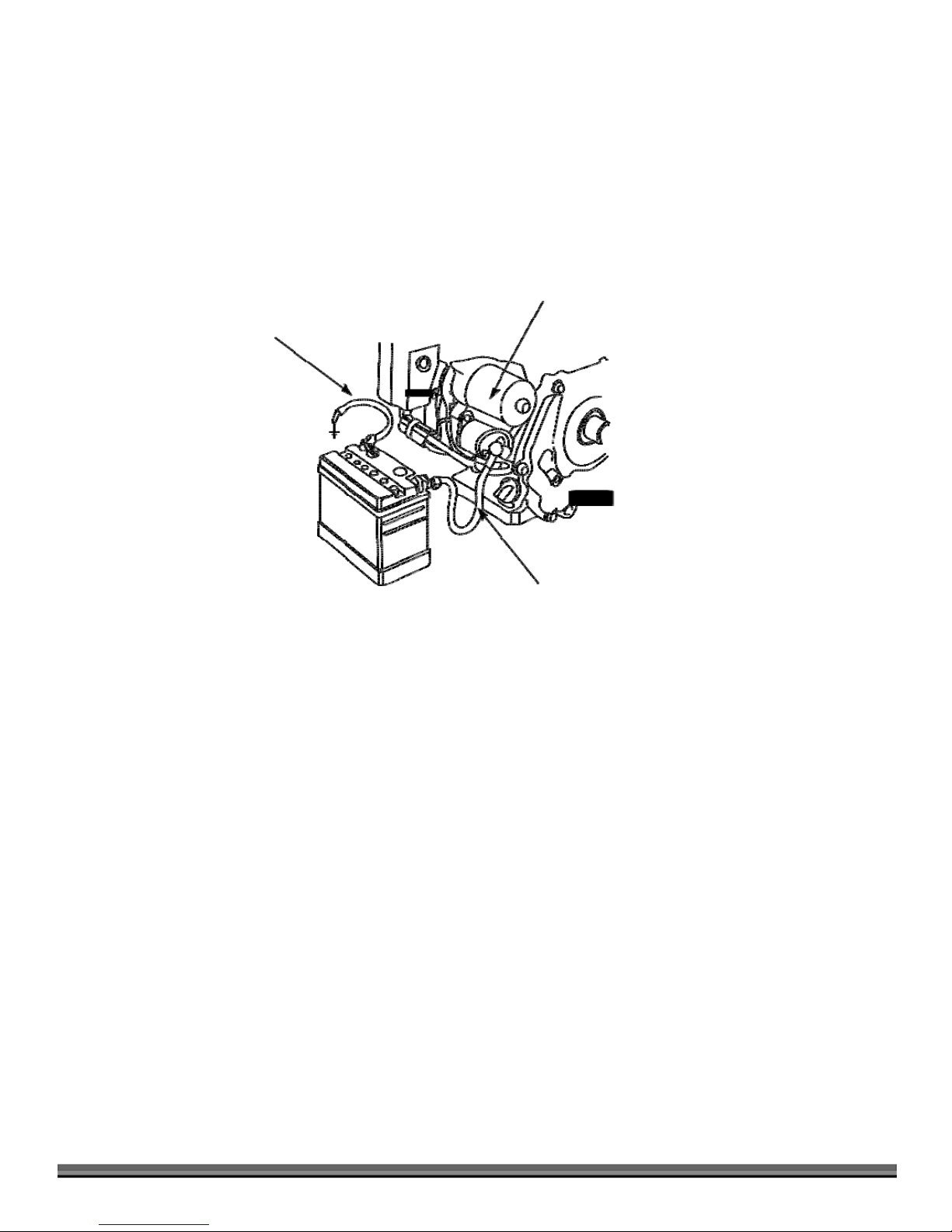

4. BATTERY CONNECTION

Use a 12V battery with your DR Engine.

Connect the battery’s positive (+) lead to the start relay terminal and connect it’s negative (-) lead to the engine mounting

Bolt, base screw or other grounding point with the engine (See the following picture).

Check the battery's connecting point; make sure that it is tight and not rusted. If rusted, clean and connect.

Start Relay

Negative

(-) Wire

Positive

(+) Wire

CONTACT US AT www.DRpower.com 7

Page 8

IV. Starting the Engine

ON

r

ON

OFF

Choke Lever

CLOSE

Fuel Shutoff

OPEN

1. Turn the fuel Shutoff to the “ON” (OPEN) position.

2. Turn the choke lever to the “CLOSE” (CHOKE) position. If the engine is hot from

use, don’t close the choke.

3. Move throttle lever to the left a little.

Throttle Leve

High Speed

Manual Engine Switch

Low Speed

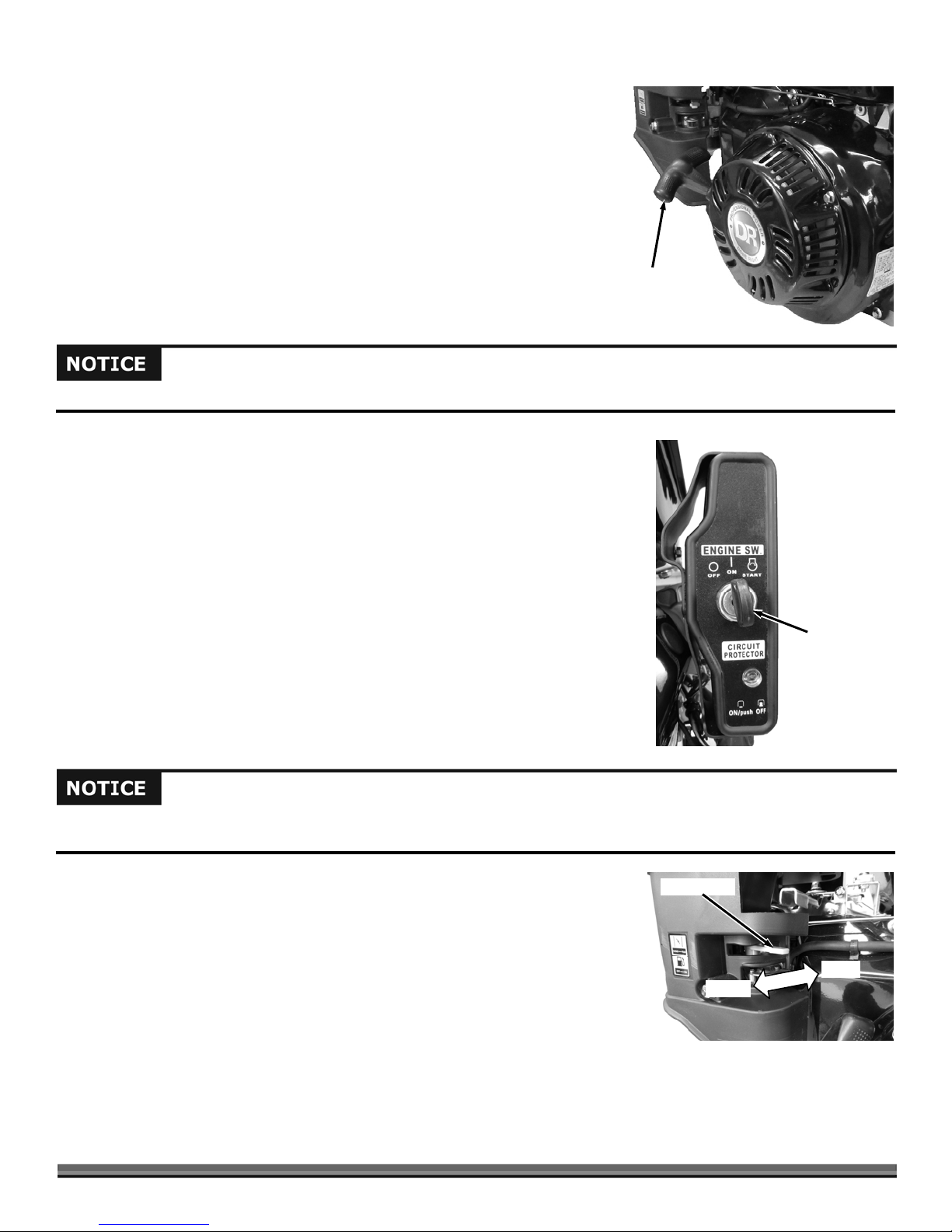

4. Starting the engine – Manual Start

a. Turn the engine switch to the “ON” (START) position.

OFF

8 DR

®

R225, R300 and R390 Engines

Page 9

b. Pull the recoil starter grip lightly until resistance is felt, then pull briskly.

Recoil Starter

Grip

Don’t allow the recoil starter grip to snap back against the engine. Return it gently to prevent damage to the starter

5. Starting the engine – Electric Start

a. Turn the engine switch to the “START” position and hold it there until the

engine starts.

b. When the engine starts, allow the engine switch to return to the “ON” position.

Engine Switch

Do not use the starter for more than 5 seconds or starter motor damage may occur. If the engine fails to start, release the switch

and wait 10 seconds before operating the starter again.

6. Once the engine is running push the choke lever to the “OPEN” position.

Choke Lever

OPEN

CLOSE

CONTACT US AT www.DRpower.com 9

Page 10

Throttle Leve

r

High Speed

To run the engine, move the throttle lever to proper position to run at the required

speed.

Low Speed

10 DR

®

R225, R300 and R390 Engines

Page 11

V. Stopping the Engine

ON

r

ON

In an emergency, rotate the engine switch to the “OFF” position.

In normal non emergency conditions, please do as follows:

1. Push the throttle lever to the right to the low speed position.

Throttle Leve

High Speed

Low Speed

2. Rotate the engine switch to the “OFF” position.

Fuel Shutoff

OFF

3. Set the fuel shutoff to “OFF” position.

Engine Switch

(Manual Start)

OFF

Engine Switch

(Electric Start)

Never stop the engine at high speed under heavy load unless there is an emergency because engine could be damaged.

CONTACT US AT www.DRpower.com 11

Page 12

Low Engine Oil Shutoff

The engine oil shutoff is specially designed to protect the engine when the engine oil in the crankcase is too low. Once the

engine oil level gets lower than the limit line, the low engine oil shutoff system will stall the engine automatically while the

engine switch is still at “ON” position.

If the engine will not start, check the engine oil level first before going to other check items.

BREAKER (Electric-start models)

The breaker will cut off automatically to protect the charging circuit of the battery in

Breaker

the case that a short circuit or incorrect connection of the battery poles occurs.

The green indicator in the breaker will pop out and the circuit will be cut off. After

finding troubleshooting and fixing the problem, depress the breaker button to turn

the breaker on.

High Altitude Kit for EPAIII Engines

3000ft to 6000ft or 6000ft to 8000ft of elevation

At high altitude, the standard carburetor air-fuel mixture will be too rich. Performance will decrease and fuel consumption will

increase. A very rich mixture will also foul the spark plug and cause hard starting. Operation at an altitude that differs from

that at which this engine was certified, for extended periods of time, may increase emissions.

The fuel system on this Engine or Equipment may be influenced by operation at higher altitudes. Proper operation can be

ensured by installing an altitude kit when required. See the table below to determine when an altitude kit is required.

Operating this engine without the proper altitude kit installed may increase the engine’s emissions and decrease fuel

economy and performance. Kits may be obtained from DR Power Equipment, and should be installed by a qualified individual.

Fuel Altitude Range* Kit Part Number

Gasoline 0 – 3000 ft Not Required

3000 – 6000 ft Altitude kit 1#

6000 – 8000 ft Altitude kit 2#

Engine, Generator Set, Pressure Washer, Walk-Behind

Compressor, Pump, Tiller

*Elevation above sea level.

etc.

Lawnmower,

This high altitude jet is to be used at elevations above 3000 feet.

At elevations above 8000 feet, the engine may experience decreased performance, even with the high altitude kit.

To prevent serious injury from fire follow the kit procedures in a well-ventilated area away from ignition sources. If the engine is

hot from use, shut the engine off and wait for it to cool before proceeding.

The warranty may be void if necessary adjustments are not made for high altitude use by installing a high altitude kit.

If a carburetor is replaced, the proper high altitude kit jet will need to be installed into the replacement carburetor.

12 DR

®

R225, R300 and R390 Engines

Page 13

VI. Exhaust Control System

With the engine running carbon monoxide, nitrogen oxide and hydrocarbons are produced and in certain conditions, nitrogen

oxide and hydrocarbon will react chemically with each other to make smoke while carbon monoxide is toxic, so proper

maintenance to control these dangers is very important.

To keep the exhaust of your engine within the standard exhaust emission, pay attention to the following:

1. Maintenance

Maintain the engine periodically in accordance with the maintenance schedule in the “Maintenance” section. The

maintenance schedule is based on normal use in normal conditions, if using under heavy load, dusty or wet circumstances or

in high temperature, service of the engine should be done more often.

2. Problems affecting exhaust emissions

Difficult starting or difficult stopping.

Unstable idling speed.

Exhausting of black smoke or consuming too much fuel.

Poor ignition, sparks or backfire.

Premature ignition.

If you are experiencing any of above problems, contact DR Power Equipment for help.

CONTACT US AT www.DRpower.com 13

Page 14

VII: Maintenance

The engine must be properly maintained to ensure safe operation, economy and trouble-free, as well as eco-friendly.

In order to keep your gasoline engine in good working condition, it must be periodically serviced. The following maintenance

schedule and routine inspection procedures must be carefully followed.

Frequency

Items

Engine oil Check- Refill

Replace

Air filter element Check

Clean

Replace

Spark Plug Check - adjust

Spark arrester Clean

Idling ( if

Check - adjust

Each Time Before

use

√

√

First month or first

20hrs of operation

√ √

√

Every 3 months or

every 50hrs of

operation

√

√

Every year or every

100 hrs of

operation

√﹡

√

equipped)﹡﹡

Valve clearance

Check-adjust

√

﹡﹡

Fuel tank & fuel

Clean

√

filter ﹡﹡

Fuel line Check Every 2 years( change if necessary)

﹡ These items should be replaced as needed.

﹡﹡ These items should be maintained and repaired by our authorized dealer, unless the owner has appropriate tools and is

proficient with mechanical maintenance.

If the gasoline engine is frequently operating under high temperature or heavy load, change the oil every 25 hours.

If the engine is frequently operating under dusty or other severe circumstances, clean the air filter element every 10 hours; If

necessary, change the air filter element every 25 hours.

Perform maintenance according to which one come first, period (month, year) or the exact time (hours).

Stop the engine before servicing. Put the engine on a level surface and remove the spark plug cap to prevent the engine from

starting. Never run your engine in a poorly ventilated room or other enclosed area, be sure to keep good ventilation in working

area. The exhaust from the engine may contain poisonous gases, inhalation can cause shock, unconsciousness and even death.

14 DR

®

R225, R300 and R390 Engines

Page 15

2. MAINTENANCE METHOD

Oil Dipstick

1) Replacement of engine oil (see “Oil Level Check” in Chapter IV to check oil level)

Drain Plug

The oil will drain more rapidly and completely when the engine is warm.

(1) Remove the oil filler cap and drain plug to drain engine oil thoroughly.

(2) Reinstall the drain plug and screw in securely.

(3) Fill with the specified engine oil up to the upper level mark.

Do not dump oil containers or discarded engine oil into rubbish boxes or onto the ground. For the sake of environmental

protection, we suggest you take in discarded engine oil with a closed container and bring to local recycling station.

(3) Reinstall the oil filler cap.

2) Maintenance of air filter

A dirty air filter can restrict air flowing into the carburetor. To keep the carburetor in good working condition, please service

the air filter periodically (clean air filter element after 20h of use). If the engine is being operated in an extremely dusty area,

clean the filter more often.

Never clean the air cleaner filter with gasoline or low flash-point detergents, or explosion may happen.

Washer

Never run the engine without an air filter because dirt and dust entering the engine can speed up engine wear and cause damage.

(1) Remove the wing nut from the filter cover and remove the cover.

(2) Remove the wing nut from air filter and pull the air filter with pre-cleaner from

Wing Nut

the threaded stud.

(3) Pull the pre-cleaner off the paper filter assembly and shake the dirt from the

foam pre cleaner and from the paper filter.

Note: If the foam Pre-cleaner or paper filter is too dirty to clean (clogged) or

Filter Cover

damaged you must replace the filter with a new filter.

(4) Clean the air filter cover and inner surface with wet cloth, be careful not to allow

the dust to enter into the carburetor.

(5) Reinstall the air filter with pre-cleaner and secure with the wing nut.

(6) Reinstall the filter cover and secure with the wing nut.

Wing Nut

Pre-Cleaner

and Filter

CONTACT US AT www.DRpower.com 15

Page 16

3) Spark plug

Spark plug type: See specification section X.

To ensure the engine will run normally, the spark plug gap must be correct and make sure there

are no deposits around the spark plug.

(1) Remove the spark plug cap.

(2) Clear away dirt from around the spark plug base.

(3) Only remove the spark plug with a spark plug wrench.

(4) Visually check the spark plug. Clean with a steel brush. If the insulator is damaged, replace

the spark plug.

(5) Measure the spark plug clearance with a feeler gage. The clearance should be .028" ~.032"

(0.7~0.8mm) If adjustment is necessary, bend the side electrode carefully.

(6) Check if the spark plug gasket is in good conditions. Screw in the spark plug as far as you can

by hand to prevent thread damage.

(7) Tighten the spark plug with a spark plug wrench and compress the gasket.

-- If a new spark plug is used, turn it 1/2 turn after compressing the gasket.

-- If reinstalling the used spark plug, turn it 1/8-1/4 turns after compressing the gasket.

Don’t touch the muffler when the engine is running to avoid burns.

The spark plug must be tightened securely or it may become very hot and damage the engine.

16 DR

®

R225, R300 and R390 Engines

Page 17

VIII. Transport and Storage

Transport with the fuel shutoff turned to the “OFF” position. Transport or store the engine when it is cool to avoid getting

burns or causing fire.

Do not excessively tilt the engine because fuel will spill. Spilled fuel or fuel vapor may ignite to cause fire.

Fuel is extremely flammable and explosive under certain conditions. Keep smoke, fire and spark away from operating site.

If the engine is not kept in use for a long period of time, be sure to store it properly.

1. Make sure the storage area is dry and free of dust.

2. Turn the fuel shutoff to the “OFF” position and set a proper container under the carburetor.

3. Remove the carburetor drain plug to remove the fuel in the carburetor float bowl.

4. Open the fuel shutoff to completely drain gasoline out of the fuel tank.

5. Reinstall the carburetor drain plug and tighten it.

6. Remove the oil drain plug, drain the oil out of the engine and reinstall the oil drain plug.

Carburetor Drain Plug

7. Remove the spark plug. Add about a spoon-full of fresh engine oil onto the cylinder. Crank the

engine with the pull cord to distribute engine oil evenly. Reinstall the spark plug.

8. Cover the engine to protect dust entering.

Please maintain according to following table when reusing after storing.

Storing time Maintaining procedure is recommended in order to prevent starting difficulty.

1 month No maintenance needed.

1-2 month Drain the used gasoline out and add the fresh gasoline

2 months to 1 year Drain the used gasoline out and add the fresh gasoline

Drain the gasoline out of the carburetor cup. Drain the gasoline out of the sediment bowl.

More than 1 year Drain the used gasoline out and add the fresh gasoline

Drain the gasoline out of the carburetor cup. Drain the gasoline out of the sediment bowl.

After removing from storage, first drain the used gasoline into approved container and don’t start before

adding fresh gasoline.

Remove the carburetor drain plug and completely drain the gasoline out of the carburetor to an approved container and

replace the drain plug. Remove the sediment bowl after closing fuel shutoff and completely pour the gasoline out the sediment

bowl. Finally reinstall the sediment bowl and screw it down.

CONTACT US AT www.DRpower.com 17

Page 18

IX: Troubleshooting

f

gg

q

pp

y

y

q

y

1. ENGINE STARTING DIFFICULTLY:

TROUBLE CAUSE REMEDY

There is not enough fuel in fuel tank and fuel shutof

is closed.

Air vent in the fuel filler cap is clogged Dredge air vent.

Fuel shutoff is clogged Clean first and then dredge

Improper or clogged main fuel flow hole. Readjust or clean, blow to get through.

Fill fuel, open fuel shutoff.

Needle valve is not closed properly or start hole is

clo

ed.

Float is damaged or sticking. Repair float

Fuel supply is not smooth or

no fuel supply.

Dismantle needle valve and repair, clean, blow to get

through.

Fuel is too filthy or deteriorated Replace

There is water in fuel. Replace

Too much fuel in engine Drain extra fuel, dry up spark plug electrodes.

Wrong fuel brand Select proper fuel brand corresponding with the

Fuel supply is

Normal spark plug spark

Something wrong with the fuel system.

normal.

Too much carbon deposit and dirt around

re

uirements.

Clear away.

electrodes.

Electrodes are burn damaged seriously or insulators

Replace spark plug.

damaged.

Normal high –

tension line

Improper electrodes gap. Adjust to proper value.

Normal high-

tension line spark

High–tension line is damaged. Replace

Ignition coil is damaged. Replace

Magneto loses magnetism. Replace

Abnormal gap between ignition coil and flywheel. Adjust gap

Normal cylinder compression

Normal fuel supply system.

High-tension line

not normal

Normal spark

plug

TROUBLE CAUSE REMEDY

Piston ring is worn to or even over its wear limit Replace

Piston ring is broken. Replace

Piston ring is sticking. Clear up carbon fouling.

Spark plug is not installed tight or without a gasket. Tighten with a gasket installed.

stem.

s

l

Air leakage between cylinder block and cylinder head. Check cylinder gasket, and the flatness of the surface

Air leakage in the valves Check valve clearance and tightness. Repair if

Abnormal cylinder compression.

Normal spark plug.

Normal fuel su

If engine will still not start, contact DR Power Equipment.

18 DR

®

R225, R300 and R390 Engines

where cylinder block contacts the cylinder head

Tighten cylinder head bolts in proper order to proper

tor

ue.

necessar

.

Page 19

y

ole clogged.

r

Rep

y

Rep

When testing the spark plug, never hold the high- voltage wire of the spark plug with a wet hand.

Make sure there is no spilled fuel outside the engine and that the spark plug isn’t dipped with fuel.

To prevent fire, keep sparks far away from the spark plug mounting hole.

2. INSUFFICIENT ENGINE POWER OUTPUT:

TROUBLE CAUSE REMEDY

Air in fuel line or fuel line clogged

Main oil flow hole is not adjusted properl

In carburetor, needle valve hole and main oil flow

h

Fuel shutoff is clogged up. Clean, replace damaged part

Too much carbon deposit in combusting chamber. Clear away

Too much carbon fouling in muffler and exhaust

pipe.

Air filter is clogged up. Clean air filter pape

Fuel supply system

Intake pipe is leaking Repair or replace

Piston or cylinder or piston ring is worn

Air leakage from the surface where the cylinder block

contacts the c

Too big or too small valve clearance. Readjust

When increasing throttle, speed increases

slow or speed decrease and engine stops

running

Valve tightness is poor. Repair

Poor

compression

linder head.

Exhaust air or dredge fuel line

Readjust

Clean and blow to get through

Clear away

element

lace worn parts

Replace cylinder gasket

3. ENGINE NOT RUNNING SMOOTHLY:

TROUBLE CAUSE REMEDY

Piston, cylinder or piston ring is worn excessively. Replace worn parts

Piston pin and piston pin hole are worn excessively. Replace piston or piston pin

Knocking sound

Abnormal

combustion

Spark

lacking

Tie rod small head is worn excessively.

Roller bearing for crankshaft main shaft is worn. Replace roller bearing

Engine is too hot Troubleshoot reasons for hot engine

Too much carbon deposit in combustion chamber Clear away

Improper gasoline brand or low gasoline quality Replace with qualified gasoline

There is water in float chamber Clean

improper spark plug electrodes clearance Adjust

Something wrong with induced coil or related parts Check and replace damaged parts

lace tie rod

CONTACT US AT www.DRpower.com 19

Page 20

4. ENGINE SUDDENLY STOPS RUNNING:

g

TROUBLE CAUSE REMEDY

Fuel tank is empty Refill fuel tank

Carburetor is clogged Check fuel line and dredge

Float is leaking Repair

Needle valve is sticking Dismantle float chamber and free up needle valve

Fuel supply

system

Spark plug is damaged, or short- circuited by carbon

Replace spark plug

deposit

Side electrode of spark plug is dropped out Replace spark plug

High-tension wire is dropped out Weld on

Ignition coil is punctured or short-circuited Replace ignition coil

Engine kill wire is touching (grounding) Locate ground and insulate

Ignition system

Cylinder is seriously scored and valve dropped out Repair or replace damaged parts

Stops suddenly when running.

Engine

internal

5. ENGINE IS OVERHEATING

TROUBLE CAUSE REMEDY

Insufficient oil Refill engine oil to proper level

Exhaust pipe blocked up Clean exhaust pipe

Shroud leaking Repair damaged part

Cooling fins blocked by foreign matter Clear cooling fins

Cooling fan loose and not working Repair cooling fan

Connection rod deformation causing piston and cylinder

bushin

side wear

Cylinder or piston or piston ring is worn and is creating

Replace connection rod

Replace the worn parts

heat between cylinder and crankcase

Improper adjustment of engine governor causing high

Readjust engine governor

speed.

Gasoline Engine Is Overheating.

Crankshaft main bearing burnt out Replace main bearing

20 DR

®

R225, R300 and R390 Engines

Page 21

6. ABNORMAL NOISES WHEN ENGINE IS RUNNING

TROUBLE CAUSE REMEDY

Piston, piston ring or cylinder is worn Replace the worn part

Connection rod or piston pin and piston pin hole are worn Replace the worn part

Crankshaft main neck is worn Replace bearing

Beating sound

Piston ring is broken Replace piston ring

Too much carbon deposit in combustion chamber Clear away carbon deposit

Too small electrode clearance of spark plug Adjust electrode clearance properly

Too much fuel supplied to engine Check relative parts such as carburetor

Improper fuel brand Replace fuel

Metal beating sound

when abnormal

Other

problems

Engine is overheated Find the cause for overheating and eliminate it

combustion occurs

Improper valve clearance Readjust valve clearance properly

Flywheel is not connected with crankshaft tightly Connect tightly

CONTACT US AT www.DRpower.com 21

Page 22

X. Specifications

Model R225 R300 R390

L×W×H

Dry Weight

Gasoline Engine Type

Displacement

Compression Ratio

Bore × Stroke

Maximum Output Power

Maximum Torque

Cooling System

Ignition System

Spark Plug

Spark Plug Clearance

Lubrication System

PTO Shaft Rotation

Manual Start

15.4x 12.6x14.2 in.

(390×320×360mm)

Electric Start

17.9x12.6x14.2 in.

(455×320×360mm)

Manual Start – 57.3 lb. (16kg)

Electric Start – 40.6 ib. (18.4kg)

4-Stroke, OHV, Single Cylinder 4-Stroke, OHV, Single

223ml 301ml 389ml

8.4:1 8.2:1 8.0:1

70×58mm 80×60mm 88×64mm

4.3kW

3,600r/min

13N·m

2,500r/min

Forced Air-cooled Forced Air-Cooled Forced Air-Cooled

Transistorized Magneto Ignition

(TCI)

BP6ES(NGK)/F6RTC(NHSP)/F6TC/

F7RTC/F7TC

.028"-.032" (0.7- 0.8mm) .028"-.032" (0.7- 0.8mm) .028"-.032" (0.7- 0.8mm)

Forced Splash Forced Splash Forced Splash

Counterclockwise Counterclockwise Counterclockwise

Manual Start

18.1x15.4x17.7 in.

(460×390×450mm)

Electric Start

20.5x15.4x17.7 in.

(520×390×450mm)

57.3 lb. (26kg) 70.5 lb. (32kg)

Cylinder

6.0kW

3,600r/min

18N·m

2,500r/min

Transistorized Magneto

Ignition(TCI)

F6TC BP6ES (NGK) / F6RTC

Manual Start

18.9x15.4x18.1 in.

(480×390×460mm)

Electric Start

21.3x15.4x18.1 in.

(540×390×460mm)

4-Stroke, OHV, Single

Cylinder

7.6kW

3,600r/min

23N·m

2,500r/min

Transistorized Magneto

Ignition(TCI)

(NHSP)

22 DR

®

R225, R300 and R390 Engines

Page 23

XI. Electrical Diagrams

W W

W W

1. Electric Start Engine with Oil Protection System

IG E ST BAT

OFF

ON

O

O

START O

Changing Coil

O

Starting Motor

W

Rectifier

Bl BLACK

Y YELLOW R RED

W WHITE G GREEN

Starting Relay

Bl/W

Protector

Br BROWN

W

Battery

Spark Plug

Bl

Oil Sensor

Ignition Coil

Bl/R

Y

Br

Engine Switch

Circuit Breaker

Y

Bl

Y

Oil Protector

Controlling Box

Bl

CONTACT US AT www.DRpower.com 23

Page 24

2. Manual Start Engine with Oil Protection System

Bl BLACK

Y YELLOW

G GREEN

Spark Plug

Y

Ignition Coil

Engine Switch

Bl

Y

Oil Sensor

Y

Oil Protector

Bl

24 DR

®

R225, R300 and R390 Engines

Page 25

Country Home Products, Inc (CHP) Engine Owner Warranty Policy

Terms and Conditions

The DR R225, R300 and R390 ENGINES are warranted for two (2) years against defects in materials or workmanship when put to ordinary

and normal consumer use; one (1) year for commercial use.

For the purposes of all the above warranties, “ordinary and normal consumer use” refers to non-commercial residential use and does not

include misuse, accidents or damage due to inadequate maintenance.

DR Power Equipment certifies that the DR

used. DR Power Equipment however, limits the implied warranties of merchantability and fitness in duration to a period of two (2) years in

consumer use, one (1) year for commercial use.

The 2-Year Limited Warranty on the DR R225, R300 and R390 ENGINES starts on the date the machine ships from our factory. The 2-Year

Limited Warranty is applicable only to the original owner.

The warranty holder is responsible for the performance of the required maintenance as defined by the manufacturer's owner's manuals. The

warranty holder is responsible for replacement of normally wearing parts such as the Air Filter and Spark Plug. Accessories to the machine

are not covered by this warranty.

During the warranty period, the warranty holder is responsible for the engine transportation charges, if required. During the warranty

period, warranty parts will be shipped by standard method at no charge to the warranty holder. Expedited shipping of warranty parts is the

responsibility of the warranty holder.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF IMPLIED WARRANTIES, SO THE ABOVE LIMITATIONS MAY NOT

APPLY TO YOU.

DR Power Equipment shall not be liable under any circumstances for any incidental or consequential damages or expenses of any kind,

including, but not limited to, cost of equipment rentals, loss of profit, or cost of hiring services to perform tasks normally performed by the

DR R225, R300 and R390 ENGINES.

R225, R300 and R390 ENGINES are fit for ordinary purposes for which a product of this type is

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO

STATE.

This Engine is manufactured for CHP by Chongqing Rato Power Manufacturing Corporation (RATO). If you have any questions

please visit www.DRPower.com or call 1-800-DR-OWNER (376-9637).

Combined Exhaust and Evaporative Emissions Control Warranty Statement

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board, the United States Environmental Protection Agency and Chongqing Rato Power

Manufacturing Corporation (RATO), are pleased to explain the emission control system warranty on your 2014-2015 model

year small off-road engine/equipment. In the United States and California, new small off-road engine/equipments must be

designed, built and equipped to meet the State's stringent anti smog standards. RATO must warrant the emission control

system on your small off-road engine/equipment for the periods of time listed below provided there has been no abuse,

neglect or improper maintenance of your small off-road engine/equipment.

Your emission control system may include parts such as the carburetor or fuel injection system, the ignition system, catalytic

converter, fuel tanks, fuel lines, fuel caps, valves, canisters, filters, vapor hoses, clamps, connectors, belts, and other

associated components. For engines less than or equal to 80 cc, only the fuel tank is subject to the evaporative emission

control warranty requirements of this section. (California only)

Where a warrantable condition exists, RATO will repair your small off-road engine/equipment at no cost to you including

diagnosis, parts and labor.

MANUFACTURER'S WARRANTY COVERAGE:

CONTACT US AT www.DRpower.com 25

Page 26

This emissions control system is warranted for two years. If any emission-related part on your small off-road

engine/equipment is defective, the part will be repaired or replaced by RATO.

OWNER'S WARRANTY RESPONSIBILITIES:

As the small off-road engine/equipment owner, you are responsible for the performance of the required maintenance listed in

your owner's manual. RATO recommends that you retain all receipts covering maintenance on your small off-road

engine/equipment, but RATO cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance

of all scheduled maintenance.

As the small off-road engine/equipment owner, you should however be aware that RATO may deny you warranty coverage if

your small off-road engine/equipment or a part has failed due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible for presenting your small off-road engine/equipment to a RATO distribution center as soon as a problem

exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact Great Lakes Technologies,

LLC at 1-855-206-5286 or E-mail: service@rato-na.com.

DEFECTS WARRANTY REQUIREMENTS:

(a) The warranty period begins on the date the engine/equipment is delivered to an ultimate purchaser.

(b) General Emissions Warranty Coverage. RATO warrants to the ultimate purchaser and each subsequent owner that the

engine/equipment is:

(1) Designed, built, and equipped so as to conform with all applicable regulations adopted by the Air Resources Board; and

(2) Free from defects in materials and workmanship that causes the failure of a warranted part for a period of two years.

(c) The warranty on emissions-related parts will be interpreted as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in the written instructions required by

subsection (d) must be warranted for the warranty period defined in Subsection (b)(2). If any such part fails during the period

of warranty coverage, it must be repaired or replaced by RATO according to Subsection (4) below. Any such part repaired or

replaced under the warranty must be warranted for the remaining warranty period.

(2) Any warranted part that is scheduled only for regular inspection in the written instructions required by subsection (d)

must be warranted for the warranty period defined in Subsection (b)(2). A statement in such written instructions to the effect

of “repair or replace as necessary” will not reduce the period of warranty coverage. Any such part repaired or replaced under

warranty must be warranted for the remaining warranty period.

(3) Any warranted part that is scheduled for replacement as required maintenance in the written instructions required by

subsection (d) must be warranted for the period of time prior to the first scheduled replacement point for that part. If the part

fails prior to the first scheduled replacement, the part must be repaired or replaced by RATO according to Subsection (4)

below. Any such part repaired or replaced under warranty must be warranted for the remainder of the period prior to the first

scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty must be performed at no charge to the owner at a

warranty station.

(5) Notwithstanding the provisions of Subsection (4) above, warranty services or repairs must be provided at all RATO

distribution centers that are franchised to service the subject engine/equipments.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is in fact

defective, provided that such diagnostic work is performed at a warranty station.

(7) RATO is liable for damages to other engine/equipment components proximately caused by a failure under warranty of any

warranted part.

(8) Throughout the emissions warranty period defined in Subsection (b)(2), RATO must maintain a supply of warranted parts

sufficient to meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided

without charge to the owner. Such use will not reduce the warranty obligations of RATO.

(10) Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of any nonexempted add-on or modified parts will be grounds for disallowing a warranty claim. RATO will not be liable to warrant

failures of warranted parts caused by the use of a non-exempted add-on or modified part.

26 DR

®

R225, R300 and R390 Engines

Page 27

(11) RATO issuing the warranty shall provide any documents that describe that manufacturer's warranty procedures or

policies within five working days of request by the Air Resources Board.

(d) Emission Warranty Parts List for exhaust (for all displacements).

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or pressure regulator or fuel injection system).

(ii) Air/fuel ratio feedback and control system.

(iii) Cold start enrichment system.

(2) Air Induction System

(i) Controlled hot air intake system.

(ii) Intake manifold.

(iii) Air filter.

(3) Ignition System

(i) Spark Plugs.

(ii) Magneto or electronic ignition system.

(iii) Spark advance/retard system.

(4) Exhaust Gas Recirculation (EGR) System

(i) EGR valve body, and carburetor spacer if applicable.

(ii) EGR rate feedback and control system.

(5) Air Injection System

(i) Air pump or pulse valve.

(ii) Valves affecting distribution of flow.

(iii) Distribution manifold.

(6) Catalyst or Thermal Reactor System

(i) Catalytic converter.

(ii) Thermal reactor.

(iii) Exhaust manifold.

(7) Particulate Controls

(i) Traps, filters, precipitators, and any other device used to capture particulate emissions.

(8) Miscellaneous Items Used in Above Systems

(i) Electronic controls.

(ii) Vacuum, temperature, and time sensitive valves and switches.

(e) Emission Warranty Parts List for Evap less than or equal to 80cc.

(i) Fuel Tank.

(f) Emission Warranty Parts List for Evap greater than 80cc.

(1) Fuel Metering System

(i) Fuel Tank.

(2) Miscellaneous Items Used in Above Systems

(i) Fuel caps, valves, canisters, filters, vapor, hoses, clamps, connectors, belts, and and assemblies.

RATO will furnish with each new engine/equipment written instructions for the maintenance and use of the

engine/equipment by the owner.

CONTACT US AT www.DRpower.com 27

Page 28

75 MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

©2014 Country Home Products, Inc. All rights reserved 350431A

Loading...

Loading...