Page 1

™

DR® POWERWAGON

4 x 2

Safety and Operating Instructions

Important!

Please read the Safety & Operating Instructions and the separate Engine Manufacturer's Owner's

Manual to become familiar with the basic features of the DR® POWERWAGON™ 4 x 2 before

operating it.

Country Home Products, Inc.

www.dr-owner.com

Page 2

And congratulations on your purchase of a

new DR® POWERWAGON™ 4 X 2!

We have done our utmost to ensure your

DR® POWERWAGON™ 4 X 2 will be one of

the most trouble-free and satisfying pieces of

equipment you have ever owned. Please let us

know of any questions or problems you may

have. We want to answer or correct them as

quickly as possible. (When you do call or

write, please have your serial number and/or

order number handy—it will speed things up!)

We also hope to hear from you on how much

you like your new helper.

And, please tell your friends about your

new DR

DR® Owners spread the word about our

products and our way of doing business is the

best advertising we can have, and the best way

to help us provide even better service in the

years to come.

Thanks once again!

®

POWERWAGON™ 4 X 2. Having

For all of us at...

COUNTRY HOME PRODUCTS

Page 3

Introduction

Your new DR® POWERWAGON™ 4 x 2 is a carefully designed product launched to meet

our customer's needs for a vehicle that can transport one or two people along with a load of

up to 500 pounds on slopes up to 20 degrees and 1000 pounds on level ground. This new

model of Powerwagon™ features easy operation, minimal effort to transport heavy loads,

low fuel consumption, and rugged construction. Since its debut, this bestseller has turned

out to be a favorite worldwide.

All of our products are designed and manufactured to meet our customer’s high standards

for rugged and quality products. This Powerwagon™ 4 x 2 has been extensively tested in

typical home and field environments. As a result, this Powerwagon™ 4 x 2 has shown

outstanding performance, high reliability and easy operation.

Your new DR® POWERWAGON™ 4 x 2 features a low center of gravity, powerful

climbing capability and large payload capacity and can operate under all weather and field

conditions. We are proud to provide you with this safe, comfortable, easy to use and

economical Powerwagon™ 4 x 2.

Please read this manual carefully before operating your DR® Powerwagon™ 4 x 2. It

contains important safety information, and instructions for set up, operation and

maintenance.

COPYRIGHT

2002 Country Home Products, Inc. All rights reserved.

Country Home Products, Inc.

Meigs Road

P.O. Box 25

Vergennes, VT 05491

Toll-free phone: 1-800-DR-OWNER (376-9637)

1-802-877-1213

Fax:

Web site: www.dr-owner.com

E-mail: info@countryhomeproducts.com

Page 3

Page 4

Table Of Contents

Introduction…………………………………………………………………………. 3

Safety Information…………………………………………………………………... 5

Safety With Gas Powered Machines…………………………………………………. 6

Special Note for California and Washington State Owners…………………………... 6

Safety Labels………………………………………………………………………… 6

Transporting the DR® Powerwagon™ 4 x 2………………………………………... 9

Preparing the DR® Powerwagon™ 4 x 2 for Operation…………………………….. 10

Checking and Adding Oil……………………………………………………………. 10

Adding Fuel…………………………………………………………………………. 11

Fuel Shut Off and Cap………………………………………………………………. 11

Connecting the Battery……………………………………………………………… 11

Operator Controls…………………………………………………………………… 12

Engine Choke………………………………………………………………………... 12

Engine Starting………………………………………………………………………. 13

Driving the DR® Powerwagon™ 4 x 2……………………………………………… 14

Installation of the Optional Side Rails……………………………………………….. 15

Cargo Bed Information……………………………………………………………… 15

Rear Cargo Door…………………………………………………………………….. 16

Cargo Bed Lock……………………………………………………………………... 16

Vehicle Weight and Cargo Capacity…………………………………………………. 16

Maintenance Information……………………………………………………………. 17

Tools Required………………………………………………………………………. 17

Engine Oil…………………………………………………………………………… 17

Changing Oil………………………………………………………………………… 17

Spark Plug…………………………………………………………………………… 18

Air Filter……………………………………………………………………………... 18

Transmission………………………………………………………………………… 18

Brake Information…………………………………………………………………… 19

Wheel Shear Bolts…………………………………………………………………… 20

Fuel Filter and System……………………………………………………………….. 20

Belt Information…………………………………………………………………….. 21

Changing Belts……………………………………………………………………… 22

Tire Information……………………………………………………………………. 22

Engine Mounts……………………………………………………………………… 22

Other Lubrication…………………………………………………………………… 22

Checking The Nuts and Bolts……………………………………………………….. 23

Torque Information…………………………………………………………………. 23

Battery Information…………………………………………………………………. 23

Warranty……………………………………………………………………………. 25

Page 4

Page 5

Safety Information

• Dress Appropriately: Wear shoes with non-slip treads or safety shoes if you have them.

Do not operate the machine while barefoot or wearing open sandals. Avoid loose

clothing or jewelry, which might get caught in the machine’s moving parts.

• Check out the area you will be operating in before using your Powerwagon™ 4 x 2.

Avoid excessively rugged or steep terrain.

•

Caution: When traveling in high gear, do not use the pedal brake and the parking brake

at the same time or pull the parking brake and press the clutch at the same time or the

transmission may be damaged.

•

Do not use the parking brake when traveling in high gear.

•

• Drive in low gear when traveling with heavy loads or over rough terrain.

• Slow down when making turns.

• Do not change direction quickly on rough terrain.

• Caution: Do not change gears while in motion. Stop the vehicle to change gears.

• Do not force the shift lever. When the vehicle is stopped pump the brake pedal and

•

• Be sure to keep pedestrians above you at all times when traveling up and down slopes.

• Caution: Only use low gear when traveling up or down slopes.

• Be sure to use the parking brake when stopped.

• Remove the key when not in use to prevent unauthorized use.

• Built in safety features are effective only when maintained and kept in place. Do not,

•

• Keep combustible substances away from engine when hot.

• When using the DR® Powerwagon ™ 4 x 2 don’t take things for granted. When in

• Do Not Overload the DR® Powerwagon™ 4 x2. Be careful of top heavy loads; the

Do not overload. The Powerwagon™ 4 x 2 is rated for 1000 pounds of cargo

weight on hard level ground and 500 on slopes up to 20 degrees.

then the clutch before trying to change gears. You may need to wait a few seconds for

the transmission to stop turning.

Do not carry passengers when traveling up, sideways, or down hills.

under any conditions, remove, cut, bend, weld or change standard parts on any

equipment. A change made on your own can make the vehicle unsafe and may void

your warranty.

Always shut off the engine, allow to cool, remove the spark plug wire, apply

parking brake and chock the wheels prior to making any adjustments to the vehicle.

doubt about the equipment or the surroundings, stop the machine and take the time to

look things over. Make sure that you have 100% control of your machine at all times.

higher the load, the higher the chance the machine may tip over. Also, loads may shift

during operation, so secure your loads and make them even, when possible to be safe.

Page 5

Page 6

• Do not rev the engine. Excessive speed or tampering with the engine governor can be

dangerous.

• Keep your hands away from the belts and pulleys when the engine is running.

• Be particularly careful of small children and pets. Never allow children to operate the

vehicle. Never carry children, adults or pets in the wagon bed. Use caution when

operating the vehicle around other people or animals.

• Do not operate the vehicle under the influence of drugs or alcohol.

Safety with Gasoline- Powered Machines

• Do not run the machine in an enclosed area or without proper ventilation.

• Store all fuel in containers specifically designed for this purpose. Plastic containers are

more likely to prevent sediment and condensation problems.

• Fill the gas tank outdoors with the engine off. Don’t handle gasoline if you or anyone

nearby is smoking, or if you are near a fire, sparks, or anything that could cause gasoline

vapors to ignite or explode.

• If gasoline is spilled, do not attempt to start the engine. Move the machine away from

the area of the spill and avoid creating any source of ignition until the gasoline vapors

have dissipated. Wipe up any spilled fuel to prevent a fire hazard, and properly dispose

of the waste.

• Allow the engine to cool before storing in any enclosure. Never store the machine near

an open flame or sparks.

• Some state and local regulations require the use of a spark arrester on gasoline powered

engines. Contact your local fire marshal or forest service for specific information in your

area. If you are required to use a spark arrester, please contact one of our Customer

Service Representatives 1-800 DR-OWNER (376-9637) who will assist you in obtaining

one.

Special Note for California and Washington State Owners

• California and Washington states require the use of spark arresters on internal

combustion engines. Failure of the owner/ operator to maintain this equipment in

compliance with state regulations is a misdemeanor under California law and may be in

violation of other state and federal regulations. Contact your local fire marshal or forest

service for specific information in your area.

Country Home Products, Inc. reserves the right to discontinue, change and improve its

products at any time without notice or obligation to the purchaser.

The descriptions and specifications contained in this manual were in effect at the time of

printing. Some equipment described in this manual may be optional. Some illustrations may

not be applicable to your machine.

Page 6

Page 7

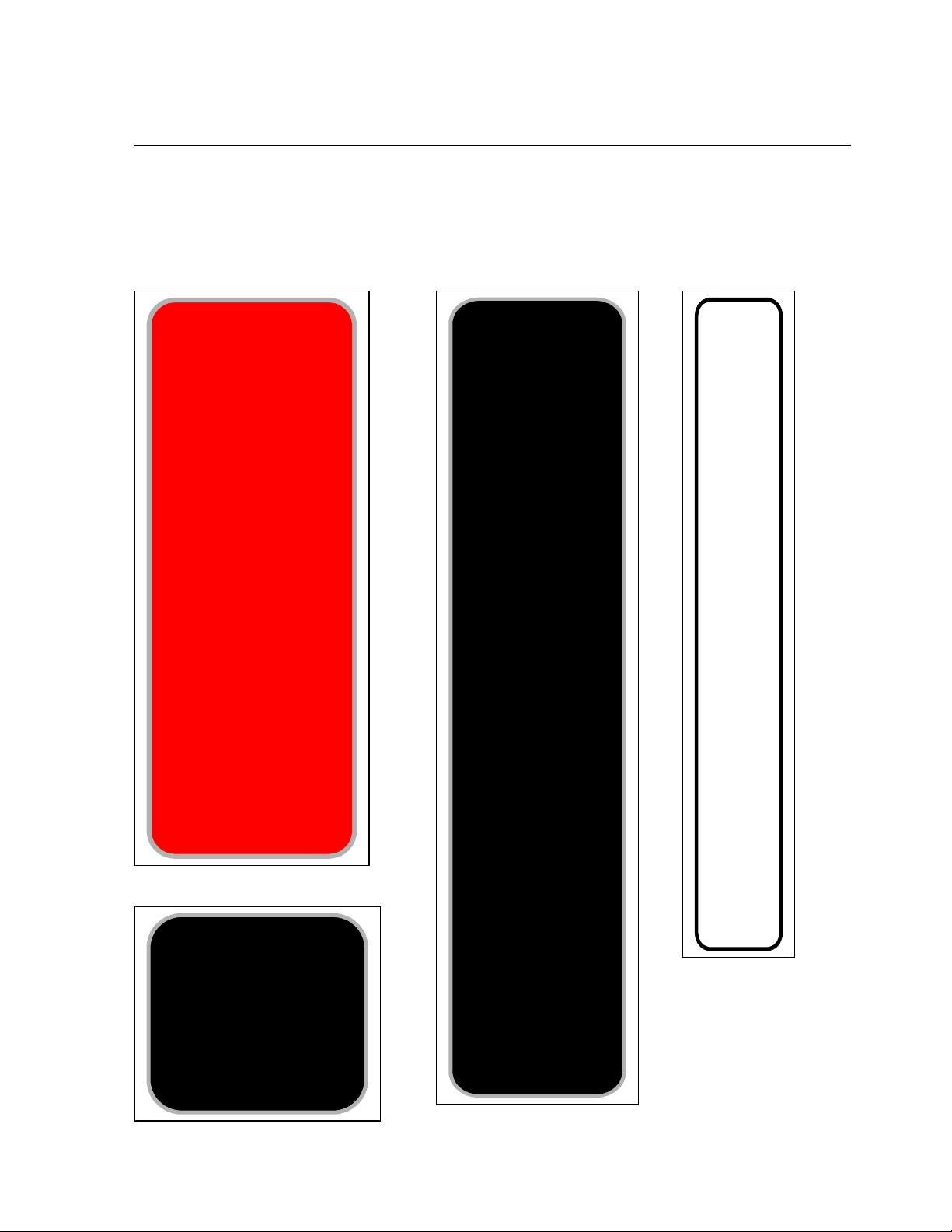

Safety Labels

Take some time to become familiar with these safety information labels. Replace missing or

damaged labels immediately. Note: these illustrations are not actual size.

OPERATE SAFELY

¾ Stop before

Shifting.

¾ Max Load is 500

pounds on a slope

and 1000 pounds on

hard, level ground.

¾ Do not operate on

slopes greater than

20 degrees.

¾ High Speed is 9

MPH. Use care in

HIGH gear.

¾ Use care in turning,

abrupt changes in

direction could cause

the vehicle to turn

over.

¾ Use LOW gear in

rough terrain, on

slopes or in wet

conditions.

¾ Set the Parking

Brake whenever the

vehicle is parked.

BEFORE STARTING

¾ Read Safety Manual

¾ Set the Parking Brake

¾ Check the gas and oil

levels

¾ Check tire pressure

¾ Check that the dump

lever latch is secure.

¾ Use choke on engine for

cold starting

TO START ENGINE

¾ Pu sh in th e clutch

and brake pedals.

¾ Release the parking

brake.

¾ Set the shift lever to

Neutral.

¾ Set the p arking

brake.

¾ Set the throttle at

the halfway position

¾ If en gin e h as not

been used recently,

set the choke lever.

¾ Turn the key to the

starting position and

hold until the engine

starts, but no longer

than 3 seconds.

¾ Release the key

when the engine

starts.

¾ If the choke was

set, then slowly return

the choke lever to the

run position.

¾ Ad just th e throttle.

¾ Release the parking

brake

¾ Set the shift lever to

HIGH, LOW, or

Reverse.

¾ Slowly release the

clutch and brake

pedals.

TO STOP ENGINE

¾ Pu sh in th e clutch

and brake pedals.

¾ Set the P arkin g

Brake.

¾ Turn the key to off.

TO DUMP

¾ Op en the tailgate

and secure it against

the side panel.

¾ Pull the dump lever

release handle.

¾ Lift the dump lever.

¾ Lower the dump

lever and be sure it is

secured.

¾ Close the tailgate.

HIGH

N -

Start

OW

L

N

R

EVERSE

Page 7

Page 8

Model # PWR8-USA

Light Utility Vehicle

Operating Vehicle Weight

650 pounds

Gross Vehicle Weight Limit

2050 pounds on Level

1650 pounds on 20

o

Slope

Choke Lever

Run Choke

SF

Page 8

Page 9

Transporting the DR® POWERWAGON™ 4 x 2

• The DR® Powerwagon™ 4 x 2 can be transported in the bed of a full size pick up truck

or vehicle that can accommodate a pallet 45 x 108 inches, weighing 750 lbs.

• You will need:

• 2 Ramps ( 2 x 10 x 7 ft. long)

• Wire cutters

• Knife

• Hammer

• Screwdriver

• Two helpers

• The DR® Powerwagon™ 4 x 2 is shipped fully assembled, fixed to a pallet. The pallet

can only be loaded on your vehicle one way at the trucking depot. The front of the DR®

Powerwagon™ 4 x 2 will be towards the front of the truck.

• Secure the DR® Powerwagon™ 4 x 2 to your vehicle.

• Upon arrival at home, carefully remove the wrapping from the machine, cut the banding

and remove the wheel chocks.

• Place the ramps from the back of the pallet to the ground. Make sure that the ramps are

lined up with the wheels.

• DO NOT ATTEMPT TO DRIVE THE VEHICLE DOWN THE RAMPS WITH THE

ENGINE RUNNING. DO NOT STAND BEHIND THE VEHICLE WHEN

OFFLOADING.

• You should become familiar with the controls prior to unloading. Please be sure to know

the location of the hand and foot brake as well as the gearshift.

• Be sure to read the Safety and Operating Instructions provided with your machine before

attempting to operate the DR® Powerwagon™ 4 x 2.

Page 9

Page 10

Preparing The DR® POWERWAGON™ 4 x 2 For Operation

A

g

We have done our utmost to make it easy to get your DR© POWERWAGON™ 4 x 2 ready

to roll. Please take a few minutes to read through this manual and your engine manual before

attempting operation.

Checking and Adding Oil:

For your convenience the DR® POWERWAGON™ 4 x 2 is shipped fully assembled, with

oil in the engine and transmission. However it is always wise to check the oil levels before

operation. Make sure that the machine is on a level surface and unscrew the oil cap as shown.

Oil should be at the level shown in figure 1. Add oil with the yellow cap off until oil starts to

drip out. You can add oil here or at the oil fill shown in figure 2.

Oil fill

Oil Level

Figure 1

Checking the Transmission Oil:

The transmission is shipped with gear oil but should

be checked before operation. If necessary, add SAE

90W gear oil until it shows 2/3 in the sight glass. See

Figure 3.

Figure 2

dd Trans. oil

Oil sight window

Drain plu

Figure 3

Page 10

Page 11

Adding Fuel:

)

Caution: Do not smoke or allow others to smoke or have any sparks or other

sources of ignition near by while filling the gas tank. Only fill the tank outdoors.

The fuel tank is located under the seat. See Figure

4. The seat is held on hinges and folds forward

to allow access to the tank. The tank holds

approximately 2 ½ gallons of gasoline. The

DR® POWERWAGON™ 4 x 2 uses regular

unleaded fuel with a minimum octane rating of

85, and should be filled to about 1 ½ inches

below the top of the filler neck to allow for fuel

expansion. Refer to your engine manual for

detailed fuel information.

Fuel Shut Off and Cap:

Please take note of the fuel level gage we have

incorporated into the gas cap. Also, there is a

fuel shut off valve at the bottom of the tank.

The lever has a red plastic handle, and off is up

and on is down. See Figure 5. Important:

Please be sure to shut off the fuel lever when

transporting the DR® POWERWAGON™ 4 x

2. Whenever you add fuel inspect the fuel system

for leaks.

Raise Seat

Fuel Tank

Figure 4

Fuel Shut Lever (Off Position

Figure 5

Connect the Battery

Do not smoke or allow others to smoke or have the battery near sparks or other

sources of ignition while performing maintenance on or connecting or disconnecting

the battery.

Your machine is shipped with negative battery cable disconnected. Unscrew the wing nut on

the negative battery post ( - ) and place the green battery wire on the post and replace the wing

nut.

Page 11

Page 12

Operator Controls

Figure 8

Please take some time to become familiar with the operator controls, and their function and

location.

Cargo Bed

Engine Start Switch

Shift

Brake Pedal

Choke

Parking Brake

Cargo Bed Release

Clutch

Figure 6

Your machine is equipped with Operator Presence Safety Devices. The machine will start only with

the handbrake actuated and the gear shift in the neutral start position. Please note that there are two

neutral positions, but only one will allow starting. The starter will crank, but the engine will not start.

After the operator shifts into forward or reverse the operator must be seated for the engine to operate.

Engine choke: The choke control is located next to the engine start switch. (Figure 7) Pulling the

knob forward activates the choke for starting. Pushing the knob fully to the rear de-activates

the choke for normal operation. If necessary, you can access the choke on the engine from the

side by reaching under the frame as shown. (Figure 8.) Move the lever to the right before starting

and then back to the run position once the engine has started.

Choke Location

Choke Cable

Figure 7

Page 12

Page 13

Page 12

p

Engine Starting

Now that you have checked the oil, transmission and fuel and are familiar with the controls

you are ready to start the engine. We know you are anxious to drive your DR®

Powerwagon™ 4 x 2 but here are just a few more tips before you are ready.

• Move choke lever to start.

• Depress the clutch pedal (left pedal) and move the gear selector to the neutral-start

position. Note: if the gear selector seems difficult to shift pump the brake.

• Make sure the parking brake is set.

• Move the throttle (on the left side of the handlebar) to S (slow). Note the throttle location

on the left side of the handlebar in Figure 8-B. We have changed the location after the

cover photo was taken.

Throttle in Slow

osition

Figure 8-B

• Depress the brake pedal (right pedal).

• Turn the key on the start switch and release when the engine starts.

• You can get off the vehicle and move the choke to run.

Page 13

Page 14

Driving the DR® Powerwagon™ 4 x 2

For your first time out it is best to not carry any passengers until you are comfortable with the

vehicle. Take a moment to review your surroundings and terrain. Be aware of all bystanders

and make sure that they are aware of you. Make sure that no bystanders or pets are in front of

or behind the vehicle.

This vehicle is not intended or equipped for public road or highway use. Do not

drive on public roads, highways or sidewalks.

• Start your engine. See Page 13.

• Depress the foot brake.

• Depress the clutch.

• Move the throttle lever to run or fast.

• Release the parking brake.

• Move the gearshift to low gear. If the gear selector does not move easily do not force it.

Slowly pump the foot brake and try again. This is normal; the rear brake and parking

brake are part of the transmission.

Caution: Never try to shift the gears while the vehicle is in motion.

• Slowly take your foot off the brake and slowly release the clutch. As you release the clutch

the vehicle will start to move.

• To stop, depress the clutch and slowly press the foot brake.

• When stopped, place the gear selector in neutral and apply the parking brake.

• Throttle the engine down

• Turn the key to the off position

This same sequence is used for reverse and high gear. Take some time to practice driving in

low and reverse before trying the high gear. The DR® Powerwagon™ will travel

approximately 8 to 9 mph in high gear and this can seem fast, and should only be used on flat

terrain. Note: Top speed is approximate and depends on many factors such as belt wear, tire

pressure, and engine condition. Your top speed may vary.

Caution: Use only low gear when traveling up or down slopes or with loads, or

damage may occur to the belts or transmission.

Page 14

Page 15

Installation of Optional Side Rails

You can purchase the

optional side rails that are

shown in full on the front

cover. Installation is quite

easy. Pry off the caps that

are in the tops of the tubes,

the install the rails as

shown. Screw in the bolts

in all the tubes and tighten

with an adjustable wrench.

Save the caps with your

Operating Manual.

Cargo Bed Information

Figure 10

Latch Bracket

Latch lever

Figure 9

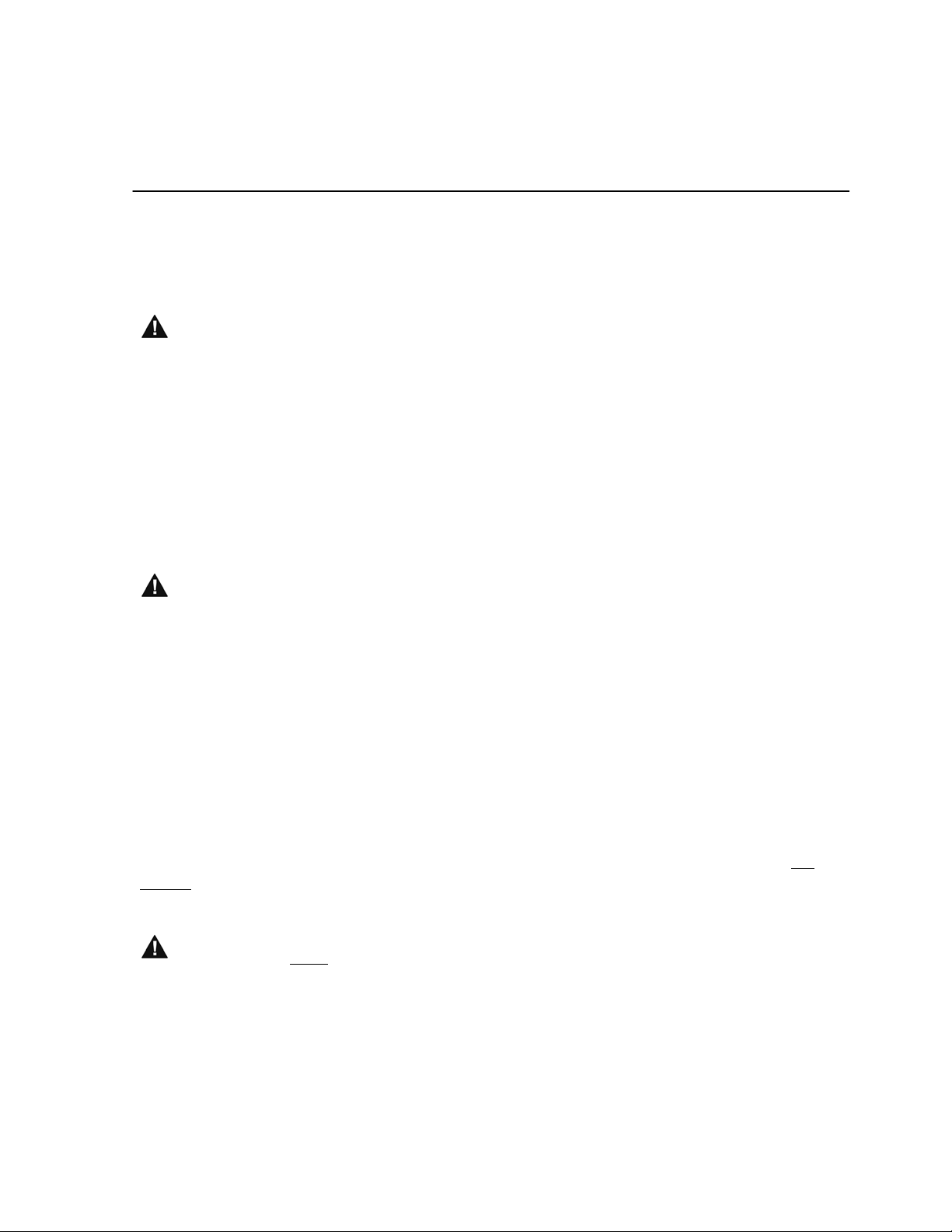

The Cargo bed has simple but sturdy latch

mechanisms as shown in Figure 10. The

sides are hinged at the bottom and the rear

door is hinged at the corner. To unlock,

move the lever to a straight up position

and slide the lever out of the latch bracket

in the direction of the arrow.

One end of the chain can slide off the

lever and hook onto the latch bracket. See

Figure 4 on page 11. This will allow the

side to lay flat if you wish.

Page 15

Page 16

Rear Cargo Door

You can unlatch the bed door the same way as

shown in Figure 10, and swing it all the way

around and latch the door to the side. Secure the

lever to the latch bracket on the bed side. See

Figure 11.

Rear Door

Latch Bracket

Important: Secure the rear bed door raising the

Rear Door

cargo bed.

Figure 11

Cargo Bed Lock

The cargo bed has a lock that can be released by pulling the release lever in the direction of the

arrow as shown in Figure 12.

Cargo Bed Lever

Cargo Bed Release

Important: Always place your hand

on the cargo bed lever when unlocking

the cargo bed to prevent the bed from

tipping with unbalanced loads.

Lift the cargo bed lever to tilt the bed.

There is a rod located above the choke

that can be raised up to keep the bed in

a tilted position.

Try to keep the loads balanced and

even.

Important: Do not overload

Figure 13

Vehicle Weight and Cargo Capacity:

1000 pounds on level ground with two people on board.

500 pounds on a 20-degree slope with one person on board.

The vehicle weighs 650 pounds without cargo or people. The maximum weight limit (vehicle

people and cargo) on level ground is 2050 pounds. On a 20-degree slope the weight limit is

1650 pounds.

Page 16

Page 17

Maintenance Information

The following section contains some useful information on the care and maintenance of your

DR® Powerwagon™ 4 x 2. One of the more important items is checking the engine oil

before you start your engine and changing the oil regularly. Never run your engine with low or

dirty oil.

Tools Required:

You will need metric and fractional wrenches, sockets and Allen wrenches. Also, a set of

straight and Phillips screwdrivers and pliers are needed. The chassis was made exclusively for

us in Taiwan and requires metric tools. The engine, gas tank, and wire harness was

manufactured in the US and requires fractional tools.

Engine Oil:

Your engine holds approximately 7/8 of a quart (28 ounces) of SAE 30 high quality detergent

oil for operation in temperatures 40 degrees F and above. Refer to your engine manual for oil

viscosity in lower operating temperatures.

Caution: The use of multi-viscosity oils (5w-30, 10w-30, etc.) will result in higher than normal

oil consumption. When using multi-viscosity oil, check the oil level often. Multi-viscosity oils

are recommended for use in temperatures below 40 degrees.

Caution: SAE 30 oil, if used below 40 degrees (4 degrees C), will result in hard starting and

possible engine bore damage due to inadequate lubrication.

Check engine oil every 8 hours or daily.

Important: Change the oil after the first 5 hours of use, then every 50 hours or every

season. Change the oil every 25 hours when operating the engine under heavy load or

in high temperatures.

Always disconnect the spark plug

when Servicing the engine or vehicle.

Oil Drain

Changing the Oil:

Allow the engine to cool.

Place a suitable container under the oil drain.

Clean the area around the oil plug and the cap.

Remove the drain plug and allow all the oil to

drain. Replace the plug, remove the oil cap

and add oil until it shows at the level in Figure

1 on Page 10. Replace the cap and recycle the

Figure 14

Oil Cap

Page 17

Page 18

used oil according to your local regulations.

Spark Plug:

The spark plug gap should be set at .030. The plug is a RC12YC resistor type plug. This plug

requires a 5/8 spark plug wrench for removal and installation.

Air Filter:

Always disconnect the spark plug wire before servicing.

Your engine has a flat cartridge type filter element. The Briggs and Stratton number is 491588.

It does not have a pre cleaner. Replacement is recommended every 25 hours or sooner in

dusty environments. Check your filter if your engine runs poorly, idles rough, or lacks power.

Removal requires a 5/16-nut driver or socket

wrench, or a flat head screwdriver. Lift the

cover about an inch so that it clears the tabs on

the bottom of the cover. Then slide the cover

down between the orange chassis and the

spring. The element can then be replaced.

When replacing the cover make sure that the

tabs in the bottom of the cover fit into the slots

on the air cleaner base.

Choke

Air Cleaner

Cover

Screw

See your engine manual for more information.

Figure 15

Transmission:

Always disconnect the spark plug wire before servicing.

The transmission is filled with gear oil at the factory, however it is wise to check it before you

run the DR® Powerwagon™ 4 x 2 and then every eight hours or daily. It requires 2 liters

(2.114 quarts) of 90w-gear oil. It is recommended that you change the oil after 200 hours. See

Figure 3 on Page 10 for the location of the drain, fill and sight glass. When checking the

engine oil make a habit of checking the transmission oil as well. The oil should show 2/3 in

the sight glass.

Page 18

Page 19

Brake Information:

Always disconnect the spark plug wire before servicing.

Adjustment and repair of the brakes should be

Cable Jam Nuts

done carefully to ensure proper braking and that

the front and rear are adjusted together.

The front and rear brakes operate simultaneously

from the foot pedal. The rear brake can be

operated from the hand (parking brake) also. They

are actuated via cables that run from the pedal to

the brake. There are three cables that run to a

Support Bracket

To Brake Pedal

support bracket located under the floor in between

the front wheels. See Figure 16. The bottom cable

Figure 16

is the rear brake. The rear brake also has a support

bracket at the rear end of the cable. See Figure 17.

The cables have adjustment nuts that can lengthen

or shorten the cables.

To Rear Brake

• To shorten the cable and increase the brake

pressure, loosen the nut toward the front of

the machine and tighten the rear nut against

the support bracket.

Rear Support Bracket

• It is recommended that you adjust the front

right and left equally.

• Loosen both forward nuts equally and tighten

Figure 17

the rear nuts so that the brakes are locked on

and then back the rear nuts off ¼ to 3/8 inch. Re-tighten the front nuts.

• Be careful not to over-tighten the cables before you back the nuts off. You just want to

tighten the cable so that the brake levers on the inside of the wheels are fully actuated.

Move those levers by hand so that you get a feel for how much to tighten the cables.

• Adjust the left and right equally or you may find that the vehicle pulls to the right or left.

Caution: After adjusting the brakes, test them. Set the parking brake, start the

engine and press the brake pedal. Depress the clutch and put the vehicle in gear.

Slowly release the clutch. If the vehicle starts to move the brakes must be adjusted

again. If the engine stalls, the brakes are operating properly. Then try operating the

vehicle carefully in low gear at a slow speed without passengers or loads.

Important: The rear wheels have two shear bolts under each wheel hub. These will allow the

rear wheels to continue to rotate for a foot or so before they engage the wheel axle. You will

notice that if you were moving forward when you applied the hand brake the vehicle can still

roll back a foot or so until the shear bolts engage. See the next section for more information.

Page 19

Page 20

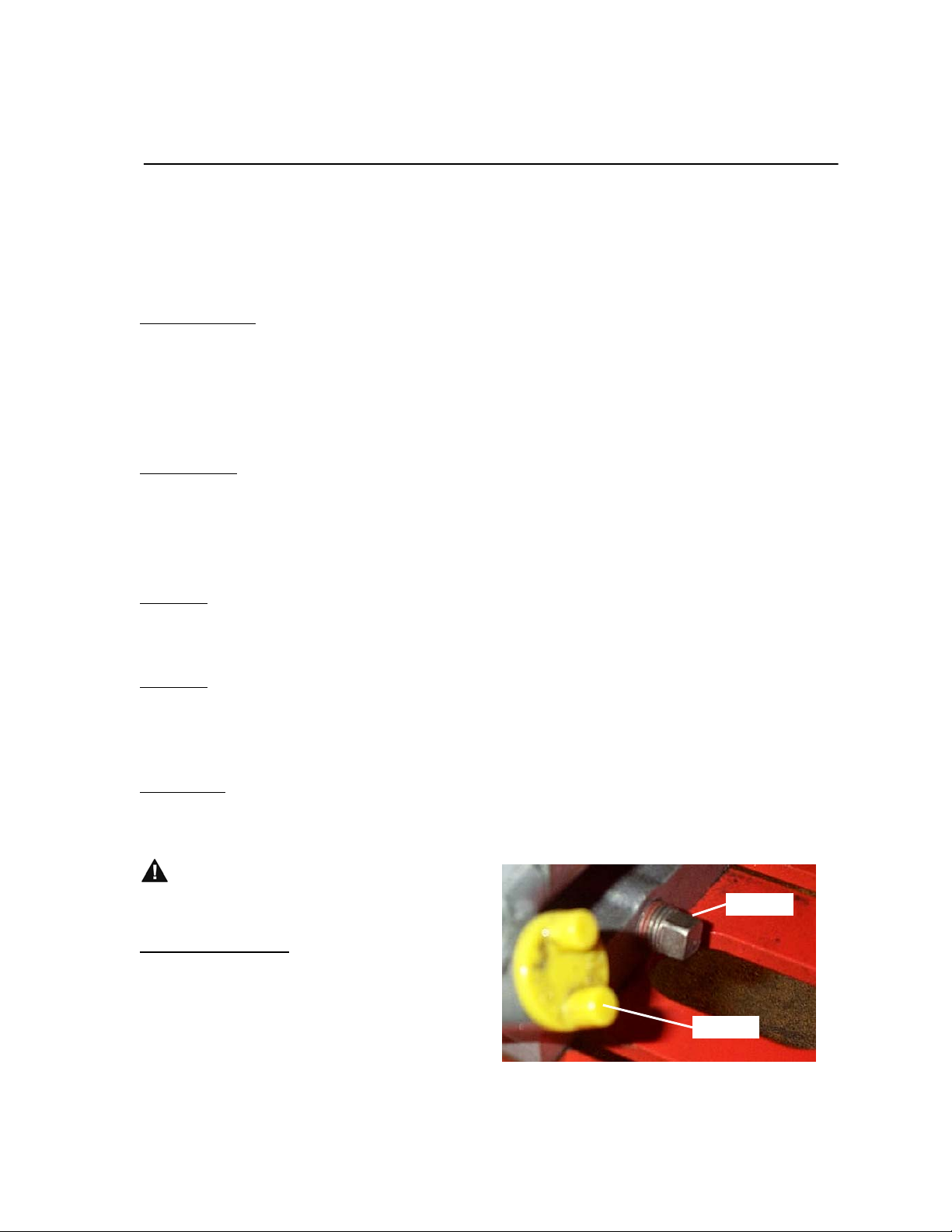

Wheel Shear Bolts:

We included two extra shear bolts with your DR® Powerwagon™ 4 x 2. These are meant to

shear before damage can be done to the transmission. If you find that only one wheel is

driving or hear rattling from the rear wheel hubs you may have broken shear bolts. These are

easy to replace. You will need a 14 mm wrench or socket and an 8 mm Allen wrench.

Always disconnect the spark plug wire

before servicing.

Shear Bolts

• Remove the wheel hubcap by removing the

bolt in the center.

• Rotate the wheel slightly to take the tension

off the bolts. The inner hub is slotted. The

Hub Slots

bolts should be away from either end of the

slots.

• If the old bolts are no longer attached, find

the through hole and install the new bolts as

Figure 18

shown in Figure 18.

Fuel Filter and System:

Always disconnect the spark plug wire before servicing.

The fuel line runs from the valve on the fuel tank to a fuel filter. The line runs from the filter

to the engine. There are no user serviceable parts in the filter and it should be replaced every

200 hours, or when it becomes clogged.

Caution: Do not smoke or allow others to smoke or have any sparks or other

sources of ignition near by while filling the gas tank or servicing the fuel system. Only

fill the tank outdoors.

To determine if the filter is clogged, close the valve under the tank. Have a suitable container

handy to catch the fuel. Disconnect the fuel line from either the engine or engine side of the

fuel filter. Put the end of the hose in the container and turn the tank valve on. Fuel should

flow freely through the filter into the container. Remember that the fuel system is gravity fed

and the hose should be lower than the tank.

Your engine does not have a fuel pump and fuel flows only because the tank is higher than the

carburetor.

• Always use fresh, regular gasoline with a minimum 85 octane.

• Only buy gasoline in quantities that you will use up in one month. Gasoline can become

stale and can cause poor engine performance.

• At the end of the season empty the gas tank, and run the engine until it runs out of gas.

This will help keep the carburetor from getting gummed up.

Page 20

Page 21

• Alternately, you can purchase gas stabilizer and add that to the fuel in the tank and then

j

run the engine. Follow the directions on the stabilizer.

Belt Information:

• The DR® Powerwagon™ is equipped with 2 agricultural duty belts. They are 55-inch

belts and the replacement number is 4340-0550L. They should be replaced in pairs.

• If you find that the vehicle is starting to lose speed and power, and the engine is operating

normally you may need to check the belts.

• Always check the engine operation before you adjust the belts. A dirty air filter, clogged

fuel filter, or a fouled spark plug can exhibit the same symptoms.

The belts become tight when you release the clutch pedal. A cable runs from the clutch pedal

to a support bracket. The end of the cable housing is attached to the support bracket with two

nuts. The cable wire then runs to the idler roller lever. The idler roller lever is spring-loaded at

the upper end. The spring runs from the lever to the spring support bracket and is connected

to a threaded adjustment rod. The adjustment rod is attached to the spring support bracket

with two nuts. With the clutch engaged the spring length should be 7 1/4 inches from the end

of the hook to the end of the opposite hook. With the clutch pedal pushed in the spring

should measure 7 7/8 inches. See Figure 21.

Caution: Improper belt tension can cause excessive belt wear and low power if too loose. If

the belts are too tight then it will be hard or impossible to shift gears and transmission damage

could occur.

There are two belt guides that are attached to

Belt Guides

the engine as shown in Figure 19. These are

set at the factory and should never need

adjustment. If you find that removal is

necessary then the upper guide should be set

at 3/8 inches from the belt, and the lower

guide should be 1/4 inch from the belt. These

guides enable the belts to slip on the engine

pulley when the clutch is disengaged. Also

note that the distance between the belts at the

idler pulley should be 2 1/2 inches with the

Clutch Idler Pulley

Clutch Cable

Figure 19

clutch engaged. See Figure 20.

3/8 inch

7 1/4 inches

Clutch Spring

ustment

2 1/2 inches

1/4 inch

Ad

Clutch Cable support bracket

Page 21

Figure 20

Figure 21

Page 22

Caution: If the belt guides are improperly set, it may cause the gears to grind when shifting, or

machine movement even when the clutch is disengaged.

Changing Belts:

Always disconnect the spark plug wire before servicing. Chock the wheels.

• Place the gear shifter in neutral.

• Loosen the nuts at the spring support bracket and disconnect the spring.

• With the belts now loose, it will be possible to roll them off the rear pulley by rotating the

pulley backwards and guiding the belt off. It is easier to roll the inside belt off to the

inside of the rear pulley.

• Take the outside belt off the front pulley.

• If you find that the front belt guides need to be loosened, first clean the area around the

guides with a rag, then scribe or mark their location with a scribe or marker. This will

make replacement easier.

• Take the inside belt off the front pulley.

• Place the new belts on the machine. It is easier to place the belts on the engine pulley first,

then roll them onto the rear pulley.

• Replace the belt guides in the original location, if they were removed.

Tire Information:

In addition to visually checking the tires daily, you should check the tire every 50 hours with a

tire pressure gage. The tires have tubes.

• Front tire pressure should be kept at 30 psi. Type: 4.00-6 4PR The maximum load rating

is 265 pounds at 31 Psi.

• Rear tire pressure should be kept at 26 psi. Type: 19 x 8.00-10 4pr The maximum load

rating is 825 pounds at 34 Psi.

Engine Mounts:

The engine mounting bolts should be checked for tightness every 50 hours. The rubber

engine mounts should be checked every 25 hours for signs of cracking. Check the engine

crankshaft pulley bolt every 50 hours.

Other Lubrication:

Lubricate cables, all pivot points such as the gear shift pivot, dump latch, seat pivot, clutch

idler, and bed pivot every 200 hours or at least once a month with SAE 30W oil.

There are two grease fittings at the rear of the front wheel mounts. These should receive

grease every 50 hours, using good quality lithium grease.

Page 22

Page 23

Checking the Bolts and Nuts:

Be sure to check for loose bolts and nuts and tighten them when necessary.

Be sure to check the wheel hub bolts after using the vehicle for 100 hours or on bi-weekly

basis.

Torque values of the bolts are given as follows: .

Specification Torque

3/8"-16 NC (Ordinary) 30 foot-lbs.

3/8"- 16 NC (Medium) 32 foot-lbs.

7/16-14 NC (Medium) 35 foot-lbs.

M14xP2.0 (Rod Joint) 70 foot-lbs.

Battery Information:

Your DR® Powerwagon™ 4 x 2 has an automotive style 12 volt lead-acid battery.

Maintenance on this battery is similar to that of your car.

Always disconnect the spark plug wire before servicing.

Caution: Always wear eye protection when servicing the battery.

Caution: Always wear acid resistant gloves when servicing the battery

Caution: Never smoke or allow others to smoke or be near any other sources of

ignition when servicing the battery.

• Remove the battery cell cap. Add distilled water to the cell or cells if needed. Replace the

cap.

Important: Remember that battery acid is corrosive and can cause burns. Your battery and

terminals and posts should be cleaned periodically with a mild solution of baking soda and

water, and then rinsed thoroughly with plain water.

Page 23

Page 24

Notes:

Page 24

Page 25

1-Year Limited Warranty

Terms and Conditions

The DR POWERWAGON™ 4 X 2 is warranted for one (1) year against defects in materials or

workmanship when put to ordinary and normal residential use; ninety (90) days for any other use. The

engine is warranted separately by the engine manufacturer.

For the purposes of all the above warranties, “ordinary and normal residential use” refers to noncommercial residential use and does not include misuse, accidents or damage due to inadequate

maintenance.

Country Home Products, Inc. certifies that the DR

purposes for which a product of this type is used. Country Home Products, Inc. however, limits the

implied warranties of merchantability and fitness in duration to a period of one (1) year in residential

use; ninety (90) days for non residential use.

The 1-Year Limited Warranty on the DR

POWERWAGON™ 4 X 2 starts from the date the machine

ships from our factory. The 1-Year Limited Warranty is applicable only to the original owner.

The owner is responsible for the performance of the required maintenance as defined by the

manufacturer's owner's manuals. The owner is responsible for replacement of normally wearing parts

such as belts, bearings, batteries and brake. Attachments and accessories to the machine are not

covered by this warranty.

During the warranty period the warranty holder is responsible for any and all shipping and

transportation charges, if required.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE LENGTH OF IMPLIED

WARRANTIES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Country Home Products, Inc. shall not be liable under any circumstances for any incidental or

consequential damages or expenses of any kind, including, but not limited to, cost of equipment

rentals, loss of profit, or cost of hiring services to perform tasks normally performed by the DR

POWERWAGON™ 4 X 2.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO

YOU.

Customer Service Hotline

Country Home Products, Inc.’s objective is to have 100% satisfied customers. For that reason, we

operate a 6-day-a-week Technical Service Department for our Owners. You can access a

Representative by dialing our TOLL-FREE Hotline at 1-800-DR-OWNER(376-9637). The sole job of

our well-trained and friendly folks is to ensure that you get any help you need in a timely fashion. They

are there to answer all your questions including (1) inquiries on any of the above warranties, (2)

inquiries about replacement parts, or (3) your questions regarding service, maintenance and operation.

Our Customer Service Representatives will also be happy to answer any of your questions regarding the

separate warranties on all engines. However, to obtain service, repair or replacement of any engine

within the time period covered by the manufacturer’s limited warranty, follow the instructions and

warranty information specifically pertaining to those items provided by their separate manufacturers.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU ALSO HAVE OTHER

RIGHTS THAT VARY FROM STATE TO STATE.

POWERWAGON™ 4 X 2 is fit for ordinary

COUNTRY HOME PRODUCTS, Inc.

Meigs Road, P.O. Box 25, Vergennes, Vermont 05491

1-800-DR-OWNER(376-9637) • www.dr-owner.com

Page 25

©2002 CHP, Inc.

Page 26

Daily Checklist for the DR® Powerwagon™ 4 x 2

To help maintain your DR® for optimum performance, we recommend you follow this

checklist each tome you use your machine.

9 GAS: Fill the gas tank with clean, fresh, unleaded gas.

9 OIL: Check the oil and add more if necessary (do not overfill).

9 SPARK PLUG: Clean the spark plug and replace if needed.

9 AIR FILTER: A clean air filter will mean an easier starting and better running engine. You

should replace the paper air filter every 25 hours of use or more frequently if you are using

the machine in dusty conditions.

9 ENGINE AIR-COOLING SYSTEM: It is important to keep the engine clean of debris.

Regularly remove debris from the blower housing and cooling fins. A dirty engine retains

heat and can cause damage to the internal engine parts.

9 BELTS: Check the belts for wear, proper alignment and tension.

9 TRANSMISSION: Check the gear oil level at the sight window and make sure it shows in

2/3 of the window. Add SAE 90 gear oil if necessary.

COUNTRY HOME PRODUCTS, Inc.

Meigs Road, P.O. Box 25, Vergennes, Vermont 05491

1-800-DR-OWNER(376-9637) • www.dr-owner.com

Page 26

©2002 CHP, Inc. 164241

Loading...

Loading...