Page 1

DR

OPTIONAL ACCESSORIES

®

ROTO-HOG™ POWER TILLER

SAFETY & OPERATING INSTRUCTIONS

DR Power Equipment

Serial No.

Order No.

Read and understand this manual and all instructions before using your accessory.

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Website: www.DRpower.com

Page 2

Table of Contents

y

Chapter 1: General Safety Rules....................................................................................................................... 3

Chapter 2: Setting Up Your Accessory For The Dr Roto-Hog Power Tiller .................................................... 4

Chapter 3: Operating Your Optional Accessory............................................................................................ 13

Chapter 4: Maintaining The Optional Accessory .......................................................................................... 15

Chapter 5: Troubleshooting Your Optional Accessory ................................................................................. 17

Chapter 6: Parts List And Schematic Diagrams ............................................................................................ 20

Conventions used in this manual

This indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

This information is important in the proper use of your machine. Failure to follow this instruction could result in damage

to

our machine or property.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time without notice or obligation

to the purchaser. The descriptions and specifications contained in this manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations may not be applicable to your machine.

2 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 3

Chapter 1: General Safety Rules

Read this safety & operating Instructions manual before you use the Optional Accessory. Become familiar with the operation and

service recommendations to ensure the best performance from your Accessory. If you have any questions or need assistance,

please contact us at www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) and one of our Technical Support

Representatives will be happy to help you.

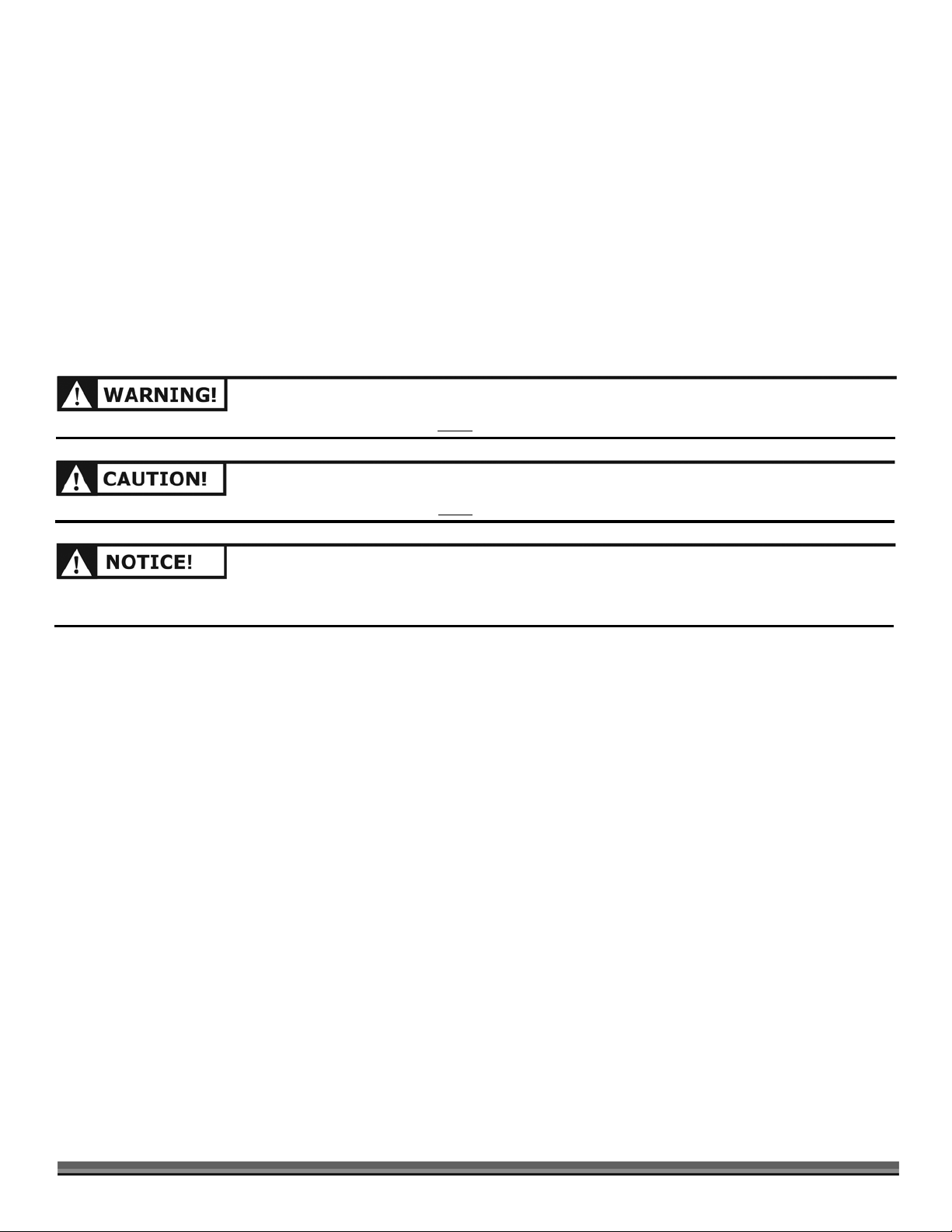

Labels

Your OPTIONAL ACCESSORY for the DR ROTO-HOG POWER TILLER carries prominent labels as reminders for its proper and

safe use. Shown below are copies of all the labels that appear on the accessories. Take a moment to study them and make a note

of their location on your OPTIONAL ACCESSORY for the DR ROTO-HOG POWER TILLER as you assemble and before you

operate the unit. Replace damaged or missing safety and information labels immediately.

DR Power Spreader:

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate the equipment.

Exercise caution at all times when operating equipment.

• Read this owners manual before attempting to assemble or operate the ACCESSORY.

• Read the vehicle owner’s manual and know how to operate your vehicle, before using the ACCESSORY.

• Do not allow anyone to ride on or sit on spreader or culti-packer frame.

• Never allow children to operate the vehicle or ACCESSORY.

• Do not allow adults to operate the vehicle or ACCESSORY without proper instructions.

• WE RECOMMEND WEARING SAFETY SHOES WHEN USING THIS MACHINE. WEAR SHOES WITH NON-SLIP TREADS TO

IMPROVE FOOTING ON SLIPPERY SURFACES. DO NOT USE THE MACHINE WEARING OPEN SANDALS OR WHILE

BAREFOOT.

• Wear eye and hand protection when handling and using lawn chemicals.

• Always begin with the VEHICLE transmission in first (low) and gradually increase speed as conditions permit.

• When using the ACCESSORY do not drive too close to a creek or ditch and be alert for holes and other hazards which could

cause you to loose control of the ACCESSORY and vehicle.

• Always operate vehicle and ACCESSORY up and down a slope, never across a slope.

• Read instructions and caution notes for handling and application of materials purchased for spreading.

• Follow maintenance and lubrication instructions as outlined in this manual.

Contact us at www.DRpower.com 3

Page 4

Chapter 2: Setting Up Your Accessory For The DR ROTO-HOG Power Tiller

A

A

This chapter outlines a few simple steps you will need to follow to set up and use your new DR ROTO-HOG POWER TILLER

OPTIONAL ACCESSORIES. If you have any questions at all, please feel free to contact our Customer Service Representatives at

our toll free number 1-800-DR-OWNER (376-9637).

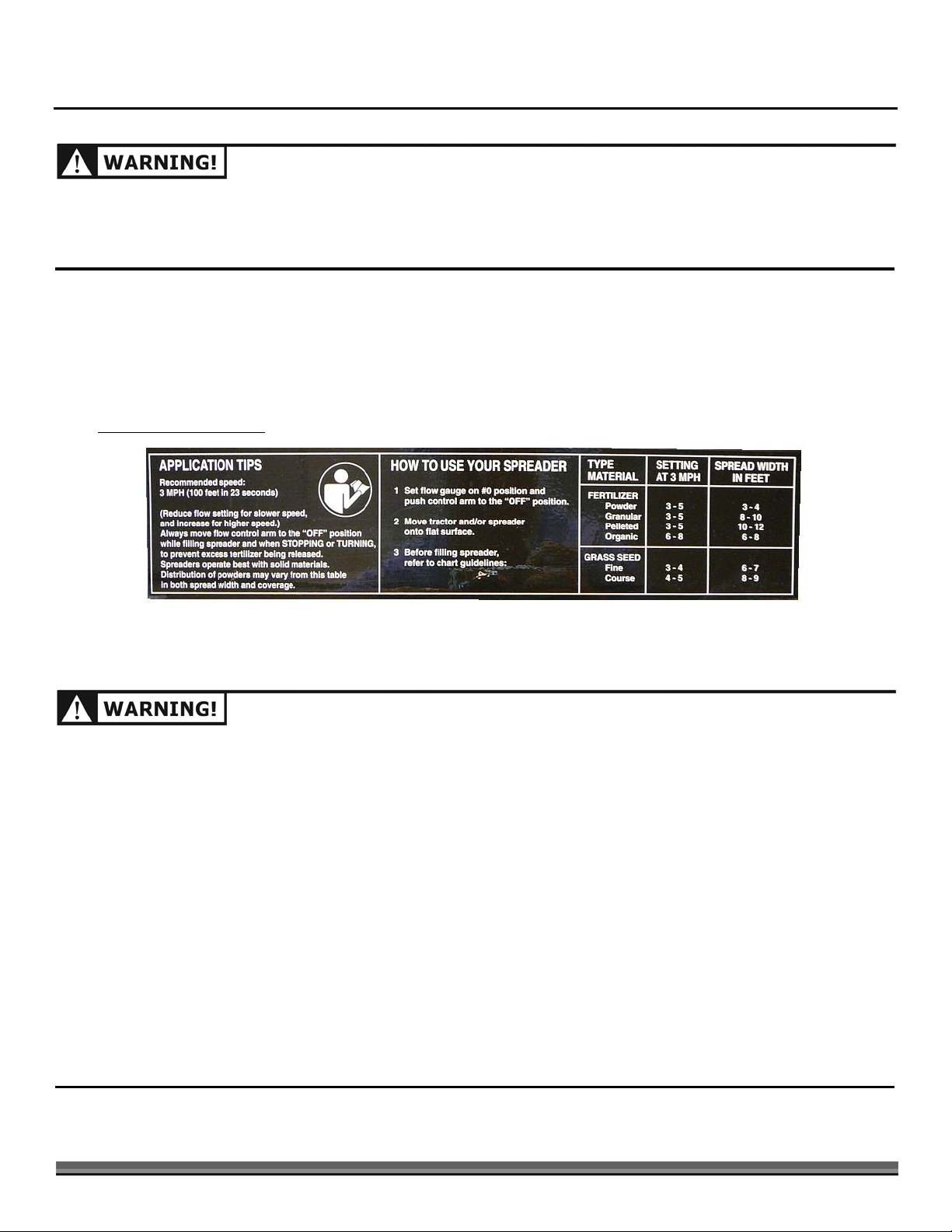

DR ROTO-HOG POWER TILLER OPTIONAL ACCESSORIES Specification Sheets

DR POWER SPREADER SPECIFICATIONS

Spreader Dimensions 34" X 30" X 32"

Shipping Dimensions 29.78" X 21.38" X 24.25"

Shipping Weight 35 lbs.

Spreader Capacity (Weight) 125 lbs.

Spreader Capacity (Volume) 14 gal.

DR CULTI-PACKER SPECIFICATIONS

Culti-packer Dimensions 20" X 12" X 38"

Shipping Dimensions 18" X 12" X 39"

Shipping Weight Approx. 60 lbs.

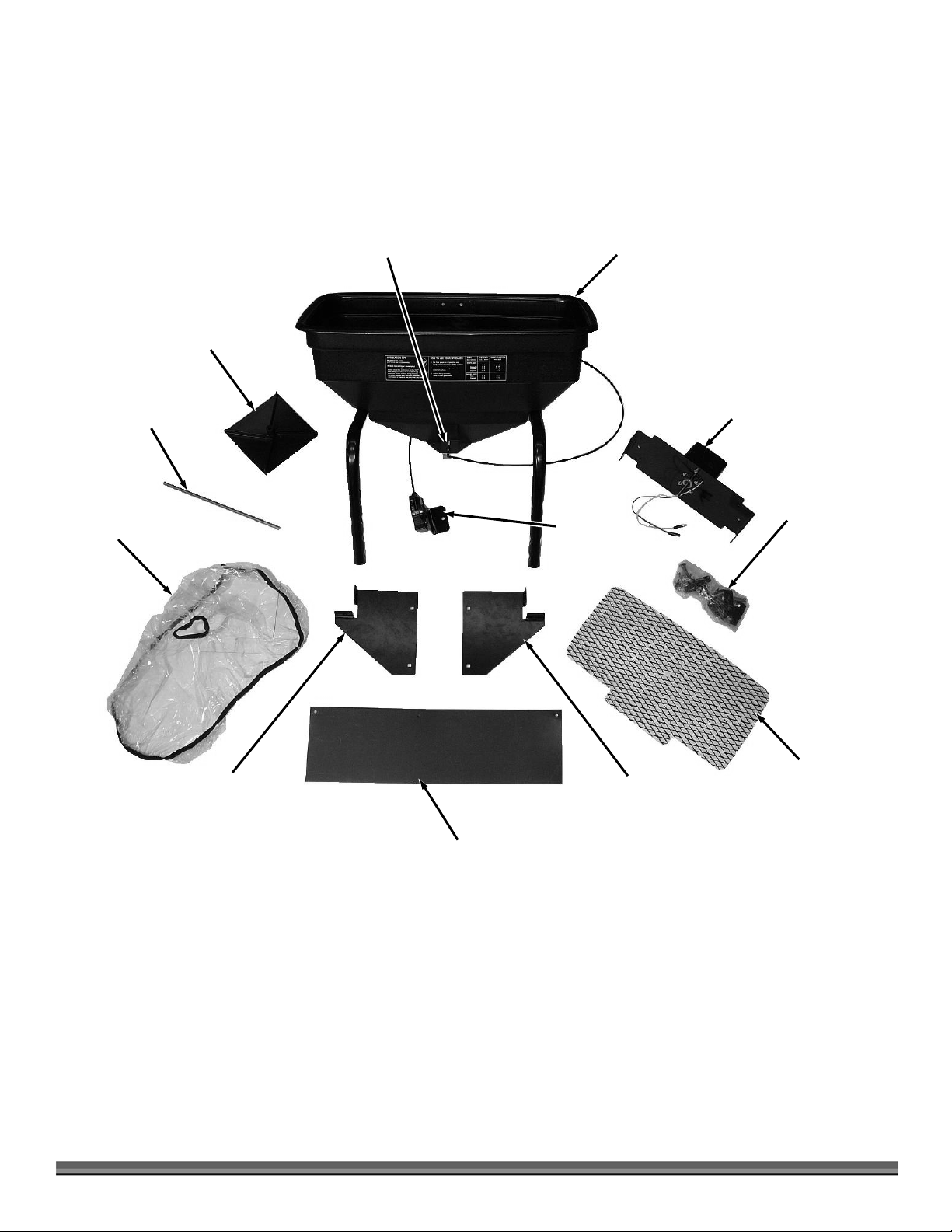

SETTING UP YOUR DR POWER SPREADER

Unpacking the DR Power Spreader

Parts Supplied:

• Hopper/Frame Assembly

• Screen

• Vinyl Cover

• Hardware Package

• Impeller Shaft

• Deflector

• Mounting Bracket, R.H.

• Mounting Bracket, L.H.

• Impeller

• Motor Mount Assembly

Tools Needed:

• Pliers

1. Open the shipping container by pulling the staples out with pliers

and opening the top flaps (Figure 1).

2. Remove the contents to a flat open area (the Mounting Brackets are

located under the bottom box flaps).

3. Open the cardboard that is wrapped around the Motor Mount

Assembly to remove the Motor Mount Assembly, Vinyl Cover,

Impeller Shaft and Hardware Package

Hopper/Frame

ssembly

Motor Mount

ssembly

Figure 1

4. See the unpacked “Major Components” (Figure 2).

NOTE: Do not discard your packaging material until you are fully satisfied with your new DR POWER SPREADER.

4 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 5

Major Components

yl C

ge)

f

p

A

A

Vin

Impeller

Sha

t

over

Im

eller

Hopper

Closure

Plate

Flow

Control

Lever

ssembly

Hopper/Frame

Assembly

Motor Mount

ssembly

Hardware

Package

(see next

pa

Mounting

Bracket, R.H.

Mounting

Bracket, L.H.

Deflector

Figure 2

Screen

Contact us at www.DRpower.com 5

Page 6

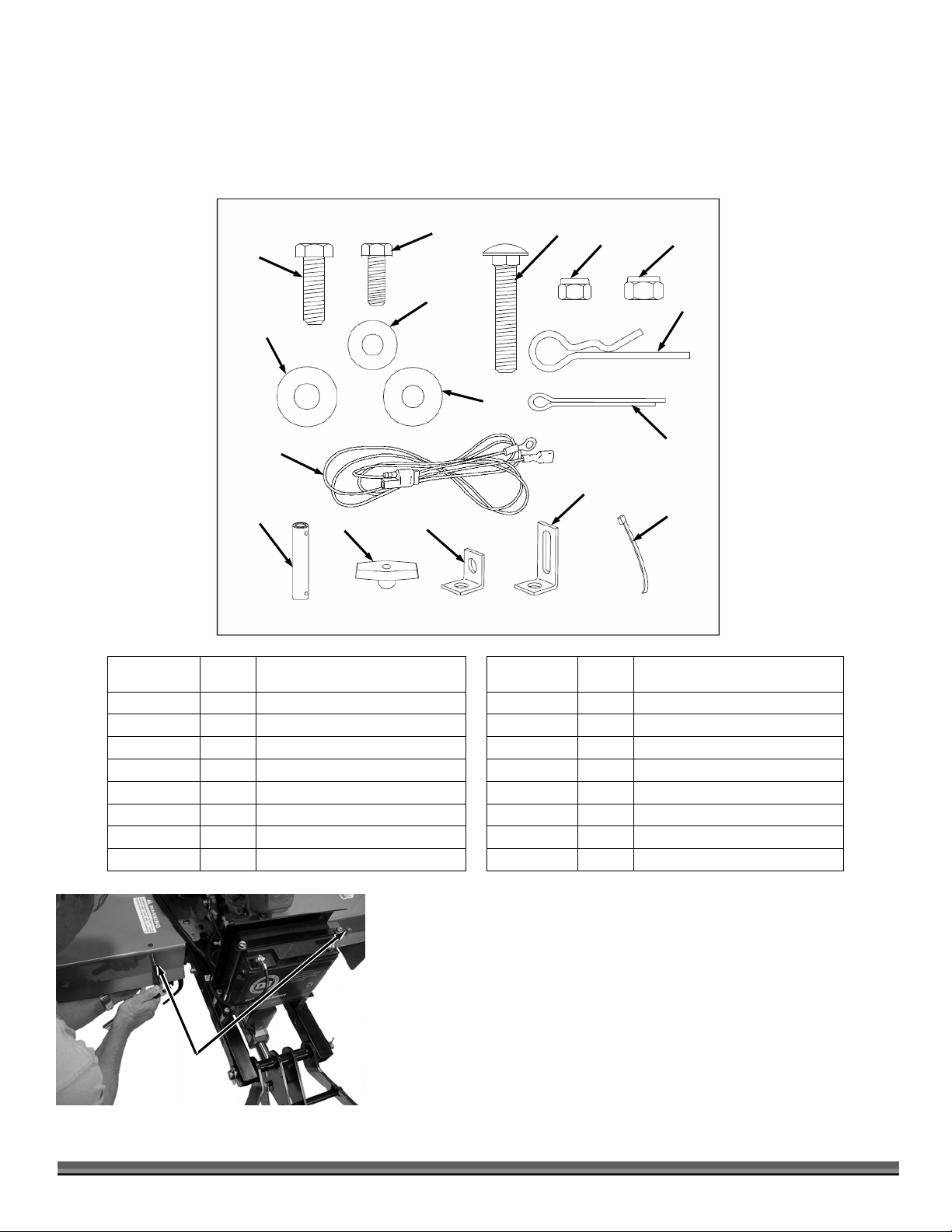

Hardware Package Contents

The item numbers on the illustration and in the table below are the same item numbers listed in the parts list and schematic

diagram in the “Parts List and Schematic Diagrams” section of chapter 7. This reference will aid in the proper location of parts as

you assemble the spreader.

28

35

6

32

5

48

37

17

ITEM NO. QTY. DESCRIPTION ITEM NO. QTY. DESCRIPTION

33

21

46

7

26

25

39

41

Tiller Fender

Figure 3

6 DR

35 4 Hex Bolt, 5/16" x 1" 25 1 Hair Pin Agitator

28 2 Hex Bolt, 1/4" x 3/4" 39 3 Cotter Pin, 1/8" x 1-1/4"

21 5 Carriage Bolt, 5/16" x 1-3/4" 37 1 Impeller Coupler

7 2 Nylock Hex Nut, 1/4" 17 5 Wing Knob

26 4 Nylock Hex Nut, 5/16" 33 2 Angle Bracket

6 2 Flat Washer , 1/4" 46 1 Mounting Clamp

32 8 Flat Washer, 5/16" 41 2 Nylon Tie

5 2 Nylon Washer

48 1 Spreader Cable

Installing the DR POWER SPREADER

Tools Needed:

• 7/16" Wrench and Socket

• 1/2" Wrench and Socket

Instructions:

Hex Head Bolts,

Washers and

Nylock Nuts

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

1. Remove two 5/16-18 X 2-1/4" Hex Head Bolts, Washers and Nylock Nuts

(1/2" Wrench) from the back face of the ROTO-HOG POWER TILLER Fender

(Figure 3).

Page 7

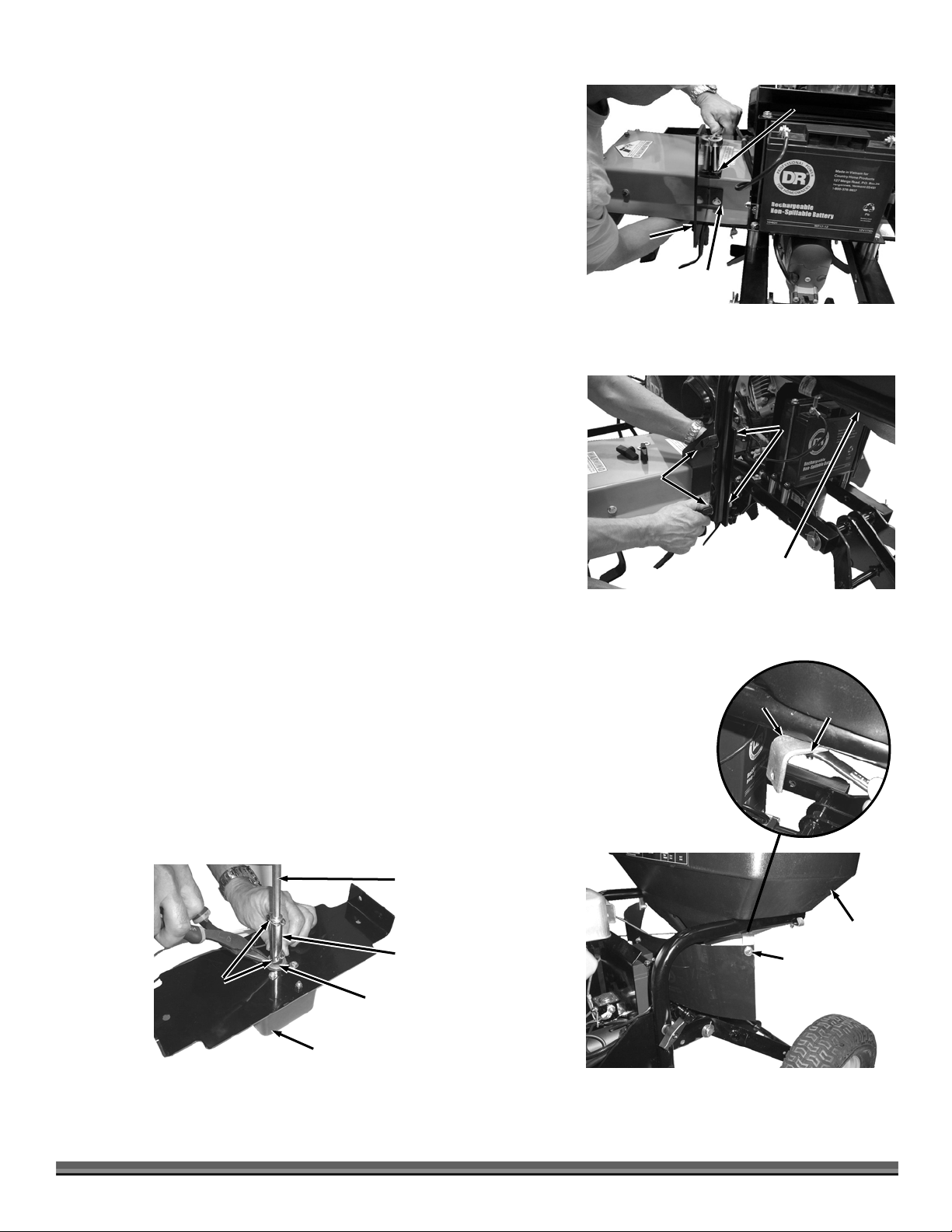

2. Position the left hand Mounting Bracket onto the back face of Tiller Fender

(Figure 4), with mounting tabs facing in, and replace the hardware you

removed in step 1. Install a 5/16-18 X 1” Hex Head Bolt (on top), Washer

and Nylon Locknut (1/2" Wrench) to secure the Bracket to top of the Tiller

Fender. Repeat this step to install the right hand Mounting Bracket.

3. Use the top and bottom holes of the Mounting Tubes on the Hopper/Frame

assembly to attach the assembly to the Spreader Mount Brackets with four

5/16-18 x 1-3/4" Carriage Bolts (1/2" Wrench), four 5/16" Washers and four

Wing Knobs (Figure 5). Make sure that the Carriage Bolt square goes fully

into the square holes of the Spreader Mount Brackets and the Wing Knobs

and Washers are on the Mounting Tube side.

4. Remove two 1/4" Nylon Locknuts (7/16" Wrench) from the Hopper

Assembly and position the two Angle Brackets and secure (hand tight) with

the two Nuts you removed (Figure 6).

Hex Head Bolt,

Washers and

Nylock Nut

Tiller Fender

Mounting

Bracket

Mounting

Tab

Figure 4

5. Position the Rear Deflector onto the Angle Brackets and secure with two 1/4-

20 x 3/4" Bolts, Washers and Nylon Locknuts.

6. Tighten the Nylon Locknuts that secure the Angle Brackets to the Hopper

Assembly.

7. Position the Impeller Coupler over the Output Shaft of the Motor Mount

Assembly and secure with 1/8" x 1-1/4" Cotter Pin (Figure 7).

NOTE: The Impeller Shaft has three holes in it. It should be mounted so that the

center hole is furthest away from the Impeller Coupler.

8. Insert the Impeller Shaft into the Impeller Coupler and secure with 1/8" x 1-

1/4" Cotter Pin.

Wing Knobs

and Washers

Figure 5

Hopper

Mounting

Tubes

Carriage

Bolts

Hopper

Assembly

Angle

Bracket

Nylock

Nut

Cotter

Pins

Figure 7

Output

Shaft

Motor Mount

Assembly

Impeller

Shaft

Impeller

Coupler

Rear

Deflector

Figure 6

Bolt,

Washer and

Nylock Nut

Contact us at www.DRpower.com 7

Hopper

Assembly

Page 8

f

Impeller

Shaft

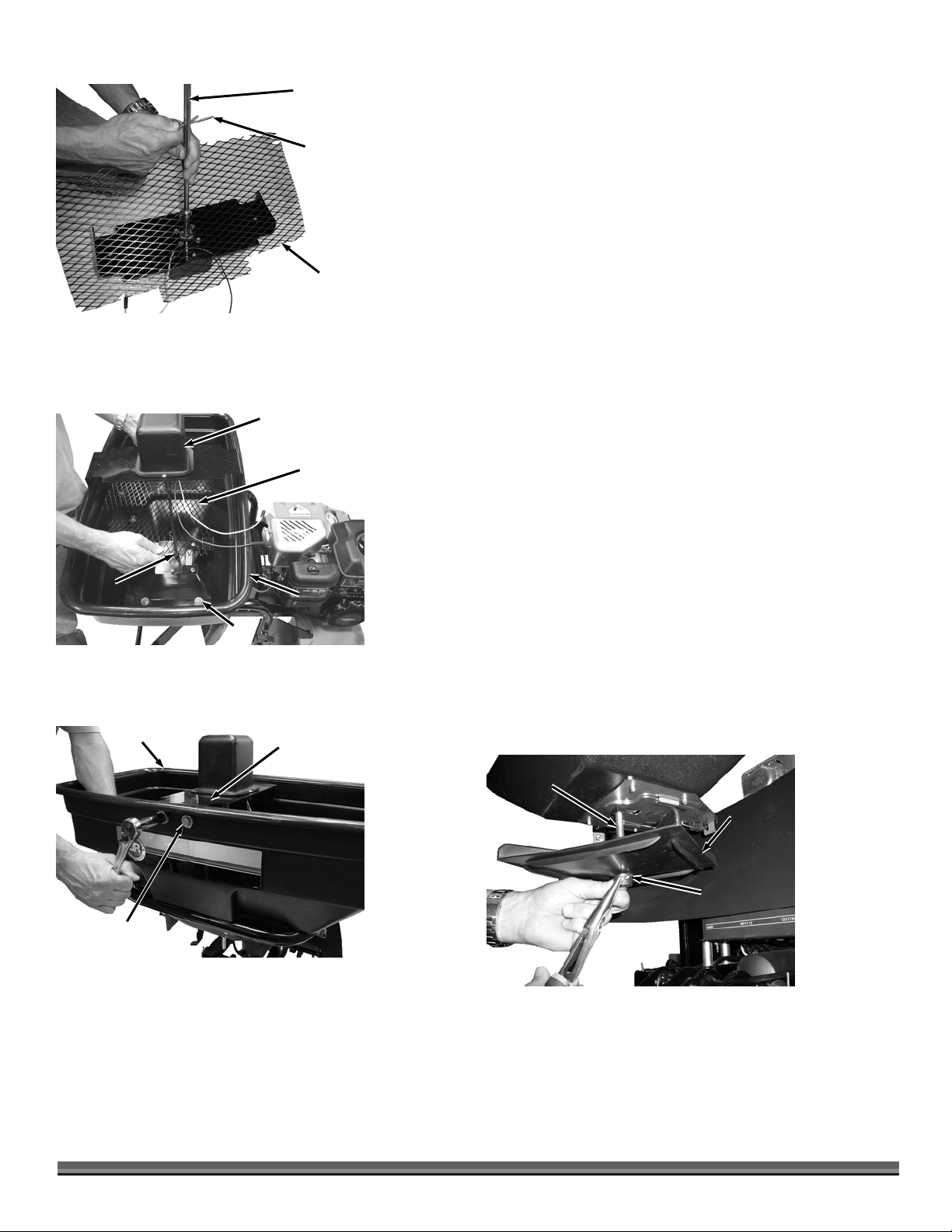

9. Slide the Impeller Shaft through the hole in Spreader Screen and insert the

Agitator Hairpin thru the center hole in the Impeller Shaft (Figure 8).

Figure 8

Impeller

Sha

t

Agitator

Hairpin

Spreader

Screen

Motor Mount

Assembly

Spreader

Screen

Hopper

10. Position the Motor Mount assembly with the Spreader Screen into the

Hopper and slide the Impeller Shaft through the hole in the bottom of the

Hopper (Figure 9). Secure the Spreader Screen into the recessed portion of

the Hopper by sliding the edge of the Screen under the Clips on both sides.

11. Line up the Motor Mount Bracket with holes in Hopper. Secure Motor

Mount Bracket to Hopper with two 5/16-18 x 1" Hex Bolts, two 5/16"

Washers, two Nylon Washers (against outside of Hopper) and two 5/16"

Nylon Locknuts (1/2" Wrench) (Figure 10).

12. Slide the Spreader Impeller onto the Impeller Shaft with the large fins facing

up and secure with 1/8" x 1-1/4" Cotter Pin (Figure 11).

Figure 9

Hopper

Bolt, Washer,

Nylon Washer

and Nylock

Nut

Figure 10

Clip

Motor Mount

Bracket

Impeller

Shaft

Spreader

Impeller

Cotter Pin

Figure 11

8 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 9

Wiring Instructions

f

1. Move the "ON-OFF" Switch on the ROTO-HOG Control Box to the “OFF”

position (Figure 12).

2. Attach the Spreader Cable Connector to the Motor Mount Assembly

Connectors (Figure 13).

3. Plug the Green Wire Connector from the Spreader Cable into the Green Wire

Connector from the Tiller (Figure 14).

4. Remove the Nylon Locknut from the Ground Stud on the Battery Mounting

Bracket.

5. Install the Black Wire Terminal from the Spreader Cable onto the Ground

Stud and reinstall the Nylon Locknut.

ROTOHOG

Control Box

Figure 12

“ON”

“OFF”

“ON-OFF”

Switch

6. Use the Nylon Ties provided to safely secure the wiring and Flow Control

Cable away from hot engine parts, rotating parts and pinch points.

Mounting the Flow Control Lever Assembly

1. Find a place on your tow vehicle to mount the Flow Control Lever Assembly

where you can operate while sitting on the vehicle. If there is not a hole in

the area to mount a 5/16” bolt then you must create one.

2. Using a 5/16" x 1-3/4" Carriage Bolt and Wing Knob from the Hardware

Package, mount the Flow Control Lever Assembly to your Tow Vehicle

(Figure 15).

3. If a different mounting position is required, use the Mounting Clamp from

your Hardware Package to change the position of the Flow Control Lever

Assembly. You will need to provide the hardware to mount the Mounting

Clamp to the tow vehicle.

Bracket

Mounting

Clamp

Flow Control

Lever

Assembly

Tiller Wire Harness

Connector

Figure 13

Black Wire

from

Spreader

Cable

Motor Mount

Assembly

Connectors

Flow Control

Cable

Ground Stud on

Battery Mounting

Bracket

Green Wire

rom Tiller

Green Wire

from Spreader

Cable

Figure 15

Figure 14

Contact us at www.DRpower.com 9

Page 10

Frame and

Wheel

Assembly

Figure 16

Transport

Hook

Hardware

Package

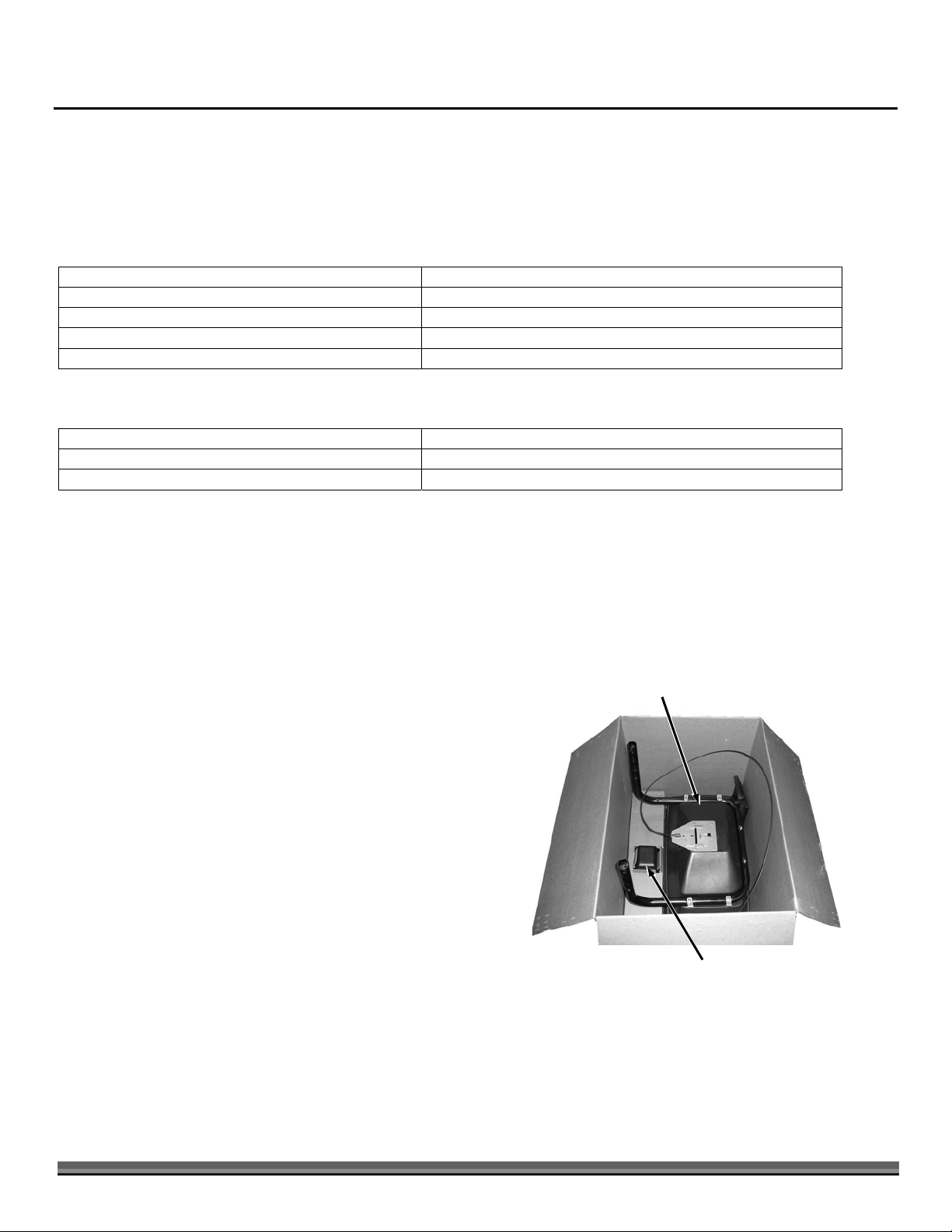

SETTING UP YOUR DR CULTI-PACKER

Unpacking the DR Culti-packer

Parts Supplied:

• Frame and Wheel Assembly

• Transport Hook

• Hardware Package

Tools Needed:

• Pliers

• Utility Knife

1. Cut the plastic away from the box with a Utility Knife.

2. Open the shipping container by pulling the staples out with pliers and

opening the top flaps (Figure 16).

3. Remove the contents to a flat open area.

4. See the unpacked “Major Components” (Figure 17).

NOTE: Do not discard your packaging material until you are fully satisfied with your

new DR CULTI-PACKER.

Major Components

Frame and

Wheel

Assembly

Hardware

Package

Transport

Hook

10 DR

Figure 17

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 11

Hardware Package Contents

k

The item numbers on the illustration and in the table below are the same item numbers listed in the parts list and schematic

diagram in the “Parts List and Schematic Diagrams” section of chapter 7. This reference will aid in the proper location of parts as

you assemble and install the Culti-packer.

17

18

5

6

ITEM NO. QTY. DESCRIPTION

17 2 Extension Spring

18 2 “S” Hook

6 2 Hairpin Clip

5 2 Clevis Pin

3

2

20

4

2 2 Bolt, Hex, 1/2" X 1-3/4"

3 2 Washer, .5312" X 1.5" X .1345"

4 2 Nut, Nylon Lock, 1/2"

Assembling the Culti-packer

Tools Needed:

• Two 3/4" Wrenches

1. Position the Hook Assembly with the Adjustment Slots facing down and line

up the mounting holes with the Frame Assembly (Figure 18).

2. Insert the Bolts, Washers and Spacers (bolt heads facing out) and secure

with the Locknuts using two 3/4" Wrenches.

Installing the Culti-packer

1. Rotate the ROTO-HOG Power Tiller Wheels to their halfway position with the

ROTO-HOG Control Box (Figure 19).

2. Position the Culti-packer at the rear of the Tiller near the wheel axle (Figure

20).

3. Rotate the Hook Assembly away from the Tiller.

Tiller

Frame

Assembly

Transport

Hook

Figure 18

Locknut

Spacer

Bolt and

Washer

Adjustment

Slots

ROTO-HOG

Power Tiller

Set at

approx.

°

Transport

Hoo

Figure 20

Figure 19

Contact us at www.DRpower.com 11

Page 12

Slotted Tube/ Culti-packer

d

Frame Assembly

Slot

4. Slide the Slotted Tubes of the Frame Assembly onto the Lower Wheel Axle

of the Tiller until the Axle is seated into the slot base of both Slotted Tubes

(Figure 21).

5. Insert the Clevis Pins into the holes at the ends of both Slotted Tubes from

the top and secure the Clevis Pins with Hairpin Clips (Figure 22).

6. Use the ROTO-HOG Control Box to Raise the Tiller Tines to their uppermost

position (Figure 23).

NOTE: The “S” Hooks have a large and small end. The large end is for the Support

Rod and the small ends are for the Springs to attach to in the next step.

7. Place the small ends of the “S” Hooks onto the Springs and hook the

Springs to the Eye Bolts (Figure 24).

Figure 21

Clevis Pin

Slotted

Tube

Figure 22

Hairpin

Clip

Lower Wheel Axle of

Tiller Assembly

8. Rotate the Culti-packer up towards the Wheel Frame and hook the “S”

Hooks to the Support Rod on the Tiller Wheel Frame Assembly.

9. Slowly lower the Culti-packer to the ground.

10. Lift the Culti-packer as you rotate the Hook Assembly forward until the

Lower Slots of the Hook Assembly can be hooked over the Support Rod

(Figure 25).

11. The Culti-packer is now in transport mode.

Support

Ro

Spring

Eye

Bolt

Figure 24

“S” Hook

Figure 23

12 DR

approx.

90°

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Transport

Hook

Figure 25

Lower

Slot

Page 13

Chapter 3: Operating Your Optional Accessory

•

•

Figure 26

ROTOHOG

Control Box

Figure 27

Adjustable

Stop

Flow

Control

Lever

“OFF”

“ON”

“OFF”

“ON-OFF”

Switch for

Spreader

Motor

OPERATING YOUR DR POWER SPREADER

Setting the Flow Control Lever

1. Slide the Adjustable Stop to the desired setting (“OFF” is fully closed, “10”

is fully open) (Figure 26).

2. Leave the Flow Control Lever at the “OFF” setting until you use the spreader.

Starting the DR Power Spreader

1. Toggle the "ON-OFF" switch of the ROTO-HOG Control Box to the “ON”

position (Figure 27). Leave the Flow Control Lever at the “OFF” position

until you use the Spreader (Figure 26).

Stopping the DR Power Spreader

1. Move the Flow Control Lever to the "OFF" position (Figure 26). Toggle the

“ON-OFF” Switch to the “OFF” position (Figure 27).

We do not recommend the use of any powdered lawn chemicals, due to

difficulty in obtaining a satisfactory or consistent broadcast pattern.

• Application rates shown in the Application chart (this page) are affected by

humidity and by the moisture content of the material (granular and pellet).

Some minor setting adjustments may be necessary to compensate for this

condition.

APPLICATION CHART

TYPE

MATERIAL

FERTILIZER

Powder

Granular

Pelleted

Organic

GRASS SEED

Fine

Coarse

FLOW SETTING

3 MPH

3-5

3-5

3-5

6-8

3-4

4-5

SPREAD

WIDTH

3'-4'

8'-10'

10'-12'

6'-8'

6'-7'

8'-9'

Using Your DR Power Spreader

1. Determine approximate square footage of area to be covered and estimate

amount of material required.

2. Verify that the Spreader Motor turns on and off and that the flow control is

operating properly.

3. Make sure the Flow Control Lever is in the “OFF” position.

4. Set the Adjustable Stop to the desired flow rate, keeping the Flow Control

Lever in the “OFF” position. Refer to the application chart and the

instructions on the Material Package to determine the proper flow rate

setting. The application chart is calculated for a vehicle speed of 3 mph (100

ft. in 23 seconds). Faster speeds require higher flow rate settings to

maintain the same application rate.

When spreading weed control fertilizers, make sure the broadcast pattern

does not hit evergreen trees, flowers, shrubs or vegetable gardens.

• follow the instructions, warnings, etc. from the manufacturer of the

material you are spreading to ensure safe operation.

• do not exceed the 125lbs. weight limit of material in the hopper.

Contact us at www.DRpower.com 13

Page 14

5. Break up any lumps as you fill the Hopper with the material to be spread.

A

6. Start the vehicle in motion and then toggle the ROTO-HOG Control Box

switch to "ON" and move the Flow Control Lever up to lock with the

Adjustable Stop.

NOTE: Move the Flow Control Lever to off (“OFF”) before turning or stopping.

7. To insure uniform coverage, make each pass so that the broadcast pattern

slightly overlaps the pattern from the previous pass (Figure 28). The

approximate broadcast widths for different materials are shown in the

application chart on this page.

8. Heavy moisture conditions may require a cover over the hopper to keep

contents dry. The Vinyl Cover acts as a wind and moisture shield, but should

not be used as a rain cover (Figure 29).

9. If fertilizer is accidentally deposited too heavily in an area, soak the area

thoroughly with a garden hose or sprinkler to prevent burning of the lawn.

Removing the DR Power Spreader

1. Disconnect the Wire Harness Connector from the Motor Mount Assembly

Connector. Remove the Flow Control Valve Assembly from the rear of the

vehicle if it is attached there.

2. Support the Spreader and remove the Wing knobs, Washers and Carriage

Bolts from the Spreader Bracket Tubes.

Figure 28

Motor

Mount

ssembly

Vinyl

Cover

3. Remove the Spreader from the tiller.

OPERATING YOUR DR CULTI-PACKER

Setting the Culti-packer to Operating Position

NOTE: The following procedure assumes the Culti-packer is in the transport position.

1. Lower the tines on the Tiller to halfway position with the Tiller Control Box.

2. Lift up on the Culti-packer as you lift up on the Hook Assembly to disengage

the Hook Assembly Slot from the Tiller Wheel Mount Assembly (Figure 30).

NOTE: Holding down on the Hook Assembly Handle will help to engage the slot

when you reach that point.

3. Slide the Hook Assembly down until the upper slot engages with the rod of

the Tiller Wheel Mount Assembly.

4. Raise the Tiller Tines to their uppermost position with the Tiller Control Box.

5. The Culti-packer Wheels are now engaged with the soil and the Tiller Wheels

are lifted off the ground.

6. The Culti-packer is now ready to use.

Operating tips

Figure 29

Transport

Hook

Figure 30

Hopper/Frame

Assembly

Upper

Slot

• For best results it may be necessary to pack the soil before seeding and then pack the soil a second time after seeding.

• The Culti-packer can be used to break up clumps and to give soils a smooth finished appearance.

• If desired, the Culti-packer can be left in the “operating” position when the Tow Vehicle is being reversed.

14 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 15

Chapter 4: Maintaining The Optional Accessory

Regular maintenance is the way to ensure the best performance and long life of your OPTIONAL ACCESSORY. Please refer to this

manual for maintenance procedures.

MAINTAINING THE DR POWER SPREADER

When performing any maintenance on the DR Spreader Attachment when the unit is still attached to the tiller, you must first make

sure the switch on the tiller control box is in the “off” position and then disconnect the wire harness of the motor mount assembly.

Regular Maintenance Check List before each use

CHECK FOR LOOSE FASTENERS

1. Before each use make a thorough visual check of the Spreader for any bolts and nuts which may have loosened. Retighten any

loose bolts and nuts.

CHECK FOR WORN OR DAMAGED PARTS

1. Check for worn or damaged parts before each use.

2. Repair or replace parts if necessary.

CLEANING

Follow all warnings, cautions etc. from the material manufacturers for proper cleaning and disposal practices before cleaning your

equipment.

1. Rinse inside of Hopper and exterior of Spreader and dry off before storing (even though the Spreader Motor is sealed, avoid

spraying the Motor and wires if possible).

2. Clean out any build up of material from the Hopper Closure Plate.

3. Clean any build up of material from your ROTO-HOG Tiller.

Storage

1. Rinse inside of Hopper and exterior of Spreader and dry off before storing (even though the Spreader Motor is sealed, avoid

spraying the Motor and wires if possible).

2. Store in a clean, dry area.

Contact us at www.DRpower.com 15

Page 16

MAINTAINING THE DR CULTI-PACKER

Regular Maintenance Check List before each use

CHECK FOR LOOSE FASTENERS

1. Before each use make a thorough visual check of the Culti-packer for any bolts and nuts which may have loosened. Retighten

any loose bolts and nuts.

CHECK FOR WORN OR DAMAGED PARTS

1. Check for worn or damaged parts before each use.

2. Repair or replace parts if necessary.

Replacing Parts

NOTE: The Culti-Packer should be lowered to the ground (with no pressure on the Wheels) or taken off the Tiller completely for replacing

parts.

REPLACING BEARINGS

1. Remove the Cotter Pins and Washers from the ends of the Shaft (Figure 31).

2. Slide the Shaft out of the Frame.

NOTE: The Spacers may slide off the end of the Tube as you perform the next

procedure. Make sure they are installed back on the tube correctly before

repositioning the Wheel Assembly into the Frame.

3. Roll the Wheels with the Tube, Bearings and Spacers away from the Frame.

4. Slide the Bearings from the Tube and install the new Bearings.

5. Roll the Wheels with the Tube, Bearings and Spacers into position on the

Frame.

6. Slide the Shaft into the Frame and through the Bearings in the Tube.

7. Install the Washers on the ends of the Shaft and secure with the Cotter Pins.

REPLACING WHEELS

1. Follow the “Replacing Bearings” section (steps 1 to 3) to disassemble the

Wheels and tube from the Frame.

2. Replace damaged Wheel(s) with new Wheel(s).

3. Follow the “Replacing Bearings” section (steps 5 to 7) to disassemble the

Wheels and tube from the Frame.

Cleaning

1. Rinse the Culti-packer and dry off before storing.

2. Clean out any build up of material from the Culti-packer Wheels.

3. Clean any build up of material from your ROTO-HOG Tiller.

Cotter

Pin

Washers

Shaft

Figure 31

Frame

Cotter Pin

Washers

Frame

Wheel

Spacer

Bearing

Storage

1. Rinse the Culti-packer and dry off before storing.

2. Store in a clean, dry area.

16 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 17

Chapter 5: Troubleshooting Your Optional Accessory

Most problems are easy to fix. Consult the Troubleshooting Tables below for common problems and their solutions. If the

procedures for fixes are not in your OPTIONAL ACCESSORIES Safety and Operating Instructions or if you continue to experience

problems, please feel free to contact our Customer Service Representatives at our toll free number 1-800-DR-OWNER (376-9637).

TROUBLESHOOTING YOUR DR POWER SPREADER

When performing any maintenance on the DR Spreader Attachment when the unit is still attached to the tiller, you must first make

sure the switch on the tiller control box is in the “off” position and then disconnect the wire harness of the motor mount assembly.

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE

Hopper closure plate does not open to the correct

position.

⇒ Material packed around plate. Clean out around closure plate.

Spreader motor doesn't run.

Motor runs when switch is shut off.

⇒ Loose connection in spreader wiring. Check and reconnect.

⇒ Loose battery connection. Tighten battery terminals.

⇒ Battery is run down. Recharge the battery.

⇒ Broken spreader wiring. Replace damaged wiring.

⇒ Spreader on-off switch is broken. Replace the switch.

⇒ Spreader motor is broken. Repair or replace motor.

⇒ Spreader on-off switch is broken. Replace the switch.

TROUBLESHOOTING YOUR DR CULTI-PACKER

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE

Culti-packer wheels do not turn when in use.

Culti-packer does not raise and lower when the

tiller control panel is operated.

The culti-packer does not touch the ground when

in operation.

⇒ Material packed around wheels. Clean out around and between wheels

⇒ Check that the culti-packer handle assembly is locked in the desired

groove. Lock the handle assembly into the desired groove.

⇒ The culti-packer is in the transport position. Move the culti-packer into

the operating position.

Contact us at www.DRpower.com 17

Page 18

Notes:

18 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 19

Notes:

Contact us at www.DRpower.com 19

Page 20

Chapter 6: Parts List And Schematic Diagrams

Parts List - DR POWER SPREADER

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 234851 Hopper

02 234811 Plug, 1/4"

03 234761 Bolt, Hex, 1/4-20" x 2-1/4"

04 234791 Bolt, Hex, 1/4-20" x 2"

05 234911 Washer, Nylon

06 232891 Washer, 1/4 Std .312 X .734

07 233031 Nut, Hex 1/4-20 Nylock

08 234651 Clip

09 234641 Plate, Side

10 234731 Bushing, Hopper

11 234591 Plate, Guide

12 234711 Rivet, Pop, 3/16"

13 234681 Cable Assembly, Control

14 234621 Bracket, Control Mount

15 234751 Bolt, Carriage, 1/4"-20 x 1-3/4"

16 234801 Nut, Hex Sims, 1/4"

17 234701 Knob, Wing

18 234741 Washer, Star

19 234901 Impeller, Spreader

20 234871 Tube, Hopper Mount

21 234721 Bolt, Carriage, 5/16"-18/ x 1-3/4"

22 234891 Screen, Spreader

23 234661 Bracket, Mount RH

24 234671 Bracket, Mount LH

Ref# Part# Description

25 234861 Hairpin, Agitator

26 233081 Nut, Hex 5/16-18 Nylock

27 234881 Cover, Vinyl

28 232841 Bolt, Hex 1/4-20 X 3/4 G5

29 234831 Deflector, Rear

30 234821 Cover, Motor

31 234931 Washer, Lock. #10

32 232871 Washer, 5/16" Std .375 X .875

33 234581 Bracket, Angle

34 232951 Washer, SAE. #10

35 232851 Bolt, Hex 5/16-18 X 1 G5

36 234631 Shaft, Impeller

37 234601 Coupler, Impeller

38 234841 Seal, Motor Lip

39 234691 Pin, Cotter, 1/8" x 1-1/4"

40 234771 Bolt, Pan Slot, #8-32 x 1/2"

41 234921 Tie, Nylon

42 234611 Bracket, Motor Mount

43 234781 Motor, 12 Volt

44 232931 Bolt, Slotted, #10-32 X 5/8"

45 233021 Nut, Nylock, #10-32

46 234571 Bracket, Mounting

47 234971 Label, Spreader Operation

48 233721 Spreader Cable

20 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 21

Schematic - DR POWER SPREADER

48

Contact us at www.DRpower.com 21

Page 22

Parts List - DR CULTI-PACKER

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

01 265451 Transport Hook

02 264501 Bolt, Hex, 1/2" X 1-3/4"

03 264521 Washer, .5312" X 1.5" X .1345"

04 110721 Nut, Nylon Lock, 1/2"

05 234231 Pin, Clevis, 3/8" X 2.25"

06 234191 Clip, Hairpin, 1/16" X 1-3/4"

07 264451 Shaft

08 264491 Cotter Pin, 1/8" X 1-1/4"

09 264481 Washer

10 234321 Spacer

11 264461 Tube

12 264471 Bearing Flange

13 234791 Wheel

14 234241 Bolt, Eye, 5/16" X 3"

15 234251 Nut, 5/16"-18

16 234261 Washer, Lock, 5/16"

17 234271 Spring, Extension

18 234281 Hook, “S”

19 264441 Frame

20 264511 Spacer

22 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

Page 23

Schematic - DR CULTI-PACKER

Contact us at www.DRpower.com 23

Page 24

Daily Checklist for the OPTIONAL ACCESSORY

To help maintain your OPTIONAL ACCESSORY for optimum performance, we recommend you follow this checklist each time

you use your Accessory.

DR POWER SPREADER CHECKLIST

[ ] Before each use make a thorough visual check of the Spreader for any bolts and nuts which may have

loosened. Retighten any loose bolts and nuts.

[ ] Check for worn or damaged parts before each use.

[ ] Repair or replace parts if necessary.

DR CULTI-PACKER CHECKLIST

[ ] Before each use make a thorough visual check of the Culti-packer for any bolts and nuts which may have

loosened. Retighten any loose bolts and nuts.

[ ] Check for worn or damaged parts before each use.

[ ] Repair or replace parts if necessary.

[ ] Check that the Culti-packer wheels are turning freely.

DR Power Equipment

MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

1-800-DR-OWNER (376-9637) • www.DR power.com ©2009 CHP, Inc. 234291B

Loading...

Loading...