Page 1

DR

SAFETY & OPERATING INSTRUCTIONS

Models: 22-Ton

28-Ton

34-Ton

®

VERTICAL/HORIZONTAL LOG SPLITTER

DR Power Equipment

Serial No.

Order No.

Read and understand this manual and all instructions before operating the DR Vertical/Horizontal Log Splitter.

Original Language

Toll-free phone: 1-800-DR-OWNER (376-9637)

Fax: 1-802-877-1213

Website: www.DRpower.com

Page 2

Table of Contents

Chapter 1: General Safety Rules ............................................................................................................................................................ 3

Chapter 2: Assembly and Setting Up The DR VERTICAL/HORIZONTAL LOG SPLITTER ................................................................. 7

Chapter 3: Operating The DR VERTICAL/HORIZONTAL LOG SPLITTER ......................................................................................... 22

Chapter 4: Maintaining The DR VERTICAL/HORIZONTAL LOG SPLITTER ...................................................................................... 28

Chapter 5: Troubleshooting .................................................................................................................................................................. 30

Chapter 6: Parts Lists and Schematic Diagrams .................................................................................................................................. 32

Conventions used in this manual

This indicates a hazardous situation, which, if not followed, will result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

This indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

This information is important in the proper use of your machine. Failure to follow this instruction could result in damage to

your machine or property.

Serial Number and Order Number

A Serial Number is used to identify your machine and is located on the Serial Number Label on your machine. An Order Number

is used to check and maintain your order history and is located on your packing slip. For your convenience and ready reference,

enter the Serial Number and Order Number in the space provided on the front cover of this manual.

Additional Information and Potential Changes

DR Power Equipment reserves the right to discontinue, change, and improve its products at any time without notice or obligation

to the purchaser. The descriptions and specifications contained in this manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations may not be applicable to your machine.

2 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 3

Chapter 1: General Safety Rules

Read this Safety & Operating Instructions manual before you use the DR VERTICAL/HORIZONTAL LOG SPLITTER. Become

familiar with the operation and service recommendations to ensure the best performance from your machine. If you have any

questions or need assistance, please contact us at www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) and one of

our Technical Support Representatives will be happy to help you.

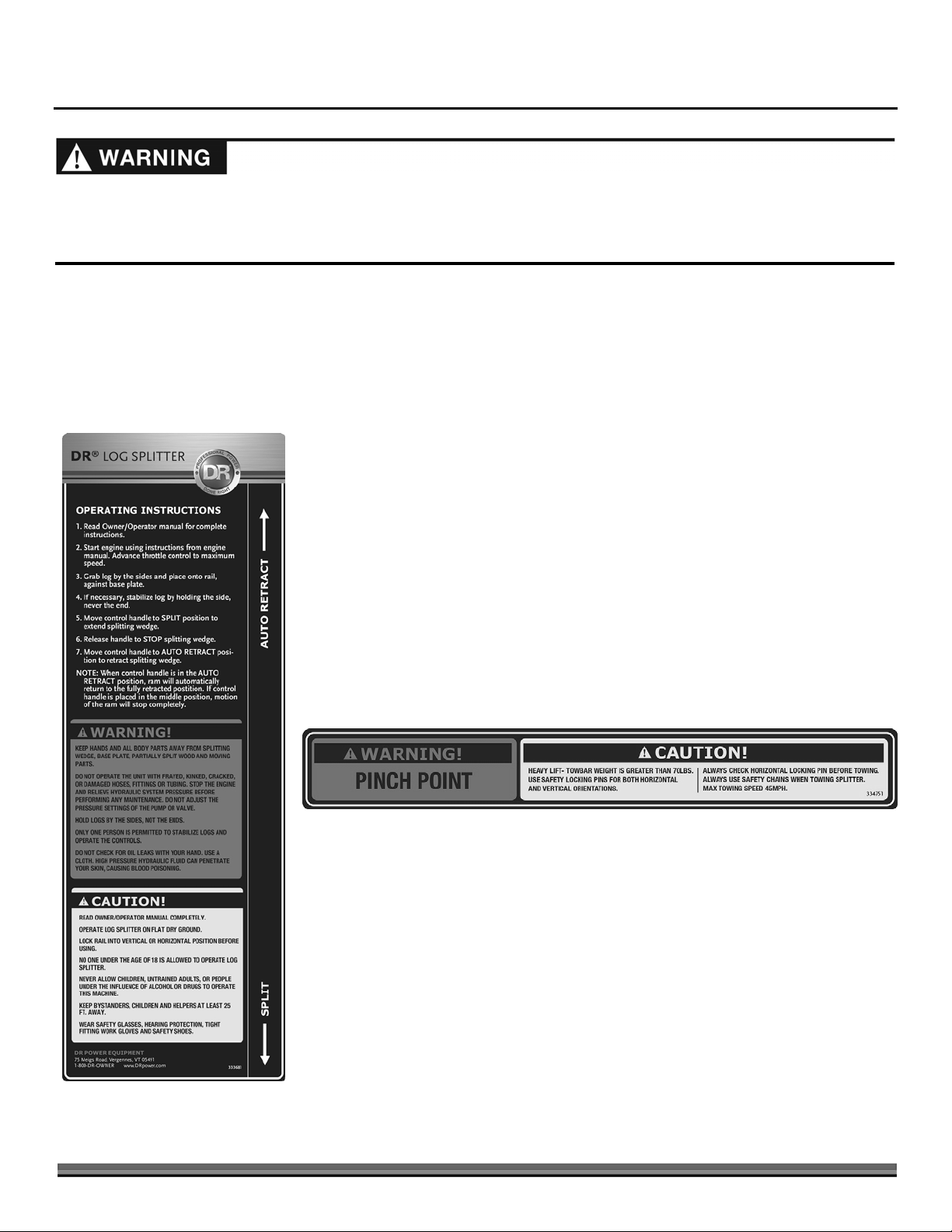

Labels

Your DR VERTICAL/HORIZONTAL LOG SPLITTER carries prominent labels as reminders for its proper and safe use. Shown

below are copies of all the Safety and Information labels that appear on the equipment. Take a moment to study them and make a

note of their location on your LOG SPLITTER as you set up and before you operate the unit. Replace damaged or missing safety

and information labels immediately.

#33368

#33457

CONTACT US AT www.DRpower.com 3

Page 4

Protecting Yourself and Those Around You

This machine was built to be operated according to the safe operation practices in this manual. As with any type of power

equipment, carelessness or error on the part of the operator can result in serious injury. This machine is capable of

amputating hands and feet and throwing debris. Failure to observe the following safety instructions could result in serious

injury or death.

Many accidents occur when more than one person operates the machine. No helper is allowed to assist in stacking logs.

Operating this Log Splitter safely is necessary to prevent or minimize the risk of death or serious injury. Unsafe operation can

create a number of hazards for you. Always take the following precautions when operating this Log Splitter:

Always wear protective goggles or safety glasses with side shields while using the Log Splitter to protect your eyes from

possible thrown debris.

Avoid wearing loose clothing or jewelry, which can catch on moving parts.

We recommend wearing gloves while using the Log Splitter. Be sure your gloves fit properly and do not have loose cuffs or

drawstrings.

Wear shoes with non-slip treads when using your Log Splitter. If you have safety shoes, we recommend wearing them. Do

not use the machine while barefoot or wearing open toed sandals.

Wear long pants while operating the Log Splitter.

Use ear protectors or ear plugs rated for at least 20 dba to protect your hearing.

Safety for Children and Pets

Tragic accidents can occur if the operator is not alert to the presence of children and pets. Children are often attracted to the

machine and the splitting activity.

precautions:

Never

assume that children will remain where you last saw them. Always follow these

Keep children and pets at least 50 feet from the working area and ensure they are under the watchful care of a responsible

adult.

Be alert and turn the machine off if children or pets enter the work area.

Never allow children to operate the Log Splitter.

Hydraulic Safety

High fluid pressures are developed in hydraulic machines. Pressurized hydraulic fluid escaping through a pin hole opening can

puncture skin and cause severe blood poisoning. Therefore, the following Instructions should be heeded at all times.

Do not operate the unit with frayed, kinked, cracked or damaged hoses, fittings, or tubing. Stop the engine, wait 5 minutes

and relieve hydraulic system pressure by cycling the valve control lever from forward to reverse several times and returning to

neutral while engine is not running before changing or adjusting fittings, hoses, tubing, or other system components.

Do not change any Log Splitter relief valve settings. They are set at the factory for best Splitter performance and safety.

Do not check for leaks with your hand. Leaks can be located by passing cardboard or wood over the suspected area: Look for

discoloration. If injured by escaping fluid, see a doctor at once. Serious infection or reaction can develop if proper medical

treatment is not administered immediately.

Always wear safety glasses to protect your eyes from hydraulic fluid.

NEVER remove the cap from the hydraulic tank or reservoir while the log splitter is running. The tank could contain hot oil

under pressure which could result in serious injury.

4 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 5

Safety with Gasoline - Powered Machines

Gasoline is a highly flammable liquid. Gasoline also gives off flammable vapor that can be easily ignited and cause a fire or

explosion. Never overlook the hazards of gasoline. Always follow these precautions:

Never run the engine in an enclosed area or without proper ventilation as the exhaust from the engine contains carbon

monoxide, which is an odorless, tasteless, and deadly poisonous gas.

Store all fuel and oil in containers specifically designed and approved for this purpose and keep away from heat and open

flame, and out of the reach of children.

Replace rubber fuel lines and grommets when worn or damaged and after 5 years of use.

Fill the gasoline tank outdoors with the engine off and allow the engine to cool completely. Don't handle gasoline if you or

anyone nearby is smoking, or if you're near anything that could cause it to ignite or explode. Reinstall the fuel tank cap and

fuel container cap securely and Never remove gas cap while the engine is hot or running.

If you spill gasoline, do not attempt to start the engine. Move the machine away from the area of the spill and avoid creating

any source of ignition until the gas vapors have dissipated. Wipe up any spilled fuel to prevent a fire hazard and properly

dispose of the waste.

Allow the engine to cool completely before storing in any enclosure. Never store a machine that has gas in the tank, or a fuel

container, near an open flame or spark such as a water heater, space heater, clothes dryer or furnace.

Never make adjustments or repairs with the engine running. Shut down the engine, disconnect the spark plug wire, keeping it

away from the spark plug to prevent accidental starting, wait 5 minutes before making adjustments, repairs or refueling.

Never tamper with the engine’s governor setting. The governor controls the maximum safe operation speed and protects the

engine. Over-speeding the engine is dangerous and will cause damage to the engine and to the other moving parts of the

machine. If required, see your authorized dealer for engine governor adjustments.

Keep combustible substances away from the engine when it is hot.

Never cover the machine while the muffler is still hot.

Do not operate the engine with the air cleaner or the carburetor air intake cover removed. Removal of such parts could create

a fire hazard. Do not use flammable solutions to clean the air filter.

The muffler and engine become very hot and can cause a severe burn; do not touch.

Towing

ALWAYS check before towing to make certain your Splitter is correctly and securely attached to the towing vehicle. Be sure

that the ball hitch you are using is the proper size for the hitch coupler on the machine. Be sure the safety chains are properly

hooked to the vehicle leaving enough slack for turning.

Always use a Class I, 2” ball with this log splitter and replace the ball or coupler if damaged.

Always confirm coupler tightness each time before towing and after towing 50 miles.

ALWAYS use accessory lights and devices when transporting on a road or highway to warn operators of other vehicles. Check

your local government regulations for DOT information.

ALWAYS allow for added length of the Splitter when turning, parking, crossing intersections, and in all driving situations.

ALWAYS be careful when backing up. You could jackknife your Splitter if care is not taken.

NEVER exceed 45 mph. when towing your Splitter. Obey all state and local regulations when towing on state and local roads

and highways. Adjust your speed for terrain and conditions, as needed. Be extra cautious when towing over rough terrain,

especially over a railroad crossing.

NEVER allow anyone to sit or ride on your Splitter.

NEVER carry any cargo or wood on your Splitter.

Do travel slowly over rough terrain, on hillsides, and around curves to prevent tipping.

Do not tow the Splitter near the edge of a ditch or excavation.

ALWAYS turn the fuel shut off valve on the engine to the “OFF” position before towing the log splitter. Failure to do so may

result in flooding the engine.

CONTACT US AT www.DRpower.com 5

Page 6

General Safety

This is a high-powered machine, with moving parts operating with high energy. You must operate the machine safely. Unsafe

operation can create a number of hazards for you, as well as anyone else in the nearby area. Always take the following precautions

when using this machine:

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property, and

themselves.

Your Log Splitter is a powerful tool, not a plaything. Exercise extreme caution at all times. The machine is designed to split

logs. Do not use it for any other purpose.

Know how to stop the Log Splitter quickly; see “stopping the engine” in chapter 3.

Never operate your unit on a slippery, wet, muddy, or icy surface. Exercise caution to avoid slipping or falling.

See manufacturer’s instructions for proper operation and installation of accessories. Only use accessories approved by DR

Power Equipment.

Never use the machine without ensuring that all guards and shields are in place.

Never, under any conditions, remove, bend, cut, fit, weld, or otherwise alter standard parts on the Log Splitter. This includes

all shields and guards. Modifications to your machine could cause personal injuries and property damage and will void your

warranty.

Allow only one person to operate the Log Splitter at any time. The adult who loads and stabilizes the log must be the person

who operates the control handle.

If the machine should start making an unusual noise or vibration, shut down the engine, disconnect the spark plug wire,

keeping it away from the spark plug to prevent accidental starting, wait 5 minutes for machine to cool down, then inspect for

damage. Vibration is generally a warning of trouble. Check for damaged parts and clean, repair and replace as necessary.

Never tamper with safety devices. Check their proper operation regularly.

Before performing any maintenance or inspection procedure on the Log Splitter shut down the engine, disconnect the spark

plug wire keeping it away from the spark plug to prevent accidental starting, wait 5 minutes for machine to cool down.

Never allow people who are unfamiliar with these instructions to use the Log Splitter. Allow only responsible individuals who

are familiar with these rules of safe operation to use your machine.

Never overload or attempt to split logs beyond the recommendations listed in this manual. Personal injury or damage to the

machine could result.

While using the Log Splitter, don't hurry or take things for granted. When in doubt about the equipment or your

surroundings, stop the machine and take the time to look things over.

Never operate the machine when under the influence of alcohol, drugs, or medication.

Use the machine only in daylight.

Stay alert for hidden hazards or traffic.

Keep all nuts and bolts tight and keep the equipment in good operating condition.

Never leave this machine unattended with the engine running.

A Note to All Users

Under California law, and the laws of some other states, you are not permitted to operate an internal combustion engine using

hydrocarbon fuels without an engine spark arrester. This also applies to operation on US Forest Lands. All DR

VERTICAL/HORIZONTAL LOG SPLITTERS shipped to California, New Mexico and Washington State are provided with spark

arresters. Failure of the owner or operator to maintain this equipment in compliance with state regulations is a misdemeanor

under California law and may be in violation of other state and/or federal regulations. Contact your State Park Association or the

appropriate state organization for specific information in your area. If the engine is equipped with a spark arrestor, clean and

inspect it regularly according to manufacturer’s instructions. Replace if damaged.

No list of warnings and cautions can be all-inclusive. If situations occur that are not covered by this manual, the operator must

apply common sense and operate this DR VERTICAL/HORIZONTAL LOG SPLITTER in a safe manner. Contact us at

www.DRpower.com or call 1-800-DR-OWNER (376-9637) for assistance.

6 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 7

J

Chapter 2: Assembly and Setting Up The DR VERTICAL/HORIZONTAL LOG SPLITTER

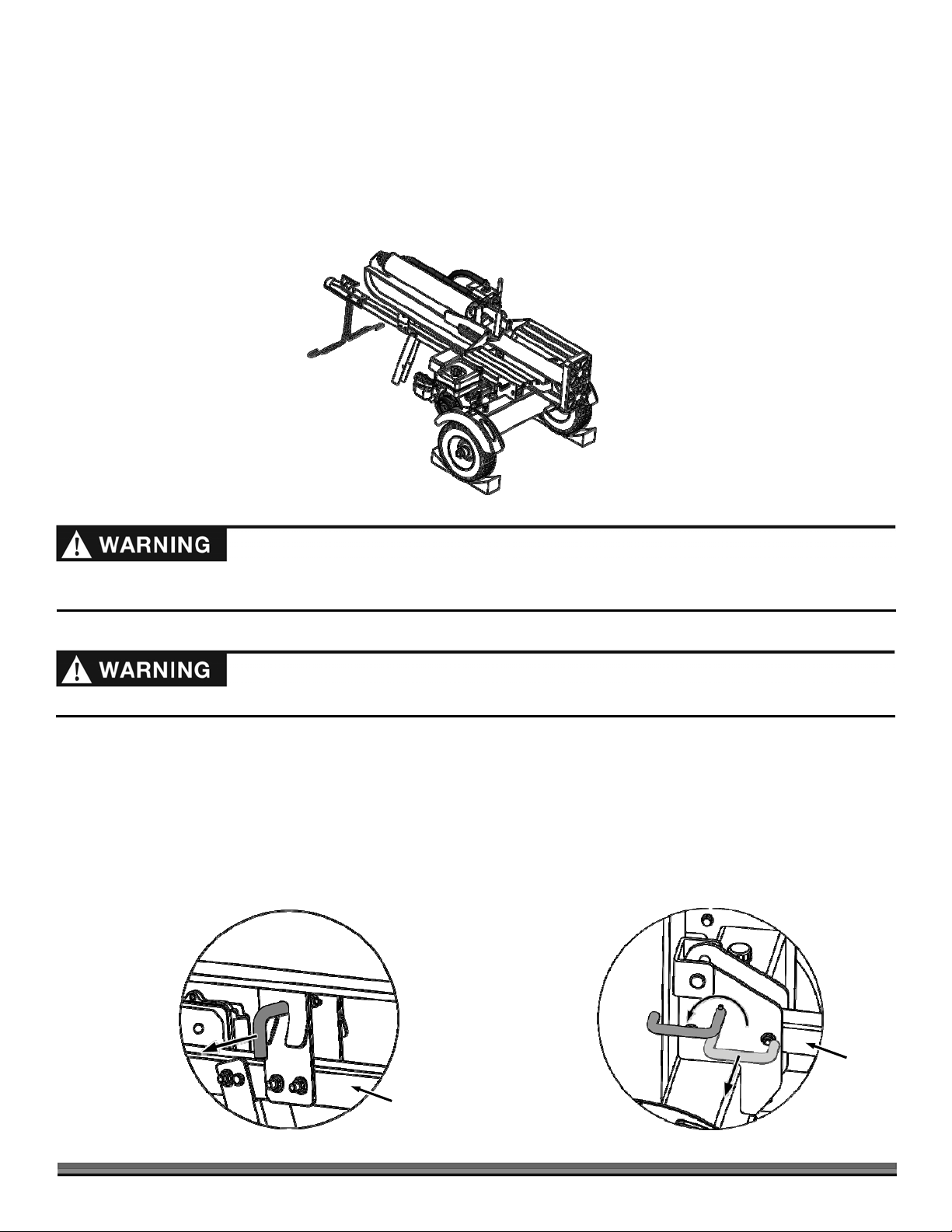

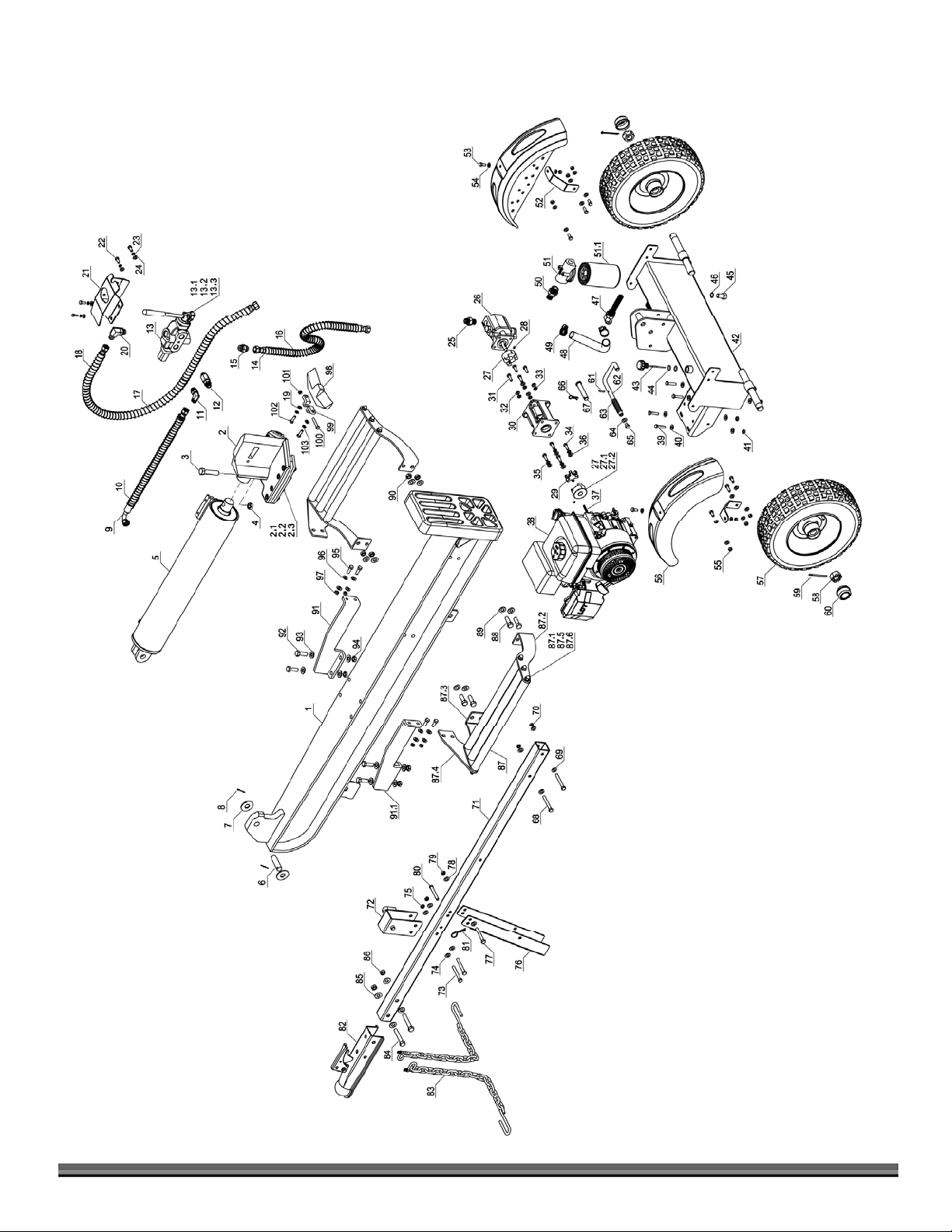

It may be helpful to familiarize yourself with the controls and features of your DR VERTICAL/HORIZONTAL LOG SPLITTER as

shown in Figure 1 before beginning these procedures. If you have any questions at all, please feel free to contact us at

www.DRpower.com.

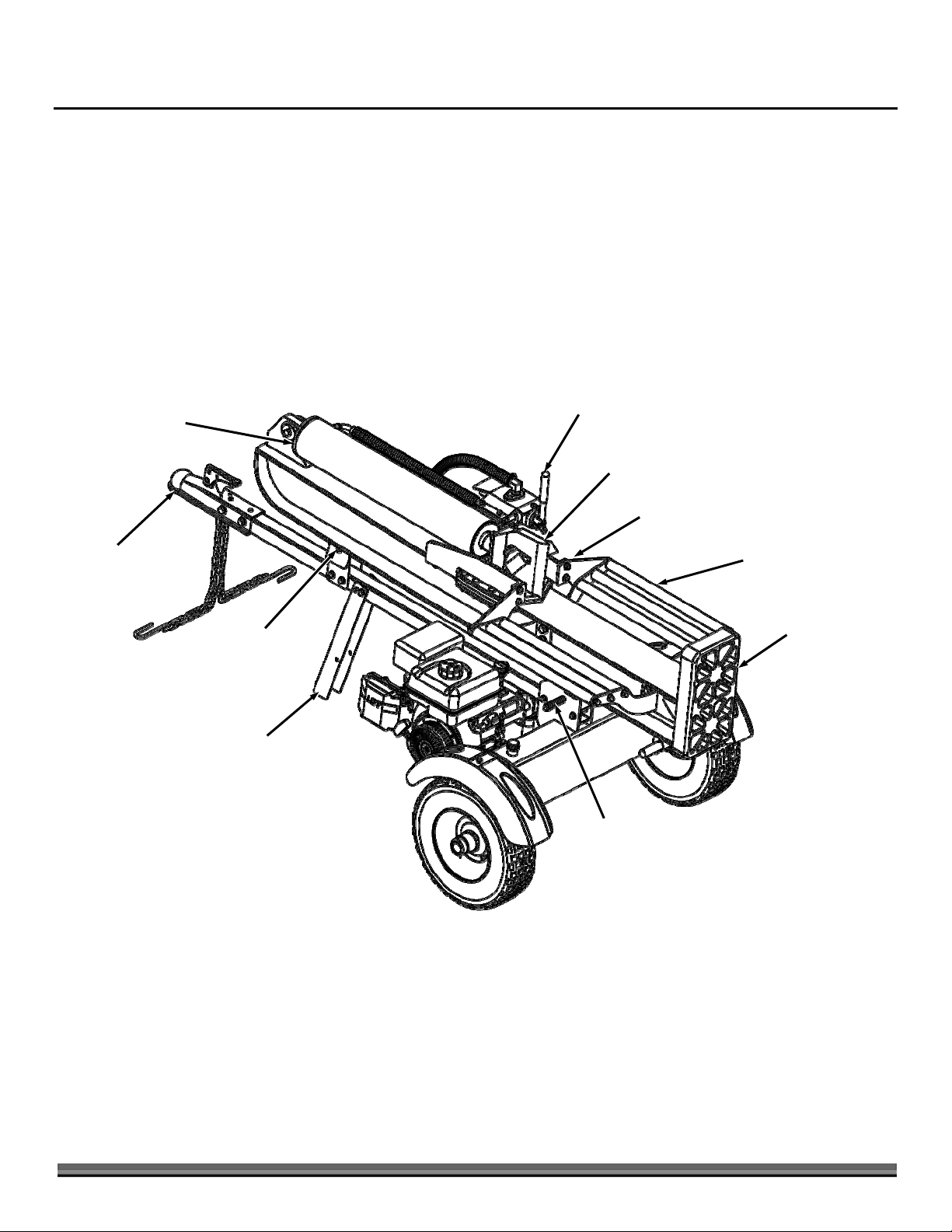

DR VERTICAL/HORIZONTAL LOG SPLITTER Controls and Features

Control Handle

Cylinder

Splitting Wedge

Log Dislodger

Tongue

Log Tray

End Plate

Horizontal

Beam Lock

ack Stand

Vertical

Beam Lock

(Figure 1)

CONTACT US AT www.DRpower.com 7

Page 8

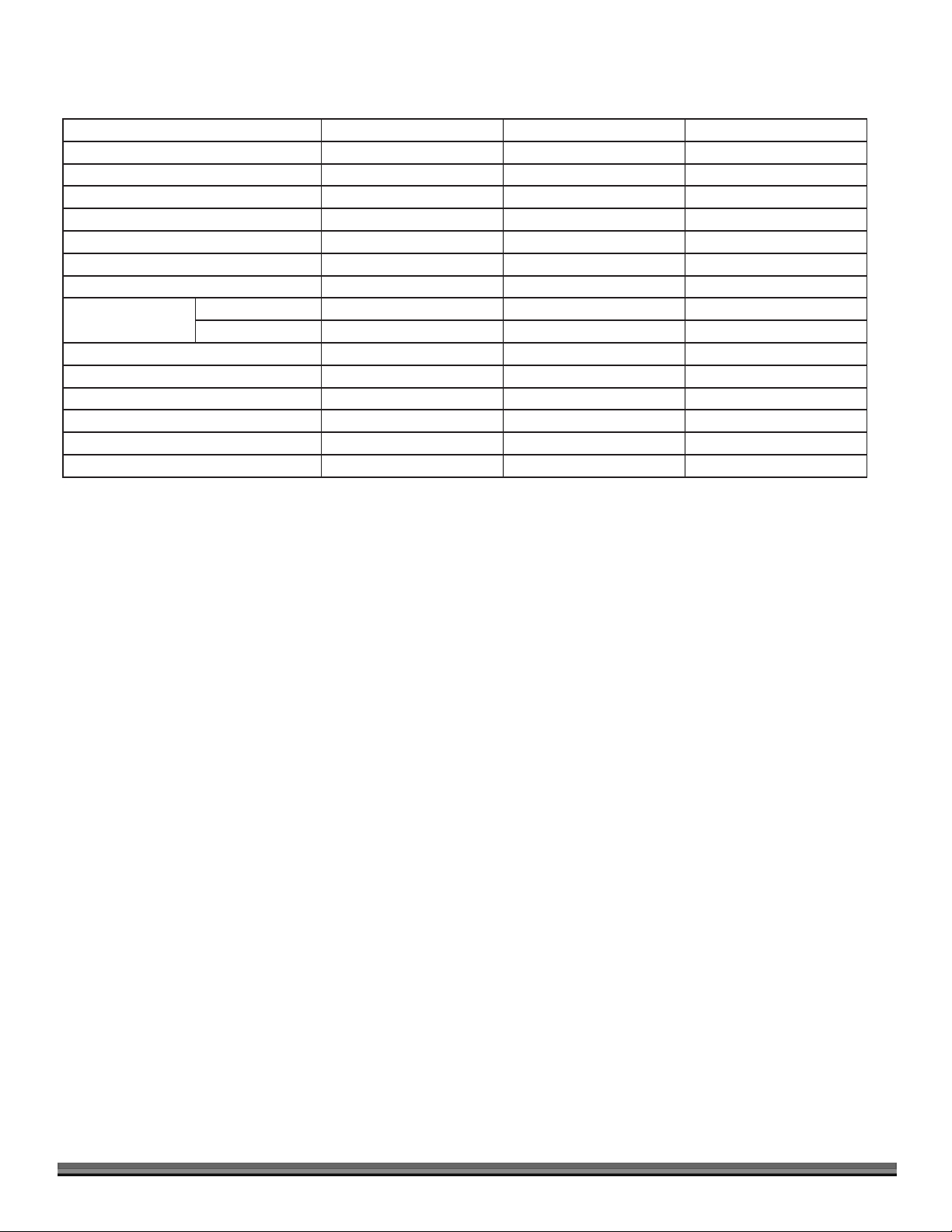

Specifications

Model

Engine

Pump

Cylinder (Bore x Stroke)

Maximum Splitting Force

Hydraulic Pressure

Maximum Log Length

Wedge Height

Cycle Time

Wheels

Hydraulic Capacity

Height (Horizontal / Vertical Position)

Length

Width

Net Weight

*Tonnage and cycle times may vary dependent upon mechanical and environmental conditions.

Forward

Reverse

22 Ton 28 Ton 34 Ton

See engine manual See engine manual See engine manual

Two-Stage, 10 gpm Two-Stage, 10 gpm Two-Stage, 15 gpm

4 in. x 24 in. 4.5 in. x 24 in. 5 in. x 24 in.

22 Tons* 28 Tons* 34 Tons*

3400 psi* 3450 psi* 3500 psi*

25 in. 25 in. 25 in.

8 in. 8 in. 8 in.

8 Seconds* 8 Seconds* 7 Seconds*

5 Seconds* 5 Seconds* 4 Seconds*

16 x 4.8 x 8 in. 16 x 4.8 x 8 in. 16 x 4.8 x 8 in.

Approx. 4 Gallons Approx. 4 Gallons Approx. 5 Gallons

41.5 / 71 in. 41.5 / 71 in. 41.5 / 71 in.

87 / 84 in. 87 / 84 in. 87 / 84 in.

41 in. 41 in. 41 in.

474 lbs 512 lbs 549 lbs

Assembly

Tools and Supplies Needed:

24mm Wrench

18mm Wrench

19mm Wrench

Pliers

Soft Faced Hammer

16mm Wrench

17mm Wrench

13mm Wrench

12mm Wrench

8mm or Flat Philips Screwdriver

Adjustable Wrench

14mm Wrench

1/2" Wrench

3mm Allen Wrench

Thread Locking Compound

27mm wrench or 1-1/16" wrench or adjustable wrench

8 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 9

Due to the weight / size of the log splitter, it’s recommended that two or more adults be present to assist with the assembling.

/

8

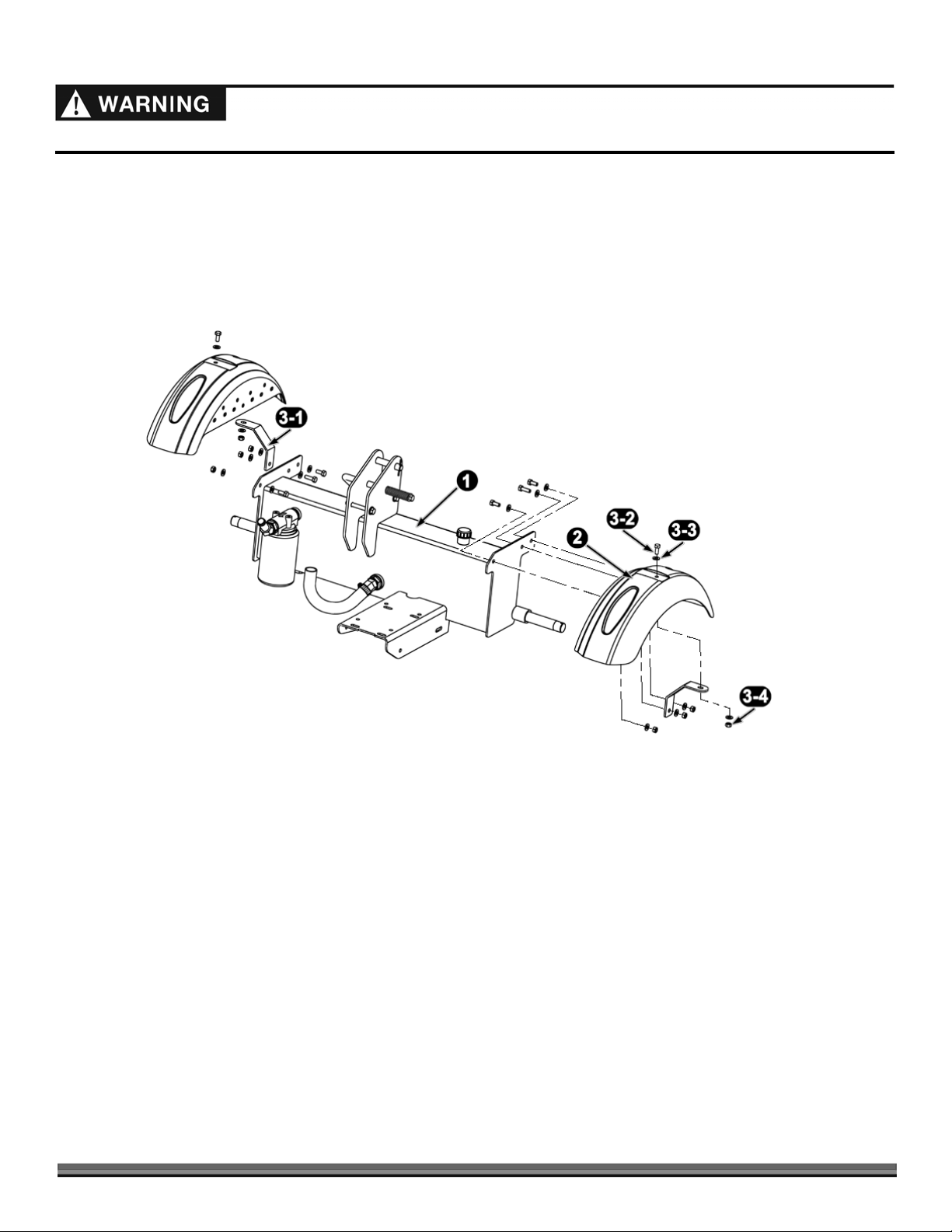

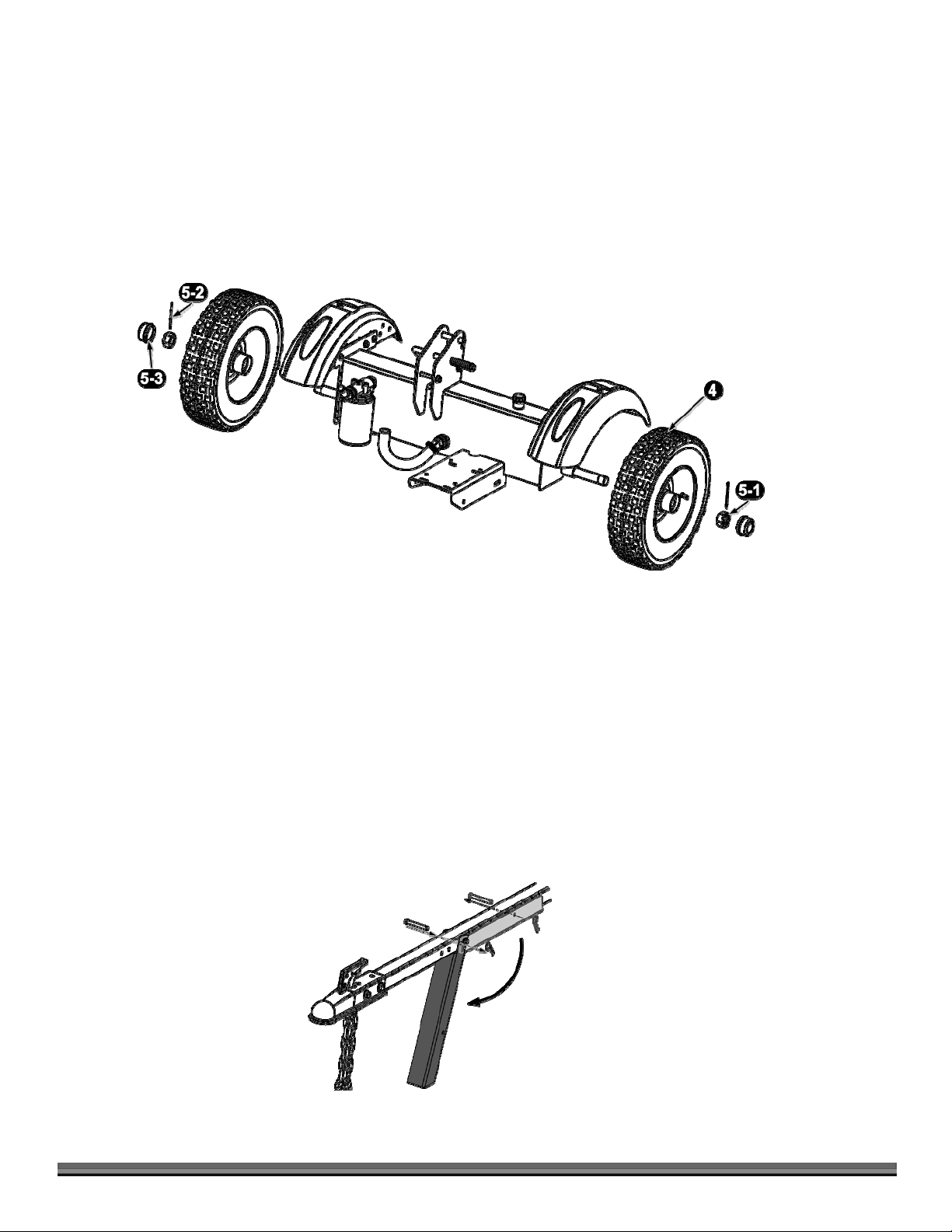

STEP 1: ASSEMBLING THE FENDERS TO THE RESERVOIR ASSEMBLY.

1. Loosely assemble the top of the fender (2) to the fender support (3-1) with a bolt (3-2), flat washer (3-3) and locknut (3-4)

using two 13mm wrenches (Figure 2).

2. Secure a fender (2) and fender support (3-1) to the reservoir assembly with three bolts (3-2), six flat washers (3-3) and

three locknuts (3-4) using two 13mm wrenches.

3. Finish tightening the hardware to secure the top of the fender to the fender support.

(Figure 2)

REF. NO. DECSRIPTION

1

................. Reservoir tank assembly .................... 1

2 ................. Fender ........................................... 2

3 ................. Hardware kit #1(not shown) .............. 1

Including:

3-1 .............. Fender support ................................ 2

..............

3-2

3-3 .............. Flat washer / M8 .............................. 16

3-4

..............

Hex head bolt / M8 x 25

Lock nut

.................... 8

M8

.................................

QTY.

CONTACT US AT www.DRpower.com 9

Page 10

STEP 2: ATTACHING THE TWO WHEELS TO THE TANK ASSEMBLY WHEEL SPINDLES.

1. Block the reservoir assembly up off the ground and insert a wheel assembly (4) onto the axle (valve stem facing out) (Figure 3).

2. Install a castle nut (5-1) as snug as you can by hand.

3. If the hole in the axle doesn’t align with the slots in the castle nut, turn the nut with a wrench only enough so the hole and slot

align.

4. Secure the nut to the axle with a cotter pin (5-2). Bend the ends of the cotter pin with pliers.

5. Install the hub cap (5-3) onto the wheel using a soft faced hammer.

(Figure 3)

REF. NO. DECSRIPTION

................ Road-Speed Tire and Wheel ............... 2

4

QTY.

5 ................ Hardware Kit #2 (not shown) ............ 1

Including:

5-1 .............. Castle nut / 1-14 .............................. 2

5-2 ..............

5-3 .............. Hub cap ......................................... 2

STEP 3: ATTACHING THE TONGUE AND JACK STAND ASSEMBLY TO THE RESERVOIR ASSEMBLY.

1. Remove the spring clip (Ø3) and clevis pin (Ø6 x 50) from the jack stand on the tongue (Figure 4).

2. Pivot the jack stand towards the ground into the operating position.

3. Secure the jack stand in position with the clevis pin and spring clip.

Cotter Pin / Ø4 x 35

Clevis Pin

......................... 2

Spring Clip

10 DR

(Figure 4)

®

VERTICAL/HORIZONTAL LOG SPLITTER

Jack Stand

Page 11

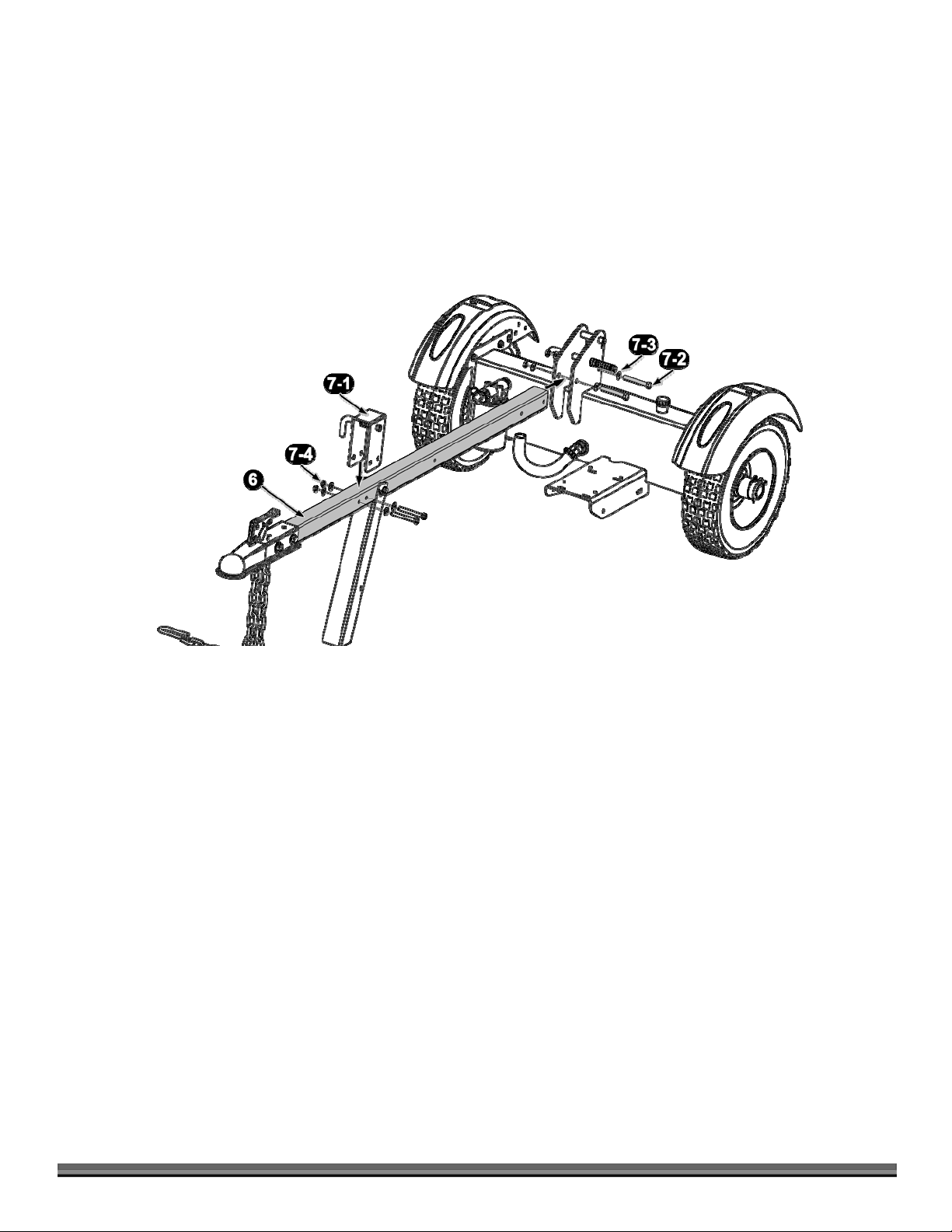

Note: The horizontal beam lock (7-1) must be installed with the handle on the right side of the splitter as shown (Figure 5). The slot in

the beam bracket will only latch properly to the handle if it on the right side.

4. Attach the horizontal beam lock to the tongue (6) with two bolts (7-2), four flat washers (7-3) and lock nuts (7-4) using a

17mm wrench for the bolt and a 18mm wrench for the lock nut.

5. Attach the tongue (6) to the reservoir assembly with two bolts (7-2), four flat washers (7-3) and lock nuts (7-4) using a 17mm

wrench for the bolt and a 18mm wrench for the lock nut.

(Figure 5)

REF. NO. DECSRIPTION

6 .................. Tongue & Jack stand assembly ............. 1

7 .................. Hardware Kit #3 (not shown) .............. 1

QTY.

Including:

7-1 ............... Horizontal beam lock ........................... 1

7-2 ............... Hex head bolt / M10 x 80 ..................... 4

7-3 ............... Flat washer / M10 ................................. 8

7-4 ............... Lock nut / M10 ...................................... 4

CONTACT US AT www.DRpower.com 11

Page 12

STEP 4: ASSEMBLING THE PUMP ASSEMBLY TO THE ENGINE.

6

)

r /

5/

4

1. Slowly pull on the engine (8-1) starter cord to position the shaft key slot at the top of the shaft.

2. Remove the set screw from the pump-side coupler half with a 3mm allen wrench (Figure 6).

3. Apply thread locking compound to the set screw and reinstall it fully tight.

4. Position the pump assembly (9-1) with the opening at the top as you guide the coupler over the engine shaft.

5. Insert only two bolts (9-2), lock washers (9-3) and flat washers (9-4) into the pump mount and tighten with a 1/2" wrench

to temporarily

6. Turn the coupler to align the slot in the coupler with the slot in the engine shaft and remove the set screw from the engine-

side coupler half.

7. Slide the square key (8-2) into the key slot of the coupler and engine shaft as far in as it will go (should hit coupler center

piece.

8. Apply thread locking compound to the set screw and reinstall it fully tight with a 3mm allen wrench.

9. Remove the two bolts, lock washers and flat washers temporarily holding the pump mount to the engine.

secure the mount to the engine.

10. Do not pull out on the pump assembly

11. Secure the pump mount to the engine with four bolts (9-2), four lock washers (9-3) and four flat washers (9-4) using a 1/2"

wrench.

(Figure

REF. NO. DECSRIPTION

................. Engine assembly (in engine box, not shown) ...........

8

8-1 .............. Engine ...............................................................

8-2 .............. Engine shaft key ..................................................

9 ................. Hardware Kit #4 (not shown) ................................

as you rotate it until the pump mount opening is at the bottom.

Including:

QTY.

1

1

1

1

Including:

9-1 .............. Two stage pump assembly ...................................

9-2 .............. Hex head bolt / 5/16-24 .......................................

9-3 .............. Spring washer / 5/16 ...........................................

9-4 .............. Flat washe

16

...............................................

1

4

4

12 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 13

STEP 5: ATTACHING THE ENGINE ASSEMBLY TO THE ENGINE MOUNT PLATE ON THE RESERVOIR ASSEMBLY.

Note: The 6.5 HP engine uses M8 hardware and the 9 HP engine uses M10.

The 6.5 HP engine mounts to the smaller 4-hole pattern. The 9 HP engine mounts to the larger 4-hole pattern.

1. For the 22-Ton and 28-Ton, install the engine to the engine mount with four bolts (10-1), eight flat washers (10-2) and four

locknuts (10-3) using two 13mm Wrenches (Figure 7).

2. For the 34-Ton, install the engine to the engine mount with four bolts (10-1), eight flat washers (10-2) and four locknuts (10-3)

using two a 16mm wrench for the bolt and a 17mm wrench for the locknut (Figure 7).

(Figure 7)

REF. NO. DECSRIPTION

............... Hardware kit #5 (not shown) ....................... 1

10

Including:

10-1 ............. Hex head bolt / M8 x 40 (22 and 28 Ton) ....... 4

QTY.

................... Hex head bolt / M10 x 40 (34 Ton) ................ 4

............. Flat washer / M8 (22 and 28 Ton) ................. 8

10-2

................... Flat washer / M10 (34 Ton) ......................... 8

............. Lock nut / M8 (22 and 28 Ton) ..................... 4

10-3

................... Lock nut / M10 (34 Ton) ............................. 4

CONTACT US AT www.DRpower.com 13

Page 14

STEP 6: ASSEMBLING THE BEAM TO THE TANK BRACKETS.

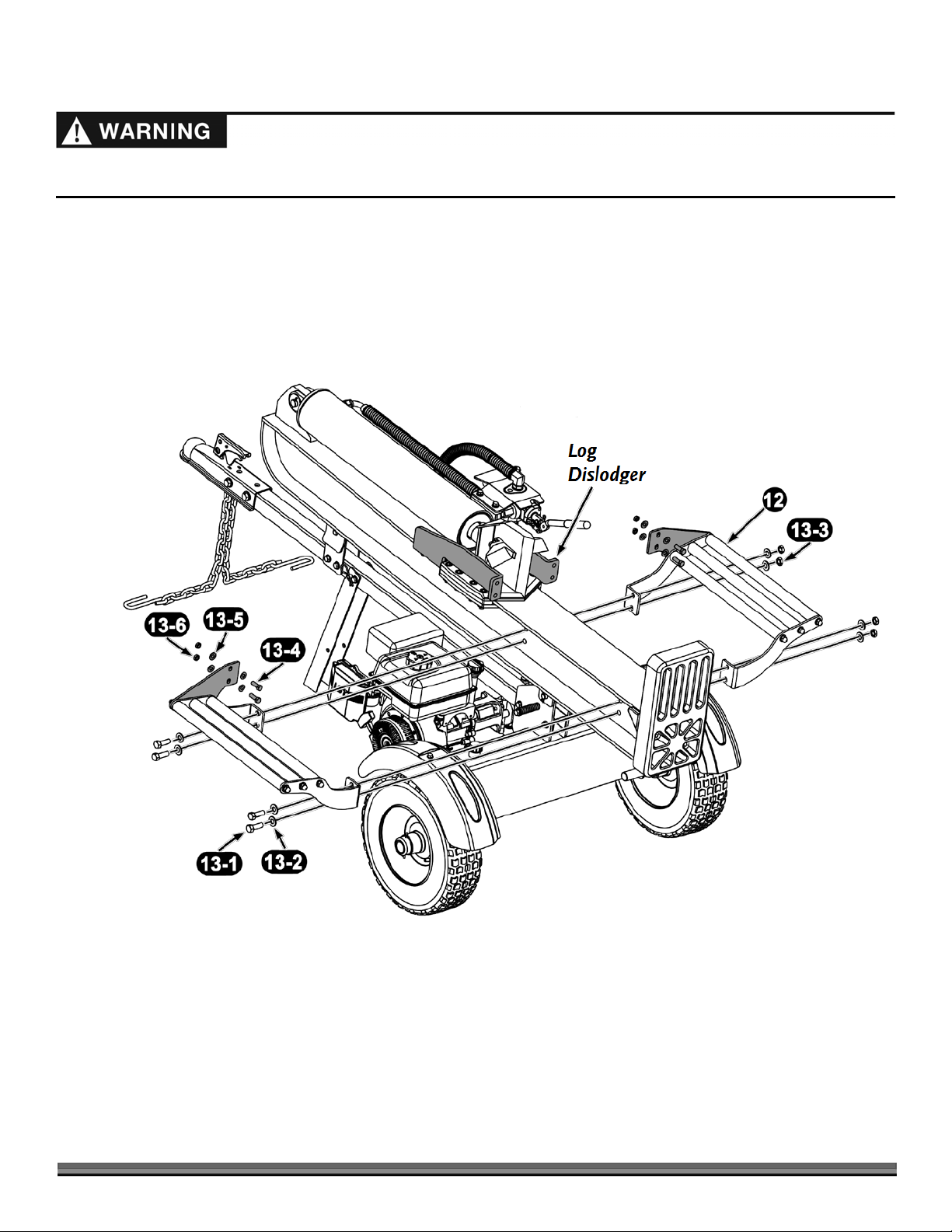

Take extra care when lifting as the beam is very heavy. You should have a second person assist with raising the beam to keep it

steady. You could be injured by lifting or if the beam falls.

1. Stand the beam up on end (Figure 8). Two or more people may be needed for this step to ensure safety. Make sure that the

beam is stable and on a level surface.

2. Remove the clevis pin and spring pin from the tank brackets. Roll the tongue/ tank assembly into position between the two

tabs on the beam. Slide the clevis pin through the aligned holes and lock in place with the spring clip.

3. Leave the beam in the upright position for the next step.

Clevis Pin

Spring Clip

(Figure 8)

14 DR

REF. NO.

............... Beam Assembly .................. 1

11

®

VERTICAL/HORIZONTAL LOG SPLITTER

DECSRIPTION

QTY.

Page 15

STEP 7: CONNECTING THE OPEN ENDS OF THE HYDRAULIC HOSES TO THEIR CORRESPONDING FITTINGS.

Note: There are three hydraulic hoses listed below, each of them has one end fixed on the fitting by the manufacturer, the other end

needs to be attached. For clear view of the hydraulic hoses, the hose protective springs are not shown in the illustration below.

1. Oil suction hose / Ø25 x 310 mm, labeled as ①, comes from the tank (Figure 9). Loosen the hose clamp / Ø30 on the

open end of this hose using a flat head screwdriver, then connect the hose to the fitting on the bottom of the pump, which

is labeled of a same ①. Tighten the hose clamp.

2. Pump / Valve connecting hose / Ø19 x 900mm, labeled as ②, comes from the bottom of the valve. Screw the open end of

this hose onto the fitting on top of the pump, which is labeled of a same②using a 27mm wrench (or 1-1/16" wrench or

adjustable wrench).

3. Oil return hose labeled as ③, comes from the top of the valve. Screw the open end of this hose onto the fitting on the

filter, which is labeled of a same ③using a 27mm wrench (or 1-1/16" wrench or adjustable wrench).

Note: Check all hydraulic hoses at both ends for tightness. Tighten as needed.

(Figure 9)

Valve

Hose

Clamp- Ø30

Filter

Pump

CONTACT US AT www.DRpower.com 15

Page 16

STEP 8: INSTALLING THE LOG TRAY TO THE LOG DISLODGER AND BEAM.

Take extra care when raising and lowering the beam as it is fairly heavy. Having a second person assist with raising or lowering the

beam is recommended to prevent injury. Be sure to keep hands away from any possible pinch points.

1. Lower the beam onto the tow bar (Figure 10).

2. Loosely install the log tray brackets to the beam with four bolts (13-1), eight flat washers (13-2) and four locknuts (13-3)

using a 18mm wrench on the bolts and a 19mm wrench on the lock nuts.

3. Install the log tray brackets to the log dislodge with four bolts (13-4), eight flat washers (13-5) and four locknuts (13-6)

using a 16mm wrench on the bolts and a 17mm wrench on the lock nuts.

4. Finish tightening the tray bracket to beam hardware.

(Figure 10)

16 DR

REF. NO. DECSRIPTION

............... Log tray & Log dislodger assembly ................ 2

12

13 ............... Hardware Kit #6 (not shown)....................... 1

Including:

13-1 ............. Hex head bolt / M12 x 45 ............................ 4

13-2 ............. Flat washer / M12 ...................................... 8

13-3 ............. Lock nut / M12 .......................................... 4

13-4 ............. Hex head bolt / M10 x 35 ............................ 4

13-5 ............. Flat washer / M10 ...................................... 8

13-6 ............. Lock nut / M10 .......................................... 4

®

VERTICAL/HORIZONTAL LOG SPLITTER

QTY.

Page 17

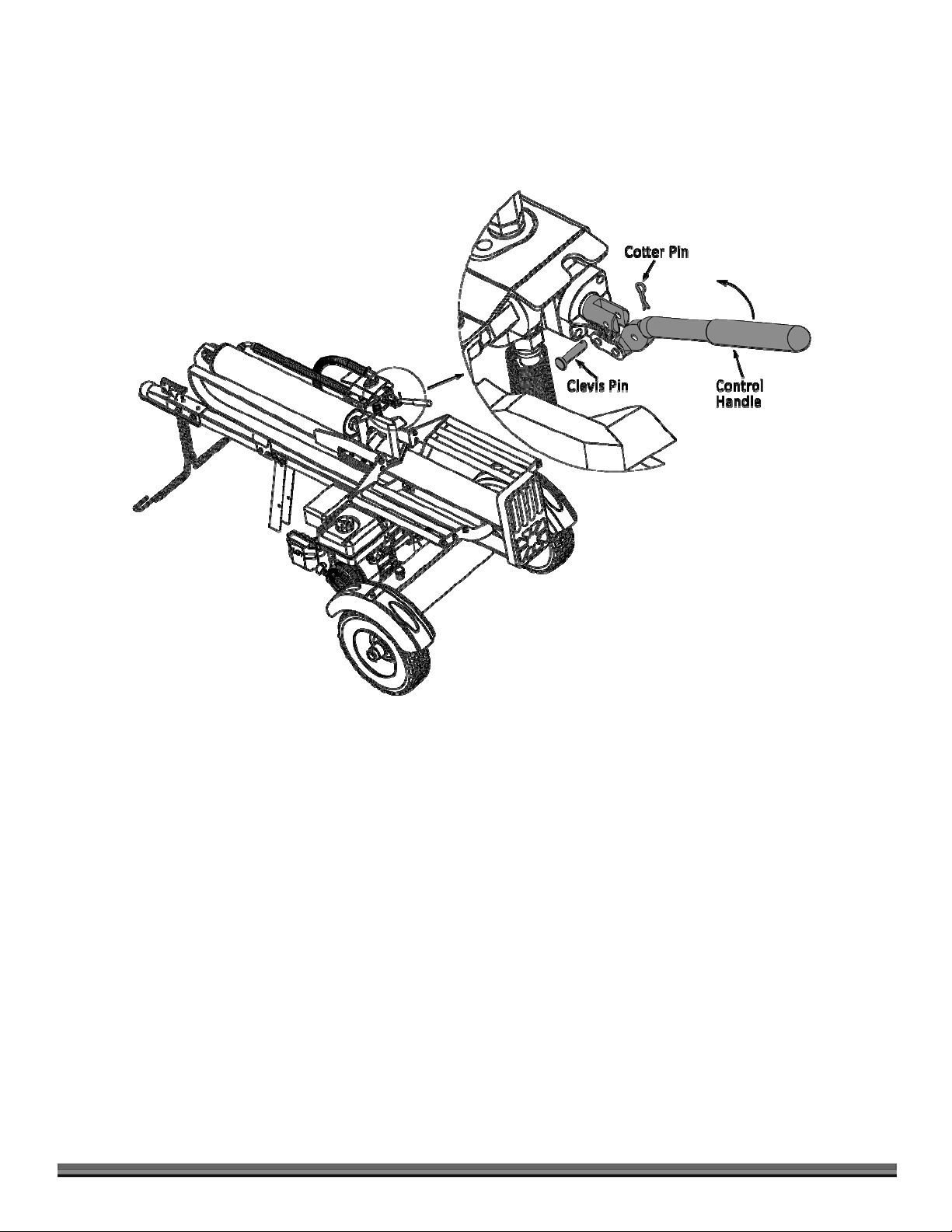

STEP 9: ASSEMBLING THE CONTROL HANDLE.

Note: The control handle is shipped hanging from the valve on the handle link

1. Remove the clevis pin and bow-tie cotter pin from the control handle (Figure 11).

2. Rotate the control handle up into the operating position and secure with the clevis pin and bow-tie cotter pin.

(Figure 11)

CONTACT US AT www.DRpower.com 17

Page 18

STEP 10: INSTALLING THE CROSS WEDGE KIT (OPTIONAL ACCESSORY).

1. Insert the cross wedge (14-1) to the rectangular hole on the splitting wedge (Figure 12).

2. Align the holes on the cross wedge, splitting wedge and the L-shape supports (14-2).

3. Loosely install the L-shaped supports to the splitting wedge with a bolt (14-3) and locknut (14-4) using two 13mm

wrenches.

4. Secure the L-shaped supports to the cross wedge with two bolts (14-5), lock washers (14-6) and flat washers (14-7) using a

13mm wrench.

5. Finish tightening the hardware to secure the L-shaped supports to the splitting wedge.

Splitting Wedge

(Figure 12)

REF. NO.

DECSRIPTION

QTY.

14 ............... Cross wedge assembly package (not shown) .......... 1

Including

14-1 ............ Cross wedge ......................................................... 1

14-2 ............ L-shape support .................................................... 2

14-3 ............ Hex head bolt / M8 x 55 ......................................... 1

14-4 ............ Lock nut / M8 ........................................................ 1

14-5 ............ Hex head bolt / M8 x 25 ......................................... 2

14-6 ............ Lock washer / M8 .................................................. 2

14-7 ............ Flat washer / M8 ................................................... 2

18 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 19

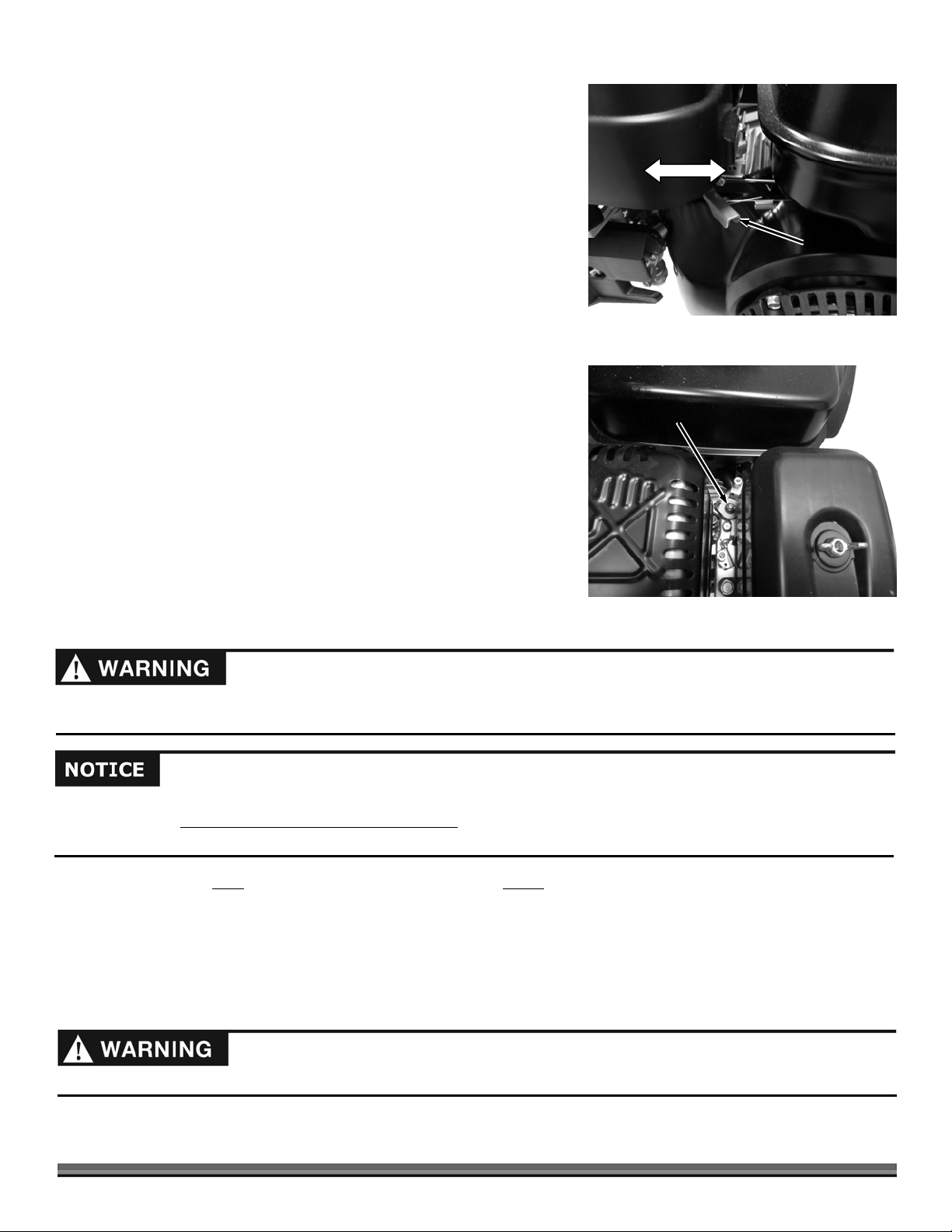

Adjusting the Throttle Linkage

After you have the Log Splitter fully assembled, the Throttle Linkage of the

Subaru (9HP) Engine will need further adjustment. This procedure must be

done before operating your Log Splitter. The following information explains the

adjustment procedure.

Tools needed:

Ratchet with Extension

10mm Socket

1. Move the Throttle Lever to check if it will stay in the RUN position or if it

returns to the IDLE position (Figure 13).

2. If the Throttle Lever stays in the RUN position then adjustment is not

needed.

3. If the Throttle Lever returns to the IDLE position, go to the next step.

Figure 13

RUN

IDLE

Throttle Lever

4. Use the Ratchet and Extension with the 10mm Socket to tighten the Throttle

Linkage Nut until the Throttle Lever will stay in the RUN position (Figure 14).

Note: The Throttle Lever Nut should be tight enough to hold the Lever in the RUN

position while operation of the Log Splitter but not so tight that it is difficult

to move the Lever back to IDLE position by hand.

Throttle Linkage Nut

SET UP

Gas and Oil Fill-Up

Service the engine with gasoline and oil as instructed in the engine manual

packed with your log splitter. Read the instructions carefully.

Use extreme care when handling gasoline. Gasoline is extremely flammable and the vapors are explosive. Never fuel the machine

indoors or while the engine is hot or running.

You must add oil before starting the engine. This machine is shipped without oil. Traces of oil may be in the reservoir from

factory testing, but you must add oil before starting the engine

avoid overfilling.

. Fill the reservoir slowly, checking the level frequently to

Figure 14

Note: Your log splitter is NOT

check the oil level before each use. Be careful not to overfill. Gasoline can be added to the engine when the log splitter is in either

the horizontal or vertical position. However, it may be easier when the splitter is in the vertical position.

shipped with motor oil in the engine. You MUST add oil before operating the splitter for the first time and

Tire Pressure

The max recommended operating pressure is shown on the side of the Tire. Never exceed the manufacturer’s recommended psi.

Maintain equal pressure on all tires.

Excessive pressure when seating beads may cause tire/rim assembly to burst with force sufficient to cause serious injury.

CONTACT US AT www.DRpower.com 19

Page 20

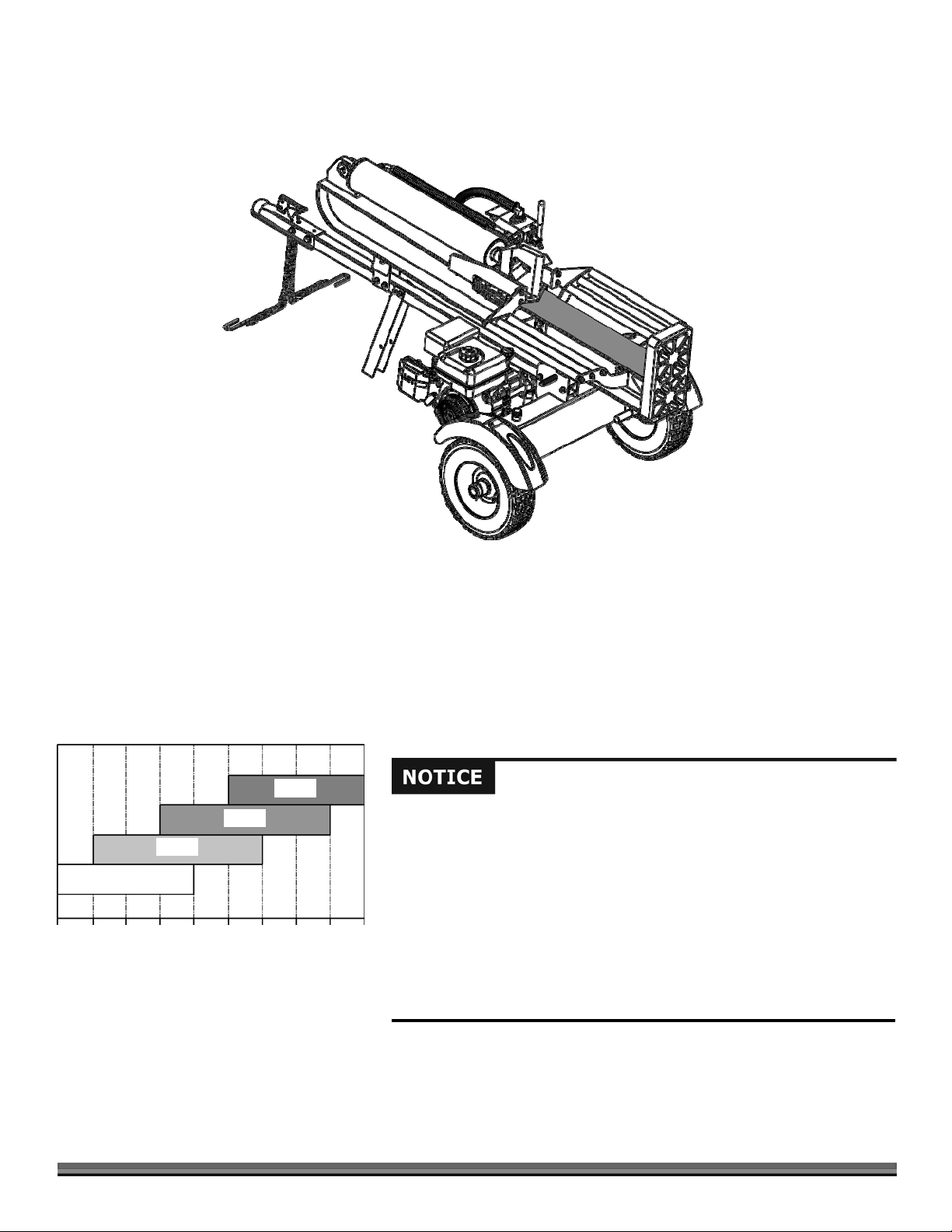

Preparing the Log Splitter

pump

1. Lubricate the beam area (where the splitting wedge will slide) with engine oil. Do not use grease (Figure 15).

(Figure 15)

HYDRAULIC OIL ISO RECOMMENDATIONS

ISO 46

ISO 32

ISO 22

0°

10°

20°

30°

40°

50°

(-18°)

(-12°)

(-7°)

(-1°)

(4°)

TEMPERATURE FAHRENHEIT (CELSIUS)

Table-1

(10°)

60°

(16°)

ISO 68

70°

(21°)

80°

(27°)

2. Fill hydraulic oil before your initial use.

Tools and Supplies Needed:

Paper Towels

Hydraulic Fluid (see table-1)

Note: you MUST check the fluid level before each use. If not touching the bottom

portion of the dippstick, proceed with the following steps:

You must add hydraulic fluid before using the splitter. This machine is

shipped without hydraulic fluid in the hydraulic tank. When performing

the following procedures, fill the hydraulic tank slowly, checking the level

frequently to avoid overfilling.

To get an accurate reading when checking the hydraulic fluid level:

- the machine should be on a level surface.

90°

(32°)

- the dipstick should be pushed in fully to ensure an accurate fluid level

reading.

Much of the original fluid has been drawn into the cylinder and hoses.

Make certain to refill the reservoir to prevent damage to the hydraulic

. DO NOT OVERFILL.

20 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 21

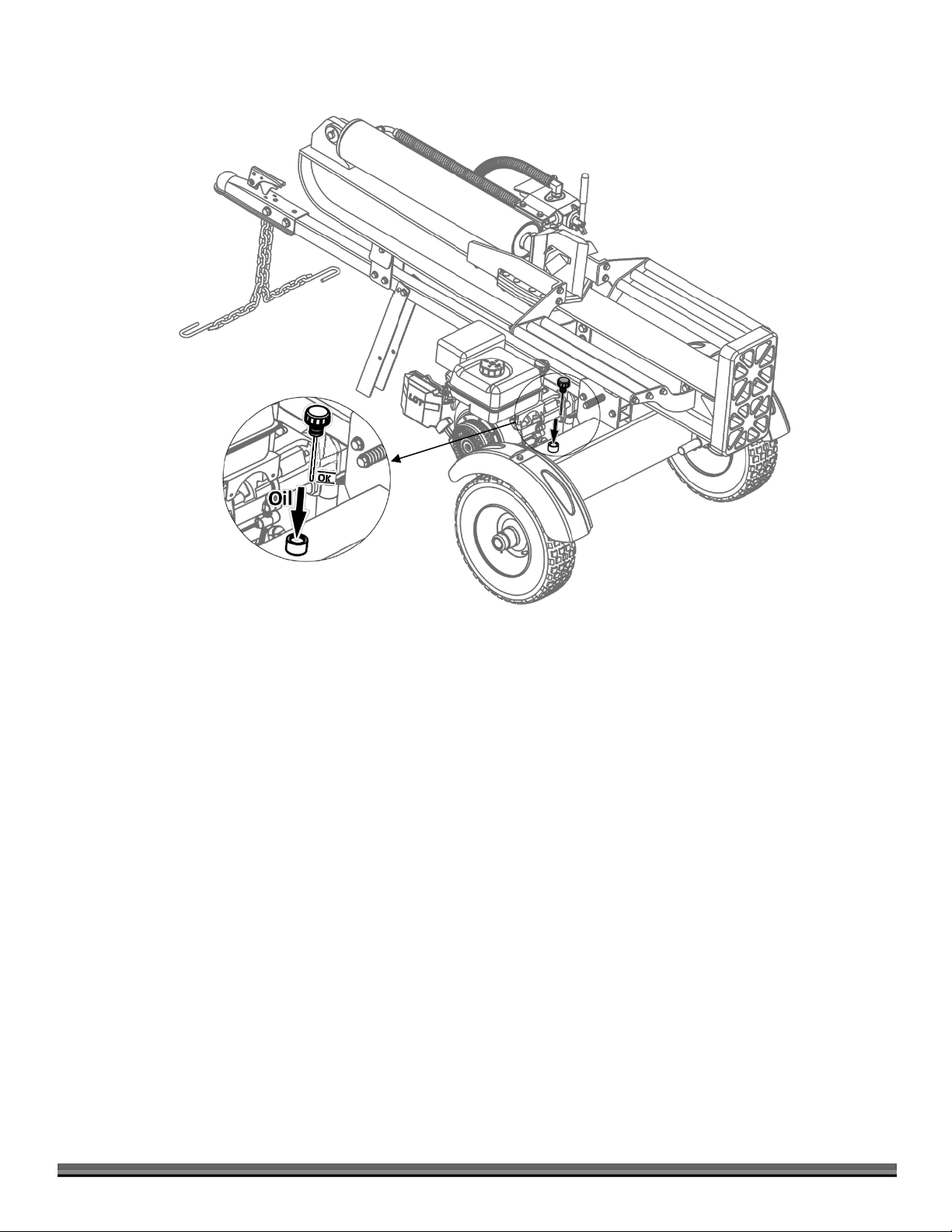

a) Remove the vented reservoir dipstick, which is located next to the engine on top of the reservoir tank (Figure 16).

(Figure 16)

b) Check the fluid level using the dipstick. Also refer to (Figure 25 and Figure26 on Page29).

c) Replace the vented dipstick.

d) Make sure the Engine is in the “STOP” position and disconnect the spark plug wire from the spark plug. Prime the

pump by pulling the recoil starter as far as it will go. Repeat approximately 10 times.

e) Reconnect the spark plug wire and start the engine, following instructions in Chapter 3.

f) Use the control handle to engage the wedge to the farthest extended position. Then retract the wedge.

g) Refill the tank as needed so the fluid just touches the end of the dipstick.

Note: Failure to refill the tank will void the splitter’s warranty.

h) Extend and retract the wedge 12 complete cycles to remove any trapped air in the system (the system is “self-

bleeding”

i) Refill the tank as needed so the fluid just touches the end of the dipstick.

CONTACT US AT www.DRpower.com 21

Page 22

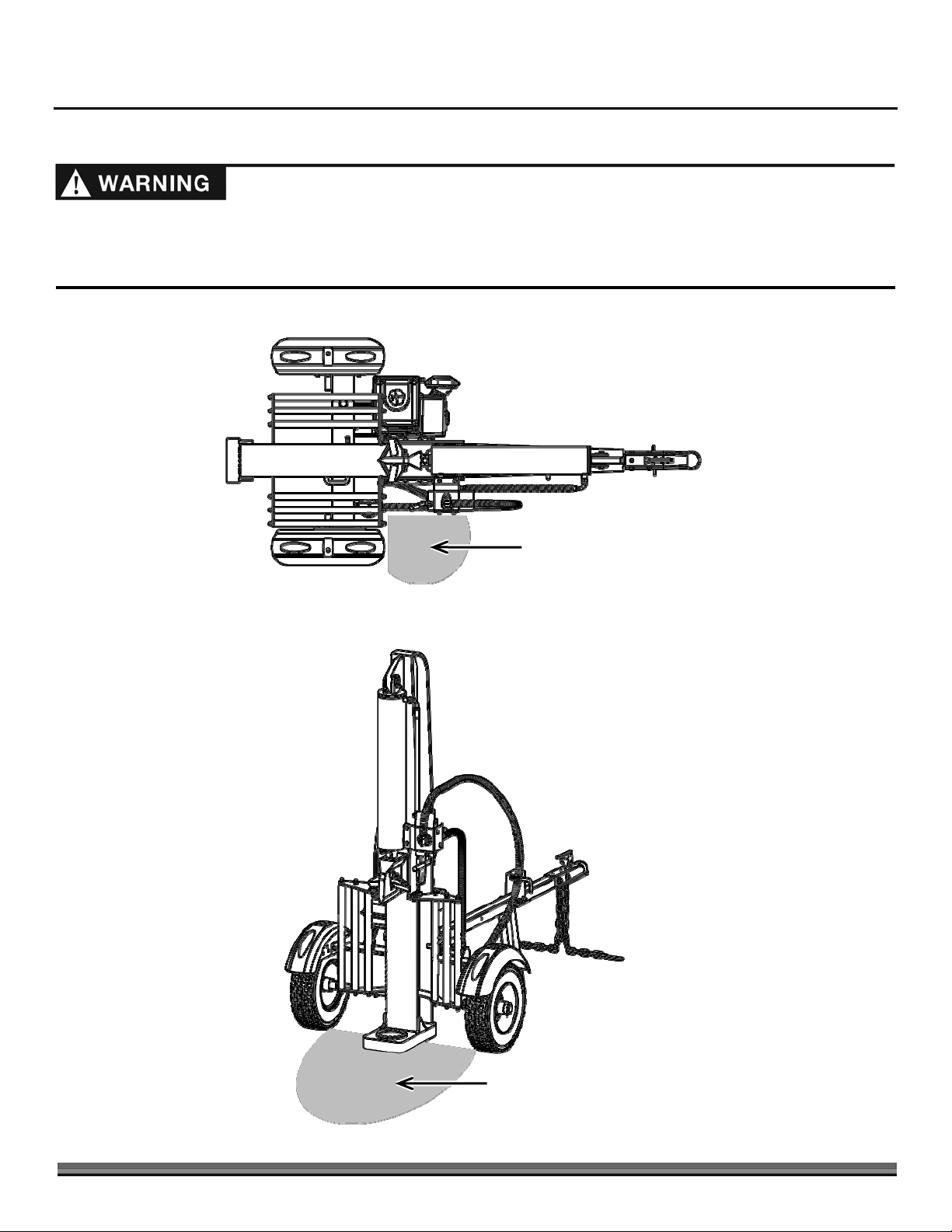

Chapter 3: Operating The DR VERTICAL/HORIZONTAL LOG SPLITTER

Operator Zone

ONLY operate the log splitter from the operator zone as shown in the diagram. The operator has the safest and most efficient

access to the control valve and the beam in this location. Operating the log splitter in another location can result in serious

injury or death

Keep the operator zone and adjacent area clear for safe, secure footing.

Horizontal Operating Position: Stand on the control lever side of the log splitter and stabilize log (Figure 17).

(Figure 17)

Operator Zone

Vertical Operating Position: Stand in front of the log splitter and stabilize log (Figure 18).

Operator Zone

(Figure 18)

22 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 23

Handling Logs:

Both ends of the log should be cut as square as possible to help prevent the log from riding out of the splitter during operation.

Uneven logs (e.g. knotted, curved, etc.) should not be used.

For logs which are not cut square, the least square end of the log should be placed toward the beam and wedge, and the square

end placed toward the end plate.

NEVER try to split two logs on top of each other. NEVER try to cross split a log.

Do not place your hands on the ends of the log when loading the Log Splitter. This is a very UNSAFE method and could result

in injury to your hands.

Do not reach or step across the rail while the Log Splitter is running. This is a very UNSAFE method which could cause

personal injury or even death.

Never attempt to split wood across the grain. The Log Splitter was not designed for cross-grain splitting. Doing so could

damage the Log Splitter and may cause personal injury.

Make sure both ends of the log you are splitting are cut as square as possible. This will prevent the log from sliding out of

position while under pressure.

When loading a log, always place your hands on the side of the log, not on the ends, and never use your foot to help stabilize

a log. Failure to do so, may result in crushed or amputated fingers, toes, hand, or foot.

When stabilizing log with left hand, remove your hand when the wedge just contacts the log or serious injury may occur.

NEVER place hands or feet between the log and splitting wedge during forward or reverse stroke as this could result in

serious injury or death. NEVER attempt to load the log splitter when the ram or wedge is in motion.

Always keep fingers away from any cracks that open in the log while splitting. They can quickly close and pinch or amputate

your fingers.

Never attempt to remove partially split wood from the wedge with your hands. Fully retract the wedge to dislodge wood with

log dislodger.

CONTACT US AT www.DRpower.com 23

Page 24

Starting and Stopping the Engine

Refer to the Engine Operator’s manual packed with your log splitter for instructions on starting and stopping the engine.

Beam Operating Positions

1. Place the log splitter on flat, dry, solid ground in a clean work area.

2. Block the front and back of both wheels (Figure 19).

(Figure 19)

3. Place the beam in either the horizontal or vertical position and lock into place.

Take extra care when raising and lowering the beam as it is fairly heavy. Having a second person assist with raising or lowering the

beam is recommended. Be sure to keep hands away from any possible pinch points.

Always use the log splitter in the vertical position when splitting heavy logs.

4. To place the beam in the Vertical Position proceed as follows:

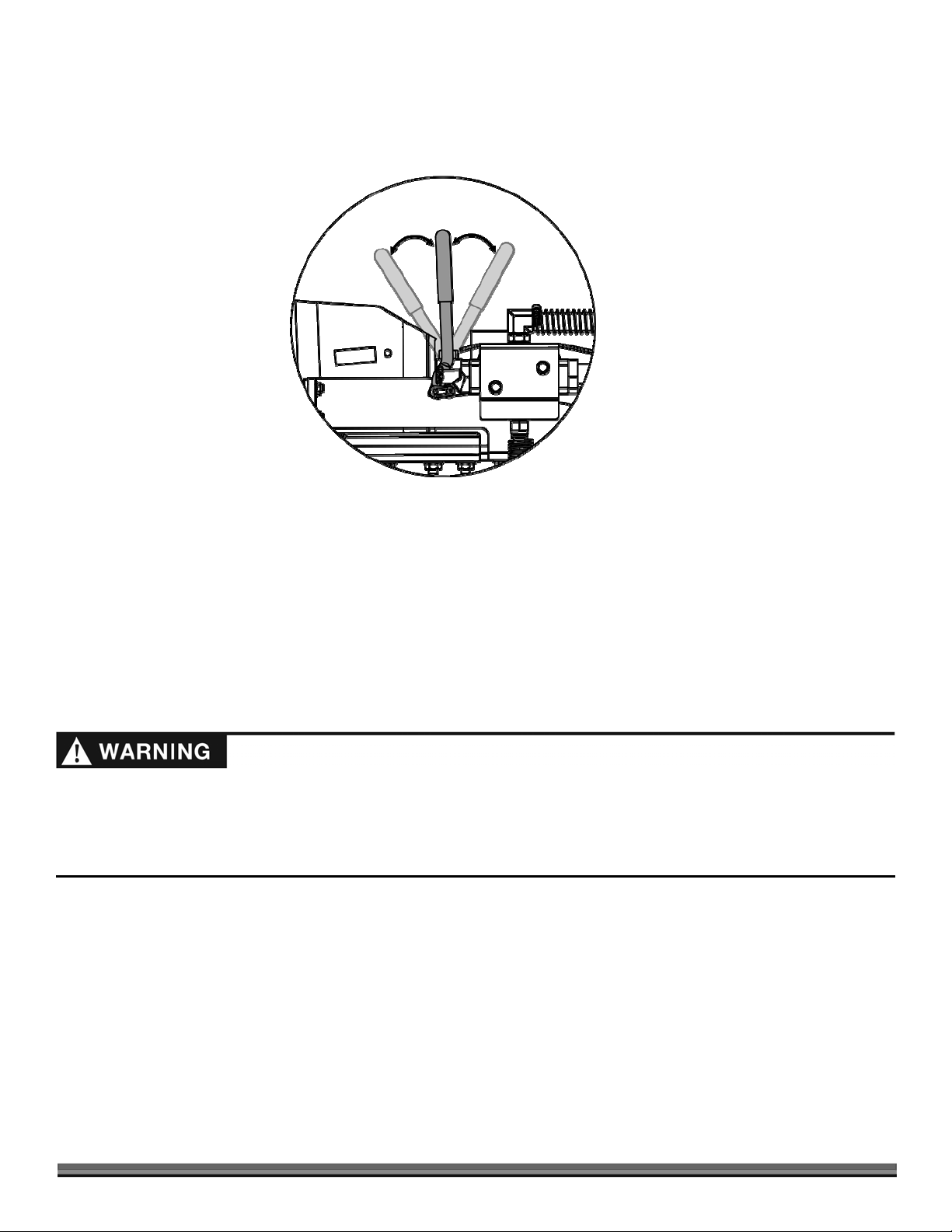

a) Pull the horizontal beam lock out to release the beam and pivot the beam to the vertical position (Figure 20).

b) To lock the beam in the vertical position, pull out on the vertical beam lock and rotate it to secure the beam (Figure

21).

5. To place the beam in the Horizontal Position proceed as follows:

a) Pull the vertical beam lock out and rotate it down. Pivot the beam to the horizontal position (Figure 21).

b) The horizontal beam lock is self-locking. The spring loaded lock will snap into place when the beam is lowered into

position.

Beam

Beam

Horizontal

Beam Lock

Vertical

Beam Lock

Tongue

(Figure 20)

24 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Tongue

(Figure 21)

Page 25

Using Control Handle

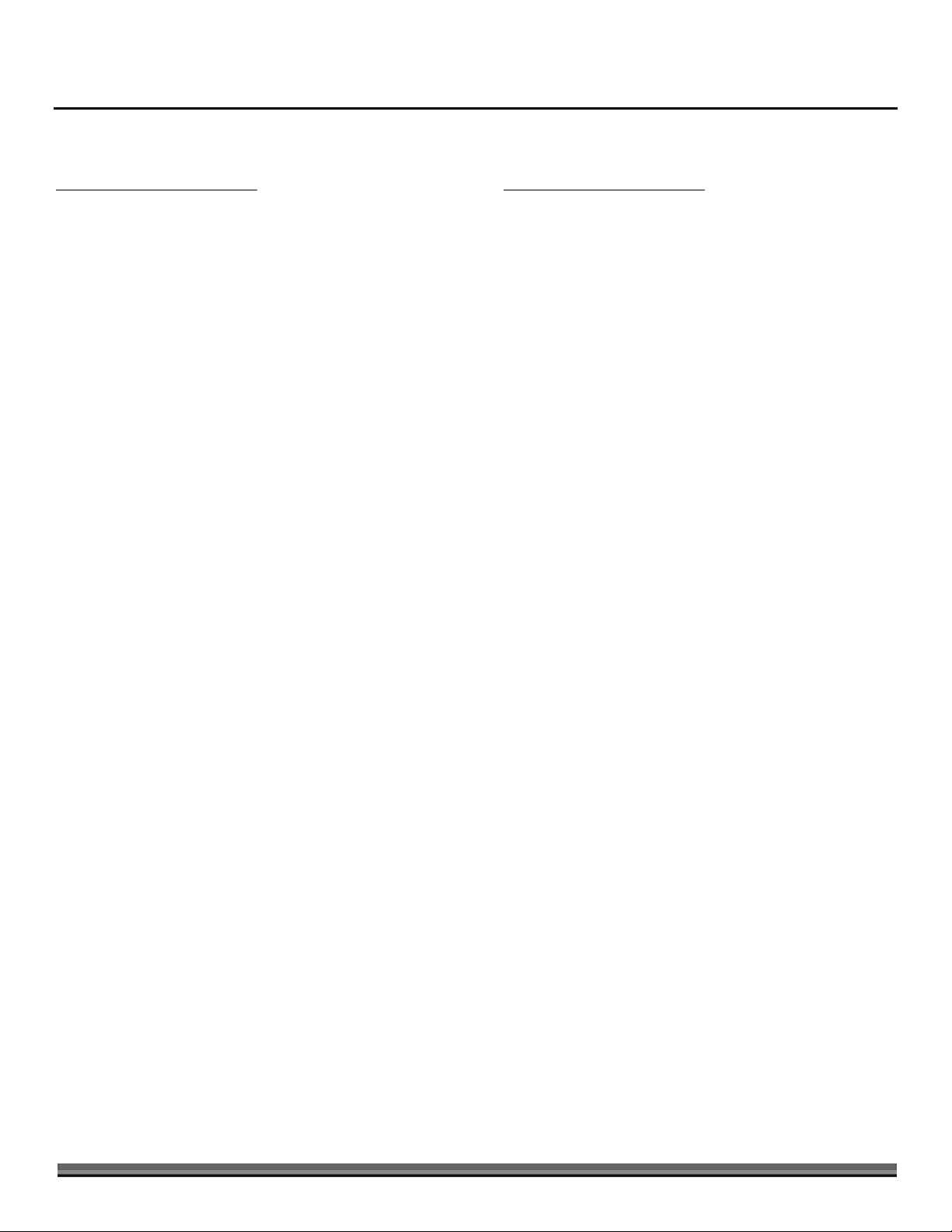

The control handle has three positions (Figure 22).

Neutral

Forward

(Figure 22)

FORWARD — To split wood. Move the control handle to the FORWARD position to move wedge toward the log to split.

Note: The control handle will return to the NEUTRAL position as soon as the handle is released (FORWARD position only).

NEUTRAL — To stop wedge. Release the control handle or move the lever to the NEUTRAL position to stop the wedge

movement.

REVERSE — To return the wedge. Move the control handle to the REVERSE position to return the wedge toward the cylinder. The

control handle returns to the NEUTRAL position automatically when fully retracted.

Do not hold the handle in the REVERSE position when fully retracted.

Note: To stop the wedge before the ram is fully retracted when in the REVERSE position, the handle must MANUALLY be put in the

NEUTRAL position.

Reverse

If the control handle on your log splitter is not functioning properly, STOP USE IMMEDIATELY and contact an authorized

service dealer.

Do not attempt to service, repair or replace control valve. Contact an authorized service dealer.

Do not attempt to adjust or modify the control valve or the hydraulic system from its original settings or manufacturer in any

way.

CONTACT US AT www.DRpower.com 25

Page 26

Splitting The Wood

1. Start the engine as instructed in the Engine Operator’s manual included with the log splitter.

2. Place the log against the end plate and only split the wood in the direction of the grain (Figure 23).

3. To stabilize the log, place your left hand on the side of the log opposite the beam.

Never place a hand on the ends of the log, between the log and the end plate or the log and the splitting wedge.

Only one operator permitted. The adult who loads and stabilizes the log, must be the person who operates the control

handle.

Remove split wood around the log splitter immediately so that you don’t stumble over it.

4. Move the control handle to the forward position to split the wood.

5. Remove left hand from the side of the log once wedge just contacts the log. Continue moving control handle forward to

split the log.

6. Release the control handle to stop the wedge movement.

7. Move the control handle to the reverse position to return the wedge.

Right Hand

Left Hand

(Figure 23)

8. Remove partially split wood from wedge.

a) Move the control handle to the REVERSE position until the wedge is fully retracted to allow split wood portion to

contact the log dislodger.

Never remove partially split wood from the wedge with your hands. Fingers may become trapped between the split wood.

b) Once removed from the wedge with the log dislodger, split the wood from the opposite end or in another location.

When splitting in the vertical position, stabilize the log before moving the control handle. Split as follows:

26 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 27

a) Place log on the end plate and turn until it leans against the beam and is stable.

J

d

b) When splitting extra-large or uneven logs, the log must be stabilized with wooden shims or split wood placed

between the log and end plate or ground

NEVER use your foot, a rope or any extension device to operate the control lever on the valve. Only use your right hand.

Transporting The Log Splitter

NEVER move the log splitter while the engine is running. Shut off the engine if you are leaving the log splitter, even for a short

period of time.

ALWAYS be careful when moving or lifting the log splitter. Get assistance if it feels too heavy to move by yourself.

Move the fuel shutoff to “OFF” before towing the Wood Splitter.

1. Lower the beam to its horizontal position. Make certain the beam is locked securely with the horizontal beam lock.

2. Change the jack stand to transporting position (Figure 24).

a) Remove the spring clip and clevis pin from the jack stand.

b) Support the tongue and pivot the jack stand up against the tongue.

c) Secure with the spring clip and clevis pin previously removed.

Clevis Pin

Spring Clip

ack Stan

(Figure 24)

3. Attach the coupler hitch to a class I or higher 2” ball on the towing vehicle latch securely.

a) If the coupler hitch does not fit on the ball, turn the adjustment nut one turn counter-clockwise.

b) If the coupler hitch is too loose on the ball, turn the adjustment nut one turn clockwise. Then recheck and adjust

accordingly.

4. Connect the safety chains to the towing vehicle.

Do not tow faster than 45mph and check the local, state and federal requirements before towing on any public road.

Use caution when backing up, using a spotter outside the vehicle is recommended.

ALWAYS disconnect your log splitter from the towing vehicle before operating it.

CONTACT US AT www.DRpower.com 27

Page 28

Chapter 4: Maintaining The DR VERTICAL/HORIZONTAL LOG SPLITTER

Regular maintenance is the way to ensure the best performance and long life of your machine. Please refer to this manual and the

engine manufacturer's owner's manual for maintenance procedures. Service intervals listed in the checklist below supersede

those listed in the engine manufacturer's owner's manual.

Before performing any maintenance procedure or inspection, stop the engine, wait five (5) minutes to allow all parts to cool.

Disconnect the spark plug wire, keeping it away from the spark plug. Refer to the Engine Operator’s manual packed with your log

splitter for all engine maintenance.

Regular Maintenance Checklist

PROCEDURE BEFORE EACH USE EVERY 25 HOURS EVERY 50 HOURS EVERY 100 HOURS

Check Engine Oil Level

Check General Equipment

Perform Rail Maintenance

Check Hydraulic Fluid Level

Check Tire Pressure

Clean Engine Exterior and

Cooling Fins

Change Engine Oil 1st time 5 hours

Replace Air Filter

Replace Hydraulic Filter

Change Hydraulic Fluid

Replace Spark Plug

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

▲

Engine Service

Refer to the Engine Operator’s manual packed with your log splitter for all engine maintenance.

Note: When draining oil from the engine on this log splitter, shield the hoses from any oil that may run down the frame and drip onto the

hoses. Thoroughly wipe any residual oil off the log splitter and hoses after completing service.

Tire Pressure

The max recommended operating pressure listed on the side of the tire. Do not, under any circumstances, exceed the

manufacturer’s recommended psi. Maintain equal pressure on all tires.

Excessive pressure when seating beads may cause the tire/rim assembly to burst with force sufficient to cause serious injury. Refer

to the sidewall of the tire for the recommended pressure.

Hose Clamps

Check the clamps on the return hose before each use and check the clamps on the suction hose once a season.

28 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 29

Hydraulic Filter

Change the hydraulic filter every 50 hours of operation. Use only a 10 micron hydraulic spin-on filter, or buy from an authorized

dealer. Order part # 51 in Exploded Diagram.

Flexible Pump Coupler

The flexible pump coupler, located between the pump and the engine shaft, has a nylon “spider” insert. Over time, the insert will

harden and deteriorate. If you detect vibration or noise coming from the area between the engine and the pump, contact us at

www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) for assistance. Change a new coupler immediately (refer to the

pump assembly STEP 4 in Page 12), if the coupler fails completely, you will experience a loss of hydraulic power.

Hydraulic Fluid

Check the hydraulic fluid level in the log splitter reservoir tank before each use. Maintain the fluid level within the range specified

on the dipstick at all times.

Change the hydraulic fluid in the reservoir every 100 hours of operation. The filter should also be changed with each hydraulic fluid

change. Follow the steps below:

1. Place a suitable oil collection container under the tank. Allow the fluid to drain into the container.

Note: The hydraulic system has a capacity of 4 gallons of hydraulic fluid for 22 Ton and 28 Ton; and 5 gallons for 34 Ton.

(Figure 25)

2. After draining, screw on the oil drain screw and tighten.

3. Refill the reservoir tank (Please follow the steps in Page 20 - 21 to fill the tank, and repel the air in the tank). The fluid

should be just touching the end portion of the dipstick.

4. Maintain the fluid level within the range specified at all times (Figure 26).

Note: When checking the fluid, always make sure to install the dipstick and push it down fully.

Note: Always dispose of any used hydraulic fluid and engine oil at approved recycling centers only. Contaminants in the fluid may

damage the hydraulic components.

(Figure 26)

Beam and Splitting Wedge

Lubricate top, sides and bottom of the beam and where it comes into contact with the splitting wedge with engine oil before each

use.

If the wedge becomes dull or nicked, it can be sharpened.

CONTACT US AT www.DRpower.com 29

Page 30

Chapter 5: Troubleshooting

Most problems are easy to fix. Consult the Troubleshooting Table below for common problems and their solutions. If you

continue to experience problems, contact us at www.DRpower.com or call toll-free 1-800-DR-OWNER (376-9637) for support.

Before performing any maintenance procedure or inspection, stop the engine, wait five (5) minutes to allow all parts to cool.

Disconnect the spark plug wire, keeping it away from the spark plug.

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE

Cylinder rod will not

move

Slow cylinder shaft

speed while extending

and retracting

Leaking at face of

Cylinder or at fittings

Wood will not split or

wood splits too slowly

Broken drive shaft; See authorized service dealer.

Shipping plugs left in hydraulic hoses; Disconnect hydraulic hoses, remove shipping plugs,

and reconnect hoses.

Set screws in coupling not adjusted properly; See authorized service dealer.

Loose shaft coupling; Correct engine/pump alignment as necessary.

Gear sections damaged; See authorized service dealer.

Damaged relief valve; See authorized service dealer.

Hydraulic lines blocked; Flush and clean hydraulic system.

Incorrect oil level; Check oil level.

Damaged control valve; See authorized service dealer.

Blocked control valve; Flush and clean hydraulic system.

Gear sections damaged; See authorized service dealer.

Excessive pump inlet vacuum; Make certain pump inlet hoses are clear, unblocked and not

kinked. Use short, large diameter inlet hoses.

Slow engine speed; See authorized service dealer.

Damaged relief valve; See authorized service dealer.

Incorrect oil level; Check oil level.

Contaminated oil; Drain oil, clean reservoir and refill.

Control valve leaking internally; See authorized service dealer.

Internally damaged cylinder; See authorized service dealer.

Worn seals; See authorized service dealer.

Scored cylinder; See authorized service dealer.

Fittings are loose; tighten as needed.

Small gear section damaged; See authorized service dealer.

Pump check valve leaking; See authorized service dealer.

Excessive pump inlet vacuum; Make certain pump inlet hoses are clear, unblocked and not

kinked.

Incorrect oil level; Check oil level.

Contaminated oil; Drain oil, clean reservoir and refill.

Control valve leaking internally; See authorized service dealer.

Overloaded cylinder; Do not attempt to split wood against the grain.

Internally damaged cylinder; See authorized service dealer.

30 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 31

Troubleshooting Table (Continued)

Before performing any maintenance procedure or inspection, stop the engine, wait five (5) minutes to allow all parts to cool.

Disconnect the spark plug wire, keeping it away from the spark plug.

SYMPTOM POSSIBLE CAUSE

Leaking pump shaft seal

Wedge continues to

move forward when

control handle is

released

Broken drive shaft; See authorized service dealer.

Engine/pump misalignment; Correct alignment as necessary.

Gear sections damaged; See authorized service dealer.

Damaged shaft seal; See authorized service dealer.

Plugged oil breather; Make certain reservoir is properly vented.

Damaged control valve; See authorized service dealer.

Control handle does not

return to neutral when

released from forward

position

Hydraulic fluid too cold; Warm up engine.

Hydraulic fluid too thick; Replace hydraulic fluid.

Hydraulic fluid contaminated; Replace hydraulic fluid.

Damaged control valve; See authorized service dealer.

CONTACT US AT www.DRpower.com 31

Page 32

Notes:

32 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 33

Chapter 6: Parts Lists and Schematic Diagrams

Parts List - DR VERTICAL/HORIZONTAL LOG SPLITTER

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

1 33727 Frame, Main (22 Ton)

33728 Frame, Main (28 Ton)

33729 Frame, Main (34 Ton)

2 33756 Wedge

2.1 36246 Bolt, SHCS, M12-1.75 X 45

2.2 30252 Washer, Flat, M12, ZP

2.3 30253 Nut, Nylon Lock, M12 X 1.75, ZP

3 33700 Bolt, HCS, M16-2 X 69, CL 8.8, ZP

4 30254 Nut, Nylon Lock, M16-2

5 33682 Cylinder, Hydraulic (22 Ton)

33683 Cylinder, Hydraulic (28 Ton)

33684 Cylinder, Hydraulic (34 Ton)

6 33747 Pin, Cylinder Mount

7 33697 Washer, M20

8 33754 Pin, Cotter, 4 X 35mm

9 33715 Hyd Hose Assembly, Valve-Cylinder

10 33749 Guard, Hose, Valve - Cylinder

11 33691 Hyd Adapter

12 33750 Hyd Adapter

13 33742 Valve, Hyd, W/ Control Handle

13.1 36113 Pin, Clevis

13.2 36114 Clip, Hitch

13.3 36249 Link, Connecting, #60 Roller Chain

14 33678 Hyd Hose Assembly, Pump - Valve

15 33695 Hyd Adapter

16 33751 Guard, Hose, Pump - Valve

17 36392 Hose, Hydraulic, 1/2"

18 33752 Guard, Hose, Valve - Tank

19 30247 Washer, M8

20 36390 Fitting, Hyd, 90 Deg Elbow, 1/2" Hose

21 33741 Bracket, Mount, Valve

22 33701 Bolt, HCS, M8-1.25 X 20, CL 8.8, ZP

23 33743 Washer, Lock, M8

24 30247 Washer, M8

25 33696 Hyd Adapter

26 33739 Hyd Pump (22 and 28 Ton)

33740 Hyd Pump (34 Ton)

27 33681 Coupling, Shaft

27.1 33679 Coupling, Shaft, 3/4" Bore

27.2 33680 Coupling, Shaft, 1" Bore

Ref# Part# Description

28 33716 Set Screw, M6-1 X 10

29 33753 Spider, Coupling, Shaft

30 33730 Mount, Pump, Hyd (22 and 28 Ton)

33731 Mount, Pump, Hyd (34 Ton)

31 33701 Bolt, HCS, M8-1.25 X 20, CL 8.8, ZP

32 30247 Washer, M8

33 33743 Washer, Lock, M8

34 13286 Bolt, HCS, 5/16-24 X .75, Gr5, ZP

35 30247 Washer, M8

36 11243 Washer, Lock, M8

37 33725 Key, Square, 3/16 X 1.75

33726 Key, Square, 1/4 X 2.165

38 33698 Engine, Kohler 6.5, Ms (22 and 28 Ton)

33699 Engine, Subaru (34 Ton)

39 33702 Bolt, HCS, M8-1.25 X 40, CL 8.8, ZP (22

and 28 Ton)

36110 Bolt, HCS, M10 x 40 (34 Ton)

40 30247 Washer, M8 (22 and 28 Ton)

30250 Washer, M10 (34 Ton)

41 30246 Nut, Nylon Lock, M8-1.25 (22 and 28

Ton)

30249 Nut, Nylon Lock, M10-1.5 (34 Ton)

42 33732 Reservoir (22 and 28 Ton)

33733 Reservoir (34 Ton)

43 33685 Dipstick

44 33744 Oring, 15 X 3.1mm

45 33746 Plug, Drain,

46 33745 Oring, 20 X 2.4mm

47 33693 Filter, Hyd, Intank

48 33736 Hyd Hose Assembly, Reservoir - Pump

49 33713 Hose Clamp, 1"

50 36391 Fitting, Hyd, Straight, 1/2" Hose

50.1 35598 Cap, Filter

51 33690 Filter, Hyd, Screw On,

52 33689 Support, Fender,

53 33703 Bolt, HCS, M8-1.25 X 25, CL 8.8, ZP

54 30247 Washer, M8

55 30246 Nut, Nylon Lock, M8-1.25

56 33688 Fender,

57 33762 Wheel,

58 25310 Nut, Slotted, 1-14, ZP

CONTACT US AT www.DRpower.com 33

Page 34

Parts List – DR VERTICAL/HORIZONTAL LOG SPLITTER (continued)

NOTE: Part numbers listed are available through DR Power Equipment.

Ref# Part# Description

59 33755 Pin, Cotter, 4 X 35mm

60 33714 Cap, Dust,

61 33748 Pin, Spring, 3 X 30mm

62 33718 Lock, Safety, Vertical Position

63 33757 Spring, Vertical Safety Lock,

64 30250 Washer, M10

65 33704 Bolt, HCS, M10-1.5 X 20, CL 8.8, ZP

66 33758 Pin, Hitch, 2.5mm

67 33676 Bolt, HCS, M8-1.25 X 20, CL 8.8, ZP

68 33705 Bolt, HCS, M10-1.5 X 80, CL 8.8, ZP

69 30250 Washer, M10

70 30249 Nut, Nylon Lock, M10-1.5

71 33737 Towbar,

72 33712 Bracket, Horizontal Beam Lock,

73 33705 Bolt, HCS, M10-1.5 X 80, CL 8.8, ZP

74 30250 Washer, M10

75 30249 Nut, Nylon Lock, M10-1.5

76 33717 Stand, Jack,

77 33705 Bolt, HCS, M10-1.5 X 80, CL 8.8, ZP

78 30250 Washer, M10

79 30249 Nut, Nylon Lock, M10-1.5

80 33677 Pin, Clevis, 10 X 70mm

81 33759 Pin, Hitch, 3.0mm

82 33711 Receiver, 2", Class Ii,

83 33734 Chain, Safety, Pair

84 33706 Bolt, HCS, M12-1.75 X 80, CL 8.8, ZP

85 30252 Washer, M12

86 30253 Nut, Nylon Lock, M12-1.75

87 33719 Tray, Log, Tube

Ref# Part# Description

87.1 33720 Assembly Rod, Tray, Log

87.2 33721 Support 1, Tray, Log

87.3 33722 Support 2, Tray, Log

87.4 33723 Endplate, Tray, Log

87.5 33724 Nut, Acorn

87.6 35840 Spacer, Tube, Log Support

88 33707 Bolt, HCS, M12-1.75 X 45, CL 8.8, ZP

89 30252 Washer, M12

90 30253 Nut, Nylon Lock, M12-1.75

91 33686 Bracket, Retraction Stop, RH,

91.1 33687 Bracket, Retraction Stop, LH,

92 35599 Bolt, HCS, M12-1.75 X 35, CL 8.8, ZP

93 30252 Washer, M12

94 30253 Nut, Nylon Lock, M12-1.75

95 33708 Bolt, HCS, M10-1.5 X 30, CL 8.8, ZP

96 30250 Washer, M10

97 30249 Nut, Nylon Lock, M10-1.5

98 33969 Wedge, 4 Way

99 33761 Bracket, Mounting, Wedge, 4 Way

100 33709 Bolt, HCS, M8-1.25 X 45, CL 4.8, ZP

101 30246 Nut, Nylon Lock, M8-1.25

102 33710 Bolt, HCS, M8-1.25 X 20, CL 4.8, ZP

103 33743 Washer, Lock, M8

Not Shown

35476 O-Ring, 11mm X 2mm

35477 O-Ring, 16mm X 2.5mm

35478 O-Ring, 19mm X 2.5mm

35479 O-Ring, 24mm X 3mm

33365 Label, 22 Ton Branding

33366 Label, 28 Ton Branding

33367 Label, 34 Ton Branding

33368 Label, Operation

33457 Label, Warning, Towbar

34 DR

®

VERTICAL/HORIZONTAL LOG SPLITTER

Page 35

Schematic – DR VERTICAL/HORIZONTAL LOG SPLITTER

CONTACT US AT www.DRpower.com 35

Page 36

Daily Checklist for the DR LOG SPLITTER

To help maintain your DR LOG SPLITTER for optimum performance, we recommend you follow this checklist each time you

use your Log Splitter.

Before performing any maintenance procedure or inspection, stop the engine, wait five (5) minutes to allow all parts to cool.

Disconnect the spark plug wire, keeping it away from the spark plug.

[ ] Check the Engine Oil and Gas Tank level.

[ ] Check the Hydraulic Oil Tank level..

[ ] Check that Engine is clean of debris.

[ ] Check the general condition of the Log Splitter, e.g.; Nuts, Bolts, Welds, etc.

[ ] Check Tire Pressure and wear.

[ ] Check the Frame for wear and damage.

[ ] Check the Wedge for nicks and wear. Sharpen if needed.

[ ] Apply a rust preventative (Fluid Film or equivalent) to any bare metal areas on the top of the Rail. This will assure the longest

possible service life of the Wear Pads.

End of Season and Storage

If the log splitter will not be used for more than 30 days, prepare it for storage as follows:

Before storing the machine, stop the engine, wait ten (10) minutes to allow all parts to cool. Disconnect the spark plug wire,

keeping it away from the spark plug.

Never store the machine with fuel in the fuel tank inside of building where fumes may reach an open flame or spark, or where

ignition sources are present such as hot water and space heaters, furnaces, clothes dryers, stoves, electric motors, etc.

The use of pressure washers or a garden hose to clean the splitter is not recommended. They may cause damage to the

bearings or the engine. The use of water will result in a shortened life and reduce serviceability.

Refer to the Engine Operator’s manual packed with your log splitter for information on the off-season storage of the engine.

Check the Wedge for nicks and wear. Sharpen if needed.

Apply a rust preventative (Fluid Film or equivalent) to any bare metal areas on the Wedge and on top of the Rail.

If your DR VERTICAL/HORIZONTAL LOG SPLITTER will be idle for more than 30 days, we recommend using a gas stabilizer.

This will prevent sediment from gumming up the Carburetor. If there is dirt or moisture in the gas or Tank, remove it by draining

the Tank. Completely fill the Tank with fresh, unleaded gas and add the appropriate amount of stabilizer or gasoline additive.

Run the Engine for a short time to allow the additive to circulate.

Clean the exterior of the unit to remove all dirt, grease, and any other foreign material. Clean dirt and debris from the Cylinder

Head Cooling Fins and Muffler area of the Engine. To prevent rust, touch up painted surfaces that have been scratched or

chipped.

Be sure all Nuts, Bolts, and Screws are securely fastened.

If possible, store the Log Splitter in a dry, protected place. If it is necessary to store the Log Splitter outside, cover it with a

protective material (especially the Engine). Do not store it next to corrosive materials, such as fertilizer.

75 MEIGS ROAD, P.O. BOX 25, VERGENNES, VERMONT 05491

©2015 Country Home Products, Inc. All rights reserved 279321C

Loading...

Loading...