Page 1

Dräger Pac 6x00 / 8x00

Technical manual

Page 2

Page 3

3

Contents

en

Contents

1 Safety-related information . . . . . . . . . . . . . . . . . . .4

1.1 Basic safety information . . . . . . . . . . . . . . . . . . . . . .4

1.2 Safety information on explosion protection . . . . . . . .4

2 Conventions used in this document . . . . . . . . . . .4

2.1 Definition of alert icons . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Typographical conventions . . . . . . . . . . . . . . . . . . . .4

2.3 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.1 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.1.1 Gas detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.3 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4.1 Preparations for use . . . . . . . . . . . . . . . . . . . . . . . . .6

4.1.1 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4.1.2 Switching on the gas detector . . . . . . . . . . . . . . . . . .6

4.1.3 Switching off the gas detector . . . . . . . . . . . . . . . . . .6

4.2 Before entering the workplace . . . . . . . . . . . . . . . . .6

4.2.1 Activating the quick menu . . . . . . . . . . . . . . . . . . . . .6

4.2.2 Opening the quick menu . . . . . . . . . . . . . . . . . . . . . .6

4.2.3 Carrying out a manual bump test . . . . . . . . . . . . . . .6

4.2.4 Information display . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.2.5 Error and warning code displays . . . . . . . . . . . . . . . .7

4.3 During operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5 Calibrating the gas detector . . . . . . . . . . . . . . . . .8

5.1 Opening the maintenance menu . . . . . . . . . . . . . . . .8

5.2 Carrying out a manual fresh air calibration . . . . . . . .8

5.3 Carrying out a manual span calibration . . . . . . . . . .9

5.4 Carrying out manual calibration with the Dräger CC-Vi-

sion Basic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.5 Carrying out an automatic calibration with the Dräger

X-dock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .10

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7.1 Configuring the gas detector . . . . . . . . . . . . . . . . . .13

7.2 Operating time alarm / end of the operating time . .13

7.3 Data logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7.4 Replacing the sensor . . . . . . . . . . . . . . . . . . . . . . .13

7.5 Replacing the battery . . . . . . . . . . . . . . . . . . . . . . .14

7.6 Replacing the dust and water filter . . . . . . . . . . . . .15

8 Device settings . . . . . . . . . . . . . . . . . . . . . . . . . . .15

8.1 Factory setting . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

8.2 Alarm settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

9 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10.1 Gas detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10.2 Technical data of the sensors and the measuring de-

vice settings for Pac 6000/6500 . . . . . . . . . . . . . . .18

10.3 Technical data of the sensors and the measuring de-

vice settings for Pac 8000 . . . . . . . . . . . . . . . . . . . .19

10.3.1 Sensors for Pac 8500 DUAL . . . . . . . . . . . . . . . . . .21

10.3.2 Cross-sensitivities . . . . . . . . . . . . . . . . . . . . . . . . . .22

Page 4

4

Safety-related informationen

1 Safety-related information

1.1 Basic safety information

Before using this product, carefully read the associated

instructions for use. This document does not replace the

instructions for use.

Incorrect calibration

An incorrect calibration leads to incorrect measured values.

► The sensitivity must be checked daily before first using the

device, with a known concentration of the gas to be

measured that corresponds to 25 to 50 % of the final

concentration. The accuracy must amount to 0 to +20 % of

the actual value. The accuracy can be corrected by

calibration.

1.2 Safety information on explosion

protection

Devices or components that are used in potentially explosive

atmospheres and which are tested and approved in

accordance with national, European or international explosion

protection guidelines may only be used under the approved

conditions in compliance with the statutory provisions.

Oxygen-enriched atmospheres

Explosion protection is not guaranteed in oxygen-enriched

atmospheres (>21 Vol% O

2

).

► Remove the device from the potentially explosive

atmosphere.

Risk of explosion!

► Do not open the gas detector in explosion-hazard areas.

Specific application conditions

In certain extreme conditions, open plastic parts and non-

earthed metal parts of the housing may store a combustible

level of electrostatic charge.

Activities such as carrying the device in a bag or attached

to a belt, operating the button field or cleaning the device

with a damp cloth do not represent a significant

electrostatic danger. However, if a mechanism which

generates static charge, such as repeated rubbing against

clothing, is identified, suitable precautionary measures

must be implemented, e.g. the use of anti-static clothing

and anti-static footwear.

2 Conventions used in this

document

2.1 Definition of alert icons

The following alert messages are used in this document to

provide and highlight areas of the associated text that require

a greater awareness by the user. A definition of the meaning of

each alert message is as follows:

WARNING

Indicates a potentially hazardous situation. If not avoided, it

could result in death or serious injury.

NOTICE

Indicates a potentially hazardous situation. If not avoided, it

could result in damage to the product or environment.

2.2 Typographical conventions

This symbol identifies information that make the product

easier to use.

2.3 Glossary

Technical term Explanation

Operation signal A periodic optical (green LED) and/or

acoustic signal.

D-Light The D-Light allows the user to check and

indicate compliance with certain settings

(e.g. bump test interval). The green LED

flashes for a short period and

superimposes the optical operation

signal.

Page 5

Description

5

en

3 Description

3.1 Product overview

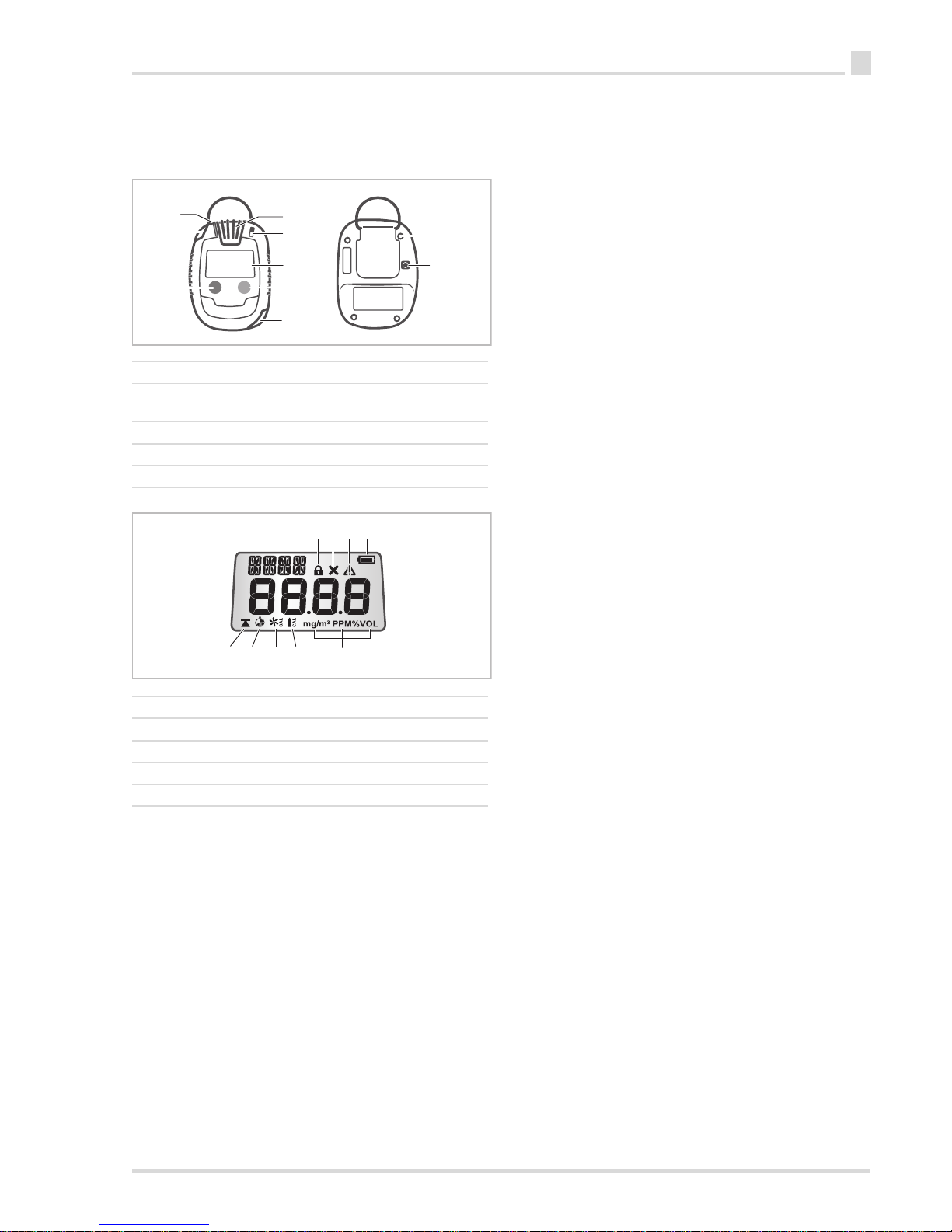

3.1.1 Gas detector

3.1.2 Display

3.2 Intended use

The Dräger Pac 6x00/8x00 is a gas detector and is used to

measure and alert the user of gas concentrations in the

ambient air.

3.3 Approvals

A copy of the name plate and the declaration of conformity are

provided in the enclosed supplementary documentation (order

no. 90 33 741).

The name plate on the gas detector must not be concealed.

1 Alarm LEDs 6 [OK] button

2 Operation signal/

D-Light

7[▼] button

3 Gas inlet 8 Screw (4x)

4 Horn 9 IR interface

5Display

1 Key word symbol 6 Span calibration

2 Error symbol 7 Fresh air adjustment

3 Information symbol 8 TWA/STEL

4 Battery charge status 9 Peak concentration

5 Measurement unit

8 (4x)

1

1

2

4

3

5

6

7

9

00333742.eps

152 3 4

6798

00733742.eps

Page 6

6

Useen

4Use

4.1 Preparations for use

4.1.1 Initial start-up

The gas detector remains in deep sleep mode upon delivery

and must be activated during the initial start-up.

1. Hold down the [▼] button for approx. 3 s.

This activates the gas detector.

4.1.2 Switching on the gas detector

1. Hold down the [OK] button for approx. 3 s.

The following is displayed or activated:

Display elements, LEDs, alarm signal and vibration alarm

Self-test

Software version and gas name

Alarm thresholds A1 and A2

Time to next calibration (configurable)

Time to expiration of the bump test interval (configurable)

Before every use, check whether the display elements and

information are displayed correctly.

A warm-up phase takes place when first switching on the gas

detector (duration depends on the sensor type; see the sensor

data sheet).

4.1.3 Switching off the gas detector

Hold down both keys for approx. 3 s, until shut-down is

complete.

4.2 Before entering the workplace

WARNING

Serious damage to health!

An incorrect calibration can lead to incorrect measurement

results, which may result in serious damage to health.

► Before performing safety measurements, check the

calibration by way of a bump test, adjust as necessary,

and check all alarm elements. If national regulations exist,

the bump test must be performed in accordance with

these regulations.

WARNING

Incorrect measurement results!

The gas inlet opening is fitted with a filter that protects against

dust and water. Contamination may change the qualities of the

dust and water filter.

► Do not damage the filter. Immediately replace damaged or

blocked filters.

To ensure correct function:

Do no cover the gas inlet opening.

Place the gas detector on clothing near the mouth.

At temperatures below -20 °C, there may be deviations of

>10 % of the measured value if the corresponding sensor

was calibrated at room temperature. Dräger recommends

calibration at the primary application temperature if

measurements will be taken at very low temperatures. This

enables the highest possible measurement accuracy.

After the gas detector has been switched on, the current

measured value is shown in the display.

Check whether the warning [!] appears. If it is displayed, we

recommend performing a bump test, see Section 4.2.3 on

Page 6.

4.2.1 Activating the quick menu

The quick menu can be activated using the Dräger CC-Vision

Basic PC software.

Up to two preferred functions can be saved in the quick menu.

The following functions are available:

Fresh air adjustment

Bump test

4.2.2 Opening the quick menu

Prerequisite:

The quick menu is activated.

To open the quick menu:

1. Press the [▼] button three times within three seconds. A

double signal tone sounds.

2. Depending on the configuration, the fresh air calibration

symbol or the bump test signal will flash.

3. Press the [OK] button to start the feature or press the [▼]

button to switch to the next feature or to return to

measuring mode (depending on the configuration).

The quick menu closes automatically after 60 s of inactivity.

4.2.3 Carrying out a manual bump test

WARNING

Danger to health! Do not inhale the test gas.

► Pay attention to the hazard information in the respective

safety data sheets.

Two modes can be selected for a bump test. Use the Dräger

CC-Vision Basic PC software to set the mode.

Quick bump test (test for alarm triggering)

Checks whether the pre-alarm threshold (A1) is

exceeded (or not reached in the case of O

2

).

Checks whether the concentration remains above the

alarm for a specified period of time.

Checks whether the test duration remains below a

specified maximum time period.

Advanced bump test (test for accuracy)

Checks whether the defined test gas concentration is

reached within a specified tolerance. The tolerance is

defined with a default value for each gas in the gas

detector, but can be adjusted by the user as needed.

Checks whether the test gas concentration remains

within the tolerance window for a specified time period.

Checks whether the test duration remains below a

specified maximum time period.

The bump test can be performed as follows:

Manual bump test (with quick menu)

Bump test with X-dock (see instructions for use for the

Dräger X-dock)

Bump test with the Dräger Bump Test Station (see the quick

reference guide on the Dräger Bump Test Station)

Page 7

Use

7

en

Prerequisites for the manual bump test:

The gas detector is switched on.

A suitable test gas cylinder is available, e.g. a test gas

cylinder (order no. 68 11 130) with the following mixed gas

ratios: 50 ppm CO, 15 ppm H

2

S, 2.5 Vol% CH4, 18 Vol%

O

2

To perform a manual bump test:

1. Prepare a Dräger test gas cylinder. The volume flow must

be 0.5 L/min and the gas concentration must be higher

than the alarm threshold concentration that is to be tested.

2. Connect the gas detector and the test gas cylinder to the

calibration adapter.

3. Press the [▼] button three times within three seconds to

open bump test mode (if configured). A signal tone sounds.

The notice symbol starts flashing.

4. Press the [OK] button to start the bump test.

5. Open the test gas cylinder valve to let test gas flow over the

sensor.

6. If the gas concentration exceeds the alarm threshold A1 or

A2, the corresponding alarm triggers.

Bump test failed: The gas detector switches to error mode

and displays an error. The error symbol flashes, and an

error code is displayed until the error is confirmed.

Subsequently, instead of the measured value, the - – –

display and the error symbol appear. In this case, repeat

the bump test or calibrate the gas detector.

Bump test passed: OK is displayed until the concentration

is below A1.

The result of the bump test (passed or failed) is saved in the

data logger (see Section 7.1 on Page 13).

4.2.4 Information display

Different information can be displayed when the device is on

and off.

The information display closes automatically after 3 s of

inactivity.

When the gas detector is off:

The following information is displayed:

Gas name, full scale deflection and measurement module.

Duration of use (Pac 6000 always, Pac 6500 and 8x00

depending on the configuration)

Device ID

To display the information:

1. Hold down the [▼] button for approx. 1 s while the device

is off.

The gas name, full scale deflection and measurement

module are displayed.

2. Press the [▼] button to display the information

consecutively. The information display closes after the

device ID.

When the gas detector is on:

The following information can be displayed depending on the

configuration:

Error codes

Peak concentration

Time-weighted average (TWA

1)

, not for Pac 6000)

Short-term exposure limit (STEL

1)

, not for Pac 6000)

Duration of use (Pac 6000 always, Pac 6500 and 8x00

depending on the configuration)

Device ID

To display the information:

1. Press the [OK] button in measuring mode.

This displays the peak concentration and the symbol for

peak concentration.

2. Press the [OK] button to display the information

consecutively. The information display closes after the

device ID.

4.2.5 Error and warning code displays

If a warning, an error or a notice is pending, the error or notice

symbol flashes and a three-digit error code appears.

To display the error and warning codes:

1. Press the [OK] button.

If there are several pending error or warning codes, the next

error or warning code can be displayed by pressing the [OK]

button.

4.3 During operation

WARNING

Danger to life and/or risk of explosion!

The following alarms indicate a danger to life and/or explosion

hazard:

A2 alarm

STEL or TWA alarm

Device error

► Immediately leave the hazard area.

The continuous operation of the gas detector is indicated by an

optical and/or acoustic operation signal that is emitted in a 60second cycle (configurable using the Dräger CC-Vision Basic

PC software).

The respective measured value is displayed as an alternating

display for dual sensors.

The operation signal must be turned on for measurements

in accordance with EN 45544 (CO, H2S) or in accordance

with EN 50104 (O2).

If the allowable measuring range is exceeded or a negative

zero drift occurs, the following message appears in the display:

(concentration too high) or (negative drift).

The measuring channels do not need to be checked after a

brief exceeding of the measuring range by the EC measuring

channels (up to one hour) (this does not apply when using

DrägerSensor XXS CO H2-CP).

In the event of an alarm, the corresponding displays, including

the visual, audible and vibration alarms, are activated, see

Section 8.2 on Page 16.

Press the [▼] button to illuminate the display.

1) configurable

Page 8

8

Calibrating the gas detectoren

5 Calibrating the gas detector

WARNING

Danger to health!

Do not inhale the test gas. Observe the hazard warnings on

the corresponding Safety Data Sheets and the instructions for

use of the gas detector! Observe national regulations when

defining calibration intervals.

For Pac 8500, two measuring channels are used for the

calibration.

Calibration must be performed by qualified personnel after

a failed bump test or after a defined calibration interval (see

EU standard EN 50073).

Recommended calibration interval for the O

2

, H2S and CO

sensors: 6 months. Calibration intervals for other gases:

see the instructions for use of the respective

DrägerSensors.

Calibration can be carried out as follows:

Manual calibration or calibration using the Dräger

CC-Vision Basic

Automatic calibration with the Dräger X-dock (see the

instructions for use for the Dräger X-dock)

Automatic calibration with the Dräger Bump Test Station

(see the quick reference guide on the Dräger Bump Test

Station)

5.1 Opening the maintenance menu

The gas detector automatically returns to measuring mode

if no button is pressed in the menu for 1 minute (with the

exception of the span calibration menus, where the menu

remains active for 10 minutes without any activity).

The maintenance menu is password protected.

Factory setting: 001

1. Hold down the [▼] button for 5 seconds.

2. Enter the password. Press the [▼] button to change the

value of the flashing position. Press the [OK] button to

confirm the value. Repeat this procedure to define the next

two values. After the last confirmation with the [OK] button,

the entire password flashes.

3. Press the [OK] button to confirm the password or the [▼]

button to cancel the password.

4. If the correct password is entered, a signal tone sounds

and the fresh air calibration symbol flashes (configurable).

5. Press the [OK] button to open the fresh air calibration or the

[▼] button to switch to the span calibration.

6. Press the [OK] button to open the span calibration or the

[▼] button to switch back to measuring mode.

5.2 Carrying out a manual fresh air

calibration

To improve accuracy, a fresh air calibration can be carried out

if there is a zero deviation.

Observe the following notices for the calibration:

During fresh air calibrations, the zero point of all sensors

(except the DrägerSensors XXS O2) is set to 0. For the

XXS O

2

, the reading is set to 20.9 Vol%.

The DrägerSensor XXS O

3

must be calibrated with a

suitable zero gas which is free from carbon dioxide / ozone

(e.g. N

2

).

To carry out the fresh air calibration:

1. Open the maintenance menu, see Section 5.1 on Page 8.

2. Press the [OK] button while the fresh air calibration symbol

is flashing. The measured value flashes.

3. Press the [OK] button to confirm the fresh air calibration or

the [▼] button to cancel the fresh air calibration.

The gas detector returns to measuring mode, or the span

calibration symbol flashes (depending on the

configuration).

Fresh air calibration passed: A short double tone sounds,

and OK / gas name is shown in an alternating display.

Press the [OK] button to return to measuring mode.

Fresh air calibration failed: A long single tone sounds.

– – – is displayed instead of the measured value. The error

symbol and the fresh air calibration symbol are displayed.

In this case, repeat the fresh air calibration or calibrate the

gas detector.

Page 9

Calibrating the gas detector

9

en

5.3 Carrying out a manual span calibration

Prepare the test gas cylinder, connect the test gas cylinder

to the calibration adapter and connect the calibration

adapter to the gas detector.

1. Open the maintenance menu, see Section 5.1 on Page 8.

2. Press the [OK] button while the span calibration symbol is

flashing. The configured test gas concentration is

displayed. The test gas concentration can be used or

adjusted according to the concentration in the test gas

cylinder.

3. Press the [▼] button to change the configured test gas

concentration. The first position flashed. Press the [▼]

button to change the value of the flashing position. Press

the [OK] button to confirm the value. Repeat this procedure

to define the next three values. After the last confirmation

with the [OK] button, the test gas concentration is

complete.

4. Open the test gas cylinder valve to let test gas flow over the

sensor (flow: 0.5 L/min).

5. Wait until the displayed measured value is stable (after at

least 120 seconds).

6. Press the [OK] button to start the span calibration. The

concentration display flashes.

7. As soon as the measured value displays a stable

concentration, press the [OK] button to confirm the span

calibration or the [▼] button to cancel the span calibration.

Span calibration passed: A short double tone sounds, and

OK / gas name is shown in an alternating display. Press

the [OK] button to return to measuring mode.

Span calibration failed: A tone sounds.

––– is displayed instead of the measured value. The error

symbol and the span calibration symbol are displayed. In

this case, repeat the span calibration.

To test the measured value configuration times, allow t90

test gas to flow over the calibration adapter on the gas

detector. Check the results in accordance with the

information in the table (see the supplementary

documentation, order no. 90 33 741) up to a reading of

90 % of the final display.

For Pac 8500, the span calibration is carried out

consecutively for the various gasses.

5.4 Carrying out manual calibration with the

Dräger CC-Vision Basic

To calibrate the gas detector using the Dräger CC-Vision Basic

PC software:

1. Connect the gas detector to a PC using the communication

module.

2. The calibration can be carried out using the Dräger

CC-Vision Basic PC software. For further information, see

the Dräger CC-Vision Basic online help.

A calibration interval can be set using the “Configurable

operating time” (in days) feature, see Section 7.1 on

Page 13.

5.5 Carrying out an automatic calibration

with the Dräger X-dock

The gas detector can be automatically calibrated using the

Dräger X-dock, see the Dräger X-dock instructions for use.

Page 10

10

Troubleshootingen

6 Troubleshooting

An error message is displayed in the event of instrument faults. The number that appears below the message is used for service

functions. If the fault remains after turning the device on and off several times, contact the service of Dräger.

Error code Cause Remedy

101 Life span of the gas detector expired. Use a new Pac gas detector.

102 The user's service life counter has elapsed. Reset the service life counter with the Dräger

CC-Vision Basic PC software.

103 Gas detector faulty. Contact the service of Dräger.

104 Program code checksum error. Contact the service of Dräger.

105 Bump test interval expired. Carry out bump test, see see Section 4.2.3 on

Page 6.

106 Calibration interval expired. Carry out a span calibration.

107 Software error Contact the service of Dräger.

109 General error. For example, menu functions cannot

be carried out.

Check the configuration, view the error code (e.g. on

the information display or with the Dräger CC-Vision

Basic PC software)

111 Alarm element test failed: Alarm lamp. Repeat the alarm element test with X-dock.

112 Alarm element test failed: Alarm horn. Repeat the alarm element test with X-dock.

113 Alarm element test failed: Vibration motor. Repeat the alarm element test with X-dock.

114 Parameter check failed. Correct the parameters and repeat the test with

X-dock.

115 Gas detector deactivated by X-dock. Activate the gas detector with X-dock.

116 Wrong software version. Update the software.

117 User parameters implausible. Check and adjust the configuration of the user

parameters.

131 Gas detector faulty. Contact the service of Dräger.

132 Parameter checksum error. Carry out a sensor inauguration using the Dräger

CC-Vision Basic PC software.

133 Wrong software version for the options board Update the software.

134 Hardware error. Contact the service of Dräger.

201 No valid zero adjustment of DrägerSensor XXS

measuring channel 1.

Carry out a fresh air calibration, see Section 5.2 on

Page 8.

202 No valid span calibration of DrägerSensor XXS

measuring channel 1.

Carry out a span calibration, see Section 5.2 on

Page 8.

203 The measured value of DrägerSensor XXS

measuring channel 1 is in the negative range.

Carry out a fresh air calibration, see Section 5.2 on

Page 8.

204 DrägerSensor XXS measuring channel 1 is faulty or

not connected.

Check DrägerSensor XXS measuring channel 1, see

Section 7.4 on Page 13.

205 Error during the bump test of DrägerSensor XXS

measuring channel 1.

Repeat the bump test and calibrate or replace

DrägerSensor XXS measuring channel 1 if

necessary, see Section 7.4 on Page 13.

206 Faulty filter test. Repeat the filter test with X-dock.

207 Faulty rise time test. Repeat the rise test with X-dock.

208 User parameters of the sensor implausible. Check and adjust the configuration of the sensor

parameters.

212 Calibration interval of DrägerSensor XXS measuring

channel 1 expired.

Carry out a calibration, see Section 5 on Page 8.

225 Compensation channel error on DrägerSensor XXS

measuring channel 1.

Carry out a calibration, see Section 5 on Page 8.

Page 11

Troubleshooting

11

en

227 Sensor hardware on the gas detector faulty. Contact the service of Dräger.

228 Compensation channel calibration error on

DrägerSensor XXS measuring channel 1.

Carry out a calibration, see Section 5 on Page 8.

301 No valid zero adjustment of DrägerSensor XXS

measuring channel 2.

Carry out a fresh air calibration, see Section 5.2 on

Page 8.

302 No valid span calibration of DrägerSensor XXS

measuring channel 2.

Carry out a span calibration, see Section 5.2 on

Page 8.

303 The measured value of DrägerSensor XXS

measuring channel 2 is in the negative range.

Carry out a fresh air calibration, see Section 5.2 on

Page 8.

304 DrägerSensor XXS measuring channel 2 is faulty or

not connected.

Check DrägerSensor XXS measuring channel 2, see

Section 7.4 on Page 13.

305 Error during the bump test of DrägerSensor XXS

measuring channel 2.

Repeat the bump test and calibrate or replace

DrägerSensor XXS measuring channel 2 if

necessary, see Section 7.4 on Page 13.

306 Faulty filter test. Repeat the filter test with X-dock.

307 Faulty rise time test. Repeat the rise test with X-dock.

308 User parameters of the sensor implausible. Check and adjust the configuration of the sensor

parameters.

312 Calibration interval for measuring channel 2 expired. Carry out a calibration, see Section 5 on Page 8.

325 Compensation channel error on DrägerSensor XXS

measuring channel 2.

Carry out a calibration, see Section 5 on Page 8.

327 Gas detector faulty. Contact the service of Dräger.

328 Compensation channel calibration error on

DrägerSensor XXS measuring channel 2.

Carry out a calibration, see Section 5 on Page 8.

Error code Cause Remedy

Warning code Cause Remedy

151 Dräger service life expired. Use a new Pac gas detector.

152 The user's service life counter will elapse soon. Reset the service life counter with the Dräger

CC-Vision Basic PC software.

153 Data memory 90% full. Read the data memory and clear it at the next

opportunity.

154 Data memory full. Read the data memory and clear it.

155 Bump test interval expired. Carry out bump test, see see Section 4.2.3 on

Page 6.

159 General warning pending. Menu functions cannot

be carried out (e.g. notice indicating a warming up

sensor).

View the notice code on the information display and

confirm it if necessary.

160 Date and time incorrect, e.g. after battery change. Set the date and time with the Dräger CC-Vision

Basic PC software.

251 DrägerSensor XXS measuring channel 1 warming

up (warm-up phase 1).

Wait until warm-up time is complete.

252 DrägerSensor XXS measuring channel 1 warming

up (warm-up phase 2).

Wait until warm-up time is complete.

253 Measuring channel 1 concentration has drifted into

the negative range.

Carry out a fresh air calibration for DrägerSensor XXS

measuring channel 1, see Section 5.2 on Page 8.

254 The temperature is too high. Operate the gas detector within the permissible

temperature range.

Page 12

12

Troubleshootingen

255 The temperature is too low. Operate the gas detector within the permissible

temperature range.

256 Calibration interval for DrägerSensor XXS

measuring channel 1 expired.

Carry out a span calibration for DrägerSensor XXS

measuring channel 1, see Section 5.3 on Page 9

275 Compensation channel calibration interval Carry out a calibration for DrägerSensor XXS

measuring channel 1, see Section 5 on Page 8.

276 Calibration necessary because of over-gassing of

the compensation channel.

Carry out a calibration for DrägerSensor XXS

measuring channel 1, see Section 5 on Page 8.

351 DrägerSensor XXS measuring channel 2 warming

up (warm-up phase 1).

Wait until warm-up time is complete.

352 DrägerSensor XXS measuring channel 2 warming

up (warm-up phase 2).

Wait until warm-up time is complete.

353 Measuring channel 2 concentration has drifted into

the negative range.

Carry out a fresh air calibration for DrägerSensor XXS

measuring channel 2, see Section 5.2 on Page 8.

354 The temperature is too high. Operate the gas detector within the permissible

temperature range.

355 The temperature is too low. Operate the gas detector within the permissible

temperature range.

356 Calibration interval for DrägerSensor XXS

measuring channel 2 expired.

Carry out a span calibration for DrägerSensor XXS

measuring channel 2, see Section 5.3 on Page 9

Warning code Cause Remedy

Page 13

Maintenance

13

en

7 Maintenance

The following maintenance instructions must be carefully read,

understood and followed to prevent flammable or combustible

atmospheres from igniting and to ensure that the intrinsic

safety of the gas detector is not impaired.

WARNING

Incorrect measurement!

► A bump test and/or calibration must be performed each

time the gas detector is opened. This includes any battery

change as well as each sensor replacement in the gas

detector.

NOTICE

Damage to components!

The gas detector contains components at risk of charging.

Before opening the gas detector, make sure that the operator

is earthed in order to prevent damage to the gas detector. For

example, earthing may be ensured by an ESD workplace

(electro static discharge).

NOTICE

Damage to the gas detector!

When replacing the battery or the sensor, make sure that no

components are damaged or short-circuited.

► Do not use sharp objects to remove the battery or the

sensor.

WARNING

Replacing components may impair the intrinsic safety of the

gas detector. The following maintenance instructions must be

carefully read, understood and followed to prevent flammable

or combustible atmospheres from igniting and to ensure that

the intrinsic safety of the gas detector is not impaired.

► When replacing the battery or a sensor, do not damage or

short-circuit any components. Do not use any sharp

objects to remove the battery or the sensor.

WARNING

Incorrect measurement results!

If a battery or sensor replacement is carried out incorrectly, this

may cause incorrect measurements.

► Carry out a bump test and/or calibration each time the gas

detector is opened.

7.1 Configuring the gas detector

The gas detector can be configured using the Dräger

CC-Vision Basic PC software. For further information, see the

Dräger CC-Vision Basic online help.

To configure the gas detector using the Dräger CC-Vision

Basic PC software:

1. Use the communication module (order no. 83 18 587) to

connect the gas detector to a PC or the Dräger X-dock

maintenance station.

2. The configuration can be carried out using the Dräger

CC-Vision Basic PC software. For further information, see

the Dräger CC-Vision Basic online help or the instructions

for use of the Dräger X-dock maintenance station.

7.2 Operating time alarm / end of the

operating time

An individual operating time can be configured using the

Dräger CC-Vision Basic PC software to, for example, set a

“calibration date”, an “inspection date”, a “switch-off date”, an

“operating time alarm” etc.

If an operating time is configured, a warning period starts

before the end of the installed operating time. After the gas

detector is turned on, the remaining operating time flashes

during this warning period, e.g. “30” / “d” ( in days).

This operating time alarm triggers at 10 % of the configured

operating time (maximum 30 days before the end of the

operating time).

7.3 Data logger

The gas detector is equipped with a data logger. The data

logger saves events and the average concentration which are

stored for the duration of a period of time which can be variably

configured using the Dräger Gas Vision PC software or the

Dräger CC-Vision Basic PC software. Depending on the

number of changing measured values, the data logger runs for

up to four weeks at an interval of one minute (configurable). If

the data logger memory is full, the data logger overwrites the

oldest data.

7.4 Replacing the sensor

WARNING

Risk of explosion! Do not replace the sensor in explosionhazard areas. Replacing components may impair the intrinsic

safety of the gas detector.

The following maintenance instructions must be carefully read,

understood and followed to prevent flammable or combustible

atmospheres from igniting and to ensure that the intrinsic

safety of the gas detector is not impaired.

► When replacing the sensor, make sure that no

components are damaged or short-circuited. Do not use

sharp objects to remove the sensor.

Page 14

14

Maintenanceen

If the gas detector can no longer be calibrated, the sensor

must be replaced!

Only use the DrägerSensor XXS with the same part

number!

1. Connect the gas detector to a PC using the communication

module.

2. In the CC-Vision Basic PC software

1)

, open the “Sensor

replacement assistant” feature and follow the instructions.

a. Switch off the gas detector.

b. Loosen the four screws on the rear part of the housing.

c. Open the front part of the housing.

d. Remove the battery (optional).

e. Remove the sensor.

f. Insert the new sensor and make a note of the sensor

code printed on the sensor.

g. If the battery was removed: Wait for 5 seconds, insert

new battery. The battery runtime is reset when the

battery is inserted.

h. Place the front part of the housing on the gas detector

and re-tighten the four screws on the rear part of the

housing.

3. Sign in the sensor with the previously recorded sensor

code.

4. After the sensor replacement, the sensor requires a warmup phase (see the sensor data sheet). The displayed

concentration flashes until the warm-up phase is complete.

5. After the sensor replacement and the warm-up phase, the

gas detector must be calibrated (see Section 5 on Page 8).

If the sensor code of the new sensor does not match that

of the previous sensor, the new sensor must be signed on

with the CC-Vision Basic PC software as described. Dräger

recommends signing on the sensor with the Dräger

CC-Vision Basic PC software, even if the sensor code is

identical to the previous one.

7.5 Replacing the battery

WARNING

Risk of explosion!

► Only the lithium battery type LBT 01** (order no.

83 26 856) may be used.

► Do not remove or replace batteries in potentially explosive

areas. Do no throw used batteries into fire or try to open

them by force. Dispose of batteries in accordance with the

national provisions.

The battery is part of the Ex approval.

1. Switch off the gas detector.

2. Loosen the four screws on the rear part of the housing.

3. Open the front part of the housing, remove battery and wait

for 5 s.

4. Insert the new battery. Make sure the battery plug is

inserted correctly (see figure). The battery runtime is reset

when the battery is inserted.

5. Place the front part of the housing on the gas detector and

re-tighten the four screws on the rear part of the housing

(torque: 35 Ncm).

6. Turn on the gas detector.

A successful battery replacement is confirmed with a

vibration (5 s) when the gas detector is turned on.

Notice 160 is displayed after the start sequence (see

Section 6 on Page 10).

7. Confirm the notice with the [OK] button.

8. After the battery replacement, the sensor requires a warmup phase (see the sensor data sheet). The displayed

concentration flashes until the warm-up phase is complete.

1) A free version of the Dräger CC-Vision Basic PC software can be

downloaded at www.draeger.com/software

35 Ncm

00533742.eps

Page 15

Device settings

15

en

7.6 Replacing the dust and water filter

1. Place the special tool on the dust and water separator.

2. Press the lever on the special tool downward and then

remove the dust and water separator.

3. Insert a new dust and water separator. The dust and water

separator must click into place.

For special gases (ozone, phosgene), the entire front casing,

including the special diaphragm, must be replaced due to the

special diaphragm.

8 Device settings

Only trained and qualified personnel may change the device

settings.

8.1 Factory setting

The factory settings may differ for customised orders.

Sensor grille:

4 units

Order no.:

40 units

Order no.:

Pac 6xx0 83 26 853 83 26 857

Pac 8xx0 83 26 852 83 26 859

Front casing: Order no.:

Pac 8000 ozone 83 26 851

Pac 8000 phosgene 83 26 854

00633742.eps

Bump test mode Quick bump test

Vibration alarm On

Bump test interval Off

Operation signal On

D-Light On

Switch off Always

Data logger interval 1 min

Usage duration (user) Off

Page 16

16

Device settingsen

8.2 Alarm settings

Alarm Display Latching Acknowledgeable LED Horn Vibration

1)

Alarm 1 A1

Alarm 2 A2

STEL STEL

TWA TWA

Pre-alarm

2)

Main alarm

3)

Instrument alarm

1) The intensity of the vibration depends on the temperature

2) After the initial battery pre-alarm, the battery’s life span amounts to between 1 day and 2 weeks under normal conditions of use. The life span is shorter at low

temperatures and/or in the event of alarms.

3) The gas detector automatically switches off after 10 s.

Page 17

Disposal

17

en

9 Disposal 10 Technical data

10.1 Gas detector

This product must not be disposed of as household

waste. This is indicated by the adjacent symbol. You

can return this product to Dräger free of charge. For

information please contact the national marketing

organizations or Dräger.

Batteries must not be disposed of as household waste.

This is indicated by the adjacent symbol. Dispose of

batteries at battery collection centers as specified by

the applicable regulations.

Ambient conditions during operation

Temperature

(temperature depending

on the sensor)

Up to -30 °C ... +55 °C

(briefly up to 1 h -40 °C ...

+55 °C)

Humidity 10 ... 90 % r.h., non-condensing

Pressure 700 ... 1300 hPa

Ambient conditions during storage:

Temperature 0 ... 40 °C

Humidity 30 ... 80 % r.h., non-condensing

Typ. battery lifetime (under normal conditions):

24 h operation/day,

1 min alarm/day

24 months

O

2

sensor: 10 months

Dual sensors (without O2):

22 months

Alarm volume approx. 90 dBA at a distance of

30 cm

Dimensions (not including

clip)

64 x 84 x 20 mm

Weight approx. 106 g (113 g with clip)

Degree of protection IP 68

Page 18

18

Technical dataen

10.2 Technical data of the sensors and the measuring device settings for Pac 6000/6500

CO-LC H

2

S-LC O

2

SO

2

Measuring range 0 ... 1999 ppm 0...100ppm 2 ... 25 Vol% 0...100ppm

Calibration gas concentration 50 ppm 20 ppm 18 Vol% 10 ppm

Temperature range, operation -40 ... 50 °C

-40 ... 122 °F

-40 ... 50 °C

-40 ... 122 °F

-40 ... 50 °C

-40 ... 122 °F

-30 ... 50 °C

-22 ... 122 °F

Alarm threshold A1

1)

1) Observe special, customer-requested settings. Device parameters can be changed with the Dräger CC-Vision Basic PC software.

30 ppm 5 ppm 19 Vol%

2)

2) For O

2

, A1 is the lower alarm threshold for displaying oxygen deficiency.

1 ppm

Acknowledgeable -

Latching

-

- -

Alarm threshold A2

1)

60 ppm 10 ppm 23 Vol% 2 ppm

Acknowledgeable - - - -

Latching

TWA threshold value

1) 3)

3) Not applicable for Pac 6000.

30 ppm 10 ppm - 1 ppm

STEL threshold value

1) 3)

60 ppm 10 ppm - 1 ppm

Mean value period 15 min 15 min - 15 min

Measurement accuracy

Zero point: ±2 ppm ±0.1 ppm ±0.2 Vol% ±0.1 ppm

Sensitivity: [% of the measured value] ±2 ± 5 ± 1 ±2

Long-term drift (20 °C)

Zero point: ±2 ppm/a ±0.2 ppm/a ±0.5 Vol%/a ±1 ppm/a

Sensitivity: [% of measured value/year] ±3 ±5 ±1 ±2/month

Sensor item number

4)

4) The sensors have a limited life span. Excessive storage periods compromise the operational life time of the sensors. The adequate temperature range for storage is 0 ... 35 °C (32 ... 95 °F).

68 13 210 68 11 525 68 10 881 68 10 885

Sensor data sheet item number 90 33 454 90 23 970 90 23 820 90 23 919

Page 19

Technical data

19

en

10.3 Technical data of the sensors and the measuring device settings for Pac 8000

NH

3

PH

3

HCN NO NO

2

-LC CO

2

Measuring range 0...300ppm 0...20ppm 0 ... 50 ppm 0 ... 200 ppm 0 ... 50 ppm 0...5Vol%

Calibration gas concentration 50 ppm in N

2

0.5 ppm in N

2

10 ppm in N

2

50 ppm in N

2

5ppm inN

2

2.5 Vol% in air

Temperature range, operation -30 ... 50 °C

-22 ... 122 °F

-20 ... 50 °C

-4 ... 122 °F

-20 ... 50 °C

-4 ... 122 °F

-40 ... 50 °C

-40...122°F

-30 ... 50 °C

-22 ... 122 °F

-20 ... 40 °C

-4 ... 104 °F

Alarm threshold A1

1)

1) Observe special, customer-requested settings. Device parameters can be changed with the Dräger CC-Vision Basic PC software.

50 ppm 0.1 ppm 10 ppm 25 ppm 0.5 ppm 0.5 Vol%

Acknowledgeable

Latching - - - - - -

Alarm threshold A2

1)

100 ppm 0.2 ppm 20 ppm 50 ppm 1ppm 1Vol%

Acknowledgeable - - - - - -

Latching

TWA threshold value

1)

20 ppm 0.1 ppm 1.9 ppm 25 ppm 0.5 ppm 0.5 Vol%

STEL threshold value

1)

40 ppm 0.1 ppm 3.8 ppm 50 ppm 1ppm 2Vol%

Mean value period 15 min 15 min 15 min 15 min 15 min 15 min

Measurement accuracy

Zero point: ±4 ppm ±0.02 ppm ±0.5 ppm ±0.3 ppm ±0.02 ppm ±0.3 Vol%

Sensitivity: [% of the measured value] ±3 ±2 ±5 ±3 ±3 ±20

Long-term drift (20 °C)

Zero point: ±5 ppm/a ±0.05 ppm/a ±2 ppm/a ±0.3 ppm/a ±0.04 ppm/a ±0.2 Vol%/a

Sensitivity:

[% of measured value/month

]

±2 ±2 ±5 ±2 ±2 ±15

Sensor item number

2)

2) The sensors have a limited life span. Excessive storage periods compromise the operational life time of the sensors. The adequate temperature range for storage is 0 ... 35 °C (32 ... 95 °F).

68 10 888 68 10 886 68 10 887 68 11 545 68 12 600 68 10 889

Sensor data sheet item number 90 23 922 90 23 920 90 23 921 90 33 091 90 33 093 90 23 923

Page 20

20

Technical dataen

Cl

2

OV

1)

1) Only for ethylene oxide.

OV-A

1)

Ozone Phosgene

Measuring range 0 ... 20 ppm 0...200ppm 0 ... 200 ppm 0 ... 10 ppm 0 ... 10 ppm

Calibration gas concentration 5ppm inN

2

20 ppm in N

2

20 ppm in N

2

0.5 ... 9 ppm O

3

3.8 ... 9 ppm

Temperature range, operation -30 ... 50 °C

-22...122°F

-20 ... 50 °C

-4 ... 122 °F

-20 ... 50 °C

-4 ... 122 °F

-20 ... 50 °C

-4 ... 122 °F

-20 ... 35 °C

-4 ... 99 °F

Alarm threshold A1

2)

2) Observe special, customer-requested settings. Device parameters can be changed with the Dräger CC-Vision Basic PC software.

0.5 ppm 10 ppm 10 ppm 0.1 ppm 0.1 ppm

Acknowledgeable

Latching - - - - -

Alarm threshold A2

1)

1ppm 20 ppm 20 ppm 0.2 ppm 0.2 ppm

Acknowledgeable - - - - -

Latching

TWA threshold value

1)

0.5 ppm - - 0.1 ppm 0.1 ppm

STEL threshold value

1)

0.5 ppm - - 0.1 ppm 0.1 ppm

Mean value period 15 min - - 15 min 15 min

Measurement accuracy

Zero point: ±0.05 ppm ±3 ppm ±5 ppm ±0.02 ppm ±0.01 ppm

Sensitivity: [% of the measured value] ±2 ±5 ±20 ±3 ±10

Long-term drift (20 °C)

Zero point: ±0.2 ppm/a ±5 ppm/a ±5 ppm/a ±0.02 ppm/a ±0.2 ppm/a

Sensitivity:

[% of measured value/month

] ±2 ±2 ±3 ±2 ±2

Sensor item number

3)

3) The sensors have a limited life span. Excessive storage periods compromise the operational life time of the sensors. The adequate temperature range for storage is 0 ... 35 °C (32 ... 95 °F).

68 10 890 68 11 530 68 11 535 68 11 540 68 12 005

Sensor data sheet item number 90 23 924 90 23 994 90 23 995 90 33 259 90 23 924

Page 21

Technical data

21

en

10.3.1 Sensors for Pac 8500 DUAL

H

2

S LC / CO LC O

2

/ CO-LC CO H

2

-CP

Measuring range 0 ... 100 ppm H

2

S

0 ... 2000 ppm CO

0...25Vol% O

2

0 ... 2000 ppm CO

0 ... 2000 ppm

Calibration gas concentration 5 ... 90 ppm H

2

S

20 ... 450 ppm CO

12 ... 20 Vol% O

2

20 ... 1800 ppm CO

1000 ppm H

2

20 ... 1800 ppm CO

Temperature range, operation -40 ... 50 °C

-40...122°F

-40 ... 50 °C

-40 ... 122 °F

-40 ... 50 °C

-40...122°F

Alarm threshold A1

1)

1) Observe special, customer-requested settings. Device parameters can be changed with the Dräger CC-Vision Basic PC software.

5 ppm H

2

S

30 ppm CO

19 O

2

30 CO

30 ppm

Acknowledgeable O

2

:

-

CO:

Latching - O

2

:

CO: -

-

Alarm threshold A2

1)

10 ppm H

2

S

60 ppm CO

23 O

2

60 CO

60 ppm

Acknowledgeable - O

2

:

-

CO: -

-

Latching O

2

:

CO:

TWA threshold value

1)

5 ppm H

2

S

30 ppm CO

-

30 ppm CO

-

30 ppm CO

STEL threshold value

1)

10 ppm H

2

S

60 ppm CO

-

60 ppm CO

-

60 ppm CO

Mean value period 15 min 15 min 15 min

Measurement accuracy

Zero point: H

2

S: 0.4 ppm

CO: 2ppm

O

2

±0.4 Vol%

CO: ±2 ppm

±6 ppm

Sensitivity: [% of the measured value] H

2

S: ±5

CO: ±2

O

2

±1

CO: ±2

±2

Long-term drift (20 °C)

Zero point: H

2

S: ±0.2 ppm/a

CO: ±2 ppm/a

O

2

±0.5 Vol%/a

CO: ±2 ppm/a

±2 ppm/a

Sensitivity:

[% of measured value/year

] H

2

S: ±5

CO: ±3

O

2

±1

CO: ±3

±1/month

Sensor item number

2)

2) The sensors have a limited life span. Excessive storage periods compromise the operational life time of the sensors. The adequate temperature range for storage

is 0 ... 35 °C (32 ... 95 °F).

68 13 280 68 13 275 68 11 950

Sensor data sheet item number 90 33 511 90 33 510 90 23 924

Page 22

22

Technical dataen

10.3.2 Cross-sensitivities

Cross-sensitivity factors

4)

CO-LC H2S O

2

Acetylene 2 No effect -0.5

Ammonia No effect No effect No effect

Carbon dioxide No effect No effect -0.04

Carbon monoxide No effect No effect 0.2

Chlorine 0.05 -0.2 No effect

Ethane No effect No effect -0.2

Ethanol No effect No effect No effect

Ethylene No effect No effect -1

Hydrogen 0.35 No effect -1.5

Hydrogen chloride No effect No effect No effect

Hydrogen cyanide No effect No effect No effect

Hydrogen sulphide 0.03 No effect

Methane No effect No effect No effect

Nitrogen dioxide 0.05 -0.25 No effect

Nitric oxide 0.2 0.03 No effect

Propane No effect No effect No effect

Sulphur dioxide 0.04 0.1 No effect

Page 23

Page 24

Dräger Safety AG & Co. KGaA

Revalstraße 1

23560 Lübeck, Germany

Tel +49 451 882 0

Fax +49 451 882 20 80

www.draeger.com

90 33 742 - TH 4623.700

© Dräger Safety AG & Co. KGaA

Edition 01 - July 2017

Subject to alteration

Loading...

Loading...