Page 1

Instructions for Use

Oxylog 2000 plus

WARNING

For a full understanding of the performance characteristics of this device,

the user should carefully read this manual before use of the device.

Title

Emergency and Transport Ventilator

Software 1.n

Page 2

Working with these Instructions for Use

Working with these Instructions for Use

The title of the main chapter in the header line

helps with orientation and navigation.

The Instructions for Use combine text and illustrations, providing a comprehensive overview of the

system. The information is presented as sequential

steps of action, allowing the user to systematically

learn how to use the device.

The text provides explanations and instructs the

user step-by-step in the practical use of the

product, with short, clear instructions in

easy-to-follow sequences.

1 Consecutive numbers indicate the steps of

action, with the numbering restarting with "1" for

each new sequence of actions.

z Bullet points indicate individual actions or

different options for action.

– Dashes indicate the listing of data, options or

objects.

(A) Letters in parentheses refer to elements in the

relevant illustration.

The illustrations show the relationship between

the text and the device. Elements mentioned in the

text are highlighted. Unnecessary details are

omitted.

Schematic renderings of screen images guide the

user and allow to reconfirm actions performed. The

actual screen images differ in lock or in configuration.

A Letters denote elements referred to the text.

Trademarks

The Dräger Oxylog

mark of Dräger.

Definitions

WARNI NG

A WARNING statement provides important

information about a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

A CAUTION statement provides important information about a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury to the user or patient or in damage to

the equipment or other property.

NOTE

A NOTE provides additional information intended

to avoid inconvenience during operation.

Abbreviations and Symbols

Please refer to "Abbreviations" on page 16 and

"Symbols" on page 17 for additional information.

®

name is a registered trade-

Typing conventions

Any text shown on the screen and any labeling on

the device are printed in bold and italics, for example PEEP, Air or Alarm Settings.

2

Instructions for Use Oxylog 2000 plus SW 1.n

Page 3

Contents

Contents

For Your Safety and that of Your Patients .5

General WARNINGS and CAUTIONS . . . . . . 7

Application . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Indications/Contraindications . . . . . . . . . . . . . 10

Environment of use. . . . . . . . . . . . . . . . . . . . . 10

System Overview . . . . . . . . . . . . . . . . . . . . . 11

Front panel with all options. . . . . . . . . . . . . . . 12

Available ventilation modes . . . . . . . . . . . . . . 14

Special modes . . . . . . . . . . . . . . . . . . . . . . . . 15

With monitoring. . . . . . . . . . . . . . . . . . . . . . . . 15

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . 16

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Concept . . . . . . . . . . . . . . . . . . . . 19

Switch ON or OFF . . . . . . . . . . . . . . . . . . . . . 20

Ventilation controls . . . . . . . . . . . . . . . . . . . . . 21

Display operating controls . . . . . . . . . . . . . . . 22

Screen window structure . . . . . . . . . . . . . . . . 23

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Dead space . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Assemble the reusable hose system . . . . . . . 29

Connect the disposable hose system. . . . . . . 31

Connecting the power supply . . . . . . . . . . . . . 32

Internal supply with rechargeable battery. . . . 32

Connecting the gas supply . . . . . . . . . . . . . . . 34

Hanging the Oxylog 2000 plus on standard rail sys-

tems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Getting Started . . . . . . . . . . . . . . . . . . . . . . . 37

Charging the battery. . . . . . . . . . . . . . . . . . . . 38

Determining the approximate pneumatic operating

time for the Oxylog 2000 plus. . . . . . . . . . . . . 39

Checking readiness for operation. . . . . . . . . . 40

Perform device check. . . . . . . . . . . . . . . . . . . 41

Preparation for use after system check . . . . . 43

Preparing ventilation mode . . . . . . . . . . . . . . 47

VC-CMV / VC-AC . . . . . . . . . . . . . . . . . . . . . 48

VC-SIMV (optional PS) . . . . . . . . . . . . . . . . . 50

SpnCPAP (optional PS). . . . . . . . . . . . . . . . . 52

O2 AirMix or 100% O2 . . . . . . . . . . . . . . . . . 55

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Screen brightness . . . . . . . . . . . . . . . . . . . . . 56

Volume loudness. . . . . . . . . . . . . . . . . . . . . . 56

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Types of alarms. . . . . . . . . . . . . . . . . . . . . . . 60

In the event of an alarm. . . . . . . . . . . . . . . . . 61

Setting alarm limits . . . . . . . . . . . . . . . . . . . . 63

Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Displaying the airway pressure . . . . . . . . . . . 66

Displaying MVe and VTe . . . . . . . . . . . . . . . . 66

Displaying O2 values. . . . . . . . . . . . . . . . . . . 66

Displaying other measured values . . . . . . . . 67

Configuration. . . . . . . . . . . . . . . . . . . . . . . . 69

Set configuration parameters / display information

70

Displaying configuration and information . . . 71

Customer Service Mode . . . . . . . . . . . . . . . . 72

Problem Solving . . . . . . . . . . . . . . . . . . . . . 79

Alarm - Cause - Remedy. . . . . . . . . . . . . . . . 80

Messages in the alarm window . . . . . . . . . . . 80

Messages in the information window . . . . . . 84

Error messages during the device check . . . 85

Cleaning, Disinfection and Sterilization . . 87

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . 88

Reprocessing procedure . . . . . . . . . . . . . . . . 91

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . 95

Maintenance intervals . . . . . . . . . . . . . . . . . . 96

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Starting operation . . . . . . . . . . . . . . . . . . . . . . 46

Instructions for Use Oxylog 2000 plus SW 1.n 3

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Safety information . . . . . . . . . . . . . . . . . . . . . 100

Disposal of batteries . . . . . . . . . . . . . . . . . . . 100

Page 4

Contents

Disposal of the medical device. . . . . . . . . . . . 100

Disposal of the disposable hose system . . . . 101

Technical Data . . . . . . . . . . . . . . . . . . . . . . . 103

Ambient conditions . . . . . . . . . . . . . . . . . . . . . 104

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Performance data. . . . . . . . . . . . . . . . . . . . . . 106

Measured value display . . . . . . . . . . . . . . . . . 107

Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Operating data . . . . . . . . . . . . . . . . . . . . . . . . 109

Device specifications . . . . . . . . . . . . . . . . . . . 111

Materials used . . . . . . . . . . . . . . . . . . . . . . . . 112

Technical Documentation for the Oxylog 2000 plus

according to EMC standard IEC/EN 60601-1-2 113

Principles of Operation . . . . . . . . . . . . . . . . 117

Ventilation modes. . . . . . . . . . . . . . . . . . . . . . 118

Functional description . . . . . . . . . . . . . . . . . . 121

List of Accessories . . . . . . . . . . . . . . . . . . . 123

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

4

Instructions for Use Oxylog 2000 plus SW 1.n

Page 5

For Your Safety and that of Your Patients

For Your Safety and that of Your Patients

Strictly follow these Instructions for Use

WARNING

Any use of the medical device requires full

understanding and strict observation of all

portions of these Instructions for Use. The

medical device is only to be used for the purpose specified under "Intended use"

on page 10 and in conjunction with appropriate patient monitoring.

Strictly observe all WARNING and CAUTION

statements throughout these Instructions for

Use and all statements on medical device

labels.

Maintenance

WARNING

The medical device must be inspected and

serviced regularly by properly trained service

personnel.

Repair of the device may also only be carried

out by properly trained service personnel.

Dräger Medical recommends that a service

contract be obtained with DrägerService and

that all repairs also be carried out by them.

Dräger Medical recommends that only authentic Dräger Medical repair parts be used for

maintenance. Otherwise, the proper functioning of the medical device may be

compromised.

Refer to the chapter "Maintenance"

on page 95 for additional information.

Accessories

WARNING

Only the accessories indicated on the list of

accessories have been tested and approved

to be used with the medical device. Accordingly, it is strongly recommended that only

these accessories be used in conjunction with

the specific medical device. Otherwise, the

correct functioning of the medical device may

be compromised.

WARNING

Any connected devices, or combination of

devices, not complying with the requirements

mentioned in these Instructions for Use may

compromise the correct functioning of the

medical device. Prior to operating the medical

device, consult the respective documentation

and Instructions for Use of all connected

devices or combination of devices.

Not for use in explosion hazard areas

WARNING

This medical device is neither approved nor

certified for use in areas where combustible or

explosive gas mixtures are likely to occur.

Safe connection with other electrical equipment

WARNING

Electrical connections to equipment, which

are not listed in these Instructions for Use,

should only be made following consultation

with the respective manufacturers. Equipment

malfunction may result as well as risk of

patient injury.

Instructions for Use Oxylog 2000 plus SW 1.n 5

Page 6

For Your Safety and that of Your Patients

Patient safety

The design of the medical device, the accompanying literature, and the labeling on the medical

device are based on the assumption that the purchase and use of the equipment are restricted to

trained professionals, and that certain inherent

characteristics of the medical device are known to

the trained operator. Instructions, warnings, and

caution statements are limited, therefore, largely to

the specifics of the Dräger design.

This publication excludes references to various

hazards which are obvious to a medical professional and operator of this medical device, to the

consequences of medical device misuse, and to

potentially adverse effects in patients with abnormal conditions.

Medical device modification or misuse can be dangerous.

CAUTION

Have a supply of extra batteries available.

Patient monitoring

Functional safety

The essential performance of the Oxylog 2000 plus

is defined as:

Accuracy of the delivery of ventilation to the patient

or generation of a technical alarm condition.

The operators of the medical device are responsible for choosing appropriate safety monitoring that

supplies adequate information on medical device

performance and patient condition.

Patient safety may be achieved through a wide

variety of means ranging from electronic surveillance of medical device performance and patient

condition, to simple, direct observation of clinical

signs.

The responsibility for the selection of the best level

of patient monitoring lies solely with the medical

device operator.

6

Instructions for Use Oxylog 2000 plus SW 1.n

Page 7

General WARNINGS and CAUTIONS

For Your Safety and that of Your Patients

The following WARNINGS and CAUTIONS apply to

general operation of the device. WARNINGS and

CAUTIONS specific to subsystems or particular

features appear with those topics in later sections

of the manual.

Note on EMC/ESD risk for the device function

General information on electromagnetic compatibility (EMC) pursuant to international EMC standard

IEC 60601-1-2:

Electromedical devices are subject to special precautionary measures concerning electromagnetic

compatibility (EMC) and must be installed and put

into operation in accordance with the EMC information. Refer to section "Technical Documentation for

the Oxylog 2000 plus according to EMC standard

IEC/EN 60601-1-2" on page 113.

Portable and mobile RF communications equipment can affect medical electrical equipment.

WARNING

Ventilation monitoring is mandatory at all

times! Whenever a patient is connected to the

ventilator, constant attention by qualified

medical staff is required in order to provide

immediate corrective action in case of a

malfunction.

The operator shall not rely on the built-in

monitoring of the ventilator only and must

always assume full responsibility for proper

ventilation and patient safety in all situations.

WARNING

Keep a manual resuscitation bag available!

If a failure is detected in the ventilator and its

life-support functions can no longer be guaranteed (e.g. in case of a power failure or interruption in the medical gas supply), ventilation

must be started without delay with an independent ventilation device (resuscitation bag)

– using PEEP and/or increased inspired O

concentration as necessary.

WARNING

Always use officially approved gas cylinders

and pressure regulators that comply with all

applicable regulations.

WARNING

For proper ventilation, always consider the

dead space of the total ventilation circuit when

setting ventilation parameters,

especially when applying small tidal volumes.

WARNING

Ventilation with increased oxygen concentra-

tions may be harmful to the patient. Oxygen

must be administered by medical professionals only.

2

Installing accessories

CAUTION

Installations to the basic device must be done in

accordance with the Instructions for Use of the

basic device. Make sure that the connection is

securely fitted onto the basic device system.

Strictly follow the Assembly Instructions and

Instructions for Use.

Instructions for Use Oxylog 2000 plus SW 1.n 7

Page 8

For Your Safety and that of Your Patients

Instructions for Use only available once

CAUTION

Only one copy of the Instructions for Use is

included in the clinical package and should therefore be kept in an accessible location for users.

8

Instructions for Use Oxylog 2000 plus SW 1.n

Page 9

Application

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . 10

Indications/Contraindications. . . . . . . . . . . 10

Environment of use . . . . . . . . . . . . . . . . . . . 10

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . 10

Indications/Contraindications. . . . . . . . . . . 10

Environment of use . . . . . . . . . . . . . . . . . . . 10

Application

Instructions for Use Oxylog 2000 plus SW 1.n 9

Page 10

Application

Intended use

The Oxylog® 2000 plus is a time-cycled, volume

controlled emergency and transport ventilator with

pressure support for patients requiring mandatory

or assisted ventilation with a tidal volume of 100 mL

upwards.

For use by and under the supervision of trained

health care professionals.

Indications/Contraindications

For patients requiring a tidal volume of 100 mL

upwards.

WARNING

The Oxylog 2000 plus ventilator may only be

used under the supervision of qualified medical personnel in order to be able to provide

immediate corrective action in case of a malfunction.

Environment of use

For use in the following environments:

– Mobile use for emergency patients, for outdoor

and indoor environments.

– During transport in ambulances or aircraft,

including helicopters.

– In accident and emergency departments.

– When moving ventilated patients around the

hospital.

– In the recovery room.

10

WARNI NG

Do not use the equipment in hyperbaric

chambers!

The device may malfunction, causing danger

to the patient.

WARNI NG

Do not use the equipment in conjunction with

magnetic resonance imaging (MRI, NMR, NMI).

The device may malfunction, causing danger

to the patient.

Instructions for Use Oxylog 2000 plus SW 1.n

Page 11

System Overview

Front panel with all options. . . . . . . . . . . . . 12

Side view, right . . . . . . . . . . . . . . . . . . . . . . . . 13

Rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reusable hose system . . . . . . . . . . . . . . . . . . 14

Disposable hose system. . . . . . . . . . . . . . . . . 14

Available ventilation modes . . . . . . . . . . . . 14

Special modes . . . . . . . . . . . . . . . . . . . . . . . 15

With monitoring . . . . . . . . . . . . . . . . . . . . . . 15

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . 16

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Overview

Instructions for Use Oxylog 2000 plus SW 1.n 11

Page 12

System Overview

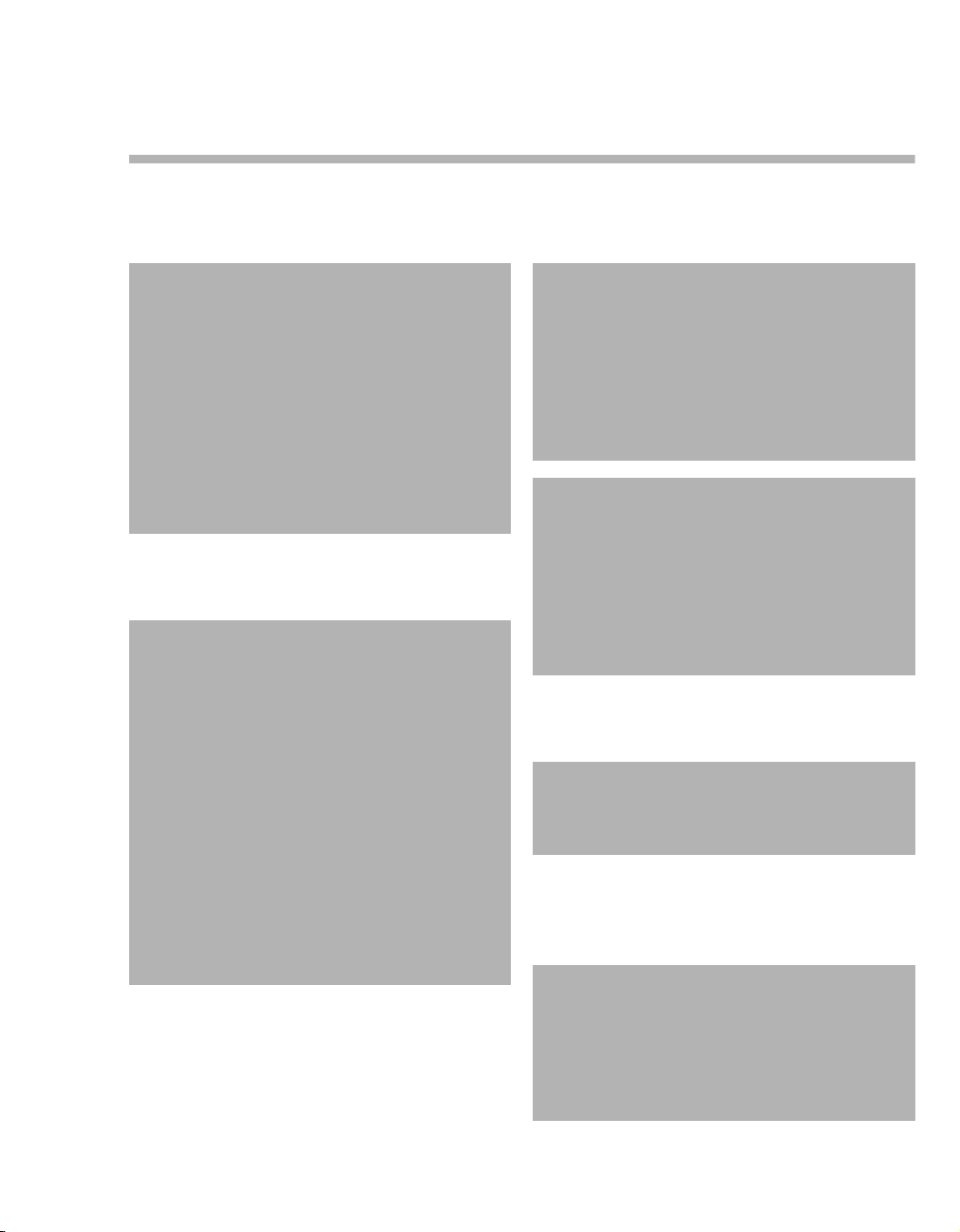

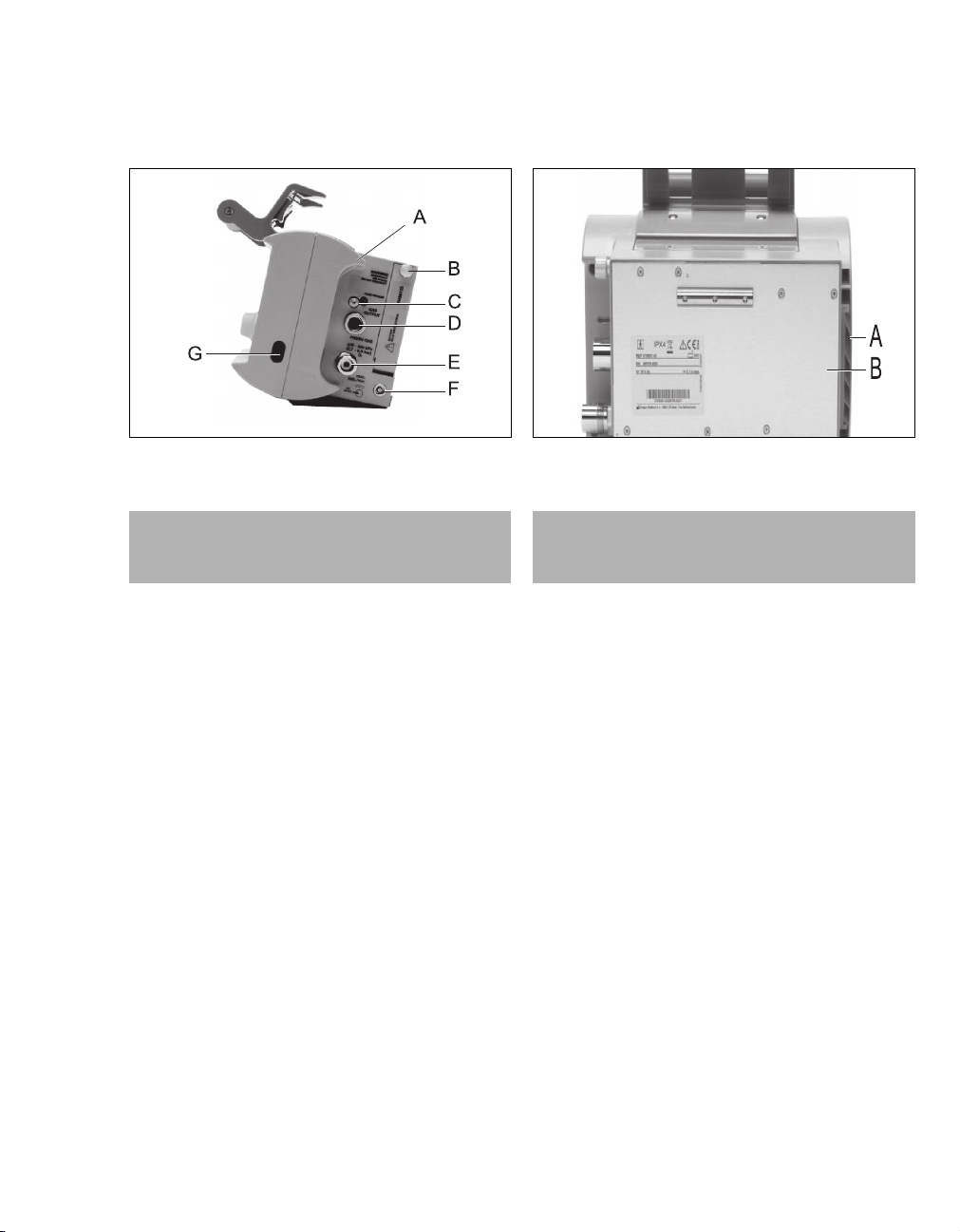

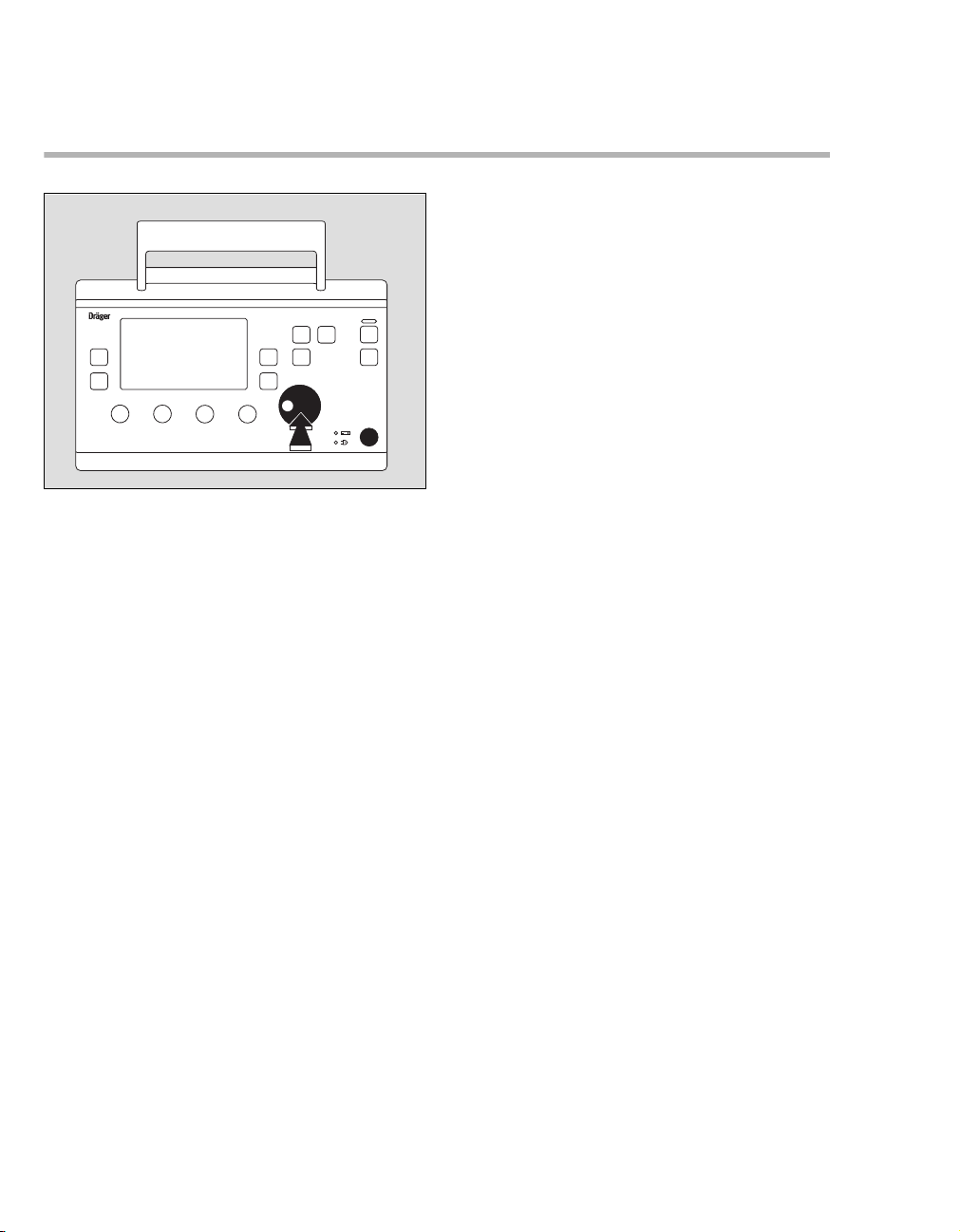

Front panel with all options

A Screen with screen pages for the specific

application

B Key Alarms for setting and displaying

alarm limits

C Key Settings for setting other

ventilation parameters on the screen

D Key for ventilation modes VC-CMV / VC-AC

E Key for ventilation modes VC-SIMV (PS)*

F Key for ventilation modes SpnCPAP (PS)*

G Red and yellow lights (LEDs) as alarm

indicators

H Key to suppress the audible alarm for

2 minutes

I Key Alarm Reset for acknowledging alarm

messages

J Start / Standby key

* VC-SIMV/PS and SpnCPAP/PS are optional features.

O

12

K Display symbols for the power supply

Charge status of the internal battery

N Mains power supply connected

L Central rotary knob for making selections /

settings and for confirming these

M Control knob for setting O

2

FiO

N Control knob for setting the maximum

inspiratory pressure Pmax

O Control knob for setting the ventilation respira-

tory rate RR

P Control knob for setting the tidal volume VT

Q Key Values to select the displayed mea-

sured values

R Key Values to select the displayed mea-

sured MVe or VTe values

Instructions for Use Oxylog 2000 plus SW 1.n

2 AirMix or 100% O2

043

Page 13

System Overview

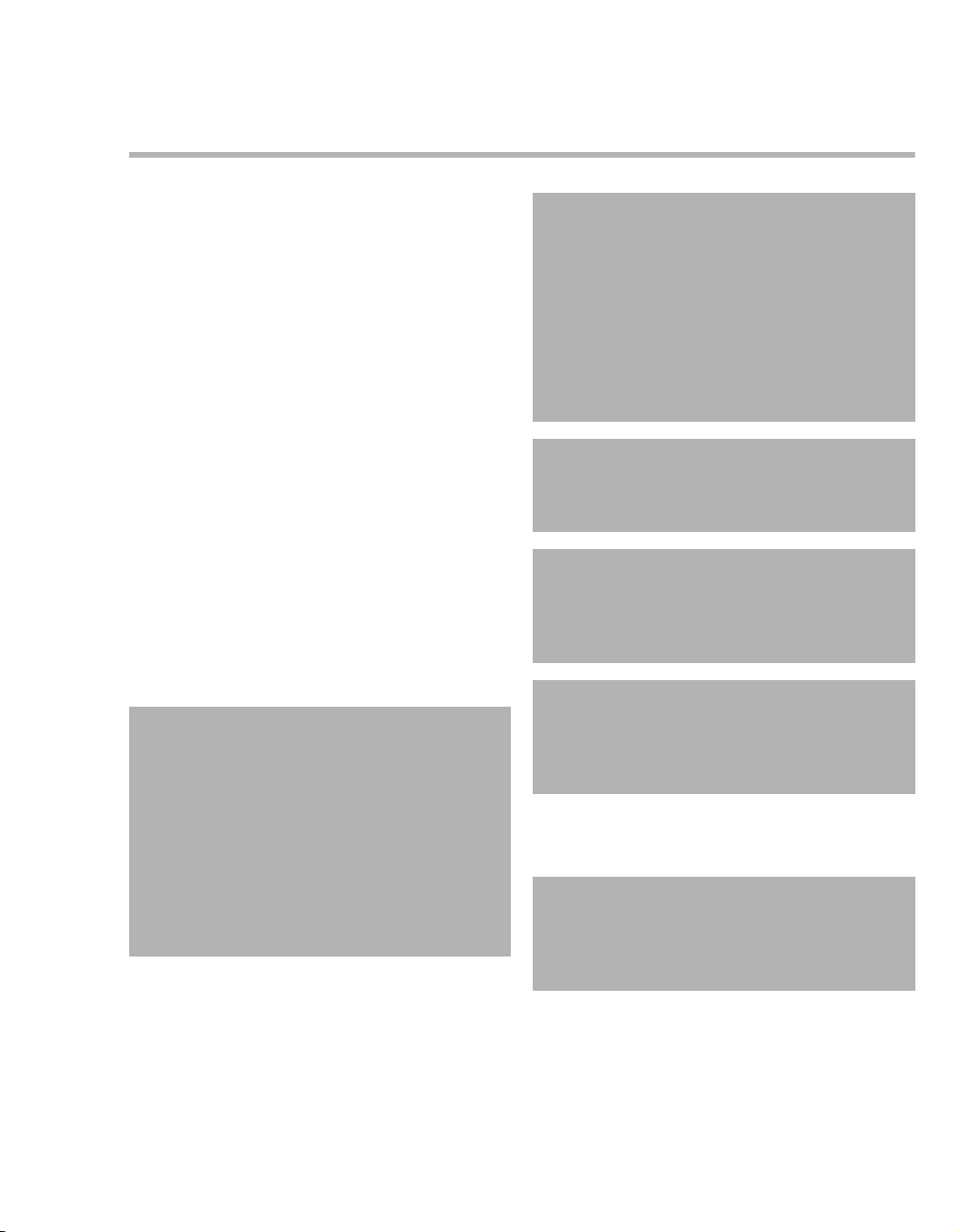

Side view, right

A Emergency air intake

WARNING

Do not block the emergency air intake. This

may result in ventilator malfunction.

B Screw to secure the battery compartment cover

C Gas outlet for flow measuring hoses

D Gas outlet for ventilation hose

E Connector for medical gas hose

F Socket for DC supply

G Window for Infrared Data Association (IrDA)

interface

Rear view

041

A Filter cartridge for intake of ambient air

CAUTION

Do not block the air intake. This may result in

ventilator malfunction.

B Rating plate

042

Instructions for Use Oxylog 2000 plus SW 1.n 13

Page 14

System Overview

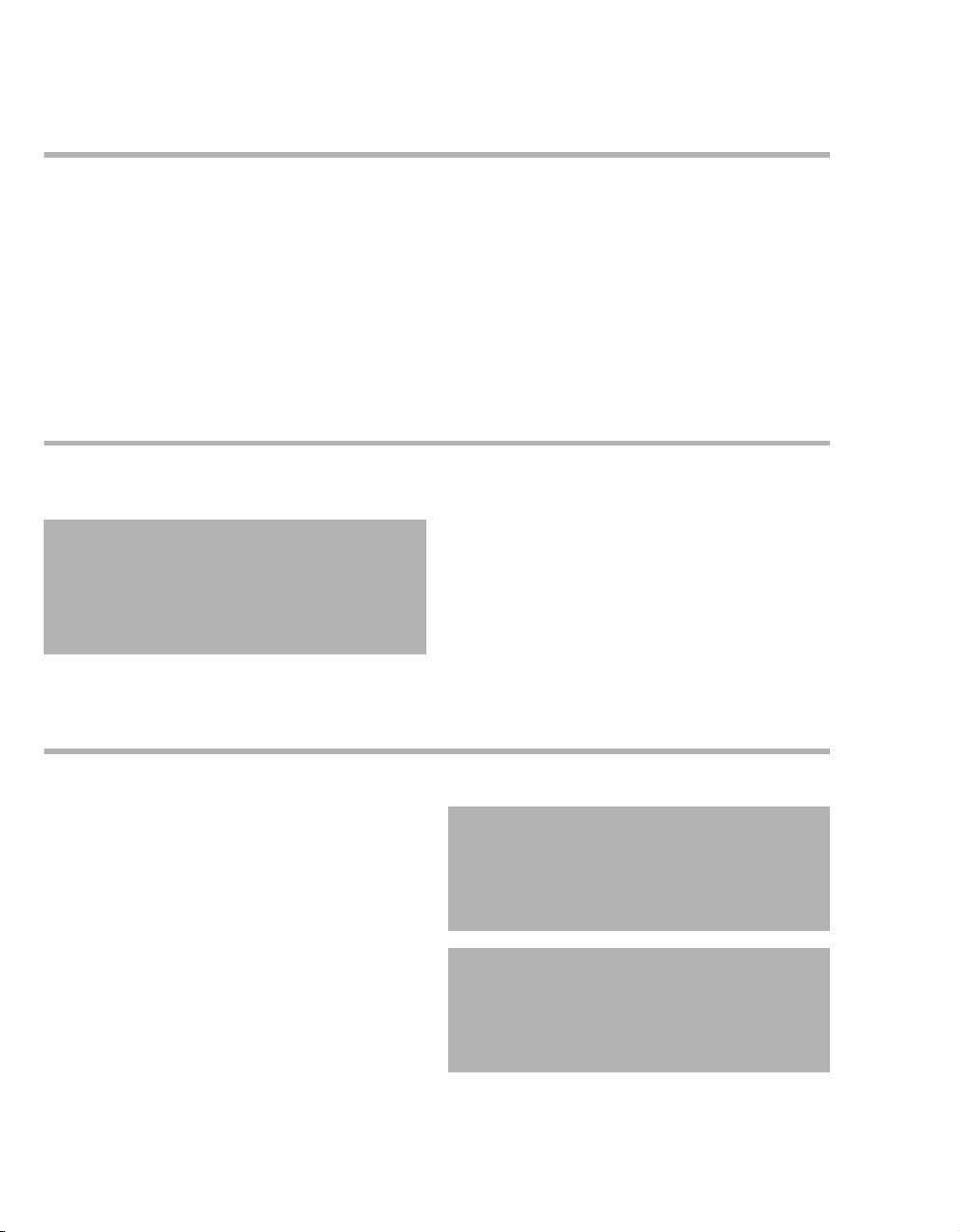

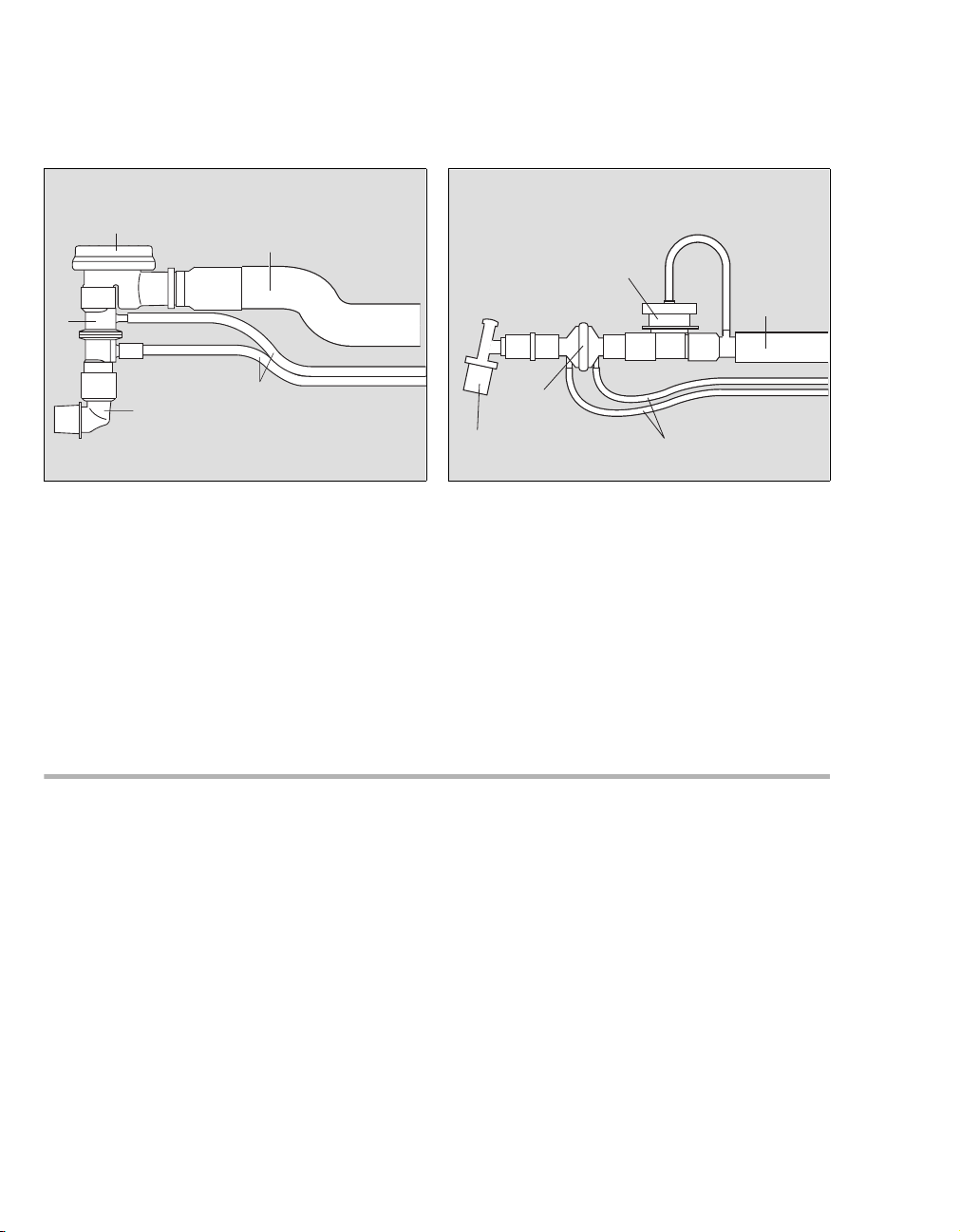

Reusable hose system

A

B

E

D

A Breathing valve

B Ventilation hose

C Flow and pressure measuring hoses

D Angled connector

E Flow sensor

C

Disposable hose system

A

D

E

001

A Breathing valve

B Ventilation hose

C Flow and pressure measuring hoses

D Flow sensor

E Angled connector

C

B

002

Available ventilation modes

– VC-CMV / VC-AC

Volume Controlled - Controlled Mechanical

Ventilation with PEEP.

Volume Controlled - Assist Control with PEEP.

– VC-SIMV (PS)

Volume Controlled - Synchronized Intermittent

Mandatory Ventilation with PEEP

(Optionally with Pressure Support).

Procedure for weaning patients off the ventilator

after they have started spontaneous breathing.

14

– SpnCPAP (PS)

Continuous Positive Airway Pressure

(Optionally with Pressure Support)

Spontaneous breathing with positive airway

pressure.

Instructions for Use Oxylog 2000 plus SW 1.n

Page 15

Special modes

In the ventilation mode SpnCPAP, two special

modes are available.

– Apnea Ventilation

To switch over automatically to volume-controlled mandatory ventilation if spontaneous

breathing stops.

– NIV

For mask ventilation to support non-invasive

ventilation of spontaneously breathing patients

with leakage compensation.

With monitoring

– Airway pressure Paw.

– Expiratory minute volume MVe.

– Apnea.

– Respiratory rate: High respiratory rate alarm.

System Overview

Instructions for Use Oxylog 2000 plus SW 1.n 15

Page 16

System Overview

Abbreviations

Abbreviation Explanation

bpm Breaths per minute

BTPS Body Temperature, Pressure

Saturated

Measured values referred to the conditions of the patient's lung, body

temperature 37

o

C, airway pressure,

water-vapor-saturated gas

C Lung compliance

EN 794-3 European standard for medical

ventilators, Part 3 "Emergency and

transport ventilators"

ESD Electrostatic discharge

∆Psupp Positive pressure above PEEP

FiO2 Fraction of inspiratory oxygen

FRC Functional Residual Capacity

HME Heat Moisture Exchange

I:E Relation inspiratory time to

expiratory time

IrDA Infrared Data Association

MVe Total expiratory minute volume

MVi Total inspiratory minute volume

spon Spontaneous minute volume

MV

NIV Non-invasive ventilation – mask ven-

tilation

2 AirMix Inspiratory gas mixture of O2 and

O

ambient air.

Paw Airway pressure

PEEP Positive end expiratory pressure

PIP Peak inspiratory pressure

Pinsp Inspiratory pressure

Pmax Maximum allowed inspiratory

pressure

Pmean Mean airway pressure

Pplat Plateau pressure

Abbreviation Explanation

PS Pressure Support, pressure assisted

spontaneous breathing

RF Radio Frequency

RR Respiratory Rate (frequency)

RRapn Respiratory Rate during apnea

ventilation

RRsp Spontaneous Respiratory Rate

Slope Speed of which inspiratory flow is

reached

SpnCPAP Continuous Positive Airway

Pressure

Spontaneous breathing with

continuous positive pressure

Tapn Time for apnea alarm

Te Expiratory time

Ti Inspiratory time

Tplat % Plateau time in % of inspiratory time

Taw Airway temperature

VC-AC Volume Controlled

Assist Control with PEEP

VC-CMV Volume Controlled

Controlled Mandatory Ventilation

VC-SIMV Volume Controlled

Synchronized Intermittent

Mandatory Ventilation

VTapn Tidal volume during apnea

ventilation

VT Tidal volume

VTe Expiratory tidal volume

VTi Inspiratory tidal volume

16

Instructions for Use Oxylog 2000 plus SW 1.n

Page 17

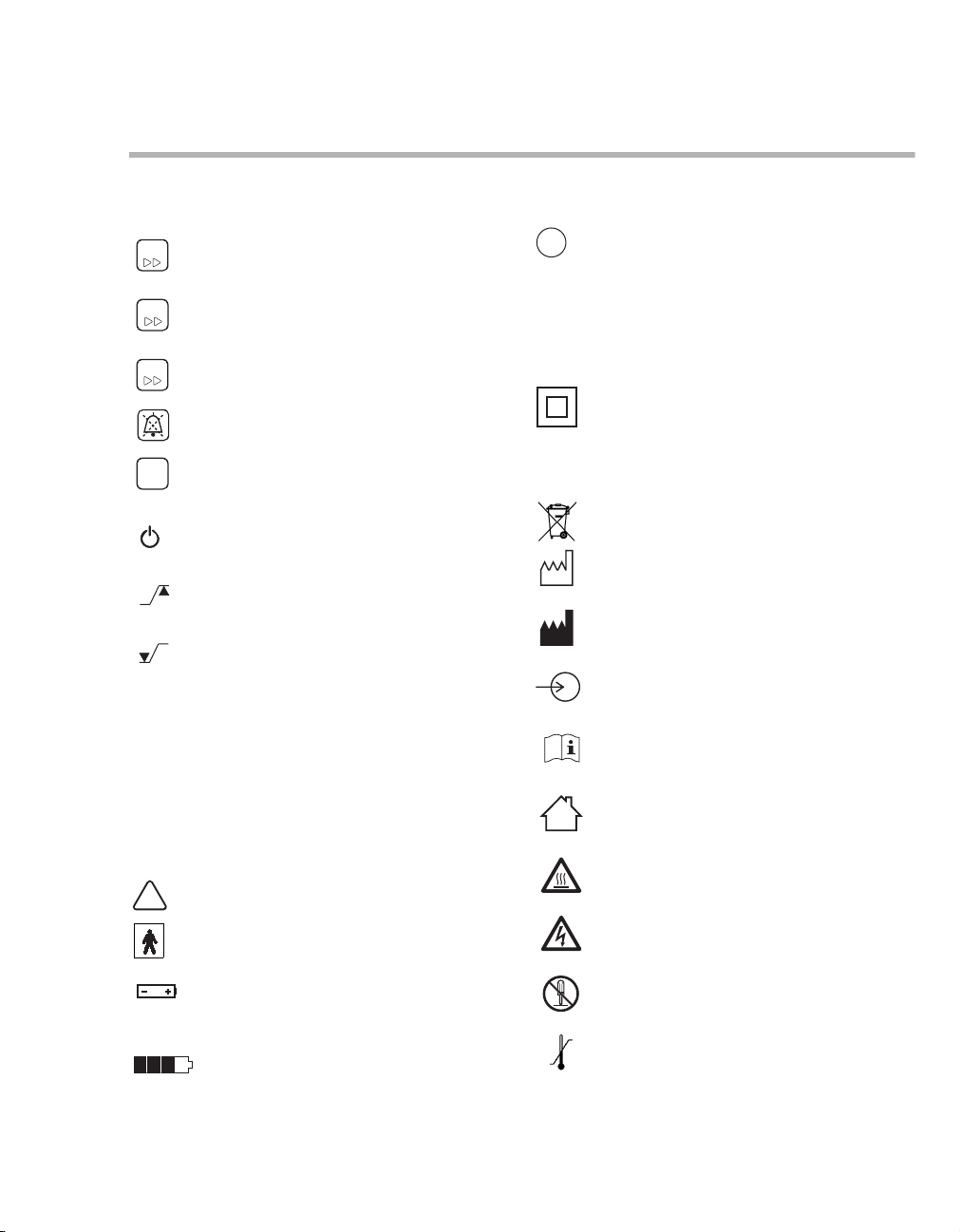

Symbols

System Overview

Symbol Explanation

Settings

Display screen window "Settings"

Alarms

Display screen window "Alarms"

Values

Display screen window measured

"Values"

Suppress audible alarm for

2 minutes

Alarm

Acknowledge alarms

Reset

Start / Standby key

Upper alarm limit only

Lower alarm limit only

! Advisory message

!! Caution message

!!! Warning message

!

Type BF applied part (body

Strictly follow the Instructions for

Use!

floating)

Charge status of the internal

battery

N Mains power supply connected

Battery charge

(example: three quarters full)

Symbol Explanation

E 4 10 R-02 XXXX

The device complies with UN

Regulation no. 10, revision 2 with

respect to EMC for use in motor

vehicles.

IPX4 Device protected from water

sprayed from all directions, limited

entrance allowed.

Class II equipment, device protected against electric shock with

additional safety precautions such

as double or reinforced insulations,

without protective earthing.

Do not dispose of the device as

municipal waste.

Manufacturing date

Manufacturer

DC input

Consult the instructions for use.

Indoor use only

Caution, hot surface!

Warning, dangerous voltage!

Do not open!

Temperature limitations

Instructions for Use Oxylog 2000 plus SW 1.n 17

Page 18

This page intentionally left blank

18 Instructions for Use Oxylog 2000 plus SW 1.n

Page 19

Operating Concept

Switch ON or OFF. . . . . . . . . . . . . . . . . . . . . 20

Switch ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Switch OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ventilation controls . . . . . . . . . . . . . . . . . . . 21

Display operating controls . . . . . . . . . . . . . 22

Changing screen pages in the windows . . . . . 23

Screen window structure. . . . . . . . . . . . . . . 23

Switch ON or OFF. . . . . . . . . . . . . . . . . . . . . 20

Switch ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Switch OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ventilation controls . . . . . . . . . . . . . . . . . . . 21

Display operating controls . . . . . . . . . . . . . 22

Changing screen pages in the windows . . . . . 23

Operating Concept

Screen window structure. . . . . . . . . . . . . . . 23

Instructions for Use Oxylog 2000 plus SW 1.n 19

Page 20

Operating Concept

Switch ON or OFF

Oxylog 2000 plus

B

A

Switch ON

z To switch ON, briefly press the O key (A).

Switch OFF

1 To switch OFF, hold down the O key (A) for

approximately 3 seconds.

2 Press the rotary knob (B) to confirm the switch

OFF process.

003

20

Instructions for Use Oxylog 2000 plus SW 1.n

Page 21

Ventilation controls

Operating Concept

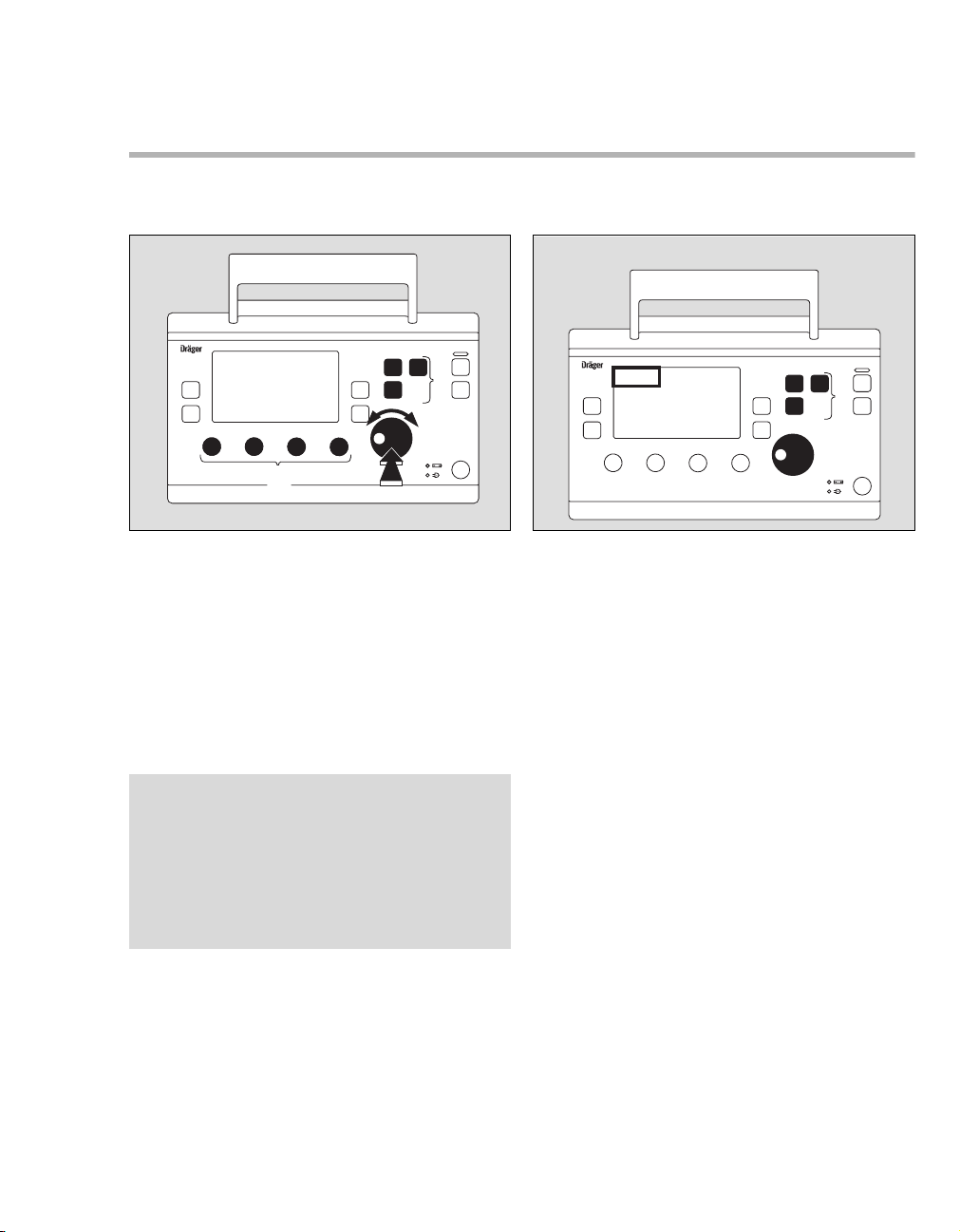

Selecting the ventilation mode

Oxylog 2000 plus

A

C

A Keys for selecting the ventilation modes:

– VC-CMV / VC-AC

– VC-SIMV (optional PS)

– SpnCPAP (optional PS).

B Rotary knob.

C Ventilation parameter controls

– Inspiratory tidal volume VT

– Ventilation respiratory rate RR [/min],

– Maximum inspiratory pressure Pmax [mbar],

2 AirMix or 100% O2 FiO2.

– O

NOTE

Different ventilation modes and their parameters

can be set in the display window via the rotary

knob (e.g. Ti, PEEP, ∆Psupp, Pinsp).

– To select the parameter: turn rotary knob.

– To activate the parameter: press rotary knob.

– To set the value: turn rotary knob.

– To confirm the value: press rotary knob.

B

[mL],

Oxylog 2000 plus

C

A

B

004

z Press the appropriate ventilation mode key (A)

for approximately 3 seconds.

Or

1 Press the appropriate ventilation mode key (A).

2 Press the rotary knob (B) to confirm. The

selected ventilation mode will be activated.

3 The active ventilation mode is displayed in the

upper left corner of the display (C).

Refer to the section "Operation" on page 45 for

additional information on ventilation mode

setting.

005

Instructions for Use Oxylog 2000 plus SW 1.n 21

Page 22

Operating Concept

Routine and additional functions keys

Frequently used keys are positioned on the upper

right corner of the front panel:

Oxylog 2000 plus

A

B

Display operating controls

Oxylog 2000 plus

A

B

C

D

E

A key for suppressing the audible alarm for

2 minutes.

B Alarm Reset key for acknowledging alarm

messages.

006

A Values key; to change screen pages in

the "Measured Values" window, to display MVe

or VTe.

B Values key; to change screen pages in

the "Measured values" window, to display the

measured values.

C Settings key; to change screen pages in

the "Setting" window, to set other ventilation

parameters.

D Alarms key; to change screen pages in

the "Alarms" window, to set and display the

alarm limits.

007

E Central rotary knob for selecting and confirming

options on the display.

22

Instructions for Use Oxylog 2000 plus SW 1.n

Page 23

Changing screen pages in the windows

To advance to the next page in a screen window:

Settings and Alarms window:

1 Press the Settings key to display the

settings pages.

2 Press the Alarms key to display the

alarms pages.

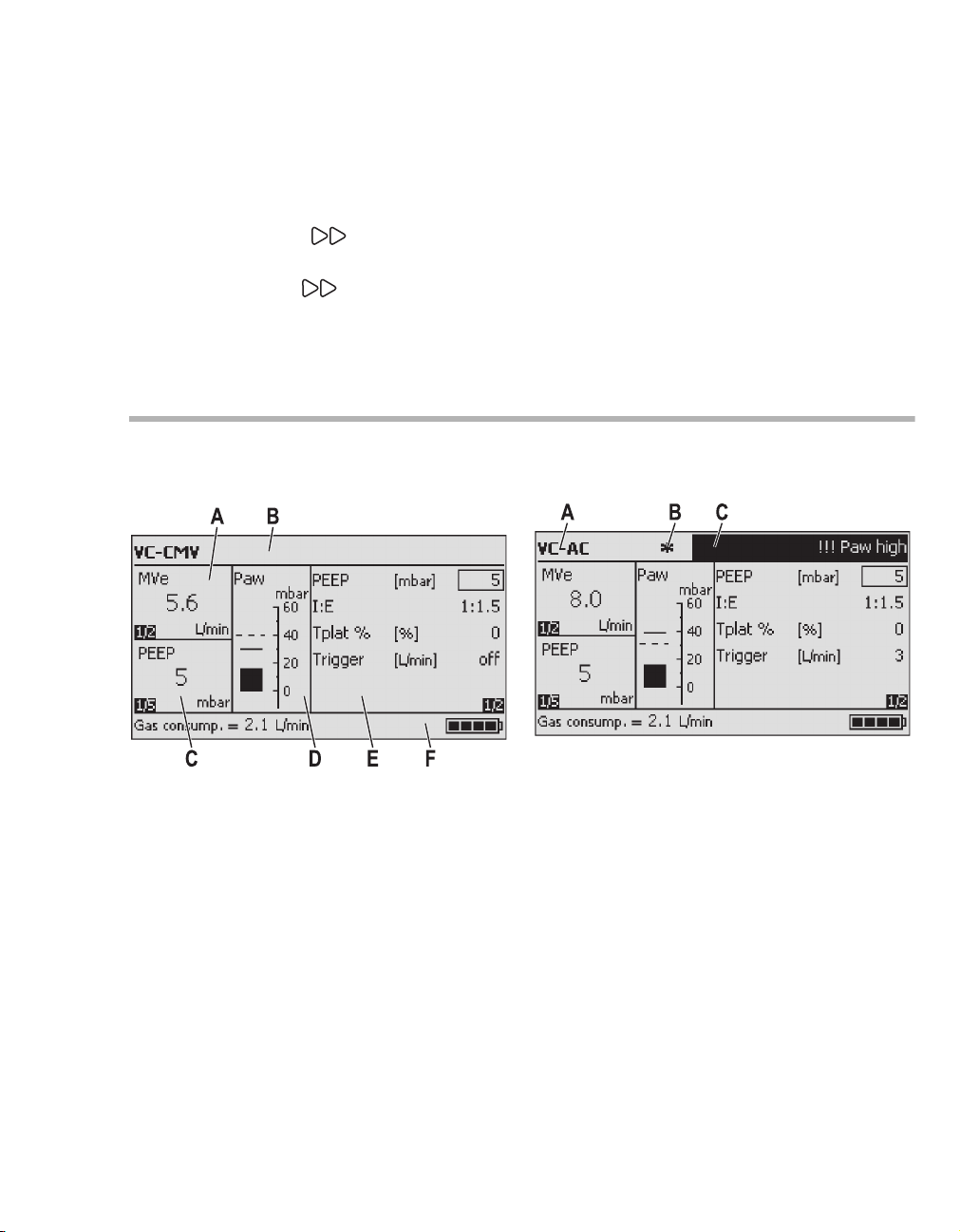

Screen window structure

Operating Concept

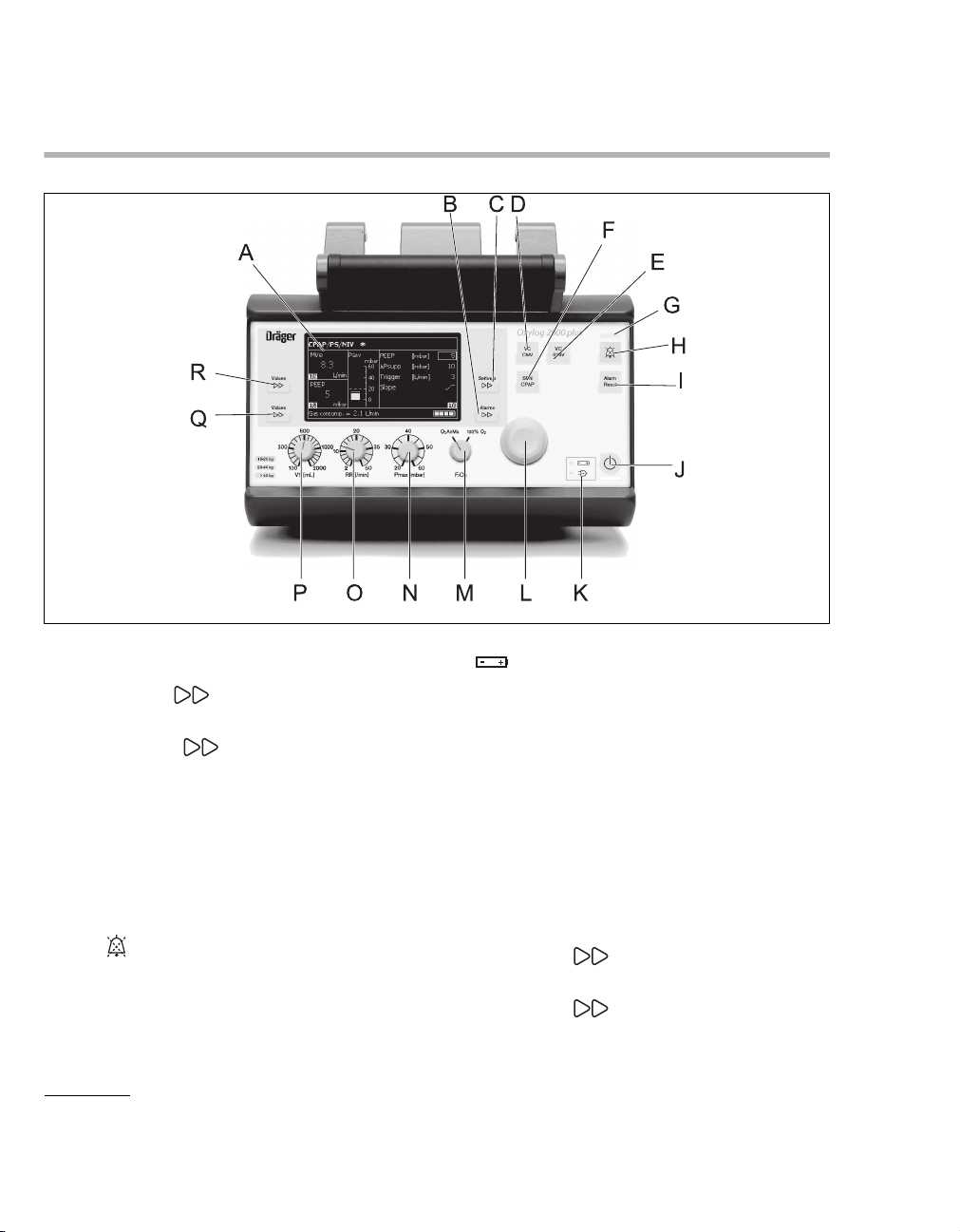

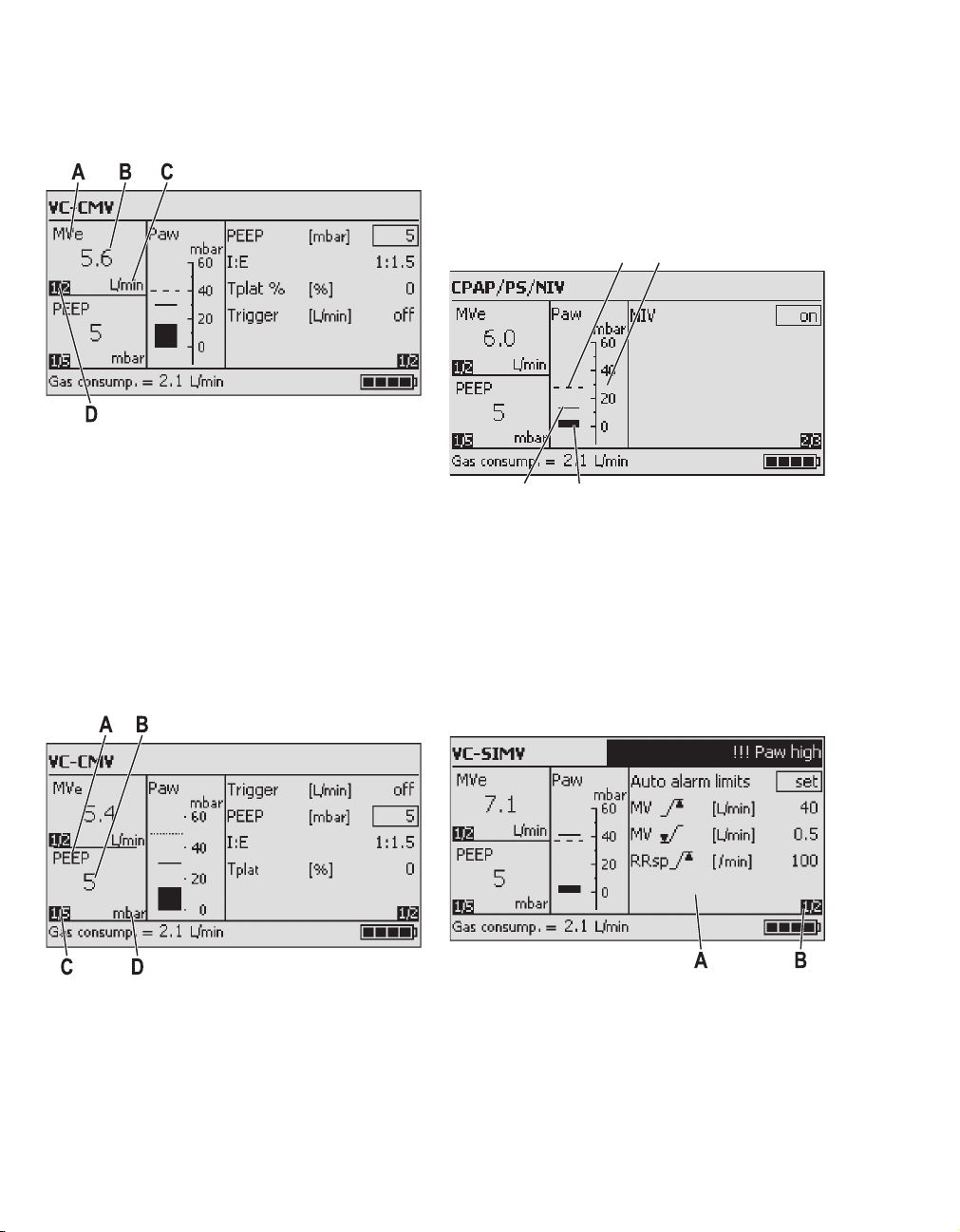

Status and alarm messages window

A Ventilation mode.

A Measured MVe / VTe window.

B Status and alarm message window.

C Measured values window.

D Airway pressure bar graph.

E Settings and alarms window.

F Information window.

Instructions for Use Oxylog 2000 plus SW 1.n 23

B Trigger indicator.

C Alarm window.

Page 24

Operating Concept

MVe / VTe window

A Parameter measured.

B Measured value.

C Unit of measure.

D Page number.

To advance to the next page:

z Press the upper Values key.

Values window

To advance to the next page:

z Press the lower Values key.

Airway pressure bar graph

AB

C D

A Pmax alarm setting.

B Unit of measure scale.

C Pressure measurement of the previous breath.

D Pressure measurement of the current breath.

Alarms window

A Parameter measured.

B Measured value.

C Page number.

D Unit of measure.

24

A Menu for alarm limits and alarm parameters.

For detailed operating instructions, see "Setting

alarm limits" on page 63.

B Page number.

1st page of 2 available pages.

Instructions for Use Oxylog 2000 plus SW 1.n

Page 25

Operating Concept

To advance to the next page:

z Press the Alarms key.

Settings window

A Menu for setting supplementary ventilation

parameters in accordance with the desired ventilation mode:

–I:E

–Ti

–PEEP

– ∆Psupp

– Tapn

– Trigger

– Tplat %

– Slope

–NIV

– Brightness

– RRapn

–VTapn

1st page of 2 available pages.

B Page number.

Messages window

A Numeric values displayed when a control knob

is turned.

Instructions for Use Oxylog 2000 plus SW 1.n 25

Page 26

Operating Concept

Battery capacity indicator

A Battery capacity indicator (example: three quar-

ters full).

O2 consumption

A Actual gas consumption based on current

settings.

26

Instructions for Use Oxylog 2000 plus SW 1.n

Page 27

Assembly

Dead space . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Assemble the reusable hose system . . . . . 29

Breathing valve assembly. . . . . . . . . . . . . . . . 29

When using a bacterial filter or HME . . . . . . . 30

Hose connections. . . . . . . . . . . . . . . . . . . . . . 30

Connect the disposable hose system . . . . 31

When using a bacterial filter or HME . . . . . . . 31

When changing the ventilation hose system . 31

Connecting the power supply . . . . . . . . . . . 32

Internal supply . . . . . . . . . . . . . . . . . . . . . . . . 32

Additional external power supply . . . . . . . . . . 32

Internal supply with rechargeable battery . 32

Replacing the battery . . . . . . . . . . . . . . . . . . . 32

Checking the charge of the battery. . . . . . . . . 32

Installing the battery . . . . . . . . . . . . . . . . . . . . 33

External power supply with DC/DC converter 33

External power supply from mains power (AC/DC

Power pack) . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Assembly

Connecting the gas supply . . . . . . . . . . . . . 34

Supply from an O2 cylinder . . . . . . . . . . . . . . 35

Supply from a piped medical gas system . . . . 35

Hanging the Oxylog 2000 plus on standard rail

systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Instructions for Use Oxylog 2000 plus SW 1.n 27

Page 28

Assembly

Reusable or disposable hose systems can be used

with Oxylog 2000 plus. Please refer to the "List of

Accessories" section for ordering information.

NOTE

If the type of the hose system used is changed, the

device must be reconfigured. Refer to the

"Configuration" section for additional information.

Dead space

Dead space is an important aspect of ventilation

management:

Dead space ventilation is the portion of the respiratory system, in which no significant gas exchange

occurs. An increase of the proportion of dead space

to alveolar ventilation may lead to an increase of

the retention of carbon dioxide by the patient.

Dead space is present as a component of the

patient’s artificial airway and hose system. If the

volume of the mechanical dead space equals or

exceeds the volume of alveolar ventilation, the

patient may not be able to adequately evacuate

carbon dioxide. Therefore, it is important to properly manage the ventilation perfusion ratio to

ensure effective elimination of carbon dioxide

gases.

28

Instructions for Use Oxylog 2000 plus SW 1.n

Page 29

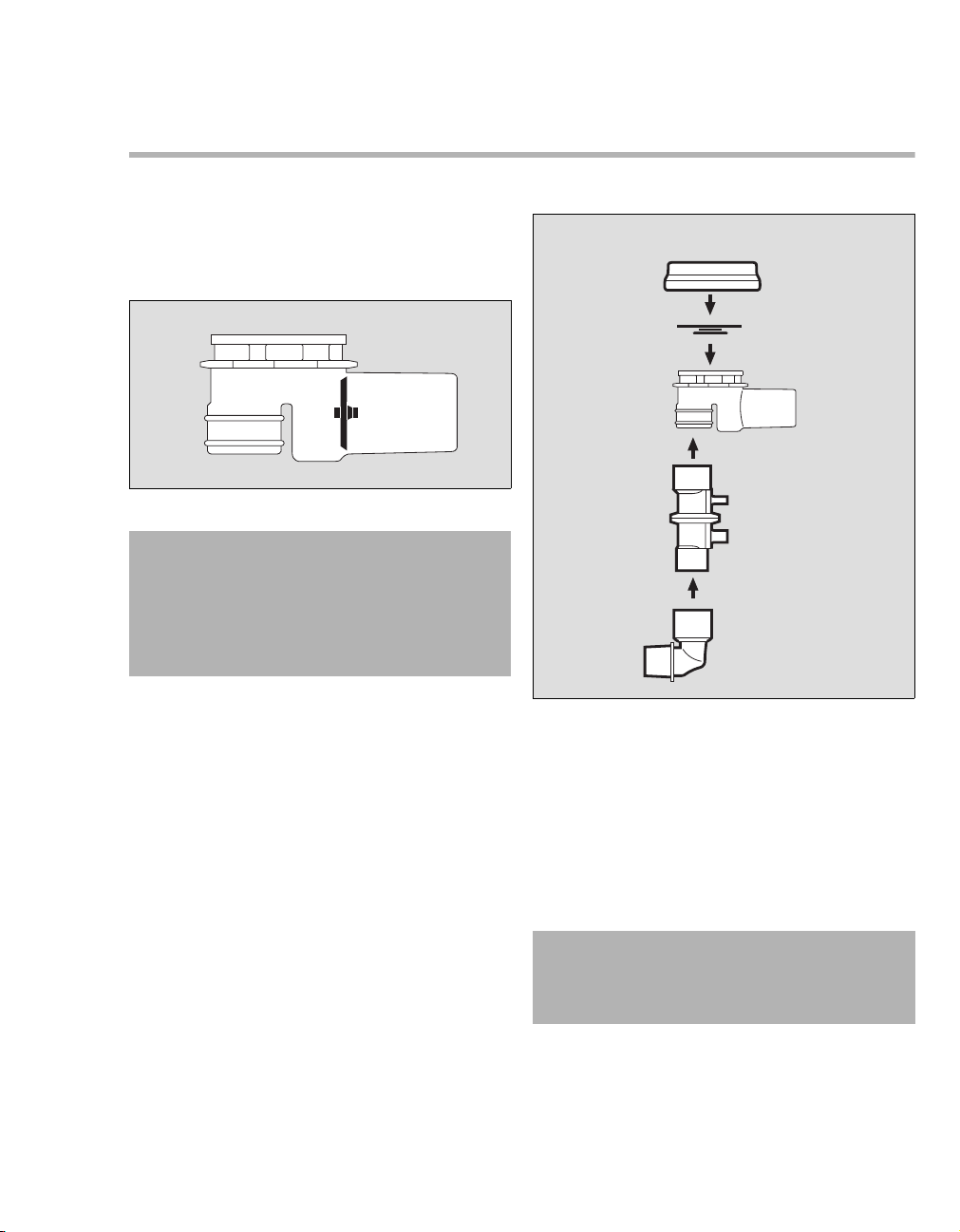

Assemble the reusable hose system

– Parts must always be sterilized before use!

Assembly

Breathing valve assembly

A

WARNING

The rubber disc (A) in the housing may not be

removed, damaged or bent, otherwise the

valve will not work properly and will endanger

the patient.

Risk of CO2 rebreathing.

A

B

008

C

D

1 Place the diaphragm (B) in the breathing valve.

Ensure that it is inserted correctly.

2 Fit the cover (A) and turn it approximately 90

clockwise to secure into position.

3 Push the flow sensor (C) into breathing valve.

Note the preferred position as indicated by the

groove.

4 Connect the angled adaptor (D) to the flow sen-

sor.

WARNING

Always use an angled adaptor. If the angled

adaptor is not used, the minute volume may

be measured incorrectly.

009

o

Instructions for Use Oxylog 2000 plus SW 1.n 29

Page 30

Assembly

When using a bacterial filter or HME

NOTE

When using a bacterial filter or HME, measured

flows may deviate from the expiratory flows, as

temperature and humidity of the gas are reduced.

z Connect the bacterial filter or HME to the angled

connector.

WARNING

Bacterial filters increase the exhalation resis-

tance and dead space volume of the ventilation system.

CAUTION

Do not use electrically conductive hoses!

Risk of electric shock.

This can endanger the patient.

A

B

010

Hose connections

A

B

B

1 Connect the ventilation hose (A) to the

breathing valve.

2 Connect the flow measuring hoses (B) to the

nozzles on the flow sensor. Note the different

diameters.

30

012

3 Connect the flow measuring (A) hoses to the

Oxylog 2000 plus.

4 Connect the ventilation hose (B) to the gas out-

put on the Oxylog 2000 plus.

011

Instructions for Use Oxylog 2000 plus SW 1.n

Page 31

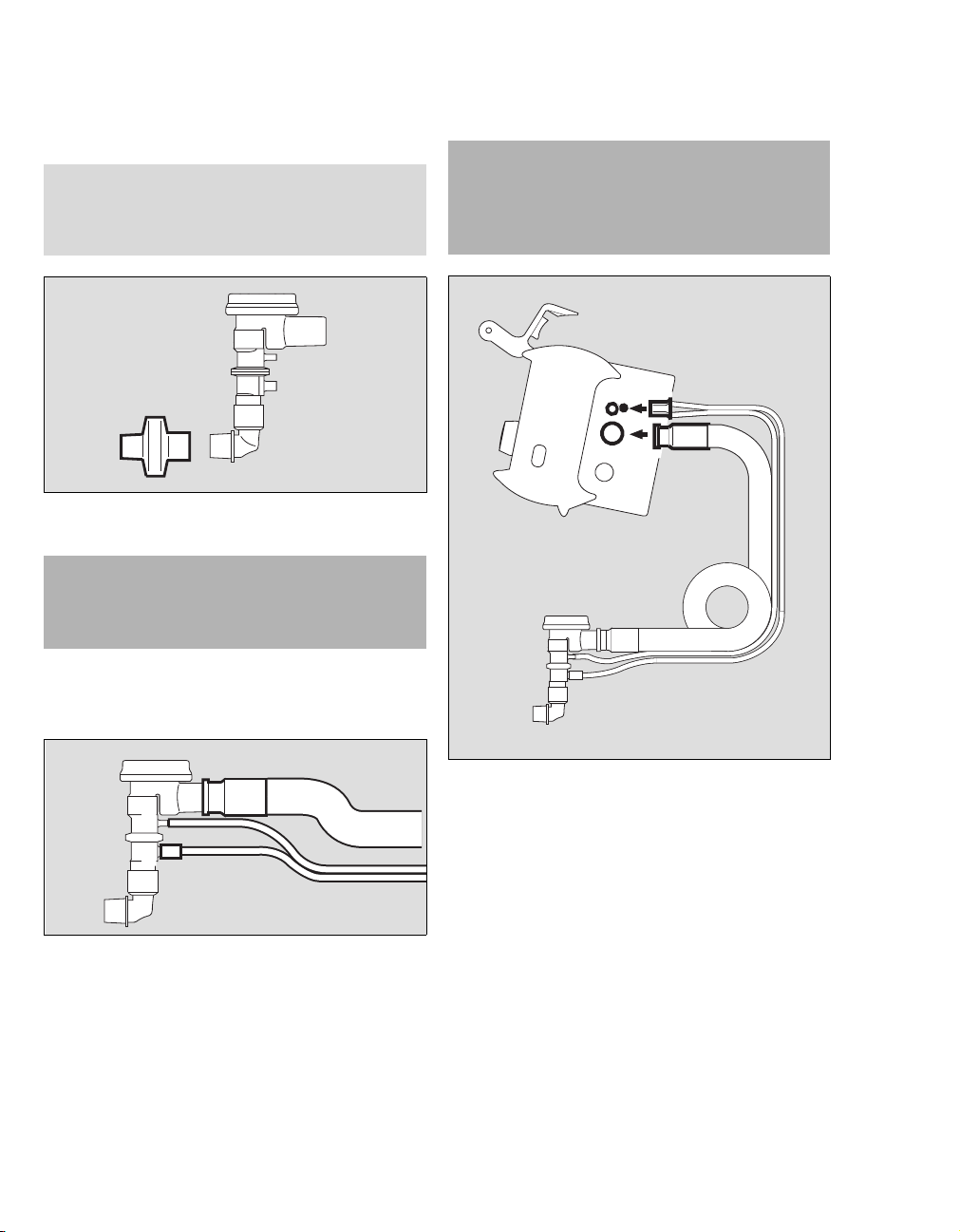

Connect the disposable hose system

WARNING

Do not use disposable hose systems other

than those on the "List of Accessories". The

minute volume may be measured incorrectly

and the device may malfunction.

A

B

C

Assembly

When using a bacterial filter or HME

NOTE

When using a bacterial filter or HME, measured

flows may deviate from the expiratory flows, as

temperature and humidity of the gas are reduced.

WARNING

Ensure that the flow measuring hoses are cor-

rectly positioned, otherwise the volume will be

measured incorrectly.

1 Connect the blue flow measuring hose (B) to

the blue gas outlet.

2 Connect the transparent flow measuring hose

(A) to the other gas outlet.

3 Connect the ventilation hose (C) to the gas out-

let on the Oxylog 2000 plus.

z Connect the bacterial filter or HME.

WARNING

Bacterial filters increase the exhalation resis-

tance and dead space volume of the ventilation equipment.

013

When changing the ventilation hose system

If the reusable ventilation hose system is to be used

instead of a disposable hose system or vice versa:

1 Have the nozzles on the device changed by

trained service specialists.

2 Reconfigure the device accordingly. Refer to

the "Customer Service Mode" on page 72 for

additional information.

014

Instructions for Use Oxylog 2000 plus SW 1.n 31

Page 32

Assembly

Connecting the power supply

The Oxylog 2000 plus is designed to operate on

power supplies with different voltages.

Internal supply

– With rechargeable battery (specified Smart

Battery, refer to the "Technical Data"

on page 103 for additional information).

Additional external power supply

To recharge the battery and to extend the electrical

operation time.

– DC voltage from the on-board power supply via

DC/DC converter or

– with AC/DC power pack

WARNI NG

A fully charged battery must always be

installed for safety reasons, even when operating from an external power supply!

To have a fully charged battery on hand, refer to the

"Getting started" section on page 38 for additional

information.

WARNI NG

Treatment of batteries:

– Do not throw into fire,

– Do not force open,

Danger of bodily injury.

Internal supply with rechargeable battery

Replacing the battery

1 Loosen the screw (C) on the battery compart-

2 Remove the battery cover.

3 Remove the battery (A) by pulling the tab.

ment cover (B) counterclockwise to release the

cover.

32

B

C

A

Checking the charge of the battery

z Press the button on the rechargeable battery.

The charge status is indicated as a percentage

by LEDs.

015

Instructions for Use Oxylog 2000 plus SW 1.n

Page 33

Installing the battery

1 Insert a fully charged battery into the battery

compartment.

2 Attach the connector at the bottom.

3 Turn the cover upwards.

4 Tighten the screw.

WARNING

The Oxylog 2000 plus will interrupt ventilation

when the battery is replaced while the device

is switched on and the external power supply

is not connected. Ventilation will resume with

the last values settings approximately 3 seconds after inserting the battery.

NOTE

It is recommended to use fully charged internal

batteries.

External power supply with DC/DC converter

Assembly

12 V DC

24 V DC

Oxylog 2000 plus

28 V DC

A

B

C

1 Plug the large connector (A) of the DC/DC con-

verter into the on-board supply.

2 Plug the small connector (B) into the DC nozzle

of the Oxylog 2000 plus.

3 When the Oxylog 2000 plus is connected to an

external supply, the indicator

and displays the internal battery status.

N (C) lights up

016

WARNING

Use only a specified DC/DC converter.

Otherwise the device can malfunction.

Refer to the "List of Accessories" on page 108

for additional information.

The DC/DC converter must be used to connect the

Oxylog 2000 plus to on-board supplies of different

voltages (12 V, 24 V, 28 V DC).

The voltage of the on-board supply may fluctuate,

depending on the amount of power required. The

supply voltage may fall below or exceed the range

permitted by the Oxylog 2000 plus. The on-board

voltage is converted into a constant DC voltage of

approximately 19 V DC by the DC/DC converter:

– When connected to an external power supply

(e.g. the on-board power supply of the vehicle),

the ventilator must always be connected via the

DC/DC converter, refer to the "List of Accessories" on page 123 for additional information.

Instructions for Use Oxylog 2000 plus SW 1.n 33

External power supply from mains

power

WARNING

Use only a specified AC/DC power pack

equipped with a correct mains plug.

Otherwise the device can malfunction.

Refer to the "List of Accessories" on page 108

for additional information.

WARNING

The AC/DC power pack may not be used

outdoors.

Risk of electric shock or equipment damage.

(AC/DC Power pack)

Page 34

Assembly

Oxylog 2000 plus

1 Connect the mains plug (A) to the mains outlet.

2 Connect the DC plug (B) to the DC outlet on the

A

Oxylog 2000 plus.

3 When the Oxylog 2000 plus is connected to an

external supply, the indicator

and displays the internal battery status.

N (C) lights up

C

B

Connecting the gas supply

Take care when handling O2:

WARNING

Secure O2 cylinders so they cannot fall over

and keep away from excessive heat.

Risk of explosion!

WARNING

Do not grease or lubricate O2 fittings, such as

cylinder valves and pressure reducers and do

not handle with greasy hands.

Risk of fire!

WARNING

Operate cylinder valves by hand and rotate

smoothly to prevent the risk of fire or

explosion.

Do not use tools.

017

WARNI NG

Only use medical grade oxygen that is dry and

free from dust and oil.

Contaminated gas can cause device

malfunction.

WARNI NG

Always provide adequate ventilation in order

to maintain ambient O2 concentration < 24%,

to prevent risk of fire.

WARNI NG

Always use extreme caution when using oxy-

gen, to prevent risk of fire.

WARNING

No smoking or open flames.

O

2 is combustible and can intensity fires.

34

Instructions for Use Oxylog 2000 plus SW 1.n

Page 35

Assembly

Supply from an O2 cylinder

WARNING

Only use compressed gas cylinders and pressure reducers, which comply with all applicable

regulations and have been approved.

1 Use a full O2 cylinder.

2 Connect the pressure reducer (270 to 600 kPa

delivery pressure, 500 kPa nominal pressure)

to the O

WARNING

Only use a pressure reducer with a relief valve at

the outlet to limit the delivery pressure to a maximum of 1000 kPa in case of a malfunction, to

prevent damage to the ventilator!

2 cylinder.

5 Rotate the cylinder valve (C) slowly and open

fully.

CAUTION

Do not connect flow control valves or flowmeters

in the gas supply to Oxylog 2000 plus.

The ventilator could malfunction!

WARNING

Always check the O2 pressure of cylinder

before use, to prevent insufficient oxylog supply during use.

Supply from a piped medical gas system

A

A

C

B

B

2

O

1 Connect the O2 medical gas hose (A) to the

Oxylog 2000 plus.

018

3 Connect the O2 medical gas hose (A) to the

Oxylog 2000 plus.

4 Connect the O

sure reducer (B).

Instructions for Use Oxylog 2000 plus SW 1.n 35

2 medical gas hose to the pres-

2 Connect the gas hose (B) to the O2 terminal unit

until the supply of O2 is confirmed.

019

Page 36

Assembly

Hanging the Oxylog 2000 plus on standard rail systems

The Oxylog 2000 plus can be hung on various rail

systems measuring up to 35 mm diameter by

means of the claw.

– Ensure that the rail is completely inserted in the

claw.

– To ensure optimal functioning of the claw, a dis-

tance of at least 25 mm between rail and wall is

required.

CAUTION

The Oxylog 2000 plus is only held by its own

weight when hung on a bar or rail. The Oxylog

2000 plus must be secured additionally when

being transported, otherwise vibrations may

cause accidental dislodgement.

36

Instructions for Use Oxylog 2000 plus SW 1.n

Page 37

Getting Started

Charging the battery . . . . . . . . . . . . . . . . . . 38

Indication of battery capacity / battery operation 38

Determining the approximate pneumatic oper-

ating time for the Oxylog 2000 plus . . . . . . 39

Checking readiness for operation . . . . . . . 40

Perform device check . . . . . . . . . . . . . . . . . 41

Connect the test lung . . . . . . . . . . . . . . . . . . . 41

Switch ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Check connections . . . . . . . . . . . . . . . . . . . . . 42

System check . . . . . . . . . . . . . . . . . . . . . . . . . 42

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 43

Preparation for use after system check . . . 43

Getting Started

Instructions for Use Oxylog 2000 plus SW 1.n 37

Page 38

Getting Started

Charging the battery

The actual screen display may differ in appearance

or configuration.

CAUTION

The ambient temperature must be between

0 and 35

o

C when charging the batteries.

When an external supply is available:

Oxylog 2000 plus

A

B

1 The green lamp N (B) lights up when the bat-

tery is actively charging.

2 A three colored indicator (A) lights up to

show the current charge status of the internal

battery:

– Green: when the battery has been fully

charged.

– Yellow: while the battery is being charged.

– Red: if a battery has not been inserted or a

technical failure occurred.

– Indicators (A) and (B) remain off while the

ventilator is being operated from the internal

battery.

Indication of battery capacity / battery operation

The remaining capacity of the battery is indicated

by Oxylog 2000 plus in 25% increments in the lower

right section of the information window when power

is ON:

– when charging from an external power supply,

– as the battery is discharged during operation.

Example: 75% charge

020

– The accuracy of the battery capacity indicator

can vary, depending on the age and condition of

the battery. Refer to "Technical Data"

on page 103 for additional information.

– The capacity indication is overwritten if higher

priority messages are activated.

– Additional alarms can draw attention to the

remaining operating time of the battery.

– When operated via the rechargeable battery,

the brightness of the ventilator screen is

reduced in order to save power.

– The screen brightness is automatically

increased to maximum for one minute while

settings are being made.

An external battery charging station connected to

the mains supply can be used to charge an extra

battery. Refer to the "List of Accessories"

on page 123 for additional information.

38

Instructions for Use Oxylog 2000 plus SW 1.n

Page 39

Determining the approximate pneumatic operating time for the Oxylog 2000 plus

Getting Started

Example for supply of medical gas:

– Cylinder pressure measured on the pressure

gauge of the pressure reducer: 2000 kPa

– Liquid capacity of the O

2 cylinder: 2.1 L

Supply of medical gas:

2.1 L x 2000 kPa = approximately 420 L

Example for pneumatic operation time:

– VC-CMV mode, respiratory rate

10 breaths /min, VT = 1 L, O

2 = 100%

– Minute volume = 10 breaths /min x 1 L =

10 L/min

Operation time =

Calculated with average gas consumption of

*

ventilator: 0.5 L/min

Operation time = = approx. 40 minutes

Medical gas supply [L]

(MV +0.5*) [L/min]

420

10.5

Example:

2 consumption = 2.1 L/min

O

The pneumatic operation time increases when

Oxylog 2000 plus operates with O2 AirMix, as

ambient air is drawn into the device.

The amount of gas from the high-pressure supply,

which is currently being consumed, is indicated by

the Oxylog 2000 plus in the lower left section of the

information window in L/min. This display is overwritten when a higher priority message is activated.

Instructions for Use Oxylog 2000 plus SW 1.n 39

Page 40

Getting Started

Checking readiness for operation

– Whenever the ventilator has been serviced or

the ventilation hoses changed.

– At the latest every six months.

The following functions are checked with the menubased test:

– Gas supply present.

– Hose system / breathing valve connected and

OK.

– Alarm functions OK.

– Ventilation functions OK.

– Monitor functions OK.

Oxylog 2000 plus interrupts the test if a fault is

detected.

The relevant fault is indicated on the screen.

WARNING

The patient may be endangered if the above

device check is not completed.

40

Instructions for Use Oxylog 2000 plus SW 1.n

Page 41

Perform device check

Getting Started

The device check consists of the following steps.

– Duration is approximately 3 minutes.

Connect the test lung

A

B

C

1 Connect the angled adapter (A) to the

breathing valve.

2 Connect the catheter connector (B), diameter

7 mm, to the angled adapter.

The catheter connector simulates the

resistance of the airways.

3 Connect the test lung (C).

Switch ON

Oxylog 2000 plus

A

B

1 To switch ON briefly press the O key (B).

The device performs a self-test and the

operator is prompted, on the display, to activate the

021

configuration menu or device check:

Press rotary knob for device check and

configuration

022screen 6

CAUTION

BTPS values of a test lung are not the same as the

BTPS values of a patient. The Oxylog 2000 plus

measures and adapts according to BTPS values of

a patient. Therefore, when a test lung is connected, the MVe and VTe indicated on display may

differ from the MVe and VTe that is set by the

operator.

Instructions for Use Oxylog 2000 plus SW 1.n 41

2 Press the rotary knob (A) to confirm, before the

bar is full.

3 Select Device check in the main menu and

confirm.

NOTE:

The device check can be discontinued at any time

by pressing the Alarm Reset key.

Page 42

Getting Started

Check connections

1 Ensure that the gas supply has been

connected.

2 Ensure that the test lung has been connected.

The Oxylog 2000 plus automatically checks if a test

lung has been connected. The device check is

aborted if a test lung is not detected within one

minute.

The check is continued when the test lung is

detected.

3 Ensure that the configured hose system has

been connected, either

– the disposable hose system

or

– the reusable hose system.

4 Confirm the appropriate hose system. The sec-

ond page of the device check appears.

If the wrong hose system has been configured:

1 Press the Alarm Reset key to cancel the device

check.

2 Select the correct hose system. Refer to "Select

hose type" on page 74.

3 Restart the device check.

System check

Oxylog 2000 plus

A

023

1 Set the controls (A) below the display to the

required values.

The Oxylog 2000 plus successively activates the

audible and visual alarm signals and prompts the

operator to acknowledge each signal.

2 Confirm the audible and visual alarm signals.

The device check continues automatically.

During the automatic test sequence, the Oxylog

2000 plus checks the flow, pressure levels and

alarm signals. Corresponding sounds are heard.

The bar graph shows the progress made by the

check.

The result is displayed on the Oxylog 2000 plus.

3 Confirm. The system returns to the menu

screen.

A monthly check of the power failure alarm is

recommended.

1 Disconnect the external power supply.

2 Remove the battery to activate the audible

alarm signal.

3 Listen for the audible alarm.

NOTE:

Contact DrägerService if no alarm is heard.

42

4 When the power failure alarm test is completed,

reinstall the battery into the battery compart-

ment of the Oxylog 2000 plus.

Instructions for Use Oxylog 2000 plus SW 1.n

Page 43

Getting Started

Troubleshooting

WARNING

The ventilator is ready for operation only after

all functional tests have been successfully performed.

If the device check is not completed successfully:

1 Refer to "Error messages during the device

check" on page 85 of the section "Problem

Solving".

2 Check the configuration, please refer to the

"Operation" section.

3 Contact your local DrägerService for support.

Preparation for use after system check

1 Assemble the Oxylog 2000 plus for

operation. Refer to the "Assembly" section.

2 Connect to the power supply and gas supply.

Refer to the "Connecting the power supply"

section.

3 Start the ventilator:

z Select Ventilation from the device check

and confirm.

Or

z Press the Alarm Reset key.

Instructions for Use Oxylog 2000 plus SW 1.n 43

Page 44

This page intentionally left blank

44 Instructions for Use Oxylog 2000 plus SW 1.n

Page 45

Operation

Starting operation. . . . . . . . . . . . . . . . . . . . . 46

Switch ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Preparing ventilation mode . . . . . . . . . . . . . 47

To activate the ventilation mode . . . . . . . . . . . 47

Set ventilation parameters . . . . . . . . . . . . . . . 47

VC-CMV / VC-AC. . . . . . . . . . . . . . . . . . . . . . 48

Trigger (VC-AC) . . . . . . . . . . . . . . . . . . . . . . . 49

For heart-lung resuscitation . . . . . . . . . . . . . . 49

VC-SIMV (optional PS) . . . . . . . . . . . . . . . . . 50

Pressure support (optional) . . . . . . . . . . . . . . 51

SpnCPAP (optional PS) . . . . . . . . . . . . . . . . 52

Apnea ventilation . . . . . . . . . . . . . . . . . . . . . . 52

Pressure support (optional) . . . . . . . . . . . . . . 53

NIV – Non-invasive ventilation Mask ventilation

(optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operation

O2 AirMix or 100% O2 . . . . . . . . . . . . . . . . . 55

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Screen brightness . . . . . . . . . . . . . . . . . . . . 56

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Instructions for Use Oxylog 2000 plus SW 1.n 45

Page 46

Operation

Starting operation

The actual screen display may differ in appearance

or configuration.

WARNING

Only use a ventilator that has been cleaned

and successfully tested for operation, to prevent a health risk for the patient and user.

Switch ON

Oxylog 2000 plus

screen 6

Upon completion of the self-test, the ventilator

automatically begins ventilation with the default

settings.

The opening display with configured settings is

displayed if the central rotary knob is not pressed.

A

z Briefly press the O key (A).

The Oxylog 2000 plus performs a self-test.

– The sef-test will be completed in approxi-

mately six seconds.

During the self-test, the system briefly displays the

starting page with the software version and a

prompt for the operator to select the configuration

menu, or to activate the device check by pressing

the rotary knob.

The bar graph indicates the progress of the selftest.

46

024

The manufacturer's default settings are:

– Ventilation mode VC-CMV.

– Ventilation time ratio I:E = 1:1.5.

– Positive end expiratory pressure

PEEP = 5 mbar.

– Plateau time Tplat % = 0%.

– Trigger = OFF.

The manufacturer's default settings can be

adjusted in Customer Service Mode. Refer to the

"Set startup settings" section.

Instructions for Use Oxylog 2000 plus SW 1.n

Page 47

Preparing ventilation mode

To activate the ventilation mode

1 Press and hold the ventilation mode key for

approximately 3 seconds.

Or

2 Press the ventilation mode key and confirm by

pressing the rotary knob.

The new ventilation mode selected is now effective.

Set ventilation parameters

1 Set the required control below the display.

Or

2 Select, set and confirm a parameter on the

display with the rotary knob.

The former settings are retained if confirmation is

not received within 15 seconds. Attention is drawn

to this fact by the advisory message ! Settings not

confirmed.

Operation

screen 7

When the PEEP-setting is increased above 10

mbar, a message Confirm PEEP above 10 mbar?

will appear to request confirmation of the change.

The PEEP setting can be increased to the desired

testting after the message is acknowledged with

the rotary knob.

Instructions for Use Oxylog 2000 plus SW 1.n 47

Page 48

Operation

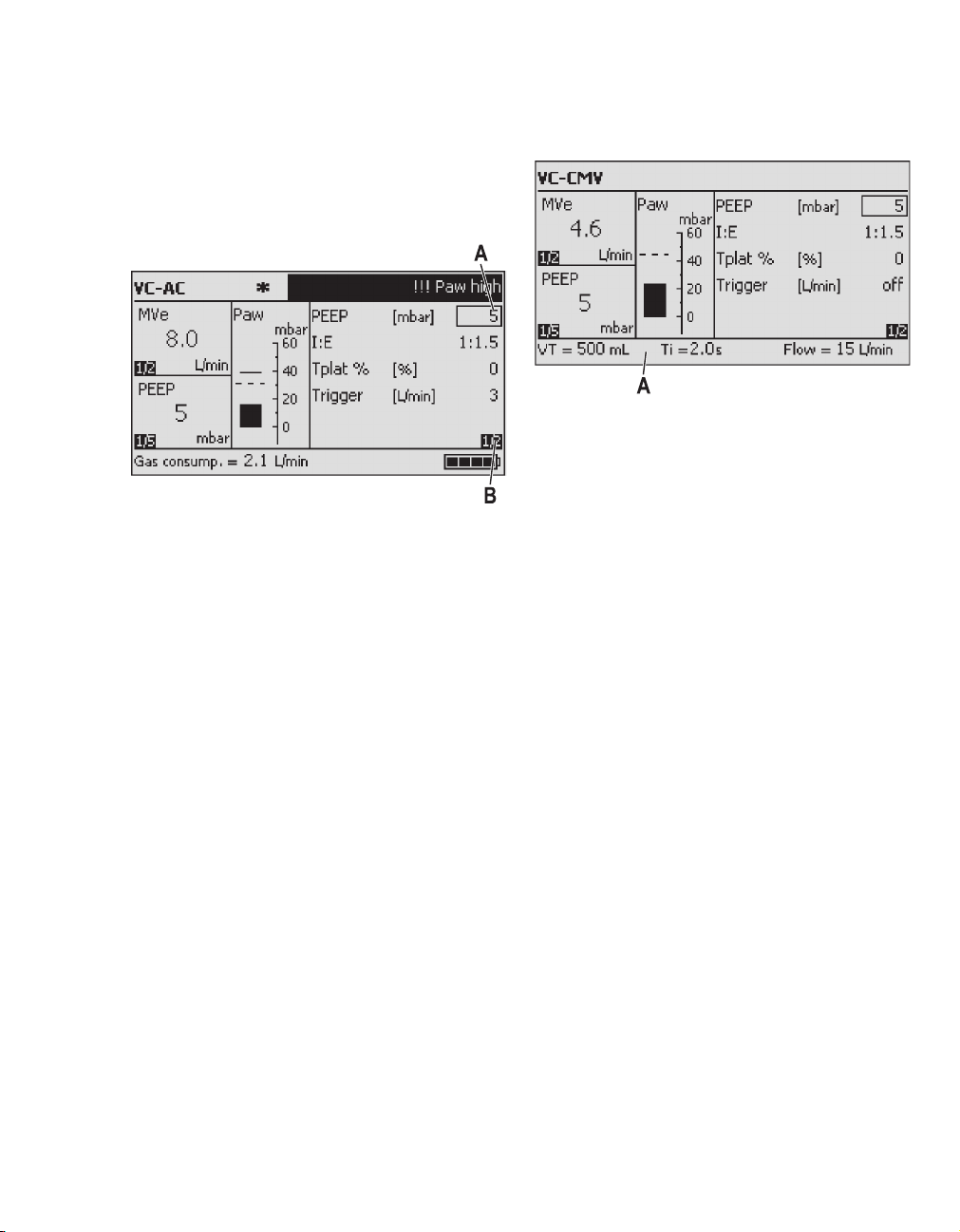

VC-CMV / VC-AC

The following can be set on the display:

Paw

Plateau time

Tplat

Pplat

Pmax

PEEP

t

Tinsp Te

1

Flow

VC-CMV – Volume Controlled - Controlled Mechanical Ventilation.

Volume-controlled ventilation with fixed mandatory

minute volume MV, set with tidal volume VT and

respiratory rate RR.

WARNING

Only use VC-CMV for patients who are not

spontaneously breathing.

Otherwise, the patient may be put at risk by not

receiving sufficient ventilation.

Use VC-AC for patients with partial

spontaneous breathing.

RR

Insp. Flow

– Positive end expiratory pressure PEEP.

– Ventilation time ratio I:E.

– Plateau time Tplat %, in % of the inspiration

t

time.

When setting the ventilation respiratory rate RR,

025

tidal volume VT or ventilation time ratio I:E, the

associated values for inspiration time Ti

inspiration flow are automatically displayed in the

information window.

screen 3

and

Set the ventilation pattern with the controls below

the display:

– Tidal volume VT.

– Ventilation respiratory rate RR.

(minimum possible respiratory rate: 5 per min).

– Maximum airway pressure Pmax.

–O

2 setting, O2 AirMix or 100% O2 FiO2.

48

Instructions for Use Oxylog 2000 plus SW 1.n

Page 49

Operation

Trigger (VC-AC)

NOTE

If in VC-CMV the trigger is set »on«, the ventilation

mode changes into VC-AC.

Refer to the previous section.

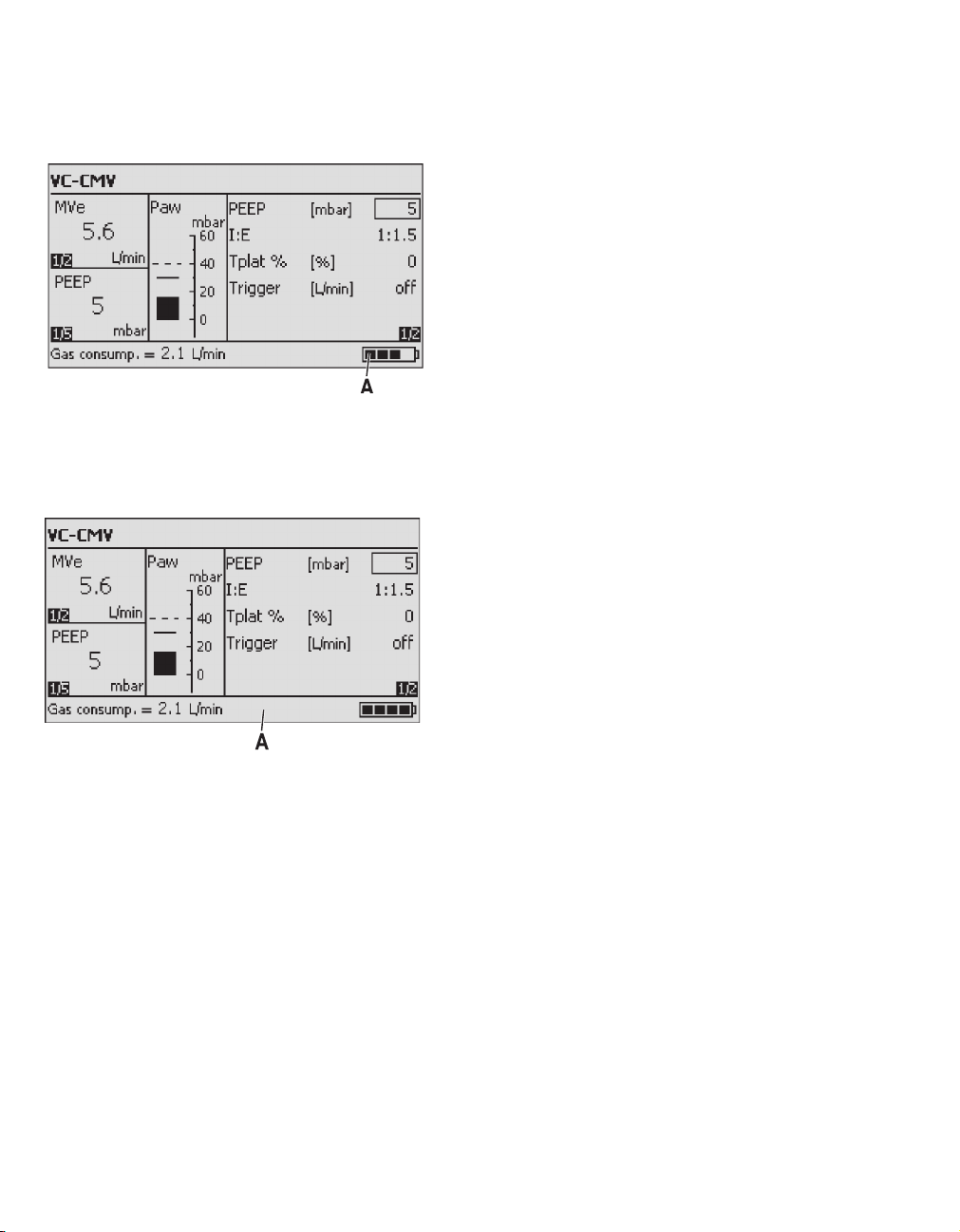

VC-AC – Volume Controlled - Assist Control

For synchronisation with the patient's spontaneous

breathing efforts.

The mandatory ventilation strokes are synchronized with the patient's spontaneous breathing

efforts when the trigger is activated and the trigger

sensitivity is set.

The actual respiratory rate may be higher than the

set ventilation respiratory rate RR in this case.

The trigger can be deactivated if synchronisation

with the patient's spontaneous breathing efforts is

not desired.

Successful patient triggering is briefly indicated by

an asterisk (*) in the middle of the status and alarm

message window.

Activating/setting the trigger

Oxylog 2000 plus

A

026

1 Press the key Settings (A) until the trig-

ger parameter is displayed.

2 Select the line Trigger on the display and then

set and confirm the value with the rotary knob.

Small value = high sensitivity.

The ventilation mode VC-AC is shown on the display.

Deactivate trigger

1 Set a value less than 3 L/min or greater than

15 L/min (off is displayed instead of a value).

2 Press the rotary knob to confirm.

The last effective trigger value is adopted by the

ventilator when changing from VC-AC to

SpnCPAP.

For heart-lung resuscitation

During heart-lung resuscitation, the airway pressure Paw is limited to the set Pmax value by the

Oxylog 2000 plus, without ending inspiration

prematurely (pressure-limited, nonconstant-volume ventilation when Pmax is reached).

If Pmax is set to a higher value, a higher minute

volume is possible.

Instructions for Use Oxylog 2000 plus SW 1.n 49

Page 50

Operation

VC-SIMV (optional PS)

The following are set on the display:

Paw

Pmax

PEEP

support PS

rapid

rise time

Pressure

slow

rise time

t

Ti

Flow

1

RR

Insp. Flow

Trigger window

t

Volume Controlled - Synchronized Intermittent

Mandatory Ventilation

For patients with inadequate spontaneous breathing, or for patients who are to be weaned gradually.

Fixed mandatory minute volume MV is set with tidal

volume VT and ventilation respiratory rate RR. The

patient can breathe spontaneously between the

mandatory ventilation strokes and thus contribute

to the total minute volume. Spontaneous breathing

can be assisted with PS.

Set the ventilation pattern with the controls below

the display:

– Tidal volume VT.

– Respiratory Rate RR.

(minimum possible respiratory rate: 2 per min).

– Maximum airway pressure Pmax.

–O

2 setting FiO2.

screen 9screen 10

– Inspiration time Ti.

– Plateau time Tplat %, in % of the inspiration

time.

– Positive end expiratory pressure PEEP.

027

– Sensitivity Trigger.

Successful patient triggering is indicated by an

asterisk (*) in the center of the status and alarm

message window.

When setting the ventilation respiratory rate RR,

tidal volume VT or inspiration time Ti, the associated values for inspiration flow time ratio I:E are

automatically displayed in the information window.

50

Instructions for Use Oxylog 2000 plus SW 1.n

Page 51

Pressure support (optional)

The following can also be set on the display for

VC-SIMV / PS:

– Setting on page 1: Pressure support ∆Psupp

above PEEP.

– Setting on page 2: Pressure rise time Slope

steep slope = short pressure rise time

flat slope = long pressure rise time.

Operation

screen 26

Instructions for Use Oxylog 2000 plus SW 1.n 51

Page 52

Operation

SpnCPAP (optional PS)

Continuous Positive Airway Pressure

WARNING

Only use SpnCPAP for patients with sufficient

spontaneous breathing.

Otherwise there is a risk of the patient

receiving insufficient ventilation.

Spontaneous breathing can optionally be assisted

with PS and NIV.

Set the ventilation pattern with the controls below

the display:

– Maximum airway pressure Pmax.

–O

2 setting FiO2.

Apnea back-up ventilation is only applicable when

using the SpnCPAP mode. In the event of an

apnea, the ventilator will automatically activate

volume-controlled mandatory ventilation

(VC-CMV).

When an apnea occurs, the device simultaneously

issues an alarm signal and switches to volume controlled ventilation with the parameters respiratory

rate RRapn, tidal volume VTapn, and the maximum airway pressure Pmax when the apnea time

Tapn has been reached. The ventilation time ratio

I:E is set to 1:1.5. The plateau time Tplat % is 0.

The patient can breathe spontaneously during

apnea ventilation. The mandatory frequency

RRapn remains constant.

Setting apnea ventilation

Apnea ventilation

Paw

Pmax

Apnea alarm time

Tapn

Flow

52

Start

apnea ventilation

with apnea alarm

RR

Oxylog 2000 plus

A

t

1

On the display:

1 Press the Settings key (A) until

page appears.

t

2/3

2 Set Tapn with the rotary knob (B) to a value

between 15 and 60 seconds.

029US

Instructions for Use Oxylog 2000 plus SW 1.n

BC

030

Page 53

Operation

The parameters RRapn and VTapn, which are

required for setting apnea ventilation, are now

displayed:

3 Set RRapn and VTapn.

4 Set Pmax. This determines the maximum air-

way pressure allowed during apnea ventilation.

The ventilation time ratio I:E = 1:1.5 and the plateau

time Tplat % = 0 are preset during apnea

ventilation.

To switch apnea ventilation OFF

z Set Tapn to OFF.

Pressure support (optional)

The following can additionally be set on the display

for SpnCPAP / PS:

screen 13

– Sensitivity Trigger (for synchronization with the

patient's spontaneous breathing efforts).

Successful patient triggering is briefly indicated

by an asterisk (*) in the middle of the status

alarm messages window.

– Pressure support ∆Psupp above PEEP.

– Pressure rise time Slope (for pressure

support ∆Psupp).

screen 12

To end apnea ventilation

z Press the Alarm Reset key.

The ventilator resumes ventilating with the original

mode and parameter settings.

The manufacturer default settings are:

– RRapn = 12 /min

–VTapn

=500mL

These default settings can be configured.

Refer to the "Customer Service Mode" section for

additional information.

NOTE

Apnea ventilation can only be activated in

the ventilation mode SpnCPAP without NIV.

The minimum ventilation required by the patient

must be monitored via the lower alarm limit

MV .

Instructions for Use Oxylog 2000 plus SW 1.n 53

Page 54

Operation

NIV – Non-invasive ventilation

Mask ventilation (optional)

NIV can only be activated as a supplementary

function in the pressure-controlled ventilation

modes SpnCPAP and SpnCPAP / PS. Mask leakages are detected by the device, compensated and

included in the measured values for VTe and MVe.

WARNING

If NIV is not activated, measured values for VTe

and MVe will be inconsistent if there are

leakages during ventilation.

Use of NIV

WARNING

Dead space increases when using masks.

Note the mask manufacturer's instructions!

WARNING

Application mode NIV may not be activated

with intubated patients!

Risk of undetected leaks and inadequate ventilation!

WARNING

Check MV alarm limits after deactivating NIV

mode!

– The supplement NIV appears in the upper

section of the display.

screen 14

Oxylog 2000 plus automatically adjusts to the

requirements of mask ventilation. Leakage flows

are compensated automatically and the leakage

alarm is inactive.

WARNI NG

Set the lower alarm limit MV according to

the minimum ventilation required for the

patient.

Otherwise, there is a risk of the patient

receiving insufficient ventilation.

Apnea ventilation is not permitted by the ventilator

when NIV is active.

WARNING

Avoid high airway pressure.

Risk of aspiration!

To switch on NIV

1 Press the Settings key until display page

appears.

2/3

2 Activate the line NIV off.

3 Select NIV on and confirm.

54

Instructions for Use Oxylog 2000 plus SW 1.n

Page 55

O2 AirMix or 100% O2

The FiO2 concentration can be set to O2 AirMix or

100% O2, regardless of the ventilation mode.

When set to O

Oxylog 2000 plus will draw in ambient air, to realize

2 concentration of approximately 40%.

an FiO

However, the O

realized depends on the mean airway pressure and

the inspiratory flow. The O2 concentration can

never be lower than 40%. This is shown in the following graphics:

(%)

O2

40

20

0

3

2 concentration which can be realized at a Pmean

O

of 5 mbar.

(%)

O2

40

20

0

10

2 concentration which can be realized at a Pmean

O

of 15 mbar.

2 AirMix the injector principle of the

2 concentration, which can be

80 (%)

Flow

(L/min.)

40

O2 = f(Flow, Paw)

100

82 (%)

Flow

(L/min.)

35

O2 = f(Flow, Paw)

100

Operation

(%)

O2

85 (%)

40

20

0

15

30

O

2 concentration which can be realized at a Pmean

O2 = f(Flow, Paw)

100

Flow

(L/min.)

of 30 mbar.

(%)

O2

93 (%)

031032

40

20

0

20

O2 = f(Flow, Paw)

2 concentration which can be realized at a Pmean

O

100

Flow

(L/min.)

of 60 mbar.

The O2 concentration is a calculated value. It is not

measured by an internal O

When the O

2 concentration has been set, the value

2 sensor.

will be displayed after approximately 30 seconds.

WARNING

In toxic surroundings:

– The patient must be ventilated with 100%

2 so that toxic constituents do not enter

O

into the breathing gas.

– The patient must be immediately trans-

ferred to a breathable atmosphere in order

to prevent inhalation of toxic air when

spontaneous breathing resumes.

033031

Instructions for Use Oxylog 2000 plus SW 1.n 55

Page 56

Operation

Calibration

The pressure and flow sensors are automatically

calibrated by the device at regular intervals without

interrupting ventilation.

Screen brightness

The screen brightness levels can be set on the last

page of the Settings menu, from level 1/4 to 4/4:

– The setting Brightness is active in both

mains and battery operation when adjusting the

settings on the ventilator.

Volume loudness

The volume loudness level can be set on the last

page of the Alarms menu, from level 1/4 to 4/4.

The saved calibration values are retained even

when the device is switched OFF.

– The setting Brightness is active during

battery operation, when no controls have been

set for a period longer than one minute.

56

Instructions for Use Oxylog 2000 plus SW 1.n

Page 57

Shutdown

– After disconnecting the patient

Switch the ventilator OFF:

Operation

Oxylog 2000 plus

B

1 Press the key

3 seconds. The yellow lamp flashes and

ventilation is terminated by the device.

2 Press the rotary knob (B) to acknowledge the

alarm !!! Confirm device OFF with rotary

knob.

When O

3 Close the cylinder valve.

When medical gas is supplied from the pipeline

system:

4 Disconnect the high pressure connection from

2 is supplied from a cylinder:

WARNING

The cylinder valve must be closed completely

to avoid gas flow leakage by the device.

the source.

O (A) for approximately

A

035

Instructions for Use Oxylog 2000 plus SW 1.n 57

Page 58

This page intentionally left blank

58 Instructions for Use Oxylog 2000 plus SW 1.n

Page 59

Alarms

Types of alarms . . . . . . . . . . . . . . . . . . . . . . 60

In the event of an alarm . . . . . . . . . . . . . . . . 61

Setting alarm limits . . . . . . . . . . . . . . . . . . . 63

Alarms

Instructions for Use Oxylog 2000 plus SW 1.n 59

Page 60

Alarms

Types of alarms

The actual screen display may differ in appearance

or configuration.

Oxylog 2000 plus assigns a priority to the alarm

message. This message highlights the text with the

appropriate number of exclamation marks and

generates different tone sequences for the respective alarms.

!!! = Warning

!! = Caution

! = Advisory

Refer to the list "Alarm – Cause – Remedy" on

page 79 for information on how to remedy the

faults.

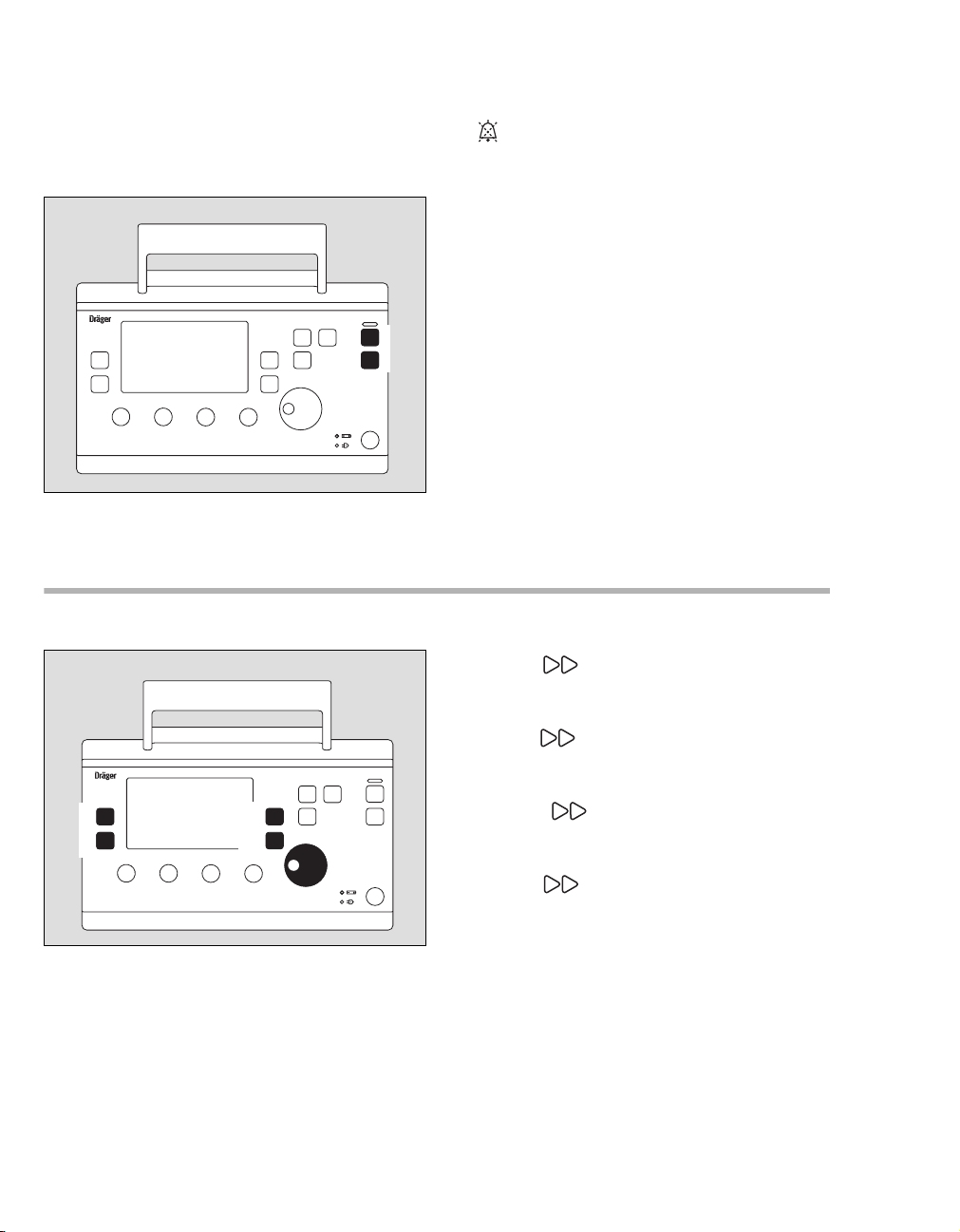

Oxylog 2000 plus

A

B

Caution

An alarm of medium priority.

z The alarm LED (A) flashes yellow.

Caution messages are highlighted by two exclamation marks.

Example: !! No int. battery ?

Oxylog 2000 plus generates a three-tone

sequence, which is repeated approximately every

20 seconds.

Advisory

An alarm of low priority.

z The yellow alarm LED (A) lights up.

Advisory messages are identified by one exclamation mark.

Example:

! Settings not confirmed

Low-priority alarm.

The Oxylog 2000 plus generates a two-tone alarm

sequence, which sounds only once.

Warning

An alarm with high priority

z The alarm LED (A) flashes in red.

Warnings are highlighted by three exclamation

marks and displayed in inverted form (B).

Example:

!!! Apnea

The Oxylog 2000 plus generates a sequence of five

tones, which sound twice and are repeated approximately every 7 seconds.

60

036

Instructions for Use Oxylog 2000 plus SW 1.n

Page 61

In the event of an alarm

Alarms

Oxylog 2000 plus

C

A

B

z The LED (A) flashes red or yellow.

Or

z The alarm message appears on the right of the

status and alarm message window (C).

When the fault has been remedied the alarm tone

is cancelled.

Alarms which have been remedied remain on the

display and can be acknowledged (reset):

1 Press the Alarm Reset key (B).

The alarm message is removed from the

display.

Every alarm which has been remedied, but not

acknowledged, will be overwritten by a new alarm

or advisory message.

Suppress alarm tones

WARNING