Page 1

Dräger X-am 2500

(MQG 0011)

Technical Manual

Page 2

Page 3

Content

Dräger X-am 2500 3

Content

1 For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 General safety statements . . . . . . . . . . . . . . . . . . . .4

1.2 Definitions of alert icons . . . . . . . . . . . . . . . . . . . . . .4

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.1 Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.2 Rear side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.4 Special symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3.1 Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3.2 Permitted power packs . . . . . . . . . . . . . . . . . . . . . . .6

2.3.3 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Preparations for use . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1.1 Charging the batteries . . . . . . . . . . . . . . . . . . . . . . . .8

3.1.2 Replacing the batteries / rechargeable batteries . . .9

3.1.3 Switching on the instrument . . . . . . . . . . . . . . . . . . .9

3.1.4 Switching off the instrument . . . . . . . . . . . . . . . . . .10

3.2 Before entering the workplace . . . . . . . . . . . . . . . .10

3.3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.1 Standard gas configuration . . . . . . . . . . . . . . . . . . .11

3.3.2 Standard instrument configuration . . . . . . . . . . . . .1 2

3.3.3 Configuring the device . . . . . . . . . . . . . . . . . . . . . .12

3.3.4 Export data memory and display graphically . . . . .12

3.4 Running the bump test . . . . . . . . . . . . . . . . . . . . . .13

3.4.1 Manual implementation without documentation of the

results in the instrument memory . . . . . . . . . . . . . .13

3.4.2 Menu implementation with the documentation of

results in the instrument memory . . . . . . . . . . . . . .13

3.4.3 Automatic implementation with the

Bump Test Station . . . . . . . . . . . . . . . . . . . . . . . . .14

3.5 During use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.6 Identifying alarms . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.6.1 Concentration pre-alarm A1 . . . . . . . . . . . . . . . . . .15

3.6.2 Concentration main alarm A2 . . . . . . . . . . . . . . . . .15

3.6.3 STEL / TWA exposure alarm . . . . . . . . . . . . . . . . .15

3.6.4 Battery pre-alarm . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.6.5 Battery main alarm . . . . . . . . . . . . . . . . . . . . . . . . .15

3.6.6 Instrument alarm . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4 Menu functions . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.1 Activating the Info mode . . . . . . . . . . . . . . . . . . . . .16

4.2 Opening Info-Off Mode . . . . . . . . . . . . . . . . . . . . . .16

4.3 Quick Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3.1 Quick menu functions . . . . . . . . . . . . . . . . . . . . . . .16

4.3.2 Opening the Quick Menu . . . . . . . . . . . . . . . . . . . .16

4.3.3 Quick menu "Displaying and deleting peak values" 16

4.4 Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.4.1 Calibration menu functions . . . . . . . . . . . . . . . . . . .16

4.4.2 Open the Calibration Menu . . . . . . . . . . . . . . . . . . .16

5 Calibrate instrument . . . . . . . . . . . . . . . . . . . . . . .17

5.1 Adjustment interval: . . . . . . . . . . . . . . . . . . . . . . . .17

5.2 Run fresh air calibration . . . . . . . . . . . . . . . . . . . . .17

5.3 1-button calibration . . . . . . . . . . . . . . . . . . . . . . . . .18

5.3.1 Calibrating the sensitivity for an individual measuring

channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.3.2 Sensitivity calibration for CatEx . . . . . . . . . . . . . . .19

6 Operation with pump . . . . . . . . . . . . . . . . . . . . . 21

7 Replacing the sensors . . . . . . . . . . . . . . . . . . . . 21

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1 Warning messages . . . . . . . . . . . . . . . . . . . . . . . . 22

8.2 Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1 Maintenance table . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.1 WEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.2 Battery disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.3 Electrochemical sensors . . . . . . . . . . . . . . . . . . . . 27

11 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.1 X-am 2500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.2 Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12 Order list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

13 Declaration of Conformity . . . . . . . . . . . . . . . . . 32

Page 4

4 Dräger X-am 2500

For Your Safety

1 For Your Safety

1.1 General safety statements

z Before using this product, carefully read the associated

Instructions for Use. This document does not replace the

Instructions for Use.

1.2 Definitions of alert icons

The following alert icons are used in this document to provide

and highlight areas of the associated text that require a greater

awareness by the user. A definition of the meaning of each

icon is as follows:

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, could result in physical injury, or damage to

the product or environment. It may also be used to

alert against unsafe practices.

NOTICE

Indicates additional information on how to use

the product.

!

!

i

i

Page 5

Description

Dräger X-am 2500 5

2 Description

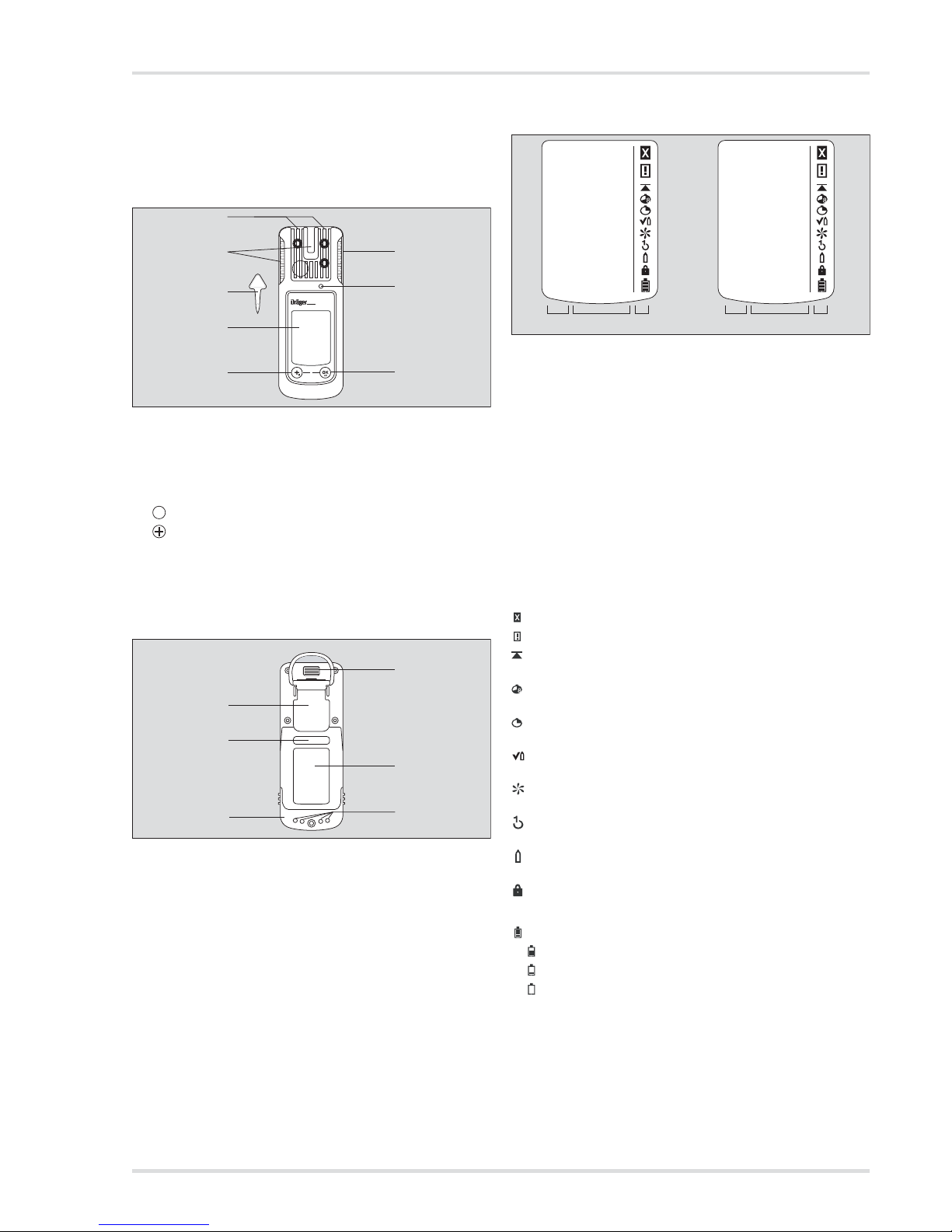

2.1 Product overview

2.1.1 Front

2.1.2 Rear side

2.1.3 Display

Display for 4 measuring channels:

otherwise:

The following only shows the instrument version with

4 measuring channels.

2.1.4 Special symbols

1

Gas entry

2

Alarm LED

3

Horn

4

key

5

key

6

Display

7

Tool for changing sensor

1

IR interface

2

Fastening clip

3

Nameplate

4

Charging contacts

5

Power pack

6

Serial no.

00133366.eps

0

1

2

6

5

4

3

2

X-am 2500

7

OK

00233366.eps

2

1

4

6

3

5

1

Measured gas display with unit

2

Measuring value display

3

Special symbols

4

Measured gas display

5

Measured value display with unit

6

Special symbols

Fault message, see section 4.1 on page 16

Warning message, see section 4.1 on page 16

Display of peak values for all measured gases,

see section 4.1 on page 16

The exposure evaluation display (TWA) for measured

gases, e.g. H

2

S and CO, see section 4.1 on page 16

The exposure evaluation display (STEL) for measured

gases, e.g. H

2

S und CO, see section 4.1 on page 16

The instrument is set to the bump test function,

see section 3.4 on page 13

The instrument is set to the fresh air calibration function,

see section 5.2 on page 17

The instrument is set to the 1-button calibration/

adjustment function, see section 5.3 on page 18

The instrument is set to the single gas calibration

function, see section 5.3.1 on page 19

Function for password input is active, see section 4.4

on page 16

Battery / rechargeable battery 100 % full

Battery / rechargeable battery 2/3 full

Battery / rechargeable battery 1/3 full

Battery / rechargeable battery empty

00333366_de.eps

456

CH4

O

2

CO

123

CH4 %UEG

0.0

O2 Vol%

20.9

CO

ppm

0.0

H2S

ppm

0.0

%UEG

0.0

Vol%

20.9

ppm

0.0

Page 6

6 Dräger X-am 2500

Description

2.2 Intended use

Portable gas detection instrument for the continuous

monitoring of the concentration of several gases in the ambient

air within the working area and in explosion-hazard areas.

Independent measurement of up to 4 gases, in accordance

with the installed Dräger sensors.

Areas subject to explosion hazards, classified by zones

The instrument is intended for the use in areas that are at risk

for explosions in Zone 0, Zone 1 or Zone 2 or in mines at risk

due to black damp. It is intended for use within a temperature

range of -20 °C to +50 °C, and for areas in which gases of

explosion groups IIA, IIB or IIC and temperature class T3 or T4

(depending on the batteries and rechargeable battery) may be

present. For zone 0, the temperature class is limited to T3.

If used in mines, the instrument is only to be used in areas

known to have a low risk of mechanical impact.

Areas subject to explosion hazards, classified by divisio ns

The instrument is intended for the use in areas that are at risk

for explosions of Class I&II, Div. 1 or Div. 2. It is intended for

use within a temperature range of –20 °C to +50 °C, and for

areas in which gases or dusts of groups A, B, C, D or E, F, G,

and temperature class T3 or T4 (depending on the batteries

and rechargeable battery) may be present.

2.3 Approvals

2.3.1 Marking

Serial no.

1

on separate sticker

2.3.2 Permitted power packs

Power pack 83 22 237;

approved as type ABT 0100

Temperature class T4

–20 °C b Ta b +50 °C

use with alkaline batteries

Duracell Procell MN1500

2

Temperature class T3

–20 °C b Ta b +40 °C

use with NiMH rechargeable batteries

GP 180AAHC

2

(1800 mAh)

or with alkaline batteries

Varta Type 4006

2

Varta Type 4106

2

Panasonic LR6 Powerline

NiMH power pack T4 (order no. 83 18 704);

approved as HBT 0000

Temperature class T4

–20 °C b Ta b +50 °C

NiMH power pack T4 HC (order no. 83 22 244);

approved as HBT 0100

Temperature class T4

–20 °C b Ta b +50 °C

CE marking: Electromagnetic compatibility

(Directive 2004/108/EC)

Explosion protection (Directive 94/9/

EEC)

1 The year of construction is coded by the third capital letter of the

serial number: D = 2012, E = 2013, F = 2014, H = 2015, J = 2016,

K = 2017, L = 2018, etc.

Example: Serial number AREH-0054, the third letter is E, so the

year of manufacture is 2013.

Dräger Safety Type: MQG 0011

23560 Lübeck, Germany

I M1 / II 1G for comb. sensor

I M2 / II 2G Um=4.6V Im=1.3A

Ex ia I/IIC T3 Ma/Ga Ex d ia I/IIC T4/T3 Mb/Gb

BVS 10 ATEX E 080X IECEx BVS 10.0053X

ANZEx 11.2003X PFG 10 G 001X

Intrinsically

safe Ex ia, CSA 11 1800517

CSA:

Class I, Div. 1, Gr. A,B,C,D TC T4/T3

Class I, Zone 0, A/Ex ia IIC T3 /Ga

Class I, Zone 1, A/Ex d ia IIC T4/T3 /Gb

-20°C Ta +50/+40°C: see Battery Pack!

For TC T4/T3: see Battery Pack!

Warning: Read manual for safety precautions.

Do

not change or charge batteries in haz loc.

≤ ≤

0158

C22.2 No.152

C US

2 Not subject to BVS10 ATEX E 080X and PFG 10 G 001X

performance approval.

Page 7

Description

Dräger X-am 2500 7

2.3.3 Safety Instructions

Only the functions of the part of the equipment used to measure

flammable gases are measured as part of the CSA approval.

WARNING

Do not replace or charge batteries in potentially

explosive areas. Explosion hazard!

Charge the NiMH power pack T4 (type HBT 0000) or

T4 HC (type HBT 0100) with the associated Dräger

charger. Charge NiMH single cells for ABT 0100

battery holder in accordance with the manufacturer's

specifications. Ambient temperature during the

charging process: 0 to +40 °C.

To reduce the danger of explosion, do not mix new

batteries with old batteries and do not mix batteries

made by different manufacturers.

Always disconnect the instrument from the power pack

before carrying out any maintenance operations.

Substitution of components may impair intrinsic safety .

Only use power packs ABT 0100 (order no. 83 22 237),

HBT 0000 (order no. 83 18 704) or HBT 0100 (order no.

83 22 244). See marking on power pack for approved

batteries and related temperature classes.

Not tested in an oxygen-enriched atmosphere

(>21 % O

2

).

High off-scale readings may indicate an explosive

concentration.

CAUTION

Re. CSA approval:

Before use each day, test the sensitivity using a known

concentration of the gas being measured,

corresponding to between 25 and 50 % of the

maximum concentration. The accuracy must be in

a range of 0 to +20 % of the actual value. Correct the

accuracy via adjustment if necessary.

!

!

Page 8

8 Dräger X-am 2500

Use

3Use

3.1 Preparations for use

z Before using the instrument for the first time, insert the

batteries provided or a charged NiMH power pack T4

(type HBT 0000; order no. 83 18 704) / T4 HC

(type HBT 0100; order no. 83 22 244), see section 3.1.2

on page 9.

z The instrument is now ready for operation.

3.1.1 Charging the batteries

z To maintain the lifetime of the batteries, charging is

temperature controlled and only performed in a temperature

range of 5 to 35 °C. When outside this temperature range,

the charging automatically interrupted and automatically

recommenced after the temperature range has been

reached again.

z The charging time is typically 4 hours.

z A new NiMH power pack reaches its full capacity after three

complete charging/discharging cycles.

z Never store the instrument for extended periods without

being connected to a power source (maximum of

2 months) because the internal buffer battery will drain.

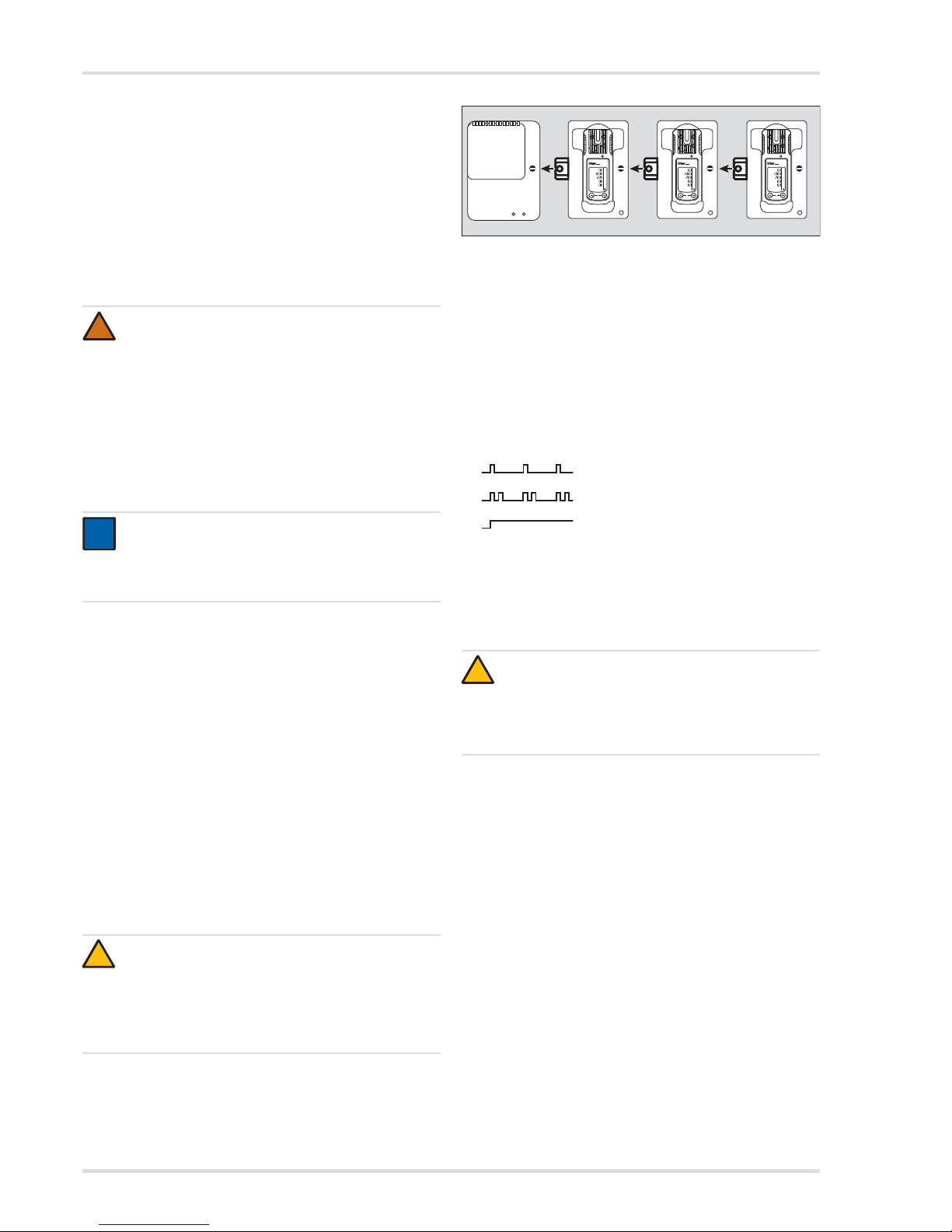

Charging with the multiple charging station

z A maximum of 20 instruments can be charged at the same

time on the power pack (order no. 83 18 805) of the

multiple charging station.

z When attaching the charging modules, disconnect the

power pack from the mains supply!

z Position the instrument on an even and level surface.

1. Turn the slots of the interlock into a horizontal position by

using a screwdriver or coin.

2. Insert the fastening lug (2) of the charger module

(simultaneous power feed) until it engages.

3. Close the lock (1) with a quarter turn (slot is positione d

vertically).

4. Attach additional charging modules in the same way.

5. Connect the power pack to the mains.

{ The green "Mai ns" LED (1) is on.

6. Insert the switched off instrument into the charger module.

{ Display LED (5) on the charging cradle:

z If a fault occurs:

{ Remove the instrument from the charging module and

insert it again.

z If the fault still occurs, have the charging module repaired.

{ It takes approx. 4 hours to fully charge an empty

rechargeable battery.

z In the event of a short circuit or if the power pack is

overloaded:

{ The red "Overload" LED (3) is on, and an audible

alarm sounds.

{ After the fault has been corrected, the alarm is switched

off automatically and the charging process is restarted.

{ In the event of a power failure, the instruments already

charged will be protected from discharging.

WARNING

Explosion hazard!

Do not charge underground or in explosion hazard areas!

The chargers are not designed in accordance with the

regulations for fire damp and explosion protection.

Charge the NiMH power pack T4 (type HBT 0000) or

T4 HC (type HBT 0100) with the associated Dräger

charger. Charge NiMH single cells for ABT 0100

battery holder in accordance with the manufacturer's

specifications. Ambient temperature during the

charging process: 0 to +40 °C.

NOTICE

Even if the instrument is not used, Dräger

recommends storing the instrument in the charging

cradle (chargingmodule X-am 1/2/5000, order no.

83 18 639).

CAUTION

Always connect or disconnect the charging modules

individually and not in groups in order to prevent the

charging station from becoming damaged. During

transportation, the power pack and the charging

modules should also always be handled individually

and without inserted instruments.

!

i

i

!

Charging

Fault

Full

CAUTION

A short circuit of the charging contacts in the charging

modules, e. g., by metallic objects that have fallen in,

does not result in damage to the charging station.

It should, however, be avoided due to possible heating

hazards and incorrect displays on the charger module.

02733366.eps

0

2

1

0

2

1

0

2

1

1

Ex

%UEG

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

Ex

%UEG

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

Ex

%UEG

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

X-am 2500

X-am 2500 X-am 2500

!

Page 9

Use

Dräger X-am 2500 9

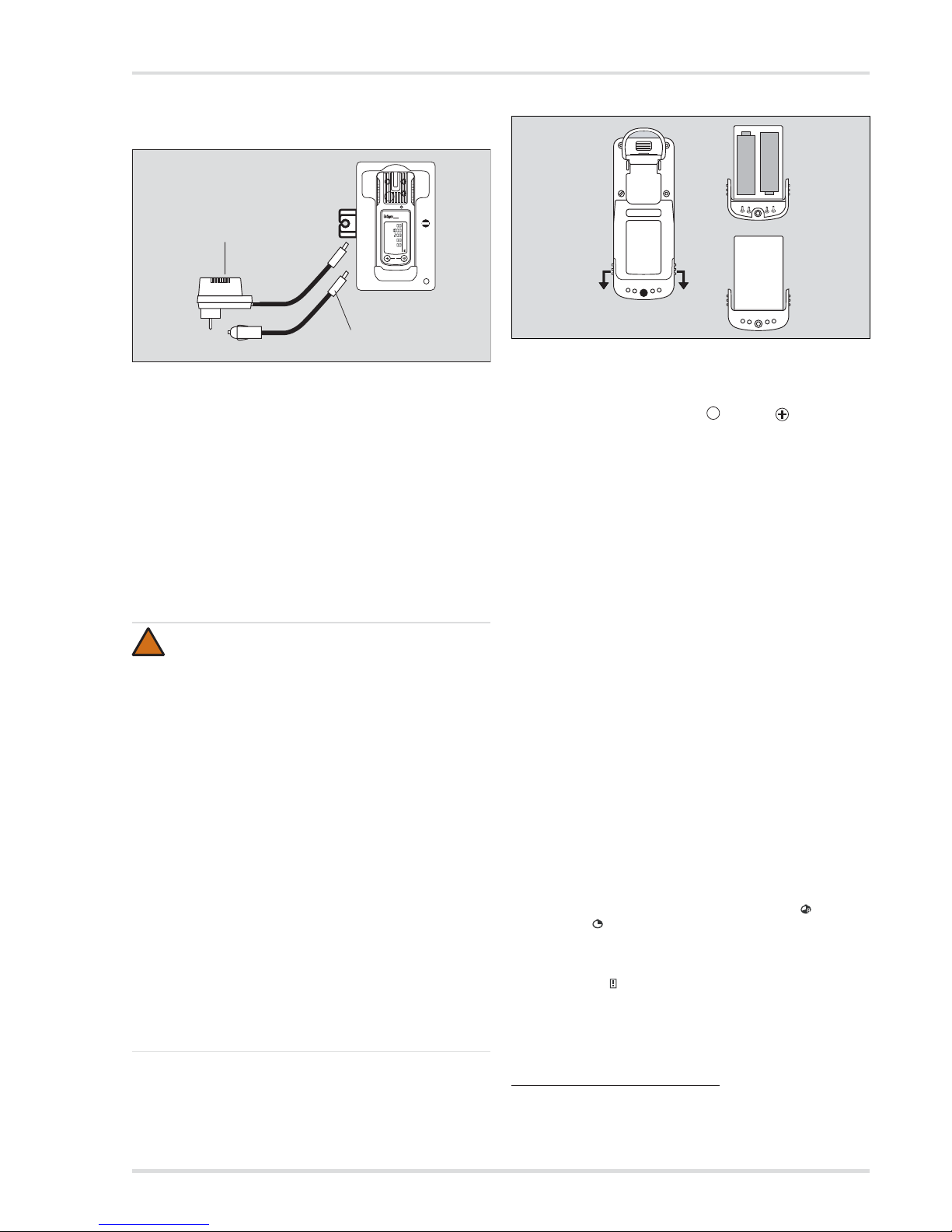

Charge using charger module and plug-in power pack or

vehicle charging adapter

z When using the power pack (order no. 83 16 994), up to

5 instruments can be charged at the same time, with power

pack (order no. 83 15 635) up to 2 instruments.

z The power pack contained in the rechargeable battery and

charging set (order no. 83 18 785) is suitable for charging

one instrument.

z When using the vehicle charging adapter (order no.

45 30 057) it is recommended that you supply every

charging module separately.

z The charging process is carried out analogous to charging

with the multiple charging station.

3.1.2 Replacing the batteries / rechargeable batteries

1. Switching off the instrument: key and key are held

down simultaneously.

2. Loosen the screw (2.0 mm hexagon socket) on the power

pack and remove the power pack.

z With battery holder (order no. 83 22 237): Replace alkaline

batteries or NiMHy rechargeable batteries. Ensure correct

polarity.

z With the T4 NiMH power pack (type HBT 0000) / T4 HC

(type HBT 0100): Completely replace the power pack.

3. Insert the power pack into the instrument and tighten

the screw, the instrument switches on automatically.

After replacing the T4 NiMH power pack (type HBT 0000)/

T4 HC (type HBT 0100), a full charge is recommended.

After the batteries have been replaced:

z The settings and data are stored when the battery is replaced.

The sensors warm up again.

3.1.3 Switching on the instrument

1. Hold down the [OK] button for approx. 3 seconds until the

»3.2.1« countdown shown on the display has elapsed.

{ All the display se gments, including the visual, audible

and vibration alarms, are activated for a short time.

{ The software version is displayed.

{ The instrument performs a self-test.

{ The sensor that is up next for calibration/adjustment is

displayed with the remaining days until the next

calibration/adjustment e. g. » Ex %LEL CAL 20 «.

{ The time until the bump test interval elapses is

displayed in days, e.g. »bt123«.

{ All alarm thresholds A1 and A2 as well as »« (TWA)

1

and »« (STEL)3) for H2S and CO are displayed

consecutively.

{ During the warm-up period of the sensors, the respective

display of the measured value flashes and the special

symbol »« (for warning) is displayed. No alarms are

issued during the warm-up period of the sensors.

See the Technical Handbook for details regarding

accelerated warm-up.

2. Press the [OK] key to cancel the display of the activation

sequence.

WARNING

Explosion hazard!

Do not throw used batteries into fire or try to open them

by force.

Do not replace or charge batteries in a hazardous area.

Batteries / rechargeable batteries are part of the

Ex approval.

Only the following types may be used:

z Alkaline batteries – T3 – (non rechargeable!)

z Panasonic LR6 Powerline

z Varta Type 4106

1

(power one) or

z Varta Type 4006

1

(industrial)

z Alkaline batteries – T4 – (non rechargeable!)

z Duracell Procell MN1500

1

z NiMHy rechargeable batteries – T3 – (rechargeable)

z GP 180AAHC

1

(1800 mAh) max. 40 °C ambient

temperature.

Charge the NiMH power pack T4 (type HBT 0000) or

T4 HC (type HBT 0100) with the associated Dräger

charger. Charge NiMH rechargeable batteries for

battery holder ABT 0100 in accordance with the

manufacturer's specifications. Ambient temperature

during the charging process: 0 to +40 °C.

1) Not part of the measurement performance tests BVS10 ATEX E 080X

and PFG 10 G 001X.

02833366.eps

83 16 994 (100 ... 240 V)

83 15 635 (100 ... 240 V)

45 30 057

0

Ex

%UEG

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

X-am 2500

!

1 Only when activated in the instrument configuration. Delivery status:

not activated.

02633366.eps

1

2

3

–

+

–

+

OK

Page 10

10 Dräger X-am 2500

Use

3.1.4 Switching off the instrument

z Press and hold the [OK] key and [+] key simultaneously

until the countdown »3.2.1« shown on the display has

elapsed.

Before the instrument is switched off, the visual,

audible and vibration alarms are activated for a short time.

3.2 Before entering the workplace

1. Switch on the instrument. The current measured values are

shown in the display.

2. Observe any warning »« or fault messages »«.

3. Check that the gas inlet opening on the instrument is

not covered.

WARNING

Before making safety-related measurements, check

the adjustment and adjust as needed, and check all

alarm elements. A bump test must be performed

according to the national regulations.

The instrument can be operated normally. If the warning

message does not disappear automatically during

operation, the instrument must be serviced after the end

of use.

The instrument is not ready to measure and requires

maintenance.

WARNING

Fractions of catalytic poisons in the measuring gas

(e.g. volatile silicone, sulphur, heavy metal compounds

or halogenated hydrocarbon) can damage the

CatEx sensor. If the CatEx sensor can no longer be

calibrated to the target concentration, the sensor must

be replaced.

In case of measurements in an oxygen-deficient

atmosphere (<8 Vol.-% O

2

) the CatEx sensor may

show incorrect displays; in this case, a reliable

measurement with a CatEx sensor is not possible.

In an oxygen enriched atmosphere (>22 Vol.-% O

2

),

the electrical operational safety cannot be guaranteed;

switch off instrument or leave work station.

!

!

Page 11

Use

Dräger X-am 2500 11

3.3 Configuration

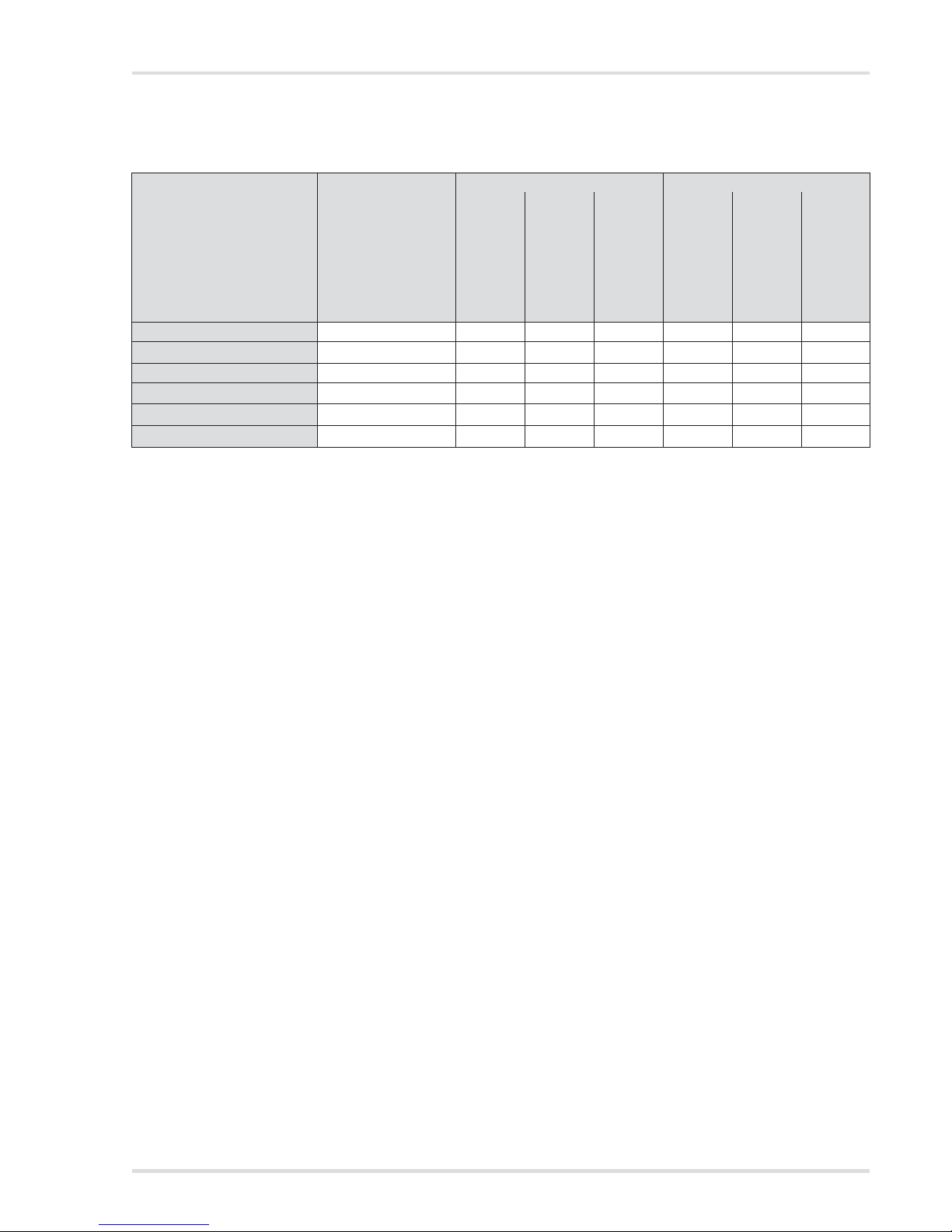

3.3.1 Standard gas configuration

DrägerSensor Measuring range

1

Alarm A1

1)

Alarm A2

1)

threshold

can be acknowledged

self-latching

threshold

can be acknowledged

self-latching

CatEx 125 PR [%LEL] 0 to 100 20 yes no 40 no yes

XXS O2 [Vol.-%] 0 to 25

19

2

no yes 23 no yes

XXS CO [ppm] 0 to 2000 30 yes no 60 no yes

XXS H2S LC [ppm] 0 to 100 1.6 yes no 3.2 no yes

XXS NO2 [ppm] 0 to 50 5 yes no 10 no yes

XXS SO2 [ppm] 0 to 100 1 yes no 2 no yes

1) Different settings can be selected to meet customer requirements on delivery. The current setting can be checked and changed with

the Dräger CC Vision software.

A version of the CC-Vision software that can be used for Dräger X-am 2500 is available for download from the product page for the X-am 2500

at the following web address: www.draeger.com

2) With O

2

, A1 is the lower alarm threshold: an alarm is triggered if the value is too low.

Page 12

12 Dräger X-am 2500

Use

3.3.2 Standard instrument configuration

Changing the configuration: see “Replacing the sensors” on

page 21.

3.3.3 Configuring the device

To individually configure a standard-configuration device,

connect the device to a PC. The installed PC software

Dräger CC Vision is used for configuration.

z Observe the documentation and online help of the software.

z A version of the CC-Vision software that can be used for

Dräger X-am 2500 is available for download from the

product page for the X-am 2500 at the following web

address: www.draeger.com

3.3.4 Export data memory and display graphically

To read the database of the instrument and display it

graphically, the instrument must be connected with a PC.

The installed Dräger GasVision PC software is used for

exporting and displaying the database.

z Observe the documentation and online help of the software.

Bump test in Quick Menu

1

1) Different settings can be selected to meet customer requirements

on delivery. The current setting can be checked and changed with

the Dräger CC Vision software.

A version of the CC-Vision software that can be used for Dräger

X-am 2500 is available for download from the product page for the

X-am 2500 at the following web address: www.draeger.com

Quick bump test

Fresh air calibration in the

Quick Menu

1)

ON

Life sign - visual only

1)

ON

Switching off

1)

allowed

LEL factor

1)

(CH4) 4.4 (vol. %)

(4.4 vol. % corresponds to

100 %LEL)

Averaging time

1)

15 minutes for STEL

8 hours for TWA

WARNING

After a basic initialisation has been carried out with the

PC software Dräger CC Vision, individual alarm

settings may have been changed.

!

IR

Calibration cradle (order no. 83 18 752)

with inserted

USB DIRA with USB cable (order no. 83 17 409)

USB DIRA with USB cable

(order no. 83 17 409)

E-Cal module Dräger X-am 125

(order no. 83 18 754)

USB 1.1

USB 1.1

USB 1.1 / COM

00733366_en.eps

0

0

0

X-am 2500

Page 13

Use

Dräger X-am 2500 13

3.4 Running the bump test

3.4.1 Manual implementation without documentation of

the results in the instrument memory

1. Prepare a test gas cylinder,

the volume flow must be

0.5 l/min and the gas

concentration must be

higher than the alarm

threshold concentration

that is to be tested.

Example test gas cylinder

68 11130 = mixed gas with

50 ppm CO, 15 ppm H

2

S,

2.5 vol. % CH

4

, 18 vol. % O

2

2. Connect the test gas

cylinder with the calibration

cradle (order no. 83 18 752).

3. Vent the test gas into

a fume cupboard or into the

open air (with a hose connected to the second connector of

the calibration cradle).

4. Switch on the instrument and insert it into the calibration

cradle – press downwards until it engages.

5. Open the test gas cylinder valve to let test gas flow over

the sensors.

Recommendation: Wait until the instrument displays the

test gas concentration with sufficient tolerance –

Ex: ±20 % of the test gas concentration

1

O2: ±0.6 vol. %

1

TOX: ±20 % of the test gas concentration

1

Wait until at least alarm threshold A1 or A2 has been

exceeded, however.

If the alarm thresholds are exceeded, the instrument

displays the gas concentration in alternation with »A1« or

»A2« depending on the test gas concentration.

6. Close the test gas cylinder valve and remove the

instrument from the calibration cradle.

If the concentration has now fallen under the A1 alarm threshold:

z Acknowledge the alarm.

If the displays are outside of the above-mentioned ranges:

z Calibrating/adjusting the instrument, see section 5 on

page 17.

3.4.2 Menu implementation with the documentation of

results in the instrument memory

The setting to "Quick bump test" or "Accelerated bump test" is

made using the PC software Dräger CC Vision.

In the "Quick bump test" a check is carried out as to whether

or not the gas concentration has exceeded alarm threshold 1

(with oxygen, the test checks that alarm threshold 1 has not

been reached).

In the "Accelerated bump test" a check is carried out as to

whether or not the gas concentration has exceeded alarm

threshold 1 (with oxygen, the test checks that the alarm

threshold has not been reached) and whether or not the gas

concentration has reached the set bump test concentration.

Setting on delivery: Quick bump test.

1. Prepare a test gas cylinder, the volume flow must be 0.5 l/min

and the gas concentration must be higher than the alarm

threshold concentration that is to be tested.

Example test gas cylinder 68 11 130 = mixed gas with

50 ppm CO, 15 ppm H

2

S, 2.5 vol. % CH4, 18 vol. % O

2

2. Connect the test gas cylinder

with the calibration cradle

(order no. 83 18 752)).

3. Vent the test gas into a fume

cupboard or into the open

air (with a hose connected

to the second connector of

the calibration cradle).

4. Switch on the instrument and insert it into the calibration

cradle – press downwards until it engages.

5. Open the Quick menu and

select the bump test,

page 16.

The current gas

concentration values and

the special symbol » «

(for bump test) flash.

6. Press the key to start

the bump test.

7. Open the test gas cylinder

valve to let test gas flow

over the sensor.

If gas concentration exceeds

the alarm thresholds A 1 or

A 2 the corresponding alarm

will occur.

CAUTION

Never inhale the test gas. Health hazard! Observe the

hazard warnings of the relevant Safety Data Sheets.

1 Upon application of the Dräger mixed gas (order no. 68 11130) the displays

should be within this range.

00833366.eps

0,5 L/min

0

!

CAUTION

Never inhale the test gas. Health hazard! Observe the

hazard warnings of the relevant Safety Data Sheets.

00833366.eps

0,5 L/min

0

!

00933366_en.eps

CH4

%LEL

O

2

Vol%

CO

ppm

H

2S

ppm

OK

Page 14

14 Dräger X-am 2500

Use

Ending the bump test:

After the set bump test

concentration has been

reached or a gas alarm has

been triggered (with "Quick

bump test"):

z The display containing the

current gas concentration

changes with the display

»OK«.

z The bump test that was

carried out is documented

with the result and date in

the instrument memory .

8. Close the test gas cylinder

valve and remove the

instrument from the calibration cradle.

z If the concentration values have now fallen under the A1

alarm thresholds, the instrument returns to the measuring

mode.

z If the set bump test concentration is not reached within the

set time, an error is issued.

{ The fault message

» « appears and

» « is displayed

instead of the measured

value on the faulty

measuring channel.

{ In this case, repeat the

bump test or calibrate

the instrument, page 21.

The bump test can also be run

automatically. The "Bump Test

Station" is required for this function, see section 3.4.3 on

page 14.

3.4.3 Automatic implementation with the Bump

Test Station

Prerequisite:

The instrument first needs to be configured for the automatic

bump test using the Dräger CC-Vision PC sofware.

z Activating the instrument for the automatic bump test.

z Composition of test gas (mixed gas) – standard on delivery:

50 ppm CO, 15 ppm H

2

S, 2.5 vol. % CH4, 18 vol. % O

2

z Define which measuring channels should participate in the

automatic bump test. All measuring channels participate in

the bump test by default.

1. Prepare the Bump T e st Stat ion according to the instructions.

2. Switch on the instrument

and insert it into the

receptacle of the Bump Test

Station until it engages.

The bump test will be

started automatically.

The special symbol » «

(for bump test) flashes.

If a gas alarm (quick bump test) is initiated and the set

bump test concentration (Accelerated bump test) is

reached within the set time, the current gas concentration

will be displayed alternately with »OK«.

3. Remove the instrument from the Bump Test Station.

z If the concentration values have now fallen under the A1

alarm thresholds, the instrument returns to the measuring

mode.

z If there is no alarm during the bump test and the current

measurements do not reach the set target concentration

("Accelerated bump test" only), an error is issued.

{ The fault message

» « appears and

»« is displayed

instead of the measured

value on the faulty

measuring channel.

{ In this case, repeat the

bump test or calibrate

the instrument, page 21.

The bump test can also be run manually, see section 3.4.1 on

page 13.

The Dräger CC Vision PC software can be used to enable the

"Automatic calibration after incorrect bump test" option.

3.5 During use

z During operation, the measured values for every measured

gas are displayed.

z If a measuring range is exceeded or not reached,

the following displays are shown instead of the measured

value display:

z Excess concentrations of flammable materials can lead to

a lack of oxygen.

01033366_en.eps

CH4

%LEL

O

2

Vol%

CO

ppm

H

2S

ppm

01133366_en.eps

CH

4

%LEL

O

2

Vol%

CO

ppm

H

2

S

ppm

01333366.eps

0

Ex

%UEG

O

2

Vol%

CO

ppm

H

2S

ppm

»«

(measuring range exceeded) or

»«

(measuring range not reached).

01133366_en.eps

CH

4

%LEL

O

2

Vol%

CO

ppm

H

2

S

ppm

01133366_en.eps

CH

4

%LEL

O

2

Vol%

CO

ppm

H

2

S

ppm

Page 15

Use

Dräger X-am 2500 15

z For O

2

concentrations under 8 vol. % an error is indi cated

with »« at the ex-channel instead of the measuring

value as long as the measuring value falls below the prewarning threshold (only if measuring range is b100 %LEL,

not for >100 %LEL (heat conductance)).

z In the event of an alarm, the corresponding displays,

including the visual, audible and vibration alarms,

are activated, see section 6 on page 21.

If the measuring range is exceeded significantly at the CatEx

channel (very high concentration of flammable materials),

a blocking alarm is triggered. This CatEx blocking alarm is

either acknowledged automatically through a functional

oxygen channel (e. g. a channel free of warnings and defects)

or manually by switching the instrument on and off in fresh air.

No blocking alarm is triggered in the "methane" configuration

setting when a measuring range is exceeded, because the

unambiguousness of the display for methane is ensured via

a separate measurement of the heat conductivity.

After the measuring range of the TOX measuring channels has

been exceeded temporarily (up to one hour), checking the

measuring channels is not necessary.

3.6 Identifying alarms

An alarm is displayed visually, audibly and through vibration in

a specific pattern.

3.6.1 Concentration pre-alarm A1

The pre-alarm A1 is not latching and stops when the

concentration has dropped below the alarm threshold A1.

z In case of A1, a single tone is audible and the alarm

LED flashes.

Acknowledging the pre-alarm:

z Press the key. Only the audible alarm and the vibration

alarm are switched off.

3.6.2 Concentration main alarm A2

z In case of A2, a double tone is audible and the alarm

LED flashes twice.

After leaving the area, when the concentration has dropped

below the alarm threshold:

z Press the key. The alarm messages are switched off.

3.6.3 STEL / TWA exposure alarm

z The STEL and TWA alarm cannot be acknowledged

or cancelled.

z Switch off the instrument. The values for the exposure

evaluation are deleted after the instrument is switched

on again.

3.6.4 Battery pre-alarm

Acknowledging the pre-alarm:

z Press the key. Only the audible alarm and the vibration

alarm are switched off.

z The battery still lasts min. 20 minutes after the first battery

pre-alarm.

3.6.5 Battery main alarm

The battery main alarm cannot be acknowledged or cancelled:

z The device automatically switches off after 10 seconds.

z Before the instrument is switched off, the visual, audible

and vibration alarms are activated for a short time.

3.6.6 Instrument alarm

z The instrument is not ready for operation.

z For corrective measures, see“Replacing the sensors” on

page 21 to page 24.

z Contact maintenance or Draeger Service to rectify

the problem.

WARNING

After exposure to concentrations above 100 %LEL,

incorrect displays may occur at the CatEx channel.

Check the zero point and sensitivity and adjust it if

necessary before continuing to use the instrument in

a concentration range of 0 to 100 %LEL.

In the event of an impact load when using a CatEx

sensor in the Dräger X-am 2500 that causes the fresh

air display to deviate from zero, the zero point and

sensitivity must adjusted.

Intermittent alarm:

Display »A1« and measured value alternating:

WARNING

Risk of fatal injury! Leave the area immediately. A main

alarm is self-latching and cannot be acknowledged or

cancelled.

Intermittent alarm:

Display » A2 and measured value alternating:

!

OK

!

WARNING

Leave the area immediately. After this alarm,

the deployment of personnel is subject to the relevant

national regulations.

Intermittent alarm:

Display »A2« and »« (STEL) or »« (TWA) and

measured value alternating:

Intermittent alarm:

Flashing special symbol »« on the right

side of the display:

Intermittent alarm:

Flashing special symbol »« on the right side

of the display:

Intermittent alarm:

Special symbol »« displayed on the right

side of the display:

OK

!

OK

Page 16

16 Dräger X-am 2500

Menu functions

4 Menu functions

4.1 Activating the Info mode

z In measuring mode, press the key for approx. 3 seconds.

z If any warning or fault messages exist, the corresponding

information or error codes will be displayed (see section 8

on page 22).

z Press the key successively for the next display.

z The peak values and the exposition values TWA

1

and

STEL

1)

are displayed.

z If no key is pressed for 10 seconds, the instrument returns

automatically to measuring mode.

4.2 Opening Info-Off Mode

z When the instrument is in a deactivated state, press the

key.

The name of the gas, measuring unit, and measuring range

limit value are displayed for all channels.

z Pressing the key again exits the Info Off mode

(or via timeout).

4.3 Quick Menu

4.3.1 Quick menu functions

4.3.2 Opening the Quick Menu

On delivery, only the fresh air calibration is activated in the

Quick Menu. The PC software Dräger CC Vision can be used

to activate the bump test for the quick menu and/or the function

for displaying and deleting peak values.

1. In measuring mode, press the key three times.

If no functions have been activated in the quick menu,

the instrument remains in measuring mode.

2. Y ou can select the activated functions of the quick menu by

pressing the key.

{ Press the key to call the selected function.

{ Press the key to cancel the active function and to

switch to measuring mode.

{ If no key is pressed for 60 seconds, the instrument

returns automatically to measuring mode.

4.3.3 Quick menu "Displaying and deleting peak values"

After the function has been

selected, the current peak

values are displayed; the peak

values special symbol appears

in the display at the same time.

1. The peak values can be

deleted by pressing the

key for 5 sec. and the

adjacent display appears,

for example.

2. Press the key to end

the function.

4.4 Calibration Menu

4.4.1 Calibration menu functions

4.4.2 Open the Calibration Menu

z The calibration menu can only be accessed by entering

a password.

Password on delivery: »001«

z The default password on delivery can be changed using

the PC software Dräger CCVision.

1 Only when activated in the instrument configuration. Delivery status:

not activated.

Warning messages are displayed. Numerical codes

of warning messages: see section 8.1 on page 22.

key

Fault messages are displayed. Numerical codes of

fault messages: see section 8.2 on page 24.

key

The peak values = the maximum measured values in

the case of, e.g., CO, H

2

S, ... or the minimum

measured values in the case of O

2

within the storage

interval are displayed

key

The average values of the exposures based on a shift

of, e.g., 8 hours (TWA) of all the active sensors for the

exposure evaluation are displayed

key

The short-term values (STEL) = average values of

the concentrations over the average value duration

of all the active sensors for th e exposure evaluation

are displayed

key

The instrument is in measuring mode again

Bump test see section 3.4 on page 13

Fresh air calibration, see section 5.2 on page 17

Display and clearing the peak values, see section 4.3.3

on page 16

OK

OK

OK

OK

OK

OK

OK

OK

Fresh air calibration, see section 5.2 on page 17

1-button calibration, see section 5.3 on page 18

Single gas calibration, see section 5.3.1 on page 19

OK

00433366_en.eps

CH4

%LEL

O

2

Vol%

CO

ppm

H

2S

ppm

00533366_en.eps

CH4

%LEL

O

2

Vol%

CO

ppm

H

2S

ppm

OK

OK

Page 17

Calibrate instrument

Dräger X-am 2500 17

1. In measuring mode, press the key for at least 4 seconds.

The function for entering the password is selected.

The special symbol » « (for the "enter password" function)

is displayed.

The display shows »000«,

with the first digit flashing.

2. Use the key to set the

flashing digit.

3. Press the key, the

second digit starts flashing.

4. Use the key to set the

flashing digit.

5. Press the key, the third

digit starts flashing.

6. Use the key to set the

flashing digit.

7. Press the key to confirm

the password once it has

been set completely.

8. The calibration menu functions can now be selected by

pressing the key.

{ Press the key to call the selected function.

{ Press the key to cancel the active function.

{ If no key is pressed for 10 minutes, the instrument

automatically returns to measuring mode.

5 Calibrate instrument

z Adjustment may not be possible due to instrument and

channel errors.

z Allow the sensors to warm up before the calibration!

z Warming-up time: see instructions for use / data sheets for

the Dräger sensors installed (product page for X-am 2500

at www.draeger.com).

5.1 Adjustment interval:

z Observe the relevant specifications in the Instructions for

Use/data sheets of the Dräger Sensors installed.

z For critical applications, observe the recommendations in

EN 60079-29-2

1

or EN 45544-42 and national regulations.

We recommend that you adjust all the channels after

6months.

z Improving the zero point accuracy – perform fresh air

calibration, page 17.

z Set the sensitivity of all sensors to the value of the

test gas – carry out the 1-button calibration, page 18.

z Set the sensitivity of a sensor to the value of the test gas –

span calibration/adjustment, page 19.

5.2 Run fresh air calibration

To improve the zero-point accuracy, a fresh air calibration can

be carried out.

z Calibrate the instrument to fresh air, free of measured

gases or other interfering gases.

z Sensors which have not warmed up or which are faulty

prevent a calibration.

{ In the case of sensors which are in the warm-up phase,

the message » 159 « is displayed with the special

symbol » « (for warning message).

{ In the case of a sensor or instrument error,

the message » 109 « is displayed with the special

symbol » « (for a fault message).

{ The message is cleared after 5 seconds and the

function is available again in the menu.

z During the fresh air calibration the zero point of all sensors

(with the exception of the DrägerSensor XXS O

2

) are set

to 0.

z In the case of the DrägerSensor XXS O

2

, the display is set

to 20.9 vol. %.

1. Switch on instrument.

2. Depending on instrument configuration:

{ Open the Quick menu and select the fresh air

calibration function, page 16.

or

{ Open the Calibration menu and select the fresh air

calibration function, page 16.

z The current gas concentra-

tion values flash.

z When the measured values

have stabilized:

3. Press the key to carry

out the fresh air calibration.

z The display containing the

current gas concentration

changes with the display

»OK«.

4. Press the key to confirm

the calibration or wait for

approx. 5 seconds.

WARNING

Always calibrate the zero-point before span.

Otherwise, the calibration will contain errors!

1 EN60079-29-2 – Guidelines for selection, installation, use and

maintenance of instruments for the detection and measurement of

flammable gases and oxygen.

2 EN 45544-4 – Electrical instruments for the direct detection and

direct concentration measurement of toxic gases and vapours –

Part 4: Guide for selection, installation, use and maintenance.

CAUTION

Never inhale the test gas. Health hazard! Observe the

hazard warnings of the relevant Safety Data Sheets.

00633366.eps

OK

OK

OK

OK

!

!

01333366_en.eps

CH

4

%LEL

O

2

Vol%

CO

ppm

H

2

S

ppm

OK

01433366_en.eps

CH4

%LEL

O

2

Vol%

CO

ppm

H

2S

ppm

OK

Page 18

18 Dräger X-am 2500

Calibrate instrument

If a fault has occurred during the fresh air calibration:

z The fault message » «

appears and » « is

displayed for the respective

sensor instead of the

measured value.

z In this case, repeat the

fresh air calibration.

z Replace the sensor if

necessary, page 21.

5.3 1-button calibration

z All sensors approved by the Dräger CC-Vision PC program

are included in the 1-button calibration.

z In the case of the 1-button calibration, the sensitivity of all

sensors is set to the value of the test gas.

When using test gas cylinder 68 111 30 = mixed gas with

50 ppm CO, 15 ppm H

2

S, 2.5 vol. % CH4, 18 vol. % O2.

z If a mixed gas with another

composition is used,

the specified concentration

values in the instrument

must be changed to the

target values of the mixed

gas used using the PC

software "Dräger CCVision".

1. Connect the test gas

cylinder with the calibration

cradle.

2. Vent the test gas into a fume

cupboard or into the open

air (with a hose connected

to the second connector of the calibration cradle).

3. Switch on the instrument

and insert it into the

calibration cradle until it

engages.

4. Call the calibration menu,

enter the password and select the 1-button calibration

function, page 16.

5. Press the key to start

the 1-button calibration.

6. Open the test gas cylinder

valve to let test gas flow

over the sensor.

The currently displayed

measured values start

to flash.

The flashing stops after a static measured value has

been reached.

The calibration is now carried out automatically.

The displayed measured values change to the values

according to the gas supplied.

7. The automatic stability monitoring can be overridden by

pressing the key. A calibration is carried out immediately .

If it is detected that no test gas has been supplied,

the 1-button calibration is cancelled. The channels then

display »n/a«. If only one sensor is included in the 1-button

calibration, an adjustment is carried out in any case when

the key is pressed.

01533366_en.eps

CH

4

%LEL

O

2

Vol%

CO

ppm

H

2

S

ppm

NOTICE

If no sensors have been approved by the Dräger

CC-Vision PC program for the 1 button calibration,

the 1-button calibration will not be available.

CAUTION

Never inhale the test gas. Health hazard! Observe the

hazard warnings of the relevant Safety Data Sheets.

i

i

00833366.eps

0,5 L/min

0

!

01633366_en.eps

CH4

%LEL

O

2

Vol%

CO

ppm

H

2S

ppm

OK

OK

OK

Page 19

Calibrate instrument

Dräger X-am 2500 19

When the calibration is completed and the displayed

measured values have stabilised:

z The display containing the

current gas concentration

changes with the display

»OK«.

8. Press the key or wait

for 5 seconds to quit the

calibration.

z The instrument changes to

the measuring mode

9. Close the test gas cylinder

valve and remove the

instrument from the

calibration cradle.

If a fault occurs during the 1-button calibration:

z The fault message » «

appears and » « is

displayed for the respective

sensor instead of the

measured value.

z In this case, repeat

the 1-button calibration or

carry out a single gas

calibration, see section

5.3.1 on page 19.

z Replace the sensor if

necessary, page 21.

5.3.1 Calibrating the sensitivity for an individual

measuring channel

z The span calibration can be carried out specifically for

individual sensors.

z In the case of the span calibration, the sensitivity of the

selected sensor is set to the value of the test gas used.

z Use a standard test gas.

Allowed test gas concentration:

1. Connect the test gas

cylinder with the calibration

cradle.

2. Vent the test gas into a fume cupboard or into the open air

(with a hose connected to the second connector of the

calibration cradle).

3. Switch on the instrument and insert it into the calibration

cradle.

4. Press the [+] ke y and keep it pressed for 5 seconds to

open the calibration menu, enter the password and select

the single gas calibration function, page 16.

5. Press the key to start the channel selection.

z The display flashes the gas

of the first measuring

channel, e.g. » Ex %LEL «.

6. Press the key to start

the calibration function of

this measuring channel,

or use the key to

select another measuring

channel (O

2

- vol. %, H2S -

ppm or CO - ppm).

5.3.2 Sensitivity calibration for CatEx

If the measuring range end

value < = 100 LEL, the

calibration for catalytic effect is

suggested.

Display on channel selection:

1. Press the key to start the

catalytic effect calibrat io n.

2. Press the key to select

the next sensor.

Ex: 40 to 100 %LEL

O

2

10 to 25 vol. %

CO: 20 to 999 ppm

H

2

S: 5 to 99 ppm

Test gas concentration of

other gases: see Instructions

for Use for the respective

DrägerSensors.

01733366_en.eps

CH

4

%LEL

O

2

Vol%

CO

ppm

H

2

S

ppm

OK

01833366_fr_es.eps

CH4

%LIE

O

2

Vol%

CO

ppm

H

2S

ppm

00833366.eps

0,5 L/min

0

CAUTION

Never inhale the test gas. Health hazard! Observe the

hazard warnings of the relevant Safety Data Sheets.

!

OK

01933366_en.eps

CH4

%LEL

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

NH

3

ppm

OK

02033366.eps

CH4

VOL%

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

NH

3

ppm

OK

02133366.eps

O2

VOL%

O

2

Vol%

CO

ppm

H

2S

ppm

NH

3

ppm

Page 20

20 Dräger X-am 2500

Calibrate instrument

If the measuring range end

value >100 LEL, the calibration

for catalytic effect and heat

conduction is suggested,

display on channelselection:

3. After pressing the key,

the following appears on

the display:

4. Press the key to start the catalytic effect calibration.

5. After pressing the key,

the following appears on

the display:

6. Press the key to start the heat conduction calibration.

7. key can be pressed to

select the next sensor.

8. Press the key to carry

out the calibration of the

selected measuring channel.

The calibration gas

concentration is displayed

9. Press the key to

confirm the calibration gas

concentration or use the [+]

key to change the calibration

gas concentration and

complete the process by

pressing the key.

The measurement value

flashes.

10.Open the te st gas cylinder valve to let test gas flow over

the sensor.

The displayed, flashing measurement value changes to the

value according to the supplied test gas.

When the displayed measurement value has stabilised:

11.Press the key to carry out the calibration.

The display containing the

current gas concentration

changes with the display

»OK«.

12.Press the key or wait for

approx. 5 seconds to quit

the calibration of this

measuring channel.

The next measuring channel

appears for calibration.

After the calibration of the

last measuring channel,

the instrument changes to

the measuring mode.

13.Close the test gas cylin der

valve and remove the instrument from the calibration

cradle.

If a fault has occurred during the sensitivity calibration:

z The fault message » «

appears and » « is

displayed for the respective

sensor instead of the

measured value.

z In this case, repeat the

calibration.

z Replace the sensor if

necessary, page 21.

Notice for the adjustment of the ex-channel to nonane as

a measuring gas:

z During the calibration of the ex-channel, propane can be

used as a substitute calibration gas.

z When using propane to adjust the ex-channel to nonane,

the display must be set to twice the used test gas

concentration.

Notice for the use in subsurface mining:

z For the calibration of the ex-channel to the measuring gas

methane, the display of the instrument must be set to

a value of 5 % (relative) higher than the used test gas

concentration.

02033366.eps

CH4

VOL%

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

NH

3

ppm

02233366_en.eps

CH

4

VOL%

<= 100%LEL

OK

OK

02333366_en.eps

CH4

VOL%

> 100%LEL

OK

02133366.eps

O2

VOL%

O

2

Vol%

CO

ppm

H

2S

ppm

NH

3

ppm

OK

OK

OK

OK

02433366_en.eps

CH

4

%LEL

OK

02533366_en.eps

CH4

%LEL

CO

2

ppm

O

2

Vol%

CO

ppm

H

2S

ppm

NH

3

ppm

Page 21

Operation with pump

Dräger X-am 2500 21

6 Operation with pump

With Dräger Pump X-am 1/2/5000

Accessories:

Dräger Pump X-am 1/2/5000, sampling hose and probes,

see section 12 on page 31.

Commissioning and performing the measurement:

z Refer to the Instructions for Use of the Dräger

Pump X-am 1/2/5000.

With manual pump adapter and rubber ball pump

Accessories:

For manual pump adapter, rubber ball pump, sampling hose

and probes, see section 12 on page 31.

Commissioning and performing the measurement:

z Refer to the Instructions for Use of the accessories used.

Observe the following during measuring mode with pump

z Wait for the flushing time to elapse:

Before every measurement, flush the Dräger sampling

hose or the Dräger probes with the air sample to be

measured.

z A flushing phase is necessary to eliminate or minimise all

effects associated with the use of a sampling hose or

a probe, e.g. memory effects, dead volume.

z The duration of the flushing phase depends on factors such

as type and concentration of the gas or vapour to be

measured, material, length, diameter, and age of the

sampling hose or probe. Generally, when using a sampling

hose (new, dry, clean), a typical flushing time of approx.

3 seconds is required for each metre. This flushin g time

applies in addition to the sensor response time (see the

Instructions for Use for the gas detection instrument used).

Example:

In the case of a sampling hose with a length of 10 m,

the flushing time is approx. 30 seconds and the sensor

response time is in addition approx. 60 seconds.

Therefore, the total time before reading the gas measuring

instrument is approx. 90 seconds.

The flow-rate alarm is delayed by 10 to 30 seconds

depending on the length of the hose.

7 Replacing the sensors

v To replace the sensors of the instrument, connect the

instrument with a PC.

v Replace the sensors using the PC program Dräger CC Vision.

Next:

v Conduct the fresh air calibration page 17.

and then:

v Calibrating sensitivity:

either

perform 1-button calibration, page18

or

run sensitivity calibration, see page19.

IR

Calibration cradle (order no. 83 18 752)

with inserted

USB DIRA with USB cable (order no. 83 17 409)

USB DIRA with USB cable

(order no. 83 17 409)

E-Cal module Dräger X-am 125

(order no. 83 18 754)

USB 1.1

USB 1.1

USB 1.1 / COM

00733366_en.eps

0

0

0

X-am 2500

Page 22

22 Dräger X-am 2500

Troubleshooting

8 Troubleshooting

List of the numerical codes of the warning and fault messages

in the info mode, see page 16.

8.1 Warning messages

Fault Cause Remedy

Not possible to switch on the instrument Discharged power pack Charge the power pack, page 8.

Discharged alkaline batteries Insert new alkaline batteries, page 21.

Not possible to switch off the instrument The instrument is not set to measuring

mode

Select measuring mode.

The instrument is configured to "Disable

prohibited"

Configure the instrument to "Disable allowed"

with Dräger CC Vision.

Display »––« Measuring range calibrated/adjusted

incorrectly

Recalibrate/adjust the measuring range,

page 21.

Electronics or sensors defective Must be repaired by Service.

Special symbol » « and

displayed numerical code:

Cause Remedy

152 Customer's service life counter about to elapse Reset the service life counter using Dräger

CC Vision.

153 Database 90 % full Read the database soon and clear memory

afterwards.

154 Database full Read the database and clear memory.

155 Interval for bump test elapsed Conduct the bump test page 21.

159 Calibration not possible. The menu function

cannot be carried out because of a message

which is preventing the function (e.g. sensors

in warm-up phase).

Determine the message code via the info menu

and switch it off, if necessary.

251 DrägerSensor CatEx 125 PR warming up Wait until warm-up time is complete.

252 DrägerSensor CatEx 125 PR warming up Wait until warm-up time is complete.

253 Ex concentration has drifted into the

negative range

Conduct the fresh air calibration page 17.

254 The temperature is too high Operate the instrument within the allowed

temperature range.

255 The temperature is too low Operate the instrument within the allowed

temperature range.

256 Calibration interval for DrägerSensor CatEx

125 PR has expired

Perform sensitivity calibration for DrägerSensor

CatEx 125 PR, page 19.

257 Alarm threshold A2 is set to greater than

60 %LEL

Set alarm threshold to less than 60 %LEL.

271 Heat conductance calibration interval for

DrägerSensor CatEx 125 PR has expired

Perform sensitivity calibration for DrägerSensor

CatEx 125 PR, page 19.

351 DrägerSensor XXS EC1 is warming up Wait until warm-up time is complete.

352 DrägerSensor XXS EC1 is warming up Wait until warm-up time is complete.

353 EC1 concentration has drifted into the

negative range

Conduct the fresh air calibration page 17.

354 The temperature is too high Operate the instrument within the allowed

temperature range.

355 The temperature is too low Operate the instrument within the allowed

temperature range.

Page 23

Troubleshooting

Dräger X-am 2500 23

356 The calibration interval for DrägerSensor XXS

EC1 has elapsed

Run sensitivity calibration for DrägerSensor

XXS EC1, page 19.

357 Alarm threshold A2 is set to greater than

60 %LEL

Set alarm threshold to less than 60 %LEL.

451 DrägerSensor XXS EC2 in the warm-up phase Wait until warm-up time is complete.

452 DrägerSensor XXS EC2 in the warm-up phase Wait until warm-up time is complete.

453 EC2 concentration has drifted into the

negative range

Conduct the fresh air calibration page 17.

454 The temperature is too high Operate the instrument within the allowed

temperature range.

455 The temperature is too low Operate the instrument within the allowed

temperature range.

456 The calibration interval for DrägerSensor

XXS EC2 has elapsed

Run sensitivity calibration for DrägerSensor

XXS EC 3, page 19.

457 Alarm threshold A2 is set to greater than

60 %LEL

Set alarm threshold to less than 60 %LEL.

551 DrägerSensor XXS EC3 in the warm-up phase Wait until warm-up time is complete.

552 DrägerSensor XXS EC3 in the warm-up phase Wait until warm-up time is complete.

553 EC3 concentration has drifted into the

negative range

Conduct the fresh air calibration page 17.

554 The temperature is too high Operate the instrument within the allowed

temperature range.

555 The temperature is too low Operate the instrument within the allowed

temperature range.

556 The calibration interval for DrägerSensor

XXS EC3 has elapsed

Run sensitivity calibration for DrägerSensor

XXS EC 3, page 19.

557 Alarm threshold A2 is set to greater than

60 %LEL

Set alarm threshold to less than 60 %LEL.

575 The calibration interval for the compensation

electrode has elapsed

Run sensitivity calibration for the compensation

electrode.

576 Calibration requested due to overgassing Run sensitivity calibration for the compensation

electrode.

651 DrägerSensor XXS EC 4 in the warm-up phase Wait until warm-up time is complete.

652 DrägerSensor XXS EC 4 in the warm-up phase Wait until warm-up time is complete.

653 EC 4 concentration has drifted into the

negative range

Conduct the fresh air calibration page 17.

654 The temperature is too high Operate the instrument within the allowed

temperature range.

655 The temperature is too low Operate the instrument within the allowed

temperature range.

656 The calibration interval for DrägerSensor

XXS EC 4 has elapsed

Run sensitivity calibration for DrägerSensor

XXS EC 4, page 19.

657 Alarm threshold A2 is set to greater than

60 %LEL

Set alarm threshold to less than 60 %LEL.

Special symbol » « and

displayed numerical code:

Cause Remedy

Page 24

24 Dräger X-am 2500

Troubleshooting

8.2 Fault messages

Special symbol »« and

displayed numerical code:

Cause Remedy

102 The customer's service life counter has elapsed Reset the service life counter using Dräger

CC Vision.

103 The instrument is defective The instrument must be repaired by Service.

104 Check sum error program code The instrument must be repaired by Service.

105 Bump test interval elapsed Run the bump test page 14.

106 The calibration interval has elapsed (at least

1 calibration interval has elapsed)

Run sensitivity calibration, see page 18 and/or

page 19.

107 Bump test error (at least 1 channel has a bump

test error)

Run bump test, page 14 or run sensitivity

calibration, page 18 and/or page 19.

108 The instrument is defective The instrument must be repaired by Service.

109 The menu function cannot be carried out

because of an error

Determine the error code via the info menu and

switch it off, if necessary .

111 Faulty alarm element test: Alarm light Repeat alarm element test using X-dock.

112 Faulty alarm element test: Alarm horn Repeat alarm element test using X-dock.

113 Faulty alarm element test: Vibration motor Repeat alarm element test using X-dock.

114 Faulty visual inspection Repeat visual inspection using X-dock.

115 Instrument deactivated by X-dock Instrumen t activated using X-dock.

116 Faulty software update The instrument must be repaired by Service.

201 No valid zero point calibration of the

DrägerSensor CatEx 125 PR

Conduct the fresh air calibration page 17.

202 No valid sensitivity calibration of the

DrägerSensor CatEx 125 PR

Run sensitivity calibration, see page 18 and/or

page 19.

203 Measurement from DrägerSensor CatEx

125 PR is in negative range

Conduct the fresh air calibration page 17.

204 DrägerSensor CatEx 125 PR not plugged in

or faulty

Check DrägerSensor CatEx 125 PR, page 21

205 Error during bump test of DrägerSensor

CatEx 125 PR

Repeat bump test, where necessary, calibrate or

replace the DrägerSensor CatEx 125 PR, page 21.

207 Faulty rise time test Repeat rise time test using X-dock.

221 Too little oxygen to operate the DrägerSensor

CatEx 125 PR

Operate sensor in an environment with at least

10 vol. % O

2

.

222 No valid zero point calibration of the

DrägerSensor CatEx 125 PR for heat

conduction

Conduct the fresh air calibration page 17.

223 No valid sensitivity calibration of the

DrägerSensor CatEx 125 PR for heat

conduction

Run heat conduction sensitivity calibration,

see page 18 and/or page 19.

301 No valid zero point calibration of the Dräger

Sensor XXS EC1

Conduct the fresh air calibration page 17.

302 No valid sensitivity calibration of the Dräger

Sensor XXS EC1

Run sensitivity calibration, see page 19 and/or

fresh air calibration, page 17.

303 The measured value of DrägerSensor XXS EC

1 is in the negative range

Conduct the fresh air calibration page 17.

304 DrägerSensor XXS EC1 is not inserted or faulty Check Dräger Sensor XXS EC1, page 21.

Page 25

Troubleshooting

Dräger X-am 2500 25

305 Error in bump test of Dräger Sensor XXS EC1 Repeat bump test, calibrate or replace

DrägerSensor XXS EC1, if necessary page 21.

306 Faulty filter test Repeat filter test using X-dock.

307 Faulty rise time test Repeat rise time test using X-dock.

326 Error during warm-up acceleration Dräger

Sensor XXS EC1

Disconnect and reconnect power pack or replace

the sensor. Sensor must not be loaded with gas

within the first 5 minutes.

401 No valid zero point calibration of the Dräger

Sensor XXS EC2

Conduct the fresh air calibration page 17.

402 No valid sensitivity calibration of the Dräger

Sensor XXS EC2

Run sensitivity calibration, page 19.

403 The measured value of DrägerSensor XXS EC2

is in the negative range

Conduct the fresh air calibration page 17.

404 DrägerSensor XXS EC2 is not inserted or faulty Check Dräger Sensor XXS EC2, page 21.

405 Error in bump test of Dräger Sensor XXS EC2 Repeat functi on test, calibrate or replace Dräger

Sensor XXS EC2, if necessary page 21.

406 Faulty filter test Repeat filter test using X-dock.

407 Faulty rise time test Repeat rise time test using X-dock.

426 Error during warm-up acceleration Dräger

Sensor XXS EC2

Disconnect and reconnect power pack or replace

the sensor. Sensor must not be loaded with gas

within the first 5 minutes.

501 No valid zero point calibration of the Dräger

Sensor XXS EC3

Conduct the fresh air calibration page 17.

502 No valid sensitivity calibration of the Dräger

Sensor XXS EC3

Run sensitivity calibration, page 19.

503 The measured value of DrägerSensor XXS EC3

is in the negative range

Conduct the fresh air calibration page 17.

504 DrägerSensor XXS EC3 is not inserted or faulty Check Dräger Sensor XXS EC3, page 21.

505 Error in bump test of Dräger Sensor XXS EC3 Repeat bump test, calibrate or replace

DrägerSensor XXS EC3, if necessary page 21.

506 Faulty filter test Repeat filter test using X-dock.

507 Faulty rise time test Repeat rise time test using X-dock.

525 No valid sensitivity calibration for the

compensation channel

Run sensitivity calibration for the compensation

electrode.

526 Error during warm-up acceleration Dräger

Sensor XXS EC3

Disconnect and reconnect power pack or replace

the sensor. Sensor must not be loaded with gas

within the first 5 minutes.

601 No valid zero point calibration of the Dräger

Sensor XXS EC4

Conduct the fresh air calibration page 17.

602 No valid sensitivity calibration of the Dräger

Sensor XXS EC4

Run sensitivity calibration, page 19.

603 The measured value of Dräger Sensor XXS EC4

is in the negative range

Conduct the fresh air calibration page 17.

604 DrägerSensor XXS EC4 is not inserted or faulty Check Dräger Sensor XXS EC4, page 21.

605 Error in bump test of Dräger Sensor XXS

EC4

Repeat bump test, calibrate or replace

DrägerSensor XXS EC4, if necessary page 21.

Special symbol »« and

displayed numerical code:

Cause Remedy

Page 26

26 Dräger X-am 2500

Troubleshooting

606 Faulty filter test Repeat filter test using X-dock.

607 Faulty rise time test Repeat rise time test using X-dock.

626 Error during warm-up acceleration Dräger

Sensor XXS EC4

Disconnect and reconnect power pack or replace

the sensor. Sensor must not be loaded with gas

within the first 5 minutes.

Special symbol »« and

displayed numerical code:

Cause Remedy

Page 27

Maintenance

Dräger X-am 2500 27

9 Maintenance

9.1 Maintenance table

The instrument should be inspected and maintained by suitab ly

qualified persons annually (consult: EN 6007 9-29-2 – Guide for

the selection, installation, use and maintenance of apparatus

for the detection and measurement of combustible gases or

oxygen, EN 45544-4 – Electrical apparatus used for the direct

detection and direct concentration measurement of toxic gases

and vapours - Part 4: Guide for selection, installation, use and

maintenance and national regulations).

Recommended calibration interval for measuring channels Ex,

O

2

, H2S and CO: 6 months.

z Depending on instrument configuration:

{ Replace the alkaline batteries or charge the battery –

see section 3.1.2 on page 9 – after each use, at the

latest after the battery alarm has been triggered or after

2 weeks.

z Calibrating the instrument – see section 5 on page 17.

{ At regular intervals, according to the sensors used and

the operating conditions. For sensor-specific calibration