Page 1

Technical manual

X-am® 3500/8000

HFG 000* / HFG 001*

Page 2

2 Technical manual | X-am® 3500/8000

This page has been left blank intentionally.

Page 3

Page 4

90%

12:02

ppmH S

2

5

90%

12:02

ppmH S

2

90%

11:07

ppmH S

2

10

90%

12:02

H S

2

90%

11:07

ppmH S

2

A

20

90%

12:02

H S

2

90%

11:07

ppmH S

2

A

0%

08:43

C

2

1

OK

2

4

3

6

5

1

OK

A

OK

J

1

2

F

5

OK

G

21 3 4

1

3

2

B

OK

231

D

E

1

2

Switching off...

Battery empty

0 %

2

1

4

5

M

3

4

5%

08:43

Warning

Battery low!

12

K

CAL

4

1

2

3

1

0.0

H S

2

ppm

20.9

Vol%O

2

0

%LELch

4

0

ppmCO

2

1

L

Page 5

Technical manual | X-am® 3500/8000 5

Contents

Contents

1 Safety-related information ......................................................................

8

1.1 Information on safety notes and warnings......................................

8

1.1.1 Safety notes......................................................................

8

1.1.2 Warnings ..........................................................................

8

1.2 Basic safety information..................................................................

8

1.3 Use in areas subject to explosion hazards .....................................

8

2 Conventions in this document ...............................................................

10

2.1 Meaning of the warning notes.........................................................

10

2.2 Trade marks....................................................................................

10

2.3 Typographical conventions.............................................................

10

2.4 Glossary..........................................................................................

10

2.5 Abbreviations ..................................................................................

11

3 Description ...............................................................................................

13

3.1 Product overview ............................................................................

13

3.2 Intended use...................................................................................

14

3.3 Limitations on use...........................................................................

14

3.4 Approvals........................................................................................

14

3.5 Label ...............................................................................................

14

3.6 Sensor slot positions X-am 3500....................................................

14

3.7 Sensor slot positions X-am 8000....................................................

15

3.8 Further device options for X-am 8000 ............................................

15

4 Operation ..................................................................................................

16

4.1 Op

erating concept ..........................................................................

16

4.2 Symbol explanations.......................................................................

16

4.2.1 feature buttons..................................................................

16

4.2.2 Displays ............................................................................

16

4.2.3 Application ........................................................................

16

4.2.4 Device status ....................................................................

17

4.2.5 Connection .......................................................................

17

4.2.6 User level..........................................................................

17

4.2.7 Display in gas channel......................................................

17

4.3 Signalling concept...........................................................................

18

4.3.1 Acoustic operation signal..................................................

18

4.3.2 Visual operation signal .....................................................

18

4.3.3 Visual operation signal with activated D-Light..................

18

4.4 Switch the gas detector on or off ....................................................

18

4.4.1 Initial start-up ....................................................................

18

4.4.2 Switching on the gas detector ..........................................

19

4.4.3 Switching off the gas detector ..........................................

19

4.5 Logging a user in or out ..................................................................

20

4.6 Preparations for operation ..............................................................

21

4.7 During operation .............................................................................

21

4.7.1 Monitoring measuring mode.............................................

22

4.7.2 Alarms ..............................................................................

23

4.7.3 Special s

tate.....................................................................

23

Page 6

6 Technical manual | X-am® 3500/8000

Contents

4.7.4 Blocking alarm ..................................................................

23

4.7.5 Deleting (application) peaks .............................................

24

4.8 Calling the Quick Menu...................................................................

24

4.9 Opening information .......................................................................

24

4.10 Measuring .......................................................................................

25

4.10.1 Special features when measuring with the pump.............

25

4.10.2 Carrying out measuring with the pump.............................

26

4.11 Measurements with wizards ...........................................................

28

4.12 Carrying out confined space entry measurements with the wizard

28

4.13 Carrying out leak searches with the wizard ....................................

29

4.14 Carrying out a benzene/pre-tube measurement with the wizard ....

30

4.14.1 Mounting the pre-tube bracket..........................................

30

4.14.2 Making measurement .......................................................

32

4.15 Configuring the device settings.......................................................

33

4.15.1 Activating day or night mode ............................................

33

4.15.2 Changing the device language .........................................

33

4.15.3 Setting the date and time..................................................

33

4.15.4 Activating silent mode.......................................................

33

4.15.5 Activating or deactivating the capture range ....................

33

4.15.6 Activating or deactivating Bluetooth

®

(X-am 8000 only)...

34

4.16 Activating an automatic over range ................................................

34

4.17 Hydrogen (H

2) added signal (for IR Ex)..........................................

34

5 Troubleshooting.......................................................................................

36

5.1 Error................................................................................................

36

5.2 Warnings.........................................................................................

37

6 Maintenance .............................................................................................

39

6.1 Maintenance intervals.....................................................................

39

6.2 Calibration intervals ........................................................................

39

6.3 Perform bump test ..........................................................................

40

6.3.1 Carrying out bump tests with the wizard...........................

40

6.4 Calibrate the gas detector...............................................................

42

6.4.1 Carrying out a fresh air calibration....................................

42

6.4.2 Carrying out a single-gas calibration ................................

43

6.4.3 Carrying out a multi-gas calibration ..................................

45

6.4.4 Carrying out a cross calibration........................................

47

6.5 Carrying out a signal test................................................................

47

6.6 Charging the battery .......................................................................

47

6.7 Exchanging, adding or removing a sensor .....................................

48

6.8 Cleaning the PID lamp (X-am 8000 only) .......................................

52

6.9 Exchange the device components..................................................

53

6.9.1 Opening the gas detector .................................................

53

6.9.2 Blind bracket / strap retainer / labelling field/label for strap

55

6.9.3 Battery ..............................................................................

55

6.9.4 RFID transponder.............................................................

56

6.9.5 F

ront housing cradle with diaphragms..............................

56

6.9.6 Vibration motor .................................................................

56

6.9.7 Sensor sealing plate.........................................................

57

6.9.8 Sensor holders .................................................................

58

6.9.9 Pump block.......................................................................

58

6.9.10 Horn / resonator................................................................

60

Page 7

Technical manual | X-am® 3500/8000 7

Contents

6.10 Labelling field/label for strap ...........................................................

61

6.11 Mounting the clip.............................................................................

61

6.12 Radio-Frequency Identification (RFID) ...........................................

61

6.13 Cleaning..........................................................................................

62

7 Configuration ...........................................................................................

63

7.1 Standard gas configuration.............................................................

63

7.2 Configuring the gas detector...........................................................

65

7.2.1 Configuring the gas detector with the Dräger X-dock and

reading the data memory

65

7.2.2 Configuring the gas detector with the PC and reading the

data memory

66

8 Device settings.........................................................................................

67

8.1 Factory settings ..............................................................................

67

8.2 Device and sensor settings.............................................................

68

8.3 Alarm settings .................................................................................

69

9 Transport ..................................................................................................

70

10 Storage......................................................................................................

71

11 Disposal ....................................................................................................

72

12 Technical data ..........................................................................................

73

12.1 Gas detector ...................................................................................

73

Page 8

8 Technical manual | X-am® 3500/8000

Safety-related information

1 Safety-related information

1.1 Information on safety notes and warnings

Safety notes and warnings warn of dangers and provide instructions for the safe

use of the product. Failure to observe these safety notes and warnings may result

in personal injury or damage to property.

1.1.1 Safety notes

This document contains sections with safety notes which warn of dangers. The type

of danger and the consequences following failure to observe the safety note are

included in every safety note.

1.1.2 Warnings

Warnings refer to steps of a task and warn of dangers which may result while the

steps are executed. Warnings appear before the steps.

1.2 Basic safety information

– Before using this product, carefully read the associated instructions for use. This

document does not replace the instructions for use.

1.3 Use in areas subject to explosion hazards

To reduce the risk of ignition of a flammable or explosive atmosphere, strictly

observe the following safety notes:

Use in areas subject to explosion hazards

Devices or components for use in explosion-hazard areas which have been tested

and approved according to national, European or international explosion protection

regulations may only be used under the conditions specified in the approval and

with consideration of the relevant legal regulations. The devices or components

may not be modified in any manner. The use of faulty or incomplete parts is

forbidden. The appropriate regulations must be observed at all times when carrying

out repairs on these devices or components.

X-am 8000: Increased hydrogen concentrations within the measuring range of

the DrägerSensor XXS H

2 HC may result in false alarms due to the additive effect

on the DrägerSensors XXS H

2S and XXS CO, XXS H2S-LC and XXS CO-LC as

well as due to the negative effect on the DrägerSensor XXS O2.

Oxygen-enriched atmospheres

Explosion protection is not guaranteed in oxygen-enriched atmospheres

(>21 vol. % O

2).

► Remove the device from the potentially explosive atmosphere.

Page 9

Technical manual | X-am® 3500/8000 9

Safety-related information

Oxygen deficient atmospheres

Measurements in oxygen deficient atmospheres (<12 vol. % O

2) may return

incorrect displays on the CatEx sensor. In this case the CatEx sensor cannot

provide a reliable measurement.

► Remove the device from the area.

The CatEx sensor in oxygen deficient or oxygen enriched environments

Incorrect measured values may be displayed in an oxygen deficient or oxygen

enriched environment.

► The CatEx sensor is intended to measure flammable gasses and vapours mixed

with air (i.e. O

2 content ≈ 21 vol. %). If the O2 content falls below 12 vol. % and

am operational O

2 sensor is available, a channel error is triggered on the CatEx

channel due to oxygen deficiency.

Incorrect calibration

CAUTION: An incorrect calibration leads to incorrect measured values.

► CSA requirement (Canadian Standard Association): The sensitivity must be

checked daily before first using the device with a known concentration of the gas

to be measured that corresponds to 25 to 50 % of the final concentration. The

accuracy must amount to 0 to +20 % of the actual value. The accuracy can be

corrected by calibration.

RFID tag (optional)

► The RFID tag must not be read out in explosion-hazard areas.

NOTICE

Damage to the CatEx sensor!

Fractions of catalytic poisons in the measuring gas (e.g. volatile silicon, sulphur,

heavy metal compounds or halogenated hydrocarbon) can damage the Cat Ex

sensor.

► If the CatEx sensor can no longer be calibrated to the target concentration,

replace the sensor.

DrägerSensor CatEx 125 PR (6812950) and CatEx 125 PR Gas (6813080)

► For this gas detector, only use sensors with serial numbers > ARLB XXXX

(starting with date of manufacture in February 2018). These sensors are certified

for use in zone 0, T4.

Page 10

10 Technical manual | X-am® 3500/8000

Conventions in this document

2 Conventions in this document

2.1 Meaning of the warning notes

The following alert icons are used in this document to provide and highlight areas of

the associated text that require a greater awareness by the user. A definition of the

meaning of each icon is as follows:

2.2 Trade marks

The brands listed are only registered in certain countries and not necessarily in the

country in which this material is sold.

2.3 Typographical conventions

2.4 Glossary

Alert icon Signal word Consequences in case of nonob-

servance

WARNING Indicates a potentially hazardous situation

which, if not avoided, may result in death or

serious injury.

CAUTION Indicates a potentially hazardous situation

which, if not avoided, may result in injury. It

may also be used to alert against unsafe

practices.

NOTICE Indicates a potentially hazardous situation

which, if not avoided, could result in damage to the product or environment.

Brand Brand owner

X-am

®

Dräger

Bluetooth

®

Bluetooth SIG, Inc.

Tex t Text in bold identifies labels on the device and text on the display.

► This triangle in warnings identifies the options available for avoiding

the hazard.

> The greater-than symbol identifies a navigation path in a menu.

This symbol indicates information that may make the use of this

product easier.

Ter m Description

Operation signal A periodic optical (green LED) and/or acoustic signal.

Measurement mode Measurement in one of the applications (monitoring,

confined space entry, leak search, benzene/pre-tube

measurement) (X-am 8000 only).

Page 11

Technical manual | X-am® 3500/8000 11

Conventions in this document

2.5 Abbreviations

Monitoring Monitoring without pump (diffusion)

Monitoring with pump (with pump adapter)

Capture range The capture range refers to a measured value range

within which minor variations in measured values (such

as signal noise, variations in concentration) do not cause

variations in the display. Measured values outside the

capture range will be displayed with the actual measured

value.

Confined space entry

wizard

Measurement with pump and any accessories (e.g.

hose, probe) for clearance measurements of specific

areas (X-am 8000 only).

Leak search wizard Leak search measurement (X-am 8000 only)

Benzene/pre-tube wiz-

ard

Benzene/pre-tube measurement (X-am 8000 only)

Peak Peak value

Quick bump test Test for alarm triggering.

Extended bump test Test for accuracy and alarm triggering.

Special state If a special state is signalled, the user is not warned of

gas concentrations which may be dangerous.

The following device features are special states:

First set-up / configuration with the PC menu, prepara-

tion phase of the wizards, maintenance wizard bump test

and calibration, warm-up 1 of the sensors.

D-Light The D-Light feature allows the user to check and indicate

compliance with certain settings.

Physical sensors The CatEx, IR, and PID sensor types are designated as

physical sensors. There are also the electrochemical

sensors.

Ter m Description

Abbreviation Explanation

A1 Pre-alarm

A2 Main alarm

CSE Confined space entry, clearance measurement (before entering

confined spaces)

FKM Fluoroelastomer

IR Infrared

PID Photoionization detector

PTFE Polytetrafluoroethylene

PVC Polyvinyl chloride

STA Short time average, average value over a short period of time

(generally 15 minutes).

STEL Short time exposure limit, threshold of an exposition over a

short period of time (generally 15 minutes).

Page 12

12 Technical manual | X-am® 3500/8000

Conventions in this document

STEV Short time exposure value, average value of exposure over a

short period of time (generally 15 minutes).

TWA Time weighted average, average shift values are generally lim-

ited to eight hours exposure per day per workplace for 5 days a

week during a work lifetime. Observe the national definition of

the occupational exposure limit.

Abbreviation Explanation

Page 13

Technical manual | X-am® 3500/8000 13

Description

3 Description

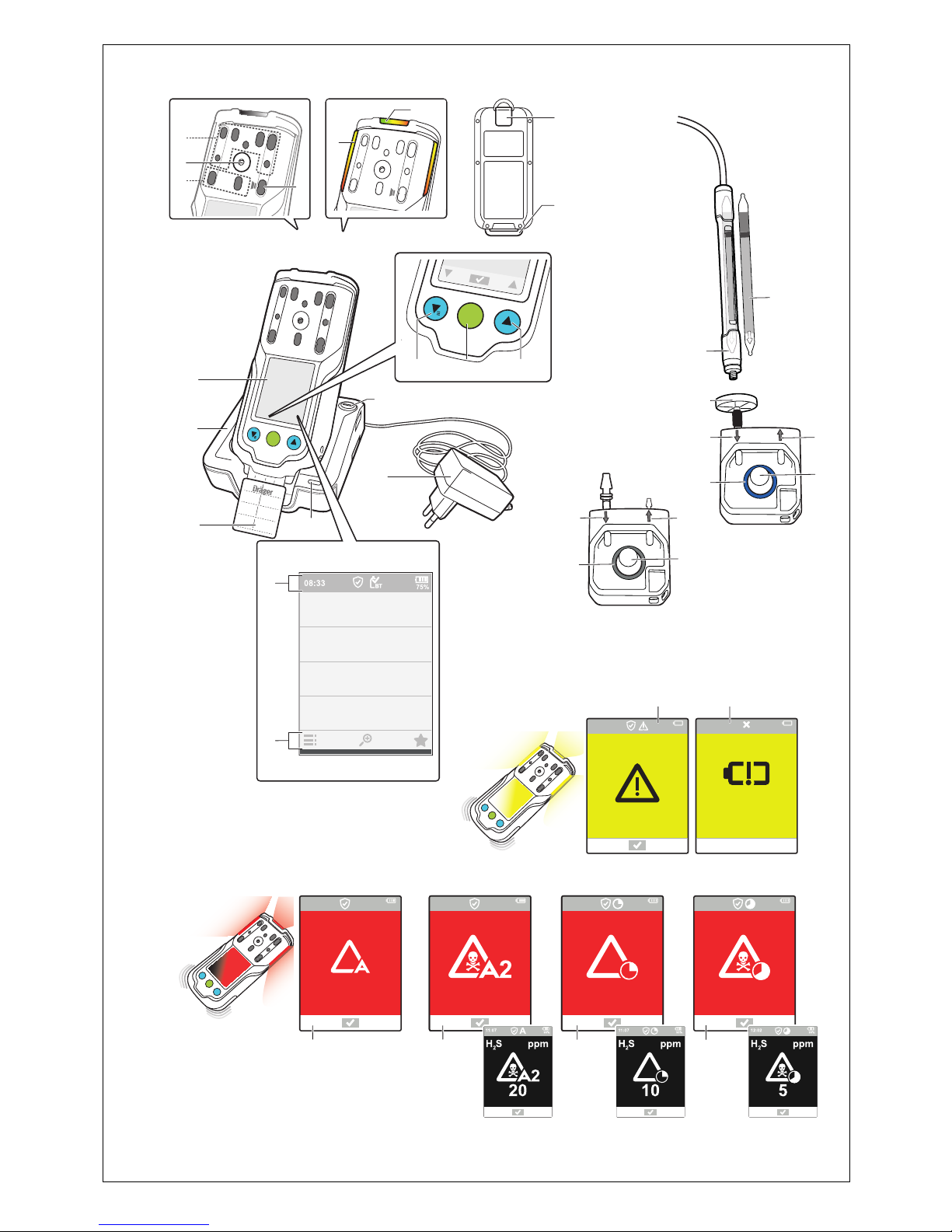

3.1 Product overview

The graphics are displayed on the fold-out page.

Graphic A

1 Display 4 Charge LED green/red

2 Locking screw for an additional

charging module

5 Labelling field (X-am 8000 only)

3 Power supply unit 6 Induction charger

Graphic B

1 Gas inlets 3 Horn

2 Thread port for pumps and calibra-

tion adapter

4 Pump outlet and inlet

Graphic C

1 LED green/yellow/red 2 LED yellow/red

Graphic D

1 feature button 1 3 feature button 3

2 feature button 2

Graphic E

1 Status information 2 Navigation bar

Graphic F

1 Clip (optional) 2 Socket for support belt for shoulder

version

(X-am 8000 only)

Graphic G

1 Alarm A1 3 STEL alarm

2Alarm A2 4TWA alarm

Graphic J

1 Battery pre-alarm 2 Battery main alarm

Graphic K

1 Calibration adapter (grey coloured

ring)

3 Exhaust

2 Gas inlet 4 Locking screw

Graphic L

1 Pre-tube bracket (X-am 8000 only) 2 Pre-tube (X-am 8000 only)

Graphic M

1 Pump adapter (blue coloured ring) 4 Exhaust

2 Gas inlet 5 Locking screw

3 Dust and water filter

Page 14

14 Technical manual | X-am® 3500/8000

Description

3.2 Intended use

Dräger X-am 3500/8000 is a portable gas detector for clearance measurements

and for the continuous monitoring of the concentration of several gases in ambient

air in the workplace and in explosion-hazard areas.

The X-am 3500 allows measuring up to 4 gases in accordance with the

DrägerSensors (XXS O

2, XXS H2S LC, XXS CO LC, XXS NO2, XXS SO2 and

CatEx 125 PR) which are installed. The gas detector can be operated in pump

mode or in diffusion mode.

X-am 8000 can measure up to 7 gasses in accordance with the installed

DrägerSensors (EC, IR, CatEx, PID). The gas detector can be operated in pump

mode (if it is equipped with a pump) or in diffusion mode.

3.3 Limitations on use

The gas detector is not suitable for measuring process gasses.

Operation of the gas detector in the charging cradle in a vehicle is only permitted

under the following conditions:

– Acoustic signalling must be deactivated (with the help of the PC software CC-

Vision).

3.4 Approvals

A copy of the rating plate and the declaration of conformity are provided in the

enclosed supplementary documentation (order no. 90 33 655).

CSA-specific information:

Only the combustible gas portion of this instrument has been tested for measuring

accuracy.

Radio approval (X-am 8000 only):

The information for radio approval can be viewed in the menu. For further

information, see the following chapter: "Opening information", page 24.

3.5 Label

The energy supply label has a mark for a service label. Here, a maximum of one

service label and one year-point label may be attached one on top of the other.

Further labels, conductive labels or labels with conductive material or parts can

have a negative effect on inductive charging.

The rating plate on the gas detector must not be concealed.

3.6 Sensor slot positions X-am 3500

Sensor slot Configuration

HPP 1 not assigned

HPP 2 CatEx sensor

EC 1-3 EC sensors

Page 15

Technical manual | X-am® 3500/8000 15

Description

3.7 Sensor slot positions X-am 8000

3.8 Further device options for X-am 8000

The following device options are available if needed:

–Pump

– RFID transponder

– Bluetooth

®

module

– Carrying clip

Sensor slot Configuration

HPP 1 PID or IR sensor

HPP 2 IR or CatEx sensor

EC 1-3 EC sensors

Page 16

16 Technical manual | X-am® 3500/8000

Operation

4 Operation

4.1 Operating concept

Navigation is done with the 3 multifeature buttons and the dynamic navigation bar

(see Graphic E on the fold-out page). The navigation bar changes dynamically

depending on the available interactions.

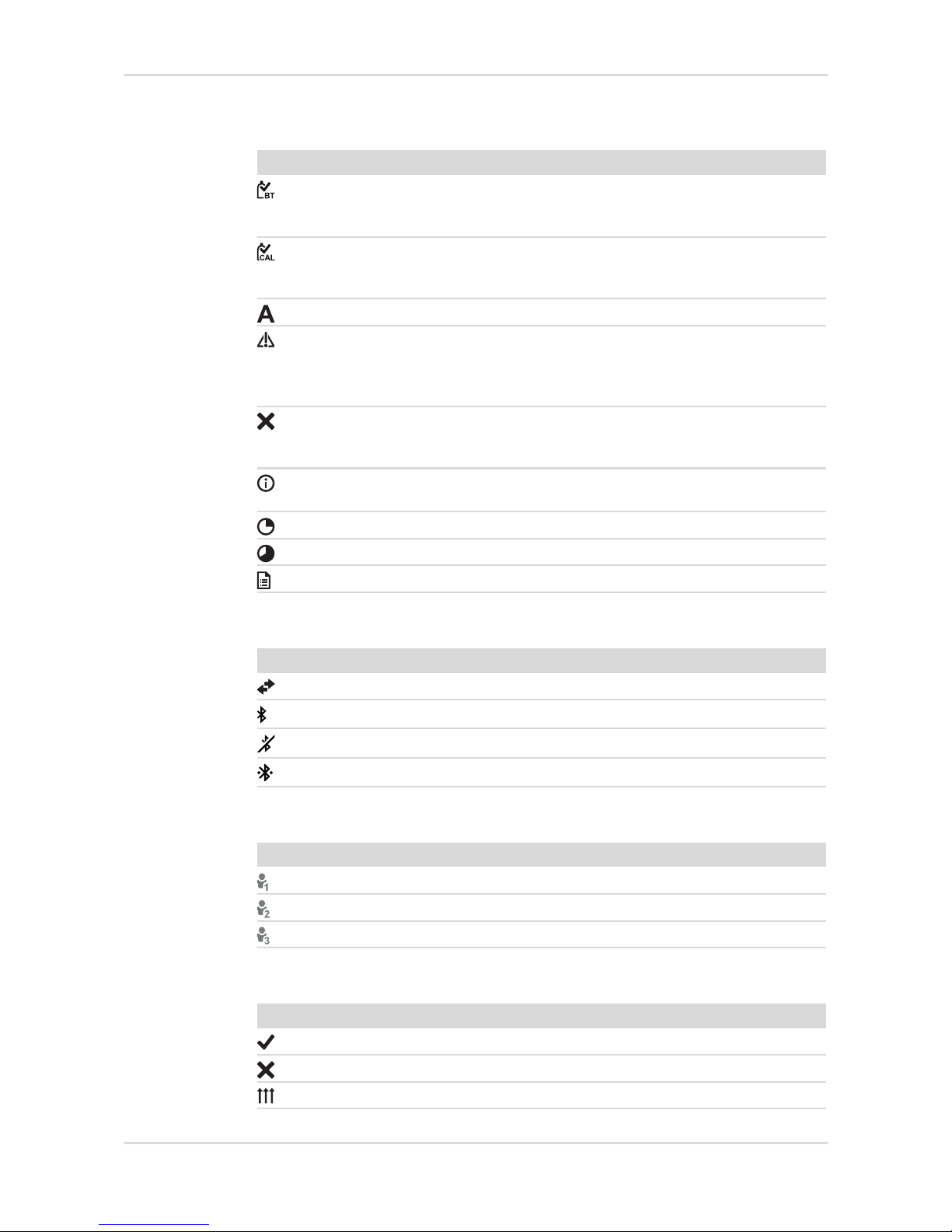

4.2 Symbol explanations

4.2.1 feature buttons

4.2.2 Displays

4.2.3 Application

Symbol Explanation

Confirm action/dialog / return to menu

Confirm all

Scroll up / through display

Scroll down / through display

Cancel action

Display quick menu

Display measuring channels individually

Display all measuring channels

Increase value

Decrease value

Repeat feature

Display menu

Symbol Explanation

Horn and vibration for gas alarm deactivated

Symbol Explanation

Messen

Clearance measurement (X-am 8000 only)

Leak search (X-am 8000 only)

Benzene/pre-tube measurement (X-am 8000 only)

Fresh air adjustment

Bump test or calibration

Page 17

Technical manual | X-am® 3500/8000 17

Operation

4.2.4 Device status

4.2.5 Connection

4.2.6 User level

4.2.7 Display in gas channel

Symbol Explanation

Overview of the bump test intervals activated (additional information for the D-Light feature).

There are no gas alarms or errors.

Monitoring of the calibration intervals activated, D-Light function

deactivated (additional information for the D-Light function).

There are no gas alarms or errors.

Alarm message

Warning message

The gas detector can be operated normally. If the warning message is still displayed after operation, the gas detector requires

maintenance. Menu Messages displays details.

Fault message

The gas detector or measuring channel is not ready to measure

and requires maintenance. Menu Messages displays details.

Information message

Menu Messages displays details.

STEL alarm message

TWA alarm message

Event report

Symbol Explanation

Maintenance mode (access to the device via PC or X-dock)

Bluetooth

®

activated

Bluetooth

®

deactivated

Bluetooth

®

connection established

Symbol Explanation

User level 1

User level 2

User level 3

Symbol Explanation

Bump test or calibration successful

Bump test or calibration failed

Measurement range exceeded

Page 18

18 Technical manual | X-am® 3500/8000

Operation

4.3 Signalling concept

4.3.1 Acoustic operation signal

A periodic acoustic signal indicates that the device is functional. The acoustic

operation signal can be deactivated. For further information, see the following

chapter: "Activating silent mode", page 33

4.3.2 Visual operation signal

A periodic pulse (increasing and decreasing intensity) of the green LED indicates:

– Monitoring, confined space entry, leak search or benzene/pre-tube

measurement application active

– There is no device or channel error, no gas alarm and no special state

4.3.3 Visual operation signal with activated D-Light

An activated D-Light feature allows the user to also check and indicate compliance

with certain settings:

– Evaluation of bump test intervals activated and complied with (factory setting) or

evaluation of the calibration intervals active and complied with

– Usage interval complied with

The D-Light feature can be activated using the Dräger CC-Vision PC software.

Signalling visually corresponds to the operating signal.

If one of the conditions listed is not fulfilled and the D-Light is activated, the greed

LED will switch on briefly at regular intervals (short flash approx. every 60 s) instead

of pulsing periodically.

4.4 Switch the gas detector on or off

4.4.1 Initial start-up

When the gas detector is switched on for the first time, a wizard starts. The wizard

guides the user through the set-up of the gas detector:

– Language selection, if applicable

– Data format and date

–Time

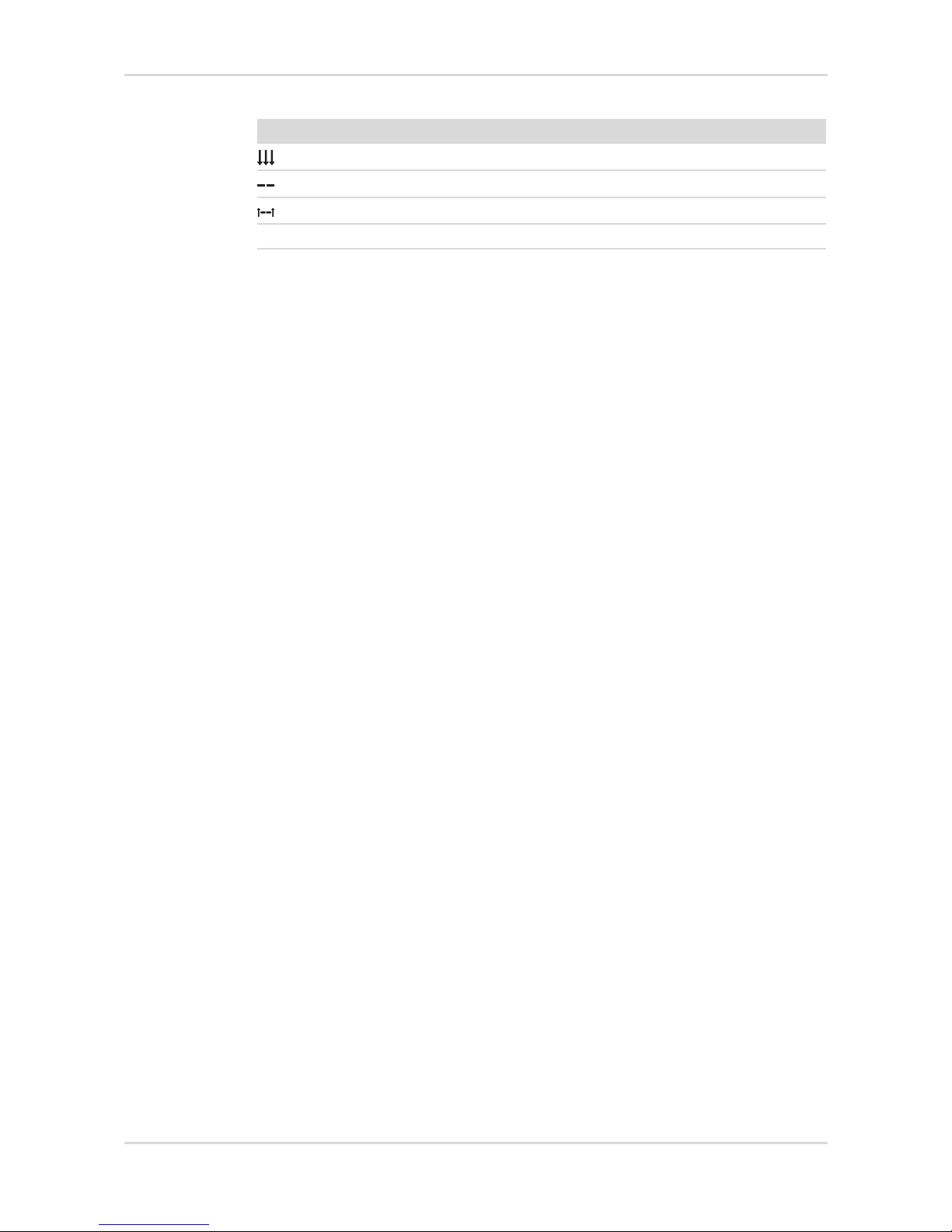

Readings below the measurement range

Channel error

Blocking alarm

##### Value too high to be displayed

Symbol Explanation

Page 19

Technical manual | X-am® 3500/8000 19

Operation

4.4.2 Switching on the gas detector

1. Hold down the OK button for approx. 3 s.

The display shows a countdown.

The switch-on sequence and the warm-up phase of the sensors start.

The following display appear one after the other:

–Start screen

– Software version

– Display test (the display alternates between black and white)

– Alarm element test (LEDs, alarm signal and vibration alarm)

– Customer-specific information screen (optional)

– Alarm thresholds, STEL, TWA (if configured) and LEL factor (if available)

– Any expired bump test or calibration interval as well as early warnings (if

configured)

– Measured value display

After the wizard is complete, a customer-specific information screen (optional and

configurable with the Dräger CC-Vision PC software) and the measured value

display appear. The remaining sensor warm-up time is displayed in the upper, lefthand corner in a yellow box.

WARNING

Incorrect device feature/settings!

Incorrect device features/settings may result in danger to life and/or risk of

explosion.

► Before every use, check whether the display elements, the alarm features and

information are displayed correctly. If one of the items listed above does not

feature correctly or is incorrect, do not use the gas detector and have it

inspected.

The following features are active during the sensor warm-up phase:

– The measured values flash

– The yellow LED is illuminated

– A warning notice is displayed

The gas detector is ready to measure when the measured values no longer flash

and the yellow LED is no longer illuminated. The warning notice may continue to

be displayed if there are warnings pending. To display the warnings, refer to the

technical manual.

No alarms are issued during the warm-up phase!

4.4.3 Switching off the gas detector

1. Hold down ▲ and ▼ simultaneously until the displayed countdown expires.

The visual, acoustic and vibration alarms activate briefly.

The gas detector is switched off.

Or

1. Select in measuring mode and confirm the dialog.

Page 20

20 Technical manual | X-am® 3500/8000

Operation

2. Select and confirm Switch off.

The gas detector may only be switched off without a prior sign-on if the Switch-

off allowed feature is activated using the Dräger CC-Vision PC software. Factory

setting: activated

When the gas detector is placed in the charging cradle, it switches off

automatically.

If the gas detector remains off for longer than 21 days and is not charged, deep

sleep mode is activated. In deep sleep mode, the gas detector can no longer be

switched on using the Dräger CC-Vision PC software or the Dräger X-dock. In this

case, the gas detector must be switched on manually.

4.5 Logging a user in or out

The gas detector has four configurable user levels. The user levels can be set using

the Dräger CC-Vision PC software. User level 0 means that the user is not signed

on. User levels 1 to 3 require a password for sign-on.

The following passwords are created by default:

Dräger recommends changing the predefined passwords after initial

commissioning.

Default setting:

User level 1: 0001

User level 2: 0002

User level 3: 0003

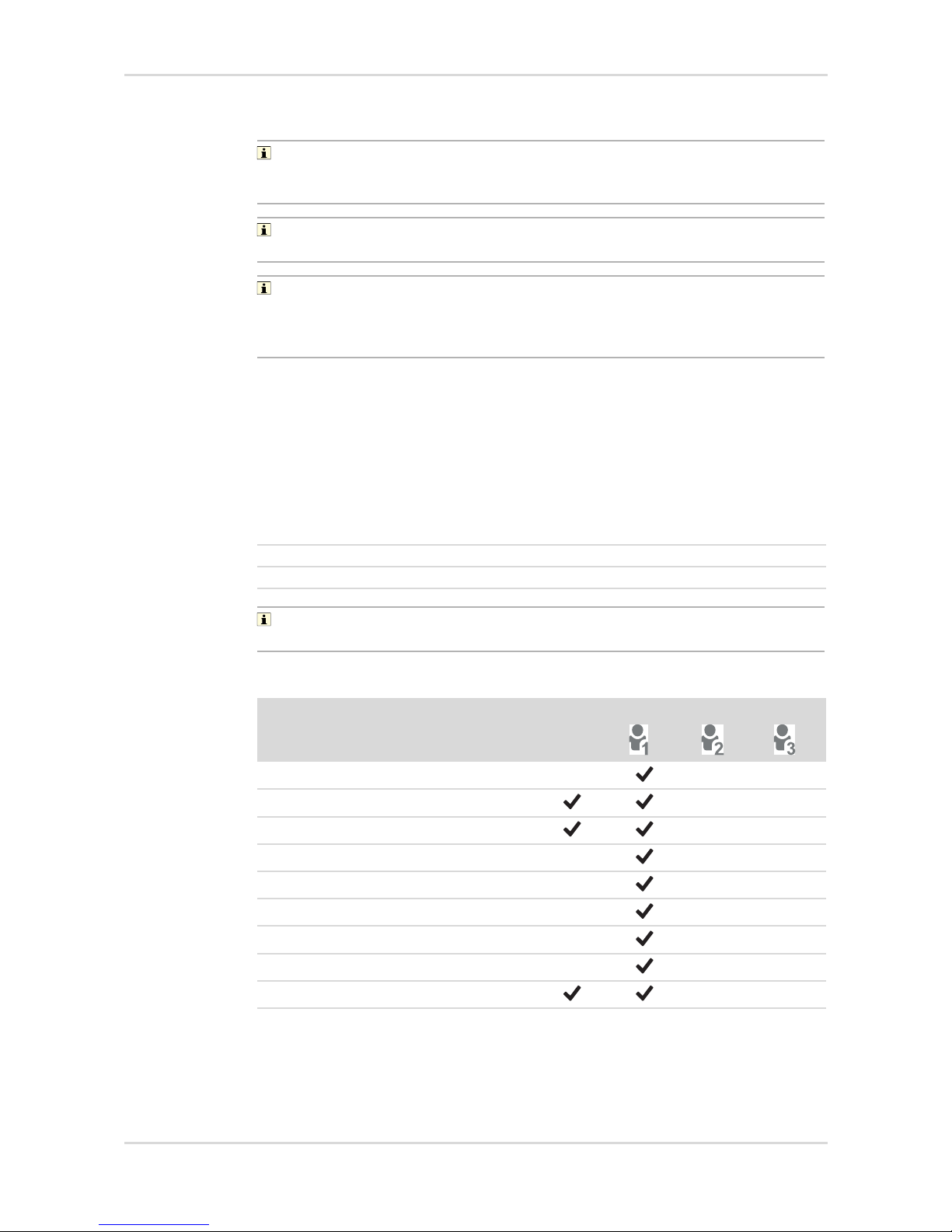

Function User level

0

Bump test

---

Fresh air adjustment

--

Clearance measurement

1)

1) X-am 8000 only

--

Leak search

1)

---

Benzene/pre-tube measurement

1)

---

Settings menu

---

Maintenance menu

---

Change measurement gas

1)2)

2) The data stored in the statistics counters are lost when the measurement gas is changed. The

Dräger GasVision PC software can be used to manually view the data via the data logger at a

later point in time. Automatic notifications via the X-dock Manager may only be available to a

limited extent.

---

Bluetooth

®1)

--

Page 21

Technical manual | X-am® 3500/8000 21

Operation

To log in a user:

1. Select in measuring mode and confirm the dialog.

2. Select and confirm Login.

3. Enter the four-digit user level password and confirm each digit.

To sign out a user:

1. Select in measuring mode and confirm the dialog.

2. Select ‘Sign out’ and confirm the dialog.

4.6 Preparations for operation

WARNING

Serious damage to health!

An incorrect calibration can lead to incorrect measured values, which may result in

serious damage to health.

► Before performing safety measurements, check the calibration by way of a bump

test, adjust as necessary, and check all alarm elements. If national regulations

exist, the bump test must be performed in accordance with these regulations.

WARNING

Risk of explosion

Only applicable if using the Dräger CSE Connect app:

The use of an unsuitable smartphone or accessories may lead to ignition of

flammable or explosive atmospheres.

► The smartphone on which CSE Connect is installed must be suitable and

approved for use in areas subject to explosion hazards.

► A list of compatible smartphones is available from Dräger.

► Use only accessories that are suitable for use in areas subject to explosion

hazards.

1. Switch on the gas detector. The current measured values are shown in the

display.

2. Observe warnings, error messages and special states.

3. Verify that the gas inlet openings and membranes are clean, freely accessible,

dry and undamaged.

4. Check that the date and time are set correctly.

4.7 During operation

WARNING

Danger to life and/or risk of explosion!

The following alarms indicate a danger to life and/or risk of explosion:

– A2 alarm

– STEL or TWA alarm

– Device/channel error

► Immediately leave the hazard area.

Page 22

22 Technical manual | X-am® 3500/8000

Operation

WARNING

Incorrect measured values!

Only for diffusion mode: If water seals the gas inlets on the gas detector (e.g. in

heavy rain or if the gas detector is submerged in water), incorrect measured values

may be returned.

► With the display facing downward, shake the gas detector to remove the water.

CAUTION

High readings outside of the LEL display range or a blocking alarm may indicate an

explosive concentration.

If the concentrations of combustible materials are too high, this may be the result of

a lack of O

2.

4.7.1 Monitoring measuring mode

In normal measuring mode, the measured values are displayed for every

measurement gas (see Graphic E on the fold-out page). The operation signal

sounds at regular interval (configurable), and the green LED pulses (e.g. visual

operation signal or D-light feature).

If a measuring range is exceeded or not reached, the respective symbol is

displayed instead of the measured value. For further information, see the following

chapter: "Symbol explanations", page 16

If, in measuring mode, a event (e.g. an alarm) occurs, the respective symbol is

displayed in the status bar (after the event is acknowledged, if necessary).

4.7.1.1 Displaying the measuring channel

To display an individual measuring channel:

1. Select in measuring mode.

2. Use ▲ or ▼ to view the individual measuring channels.

3. Select to navigate to the measuring channel overview.

4.7.1.2 Opening the event report

The following events are counted and displayed: A1/A2, STEL, shocks, incorrect

password entries.

If the gas detector is switched off and then on again, the event report is deleted.

To open the event report:

1. Select > Info > Device information in measuring mode.

2. Use ▲ or ▼ to scroll through the individual pages until the event report.

The symbol indicates a failed sign-on only after 5 attempts.

Page 23

Technical manual | X-am® 3500/8000 23

Operation

4.7.1.3 Activating the pump

To activate the pump in (normal) measuring mode:

1. Place, align and tighten the pump adapter on the thread port on the top cover.

Check that the pump adapter is mounted correctly. Avoid bending the pump

adapter. The gas detector automatically switches to pump mode as soon as the

pump adapter is mounted.

The leak test starts automatically.

2. When the leak test is displayed, the suction inlet on the probe or hose closes

within 60 s and remains closed until the leak test is complete.

3. Release the inlet opening.

● Leak test successful: Measurement starts.

● Leak test failed: Inspect the accessories and the pump adapter and then

repeat the leak test.

4. Observe the flushing times. For further information, see the following chapter:

"Special features when measuring with the pump", page 25

4.7.2 Alarms

In the event of an alarm, corresponding displays, the optical alarm, vibration alarm

as well as, if necessary, the acoustic alarm are activated (configurable). For further

information, see the following chapter: "Alarm settings", page 69

To acknowledge an alarm:

1. Select .

4.7.3 Special state

The operation signal is deactivated during a special state. Special states are

displayed by the following visual signals:

– Yellow LED flashing – ‘warm-up 1’ special state

– Yellow LED continuously illuminated – general special state

No alarms are issued during a special state.

Exception: The calibration adapter is mounted in measuring mode. In this case,

alarms continued to be issued as long as the measurement gas can reach the

sensors.

WARNING

Incorrect measurement!

A mounted calibration adapter blocks free gas diffusion to the sensors. Correct

measured values and alarms can no longer be guaranteed.

► It is imperative to actively bump the sensors (e.g. test gas cylinder with pressure

reducer, flow 0.5 L/min).

4.7.4 Blocking alarm

The blocking alarm protects the CatEx sensor.

Page 24

24 Technical manual | X-am® 3500/8000

Operation

If the measuring range is exceeded significantly at the CatEx channel (very high

concentration of flammable materials), a blocking alarm is triggered. This CatEx

blocking alarm can be acknowledge by switching the gas detector off and then on

again in fresh air.

X-am 8000 only: This does not apply in the case of an activated over range for

methane.

4.7.5 Deleting (application) peaks

1. Select in measuring mode.

2. Select Clear app. peak and confirm the dialog.

The function must be activated in the quick menu. Alternatively, this function can

also be called via the menu.

4.8 Calling the Quick Menu

The Dräger CC-Vision software can be used to save up to 6 preferred features.

The following features are default settings:

– Device information

– Switch between day and night mode

– Display messages

– Display shift peaks

– Display application peaks

– Delete application peaks

To open the quick menu:

1. Select in measuring mode.

2. Select and confirm the desired feature.

4.9 Opening information

1. Select > Info in measuring mode.

The following options are available:

Option Description

Messages The pending warnings and errors are

displayed.

Device information Device information and information

about the Bluetooth® module (optional,

X-am 8000 only) is displayed (e.g. MAC

address, serial number, firmware version etc.).

Page 25

Technical manual | X-am® 3500/8000 25

Operation

4.10 Measuring

4.10.1 Special features when measuring with the pump

NOTICE

Magnetic media may be damaged!

The pump adapter and calibration adapter contain a magnet which may delete data

from a magnetic stripe.

► Do not bring magnetic media (e.g. credit cards) into close proximity to the pump

adapter or calibration adapter.

– Use the dust and water separators when taking measurements with the pump.

– Following a bump test with aggressive gases (such as biogas or chlorine), flush

the pump with clean air for several minutes to extend the service life of the

pump.

Gas statistics The following gas statistics are avail-

able:

–Select Shift peak to display the

exposure peaks for all gasses.

–Select Application peak to display

the application peaks for all gasses.

–Select TWA values to display the

available TWA values for all gasses.

–Select STEL values to display the

available STEL values for all gasses.

Intervals The following intervals are available:

– Select the bump test interval (Bump

test interval) to display the days

remaining until the next bump test for

all channels. For details, select and

confirm the respective channel.

–Select Calibration interval to dis-

play the days remaining until the next

calibration for all channels. For

details, select and confirm the

respective channel.

–Select Life time to display the

remaining life time.

Capture ranges Capture ranges are displayed.

Battery The battery state of charge is displayed

(large).

Approvals

(X-am 8000 only with the Bluetooth®

module)

Approval information is displayed (eLabel).

Option Description

Page 26

26 Technical manual | X-am® 3500/8000

Operation

The wizards are only available for X-am 8000.

For the DrägerSensors XXS CI2, COCI2, O3 as well as amine and odorants, there

are no wizards for confined spaces and leak searching, as these materials can not

be pumped (properly) through tubes. In addition to the materials listed above, there

may also be other materials for which there are no flushing times available in the

gas detector. There is no confined space entry wizard for these materials.

Flush the Dräger sampling hose or Dräger probes prior to each measurement with

the gas to be measured. The flushing phase is necessary to reduce negative effects

associated with the use of a sampling hose or a probe, e.g. gas transport time,

memory effects, dead volume. The duration of the flushing phase depends on

factors such as type and concentration of the gas or vapour to be measured as well

as material, length, diameter and age of the sampling hose or probe. In addition to

the flushing time, the sensor response time must be observed (refer to the

instructions for use for the DrägerSensors used).

Generally, when using a sampling hose (3 mm internal diameter, new, dry, clean)

with standard gasses, a typical flushing time of approx. 3 s/m is required.

Example:

The flushing time for oxygen with a 10 m hose is approx. 30 seconds. The assumed

sensor response time is approx. 10 seconds in addition. Thus, the overall time

before reading the gas detector is approx. 40 seconds.

A flow-rate alarm is delayed by 10 to 30 seconds depending on the length of the

hose.

X-am 8000: For benzene/pre-tube measurements, the maximum hose length is

10 m.

4.10.2 Carrying out measuring with the pump

Requirements:

– The gas detector is equipped with a pump and is switched on.

– All installed sensors are warmed up.

– The gas detector is ready to take measurements.

– The thread port for the pump adapter and calibration adapter must be clean.

1. Connect the hose (3 mm internal diameter) with the dust and water filter to the

inlet spout (see figure M on page 3) of the pump adapter.

Page 27

Technical manual | X-am® 3500/8000 27

Operation

2. Mount the pump adapter to the gas detector. Make sure that both guide pins are

in the correct grooves.

Check that the pump adapter is mounted correctly. If the pump adapter is

mounted correctly, the leak test starts automatically. If the leak test does not

start, the gas detector is not ready for use. Avoid bending the pump adapter.

The gas detector automatically switches to pump mode as soon as the pump

adapter is mounted.

The leak test starts automatically.

3. When the leak test is displayed, the suction inlet on the probe or hose closes

within 60 s and remains closed until the leak test is complete.

4. Open the suction inlet.

– Leak test successful: Measuring starts. Observe the purging times!

– Leak test failed: Inspect the probe, hose and adapter and repeat the leak

test.

5. Place the probe or the end of the hose on the sampling location.

The temperature at the measurement location may deviate from the temperature

in the gas detector, which may influence the measured value display. The correct

functioning of the temperature correction can only be guaranteed on the gas

detector.

To stop measuring with the pump:

1. Loosen the screw on the pump adapter.

34964

!

Page 28

28 Technical manual | X-am® 3500/8000

Operation

2. Remove the pump adapter.

✓ The pump is flushed and the gas detector automatically switches to diffusion

mode.

4.11 Measurements with wizards

The gas detector has wizards for easily preparing the measurements and for

measurement displays optimised for the measurement.

There are wizards for the following applications:

– Confined space entry: for measuring with a probe/hose, e.g. In a container

– Leak search: for detecting gas leaks

– Benzene/pre-tube measurement: for using pre-tubes as a filter for the PID

While the wizard loads, the gas detector is in a special state.

The wizards are not supported if the gas detector does not have the required

material-specific properties for the gas to be measured, or if the gas detector is not

within the permissible temperature range (typically 0 to 40 °C for confined spaces

and benzene/pre-tube measurements).

4.12 Carrying out confined space entry measurements with

the wizard

During confined space entry measurements, the duration of the measurement (in

mm:ss) is displayed for a maximum of one hour in place of the time. Afterwards, the

time is displayed again. The measurement duration is restarted after each flow

alarm.

Requirements:

– The gas detector is switched on.

– The user is signed in with the corresponding user level.

To carry out a confined space entry measurement:

1. Sign in with the required user level, if necessary.

2. Select > Confined Space in measuring mode (if configured using the Dräger

CC-Vision PC software). Follow the directions of the wizard.

The hose length or probe selection is displayed.

3. Select the hose length / probe.

The leak test starts.

4. Confirm the successful leak test.

The start dialog for the measurement is displayed.

5. Place the probe or the hose on the sampling location.

6. Confirm the dialog to start the measurement.

The hose is flushed, and the remaining flushing time is displayed. If, during the

flushing time, an alarm threshold is or the permissible temperature range is

exceeded, the countdown is stopped, the alarm or message is displayed and the

special state is exited.

Page 29

Technical manual | X-am® 3500/8000 29

Operation

The displayed flushing time shows the minimum wait time required for the

measurement gas to reach the sensor from the sampling location in an ideal

scenario. This applies to the use of a Dräger sampling hose (fluoroelastomer,

brand new, dry, clean) with an internal diameter of 3 mm. Other fixtures (e.g.

pre-tube) extend the minimum wait time and must also be taken into

consideration. The flushing time only applies to the configured measurement

gas.

The flushing times recommended by the gas detector are ascertained according

to the state of technology. Dräger is not liable for their use. The user is responsible

for evaluating the wait time for their application. After the wait time expires,

evaluation is required to determine if the measured value is stable or if the wait time

was possibly insufficient. The same applies if the countdown was stopped

unexpectedly.

The measurement of other gasses or vapours than the selected measurement

gas per measuring channel causes additional wait time which must also be

considered in addition to the minimum wait time.

The confined space entry measurement is displayed when after the flushing time

is complete.

To end the confined space entry measurement:

1. Select during the confined space entry measurement and confirm the dialog.

A dialog for performing another confined space entry measurement is

displayed.

2. Select to end the wizard.

3. Remove the pump adapter.

4. Return to normal measuring mode.

4.13 Carrying out leak searches with the wizard

During a leak search, the duration of the measurement (in mm:ss) is displayed for a

maximum of one hour in place of the time and the measured values can be

displayed in the form of a bar chart (configurable with the CC-Vision PC software).

Afterwards, the time is displayed again. The measurement duration is restarted

after each flow alarm.

During a leak search, the Clear app. peak feature should be stored in the quick

menu using the Dräger CC-Vision PC software. This feature can be used to delete

the application values in the bar chart.

Because of the physical flushing times, Dräger recommends carrying out

measurements with the leak search wizard without a hose/probe or with only a

short hose (max. 2 m).

Requirements:

– The gas detector is equipped with a pump and is switched on.

– All installed sensors are warmed up.

– The gas detector is ready to take measurements.

Page 30

30 Technical manual | X-am® 3500/8000

Operation

To carry out a leak search:

1. Sign in with the required user level.

2. Select > Leak Search in measuring mode.

3. Confirm the successful leak test to start the measurement.

The device emits tones in the “Individual measuring channel” display which

increase in frequency as the gas concentration increases. If the pre-alarm threshold

is reached, the gas alarm appears.

To end the leak search:

1. Select in leak search mode and confirm the dialog.

2. Remove the pump adapter.

3. Return to normal measuring mode.

4.14 Carrying out a benzene/pre-tube measurement with the

wizard

Observe the instructions for use of the respective tube!

The use of a pre-tube is only possible when using the wizard.

During the benzene/pre-tube measurement, the visual alarm, acoustic alarm,

vibration alarm and alarm evaluation are deactivated.

A benzene/pre-tube measurement (photoionisation detector) with a pre-tube (e.g.

benzene pre-tube) can only be done with the benzene/pre-tube wizard.

During the benzene/pre-tube measurement, the gas to be measured and the PEAK

values are visible on the display. All other sensors are not evaluated.

4.14.1 Mounting the pre-tube bracket

Fast temperature and humidity changes influence the measured signal. If

temperature and humidity jumps are anticipated, Dräger recommends using a

damp pre-tube for the measurement.

Page 31

Technical manual | X-am® 3500/8000 31

Operation

1. Mount the pump adapter to the gas detector. Make sure that both guide pins are

in the correct grooves.

2. Connect the dust and water filter (3) to the short hose piece (4) on the pump

adapter (5).

3. Mount the pre-tube bracket (2) to the dust and water filter (3).

4. Mount the hose or bar probe (1) to the pre-tube bracket (2) (max. hose length:

10 m).

5. As necessary: Use a floating probe.

3496434965

!

1

2

5

3

4

Page 32

32 Technical manual | X-am® 3500/8000

Operation

Use an adapter piece for varying hose diameters if necessary (minimum internal

diameter: 3 mm).

4.14.2 Making measurement

Use a new pre-tube for each individual measurement with a pre-tube.

Requirements:

– The gas detector is switched on.

– The user is signed in with the corresponding user level.

– Warm-up phase 1 of the PID is complete.

– The pre-tube bracket and the dust and water filter are mounted on the pump

adapter.

To carry out a benzene/pre-tube measurement:

1. Select > Benzene / Pre-tube in measuring mode (if configured using the

Dräger CC-Vision PC software).

A dialog for performing the fresh air calibration is displayed.

2. Carry out a fresh air calibration with an activated charcoal tube or skip this step

by pressing .

3. When selecting the fresh air calibration:

4. Follow the directions of the wizard.

5. After a successful fresh air calibration, remove the activated charcoal tube.

6. The pre-tube selection is displayed.

7. Select the pre-tube.

If a benzene pre-tube is selected, the PID automatically switches to benzene.

8. Open the pre-tube, insert it in the pre-tube bracket (arrow marking in the

direction of the gas detector; see figure L on page 3) and confirm the dialog.

The hose length selection is displayed.

9. Select the hose length or probe.

The leak test starts.

10.Confirm the successful leak test.

The start dialog for the measurement is displayed.

11. Place the probe or the end of the hose on the sampling location.

12.Select to start the measurement.

The hose is flushed, and the remaining flushing time is displayed.

The benzene/pre-tube measuring mode is displayed after the flushing time is

complete.

To end the benzene/pre-tube measurement:

1. Select in benzene/pre-tube measuring mode and confirm the dialog.

A dialog for removing the pre-tube appears.

2. Remove the pre-tube.

A dialog for a further benzene/pre-tube measurement appears.

3. Select to end the benzene/pre-tube measurement.

4. Remove the pump adapter with the pre-tube bracket if necessary.

Page 33

Technical manual | X-am® 3500/8000 33

Operation

4.15 Configuring the device settings

Briefly press and simultaneously to navigate to Monitoring.

To open the device settings:

1. Select in measuring mode and confirm the dialog.

2. Sign in with the required user level, if necessary.

3. Select and confirm Settings.

4.15.1 Activating day or night mode

1. Open the device settings.

2. Select and confirm Night mode / Day mode.

4.15.2 Changing the device language

1. Open the device settings.

2. Select Changing language....

3. Select and confirm the desired language.

4.15.3 Setting the date and time

1. Open the device settings.

2. Select Date & Time.

3. Select Set date format and then select and confirm the date format.

4. Select Set date and then set and confirm the date.

5. Select Set time and then set and confirm the time.

The user must manually switch between summer and winter time.

When using the X-dock maintenance station, automatic time synchronisation is

possible.

4.15.4 Activating silent mode

Silent mode can be activated for 15 minutes on the gas detector. When silent mode

is active, vibration and the horn are deactivated. Permanent deactivation is possible

using the Dräger CC-Vision PC software.

Silent mode may not be permanently activated for applications according to ATEX.

4.15.5 Activating or deactivating the capture range

1. Open the device settings.

2. Select Capture ranges.

3. Activate or deactivate the capture range.

Dräger recommends that you activate the capture ranges function.

Page 34

34 Technical manual | X-am® 3500/8000

Operation

4.15.6 Activating or deactivating Bluetooth® (X-am 8000 only)

1. Open the device settings.

2. Select Bluetooth.

3. Activate or deactivate Bluetooth

®

.

4.16 Activating an automatic over range

An automatic over range can only be activated for the sensors DrägerSensor CatEx

125 PR (order number 68 12 950) and CatEx 125 PR Gas (order number

68 13 080) with the measurement gas methane.

Prerequisite:

– The measuring ranges %LEL (heat of reaction) and vol. % (thermal

conductions) are calibrated.

1. The automatic over range can only be activated with the Dräger CC-Vision PC

software.

WARNING

Risk of explosion!

Only for CatEx sensors: The automatic over range only applies for methane in the

air. Any other gas composition has an impact on the measured signal, may cause

an incorrect display of the results and may cause permanent damage to the sensor.

► Only use the automatic over range to measure methane in the air.

When the automatic over range is activated, the device automatically switches to

the vol. % range if the 100 %LEL methane range is exceeded.

When the values return to the <100 %LEL methane range, the measured value

display alternates with the transitional phase indicator (circle arrow).

4.17 Hydrogen (H2) added signal (for IR Ex)

The H2 added signal can be adjusted using the Dräger CC-Vision PC software.

Requirements:

– At least one DrägerSensor XXS H

2 HC (68 12 025) is activated. H2 is set as the

measurement gas.

– An Ex channel on the DrägerSensor DUAL IR Ex/CO

2 (6811960) or

DrägerSensor IR Ex (68 12 180) is activated.

– Both channels are set to the unit %LEL/%LEL/%LIE.

–The H

2 added signal is only possible with a DrägerSensor XXS H2 HC and an

IR Ex channel.

When the H

2 added signal is activated, the LEL gas concentrations of both selected

sensors are added together and the result is shown in the display in the place of the

IR Ex display.

An activated H

2 added signal is displayed with a + next to the gas name of the

IR Ex sensor in the display.

Page 35

Technical manual | X-am® 3500/8000 35

Operation

Previously set alarm thresholds are maintained in order to ensure that in the

presence of hydrogen (H

2) the alarm of the IR Ex Channel is triggered earlier if

required.

Page 36

36 Technical manual | X-am® 3500/8000

Troubleshooting

5 Troubleshooting

If the following remedial measures are unsuccessful, contact DrägerService.

5.1 Error

Error Cause Remedy

Life time expired Life time of the gas detec-

tor expired

Reconfigure the life time

with the Dräger CC-Vision

PC software.

Device locked Gas detector locked by X-

dock

Unlock the gas detector

with X-dock or the X-dock

manger.

Bump test interval

expired

Bump test interval expired Carry out bump test.

Calibration expired Calibration interval expired Carry out the span calibra-

tion.

Hardware error An internal fault has been

detected.

Switch the instrument off

then on again, or remove

and reconnect the battery.

Pressure too low Ambient pressure below

the minimum range

Check the ambient pressure and restore the

device to a permissible

range.

Pressure too high Ambient pressure above

the maximum range

2 adapters identified More than one magnetic

sensor detected

Remove the faulty magnetic fields.

LED failure Failed alarm element test

with X-dock: Alarm lamp

Repeat the alarm element

test with X-dock.

Horn failure Failed alarm element test

with X-dock: Alarm horn

Repeat the alarm element

test with X-dock.

Vibrator failure Alarm element test result

with X-dock: Vibration

motor faulty

Repeat the alarm element

test with X-dock.

Alarm test failed Alarm test with X-dock

failed

Repeat the alarm test with

X-dock.

Battery com. error Data connection to battery

interrupted. (Screws may

not be tightened properly)

Re-mount the battery.

Bump test failed Bump test failed Carry out a bump test or a

span calibration

Zero calibration failed Zero-point calibration

failed

Carry out a zero-point

adjustment

Span calibration failed Span calibration failed Carry out a span calibra-

tion

Capturing is on Response time test with X-

dock failed

Repeat the response time

test with X-dock.

Page 37

Technical manual | X-am® 3500/8000 37

Troubleshooting

5.2 Warnings

Oxygen deficiency Insufficient oxygen for the

correct functionality of the

CatEx sensor

Operate the gas detector

in atmospheric conditions.

Value negative Measured value in nega-

tive range

Carry out a fresh air calibration / zero-point calibration

Sensor missing Sensor faulty or not con-

nected

Connect sensor or check

contacts

Span calibration compensation channel failed

Failed span calibration of

the horizontal electrode

Carry out a span calibration for the horizontal electrode

SDS parameter error

1)

IR sensor error detected. Switch the device off and

then on again; exchange

the IR sensor.

Sensor subsystem

error

1)

IR sensor error detected:

IR-sensor reports an error

IR sensor peak

1)

IR sensor error detected:

IR signal quality

Error acknowledges itself

automatically if the error

condition is no longer

present.

Overrange after warm-up 1Overgassing detected on

CatEx sensor immediately

after warm-up 1

Carry out a zero-point

adjustment

CatEx contaminated CatEx sensor poisoning Exchange the CatEx sen-

sor

Invalid part no. Sensor part number

invalid or not supported.

Check the sensor date

(inauguration code); use

the current sensor or

update the firmware.

No pump installed The pump adapter is con-

nected, but he pump is not

usable (or not available)

Remove the pump adapter

from the device

Pump flow range Contact Dräger service

Pump error Exchange the pump

Pump flow too low Inspect the pump adapter,

hose and hose connections

1) X-am 8000 only

Error Cause Remedy

Warnings Cause Remedy

Life time expires soon Life time of the device

expires soon

Reconfigure the life time

with the Dräger CC-Vision

PC software.

Bump test interval

expires soon

Bump test interval expires

soon

Perform bump test

Bump test interval

expired

Bump test interval expired Perform bump test

Page 38

38 Technical manual | X-am® 3500/8000

Troubleshooting

Calibration expires soon Calibration interval expires

soon

Carry out a span calibration

Calibration expired Calibration interval of the

(compensation)channel

expired

Carry out a span calibration

Logger almost full Data logger memory 90 %

full

Read out the data memory

(with the GasVision PC

software) and/or delete it.

Or switch to “overwrite”.

Logger full Data logger memory 100%

full

Temperature too high Ambient temperature too

high.

Reduce the ambient temperature; calibrate the

sensor.

Temperature too low Ambient temperature too

low.

Increase the ambient temperature; calibrate the

sensor.

Pressure too high Pressure above the maxi-

mum range

Lower the ambient pressure

Pressure too low Pressure below the mini-

mum range

Increase the ambient pressure

Battery too hot Battery sub-system too hot Reduce the ambient tem-

perature

Battery too cold Battery sub-system too

cold

Increase the ambient temperature

Battery com. error Data connection to battery

interrupted. (Screws may

not be tightened properly)

Re-mount the battery

Peak detected

1)

IR sensor error detected:

IR signal quality

Switch the device off and

then on again; exchange

the IR sensor.

Warm-up 1 Device not yet measure-

ment-ready

Wait until warm-up time 1

is complete

Warm-up 2 The warm-up time of the

sensors varies depending

on the ambient conditions.

Wait until warm-up time 2

is complete (e.g. required

before calibration can be

carried out)

CatEx protection CatEx sensor blocking

alarm caused by overgassing

Switch the device off and

then on in fresh air

Value negative Measured value in nega-

tive range

Carry out a fresh air calibration / zero-point calibration.

Pump error Replace the pump.

1) X-am 8000 only

Warnings Cause Remedy

Page 39

Technical manual | X-am® 3500/8000 39

Maintenance

6 Maintenance

WARNING

Risk of explosion!

To reduce the risk of ignition of a flammable or explosive atmosphere, observe the

following:

► Do not open the gas detector in explosion-hazard areas.

WARNING

Danger to health!

Test gas may damage health if inhaled.

► Do not inhale the test gas. Observe the hazard warnings of the relevant Safety

Data Sheets and the instructions for use of the gas detector! Observe the

national regulations when defining calibration intervals.

6.1 Maintenance intervals

For inspections and maintenance, see:

– EN 60079-29-2 – Guidelines for selection, installation, use and maintenance of

instruments for the detection and measurement of flammable gases and oxygen

– EN 45544-4 – Electrical apparatus used for the direct detection and direct

concentration measurement of toxic gases and vapours – Part 4: Guide for

selection, installation, use and maintenance

– National regulations

6.2 Calibration intervals

Observe the relevant specifications in the Sensor Handbook or in the instructions

for use/data sheets of the DrägerSensors installed.

Recommended calibration intervals for DrägerSensors:

Tes t Interval

Inspection and maintenance by specialists.

Every 12 months

DrägerSensor Calibration interval

CatEx, O

2, H2S, H2S LC, CO LC, SO2,

NO

2

Every 6 months

IR Ex/CO

2 Every 12 months

PID HC, PID LC ppb Depending on the application condi-

tions, daily calibration may be necessary. The interval can be extended littleby-little to 30 days if there are no calibration deviations on consecutive

inspections.

Other DrägerSensors See the special data sheets for the

respective sensors.

Page 40

40 Technical manual | X-am® 3500/8000

Maintenance

6.3 Perform bump test

The bump test can be performed as follows:

– Bump test with the wizard (quick bump test)

– Bump test with X-dock (quick or extended bump test)

Dräger recommends using the extended bump test for cross calibrations (Dräger

X-dock instructions for use).

X-am 8000: If the gas detection instrument is equipped with a PID sensor, Dräger

recommends not to use the Nonane tester (order no. 83 25 61) for the bump test

because of the long saturation time of the PID sensor.

6.3.1 Carrying out bump tests with the wizard

WARNING

Incorrect alarm behaviour!

A closed gas path causes incorrect measured values. This may cause alarms to be

triggered incorrectly.

► Never close the outlet of the calibration adapter.

Dräger recommends a test gas concentration of <60 %LEL for CatEx and IR

sensors and a measuring range of 0 % to 100 %LEL.

For bump tests with the wizard and the X-dock, the results are saved in the device

memory.

Requirements:

– A bump test can only be carried out if at least one sensor has been configured

for the bump test with the Dräger CC-Vision PC software.

– The gas detector is switched on and warm-up phase 1 is complete.

– The thread port for the pump adapter and calibration adapter must be clean.

– A suitable test gas cylinder is available, e.g. a test gas cylinder (order number

68 11 130) with the following mixed gas ratios: 50 ppm CO, 15 ppm H

2S,

2,5 vol. % CH4, 18 vol. % O

2

Other test gas cylinder can be added upon request.

Page 41

Technical manual | X-am® 3500/8000 41

Maintenance

To perform a bump test:

1. Mount the calibration adapter to the gas detector. Make sure that both guide

pins are in the correct grooves.

2. Connect the hose to the test gas cylinder and the inlet on the calibration adapter.

3. If needed, connect a second hose (max. length: 2 m) to the outlet on the

calibration adapter to direct the test gas to an exhaust or outside. Make sure that

these is sufficient ventilation in room or vehicles.

4. Open the bump test (depending on the configuration).

a. Select > Maintenance > Bump test (if configured using the Dräger CC-

Vision PC software).

b. > Login

Enter and confirm the password.

Select Maintenance > Bump test.

5. Open the valve on the test gas cylinder, the volume flow must be 0.5 /min and

the gas concentration must be higher (lower with oxygen) than the alarm

threshold concentration that is to be tested.

6. Select to start the bump test.

All measuring channels which are included in the bump test flash, and all

others are greyed out. When a measuring channel successfully passes the

test, appears.

7. The bump test is complete when all measuring channels included in the test

successfully passed or failed the test.

8. Close the valves on the test gas cylinder.

● Select and then confirm the dialog to discard the result.

● Select to confirm the result.

34964

!

Page 42

42 Technical manual | X-am® 3500/8000

Maintenance

9. Remove the calibration adapter.

If there was an error during the bump test:

1. An error is displayed for the measuring channel.

2. Repeat the bump test.

3. If necessary, replace the sensor.

6.4 Calibrate the gas detector

WARNING

Incorrect measured values!

An incorrect calibration may prevent alarms from triggering, or alarms may trigger

late.

► Do not close the outlet of the calibration adapter / exhaust gas hose.

► Always carry out the fresh air / zero adjustment before the span calibration.

NOTICE

Damage to the sensors!

When using the exhaust gas hose, the sensors may be damaged in the case of

direct suction on the exhaust gas hose.

► If necessary, lead the exhaust gas hose (max. length 2 m) to an exhaust of

outside.

Adjustment may not be possible due to instrument and channel errors.

6.4.1 Carrying out a fresh air calibration

To improve accuracy, a fresh air calibration must be carried out if there is a zero

deviation.

Observe the following notices for the calibration:

● For calibrating the XXS O

2 with fresh air, set the display to 20.9 Vol%.

● There may be deviations of >10 % of the measured value for temperatures

below –20 °C if the respective sensor is calibrated at room temperature. Dräger

recommends calibrating the sensor at the planned operating temperature if the

measurement is to be carried out at very low temperatures. This allows a

possible deviation to be reduced.

X-am 8000:

● An activated H

2 added signal is automatically deactivated duration of a bump

test or a calibration.

● During fresh air calibrations, the zero-point of all sensors (except the

DrägerSensors XXS O

2, DUAL IR CO2 and IR CO2, XXS O3) is set to 0.

● The DrägerSensors DUAL IR CO

2, IR CO2 and XXS O3 must be calibrated with

a suitable gas which is free of carbon dioxide / ozone (e.g. N

2).

● The DrägerSensor PID LC ppb can be calibrated with the zero gasses nitrogen

or synthetic air.

Page 43

Technical manual | X-am® 3500/8000 43

Maintenance

Requirements:

– Fresh air calibration can only be carried out if at least one sensor supports the

fresh air calibration.

– The fresh air must be free of measurement or interfering gasses.

– The gas detector is switched on and warm-up phases 1 and 2 are complete.

To carry out a fresh air calibration:

1. Switch on the gas detector.

2. Open the fresh air calibration (depending on the configuration):

If the fresh air calibration was released for user level 0 by the Dräger CC-Vision

PC software:

● Select > Maintenance > Fresh air cal..

If the fresh air calibration was not released for user level 0 by the Dräger CCVision PC software:

a. > Login

b. Enter and confirm the password.

c. Select Maintenance > Fresh air cal..

3. Select to start the fresh air calibration.

All measuring channels which are included in the fresh air calibration flash,

and all others are greyed out.

The result is displayed as follows for every measuring channel:

fresh air calibration successful.

fresh air calibration failed.

4. If necessary, press to overrule the stability control. In this case, a calibration

happens immediately.

Dräger recommends using the automatic stability control (wait until the gas

detector has automatically carried out the calibration).

The new measured value is displayed for confirmation.

The result is displayed as follows:

fresh air calibration successful.

fresh air calibration failed.

5. The fresh air calibration is complete when all measuring channels included in

the calibration have successfully passed or failed the calibration.

► Select and then confirm the dialog to discard the result.

► Select to confirm the result.

If there was an error during the fresh air calibration:

– Repeat the fresh air calibration.

– If necessary, replace the sensor.

6.4.2 Carrying out a single-gas calibration

For a single-gas calibration, you can choose either the zero-point calibration and

span calibration.

With a zero-point calibration, the zero-point of the selected sensor is set to zero.

With a span calibration, the sensitivity of the selected sensor is set to the defined

value of the test gas used.

Page 44

44 Technical manual | X-am® 3500/8000

Maintenance

X-am 8000 only: When implementing an active over range with the CatEx sensor