DPA Microphone Type 4051, Type 4052, Type 4053, Type 3552 User's Manual

1

CONTENTS

Technical Description 2

Specifications 8

3552: Compact omni kit, 48V. 11

Care of Microphone 13

Service and Repair 16

War ranty 16

CE Marking 16

USER’S MANUAL

Compact Omnidirectional Microphones Ø16 mm

Included in kit solutions

Type

4051

Type

4052

Type 4053

Type 3552

32

TECHNICAL DESCRIPTION

The cartridge

Types 4051, 4052 and 4053 are Omnidirectional (pressure) microphones that use the same microphone capsule as the standard

microphones Types 4003 and 4006 - a 16 mm (0.63 in) diameter

prepolarized condenser cartridge. The diaphragm is a nickel foil

which has been coated with an ultra-thin polymer layer for optimum

corrosion resistance. The microphone housing is of German silver,

an alloy with a high content of nickel to match the stable thermal

qualities of the diaphragm. The cartridge has low self noise (typical

15 dB(A) re 20 mPa) and high sensitivity (30 mV/Pa). For optimum

stability the microphone cartridge has undergone a special preaging process which releases all tensions in the materials and stabilizes the polarization voltage.

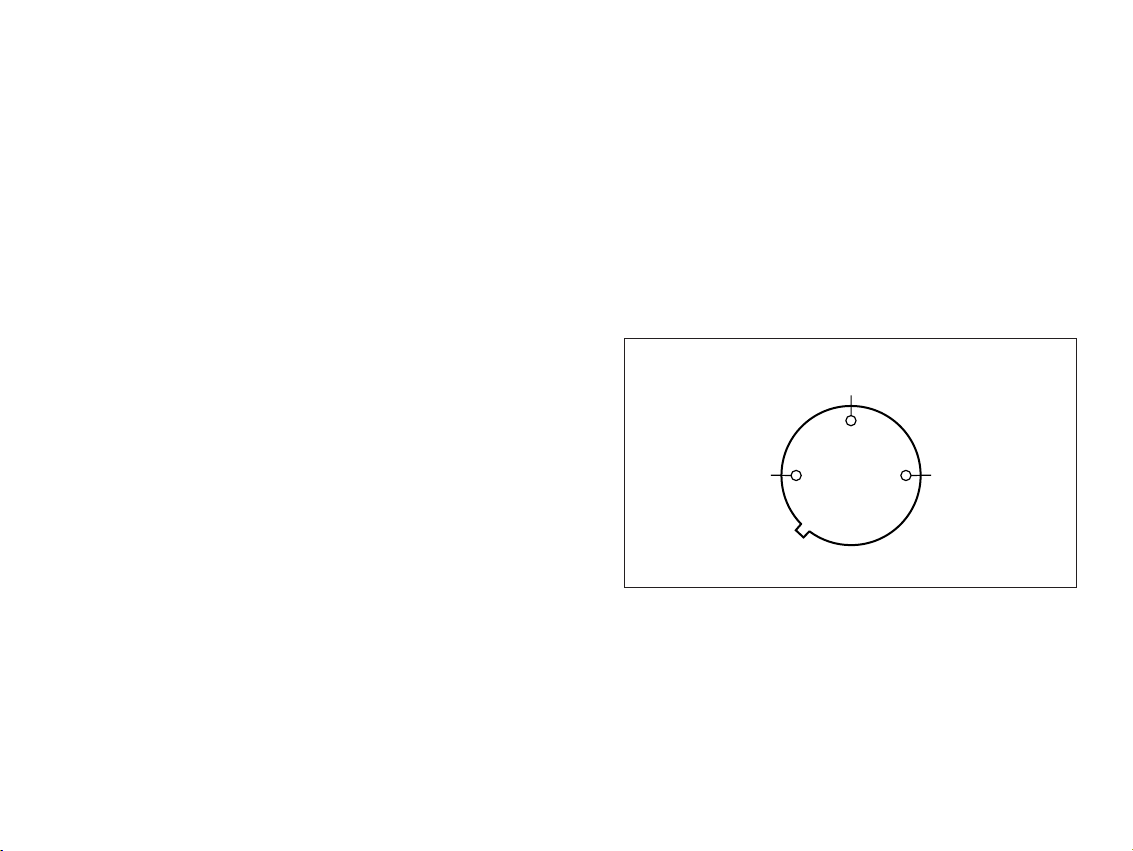

The preamplifier

The Compact Omnidirectional Microphones use built-in ultra-small,

thickfilm preamplifiers with unity-gain, low noise FET-amplifier technology. The thick-film technology enables the microphone cartridge

to be mounted on an exceptionally compact microphone housing

with the preamplifier mounted directly behind the microphone cartridge. A circuit of passive components in the standard 3-pin XLR

connector adapts the P48 phantom powering, separates the supply

voltage from the audio signal and acts as an impedance balancing

circuit for optimum noise immunity. The preamplifier has a cable

drive capability of up to 100 m (3.94 in) after the XLR-connector

(See Fig. 1 for pin designation).

All microphones come with an individual calibration chart of the selfnoise, sensitivity and the individual frequency response.

Fig. 1. External view of the output socket of the standard 3-pin

XLR-connector used in the Types 4051, 4052 and 4053.

GroundSignal +

Signal -

3

2

1

Important: The microphones will only operate within their

specifications if powered correctly.

The mechanical design

Types 4051, 4052 and 4053 are acoustically identical, but differ in

their mechanical design. All Compact Omnidirectional Microphones

are delivered with 5 m (16.4 ft) of extremely flexible, high quality

microphone cable as standard. The 4051 cable is side-mounted on the

microphone and the 4052 cable is rear-mounted. The 4053 feature

a co-axial Lemo-connector, for simple and safe attachment mounting of the microphones to DPA Compact Active Poles.

5

The Near-field Grid

The Near-field Grid DD0251 on the microphone cartridge is

designed to have a linear on-axis frequency response for near-field

applications (see Fig. 2 for frequency responses measured with the

Near-field Grid). The grid is factory mounted but can be exchanged

with the DD0297 Diffuse-f ield Grid or the UA0777 Nose Cone.

Please be extremely careful not to touch the exposed diaphragm

when changing the grids.

The Diffuse-field Grid

The Diffuse-field Grid DD0297 is supplied as st andard. It is

designed for diffuse-field recordings, or recordings in the far f ield.

The grid gives a high-frequency boost on-axis of 6 dB around 15 kHz

(see Fig. 3) without adding noise to the recording. This boost gives

a linear diffuse-field (far field) response up to 15 kHz.

The Nose Cone

The Nose Cone UA0777 is included in the 3552 kit and is available

as an optional accessory for 4051, 4052 and 4053. As with the

Diffuse-field Grid DD0297, the Nose Cone is simply screwed onto

the microphone cartridge in place of the Near-field Grid DD0251.

When fitted, the Nose Cone gives the microphone a true omnidirectional response even at high frequencies (see Fig. 6) and a linear diffuse-field response (see Fig. 4). These qualities are useful at any

distance for an even tonal balance of sound arriving at all angles of

incidence, e.g. room reverberation or several sound sources placed

around the microphone. The diaphragm is placed in a slot behind

the solid cone and sound waves only have access to the diaphragm

through the side of the Nose Cone. This way the Nose Cone prevents an on-axis, high frequency sound pressure build-up on the

microphone, which is the reason for normal flat fronted omnidirectional microphones becoming more and more directional for higher

frequencies. There is however, a slight high frequency boost on

axis.

4

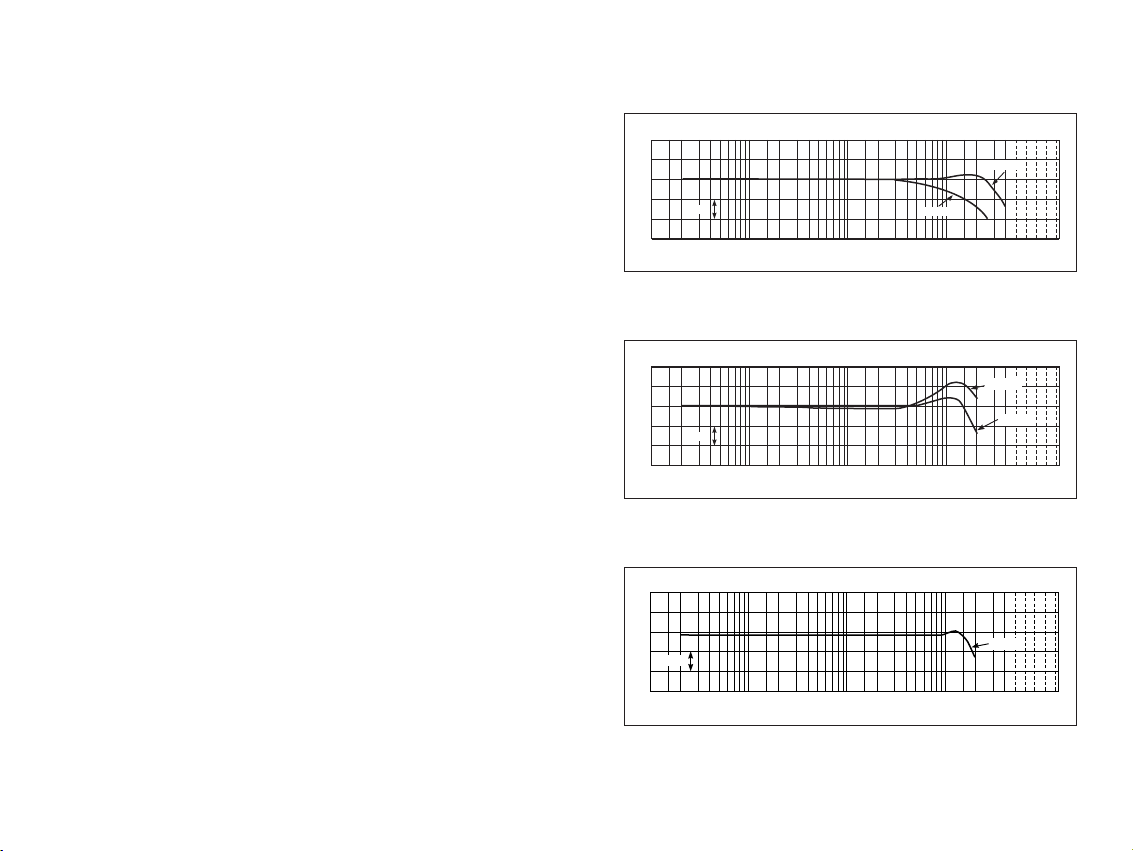

Fig. 2. On-axis and diffuse-field responses of Types 4051, 4052 and

4053 with the Near-field Grid DD0251 fitted.

Fig. 3. On-axis and diffuse-field responses of Types 4051, 4052 and

4053 with the Diffuse-f ield Grid DD0297 fitted.

25

dB

20

15

10

5

0

10 20 Hz 50 100 200 500 1 kHz 2 5 10 20 40D A B C Lin.

5 dB

Diffuse

Fig. 4. Diffuse-field response of Types 4051, 4052 and 4053 with

Nose Cones UA0777 fitted.

25

dB

20

15

10

5 dB

5

0

10 20 Hz 50 100 200 500 1 kHz 2 5 10 20 40 D A B C Lin.

Diffuse

On-axis

25

dB

20

15

10

5 dB

5

0

10 20 Hz 50 100 200 500 1 kHz 2 5 10 20 40 D A B C Lin.

On-axis

Diffuse

Loading...

Loading...