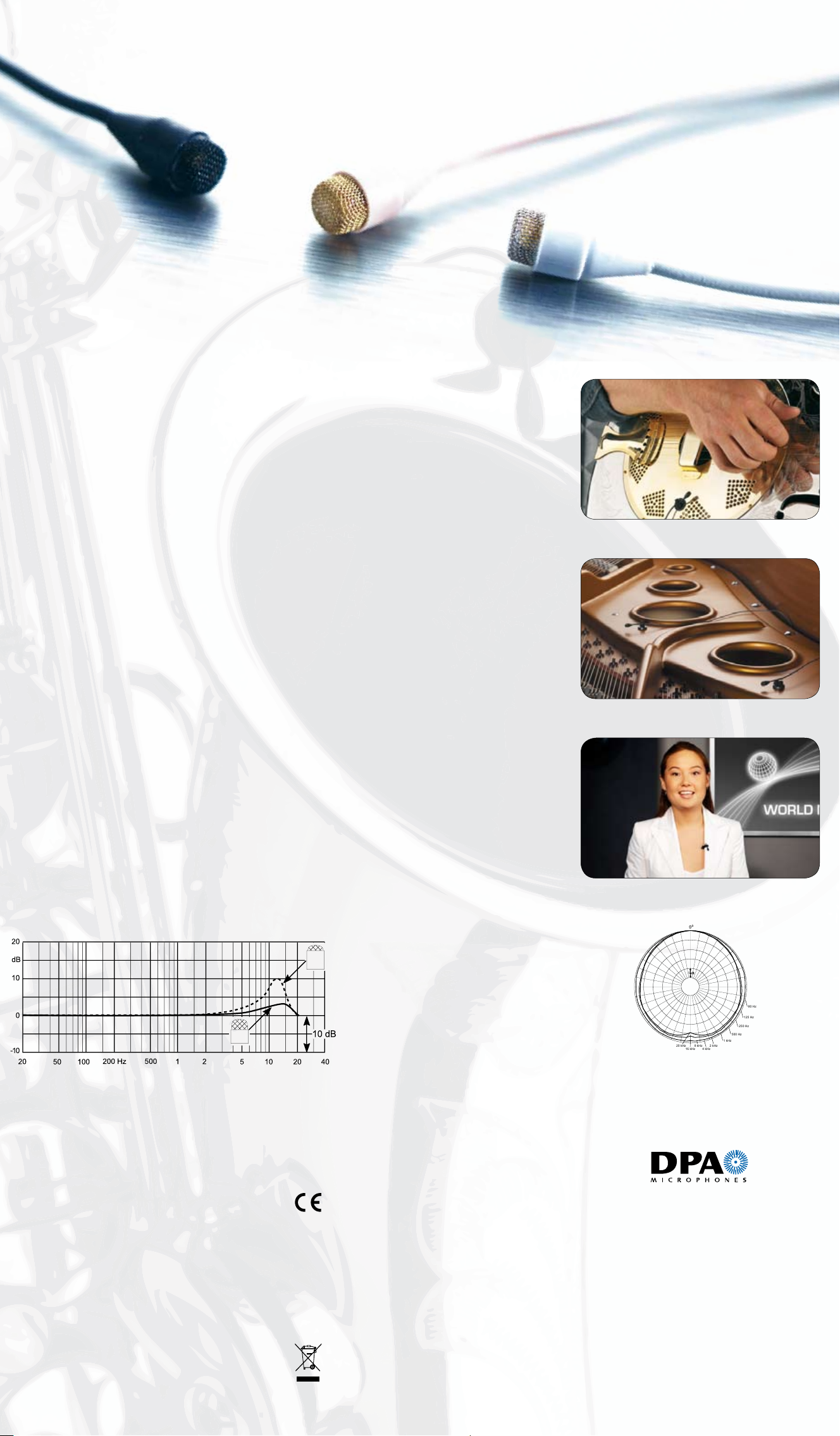

DPA Microphone DPA 4060, DPA 4061, DPA 4062, DPA 4063 User's Manual

Introduction

The DPA Miniature Omnidirectional Microphones are designed for use with wireless systems in theatre, television and

close-miking instrument applications.

To ensure optimal performance of your DPA Miniature Microphone, please follow the simple care and maintenance

instructions below. Miniature Microphones from DPA are

designed to be very resistant to humidity, moisture and

sweat. Highly resistant materials like gold plated stainless

steel, and features like the double-vent protection system are

used in construction of the microphones, to avoid damage

by hostile fluids. In any case, it is still a good idea to keep

the Miniature Microphones away from any kind of unnecessary exposure to water and cleaning fluids and to keep the

microphone element dry at all times.

Cleaning Guide

The cable and protection grid are the only parts that may

be cleaned if necessary. Do not use any kind of cleaning

fluid other than distilled water. Avoid all kinds of spray or

fluids, which contain chemical components to remove static

electricity on or close to the microphone as this could cause

damage to the electret layer. When mounting the Miniature

Microphone directly on the skin of a performer, care should

be taken to avoid sweat from running directly into the mi-

Cleaning the microphone grid

During use in environments where the microphone is

exposed to make-up or dusty materials, the grid may

get clogged up. Remove the microphone grid from the

microphone element and clean the grid using a soft cloth

and distilled water only. Make sure the grid is dry before

remounting it on the microphone element.

Cleaning the microphone cable

Residue from tape, glue or make-up on the cable must be

removed after use. Leaving these substances on the cable

over longer periods of time may etch into the cable jacket

and will make the cable more susceptible to breaks. The

cable can easily be cleaned using organic oil (e.g. olive oil)

or lukewarm, distilled water. Do not bend the cable or rub

it harshly since this may stress the inner cores of the cable

and cause them to break over time.

Correct use of microphone grids

The two different protection grids that are supplied with the

Miniature Microphones DPA 4060, 4061, 4062, 4063 are for

acoustical equalization, according to the placement on the

body of the performer. When mounted on the head of

the performer, the microphone normally needs a 3 dB soft

boost at 8-20 kHz, provided by the soft boost grid.

crophone. If the microphone gets filled up with water it will

not be damaged, but possibly turn deaf while the water is

captured inside the microphone, behind the protection grid.

Remove the water by shaking the microphone or drying it

with a piece of lint free cloth.

Note: If the microphone has been exposed to sweat it

must be rinsed out in distilled water and left to dry out to

recover its original specifications. Drying out the Miniature

Microphone between exposures to humidity will also help

to extend its lifetime.

The microphone is supplied with the soft boost grid fitted.

This grid must be removed before being replaced by the

high boost grid.

Correct use of the microphone element

The diaphragm in the microphone element is the most

sensitive part of the unit and as emphasized earlier, it

must be left untouched to preserve its original characteristics. Do not spray any substances such as hair spray

directly into the microphone and avoid getting make-up

or paint on the microphone element and housing. The

protection grids are available in four standard colours:

Black, brown, beige and white. Check if a different coloured protection grid will be less visible before painting

or colouring a microphone grid.

Correct treatment of the microphone cable

The cable is usually longer than required for its actual purpose. Ensure that superfluous cable is wound up in soft loops

(preferably 6-8 cm in diameter). Avoid ’kinks’ in the cable.

Correct use of adapters and MicroDot connectors

To provide users with safe and compact mounting of connectors, all Miniature Microphones from DPA are fitted with

the MicroDot connector as standard. A broad range of connection adapters is offered as optional accessories for most

VHF and UHF systems for professional use.

A connector-tightening tool is supplied with each adapter

and should be employed whenever the MicroDot connec-

tor needs to be tightened safely onto the adapter for

long periods of time. Never attempt to loosen or tighten

the connector by the cable or its strain relief! Various

wireless systems require the use of electronic components

inside the adapter to optimise the signal level, the DCoffset filtering and powering of the built-in microphone

preamplifier. Using the adapters from DPA Microphones

ensures the correct electronic circuit with the listed types

of wireless systems at all times. Do not attempt to employ

non-standard adapters or connectors as you might damage the microphone preamplifier.

w w w. d p a m i c r o p h o n e s . c o m

IMK4061 Instrument Microphone Kit

This kit is designed to be used as a close-miking solution

for a wide variety of musical instruments. The condenser microphone offers a very clean, detailed and natural sound

quality, leaving placement up to the user, in order to receive

the desired timbre for studio use or amplification for live use.

Included are holders for strings, universal surface mounts with

double sided tape, magnet mount and foam windscreens.

The 4061 can handle 144 dB SPL before clipping, allowing

the microphone to be used even for snare drums, trumpets, guitar/bass speaker cabinets or other high level sound

sources.

IMK4061 includes:

4061-BM Miniature Microphone

DAD6001 XLR Adapter

MHS6001 Microphone Holder for Strings

DUA0560 Miniature Windscreens

DMM0007 Universal Surface Mounts

DMM0011-B Magnet Mount

See www.dpamicrophones.com for further information

about miking musical instruments.

Download the complete user´s manual at ww w.dpami crophon es.com

5

250 Hz

125 Hz

20 kHz

16 kHz

8 kHz

2 kHz

1 kHz

500 Hz

80 Hz

Specifications

DPA 4060/4061/4062/4063

Directional characteristics:

Omnidirectional

Principle of operation:

Pressure

Cartridge type:

Pre-polarized condenser

Power supply:

4060, 4061, 4062: Min 5 V

– max 50 V through DPA adapter

4063: Min 3 V – max 50 V through DPA adapter

Frequency response, ±2 dB :

Soft boost grid:

20 Hz - 20 kHz, 3 dB soft boost at 8-20 kHz

High boost grid:

20 Hz - 20 kHz, 10 dB boost at 12 kHz

Dynamic Range:

Typ. 100 dB

Max SPL peak before clipping:

4060: 134 dB

4061: 144 dB

4062: 154 dB

4063: 138 dB

Output impedance:

30- 40 Ohm

Sensitivity, nominal (± 3 dB at 1 kHz):

4060: 20 mV/Pa; -34 dB re. 1 V/Pa

4061: 6 mV/Pa; -44.5 dB re. 1 V/Pa

4062: 1 mV/Pa; -60 dB re. 1 V/Pa

4063: 6 mV/Pa; -44.5 dB re. 1 V/Pa

Equivalent noise level A-weighted:

4060: Typ. 23 dB(A) re. 20 μPa (max. 26 dB(A))

4061: Typ. 26 dB(A) re. 20 μPa (max. 28 dB(A))

4062: Typ. 33 dB(A) re. 20 μPa (max. 37 dB(A))

4063: Typ. 26 dB(A) re. 20 μPa (max . 28 dB(A))

Polarity:

Inward movement of diaphragm produces positive going voltage on MicroDot pin

Cable drive capability:

Up to 300 m (984 ft)

WARRANTY

All products from DPA Microphones are covered by

a two-year limited warranty on both mechanical functionality and documented specifications as long as the

items are not mistreated, abused or modified in any way.

In case of a warranty claim your invoice is your warranty

registration.

CE-MARKING

The CE-mark guarantees that the product conforms with

relevant Directives approved by the European Commission.

EMC Directive: 89/336/EC, amended by 92/31/EC and

93/68/EC

Low voltage Directive: 73/23/EC, amended by 93/68/EC

ENVIRONMENTAL POLICY

This product is comprised by the Waste (WEEE) directive and

should not be thrown in the garbage bin when obsolete.

Instead, return it to your local DPA representative (or DPA

Microphones A/S directly) who will dispose of the product

in accordance with the current environmental standards.

SERVICE & REPAIR

Products from DPA Microphones are extremely stable

and there should not be any significant change in the

specifications with time and use. If, however, you are

not totally satisfied with the characteristics exhibited by

these products, contact your nearest DPA Microphones

representative for further details of service and the repair

facilities that are available.

S/N ratio, re. 1 kHz at 1 Pa (94 dB SPL):

4060: 71 dB (A)

4061: 68 dB (A)

4062: 61 dB (A)

4063: 68 dB (A)

Total Harmonic Distortion (THD):

<1% THD up to 123 dB SPL peak

<1% THD up to 123 dB SPL RMS sine

On-Axis Frequency Response of Miniature Microphones.

Dotted line is with high boost grid and solid line with soft boost grid.

Polar Pattern

Directional Charateristics (normalised)

DP Z- 4060

Headquarters:

DPA Microphones A/S

Gydevang 42-44

DK-3450 Alleroed, Denmark

Ph: +45 4814 2828

Fax: +45 4814 2700

info@dpamicrophones.com

www.dpamicrophones.com

United States:

DPA Microphones, Inc.

691 Gray Mountain Drive

Lyons, CO 80540

Ph: +1 303 823 8878

Fax: +1 303 823 5830

info-usa@dpamicrophones.com

www.dpamicrophones.com

Z-Card©Pocketmedia© This product is protected by European patent no: 0288472. 22009/26 2:2

Loading...

Loading...