Page 1

Horizontal multi-stage centrifugal pumps

Installation and operating instructions

series: DPHM(C)

Page 2

2

Table of Contents

1: Manual Introduction

1.1 Preface................................................................................................................................................... 3

1.2 Icons and symbols ................................................................................................................................. 3

2: Identification, service and technical support

2.1 Obtaining data and information DPHM(C) 2/4/6 .................................................................................... 4

2.2 Seal codes ............................................................................................................................................. 5

2.3 Current ................................................................................................................................................... 5

2.4 Supplementary documentation .............................................................................................................. 5

3: Warranty

3.1 Terms of warranty .................................................................................................................................. 6

4: Safety and environment

4.1 General .................................................................................................................................................. 7

4.2 Users...................................................................................................................................................... 7

4.3 Safety provisions.................................................................................................................................... 7

4.4 Safety precautions ................................................................................................................................. 7

4.5 Environmental aspects........................................................................................................................... 8

5: Pump Introduction

5.1 Model key............................................................................................................................................... 9

5.2 Description of the product ...................................................................................................................... 9

5.3 Intended use .......................................................................................................................................... 9

5.4 Operation ............................................................................................................................................... 9

5.5 Measuring, draining and venting.......................................................................................................... 10

5.6 Working range...................................................................................................................................... 10

6: Transport

6.1 Transport...............................................................................................................................................11

6.2 Storage..................................................................................................................................................11

7: Installation instructions

7.1 Setting up the pump............................................................................................................................. 12

7.2 Electrical installation ............................................................................................................................ 13

7.3 Commissioning .................................................................................................................................... 13

8: Operation

8.1 Operation ............................................................................................................................................. 15

9: Maintenance

9.1 Introduction .......................................................................................................................................... 16

9.2 Maintaining the pump for an extended period of non-operation .......................................................... 16

10: Failures

10.1 Failure table ......................................................................................................................................... 17

10.2 Torques of vent and draining plugs...................................................................................................... 19

11: Annexes

11.1 EC declaration of conformity................................................................................................................ 20

Page 3

3

1 Manual Introduction

1.1 Preface

This manual contains important information for

reliable, proper and efficient operation. Compliance

with the operating instructions is of vital importance to

ensure reliability and a long service life of the product

and to avoid any risks.

The first chapters contain information about this

manual and safety in general. The following chapters

provide information about normal use, installation,

maintenance and repairs of the product. The annex

contains the declaration(s) of conformity.

• Make yourself familiar with the content.

• Accurately follow the directions and instructions.

• Never change the sequence of the operations to

be carried out.

• Keep this manual or a copy of it together with the

logbook in a fixed place near the product which

can be accessed by all personnel.

1.2 Icons and symbols

In this manual and in all accompanying

documentation the following icons and symbols are

used.

WARNING

Danger of electric Voltage. Safety sign

according to IEC 417 - 5036

WARNING

Operations or procedures, if carried out

without caution, may cause personal

injury or damage to the product.

General hazard sign according to ISO

7000-0434

ATTENTION

Is used to introduce safety instructions

whose non-observance may lead to

damage to the product and its

functions.

ENVIRONMENTAL INSTRUCTION

Remarks with respect to the

environment.

Page 4

4

2 Identification, service and technical

support

2.1 Obtaining data and

information DPHM(C) 2/4/6

The name plate indicates the type series / size, main

operating data and identification number. Please

quote this information in all queries, repeat orders

and particularly when ordering spare parts. If you

need any additional information or instructions

exceeding the scope of this manual or in case of

damage, please contact DP-Pumps nearest customer

service centre.

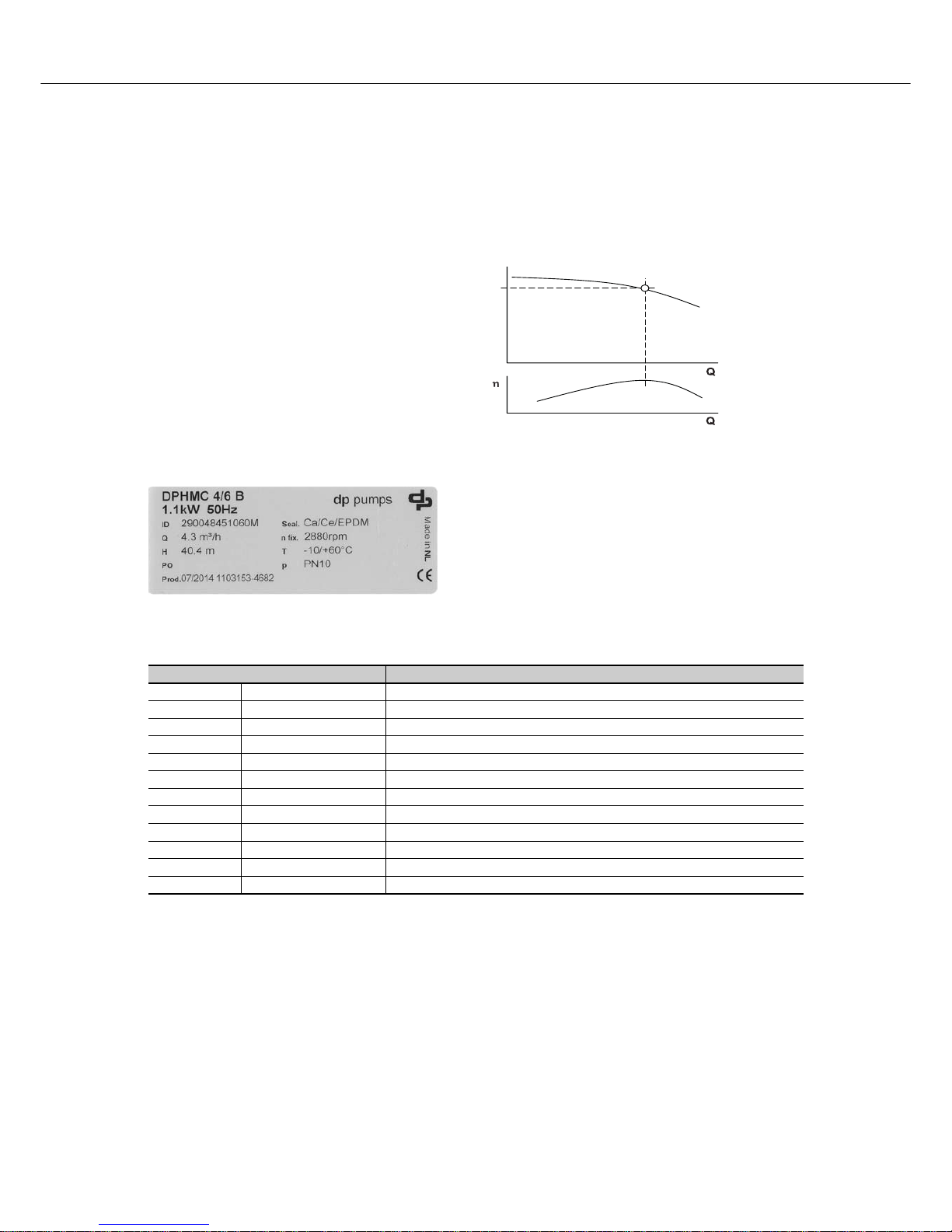

Table 1: Description nameplate

ID3297

Figure 1: Pump with motor

4374

Figure 2: Duty point

3060

H

Indication Meaning

DPHMC 4/6 B Model key (design version B)

1.1 kW Installed motor power

50 Hz Nominal frequency

ID 290048451060M Pump ID

Q 4.3 m

3

/h Optimum capacity running at n

fix

(see fig. 2: Duty point)

H 40.4 m Optimum head running at n

fix

(see fig. 2: Duty point)

PO Purchase order number

Prod. 07/2014 1103153-4682 Production week/year and production serial number > as built file

Seal. Ca/Ce/EPDM Mechanical Seal Surface Code and elastomer, see fig. 2.2: Seal codes

n fix. 2880 rpm Rotation speed indication at which Q/H are given

T -10/+60°C Temperature range

p PN10 Pressure Class connection

Page 5

5

2.2 Seal codes

Table 2: Material code shaft seal

2.3 Current

2.3.1 Nominal current

The nominal allowable current of the motor is stated

on the motor plate. This shows the nominal working

range of the motor and can be used to protect the

motor.

Measuring the actual current of the pump during

operation can be used to pre-set the motor protection

switch to protect the pump/motor combination.

This current value can also be used to determine the

proper electrical equipment such as variable

frequency drive, main switch, wiring diameter etc.

WARNING

Not only the motor, but also the pump

has to be protected in its application.

2.3.2 Motor protection

Standard single phase motors are delivered including

motor protection. The motor protection is provided

either by a thermal circuit breaker or by a motor

winding protection.

Please contact your supplier for more detailed

information about your motor protection.

2.4 Supplementary

documentation

Apart from this manual, the documentation given

below is also available:

Table 3: Supplementary documentation

Code acc. to EN 12756 Description Material Note

B Spring loaded ring Carbon graphite Ca Resin impregnated

V Seat ring Ceramic Ce Aluminium oxide

E

P

Elastomers EPDM

NBR

EPDM

NBR

Ethylene propylene rubber

Nitrile butadiene rubber

F Spring CrNi steel

F Other metal parts CrNi steel

Protection device

variant

Type of protection

Suitable for ambient

temperature [°C]

Located in

Reset

1 Thermal

circuit breaker

20 - 30 Thermal

box

Manual

2 Winding

protection

-20 - 50 Motor

winding

Automatic

Document Code

General terms of delivery 119 / 1998

DPHM(C) 2/4/6

Technical Data 50/60 Hz Version B 97004494

See also www.dp-pumps.com

Page 6

6

3 Warranty

3.1 Terms of warranty

The warranty period is settled by the terms of your

contract or at least by the general terms and

conditions of sales.

ATTENTION

Modifications or alterations of the

product supplied are only permitted

after consultation with the

manufacturer. Original spare parts and

accessories authorized by the

manufacturer ensure safety. The use of

other parts can invalidate any liability of

the manufacturer for consequential

damage.

ATTENTION

The warranty relating to the operating

reliability and safety of the product

supplied is only valid if the product is

used in accordance with its designated

use as described in the following

sections of this manual. The limits

stated in the data sheet must not be

exceeded under any circumstances.

The warranty becomes invalid if one or more of the

points below occur.

• The buyer makes modifications himself.

• The buyer carries out repairs himself or has

these carried out by a third party.

• The product has been handled or maintained

improperly.

• The product has non original DP-Pumps spare

parts fitted.

DP-Pumps repairs defects under warranty when:

• They are caused by flaws in the design, the

material or the production.

• They are reported within the warranty period.

Other terms of warranty have been included in the

general terms of delivery, which are available upon

request.

Page 7

7

4 Safety and environment

4.1 General

This DP-Pumps product has been developed using

state-of-the-art technology; it is manufactured with

utmost care and subject to continuous quality control.

DP-Pumps does not accept any liability for damage

and injury caused by not observing the directions and

instructions in this manual, or in cases of

carelessness during the installation procedure, use

and maintenance of the product.

Non-compliance with safety instructions can

jeopardize the safety of personnel, the environment

and the product itself. Non-compliance with these

safety instructions will also lead to forfeiture of any

and all rights to claims for damages.

For example, in particular non-compliance can result

in:

• failure of important pump/system functions,

• failure of prescribed maintenance and servicing

practices,

• injury to persons by electrical, mechanical and

chemical effects,

• hazard of the environment due to leakage of

hazardous substances,

• explosions.

Depending on specific activities, extra safety

measures may be required. Contact DP-Pumps if a

potential danger arises during use.

ATTENTION

The owner of the product is responsible

for compliance with the local safety

regulations and internal company

guidelines.

ATTENTION

Not only must the general safety

instructions laid down in this chapter

on "Safety" be complied with, but also

the safety instructions outlined under

specific headings.

4.2 Users

All personnel involved in the operation, maintenance,

inspection and installation of the product must be fully

qualified to carry out the work involved and be aware

of all applicable responsibilities, authorisations and

super visions. If the personnel in question is not

already in possession of the required know-how,

appropriate training and instruction must be provided.

If required, the operator may commission the

manufacturer / supplier to take care of such training.

In addition, the operator is responsible for ensuring

that the contents of the operating instructions are fully

understood by the responsible personnel.

4.3 Safety provisions

The product has been designed with the greatest

possible care. Original parts and accessories meet

the safety regulations. Modifications in the

construction or the use of non-original parts may lead

to a safety risk.

ATTENTION

Make sure that the product operates

within its working range. Only then the

product performance is guaranteed.

4.3.1 Labels on the product

The icons, warnings and instructions applied to the

product are part of the safety provisions. The labels

may not be removed or covered. Labels must remain

legible during the entire life of the product. Replace

damaged labels immediately.

4.4 Safety precautions

4.4.1 During normal use

• Contact the local electricity company for

questions about the power supply.

• Protect the parts that can become hot, making

direct contact impossible.

• When applicable, always place undeformed

coupling guards to protect the coupling, before

putting the pump into use. Make sure that the

coupling guards are never in contact with the

rotating coupling.

• Always close the terminal box of the motor.

• Always close the control panel where applicable

Page 8

8

4.4.2 During installation, maintenance and

repair

Only authorised personnel may install, maintain and

inspect the product and repair electrical components.

Observe the local safety regulations.

WARNING

Always disconnect the energy supply to

the product first, before installation,

maintenance and repairs. Secure this

disconnection.

WARNING

Surfaces of a pump can be hot after

continuous operation.

WARNING

Make sure that no one can be near

rotating components when starting a

pump.

WARNING

Handle a pump with dangerous liquids

with the utmost care. Avoid danger for

persons or the environment when

repairing leakages, draining liquids and

venting. It is strongly recommended to

place a leakage tray under the pump.

WARNING

Immediately following completion of

the work, all safety-relevant and

protective devices must be re-installed

and / or re-activated.

WARNING

Please observe all instructions se t out

in the chapter "Commissioning/Startup" before returning the product to

service.

4.5 Environmental aspect s

4.5.1 General

The products of DP-Pumps are designed to function

in an environmentally friendly way during their entire

lifetime. Therefore, when applicable, always use

biodegradable lubricants for maintenance.

ENVIRONMENTAL INSTRUCTION

Always act according to the laws, bylaws regulations and instructions with

respect to health, safety and the

environment.

4.5.2 Dismantling

The owner is responsible for the dismantling and

environmentally friendly disposal of the product.

ENVIRONMENTAL INSTRUCTION

Ask at the local government about the

re-use or the environmentally friendly

processing of discarded materials.

Page 9

9

5 Pump Introduction

5.1 Model key

Table 4: Model key Example

5.2 Description of the product

The horizontal multi-stage centrifugal pump is

designed for pumping clean, or slightly aggressive,

watery mediums. The pump is easy to install,

commission and operate.

The hydraulic assembly is driven by an electric motor.

All hydraulic parts of the pump are made of stainless

steel. Pump casings are available in stainless steel or

cast-iron.

5.3 Intended use

The pumps DPHM are suitable to transport and

increase the pressure of cold and hot water without

wear to parts within the indicated working range. The

transport of liquids with a different viscosity or density

than water is possible as well. For this a motor with an

adjusted power could be required. Ask DP-Pumps or

your distributor for advice.

Any other or further use of the pump is not in

conformity with its intended use. DP-Pumps does not

accept any liability for any damage or injury that

results from this. The pump is produced in

accordance with the current standards and

guidelines. Use the pump only in a perfect technical

state, in conformance with the intended use

described below.

The Intended use as laid down in ISO 12100:2010 is

the use for which the technical product is intended

according to the specifications of the manufacturer.

The use of the product has been described in the

sales brochure and in the user manual. Always

observe the instructions given in the user manual.

When in doubt the product must be used as becomes

evident from its construction, version and function.

5.4 Operation

The rotating impeller causes the pressure at the inlet

of the impeller to drop. This decrease in pressure

creates the flow through the suction connection (A).

Every stage (B) consists of an impeller and a diffusor.

The capacity of the pump is determined by the size of

the passageway of the stage. The pressure of the

stage is determined by the diameter of the impeller.

Because of the modular type of construction it is

possible to choose the number of impellers most

suited to the required duty point. After leaving the last

impeller the medium flows between the pump stages

and the outer sleeve (C) and exits the pump at the

discharge connection (D)

DP H M C 2 /2 B

Label DP Product Label

Material/

Construction

H Horizontal

M All hydraulic parts Stainless Steel 1.4301 / AISI 304 with close coupled motor

C Cast Iron pump casing

Connections DIN connection size: suction G 5/4 - discharge G 1

2 Size (Capacity in m

3

/h at Q

opt

)

/2 Number of stages

B Design version B

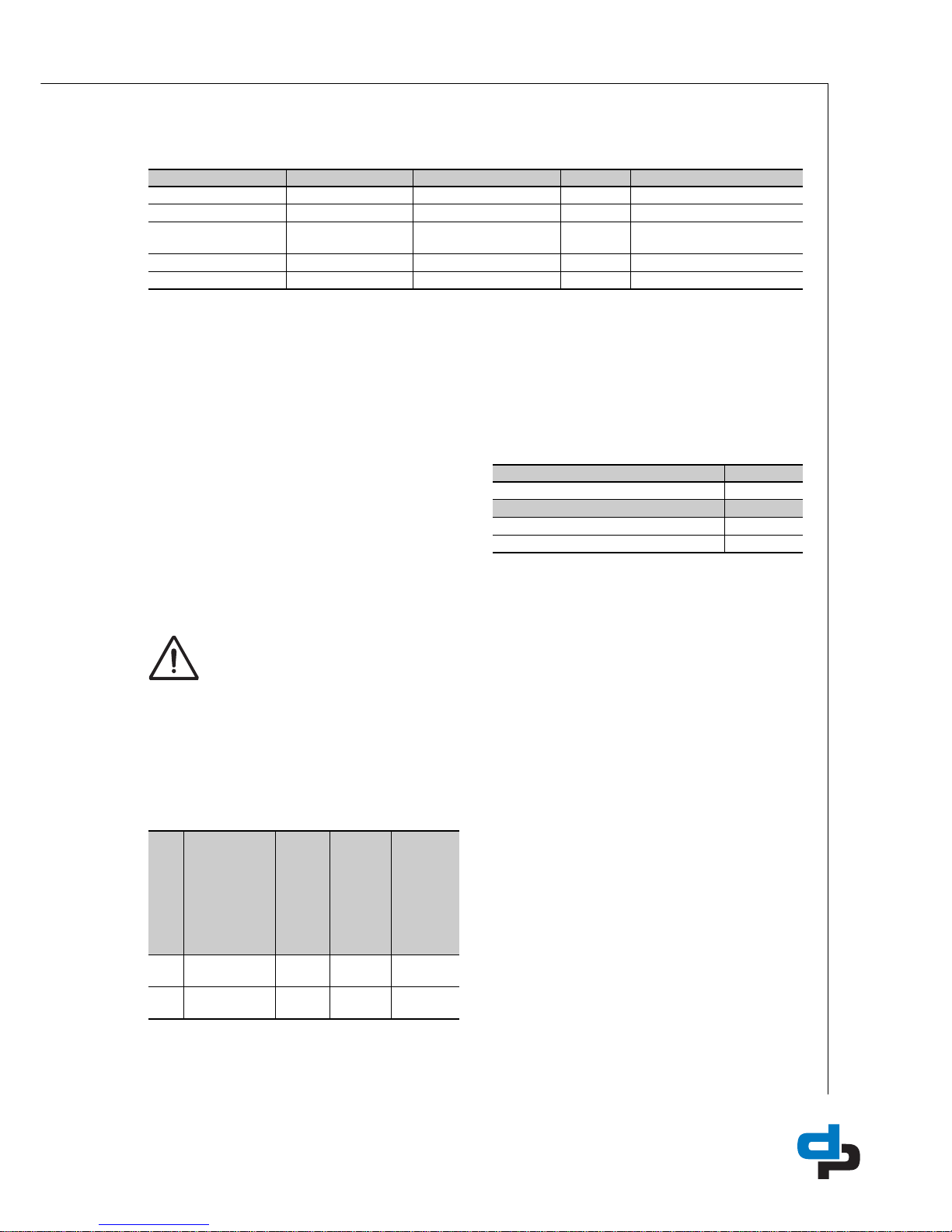

ID4376

Figure 3: DPHM(C) 2/4/6

20131394

A

D

E

F

B

C

Page 10

10

5.5 Measuring, draining and

venting

The pump is provided with plugs for measuring,

draining and venting.

Connection (E) is meant to fill and vent the pump, or

to measure the inlet / suction pressure using a G ¼

connection.

Connection (F) is meant to drain the pump, or to

measure the discharge pressure using a G ¼

connection.

5.6 Working range

Table 5: General working range specification

ATTENTION

The temperature difference between the

medium and the pump should never

exceed 60 °C. The pump must be filled /

heated-up slowly in any case where the

difference between pump and medium

is more then 30 °C to avoid any chance

of a thermal shock.

For minimum/maximum flow at medium temperature

of 20

o

C see table 6: Minimum/maximum capacity

(Qmin/max); for higher temperatures see figure 4:

Minimum capacity vs. temperature (in % of Q

optimum)

Table 6: Minimum/maximum capacity (Q

min/max

)

Pump type DPHM note

Ambient temperature [°C] -20 up to 30 (50)

1,2,3

1. Avoid freezing the pump.

2. If the ambient temperature exceeds the above value or

the motor is located more than 1000 m above sea

level, the motor cooling is less effective and could

require an adapted motor power. Please contact your

supplier for more detailed advice.

3. Single phase motors are equipped either with a ther-

mal circuit breaker or motor winding protection (see

2.3.2 Motor protection). Please contact your supplier

for more detailed information about your motor protec-

tion.

Medium temperature [°C] -10 up to 60

Minimum inlet pressure NPSH

req.

+ 1 m

Viscosity [cSt] 1-100

4

4. Deviation in viscosity and/or density could require an

adapted motor power. Please contact your supplier for

more detailed advice.

Density [kg/m

3

] 1000-2500

2

Cooling forced motor cooling

Minimum frequency [Hz] 30

Maximum frequency [Hz] 60

5

5. Pumps that are intended for 50 Hz operation, may not

be connected to 60 Hz power supply.

Maximum number of starts see motor data sheet

6

6. Frequent start/stops, in particular in combination with

higher pressure differences (Δp) may result in a short-

ened product lifetime. Consult your supplier for such

applications.

Noise emission see motor data sheet

7

7. Only the noise emission of the motor is documented.

Allowable size of solids

pumped

5 µm to 1 mm

size Q

min/max

[m3/h]

2 pole

50 Hz 60 Hz

Min. Max. Min. Max.

2 0.2 3.3 0.2 4.0

4 0.4 6.5 0.5 7.8

6 0.6 9.0 0.8 10.8

4431

Figure 4: Minimum capacity vs. temperature

(in % of Q optimum)

4431

9

9,5

10

10,5

11

40 45 50 55 60

Q%

T[°C]

Page 11

11

6 Transport

6.1 Transport

Always observe the directions as indicated on the

installation by means of stickers.

1. Transport the installation in the position as

indicated on the pallet or packaging.

2. Make sure that the installation is stable.

3. Observe the instructions on the packaging (if

present).

6.2 Storage

Fill the pump with glycol in order to protect it against

the risk of frost.

Table 7: Storage

6.2.1 Inspection during storage

1. Turn the shaft every three months and just

before putting into operation.

Storage

t

ambient

[°C] -10/+40

Max. rel. humidity 80% at 20 °C not condensing

Page 12

12

7 Installation instructions

7.1 Setting up the pump

ATTENTION

Avoid stress in the pump casing caused

by misalignment in the piping system.

Please see table below.

ATTENTION

Pumps which do not stand steady or

stable on their own, shou ld be mounted

on a rigid and stable base.

ATTENTION

Locate the pump at the place with the

lowest risk for noise nuisance.

1. Place and install the pump on a level, stable

surface in a dry and frost-proof room.

2. Place the pump as close to the source/tank as

possible.

3. Make sure that sufficient air can reach the

cooling fan of the motor. For this purpose the

free space above the cooling fan should be at

least 1/4 of the diameter of the fan hood air

intake.

4. It is advised to install a shut off valve on the

supply and on the delivery connection of the

pump.

5. To avoid medium flowing back through the

pump, when idle, make sure a non-return valve

is installed.

6. To the suction line should apply:

1. 100% airtight.

2. No camber.

3. Running from the lowest point in the tank

straight to the pump.

4. Provided with a foot valve that shuts off

well, making sure that the suction line is

always filled with water.

5. If the diameter of the suction line is larger

than the pump-suction connection, then

install an eccentric adapter in order to

prevent air pockets and swirling.

7.1.1 Indicators

The arrow (A) on the fan hood indicates the rotating

direction of the motor in case of a 3 phase motor.

7.1.2 Install bypass

Install a bypass if the pump may operate against a

closed valve for a long period. The required capacity

of the bypass is at least 10% of the maximum volume

flow. At high operating temperatures a higher volume

flow is required. With temperatures above 60ºC the

required capacity is more than 10%.

ATTENTION

Do not make use of quick-closing

valves and/or shut-off valves to prevent

pressure impulses in the pump and in

the lines as a result of changes in the

flow rate

Figure 5: DPHM(C) not connected

20131398

ID4377

Figure 6: Terminal box and fan hood sticker

20131395

A

Page 13

13

7.2 Electrical installation

WARNING

In accordance with the local regulations

only authorised personnel is allowed to

make electrical connections to the

motor.

ATTENTION

Connect the motor according to figure

7: Motor connections and always check

the rotation direction.

Electrical connections:

• Make sure that the motor specifications

correspond with the power supply to which the

pump motor is connected. Consult "Electrical

diagrams" for the correct connection diagram.

• Connect the motor using a motor safety switch.

7.3 Commissioning

WARNING

The pump must be switched off when it

is not completely filled up.

ATTENTION

Check the direction of rotation

according to fig. 6: Terminal box and

fan hood sticker. In case of a 3-phase

motor the rotation direction can be

changed by exchanging two of the 3

phases.

Example may differ upon chosen motor

ID2482

Figure 7: Motor connections

20140034

Page 14

14

7.3.1 Prime the pump

• Close the discharge shut-off valve (B);

• Close the suction shut-off valve (A);

• Unscrew the fill plug (C);

• Gradually open the suction shut-off valve (A)

until the liquid flows from the fill plug (C);

• Close the fill plug (C);

• Open shut-off valve (B);

• Vent the pump on discharge side for example

via a venting valve (D) on discharge side (see

Figure 8: Example: installation of a pump under

pressure operation);

• Close the venting option on discharge side;

• Close the discharge shut-off valve (B);

• repeat these steps until all air is removed from

the pump;

• Make sure that the suction shut-off valve is

entirely open.

• Open the discharge shut-off valve (B);

• Remove the fill plug (C);

• Put a funnel into the port (C) and completely fill

the pump with the liquid to be pumped;

• Vent the pump on discharge side for

example via a venting valve (D) on

discharge side (see Figure 9: Example:

installation of a pump in suction-operation);

• Make sure all air is removed from the

pump;

• Close the venting option on discharge side;

• Close the discharge shut-off valve (B);

• Close the fill plug (C).

7.3.2 Start the pump

• Start the motor;

• Gradually open the discharge shut-off valve (B);

• Make sure the pump started correctly within 20

seconds, if not then:

• Switch off the motor;

• Re-prime the pump;

• Start the motor again;

• Switch the pump off and on for 2-3 times, after

running continues for 30 seconds and make sure

all air is removed from the pump.

7.3.3 After an extended period of nonoperation or storage

During first start-up, check the mechanical seals for

leakage due to seizure or dehydration of the

lubricating film. If so, please proceed as following:

1 Turn shaft manually;

2 Check if the mechanical seal is still leaking.

If the mechanical seal is still leaking:

1 Disassemble the mechanical seal;

2 Thoroughly clean and degrease the running

surfaces;

3 Assemble the mechanical seal again and retry

start-up.

If this doesn’t solve the shaft leakage, replacement of

the mechanical seal is necessary.

Figure 8: Example: installation of a pump

under pressure operation

20131396-A

Figure 9: Example: installation of a pump

in suction-operation

20131397-A

A

B

C

D

CB D

Page 15

15

8 Operation

8.1 Operation

The pump is controlled externally and therefore does

not need any operation guidance.

Page 16

16

9 Maintenance

9.1 Introduction

WARNING

Observe the general safety precautions

for installation, ma inte nance and repair .

Regular maintenance is necessary for the correct

operation of a pump. Please contact your supplier for

maintenance of the pump.

9.2 Maintaining the pump for an

extended period of nonoperation

Turn the shaft every three months1. This protects the

seals from seizure.

Protect the pump if there is a risk of frost. Proceed as

follows:

1. Close all pump valves.

2. Drain each pump and/or the system.

3. Remove all plugs from the pump.

4. Open the shut-off and fill/air vent plug, if present.

1. period may vary per application or medium. Please

consult your sales representative for application

details.

Page 17

17

10 Failures

10.1 Failure table

WARNING

Observe the general safety precautions

before installation, maintenance and

repair.

Problem Possible cause Possible solution Checkpoints

Leakage along the shaft. Running surfaces of the

mechanical seal worn or

damaged.

Replace the mechanical

seal.

Check the pump for dirt /

abrasive parts.

New pump: seal stuck due

to assembly.

Open and close the outlet

shut-off valve quickly dur-

ing operation.

Mechanical seal mounted

incorrectly.

Install the mechanical seal

correctly. Use water and

soap as a lubricant.

Elastomers affected by

medium.

Use the right rubber com-

pound for the mechanical

seal.

Pressure too high. Use the right type of

mechanical seal.

Shaft worn. Replace shaft and

mechanical seal.

Pump has been operating

without water.

Replace the mechanical

seal.

Leakage along the shroud

at the top bracket or at the

pump casing.

O-ring worn Replace the O-ring.

O-ring not resistant to the

medium to be pumped

Replace O-ring by an O-

ring with better resistance

Too much stress on the

pump casing; it becomes

oval.

Decrease stress on piping.

Mount the pump casing

without stress.

Support the connections.

Pump is vibrating or noisy. Coupling mounted incor-

rectly.

Install the coupling in par-

allel.

Faulty setting of the

hydraulic assembly.

Adjust the assembly

according to the manual.

There is no water in the

pump.

Fill and vent the pump.

No supply of medium. Make sure there is suffi-

cient supply. Check for

blockages in the supply

line.

Bearings of pump and/or

motor worn.

Have the bearings

replaced by a certified

company.

Available NPSH too low

(cavitation).

Improve suction condition.

Page 18

18

Pump is vibrating or noisy. Pump does not work in its

working range.

Select another pump or

adjust the system to work

within its working range.

Pump is standing on an

uneven surface.

Level the surface.

Malfunction. Internal blockage in the

pump.

Have the pump inspected

by a certified company.

Pump does not start. No voltage on the power

terminal.

Check the power supply.

• Circuit

• Main switch

• Fuses

Check the motor safety

relay

• Earth leakage switch

• Protective relay

Thermal motor safety

switch triggered.

Reset the thermal motor-

safety. Contact the sup-

plier, if this problem occurs

more often.

Check if the correct value

is set. Find the correct

value (I

nom

) on the motor

type plate.

The motor is running, but

the pump does not work.

The coupling between

pump- and motor shaft is

loose (when applicable).

Tighten the connecting

screws to the required

torque.

The pump shaft is broken. Contact the supplier.

Pump supplies insufficient

capacity and/or pressure.

Outlet and/or inlet shut-off

valve is closed.

Open both shut-off valves.

There is air in the pump. Vent the pump.

The suction pressure is

insufficient.

Increase the suction pres-

sure.

Pump rotates in the wrong

direction.

Change over L1 and L2 of

the three phase supply.

The suction line has not

been vented.

Vent the suction line.

Air bubble in the suction

line.

Install the suction line with

pump end higher than the

other end.

Pump sucks air because

of leakage in the suction

line.

Repair the leakage.

Water flow too low. So air

bubbles clog up in the

pump.

Make sure the flow

increases or use a smaller

pump.

The diameter of the suction line is too small.

Increase the diameter of

the suction line.

Capacity of water meter in

the supply line is too

small.

Increase the capacity of

the water meter.

Foot valve blocked. Clean the foot valve.

The impeller, the diffuser

or stage is blocked.

Clean the inside of the

pump.

O-ring between impeller

and diffuser is gone.

Replace the O-rings.

O-ring not resistant to the

medium to be pumped.

Replace O-ring by an O-

ring with better resistance.

Problem Possible cause Possible solution Checkpoints

Page 19

19

10.2 Torques of vent and draining

plugs

Table 8: Torques

Material

Dimensions

Torques

[Nm]

Figure

PEHD G 1/4 3 Locations E and F in

fig. 3: DPHM(C) 2/4/6

Page 20

20

11 Annexes

11.1 EC declaration of conformity

DP-Pumps

Kalkovenweg 13

2401 LJ Alphen aan den Rijn, The Netherlands

Tel: (+31)(0)-172-48 83 88

Hereby declares as manufacturer entirely on his own responsibility, that the products:

Horizontal multi-stage centrifugal pumps, series: DPHM(C)

The pump is subject to this declaration of conformity as a stand alone product. Make sure the appliance or

installation in which the pump is built in, has got a declaration of compliance with the directives listed above, for its

complete assembly.

Alphen aan den Rijn

01/03/2014

Authorized representative

W. Ouwehand, technical director.

Serial number: 18/2012 1000000-0001 [...] 52/2016 9999999-9999

to which this declaration refers, is in accordance with the following standard: EN 809: 1998+A1:2009/AC:2010

according to the provisions of the harmonized standard for pumps and which implies the regulations of Machine

directive 2006/42/EC, EMC directive 2004/108/EC, in the most recent form

Page 21

21

Page 22

22

Page 23

23

Page 24

dp pumps

dp pumps

P.O. Box 28

2400 AA Alphen aan den Rijn

The Netherlands

t +31 172 48 83 88

f +31 172 46 89 30

dp@dp-pumps.com

www.dp-pumps.com

11/2014

BE00000554-B

Can be changed without prior notice

Original instructions

Loading...

Loading...