Page 1

ARTISAN OVENS

IMPORTANT SAFETY INSTRUCTION

SAVE THESE INSTRUCTIONS

DANGER

TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHOCK,

CAREFULLY FOLLOW THESE INSTRUCTIONS

TABLE OF CONTENTS

SECTION « A » DESCRIPTION PAGE

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2

Installation warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3

Distances to respect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A5

Digital control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A6

Operation / instruction for oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A7

Operation / instruction for proofer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A9

Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A10

For more information, please contact our office . . . . . . . . . . . . . . . . . . . . A11

SECTION « B » DIMENSIONS

1T - Table of total dimensions height . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1T - Front view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1T - Side view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1T - Back view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Table of total dimensions height . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Front view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Side view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Back view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Table of total dimensions height . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Front view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Side view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Back view of dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION « E » COMPONENT PARTS

1T - Front view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

E1

Page 2

1T - Front view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . .

1T - Side view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1T - Side view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . . .

1T - Back view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1T - Back view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Front view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Front view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Side view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Side view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Back view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2T - Back view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Front view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Front view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Side view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Side view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Back view of component parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3T - Back view of table component parts . . . . . . . . . . . . . . . . . . . . . . . . .

E2

E3

E4

E5

E6

E7

E8

E9

E10

E11

E12

E13

E14

E15

E16

E17

E18

SECTION « G » ELECTRIC SCHEMATICS

1T - 208V/3PH, 220V/3PH & 240V/3PH/60HZ . . . . . . . . . . . . . . . . . . .

2T - 208V/3PH, 220V/3PH & 240V/3PH/60HZ . . . . . . . . . . . . . . . . . . . .

3T - 208V/3PH, 220V/3PH & 240V/3PH/60HZ . . . . . . . . . . . . . . . . . . . .

1T - PROOFER - 208V/3PH, 220V/3PH & 240V/3PH/60HZ . . . . . . . . .

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARTISANA.DOC Rev. 13/04/05

G1

G2

G3

G4

Page 3

SECTION

A

DESCRIPTION

Page 4

A1

INTRODUCTION

The manufacturer suggests to read this manual carefully.

This Artisan oven is manufactured with first quality material by experienced technicians. Proper

installation and maintenance will guarantee a reliable service for years to come.

A nameplate fixed to the front or right side of the oven specifies the model number, serial number,

voltage and amperage.

Drawings, electrical diagram and replacement parts numbers are included in this manual. The

electrical diagram is affixed in the control panel at the back of the oven.

ATTENTION

DOYON is not responsible for damages to the property or the equipment caused

by personnel who is not certified by known organizations. The customer is

responsible for finding qualified technicians in electricity and plumbing for the

installation of the oven.

Page 5

A2

CONSTRUCTION

You just bought the most advanced oven of its category, "DOYON" technology at its best. This

oven is manufactured using the highest quality components and material.

The oven gives a uniform baking with its unique heating system. The DOYON artisan deck oven is

designed with parts that are easy to find.

SHIPPING

For your safety, this equipment has been verified by qualified technicians and carefully crated before

shipment. The freight company assumes full responsibility concerning the delivery in good condition

of the equipment in accepting to transport it.

IMPORTANT

RECEPTION OF THE MERCHANDISE

Take care to verify that the received equipment is not damaged before signing the delivery receipt. If

a damage or a lost part is noticed, write it clearly on the receipt. If it is noticed after the carrier has

left, contact immediately the freight company in order that they do their inspection.

We do not assume the responsibility for damages or losses that may occur during transportation.

Page 6

A3

INSTALLATION WARNINGS

POWER FAILURE WARNING

WHEN YOU HAVE A POWER FAILURE, SHUT OFF THE OVEN POWER SWITCH TO

PROTECT THE ELECTRONIC COMPONENTS WHEN THE POWER COMES BACK.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY APPLIANCE.

INSTALLATION AND SERVICE

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

Installation and service must be done by specialized technicians. Contact a certified electrician and

plumber for set up.

The oven must be connected to the utility and electrically grounded in conformity to the effective

local regulations. If these are not established, the oven must be connected according to the Canadian

Electrical Code (CSA-C22.1-XX) or National Electrical Code (NFPA 70-XX). Refer to last

edition year for XX. Installation must also allow proper access for service (24 inches each side and

back).

The ovens must be installed with a proper ventilation according with the local building code.

Page 7

A4

DISTANCES TO RESPECT

A) Back of the oven: 1 inch (2.5 cm).

B) Top of the oven: a clearance of 6 inches (15.2 cm) to the ceiling must exist to permit

adequate venting and to give proper access to a technician.

C) Sides of the oven: do not install other than easily removable equipment for service and

maintenance (not closer than 1 inch (2.5 cm)).

D) It is recommended to have a certain length of water pipe, electric cable between oven and

wall to help gain access for service.

Page 8

A5

INSTALLATION

IN GENERAL

Take off the packaging material with care. Take off all the material used for packing and accessories.

1. To the electrician

Electrical supply installation must be in accordance with the electrical rating on the nameplate.

Utility connections shall be designed to be disconnected without the use of tools or shall be of

sufficient length to permit the equipment to be moved for cleaning.

WARNING

The electrician must make sure that the supply cable does not come in contact

with the oven top which becomes hot.

2. To the plumber

This equipment is to be installed to comply with the applicable federal, state or local plumbing

codes.

Utility connections shall be designed to be disconnected without the use of tools or shall be of

sufficient length to permit the equipment to be moved for cleaning.

Connect the steam system (1/2 NPT) to the water distribution network. We highly recommend a

water softener to eliminate minerals in the water. We suggest to use CUNO # CFS6135 (Doyon part

number PLF240).

Connect the drain of the oven (1/2 NPT) to the drain system of the building or install a recipient to

retrieve the surplus of hot water from the steam system.

Page 9

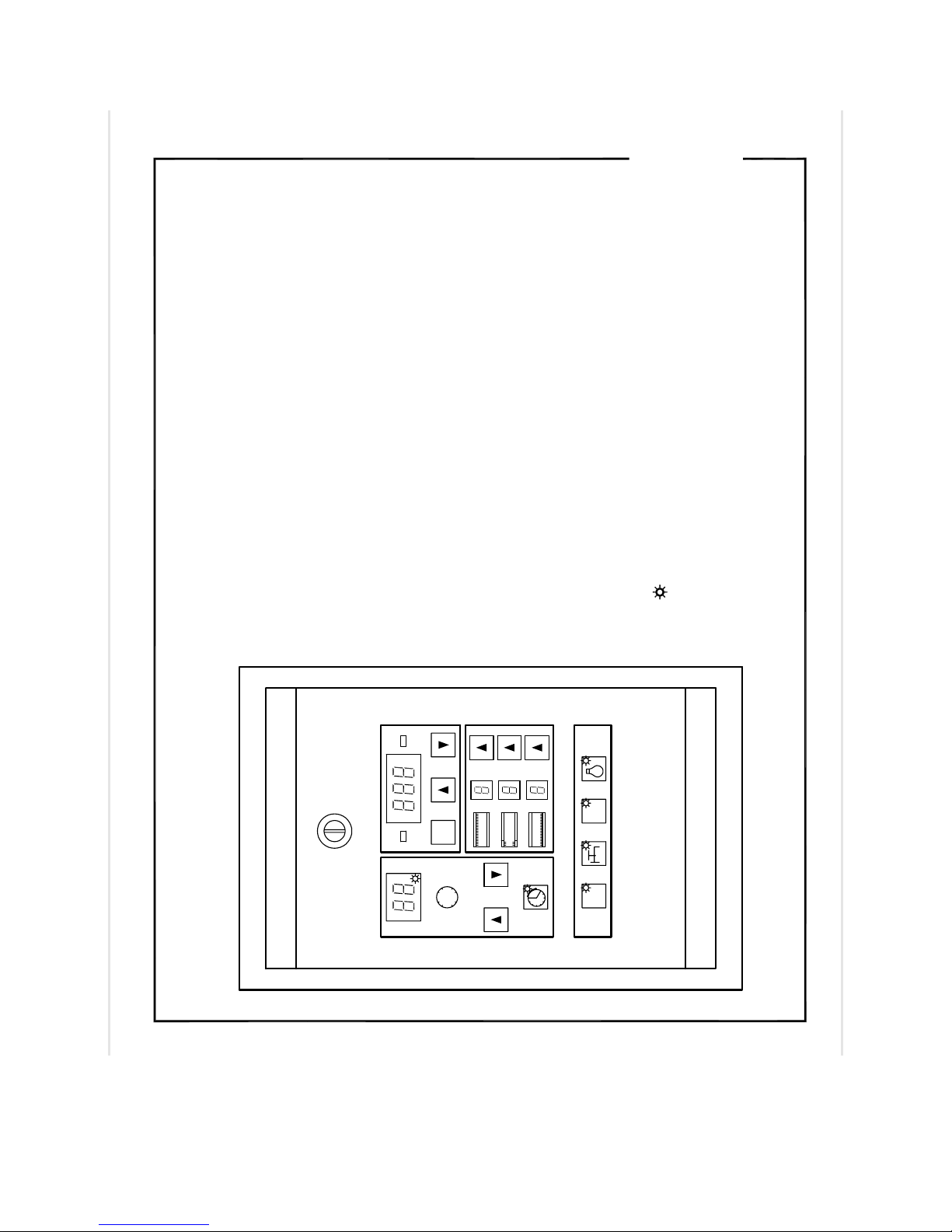

A6

CONTROL

CONTROL

1− TEMPERATURE INDICATOR

2− TEMPERATURE DISPLAY

3− HEATING MODE

4− SET POINT ADJUSTMENT SWITCH

5− UP ARROW TEMPERATURE SETTING

6− DOWN ARROW TEMPERATURE SETTING

7− ELEMENT PERCENTAGE EFFICIENCY

8− ELEMENT PERCENTAGE EFFICIENCY SELECTOR

9− OVEN SECTION ON / OFF SWITCH

10− STEAM INJECTION SWITCH

11− ECONO MODE SELECTOR

Y

3

456

SET

39

6

12

TIMER

78

A

14 15

2

1

OK

ALARM

13

12− OVEN LIGHT ON / OFF SWITCH

13− COOKING TIMER DISPLAY

14− UP ARROW TIME ADJUSTMENT

C

B

16

A− TOP ELEMENT

15− DOWN ARROW TIME ADJUSTMENT

16− START / STOP TIMER SWITCH

ON ECO

9101112

− INDICATOR LIGHT

B− FRONT ELEMENT

C− BOTTOM ELEMENT

Page 10

A7

OPERATION OF THE OVEN

1. Turn the switch to the ‘ON” position.

• The display on the control panel will light.

2. Adjust the thermostat at the desired setting (see THERMOSTAT INSTRUCTIONS below).

NOTE: The digital display must be ON. If not, check the breaker on the inside side of the oven

near the electrical connectors and the main breaker of the oven.

3. Heat the unit until you reach the baking temperature (see preheating time below). The green

light "OK" on the thermostat will light. (If the digital display is on and the oven does not

produce heat, call for service.)

4. If you use the steam, be sure that the light indicator on the steam switch does not flash before

the next step.

5. Load the oven as fast as possible to avoid letting out too much heat.

6. Inject steam if desired.

7. Set the timer to the desired value and start it. (See timer adjustment on next page.)

NOTE: The timer does not shut off the oven at the end of its cycle, it simply activates the buzzer.

THERMOSTAT INSTRUCTIONS

IMPORTANT: Never heat the oven more than 650°F/350°C

To obtain a very good thermal stability, we use a digital temperature controller with thermocouple.

The thermostat controls the heat of the elements to the desired set point “SET”. This temperature

control also has the possibility to adjust the element efficiency percentage to obtain more or less heat

according to the used product. It is possible to increase or decrease the heat produced by the top

elements "A", in front near the door "B" and bottom "C" by using the controls 7 and 8 underneath the

thermostat. It is possible to adjust A, B and C from 0=0% to 11=100% for each element section.

Element "A" (top) base adjustment recommended for: bread 3 and pizza 3.

Element "B" (front) base adjustment recommended for: bread 4 and pizza 5.

Element "C" (bottom) base adjustment recommended for: bread 3 and pizza 5.

The temperature of the oven is always shown on the display of the thermostat and a red indicator

light "Y" indicates that the oven is in heating mode or a green indicator light "OK" indicates that the

desired temperature is reached.

To adjust the temperature, you have to press the "SET" button and hold it until the numbers flash.

Use the arrows to set the desired value. Press the ‘SET’ button to return to operating mode. The red

indicator light "Y" will light to indicate that the oven is on heating mode, when the temperature is

reached, the green indicator light "OK" will light up.

ECONO MODE

If you select the ECONO mode, the oven element will heat at 60% or 80% to save energy.

Press and hold the ECONO button to change form 60 % or 80%.

Page 11

A8

INSTRUCTIONS FOR OVEN

BAKING

ONLY BREAD OR PIZZA DOUGH CAN BE BAKED DIRECTLY ON THE STONES

The suggested temperature may be different depending on the type of dough. Always test with

your products before doing a complete production.

400oF/200°C (Croissants – Sweet doughs – Small rolls)

440oF/225°C (Baguette bread – round loaf - 10 oz bread and more)

N.B. Open the doors as little as possible. This will affect the baking.

COOKING TIMER

Set the baking time required with the push button # 16 on the timer.

Press and hold the button START/STOP # 16 until the display flashes. With the up and down

arrows, adjust the desired time for your cooking. Press the START/STOP #16 button again to return

to timer mode.

Example: 25 minutes = 25 (on green display)

After setting, push the START/STOP #16 button. The indicator light, on the START/STOP #16,

will flash and the green display will begin its countdown. When the time expires, the buzzer will

ring, push the START/STOP #16 button to stop the buzzer. If you want to add or take off time on

the green display during the baking, use the up and down arrows to re-adjust the time. When the time

expires, the timer will return to its initial time.

N.B. The timer is simply a reminder for the approximate duration of the baking time. It does not

stop the oven.

STEAM INJECTION

VERY IMPORTANT

STEAM INJECTION WILL ONLY WORK WHEN THE STEAM INDICATOR LIGHT OF

THE STEAM BUTTON IS OFF (NOT FLASHING).

To inject steam in the oven, press and hold the steam button one or two seconds.

N.B. Do not inject steam more than once each time you bake. Always be sure that the steam is

ready to use (the indicator light of the steam button does not flash) before loading the oven.

EUROPEAN STYLE PROOFER

To inject steam in the proofer, the thermostat must be set at 300ºC. When the pilot light of the

thermostat turns off at 300ºC (this indicates that the steam injection system is ready to use), press and

hold the steam button one or two seconds every 15 minutes to inject steam. The proofer cabinet only

has a steam injection system, it is not a warmer.

Page 12

A9

TROUBLESHOOTING

BEFORE CALLING FOR SERVICE

ANSWERS TO MOST FREQUENT QUESTIONS

Always cut off the main power before replacing any parts. Be careful with the water and

electric wire supply system when pulling the oven.

Control parts

Questions Solutions

The oven does not turn on.

Oven does not produce heat.

Uneven baking.

If steam device of the oven does not work

properly.

No light in the oven.

If there is no humidity in the proofer.

Remove the side panel of the oven by screwing

out the screws.

If the display does not light up, check the

breakers of the building and the oven, located

behind the panel on the right side facing the

oven.

If the red light (Y) does not light up.

Check if the thermostat is adjusted high enough

to turn on the pilot light.

Check breakers of the oven.

Check element efficiency percentage and adjust

to obtain more or less heat.

Check if the main water valve is opened.

Always be sure that the steam is ready to use

(the indicator light of the steam button does not

flash) before loading the oven.

Check breakers of the oven, located behind the

panel on the right side facing the oven.

Check if the light bulb is burned out.

Check if the pilot light of the proofer thermostat

has reached 300ºC. The pilot light must shut off

to indicate that the temperature is hot.

When you press the steam button, the light of the

steam button must turn on, if not, check breaker.

Page 13

A10

OVEN MAINTENANCE AND CLEANING

MAINTENANCE OF THE OVEN

• It is recommended to use a water filter and to clean or replace it regularly to avoid

accumulation of minerals inside the unit.

Step by step Recommendations

Clean the inside of the oven and the proofer.

Do not wash the stone with water and soap.

To clean the stone, remove it from the oven

and scrub with a scratch pad until you have

a clean and soft surface.

Clean the oven windows with products like

Brasso or equivalents. They are copper

cleaners but good for this use.

Clean the oven exterior with a stainless steel

cleaner.

We recommend and sell:

Dirt Buster III.

Action foam cleaner

Part number : NEB201

We recommend :

Scratch pad

We recommend and sell:

Glass cleaner

Part number : EXC300

We recommend and sell:

Stainless steel cleaner

Part number : NES201

Page 14

A11

FOR MORE INFORMATION,

PLEASE CONTACT OUR OFFICE:

DOYON EQUIPMENT INC.

1255, rue Principale

Linière, Qc, Canada G0M 1J0

Tel. : 1 (418) 685-3431

Canada : 1 (800) 463-1636

U.S. : 1 (800) 463-4273

FAX : 1 (418) 685-3948

Internet: http://www.doyon.qc.ca

E-Mail : doyon@doyon.qc.ca

Page 15

SECTION

B

DIMENSIONS

Page 16

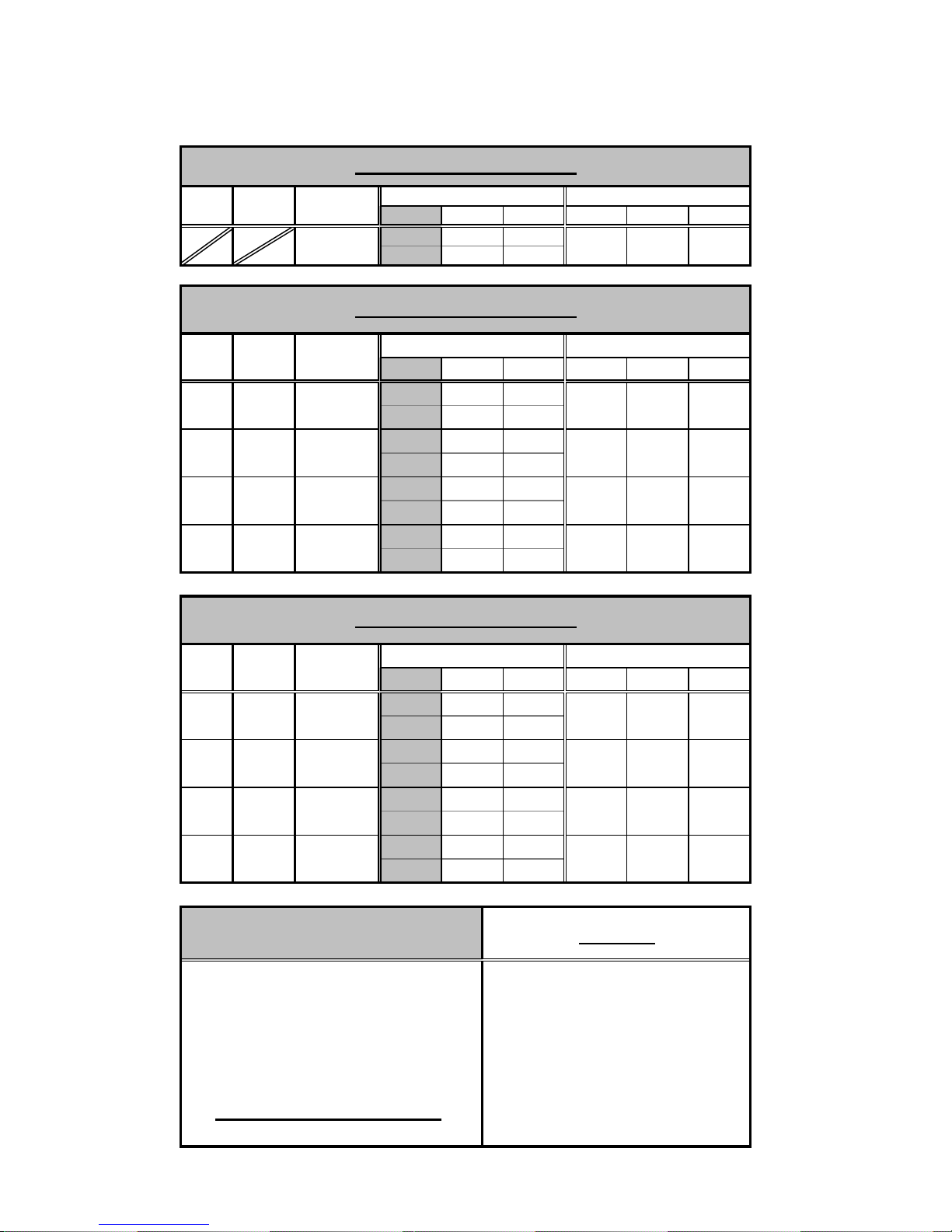

44

HEIGHT

M

OD.

N

UM

OD.

M

N

UM

1TCN

1TCA

1TSA

1TSS

B1

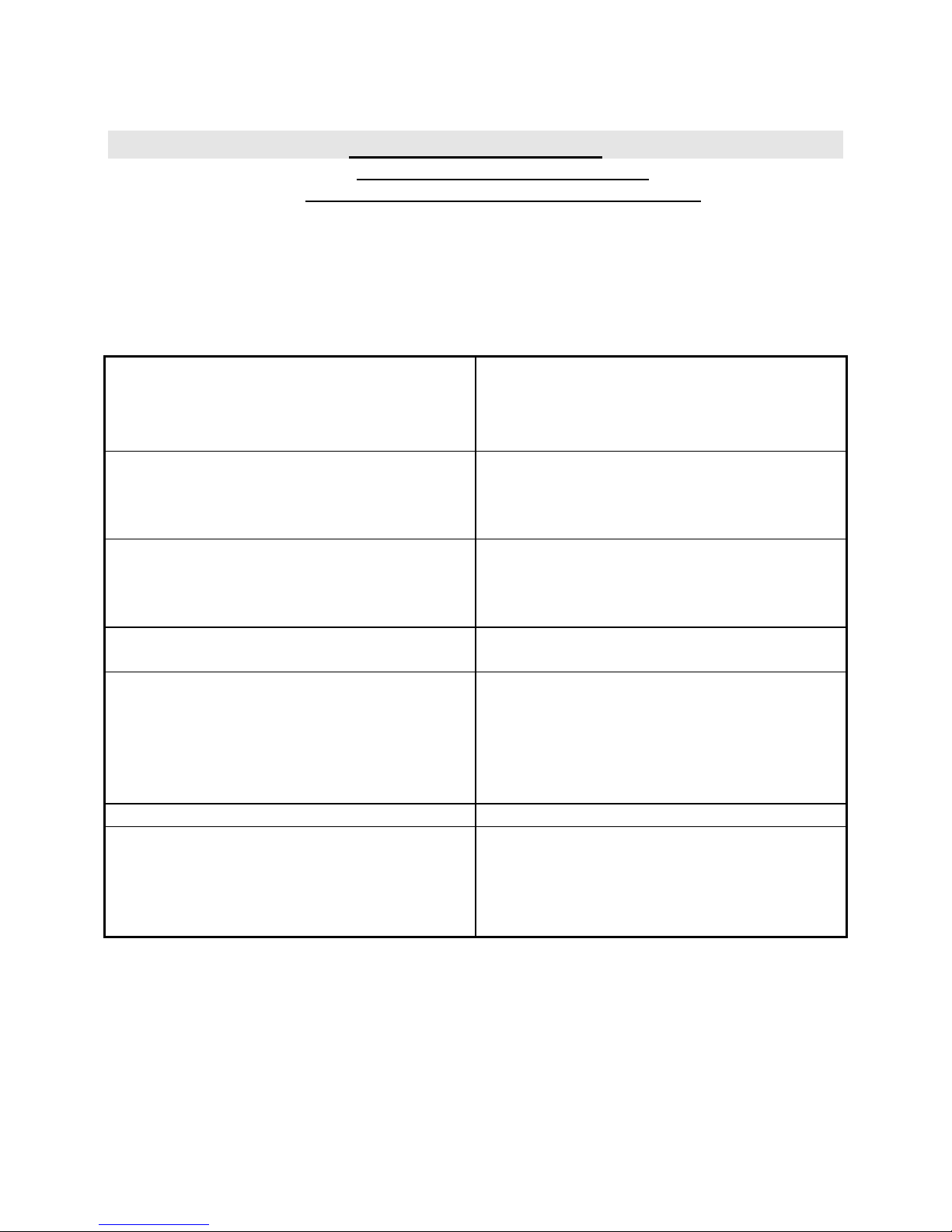

ARTISAN DECK OVEN 1T

TABLE OF DIMENSIONS "A"

I

P

AN

CAPAC. HEIGHT WIDTH DEPTH

T

C

OVER

YPE

E

XT. DIMENSIONS

5 34 1/2

(127) (876) (1 118)

TABLE OF DIMENSIONS "B"

P

AN

CAPAC.

1

1

1

1

T

YPE

N

ORMAL

H

IGHT

S

UPER

H

IGHT

UPER

S

S

UPER

H

IGHT

E

XT. DIMENSIONS

HEIGHT

12 7/8

(327)

14 7/8

WIDTH DEPTH

34 1/2

(876)

34 1/2

(378) (876)

16 7/8

34 1/2

(876)(429)

18 7/8

(479)

34 1/2

(876) (305)

46 1/4

(1 175)

46 1/4

(1 175)

46 1/4

(1 175)

46 1/4

(1 175)

NT. DIMENSIONS

-

I

NT. DIMENSIONS

HEIGHT WIDTH

6

(152)

8

(203)

10

(254)

12

WIDTH DEPTH

--

DEPTH

18 1/2

(470)

18 1/2

30

(762)

30

(470)30(762)

18 1/2

(470)

(762)

18 1/2

(470)30(762)

TABLE OF DIMENSIONS "C"

M

OD.

N

UM

1T

1T

1T

1T

P

AN

S

TACKED

CAPAC.

11

12

13

14

TABLE OF DIMENSIONS "D"

TOTAL HEIGHT OF OVEN

DIM "A"

(DIM "B" CN X QTY)

(DIM "B" CA X QTY)

+

(DIM "B" SA X QTY)

(DIM "B" SS X QTY)

DIM "C"

E

XT. DIMENSIONS

HEIGHT WIDTHCHAMBERS DEPTH

38

34 1/2 46

(965) (876) (1 168)

29

34 1/2 46

(737) (876) (1 168)

26

(660)

14

34 1/2

(876) (1 168)

34 1/2

46

(356) (876) (1 168)

FOR TOTAL HEIGHT,

ADD TOP HEIGHT, ALL

THE DECKS HEIGHT AND

BOTTOM STAND HEIGHT

I

NT. DIMENSIONS

HEIGHT WIDTH DEPTH

--

--

-

-

---

--46-

NOTES

TOTAL

Page 17

"A"

"B"

"B"

B2

34 1/2

ALARM

TIMER

ON ECO

ALARM

TIMER

ON ECO

OK Y

SET

OK Y

SET

1T_TABLE

"D"

"B"

"C"

ALARM

TIMER

ON ECO

OK Y

SET

10

5 1/8

7 1/2

1T_TABLE

Page 18

"A"

"B"

B3

40 3/4

46

1T_TABLE

44

3 1/4

"D"

"B"

"B"

5 1/8

"C"

7 1/2

1T_TABLE

Page 19

B4

1T_TABLE

ELECTRIC

INLET

Ø1 3/8"

"D"

"A"

"B"

"B"

"B"

3 1/2

2 1/2

34 1/2

3 1/4

5

1T_TABLE

"C"

5 1/8

WATER INLET

1/2" NPT

DRAIN

1/2" NPT

7 1/2

Page 20

M

HEIGHT

44

OD.

N

UM

M

OD.

N

UM

2TCN

2TCA

2TSA

2TSS

B5

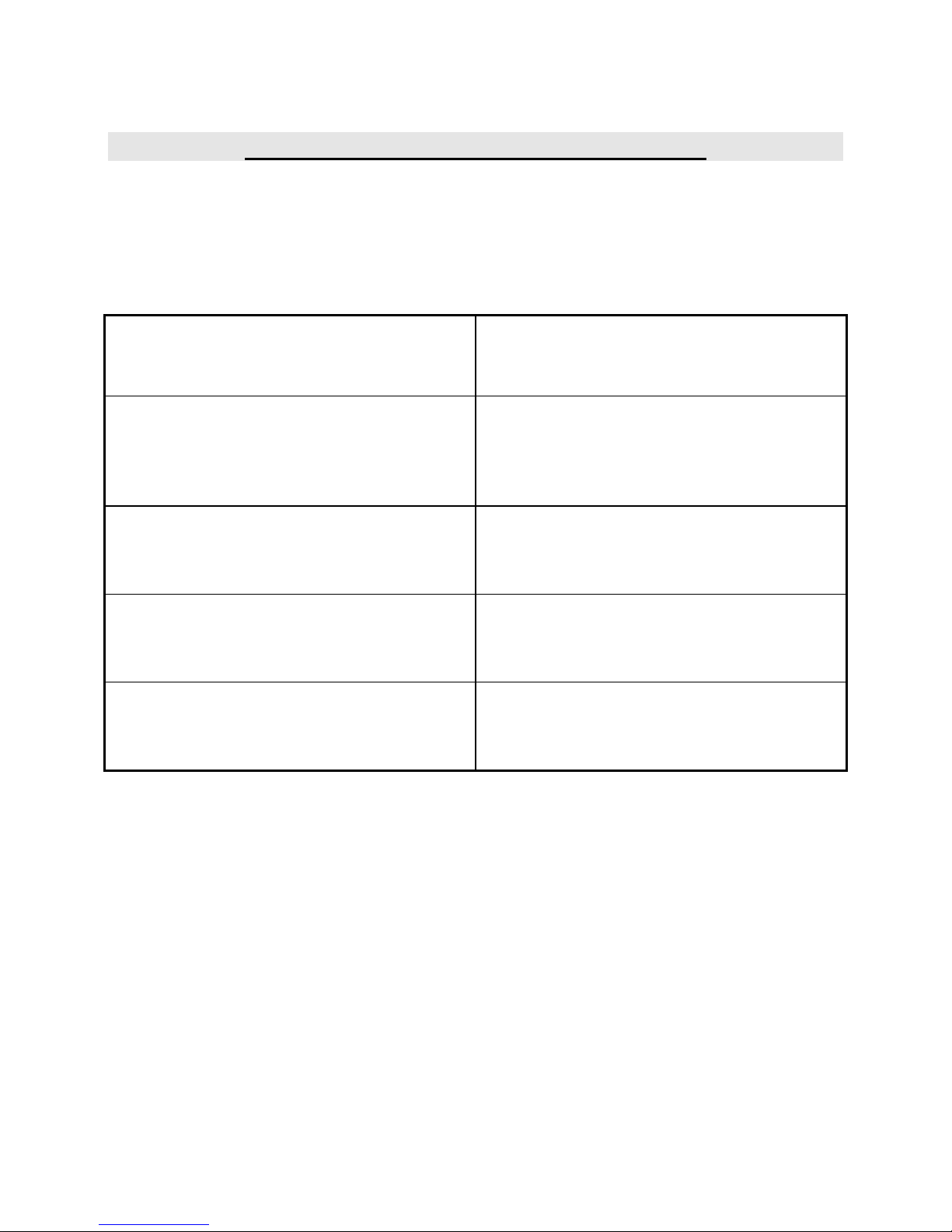

ARTISAN DECK OVEN 2T

TABLE OF DIMENSIONS "A"

P

AN

CAPAC. HEIGHT WIDTH DEPTH

T

C

OVER

YPE

TABLE OF DIMENSIONS "B"

P

AN

CAPAC.

2

2

2

2

T

YPE

N

ORMAL

H

IGHT

S

UPER

H

IGHT

S

UPER

S

UPER

H

IGHT

E

XT. DIMENSIONS

5 56 1/4

(127) (1 429) (1 118)

E

XT. DIMENSIONS

HEIGHT

12 7/8

(327)

14 7/8

(378) (762)

16 7/8

18 7/8

(479) (953)30(762)

WIDTH DEPTH

56 1/4

(1 429)

56 1/4

46 1/4

(1 175)

46 1/4

(1 175)(1 429)

56 1/4

(1 429)(429)

56 1/4

(1 429) (305)

46 1/4

(1 175)

46 1/4

(1 175)

I

NT. DIMENSIONS

-

I

NT. DIMENSIONS

HEIGHT WIDTH

6

(152)

8

(203)

10

(254)

12

WIDTH DEPTH

--

DEPTH

37 1/2

(953)

37 1/2

30

(762)

30

(953)

37 1/2

(953)

30

(762)

37 1/2

TABLE OF DIMENSIONS "C"

S

M

OD.

N

UM

2T

2T

2T

2T

P

AN

CAPAC.

21

22

23

24

TACKED

CHAMBERS DEPTH

TABLE OF DIMENSIONS "D"

TOTAL HEIGHT OF OVEN

DIM "A"

(DIM "B" CN X QTY)

(DIM "B" CA X QTY)

+

(DIM "B" SA X QTY)

(DIM "B" SS X QTY)

DIM "C"

E

XT. DIMENSIONS

HEIGHT WIDTH

38

56 1/4

46

(965) (1 429) (1 168)

29

56 1/4

46

(737) (1 429) (1 168)

26

(660)

14

(356)

56 1/4

46

(1 429) (1 168)

56 1/4

(1 429) (1 168)

FOR TOTAL HEIGHT,

ADD TOP HEIGHT, ALL

THE DECKS HEIGHT AND

BOTTOM STAND HEIGHT

I

NT. DIMENSIONS

HEIGHT WIDTH DEPTH

--

--

-

-

---

--46-

NOTES

TOTAL

Page 21

"A"

"B"

"B"

B6

56 1/4

2T_TABLE

OK Y

ALARM

SET

TIMER

ON ECO

OK Y

ALARM

SET

TIMER

ON ECO

"D"

"B"

"C"

ALARM

TIMER

ON ECO

OK Y

SET

10

5 1/8

7 1/2

2T_TABLE

Page 22

"A"

"B"

B7

44

40 3/4

46

2T_TABLE

3 1/4

"D"

"B"

"B"

5 1/8

"C"

7 1/2

2T_TABLE

Page 23

B8

2T_TABLE

ELECTRIC

INLET

Ø1 3/8"

"D"

"A"

"B"

"B"

"B"

3 1/2

2 1/2

56 1/4

3 1/4

5

2T_TABLE

"C"

WATER INLET

1/2" NPT

5 1/8

DRAIN

1/2" NPT

7 1/2

Page 24

44

HEIGHT

M

OD.

N

UM

M

OD.

UM

N

3TCN

3TCA

3TSA

3TSS

B9

ARTISAN DECK OVEN 3T

TABLE OF DIMENSIONS "A"

I

P

AN

CAPAC. HEIGHT WIDTH DEPTH

T

C

OVER

YPE

E

XT. DIMENSIONS

575

(127) (1 905) (1 118)

TABLE OF DIMENSIONS "B"

P

AN

CAPAC.

3

3

3

3

T

YPE

N

ORMAL

H

IGHT

S

UPER

IGHT

H

UPER

S

S

UPER

H

IGHT

E

XT. DIMENSIONS

HEIGHT

12 7/8

(327)

(378) (762)

16 7/8

18 7/8

(479)

WIDTH DEPTH

75

(1 905)

75

46 1/4

(1 175)

46 1/4

(1 175)(1 905)

75

(1 905)(429)

75

(1 905) (305)

46 1/4

(1 175)

46 1/4

(1 175)

NT. DIMENSIONS

-

I

NT. DIMENSIONS

6

8

(203)

10

(254)

12

WIDTH DEPTH

--

DEPTHHEIGHT WIDTH

56

(1 422)(152)

56

30

(762)

3014 7/8

(1 422)

56

(1 422)

30

(762)

56

(1 422)30(762)

TABLE OF DIMENSIONS "C"

M

OD.

N

UM

P

CAPAC.

3T

3T

3T

3T

S

AN

3

TACKED

CHAMBERS DEPTH

1

32

33

34

TABLE OF DIMENSIONS "D"

TOTAL HEIGHT OF OVEN

DIM "A"

(DIM "B" CN X QTY)

(DIM "B" CA X QTY)

+

(DIM "B" SA X QTY)

(DIM "B" SS X QTY)

DIM "C"

E

XT. DIMENSIONS

HEIGHT WIDTH

38

75

46

(965) (1 905) (1 168)

29

75

46

(737) (1 905) (1 168)

26

(660)

14

(356)

75

(1 905) (1 168)

75

(1 905) (1 168)

46

FOR TOTAL HEIGHT,

ADD TOP HEIGHT, ALL

THE DECKS HEIGHT AND

BOTTOM STAND HEIGHT

I

NT. DIMENSIONS

HEIGHT WIDTH DEPTH

--

--

-

-

-

--

--46-

NOTES

TOTAL

Page 25

"A"

"B"

"B"

B10

75

3T_TABLE

OK Y

ALARM

SET

TIMER

ON ECO

OK Y

ALARM

SET

TIMER

ON ECO

"D"

"B"

"C"

ALARM

TIMER

ON ECO

OK Y

SET

10

5 1/8

7 1/2

3T_TABLE

Page 26

"A"

"B"

B11

40 3/4

46

3T_TABLE

44

3 1/4

"D"

"B"

"B"

5 1/8

"C"

7 1/2

3T_TABLE

Page 27

B12

3T_TABLE

ELECTRIC

INLET

Ø1 3/8"

"A"

"B"

"B"

"D"

"B"

3 1/2

2 1/2

75

3 1/4

5

"C"

3T_TABLE

WATER INLET

1/2" NPT

5 1/8

DRAIN

1/2" NPT

7 1/2

Page 28

SECTION

E

COMPONENT PARTS

Page 29

11

E1

10

1T_TABLE

OK Y

ALARM

SET

TIMER

ONECO

OK Y

ALARM

SET

TIMER

9

ON ECO

3

5 6

1 2

8

OK Y

ALARM

SET

TIMER

ON ECO

10

4

7

1T_TABLE

Page 30

E2

Front view

Item Part Number Description Quantity

1 MPA168 LOCKING CASTER (FRONT OF THE OVEN) 2

& MPA167 NON LOCKING CASTER (BACK OF THE OVEN) 2

2 PA0341C LEGS WITHOUT CASTERS (25") 4

OR PA0342C LEGS WITHOUT CASTERS (16") 4

OR PA0343C LEGS WITHOUT CASTERS (13") 4

OR PA0344C LEGS WITHOUT CASTERS (1") 4

3 PA009CN BLACK KNOB FOR STEAM DAMPER (CN CHAMBER) 1

OR PA009CA BLACK KNOB FOR STEAM DAMPER (CA CHAMBER) 1

OR PA009SA BLACK KNOB FOR STEAM DAMPER (SA CHAMBER) 1

OR PA009SS BLACK KNOB FOR STEAM DAMPER (SS CHAMBER) 1

4 MPP089 DOOR HANDLE 1

& FMB601 DIA. 5/16” WASHER 1

& AZRB200 DIA. 5/16” LOCK WASHER 1

& FMB552 M8 NUT 1

& MPP211 ALLUMINIUM CAP NUT 1

5 PA023-1TCN DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 1TCN 1

OR PA023-1TCA DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 1TCA 1

OR PA023-1TSA DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 1TSA 1

OR PA023-1TSS DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 1TSS 1

6 MPV001 EXTERIOR TINTED DOOR GLASS (18 7/16"x4 3/4"x1/4") 1TCN 1

OR MVP003 EXTERIOR TINTED DOOR GLASS (18 7/16"x6 3/4"x1/4") 1TCA 1

OR MVP005 EXTERIOR TINTED DOOR GLASS (18 7/16"x8 3/4"x1/4") 1TSA 1

OR MVP007 EXTERIOR TINTED DOOR GLASS (18 7/16"x10 3/4"x1/4") 1TSS 1

7 MEC024 MAIN SWITCH KNOB 1

& MEC031 MAIN SWITCH LIGHT’S SOCKET 1

& MEC034 MAIN SWITCH CONTACT (NO) 1

& MER061

8 MEC008 CONTROL PANEL 1

& MEC066 OVEN THERMOCOUPLE TYPE K 1

& MEC067 STEAM THERMOCOUPLE TYPE K 1

9 MPR037 STONE DECK FOR 1T (PINK) 1

OR PA021R-1T

10 MVP002 INTERIOR NON TINTED DOOR GLASS (15 1/4"x4 3/4"x1/4") 1TCN 1

OR MVP004 INTERIOR NON TINTED DOOR GLASS (15 1/4"x6 3/4"x1/4") 1TCA 1

OR MVP006 INTERIOR NON TINTED DOOR GLASS (15 1/4"x8 3/4"x1/4") 1TSA 1

OR MVP008 INTERIOR NON TINTED DOOR GLASS (15 1/4"x10 3/4"x1/4") 1TSS 1

11 MPR021 1

1T ARTISAN DECK OVEN (FRONT VIEW)

Page 31

E3

1T_TABLE

4 6 7 8 9 10

3

2

1

5

11

C40 C10 C6 C10

1 : ON1 : ON 1 : ON 1 : ON1 : ON1 : ON

12 13

1 : ON1 : ON

1T_TABLE

Page 32

E4

Side view

Item Part Number Description Quantity

1 MER001 ELEMENT BLOCK 208V – 240V (1T) 12

OR MER001A ELEMENT BLOCK 480V (1T) 12

2 MER011 LIGHT BULB TYPE MR16 1

& MER019 SOCKET FOR 20W LIGHT BULB 1

3 MER068 TRANSFORMATOR 240V > 12V, 24V 1

& TRANSFORMATOR 240 > 24 IF WATER SOLENOID VALVE IS 24 VAC 1

4 TERMINAL BLOCK FOR BUZZER 2

5 MEC042 1

& MEC042B 1

6 TERMINAL BLOCK FOR CONTROL 6

7 MEC062 CONTACTO FOR OVEN ELEMENTS 3

8 MEC062 CONTACTOR FOR STEAM ELEMENT 1

9 MEP054 TRIPLE BREAKER 40A 1

10 DOUBLE BREAKER 10A 1

11 MEP005 DOUBLE BREAKER 6A 1

12 MEP003 SINGLE BREAKER 10A 1

13 MEL159 TERMINAL BLOCK 1

& MEL157 GROUND TERMINAL BLOCK 1

1T ARTISAN DECK OVEN (SIDE VIEW)

Page 33

E5

1T_TABLE

3

1

2

1T_TABLE

Page 34

E6

Back view

Item Part Number Description Quantity

1 STEAM GENERATOR BOX ASSY 1

& WATER INJECTOR 1

2 MER059 ELEMENT 600W 230V FOR THE STEAM GENERATOR 2

OR MER027A ELEMENT 600W 40V FOR STEAM 2

3 MEC014A SOLENOID VALVE 24 VAC 50 Hz 27 VA 1

OR MEC014B SOLENOID VALVE 12 VAC 50 Hz 27 VA 1

1T ARTISAN DECK OVEN (BACK VIEW)

Page 35

11

TABLE

E7

2T_

OK Y

ALARM

SET

TIM

ER

ON ECO

OK Y

ALARM

SET

9

10

TIMER

ON ECO

8

OK Y

ALARM

SET

TIMER

ON ECO

10

5 6

4

3

1

2

7

2T_TABLE

Page 36

E8

Front view

Item Part Number Description Quantity

1 MPA168 LOCKING CASTER (FRONT OF THE OVEN) 2

& MPA167 NON LOCKING CASTER (BACKOF THE OVEN) 2

2 PA0341C LEGS WITHOUT CASTERS (25") 4

OR PA0342C LEGS WITHOUT CASTERS (16") 4

OR PA0343C LEGS WITHOUT CASTERS (13") 4

OR PA0344C LEGS WITHOUT CASTERS (1") 4

3 PA009CN BLACK KNOB FOR STEAM DAMPER (CN CHAMBER) 1

OR PA009CA BLACK KNOB FOR STEAM DAMPER (CA CHAMBER) 1

OR PA009SA BLACK KNOB FOR STEAM DAMPER (SA CHAMBER) 1

OR PA009SS BLACK KNOB FOR STEAM DAMPER (SS CHAMBER) 1

4 MPP089 DOOR HANDLE 2

& FMB601 DIA. 5/16” WASHER

& AZRB200 DIA. 5/16” LOCK WASHER

& FMB552 M8 NUT

& MPP211 ALLUMINIUM CAP NUT

5 PA023-2TCN DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 2TCN 1

OR PA023-2TCA DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 2TCA 1

OR PA023-2TSA DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 2TSA 1

OR PA023-2TSS DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 2TSS 1

6 MPV009 EXTERIOR TINTED DOOR GLASS (37 3/16"x4 3/4"x1/4") 2TCN 1

OR MVP011 EXTERIOR TINTED DOOR GLASS (37 3/16"x6 3/4"x1/4") 2TCA 1

OR MVP013 EXTERIOR TINTED DOOR GLASS (37 3/16"x8 3/4"x1/4") 2TSA 1

OR MVP015 EXTERIOR TINTED DOOR GLASS (37 3/16"x10 3/4"x1/4") 2TSS 1

7 MEC024 MAIN SWITCH KNOB 1

& MEC031 MAIN SWITCH LIGHT’S SOCKET 1

& MER061

& MEC034 MAIN SWITCH CONTACT (NO) 1

8 MEC008 CONTROL PANEL 1

& MEC066 OVEN THERMOCOUPLE TYPE K 1

& MEC067 STEAM THERMOCOUPLE TYPE K 1

9 MPR037 STONE DECK FOR 2T (PINK) 1

OR PA021R-2T

10 MVP010 INTERIOR NON TINTED DOOR GLASS (34"x4 3/4"x1/4") 2TCN 1

OR MVP012 INTERIOR NON TINTED DOOR GLASS (34"x6 3/4"x1/4") 2TCA 1

OR MVP014 INTERIOR NON TINTED DOOR GLASS (34"x8 3/4"x1/4") 2TSA 1

OR MVP016 INTERIOR NON TINTED DOOR GLASS (34"x10 3/4"x1/4") 2TSS 1

11 MPR021 1

2T ARTISAN DECK OVEN (FRONT VIEW)

Page 37

E9

TABLE

2T_

3

2

1

4

678 9 10

5

11

C40 C10 C6 C10

1 : ON1 : ON 1 : ON 1 : ON1 : ON1 : ON

12 13

1 : ON1 : ON

2T_TABLE

Page 38

E10

Side view

Item Part Number Description Quantity

1 MER006 ELEMENT BLOCK 208V – 240V (2T) 12

OR MER006A ELEMENT BLOCK 480V (2T) 12

2 MER011 LIGHT BULB TYPE MR16 1

& MER019 SOCKET FOR 20W LIGHT BULB 1

3 MER068 TRANSFORMATOR 120V > 12V, 24V 1

4 TERMINAL BLOCK FOR BUZZER 2

5 MEC042 1

& MEC042B 1

6 TERMINAL BLOCK FOR CONTROL 6

7 MEC062 CONTACTOR OMRON J7K-CM FOR OVEN ELEMENTS 3

8 MEC062 CONTACTOR FOR STEAM ELEMENT 1

9 MEP054 TRIPLE BREAKER 40A 1

10 DOUBLE BREAKER 10A 1

11 MEP005 DOUBLE BREAKER 6A 1

12 MEP003 SINGLE BREAKER 10A 1

13 MEL159

& M TERMINAL BLOCK 1

2T ARTISAN DECK OVEN (SIDE VIEW)

Page 39

E11

3

2T_TABLE

1

2

2T_TABLE

Page 40

E12

Back view

Item Part Number Description Quantity

1

2 MER059 ELEMENT 600W 230V FOR STEAM GENERATOR 2

3 MEC014A SOLENOID VALVE 24 VAC 50 Hz 27 VA 1

OR MEC014B SOLENOID VALVE 12 VAC 50 Hz 27 VA 1

2T ARTISAN DECK OVEN (BACK VIEW)

Page 41

11

E13

3T_TABLE

OK Y

AL

AR

M

SE

T

TIMER

ON ECO

OK Y

ALARM

SET

9

10

TIMER

ON ECO

5 6

4

3

1 2

ALARM

TIMER

ON ECO

OK Y

SET

10

8

7

3T_TABLE

Page 42

E14

Front view

Item Part Number Description Quantity

1 MPA168 LOCKING CASTER (FRONT OF THE OVEN) 2

& MPA167 NON LOCKING CASTER (BACKOF THE OVEN) 2

2 PA0341C LEGS WITHOUT CASTERS (25") 4

OR PA0342C LEGS WITHOUT CASTERS (16") 4

OR PA0343C LEGS WITHOUT CASTERS (13") 4

OR PA0344C LEGS WITHOUT CASTERS (1") 4

3 PA009CN BLACK KNOB FOR STEAM DAMPER (CN CHAMBER) 1

OR PA009CA BLACK KNOB FOR STEAM DAMPER (CA CHAMBER) 1

OR PA009SA BLACK KNOB FOR STEAM DAMPER (SA CHAMBER) 1

OR PA009SS BLACK KNOB FOR STEAM DAMPER (SS CHAMBER) 1

4 MPP089 DOOR HANDLE 1

5 PA0233TCN DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 3TCN 1

OR PA0233TCA DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 3TCA 1

OR PA0233TSA DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 3TSA 1

OR PA0233TSS DOOR FRAME INCLUDES BOTH GLASSES (NO HANDLES) 3TSS 1

6 MPV017 EXTERIOR TINTED DOOR GLASS (55 5/8”x4 ¾”x1/4”) 3TCN 1

OR MVP019 EXTERIOR TINTED DOOR GLASS (55 5/8”x6 ¾”x1/4”) 3TCA 1

OR MVP021 EXTERIOR TINTED DOOR GLASS (55 5/8”x8 ¾”x1/4”) 3TSA 1

OR MVP023 EXTERIOR TINTED DOOR GLASS (55 5/8”x10 ¾”x1/4”) 3TSS 1

7 MEC024 MAIN SWITCH KNOB 1

& MEC031 MAIN SWITCH LIGHT 1

& MEC034 MAIN SWITCH CONTACT (NO) 1

8 MEC008 CONTROL PANEL 1

& MEC066 OVEN THERMOCOUPLE TYPE K 1

& MEC067 STEAM THERMOCOUPLE TYPE K 1

9 MPR044 STONE DECK FOR 3T 1

10 MVP018 INTERIOR NON TINTED DOOR GLASS (52 3/8”x4 ¾”x1/4”) 3TCN 1

OR MVP020 INTERIOR NON TINTED DOOR GLASS (52 3/8”x6 ¾”x1/4”) 3TCA 1

OR MVP022 INTERIOR NON TINTED DOOR GLASS (52 3/8”x8 ¾”x1/4”) 3TSA 1

OR MVP024 INTERIOR NON TINTED DOOR GLASS (52 3/8”x10 ¾”x1/4”) 3TSS 1

11 MPR021 1

3T ARTISAN DECK OVEN (FRONT VIEW)

Page 43

E15

3T_TABLE

6

3

5

4

2

1

7

8 9 10

11

C40 C10 C6 C10

1 : ON1 : ON 1 : ON 1 : ON1 : ON1 : ON

12 13

1 : ON1 : ON

3T_TABLE

Page 44

E16

Side view

Item Part Number Description Quantity

1 MER002 ELEMENT BLOCK 208V – 240V (2T) 12

OR MER002A ELEMENT BLOCK 480V (2T) 12

2 MER011 LIGHT BULB TYPE MR16 1

& MER019 SOCKET FOR 20W LIGHT BULB 1

3 TRANSFORMATOR 120V > 12V, 24V 1

4 TERMINAL BLOCK FOR BUZZER 2

5 MEC042 1

& MEC042B 1

6 TERMINAL BLOCK FOR CONTROL 6

7 MEC069 CONTACTOR OMRON J7K-CM FOR OVEN ELEMENTS 3

8 MEC062 CONTACTOR FOR STEAM ELEMENT 1

9 TRIPLE BREAKER 40A 1

10 DOUBLE BREAKER 10A 1

11 MEP005 DOUBLE BREAKER 6A 1

12 MEP003 SINGLE BREAKER 10A 1

13 TERMINAL BLOCK 1

3T ARTISAN DECK OVEN (SIDE VIEW)

Page 45

E17

3T_TABLE

1

3

2

3T_TABLE

Page 46

E18

Back view

Item Part Number Description Quantity

1

2 MER059 ELEMENT 600W 230V FOR STEAM GENERATOR 2

3 MEC014A SOLENOID VALVE 24 VAC 50 Hz 27 VA 1

OR MEC014B SOLENOID VALVE 12 VAC 50 Hz 27 VA 1

3T ARTISAN DECK OVEN (BACK VIEW)

Page 47

SECTION

G

ELECTRIC SCHEMATICS

Page 48

G1

250VA

12V

q1

220V

123

7085

PAINEL INTEGRADO

A2

g1

b1

b4

3

45896

7

11

10

MALHA

PARA

OUTROS

(CASA)

12

16

17

1819

−

+

24V

13

14

15

A1

VAPOR

c4

A2

LAR

A1

c3

A2

A1

PORTAc1

A2

A1

TECTO

c2

HIGH LIMIT

BUZZER

f1

−

+

−

+

VAPOR

SONDA

SONDA

FORNOS

d1

208 24A 24A 24A 8.6W

b3

L1L2L3

1 / 1

1T_3PH

1T

1T ARTISAN STONE OVEN

220 29A 29A 29A 10.3W

23/09/04 M. FAUCHER 2

240 32A 32A 32A 12.3W

NONE

TOTAL POWER: 3 PH. 60 Hz

k1

k2

b2

b1

A1

A2

VAPOR

c4

VAPORISADOR

RESISTENCIAS

A2

LAR

A1

c3

A2

A1

TECTO

c2

A2

A1

PORTA

c1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

Page 49

G2

250VA

12V

q1

220V

123

7085

PAINEL INTEGRADO

A2

A1

g1

b1

b4

3

45896

7

11

10

MALHA

PARA

OUTROS

12

1819 1716

(CASA)

−

+

24V

151413

VAPOR

c4

A2

A1

c3 LAR

A2

A1

PORTAc1

A2

A1

TECTO

c2

HIGH LIMIT

BUZZER

f1

−

+

−

+

SONDA

SONDA

VAPOR

d1

FORNOS

208 41A 41A 41A 14W

b3

L3

L1L2

1 / 1

2T_3PH

2T

2T ARTISAN STONE OVEN

220 43A 43A 43A 15.6W

23/09/04 M. FAUCHER 1

240 47A 47A 47A 18.6W

NONE

TOTAL POWER: 3 PH. 60 Hz

k1

k2

b2

b1

A1

A2

VAPOR

c4

VAPORISADOR

RESISTENCIAS

A2

LAR

A1

c3

A2

A1

TECTO

c2

A2

A1

PORTA

c1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

Page 50

G3

250VA

12V

q1

220V

123

7085

PAINEL INTEGRADO

A2

g1

b1

b4

3

45896

7

11

10

MALHA

PARA

OUTROS

12

1819 17 16

(CASA)

−

+

24V

151413

A1

VAPOR

c4

A2

A1

c3 LAR

A2

A1

PORTAc1

A2

A1

TECTO

c2

HIGH LIMIT

BUZZER

f1

−

+

−

+

SONDA

SONDA

VAPOR

d1

FORNOS

208 56A 56A 56A 19.5W

b3

k1

k2

b2

A1

A2

VAPOR

c4

VAPORISADOR

RESISTENCIAS

j1

R1

L3

L1L2

j1

R2

R2

R1

1 / 1

3T_3PH

3T

3T ARTISAN STONE OVEN

220 59.5A 59.5A 59.5A 21.8W

23/09/04 M. FAUCHER 3

240 65A 65A 65A 26W

NONE

TOTAL POWER: 3 PH. 60 Hz

R2

R1

b1

A1

A1

A1

LAR

c3

TECTO

c2

PORTA

c1

A2

A2

A2

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

Page 51

G4

1 / 1

250VA

12V

q1

220V

123

7085

PAINEL INTEGRADO

g1

b1

b4

3

45896

7

11

10

MALHA

PARA

OUTROS

12

1819 1716

(CASA)

−

+

24V

13

14

15

6A

b3

A2

A1

VAPOR

c4

A2

A1

c3 LAR

A2

A1

PORTAc1

A2

A1

TECTO

c2

HIGH LIMIT

BUZZER

f1

−

+

−

+

SONDA

SONDA

VAPOR

FORNOS

d1

10A

b3

STEAM

PROOFER

d1

220V

HIGH LIMIT

12V

220V

STEAM

1T ARTISAN STONE OVEN

1KW

1.1KW

220 29A 29A 29A 10.3

L1L2L3

208 27.5A 27.5A 27.5A 9.2

8/04/05 M. FAUCHER 1

1.3KW

240 32A 32A 32A 12.3

1T_OP_C2

1T

OVEN / PROOFER

NONE

TOTAL POWER: 3 PH. 60 Hz

k2

k1

b2

A2

A1

VAPOR

c4

VAPORISADOR

RESISTENCIAS

j1

R2

R1

j1

R2

R1

R2

R1

b1

A2

LAR

A1

c3

A2

A1

TECTO

c2

A2

A1

PORTA

c1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

R2

R1

j1

j1

R2

R1

R2

R1

j1

j1

R2

R1

R2

R1

j1

Page 52

LIMITED WARRANTY

(Continental United States Of America And Canada Only)

Doyon Equipment Inc. guarantees to the original purchaser only that its product are free of defects in

material and workmanship, under normal use.

This warranty does not cover any light bulbs, thermostat calibration or defects due to or resulting

from handling, abuse, misuse, nor shall it extend to any unit from which the serial number has been

removed or altered, or modifications made by unauthorized service personnel or damage by flood,

fire or other acts of God. Nor will this warranty apply as regards to the immersion element damaged

by hard water.

The extent of the manufacturer’s obligation under this warranty shall be limited to the replacement

or repair of defective parts within the warranty period. The decision of the acceptance of the

warranty will be made by Doyon Equipment service department, which decision will be final.

The purchaser is responsible for having the equipment properly installed, operated under normal

conditions with proper supervision and to perform periodic preventive maintenance.

If any parts are proven defective during the period of one year from date of purchase, Doyon

Equipment Inc. hereby guarantees to replace, without charge, F.O.B. Linière, Quebec, Canada, such

part or parts.

Doyon Equipment Inc. will pay the reasonable labor charges in connection with the replacement

parts occurring within one year from purchase date. Travel over 50 miles, holiday or overtime

charges are not covered. After one year from purchase date, all labor and transportation charges in

connection with replacement parts will be the purchaser’s responsibility.

Doyon Equipment Inc. does hereby exclude and shall not be liable to purchaser for any

consequential or incidental damages including, but not limited to, damages to property, damages for

loss of use, loss of time, loss of profits or income, resulting from any breach or warranty.

In no case, shall this warranty apply outside Canada and continental United States unless the

purchaser has a written agreement from Doyon Equipment Inc.

Loading...

Loading...