Page 1

INC.

BAKING EQUIPMENT SPECIALISTS

Oven built in one piece

(Modular baking chambers available on special orders)

1T

1 pan

(shown with optional proofer

and optional canopy)

3T

3 pans

wn with optional low profile proofer)

(sho

Artisan stone deck ovens

For the artisan baker, Doyon offers the best choice for baking Old-World artisan-style crusty breads with thick and crispy crust but still soft inside. Our

ovens offer perfect heat distribution and our outstanding steam injection sys-

our oven chamber. Doyon Artisan ovens

er y

v

ou complete contr

es y

tem giv

are quick and easy to install and are the perfect choice for a variety of quality

hearth breads, pastries, cookies, pies, cakes, pizzas, roasts, fast foods and much

more.

ol o

2T

2 pans

4T

4 pans

(shown with optional low profile proofer)

ARTISAN

“Superior quality product

at an affordable price !”

ARTISAN STONE DECK OVENS

FEATURING

• Built in one piece with up to 4 oven chambers

• Single point electrical connection

• Single point water inlet and drain

• 8” (203 mm) baking chamber height (other heights

available on special orders, call factory)

• Independant baking chambers

• Chambers capacity of 1, 2 , 3 or 4 pans

• Oversized, 1” (25 mm) thick refractory stone decks

• As many as 16 18” X 26” (457 mm X 660 mm) pans

• Individual self-contained steam injection system included

• Includes stand with casters and oven cover

• Digital electronic control board independent for each

chamber:

- Baking temperature and time

- Advanced independent temperature regulation for

bottom, top and front heat ratio

- Preset timed steam injection or manual,

independent for each chamber

• Main electronic keyboard with microprocessor which

controls the comsumption of energy (savings up to 40%)

compared to conventional systems

• High quality thermal insulation to avoid heat dispersion

from each chamber

• Oven can rest on an optional proofer or on a stainless

steel base with legs on casters

• Virtually maintenance-free, extremely elegant and durable

• Brightly lit

• ETL & ETL Sanitation listed

• One year parts and labor limited warranty

OPTIONAL

• European style proofer: standard height or low profile

6”, 10” or 12” high baking chambers available on special

ders, please call factory

or

• Modular oven chambers available on special orders

• Marine specification ovens

• 208V to 240V 1Ph oven chambers available, call factory

for details

en chambers available, call factory

380V to 480V 3Ph o

•

for details

• Canopy (Type II baking)

v

www.doyon.qc.ca

Page 2

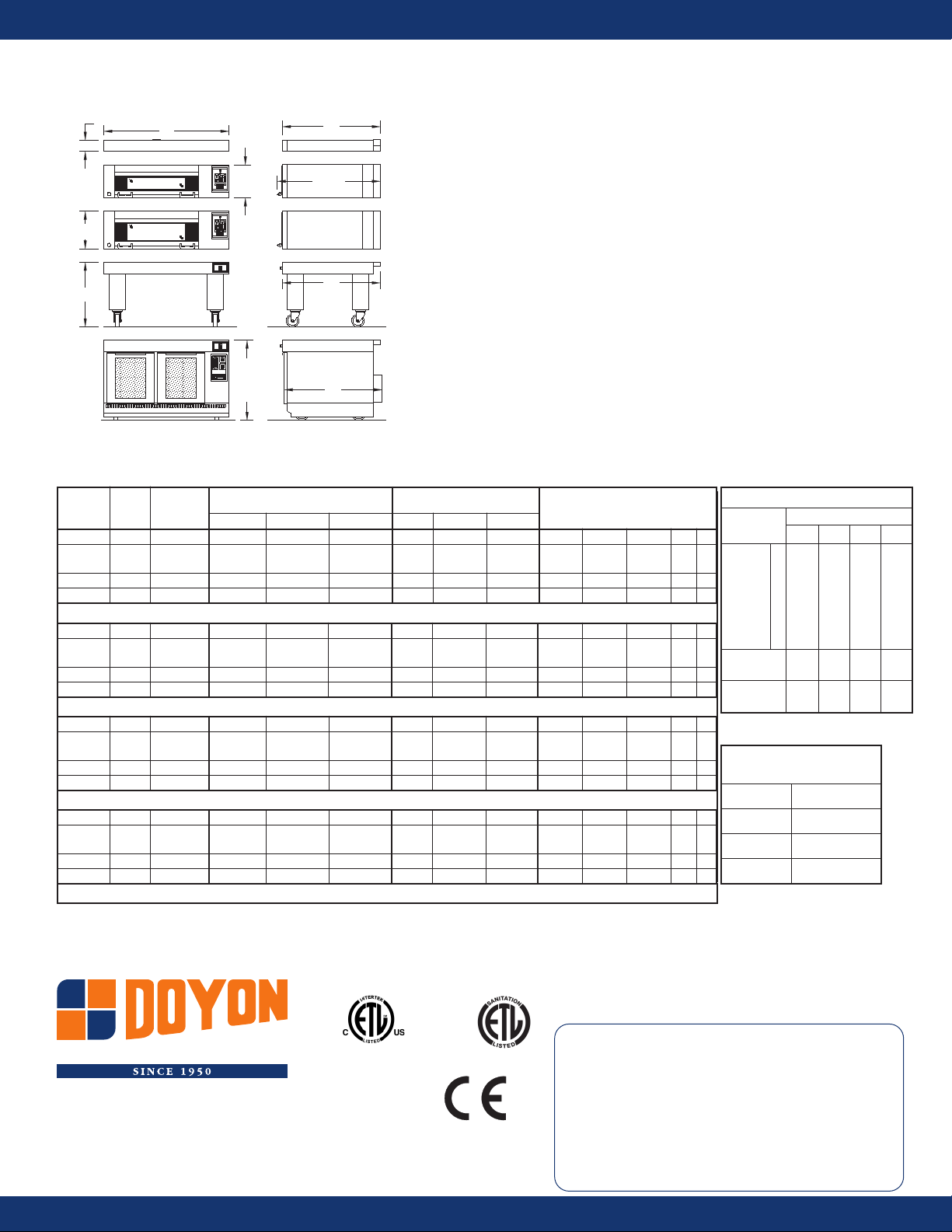

OPTIONAL PROOFER

44"

44"

44"

46 1/4"

"B"

36" OR

25 3/8"

STAND

"C"

1

0

A

LARM

T

IMER

12

6

3

9

ONE

CO

S

ET

O

KY

1

0

A

LARM

T

IMER

12

6

3

9

ONE

CO

S

ET

O

KY

OPTIONAL PR

OOFER

STAND

"B"

"B"

"A"

5"

INC.

BAKING EQUIPMENT SPECIALISTS

Oven built in one piece

(Modular baking chambers available on special orders)

Please note :

• Oven must be installed with proper ventilation in accordance with the local

building code.

• Minimum clearance from all combustible material : back and sides 1” (25

mm), top 6” (152 mm).

• Electrical specifications are for each deck (multiply electrical power by

number of decks).

• When viewed from the back, single point electrical connection located at the

left corner of oven cover

• 1/2” NPT water inlet (minimum water pressure of 60 psi) and 1/2” NPT

drain located at the back of the bottom baking chamber.

• A water softener system with a minimum flow rate of 3 gpm is highly

ecommended.

r

• Exhaust (3 1/4”) located at the back of the unit.

• For ovens with 3 baking chambers, it is recommended to choose the low

profile proofer.

• Proofer option is not available for ovens with 4 baking chambers.

Specifications and design subject to change without notice.

Model

Capacity

(pan)

Type

Exterior dimensions

(per chamber)

Height(B) Width (A) Depth Height Width Depth

– COVER 5” (127) 34 1/4”(870) 44”(1 120) – – – 208 V 240 V 480 V Hz Ph

1T 1

BAKING

CHAMBER

14 7/8” (378) 34 1/4”(870) 46 1/4” (1175) 8”(203) 18 1/2” (470) 30”(762)

ES1T 6 PROOFER 36” (914) 34 1/4”(870) 44”(1 120)

ES1TP 3 LOW PROOFER 25 3/8”(644) 34 1/4”(870) 44”(1 120)

1T modular chambers are 3/8” higher and have a width of 34 1/4”

COVER 5” (127) 56 1/4”(1 430) 44”(1 120) – – –

2T 2

BAKING

CHAMBER

14 7/8” (378) 56 1/4”(1 430) 46 1/4” (1175) 8”(203) 37 1/2” (953) 30”(762)

ES2T 12 PROOFER 36” (914) 56 1/4”(1 430) 44”(1 120)

ES2TP 6 LOW PROOFER 25 3/8” (644) 56 1/4”(1 430) 44”(1 120)

2T modular chambers are 3/8” higher and have a width of 52 7/8”

COVER 5” (127) 75”(1 905) 44”(1 120) – – – 208 V 240 V 480 V

3T 3

BAKING

CHAMBER

14 7/8” (378) 75”(1 905) 46 1/4” (1175) 8” (203) 56” (1 420) 30” (762)

ES3T 18 PROOFER 36” (914) 75”(1 905) 44”(1 120)

ES3TP 9 LOW PROOFER 25 3/8” (644) 75”(1 905) 44”(1 120)

3T modular chambers are 3/8” higher and have a width of 71 5/8”

COVER 5” (127) 75”(1 905) 51”(1 295) – – – 208 V 240 V 480 V

4T 4

BAKING

CHAMBER

14 7/8”

(378)

75”(1

ES3T 18 PROOFER 36” (914) 75”(1 905) 51”(1 295)

ES3TP 9 LOW PROOFER 25 3/8” (644) 75”(1 905) 51”(1 295)

4T modular chambers are 3/8” higher and have a width of 71 5/8”

Please note : 4T, side loading chambers

905)

53 1/4”

–

– – –

–

– – –

–

– – –

(1355)8”(203)

–

– – –

Interior dimensions

(per chamber)

–

–

–

(1 420)

56”

37”

–

–

–

–

(939)

–

Electrical system

(per chamber)

7.5 kW/21 A

10.0 kW/24 A 7.7 kW/9.2 A 50/60 3

1.6 kW/7.8 A

2.2 kW/9 A 2 kW/4.1 A

1.6 kW/7.8 A

2.2 kW/9A 2 kW/4.1 A

11.5 kW/32 A

15.3 kW/37 A 11.6 kW/14 A

1.6 kW/7.8 A

2.2 kW/9 A 2 kW/4.1 A

1.6 kW/7.8 A

2.2 kW/9 A 2 kW/4.1 A

15.7 kW/44 A

20.9 kW/50 A 15.7 kW/19 A

2.3 kW/11 A

3 kW/12.7 A 2.8 kW/5.8 A

2.3 kW/11 A

3 kW/12.7 A 2.8 kW/5.8 A

18.1/ kW/50 A

24.1 kW/67 A 18.1 kW/22 A

2.3 kW/11 A

3 kW/12.7 A 2.8 kW/5.8 A

A

2.3 kW/11

3 kW/12.7 A 2.8 kW/5.8 A

50/60 1

50/60 1

50/60

50/60 1

50/60 1

– –

50/60

50/60 1

50/60 1

– –

50/60

50/60 1

50/60 1

Stand dimensions

HEIGHT(C) Model

1T 2T 3T 4T

Number of 1 38” 38” 38” 38”

(965) (965) (965) (965)

chambers 2 29” 29” 29” 29”

(737) (737) (737) (737)

3 26” 26” 26” 26”

(660) (660) (660) (660)

4 14” 14” 14” 14”

(356) (356) (356) (356)

3

WIDTH (A) 34 1/4” 56 1/4” 75” 75”

(870) (1 430) (1 905) (1 905)

DEPTH 46” 46” 46” 51”

3

Approximative shipping weight

(1 170) (1 170) (1 170) (1 295)

(per chamber)

1T 580 lb (263 kg)

2T 700 lb (318 kg)

3

3T

4T

Note : Water inlet & drain 1/2” NPT

900 lb (408 kg)

950 lb (431 kg)

1255, rue Principale

Linière, Beauce, Québec, Canada G0M 1J0

elephone : (418) 685-3431

T

Canada : (800) 463-1636

E-Mail : doyon@doyon.qc.ca Internet: http://www.doyon.qc.ca

Fax: (418) 685-3948

U.S.: (800) 463-4273

Conforms to ANSI/UL std. 197

Certified to CSA C22.2 no.109

www.doyon.qc.ca

Conforms to

ANSI/NSF-4

our local distributor:

Y

Printed in Canada Rev: 102010q

Loading...

Loading...