UN ITED STATES . I NSTALL ATI ON INFOR MATION . R ESI DEN TIA L

I N S T A L L AT I O N P R O C E D U R E S F O R

T H E R M A X ™ O R S T Y R O F O A M ™

B R A N D R I G I D I N S U L AT I O N

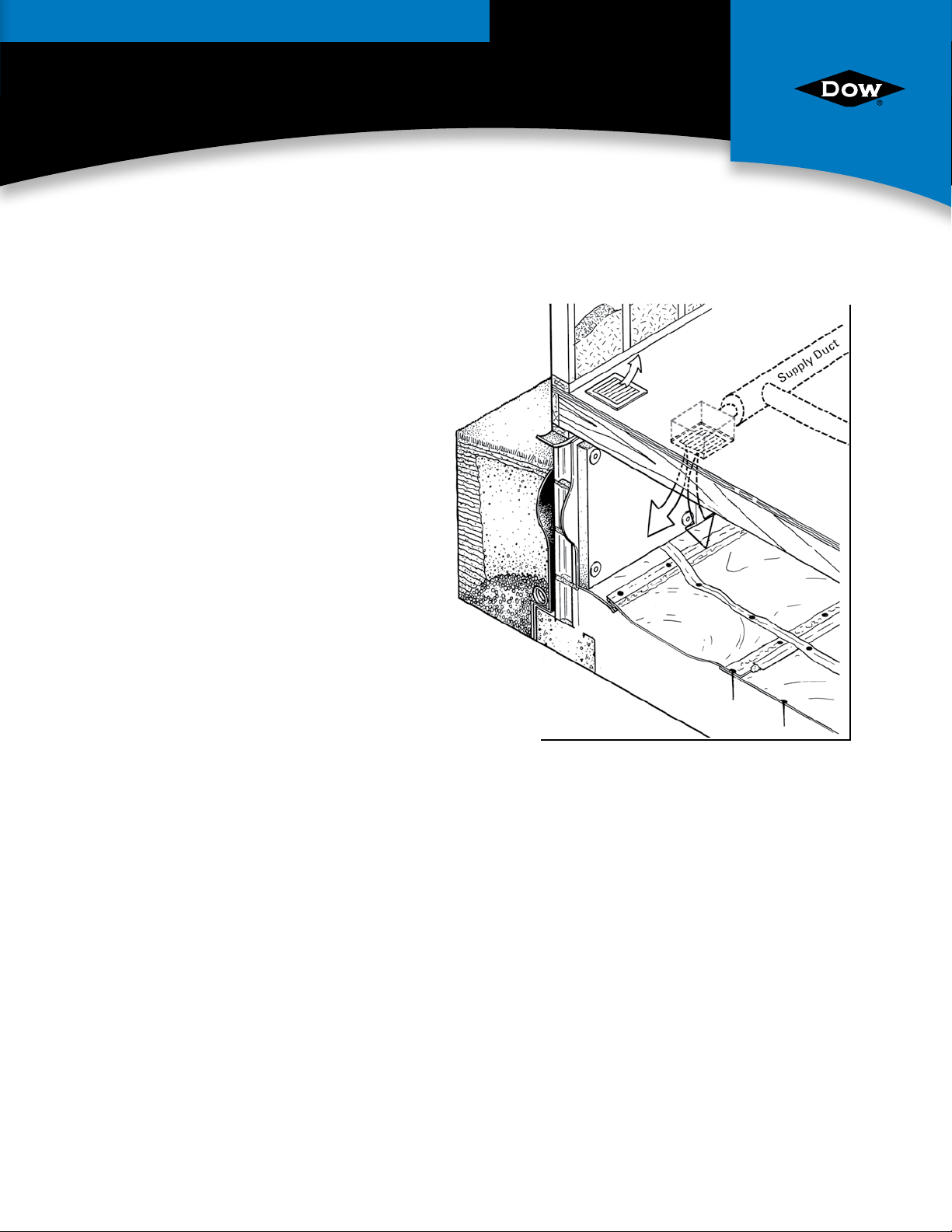

Closed Crawl Space

The closed crawl space is gaining popularity

for its effectiveness in reducing energy loss

and minimizing the potential for moisture

problems. Dow offers the following guidelines

for constructing a closed crawl space with an

insulation system that includes THERMAX™ or

STYROFOAM™ brand rigid insulation on interior

crawl space walls, a continuous poly vapor barrier

to prevent evaporation of ground moisture into

the crawl space, and a means to condition the

crawl space to keep the relative humidity below

70 percent to mitigate mold and mildew growth.

(See Figure 1.)

A b o u t T H E R M A X ™

R i g i d I n s u l a t i o n

THERMAX™ rigid insulation boards have a glassfiber-reinforced polyisocyanurate foam core,

with special laminated aluminum facers that

enhance moisture and damage resistance. This

reinforcement is chemically modified to provide

improved fire performance. THERMAX rigid

insulation boards can be left exposed in crawl

spaces per National Evaluation Services report

NER-681. THERMAX rigid insulation boards are

also Factory Mutual approved as a “Wall-Ceiling

Construction, FM Approvals Standard FM 4880,

Metal-Faced – Class 1 Fire Rated to a max, 30

ft. high.” Consult the local building codes in your

area before starting construction.

A b o u t S T Y R O F O A M ™ B r a n d

R i g i d I n s u l a t i o n

STYROFOAM™ brand rigid insulation boards are

made from extruded polystyrene foam insulation

and have exceptional water resistance, longterm thermal performance and high compressive

strength. ASTM C578 Type X and ASTM

C578 Type IV STYROFOAM Brand Extruded

Polystyrene Foam Insulation boards, with a

maximum nominal thickness of 2 inches (51mm),

may be installed on surfaces (wall, ceiling) of a

crawl space with no coverings (no thermal or

ignition barrier) applied to the crawl space side of

the foam plastic insulation per International Code

Council Evaluation Service (ICC-ES) Evaluation

Report ESR-2142.

Figure 1

Please note that closed crawl spaces may include

components not shown, such as other ventilation

options, floor drains, radon mitigation, etc.

Before You Begin

Before installing THERMAX™ or STYROFOAM™ brand rigid insulation boards on the interior crawl space wall, remove anything

that will interfere with installation. Best results are achieved when waterproofing or damp-proofing is applied from footer to grade

on the exterior of the crawl space wall. Install foundation drainage per code requirement.

The crawl space may contain utilities including, but not limited to, mechanical equipment, electrical wiring, fans, plumbing, gas

or electric hot water heaters, and gas or electric furnaces. When THERMAX or STYROFOAM brand insulation boards are used as

stated above in the crawl space, the following conditions must be met:

1. Under-floor (crawl space) ventilation is provided in accordance with IBC Section 1203.3 or IRC Section R408.1, as applicable; or

unvented crawl spaces are permitted under the conditions prescribed in IRC Section 408.3.

2. Combustion air is provided in accordance with IMC (International Mechanical Code) Section 701 and 703,

or IRC Section M1701 and M1703.

Installation on the interior of the crawl space wall should comply with 2009 IRC Section R408, 2009 IECC Section 402.2.9, Dow’s

ESR 2142 report and all other applicable code requirements. Additional useful information on closed crawl space systems can be

found at www.crawlspaces.org. Consult the local building codes in your area before beginning construction.

Materials Checklist

To insulate closed crawl spaces,

you will need:

• THERMAX™ or STYROFOAM™

brand rigid insulation boards –

select from any of the following:

- STYROFOAM Brand

Square Edge (25psi)

Insulation

- STYROFOAM Brand

Scoreboard (25psi) Insulation

- STYROFOAM Brand

Tongue and Groove

(25psi) Insulation

- THERMAX Sheathing

(with foil facing)

- THERMAX White Finish

Insulation

• Utility knife or small handsaw

• Straight edge

• Measuring tape

• Pencil

• Safety glasses

• Water-based adhesive mastic

• 6-mil poly liner

• Duct tape

• WEATHERMATE™

Construction Tape (optional)

• Spray urethane foam such as

GREAT STUFF PRO™ Gaps

& Cracks Insulating Foam

Sealant (optional)

• FROTH-PAK™ Foam Insulation

kit (optional)

• 6" galvanized nails

• 1" nailing tins

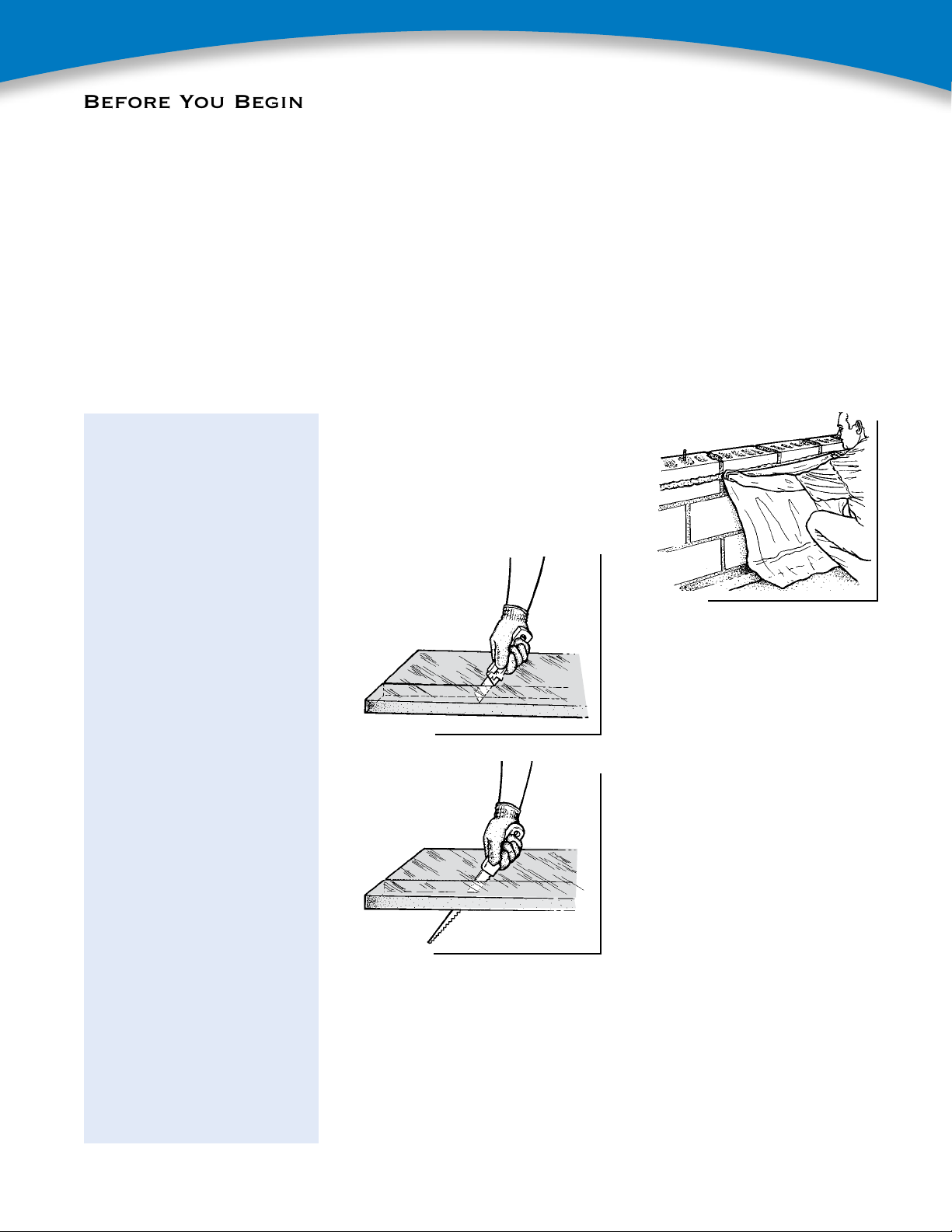

Cutting The Boards

THERMAX™ or STYROFOAM™ brand

rigid insulation boards may be cut

with a straight edge and utility knife or

with a small handsaw. (See Figures

2a and 2b.)

Figure 2a

Figure 2b

Installation

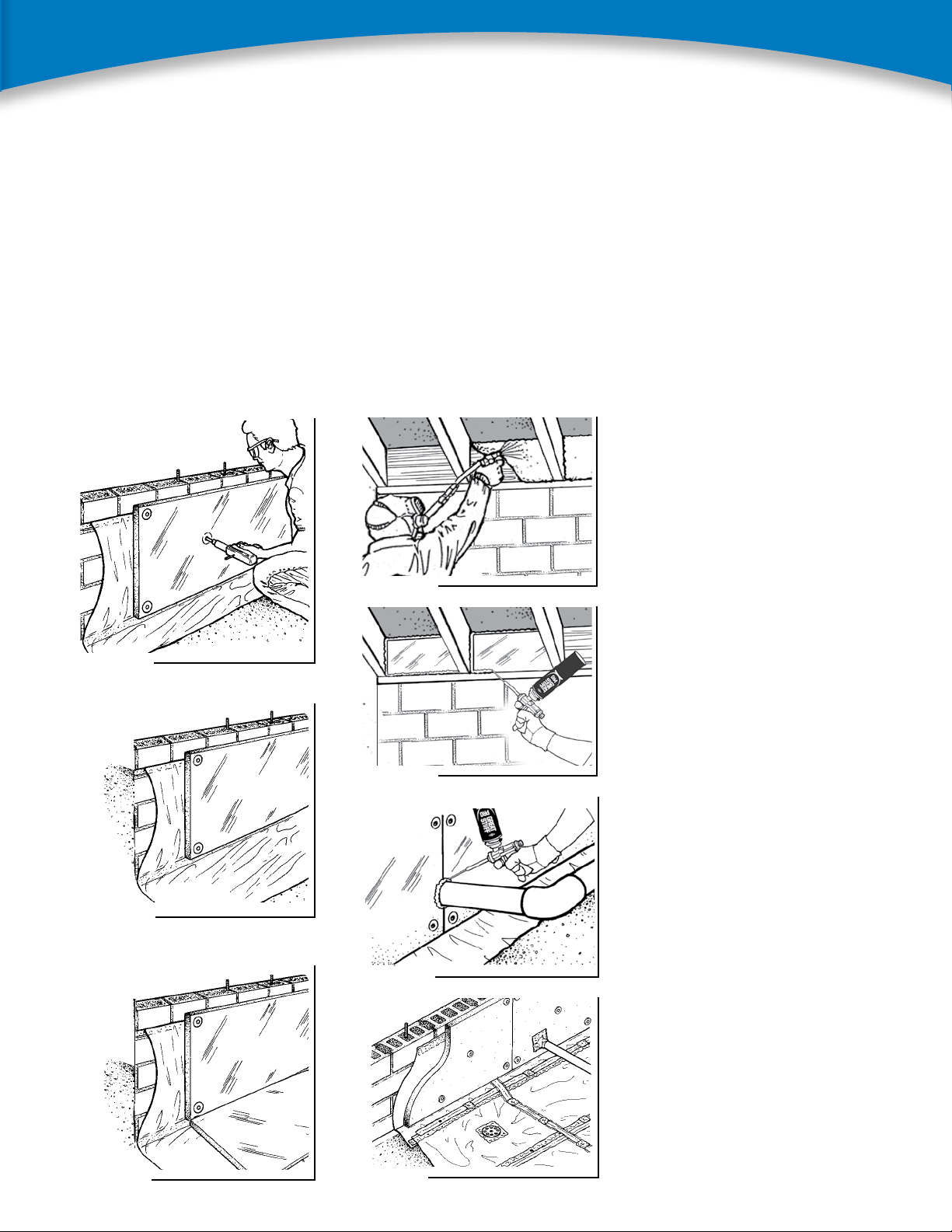

1. Attach a Type 1 Vapor Retarder such

as a 6-mil poly liner to the interior

stem wall with water-based adhesive

mastic. The edges of the vapor

retarder should extend at least 6

inches up the stem wall. Extend the

wall poly liner onto the ground about

1 to 2 feet from the wall. (See

Figure 3.)

Figure 3

2. Fasten the THERMAX™ or

STYROFOAM™ brand insulation

boards to the interior of the

crawl space wall using powerdriven masonry nails with 1-inch

washers or caps. The boards

shall be permanently fastened to

the interior of the stem wall and

extend downward from the top

of the stem wall to the exterior

finished grade level and then

vertically and/or horizontally

for at least 24 inches. In some

situations, an inspection strip may

be appropriate. An inspection strip

is a 2-inch to 3-inch strip around

the top of the stem wall without

insulation, which allows inspection

for termites. (Check with your local

code officials and pest control

operators regarding this option.)

Space fasteners approximately

2 feet on center vertically and

4 feet on center horizontally.

(See Figure 4a.)

Note: If the distance between

the exterior grade level and the

crawl space floor is greater than

24 inches, the rigid insulation

board on the wall should extend at

least 24 inches below the exterior

grade. (See Figure 4b). If the

2

distance between the exterior grade

level and the crawl space floor is less

than 24 inches, the board on the wall

should extend to the crawl space floor

and then horizontally on the floor so

the total board length below exterior

grade (both vertically and horizontally)

equals at least 24 inches. (See

Figure 4c.)

3. Insulate the rim joist and sill plate.

There are three options for this step:

a. Option 1: Use FROTH-PAK™

Foam Insulation kits up to

2 inches in thickness. (See

Figure 5a.)

b. Option 2: Use STYROFOAM™

brand rigid insulation

boards up to 2 inches in

thickness, cut to fit between

the floor joists, and seal

the edges of the foam with

GREAT STUFF PRO™ Gaps &

Cracks. (See Figure 5b.)

c. Option 3: Use THERMAX™

rigid insulation boards up to

4 inches in thickness, cut to fit

between the floor joists, and

seal the edges of the foam

with GREAT STUFF PRO Gaps

& Cracks. (See Figure 5b.)

Figure 5a

4. Seal all penetrations through

the crawl space wall with spray

urethane foam such as GREAT

STUFF PRO Gaps & Cracks. (See

Figure 6.) Joints between boards of

insulation may also be taped with

WEATHERMATE™ Construction

Tape, if desired.

5. Install a temporary “construction”

poly liner as soon as the house is

“dried in” (i.e., tar paper is on the

roof). Cover the floor area with poly,

but leave seams unsealed. This will

temporarily prevent moisture from

the soil from evaporating into the

crawl space.

6. Before installing the permanent poly

ground cover, temporary installation

of a small dehumidifier will help dry

out the moisture that already exists

in the crawl space. Set the drain

tube to discharge outside of the

crawl space.

7. When the house is near

completion, remove the temporary

“construction” poly and discard.

Figure 4a

Figure 4b

Figure 5b

Figure 6

8. Roll out and install a permanent

Type I Vapor Retarder such as a

6-mil poly liner. The vapor retarder

sheets should overlap each other

by at least 6 inches. Carefully seal

the seams at the wall poly liner with

duct tape and mastic. Also seal

all joints and penetrations in the

field. (See Figure 7.) Secure each

joint with duct tape, then brush on

a layer of mastic. Mastic should

extend at least 1 inch beyond the

tape on each side.

9. Secure vapor retarder to the ground

with a 6-inch galvanized spike

through 1-inch diameter nailing tins.

For reinforcement and a tight seal,

apply duct tape and mastic over

spikes and tins.

The steps outlined here are intended to

make the crawl space clean, dry, wellinsulated, airtight and vapor tight. There

are other important components in a

closed crawl space system. Consult IRC

Section 408 or www.crawlspaces.org for

other components such as ventilation

options.

Figure 4c

Figure 7

3

A d d i t i o n a l

R e c o m m e n d a t i o n s

and polyol. Do not breathe vapor

or mist. Use only in well-ventilated

areas or with proper respiratory

• Builders may wish to install a

humidity sensor in the crawl space,

wired to a digital readout and alarm

upstairs, to help homeowners

monitor relative humidity.

• To minimize damage to the poly

liner, install carpet runners from the

access door to the water heater,

furnace and other appliances as a

path for service technicians.

• The homeowner should be

informed that a closed crawl space

should be treated as part of the

main house and must not be used

for storage of lawn equipment,

pesticides, fuel, etc.

protection. Supplied air or an

approved air-purifying respirator

equipped with an organic vapor

sorbent and a particle filter may

be required to maintain exposure

levels below ACGIH, OSHA, WEEL

or other applicable limits. For

situations where the atmospheric

levels may exceed the level for

which an air-purifying respirator is

effective, use a positive-pressure,

air-supplying respirator (air line

or self-contained breathing

apparatus).

• Isocyanate is irritating to the

eyes, skin and respiratory system,

and may cause sensitization by

inhalation or skin contact.

S A F E T Y A N D

C O N D I T I O N S O F U S E

FROTH-PAK™ Foam Insulation

• Read the instructions and Material

Safety Data Sheets carefully before

use.

• FROTH-PAK™ Foam will adhere

to most surfaces and skin. Do not

get foam on skin. Wear gloves,

goggles or safety glasses, and

protective clothing. Cured foam

must be mechanically removed or

allowed to wear off in time.

• The contents are under pressure.

• FROTH-PAK™ Polyurethane

Spray Foam contains isocyanate,

hydrofluorocarbon blowing agent

www.insulateyourhome.com

FOR TECHNICAL INFORMATION: 1-866-583-BLUE (2583)

FOR SALES INFORMATION: 1-800-232-2436

THE DOW CHEMICAL COMPANY

Dow Building Solutions • 200 Larkin • Midland, MI 48674

GREAT STUFF PRO™ Gaps &

Cracks Insulating Foam Sealant

• Read the label and Material Safety

Data Sheet carefully before use.

• GREAT STUFF PRO™ Gaps &

Cracks contains isocyanate and a

flammable blowing agent. Vapor

may travel to other rooms. Ensure

adequate ventilation. Shut off all

pilot lights and extinguish open

flames; eliminate all sources of

ignition before use. Do not smoke

or use lighters or matches while

dispensing foam.

• Do not breathe vapor or mist. Use

in well-ventilated areas or wear

proper respiratory protection.

Isocyanate is irritating to the

eyes, skin and respiratory system,

and may cause sensitization by

inhalation or skin contact.

• GREAT STUFF PRO™ Gaps &

Cracks is very sticky and will

adhere to most surfaces and

skin. Do not get foam on skin.

Wear gloves, and safety glasses

or goggles. Cured foam must be

mechanically removed or allowed

to wear off in time.

• The contents are under pressure.

The can may burst if left in areas

susceptible to high temperatures,

such as motor vehicles, or near

radiators, stoves or other sources

of heat. Do not place can in hot

water. Do not puncture, incinerate

or store at temperatures above

120°F (49°C).

STYROFOAM™ Brand Extruded Polystyrene Foam Insulation is combustible. Protect from high heat sources. A protective barrier or thermal barrier may be required as specified in the appropriate building

code.

THERMAX™ Polyisocyanurate Sheathing is combustible and shall only be used as specified by the local building code with respect to flame spread classification and to the use of a suitable barrier.

FROTH-PAK™ Polyurethane Spray Foam contains isocyanate, hydrofluorocarbon blowing agent and polyol. Read the instructions and Material Safety Data Sheets carefully before use. Wear protective clothing,

gloves, goggles or safety glasses, and proper respiratory protection. Supplied air or an approved air-purifying respirator equipped with an organic vapor sorbent and a particle filter may be required to maintain

exposure levels below ACGIH, OSHA, WEEL or other applicable limits. Provide adequate ventilation. Contents under pressure. Consult the instructions and Material Safety Data Sheet carefully before use.

GREAT STUFF PRO™ Insulating Foam Sealant contains isocyanate and a flammable blowing agent. Read the label and Material Safety Data Sheet carefully before use. Eliminate all sources of ignition before

use. Wear gloves, and safety glasses or goggles. Provide adequate ventilation or wear proper respiratory protection. Contents under pressure.

CAUTION: These products are combustible and shall only be used as specified by the local building code with respect to flame spread classification and to the use of a suitable thermal barrier. For more information call Dow at 1-866-583-BLUE (2583) or contact your local building inspector. In an emergency, call 1-989-636-4400.

Building and/or construction practices unrelated to building materials could greatly affect moisture and the potential for mold formation. No material supplier including Dow can give assurance that mold

will not develop in any specific system.

NOTICE: No freedom from any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is

responsible for determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance

with applicable laws and other government enactments. Dow assumes no obligation or liability for the information in this document. NO EXPRESS WARRANTIES ARE GIVEN EXCEPT FOR ANY APPLICABLE

WRITTEN WARRANTIES SPECIFICALLY PROVIDED BY DOW. ALL IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY

EXCLUDED.

Printed in U.S.A.

®™

Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

Form No. 179-07259-1009XBBI

McKAY200501

Loading...

Loading...