Page 1

I N F O R M A T I O N . C O M M E R C I A L . U S / C A N A D A

V e g e t a t i v e R o o f P M R – A D e s i g n P r i m e r

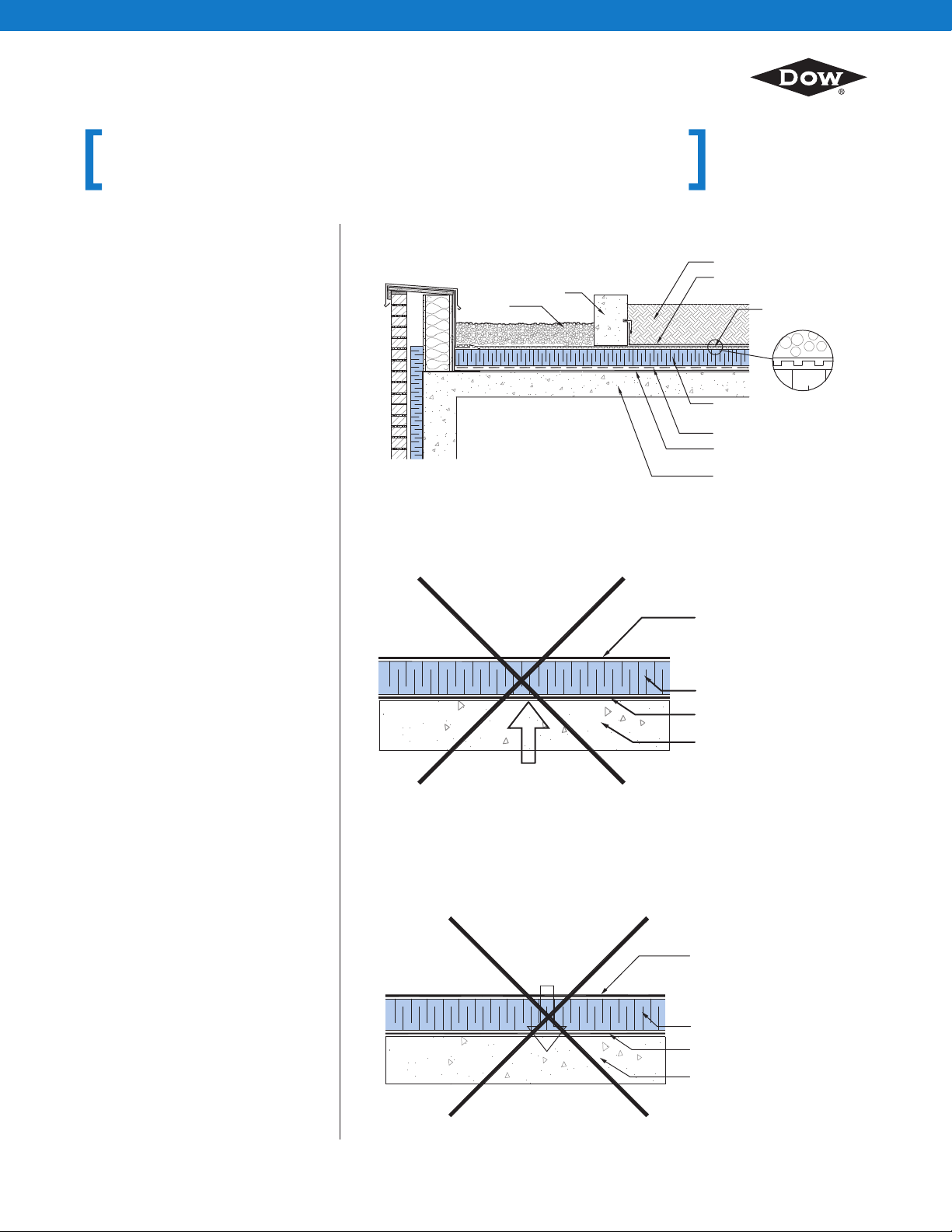

A protected membrane roof (PMR)

design is an ideal solution for “green”

roofs where landscaping or plantings are used on the top surface.

Preventing leaks is crucial in any

roof, and even more so in a vegetative roof, because repairing this

type of roof can be costly.

In a vegetative roof PMR, typically

a fully adhered membrane is installed

over a concrete deck and the desired

thickness of STYROFOAM

™

Brand

Extruded Polystyrene Foam Insulation

and a root barrier are installed above

the membrane (Figure 1).

This layer of insulation serves a

dual function of providing both

long-term thermal insulation value as

well as mechanical protection of

the crucial waterproofing membrane

during the installation of the roof

landscaping, including drainage layers, drainage materials and plantings,

and the assorted equipment used

during the installation process.

WHE RE SHO ULD THE

DRA INA G E L AY ER BE

LOC ATED ?

The drainage layer should always

be above the STYROFOAM

Extruded Polystyrene Foam

Insulation to ensure that any water

is quickly drained away and the full

value of the insulation is maintained.

In vegetative roof PMR deck

designs, a drainage layer above the

insulation allows water to drain off

the top surface of the insulation,

creating a “diffusion open” assembly.

If the insulation is sandwiched

between a vapor retarder (e.g.,

saturated drainage felt) and the

underlying membrane, vapor cannot

escape, so there is the potential for

it to be driven back into the insulation

(Figures 2 and 3). To create a “diffusion

open” layer, ensure that the top surface

of the insulation has a ventilating air

space as well as provides a good

slope for drainage.

Note: Never install a polyester

mat or moisture retention blanket

directly on the insulation. If used,

ensure a clear drainage layer

separates the moisture retention

blanket and the insulation.

™

Brand

Figure 1: Vegetative Roof PMR*

Landscaping Curb

Ballast

Figure 2: Creating “Diffusion Closed” Situations

(colder areas in North America)*

Vapor Impermeable Surface

Cold Exterior

40°F (4°C), 20% RH

Warm, Humid Interior

70°F (21°C), 40% RH

Vapor

Drive

(standing water, retention mat)

STYROFOAM™ Brand

Foam Insulation

Fully Adhered

Waterproofing Membrane

Structural Concrete Deck

Figure 3: Creating “Diffusion Closed” Situations

(warm, high-humidity areas in North America)*

Vapor Impermeable Surface

(standing water, retention mat)

STYROFOAM™ Brand

Foam Insulation

Fully Adhered

Waterproofing Membrane

Structural Concrete Deck

Warm, Humid Exterior

90°F (32°C), 50% RH

Cool Interior

70°F (21°C), 40% RH

Vapor

Drive

lanting Layer

P

ilter Fabric

F

rainage Layer

D

shown: preformed

(

rainage sheet)

d

STYROFOAM™ Brand

Foam Insulation

Root Barrier Membrane

ully Adhered

F

aterproofing Membrane

W

Structural Concrete Deck

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

*Not to scale. For reference purposes only.

Page 2

I N F O R M A T I O N . C O M M E R C I A L . U S / C A N A D A

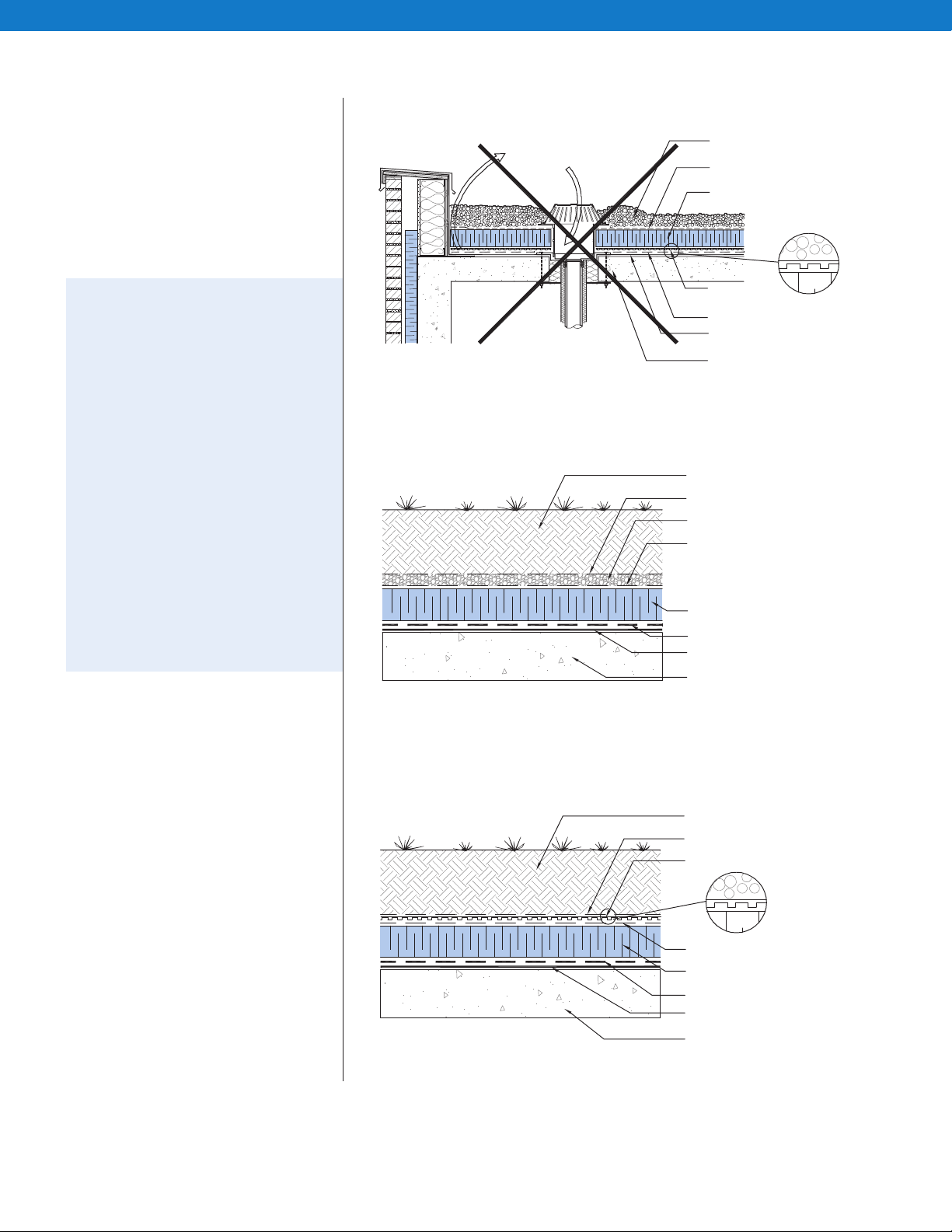

Installing the drainage layer under

the insulation can potentially minimize

the overall benefits of the insulation

by creating a convective loop below

the thermal insulation (Figure 4). In

this case, air can move through the

drainage layer and reduce the overall

insulation value. Installing the drainage

layer above the insulation ensures

that the insulation value is maximized.

IMPORTANT: When scheduling or

weather conditions delay installation

of plaza, patio deck or vegetative roof

PMR areas, care must be taken to

ensure that dark-colored products,

such as black plastic drainage boards

(dimple boards) or dark fabric, are

not placed over the insulation and

then left exposed. Dark-colored

products can lead to extremely high

surface temperatures, increasing the

potential for distortion of rigid foam

boards.

If STYROFOAM

™

Brand Extruded

Polystyrene Foam Insulation is already

installed, cover it with a white opaque

polyethylene film to protect it during

the delay. Otherwise, schedule the

insulation installation for a time when

the entire installation process can be

completed in a timely manner.

Figure 4: Potential for Convective Looping When Installing the

Drainage Layer Under the Insulation*

Ballast or

onvective Loop

C

Drain

Planting Layer

Filter Fabric

STYROFOAM™ Brand

Foam Insulation

Preformed

Drainage Sheet

Root Barrier Membrane

Fully Adhered

Waterproofing Membrane

Structural Concrete Deck

Figure 5: Option 1 – Drainage Layer Consisting of 1" (25 mm)

Granular Layer*

lanting Layer

P

Filter Fabric

'' Pea Gravel

1

ilter Fabric

F

STYROFOAM™ Brand

Foam Insulation

Root Barrier Membrane

Fully Adhered

Waterproofing Membrane

Structural Concrete Deck

WHAT PR O DUC TS C A N

BE US E D TO CRE AT E A

DRA INA G E L AY ER?

A number of products can be easily

incorporated, depending on the

drainage requirements, budget and

other preferences. The main

categories of products include:

• 1" (25 mm) (min) layer of pea gravel,

free of fines, with a filter fabric

above and below the ballast

(Figure 5)

• 3/8" to 1/2" (12 mm to 12.7 mm)

dimpled, preformed plastic drainage

sheet. Where possible, specify a

product that minimizes contact

with the insulation (e.g., place

dimpled side down) (Figure 6)

• Any other product that provides

adequate drainage while providing

minimal direct contact on the

underlying insulation (Figure 7)

Figure 6: Option 2 – Drainage Layer Consisting of a Preformed

Plastic Drainage Sheet*

Planting Layer

Filter Fabric

Preformed Drainage Sheet

Filter Fabric

STYROFOAM™ Brand

Foam Insulation

Root Barrier Membrane

Fully Adhered

Waterproofing Membrane

Structural Concrete Deck

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

*Not to scale. For reference purposes only.

Page 3

I N F O R M A T I O N . C O M M E R C I A L . U S / C A N A D A

igure 7: Option 3 – Drainage Layer Consisting of a Commercially

F

Available Mat and Filter*

Planting Layer

Filter Fabric

Drainage Layer

Filter Fabric

STYROFOAM™ Brand

Foam Insulation

oot Barrier Membrane

R

Fully Adhered

Waterproofing Membrane

Structural Concrete Deck

WHAT TYPE OF STYROFOAM

BRAND INSULATION SHOULD

BE SPECIFIED?

The insulation must be able to perform

long term under both sustained (dead

loads from plantings, planters, etc.)

and cyclic loading (live loads from

maintenance vehicles, foot traffic,

etc.). Because the design of each

vegetative roof is unique, it is important that the designers calculate

both the live and dead loads created

on the insulation layer. STYROFOAM

Brand Extruded Polystyrene Foam

™

™

Regardless of the type of insulation,

where more than one layer of insulation

is required, follow these guidelines:

• The bottom layer of insulation (the

layer directly on the root barrier)

must be at least 2" (50 mm) thick.

• The bottom layer must be the

thickest or, at minimum, equal

to the top layer (e.g., 3" [75 mm]

bottom and 3" [75 mm] top).

• Lay succeeding layers of insulation

unbonded or unadhered.

• Stagger or offset all joints from

those of the underlying layer.

Insulation is available in a range of

compressive strengths from 35-100

psi (240-690 kPa) to address the

specific design loading requirements

for each project.

For a vegetative roof PMR that is

exposed to limited pedestrian traffic

and minor landscape maintenance

using light power tools, typically

STYROFOAM

™

Brand ROOFMATE

™

Insulation or STYROFOAM™Brand

HIGHLOAD 40 Insulation may be

specified, depending on design loads

from the planting layer and other

dead loads. Where vehicular traffic

or large design loads are anticipated,

STYROFOAM

or STYROFOAM

100 Insulation may be required.

STYROFOAM

™

Brand HIGHLOAD 60

™

Brand HIGHLOAD

™

Brand PLAZAMATE

TA BL E 1: RE QU IRE D BA LL A ST AR OU ND P E RI ME TER S

AN D PEN ET RATI ONS

STYROFOAM™ THICKNESS, REQUIRED WEIGHT OF APPROXIMATE THICKNESS

IN (MM) STONE BALLAST, LB/FT2(KG/M2) OF BALLAST, IN (MM)

Up to 2 (50) 12 (60) 1-3/4 (40)

3 (75) 17 (84) 2-1/4 (60)

4 (100) 22 (108) 3 (75)

5 (125) 27 (132) 3-1/2 (90)

6 (150) 32 (156) 4-1/4 (105)

7 (175) 37 (180) 5 (125)

8 (200) 42 (204) 5-1/2 (140)

™

Insulation (U.S. only) is also available.

Note: These are guidelines only;

it is the responsibility of designers and/or engineers to calculate

and accommodate live and dead

loads in a vegetative roof PMR

design. If required, contact a Dow

representative for additional

information on the live and dead

load design limits for STYROFOAM

rand Extruded Polystyrene Foam

B

Insulation.

WHAT AR E T HE WEI GHT

REC OMM E NDATI ONS FOR

BAL L A ST AN D T HE

PLAN T ING L AYE R ?

When designing a vegetative roof

PMR, the stone ballast typically

specified in a PMR is effectively

replaced by the planting layer to

minimize any potential for flotation.

As detailed in Dow literature and

Tech Solutions 508.1 (Ballast Design

Guide for PMR Systems [U.S.]), the

minimum stone ballast requirement

of 10-12 lb/ft

replaced with a similar weight of a

dry and unsaturated planting layer,

with additional ballast required

around any penetration(s) and the

roof perimeter. Refer to Table 1 for

either weight or thickness of additional ballast, depending on the

thickness of insulation. For additional

literature, visit www.dowpmr.com

or call 1-866-583-BLUE (2583).

2

(50-60 kg/m2) can be

™

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

*Not to scale. For reference purposes only.

Page 4

I N F O R M A T I O N . C O M M E R C I A L . U S / C A N A D A

C A N THI S P MR TY P E QUA L IFY F O R LEE D C RED I TS?

A vegetative roof PMR can provide valuable credits when obtaining the

U.S. Green Building Council’s LEED** (Leadership in Energy and

Environmental Design) rating. Refer to Table 2 for examples of possible

redits.

c

For more details, refer to the “STYROFOAM

and Green Roof Assemblies” brochure (Form # 179-05082/178-00698)

at www.dowpmr.com.

For more information on LEED, refer to www.usgbc.org (U.S.) or

www.cagbc.org (Canada).

TA BL E 2: PO TE NTI AL LEED P OI NT S F OR GRE E N RO OF

SY S TE MS BA SE D ON LE ED REFE RE NCE G UI DE FO R

GR E EN BUIL DI NG DE SI GN A ND CO NS TRU CT ION 2 00 9

ED I TI ON

REDIT NUMBER CREDIT NAME NUMBER OF POINTS

C

SS Credit 5.1 Site Development, protect or 1

SS Credit 5.2 Site Development, maximize open space 1

SS Credit 6.1 Stormwater Design, quantity control 1

SS Credit 6.2 Stormwater Design, quality control 1

SS Credit 7.2 Heat Island Effect, roof 1

WE Credit 1 Water Efficient Landscaping 2-4

EA Prerequisite 2 Minimum Energy Performance Required

EA Credit 1 Optimize Energy Performance 1-19

MR Credit 3 Material Reuse 1-2

MR Credit 4 Recycled Content 1-2

MR Credit 5 Regional Materials, 10%/20% extracted, 1-2

EQ Credit 7.1 Thermal Comfort, design 1

ID Credit 1.1 100% green roof for exemplary performance 1

ID Credit 1.2 Green roof accounts for 40% of the project 1

ID Credit 1.3 Green Roof area doubles the requirements 1

restore habitat

(post consumer+1/2 preconsumer)

processed and manufactured regionally

of SS Credit 7.2

site area for SS Credit 5.1

of SS Credit 5.2 depending on local zoning

open space requirements.

™

Brand Insulation, LEED

WHAT P R ODU CTS CAN

BE USED IN MA IN TAINING

THI S P MR T Y PE?

Often chemicals are used in maintaining a vegetative roof PMR,

including fertilizers, pesticides and

herbicides. Because of the many

different components in the roof

assembly, it is recommended that

chemical compatibility be checked

or each component (e.g., filter

f

products, preformed drainage layers

and membranes). In general, for

STYROFOAM

Polystyrene Foam Insulation, always

use a solvent-free product. Contact

your Dow representative or call

1-866-583-BLUE (2583) for more

information.

™

Brand Extruded

www.dowpmr.com

Technical Information

1-866-583-BLUE (2583) (English)

1-800-363-6210 (French)

The information in this document is not intended to replace the need for design by appropriate professionals such as architects or engineers.

NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is

responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws

and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all

countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO

WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

STYROFOAM™ Brand Extruded Polystyrene Foam Insulation

CAUTION: This product is combustible. Protect from high heat sources. A protective barrier or thermal barrier may be required as specified in the appropriate building code. For more information, consult MSDS, call Dow at

1-866-583-BLUE (2583) or contact your local building inspector. In an emergency, call 1-989-636-4400 in the U.S. or 1-519-339-3711 in Canada.

WARNING: Rigid foam insulation does not constitute a working walkable surface or qualify as a fall protection product.

Building and/or construction practices unrelated to building materials could greatly affect moisture and the potential for mold formation. No material supplier including Dow can give assurance that mold will not develop in any

specific system.

Printed in U.S.A.

Sales Information

1-800-232-2436 (English)

1-800-565-1255 (French)

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow Form No. 179-05268X-0713MCK

IN THE U.S.

THE DOW CHEMICAL COMPANY

200 Larkin

Midland, MI 48674

IN CANADA

DOW CHEMICAL CANADA ULC

450 – 1st St. SW . Suite 2100

Calgary, AB T2P 5H1

178-00590X-0713MCK

McKAY219304

Loading...

Loading...