Page 1

FROTHPAK™

REFILL SYSTEMS

MANUAL

INSTALL MANUAL | United States | COMMERCIAL/RESIDENTIAL

2014 EDITION

Manual

Page 2

Table of Contents

FROTHPAK™ Refill System Installation .........................................................A1

Nitrogen Regulator Assembly.................................................................... A2

INSTAFLO™ Gun...............................................................................A3

Anti-crossover Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A4

Introduction ................................................................................................... 2

Section 1: System Information

1.1 Ordering Information ..........................................................................3

1.2 Refill Accessories .............................................................................3

1.3 Anti-crossover Nozzles (25 Pack) ..............................................................4

1.4 Shipping Weights..............................................................................4

1.5 Tank Dimensions ..............................................................................4

1.6 Freight Classification for Tank Return ..........................................................5

Section 2: Safety Precautions

2.1 Respiratory Protection.........................................................................6

2.2 Isocyanate-induced Occupational Asthma .....................................................6

2.3 Safety Clothing................................................................................6

2.4 Skin Contact ..................................................................................6

2.5 Eye Contact ...................................................................................6

2.6 Ingestion ......................................................................................7

2.7 Removal of Cured Foam on Skin ...............................................................7

2.8 Overfilling Restricted Spaces ..................................................................7

2.9 Chemical Information ..........................................................................7

2.10 Chemical Spills...............................................................................7

2.10.1 “A” Chemical .........................................................................7

2.10.2 “B” Chemical.........................................................................7

2.11 Cautions .....................................................................................7

2.11.1 Storage Temperature ................................................................7

2.11.2 Building Codes ......................................................................7

2.11.3 Surface Temperature Restrictions ....................................................7

2.11.4 Open Flame/Spark Source...........................................................7

2.11.5 Excessive Foam Dispensing..........................................................7

2.12 Training ......................................................................................7

Section 3: System Installation

3.1 Initial Tank Set-up .............................................................................8

3.2 Tank Positioning...............................................................................9

3.3 Nitrogen Regulator Installation................................................................ 9

3.4 Chemical Hose Installation....................................................................10

Section 4: Start-up Procedure

4.1 System Pressurization ........................................................................10

4.2 Calibration Instructions .......................................................................11

4.3 System Purging and Testing ..................................................................13

4.4 Nozzle Replacement..........................................................................13

Page 3

Section 5: INSTAFLO™ Gun Operation...................................................................13

5.1 Spraying ....................................................................................13

5.2 INSTAFLO

™

Gun Operation .................................................................14

Section 6: Shut-down Procedure ................................................................... 14

Section 7: Storage................................................................................. 15

Section 8: Re-start Procedure ......................................................................15

8.1 System Pressurization .......................................................................15

8.2 System Purging and Testing .................................................................16

Section 9: Tank Change-over....................................................................... 16

9.1 “A” Tank Change-over........................................................................17

9.2 “B” Tank Change-over .......................................................................18

9.3 Tank Return ................................................................................. 18

9.4 System Pressurization .......................................................................19

9.5 System Purging and Testing .................................................................19

Section 10: Troubleshooting......................................................................... 19

10.1 Temperature .............................................................................19

10.2 Foam Color and Quality ....................................................................19

Section 11: Yield Notes ............................................................................. 21

11.1 Operator Technique ........................................................................ 21

11.2 Application.................................................................................21

11.3 Temperature ...............................................................................21

Section 12: Ratios and Output....................................................................... 22

Section 13: Anti-crossover Nozzles.................................................................. 22

Section 14: Nitrogen Regulator...................................................................... 22

14.1 Safety Information .........................................................................22

14.1.1 Instructions .......................................................................22

Section 15: Tank Heating ............................................................................23

15.1 Usage .....................................................................................23

15.2 Installation Procedure - Tank Heater Band.................................................. 23

15.3 Powerblanket warming equipment ......................................................... 23

15.4 Glas-Col Power Control Description and Operation ......................................... 23

Section 16: Arctic Pak Hose Replacement Set .......................................................24

16.1 General Information........................................................................ 24

16.2 Preparing and Installing the Arctic Pak ......................................................24

16.3 Spare Parts and Maintenance ..............................................................25

Section 17: Warranty................................................................................ 26

Section 18:

Page 4

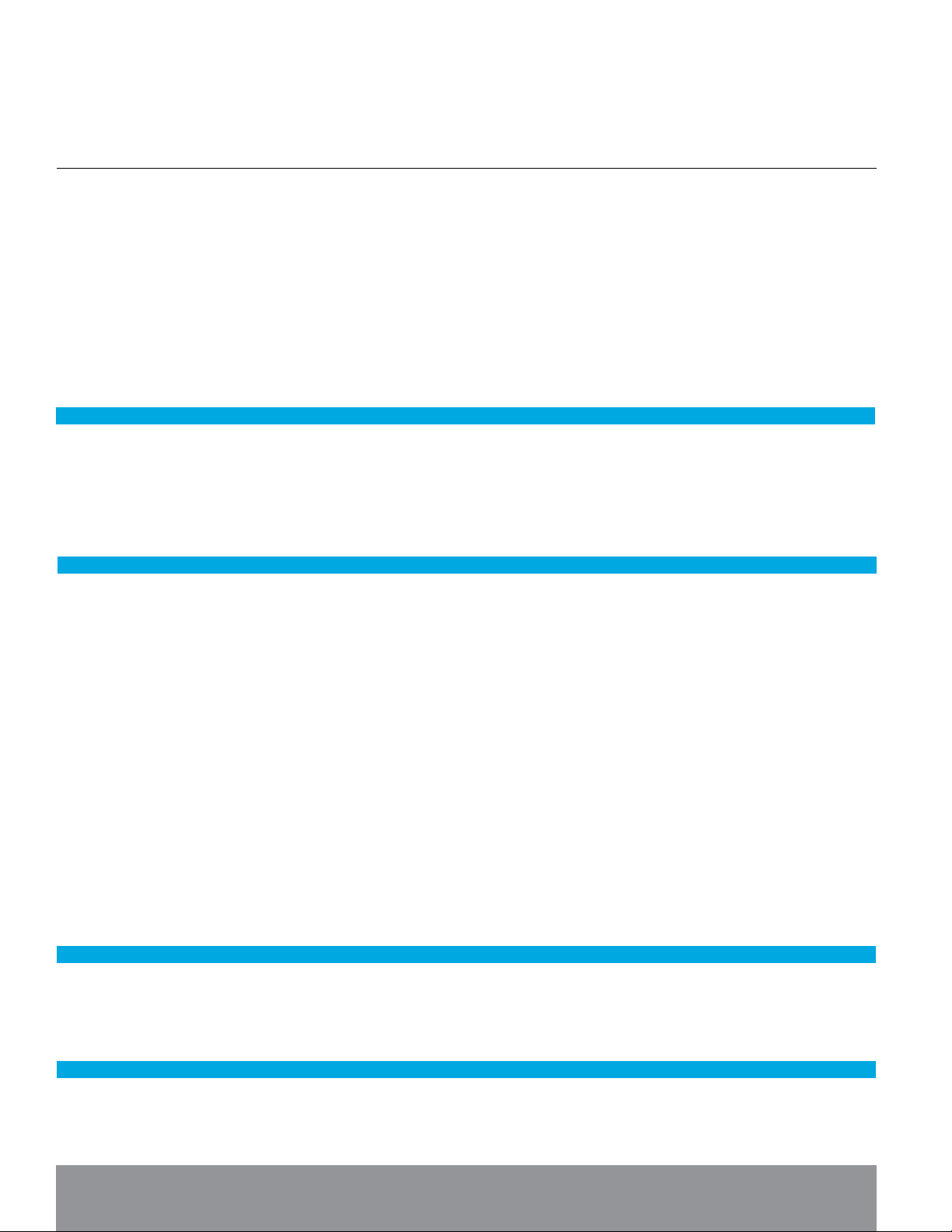

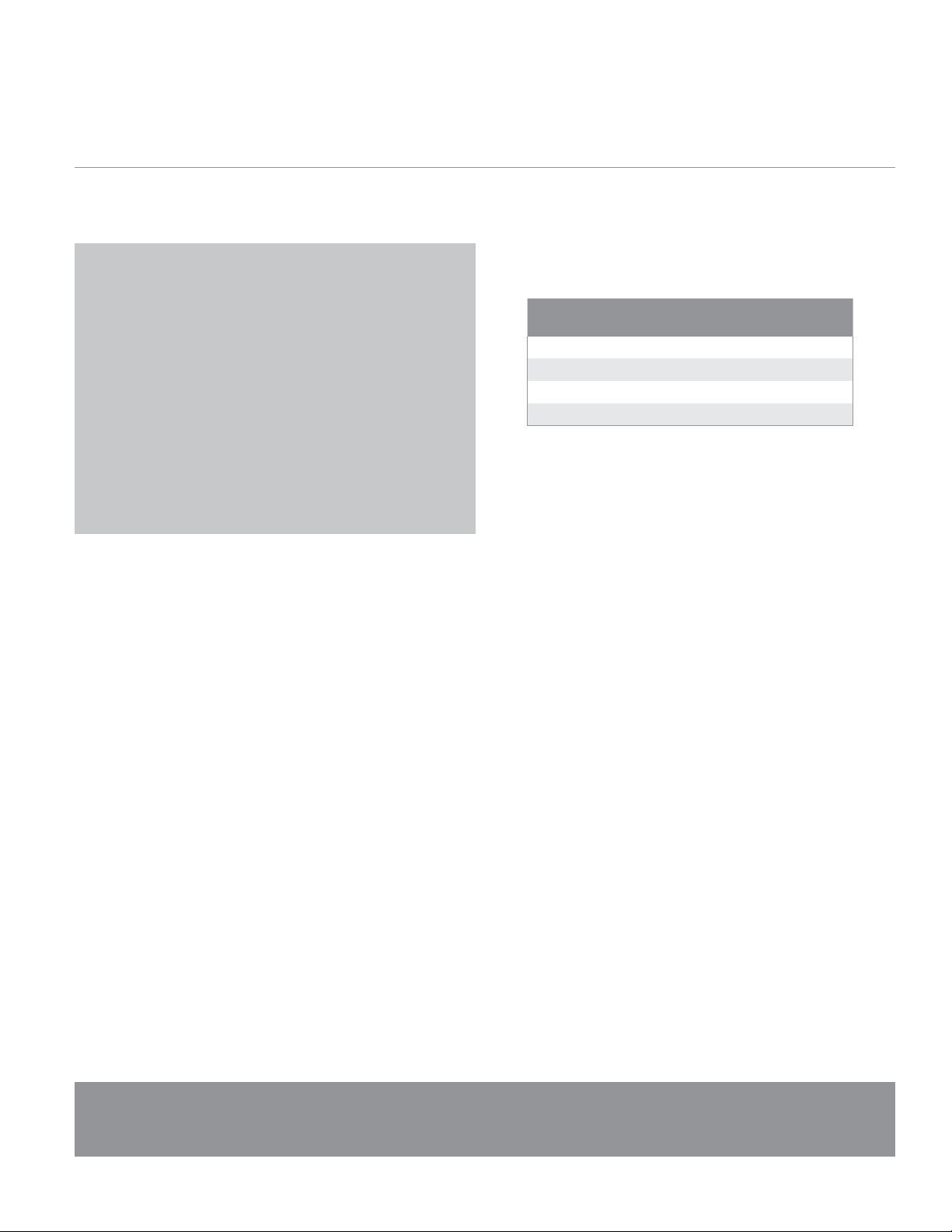

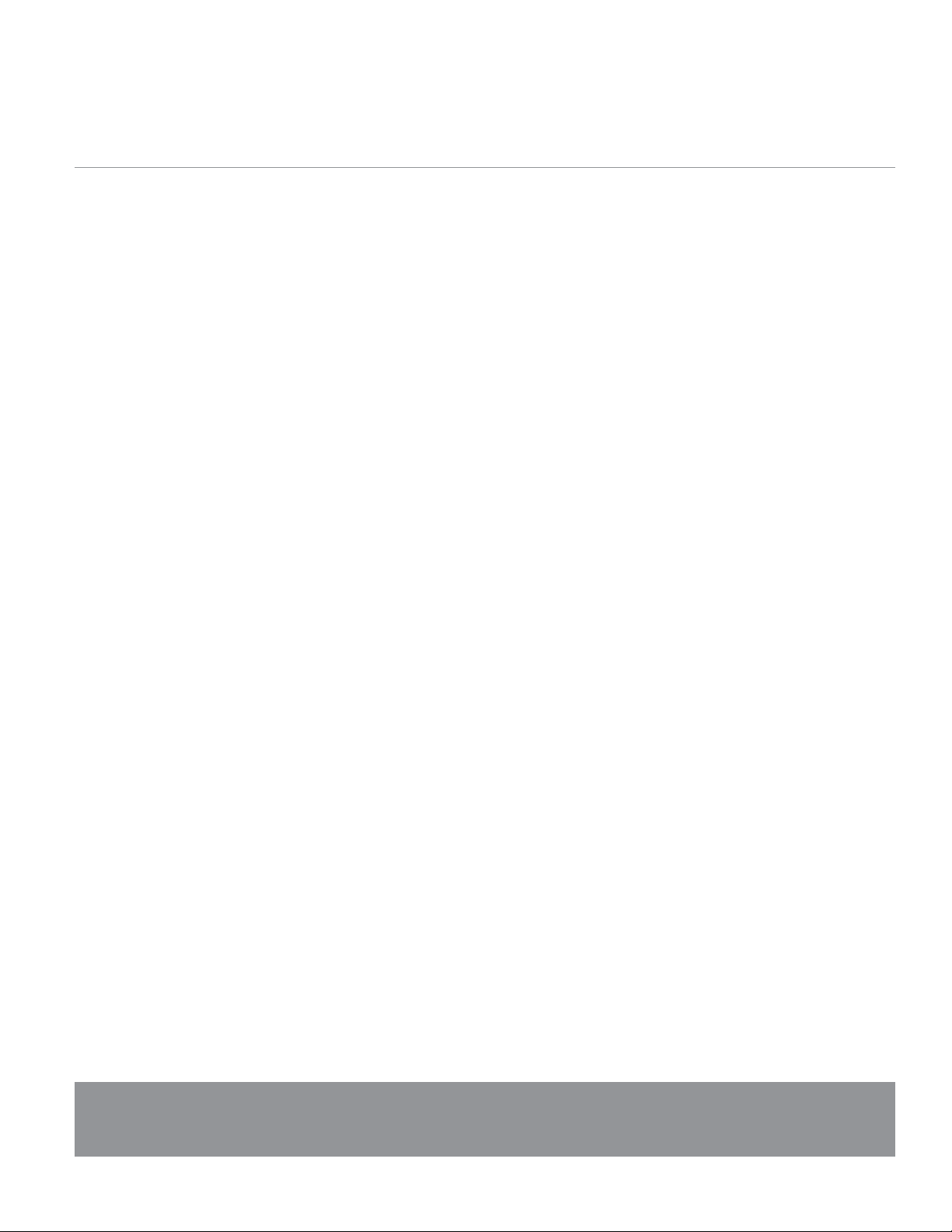

Dow Building Solutions

FROTHPAK™ Refill

System Installation

PRECAUTIONS:

DO NOT breathe vapor or spray. Proper

Personal Protective Equipment and

ventilation are required. See product

(Material) Safety Data Sheet ((M)SDS)

and Section 2 of this manual for further

information. Follow all precautions

for product.

INSTAFLO™

Gun

Anti-crossover

Nozzle

8 In. Hoses

In-line On-off

Ball Valves

30 Ft. Double nut

Chemical Hoses

On-off Swivel

Ball Valves

DO NOT expose container to

temperatures above 120

DO NOT incinerate, cut, puncture, or

weld on or near container.

DO NOT expose container to sparks

or flames.

A1

o

F (49oC).

Page 5

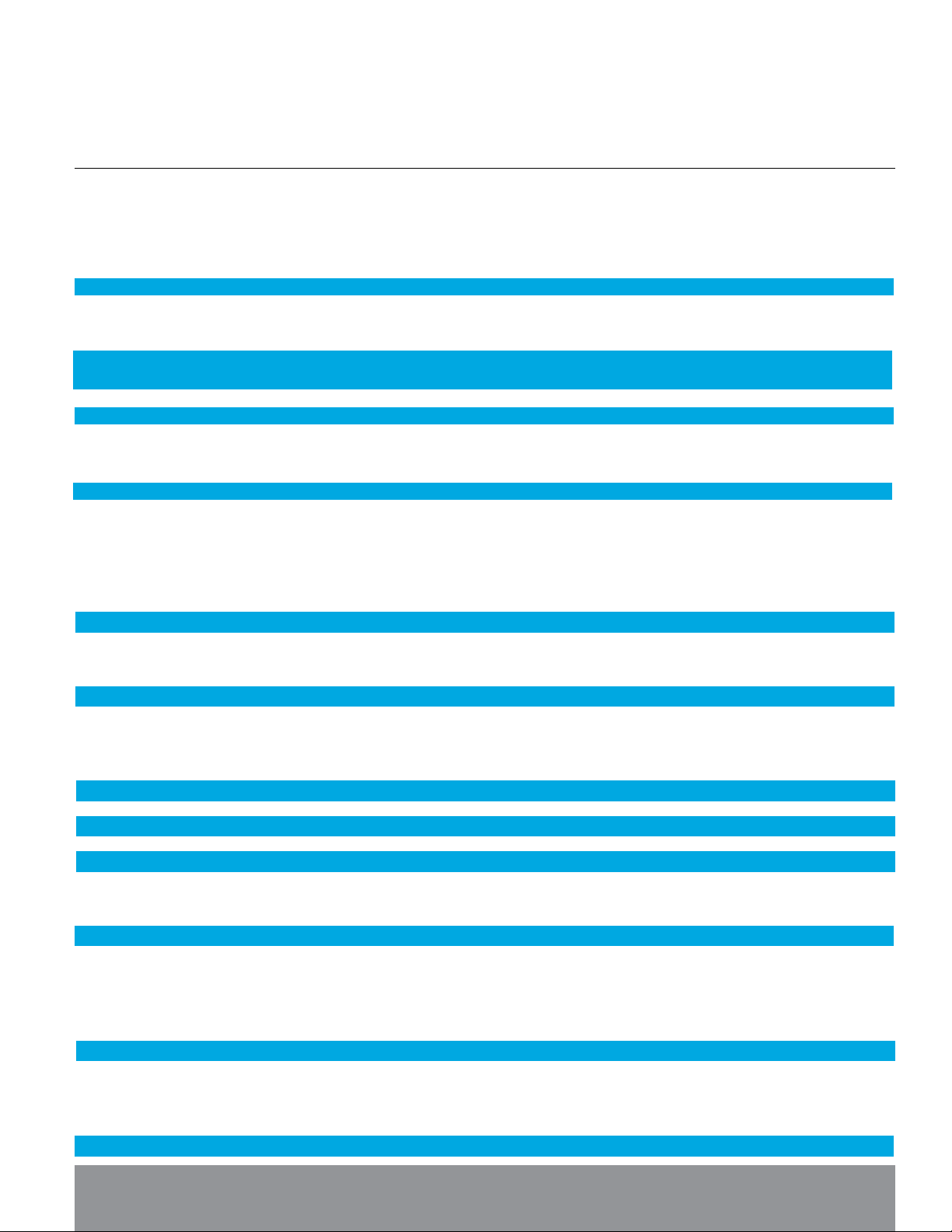

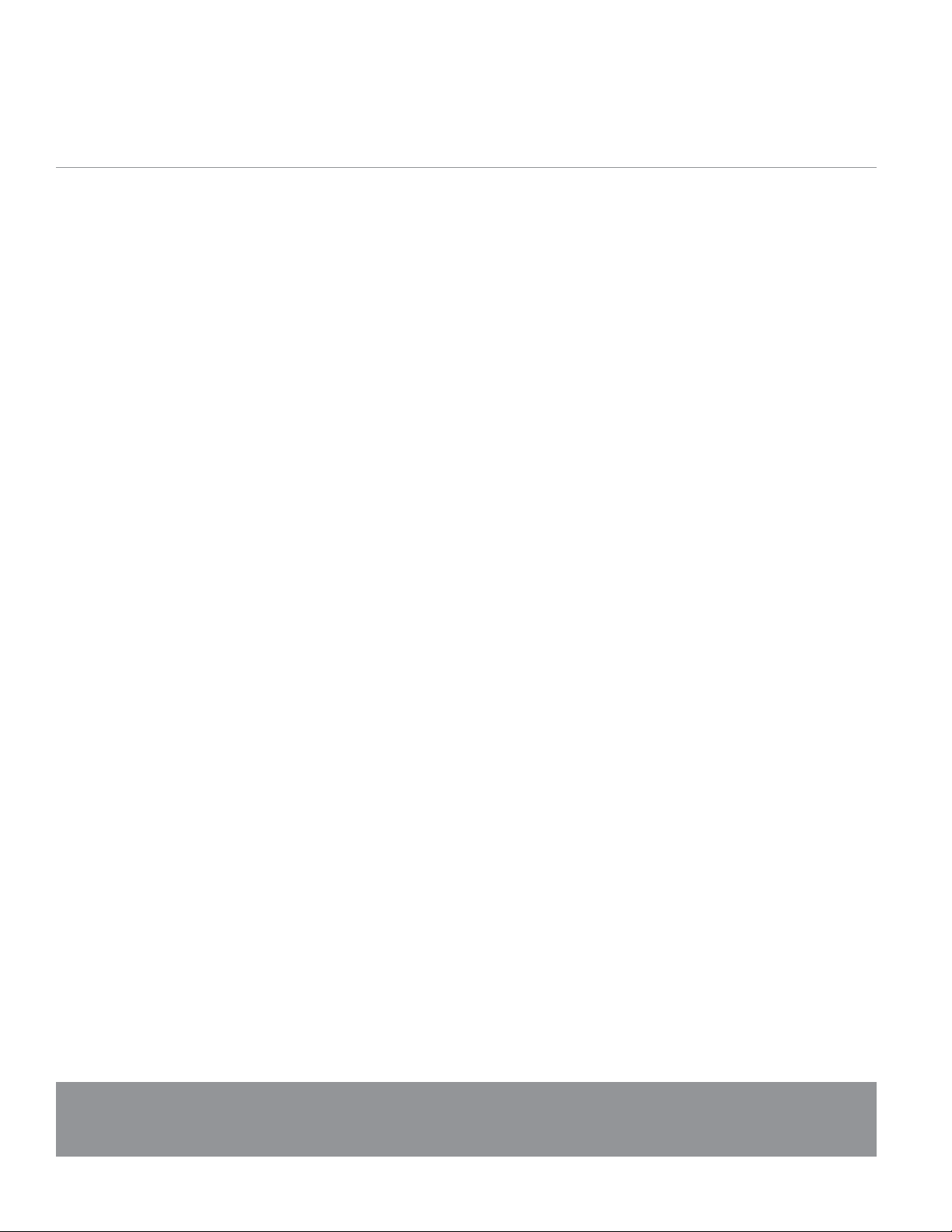

Nitrogen

Hoses

Dow Building Solutions

Chemical

Filter

Chemical

Filter

Tank Valves

Nitrogen

Intake Tank

Valves

Protective Plug: Remove and save

for return shipment of empty tanks.

“A” Tank

Protective Plug: Remove and save

for return shipment of empty tanks.

“B” Tank

A1

Page 6

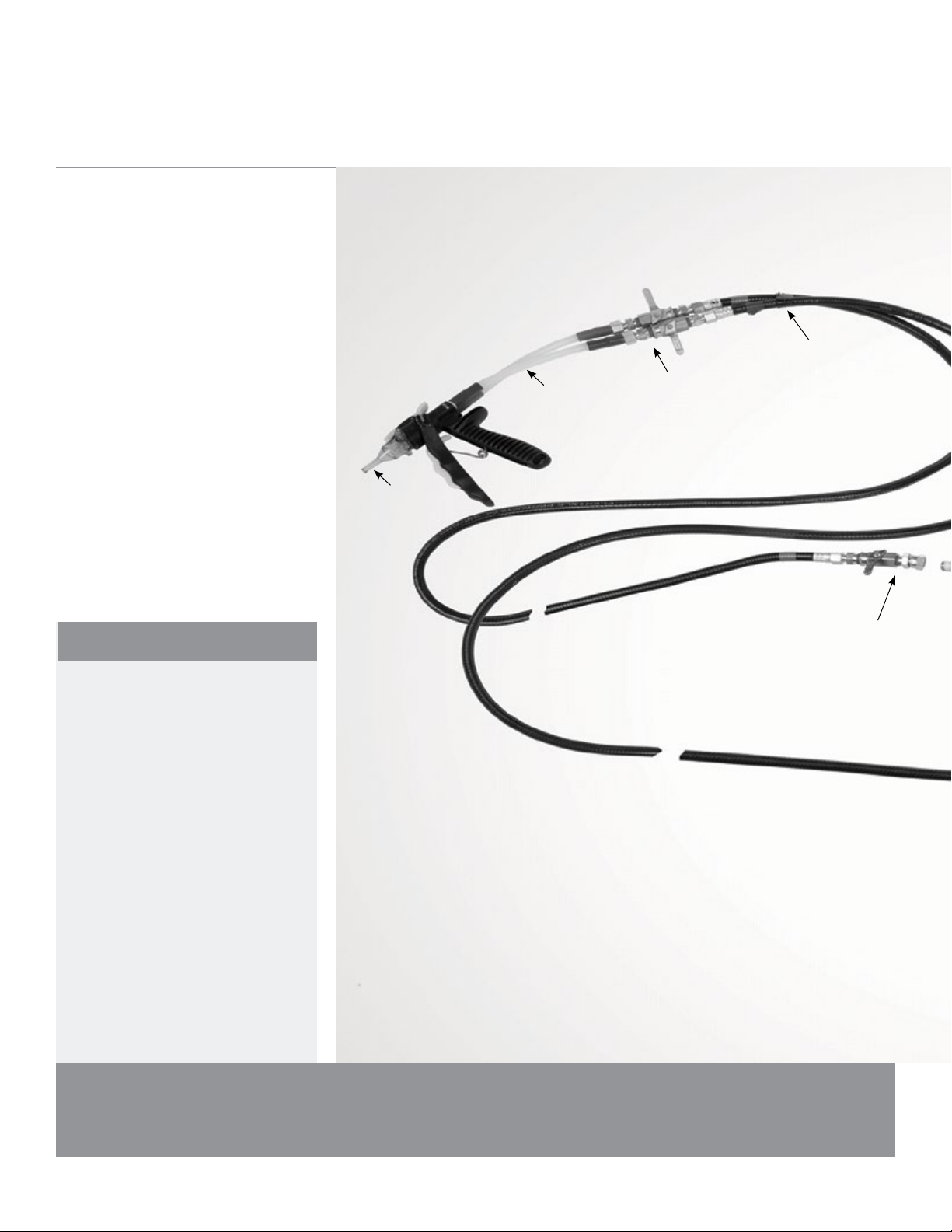

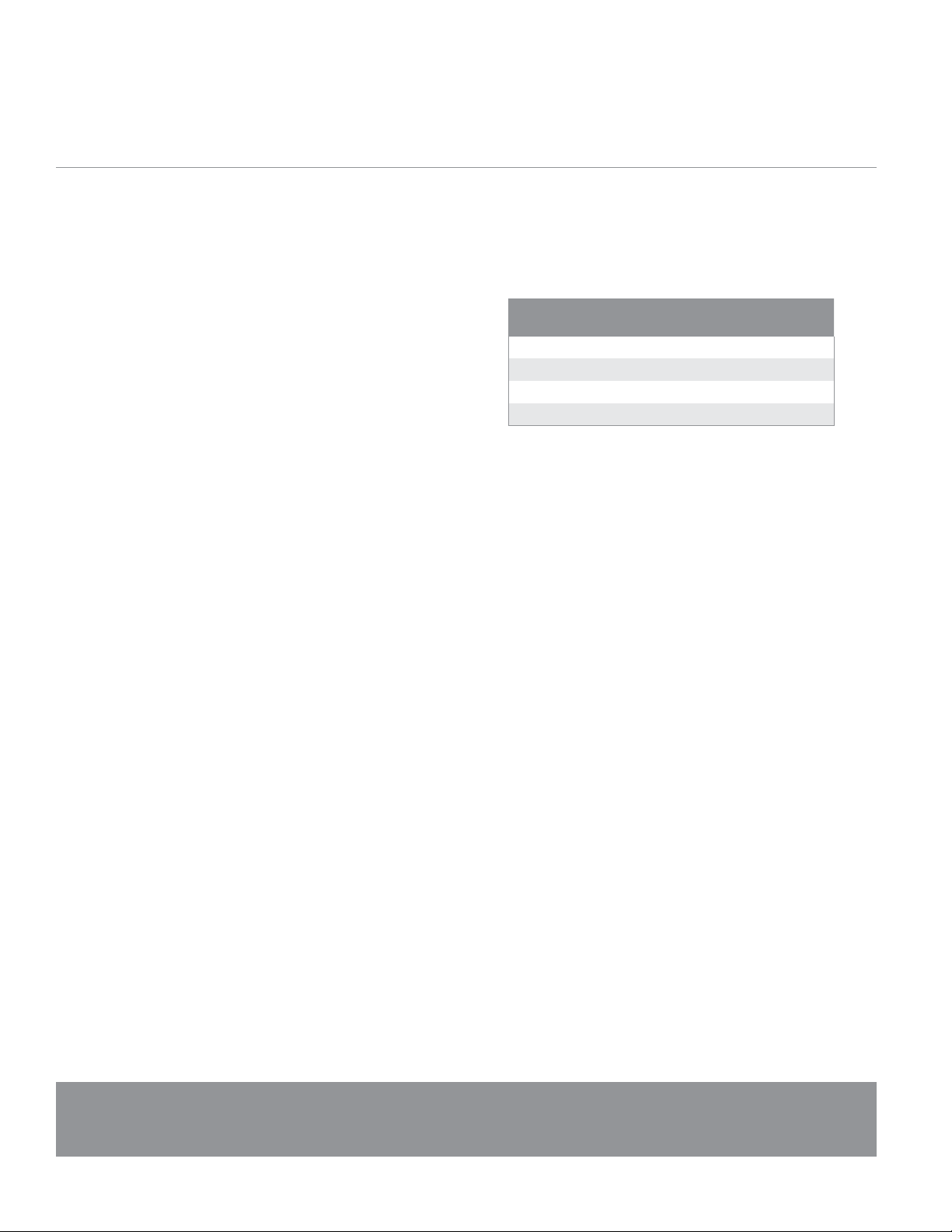

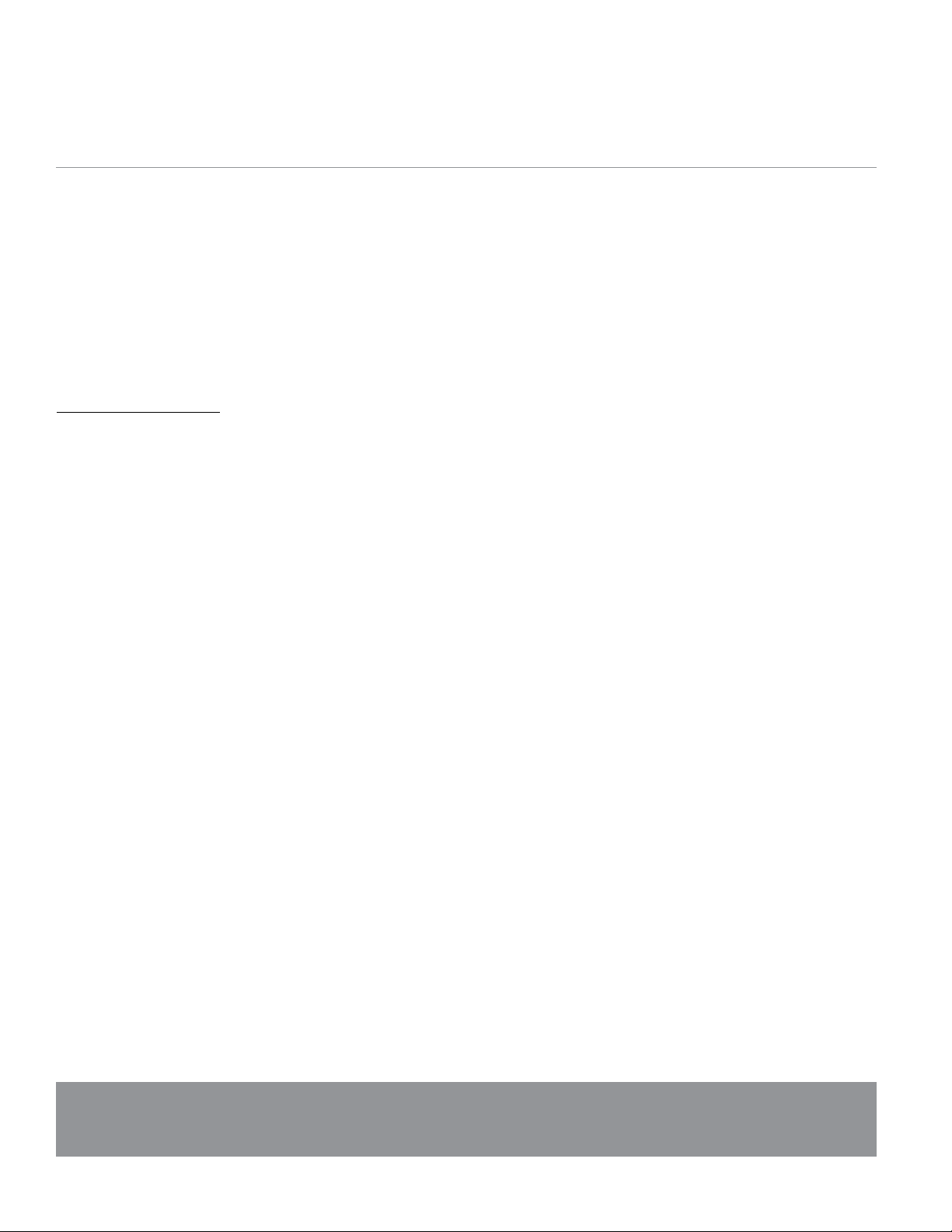

Dow Building Solutions

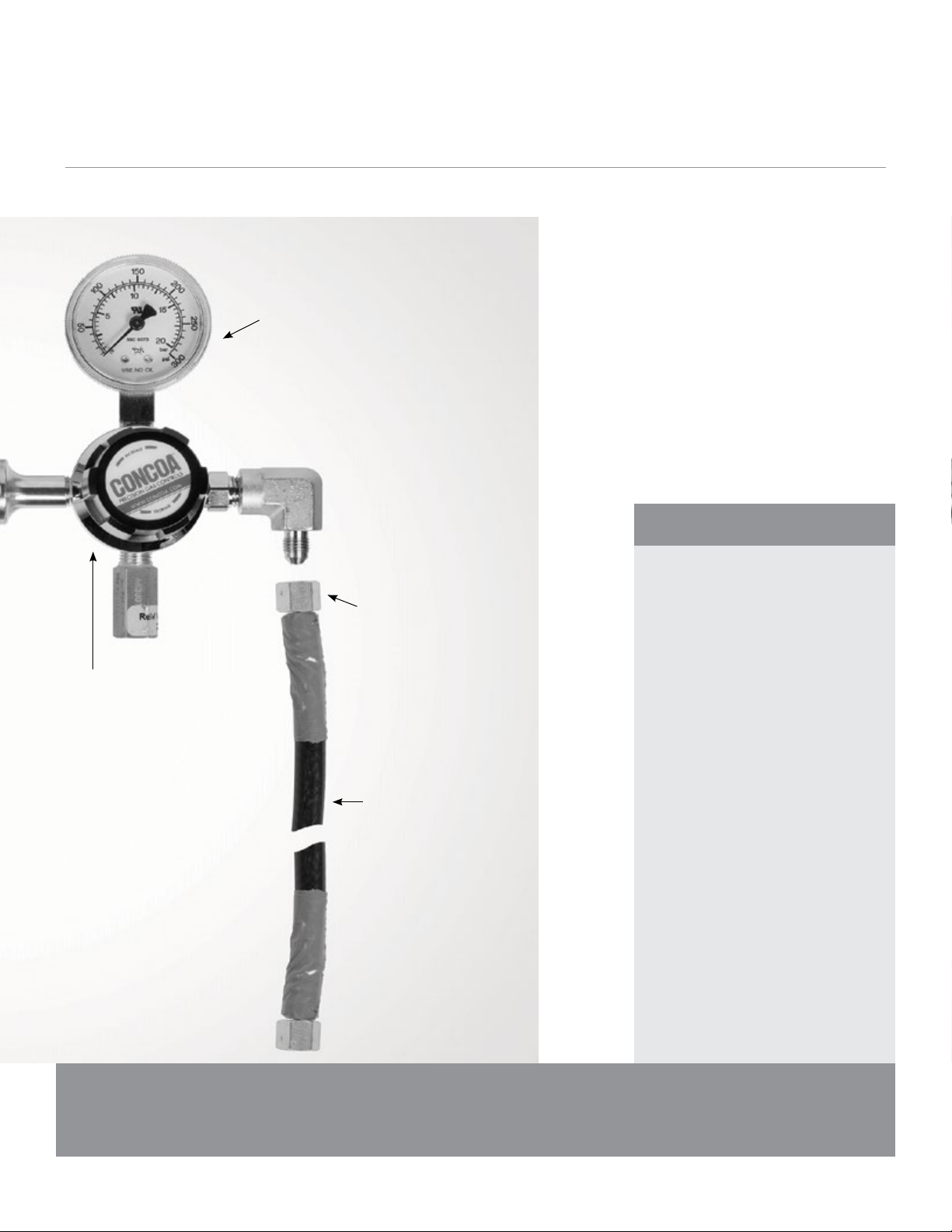

Nitrogen Regulator Assembly

(7.5 ft. nitrogen lines sold separately.

Two lines required for system operation)

Pressure Gauge

“A” Tank

Plastic Protective Cap.

(Remove before

attaching hoses)

Pressure Gauge

Nitrogen Cylinder

“A” Tank Nitrogen Hose

(mark hose ends

with yellow & red

electrical tape)

“A” Pressure Regulator

A2

Page 7

Pressure Gauge

“B” Tank

Dow Building Solutions

“B” Pressure Regulator

Plastic Protective Cap.

(Remove before

attaching hoses)

“B” Tank Nitrogen

Hose (mark hose

ends with yellow

& blue electrical tape)

WARNINGS:

NEVER use oxygen regulators on cylin-

ders of which the gas pressure exceeds

3000 pounds per square inch.

NEVER use oil or petroleum base grease

on regulator, inlet connection, or cylinder

valve. An explosion or fire could result. The

lubricant used on this regulator adjusting

screw is Dow-Corning No. 44 silicone

grease which is a non-petroleum base

grease.

NEVER stand in front of, or behind a

regulator while opening the cylinder valve.

DO NOT use WD40

INSTAFLO

®

Trademark of the WD40 Company.

™

Gun parts.

®

or DC44 on any

A2

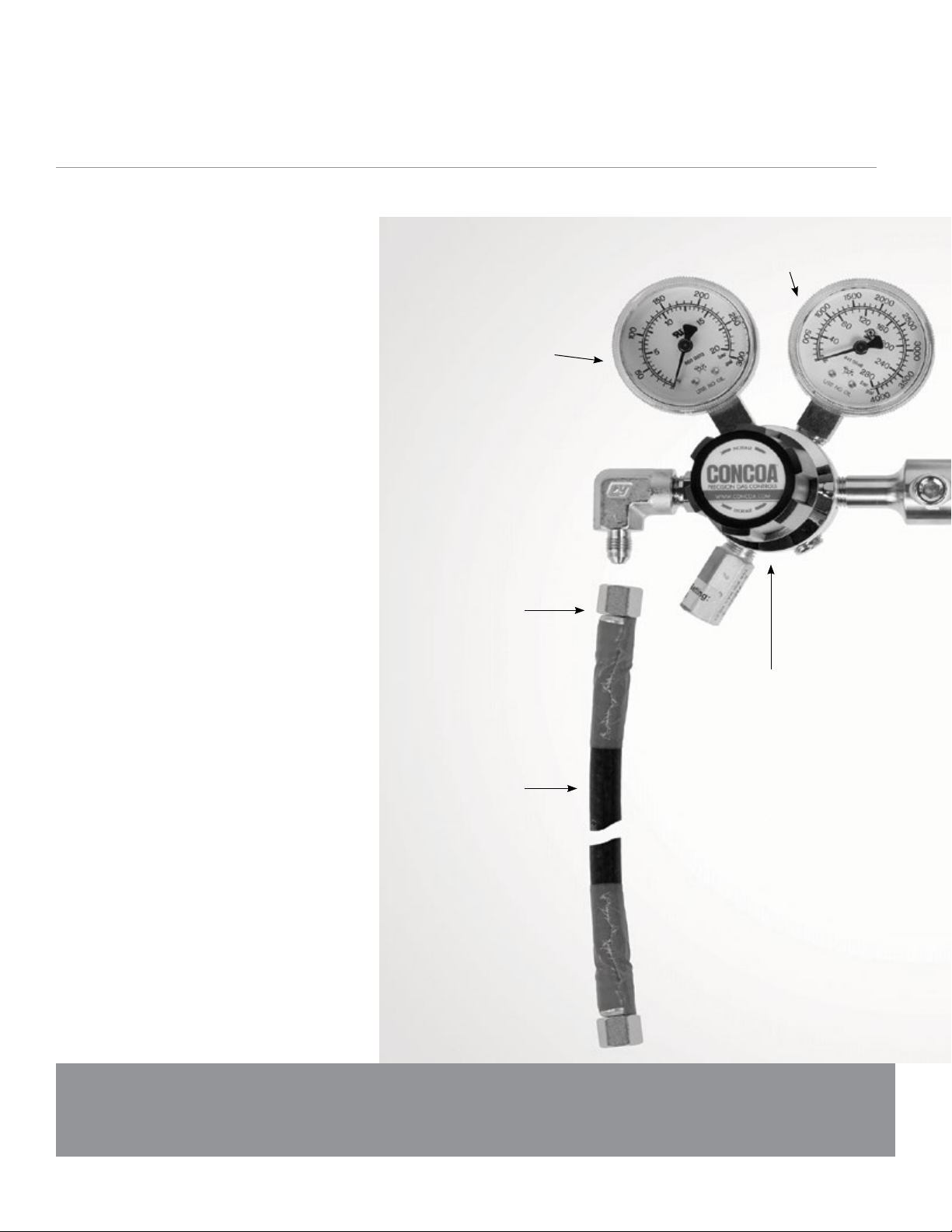

Page 8

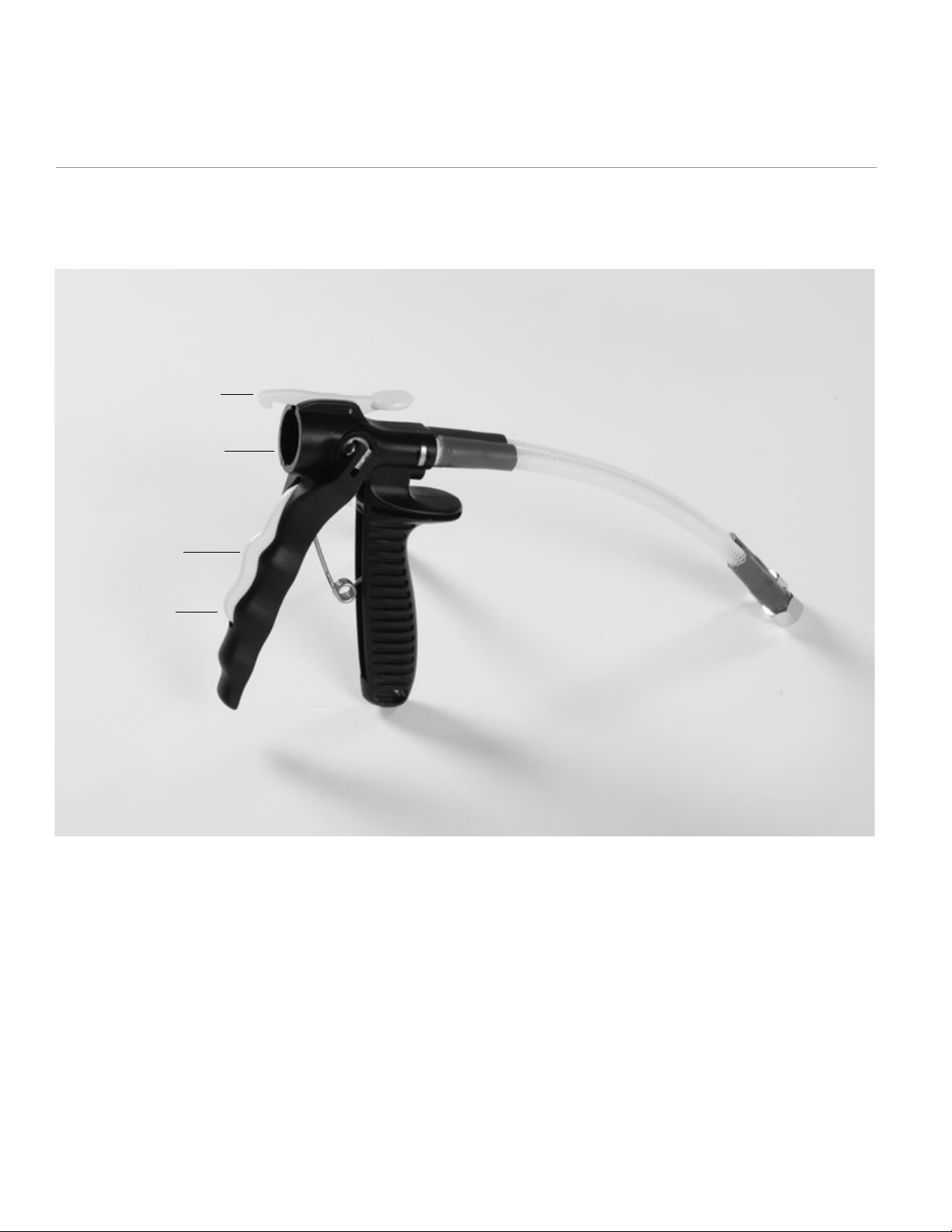

INSTAFLO™ Gun

Nozzle Ejector

Anti-crossover

Nozzle

Safety

Trigger

A3

Page 9

Dow Building Solutions

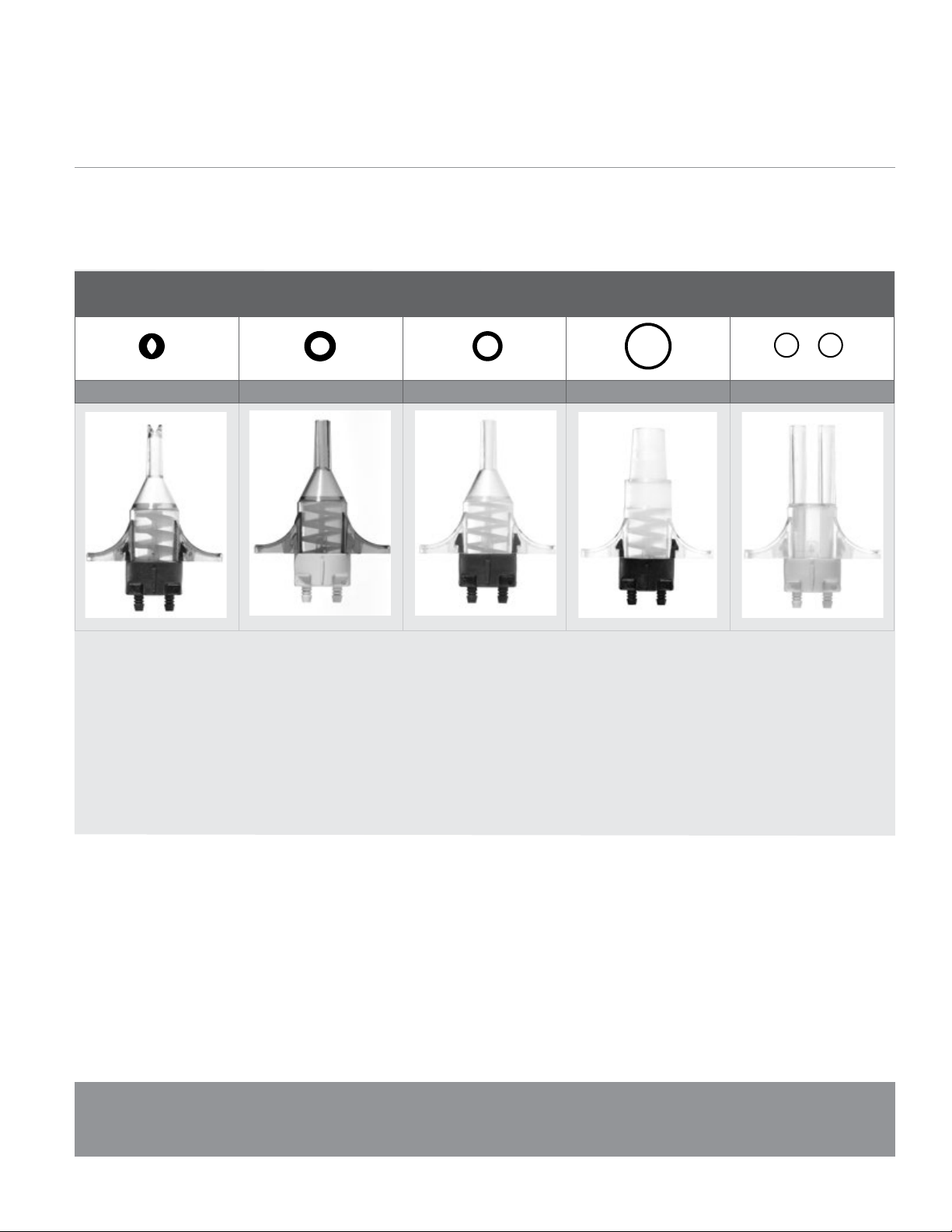

Anti-crossover Nozzles

(See page 3 for part numbers)

Fan Caulking Cone Pour Calibration

Nozzle Opening Nozzle Opening Nozzle Opening Nozzle Opening Nozzle Opening

A4

Page 10

Dow Building Solutions

Introduction

The FROTHPAK™ Refill System is a polyurethane foam

dispensing system for users who require large quantities of

foam. The system consists of “A” and “B” chemical tanks,

chemical filters, a high pressure regulator, nitrogen lines,

chemical dispensing hoses, and a Gun/Hose Assembly Kit.

The system requires dry nitrogen for chemical tank pressuriza-

tion and is not supplied.

The FROTHPAK™ Refill System is designed for

ease-of-use. The following instructions should be followed

strictly to ensure maximum equipment performance

and efficiency.

FROTHPAK™ Foam Insulation and Sealant

Application guidelines as provided by Dow Building Solutions should

be followed exactly in order to ensure compliance with building codes

and worker safety regulations. Read all information bulletins, (Material)

Safety Data Sheets ((M)SDS) and “Product Information” sheets. The SDS

is available at www.building.dow.com/na/en/literature/index.htm.

Application of this product is considered a “low pressure” process. It is

recommended that workers obtain spray foam training. Workers must be

respirator fit tested. Employers must have a documented respiratory and

personal protective equipment (PPE) plan. See Section 2 for further

PPE information.

Refill Systems

Manual

FROTHPAK™ Foam Insulation and Sealant contain isocyanate, polyol

and hydroflurocarbon blowing agents. See section 2 for further PPE

information. Do not breathe vapor or spray. Use only with supplied air

or an approved air purifying respirator equipped with an organic vapor

sorbent and a particle filter to maintain exposure levels below ACGIH,

OSHA, WEEL or other applicable limits. For situations where the atmospheric levels may exceed the level for which an air purifying respirator

is effective, use a positive-pressure air supplying respirator. The spray

foam applicator, and anyone within 25 feet of the applicator, must use

an approved air purifying respirator equipped with an organic vapor

sorbent and a particle filter at a minimum. If there is ever a doubt as to the

potential limits for worker exposure, Dow always recommends using the

highest level of worker protection. Additionally, use barrier tape to mark

the working perimeter and install warning signs.

It is important to ensure that the spray area is well ventilated during

application and one hour after spraying. Ventilation in Air Changes

per Hour (ACH):

• During application a minimum of 10 ACH is required. Cross

ventilation is recommended with negative pressure in the

spray area and exhaust to a secured empty area. A commercial

ventilation unit is recommended for increased ventilation rates.

• Continue to ventilate area for at least 1 hour after the job is

completed at no less than 10 ACH.

• Re-entry into an application site less than 1 hour post spray with

proper ventilation requires the use of an approved air purifying

respirator equipped with an organic vapor sorbent and a

particle filter.

• Ensure ventilation hose output is in a safe and secure location that

will not be accessible to individuals without proper PPE in a 25 foot

radius and is not near an air intake for a structure.

Safe Use and Training videos are available on line at:

http://building.dow.com/na/en/tools/training/

2

Page 11

System Information

1.1 Ordering Information

System Density / Type “A” Tank Part# / Color “B” Tank Part# / Color

1,2

17 Gallon System:

27 Gallon System:

60 Gallon System:

120 Gallon System:

350 Gallon System:

1 Formerly marked with a green colored stripe

2 Includes a Bill of Lading for tank return and a chemical filter

1.75 Foam Sealant

1.75 Foam Insulation (Class A)

1.75 Foam Sealant

1.75 Foam Insulation (Class A)

1.75 Foam Sealant

1.75 Foam Insulation (Class A)

1.75 Foam Sealant

1.75 Foam Insulation (Class A)

1.75 Foam Sealant

1.75 Foam Insulation (Class A)

341167 / white w/red stripe

340334 / white w/red stripe

1,2

11042106 / white w/green stripe

11042108 / white w/blue stripe

1,2

341165 / white w/red stripe

340337 / white w/red stripe

341168 / white w/red stripe

340336 / white w/red stripe

341166 / white w/red stripe

340338 / white w/red stripe

1,2

1,2

1,2

1,2

1,2

345347 / white w/blue stripe

11096260 / white w/purple stripe

1,2

11042107 / white w/green stripe

11096266 / white w/blue stripe

345344 / white w/blue stripe

11096263 / white w/purple stripe

345346 / white w/blue stripe

11096261/ white w/purple stripe

345348 / white w/blue stripe

11096264 / white w/purple stripe

Dow Building Solutions

1,2

1.2 Refill Accessories

Part# Description

158336 INSTAFLO™ Gun (1 - INSTAFLO™ Gun with 8” hoses)

158403

30 ft. Refill Gun/Hose Assembly Kit (1 - INSTAFLO™ Gun with 8” hoses, 2 - 30 ft. double nut hoses,

2 - on-off in-line ball valves, 2 - on-off swivel ball valves, 1 - wrench 9/16”)

238107 Nitrogen Regulator Assembly – (Requires two 7.5’ hoses – 158420)

158428 On/Off Valve, Chemical (Tank to hose)

158432 In Line On/Off Valve (Hose to dispenser)

158420 7.5 ft. Hose (Use single hose for chemical and/or nitrogen)

158421 15 ft. Hose (Buy in pairs for both A and B sides of chemical)

158422 30 ft. Hose (Buy in pairs for both A and B sides of chemical)

259202 Coupling - ACC Fitting 8 JIC (Connects hoses)

216151 Replacement Tank Filter

328507 ARCTIC PAK Wrap Heated Hose System (Includes wrap, controller assembly and extended length hose)

328508 ARCTIC PAK Wrap and Controller Assembly (Without hoses)

328509 ARCTIC PAK Wrap Controller Only

334489 ARCTIC PAK Replacement Hose Set (A and B side extended length hoses)

3

Page 12

Dow Building Solutions

1.3 Anti-crossover Nozzles (25 Pack)

Part# Output / Lbs. Min Nozzle Type Front / Back - Nozzle Color

259212 Low / 2lbs. Min Caulking Green / Yellow

259219

259211

259216

259218

259215

259217

259214

259220

259208

259210

259207

259206

Medium / 4lbs. Min

Medium / 4lbs. Min

Medium / 4lbs. Min

High / 67lbs. Min

High / 67lbs. Min

Highest / 810lbs. Min

Highest / 810lbs. Min

Highest / 810lbs. Min

Dual Stream

Dual Stream

Dual Stream

Dual Stream

1.4 Shipping Weights

System

Empty Tank with Fittings 60 lbs. Each

17 Gallon System:

Chemical 150 lbs. Net Each

Total Tank Weight 210 lbs. Each

Total System Weight 420 lbs

Empty Tank with Fittings 150 lbs. Each

27 Gallon System:

Chemical 239 lbs. Net Each

Total Tank Weight 389 lbs. Each

Total System Weight 780 lbs.

Empty Tank with Fittings 250 lbs. Each

60 Gallon System:

Chemical 500 lbs. Net Each

Total Tank Weight 750 lbs. Each

Total System Weight 1500 lbs.

Empty Tank with Fittings 400 lbs. Each

120 Gallon System:

Chemical 1125 lbs. Net Each

Total Tank Weight 1525 lbs. Each

Total System Weight 3050 lbs.

Empty Tank with Fittings 1000 lbs. Each

350 Gallon System:

Chemical 3200 lbs. Net Each

Total Tank Weight 4200 lbs. Each

Total System Weight 8400 lbs

Cone

Caulking

Fan

Cone

Fan

Cone

Fan

Pour

Calibration

Calibration

Calibration

Calibration

Clear / White (Included in FROTHPAK kits)

Green / White

Blue / White (Included in FROTHPAK kits)

Clear / Gray

Blue / Gray

Clear / Black

Blue / Black

Clear / Black

Clear / Yellow

Clear / White

Clear / Gray

Clear / Black

1.5 Tank Dimensions

Tank Size Dimensions

17 Gallon: 15” Diameter x 34” Height

27 Gallon: 14.5” Diameter x 44” Height

60 Gallon: 24” Diameter x 57” Height

120 Gallon: 30” Diameter x 59” Height

350 Gallon 76” Length x 41” Diameter x 54” Height

4

Page 13

1.6 Freight Classification for Tank Return

CAUTION:

The contents of both tanks are pressurized with Fluorinated

Hydrocarbons (HFC’s). The “A” tank contains polymeric

isocyanates and the “B” tank contains polyols with amines.

Mark each bill of lading as follows:

Full Tanks

CHEMICAL UNDER PRESSURE, N.O.S.

(1,1,1,2TETRAFLUOROETHANE),

Class 2.2, UN3500

Plastic Materials Other Than Expanded

NMFC#: 156240

ERG#: 126, Freight Class: 60

24-hour Emergency Contact Number:

Chemtrec 8004249300

Dow Building Solutions

Empty Tanks (17 gal., 27 gal., 60 gal., 120 gal.)

CHEMICAL UNDER PRESSURE, N.O.S.

(1,1,1,2TETRAFLUOROETHANE), Class 2.2, UN3500

Cylinders: NMFC#: 41160 SUB 3

ERG#: 126, Freight Class: 55

24-hour Emergency Contact Number:

Chemtrec 8004249300

Empty Tanks (350 gal. only)

CHEMICAL UNDER PRESSURE, N.O.S.

(1,1,1,2TETRAFLUOROETHANE), Class 2.2, UN3500

Tanks: NMFC # 181420 SUB 3

ERG#: 126, Freight Class: 85

24-hour Emergency Contact Number:

Chemtrec 8004249300

NOTE: Empty tanks should be marked “EMPTY”. A non-flammable gas label (green

diamond, Class 2) must be on each tank. Return bills of lading are provided on each

tank. An ‘X’ must be marked in the HM (hazardous materials) column.

All other appropriate information must be filled in as outlined above.

5

Page 14

Dow Building Solutions

Section 2

Safety Precautions

WARNING:

The FROTHPAK™ cylinders contain isocyanate, hydrofluorocarbon

blowing agent and polyols under pressure. Read and follow these

instructions and the Safety Data Sheets (SDSs) (formerly MSDSs or

Material Safety Data Sheets) carefully before use. The safety precautions

and personal protective equipment indicated below are designed to protect the user and allow for the safe use and handling of the spray system.

Follow all applicable federal, state, local and employer regulations.

IMPORTANT: Proper Personal Protective Equipment (PPE) consists

of respirator, chemical resistant gloves, protective suit with hood/coveralls, and chemical goggles which must be worn by all participants prior

to the nitrogen and chemical valves being opened and during operation.

2.1 Respiratory Protection

Workers must be respirator fit tested. Employers must have a

documented respiratory and PPE plan.

DO NOT breathe vapors or spray. Use only in a well ventilated area

with visible air movement away from the point of application. Depending

on the area of spray, the amount of foam being sprayed, the amount

of ventilation and the type of spray nozzle used, respiratory protection

equipment may differ in order to offer optimum protection to the

applicator from exceeding established exposure limits of isocyanate

and other components. Supplied air or an approved air purifying respirator equipped with an organic vapor sorbent cartridge and a P100

particulate filter may be required to maintain exposure levels below

ACGIH, OSHA, WEEL or other applicable limits. For situations where

the atmospheric levels may exceed the level for which an air-purifying

respirator is effective, use a positive-pressure, air supplying respirator

(air line or self-contained breathing apparatus). The spray foam applicator, and anyone within 25 feet of the applicator, must use approved

respiratory protection. If there is ever a doubt as to the potential limits

for worker exposure, Dow always recommends using the highest level

of protection. Use barrier tape and warning signs to mark the working

perimeter for respiratory hazards until 1 hour post spray.

• During application a minimum of 10 Air Changes per Hour (ACH) is

required. Cross ventilation is recommended with negative pressure

in the spray area and exhaust to a secured empty area. A commercial

ventilation unit is recommended.

• Continue to ventilate area for at least 1 hour after the job is completed

at no less than 10 ACH.

• Re-entry into an application site occurring less than 1 hour

post spray with proper ventilation requires the use of an approved

air purifying respirator equipped with an organic vapor sorbent

and a particle filter.

• Ensure ventilation hose output is in a safe and secure location that will

not be accessible to individuals without proper PPE in a 25 foot radius

and is not near an air intake for a structure..

2.2 Isocyanate-induced Occupational Asthma

Inhalation of vapors or mist at concentrations in excess of permissible

limits may result in an allergic respiration response and the development of sensitization. Skin contact with diisocyanates may play a role

in respiratory sensitization. Anyone who has been sensitized in the past

should not operate nor be in close proximity to the operation of these

systems as isocyante concentrations below exposure guidelines may

cause allergic respiratory reactions in individuals who are already sensitized. Asthma-like symptoms may include coughing, difficulty breathing,

and a feeling of tightness in the chest. Occasionally, breathing difficulties may be life-threatening. Follow all ventilation and PPE guidelines.

2.3 Safety Clothing

Personal Protection Equipment required when using

FROTHPAK™ includes chemical goggles and chemical resistant

gloves preferably made from nitrile, neoprene, butyl or PVC. Long

sleeves and pants or chemical resistant coveralls/protective suit with

hood should be worn. Shoe covers may also be worn.

2.4 Skin Contact

Avoid ALL contact with skin. May cause irritation or sensitization.

If skin contact occurs, remove contaminated clothing; carefully remove

uncured material without spreading; wash skin with soap and water. If

irritation occurs or persists, seek medical attention.

2.5 Eye Contact

Avoid ALL contact with eyes. Causes irritation. If contact with eyes

occurs, flush with clean, low pressure water for 15 minutes while

holding eyelids open. Seek medical attention.

6

Page 15

Dow Building Solutions

2.6 Ingestion

If swallowed, give large amounts of liquids. DO NOT induce vomiting.

Seek medical attention.

2.7 Removal of Cured Foam on Skin

FROTHPAK™ foam will adhere to most surfaces and skin. Avoid ALL

skin contact. Wear gloves and protective clothing. Cured foam is

difficult to remove. Cured foam must be mechanically removed or

allowed to wear off in time.

2.8 Overfilling Restricted Spaces

Avoid overfilling restricted spaces. The reaction of these chemicals

causes expansion and may exert enough force to cause an uncontrolled

stream of foam, spraying the work area and possibly the operator.

2.9 Chemical Information

For more specific information about the chemical components

“A” and “B”, refer to the appropriate SDS. KEEP OUT OF REACH

OF CHILDREN.

2.10 Chemical Spills

Consult SDS section 6 for Accidental Release Measures.

2.10.1 “A” Chemical

If “A” liquid spills from the tank, hose, or INSTAFLO™ Gun,

provide proper ventilation, wear all PPE and isolate the spill area.

Keep unnecessary and unprotected personnel from entering the

area. Dike the area and soak up the spill with an oil absorbent

material (vermiculite, sawdust, etc.). Neutralize the spillage area

with a solution of 90% water, 2% dishwashing detergent, and 8%

ammonia. The amount of this solution should be in excess of

the volume of the spill. Allow the mixture to react for at least

10 minutes. Collect in an open top waste container and treat

with additional ammonia solution. Remove the container to a

safe and secure location that will not be accessible to individuals

without proper PPE, loosely cover, and allow it to stand at least

24 hours. Dispose of the waste container in accordance with

federal, state, and local regulations.

2.10.2 “B” Chemical

If the “B” chemical spills from the tank, hose, or INSTAFLO Gun,

wear all PPE, dike and isolate the spill area. Keep unnecessary

and unprotected personnel from entering the area. Soak up the

residue from the surface with soap and water. Discard in accordance with federal, state, and local regulations.

2.11 Cautions

2.11.1 Storage Temperature

Recommended storage temperature:

60°– 80°F (16°–27°C).

Storage below 60°F (16°C) is not recommended.

Do not store at temperatures above 120°F (49°C).

2.11.2 Building Codes

In many areas, building codes may restrict the use of cellular

plastics or polyurethane foam in exposed, interior finishing

material applications. Under certain application code, the use of

these materials may be prohibited. The foam produced by this

product is organic and may constitute a fire hazard if improperly

applied. Consult local building codes.

2.11.3 Surface Temperature Restrictions

Polyurethane foam should not be used in direct contact with

chimneys, heat vents, steam pipes, or other surface areas that

exceed 240°F (116°C). The foam should not be left exposed or

inadequately protected for both interior and exterior finishing

materials. It is strongly recommended in all applications that the

foam be protected by approved facings and coatings.

2.11.4 Open Flame / Spark Source

Do not smoke or operate the system in close proximity

to an open flame or spark source. Ensure pilot lights are off.

Welding on or near cured polyurethane foam requires special

precautions. Consult The Dow Chemical Company for instructions.

2.11.5 Excessive Foam Dispensing

Do not apply excessive thicknesses at one time as this may result

in spontaneous combustion. For thickness greater than two

inches of cured foam, dispense foam in multiple layers, allowing

the heat from foaming to dissipate between sprayings.

2.12 Training

It is recommended that product users receive spray foam training.

Safe use and training videos are available at:

http://building.dow.com/na/en/tools/training/. For hands on

training information contact your Dow sales representative.

Further information is available at

http://www.spraypolyurethane.org/

7

Page 16

Dow Building Solutions

Section 3

System Installation

NOTE: Dry nitrogen is used for pressurizing the Refill System and is not supplied.

It may be obtained for a nominal rental charge from any local welding supplier.

Order standard size (industrial grade) cylinder with CGA 580 nitrogen fitting.

Refer to FROTHPAK™ Refill System Installation drawing, page A1.

3.1 Initial Tank Set-up

1) Be sure that the tanks are at the optimum temperature of

70 –80 degrees F., minimum 6065 degrees. If they are

below this range, utilize heating blankets or a box heater to

bring them up to the proper range. This is very important!

Consult your Dow Rep or Dow Technical Service if you

need assistance.

2) Color code all hoses with electrical tape (the nitrogen and

chemical transfer hoses, as well as the gun) red for the A Side

(ISO) and blue for the B Side (Polyol) to prevent chemical cross

contamination. Place colored tape at each end of the hoses for

proper identification.

3) Attach the nitrogen regulator to nitrogen tank.

a) Order a five (5) foot high nitrogen tank. At this height the

regulator is much easier to view.

b) Make sure nitrogen regulator handles are all turned out

(counterclockwise) until they cannot be turned any more.

This is the closed position.

c) Hand tighten the regulator to the tank and level the regulator

for easy viewing purposes.

d) Once level, fully tighten regulator with an adjustable wrench.

You will need about 30 lb-ft of force. Do not over tighten.

4) Attach the nitrogen hoses to the nitrogen regulator.

a) Remove the two protective caps from the nitrogen tank

regulator where the hoses will be connected.

b) The A side (red) should be on the operator’s left side as you

are facing the nitrogen tank/regulator. Attach red/yellow-

coded nitrogen hose to the regulator with about 30 lb-ft of

force. Do not over tighten.

c) Note that all the hose connections are flare fittings. These

do not require any sealant or Teflon tape. They just need to

be tight.

d) The B side (blue) should be on the operator’s right side as

you are facing the nitrogen tank/regulator. Attach blue/

yellow-coded nitrogen hose to the regulator with about

30 lb-ft of force. Do not over tighten.

5) Attach the nitrogen hoses to the chemical tank.

a) Remove cap covers from chemical tank connection on the

A side (red) and attach nitrogen hose to the flare fitting on

the valve that is in a vertical position (pointing straight up).

Tighten to about 30 lb-ft of force. Do not over tighten.

(Save the cap covers for when the tanks are returned

to Dow.)

b) Remove cap from chemical tank connection on the B side

(blue) and attach nitrogen hose to the flare fitting on the

valve that is a vertical position (pointing straight up). Tighten

to about 30 lb-ft of force. Do not over tighten. (Save the

cap covers for when the tanks are returned to Dow.)

6) Attach the filters to the chemical valve connections.

a) Remove the chemical valve plug on the A side (red). Save

the plug for return shipment to Dow, just leave inside

the ring on the top of the tank. On the A side only, it is

necessary to clean the petroleum jelly from the inside of the

valve with a cotton swab. (If you don’t have cotton swabs,

take the small cloth bag that the filter came in and wrap it

over the end of a screwdriver. Use this to clean the petro leum jelly out of the valve.) Next, connect the filter with the

arrow (arrow is engraved on the valve) flowing out or away

from tank and tighten to about 30 lb-ft. Note that the filter

is pipe thread and DOES need sealant or Teflon tape. It

should be taped from the factory but just check to be sure.

b) Remove the chemical valve plug on the B side (blue) from

the chemical tank. Save the plug for return shipment to

Dow, again just leave it in the ring on the top of tank.

Connect filter with arrow (arrow is embossed on the valve)

flowing out or away from tank and then tighten to about

30 lb-ft. Again, this is pipe thread and DOES require seal

ant or tape. Do not over tighten.

7) Attach the ball valves to the chemical filters.

a) At the end of the filter, attach a ball valve. Tighten both

ball valves on the A and B side to about 30 lb-ft but do not

over tighten. Again, this is pipe thread.

8) Attach the chemical hoses to the ball valve on the chemical

tanks.

a) Attach the A side (red) hose to the A side ball valve and make

sure to keep the ball valve in the upward position and in the

closed position. Tighten to about 30 lb-ft. Do not over

tighten.

8

Page 17

Dow Building Solutions

b) Attach the B side (blue) hose to the B side ball valve and

make sure to keep the ball valve in the upward position and

in the closed position. Tighten to about 30 lb-ft. Do not

over tighten.

9) Unroll chemical hoses and remove any kinks in the hose.

a) Attach the shutoff valves to the end of the hoses on the

A and B side. Make sure the arrow on the shutoff valves is

directed towards the gun. Tighten to about 30 lb-ft but do

not over tighten.

b) Attach the gun to the two shutoff valves at the end of the

hose. Keep the ball valve in the upward position and in the

closed position. Complete this for both the A and B sides.

c) Use black electrical tape to tape the A and B side hoses

together. Start this taping process at the gun end and work

your way back towards the tanks. Tape the hoses together

every 18 inches.

d) Tighten the ball valves to about 30 lb-ft but do not

over tighten.

e) At this point, check to make sure all hose, valve and filter

connections have been properly tightened to assure no

nitrogen or chemical leaks.

Note: If a 30’ hose extension is required, you will need to attach a coupling to the end

of the hose coming from the chemical tank and connect the hose sections together.

A standard ¼” male flare coupling from a hardware store works just fine. Tighten to

about 30 lb-ft but do not over tighten. Complete for both the A and B sides (total hose

length is not recommended to exceed 120 feet). Once the hose extensions have been

added, attach the shutoff valves to the end of the hose extensions where the gun is

connected.

Note: If you are using the Arctic Pak heated hose assembly, it is recommended that

you remove the yellow insulation during the summer months) from the hoses and store

it to prevent wear and tear on the insulation. This will extend the life of the insulation.

During the colder temperature months, place the yellow insulation back over the hoses.

If you remove the yellow insulation during the warm weather months, continue taping

the A and B side hoses together every 18 inches.

3.3 Nitrogen Regulator Information

1. Remove the orifice protector on the nitrogen cylinder.

Insert the nitrogen regulator assembly stem into the

orifice and hand tighten. Snug firmly using an adjust able wrench. Be careful not to strip the brass fitting.

2. Verify that the valve stems are freewheeling. This

indicates that the regulator stems are backed out.

3. Remove the thread protectors on the bottom of the

nitrogen regulator.

4. Connect a yellow & red-taped nitrogen line to the left

fitting on the nitrogen regulator assembly. Snug firmly

with an adjustable wrench.

5. Locate the yellow-coded nitrogen intake valve on the “A”

tank. Verify that the valve is closed. The handle should

be perpendicular to the valve. Loosen and remove the

nitrogen intake cap on the “A” tank.

6. Connect the other end of the yellow & red-taped-coded

nitrogen line to the nitrogen intake valve of the “A” tank.

Snug firmly with an adjustable wrench.

7. Connect the other yellow & blue-taped nitrogen line to

the right fitting on the nitrogen regulator assembly.

Snug firmly with an adjustable wrench.

8. Locate the yellow-coded nitrogen intake valve on the

“B” tank. Verify that the valve is closed. The handle should

be perpendicular to the valve. Loosen and remove the

nitrogen intake cap on the “B” tank.

3.2 Tank Positioning

1. Position the “A” tank to the left and the “B” tank to the

right. This is the standard in the polyurethane industry.

2. Place a nitrogen cylinder between the “A” and “B” tanks.

3. Secure the nitrogen cylinder to prevent it from falling

if bumped.

9. Connect the other end of the yellow & blue-taped coded

nitrogen line to the nitrogen intake valve of the “B” tank.

Snug firmly with an adjustable wrench.

9

Page 18

Dow Building Solutions

3.4 Chemical Hose Installation

1. Verify that the chemical tank valves are closed. The handle

should be perpendicular to the valve. Remove the chemical

valve plugs from the “A” and “B” tanks and place the plugs on

top of the tank.

2. Carefully remove all of the vaseline in the “A” chemical

tank valve.

3. Remove the chemical filters from the canvas bags on

top of each tank. Verify that the filter and the cartridge

are free by shaking the filter until you hear a clicking

sound.

NOTE: Air blown into end in the direction of arrow will pass

freely through the filter.

4. Connect a chemical filter to each tank valve with the

filter arrow pointing away from each tank. The arrow

represents the chemical flow. Tighten the filters with

an adjustable wrench. The filter prevents chemical

from flowing back into the tank.

5. Take the on-off valves with the swivel ends and

connect them to each tank filter. Tighten the connec tions with an adjustable wrench.

6. Uncoil the chemical lines. Tape them together every

few feet with tape.

7. Connect the “A” labeled chemical hose to the “A”

tank on-off valve. Tighten the connection with an

adjustable wrench.

8. Connect the other chemical hose to the “B” tank on-off

valve. Tighten the connection with an adjustable wrench.

9. Connect an in-line on-off valve to the other end of

each chemical hose. Verify that the arrow on each

valve points away from the hose being connected –

arrow indicates chemical flow. Tighten each connec tion with two adjustable wrenches.

10. Connect the Gun/Hose Assembly to the in-line valve

of each hose, “A” labeled hose to “A” labeled hose, the

unlabeled hose to the unlabeled hose. Tighten each

connection using two adjustable wrenches.

Section 4

Start-up Procedure

DO NOT breathe vapor or spray. Proper PPE and ventilation are

required. See product SDS and Section 2 of this manual for further

information. Follow all precautions for product.

4.1 System Pressurization

1. Verify that the valve stems on the regulator are backed

out and are freewheeling.

2. Open the nitrogen bottle valve by turning the knob

on top of the cylinder counterclockwise. If a hissing

sound occurs, further tighten the nitrogen regulator

valve stem with an adjustable wrench.

3. Verify the nitrogen cylinder pressure using the center

gauge of the nitrogen regulator assembly. The system

WILL NOT operate efficiently if the pressure falls below

500 psi. If below 500 psi, replace the nitrogen cylinder.

4. Turn the left regulator stem clockwise to the proper

pressure setting of the “A” tank (120160psi – Do not

go over 225psi) (see section 12). If a hissing sound

occurs, further tighten the yellow-coded nitrogen line

connection to the nitrogen regulator assembly and/or

the nitrogen intake valve connection on the “A” tank

using an adjustable wrench. If the left gauge fails to

indicate a pressure setting, contact your Dow Chemical

Sales Representative.

10

Page 19

Dow Building Solutions

5. Turn the right regulator stem clockwise to the proper

pressure setting of the “B” tank (120160 psi – Do not

go over 225psi) (see section 12). If a hissing sound

occurs, further tighten the yellow-coded nitrogen line

connection to the nitrogen regulator assembly and/or

the nitrogen intake valve connection on the “B” tank

using an adjustable wrench. If the right gauge fails to

indicate a pressure setting, contact your Dow Chemical

Sales Representative.

6. Slowly open the nitrogen intake valve of each tank.

The valve handles should be parallel with the

nitrogen lines.

7. Slowly turn on the chemical valve of each tank. The

valve handles should be parallel to the chemical lines.

Verify that the filter connection of each tank is tight

and that no chemical leaks are present.

8. Slowly turn on the on-off valves. The handles should

be parallel to the chemical lines. Verify that the

connections of each valve are tight and that no

chemical leaks are present.

9. Slowly turn on the in-line on-off valves. The handles

should be parallel to the chemical lines. Verify that

the connections of each valve are tight and that no

chemical leaks are present.

4. Know the bag weight so the weights may be subtracted

out of the total weight of the chemical, i.e.

180 divided by 162 equals 1.11 ratio

(A) (B)

Weight 188gms 170gms

Bag Weight -08gms -08gms

180gms 162gms

5. Place calibration nozzle in the dispenser. Before dispensing

material into bags, pull trigger to ensure material is

flowing properly through both tubes.

6. Hold two bags together, place one tube in each bag and pull

trigger for six to eight seconds.

7. Weigh bags separately. Always divide the weight of (B)

into the weight of (A). If the ratio is too high increase

the pressure of the “B” tank, and if the ratio is too

low increase the pressure of the “A” tank.

8. Most acceptable ratios are 1.10 to 1.20 for FROTHPAK

™

Class A Foam Insulation and 1.05 to 1.15 for FROTHPAK

Foam Sealant.

Pressure gauges in line with the regulator. Verify both sides. To verify corresponding

pressures of tanks, install pressure gauges in line with each tank. Perform this task on

the nitrogen inlet valve. Should pressure need to be reduced in a tank, slowly bleed off

pressure. NEVER bleed below 120 psi.

™

10. Remove the used nozzle by pushing down the

nozzle ejector.

4.2 Calibration Instructions

Equipment needed: PPE, scale capable of weighing in grams, paper

bags (lunch bags), calibration nozzles, and pressure gauges.

1. Ensure chemical temperature in tanks and lines are

70°F (21°C) or higher.

2. Set pressures at recommended settings (120160psi –

Do not go over 225psi).

3. Ensure chemical is flowing properly through dispenser

with a calibration nozzle in place.

9) Collect items needed for calibration (scale that weighs in

grams or ounces, lunch bags, marker, calculator, pen, writing

pad, petroleum jelly)

DO NOT breathe vapor or spray. Proper PPE and ventilation

are required. See product SDS and Section 2 of this manual for

further information. Follow all precautions for product.

10) Pressurize the system.

a) Fully open the valve on the nitrogen bottle.

b) Ensure the tank has at least 500 PSI pressure on

the main tank pressure gauge. If at or below this, order

a new tank. Do not operate under 300 PSI.

11

Page 20

Dow Building Solutions

c) Now set the A and B side regulators to their initial

pressure. Turn the handle clockwise to increase the

pressure. A good starting point is 160170 PSI on the

A Side and 140150 PSI on the B Side. Higher hose

lengths will require higher pressures. Follow the nitrogen

hoses to the tank and slowly open the nitrogen valves on

the tank to pressurize the tanks. You will hear the nitrogen

flowing as it pressurizes the cylinders. Check for nitrogen

leaks as you are pressurizing the tanks.

d) Slowly open the chemical valves on both the A and B

sides at the tanks to pressurize the hoses. For each side,

there are two valves to open; one valve at the tank and

one ball valve at the filter/hose connection. On the A-side,

open the tank valve first and then open the ball valve.

Repeat for the B side. Check for chemical leaks as you

are pressurizing the hoses.

Note: Should you experience any nitrogen or chemical leaks,

immediate close all chemical and nitrogen valves and correct the

situation before proceeding.

11. Check the gun to make sure it is working properly.

a) Open the two chemical valves at the gun. You will see

chemical flowing into the gun when they are opened.

b) Fully depress the gun trigger and spray the gun into a

lined waste receptacle to purge the gun and chemical

lines of nitrogen. You should see two good chemical

streams coming from the gun.

c) Spray GREAT STUFF PRO

™

gun cleaner into the face

of the gun to clean away any chemical residue. It is

important to keep the gun face clean to avoid plugging

of the chemical flow and to ensure that the nozzle makes

a leak proof connection.

d) Place a small amount of petroleum jelly on outside face

of gun where the nozzle fits in to ease the process of

attaching the nozzle. It is important that you do not

cover the chemical passage/orifices in the gun with

petroleum jelly.

12. Attach the appropriate calibration nozzle. The calibration

nozzle has 2 tubes protruding from the front of the nozzle.

For calibration purposes, the back cap color of calibration

nozzle should match the color of the spray nozzles that you

intend to use.

13. The nozzles are a tight fit. Typically you will hear two clicks.

Ensure that the yellow catch is fully latched over the

extension on the nozzle.

14. Label 2 bags; one bag A and one bag B. Place the A side

nozzle in the bag labeled A and the B side nozzle in the bag

labeled B. Fully depress the gun trigger and spray the

chemical into the 2 bags for 510 seconds or until the bags

are about 2/3 full.

15. Weigh the A side first and record the weight (in grams).

Next, weigh the B side and record the weight (in grams or –

be sure to use the same units on the A and B side).

16. Calculate the A to B ratio from the data you recorded. Enter

the A Side weight into the calculator and divide it by the B

Side weight. An A to B ratio of 1.10 to 1.20 is ideal.

17. Once the tank set has been calibrated, remove the calibration

nozzle, clean the gun face and insert the new spray nozzle

(of the same color). This calibration is good until the sets are

empty or until you need to replace the nitrogen tank as long

as there are no significant temperature changes to the tanks

and their contents. When in doubt, recalibrate.

Note: If the foam is off ratio (outside of the 1.10 to 1.20 range), adjustment of the

nitrogen regulator will be required.

™

• If the ratio is below 1.10 for FROTHPAK

FROTHPAK

• If the ratio is above 1.20 for FROTHPAK

FROTHPAK

• Do not operate the system above 220 PSI on either side, 200 PSI gives an even

larger safety factor to avoid opening the pressure relief valves on the tanks. If you

are near this pressure, then the pressure on the opposite side will need to be

reduced. So if the A Side is near 200 PSI and the ratio is still too high, bleed down

the B Side tank to increase the differential pressure between the tanks.

• To do this, shut the main nitrogen tank valve and shut the nitrogen inlet valve on

the product tank.

• Slowly loosen the nitrogen hose connection at the regulator. Do this slowly to let

the pressure bleed off.

• Hold the end of the hose in one hand and direct it towards the ground and away

from any people. With the other hand, slowly open the nitrogen inlet valve on

the tank to bleed down the pressure. Be patient and do this slowly. It may take a

few minutes. You do not need to bleed off all the pressure. Shut the tank valve.

™

Foam Sealant)

™

Foam Sealant).

Class A Foam Insulation (1.05 for

™

Class A Foam Insulation (1.15 for

12

Page 21

Dow Building Solutions

• Go back to the regulator for the hose you disconnected and turn the handle

counterclockwise all the way out.

• Reconnect the nitrogen line and tighten.

• Open the tank valve and read the pressure on the tank. It should be at least

40 – 50 PSI lower than when you started.

• Slowly turn the regulator handle clockwise until the pressure just starts to

increase. You are just bringing the regulator to the tank pressure. Now set the

pressure 20 – 30 PSI lower than when you last calibrated as a starting point.

When in doubt, go lower, you can easily increase it if needed.

Repeat as needed until the A to B ration is between 1.10 and 1.20.

Note: The pressure settings are just a starting point. There are many factors that

impact the actual ratio, including material temperature, hose age and possible partial

blockage, and gun condition. Likewise each set of gauges has a small range of

accuracy. The important thing to remember is that the ratio calculated during calibration is the FINAL WORD, the tank pressures are the means to get on ratio. If you need

to go outside the ranges listed above (assuming they are under 220 PSI MAX) that is

fine as long as you get the ratio in range.

4.3 System Purging and Testing

1. DO NOT breathe vapor or spray. Proper PPE and ventilation

are required. See product SDS and Section 2 of this manual

for further information. Follow all precautions for product.

2. Dispense chemicals in an appropriate container.

This is to verify proper chemical flow.

3. Clean any chemical from the INSTAFLO

using a rag.

4. Insert an unused nozzle with the key slot down.

Push in firmly until the nozzle ejector is seated over

the back rim of the nozzle.

™

Gun face

This chart is for the cone and fan type nozzles. Other

specialty nozzles may have different elapsed paused times.

Chemical Temp Elapsed Paused

Spraying Time

70°F (21°C) 35 Seconds

75°F (24°C) 30 Seconds

80°F (27°C) 25 Seconds

85°F (29°C) 20 Seconds

2. To replace the used nozzle, push down the nozzle

ejector. The used nozzle should eject.

3. Insert an unused nozzle with the key slot down.

Push in firmly until the nozzle ejector is seated over

the back rim of the nozzle. The refill system is ready

to operate.

Section 5

DO NOT breathe vapor or spray. Proper PPE and ventilation are

required. See product SDS and Section 2 of this manual for further

information. Follow all precautions for product.

5.1 Spraying

1. Once the calibration is complete, chose the nozzle with the

pattern and flow rate appropriate for the job. Attached

the nozzle.

5. Dispense foam to verify proper chemical mixing.

If improper mixing or poor foam quality, refer to the

Troubleshooting section, Section 10 of this manual.

4.4 Nozzle Replacement

1. The life of a nozzle depends on elapsed paused

spraying time and chemical temperature. Replace a

previously used nozzle if the elapsed paused spraying

time is exceeded using the chart on the right as a guide.

2. Practice on scrap material or plastic sheet to get the feel

of spraying and to ensure you are making good foam.

3. Hold the gun a consistent distance from the work and

perpendicular to the work. Move in a steady side to side

stroke. Avoid swinging the gun, it will result in variable thick nesses of foam. The speed of your movement and the dis-

tance from the work will determine the thickness of the foam.

4. Always fully engage the trigger of the gun. Partial engage ment can result in off ratio foam.

13

Page 22

Dow Building Solutions

5. Let the foam cure (a minute or two) Look for an even tan

color foam. Watch to see that it rises 3 or 4 times the original

thickness. Make sure the foam has cured and is firm.

6. If the foam looks unusual, verify the calibration settings and

that the tanks are 70 – 80 degrees. (Minimum 60 – 65

degrees). Then remove the nozzle and purge material into a

waste container for 15 – 30 seconds. Clean the face of the

gun, insert a new nozzle and perform a test spray again.

7. If problems persist call your Dow rep or Dow Technical service.

8. While spraying, always watch for signs of unusual looking

foam. Troubleshoot as outlined above.

9. Watch for any bubbles in the translucent hoses near the

gun and listen for any sputtering. This may be a sign of an

empty tank.

5.2 INSTAFLO™ Gun Operation

The INSTAFLO Gun provides greater flow control and minimizes

waste when used properly. The following operating instructions ensure

maximum efficiency and performance of the INSTAFLO Gun.

1. DO NOT breathe vapor or spray. Proper PPE and ventilation

are required. See product SDS and Section 2 of this manual

for further information. Follow all precautions for product.

2. To insert an unused nozzle, verify that the key slot on the

nozzle is in the down position. Push in firmly until the nozzle

ejector is seated over the back rim of the nozzle.

This chart is for the cone and fan type nozzles. Other specialty

nozzles may have different elapsed paused spraying times.

Chemical Temp Elapsed Paused

Spraying Time

70°F (21°C) 35 Seconds

75°F (24°C) 30 Seconds

80°F (27°C) 25 Seconds

85°F (29°C) 20 Seconds

5. When spraying is completed, remove the used nozzle

by pushing down on the nozzle ejector.

6. Apply petroleum jelly to the face of the INSTAFLO Gun.

7. Reinsert the used nozzle. This provides an airtight seal

during storage.

Refer to INSTAFLO™ Gun drawing, page A3

Section 6

Shut Down

1. When shutting down the refill system for the day, leave the

cured nozzle attached to the gun to keep moisture from

penetrating the hoses.

2. Shut off the A and B side valves on gun and the two sets of

valves on the chemical tanks for the A and B sides.

3. To meter the INSTAFLO

™

Gun, engage the trigger

one-third to one-half. This should be done sparingly

due to the ratio of the foam being affected.

4. The life of a nozzle depends on elapsed paused spraying time

and chemical temperature. Replace a previously used nozzle

if the elapsed paused spraying time is exceeded using the

chart on the right as a guide.

14

3. Leave all hoses attached.

4. Shut off the main nitrogen valve at the nitrogen tank. Do not

adjust the regulator levels that were established during cali bration. These settings can be used until the chemical tanks

are empty or the nitrogen tank is replaced as long as there

are no big temperature swings.

Page 23

Dow Building Solutions

Shut-down Procedure

1. Remove the used nozzle by pushing down on the

nozzle ejector.

2. Apply petroleum jelly to the face of the INSTAFLO™ Gun.

3. Reinsert the used nozzle. This provides an airtight

seal during storage.

4. Turn off the in-line on-off valves. The valve handles

should be perpendicular to the chemical lines.

5. Turn off the on-off valves located near the chemical filters.

The valve handles should be perpendicular to the

chemical lines.

6. Turn off the chemical tank valves of the “A” and “B” tanks. The

handles should be perpendicular to the valves.

7. Turn off the yellow-coded nitrogen intake valves of the “A” and

“B” tanks. The handles should be perpendicular to the valves.

8. Turn off the nitrogen cylinder by turning the valve on the top

of the nitrogen cylinder in a clockwise direction.

9. Back out both nitrogen regulator valve stems until they are

freewheeling.

10. Coil the chemical lines to prevent possible tripping

and damage.

6. DO NOT store near chimneys or heat vents.

7. If a partially used system remains inactive for a period of time,

the system should be pressurized and purged every two weeks.

This will prevent crystallization of the chemical in the hoses.

8. Unopened chemical tanks have a shelf life of approximately

one year.

Section 8

DO NOT breathe vapor or spray. Proper Personal Protective Equipment

and ventilation are required. See product SDS and Section 2 of this

manual for further information. Follow all precautions for product.

Re-Start-Up

1. Open the nitrogen valve fully to pressurize the system.

2. Open the two sets of valves on the chemical tanks for the A and

B sides and then the valves on the gun.

3. Remove the cured nozzle that you left attached to the gun.

4. Spray into a waste container. Ensure that you have good flow

from both the A and B side hoses.

5. Clean the face of the gun. Attach a new nozzle.

6. Spray a test sample to ensure good quality foam.

Section 7

Storage

1. Store in a dry area.

2. Store between 60°–80°F (16°–27°C).

3. Short term storage between 45°–60°F (7°–16°C) is permitted.

4. DO NOT store at temperatures above 120°F (49°C).

5. DO NOT not store near steam or hot water pipes.

7. Resume spraying.

Re-start Procedure

8.1 System Pressurization

1. Verify that the valve stems on the regulator are backed

out and are freewheeling.

2. Open the nitrogen bottle valve by turning the knob on top of

the cylinder counter-clockwise. If a hissing sound occurs,

further tighten the nitrogen regulator valve stem with an

adjustable wrench. Use only in well ventilated areas. Wear

suitable respiratory protection.

15

Page 24

Dow Building Solutions

3. Verify that the nitrogen cylinder pressure using the center

gauge of the nitrogen regulator assembly. The system WILL

NOT operate efficiently if the pressure falls below 500 psi.

If below 500 psi, replace the nitrogen cylinder.

4. Turn the left regulator stem clockwise to the proper

pressure setting of the “A” tank (120160psi – Do not go

over 225psi) (see section 12).

If a hissing sound occurs, further tighten the yellow/red-

coded nitrogen line connection to the nitrogen regulator

assembly and/or the nitrogen intake valve connection on the

“A” tank using an adjustable wrench. If the left gauge fails

to indicate a pressure setting, contact your Dow Sales

Representative.

5. Turn the right regulator stem clockwise to the proper

pressure setting of the “B” tank (120160psi – Do not

go over 225psi) (see section 12).

If a hissing sound occurs, further tighten the yellow/blue coded nitrogen line connection to the nitrogen regulator

assembly and/or the nitrogen intake valve connection on the

“B” tank using an adjustable wrench. If the right gauge fails

to indicate a pressure setting, contact your Dow Sales

Representative.

6. Slowly open the nitrogen intake valve of each tank. The valve

handles should be parallel with the nitrogen lines.

7. Slowly turn on the chemical valve of each tank. The valve

handles should be parallel to the chemical lines. Verify that

the filter connection of each tank is tight and that no chemical

leaks are present.

8. Slowly turn on the on-off valves. The handles should be

parallel to the chemical lines. Verify that the connections of

each valve are tight and that no chemical leaks are present.

9. Slowly turn on the in-line on-off valves. The handles should

be parallel to the chemical lines. Verify that the connections of

each valve are tight and that no chemical leaks are present.

8.2 System Purging and Testing

1. DO NOT breathe vapor or spray. Proper PPE and ventilation

are required. See product SDS and Section 2 of this manual

for further information. Follow all precautions for product.

2. Dispense chemicals in an appropriate container.

This is to verify proper chemical flow.

3. Clean any chemical from the INSTAFLO™ Gun face

using a rag or paper towel.

4. Insert an unused nozzle with the key slot down. Push

in firmly until the nozzle ejector is seated over the

back rim of the nozzle.

5. Dispense foam to verify proper chemical mixing.

If improper mixing or poor foam quality, refer to the

Troubleshooting section, Section 10 of this manual.

Section 9

Tank Change-over

1. DO NOT breathe vapor or spray. Proper PPE and ventilation

are required. See product SDS and Section 2 of this manual

for further information. Follow all precautions for product.

2. Putting on a fresh set of tanks is essentially the same process

as the initial start-up. One big difference is that the lines have

chemicals in them. If exposed to the atmosphere for more

than a few minutes, the A Side line will become plugged. So

keep the lines hooked up to the empty tanks until you are

ready to put on the fresh set.

3. Double check that the nitrogen tank is above 500 PSI.

4. Prep the new tanks as outlined above right to the point of

hooking up lines.

10. Remove the used nozzle by pushing down the nozzle ejector.

16

Page 25

5. When ready for this, be sure the tank valves are closed on

the empty tanks. Bleed off any pressure in the lines by pulling

the trigger of the gun while aimed into a waste container.

6. Disconnect the lines and transfer to the new set. Be sure to

have on proper protective equipment as some residual

material will be in the lines.

7. Back out the regulator valve handles (counterclockwise) and

then proceed with the calibration process as outlined above.

8. Replace the plugs and caps on the tank connections. Attach

the Bill of Lading to the empty tanks and call them in to be

picked up along with the paperwork that came with the tanks.

9. Remove the used nozzle by pushing down on the

nozzle ejector.

Dow Building Solutions

9.1 “A” Tank Change-over

1. Position the new “A” tank next to the empty “A” tank.

2. Verify that the nitrogen intake and chemical valves

of the new “A” tank are closed. The handles should be

perpendicular to the valves.

3. Remove the yellow-coded cap on the nitrogen intake

valve of the new “A” tank.

4. Relieve the nitrogen pressure by loosening and

removing the yellow/red coded nitrogen regulator line

from the nitrogen intake valve of the empty “A” tank

using an adjustable wrench.

5. Reconnect the “A” yellow/red coded nitrogen line to the

nitrogen intake valve of the new “A” tank. Tighten the

connection with an adjustable wrench.

10. Turn off the chemical tank valves. The handles should

be perpendicular to the valves.

11. Depressurize the chemical lines by engaging the trigger,

dispensing the chemical in an appropriate container.

12. Clean any chemical on the INSTAFLO™ Gun face

with a rag.

13. Turn off the on-off valves located near the tank filter.

The valve handles should be perpendicular to the

chemical lines.

14. Turn off the yellow-coded nitrogen intake valves of

the “A” and “B” tanks. The handles should be perpen dicular to the valves.

15 Turn off the nitrogen cylinder by turning the valve in

a counter-clockwise direction.

16. Back out both nitrogen regulator valve stems until

they are freewheeling.

6. Remove the chemical valve plug of the new “A” tank

and place the plug on top of the new “A” tank.

7. Carefully remove the vaseline in the “A” chemical

tank valve.

8. Remove the fluid filter from the canvas bag on top of

the new “A” tank. Verify that the filter and the cartridge are

free by shaking the filter until you hear a “clicking sound”.

NOTE: Air blown into end in the direction of arrow will pass freely through

the filter.

9. Connect the filter to the new “A” tank chemical valve with the

filter arrow pointing away from the tank. The arrow represents

the chemical flow. Tighten the filter with an adjustable wrench.

The filter prevents chemical from flowing back into the tank.

CAUTION: When disconnecting chemical lines, always cover the

connections with a rag to minimize chemical spray or spillage.

10. Disconnect the “A” on-off valve from the filter of the

empty “A” tank, covering the connection with a rag.

17

Page 26

Dow Building Solutions

11. Reconnect the “A” on-off valve to the filter of the new

“A” tank. Tighten with an adjustable wrench.

12. Remove the filter from the empty “A” tank and

dispose accordingly.

13. Reconnect the plug on the empty “A” tank to the

chemical valve. Tighten with an adjustable wrench.

14. Depressurize the empty “A” tank by slowly opening

the nitrogen intake valve.

15. When the tank has been depressurized, close the nitrogen

intake valve of the empty “A” tank and reconnect

the yellow-coded cap. Tighten with an adjustable wrench.

16. Remove the empty “A” tank and position the new “A”

tank in its place.

17. Write “EMPTY” on the empty “A” tank

9.2 “B” Tank Change-over

1. Position the new “B” tank next to the empty “B” tank.

2. Verify that the nitrogen intake and chemical valves of

the new “B” tank are closed. The handles should be

perpendicular to the valves.

3. Remove the yellow-coded cap on the nitrogen intake

valve of the new “B” tank.

4. Relieve the nitrogen pressure by loosening and removing

the yellow/blue coded nitrogen regulator line from the

nitrogen intake valve of the empty “B” tank using an

adjustable wrench.

5. Reconnect the “B” yellow/blue coded nitrogen line to the

nitrogen intake valve of the new “B” tank. Tighten the

connection with an adjustable wrench.

6. Remove the chemical valve plug of the new “B” tank and

place the plug on top of the new “B” tank.

7. Remove the fluid filter from the canvas bag on top of the

new “B” tank. Verify that the filter and the cartridge are

free by shaking the filter until you hear a “clicking sound.”

NOTE: Air blown into this end will pass freely through the filter.

8. Connect the filter to the new “B” tank chemical valve

with the filter arrow pointing away from the tank. The

arrow represents the chemical flow. Tighten the filter

with an adjustable wrench. The filter prevents

chemical from flowing back into the tank.

CAUTION: When disconnecting chemical lines, always cover the

connections with a rag to minimize chemical spray or spillage.

9. Disconnect the “B” on-off valve from the filter of the

empty “B” tank, covering the connection with a rag.

10. Reconnect the “B” on-off valve to the filter of the new

“B” tank. Tighten with an adjustable wrench.

11. Remove the filter from the empty “B” tank and

dispose appropriately.

12. Reconnect the plug on the empty “B” tank to the

chemical valve. Tighten with an adjustable wrench.

13. Depressurize the empty “B” tank by slowly opening

the nitrogen intake valve.

14. When the tank has been depressurized, close the

nitrogen intake valve of the empty “B” tank and

reconnect the yellow-coded cap. Tighten with an

adjustable wrench.

15. Remove the empty “B” tank and position the new “B”

tank in its place.

16. Write “EMPTY” on the empty “B” tank.

9.3 Tank Return

1. Complete the bill of lading on the empty tanks as

described on page 5 of this manual.

18

Page 27

Dow Building Solutions

9.4 System Pressurization

1. Open the nitrogen bottle valve by turning the knob

on top of the cylinder counter-clockwise. If a hissing

sound occurs, further tighten the nitrogen regulator

valve stem with an adjustable wrench.

2. Verify that nitrogen cylinder pressure using the center

gauge of the nitrogen regulator assembly. The system

WILL NOT operate efficiently if the pressure falls below

500 psi. If below 500 psi, replace the nitrogen cylinder.

3. Turn the left regulator stem clockwise to the proper

pressure setting of the “A” tank (120160psi – Do not

go over 225psi). If a hissing sound occurs, further

tighten the yellow-coded nitrogen line connection to

the nitrogen regulator assembly and/or the nitrogen

intake connection on the “A” tank using an adjustable

wrench. If the left gauge fails to indicate a pressure

setting, contact your Dow Sales Representative.

4. Turn the right regulator stem clockwise to the proper

pressure setting of the “B” tank (120160psi – Do not go

over 225psi). If a hissing sound occurs, further tighten the

yellow-coded nitrogen line connection to the nitrogen

regulator assembly and/or the nitrogen intake valve

connection on the “B” tank using an adjustable wrench.

If the right gauge fails to indicate a pressure setting,

contact your Dow Sales Representative.

3. Insert an unused nozzle with the key slot down. Push in

firmly until the nozzle ejector is seated over the back rim of

the nozzle.

4. Dispense foam to verify proper chemical mixing. If improper

mixing or poor foam quality, refer to the Troubleshooting

section, Section 10 of this manual.

Section 10

Troubleshooting

The FROTHPAK™ Refill System is virtually maintenance-free and

many problems can be corrected through simple troubleshooting

techniques. When troubleshooting, confirm that the system is pressurized correctly, and that all nitrogen and chemical valves are in the open

position. One closed valve can cause a system shut-down.

10.1 Temperature

Chemical temperature can affect foam quality. If the chemical temperature is below 65

temperature range is 70

10.2 Foam Color and Quality

Changes in foam quality indicate an off-ratio foam. If the foam is crusty

after curing, the foam is “A” rich and a blockage of “B” chemical exists.

°F (18°C), poor quality foam may result. The ideal

°-90°F (21°-32°C).

5. Slowly open the nitrogen intake valve of each tank.

The valve handles should be parallel with the nitrogen lines.

6. Slowly turn on the chemical valve of each tank and the on-off

valve of each chemical line. The valve handles should be

parallel to the chemical lines. Verify that the filter connection

of each tank is tight and that no chemical leaks are present.

9.5 System Purging and Testing

1. Dispense chemicals in an appropriate container.

This is to verify proper chemical flow.

2. Clean any chemical from the INSTAFLO™ Gun face

using a rag.

If the foam is mushy, and remains soft after two minutes, the foam is “B”

rich and a blockage of “A” chemical exists.

To identify and correct the problem, initiate the following procedure:

1. DO NOT breathe vapor or spray. Proper PPE and ventilation

are required. See product SDS and Section 2 of this manual

for further information. Follow all precautions for product.

2. Remove the used nozzle by pushing down the nozzle

ejector. Use only in well ventilated areas. With insuf-

ficient ventilation, wear suitable respiratory protection.

19

Page 28

Dow Building Solutions

3. Dispense chemicals in an appropriate container and

examine the chemical streams. If the streams are

equal, the problem existed in the nozzle. Continue

with steps 47 below. If the problem is not corrected,

the blockage exists in the system. Continue with

CAUTION – below step 7.

4. Clean any chemical from the INSTAFLO™ Gun face

using a rag.

5. Insert an unused nozzle.

6. Dispense chemical in an appropriate container.

7. Check the quality of the foam. If the foam is good,

the system is ready to operate. If the problem is not

corrected, the blockage exists in the system.

(Continued from step 3)

CAUTION: When disconnecting chemical lines, always

cover the connections with a rag to minimize chemical

spray or spillage.

8. Turn off the “A” and “B” lines with the in-line on-off

valves. The valve handles should be perpendicular to

the chemical lines.

9. Depressurize the Gun/Hose Assembly by pulling

the trigger, dispensing chemicals in an appropriate

container.

10. Disconnect the INSTAFLO Gun from the in-line on-off

valve using two adjustable wrenches.

11. While holding the chemical line over an appropriate

container, carefully open the valve of the “A” hose

and dispense chemical into the container. Check the

flow. Repeat for the ‘B’ hose.

12. If the flow was adequate from both hoses, the problem

was with the INSTAFLO™ Gun/Hose Assembly.

Discard the old INSTAFLO Gun/Hose Assembly and

replace with a new one according to steps 1320.

If a blockage persists, continue with step 21.

13. Connect the new INSTAFLO Gun/Hose Assembly.

14. Tighten all connections with two adjustable wrenches.

15. Verify that all chemical line valves are on. The valve

handles should be perpendicular to the chemical lines.

16. Dispense chemicals in an appropriate container to

verify proper chemical flow.

17. Clean any chemical from the face of the INSTAFLO

Gun with a rag.

18. Insert an unused nozzle with the key slot down. Push

in firmly until the nozzle ejector is seated over the

back rim of the nozzle.

19. Dispense chemicals in an appropriate container.

20. Check the quality of the foam. If the foam quality is

good, the system is ready to operate. If problems

persist, go back to step 2.

21. Turn off the on-off valve located near the tank filter

of the blocked line.

22. Turn on the in-line on-off valve of the blocked line

to depressurize the hose, allowing the chemical to

dispense in an appropriate container.

23. Close the in-line on-off valve when the hose has

depressurized.

24. Disconnect the obstructed chemical hose from the

on-off valve located next to the tank filter.

20

Page 29

25. Re-open the on-off valve located near the filter and

allow the chemical to flow in an appropriate container.

If the chemical flow is unobstructed, the blockage

exists in the chemical hose which must be replaced.