Page 1

US/CANADA . INSTALLATION INFORMATION . RESIDENTIAL

installation recommendations for

FLOATING DOCKS, RAFTS

AND BOAT WELLS

CREATE BUILD-IT-YOURSELF

FLOATING STRUCTURES WITH

STYROFOAM™ BRAND BUOYANCY

BILLETS

These instructions describe the materials

needed and guidelines for building

floating docks, rafts and boat wells/docks

with STYROFOAM™ Brand Buoyancy

Billets.

Extremely buoyant and durable, the

billet material is composed of millions of

tiny non-interconnecting air cells – each

serving as an independent buoyancy

chamber. These billets won’t lose their

buoyancy, even if punctured. It takes

only 1 cubic foot (0.03 cubic meter) of

STYROFOAM™ Brand Buoyancy Billets to

float 55 pounds (25 kilograms).

Lightweight, the billets are easy to

install. And they stay on the job year after

year under normal conditions. They resist

the attack of destructive marine growths,

are unaffected by salt or fresh water, won’t

become waterlogged and won’t corrode.

MATERIALS CHECKLIST

•Handsaw

•Framing square

•Handheld drill

•Hammer

•Wrench

•Carriage bolts/washers/nuts (see Table 1)

•Treated wood* (see Table 1)

•Nails (see Table 1)

•Scrap of 1/2" (13 mm) plywood

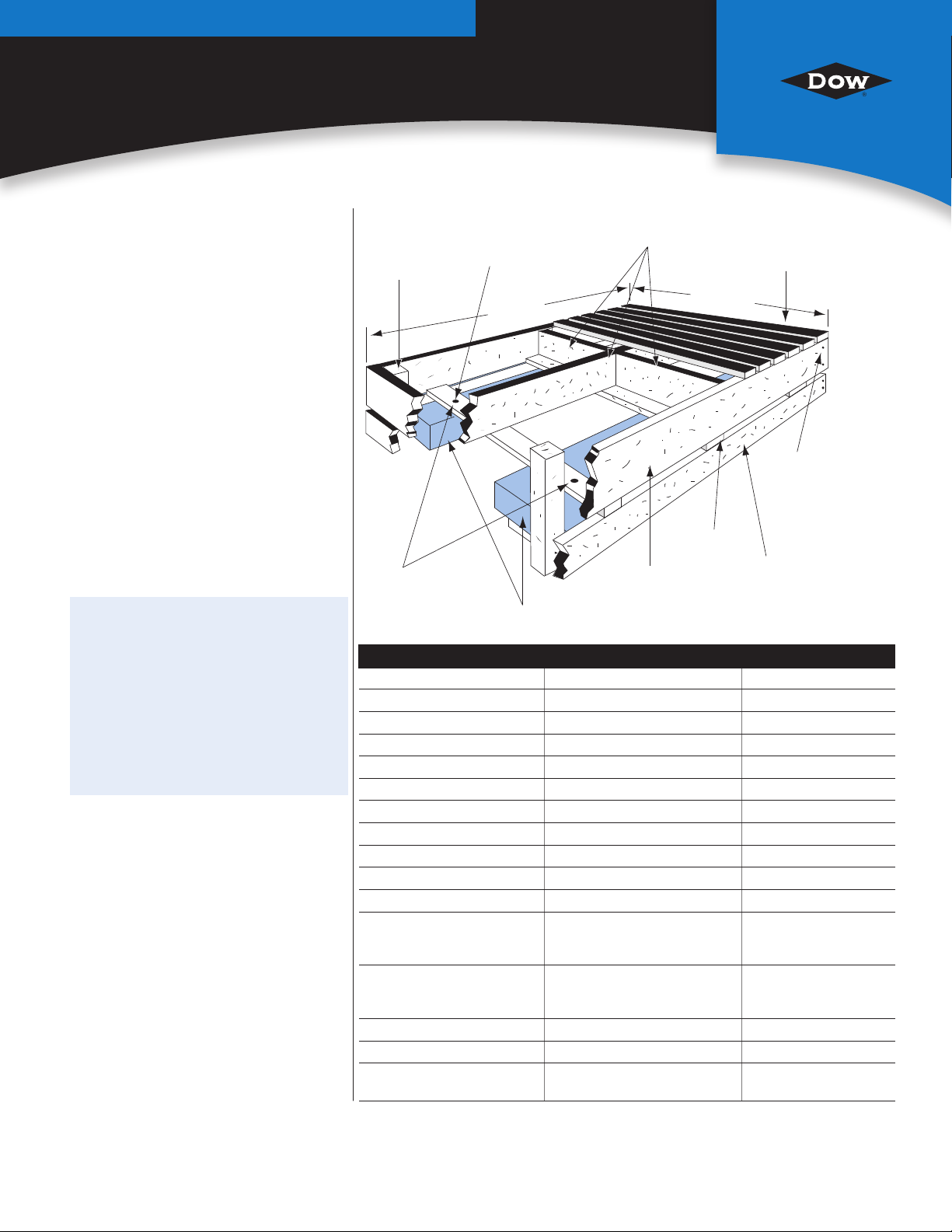

PLANS FOR A FLOATING DOCK

These instructions describe the materials

needed and guidelines for building a 6' x

10' (1.8 m x 3 m) floating dock. Additional

sections can be made to increase the

length of the dock. The materials needed

for one section are shown in Table 1. The

plans for the floating dock are shown in

Figure 1.

figure 1: floating dock plan

Corners

Counterbore

1/2" (1.3 cm)

for carriage bolts

16" (41 cm)

Carriage bolt –

washer under nut

10' (3 m)

STYROFOAM™ Brand Buoyancy Billets –

combined 1220 lbs (553 kg) buoyancy

Deck braces

Sides and ends

Decking

6' (1.8 m)

6" (15 cm)

Carriage bolts –

washer under nut

Cross ties

Skirts

all around

table 1: materials for dock

Part Name Size, inch (cm) Quantity Needed

Deck Braces 2 x 10 x 117 (5 x 25 x 297) 1

Deck Braces 2 x 10 x 33-3/4 (5 x 25 x 85.7) 2

Deck Sides 2 x 10 x 120 (5 x 25 x 305) 2

Deck Ends 2 x 10 x 72 (5 x 25 x 183) 2

Skirts 2 x 6 x 120 (5 x 15 x 305) 2

Skirts 2 x 6 x 72 (5 x 15 x 183) 2

Cross Ties 2 x 6 x 72 (5 x 15 x 183) 3

Decking 2 x 6 x 72 (5 x 15 x 183) 20

Skids 2 x 6 x 108 (5 x 15 x 274) 2

Corners 4 x 4 x 16-1/4 (10 x 10 x 41) 4

Galvanized Carriage Bolts

with Nuts (or threaded rod

cut to required length)

Galvanized Carriage Bolts

with Nuts (or threaded rod

cut to required length)

Galvanized Nails Length: 3-1/2 (9) 6 lbs (2.7 kg)

Galvanized Washers Diameter: 3/8 (0.95) 22

STYROFOAM™ Brand

Buoyancy Billets

Diameter: 3/8 (0.95)

Length: 16 (41)

Diameter: 3/8 (0.95)

Length: 6 (15)

10 x 20 x 96 (25 x 51 x 244) 2

6

16

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

*Use treated wood (or wood naturally resistant to decay/insect attack). Wood should be clean, dry and free from oil residue.

Page 2

CONSTRUCTION STEPS

1. Following the illustrations, create the

framework shown in Figure 2. With the

frame structure upside down, nail on

the three cross ties and the four skirt

boards.

2. Consulting Figure 3, lay the

STYROFOAM™ Brand Buoyancy Billets

across the cross ties. Place skids on

the foam as shown. To connect the

foam, drill six holes through the skids,

foam, and the cross ties. Insert the

long bolts and reach under the cross

ties to apply washers and nuts.

3. Turn the structure over and tighten the

nuts to a snug fit.

4. Install lengthwise brace. Then install

cross bracing.

5. Nail on deck boards using a piece of

1/2" (13 mm) plywood to space boards

1/2" apart (Figure 4).

figure 2: bottom view of dock

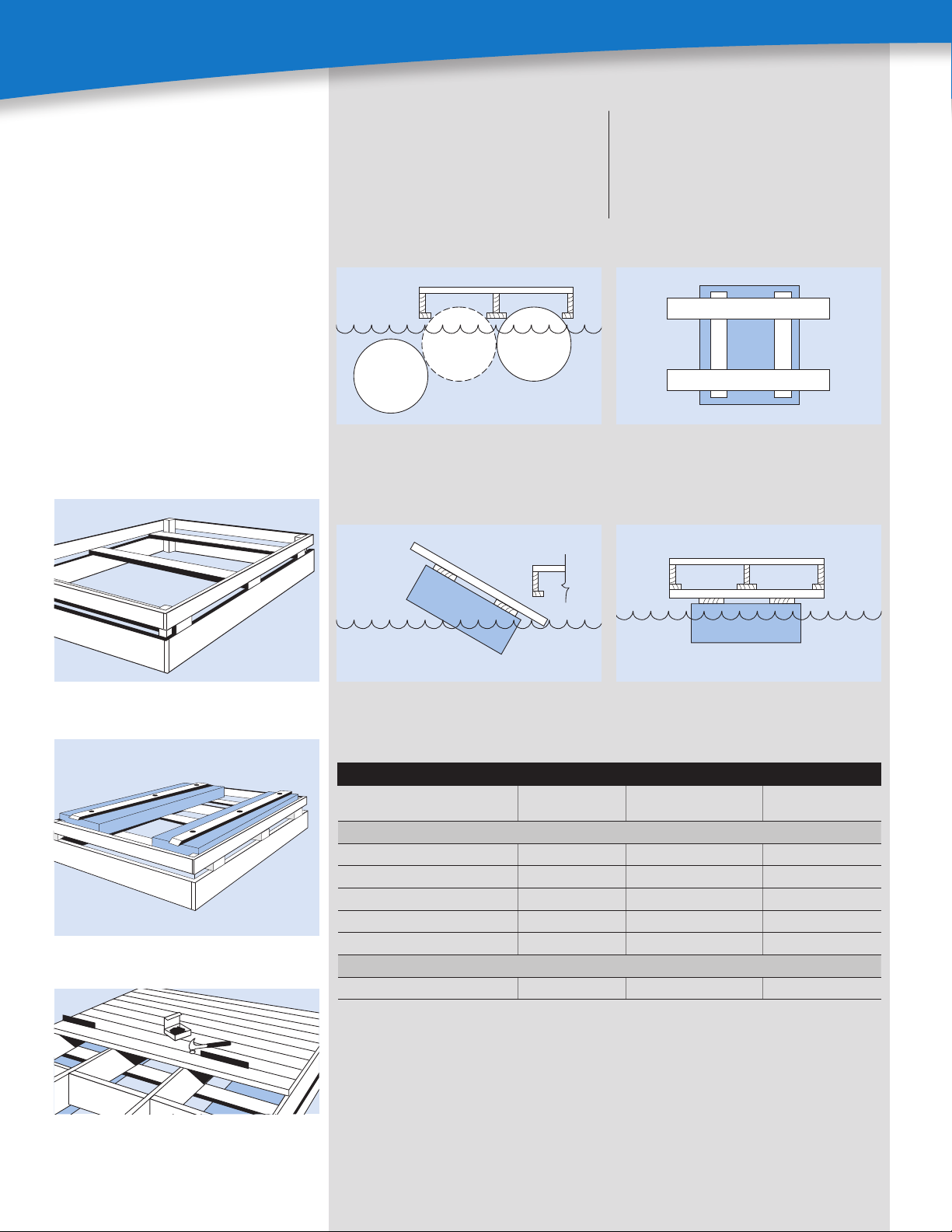

REPLACING EXISTING DRUMS

Easily replace drums on a boat well/wharf

with buoyancy billets while the floating

structure is still in the water. The rocking

that is usually experienced in drum-floated

structures is greatly reduced by using

STYROFOAM™ Brand Buoyancy Billets.

DRUM REPLACEMENT STEPS

1. Replace small sections one at a time.

Sink and remove only two side-by-side

drums at a time.

Plus, there are no hollow drumming

noises to listen to at night.

One 10" x 20" x 96" (25 x 51 x 244 cm)

STYROFOAM™ Brand Buoyancy Billet

has an average buoyancy that is

approximately 150 percent greater than a

55-gallon (208-liter) drum (Table 2).

2. Build a crib from lumber – 2" x 8"

(5 x 20 cm) boards are suggested.

Fasten the crib to the STYROFOAM™

Brand Buoyancy Billet. Cross members

should be longer than the wharf is wide.

figure 3: attaching billets

to bottom of dock

figure 4: attaching decking

to top of raft or dock

3. Tilt crib and push under wharf using

the 2" x 8" boards as handles.

4. Center under the wharf. Secure with

16 pennyweight (16d) nails. Saw off

protruding 2" x 8" handles.

table 2: comparative size and buoyancy data

Product Cubic Feet

Billet Size, inch (cm)

7 x 20 x 96 (18 x 51 x 244) 7.7 (0.22) 14 (6.4) 425 (192.8)

10 x 20 x 96 (25 x 51 x 244) 11.1 (0.31) 20 (9.1) 610 (276.7)

7 x 20 x 108

10 x 20 x 108

10 x 24 x 96

Drum Size

55-gallon (208-liter), 18-gauge 7.8 (0.22) 48.5 (22.0) 440 (199.6)

(1) Available in the U.S. only

(1)

(1)

(1)

13.3 (0.38) 24 (10.9) 730 (331.1)

(Cubic Meters)

8.6 (0.24) 16 (7.3) 480 (217.7)

12.5 (0.35) 23 (10.4) 690 (313.0)

Approximate Weight,

lbs (kg)

Approximate

Buoyancy, lbs (kg)

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

Page 3

PLANS FOR A SWIMMING RAFT

These instructions describe the materials

needed and guidelines for building an 8'

x 12' (2.4 m x 3.7 m) swimming raft. The

materials needed are shown in Table 3.

The plans for the raft are shown in Figure 5.

CONSTRUCTION STEPS

1. Following the illustrations, create the

framework shown in Figure 6. With the

frame structure upside down, nail on

the four cross ties and the four skirt

boards.

2. Cut the three STYROFOAM™ Brand

Buoyancy Billets in half for the six

shorter pieces shown in Figure 7.

3. Consulting Figure 7, lay the sections

of the STYROFOAM™ Brand Buoyancy

Billets across the cross ties. Place

skids on the foam as shown. To

connect the foam, drill six holes

through the skids, foam and the cross

ties. Insert the long bolts and reach

under the cross ties to apply washers

and nuts.

4. Turn the structure over and tighten the

nuts to a snug fit.

5. Install lengthwise bracing first, then

install cross bracing.

6. Consulting Figure 4, nail on deck

boards using a piece of 1/2" (13 mm)

plywood to space boards 1/2" apart.

figure 5: swimming raft plan

Corners

12' (3.7 m)

16" (41 cm)

Carriage bolt –

washer under nut

Skids –

counterbore

1/2" (1.3 cm)

for carriage bolts

STYROFOAM™ Brand Buoyancy Billets –

combined 1830 lbs (830 kg) buoyancy

figure 6: bottom view of raft

Deck braces

Decking

8' (2.4 m)

Skirts

all around

Cross ties

Sides and ends

6" (15 cm)

Carriage bolt –

washer under nut

table 3: materials for swimming raft

Part Name Size, inch (cm) Quantity

Sides 2 x 10 x 144 (5 x 25 x 366) 2

Ends 2 x 10 x 93 (5 x 25 x 236) 2

Deck Braces 2 x 10 x 141 (5 x 25 x 358) 2

Deck Braces 2 x 10 x 330 (5 x 25 x 76) 3

Skirts 2 x 6 x 144 (5 x 15 x 366) 2

Skirts 2 x 6 x 93 (5 x 15 x 236) 2

Cross Ties 2 x 6 x 96 (5 x 15 x 244) 4

Decking 2 x 6 x 96 (5 x 15 x 244) 24

Skids 2 x 6 x 134 (5 x 15 x 340) 3

Corners 4 x 4 x 16-1/4 (10 x 10 x 41) 4

Galvanized Carriage Bolts with Nuts

(or threaded rod cut to required length)

Galvanized Carriage Bolts with Nuts

(or threaded rod cut to required length)

Galvanized Nails Length: 3-1/2 (9) 6 lbs (2.7 kg)

Galvanized Washers Diameter: 3/8 (0.95) 28

STYROFOAM™ Brand Buoyancy Billets 10 x 20 x 96 (25 x 51 x 244) 3

Diameter: 3/8 (0.95)

Length: 16 (41)

Diameter: 3/8 (0.95)

Length: 6 (15)

Needed

12

16

figure 7: attaching billets

to bottom of raft

Page 4

HOW TO SECURE FLOATING DOCKS AND RAFTS

Washer and

cotter pin

Float number 1 Float number 2

Galvanized washers

at both ends

of eye bolts

Loose-fitting steel rod

Galvanized eye bolts

Washer and

cotter pin

Float number 1 Float number 2

Galvanized washers

at both ends

of eye bolts

TOP VIEW

SIDE VIEW

Float

Leave Clearance

Piling

Pipe nipples

(free fit on chain)

Bolt

Eye bolt washers

at both ends

Lt.

anchor chain

Bolt for

retaining pipe

nipples

TOP VIEW

DOCK TO SEAWALL FOR TIDAL

VARIATION

Bolt

through

pipe into

sea wall

Guide plate

bolted to

float (loose

fit on pipe)

TOP VIEW

Standoff

nipple

Guide pipe

SIDE VIEW

RAFT TO BOTTOM

FLOAT

Use weighted sentinel

if necessary for added holding

SIDE VIEW

DOCK TO DOCK

Loose-fitting steel rod

Chain bridle

Single chain

Galvanized eye bolts

TOP VIEW

SIDE VIEW

DOCK TO SHORELINE

Cable stays to

pipe stakes

TOP VIEW

Float

DOCK TO PILING FOR TIDAL

VARIATION

Leave Clearance

Bolt

Lt.

anchor chain

Bolt for

retaining pipe

nipples

TOP VIEW

Welded pipe frame

Pivot bracket

Eye bolt washers

at both ends

Piling

Pipe nipples

(free fit on chain)

Float

1/2" Section

8" Pipe

PRECAUTIONS

STYROFOAM™ Brand Buoyancy Billets are sold for use in marine applications only. Billets are combustible. Protect from high heat sources. Care should be taken not

to expose material to open flame or other ignition sources. For more information, consult MSDS, call Dow at 1-866-583-BLUE (2583) or contact your local building

inspector. In an emergency, call 1-989-636-4400 in the U.S. or 1-519-339-3711 in Canada.

Pipe frame

SIDE VIEW

Cable

Pipe

driven deep

The foam is subject to attack by some chemicals, including concentrated quantities of gasoline and oil. If this, or pollution by industrial waste is suspected, reaction

of the foam should be checked prior to construction. In case of extreme pollution, additional protection – such as solvent-free epoxy coatings – may be required.

Compatibility of the coating to the billet should be checked prior to applying the coating.

Skirt boards will protect foam from mechanical damage and degradation from ultraviolet light.

NOTICE: No freedom from any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether

products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance with applicable laws and other government enactments. The product

shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries or regions. Dow assumes no obligation or liability for the

information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO EXPRESS WARRANTIES ARE GIVEN EXCEPT FOR ANY APPLICABLE

WRITTEN WARRANTIES SPECIFICALLY PROVIDED BY DOW. ALL IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

www.dowbuildingsolutions.com

THE DOW CHEMICAL COMPANY . Dow Building Solutions . 200 Larkin . Midland, MI 48674

DOW CHEMICAL CANADA ULC . Dow Building Solutions . Suite 2100 . 450 – 1st St., SW . Calgary, AB T2P 5H1

For Technical Information: 1-866-583-BLUE (2583) (English) . 1-800-363-6210 (French)

Printed in U.S.A. Form No. 179-04291X-0511P&M

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

For Sales Information: 1-800-232-2436 (English) . 1-800-565-1255 (French)

178-00548X-0511P&M

Loading...

Loading...