Page 1

INSTALLATIEVOORSCHRIFTEN EN GEBRUIKSAANWIJZING

HOUTKACHEL

INSTALLATION INSTRUCTIONS AND OPERATING MANUAL

WOOD STOVE

INSTALLATION ET MODE D’EMPLOI

POELE A BOIS

EINBAUANLEITUNG UND GEBRAUCHSANWEISUNG

HOLZ-FEUERSTÄTTE

INSTRUCCIONES DE INSTALACIÓN Y USO

ESTUFA DE LEÑA

03.27681.100 - 04 2011

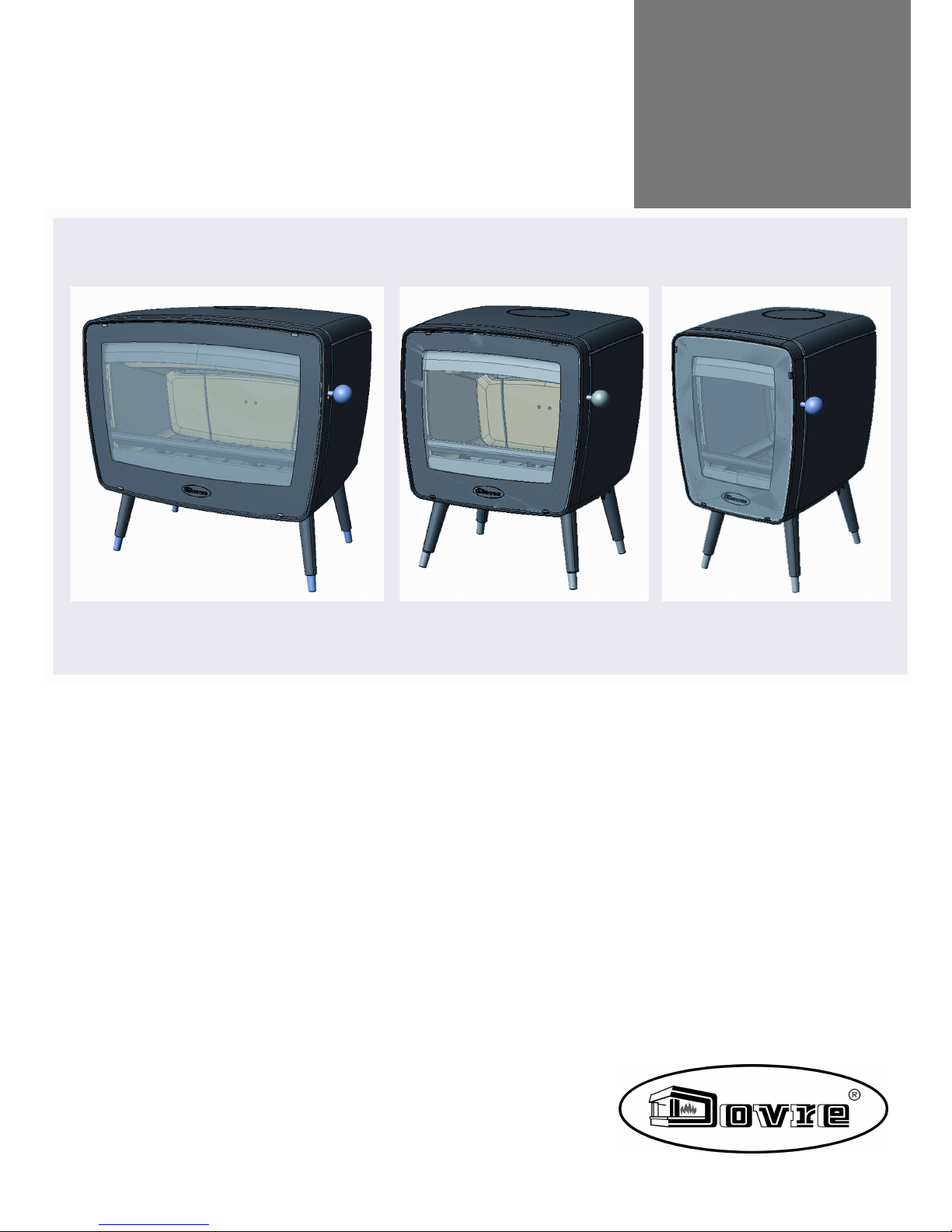

Vintage 50-35-30

Page 2

Inhoud

Inhoud

Inhoud 2

Inleiding 3

Conformiteitsverklaring 4

Veiligheid 5

Installatiecondities 6

Algemeen 6

Schoorsteen 6

Ventilatie van deruimte 7

Vloer en wanden 7

Productbeschrijving 8

Installatie 9

Algemene voorbereiding 9

Deursluiting 10

Schoorsteenaansluiting voorbereiden 11

Buitenluchtaansluitingvoorbereiden 12

Plaatsen enaansluiten 13

Gebruik 14

Eerste gebruik 14

Brandstof 14

Aanmaken 14

Stoken met hout 15

Regeling van de verbrandingslucht 16

Doven van het vuur 16

Ontassen 16

Nevel en mist 17

Eventueleproblemen 17

Onderhoud 18

Schoorsteen 18

Schoonmaken enander regelmatig

onderhoud 18

Bijlage 1: Technische gegevens 22

Bijlage 2: Afmetingen 23

Bijlage 3: Afstand tot brandbaar materiaal 26

Bijlage 4: Diagnoseschema 29

Index 30

2

Wijzigingen op grond vantechnischeverbeteringen voorbehouden

Page 3

Introduction

Introduction

Dear user,

In buying this DOVRE heating appliance, you have

chosen a high quality product. This product is part of a

new generation of energy saving and environmentally

friendly heating appliances. These appliances make

optimal use of convection heat as well as thermal

radiation (radiant heat).

Your DOVRE appliance has beenmanufactured

with state-of-the-art production means. In the

unlikely event of a malfunction, you can always

rely on DOVRE for support and service.

The appliance is not to be modified; always use

original parts.

The appliance is intended for use in a living room. It

must be connected hermetically to a wellfunctioning chimney.

We advise you to let an authorized andcompetent

installation company install the appliance.

DOVRE cannot be held liable for any problems or

damage resulting from an incorrect installation.

Observe the following safety rules when installing

andusing the appliance.

In this manual, you can read how the DOVRE heating

appliance can beinstalled, used and maintained

safely. Should you require additional informationor

technical data, orshould you be experiencing a

installation problem, please contact your supplier in

the first instance.

© 2010 DOVRE NV

2

Subjectto change because of technicalimprovements

Page 4

Declaration of

conformity

Notified body: 1625

Dovre nv, Nijverheidsstraat 18 B-2381 Weeldehereby

declares

that houtkachel Vintage 50, Vintage 35en Vintage 30

has been producedin accordance with EN 13240.

Weelde19-01-2011

In het kader van een continue productverbetering,

kunnen specificaties van het geleverde toestel

afwijken van de beschrijvingin deze brochure, zonder

voorafgaande kennisgeving.

DOVRE N.V.

Nijverheidsstraat 18 Tel: +32 (0) 14 65 91 91

B-2381 Weelde Fax: +32 (0) 14 65 90 09

België E-mail: info@dovre.be

Declaration of conformity

Subjectto change because of technicalimprovements

3

Page 5

Safety

Safety

Please note: All safety regulations must be

compliedwith strictly

Carefully read the instructions for installation,

use andmaintenance before you start using

the appliance.

The appliance must be installed in accordance

with the laws and requirements of your

country.

All local regulations and the regulations relating

to national and European standards must be

observed when installingthe appliance.

Read the instructions for installation, use and

maintenance that weresupplied with the

appliance.

It is preferableto have the appliance installed

by an authorized and competent installation

company. They will be aware of the applicable

regulations and requirements.

The appliance is designed for heating

purposes. All surfaces, including the glass and

the connecting tube, can get very hot (over100

°C)! For operation, use a so-called "cold hand"

or anoven glove.

Don't place any curtains, clothes, laundry or

othercombustible materials on or near the

appliance.

Don't use flammable or explosive substances

near the appliance when it is in use.

Avoid a chimney fire by having the chimney

swept regularly. Never burn woodwith an open

door.

In the case of a chimney fire: close all air inlets

of the appliance andalert the fire brigade.

If the glass in the appliance is broken or

cracked, it must be replacedbefore you can

use the appliance again.

Make sure there is adequate ventilation in the

room where the appliance is installed. The

combustion will be incomplete in case of

insufficient ventilation, which results in toxic

gases being producedand spread through the

area. See the chapter "Installation

requirements" for more information on

ventilation.

4

Subjectto change because of technicalimprovements

Page 6

Installation

requirements

General

The appliance must be connected tightly to a wellfunctioning chimney.

For the connection measurements: see the

appendix "Technical data".

Ask the fire brigade and/or your insurance

company about any specific requirements and

regulations.

Flue or chimney

The flue or chimney is needed for:

Disposing of the combustion gases through natural

draught.

The warm air in the flue or chimney is lighter

than the outside air so it rises.

The intake of air, needed for the combustion of fuel

in the appliance.

A poorly functioning flue or chimney can cause smoke

to escape into the room when the door is opened.

Damage caused by smoke emissions into the room is

not covered by the warranty.

Do not connect multiple appliances (such as a

boiler for central heating)to the same flue,

unless local or national regulations allow this.

Ask your installer for advice regarding the flue. Refer

to the Europeannorm EN13384 for a correct

calculation for the flue.

The flue must satisfy the followingrequirements:

The flue or chimney must be made of fire resistant

material, preferably ceramics or stainless steel.

The flue or chimney must be airtight and well

cleaned and guarantee sufficient draught.

A draught /vacuum of 15 - 20Pa during normal

operationis ideal.

Starting from the flue spigot, the flue must runas

vertically as possible. Changes in direction and

horizontal pieces disrupt the outward flow of

combustion gases and may cause the deposit of

soot.

The interior measurements should not be too big, to

prevent the combustion gases from cooling down

too much, thereby reducing the draught.

The flue or chimney must ideally have the same

diameter as the connection collar.

For the nominal diameter: see the appendix

"Technical data". If the smoke channel is well

insulated, the diameter may be slightly bigger

(upto 2x the section of the connection collar).

The section (area ) of the smoke channel must be

constant. Wider segments and (in particular)

narrowersegments disrupt the outward flow of

combustion gases.

When usinga cover plate or exhaust hood : make

sure that the cover does not restrict the flue outlet

andthat the cap does not impedethe outward flow

of combustion gases.

The chimney must end in a zone that is not

affected by surrounding buildings, adjacent trees or

otherobstacles.

The chimney part outside the house must be

insulated.

The chimney must be at least 4 metres high.

As a rule of thumb: 60 cm above the ridge of the

roof.

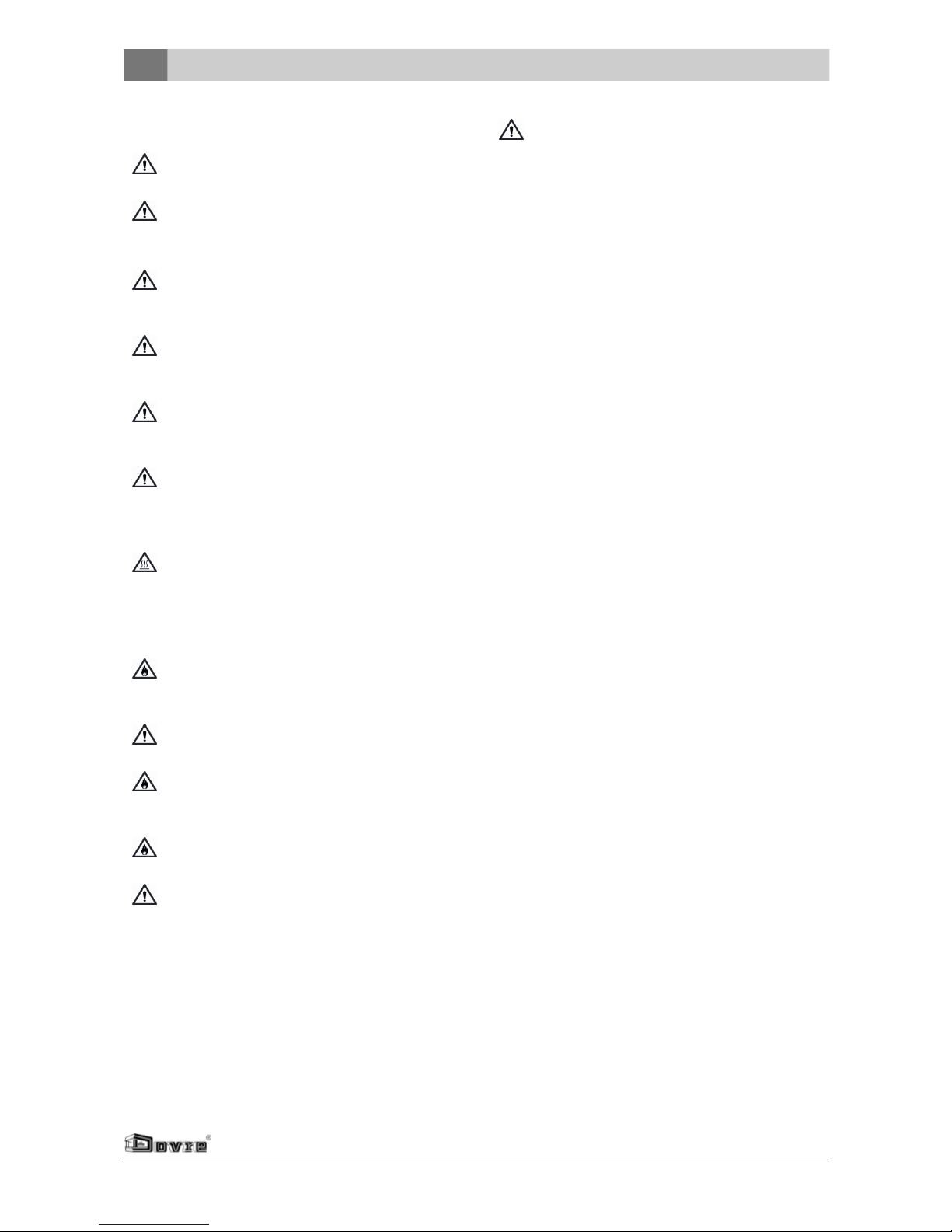

If the ridge of the roof is morethan3 metres away

from the flue: stick to the measurements in the

following figure. A = the highest point of the roof

within a distance of 3 metres.

Installation requirements

Subjectto change because of technicalimprovements

5

Page 7

Installation requirements

Ventilation of the area

For good combustion, the appliance needs air

(oxygen). That air is suppliedvia adjustable air inlets

from the area where the appliance is installed.

The combustion will beincomplete in case of

insufficient ventilation, which results in toxic

gases being producedand spread through the

area.

As a rule of thumb, the air supply should be

5.5cm²/kW. Extra ventilation is needed when:

The appliance is in an area that is well insulated.

There is mechanical ventilation, for example a

central extraction system or anextraction hood in

an open kitchen.

You can provide extra ventilation by having a

ventilation louvre installed in the outside wall.

Make sure that otherair consumingappliances (such

as tumble-driers, other heating appliances or a bath

room fan) have theirown supply of outside air, or are

switched off when you use the appliance.

You can also connect the appliance to a supply

of outside air. Forthis purpose, a connecting

kit has been included. Extra ventilation is not

needed in that case.

Floor and walls

The floor on which the appliance is placed must have

sufficient load bearing capacity. For the appliance

weight: see the appendix "Technical Data".

Protect a flammablefloorfrom heat radiation

by means of a fireproof protective plate. See

the appendix "Distance from combustible

material".

Keep enough distance between the appliance

andcombustible materials such as wooden

walls and furniture.

The connecting tube radiates heat too. Ensure

that there is sufficient distance or a shield

between the connecting tube and combustible

material.

The rule of thumb for a single-walled tube is a

distance of 3x the diameter. If a lining shell is

fitted around the tube, a distance of 1x the

diameter is permissible.

Carpets and rugs must be at least 80 cm away

from the fire.

Protect a flammablefloorfrom possible falling

ash in front of the fire with the aid of a fireproof

protective plate. Theprotective plate must

comply with national standards.

For further requirements with respect to fire

safety, see the appendix "Distance from

combustible material".

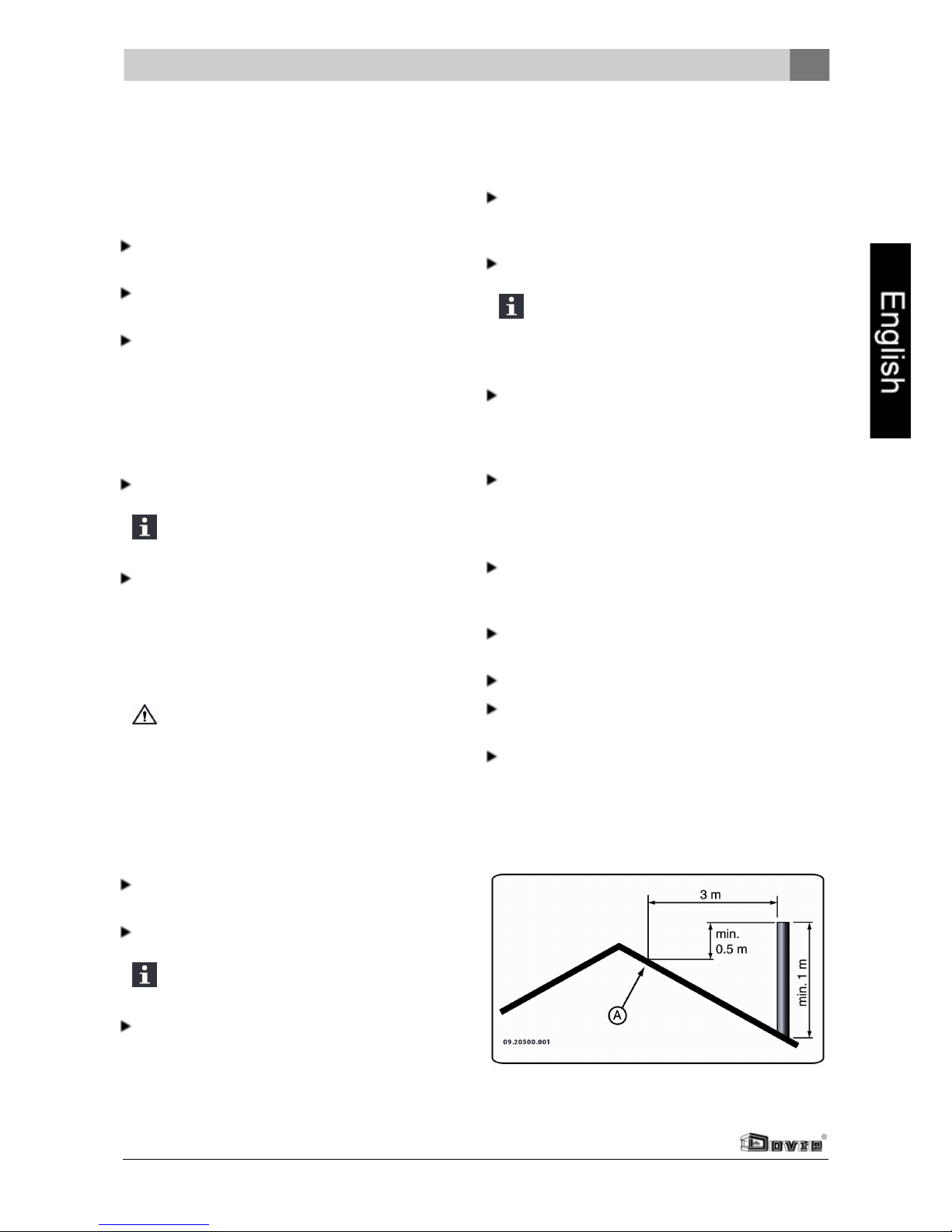

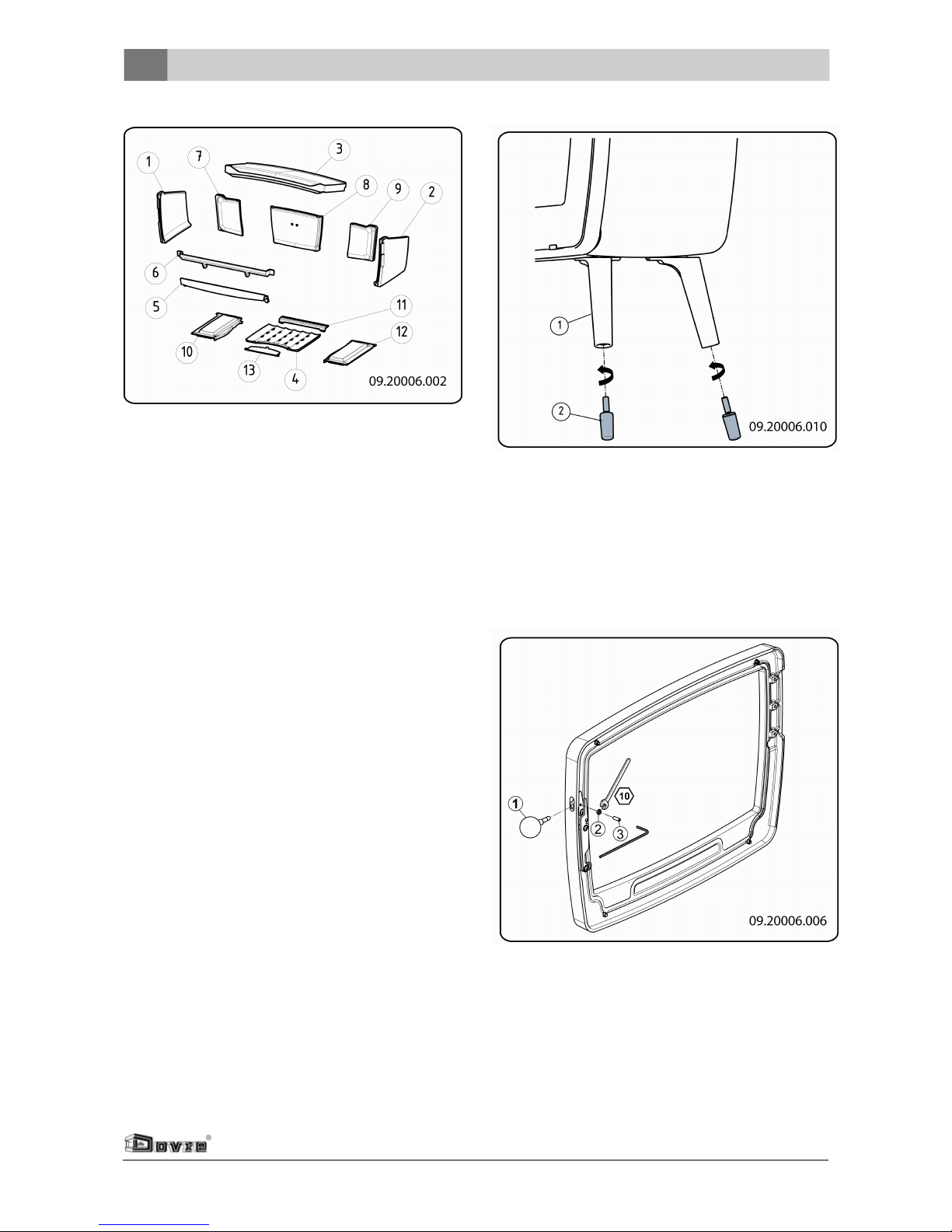

Product description

1. Top plate

2. Latch button

3. Bottom of the fire compartment

4. Door

5. Secondary air slide

6. Leg

7. Primary air slide

6

Subjectto change because of technicalimprovements

Page 8

Installation

General preparation

Please check the appliance for damage caused

during transport or any other damage or defects

immediately after delivery. The appliance is

attached to the pallet with screws at the bottom.

If you detect damage causedduringtransport

or any other damage ordefects, do not use the

appliance and notify the supplier.

Remove the removableparts (fire-resistant inner

plates, fire grate, top plate, ashtray) from the

appliance before you start installing the appliance.

By removing removable parts, it is easier to

move the appliance and to avoid damage.

Note the location of those removable parts, so

that you have nodifficulties in installingthe

parts in the right place later on. The appliance

is attached to the pallet with screws at the

bottom.

1. Openthe door; see the following figure.

2. Remove the fire-resistant inner plates; see the

following figure.

The following tips may helpin the removal of the

inner plates:

a. Lift baffle plate 3 on the front and pull it

forwards by 2 cm.

b. Now, lift the baffle plate on the left-hand side

andremove the left-hand inner plate 1 first.

c. Then remove baffle plate 3 followed by inner

plates 7, 8, 9, 2 etc.

Vermiculite inner plates are light andtend

to be ochrous in colour when delivered.

They insulate the combustion chamber to

boost combustion. Cast iron inner plates

protect the combustion chamber and

dissipate heat to the environment.

Installation

Subjectto change because of technicalimprovements

7

Page 9

Installation

Removable internal sections

1 left-hand side inner plate

2 right-hand side inner plate

3 baffle plate

4

centre bottom of the fire

compartment

5 bottom fire basket not for Vintage 30

6 top fire basket

7 left-hand rear inner plate not for Vintage 30

8 centre rear inner plate not for Vintage 30

9 right-hand rear inner plate not for Vintage 30

10

left-hand bottom of the fire

compartment

not for Vintage 30

11

rear bottom of the fire

compartment

not for Vintage 30

12

right-hand bottom of the

fire compartment

not for Vintage 30

13 ash removal port not for Vintage 30

3. Remove the ashtray.

Please note:the Vintage 30 does not have an

ashtray.

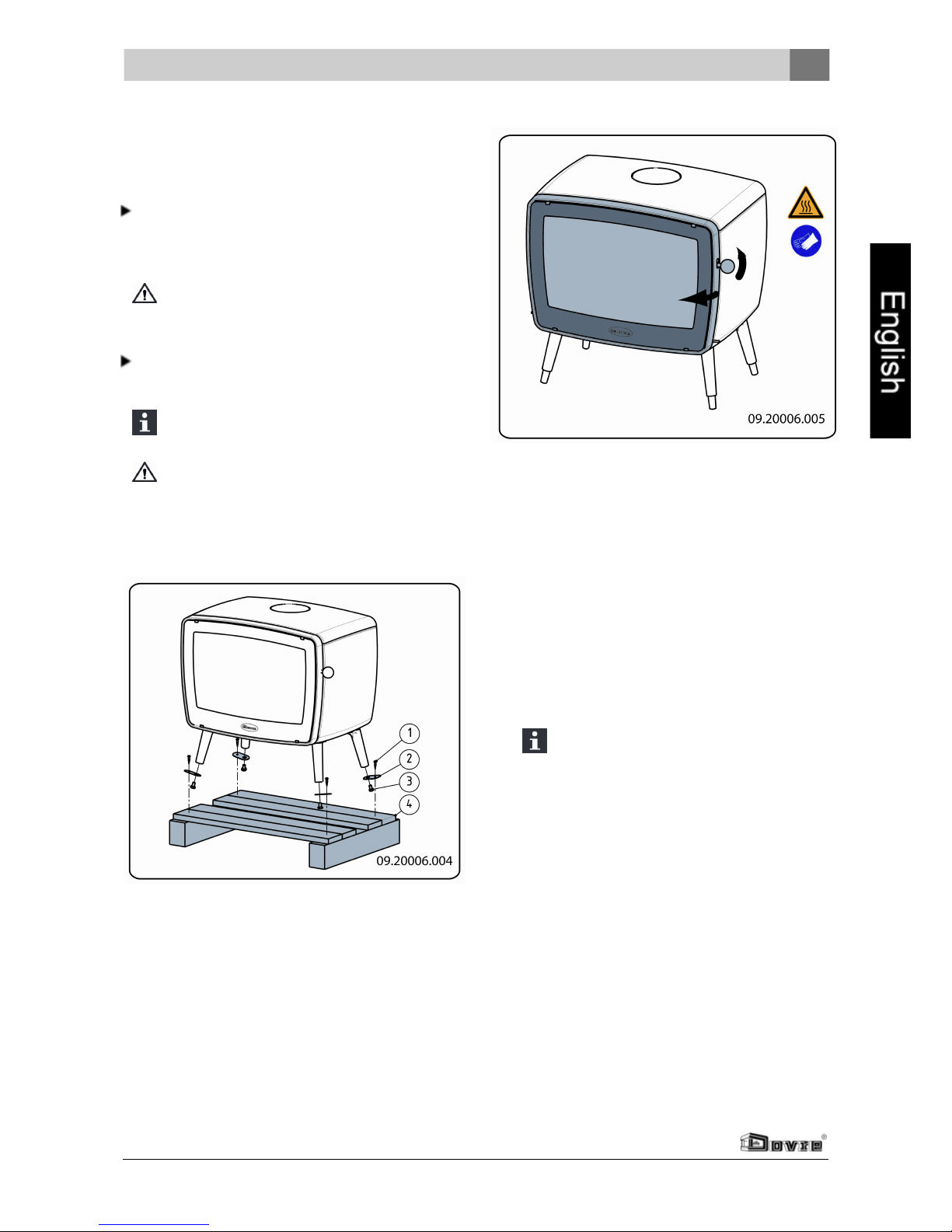

4. Install the adjustable feet under the legs, see

figure. When used on a slippery floor surface, it is

recommended that a rubber mat is used under the

legs.

Door lock

The appliance is supplied with the latch button

installed. You coulddecide to use the latch button as

a "cold hand".

1. Loosennut (2) slightly and loosen the set screw

(3)until the latch button is released.

2. Re-tighten nut (2).

3. Install the latch retainer on the base, see figure.

8

Subjectto change because of technicalimprovements

Page 10

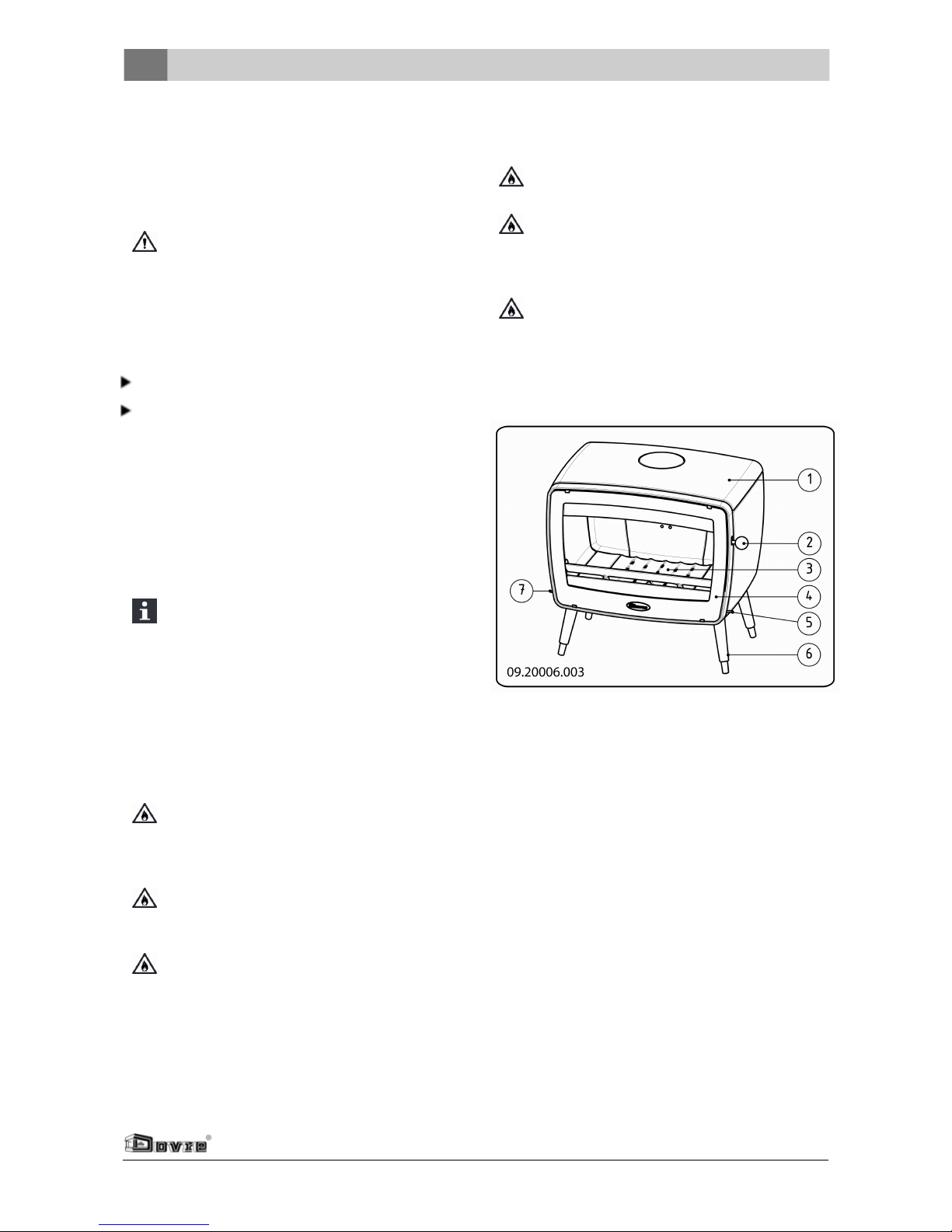

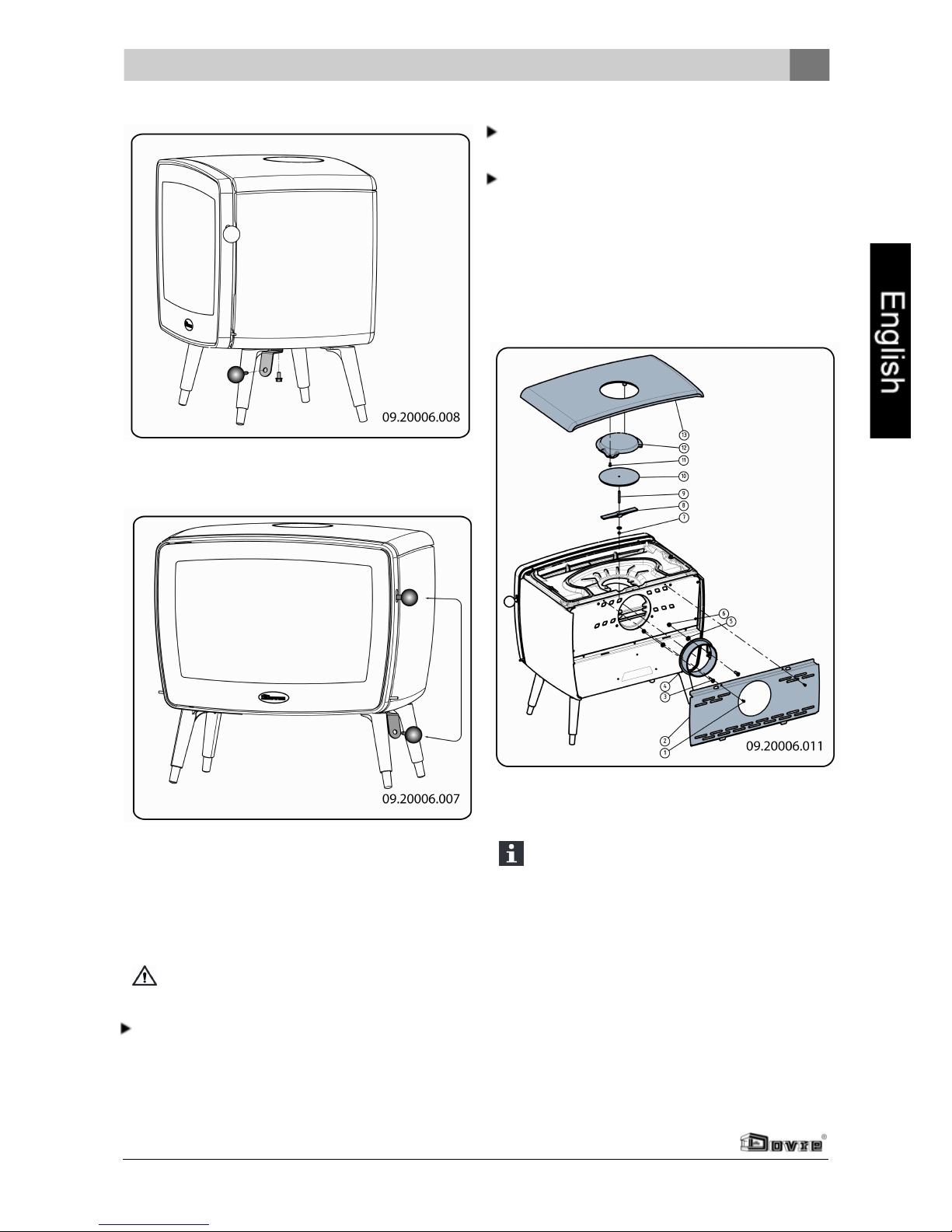

4. Place the latch button into the latch retainer, see

figure.

Preparing the connection to

chimney

When connecting the appliance to a chimney, you can

choose the top or rear of the appliance.

When the appliance is delivered, the

connection on the rear is left open.

Plug the outlet that you don't want to use with the

corresponding cover that was supplied.

Install the corresponding connection collar that

was supplied on the outlet that you want to use.

Sealant and materials are supplied.

Connecting to the rear

1. Apply supplied fibre glass sealing tape of 10x3mm

to the contact surface of the connection collar.

2. Install the connection collar to the back wall with

the materials.

Connect to top

1. Remove the top plate.

The top plate can be taken off the appliance

just like that.

2. Remove the decorative cover (12) from the top

plate.

3. Remove the cover (10) from the inner top plate.

4. Apply sealing tapemeasuring 10 x 3mm to the

contact surface of the connection collar.

5. Install the connection collar to the inner top plate

with the materials.

Installation

Subjectto change because of technicalimprovements

9

Page 11

Installation

6. Install the cover to the back wall with the

materials.

Preparing the connection to

the outside air

If the appliance is installed in a room without sufficient

ventilation, you can install the connecting kit on the

appliance (supplied with the appliance) for the supply

of outside air. Some of the airinlets on the appliance

must then be plugged with the blanking material

provided.

The air supply tube has a diameter of 100mm. If the

tube is smooth, it may be nolongerthan 12m. If

accessories such as bends are used, the maximum

length (12m)must be reducedby 1m for each

accessory used.

Outside air connection via the floor

1. Make an openingin the floor(see Appendix 2,

Measurements, for the correct position of the

opening).

2. Hermetically close the air supply tubeat the floor.

3. Install the connection collar on the bottom plate

andclose the rear wall with the cover.

The guardis no 3 on the diagram.

Connection to outside air via the

rear of the appliance:

1. Make an openingin the wall (see Appendix 2,

Measurements, for the correct position of the

opening).

2. Hermetically close the air connection tubeat the

wall.

3. Install the connection collar on the back wall and

close the opening in the bottom plate with the

cover.

The guardis no 4 on the diagram.

10

Subjectto change because of technicalimprovements

Page 12

Install and connect

1. Install the appliance in the right place, and make

sure it is level.

2. Connect the appliance hermetically to the flue.

3. In the case of connection to outside air: attach the

connection to the outside air to the connecting set

that you have attached to the appliance.

4. Install all the parts you had removed in the right

places in the appliance.

Never use the appliance without the fireresistant inner plates.

The appliance is now ready for use.

Installation

Subjectto change because of technicalimprovements

11

Page 13

Use

Use

First use

When you use the appliance for the first time, make

an intense fire and keep it going for a good few hours.

This will cure the heat-resistant paint finish. This may

result in some smoke andodours. You couldopen

windows and doors for a while in the area where the

appliance is located.

Fuel

This appliance is only suitablefor the burning of

natural wood; sawn and chopped woodthat is

sufficiently dry.

Do not use otherfuels, as they can lead to serious

damage to the appliance.

You are not allowed to use the following fuels, as they

pollute the environment, and because they heavily

pollute the appliance and flue, which may lead to a

chimney fire:

Treated wood, such as scrapwood, painted wood,

impregnated wood, preserved wood, plywoodand

chipboard.

Plastics, scrap paperand domestic waste.

Wood

Hardwood, such as from oaks, beeches, birches

andfruit trees, is the ideal fuel for your stove. This

type of wood burns slowly with calm flames.

Softwood contains more resins, burns faster and

gives off more sparks.

Use dried woodthat contains no more than 20%

moisture. The wood must have dried for at least 2

years.

Saw the wood to size andsplit it when it is still

fresh. Fresh wood is easier to split, and split wood

dries more easily. Storethe woodunder a roof

wherethe wind has wind freeaccess.

Do not use damp wood. Damp logs do not produce

heat as all of the energy is used in the evaporation

of the moisture. This will result in a lot of smoke

andsoot deposits onthe door of the appliance and

in the chimney. The water vapour will condense in

the appliance and can leak away through chinks in

the appliance, causing black stains on the floor. It

may also condense in the chimney andform

creosote. Creosote is a highly flammable

compound and may cause a chimney fire.

Lighting

You can check whetherthe flue has enough draught

by lighting a ball of paperabove the baffle plate. A cold

flue often does not have enough draught and

consequently, some smoke may escapeinto the room

instead of up the chimney. By lighting the fire in the

way described here, you can avoid this problem.

1. Stack two layers of medium sized logs crosswise.

2. Stack two layers of kindling crosswise on top of

the logs.

3. Place a firelightercubein the lowerlayer of

kindlingand light the cube according to the

instructions on the packaging.

4. Close the door of the appliance and open the

primary air inlet and the secondary air inlet of the

appliance; see the following figure.

5. Let this fire develop into a good blaze until there is

glowingbed of charcoal. You can thenadd fuel

andadjust the appliance, see the chapter on

burning wood.

12

Subjectto change because of technicalimprovements

Page 14

Primary air slide

Secondary air slide

Burning wood

After you have followed the instructions for lighting :

1. Slowly open the door of the appliance.

2. Spread out the charcoal bed evenly across the

bottom of the fire compartment.

3. Stack a few logs on the charcoal bed.

Open stacking

If the logs are stacked openly, the wood will burn

quickly as the oxygen can reach each log easily. If

you want to use the stove for a short while, make an

open stack.

Compact stacking

If the logs are stacked tightly, the wood will burnmore

slowly as the oxygen can only reach some logs

Use

Subjectto change because of technicalimprovements

13

Page 15

Use

easily. If you want to burn wood for a longer period,

make a compact stack.

3. Close the door of the appliance.

4. Close the primary air inlet and leave the secondary

air inlet open.

Fill the appliance up to onethird capacity.

Controlling the air

The appliance has various features for the air control

(see figure).

The primary air slide controls the airflow under the

grille (1).

The secondary air slide controls the air flow for the

glass and the vents in the back wall (2).

The baffle plate has permanent vents (3) that allow for

post-combustion.

Advice

Never burn wood with an open door.

Regularly burnwood with intense roaringfires.

If you frequently have low intensity fires, tar

andcreosote may be deposited in the chimney

. Tar and creosote are highly combustible

substances. Thicker layers of these

substances might catch fire when the

temperature in the chimney increases

suddenly and steeply. Thereforeit is

necessary for the fire to regularly burn very

intensely, so that layers of tar and creosote

disappear.

Low intensity fires also cause tar deposits on

the stove window and door.

When the outside temperatureis not very low,

it is better to burn wood intensely for a few

hours instead of having a low intensity fire for a

longperiodof time.

Control the air supply with the secondary air inlet.

The secondary air inlet not only supplies air to

the fire but to the glass as well, so that it does

not get dirty so quickly.

Open the primary air inlet for the time being if the air

supply by the secondary air inlet is inadequate orif

you want to fan the fire.

It is better to add a small amount of logs regularly

than to add many logs at the same time.

Extinguishing the fire

Do not add fuel and just let the fire go out. If a fire is

damped down by reducingthe supply of air, harmful

substances will be produced and released. Therefore,

let the fire go out naturally. Keep aneye on the fire

until it is gone out. If the fire has diedcompletely, all

air inlets can be closed.

Removing ashes

After the wood has been burnt, a relatively small

amount of ashes is left over. This bed of ashes is a

good insulatinglayer for the bottom of the fire

compartment andimproves combustion. Therefore,

you can leave a thin layer of ashes on the bottom of

the fire compartment.

However, the air supply through the bottom of the fire

compartment must not be impeded and no ash should

be allowed to accumulate behind a cast iron inner

plate. Therefore, remove any excess ash frequently.

14

Subjectto change because of technicalimprovements

Page 16

1. Openthe door of the appliance.

2. Use the scraper to open the ash removal port in

the bottom of the fire compartment (1).

3. Using the scraper, sweep the excess ash (2)

through the ash removal port into the ashtray

underneath.

4. Close the ash removal port.

5. Remove the ashtray (3) using the glove provided

andempty the ashtray.

6. Install the ashtray and close the appliance door.

Comment: The Vintage30 has no ashtray. Remove

the ash with the aid of a spoon oruse an "ash clean

system" on the vacuum cleaner.

Fog and mist

Fog and mist hinder the ventingof smoke gases

through the flue. Smoke can precipitate andcause a

stench. If it is not strictly necessary, it is better not to

use the stove with fog andmist.

problems

Refer to the appendix "Diagnostic diagram" to

solve any problems in using the appliance.

If the appliance does not give off enough heat:

Refer to the appendix "Diagnostic diagram" and

also check whether you are burning enough fuel.

Use

Subjectto change because of technicalimprovements

15

Page 17

Maintenance

Maintenance

Follow the maintenance instructions in this chapter to

keep the appliance in good condition.

Chimney

In many countries, people are legally required to have

their chimney checked and maintained.

At the beginning of the heating season: have the

chimney swept by an expert.

Duringthe heating season and after the chimney

has not been used for a long time: have the

chimney checked for soot deposits.

After the heating season: seal off the chimney with

a ball of paper.

Cleaning and other regular

maintenance activities

Do not clean the appliance when it is still

warm.

Clean the exterior of the appliance with a dry lintfree cloth.

At the end of the heatingseason, you can cleanthe

interior of the appliance thoroughly:

If necessary, first remove the fire-resistant inner

plates. See the chapter "Installation" for

instructions on removing and installing the inner

plates.

If necessary, cleanthe airsupply channels.

Remove the top plate to this end. The top plate lies

loosely on the appliance.

If required, remove the baffle plate at the top of the

appliance and clean it.

Checking fire-resistant inner plates

The fire-resistant inner plates are consumables and

subject to wear . Check the fire-resistant inner plates

frequently and replace them whennecessary.

See the chapter "Installation" for instructions on

removing andinstalling the inner plates.

The insulating vermiculite inner plates may

develop hairline cracks, but that does not

affect their performance adversely.

Cast-iron inner plates go a long way if you

frequently remove the ash that may pile up

behind it. If accumulated ash behind a cast-iron

plate is not removed, the plate cannot dissipate

the heat anymore to its surroundings andthat

may cause the plate to warp or crack.

Never use the appliance without the fireresistant inner plates.

Cleaning glass

Dirt clings less easily to well cleanedglass. Proceed

as follows:

1. Remove dust and loose soot with a moist cloth.

2. Clean the glass with stove window cleaner:

a. Apply stove window cleaner to a kitchen

sponge, rub down the entire glass surface and

expose it to the cleaningagent.

b. Remove the dirt with a moist cloth or kitchen

tissue.

3. Clean the glass again with a normal glass cleaning

product.

4. Rub the glass cleanwith a dry cloth or kitchen

tissue.

Do not use abrasive or aggressive products to

clean the glass.

Wear household gloves to protect your hands.

If the glass in the appliance is broken or

cracked, it must be replacedbefore you can

use the appliance again.

Make sure that no stove window cleaner runs

between the glass and the cast-iron door.

Maintaining enamelled fire

Never clean the appliance whenit is still hot. The

enamelled surface of the fire can becleaned most

effectively with a mild green soap and lukewarm

water. Use as little water as possible, rubthe surface

dry andprevent the formation of rust. Wire wool or

otherabrasives should never be used. Never place a

kettle directly onto an enamelledfire; use a stand and

prevent damage from occurring.

16

Subjectto change because of technicalimprovements

Page 18

Lubrication

Although cast-iron is slight self-lubricating, you will

still have to lubricate moving parts frequently.

Lubricate the moving parts (such as hinge pins,

latches and air slides) with heat resistant grease

that is available in the specialist trade.

Re-adjusting the door lock

1. Loosenthe hexagon nut (1)slightly.

2. Screw the locking cam (2) in or out with the help of

a screwdriver.

3. Re-tighten the locking nut.

Readjusting the hinge

1. Loosenthe screws (2) and (3)slightly.

2. Screw setscrew (1) in if the doormust be raised

andout if the door must be lowered.

3. Retighten the screws (2) and (3) firmly.

Removing the glass pane

1. Loosenthe 2xM5 nuts on the top only.

2. Tilt the pane forwards and lift the pane out of the

bottom fixing lips.

Beforereplacing:

1. Place the glass pane together with the two glass

fixings.

2. Tighten the 2xM5 nuts.

Maintenance

Subjectto change because of technicalimprovements

17

Page 19

Maintenance

Touching up the finish

Small areas of damaged paint finish can be touched

up with a spraying can of special heat-resistant paint

finish availablefrom your supplier.

Areas of damagedenamel can betouched up with a

special heat-resistant paint finish that is available

from your supplier.

Checking the seal

Check whether the sealing ropeof the door is still

in good conditionand works well. The sealing rope

is subject to wear and needs to be replacedin time.

Check the appliance for air leaks. Close any

chinks with stove sealant.

Let the sealant harden fully beforeyou start a

fire in the appliance, because otherwise any

moisture in the sealant will evaporate in

bubbles and cause a new air leak.

Vintage 50 spare parts

Pos. Description Description Quantity

1 03.77393.000 left-hand side inner

plate

1

2 03.77394.000 right-hand side inner

plate

1

3 03.77395.000 baffle plate 1

4 03.66534.000 centre bottom of the fire

compartment

1

5 03.77405.000 bottom fire basket 1

6 03.77406.000 top fire basket 1

7 03.77396.000 left-hand rear inner plate 1

8 03.77392.000 centre rear inner plate 1

9 03.77397.000 right-hand rear inner

plate

1

10 03.56328.000 left-hand bottom of the

fire compartment

1

11 03.56329.000 rear bottom of the fire

compartment

1

12 03.56327.000 right-hand bottom of the

fire compartment

1

13 03.05407.000 ash removal port 1

18

Subjectto change because of technicalimprovements

Page 20

Vintage 35 spare parts

Pos. Description Description Quantity

1 03.77393.000 Left-hand side inner plate 1

2 03.77394.000 right-hand side inner

plate

1

3 03.77500.000 baffle plate 1

4 03.66534.000 centre bottom of the fire

compartment

1

5 03.77410.000 bottom fire basket 1

6 03.77408.000 top fire basket 1

7 03.77501.000 left-hand rear inner plate 1

8 03.77399.000 centre rearinner plate 1

9 03.77502.000 right-hand rear inner plate 1

10 03.56330.000 left-hand bottom of the

fire compartment

1

11 03.56329.000 rear bottom of the fire

compartment

1

12 03.56331.000 right-handbottom of the

fire compartment

1

13 03.05407.000 ash removal port 1

Vintage 30 spare parts

Pos. Description Description Quantity

1 03.77393.000 Left-hand side inner

plate

1

2 03.77394.000 right-handside inner

plate

1

3 03.77398.000 baffle plate 1

4 03.66535.000 bottom of the fire

compartment

1

5 03.77409.000 bottom fire basket 1

6 03.77407.000 top fire basket 1

Maintenance

Subjectto change because of technicalimprovements

19

Page 21

Appendix 1: Technical data

Appendix 1: Technical data

Model Vintage 50 Vintage 35 Vintage 30

Nominal output 9 kW 7 kW 5 kW

Flue connection (diameter) 150mm 150mm 150 mm

Weight +/- 155 kg +/- 125 kg +/- 95 kg

Recommended fuel Wood Wood Wood

Fuel property, max. length 50 cm 35 cm 30 cm

Mass flow of flue gases 6.4 g/s 4.9 g/s 4.2 g/s

Flue gas temperature measured in the

measurement section

232 251 244

Temperature measured downstream from the flue

spigot

328 298 305

Minimum draught 12 Pa 12 Pa 12 Pa

CO emission (13%O2) 0,10 % 0,05 % 0,05 %

NOx emission (13% O2) 112mg/Nm³ 84 mg/Nm³ 127 mg/Nm³

CnHm emission (13%O2) 96 mg/Nm³ 82 mg/Nm³ 48 mg/Nm³

Particulate emission 27.1 mg/Nm³

16.4

mg/Nm³

6.0 mg/Nm³

Particulate emission in accordance with NS3058NS3059

4.94 gr/kg 4,99 gr/kg 1.38 gr/kg

Efficiency 84,2 % 83 % 80,4 %

20

Subjectto change because of technicalimprovements

Page 22

Appendix 2: Measurements

Vintage 50

Appendix 2: Measurements

Subjectto change because of technicalimprovements

21

Page 23

Appendix 2: Measurements

Vintage 35

22

Subjectto change because of technicalimprovements

Page 24

Vintage 30

Appendix 2: Measurements

Subjectto change because of technicalimprovements

23

Page 25

Appendix 3: Distance from combustible material

Appendix 3: Distance from combustible material

Vintage 50 - Minimum distances for versions without heat shield:

1. Combustible material

2. Incombustible material, thickness 100mm

Vintage 50 - Minimum distances for versions with heat shield:

Comment: heat shield is available as an option.

1. Combustible material

2. Incombustible material, thickness 100mm

24

Subjectto change because of technicalimprovements

Page 26

Vintage 35 - Minimum distances for versions without heat shield:

1. Combustible material

2. Incombustible material, thickness 100mm

Vintage 35 - Minimum distances for versions with heat shield:

Comment: heat shield is available as an option.

1. Combustible material

2. Incombustible material, thickness 100mm

Appendix 3: Distance from combustible material

Subjectto change because of technicalimprovements

25

Page 27

Appendix 3: Distance from combustible material

Vintage 30 - Minimum distances for versions without heat shield:

1. Combustible material

2. Incombustible material, thickness 100mm

Vintage 30 - Minimum distances for versions with heat shield:

Comment: heat shield is available as an option.

1. Combustible material

2. Incombustible material, thickness 100mm

26

Subjectto change because of technicalimprovements

Page 28

Appendix 4: Diagnostic diagram

Problem

Wood does not keep burning

Gives off insufficient heat

Smoke emissions into the room when adding wood

Fire in appliance is too intense, is hard to adjust

Deposit on the glass

possible cause possible solution

Insufficient draught

A cold flue usuallyfailsto create sufficient draught. Follow the

instructionsfor lightingin the "Usage" chapter; open a window.

Wood too damp Use wood with no more than 20% moisture.

Piecesof wood too big

Use small pieces of kindling.Use split logsno larger than 30 cmin

circumference.

Wood stacked up incorrectly

Stackup the wood in a way that allows an adequate air flow between

the logs(open stacking, see "Burning wood")

Chimney does not work properly

Check whether the chimneymeets the requirements: at least 4

metres high, right diameter, wellinsulated, smooth inside,not too

many bends, no obstructions in chimney(bird's nest, too much soot

deposit), hermetically tight (no chinks)

Chimney stack incorrect Sufficiently high above the roof, no obstacles in itsvicinity

Air inlets setincorrectly Openthe air inlets completely.

Applianceconnected to chimney

incorrectly

Connection should be hermeticallytight.

Vacuum in area where appliance is

installed

Switch off extraction systems.

Insufficient supplyof fresh air

Provide an adequate air supply,if necessary useconnection to

outside air.

Adverse weather conditions?

Inversion (reversed air flow in chimney

because of a high outside temperature),

extreme wind velocities

We recommend youdon't use the appliance in the case of inversion.

Installan extra hood on the flue to increase the draught if need be.

Draught inthe living room

Avoiddraught inthe living room, do not place the appliance near a

door, or heating air channels.

Flames touchthe glass

Make sure the wood doesnot lietoo close to the glass. Slide the

primary air inlet cover closer to the "Closed" position.

Applianceisleaking air Check the door seals and the device chinks.

Appendix 4: Diagnostic diagram

Subjectto change because of technicalimprovements

27

Page 29

Index

Index

A

Adding fuel 14

Adding wood

smoke emissions into the room 27

Air control 14

Air inlets 12

Air leak 18

Air supply for fire 14

Ash removal port 15

Ashes

remove 14

Ashtray

open 15

B

Burning wood 13

addfuel 14

adding logs 13

appliance is hardto adjust 27

fire is too intense 27

insufficient heat 15, 27

C

Carpet 6

Cast iron inner plates 7

Chimney

height 5

prepare connection 9

sweep 16

Chinks in appliance 18

Clean

glass 16

Cleaning

appliance 16

Combustible material

distance from 24

Connection

measurements 21

Connection collar for connection to chimney 9

Connection to chimney 9

at top 9

top 9

Connection to supply of outside air 10

Control air supply 14

Control of air 14

Cover on flue 5

Creosote 14

D

Damage 7

Damp wood 12

Door

open 7

sealingrope 18

Draught 20

Drying of wood 12

E

Efficiency 20

F

Filling height 14

Fire

extinguishing 14

lighting 12

Fire going out 14

Fire safety

distance from combustible material 24

floor 6

furniture 6

walls 6

Fire-resistant inner plates

maintenance 16

remove 7

warning 11

Floors

fire safety 6

loadbearing capacity 6

Flue

connection diameter 20

connection to 11

maintenance 16

requirements 5

Flue gas

mass flow 20

28

Subjectto change because of technicalimprovements

Page 30

Subjectto change because of technicalimprovements

29

Index

temperature 20

Fog, do not burn wood 15

Foot

cover 10

Fuel

adding 14

adding wood 14

necessary amount 15

suitable 12

unsuitable 12

G

Glass

clean 16

deposit 27

H

Heat

insufficient 27

Heat, insufficient 15

Hood onthe flue 5

I

Innerplates, fire-resistant

remove 7

Installation

measurements 21

K

Kindled fire 12

Kindling 27

L

Lighting 12

Load bearing capacity of floor 6

Lubricant 17

Lubricate 17

M

Maintenance

chimney 16

clean glass 16

cleaning the appliance 16

fire-resistant inner plates 16

lubrication 17

seal 18

Measurements 21

Mist, do not burn wood 15

N

Nominal output 15, 20

O

Open

ash removal port 15

ashtray 15

door 7

P

Paint finish 12

Particulate emission 20

Parts, removable 7

Prevent a chimney fire 14

Primary air inlet 12

R

Removable parts 7

Removal of ashes 14

Remove

fire-resistant inner plates 7

Remove ashes 14

S

Scraper for ash removal 15

Screens

clean 16

deposit 27

Sealing ropefor door 18

Secondary air inlet 12

Smoke

on first use 12

Smoke emissions into the room 5, 27

Softwood 12

Solving problems 15, 27

Page 31

Index

Stacking logs 13

Storingwood 12

Stove window cleaner 16

Suitable fuel 12

Supply of outside air 6, 10

connection to 11

Sweep chimney 16

T

Tar 14

Temperature 20

U

Unsuitable fuel 12

V

Ventilation 6

connect supply of outside air 10

ruleof thumb 6

Ventilationlouvre 6

Vermiculite inner plates 7

W

Walls

fire safety 6

Warning

chimney fire 4, 12, 14

combustible materials 4

fire-resistant inner plates 11

glass broken or cracked 4, 16

hot surface 4

regulations 4

stove window cleaner 16

terms and conditions for insurance 5

ventilation 4, 6

Weatherconditions, do not burn wood 15

Weight 20

Wood 12

damp 12

does not keepburning 27

drying 12

right sort 12

storing 12

30

Subjectto change because of technicalimprovements

Page 32

Loading...

Loading...