Page 1

INSTALLATIEVOORSCHRIFTEN EN GEBRUIKSAANWIJZING

KACHEL

INSTALLATION INSTRUCTIONS AND OPERATING MANUAL

STOVE

INSTALLATION ET MODE D’EMPLOI

POELE

EINBAUANLEITUNG UND GEBRAUCHSANWEISUNG

FEUERSTÄTTE

INSTRUCCIONES DE INSTALACIÓN Y USO

ESTUFA

ISTRUZIONI PER L'INSTALLAZIONE E L'USO

STUFA

MONTERINGS- OG BRUKSANVISNING

ILDSTED

03.27148.000 - 09/2014

TAI 45M, TAI 45C

Page 2

Table of contents

Introduction 3

Performance declaration TAI 45M 4

Performance declaration TAI 45C 6

Performance declaration TAI 55M 8

Performance declaration TAI 55C 10

Safety 12

Installation requirements 12

General 12

Flue 12

Room ventilation 13

Floorand walls 13

Product description 14

Installation 15

Preparation 15

Preparing the connection to the flue 15

Installing and connecting 15

Use 16

First use 16

Fuel 16

Lighting 17

Burning wood (TAI M) 17

Burning brown coal briquettes (TAI M) 18

Burning anthracite coal (TAI M and TAI C) 18

Heating recommendations 19

Extinguishingthe fire 19

Removing ash 20

Fog and mist 20

Resolving problems 20

Maintenance 20

Flue 20

Cleaning and other regularly maintenance 21

Appendix 1: Technical data 23

Appendix 2: Dimensions 25

Appendix 3: Distance from combustible

material 27

Appendix 4: Diagnosis diagram 29

Index 30

2

Subjectto change because of technicalimprovements

Page 3

Introduction

Dear user,

By purchasingthis heating appliance from DOVRE

you have selected a quality product. This product is

part of a new generation of energy-efficient and environmentally-friendly heating appliances. These appliances make optimum use of convection heat as well

as thermal radiation (radiant heat).

Your DOVRE appliance has beenmanufactured

with state-of-the-art production equipment. In the

unlikely event of a malfunction, you can always

rely on DOVRE for support and service.

The appliance should not be modified; please

always use original parts.

The appliance is intended for use in a living room. It

must be hermetically connected to a properly working flue.

We advise you have the appliance installed by an

authorized and competent installer.

DOVRE cannot be heldliable for any problems or

damage resulting from incorrect installation.

Observe the following safety regulations when

installing and using the appliance.

In this manual, you can read how the DOVRE heating

appliance can beinstalled, used andmaintained

safely. Should you requireadditional information or

technical data, or should you experience an installation problem, please first contact your supplier.

© 2014 DOVRE NV

Subjectto change because of technicalimprovements

3

Page 4

Performance declaration TAI 45M

In accordance with construction products regulation 305/2011

No. 035-CPR-2014

1. Unique identification code of the product type:

TAI 45M

2. Type, batch or serial number or other form of identification of the construction product, as determined in article 11, subsection 4:

Uniqueserial number.

3. Intended use of the construction product in accordance with the applicable harmonised technical

specification, as specified by the manufacturer:

Stove for solid fuel without hot water supply in accordance with EN 13240.

4. Name, registered trade name or registered trademark and contact address of the producer, as prescribed in article 11, subsection 5:

Dovre N.V. Nijverheidsstraat 18 2381Weelde Belgium.

5. If applicable, name and contact address of the authorised party whose mandate covers the tasks specified in article 12, subsection 2:

-

6. The system or systems for the assessment and verification of the performance durability of the construction product, specified in appendix V:

System 3

7. If the performance declaration refers to a construction product that falls under a harmonised standard:

The appointed agency ARGB/KVBG, registered under the number 2013, has performed a type test under system 3 and has issued the test report no. H20140033.

8. If the performance declaration concerns a construction product for which a European technical

assessment is issued:

-

4

Subjectto change because of technicalimprovements

Page 5

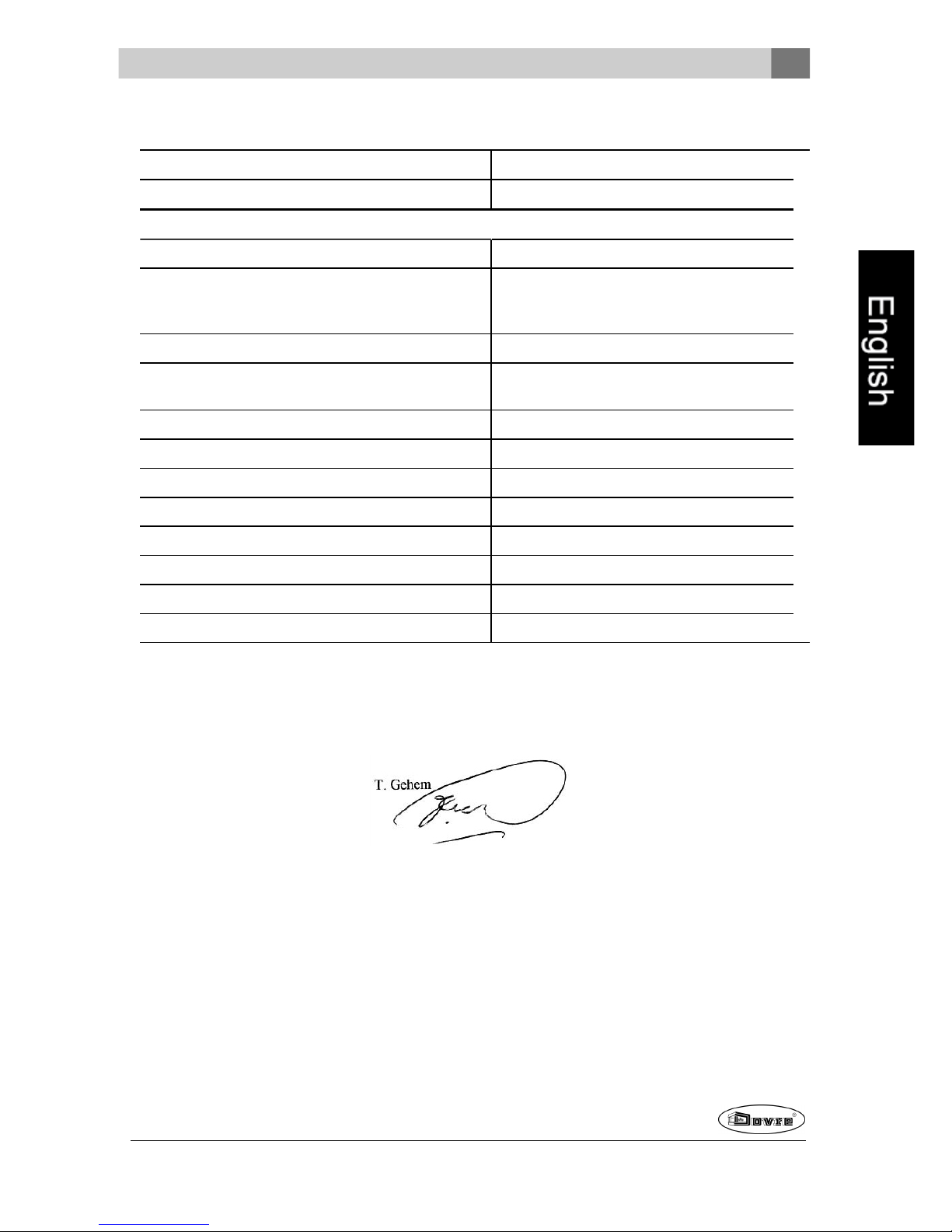

9. Declared performance:

The harmonised norm EN 13240 :2001/A2 :2004/AC :2007

Essential characteristics Wood | Coal | Brown coal

Fire safety

Fire resistance A1

Distance from combustible material

Minimum distance in mm

Rear: 300

Side: 450

Risk of glowing particles falling out Conform

Emission of combustion products

CO: 0.09% (13%O2) | CO: 0.08% (13%O2)|

CO: 0.07% (13%O2)

Surface temperature Conform

Electrical safety -

Ease of cleaning Conform

Maximum operating pressure -

Flue gas temperature at nominal output 273°C | 282°C |286°C

Mechanical resistance (carrying weight of chimney) Not determined

Nominal output 9 kW

Efficiency 75.3% | 79.5% | 75%

10. The performance of the product described in points 1 and 2 conform with the performance reported

in point 9.

This performance declaration is supplied under the exclusive responsibility of the producer specified

in point 4:

01/09/2014 Weelde

Tom Gehem

CEO

Due to continuous product improvement, the supplied appliance specifications may vary from the descriptionin

this brochure without prior notice having beengiven.

DOVRE N.V.

Nijverheidsstraat 18 Tel : +32 (0) 1465 91 91

B-2381 Weelde Fax : +32 (0) 14 65 90 09

Belgium E-mail : info@dovre.be

Subjectto change because of technicalimprovements

5

Page 6

Performance declaration TAI 45C

In accordance with construction products regulation 305/2011

No. 036-CPR-2014

1. Unique identification code of the product type:

TAI 45C

2. Type, batch or serial number or other form of identification of the construction product, as determined in article 11, subsection 4:

Uniqueserial number.

3. Intended use of the construction product in accordance with the applicable harmonised technical

specification, as specified by the manufacturer:

Stove for solid fuel without hot water supply in accordance with EN 13240.

4. Name, registered trade name or registered trademark and contact address of the producer, as prescribed in article 11, subsection 5:

Dovre N.V. Nijverheidsstraat 18 2381Weelde Belgium.

5. If applicable, name and contact address of the authorised party whose mandate covers the tasks specified in article 12, subsection 2:

-

6. The system or systems for the assessment and verification of the performance durability of the construction product, specified in appendix V:

System 3

7. If the performance declaration refers to a construction product that falls under a harmonised standard:

The appointed agency ARGB/KVBG, registered under the number 2013, has performed a type test under system 3 and has issued the test report no. H20140033.

8. If the performance declaration concerns a construction product for which a European technical

assessment is issued:

-

6

Subjectto change because of technicalimprovements

Page 7

9. Declared performance:

The harmonised norm EN 13240 :2001/A2 :2004/AC :2007

Essential characteristics Coal Performance

Fire safety

Fire resistance A1

Distance from combustible material

Minimum distance in mm

Rear: 400 with insulation

Side: 450with insulation

Risk of glowing particles falling out Conform

Emission of combustion products CO: 0.08% (13%O2)

Surface temperature Conform

Electrical safety -

Ease of cleaning Conform

Maximum operating pressure -

Flue gas temperature at nominal output 282 °C

Mechanical resistance (carrying weight of chimney) Not determined

Nominal output 9 kW

Efficiency 79.5%

10. The performance of the product described in points 1 and 2 conform with the performance reported

in point 9.

This performance declaration is supplied under the exclusive responsibility of the producer specified

in point 4:

01/09/2014 Weelde

Tom Gehem

CEO

Due to continuous product improvement, the specifications of the appliance supplied can vary from the description in this brochure without prior notice.

DOVRE N.V.

Nijverheidsstraat 18 Tel : +32 (0) 1465 91 91

B-2381 Weelde Fax : +32 (0) 14 65 90 09

Belgium E-mail : info@dovre.be

Subjectto change because of technicalimprovements

7

Page 8

Performance declaration TAI 55M

In accordance with construction products regulation

305/2011

1.

Unique identification code of the product

type:

2. Type, batch or serial number or other form of identification of the construction product, as determined in article 11, subsection 4:

Uniqueserial number.

3. Intended use of the construction product in accordance with the applicable harmonised technical

specification, as specified by the manufacturer:

Stove for solid fuel without hot water supply in accordance with EN 13240.

4. Name, registered trade name or registered trademark and contact address of the producer, as prescribed in article 11, subsection 5:

Dovre N.V. Nijverheidsstraat 18 2381Weelde Belgium.

5. If applicable, name and contact address of the authorised party whose mandate covers the tasks specified in article 12, subsection 2:

-

6. The system or systems for the assessment and verification of the performance durability of the construction product, specified in appendix V:

System 3

7. If the performance declaration refers to a construction product that falls under a harmonised standard:

The appointed agency ARGB/KVBG, registered under the number 2013, has performed a type test under

sys-tem 3 and has issued the test report no.

8. If the performance declaration concerns a construction product for which a European technical

assessment is issued:

-

8

Subjectto change because of technicalimprovements

Page 9

9. Declared performance:

The harmonised norm

Essential characteristics

Fire safety

Fire resistance A1

Distance from combustible material

Minimum distance in mm

Rear:

Side:

Risk of glowing particles falling out Conform

Emission of combustion products

CO: % (13%O2)

Surface temperature Conform

Electrical safety -

Ease of cleaning Conform

Maximum operating pressure -

Flue gas temperature at nominal output

°C

Mechanical resistance (carrying weight of chimney) Not determined

Nominal output X kW

Efficiency

%

10. The performance of the product described in points 1 and 2 conform with the performance reported

in point 9.

This performance declaration is supplied under the exclusive responsibility of the producer specified

in point 4:

01/09/2014 Weelde

Tom Gehem

CEO

Due to continuous product improvement, the supplied appliance specifications may vary from the descriptionin

this brochure without prior notice having beengiven.

DOVRE N.V.

Nijverheidsstraat 18 Tel : +32 (0) 1465 91 91

B-2381 Weelde Fax : +32 (0) 14 65 90 09

Belgium E-mail : info@dovre.be

Subjectto change because of technicalimprovements

9

Page 10

Performance declaration TAI 55C

In accordance with construction products regulation

1.

Unique identification code of the product

type:

2. Type, batch or serial number or other form of identification of the construction product, as determined in article 11, subsection 4:

Uniqueserial number.

3. Intended use of the construction product in accordance with the applicable harmonised technical

specification, as specified by the manufacturer:

Stove for solid fuel without hot water supply in accordance with EN 13240.

4. Name, registered trade name or registered trademark and contact address of the producer, as prescribed in article 11, subsection 5:

Dovre N.V. Nijverheidsstraat 18 2381Weelde Belgium.

5. If applicable, name and contact address of the authorised party whose mandate covers the tasks specified in article 12, subsection 2:

-

6. The system or systems for the assessment and verification of the performance durability of the construction product, specified in appendix V:

System 3

7. If the performance declaration refers to a construction product that falls under a harmonised standard:

The appointed agency ARGB/KVBG, registered under the number 2013, has performed a type test under

sys-tem 3 and has issued the test report

8. If the performance declaration concerns a construction product for which a European technical

assessment is issued:

-

10

Subjectto change because of technicalimprovements

Page 11

9. Declared performance:

The harmonised norm

Essential characteristics

Fire safety

Fire resistance A1

Distance from combustible material

Minimum distance in mm

Rear:

Side:

Risk of glowing particles falling out Conform

Emission of combustion products

CO: % (13%O2)

Surface temperature Conform

Electrical safety -

Ease of cleaning Conform

Maximum operating pressure -

Flue gas temperature at nominal output

°C

Mechanical resistance (carrying weight of chimney) Not determined

Nominal output X kW

Efficiency

%

10. The performance of the product described in points 1 and 2 conform with the performance reported

in point 9.

This performance declaration is supplied under the exclusive responsibility of the producer specified

in point 4:

01/09/2014 Weelde

Tom Gehem

CEO

Due to continuous product improvement, the supplied appliance specifications may vary from the descriptionin

this brochure without prior notice having beengiven.

DOVRE N.V.

Nijverheidsstraat 18 Tel : +32 (0) 1465 91 91

B-2381 Weelde Fax : +32 (0) 14 65 90 09

Belgium E-mail : info@dovre.be

Subjectto change because of technicalimprovements

11

Page 12

Safety

Please note: All safety regulations must be

compliedwith strictly.

Please read carefully the instructions supplied

with the appliance for installation, use and

maintenance before using the appliance.

The appliance must be installed in accordance

with the legislation andrequirements applicablein yourcountry.

All local regulations and the regulations relating

to national and European standards must be

observed when installing the appliance.

The appliance should preferably be installed by

an authorisedinstaller. Installers will be aware

of the applicable regulations and requirements.

The appliance is designed for heating purposes. All surfaces, including the glass and

connecting tube, can become very hot (over

100°C)! When operating, use a so-called "cold

hand" or an oven glove.

Ensurethat there is adequate screening if

youngchildren, disabled people, the elderly or

animals are present in the vicinity of the appliance.

Safety distances from flammable materials

must be strictly adhered to.

Do not place any curtains, clothes, laundry or

othercombustible materials on or near the appliance.

When in use, do not use flammable orexplosive substances in the vicinity of the appliance.

Avoid chimney fires by having the chimney

swept regularly. Never burnwoodwith the door

open.

In the event of a chimney fire: close all the

appliance's air inlets and alert the fire service.

If the glass in the appliance is broken or

cracked, it must be replacedbefore you can

use the appliance again.

Ensurethat there is adequate ventilation in the

room in which the appliance is installed. If ventilation is insufficient, combustion will be

incomplete whereby in toxic gases can spread

through the room. See the chapter "Installation

requirements" for more information onventilation.

Installation

requirements

General

The appliance must be connected tightly to a wellfunctioning flue.

For connection measurements: see "Technical

data" appendix.

Ask the fire service and/or yourinsurance company about any specific requirements and regulations.

Flue

The flue is needed for:

Removal of combustion gases via natural draught.

As the warm airin the flue orchimney is lighter

than the outside air, it rises.

Air intake, needed for the combustion of fuel in the

appliance.

A poorly-functioning flue or chimney can cause smoke

to escape into the room when the door is opened.

Damage caused by smoke emissions into the room is

not covered by the warranty.

Do not connect multiple appliances (such as a

boiler for central heating) to the same flue,

unless local or national regulations allow this.

In the event of two connections ensurethat the

difference in height between the connections is

no less than 200 mm.

Ask your installer for advice regardingthe flue. Refer

to the Europeannorm EN13384 for a correct calculations for the flue.

The flue must satisfy the followingrequirements:

The flue or chimney must be made of fire-resistant

material, preferably ceramics or stainless steel.

12

Subjectto change because of technicalimprovements

Page 13

The flue or chimney must be airtight andwellcleaned andguarantee sufficient draught.

A draught/vacuum of 15 - 20Pa duringnormal

operationis ideal.

Starting from the flue spigot, the flue must run as

vertically as possible. Changes in direction and

horizontal pieces disrupt the outward flow of combustion gases and may cause soot deposits.

To prevent combustion gases from cooling down

too much, which reduces the draught, ensurethat

the interior diameter is not too big.

The flue or chimney should ideally have the same

diameter as the connection collar.

For nominal diameter: see "Technical data"

appendix. If the smoke channel is well insulated, the diameter may be slightly bigger (up to

2x the section of the connection collar).

The section (area) of the smoke channel must be

constant. Wider segments and (in particular)narrowersegments disrupt the outward flow of combustion gases.

In fitting a cover plate/exhaust cap to the flue:

make sure that the cover does not restrict the flue

outlet and that the cap does not impede the outward flow of combustion gases.

The flue must end in a zone that is not affected by

surrounding buildings, trees or other obstacles.

The flue outside the house must be insulated.

The flue should be at least 4 metres high.

As a rule of thumb: 60 cm above the ridge of the

roof.

If the ridge of the roof is more than 3 metres from

the flue: use the measurements given in the following figure. A = the highest point of the roof

within a distance of 3 metres.

Room ventilation

For good combustion, the appliance needs air (oxygen). This air is supplied via adjustable air inlets from

the area in which the appliance is installed.

If ventilationis insufficient, combustion will be

incomplete, which may lead toxic gases to

spread through the room.

As a rule of thumb, the air supply should be

5.5cm²/kW. Extra ventilation is needed when:

The appliance is in a well-insulated area.

There is mechanical ventilation, for example, a

central extraction system or an extraction hood in

an open kitchen.

You can provide extra ventilation by having a ventilation louvre fitted onthe outside wall.

Make sure that otherair consumingappliances (such

as tumble-driers, other heating appliances or a bathroom fan) have their own supply of outside air, or are

switched off when you use the appliance.

Floor and walls

The floor on which the appliance is placed must have

sufficient bearing capacity. The weight of the appliance is given in the appendix “Technical Data

appendix”.

Protect flammableflooring from heat radiation

by means of a fireproof protective plate. See

the appendix "Distance from combustible

material".

Subjectto change because of technicalimprovements

13

Page 14

Remove combustible material such as linoleum, carpets/rugs and similar materials below

the fireproof protective plate.

Keep sufficient distance between the appliance and combustible materials such as

wooden walls and furniture.

The connecting tubealso radiates heat. Ensure

that there is sufficient distance or a shield

between the connecting tube andcombustible

material.

The rule of thumb for a single-walledtubeis a

distance of 3x the diameter. If a lining shell is

fitted around the tube, a distance of 1x the diameter is permissible.

Carpets and rugs must be at least 80 cm away

from the fire.

Use a fireproof floorplate to protect a flammablefloorfrom any ash which may fall in front

of the stove. Thefloorplate must comply with

national standards.

For the dimensions of the fireproof protective

plate: see the appendix "Distance from combustible material".

For further requirements with respect to fire

safety, see the appendix "Distance from combustible material".

Product description

This manual describes the multi-fuel appliance

TAI M and the coal appliance TAI C.

1

2

5

3

6

7

4

8

9

10

11

12

13

09-20020-357

1. Filling lid

2. Secondary air slide

3. Door

4. Door bolt

5. Side filling door (TAI M only)

6. Side filling door bolt (TAI M only)

7. Riddling grate bar(TAI M only)

8. Fire basket

9. Ash pan door

10. Ash pan door bolt

11. Flue gas connection

12. Primary air slide / Thermostat

13. Fuel choice selector

14

Subjectto change because of technicalimprovements

Page 15

Appliance features

The TAI M appliance can be usedto burn wood,

coal (anthracite) and brown coal briquettes. The

appliance comes with a side filling door.

The TAI C appliance can be used to burn coal

(anthracite) for continuous use. The appliance is

equipped with a coal bunker as standard.

The appliance can be connected to the chimney at

the rear.

The appliance comes with a “cold hand” to manipulate the riddlinggrate (TAI M), to open the filling lid

andto remove the ash pan.

The multi-fuel appliance (TAI M) is equipped with a

separate door for adding the fuel, the ‘side filling

door’.

The coal bunker can easily be removed via the

filling lid.

The TAI M appliance is equipped with a riddling

grate.

The TAI C appliance is equipped with a fixed burning grate.

The appliance has two access ports for ash

removal.

The appliance is equipped with an adjustable thermostat.

The appliance is equipped with chamotte or refractory stone interior cladding.

Installation

Preparation

Please check the appliance immediately after delivery for damage duringtransport or any other damageor defects. Theappliance is attached to the

pallet with screws at the bottom.

If you detect transport damageor any other

damage ordefects, do not use the appliance

andnotify the supplier.

Remove the removableparts (fire-resistant inner

plates, ash pan, grates, bunkerand filling lid) from

the appliance before installing the appliance.

By removing removable parts, it is easier to

move the appliance and to avoid damage.

Note the location of the removable parts, so

that you can re-position the parts in the correct

place lateron.

Chamotte inner plates are ochrous on delivery.

They insulate the combustion chamber to

improve the combustion, and they can withstand burninganthracite.

Preparing the connection to

the flue

You can connect the appliance to the chimney at the

rear.

Installing and connecting

1. Position the appliance in the correct place, and

make sure it is level.

2. Connect the appliance to the flue hermetically.

3. Re-position all removed parts in the correct places

in the appliance.

Never use the appliance without the fire-resistant inner plates.

If it is found that there is inadequate draw, the

recuperator plate at the back of the appliance

can be moved to reduce the dampening. See

next figure.

Subjectto change because of technicalimprovements

15

Page 16

2 1

2 1

09-20020-360

Position 1: factory setting for a standard hearth.

Position 2: the setting for a hearth with less draw.

The appliance is now ready for use.

Use

First use

When you use the appliance for the first time, make

an intense fire and keep it going for a good few hours.

This will cure the heat-resistant paint finish. This may

result in some smoke andodours. You could open windows and doors for a while in the area in which the

appliance is located.

Fuel

Appliance TAI M can be used to burn brown coal briquettes, anthracite coal andnatural wood; sawn and

split and adequately dry.

Appliance TAI C is only suitable for burning anthracite

coal.

Do not use other fuels, as they can cause serious

damage to the appliance.

The following fuels may not be used as they pollute

the environment, and because they heavily pollute the

appliance and flue, which may leadto a chimney fire:

Treated wood, such as scrapwood, painted wood,

impregnated wood, preserved wood, plywood and

chipboard.

Plastics, scrap paperand domestic waste.

Wood

Hardwood, such as oak, beech, birch andfruit tree

wood is the ideal fuel for yourstove. This type of

wood burns slowly with calm flames. Softwood

contains more resins, burns faster and sparks

more.

Use seasoned woodthat contains no more than

20% moisture. The wood should have been

seasoned for at least 2 years.

Saw the wood to size andsplit it while it is still

fresh. Fresh wood is easier to split, andsplit wood

dries more easily. Store the woodundera roof

wherethe wind has freeaccess.

Do not use damp wood. Damp logs donot produce

heat as all the energy is used in the evaporation of

moisture. This will result in a lot of smoke andsoot

deposits on the appliance door and in the flue. The

water vapour will condense in the appliance and

can leak away through chinks in the stove, causing

black stains on the floor. It may also condense in

the chimney and form creosote. Creosote is a

highly flammable compound and may cause a chimney fire.

Brown coal briquettes

Brown coal briquettes have approximately the same

burningcharacteristics as wood.

Ensurethere is a good charcoal bedbeforeyou

start burning brown coal briquettes.

For lighting the fireplace, follow the instructions in

the "Lighting" paragraph.

16

Subjectto change because of technicalimprovements

Page 17

Anthracite coal

Anthracite coal is divided into various categories on

the basis of characteristics, sometimes specified by

law, such as the percentageof volatile compounds.

The ash content of anthracite coal is between 3% and

13%. The lowerthe ash content, the higher the net

heating value and the less often you have to remove

ash.

Preferably use category A anthracite coal with a

low ash content.

Use the recommended size 12/22 or20/30.

For lighting the fireplace, follow the instructions in

the "Lighting" paragraph.

Lighting

You can check whether the flue has sufficient draught

by lighting a ball of paperabove the baffle plate. A cold

flue often has insufficient draught andconsequently,

some smoke may escape into the room instead of up

the chimney. You can avoidthis problem by lighting

the fire as described below.

1. Stack two layers of medium sized logs crosswise.

2. Stack two layers of kindling crosswise on top of

the logs.

3. Place a firelightercubein the lowerlayer of kindling and light the cube according to the instructions

on the packaging.

4. Close the door of the appliance and open the

primary and secondary air inlets by completely

openingthe primary andsecondary air sliders; see

the following figure. If there is inadequate draw,

the ash pan can be set at a small tilt for some

time.

5. Let the fire develop into a good blaze until there is

glowingbed of charcoal. After this, you can add

morefuel and adjust the appliance; see the sections on "Burning wood", "Burning brown coal briquettes (forTAI M only)" and"Burning anthracite

coals (for TAI M and TAI C)" .

09-20020-355

o

= Open l = Closed

Burning wood (TAI M)

After you have followed the instructions for lighting:

1. Slowly open the door of the appliance.

2. Spread the charcoal evenly across the bottom of

the stove base.

3. Stack a few logs on the charcoal.

Subjectto change because of technicalimprovements

17

Page 18

Open stacking

If the logs are stacked openly, the wood will burn

quickly as the oxygen can reach each log easily. If

you want to use the stove for a short while, make an

open stack.

Compact stacking

If the logs are stacked tightly, the wood will burnmore

slowly as the oxygen can only reach some logs easily. If you want to burn wood for a longer period, make

a compact stack.

4. Close the door of the appliance.

5. Close the primary air inlet and leave the secondary

air inlet open.

Do not fill the appliance by more than a third.

6. To subsequently add fuel, use the filling door of

the appliance.

Burning brown coal

briquettes (TAI M)

Brown coal briquettes burn in almost the same way as

wood. Using the primary air inlet, ensure sufficient

supply of air under the fire. For further information see

the paragraph"Burning wood".

Burning brown coal briquettes creates a lot of ash.

Regularly remove excess ash. See the paragraph

"Removing ashes" for instructions.

For the properties and use of brown coal briquettes: consult your brown coal briquette supplieror see the brown coal briquette packaging.

After you have followed the instructions for lighting:

1. Slowly open the door of the appliance.

2. Spread the charcoal evenly across the bottom of

the stove base.

3. Place the brown coal briquettes onthe charcoal

bed.

4. Close the door.

Burning anthracite coal (TAI

M and TAI C)

When burning anthracite coal, always close

the secondary air slide and close the cover

plate (fuel selection) in the back wall.

Burning coal without bunker

After you have followed the instructions for lighting:

1. Openthe primary air slide completely.

2. Slowly open the door of the appliance.

3. Spread the charcoal evenly across the bottom of

the stove base.

4. Spread a shovelful of coal on the charcoal bed and

wait with the next shovelful until the coals start to

glow.

5. Now add more coal.

18

Subjectto change because of technicalimprovements

Page 19

Be careful not to smother the fire by adding too

much coal at once.

You have added as much as you can when the

glow from the previous loadis only just visible.

6. Close the door.

7. Allow the coal to burn well for a few minutes and

then set the thermostat to the desired position.

If the coal basket begins to glow red, the fire is

burningtoo strongly.

Burning coal with bunker

After you have followed the instructions for lighting:

1. Openthe primary air slide (thermostat) all the way.

2. Slowly open the door of the appliance.

3. Spread the charcoal evenly across the bottom of

the stove base.

4. Close the door.

5. Slowly open the filling panel in the top plate.

09-20020-359

6. Fill the bunker with coal to below the rearmost air

openings in the bunker.

7. Close the filling lid.

8. Allow the coal to burn well for a few minutes and

then set the thermostat to the desired position.

The filling frequency depends on the output

demanded.

To keep the stove burning at night, the thermostat is turned down to around position 1.

The correct position depends on the flue and

the weather conditions.

If the coal basket begins to glow red, the fire is

burningtoo strongly.

Heating recommendations

Never burn wood with an open door.

Regularly burnwoodwith intense roaringfires.

If you burn at a low setting frequently, tar and

creosote may be deposited in the flue. Tar and

creosote are highly combustible substances.

Thicker layers of these substances may catch

fire if the temperature in the flue increases suddenly. By allowing the fire to burn very

intensely regularly, layers of tar and creosote

will disappear.

Low intensity fires can also cause tar deposits

on the stove window anddoor.

When the outside temperatureis mild, it is better to burn wood intensely for a few hours

instead of having a low intensity fire for a long

period of time.

Regulate the air supply usingthe secondary air

inlet (only when burning wood).

The secondary air inlet not only supplies air to

the fire but to the glass as well, so that it does

not quickly become dirty.

Open the primary air inlet for the time being if the air

supply by the secondary air inlet is inadequate orif

you want to fan the fire.

Topping upwith a few logs regularly is better than

adding many logs in one go.

Regularly adding small amounts of brown coal briquettes oranthracite coal is better than addinga

large amount of brown coal briquettes or anthracite

coal in onego.

Extinguishing the fire

Do not add fuel and just let the fire go out. If a fire is

damped down by reducing the air supply, harmful substances will be released. For this reason, the fire

shouldbe allowed to go out naturally. Keep aneye on

Subjectto change because of technicalimprovements

19

Page 20

the fire until it has goneout. All air inlets can be closed

once the fire has died completely.

Removing ash

A relatively largeamount of ash is left over after burning brown coal briquettes and anthracite coal.

Remove the excess ash regularly.

After wood has been burnt, a relatively small amount

of ash remains. This ash bed is a good insulating layer

for the stove base plate and improves combustion. It

is a good idea to leave a thin layer of ash onthe stove

base plate.

The flow of air through the fire plate must not be

obstructed, however, and no ash may be allowed to

accumulate behind a cast-iron inner plate. Remove

the excess ash regularly.

The ash should never reach the bottom of the grate.

This will cause the grate to overheat andbe damaged.

1. Use the “cold hand”provided to manipulate the riddling grate (TAI M).

2. Openthe ash door.

3. Use the pokerprovided to break up the ashes

through the access openings above the grate.

09-20020-352

4. Remove the ash panusing the "cold hand"

provided and empty the ash pan; see next figure.

09-20020-353

5. Install the ash pan and close the ash door of the

appliance.

Fog and mist

Fog and mist hinder the flow of flue gases throughthe

flue. Smoke can blow back and cause a stench. If it is

not strictly necessary, it is better not to use the stove

in foggy andmisty weather.

Resolving problems

Refer to the appendix "Diagnostic diagram" to resolve

any problems in using the appliance.

Maintenance

Follow the maintenance instructions in this chapter to

keep the appliance in good condition.

Flue

In many countries, you are required by law to have

your chimney checked and maintained.

At the start of the heatingseason: have the chimney swept by a recognisedchimney sweep.

Duringthe heating season and after the chimney

has not been used for a long time: have the chimney checked for soot.

20

Subjectto change because of technicalimprovements

Page 21

At the end of the heatingseason: close off the chimney andplug with newspaper.

Cleaning and other regularly

maintenance

Do not clean the appliance whenit is still

warm.

Clean the exterior of the appliance with a dry lintfree cloth.

You can cleanthe insideof the appliance thoroughly

at the end of the heating season:

Remove the filling lid and the coal bunker.

If necessary, first remove the fire-resistant inner

plates.

If necessary, clean the air supply ducts.

Remove the recuperator at the top of the appliance

andcleanit. See the chapter on "Installation" for

instructions on removing and installing the recuperator.

Checking fire-resistant inner plates

The fire-resistant inner plates areconsumables that

aresubject to wear andtear. Vermiculite innerplates

arefragile. Do not knock the inner plates with logs.

Check the fire-resistant inner plates frequently and

replace them when necessary.

See the chapter "Installation" for instructions on

removing andinstalling the inner plates.

The refractory inner plates may begin to show

hairline cracks, but this does not negatively

affect their functioning.

Never use the appliance without the fire-resistant inner plates.

Cleaning the glass

Dirt clings less easily to well-cleaned glass. Proceed

as follows:

1. Remove dust and loose soot with a dry cloth.

2. Clean the glass with stove glass cleaner:

a. Apply stove glass cleanerto a kitchen sponge,

rubdown the entireglass surface and give the

cleaning agent time to react.

b. Remove the dirt with a moist cloth or kitchen

tissue.

3. Clean the glass again with a normal glass cleaning

product.

4. Rub the glass cleanwith a dry cloth or kitchen tissue.

Do not use abrasive or aggressive products to

clean the glass.

Wear household gloves to protect your hands.

If the glass in the appliance is broken or

cracked, it must be replacedbefore you can

use appliance again.

Ensurethat no stove glass cleanerruns

between the glass and the cast-iron door.

Enamelled stove maintenance

Never clean the appliance while it is still hot. The

most effective way to clean the enamelled surface of

the stove is with a mild green soap and lukewarm

water. Use as little water as possible, rub the surface

dry andprevent the formation of rust. Wire wool or

otherabrasives should never be used. Never place a

kettle directly onto an enamelledstove; use a standto

prevent damage. Attention: Do not allow aggressive

acidic products to get onto enamelled components.

Lubrication

Although cast-iron is slightly self-lubricating, you will

still need to lubricate moving parts frequently.

Lubricate the movingparts (such as guide systems,hingepins, latches andair slides) with heat

resistant grease that is available in the specialist

trade.

Touching up damaged paint

Small areas of damaged paint finish can be touchedup with a spray can of special heat-resistant paint,

available from your supplier.

Touching up the enamelled surface

Enamelling is a process carried out by traditional methods, meaning that it is possible that small colour differences and damage may occur. The appliances

Subjectto change because of technicalimprovements

21

Page 22

undergo a visual inspection in the factory, that is to

say, the inspector looks at the surface for a period of

10 seconds from a distance of 1 metre.

Any damage that does not stand out is regarded as

OK. A special heat-resistant paint is supplied with the

appliance to touch up any minor damage caused during transport.

Apply the heat-resistant paint in thin layers and leave

to dry well before using the appliance.

Some enamel colours are temperature-sensitive. It

can happenthat the colour changes during use.

The original colour will returnafter the appliance

has cooleddown.

If enamelled surfaces becomevery hot, hairline

cracks can occur. This is a normal phenomenon

andhas no impact on the functioning of the stove.

Ensurethat the stove is not overburdened. If it

does become overburdened thenthe surface

gets very hot possibly resulting in lasting damageto the enamel.

Checking the seal

Check whether the door sealing rope is still in good

conditionand works well. The sealing rope is subject to wear and will need to be replacedover time.

Check the appliance for air leaks. Close any

chinks with stove sealant.

Allow the sealant to harden fully before lighting

the appliance, as any moisture in the sealant

will form bubbles, resulting in a new air leak.

22

Subjectto change because of technicalimprovements

Page 23

Appendix 1: Technical data

Model 45M 45M 45M 45C

Nominal output 9 kW 9 kW 9 kW 9 kW

Flue connection (diameter) 150 mm 150 mm 150 mm 150 mm

Weight 155 kg 155kg 155 kg 160 kg

Recommended fuel Wood Coal Brown coal Coal

Fuel property, max. length wood 45 cm 12/22 - 20/30 3" - 6" - 7" 12/22 - 20/30

Mass flow of flue gasses 8.5 g/s 7.6 g/s 8.8 g/s 7.6 g/s

Temperature increase measured in the

measuring section

273°C 282 °C 286 °C 282°C

Temperature measuredat appliance

exit

410°C 389 °C 395 °C 389°C

Minimum draught 12 Pa 12 Pa 12 Pa 12 Pa

CO emission (13%O2) 0.09% 0.08% 0.07% 0.09%

NOx emission (13% O2) 60 mg/Nm³ - - -

CnHm emission (13%O2) 96 mg/Nm³ 136 mg/Nm³ 109 mg/Nm³ 136mg/Nm³

Particulate emission 13 mg/Nm³ <40 mg/Nm³ 12.3 mg/Nm³ <40 mg/Nm³

Particulate emission in accordance

with NS3058-NS3059

- - - -

Efficiency 75.30% 79.50% 75% 79.50%

Model 55M 55M 55M 55C

Nominal output 9 kW 9 kW 9 kW 9 kW

Flue connection (diameter) 150 mm 150 mm 150 mm 150 mm

Weight 155 kg 155kg 155 kg 160 kg

Recommended fuel Wood Coal Brown coal Coal

Fuel property, max. length wood 45 cm 12/22 - 20/30 3" - 6" - 7" 12/22 - 20/30

Mass flow of flue gasses 8.5 g/s 7.6 g/s 8.8 g/s 7.6 g/s

Temperature increase measured in the

measuring section

273°C 282 °C 286 °C 282°C

Temperature measuredat appliance

exit

410°C 389 °C 395 °C 389°C

Subjectto change because of technicalimprovements

23

Page 24

Model 55M 55M 55M 55C

Minimum draught 12 Pa 12 Pa 12 Pa 12 Pa

CO emission (13%O2) 0.09% 0.08% 0.07% 0.09%

NOx emission (13% O2) 60 mg/Nm³ - - -

CnHm emission (13%O2) 96 mg/Nm³ 136 mg/Nm³ 109mg/Nm³ 136mg/Nm³

Particulate emission 13 mg/Nm³ <40 mg/Nm³ 12.3 mg/Nm³ <40 mg/Nm³

Particulate emission in accordance

with NS3058-NS3059

- - - -

Efficiency 75.30% 79.50% 75% 79.50%

24

Subjectto change because of technicalimprovements

Page 25

Appendix 2: Dimensions

TAI 45M / TAI 45C

800

615

230

150

390

665

425

09-20020-358

Subjectto change because of technicalimprovements

25

Page 26

TAI 55M / TAI 55C

230

150

390

665

09-20020-361

800

715

425

26

Subjectto change because of technicalimprovements

Page 27

Appendix 3: Distance from combustible material

TAI 45M and 45C / TAI 55M and 55C - Minimum distances in millimetres

1350

940

1210

1070

1020

860

300

100

100

100

100

300

450

100

100

1212121

2

09-20020-356

.

1 Combustible material

2 Incombustible material, thickness 100 mm

Subjectto change because of technicalimprovements

27

Page 28

TAI 45M and 45C / TAI 55M and 55C - Incombustible floor plate dimensions

A

B B

09-20002-004

Minimum dimensions of fireproof floor plate

A (mm) B (mm)

Din 18891 500 300

Germany 500 300

Finland 400 100

Norway 300 100

28

Subjectto change because of technicalimprovements

Page 29

Appendix 4: Diagnosis diagram

Problem

Wood will not stay lit

Gives off insufficient heat

Smoke emissions into the room when adding wood

Fire in appliance is too intense, is hard to adjust

Deposit on the glass

possible cause possible solution

Insufficient draught

A cold flue usuallyfailsto create sufficient draught. Follow the instructionsfor starting a fire inthe ‘Use’section; open a window.

Wood too damp Use wood with no more than 20% moisture.

Logs too large

Use small pieces of kindling.Use split logs no larger than 30 cm in circumference.

Wood stacked incorrectly

Stackthe logsin a way that allows adequate air flow between the

logs(open stacking, see "Burning wood")

Flue does not work properly

Check whether the chimneymeets the requirements: at least 4

metres high, correct diameter, well-insulated, smooth inside, not too

many bends, no obstructions in chimney(bird's nest, too much soot

deposit), hermetically tight (no chinks).

Chimney stack incorrect Sufficiently high above the roof, no obstacles in the vicinity

Air inlets setincorrectly Open the air inlets completely.

Applianceconnected to the flue incorrectly

Connection should be hermeticallytight.

Vacuum in area in whichthe applianceis

installed

Switch off extraction systems.

Insufficient supplyof fresh air

Provide an adequate air supply; ifnecessary use outside air connection.

Bad weather

? Inversion(reversed air flow in chimney

because of a highoutside temperature),

extreme wind speeds

We recommend you don't use the appliance inthe caseof inversion.

If required, install an extra hood on the flue to increase the draught.

Draught in the living room

Avoiddraught inthe living room, do not placethe appliancenear a

door or heating air ducts.

Flames touchthe glass

Make sure the wood isnot positioned too closeto the glass. Slide the

primary air inlet cover closer to the "Closed" position.

Applianceisleaking air Check the door sealsand appliancejoints.

Subjectto change because of technicalimprovements

29

Page 30

Index

A

Adding

anthracite coal 19

brown coal briquettes 19

Adding fuel 19

Adding wood

smoking stove 29

Adverse weather conditions, do not burnwood 20

Aerating the fire 19

Air inlets 17

Air leak 22

Anthracite coal 17

ash 20

Ashes

breaking 20

remove 20

B

Bearing capacity of floor 13

Breaking

ashes 20

Brown coal

ash 18

Brown coal briquettes 16

buring 18

Burning 17

adding fuel 17-18

anthracite coal 18

appliance is hardto adjust 29

brown coal briquettes 18

fire is too intense 29

insufficient heat 29

topping up fuel 19

Burning wood

insufficient heat 20

C

Cap on the flue 13

Carpet 13

Cast iron inner plates

warning 15

Chimney fire prevention 19

Chinks in appliance 22

Cleaning

appliance 21

glass 21

Coals

ash content 17

Combustible material

distance from 27

Connecting

dimensions 25

Controlling air supply 19

Creosote 19

D

Damp wood 16

Dimensions 25

Door

sealingrope 22

Draught 23-24

Drying wood 16

E

Efficiency 5, 7, 9, 11, 23-24

Email

maintenance 21

External airsupply

connecting to 15

Extinguishingthe fire 19

F

Filling level of the appliance 18

Finishingcoat, maintenance 21

Fire

extinguishing 19

kindle

Lighting 17

Fire-resistant inner plates

maintenance 21

warning 15

Fire safety

distance from combustible material 27

floor 13

furniture 13

walls 13

Floors

bearingcapacity 13

fire safety 13

30

Subjectto change because of technicalimprovements

Page 31

Subjectto change because of technicalimprovements

31

Flue

connecting to 15

connection diameter 23

height 13

maintenance 20

requirements 12

Flue cap 13

Flue gas

temperature 5, 7, 9, 11

Flue gasses

mass flow 23

Fog, do not burn wood 20

Fuel

adding 18-19

anthracite coal 16-17

brown coal 16

brown coal briquettes 16

necessary amount 20

suitable 16

topping up 19

unsuitable 16

wood 16

G

Glass

cleaning 21

deposit 29

H

Heat, insufficient 20, 29

I

Installing

dimensions 25

K

Kindling 29

L

Lighting fire 17

Lubricant 21

Lubricate 21

M

Maintenance

Clean appliance 21

cleaning the glass 21

emai 21

Fire-resistant inner plates 21

flue 20

lubrication 21

sealing 22

measuring section 23

Mist, do not burn wood 20

N

Nominal output 20, 23

P

Paint

Smoke

during first use 16

Particulate emission 23-24

Primary air inlet 17

R

Removing ash 20

brown coal 18

S

Screens

deposit 29

Sealing rope for door 22

Secondary air inlet 17

Smoke emissions into the room 12

Smoking appliance 29

Softwood 16

Solving problems 20, 29

Stacking logs 18

Storingwood 16

Stove glass cleaner 21

Suitable fuel 16

Sweeping flue 20

T

Tar 19

Temperature 23

Temperature increase 23

Topping upwith fuel 19

U

Unsuitable fuel 16

Page 32

V

Ventilation 13

ruleof thumb 13

Ventilationlouvre 13

W

Walls

fire safety 13

Warning

cast iron inner plates 15

chimney fire 16, 19

chimney fires 12

fire-resistant innerplates 15

flammable materials 12

glass broken or cracked 12, 21

hot surface 12

requirements 12

stove glass cleaner 21

terms and conditions for insurance 12

ventilation 12-13

Weight 23

Wood 16

damp 16

drying 16

right sort 16

storing 16

will not stay lit 29

32

Subjectto change because of technicalimprovements

Loading...

Loading...