Page 1

SAPPHIRE DV450S

DIRECT VENT ROOM HEATER

OWNER’S MANUAL

AND INSTALLATION INSTRUCTIONS

WARNING!

If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

-Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information, consult a qualified installer ,

service agency or the gas supplier.

FOR YOUR SAFETY

The appliance area must be kept clear and free from combustible materials, gasoline and other flammable vapors and

liquids.

This manual must be used for installation of the DV450S Direct Vent Heater and retained by the homeowner for operating and

maintenance instructions. This heater may be installed with a vertical or horizontal direct vent terminator system.

1445 North HIghway

Colville, WA 99114

A Division of Hearth Technologies Inc.

#29863C 12/2000

Shown here with optional accessories (door trim and

warming shelf).

This appliance may be installed in an aftermarket,

permanently located, Manufactured (Mobile) Home,

where not prohibited by Local Codes.

This appliance is only for use with the type of fuel

indicated on the Rating Plate. This appliance is not

convertible for use with other gases, unless a certified Conversion Kit is used.

O-T L

Beaverton

Oregon USA

Tested and

Listed by

C

OMNI-Test Laboratories, Inc.

aladdin@aladdinhearth.com

ahpfireup.com

Page 2

DV450S DIRECT VENT ROOM HEATER

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

Serial/Rating Label (Listings and Code Approvals) ...........3

Listing & Code Approvals ..................................................4

Installer Information...........................................................4

Description of Heater....................................................... 5

Heater System Components .......................................... 5

Dimensions...................................................................... 6

Clearances to Combustibles..............................................6

Venting Components .........................................................7

Termination Examples .......................................................8

INSTALLATION:

A. Horizontal Termination................................................ 9

B. Vertical Termination ...................................................12

C. Existing Masonry Chimney Installation ......................14

D. Existing Class A Metal Chimney ................................15

Gas Line Installation........................................................16

Gas Pressure...................................................................16

Fuel Conversion ..............................................................16

High Altitude Installation..................................................17

Optional Accessories.......................................................18

Thermostat Wiring Diagram.............................................19

FIREBOX ENTRY

Removing Front Face ......................................................20

Removing Glass ..............................................................20

Log Placement.................................................................20

Creating Coal Bed Look ..................................................20

Adjustable Flue Restrictor ...............................................21

Reinstallation of Glass.....................................................21

DoorTrim Kit Installation...................................................21

Replacing Front Face ......................................................21

Pre-Use Check ................................................................21

Lighting Instructions ........................................................22

Air Shutter Adjustment.....................................................23

Seasonal Shutdown.........................................................23

Operation & Shutdown During Regular Use....................23

Maintenance....................................................................24

Trouble Shooting..............................................................25

Replacement Parts..........................................................28

Warranty..........................................................................30

Owner's Notes .................................................................31

Safety Precautions

1. PLEASE READ THESE INSTALLATION INSTRUCTIONS COMPLETELY BEFORE BEGINNING INSTALLATION PROCEDURES.

FAILURE TO FOLLOW THEM COULD CAUSE AN APPLIANCE MALFUNCTION RESULTING IN SERIOUS INJURY AND/OR

PROPERTY DAMAGE.

2. DUE TO HIGH TEMPERATURES THE APPLIANCE SHOULD BE LOCATED OUT OF TRAFFIC AND AWAY FROM FURNITURE

AND DRAPERIES.

3. CHILDREN AND ADULTS SHOULD BE ALERTED TO THE HAZARDS OF HIGH SURFACE TEMPERATURES AND SHOULD STAY

AWAY TO AVOID BURNS OR CLOTHING IGNITION.

4. YOUNG CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY ARE IN THE SAME ROOM AS THE APPLIANCE.

5. CLOTHING OR OTHER FLAMMABLE MATERIAL SHOULD NOT BE PLACED ON OR NEAR THE APPLIANCE.

6. ANY SAFETY SCREEN OR GUARD REMOVED FOR SERVICING AN APPLIANCE MUST BE REPLACED PRIOR TO OPERATING

THE APPLIANCE.

7. WARNING: DO NOT OPERATE APPLIANCE WITH THE PANEL(S) REMOVED, CRACKED OR BROKEN. REPLACEMENT OF

THE PANEL(S) SHOULD BE DONE BY A LICENSED OR QUALIFIED SERVICE PERSON.

8. INSTALLATION AND REPAIR SHOULD BE DONE BY A QUALIFIED SERVICE PERSON. THE APPLIANCE SHOULD BE

INSPECTED BEFORE USE AND AT LEAST ANNUALLY BY A QUALIFIED SERVICE PERSON. MORE FREQUENT CLEANING

MAY BE REQUIRED DUE TO EXCESSIVE LINT FROM CARPETING, BEDDING MATERIAL, ETC. IT IS IMPERATIVE THAT

CONTROL COMPARTMENTS, BURNERS AND CIRCULATING AIR PASSAGEWAYS OF THE APPLIANCE BE KEPT CLEAN.

9. ENSURE THAT THE FLOW OF COMBUSTION AND VENTILATION AIR NOT BE OBSTRUCTED.

10. ENSURE THAT ADEQUATE COMBUSTION AND VENTILATION AIR ARE PROVIDED.

NOTE: Illustrations throughout these instructions reflect typical installations and are for design purposes only. Actual

installation may vary slightly due to individual design preferences. However, minimum and maximum clearances

must be maintained at all times.

The illustrations and diagrams used throughout these installation instructions are not drawn to scale.

01-01 Page 2 29863C

Page 3

DV450S DIRECT VENT ROOM HEATER

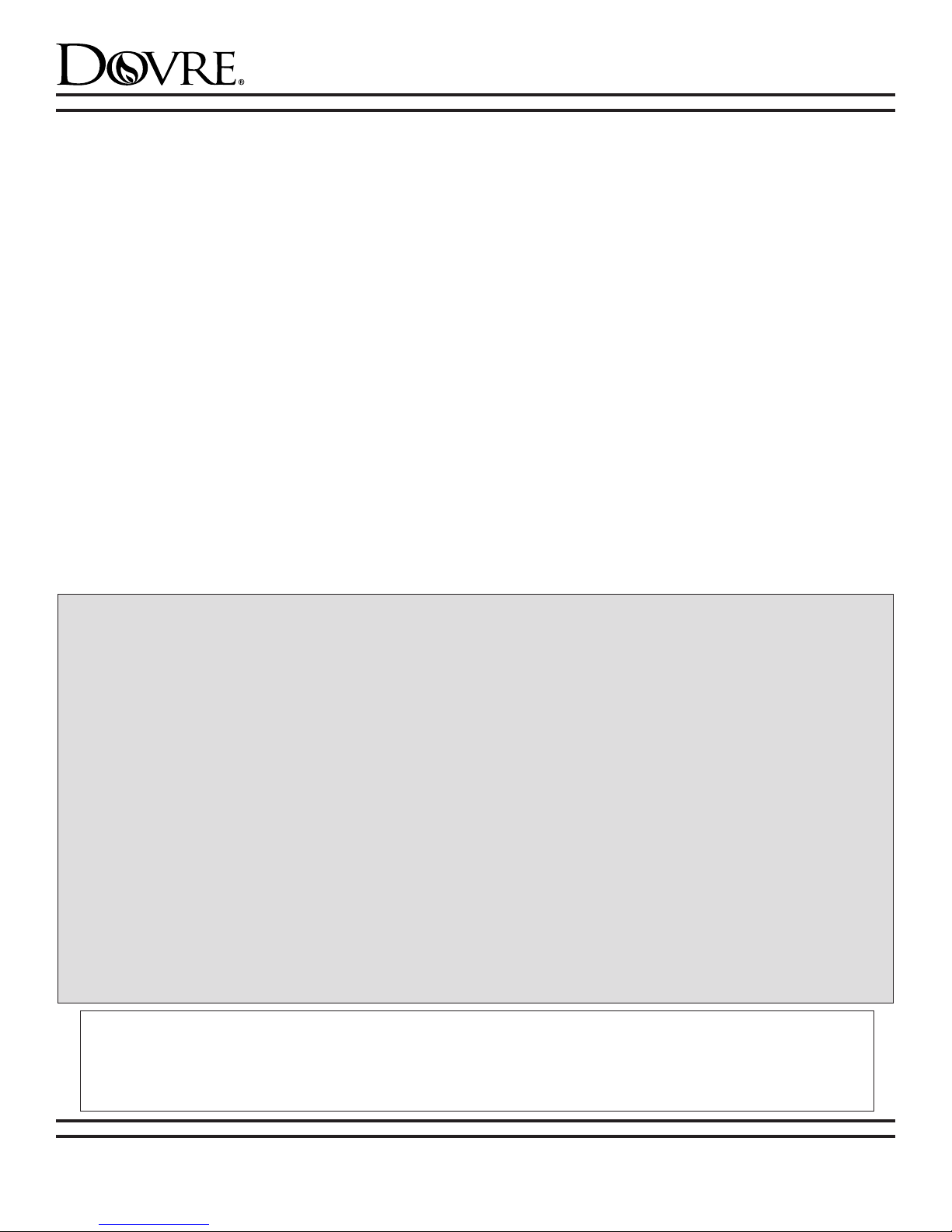

DO NOT REMOVE THIS LABEL /

NE PAS ENLEVER L’ÉTIQUETTE

Made in U.S.A. /

F

a

it Aux États-Unis

Date of Manufacture / Date du Manufacturier

Keep burner and control compartment clean. See installation and operating instructions accompanying

this appliance.Gardez le brûleur et le compartiment de contrôle propres. Vérifiez les instructions d’installation et

d

’opération qui accompagnent cet appareil.

This vented gas fireplace heater is not for use with air filters. / Cet appareil de chauffage au gaz n’est pas

pour l’usage avec des filtres d’air.

2001 2002 2003 Feb Mar Apr May Jun Jul Aug Sep Oct Nov DecJan

MODEL / MODELE: DV450 VENTED GAS FIREPLACE HEATER

FOURNAISE AU GAZ AVEC VENTILATION

NOT FOR USE WITH SOLID FUEL / NE PAS UTILISER AVEC LE COMBUSTIBLE SOLIDE

SERIAL NO.

A Division of Hearth Technologies Inc.

1445 North Highway Colville,

W

A

99114

O-T L

Tested and

Listed by

Beaverto

n

O

regon USA

OMNI-Test Laboratories, Inc.

C

Report No. / Rapport Numero

061-S-24-5

For use with Natural Gas For use with Propane

Usage Au Gaz Naturel Usage Au Gaz Propane

0-4500’ 0-4500’

Input Rate on “HI” (BTU/Hr) 40,000 38,000

Puissance Évaluée à “HI” (BTU/Hr)

Input Rate on “LO” (BTU/Hr) 29,000 25,000

Puissance Évaluée à “LO” (BTU/Hr)

Maximum Output (BTU/Hr) 28,800 27,740

Puissance Maximum (BTU/Hr)

Main Burner Orifice .125/3.18 DIA./mm .073/1.85 DIA./m

m

Orifice du Brûleur Principal

Minimum Inlet Pressure (Inches W.C.) 4.5” 11”

Pression Minimum de la Valve (pouces W.C.

)

Maximum Inlet Pressure (Inches W.C.) 7.0” 14”

Pression Maximum de la Valve (pouces W.C.

)

Manifold Pressure on “HI” (Inches W.C.) 3.5” 10”

Pression du Collecteur d’ Échappement à “HI” (pouces W.C.

)

T

his appliance equipped for altitudes 0-2000’ (0-610m) in USA; and in Canada for altitudes of 0-

4500’ (0-1370m). In USA

for Altitudes above 2000’, the vent configuration, orifice, or combination of

b

oth may need to be changed. See Owner’s Manual for information on making these changes

.

Cet appareil est équipé pour les altitudes de 0-2000’ (0-610m) aux États-Unis; et au Canada pour

l

es altitudes de 0-4500’ (0-1370m). Pour les altitudes au dessus de 2000’ aux États-Unis, la

configuration du ventilateur, son orifice ou les deux peuvent possiblement avoir à être changé.

Vo

ye

z le manuel du propriétaire pour les informations sur ces changements.

This appliance

must be installed in accordance with local codes, if any; if none, follow ANSI Z223.1

in USA, CAN 1-B149 in Canada.

ELECTRICAL SUPPLY / FOURNITURE ÉLECTRIQUE: 120 Volts, 1.2 Amps, 60 Hz

APPROVED FOR CANADA AND USA TO:

A

NSI Z21.88b-1999 / CSA 2.33b-M99

Ve

nted Gas Fireplace Heaters,

a

nd applicable sections of UL307b Gas Burning

Heating Appliances for Manufactured Homes and Recreational Vehicles,

C

AN/CGA 2.17-M91 “Gas Fired Appliances for

use at High Altitudes.”T

his appliance is manufactured for operation with Natural Gas.

For conversion to propane Manufacturer’s

P

art #844-9230 and instructions must be used.

This appliance may be installed in a bedroom or bedsitting room; in Canada remote thermostat installation is required.

APPROUVÉ POUR LE CANADA ET LES ÉTATS-UNIS:

ANSI Z21.88b-1999 / CSA 2.33b-M99 Fournaises au Gaz avec

Ve

ntilation, et les sections applicables de UL 307b

Appareils de Chauffa

ge A

u Gaz pour les Maisons Mobiles et les

Vé

hicules Motorisés, CAN/CGA 2.17-M91 “Gas Fired

Appliances for use at High Altitudes”.

Cet appareil est manufacturé pour l’opération avec le Gaz Naturel.

Po

ur une conversion au gaz propane les pièces du Manufacturier #844-9230 et ses instructions doivent être

u

tilisées.

Cet appareil peut être utilisé dans une chambre à coucher ou salle de séjour; au Canada, l’installation d’un

thermostat à distance est exigée

.

HEARTH: A non-combustible hearth pad is not required. However, the floor beneath the stove must be stable,

level, and strong enough to support the stove without a tipping hazard.

F

oyer: Un coussinet non-combustible

d

e foyer n’est pas exigé. Cependant, le plancher en dessous du poêle doit être droit, à niveau et assez fort

pour supporter le poêle sans le hasard de basculer

.

FAN TYPE VENTED CIRCULATOR / VENTILATEUR CIRCULATOIRE

Blower Electrical Rating / Évaluation du Ventilateur Électrique: 115 V., 1.5 Amps, 60 Hz, 150 Watts

Thermal Efficiency / Efficacité Thermique* 72% NG

A. Sides of stove to wall 9" (229 mm)

D

u coté du poêle au coté du mu

r

B

. Back

of sto

v

e to w

a

ll 6" (152 mm)

Le contrôle ar

r

i

ère au m

u

r arr

ièr

e

C

. Cor

ner of sto

v

e to side w

a

ll 4" (102 mm)

Du Coin du poêle du mur

D. Top of stove to ceiling 42" (1829 mm)

du dessus de poele au plaf

o

n

d

E

.

Max.

Alcove

Depth 48" (1219 mm)

Profondeur maximale de l'alcôve

M

INIMUM CLEARANCES TO COMBUSTIBLES / ESP

AC

E MINIMUM

AU

X COMBUSTIBLE

S

M

inimum clearances required from combustible construction for all appliance surfaces. /

Espaces minimum exigés de la construction combustible aux surfaces de l’appareil

.

This appliance is only for use with the type of gas indicated on the rating plate and may be

in

stalled in an afte

rma

rket, per

ma

nently located, manufactured (mobile) home where not

prohibited by local codes. See owner's manual for details. This appliance is not convertible

f

or use with other gases, unless a certified kit is used.

Cet appareil doit etre utilise uniquement avec le type de gaz indique sur la plaque

signaletique et peut etre installe dans une maison prefabr

iq

uee (mobile) installee a demeure

si les reglements locaux le permettent. Voir la notice du proprietaire pour plus de details. Cet

appareil ne peut etre converti a d'autres gaz sauf si une trousse de conversion certifiee est

utilisee.

T

his appliance must be properly connected to a venting system in accordance with the

manufacturer's installation instructions. If venting is disconnected for any reason, the vent-air

i

ntake system must be properly resealed and reinstalled.

Cet appareil doit ê correctement raccordé á un système d'évacuation, conformément aux

in

structions du fabr

ic

ant.

A

A

B

C

C

D

E

250-5891

SERIAL/RATING LABEL

01-01 Page 3 29863C

Page 4

DV450S DIRECT VENT ROOM HEATER

LISTING & CODE APPROVALS

U.S. CERTIFICATION

The DV450S Series Room HEater has been tested in accordance

with the ANSI standard Z21.88 1998 and UL307B and has

been listed by OMNI-Test Labs for installation and operation as

described in these installation and operation instructions. All

components are A.G.A. or UL safety certified.

Canada Certification

The DV450S Series Room HEater has been tested in accordance

with CSA 2.33-M98 and has been listed by OMNI-Test Labs for

installation and operation as described in these installation and

operating instructions. All components are C.G. A. or C.S.A.

safety certified.

Local Codes

This installatin must conform with local codes or, in the absence

of local codes, with theNational Fuel Gas Code, ANSI Z223.1latest edition, in the U.S.A. and the CAN/CGA B149-latest edition,

in Canada.

Efficiency

The efficiency rating of the appliance is a product thermal

efficiency rating determined under continuous operating

conditions and was determined independently of any installed

system.

INSTALLER INFORMATION

INSTALLATION AND REPAIR SHOULD BE DONE

BY A QUALIFIED SERVICE PERSON. THE HEATER

SHOULD BE INSPECTED BEFORE USE AND AT

LEAST ANNUALLY BY A QUALIFIED SERVICE

PERSON. MORE FREQUENT CLEANING MAY

BE REQUIRED DUE TO EXCESSIVE LINT FROM

CARPETING, BEDDING MATERIAL, ETC. IT IS

IMPERATIVE THAT CONTROL COMPARTMENTS,

BURNERS AND CIRCULATING AIR PASSAGEWAYS

OF THE HEATER BE KEPT CLEAN.

WARNING:

BEFORE STARTING, DO THE FOLLOWING:

1. WEAR GLOVES AND SAFETY GLASSES FOR

PROTECTION.

2. KEEP HAND TOOLS IN GOOD CONDITION.

SHARPEN CUTTING EDGES AND MAKE

SURE TOOL HANDLES ARE SECURE.

3. ALWAYS MAINTAIN THE MINIMUM AIR SPACE

REQUIRED TO THE ENCLOSURE TO

PREVENT FIRE.

This Heater is approved for installation in bedrooms and

mobile homes in the United States and Canada.

Tools and building supplies normal-

ly required for installation:

Saw

Efficiency

The efficiency rating of the appliance is a product thermal efficiency rating determined under continuous operating conditions

and was determined independently of any installed system.

*High Temperature Sealant Material. Sealants that will

withstand high temperatures; General Electric RTV103

(Black), or equivalent. Rutland, Inc. Fireplace Mortar #63,

or equivalent; Dow Corning 732 or equivalent.

01-01 Page 4 29863C

Pliers

Phillips Screwdriver

Tape Measure

Plumb Line

Level

Electrical Drill and Bits

Square

High Temperature Sealant Material*

Page 5

DV450S DIRECT VENT ROOM HEATER

VENT

SECTION

VENT

SECTION

VENT

SECTION

90û ELBOW

ROUND

SUPPORT

BOX/WALL

THIMBLE

HORIZONTAL

TERMINATION

CAP

VERTICAL

TERMINATION

CAP

STORM

COLLAR

VERTICAL

TERM.

ADAPTER

FLASHING

FIRESTOP

SPACER

ROUND

SUPPORT

BOX/WALL

THIMBLE

CATHEDRAL

CEILING

SUPPORT

BOX

DESCRIPTION OF THE HEATER SYSTEM

The DV450S is a Direct Vent Room Heater. Combustion air

is supplied from outside, not from inside the house as with

other types of heaters.

The installation of this DOVRE DV450S system consists of the following:

1. Appliance

2. Venting System

3. T

ermination

Optional components include:

1. Blower Kit

2. Decorative Glass Accent

3. Warming Shelf

4. Bracket with Mitten Rod

5. Remote Control

NOTE: Operation of a Direct Vent

Heater may be sporadic in high

wind situations.

The table below is a list of only those components which may be safely used with this appliance.

Catalog # DESCRIPTION

839-0610 Direct vent Room Heater - matte black - natural gas, standing pilot

839-0630 Direct vent Room Heater - porcelain black - natural gas, standing pilot

839-0650 Direct vent Room Heater - porcelain creme - natural gas, standing pilot

839-0670 Direct vent Room Heater - porcelain green - natural gas, standing pilot

839-0690 Direct vent Room Heater - porcelain blue - natural gas, standing pilot

844-0150 Fan Kit, variable speed, thermostat “ON/OFF”

844-0140 Decorative Glass accent - gold

844-7900 Warming Shelf - matte black (pr.)

844-7910 Warming Shelf - porcelain black (pr.)

844-7930 Warming Shelf - porcelain creme (pr.)

844-7940 Warming Shelf - porcelain green (pr.)

844-7920 Warming Shelf - porcelain blue (pr.)

844-7970 Warming Shelf Bracket - w/mitten rod, black (pr.)

844-7980 Warming Shelf Bracket - w/mitten rod, gold (pr.)

844-9230 LP Conversion Kit

844-8250 NG Conversion Kit

HEATER SYSTEM COMPONENTS

01-01 Page 5 29863C

Page 6

28"

27 - 3/8"

30 - 3/8"

16 - 3/4"

19 - 1/8"

22 - 5/8"

8"

5 - 1/8"

39"

DIMENSIONS

STOVE

STOVE

6"

9"

6"

9"

48"

MAX.

4"

4"

STOVE

DV450S DIRECT VENT ROOM HEATER

DV450S Front View - With and Without Optional Warming Shelves

The following clearances to combustibles must be maintained:

Minimum clearances to the floor - 0"

Back of unit to wall - 6”

Sides of unit to wall - 9"

Base of the unit to ceiling - 72".

Minimum clearances to Venting are as follows:

Horizontal runs require a 1-1/2” minimum Air Space on the top and

an 1/2” minimum Air Space on the sides and bottom of the outer

Vent Section. If an Elbow is being used,in an enclosed wall, floor

or ceiling, a top Air Space clearance of 3” must be maintained.

Vertical rise sections require a 1” minimum Air Space completely

around the Vent section. These clearances must be maintained

at all times.

This appliance is certified for installation in a bed/sitting sitting room

in the U.S. and Canada.

Mobile Home Installations. Appliances installed in Mobile Homes

must be secured to the floor in a minimum of two locations.

Positioning the Appliance.

This appliance may be placed on a combustible or non-combustible continuous, flat surface. When the appliance is installed

directly on carpeting, tile or other combustible material other than

wood flooring, the appliance shall be installed on a metal or wood

panel extending the full width and depth of the appliance. Slide

the Heater into position and level the Heater from side-to-side

and front-to-back. Shim as necessary.

CLEARANCES

DV450S - With Optional Blower

Figure 1

Minimum Clearances To Combustibles

01-01 Page 6 29863C

Page 7

DV450S DIRECT VENT ROOM HEATER

DURA-VENT VENTING COMPONENTS

Dura-Vent

PART # DESCRIPTION:

Termination Caps & Snorkles:

991 High Wind Vertical Termination Cap

986 High Wind Horizontal Termination Cap

980 Vertical Termination Cap w/Wind Halo

983 Vertical Termination

984 Horizontal Termination Cap

981 Snorkel Termination (36”)

982 Snorkel Termination (14”)

950 Vinyl Siding Standoff

Flashing:

941 Cathedral Ceiling Support Box

943 Flashing, 0/12 to 6/12 Roof Pitch

943S Flashing, 7/12 to 12/12 Roof Pitch

943F Flashing, Flat Roof

Support Boxes/Thimbles:

940 Round Ceiling Support/

Wall Thimble Cover

941 Cathedral Ceiling Support Box

Pipe:

908 6” Pipe Length, Galv.

908B 6” Pipe Length, Black

907 9” Pipe Length, Galv

907B 9” Pipe Length, Black

906 12” Pipe Length, Galv.

906B 12” Pipe Length, Black

904 24” Pipe Length, Galv.

904B 24” Pipe Length, Black

903 36” Pipe Length, Galv.

903B 36” Pipe Length, Black

902 48” Pipe Length, Galv.

902B 48” Pipe Length, Black

911 11” -14 5/8” Pipe, Adj. Glv.

911B 11” -14 5/8” Pipe, Adj. Blk.

912 12” - 17” Pipe, Adj. Glv.

912B 12” - 17” Pipe, Adj. Blk.

917 17” -24” Pipe, Adj. Glv.

917B 17” -24” Pipe, Adj. Blk.

945 45° Elbow, Galv.

945B 45° Elbow, Black

990 90° Elbow, Galv.

990B 90° Elbow, Black

Misc.

953 Storm Collar

963 Ceiling Firestop

988 Wall Strap

9546 Attic Insulation Shield

942 Wall Thimble/Cathedral Ceiling Collar

SDV KITS

970A Standard Termination Kit includes

1 each of:“ 990B, 940, & 985

See Note #1 below.

971HW Standard Termination Kit includes

1 each of:“990B, 940, 985, 904B, 911B

973 Vertical Termination Kit includes 1 each

of:“943, 953, 991 (support box NOT

included)

Note #1: Straight pipe lenghts are needed to complete

installation, the black 45° elbow is NOT included in kit.

The following venting parts are available from your

Dealer:

HHW2 Horizontal High Wind Cap

HHW2K Horizontal Kit includes 90° Black Elbow,

Wall Thimble, 24" Black Pipe, 11" - 14

5/8" Adjustable Vent, HHW2

Termination Cap.

The VTA1, Vertical Termination Adapter Kit, may also be

safely used with this Heater. It is composed of a Vertical

Termination Cap and Cover Plate for existing vertical

chimney.

01-01 Page 7 29863C

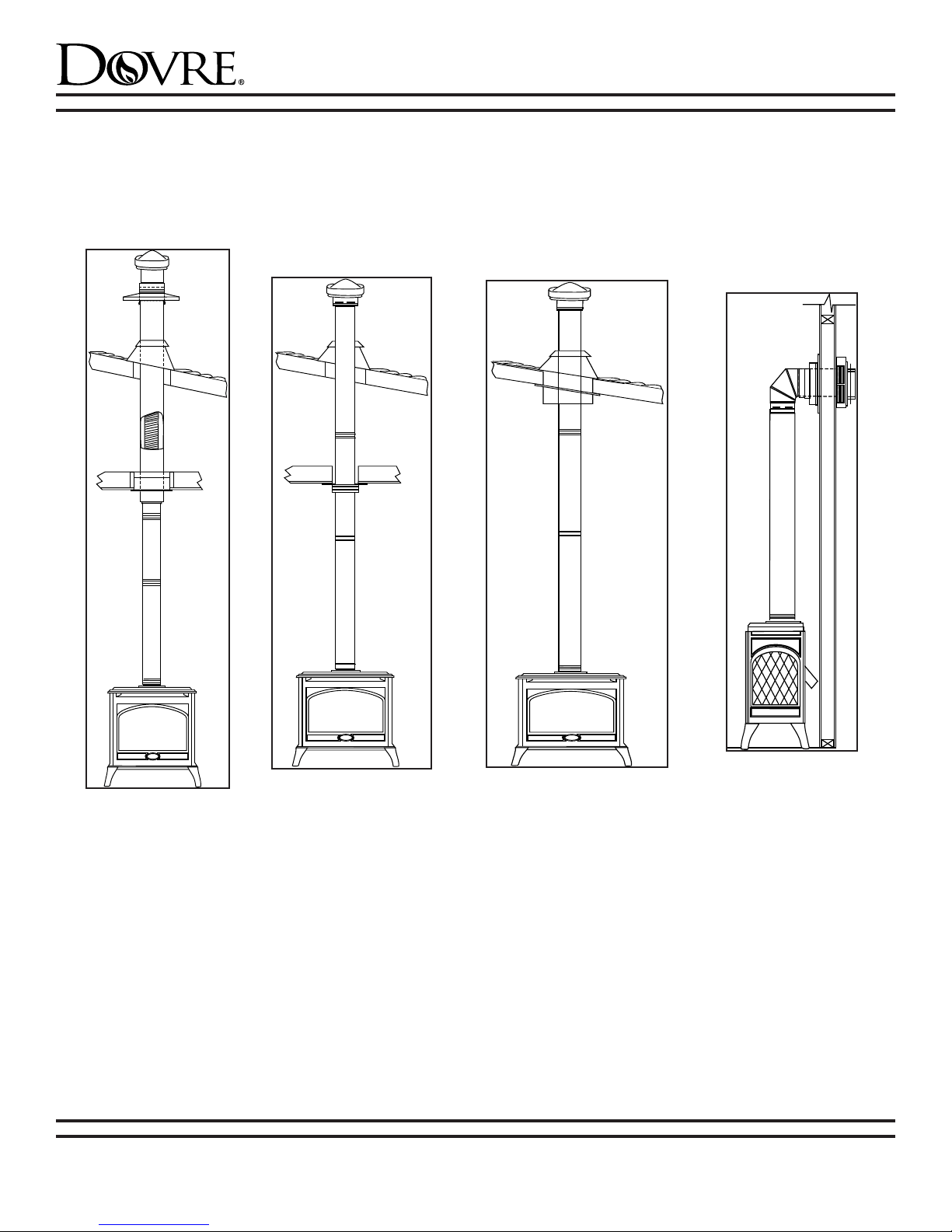

Page 8

DV450S DIRECT VENT ROOM HEATER

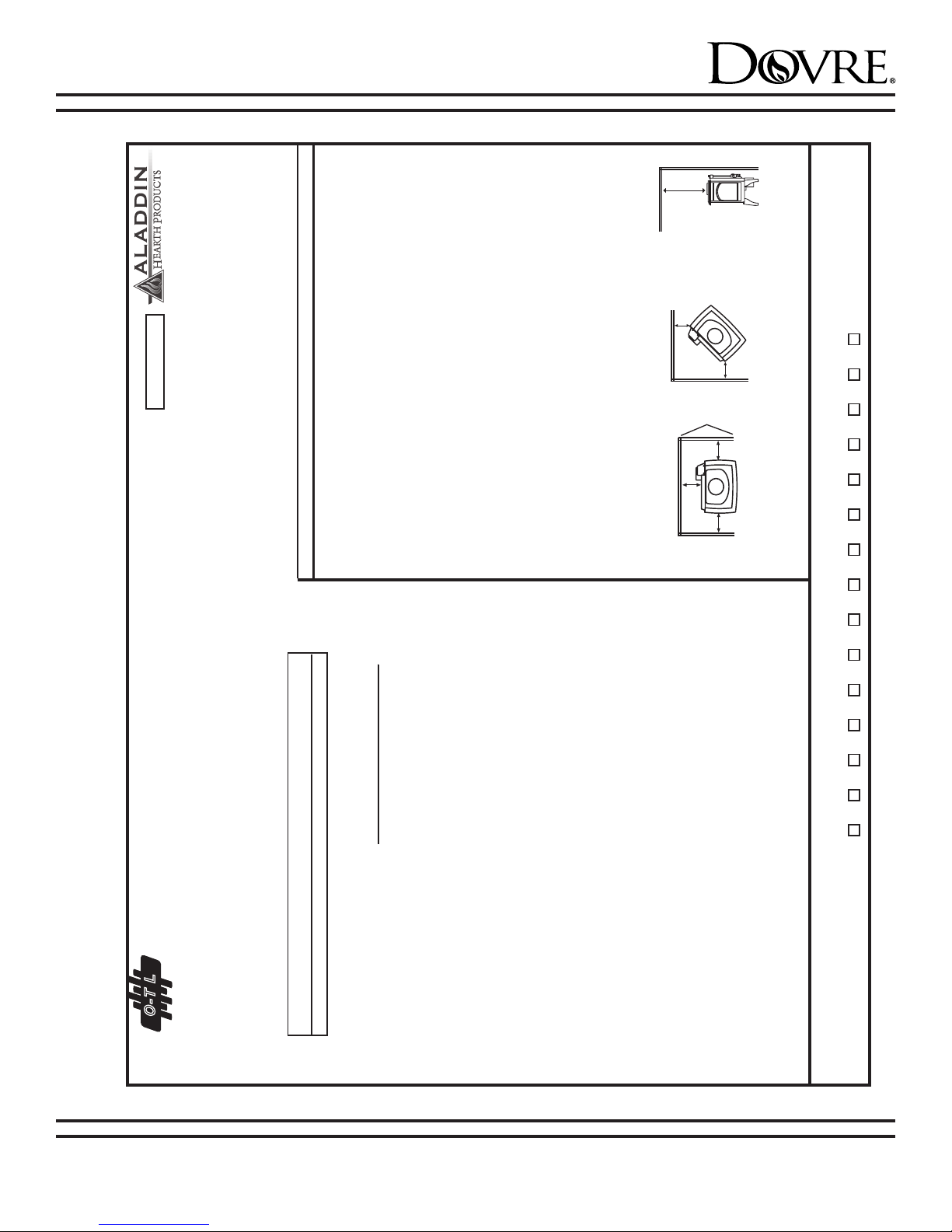

TERMINATION EXAMPLES

Four types of Termination are possible for this Heater: Horizontal, Vertical, Existing Masonry or Existing Class A

Class A Metal Chimney

01-01 Page 8 29863C

Vertical Flat Ceiling

Cathedral Ceiling

Horizontal Termination

Page 9

DV450S DIRECT VENT ROOM HEATER

16'

MAX.

15' MAX.

VENTING CAN ONLY TERMINATE

WITHIN THIS AREA.

2'

MIN.

10' MAX.

15" MIN.

4'

29"

591/2"*

* MINIMUM VENT

HEIGHT (CENTER)

(SEE NOTE)

15' MAX. HORIZONTAL RUN

2' 3' 4' 5' 6' 7' 8' 9' 10' 11' 12' 13' 14' 15'

16'

Thru

4'

3'

2'

X

X

XXX

X

X X

X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X X X

X X X X X

X

X

X X X X X

X

X

X

X

X

X

X

X

X

X

V

E

R

T

I

C

A

L

R

I

S

E

INSTALLATION

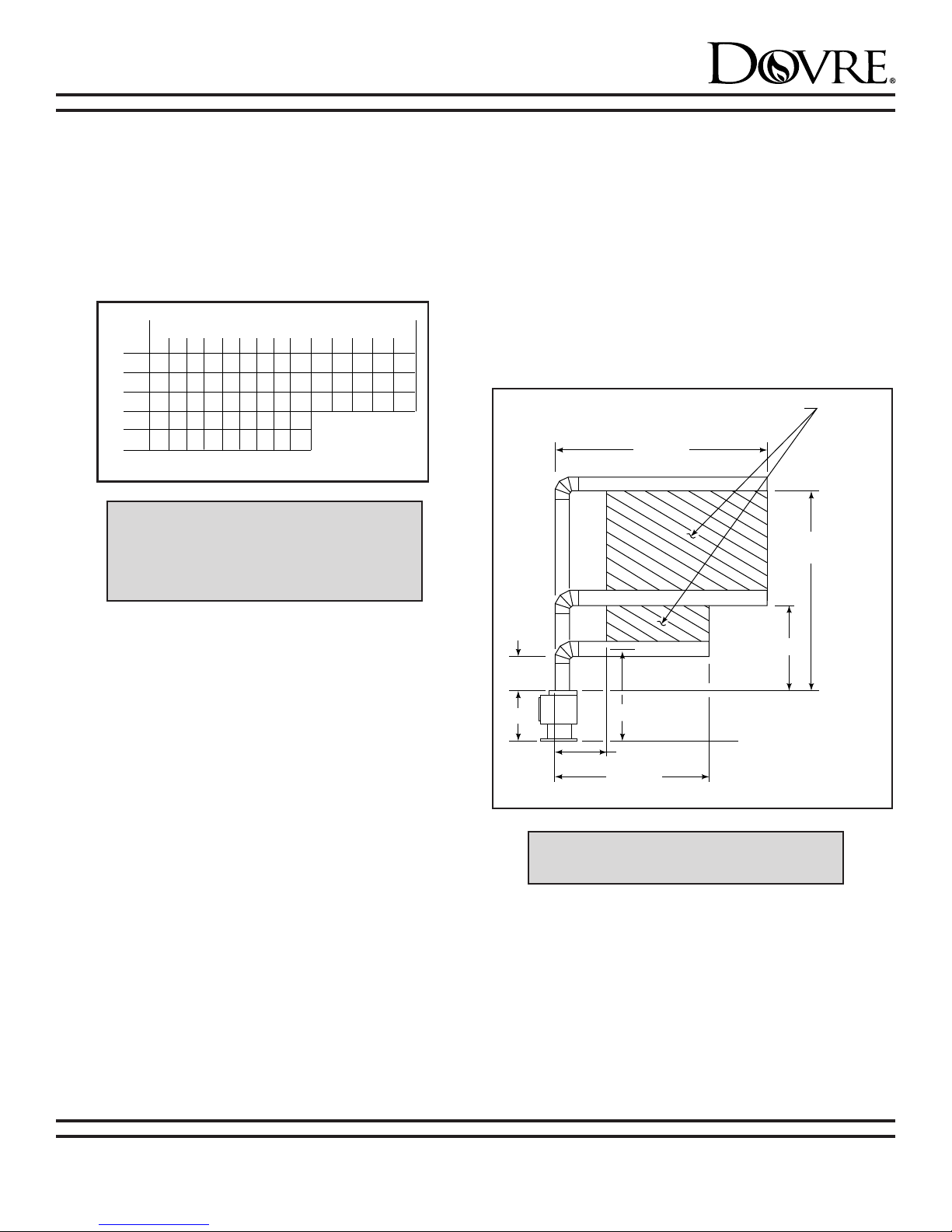

A. Horizontal Termination

Refer to Chart A for horizontal venting recommendations. The

minimum vertical rise allowed for horizontal termination is 2' from

the top of the heater. The maximum horizontal run allowed for

venting is 15' with a minimum 4' rise.

CHART A

Note: A horizontal run of vent must have

a 1/4" rise for every 1 ft. of run towards

the termination. Never allow the vent to

run downward. This could cause high

temperatures and the possibility of a fire.

Fig. 3 - Horizontal Lenth

A single vertical to horizontal elbow is already calculated into the

allowable 15' run. Each additional elbow reduces the maximum

horizontal distance by three feet. Example: When using three

elbows, the maximum horizontal distance has been reduced to

9' (3 - 1 = 2 elbows x 3' = 6'; 15' max. - 6' of elbows = 9' of

horizontal run). Even with only these three elbows (the equivalent

of 6' additional horizontal feet) you now need a minimum of 4' of

vertical rise. See Chart A.

If a vertical-to-horizontal elbow is enclosed within a wall, floor or

ceiling, an air space clearance of 3" must be maintained.

Due to the many different combineations that can be used when

constructing venting, the number of vent sections required can

only be determined by the installer.

Horizontal venting must terminate within the shaded area shown in

Fig. 2. Chart A illustrates the figures included in that shaded area.

For example, if your vertical rise is the minimum two foot, venting

can terminate anywhere between 20 -1/2" (includes wall thickness

and assumes 4", and venting required to termination cap) and 10'.

Vent termination must not be recessed into the wall or siding.

Fig. 3 illustrates termination cap location and minimum dimensions

for each termination application. Or, follow ANSI Z223.1, latest

edition.

01-01 Page 9 29863C

Note: Horizontal runs will require the use of

one vent support for every 3' of vent.

Page 10

DV450S DIRECT VENT ROOM HEATER

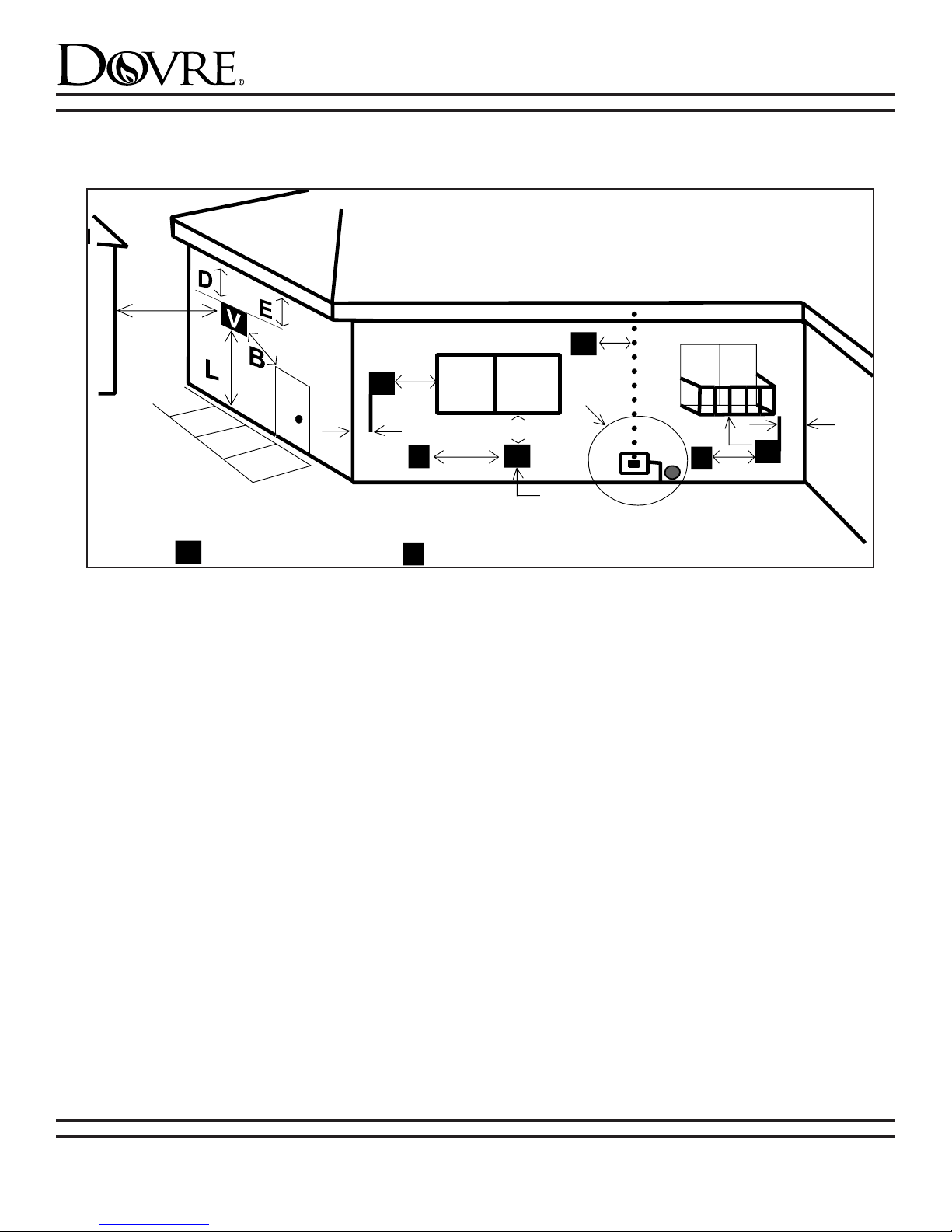

A

Openable

Fixed

Closed

B

C

F

G

H

I

A

V

V

V

V

K

A

J

M

N

V

= vent terminal

A

= air supply inlet

HORIZONTAL TERMINATION CAP LOCATIONS

A. *12” (30cm) minimum: Clearance above grade, veranda, porch, deck, or balcony.

B. *12” (30cm) minimum: Clearance to window or door that may be opened.

C. 12” (30cm) minimum: Clearance to permanently closed window (recommended to prevent condensation on window.

D. 18” (46cm) minimum: Vertical clearance to ventilated soffit located above the terminal within a horizontal distance of 2’

(60cm) from the centerline of the terminal.

E. 12” (30)cm) minimum: Clearance to unventilated soffit.

F. 6” (15cm): Clearance to outside corner.

G. 9” (23cm): Clearance to inside corner.

*Not to be installed above a meter/regulator (gas or electrical) assembly within 3’ (90cm) horizontally from the centerline

of the meter/regulator.

H. *6’ (1.8m) minimum: Clearance to service regulator vent outlet.

I. *12” (30cm) minimum: Clearance to nonmechanical air supply inlet to building or the combustion air inlet to any other

appliance.

J. *6’ (1.8m) minimum: Clearance to a mechanical air supply air inlet.

K. *+7’ (2.1m) minimum: Clearance above paved sidewalk or a paved driveway located on public property.

L. *#12” (30 cm) minimum: Clearance under veranda, porch, deck, or balcony.

M. 6” (15 cm) minimum: Clearance to adjacent building or deck.

N. 6” (15 cm) minimum: Clearance to nearby building

+A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single-family dwellings and

serves both dwellings.*

#Only permitted if veranda, porch, deck, or balcony, is fully open on a minimum of two sides beneath the floor.*

*As specified in CGA B149 Installation Codes

Note: Local Codes or regulations may require different clearances.

01-01 Page 10 29863C

Page 11

DV450S DIRECT VENT ROOM HEATER

EXTERIOR

WALL

HOLE TO BE

VENTED

THROUGH

10''x 10'' DURAVENT MINIMUM

54

1

/2''

59

1

/2''

Female

Locking

Lugs

Male

Locking

Lugs

1. Preparing the Wall for Horizontal Termination. A hole

measuring 10” wide and 10” high must be cut and framed in the

exterior wall where venting will be terminated.

The height of the hole must be located to meet all local and

national codes and not be easily blocked or obstructed. The

1

minimum height to the center of the horizontal vent is 59

/2''

from the base of the unit. This figure will increase by the length

of each vertically positioned vent section added to the venting

system. See Figure 4.

Figure 4 - Exterior Wall Hole

If the wall being penetrated is constructed of non-combustible

material (i.e.: masonry block or concrete) a 7 inch diameter

hole is acceptable. It is recommended that for masonry walls the

vent be wrapped with fiberglass insulation to prevent contact with

the masonry as the contact promotes premature deterioration of

the vent.

2. Assembling Venting Sections. Use only vent supplied or

listed for use with this Heater. To attach a straight section to

the top of the Heater, female end down, slide the pipe over the

outer Collar on the Heater while the inner flue will slip over the

Vent Inner.

MAINTAIN MINIMUM CLEARANCES OR GREATER AROUND

THE VENT SYSTEM. Do not pack air spaces with insulation or

other material.

Figure 5 - Twist-lock procedure

The Dura-Vent GS is unitized and twist-locks together. For the

twist-lock procedure, consult Figure 5 and do the following:

(1) Four indentations, located on the female ends of pipes and

fittings, are designed to slide straight onto the male ends of

adjacent pipes and fittings, by orienting the four pipe indentations

so they match and slide into the four entry slots on the male

ends. See Figure 5. Push the pipe sections completely together,

then twist-lock one section clockwise approximately one-quarter

turn, until the two sections are fully locked. The female locking

lugs will not be visible from the outside, on the Black Pipe or

fittings. They may be located by examining the inside of the

female ends.

(2) Horizontal runs of vent must be supported every three feet.

Wall Straps are available for this purpose.

Before connecting the horizontal run of vent pipe to the vent

termination, slide the black decorative wall thimble cover over the

vent pipe.

When using the adjustable section, maintain a 1” overlap on

pipe sections and secure. It is also important that the vent pipe

extends a minimum of 1 1/2” into vent cap.

3. Termination Cap. Position the horizontal vent termination so

that 1 1/2” clearance is maintained on top of the vent sections

and 1 1/2” on sides.

Before attaching the Vent Termination to the exterior wall, run a

bead of non-hardening mastic around the outside edges to make

a seal between the Cap and the wall.

Attach Cap to exterior wall with four (4) wood screws, making

sure that arrow on Cap is pointing up. After Cap is attached,

make sure that a 1 1/2” is maintained from top of vent to combustibles.

Secure the connection between the vent pipe and the vent cap

by attaching the two sheet metal strips extending fromthe vent

cap assembly into the outer wall of the vent pipe. Use the two

sheet metal screws provided to connectthe strips to the pipe section. Bend any remaining portion of the sheet metal strip back

towards the vent cap, so it will be concealed by the decorative

wall thimble cover. See Fig.6.

Slide the Decorative Wall Thimble up the wall surface and attach

with the screws provided. Apply Decorative Brass or Chrome

Trim if desired. See Fig. 7.

4. Vertical Rise on the Exterior. For installations requiring

a vertical rise on the exterior of a building, 14” and 36” tall

Snorkel Terminations are available. Follow the same installation

procedures that are used for the standard horizontal termination

found in Step 3.

01-01 Page 11 29863C

NOTE: For buildings with vinyl siding, a Vinyl Siding

Standoff should be installed between the vent cap and

the exterior wall. Attach the Vinyl Siding Standoff

to the Horizontal Vent Termination. The Vinyl Siding

Standoff prevents excessive heat from possible melting the vinyl siding material. NOTE: The HHW2 cap

incorporates it's own vinyl siding standoff. See Fig. 8.

Page 12

DV450S DIRECT VENT ROOM HEATER

VINYL

SIDING

APPLY SEALANT TO ALL

FOUR SIDES

VINYL SIDING

STANDOFF

SCREW

BOLT HORIZONTAL

TOP TO VINYL

STANDOFF

WALL

THIMBLE

STRAP

90° ELBOW

90° ELBOW

VENT

STABILIZER

Figure 6 - Insertion of Vent Pipe

Figure 7 - Decorative Wall Thimble

B. Vertical Termination.

The following figures are the maximum distances from the top

of the unit, as well as the minimum air space clearances that

must be maintained: Maximum straight unsupported rise - 25';

Maximum height - 40' from the top of the unit. Maximum horizontal unsupported run - 3'; air space clearances around vertical

venting - 1" on all sides; air space clearances around horizontal

venting - 1

is being used in an enclosed wall, floor, or ceiling a top air space

clearance of 3" must be maintained. These clearances must be

maintained at all times.

1. Position the Heater.

Position the heater in its desired location. Maintain all clearances

to combustibles.

2. Preparing the Ceiling.

Drop a plumb bob down from the ceiling to the position of

the heater flue exit and mark the location where the vent will

penetrate the roof. Drill a small hole at this point. Next drop

a plumb bob from the roof to the hole previously drilled in the

ceiling and mark the spot where the vent will penetrate the

roof. Determine if ceiling joists, roof rafters, or other framing will

obstruct the venting system. You may wish to relocate or offset

the appliance to avoid cutting load bearing members.

To bypass any overhead obstructions the vent system may be

offset using a 45° elbow or a 90° elbow. Vent stabilizers have

straps for securing these parts to joists or rafters. lumbers tape

may be purchased locally and used in conjunction with vent

stabilizers. See Fig. 9

1

⁄2" on top and 1⁄2" on sides and bottom. If an elbow

Figure 9 - Elbows with Stabilizer

Figure 8 - Vinyl Standing Standoff

01-01 Page 12 29863C

3. Assembling vent sections. Only use vent supplied and

listed for use with this Heater.

To attach a straight section to the top of the Heater, with

the female end down, slide that pipe over the outer Collar

on the Heater while the Vent Inner slips into the Flue of

the Heater. MAINTAIN MINIMUM 1" CLEARANCES OR

GREATER AROUND THE VENT SYSTEM. Do not pack air

spaces with insulation or other material.

Page 13

DV450S DIRECT VENT ROOM HEATER

H (MIN.)-MINIMUM HEIGHT

FROM ROOF TO LOWEST

DISCHARGE OPENING

ROOF PITCH IS X/12

LISTED

CAP

LOWEST

DISCHARGE

OPENING

12

X

2 Ft.

Min.

2 Ft. Min.

VERTICAL WALL

HORIZONTAL OVERHANG

Roof Pitch H (min.) ft.

flat to 6/12 1.0

6/12 to 7/12 1.25

over 7/12 to 8/12 1.5

over 8/12 to 9/12 2.0

over 9/12 to 10/12 2.5

over 10/12 to 11/12 3.25

over 11/12 to 12/12 4.0

over 12/12 to 14/12 5.0

over 14/12 to 16/12 6.0

over 16/12 to 18/12 7.0

over 18/12 to 20/12 7.5

over 20/12 to 21/12 8.0

The Dura-Vent GS is unitized and twist-locks together. For the

twist-lock procedure, consult Figure 5 and do the following:

(1) Four indentations, located on the female ends of pipes and

fittings, are designed to slide straight onto the male ends of

adjacent pipes and fittings, by orienting the four pipe indentations

so they match and slide into the four entry slots on the male

ends. (Figure 5.) Push the pipe sections completely together,

then twist-lock one section clockwise approximately one-quarter

turn, until the two sections are fully locked. The female locking

lugs will not be visible from the outside, on the Black Pipe or

fittings. They may be located by examining the inside of the

female ends.

(2) Horizontal runs of vent must be supported every three feet.

Wall Straps are available for this purpose.

Assemble the desired lengths of black pipe and elbows. It is

necessary to reach from the Heater up through the round support

box. Ensure that all pipe and elbow connections are in their fully

twist lock position.

Using the mark from Step 2, drive a nail up through the roof to

mark the center. Measure to either side of the nail and mark

the opening required. This is measured on the horizontal; actual

length may be larger depending on the pitch of the roof. Cut out

and frame the opening. See chapter 25 of the Uniform Building

Code for Roof Framing details. A one inch minimum air space

clearance must be maintained between the vent system and the

roof.

Assemble lengths of pipe and elbows necessary to reach from

the ceiling support box up through the roof line. Galvanized pipe

and elbows may be utilized in the attic, as well as above the roof

line. The galvanized finish is desirable above the roof line due to

its higher corrosion resistance.

4. Installing the Roof Flashing or Site-Produced Chase Top.

Position a Roof Flashing (or construct a Chase and Chase Top)

and secure in place with nails.

Continue to add Vent sections through the Roof Opening, maintaining at least 1” Air Space clearance. Major Building Codes

specify a minimum Vent (Chimney) height above the Roof top

depending on Roof Pitch. See Figure 10. Add Pipe sections

until the height of the Vent Cap meets the minimum Building Code

requirements described in Figure 10. Note that for steep roof

Pptches, the vent height must be increased.

These Vent System heights are necessary in the interest of

safety, however, they do not ensure draft-free operation. Trees,

buildings, adjoining Roof lines, adverse wind conditions, etc., may

create a ned for a taller Vent System should down drafting occur.

5. Termination Cap. Twist lock the Vent Cap.

01-01 Page 13 29863C

Figure 10 -Vent (Chimney) Height

WARNING!

THIS APPLIANCE MAY ONLY USE THE APPROVED

VENTING SYSTEMS SHOWN IN THESE

INSTALLATION INSTRUCTIONS. IT MUST NOT BE

CONNECTED TO CHIMNEY FLUE SERVICING A

SEPARATE SOLID FUEL OR GAS FUEL BURNING

APPLIANCE.

Page 14

DV450S DIRECT VENT ROOM HEATER

WALL THIMBLE/

TRIM COLLAR

INSIDE CHIMNEY

DIAMETER

6" MINIMUM

4'' UL 1777 LISTED

GAS VENT INNER

FLEX LINER

24" MINIMUM

VERTICAL HEIGHT

DURA-VENT GS

VENTING

6"

INTAKE AIR

EXHAUST

SEAL WITH SILICONE

SEAL WITH SILICONE

RIGID FLASHING

(ATTACHED TO CHIMNEY

WITH SCREWS WITH

SILICONE SEALANT

UNDERNEATH)

SILICONE SEALANTVTA

6" LINER (OPTIONAL)

WARNING

WHEN VENT SECTIONS EXCEEDING 3 FEET IN

LENGTH ARE INSTALLED BETWEEN AN OFFSET/

RETURN, STRUCTURAL SUPPORT MUST BE

PROVIDED TO REDUCE OFF-CENTER LOADING AND

PREVENT VENT SECTIONS FROM SEPARATING AT

THE VENT JOINTS.

C. Existing Masonry Chimney Installation

This installation is subject to local jurisdiction. Some codes

may require the use of another liner for intake air. If so, the

4” aluminum liner should be inside a 6” UL 181 listed liner.

This Heater can be vented through an existing Masonry Chimney

but the chimney must be lined with one UL 1777 listed 4” aluminum flexible gas vent liner for exhaust. The existing Flue will

be used to supply the air intake to the galvanized steel Flue

system. See Figure 11. Before installing the liner system, the

chimney passageway should be cleaned and examined to

verify it is unobstructed and in good structural condition.

Measure and record the chimney dimensions to determine total

flexible liner requirements.

Follow the liner manufacturer’s instructions for installing the liner

in the chimney. Attach a flexible liner puller to the liner and secure

a rope to the puller. One person should feed the liner through

the chimney, and another person should pull the liner from the

bottom, with the rope, guiding the liner down the chimney. After

feeding the liner down the chimney, form a 90˚ angle and bring

the liner through the hole in the chimney wall. (If running two

liners, run the 6” liner first and then the 4” inside of it.) Extend the

liner through the wall of the chimney and attach it to the venting

system extending from the top of the Heater.

Construct a metal flashing large enough and strong enough

to cover the chimney opening and support the Heater Vertical

Termination Cap. The flashing needs to fold down over and

around the outside of the masonry chimney so that it can be

secured to the chimney by 4 screws. See Figure 12. The

flashing will require a hole at least 6 1/2'' in diameter. (If using a

6” liner, extend the 6'' flexible liner through the flashing and attach

it to the VTA (Vertical Termination Adapter) with screws provided.)

Secure the VTA to the flashing with the screws provided and seal

the VTA/Flashing joint with a silicone sealant to prevent moisture

from running down the liner into the chimney.

Attach the 4'' gas vent liner to the Vertical Termination Cap with

screws provided, then attach the Termination Cap to the VTA with

screws provided. See Figure 12.

Figure 11

Adaptation to Masonry Chimney

01-01 Page 14 29863C

Figure 12

Masonry Termination

Page 15

DV450S DIRECT VENT ROOM HEATER

VERTICAL

TERMINATION

CAP

VERTICAL

TERMINATION

ADAPTER

UL1777 LISTED

4'' GAS VENT

FLEX LINER

EXISTING

CLASS A

METAL

CHIMNEY

(6'' MIN. DIAMETER)

DURAVENT GS

VENT SECTIONS

D. Existing Class A Metal Chimney Termination

In many cases where a DOVRE DV450S is replacing a woodstove, much of the existing Class A Metal Chimney can be

incorporated into the direct vent system.

The existing chimney must comply with NFPA-211 codes and any

local code requirements.

The chimney should be cleaned and examined to verify

it is unobstructed and in good structural condition. Any

structural weaknesses such as cracks, leaky joints, corroded or warped surfaces can have an adverse effect on

the performance of this Heater and should be replaced or

repaired.

Whenever an existing Class A Metal Chimney is on an outside

wall, removal of the chimney and the use of the minimum horizontal direct vent termination kit may be less expensive.

When using an existing Class A Metal Chimney the following

requirements are necessary:

Minimum size diameter is 6 inches.

Minimum height from the base of the stove to the top of termina-

tion cap is 9 feet.

The vent from the top of the Heater to the Chimney must be rigid

vent sections. A 4'' UL 1777 listed gas vent aluminum flexible

liner can be used inside the chimney. The flexible liner must

be secured to the last rigid section with three (3) sheet metal

screws. A minimum 3 inch overlap is required. Remove and

discard the existing chimney termination cap.

Determine the length of the 4'' UL 1777 listed gas vent flex liner

required to meet the vent sections at the top of the Heater.

Follow the liner manufacturer’s instructions for installing the liner

in the chimney. Attach a flexible liner puller to the liner and

secure a rope to the puller. One person should feed the liner

through the chimney, and another person should pull the liner

from the bottom, with the rope, guiding the liner down the chimney. Extend and run the 4'' gas vent liner down the chimney

leaving 10'' extending from the top of the chimney stack.

Install and secure the VTA (Vertical Termination Adapter) onto the

chimney with the brackets provided.

Place and secure the Termination Cap on the VTA with the

screws provided. See Figure 13.

Figure 13

Retro-Fit to Metal

Chimney

01-01 Page 15 29863C

Page 16

GAS LINE INSTALLATION

The Valve is located near the lower Right Rear Corner of the

appliance. Install the Gas Supply Line to the backside of the

unit to ease installation of the unit to the Supply Line, a flexible

connector and Manual Shut - Off Valve are supplied. The Manual

Shut - Off Valve should be installed onto the Supply Line, ahead

of the flex. All connections must be checked for leaks with a soap

and water solution or Gas Sniffer.

DV450S DIRECT VENT ROOM HEATER

GAS PRESSURE

For natural gas, the minimum inlet gas supply pressure is 4.5

inches water column, and the maximum inlet gas pressure is 7.0

inches water column, for the purpose of input adjustment. Input

rate is 40,000 Btu/hr. For propane gas, the inlet gas supply pressure must be at least 11.0 inches water column and a maximum

14.0 inches water column. Input rate is 38,000 Btu/hr.

Manifold pressure for this Heater is 1.6 - 3.5 inches water column

for natural gas and 6.3 - 10.0 inches water column for propane

gas. This Heater has a variable adjust manifold.Pressure taps

are located on the front of the valve for both inlet and outlet

pressure.

FUEL CONVERSION

For conversion of the DV450S unit, use Kit # 844-9230 to

convert from Natural Gas to LP.

A. Gas and Power Supply.

1. Shut off the Gas Supply to the unit.

2. Unplug the Blower Cord from the Power Supply.

3. Carefully remove the Logs and Burner from the

Firebox. See Figure A for burner removal.

B. Burner Orifice.

Adjust Air Shutter Adjustment Screw as necessary to slide the Air

Shutter off the Burner Orifice.

1. Loosen and remove the Retaining Nut on the Burner Orifice

with a 5/8” wrench. See Figure B.

2. Replace the Burner Orifice with the .073 LP Main Burner

Orifice supplied in kit. Reposition the Air Shutter onto the Burner

Orifice. Refer to Section IX., on the following page, for High

Altitude Installation.

C. Pilot Orifice.

1. Remove top of pilot hood. See Figure C.

2. Use an Allen Wrench to remove the pilot injector orifice. See

Figure D.

3. Replace the pilot hood ensuring that it is seated and aligned.

5. Replace burner into the unit.

Figure A

Figure B

Figure C

01-01 Page 16 29863C

Figure D

Page 17

DV450S DIRECT VENT ROOM HEATER

D. Valve - Adjustable Regulator.

1. Gain access to the Valve Regulator Head by lifting up on the

Valve Cover and removing the Tabs from the Slots on the Back

Shield.

2. Follow Steps 1 - 3 in the Instructions included with the

Regulator. Save the Label included in the Kit for later attachment

to the unit.

3. Replace the Valve Cover after the Valve has been checked

for leaks.

E. Leak Check.

1. Turn on the Gas Supply to the unit to check for gas leaks

with soap and water.

2. Turn the Gas Control Knob to the “Pilot” position.

Push the Knob in all the way and hold. At the same time, push in

the Red Ignitor button repeatedly until the Pilot lights. Never hold

the Gas Control Knob for more than [10] seconds if the Pilot does

not light. Once the Pilot lights, continue to hold the Control Knob

in for 15 seconds. Release the Gas Control Knob and it will pop

back out. Test for leaks at the Pilot Assembly using a soap and

water solution or a a Gas Sniffer. Turn the Gas Control Knob to

the “ON” position and turn the Switch On. Check for leaks around

the Valve and the Burner Orifice

WARNING!

THE INSTALLATION OF THIS

CONVERSION KIT MUST ONLY

BE UNDERTAKEN BY A QUAL-

IFIED AND CERTIFIED GAS

APPLIANCE INSTALLER.

HIGH ALTITUDE INSTALLATION

For U.S. installation, units are tested and approved for elevations

from 0-2000 feet.

When installing this unit at an elevation above 2000 feet, it may

be necessary to decrease the input rating by changing the existing Burner Orifice to a smaller size. Input should be reduced

4 percent for each 1000 feet above sea level. Check with the

local gas utility for proper Orifice size identification. This unit is

shipped with a .125 in./3.18 mm. Main Burner Orifice size for

Natural Gas.

For Canadian installation, units are certified for elevations from

0-4500 feet. When installing this unit at an elevation between

0-4500 feet in Canada, the input rating does not need to be

reduced.

When installing this unit at an elevation above 4500 feet in

Canada, check with local authorities.

Consult your local gas company for assistance in determining

the proper Orifice for your location or refer to ANSI Z223.1-latest

edition, Appendix F.

NOTE: This Heater DOES NOT require a 110VAC supply for operation.

NOTE: This Heater must be electrically wired and

grounded in accordance with Local Codes or, in the

absence of Local Codes, with the National Electric

Code ANSI/NFPA 70-latest edition, or the Canadian

Electrical Code, CSA C22.1.

NOTE: This appliance and its individual Shut - Off

Valve must be disconnected from the Gas Supply

Piping System during any Pressure testing of that

System at Test Pressures in excess of 1/2 psi (3.5kPa).

The appliance must be isolated from the Gas Supply

Piping System by closing its individual Manual Shut

- Off Valve during any Pressure testing of the Gas

Supply Piping System at test levels equal or less than

1/2 psi (3.5 kPa).

This conversion kit shall be installed by a qualied service agency in accordance

with the manufacturer’s instructions and all applicable codes and requirements of the

authority having jurisdiction. If the information in these instructions is not followed

exactly, a re, explosion or production of carbon monoxide may result causing property

damage, personal injury or loss of life. The qualied service agency is responsible

for the proper installatin of this kit. The installation is not proper and complete until

the operation of the converted appliance is checked as specied in the manufacturer’s

instructions supplied with the kit.

01-01 Page 17 29863C

WARNING !

Page 18

OPTIONAL ACCESSORIES

Receptacle

Blower

Control

Box

Optional accessories may be added now or at a later date.

A. Optional Fan

The Optional Fan Kit (844-0150) requires a 110VAC supply.

Blower Installation:

1. Remove the Knockout Plate from the Backshield of the

DV450S by prying out on the plate and clip or break the tabs that

hold it in place. See Figure 1 below.

2. Remove the tape from the back of the strip of Gasket Material

included with the blower kit, and position the Gasket over the edge

of the opening of the Backshield. See Figure 2 below. (This will

eliminate vibration.)

3. Install the Blower into the Backshield by hooking the bottom

of the Blower Housing into the opening and rock the top of the

Blower forward. Fasten the blower in place with the screws

included in the Fastener Pack. See Figure 3 on this page.

4. Attach the Switch Control Box on the Backshield with the

screws provided. See Figure 4, this page.

DV450S DIRECT VENT ROOM HEATER

Figure 3

Fan Installation on Back Shield

5. Plug the Connector on the wiring assembly into the Receptacle

on the top of the Blower Housing. See Figure 5, this page.

Figure 1

Removal of Knockout Plate

Figure 4

Attach Switch Control Box

Placing Blower Gasket on Back Shield

01-01 Page 18 29863C

Figure 2

Figure 5

Receptacle

Page 19

DV450S DIRECT VENT ROOM HEATER

20613 (1)

14212 (1)

25385 (1)

25579 (1)

25580 (1)

28749 (1)

18164 (1)

23998 (1)

Rocker Switch / Wall Thermostat / Remote

Variable

Regulator

Pilot

Adjustment

Cap

Manifold Pressure

Inlet Pressure

Push Button

Ignitor

Ignitor

Thermopile

Pilot

Thermocouple

WARNING!

Electrical Grounding Instructions

This appliance is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong

from this plug.

Blower Wiring Diagram

C. Remote Control

A remote control thermostat may be installed on this stove.

Contact your dealer for the correct model.

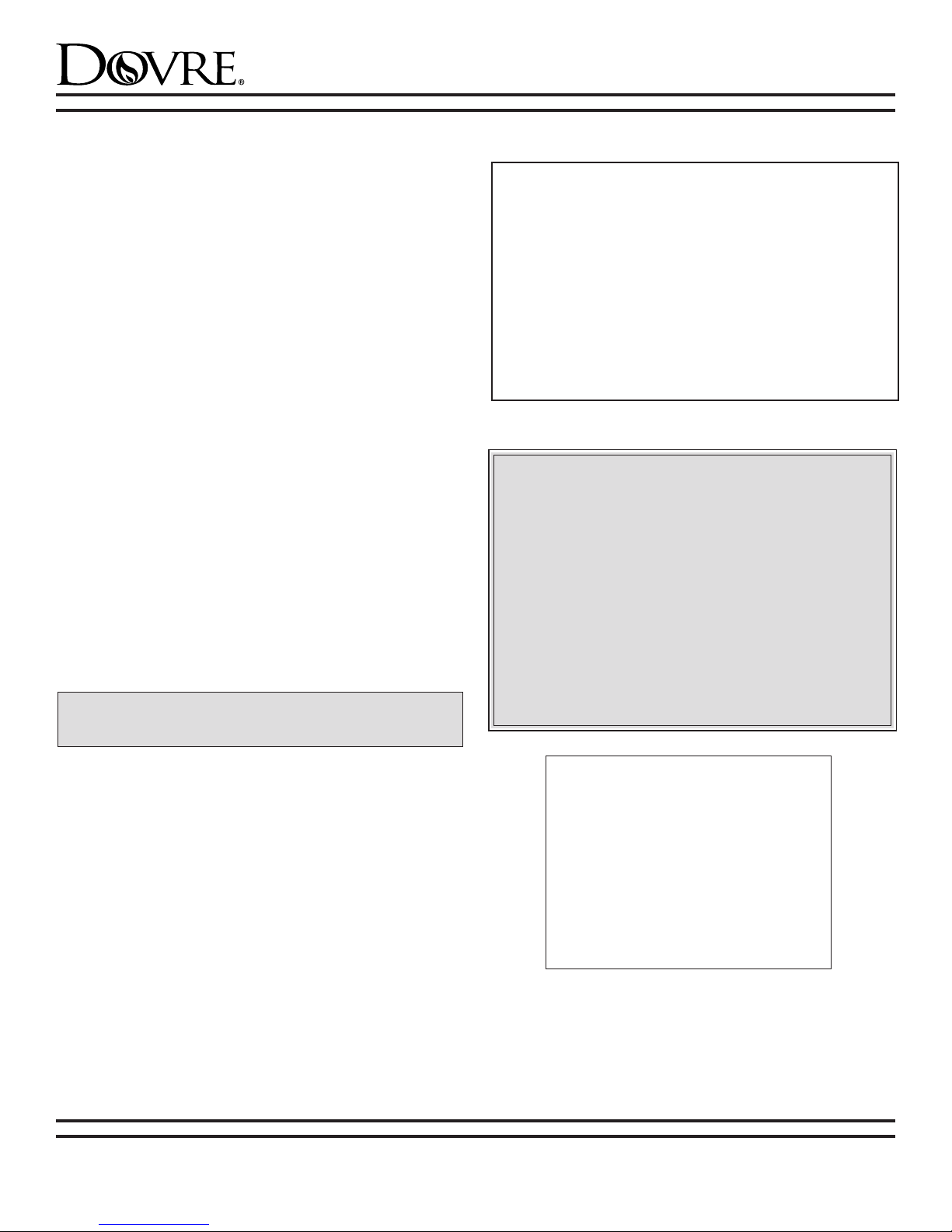

D. Warming Shelves/Brackets

Please see the Installation Instructions included with the Shelves.

Refer to page 5, Heater System Components, for ordering purposes.

B. Optional Wall Thermostat

The use of a millivolt Thermostat is allowed. It must be located

Warming Shelf and Bracket

within 20 feet of the appliance. In order for the Thermostat to

work, the “ON/OFF” Switch must be in the “ON” position.

Figure 12 shows how to connect a millivolt Thermostat without

the “ON/OFF” Switch in the Circuit. Disconnect the “ON/OFF”

Switch from the Valve and wire the millivolt Thermostat as indicated.

E. Door Trim

Part # 844-0140. Please the Installation Instructions included

with the Door Trim.

Decorative Glass Accent

Figure 12 - Wiring Diagram

01-01 Page 19 29863C

Page 20

DV450S DIRECT VENT ROOM HEATER

Firebox Entry

A. Removing the Front Face.

1. Losen the Thumb Screw from the bottom of the unit that holds

the Front Face in position. See Figure 20.

2. Carefully lift the Front Face up and pull the bottom forward.

Place in a safe place.

Figure 20 - Bottom Thumb Screw

B. Removing the Glass.

3. Remove the Glass Frame Assembly by pulling the Latch

Releases forward and upward. See Figure 21. Lift the Glass

Frame Assembly up, sliding the [3] tabs at the bottom out of

the slots.

C. Log Placement.

The logs are shipped in separate packaging. Refer to Fig. 22 for

identification for the installation process.

1. Place rear log over two white pins on the firebox floor at the

back of firebox. See Fig. 23.

2. Set left log over two pins on left side of firebox floor. Fig. 24.

3. Set right log over two pins on right side of firebox floor.

4. Set left twig over one pin on top left of rear log and into groove

on front left log.

5. Set right twig over two pins on top right of rear log and into

groove on front right log.

Figure 23

Rear Log

Placement

Figure 24

Left and Right

Log Placement

Figure 21 - Removal of Sealed Glass

REAR LOG

LEFT

TWIG

LEFT LOG

Figure 22 - Log Identification

01-01 Page 20 29863C

RIGHT LOG

RIGHT

TWIG

D. Creating the Coal Bed Look.

Ember Chunks.

Randomly place the Ember Chunks on the Burner Pan between

and in line with the two front logs, creating a small wall of

embers. Do not allow the Chunks to cover the burner ports or air

holes in the Burner Pan as this may restrict air and/or gas flow,

creating a less than satisfactory performance. Too much restriction can cause improper combustion and sooting (especially with

an appliance using propane gas). It is not necessary to use all of

the Chunks supplied with the unit.

Once the Burner Pan has been correctly covered with Ember

Chunks, place a single row of ember Chunks on the ember tray

located at the front of the Log Assembly.

Once the Ember Chunks are in place, a thin layer of Mineral Wool

may be bridged over the Chunks for greater enhancement.

Lava Rock.

Distribute the lava rock over the surface of the hearth pan next

to the glass being careful not get lava rock down into the air

inlet slots or onto the surface of the Burner Pan. The lava rock

does not change the flame and does not have to be used. A

different look to to the front of the unit is to add a row of ember

Chunks.

Page 21

DV450S DIRECT VENT ROOM HEATER

E. Adjustable Flue Restrictor

The DV450 has an adjustable flue restrictor for maximum performance for vertical installations. The unit is shipped with the

restrictor in the open position and should be left open with any

horizontal installations.

The adjustment screw can be accessed by reaching through

the center air outlet slot at the top of the front face. See Figure

25. The slot of the screw head indicates the position of the

restrictor. See Figure 25. Turn the screw with a straight blade

screwdriver to close the restrictor as necessary.

The amount to close the restrictor will depend on the vent

height. If the vertical height is 20 feet or more, the restrictor

can be closed all the way. Anything less will require some

setting less than closed. The setting will vary depending on

the installation.

Any offsets in a vertical installation will restrict the system and

the flue restrictor will not need to be closed as much.

Figure 26 - Door Trim Installation

Step 14 - Replacing the Front Face

Carefully lift the front face into position and replace the thumb

screw to hold it in position.

WARNING!

NEVER OPERATE THIS APPLIANCE WITH THE

DOOR AND/OR GLASS REMOVED OR NOT

SEALED.

Figure 25 - Adjustable Flue Restrictor

Step 11 - Clean the Glass

To clean the glass, use a non-abrasive, mild cleaning solution.

(For example, a glass cleaner or for stubborn film, an oven

cleaner.) Apply an adequate amount to the glass and wipe off

with a damp cloth. Be sure all cleaner is thoroughly rinsed from

the glass.

Step 12 - Install the Glass

After cleaning the glass, carefully place the Glass Frame

Assembly onto the unit by positioning the tabs at the bottom of

the frame into the slots. Pull the latch releases forward and hook

over the glass frame.

Step 13 - Optional Door Trim Kit Installation

The decorative trim can be installed at this time.

1. Lay the front face on a flat surface being careful not to

damage it.

2. Remove the lower shield by removing the (3) screws.

3. Lay the door trim onto the front face and put the shield back in

position and attach with the screws provided and those removed

earlier.

The screws are thread cutters and a power screwdriver is necessary to drive the screws into position. See Figure 26.

WARNING!

DO NOT OPERATE APPLIANCE WITH THE

PANEL(S) REMOVED, CRACKED OR BROKEN.

REPLACEMENT OF THE PANEL(S) SHOULD BE

DONE BY A LICENSED OR QUALIFIED SERVICE

PERSON.

Pre-Use Check List

Before operating this heater, please review the safety precautions given on page 2 as well as the items listed below:

1. Check to make sure the logs are securely in place and

the rock wool, lava rock and Chunks have all been placed

correctly. (Refer to Steps 8 and 9.)

2. Check to see that all wiring is correct and enclosed to prevent

possible shock.

3. Check to ensure there are no gas leaks. This may be done

with a soap and water solution.

4. Make sure the glass is sealed and in its proper position.

Never operate this heater with the face removed or glass

removed or not sealed.

5. Verify that all venting and caps are unobstructed. Exhaust

gases are extremely hot. Check for obstructions from trees,

bushes, snow drifts, etc.

6. Read and understand these Instructions thoroughly before

attempting to operate this heater.

01-01 Page 21 29863C

Page 22

DV450S DIRECT VENT ROOM HEATER

PILOT

!

!

!

LIGHTING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING!

If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

A. This gas appliance has a manual ignition device that lights the pilot.

When lighting the pilot, follow these instructions exactly.

B. STOP! BEFORE READING FURTHER, smell around the appliance

area for gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle to the floor.

WHAT TO DO IF YOU SMELL GAS:

*Do not try to light the appliance.

*Do not touch any electric switch; do not use any telephone

in your building.

*Immediately call your gas supplier from a neighbor’s

telephone. Follow the instructions of your utility.

*If you cannot reach your utility, call the fire department.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Turn off all electric power to the appliance. If your appliance has a

thermostat, set to lowest setting.

3. Open control access panel.

4. Find the pilot. The pilot is inside the combustion chamber next to the

main burner.

C. IF THE PILOT LIGHT AND BURNER WENT OUT DURING USE,

YOU MUST TAKE THE GLASS OFF THE APPLIANCE AND WAIT TO

CLEAR OUT ANY GAS. FOLLOW THE LIGHTING INSTRUCTIONS

BELOW.

D. Use only your hand to push in or turn the gas control knob to light

the pilot. Never use tools. If the knob will not push in or turn by hand,

do not try to repair it; call a qualified service technician. Using a tool

or attempting repairs may result in a fire or explosion.

E. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas

control that has been under water.

7. Smell for gas, including near the floor. If you don’t smell gas, go to

the next step. If you smell gas, wait another five (5) minutes or until

the gas odor is no longer present before continuing. If the odor of gas

does not disappear after fifteen (15) minutes, STOP! Follow “B” in the

safety information above.

8. Replace glass panel if it has been removed.

9. Turn gas control knob counterclockwise to the “PILOT”

position.

10. Push the gas control knob in all the way and hold. At the same time,

push in red ignition button repeatedly until the pilot lights. Never hold the

gas control knob in for more than ten (10) seconds if the pilot does not

light. Once the pilot lights, continue to hold the gas control knob in for 15

seconds. Release the gas control knob and it will pop back up. If pilot

does not remain lit, repeat steps 6 through 9.

5. If the gas control knob is at the “OFF” position, go to step 7. If the gas

control knob is at the “ON” position, go to step 6.

6. If the pilot light went out during normal use with the gas control knob at

the “ON” position, turn the gas control knob to the “OFF” position. REMOVE

THE FIXED GLASS PANEL. Wait ten (10) minutes to clear out any gas.

9. Turn gas control knob counterclockwise to the “PILOT”

TO TURN OFF GAS TO APPLIANCE

1. Turn rocker switch to OFF or the wall thermostat to lowest setting if your

unit is so equipped.

2. Turn off all electric power to the appliance if service is to be performed.

01-01 Page 22 29863C

*If gas control knob does not pop back up when released, turn the knob

to “OFF” and call your service technician or gas supplier.

*If the pilot will not stay on after two attempts, turn the gas control knob to

“OFF” and call your service technician or gas supplier.

11. Turn gas control knob counterclockwise to the

“ON” position. The knob can be turned to the “ON” position only if it

is popped out.

12. Close the access panel.

13. Turn on electrical power to the appliance. If equipped with a

thermostat, set to the desired setting.

3. Open control access panel.

4. Turn gas control clockwise to “OFF”.

5. Close control access panel.

Page 23

DV450S DIRECT VENT ROOM HEATER

Upon completing the gas line connection, a small amount of air

will be in the lines. When first lighting the pilot light, it will take a

few minutes for the lines to purge themselves of this air. Once the

purging is complete, the pilot and burner will light and operate.

Subsequent lightings of the appliance will not require such

purging. When lit for the first time, the appliance will emit a slight

odor for an hour or two. This is due to paint and lubricants used in

the manufacturing process. Additionally, for the first few minutes

after each lighting, vapor may condense and fog the glass and

the flames may be blue. After a few minutes, this moisture will

disappear and within 15-30 minutes the flames should become

yellow.

CAUTION: During the initial purging and sub-

sequent lightings, NEVER allow the gas valve

control knob to remain depressed in the “pilot”

position without pushing the red ignitor button at

least once every second.

ON/OFF SWITCH FOR THE BURNER

The on/off switch for the burner is located at the rear of the unit.

The knob beside the switch controls the flame setting. Turning

clockwise increases the flame and counter-clockwise turns the

flame to low. See Figure 27.

Figure 27 Flame Adjustment

Figure 28

Air Shutter Adjustment

Note:

Allow the unit to cool before replacing the front face.

Allow the unit to operate about 15-20 minutes. This will give

the flame time to reach its height and color before making

adjustments to the air shutter. As the shutter is closed, the flame

should get taller and darker.

The appliance may produce a noise, caused from metal

expansion and contraction as it heats up and cools down. This

noise is similar to one that a furnace or heat duct may produce

and does not affect the operation or longevity of the the unit.

Keep the control compartment, logs, and burner area surrounding

the logs clean by vacuuming or brushing at least twice a year.

CAUTION: The Logs can get very hot -

handle only when cool.

SEASONAL SHUTDOWN

Turning the valve to off at the end of the season will prevent gas

from running to the appoiance while not in use in the off season.

However, leaving the pilot on does not consume a large amount

of gas and the pilot will help keep the moisture and insects out

of the system.

AIR SHUTTER ADJUSTMENT

The air shutter adjusts the amount of air that mixes with the gas

as it enters the Burner Pan. It is used to fine tune the flame as

necessary for differences in altitude and vent configuration. The

shutter is shipped in the open position.

It can be adjusted by removing the front face and turning the

adjustment screw. See Figure 28.

Turning the screw in will close the shutter; turning the screw out

will open the shutter.

The shutter can be adjusted while the unit is in operation.

However, the unit should be shut off and allowed to cool before

removing the front face.

01-01 Page 23 29863C

OPERATION PROCEDURE DURING REGULAR USE

Simply turn the switch/thermostat to the ON position. THis will

ignite the main burner.

SHUTDOWN DURING REGULAR USE

Simply turn the switch/thermostat to OFF. This will disengage the

burner and the falmes will extinguish.

Page 24

MAINTENANCE INSTRUCTIONS

Pilot Hood

Thermopile

Flame covers top 1/2" of

thermopile and thermocouple.

(Pilot Sensor)

Thermocouple

Correct

Flames should be blue at the base,

yellow-orange on the top.

Not Enough Air

If the flames are tall or sooty on

the ends, open the air shutte

r.

Too Much Air

If the flames are all blue, short

and transparent, close the air shutte

r

.

DV450S DIRECT VENT ROOM HEATER

Cleaning the burner and control compartment

Keep the burner compartment clean. Brush this area with a

clean, dry paint brush and vacuum at least once a year. Always

turn off the gas valve and ON/OFF switch before cleaning.

Checking flame patterns

Visually check the flame of the burner periodically, making sure

the flames are steady; not lifting or floating. The flame color

should be blue with yellow tips. The thermopile tip should be

covered with flame. See Figure 20.

NOTE: If the air shutter is open all the way and the

flames remain sooty, shut off gas to the appliance and

contact a qualified gas service technician.

If the vent configuration is installed incorrectly, the vent

may cause the flames inside the appliance to lift or

“ghost” - a dangerous situation. Inspect the flames after

installation to ensure proper performance. If the vent

configuration is correct, yet the flames are lifting or ghosting, shut off gas to the appliance and contact the dealer

for information on remedying the problem.

Venting system inspection

The heater and venting system should be inspected before use

each season, and at least annually, by a qualified field service

person, to ensure that the flow of combustion and ventilation

air is not obstructed.

Cleaning the glass

It is recommended to wear gloves while handling or removing

the glass. DO NOT REMOVE THE GLASS WHEN HOT.

WARNING!

Do not use this heater if any part has been under

water. Immediately call a qualified service technician to inspect the heater and to replace any part of

the control system and any gas control which has

been under water.

Figure 20 - Standing Pilot

Note: Operation of a Direct Vent Heater may

be sporadic in high wind situations.

Note: When cleaning the glass, NEVER use abrasive

materials. NEVER clean glass when hot.

To clean the glass, use a non-abrasive, mild cleaning solution.

(For example, a glass cleaner for stubborn film, or an oven

cleaner.) Apply an adequate amount to the glass and wipe

off with a damp cloth. Be sure all cleaner is thoroughly rinsed

from the glass.

Never operate this heater without the glass properly secured in

place or if the glass is broken.

In the event of glass breakage, follow door removal instructions. This will allow the removal of all glass fragments and

sheet metal edge protection strips. Vacuum all remaining glass

pieces with a shop vac. (DO NOT VACUUM IF PIECES ARE

HOT.) Replace glass ordered direct or through your local

distributor. Never use substitute material. Only ceramic glass

may be used on this heater.

Log cleaning

Carbon build-up can be removed with a vacuum cleaner.

01-01 Page 24 29863C

Figure 21 - Flame Patterns

CAUTION:

Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify

proper operation after servicing.

Page 25

DV450S DIRECT VENT ROOM HEATER

TROUBLE SHOOTING

Problem: Possible Cause: Solutions:

Pilot will not light. Air in Gas Lines. Bleed air from Gas Line.

Wrong Inlet Pressure. Check Gas Line pressure (7” Nat., 11” L.P.).

Defective Spark Replace Electrode if the Insulator is cracked or the Tip is

Electrode. corroded. Verify that the Spark Gap between the Pilot and

the Electrodes correct.

Defective Piezo Wire. Replace Piezo Wire if Insulation is damaged, broken, or

corroded.

Safety Interlock Allow Thermocouple to cool until the mV drops below the

Function engaged. hold - in requirements of the Safety Magnet (30 seconds or

less). Relight Pilot.

Pilot will not hold. Wrong Inlet Pressure. Check Gas Line pressure (7” Nat., 11” L.P.).

Pilot Adjustment Screw After the Pilot has been lit for approximately [3] min., and only

not adjusted properly. the Thermo-generator wires connected to the Main Operator

Head, measure the voltage across TPTH and TP. This Open

Circuit voltage should be between 500mV and 750mV. Tune

the Pilot Adjustment Screw until the mV reading falls within

these parameters. Counter-clockwise increases the mV

reading, Clockwise decreases it. Turn with a Wrench.

Thermocouple or

Thermo-generator has clean the upper 3/8” with a very fine Emery cloth.

Film build-up on Tip.

Electrical Resistance Using a very fine Emery cloth, clean the Thermo-generator

too high. and Thermocouple connections at the Valve. Tighten

Thermocouple into Valve, hand tight, adding a 1/4 turn

with a wrench.

Defective Verify that the Thermocouple is not kinked or damaged.

Thermocouple. Check Open-Circuit voltage of Thermocouple. Voltage should

(mV Plus System) be between 18mv and 28mv. If voltage is less than 14mv,

replace the Thermocouple.

Defective Thermo- After the Pilot has been lit for approximately [3] min.,and only

generator. the Thermo-generator wires connected to the Main Operator H

(millivolt System) Head, measure the voltage across TPTH and TP. This Open

Circuit voltage should be between 500mV and 750mV. Tune

the Pilot Adjustment Screw until the mV reading falls within

these parameters. Counter-Clockwise increases mV reading,

Clockwise decreases it.

Defective Safety Magnet Verify operation of Safety Magnet in the following manner:

(mV Plus Systems). (A) Depress and hold the Pilot Button.

(B) Verify Open-Circuit Thermocouple voltage as described

in previous Step.

(C) Reconnect Thermocouple to the Valve.

(D) Measure the millivoltage between the Solder Button on

With the Thermocouple and Thermo-generator Tips cool,

01-01 Page 25 29863C

Page 26

DV450S DIRECT VENT ROOM HEATER

TROUBLE SHOOTING (continued)

Problem: Possible Cause: Solutions:

Pilot will not Defective Magnet

Hold (Cont.). (mV Plus systems).

If the mV reading is above 6mV and the Safety Magnet

does not hold, replace the Valve.

(E) If Closed-Circuit mV reading is the same as the

Open-Circuit reading, the Coil is electrically “Open”.

Replace the Valve.

Defective Savety Magnet

Pilot Drops Pilot Orifice blocked. Replace Orifice with a new Orifice of the exact size and type.

Out. Wrong Pilot Orifice. Replace the Orifice with a new Orifice supplied specifically

for the appliance and gas in question.