Page 1

INSTALLATIEVOORSCHRIFTEN EN GEBRUIKSAANWIJZING

HOUTKACHEL

INSTALLATION INSTRUCTIONS AND OPERATING MANUAL

INSTALLATION ET MODE D’EMPLOI

EINBAUANLEITUNG UND GEBRAUCHSANWEISUNG

INSTRUCCIONES DE INSTALACIÓN Y USO

REQUISITI PER L'INSTALLAZIONE E ISTRUZIONI PER L'USO

MONTERINGS- OG BRUKSANVISNING

WOOD STOVE

POELE A BOIS

HOLZ-FEUERSTÄTTE

ESTUFA DE LEÑA

STUFA A LEGNA

PEISOVN

BOLD 300 BOLD 400

BOLD

03.27170.200 - 04-2016

Page 2

Table of contents

Introduction 2

Performance declaration 3

Safety 5

Installation requirements 5

General 5

Flue 5

Room ventilation 6

Floor and walls 6

Product description 7

Installation 7

General preparation 7

Preparing the connection to the flue 8

Preparing the outside airconnection 9

Installing and connecting 9

Use 10

First use 10

Fuel 10

Lighting 10

Burning wood 11

Maximum amount of wood 12

Controlling combustion air 12

Extinguishingthe fire 13

Removing ash 13

Fog and mist 13

Resolving problems 13

Maintenance 14

Flue 14

Cleaning and other regularly maintenance 14

BOLD spareparts 16

Appendix 1: Technical data 17

Appendix 2: Dimensions 18

Appendix 3: Distance from combustible

material 20

Appendix 4: Diagnosis diagram 23

Index 24

Subjectto change because of technicalimprovements

1

Page 3

Introduction

Dear user,

By purchasing this heating appliance from DOVRE

you have selected a quality product. This product is

part of a new generation of energy-efficient and environmentally-friendly heating appliances. These appliances make optimum use of convection heat as well

as radiant heat.

Your DOVRE appliance has beenmanufactured

with state-of-the-art production equipment. In the

unlikely event of a malfunction, you can always

rely on DOVRE for support and service.

The appliance should not be modified; please

always use original parts.

The appliance is intended for use in a living room. It

must be hermetically connected to a properly working flue.

We advise you have the appliance installed by an

authorized and competent installer.

DOVRE cannot be heldliable for any problems or

damage resulting from incorrect installation.

Observe the following safety regulations when

installing and using the appliance.

In this manual, you can read how the DOVRE heating

appliance can beinstalled, used and maintained

safely. Should you require additional information or

technical data, or should you experience an installation problem, please first contact your supplier.

© 2016 DOVRE NV

2

Subjectto change because of technicalimprovements.

Page 4

Performance declaration

In accordance with construction products regulation 305/2011

No. 051-CPR-2015

1. Unique identification code of the product type:

BOLD 300 -400 / 7kW

2. Type, batch or serial number or other form of identification for the construction product, as prescribed in article 11, subsection 4:

Uniqueserial number.

3. Intended use for the construction product, in accordance with the applicable harmonised technical

specification, as specified by the producer:

Stove for solid fuel without production of warm water in accordance with EN 13240.

4. Name, registered trade name or registered trademark and contact address of the producer, as prescribed in article 11, subsection 5:

Dovre N.V. Nijverheidsstraat 18 2381 Weelde Belgium.

5. If applicable, name and contact address for the authorised whose mandate covers the tasks specified in article 12, subsection 2:

-

6. The system or systems for the assessment and verification of the performance durability of the construction product, specified in appendix V:

System 3

7. If the performance declaration refers to a construction product that falls under a harmonised standard:

The appointed agency KVBG, registered under the number 2013, has performed a type test under system 3

andhas issued the test report No. H2015/0078.

8. If the performance declaration concerns a construction product for which a European technical

assessment is issued:

-

Subjectto change because of technicalimprovements.

3

Page 5

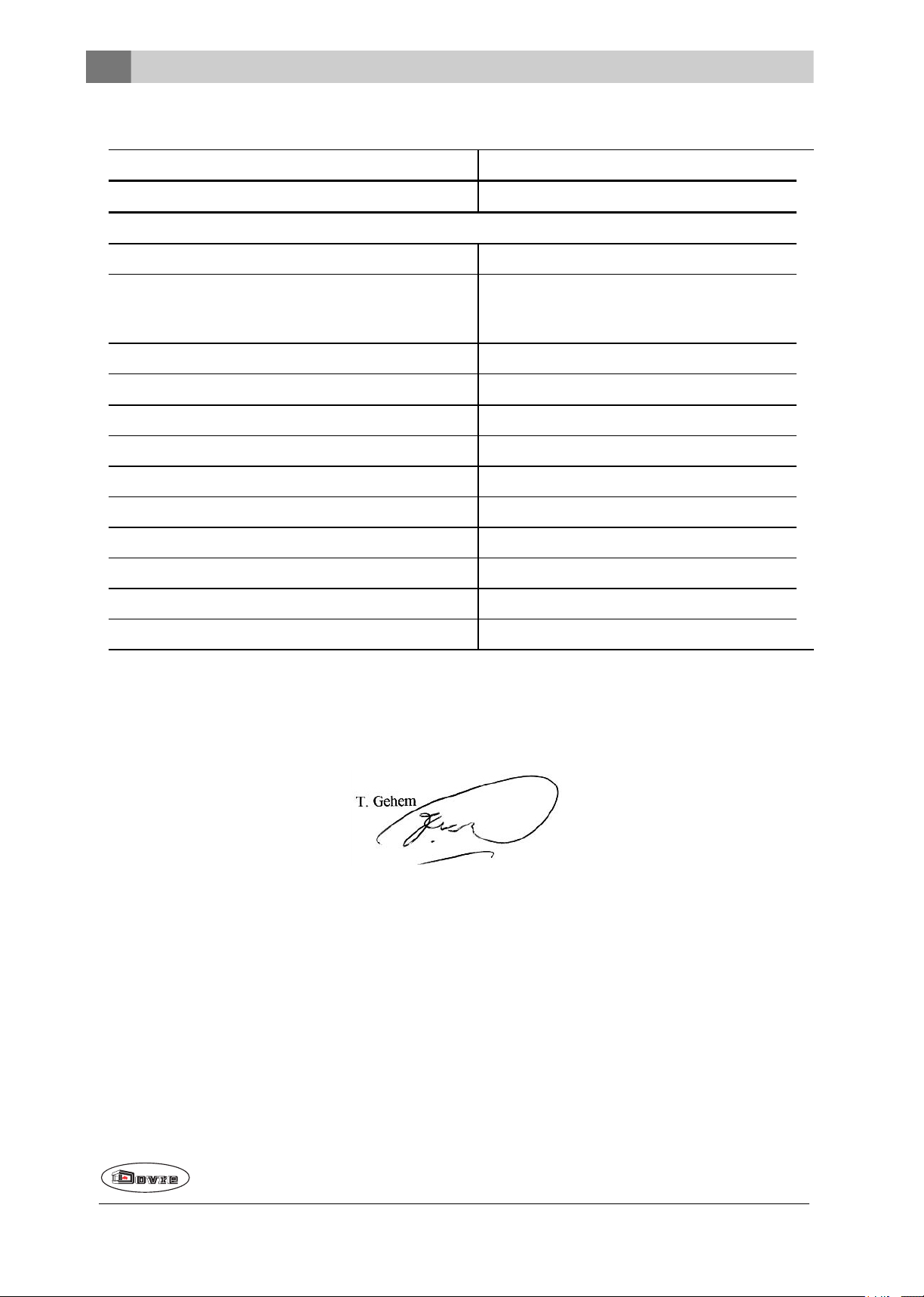

9. Declared performance:

The harmonised norm EN 13240:2001/A2 ;2004/AC :2007

Essential characteristics Performance Wood

Fire safety

Fire resistance A1

Minimum distance in mm

Distance from combustible material

Rear: 300

Side: 250

Risk of glowing particles falling out Conform

Emission of combustion products

CO: 0.10% (13%O2)

Surface temperature Conform

Electrical safety -

Ease of cleaning Conform

Maximum operating pressure -

Flue gas temperature at nominal output 246 °C

Mechanical resistance (carrying weight of chimney) Not determined

Nominal output 7 kW

Efficiency 80 %

10. The performance of the product described in points 1 and 2 conform with the performance reported

in point 9.

This performance declaration is supplied under the exclusive responsibility of the producer specified

in point 4:

01/10/2013 Weelde

Tom Gehem

CEO

Due to continuous product improvement, the specifications of the appliance supplied can vary from the description in this brochure without prior notice.

DOVRE N.V.

Nijverheidsstraat 18 Tel : +32 (0) 1465 91 91

B-2381 Weelde Fax : +32 (0) 14 65 90 09

Belgium E-mail : info@dovre.be

4

Subjectto change because of technicalimprovements.

Page 6

Safety

Please note: All safety regulations must be

complied with strictly.

Please read carefully the instructions supplied

with the appliance for installation, use and

maintenance before using the appliance.

The appliance must beinstalledin accordance

with the legislation andrequirements applicablein yourcountry.

Ensurethat there is adequate ventilation in the

room in which the appliance is installed. If ventilation is insufficient, combustion will be incomplete whereby toxic gases can spread through

the room. See the chapter"Installation requirements" for more information onventilation.

Installation requirements

All local regulations and the regulations relating

to national and European standards must be

observed when installingthe appliance.

The appliance should preferably be installed by

an authorised installer. Installers will be aware

of the applicable regulations and requirements.

The appliance is designed forheating purposes. All surfaces, including the glass and

connecting tube, can become very hot (over

100°C)! When operating, use a so-called "cold

hand" or an oven glove.

Ensurethat the appliance is adequately

guarded if young children, disabledpeople, the

elderly or animals are present in the vicinity.

Safety distances from flammable materials

must be strictly adhered to.

Do not place any curtains, clothes, laundry or

other combustible materials on or near the appliance.

When in use, do not use flammable or explosive substances in the vicinity of the appliance.

Avoid chimney fires by having the chimney

swept regularly. Never burn wood with the door

open.

In the event of a chimney fire: close all the

appliance's air inlets and alert the fire service.

If the glass in the appliance is broken or

cracked, it must be replacedbefore the stove

is used again.

Do not exert force on the door, donot allow children to pull on the opened door, never standor

sit on the opened door and do not place heavy

objects on the door.

General

The appliance must beconnected tightly to a wellfunctioning flue.

For connection measurements: see "Technical

data" appendix.

Ask the fire service and/or yourinsurance company about any specific requirements and regulations.

Flue

The flue is needed for:

Removal of combustion gases via natural draught.

As the warm airin the flue orchimney is lighter

than the outside air, it rises.

Air intake, needed for the combustion of fuel in the

appliance.

A poorly-functioning flue or chimney can cause smoke

to escape into the room when the door is opened.

Damage caused by smoke emissions into the room is

not covered by the warranty.

Do not connect multiple appliances (such as a

boiler for central heating) to the same flue,

unless local or national regulations allow this.

In the event of two connections ensurethat the

difference in height between the connections is

no less than 200 mm.

Ask your installer for advice regardingthe flue. Refer

to the European norm EN13384 for a correct calculations for the flue.

The flue must satisfy the following requirements:

The flue or chimney must be made of fire-resistant

material, preferably ceramics or stainless steel.

Subjectto change because of technicalimprovements.

5

Page 7

The flue or chimney must be airtight and wellcleaned andguarantee sufficient draught.

A draught/vacuum of 15-20Pa during normal

operation is ideal.

Starting from the flue spigot, the flue must run as

vertically as possible. Changes in direction and

horizontal pieces disrupt the outward flow of combustion gases and may cause soot deposits.

Room ventilation

For good combustion, the appliance needs air (oxygen). This air is supplied via adjustable air inlets from

the area in which the appliance is installed.

If ventilation is insufficient, combustion will be

incomplete, which may lead toxic gases to

spread through the room.

To prevent combustion gases from cooling down

too much, which reduces the draught, ensurethat

the interior diameter is not too big.

The flue or chimney shouldideally have the same

diameter as the connection collar.

For nominal diameter: see "Technical data"

appendix. If the smoke channel is well insulated, the diameter may beslightly bigger (upto

2x the section of the connection collar).

The section (area) of the smoke channel must be

constant. Wider segments and (in particular) narrower segments disrupt the outward flow of combustion gases.

In fitting a cover plate/exhaust cap to the flue:

make sure that the cover does not restrict the flue

outlet and that the cap does not impede the outward flow of combustion gases.

The flue must end in a zone that is not affected by

surrounding buildings, trees orother obstacles.

The flue outside the house must beinsulated.

The flue should be at least 4metres high.

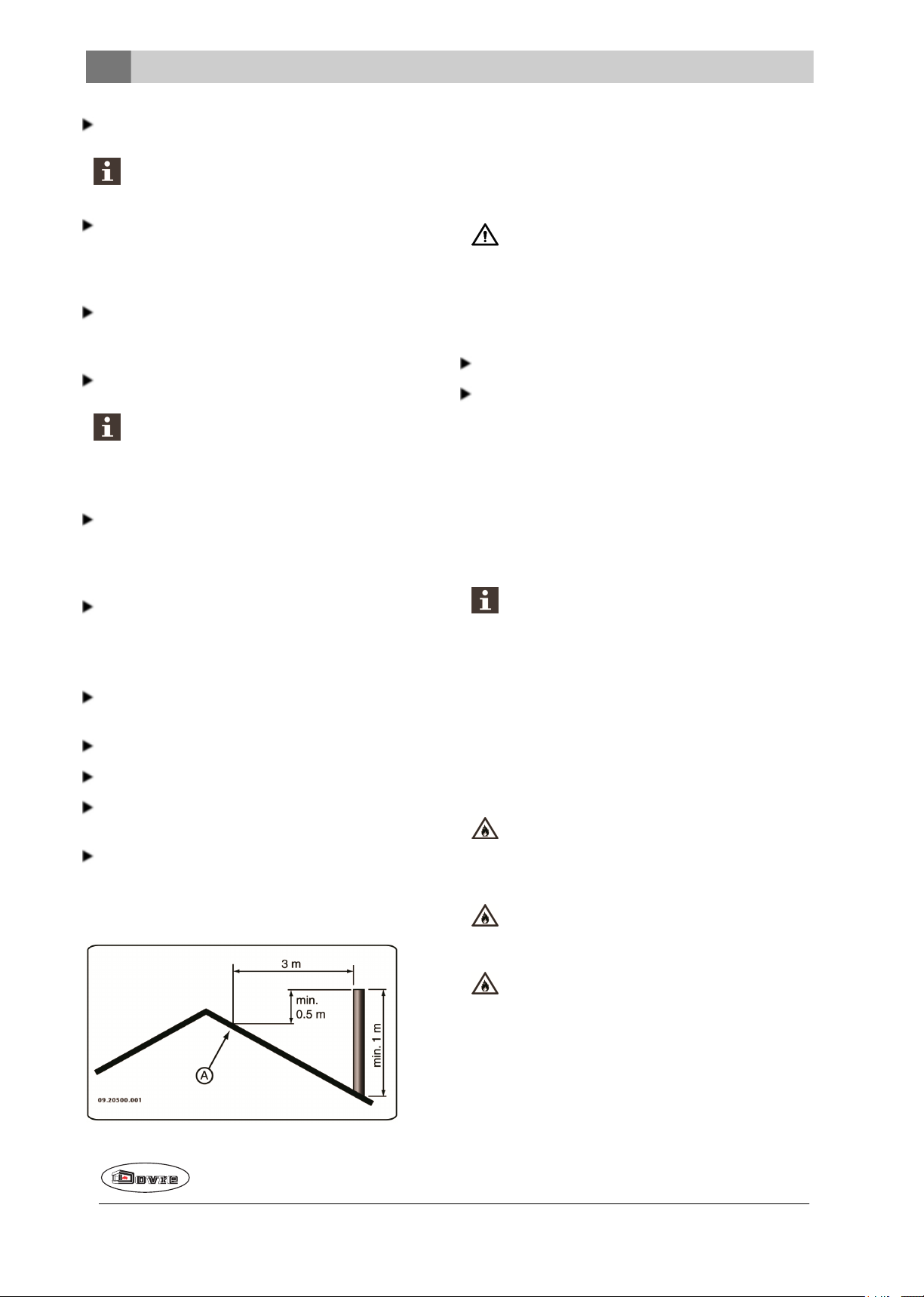

As a rule of thumb: 60cm above the ridge of the

roof.

If the ridge of the roof is more than 3metres from

the flue: use the measurements given in the following figure. A = the highest point of the roof

within a distance of 3metres.

As a rule of thumb, the air supply should be

5.5cm²/kW. Extra ventilation is needed when:

The appliance is in a well-insulated area.

There is mechanical ventilation, for example a central extraction system or an extraction hood in an

open kitchen.

You can provide extra ventilation by having a ventilation louvre fitted on the outside wall.

Make sure that other air consuming appliances (such

as tumble-driers, other heating appliances or a bathroom fan) have their own supply of outside air, orare

switched off when you use the appliance.

You can also connect the appliance to an outside air supply. A connection kit is supplied for

this purpose. This makes additional ventilation

unnecessary.

Floor and walls

The floor on which the appliance is placed must have

sufficient bearing capacity. Theweight of the appliance is given in the appendix “Technical Data

appendix”.

Protect flammableflooring from heat radiation

by means of a fireproof protective plate. See

the appendix "Distance from combustible

material".

Remove combustible material such as linoleum, carpets/rugs and similar materials below

the fireproof protective plate.

Keep sufficient distance between the appliance and combustible materials such as

wooden walls and furniture.

6

Subjectto change because of technicalimprovements.

Page 8

The connecting tubealso radiates heat. Ensure

09-20021-092

1

2

3

4

09-20021-090

1

2

3

that there is sufficient distance or a shield

between the connecting tube andcombustible

material.

The rule of thumb for a single-walledtubeis a

distance of 3x the diameter. If a lining shell is

fitted around the tube, a distance of 1x the diameter is permissible.

Carpets and rugs must be at least 80cm away

from the fire.

Use a fireproof floorplate to protect a flammable floor from any ash which may fall in front

of the stove. Thefloorplate must comply with

national standards.

a glove has been supplied which you can use to protect your hand.

Installation

General preparation

Please check the appliance immediately after delivery for damage duringtransport or any other damageor defects. Theappliance is attached to the

pallet with screws at the bottom.

If you detect transport damageor any other

damage ordefects, do not use the appliance

andnotify the supplier.

For the dimensions of the fireproof protective

plate: see the appendix "Distance from combustible material".

For further requirements with respect to fire

safety, see the appendix "Distance from combustible material".

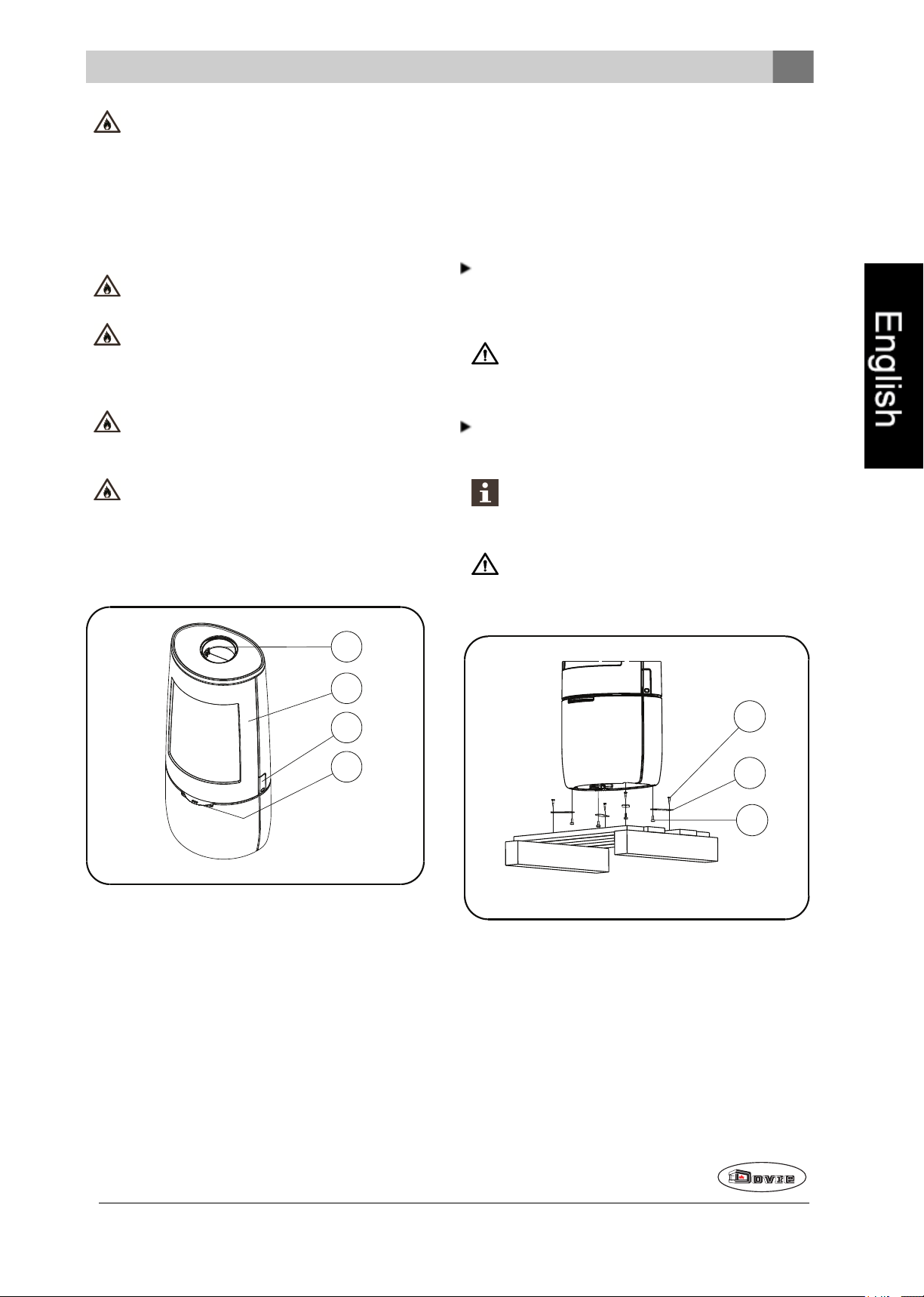

Product description

Remove removableparts (fire-resistant inner

plates, fire grate, top plate, ashtray) from the appliance before startinginstallation.

It is easier to move the appliance and to avoid

damage if the removable parts have been

removed.

Note the location of the removable parts, so

that you can re-position the parts in the correct

place later on.

1. Connection collar

2. Door

3. Latch

4. Air slide

Door lock

The appliance is supplied with the latch button (4)

installed. Thedoor is opened by pressing in the latch

button. As the latch button becomes warm during use,

Subjectto change because of technicalimprovements.

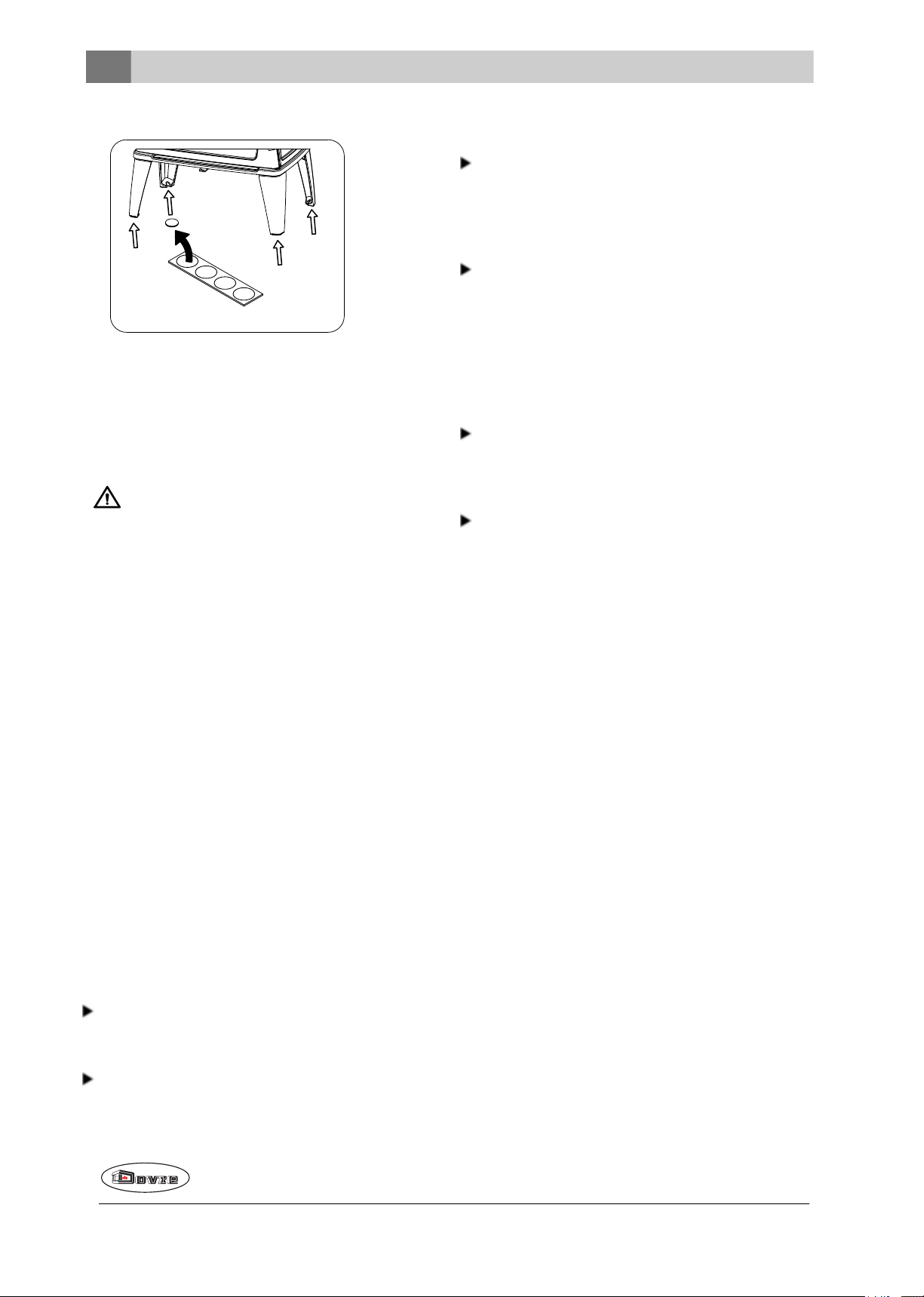

1. Remove the stove from the pallet by removing the

bolts (1).

2. Remove the mounting brackets (2) by turning the

adjustable feet (3) out.

3. Reassemble the adjustable feet (3).

4. Openthe door; see the following figure:

7

Page 9

09-20021-093

09-20021-099

01

02

03

04

05

06

07

08

09

10

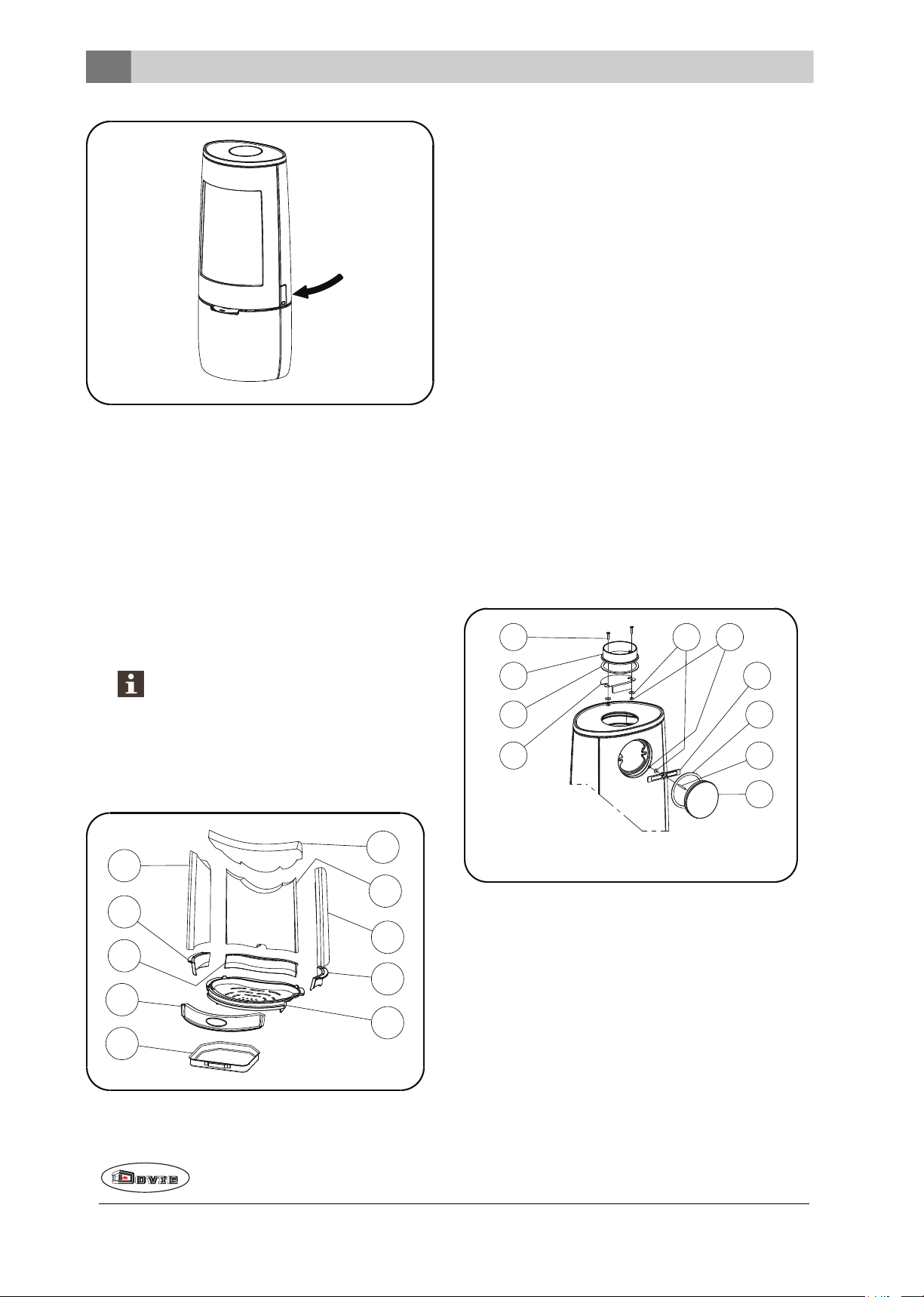

Removable internal parts

09-20021-100

1

2

3

4

5 6

9

4

8

7

01 fire compartment base

02 fire basket rear

03 fire basket right

04 fire basket left

05 baffle plate

06 rear inner plate

07 inner plate right

08 inner plate left

09 fire basket front

10 ash pan

Preparing the connection to the flue

5. Remove the fire-resistant inner plates; see the following figure:

a. First remove the baffle plate(05).

b. Remove the inner plates right (07) and left (08).

c. Remove the rear inner plate (06).

d. Remove the fire basket at the front (09).

e. Remove the fire basket left (04) and right (03).

f. Remove the fire basket at the back (02).

g. Remove the grate (01)and the ash pan (10).

Vermiculite inner plates are light and tend

to be ochrous in colour on delivery. They

insulate the combustion chamber to boost

combustion.

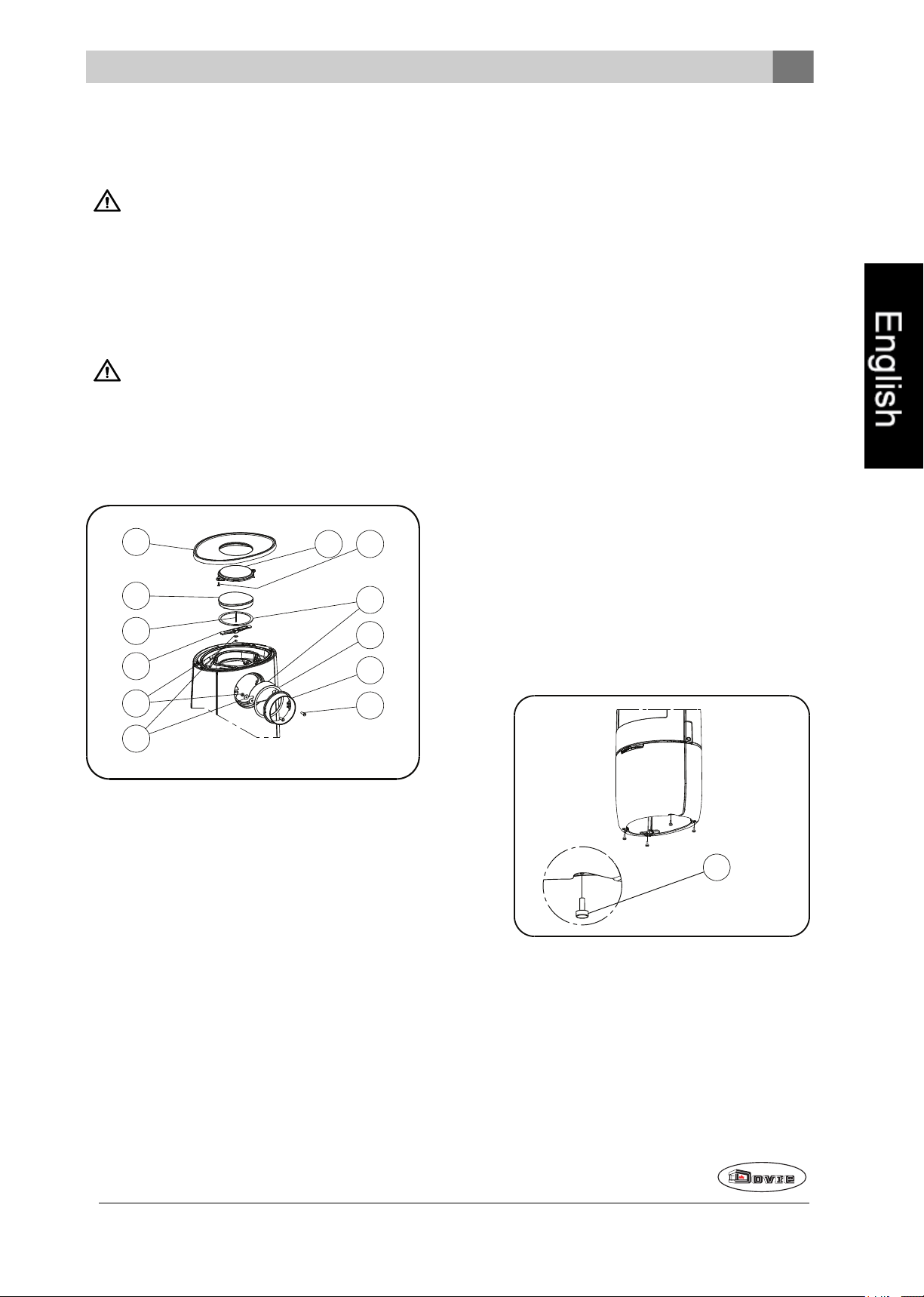

When connecting the appliance to the flue, you can

choose to connect to the top orto the rear of the appli-

ance

Connecting to the top

As standard, the appliance is delivered with the connection collar fitted for a connection at the top, see following figure.

Connecting to the back

For a connection to the rear, the position of the connection collar needs to be changed. The connection

collar is attached with 2 M8 nuts (key 13). Proceed as

follows:

8

Disassembly (see previous drawing)

1. First remove the baffle plate.

Subjectto change because of technicalimprovements.

Page 10

2. Remove the cover (7) from the back wall by remov-

09-20021-101

4

3

2

1

7

8

9

6

5

A

B

C

09-20021-091

1

ing the nut (6) and the clamping bracket (9).

3. Remove the cover (7) and the seal (8).

Check that the sealing tape onthe contact surface is not damaged. Replace the sealing tape

if it is damaged.

4. Disassemble the connecting collar(2) by undoing

the bolts (1).

5. Remove the connection collar (2), the seal (3) and

the materials supplied (1, 5, 6).

Preparing the outside air connection

If the appliance is installed in a room with insufficient

ventilation, you can install the outside air connecting

kit to the appliance.

The air supply tube is 100mm in diameter. If the tube

is smooth, it may be no longer than 12metres. If

accessories such as bends are used, the maximum

length (12m) must be reducedby 1m for each accessory used.

Check that the sealing tape onthe contact surface is not damaged. Replace the sealing tape

if it is damaged.

6. Remove the brake plate (4).

Assembly (see drawing below)

1. Remove the top plate (A).

Outside air connection via the wall

1. Make an opening in the wall (see the appendix,

"Measurements", for the correct position of the

opening).

2. Close the airconnection hermetically to the wall.

Installing and connecting

1. Position the appliance in the correct place, and

make sure it is level. The appliance is designed

with adjustable feet, which may already be mounted on the appliance or be included. Use these

adjustable feet so that the appliance can be placed

perfectly level.

2. Assemble the decorative cover (B) using the

materials supplied (C).

3. Fit the connecting collar (2), the seal (3)and the

brake plate (4) with the materials supplied (1, 5, 6)

on the back wall

4. Assemble the connection collar (7) and the seal (4)

with the materials supplied (8, 9, 5, 6).

5. Place the top plate (A) with assembleddecorative

cover (B) on the appliance and note the positioning

ridges.

Subjectto change because of technicalimprovements.

2. If the appliance is to be placed on a smooth floor,

the four anti-slip pads can be placed beneath the

adjustable feet to prevent the appliance from moving, see next image.

9

Page 11

09-20500-015

3. Connect the appliance to the flue hermetically.

4. For outside airsupply connection: connect the outside air supply to the connection kit which is fitted

to the appliance.

5. Re-position all removed parts to the correct places

in the appliance.

Never use the appliance without the fire-resistant inner plates.

The appliance is now ready for use.

Use

First use

When you use the appliance for the first time, make

an intense fire and keep it going for a good few hours.

This will cure the heat-resistant paint finish. This may

result in some smoke and odours. You could open windows and doors for a while in the area in which the

appliance is located.

Fuel

This appliance is only suitable for burning natural

wood; sawn and chopped wood that is sufficiently dry.

Do not use other fuels, as they can cause serious

damage to the appliance.

The following fuels may not be used as they pollute

the environment, and because they heavily pollute the

appliance and flue, which may lead to a chimney fire:

Treated wood, such as scrap wood, painted wood,

impregnated wood, preserved wood, plywood and

chipboard.

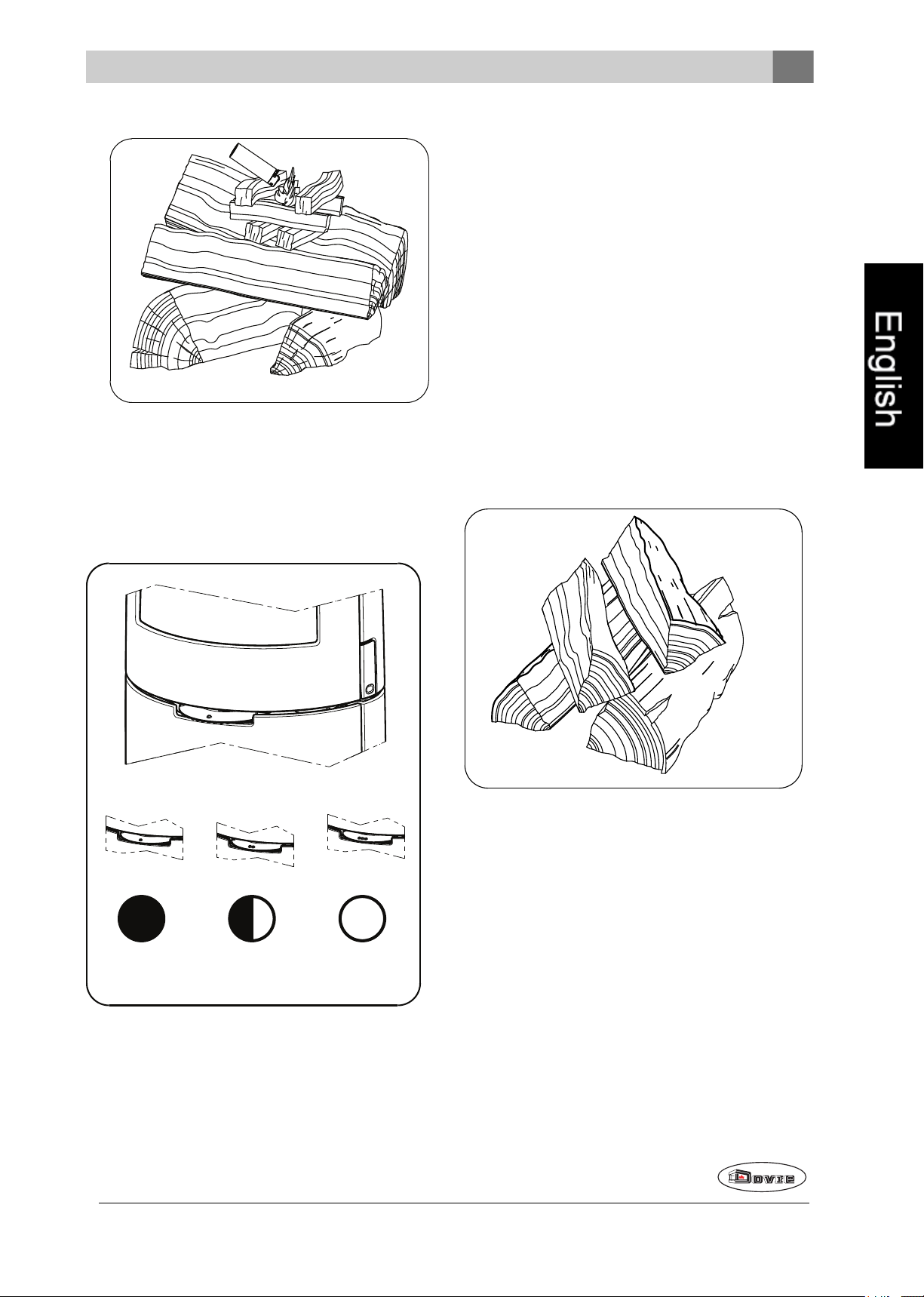

Wood

Hardwood, such as oak, beech, birch and fruit tree

wood is the ideal fuel for your stove. This type of

wood burns slowly with calm flames. Softwood

contains more resins, burns faster and sparks

more.

Use seasoned wood that contains no morethan

20% moisture. The wood should have been

seasoned for at least 2 years. Wood with a moisture content of 20% provides 4.2 kWh per kg wood.

Wood with a moisture content of 15% provides 4.4

kWh per kg wood. Freshly felled wood has a moisture content of 60% and only provides 1.6 kWh per

kg wood.

Saw the wood to size andsplit it while it is still

fresh. Fresh wood is easier to split, andsplit wood

dries more easily. Store the woodunder a roof

where the wind has free access.

Do not use damp wood. Damp logs do not produce

heat as all the energy is used in the evaporation of

moisture. This will result in a lot of smoke and soot

deposits on the appliance door and in the flue. The

water vapour will condense in the appliance and

can leak away through chinks in the stove, causing

black stains on the floor. It may also condense in

the chimney and form creosote. Creosote is a

highly flammable compound and may cause a chimney fire.

Lighting

You can check whether the flue has sufficient draught

by lighting a ball of paperabove the baffle plate. A cold

flue often has insufficient draught and consequently,

some smoke may escape into the room instead of up

the chimney. You can avoid this problem by lighting

the fire as described below.

1. Stack two layers of medium sized logs crosswise.

2. Stack two to threelayers of kindling crosswise on

top of the logs.

3. Place a firelighterbetween the bottom layer of kindling and light the firelighter according to the instructions on the packaging.

Plastics, scrap paperand domestic waste.

10

Subjectto change because of technicalimprovements.

Page 12

09-20500-016

4. Close the appliance door and open the primary

09-20021-096

A

B

C

09-20500-017

andsecondary air inlets; see the following figure.

B:

o o Secondary air open (glass wash)

o Air for post-combustion open

A:

o Air for post-combustion open

(never close entirely for proper combustion)

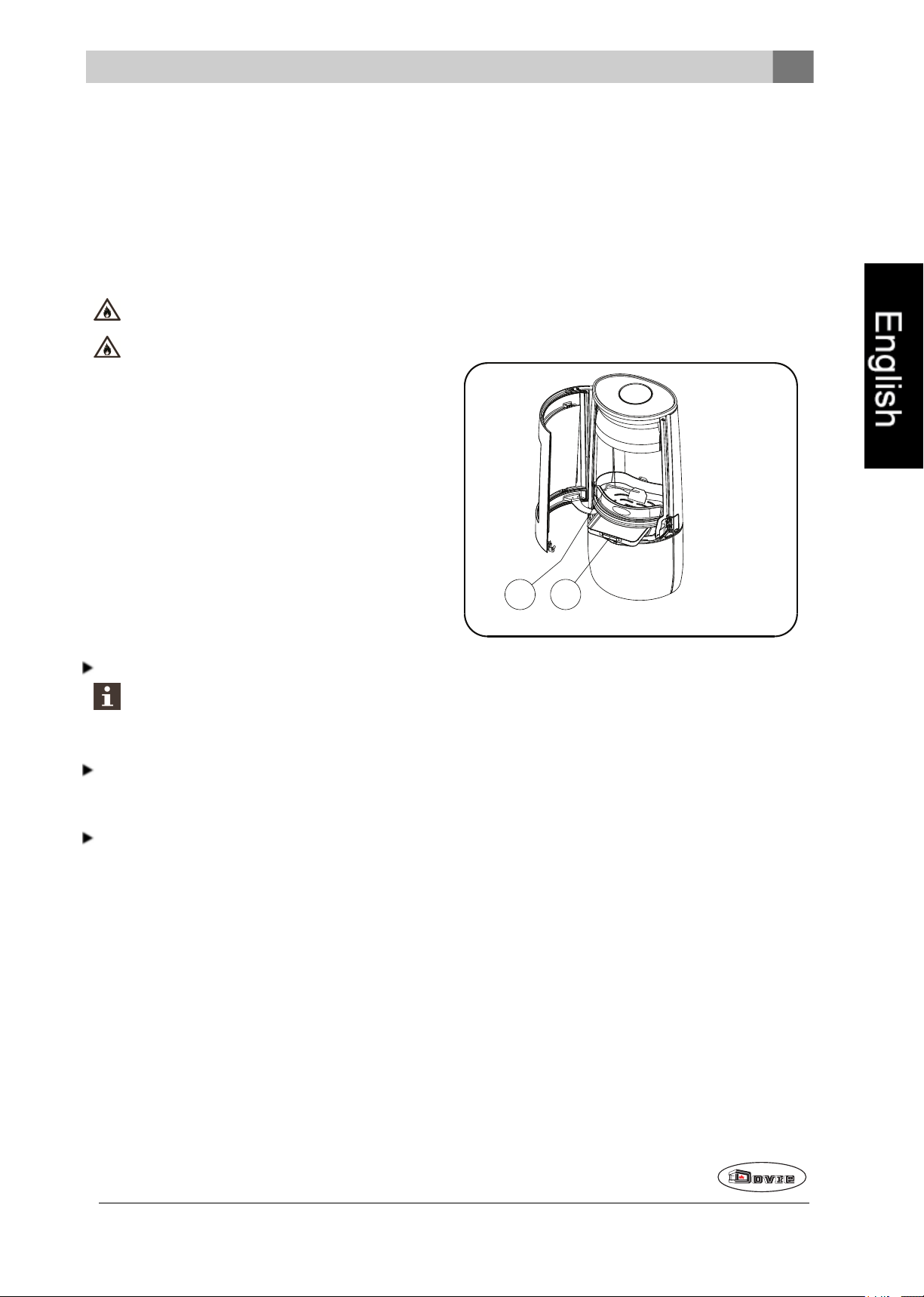

Burning wood

After you have followed the instructions for lighting:

1. Slowly open the door of the appliance.

2. Spread the charcoal evenly across the bottom of

the stove base.

3. Stack a few logs on the charcoal.

5. Allow the fire develop into a good blaze until there

is a glowing bedof charcoal. You can then add fuel

andadjust the appliance, see the chapter "Stoking

with wood".

Open stacking

If the logs are stacked openly, the wood will burn

quickly as the oxygen can reach each log easily. If

you want to use the stove for a short while, make an

open stack.

C:

o o o Primary air open (when lighting the stove)

o o Secondary air open (glass wash)

o Air for post-combustion open

Subjectto change because of technicalimprovements.

11

Page 13

Compact stacking

09-20500-018

09-20021-095

1

2

3

09-20021-096

A

B

C

If the logs are stacked tightly, the wood will burnmore

slowly as the oxygen can only reach some logs easily. If you want to burn wood for a longer period, make

a compact stack.

4. Close the door of the appliance.

5. Close the primary air inlet and leave the secondary

air inlet open.

Fill the appliance to a maximum of a third.

Maximum amount of wood

To stoke continuously at the rated power, wood must

be addedevery 45 minutes. If you use a smaller

amount of wood each time, you can add wood more

often. Each stove is designed to work with a specific

maximum amount of wood. If you use a largerquantity

of wood, the heat output increases: As a result, the

hearth can become overloaded and parts can be damaged.

Permitted maximum quantity of fuel for wood with a

moisture percentage of 15%:

BOLD 7 KW has maximum filling of 1.5 kg wood per

45 minutes. Do not fill the combustion chamber more

that one third full, and neverstack woodabove the

openings for secondary air.

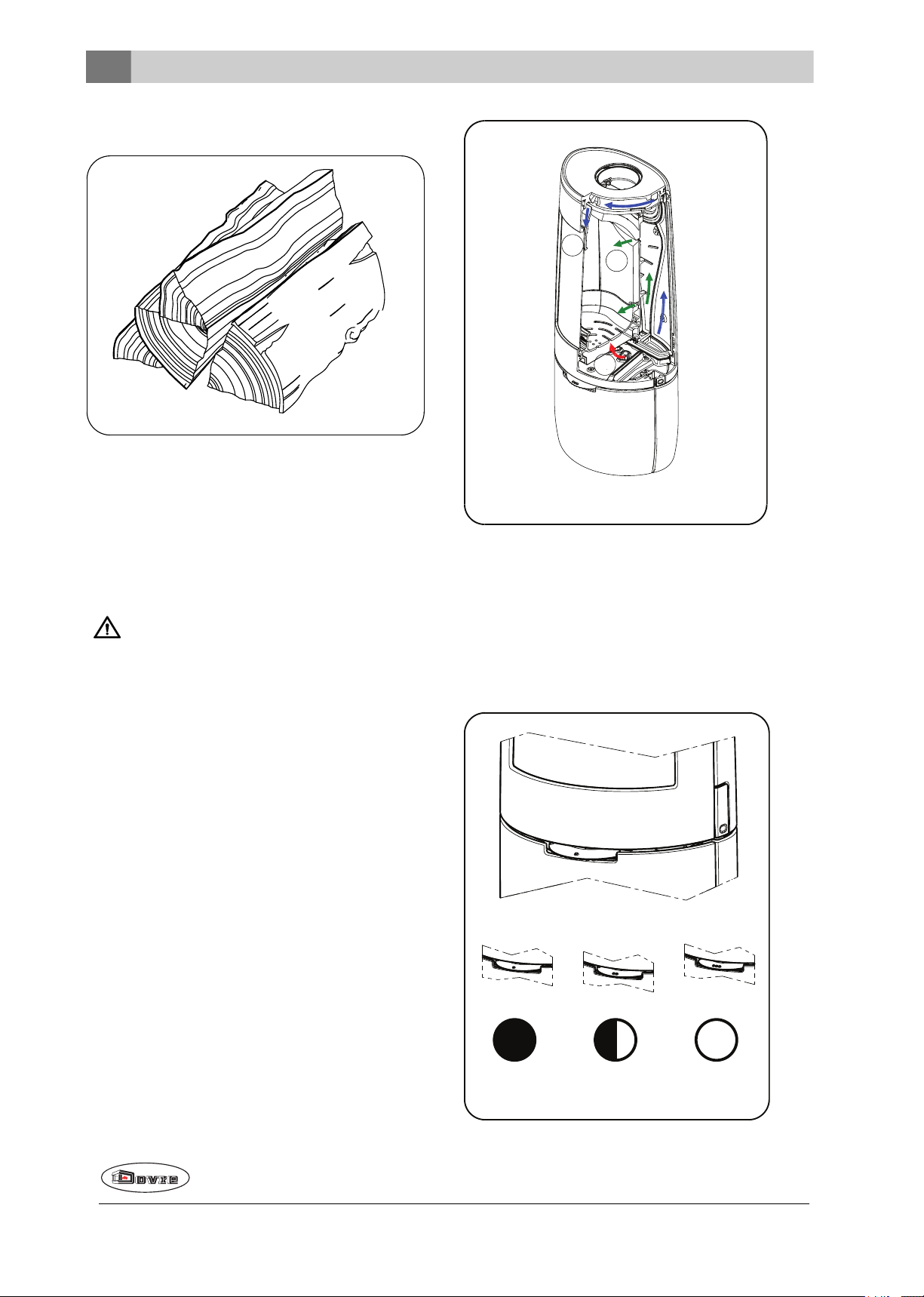

Controlling combustion air

The appliance has one air slide that regulates both the

primary air and the secondary air inlet. If the air slide is

in position 3, the primary andthe secondary air inlet is

open. As the air slide is further closed, the primary air

inlet andthenthe secondary airinlet is closed. If the

air slide is completely closed in position 1, a small air

vent remains open to allow for post-combustion under

the baffle plate.

The appliance has various features for air control; see

next figure.

12

Subjectto change because of technicalimprovements.

Page 14

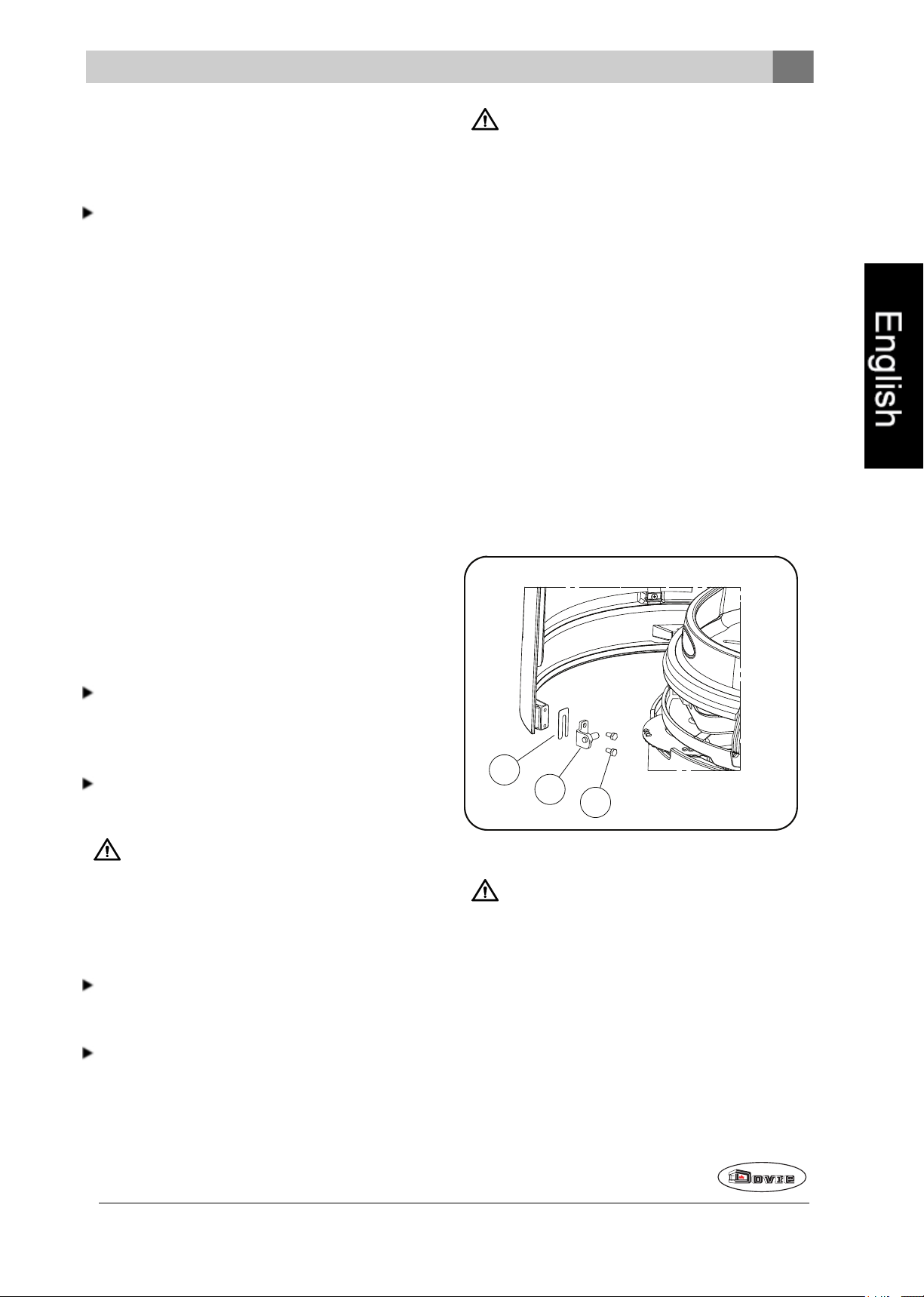

The primary airinlet regulates the air under the grate

09-20021-097

21

(1).

Removing ash

The secondary airinlet regulates the air for the glass

(airwash) (2).

The back wall has permanent vents (3) below the

baffle plate that allow for post-combustion.

Advice

Never burn wood with an open door.

Regularly burnwoodwith intense roaring fires.

If you burn at a low setting frequently, tar and

creosote may be deposited in the flue. Tar and

creosote are highly combustible substances.

Thicker layers of these substances may catch

fire if the temperature in the flue increases suddenly. By allowing the fire to burn very

intensely regularly, layers of tar and creosote

will disappear.

Low intensity fires can also cause tar deposits

on the stove window anddoor.

When the outside temperature is mild, it is better to burn wood intensely for a few hours

instead of having a low intensity fire for a long

period of time.

Control the airsupply using the air vent.

The air inlet not only supplies airto the fire but

to the glass as well, so that it does not quickly

become dirty.

Open the primary air inlet for the time being if the air

supply by the secondary air inlet is inadequate or if

you want to fan the fire.

After wood has been burnt, a relatively small amount

of ash remains. This ash bed is a good insulating layer

for the stove base plate and improves combustion. It

is a good idea to leave a thin layer of ash onthe stove

base plate.

The flow of air through the fire plate must not be

obstructed, however, and no ash may be allowed to

accumulate behind a cast-iron inner plate. Remove

the excess ash regularly.

1. Openthe door of the appliance.

2. Use the scraper supplied to sweep the excess ash

into the ash pan.

3. Using the glove supplied, remove the ash pan and

empty it.

4. Replace the ash pan and close the door of the

appliance.

Topping upwith a few logs regularly is better than

adding many logs in one go.

Extinguishing the fire

Do not add fuel and just let the fire go out. If a fire is

damped down by reducing the air supply, harmful substances will be released. Forthis reason, the fire

should be allowedto go out naturally. Keep an eye on

the fire until it has goneout. All air inlets can be closed

once the fire has died completely.

Subjectto change because of technicalimprovements.

Fog and mist

Fog and mist hinderthe flow of flue gases through the

flue. Smoke can blow back and cause a stench. If it is

not strictly necessary, it is better not to use the stove

in foggy and misty weather.

Resolving problems

Refer to the appendix "Diagnostic diagram" to resolve

any problems in using the appliance.

13

Page 15

Maintenance

Follow the maintenance instructions in this chapter to

keep the appliance in goodcondition.

Flue

In many countries, you are required by law to have

your chimney checked and maintained.

At the start of the heatingseason: have the chimney swept by a recognised chimney sweep.

Duringthe heating season and after the chimney

has not been used for a long time: have the chimney checked for soot.

At the end of the heating season: close off the chimney and plug with newspaper.

Cleaning and other regularly maintenance

Do not clean the appliance whenit is still

warm.

Clean the exterior of the appliance with a dry lintfree cloth.

You can cleanthe appliance interiorthoroughly at the

endof the heating season:

If necessary, first remove the fire-resistant inner

plates. See the chapter "Installation" for instructions on removing and installing the inner plates.

If necessary, clean the air supply ducts.

Remove the baffle plate at the top of the appliance

andcleanit.

Checking fire-resistant inner plates

Cast-iron inner plates last a long time if you

remove frequently the ash that can accumulate

behind them. If accumulated ash behind the

cast-iron plate is not removed, the plate will no

longer beable to dissipate the heat to the surroundings and this may cause the plate to warp

or crack.

Never use the appliance without the fire-resistant inner plates.

Cleaning the glass

Dirt clings less easily to well-cleaned glass. Proceed

as follows:

1. Remove dust and loose soot with a dry cloth.

2. Clean the glass with stove glass cleaner:

a. Apply stove glass cleaner to a kitchen sponge,

rubdown the entireglass surface and give the

cleaning agent time to react.

b. Remove the dirt with a moist cloth or kitchen

tissue.

3. Clean the glass again with a normal glass cleaning

product.

4. Rub the glass cleanwith a dry cloth or kitchen tissue.

Do not use abrasive or aggressive products to

clean the glass.

Wear household gloves to protect your hands.

If the glass in the appliance is broken or

cracked, it must be replacedbefore you can

use appliance again.

Ensurethat no stove glass cleaner runs

between the glass and the cast-iron door.

The fire-resistant inner plates areconsumables that

aresubject to wear andtear. Vermiculite inner plates

arefragile. Do not knock the inner plates with logs.

Check the fire-resistant inner plates frequently and

replace them when necessary.

See the chapter "Installation" for instructions on

removing and installing the inner plates.

The insulating vermiculite orchamotte inner

plates may develop hairline cracks, but this

does not affect their performance adversely.

14

Enamelled stove maintenance

Never clean the appliance while it is still hot. The

most effective way to clean the enamelled surface of

the stove is with a mild green soap and lukewarm

water. Use as little water as possible, rub the surface

dry and prevent the formation of rust. Wire wool or

other abrasives should never be used. Never place a

kettle directly onto an enamelled stove; use a stand to

prevent damage. Attention: Do not allow aggressive

acidic products to get onto enamelled components.

Subjectto change because of technicalimprovements.

Page 16

Lubrication

09-20021-094

2

3

1

Although cast-iron is slightly self-lubricating, you will

still need to lubricate moving parts frequently.

Lubricate the movingparts (such as guide systems,hingepins, latches and air slides) with heat

resistant grease that is available in the specialist

trade.

Touching up damaged paint

Small areas of damaged paint finish can be touchedup with a spray can of special heat-resistant paint,

available from your supplier.

Touching up the enamelled surface

Enamelling is a process carried out by traditional methods, meaning that it is possible that small colour differences and damage may occur. Theappliances

undergo a visual inspection in the factory, that is to

say, the inspector looks at the surface for a period of

10 seconds from a distance of 1 metre.

Any damage that does not stand out is regarded as

OK. A special heat-resistant paint is supplied with the

appliance to touch up any minor damagecaused during transport.

Apply the heat-resistant paint in thin layers and leave

to dry well before using the appliance.

Allow the sealant to harden fully before lighting

the appliance, as any moisture in the sealant

will form bubbles, resulting in a new air leak.

Adjust door closing

Check if the door closes properly. If required, the closing of the door can be set looseror tighter by adjusting

the distance between the locking cam and the door.

Proceed as follows:

1. Openthe door. The locking cam (2) is now freely

accessible; see next figure.

2. Unscrew the two screws (1) with which the locking cam is attached.

3. By removing the packing plate (3)behind the locking cam (2), the doorcloses more tightly. If the

door closes too tightly then insert an additional

packing plate behind the locking cam.

4. Tighten the two screws and check the closing of

the door once again.

Some enamel colours are temperature-sensitive. It

can happenthat the colour changes during use.

The original colour will return after the appliance

has cooled down.

If enamelled surfaces becomevery hot, hairline

cracks can occur. This is a normal phenomenon

andhas no impact on the functioning of the stove.

Ensurethat the stove is not overburdened. If it

does become overburdened thenthe surface

gets very hot possibly resulting in lasting damageto the enamel.

Checking the seal

Check whether the door sealing rope is still in good

condition and works well. The sealing rope is subject to wear and will need to be replaced over time.

Check the appliance for air leaks. Close any

chinks with stove sealant.

Replacing the glass

If the glass in the appliance is broken or

cracked, it must be replacedbefore the stove

is used again.

Proceed as follows:

1. Unscrew the four glass fixings with parts (3) and

(4)and remove the glass (2), see followingfigure.

2. Check the glass seal and, if necessary, fit a new

sealingrope.

3. Place the new glass in the grove andtighten the

glass fixings.

Subjectto change because of technicalimprovements.

15

Page 17

09-20021-098

1

2

3

4

BOLD spare parts

09-20021-099

01

02

03

04

05

06

07

08

09

10

13 70.79870.000 service kit cord

6 mm

14 70.79869.000 service kit cord

8 mm

15 70.79868.000 service kit self-

adhesive tape

16 70.72629.000 service kit spring

self-closing door

17 70.64315.000 service kit lock 1

1

1

1

1

BOLD 300/400

Pos. Part number Description Quantity

01 70.66559.021 fire compartment

base

02 70.77467.021 fire basket rear 1

03 70.77466.021 fire basket right 1

04 70.77465.021 fire basket left 1

05 70.76191.000 baffle plate 1

06 70.77564.000 rear inner plate 1

07 70.77563.000 side inner plate right 1

08 70.77562.000 side inner plate left 1

09 70.77458.021 fire basket 1

10 70.05216.000 ash pan 1

11 70.26384.000 curved glass 1

12 70.26101.041 service kit glass

fixing

16

1

1

Subjectto change because of technicalimprovements.

Page 18

Appendix 1: Technical data

Model BOLD 300/400

Nominal output 7 kW

Flue connection (diameter) 150mm

Weight 130 kg - 145 kg

Recommended fuel Wood

Fuel property, max. length 35 cm

Mass flow of flue gasses 5.6 g/s

Flue gas temperature measuredin the measurement section 246 °C

Temperature measured at appliance exit 356°C

Minimum draught 12 Pa

CO emission (13%O2)

NOx emission (13% O2)

CnHm emission (13%O2)

Particulate emission 22 mg/Nm³

Particulate emission in accordance with NS3058-NS3059 2.64 g/kg

Efficiency 80 %

0.10 %

90 mg/Nm³

102mg/Nm³

Subjectto change because of technicalimprovements.

17

Page 19

Appendix 2: Dimensions

09-20021-103

1 0 1 0

2 6 0

1 5 0

8 5 0

2 4 0

1 5 0

4 2 0

1 5 0

4 9 0

1 6 5

BOLD 300

18

Subjectto change because of technicalimprovements.

Page 20

BOLD 400

09-20021-102

1 1 3 0

3 8 0

3 7 5

9 8 5

4 1 5

1 0 0

1 5 0

4 9 0

1 9 0

1 5 0

Subjectto change because of technicalimprovements.

19

Page 21

Appendix 3: Distance from combustible material

09-20021-104

1

2

3 0 0

2 0 0 *

5 0

9 0 0

5 0

9 0 0

3 0 0

2 0 0 *

2 5 0

8 0 0

6 5 0

5 0

5 0

8 0 0

6 5 0

5 0

5 0

1 5 0

1 5 0

7 5 0

7 5 0

5 0

5 0

7 5 0

7 5 0

5 0

5 0

BOLD 300/400 - Minimum distances in millimetres for version without heat

shield

* with insulated stovepipe

1 Combustible material

2 Incombustible material, thickness 100 mm

Please note: In order to guarantee the supply of combustion air when there is no outside air supply connection, the distance from the connection collar for the outside air to the wall must be at least 20 mm. If

necessary, the connection collar can be removed.

20

Subjectto change because of technicalimprovements.

Page 22

BOLD 300/400 - Minimum distances in millimetres for version with heat

09-20021-106

1

2

5 0

5 0

9 0 0 90 0

5 0

2 5 0

5 0

5 0

5 0

8 0 0

6 5 0

5 0

5 0

8 0 0

6 5 0

1 0 0

1 0 0

5 0

5 0

7 5 0

7 5 0 7 5 0

7 5 0

5 0

5 0

shield and insulated stovepipe

1 Combustible material

2 Incombustible material, thickness 100 mm

Please note: In order to guarantee the supply of combustion air when there is no outside air supply connection, the distance from the connection collar for the outside air to the wall must be at least 20 mm. If

necessary, the connection collar can be removed.

Subjectto change because of technicalimprovements.

21

Page 23

BOLD - Dimensions of fireproof floor plate

09-20021-105

A

B

B

Minimum dimensions of fireproof floor plate

A (mm) B (mm)

Din 18891 500 300

Germany 500 300

Finland 400 100

Norway 300 5

22

Subjectto change because of technicalimprovements.

Page 24

Appendix 4: Diagnosis diagram

Problem

Wood will not stay lit

Gives off insufficient heat

Smoke emissions into the room when adding wood

Fire in appliance is too intense, is hard to adjust

Deposit on the glass

possible cause possible solution

Insufficient draught

Wood too damp Use wood withno more than 20%moisture.

Logs too large

Wood stacked incorrectly

Flue does not work properly

Chimney stack incorrect Sufficientlyhigh above the roof, no obstacles in the vicinity

Air inlets set incorrectly Open the air inlets completely.

Appliance connected to the flue incorrectly

Vacuum in area in whichthe applianceis

installed

Insufficient supplyof fresh air

Bad weather

? Inversion (reversed air flow inchimney

because of a highoutside temperature),

extreme wind speeds

A cold flue usuallyfailsto create sufficient draught. Follow the instructionsfor starting a fire in the ‘Use’ section; open a window.

Use small pieces ofkindling.Use split logs no larger than 30 cm incircumference.

Stackthe logsin away that allows adequate air flow between the

logs(open stacking, see "Burning wood")

Check whether the chimney meets the requirements: at least 4

metres high, correct diameter, well-insulated, smooth inside, not too

many bends, no obstructions in chimney(bird's nest, too much soot

deposit), hermetically tight (no chinks).

Connection should be hermeticallytight.

Switch off extraction systems.

Provide an adequate air supply; ifnecessary use outside air connection.

We recommend youdon't use the appliance in the case of inversion.

If required, install an extra hood on the flue to increase the draught.

Draught in the livingroom

Flames touchthe glass

Appliance isleakingair Check the door seals and appliancejoints.

Subjectto change because of technicalimprovements.

Avoiddraught in the livingroom, do not place the appliance near a

door or heating air ducts.

Make sure the wood isnot positioned too close to the glass. Slide the

primary air inlet cover closer to the "Closed" position.

23

Page 25

Index

A

Adding wood

smoking appliance 23

Adverse weather conditions, do not burn wood 13

Aerating the fire 13

Air combustion control 12

Air control 12

Air inlets 11

Air leak 15

ash 13

Ash pan

open 13

Ashes

remove 13

Controlling air supply 13

Creosote 13

D

Damage 7

Damp wood 10

Dimensions 18

Door

adjust 15

closing 15

Locking cam

packing plate 15

opening 7

sealingrope 15

Draught 17

Drying wood 10

B

Bearing capacity of floor 6

Burning 11

adding fuel 11

appliance is hardto adjust 23

fire is too intense 23

insufficient heat 23

topping up fuel 13

Burning wood

insufficient heat 13

C

Cap on the flue 6

Carpet 6

Cast iron inner plates 8

Chinks in appliance 15

Cleaning

appliance 14

glass 14

Combustible material

distance from 20

Connecting

dimensions 18

Connecting outside air supply 9

Connection collar for connection to chimney 8

Connection to chimney

at the rear 8

at the top 8

rear 8

top 8

E

Efficiency 4, 17

Email

maintenance 14

External air supply

connecting to 10

Extinguishingthe fire 13

F

Fan 6

connecting outside air supply 9

ruleof thumb 6

Fan louvre 6

Filling level of the appliance 12

Finishing coat, maintenance 15

Fire

extinguishing 13

kindle

Lighting 10

Fire-resistant inner plates

maintenance 14

remove 8

Fire safety

distance from combustible material 20

floor 6

furniture 6

walls 6

Fireproof inner plates

warning 10

24

Subjectto change because of technicalimprovements.

Page 26

Floor

smooth 9

Floors

bearingcapacity 6

fire safety 6

Flue

connecting to 10

connection diameter 17

height 6

maintenance 14

requirements 5

Flue cap 6

Flue gas

temperature 4, 17

Flue gasses

mass flow 17

Fog, donot burn wood 13

Fuel

adding 12

necessary amount 13

suitable 10

topping up 13

unsuitable 10

wood 10

G

L

Lighting fire 10

Lubricant 15

Lubricate 15

M

Maintenance

Clean appliance 14

cleaning the glass 14

emai 14

Fire-resistant inner plates 14

flue 14

lubrication 15

sealing 15

Mist, do not burn wood 13

N

Nominal output 13, 17

O

Open

ash pan 13

Opening

door 7

Outside air supply 6, 9

Glass

cleaning 14

cracked 15

deposit 23

replacing 15

Glass damaged 15

H

Heat, insufficient 13, 23

Hinge

adjust 15

I

Inner plate

vermiculite 8

Inner plates, fire-resistant

remove 8

Installing

dimensions 18

K

Kindling 23

P

Paint

Smoke

during first use 10

Particulate emission 17

Parts, removable 7

Positioning

anti-slip 9

Preventing chimney fire 13

Primary air inlet 11

R

Removable parts 7

Remove

fire-resistant innerplates 8

Removing ash 13

Replacing

glass 15

Subjectto change because of technicalimprovements.

25

Page 27

S

Screens

deposit 23

Sealing rope for door 15

Secondary air inlet 11

Smoke emissions into the room 5

Smoking appliance 23

Smooth floor 9

Softwood 10

Solving problems 13, 23

Stacking logs 11

Storingwood 10

Stove glass cleaner 14

Suitable fuel 10

Sweeping flue 14

T

Tar 13

Temperature 17

Topping upwith fuel 13

drying 10

right sort 10

storing 10

will not stay lit 23

U

Unsuitable fuel 10

V

Vermiculite

fire-resistant 8

Vermiculite inner plates 8

W

Walls

fire safety 6

Warning

chimney fire 10, 13

chimney fires 5

fireproof inner plates 10

flammable materials 5

glass broken or cracked 5, 14-15

hot surface 5

placinga load on door 5

requirements 5

stove glass cleaner 14

terms and conditions for insurance 5

ventilation 5-6

Weight 17

Wood 10

damp 10

26

Subjectto change because of technicalimprovements.

Page 28

Page 29

Innhold

Innledning 2

Ytelseserklæring 3

Sikkerhet 5

Monteringsvilkår 5

Generelt 5

Skorstein 5

Ventilasjonav rommet 6

Gulv og vegger 6

Produktbeskrivelse 7

Montering 7

Generelle forberedelser 7

Forberede tilknytning til skorstein 8

Forberede direkte tilførsel av forbrenningsluft 9

Plasseringog tilkobling 9

Bruk 10

Første gangs bruk 10

Brensel 10

Opptenning 10

Fyring med ved 11

Maksimal vedmengde. 12

Reguleringav forbrenningsluft 12

Bålet slukker 13

Tømme aske 13

Tåke 13

Eventuelle problemer 13

Vedlikehold 13

Skorstein 13

Rengjøring og annet regelmessig vedlikehold 13

Utskiftingsdeler deler BOLD 16

Vedlegg 1: Tekniske data 17

Vedlegg 2: Mål 18

Vedlegg 3: Avstand til brennbart materiale 20

Vedlegg 4: Diagnoseskjema 23

Indeks 24

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

1

Page 30

Innledning

Kjære bruker,

Ved å kjøpe dette ildstedet fra DOVRE har du valgt et

kvalitetsprodukt. Dette produktet inngåri en ny

generasjon med energieffektive og miljøvennlige

ildsteder. Disse ildstedene gjør optimal bruk av både

konveksjonsvarmen og strålingsvarmen.

Ditt DOVRE ildsted erprodusert ved hjelp av de

mest moderne produksjonsmetoder. Hvis det

skulle være noe i veien med ditt ildsted, kan du

alltid få hjelp av DOVRE service.

Ildstedet må ikke modifiseres; bruk kun originale

deler.

Ildstedet er beregnet på installasjon i en stue.

Ildstedet må tilkobles til en skorstein som fungerer

godt.

Vi anbefaler at ildstedet tilsluttes av en autorisert

installatør.

DOVRE kan ikke holdes ansvarlig for problemer

ellerskade som skyldes feil montering.

Ved monteringog bruk må man følge

sikkerhetsforskriftene som beskrives nedenfor.

I denne anvisningen leser du hvordan du monterer,

bruker og vedlikeholder ditt DOVRE ildsted. Hvis du

ønsker merinformasjoneller tekniske data eller hvis

det oppstår problemer under monteringen, bør du først

ta kontakt med leverandøren.

© 2016 DOVRE NV

2

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

Page 31

Ytelseserklæring

I samsvar med byggevareforordning 305/2011

Nr. 051-CPR-2015

1. Unik identifikasjonskode for varetypen:

BOLD 300 -400 / 7kW

2. 2. Type-, parti- eller serienummer, eller annen identifiseringsmåte for byggeproduktet, som

foreskrevet i paragraf 11, fjerde ledd:

Unikt serienummeret.

3. Tilsiktet bruk av byggeproduktet, i overensstemmelse med den gjeldende harmoniserte tekniske

spesifikasjonen, slik det er bestemt av produsenten:

Ildsted fyrt medfast brensel uten produksjon av varmtvanni henhold til EN 13240.

4. Navn, registrert handelsnavn eller registrert handelsmerke og kontaktadresse til produsenten, som

foreskrevet i paragraf 11, femte ledd:

Dovre N.V. Nijverheidsstraat 18 2381 Weelde Belgium.

5. Hvis aktuelt, navn og kontaktadresse til fullmaktshaver hvis mandat omfatter de oppgaver nevnt i

paragraf 12, andre ledd:

-

6. Systemet eller systemene for bedømmelse og verifisering av prestasjonsbestandigheten til

byggeproduktet, nevnt i vedlegg V:

System 3

7. Hvis ytelseserklæringen gjelder et byggeprodukt som faller under den harmoniserte normen:

Instansen KVBG, registrert under nummer 2013, har under engasjement utført en typegodkjenning under

system 3 og har levert testrapport nr. H2015/0078.

8. Hvis ytelseserklæringen gjelder et byggeprodukt som det er avgitt en europeisk teknisk

bedømmelse av:

-

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

3

Page 32

9. Angitt prestasjon:

Den harmoniserte normen EN 13240:2001/A2 ;2004/AC :2007

Grunnleggende karakteristikker Prestasjoner Ved

Brannsikkerhet

Ildbestandighet A1

Minimal avstand i mm

Avstandtil brennbart materiale

Bakside: 300

Side: 250

Risiko for utfallende glødende deler Oppfyller kravet

Utslipp av forbrenningsprodukter

CO: 0,10 % (13 % O2)

Overflatetemperatur Oppfyller kravet

Elektrisk sikkerhet -

Lett å rengjøre Oppfyller kravet

Maksimalt arbeidstrykk -

Røykgasstemperaturved nominell effekt 246 °C

Mekanisk motstand (båret vekt av skorstein) Ikke bestemt

Nominell effekt 7kW

Utnyttelse 80 %

10. Prestasjonene til produktet som er beskrevet i punkt 1 og 2 oppfyller kravene til prestasjonene i

punkt 9.

Denne ytelseserklæringen gis under det eksklusive ansvaret til fabrikanten meldt i punkt 4:

01/10/2013 Weelde

Tom Gehem

CEO

På grunn av fortløpende produktutvikling forbeholdervi oss retten til å endre spesifikasjonene i denne brosjyren

uten forutgående kunngjøring.

DOVRE N.V.

Nijverheidsstraat 18 Tlf.: +32 (0) 14 65 91 91

B-2381 Weelde Faks: +32 (0) 14 6590 09

Belgia E-post : info@dovre.be

4

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

Page 33

Sikkerhet

NB! Alle sikkerhetsregler må følges nøye.

at det kan komme giftige gasser inn i rommet.

Se kapitlet "Monteringsvilkår" for mer

informasjon om ventilasjon.

Les nøye anvisningene om montering, bruk og

vedlikehold som medleveres til ildstedet, før du

tar ildstedet i bruk.

Ildstedet må monteres i samsvar med reglene

som gjelder i ditt land.

Alle lokale forskrifter og bestemmelser i

nasjonale ogeuropeiske standarder må

overholdes ved montering av ildstedet.

Vi anbefaler at ildstedet monteres av en

autorisert installatør. Denne kjenner til de

gjeldende bestemmelsene og forskriftene.

Ildstedet er konstruert for oppvarming. Alle

overflater, også glasset og tilkoblingsrøret, kan

bli svært varme (over 100°C)! Bruk et

kaldhåndtak eller en varmebestandig hanske.

Sørg for tilstrekkelig avskjerming hvis små

barn, funksjonshemmede, eldre eller dyr

befinner seg i nærheten av ildstedet.

Sikkerhetsavstandene til brennbart materiale

må nøye overholdes.

Monteringsvilkår

Generelt

Ildstedet må tilkobles til en skorstein som fungerer

godt.

For tilkoblingsmålene: se vedlegget "Tekniske

data".

Forhør deg med brannvesenet og/eller

forsikringsselskapet om eventuelle spesifikke krav

og forskrifter.

Skorstein

Skorsteinen er nødvendig for:

Fjerning av røykgassene ved naturlig trekk.

Den varme luften i skorsteinen er lettere enn

uteluften ogvil derfor stige.

Inntak av luft som er nødvendig for forbrenningen

av brenselet i ildstedet.

Legg ikke gardiner, klær, klesvask eller annet

brennbart materiale på eller i nærheten av

ildstedet.

Bruk ikke lett antennelige eller eksplosive

stoffer i nærhetenav ildstedet mens det er i

bruk.

Forebygg pipebrann ved å få utført regelmessig

feiing av skorsteinen. Fyr aldri mens ildstedets

dør er åpen.

Ved pipebrann: steng ildstedets luftregulatorer

og tilkall brannvesenet.

Hvis ildstedets glass er knust eller sprukket,

må glasset skiftes før ildstedet brukes igjen.

Ikke bruk makt på døren, unngåat barn trekker

i den åpne døren, sitt ellerstå aldri på den åpne

døren, og plasser aldri tunge gjenstander på

den.

Sørg for at det er tilstrekkelig ventilasjon i

rommet hvor ildstedet står. Ved utilstrekkelig

ventilasjon blir forbrenningen ufullstendig, slik

En skorstein som ikke fungerergodt kan forårsake

røyk i rommet når døren åpnes. Skade pågrunn av

tilbakeslag av røyk dekkes ikke av garantien.

Ikke tilknytt flere ildsteder (f.eks.

sentralfyrkjele) på den samme skorsteinen,

med mindre lokale eller nasjonaleforskrifter

tillater det. Hvis to ildsteder skal tilknyttes må

det være en høydeforskjell på minimum 200

mm mellom dem.

Rådfør deg med din installatør vedrørende råd om

skorsteinen. Se den europeiske standarden EN13384

for riktig beregning av skorsteinen.

Skorsteinen må oppfylle følgende krav:

Skorsteinen må være laget av ildfast materiale,

helst keramikk eller rustfritt stål.

Skorsteinen må være lufttett, godt feid og ha

tilstrekkelig trekk.

15-20Pa trekk/undertrykk ved normal

belastning er ideelt.

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

5

Page 34

Skorsteinen må være mest mulig vertikal, fra

ildstedets røykuttak. Bend og horisontale deler

forstyrrerutslippet av røykgasser og kan føre til

opphoping av sot.

Den innvendigediameteren må ikke være for stor,

for å unngå at røykgassene blir for mye avkjølt slik

at trekken avtar.

Skorsteinen bør helst ha sammediameter som

røykrørstussen.

For nominelle diameteren : se vedlegget

"Tekniske data". Hvis skorsteinen er godt

isolert, kan diametereneventuelt være større

(maksimalt det doble tverrsnittet av

røykrørstussen).

Tverrsnittet på skorsteinen må være konstant.

Videre deler og (særlig) innsnevringer forstyrrer

utslippet av røykgasser.

Ved bruk av pipehatt/røykhatt: Pass på at

pipehatten ikke innsnevrer skorsteinens utløp og at

pipehatten ikke hindrer røykgassene.

Skorsteinens munning må befinne seg i en sone

som ikke forstyrres av bygninger, trær eller andre

hindringer i nærheten.

Den delen av skorsteinen som befinner seg utenfor

huset må være isolert.

Ventilasjon av rommet

Ildstedet trenger luft (oksygen)for å oppnå god

forbrenning. Luften tilføres fra rommet hvor ildstedet

står gjennom luftregulatorer.

Ved utilstrekkelig ventilasjon blir forbrenningen

ufullstendig, slik at det kan komme giftige

gasser inn i rommet.

Tommelfingerregelen er at lufttilførselen skal være

5,5cm²/kW. Det kreves ekstra ventilasjon hvis:

Ildstedet står i et godt isolert rom.

I rom med mekanisk ventilasjon, f.eks. sentralt

avtrekkssystem eller avtrekksvifte i et åpent

kjøkken.

Det oppnås ekstra ventilasjonved å montere en

ventilasjonsrist i ytterveggen.

Sørg for at annet utstyr som bruker luft (f.eks.

tørketrommel, et annet ildsted eller baderomsvifte) har

egen tilknytningtil friskluft, eller er slått av når du fyrer

med ildstedet.

Ildstedet kan også tilkobles frisklufttilførsel. Et

tilkoblingssett for dette medfølgAer. Ved bruk

av et slikt sett er ekstra ventilasjon ikke

nødvendig.

Skorsteinen må ha en høyde på minst 4meter.

En tommelfingerregel: 60cm over takets høyeste

punkt.

Hvis takets høyeste punkt befinnerseg mer enn

3meter fra skorsteinen: følg målenesom vises i

neste figur. A = takets høyeste punkt innenfor en

avstand på 3meter.

Gulv og vegger

Gulvet som ildstedet monteres på må hatilstrekkelig

bæreevne. For ildstedets vekt: se vedlegget

"Tekniske data".

Beskytt et brennbart gulv med en brannsikker

gulvplate mot varmestråling. Se vedlegget

"Avstand til brennbart materiale".

Fjern brennbart materiale som linoleum, teppe

osv. underden brannsikre gulvplaten.

Sørg for tilstrekkelig avstand mellom ildstedet

og brennbart materiale som f.eks. treveggerog

møbler.

Tilkoblingsrøret utstråler også varme. Sørg for

tilstrekkelig avstand og avskjerming mellom

tilkoblingsrøret og brennbare materialer.

Tommelfingerregelen for et enkeltvegget rør er

en avstand på tre ganger diameteren. Hvis det

6

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

Page 35

er enkledning rundt røret, er en avstand som

09-20021-092

1

2

3

4

09-20021-090

1

2

3

tilsvarer diameteren tillatt.

Montering

Et teppe må ligge minimal 80cm fra ilden.

Beskytt et brennbart gulv foran ildstedet med

en brannsikker gulvplate mot aske som kan

falle ut av ildstedet. Gulvplaten må oppfylle

dennasjonale standarden.

For målene til den ikke-brennbare gulvplaten:

se vedlegget: se vedlegget "Avstandtil

brennbarematerialer".

For andre krav i forbindelse med

brannsikkerhet: se vedlegget "Avstand til

brennbarematerialer".

Produktbeskrivelse

Generelle forberedelser

Kontroller ildstedet på (transport)skade og

eventuelle mangler umiddelbart etter at det er

levert. Ildstedet er montert på undersiden til pallen.

Hvis du konstaterer (transport)skade eller

mangler, må duikke ta ildstedet i bruk men

varsle leverandøren.

Fjern de demonterbare delene (indre brennplater,

bunnrist, topplate og askeskuff) fra ildstedet før du

monterer ildstedet.

Ved å fjerne de demonterbare delene, blir det

lettere å flytte ildstedet og unngå skader.

Pass på deres opprinnelige posisjon når du

fjerner demonterbare deler, slik at dekan

monteres på riktig sted senere.

1. Rørstusse

2. Dør

3. Lukkemekanisme

4. Luftventil

Dørlukker

Ildstedet leveres med montert dørhendel (4). Døren

åpnes ved å trykke dørhendelen inn. Dørhendelen kan

bli meget varm underbruk, og derfor følger det med en

hanske som kan brukes til beskyttelse av hånden.

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

1. Ta ildstedet av pallen ved å fjerne boltene (1).

2. Fjern traversene(2) ved å skru ut

justeringsbeinene (3).

3. Monter justeringsbeinene (3) igjen.

4. Åpne døren; se neste figur.

7

Page 36

09-20021-093

5. Fjern de indrebrennplatene; se neste figur.

09-20021-099

01

02

03

04

05

06

07

08

09

10

09-20021-100

1

2

3

4

5 6

9

4

8

7

a. Fjern først hvelvplaten(05).

b. Fjern brennplatene til høyre (07) og venstre

(08).

c. Fjern brennplaten bak (06).

02 kubbestopper bak

03 kubbestopper høyre

04 kubbestopper venstre

05 hvelvplate

06 brennplaterbak

07 brennplate høyre

08 brennplate venstre

09 kubbestopper foran

10 askeskuff

Forberede tilknytning til skorstein

Ved tilkobling av ildstedet til en skorstein kan man

velge tilkoblingpå ildstedets topp ellerbakside .

Tilkobling til toppen

Ildstedet leveres standard med rørstussen montert for

tilkobling påtoppen, se neste figur.

d. Fjern kubbestopperen på forsiden (09).

e. Fjern kubbestopperene til venstre (04) og

høyre (03).

f. Fjern kubbestopperen på baksiden (02).

g. Fjern risten (01) ogaskeskuffen(10).

Ildfaste indre brennplater av vermikulitt har

lav vekt og ersom regel okerfarget ved

levering. De isolerer brennkammeret slik at

forbrenningen blir bedre.

Tilkobling på baksiden

For tilkobling til baksiden må rørstussens posisjon

endres. Rørstussen er festet med 2 M8-muttere(13

mm nøkkel). Gå fram slik:

Demontering (forrige tegning)

1. Fjern hvelvplaten.

2. Demonter blindlokket (7) fra bakveggen, ved å

løsne mutteren (6) og fjerne klembøylen (9).

Løse innvendige deler

01 brenselrist

3. Fjern blindlokket (7) og tettingen (8).

Kontroller om tetningsbåndet på kontaktflaten

8

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

Page 37

er uten skader. Skift tetningsbåndet hvis det er

09-20021-101

4

3

2

1

7

8

9

6

5

A

B

C

09-20021-091

1

09-20500-015

skadet.

4. Demonter rørstussen (2) ved å løsne boltene (1).

5. Fjern rørstussen (2), tettingen (3) og

festematerialene(1, 5, 6).

Kontroller om tetningsbåndet på kontaktflaten

er uten skader. Skift tetningsbåndet hvis det er

skadet.

12 meter. Hvis det brukes deler som bend o.l. skal

det trekkes fra 1meter fra den maksimale lengden (12

meter) for hvert bend o.l.

Frisklufttilførsel gjennom veggen

1. Lag et tilkoblingshull i veggen (se vedlegget,

"Mål", for riktig posisjon for tilkoblingshull).

2. Lufttilførselsrøret skal tilkobles lufttett til veggen.

6. Fjern bremseplaten (4).

Montering (se etterfølgende tegning)

1. Fjern topplaten (A).

2. Monter det medsendte pyntelokket (B) med de

tilhørende festematerialene (C).

3. Monter røykrørstussen (2) og tetningen (3)og

bremseplaten (4) med festematerialene (1, 5, 6) til

bakveggen.

4. Monter blindlokket (7)og tettingen (4) med

festematerialene(8, 9, 5, 6).

Plassering og tilkobling

1. Sett ildstedet på riktig sted, jevnt og i vater.

Ildstedet harjusteringsbensom alleredeer

montert til ildstedet eller leveres løse. Bruk disse

justeringsbena slik at ildstedet kan justeres helt i

vater.

2. Hvis ildstedet står på et glatt underlag, kan du

plassere de fire antiskliputene under

justeringsbeinene for å unngå at ildstedet

forskyves, se neste bilde.

5. Plasser topplaten (A) med det monterte

pyntelokket (B) på ildstedet og pass på

posisjoneringstappene.

Forberede direkte tilførsel av forbrenningsluft

Hvis ildstedet monteres i et rom med utilstrekkelig

ventilasjon, kan dumonteretilkoblingssettet for

frisklufttilførsel på ildstedet.

Lufttilførselsrøret har en diameter på 100mm. Hvis

det brukes et glatt rør kan dette ha en lengdepå maks.

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

3. Koble ildstedet hermetisk tett på skorsteinen.

4. Ved utelufttilførsel: Tilførselskanalen kobles til

stussen for uteluft som er montert til ildstedet.

9

Page 38

5. Sett alle delenesom er demontert tilbake på riktig

09-20500-016

sted i ildstedet.

Ildstedet må aldri brukes uten de indre

brennplatene.

Ildstedet kan nå tas i bruk.

Bruk

Ikke bruk rå ved. Rå ved gir ikke varme fordi all

energien brukes til fordamping av vannet. Det gir

mye røyk og sotbelegg på ildstedets dør og i

skorsteinen. Vanndampen som kondenserer i

ildstedet kan lekke ut gjennom sprekker slik at det

oppstår svarte flekker på gulvet. Vanndampen kan

også kondensere i skorsteinen slik at det dannes

kreosot. Kreosot er meget brennbart og kan føre til

pipebrann.

Første gangs bruk

Fyr godt i noen timer første gang du bruker ildstedet.

Det sørger for at denvarmebestandige lakken herder.

Det kan oppstå litt røyk og lukt underdenne

prosessen. Luft eventuelt rommet hvor ildstedet står

ved å åpne vinduer og dører en liten stund.

Brensel

Dette ildstedet er kun egnet til fyring mednaturlig ved;

kappet og kløyvd og tilstrekkelig tørr.

Bruk ikke annen brensel, for det kan føre til alvorlig

skade på ildstedet.

Det er ikke tillatt å bruke følgende brensel fordi det

forurenser miljøet, og fordi det i høy grad forurenser

ildstedet og skorsteinen slik at det kan oppstå

pipebrann:

Behandlet tre, f.eks. rivningsvirke, malt virke,

impregnert tre, kryssfiner og sponplater.

Plastikk, papiravfall og husholdningsavfall.

Opptenning

Du kan kontrollere om det er tilstrekkelig trekk i

skorsteinen ved å tenne på litt sammenkrøllet

avispapir over hvelvplaten. Når skorsteinen er kald er

det ofte for dårlig trekk i skorsteinen slik at det

kommer røyk inn i rommet. Ved opptenning som

beskrevet nedenfor unngår du dette problemet.

1. Leggto lag medmiddels stor ved i kryss over

hverandre.

2. På toppenav veden legges to lag med

opptenningsved i kryss over hverandre.

3. Leggen opptenningsbrikett i det underste laget

opptenningsved og tenn på opptenningsbriketten

iht. anvisningen på emballasjen.

Ved

Bruk helst hard løvved som eik, bøk, bjørk og

frukttrær. Slik ved brenner langsomt og med rolige

flammer. Bartrær har høyere innhold av sevje,

brenner raskere og gir mer gnister.

Bruk tørr ved medet vanninnhold på maks. 20 %.

Det betyr at veden må ha tørket i minst 2 år. Ved

med et vanninnhold på 20 % gir 4,2 kWh perkg

ved. Ved med et vanninnhold på 15 % gir4,4 kWh

perkg ved. Nykappet ved har et vanninnhold på 60

% og gir kun 1,6 kWh per kg ved.

Sag veden i passendelengder og kløyv veden

mens den er fersk. Fersk ved erlettere å kløyve og

tørker bedre. Veden skal lagres underet tak slik at

vindenfår fritt spill.

10

4. Lukk ildstedets dørog åpne ildstedets primære

luftregulator og sekundæreluftregulator; se neste

figur.

5. La opptenningsbålet brenne godt til det oppstår et

glødende lag med trekull. Deretter kan du legge i

neste påfylling ogregulere ildstedet; se avsnittet

"Fyring medved".

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

Page 39

09-20021-096

A

B

C

Løst ilegg

09-20500-017

09-20500-018

Ved løst ilegg forbrenner veden raskt fordi det lettere

kommer oksygen til hver treski. Bruk løst ilegg hvis du

skal fyre en kort stund.

Kompakt ilegg

C:

o o o Primærluft åpen (ved opptenning)

o o Sekundærluft åpen(glasspyling)

o Luft for etterbrenning åpen

B:

o o Sekundærluft åpen(glasspyling)

o Luft for etterbrenning åpen

A:

o Luft for etterbrenning åpen

(lukkes aldri helt, for å oppnå god

forbrenning)

Fyring med ved

Etter at du har fulgt anvisningene for opptenning:

1. Åpne langsomt ildstedets dør.

2. Fordel trekullaget jevnt over brenselristen.

3. Leggnoen vedskier på trekullaget.

Ved kompakt ilegg forbrenner veden saktere fordi det

kommer oksygen til bare noenav vedskiene. Bruk

kompakt ilegghvis du skal fyre lengre.

4. Lukk ildstedets dør.

5. Lukk den primære luftregulatoren og la den

sekundære luftregulatoren være åpen.

Fyll ildstedet maks. en tredjedel.

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

11

Page 40

Maksimal vedmengde.

09-20021-095

1

2

3

09-20021-096

A

B

C

For å kunne fyre oppmot den nominelle effekten må

det legges inn ny ved hvert 45. minutt. Hvis du

reduserer vedmengden hver gang duleggerinn ved

kan du fylle oftere. Hvert ildsted er konstruert for å

funksjonere med en viss vedmengde. Hvis du bruker

en størrevedmengde blir varmeavgivelsen større.

Dette kan føretil at ovnen blir overbelastet, og deler

kan skades.

Tillat maksimal mengde brensel for ved medet

vanninnhold på 15 %:

BOLD 7 kW haren maksimal fylling på 1,5 kg ved per

45 minutter. Fyll forbrenningskammeret maks en

tredjedel fullt, og fyll aldri ved overåpningen til

sekundærluften.

Regulering av forbrenningsluft

Ildstedet harfleremuligheter for luftregulering; se

neste figur.

trekkventilen står helt lukket i posisjon 1, vil det

fortsatt være en liten luftåpning som sørger for luft til

etterbrenningen under hvelvplaten.

Ildstedet harén luftregulator som regulerer både den

primære og sekundære luften. Hvis luftregulatoren

står i posisjon 3, er både det primære og sekundære

luftinntaket åpent. Etter hvert som luftregulatoren

stenges, lukkes først det primære luftinntaket og

deretter det sekundære luftinntaket. Hvis

Den primære luftregulatoren regulerer luften under

risten (1).

Den sekundære luftregulatoren regulerer luften for

glasset (air-wash) (2).

Underhvelvplaten har bakveggen permanente

luftåpninger (3) som sørger for etterforbrenning.

Råd

Fyr aldri med åpen dør.

Fyr kraftigere i ildstedet med jevne mellomrom.

Hvis du fyrer lenge med svak varme, kan det

dannes tjære og kreosot i skorsteinen. Tjære

og kreosot er meget brennbart. Hvis det

dannes for mye av disse stoffene, kan det

oppstå pipebrann ved en plutselig høy

temperatur. Ved å fyre kraftigere med jevne

mellomrom, forsvinner eventuelle belegg av

tjære og kreosot.

Dessuten kan det oppstå tjærebelegg på

ildstedets glass og dør hvis man fyrermed for

lav temperatur.

Ved en høyere utetemperatur er det derfor

12

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

Page 41

bedre å fyre godt i ildstedet et par timer enn å

09-20021-097

21

fyre lenge med lav temperatur.

Reguler lufttilførselen med luftregulatoren.

1. Åpne ildstedets dør.

2. Bruk askeraken for for å skyve den overflødige

asken gjennom risten i askeskuffen

Sekundærluftregulatoren tilfører

forbrenningsluft og sørger samtidig for spyling

av glasset for å redusere sotbelegget.

Åpne de primærelufttilførselen midlertidig hvis det

er utilstrekkelig lufttilførsel gjennom den

sekundære lufttilførselen eller hvis du ønsker å

stimulere bålet.

Det er bedre å legge inn litt ved med jevne

mellomrom enn mange vedkubber påen gang.

Bålet slukker

Ikke leggpå brensel og la ildstedet slukke av seg

selv. Hvis man demper flammeneved å strupe

lufttilførselen, frigjøres skadelige stoffer. La derfor

ilden brenne ut av seg selv. Pass på bålet til det erhelt

slukket. Når bålet er helt slukket kan manlukke alle

luftregulatorer.

Tømme aske

Etter fyring med ved oppstår det en relativt liten

mengde aske. Dette askebedet er en god isolator for

brenselristen oggir bedre forbrenning. La derfor et tynt

askelag ligge på brenselristen.

Lufttilførselen gjennom brenselristen må imidlertid

ikke hindres og aske må ikke akkumuleres bak en

indre brennplate av støpejern. Fjern derfor

regelmessig overskuddet av aske.

3. Ta ut askeskuffen ved hjelp av den medleverte

hansken og tøm askeskuffen.

4. Sett askeskuffen tilbake og lukk døren til

ildstedet.

Tåke

Tåke hindrer strømmen av røykgasser ut av

skorsteinen. Det kan oppstå røyknedslag som gir

plagsom lukt. Hvis det ikke er nødvendig, bør man

ikke fyre i ildstedet mens det er tåke.

Eventuelle problemer

Se vedlegget "Diagnoseskjema" for å løse eventuelle

problemer i forbindelse med bruk av ildstedet.

Vedlikehold

Følg vedlikeholdsanvisningene i dette kapitlet for å

holde ildstedet i god stand.

Skorstein

I mange land er det lovpålagt krav til kontroll og

vedlikehold av skorsteinen.

Ved starten av fyringssesingen: la en autorisert

feier feie skorsteinenr.

I løpet av fyringssesongen og etter at skorsteinen

ikke har vært brukt på lang tid:

Det tas forbehold om endringer p.g.a. tekniske forbedringer.

Etter avsluttet fyringssesong: tett skorsteinen med

en proppav avispapir.

Rengjøring og annet regelmessig vedlikehold

Ikke rengjør ildstedet mens det fremdeles er

varmt.

Rengjør ildstedet utvendig med en tørrklut som

ikke loer.

Etter at fyringssesongen er avsluttet kan ildstedet

rengjøres grundig innvendig:

13

Page 42

Fjern eventuelt brennplatene først. Se kapitlet

"Montering" for anvisninger om demontering og

montering av brennplatene.

Rengjør eventuelt lufttilførselskanalene.

Fjern hvelvplaten øverst i ildstedet og gjør den ren.

Kontroll av brennplater

De ildfaste brennplatene er forbruksdeler som

utsettes for slitasje. Brennplatene av vermikulitt er

sårbare. Pass på at du ikke støter borti brennplatene

med vedkubbene. Kontroller brennplatene med jevne

mellomrom og skift dem om nødvendig.

Se kapitlet "Montering" for anvisninger om

demontering og montering av brennplatene.

Det kan oppstå krakelering i de isolerende

brennplateneav vermikulitt ellerskamolx, men

det reduserer ikke deres virkning.

Bruk husholdningshansker for å beskytte hendene.

Hvis ildstedets glass er knust eller sprukket,

må glasset skiftes før ildstedet brukes igjen.

Unngåat det renner rengjøringsmiddel for

ovnsglass mellom glasset ogdøren av

støpejern.

Vedlikehold emaljert ildsted

Rengjør aldri ildstedet mens det er varmt. Det er best

å rengjøre ildstedets emaljeoverflate med grønnsåpe

og lunkent vann. Bruk minst mulig vann, og tørk godt

av ildstedet for å unngå rustdannelse. Bruk aldri stålull

ellerslipemiddel. Sett aldri en vannkjele rett på et

emaljert ildsted; bruk et kjeleunderlag for å unngå

skader. Pass på at det ikke kommeraggressive

syreholdige produkter på emaljerte deler.

Smøring

Brennplater av støpejern holderlenge hvis du

regelmessig fjerneasken som kan

akkumuleres bak dem. Hvis man ikke fjerner

asken som akkumuleres bak en plate av

støpejern, kan ikke platenlenger avgi varme til

omgivelsene og platen kan bli deformert eller

sprekke.

Ildstedet må aldri brukes uten de indre

brennplatene.

Glass rengjøring

Hvis glasset er grundig rengjort blir det mindre fort

skittent. Gå fram slik:

1. Fjern støv og løstsittende sot med en tørr klut.

2. Rengjør glasset med et rengjøringsmiddel for

ovnsglass:

a. Ha rengjøringsmiddel for ovnsglass på en

kjøkkensvamp, påfør på hele glassoverflaten

og la middelet virke litt.

b. Fjern skitten med en fuktig klut eller

tørkepapir.

3. Rengjør glasset engang til med et vanlig

rengjøringsmiddel for glass.

4. Tørk glasset med en tørr klut eller tørkepapir.

Ikke bruk slipende eller etsendeprodukter til

rengjøring av glasset.

Selv om støpejern er litt selvsmørende, må de

bevegeligedelenesmøres regelmessig.

Smør de bevegelige delene (slik som

føringssystemer, hengseltapper, hendlerog

luftregulatorer) med varmefast fett som kan kjøpes

i spesialforretninger.

Etterbehandling av lakkskader

Små lakkskader kan behandles med varmebestandig