Page 1

Aladdin Hearth Products

401 N. Wynne

ADivision of Hearth Technologies Inc.

Colville, WA99114

THE MODEL 400

WOODSTOVE

INSTALLATION & OPERATING

INSTRUCTIONS

IF THIS STOVE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. FOR

YOUR SAFETY, FOLLOW THE INSTALLATION DIRECTIONS. CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION

REQUIREMENTS IN YOUR AREA.

Model 400 Woodstove

SAFETY NOTICE:

Page 2

5-98 2 72308B

MODEL 400 WOODSTOVE

PLEASE RETAIN THIS MANUALFOR FUTURE REFERENCE.

Table of Contents

A. Listings and Code Approvals..........................................................................................................................3

B. Woodstove System Components...................................................................................................................3

C. Pre-Installation Preparation............................................................................................................................4

1. Minimum Clearances to Combustibles.....................................................................................................4

2. Floor Protection........................................................................................................................................6

3. Chimney Height Requirements................................................................................................................7

4. Flue Systems............................................................................................................................................8

5. Masonry Chimney....................................................................................................................................9

6. Listed Factory-Built Chimney.................................................................................................................12

D. Step-By-Step Installation of the Woodstove.................................................................................................15

E. Operating Instructions ..................................................................................................................................17

F. Maintenance Instructions.............................................................................................................................21

G. Flue Draft .....................................................................................................................................................23

H. Installation of Replacement Glass................................................................................................................25

Limited Warranty...........................................................................................................................................27

Safety Precautions:

1. Please read these installation instructions com-

pletely before beginning installation procedures.

Failure to follow them could cause a woodstove

malfunction resulting in serious injury and/or

property damage.

2. Always check your local building Codes prior to

installation. The installation must comply with all

local, regional, state and national Codes and

Regulations.

3. An adequate supply of replacement combustion

air from outside the house must be available to

the fire for the woodstove to operate properly.

Aladdin is not responsible for any smoking or

related problems that may result from the lack of

adequate combustion air. It is the responsibility

of the builder/contractor to ensure that adequate

combustion air has been provided for the woodstove.

4. NEVER leave children unattended when there is

a fire burning in the woodstove.

5. This woodstove is built for solid fuel only. DO

NOT use chimney cleaners or flame colorants in

your fireplace.

6. NEVER use gasoline, gasoline type lantern fuel,

kerosene, charcoal lighter fluid, or similar liquids

in this woodstove. Keep any flammable liquids a

safe distance from the unit.

7. To ensure a safe woodstove system and to prevent the buildup of soot and creosote, inspect and

clean the woodstove and chimney prior to use

and periodically during the burning season.

Page 3

These installation instructions describe the installation

and operation of the D O V R E®Model 400 woodstove.

This stove meets the U.S. Environmental Protection

Agency's 1990 particulate emission standards. Under

specific test conditions this stove has been shown to

deliver heat at rates ranging from 8,700 to 22,500

BTU/HR.

The D O V R E®Model 400 is listed by Underwriters

Laboratories Inc. to UL Safety Standard 1482 and

ULC Safety Standard S627.

Check with your local Building Code Agency before

you begin your installation to ensure compliance with

local Codes, including the need for Permits and

follow-up inspections. Be sure local building Codes

do not supersede UL specifications and always obtain

a Building Permit so that insurance protection benefits

cannot be unexpectedly canceled. If any assistance

is required during installation, please contact your

local dealer or the Dovre Customer Relations

Department, 401 N. Wynne, Colville, WA99114.

D O V R E®is a registered trademark of Aladdin Hearth

Products. Aladdin Hearth Products is a Division of

Hearth Technologies Inc.

I t ’s a good idea to plan your installation on paper,

using exact measurements for clearances and floor

protection, before actually beginning the installation. If

you’re not using an existing chimney, place the stove

where there will be a clear passage for a factory-built

listed chimney through the ceiling and roof.

We also recommend that you have a qualified building

inspector and your insurance company representative

review your plans before installation.

5-98 3 72308B

MODEL 400 WOODSTOVE

A. LISTINGS AND CODE APPROVALS

B. WOODSTOVE SYSTEM COMPONENTS

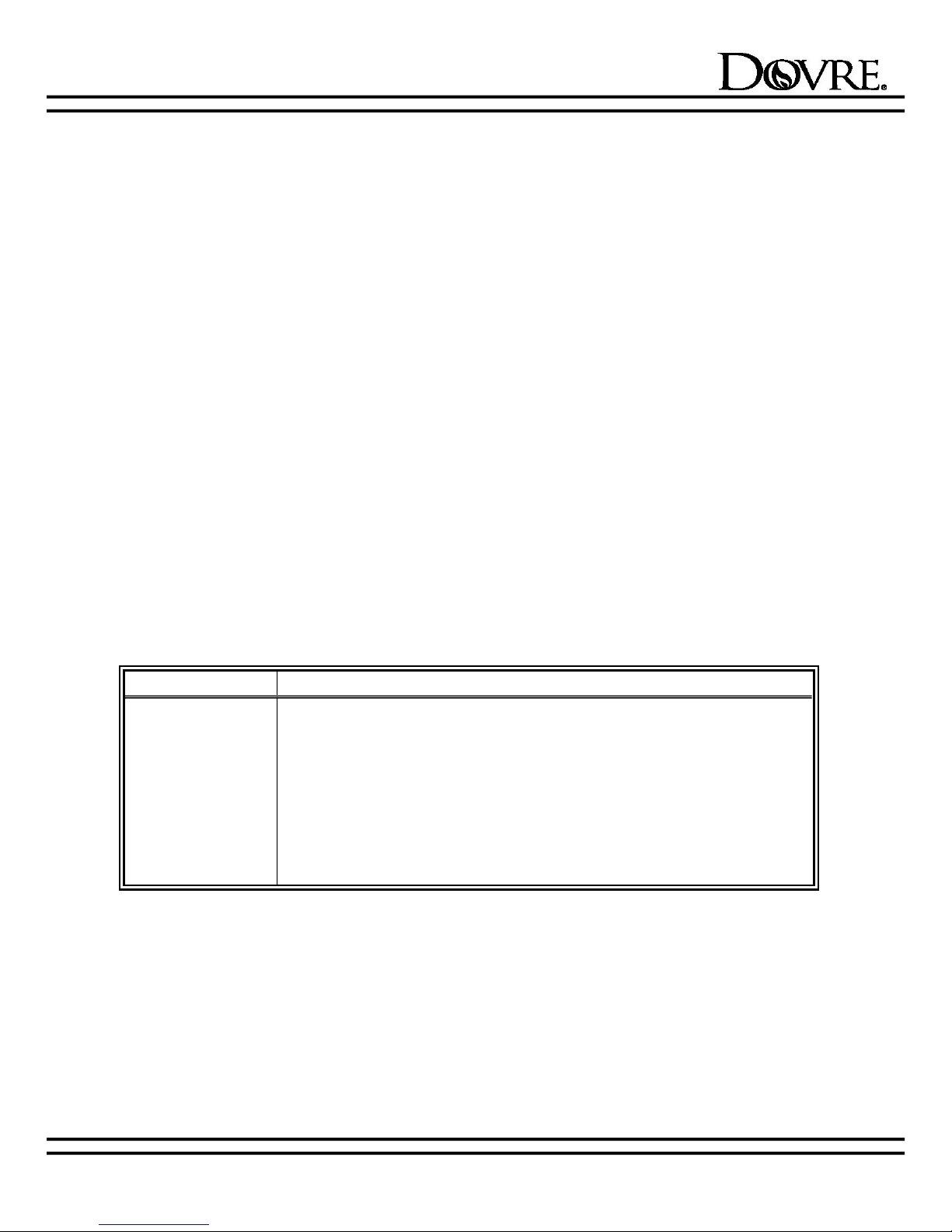

The D O V R E®Model 400 has several options available for installation and appearance. These options are

packaged separately and are listed below and pictured on page 4.

Catalog Number Description:

400 Non-catalytic - painted black with ash pan

400PBK Non-catalytic - black porcelain enamel with ash pan

400PCR Non-catalytic - creme porcelain enamel with ash pan

400PGR Non-catalytic - green porcelain enamel with ash pan

400PBL Non-catalytic - blue porcelain enamel with ash pan

400HSB Back shield to reduce clearances & allows use of fan kit

DFK1 Fan kit (requires use of 400HSB for completion)

DT6BK Door trim kit, black

DT6G Door trim kit, gold

Page 4

DOOR TRIM

MODEL 400 WOODSTOVE

DT6BK

DT6G

HEATSHIELD FAN KIT

400HSB

DFK1

C. PRE-INSTALLATION PREPARATION

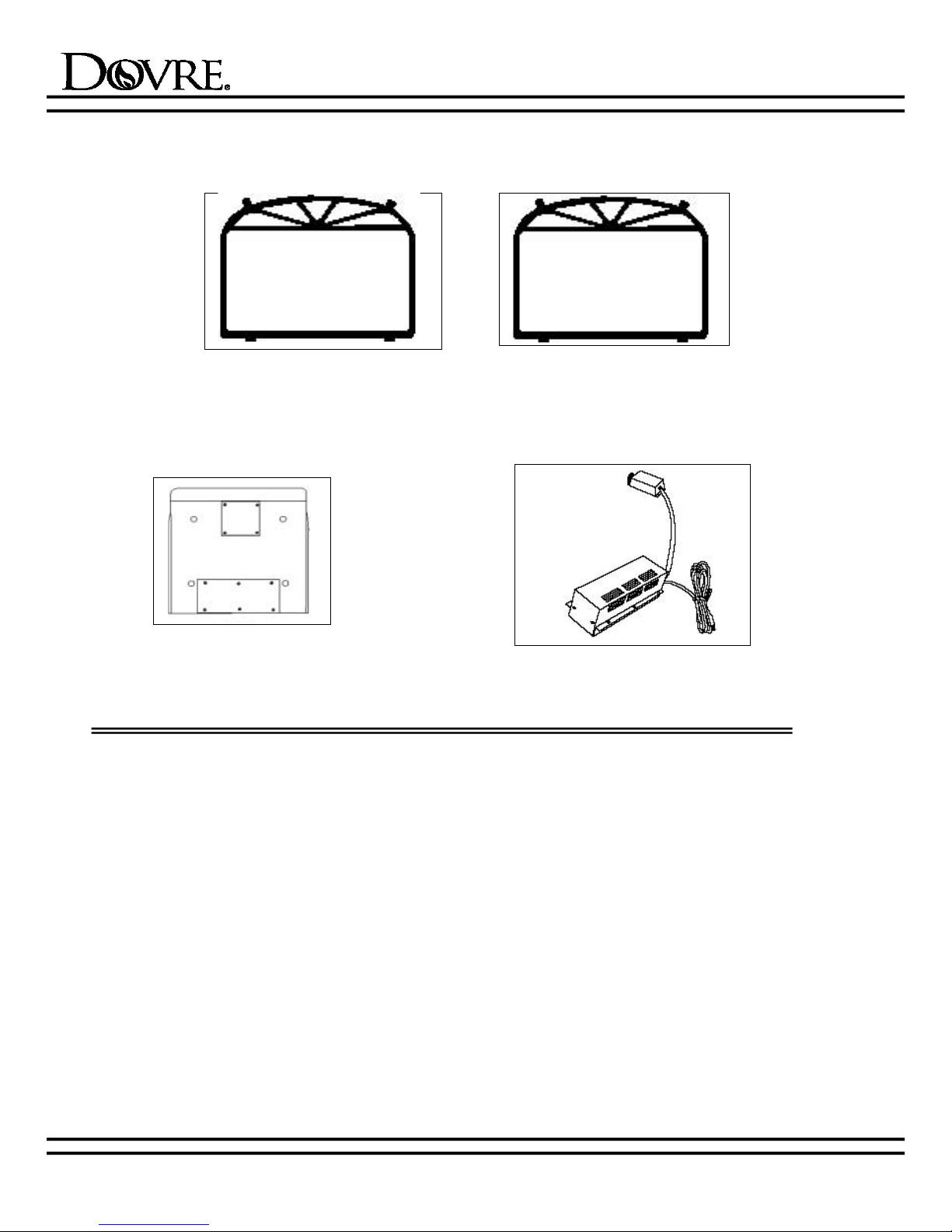

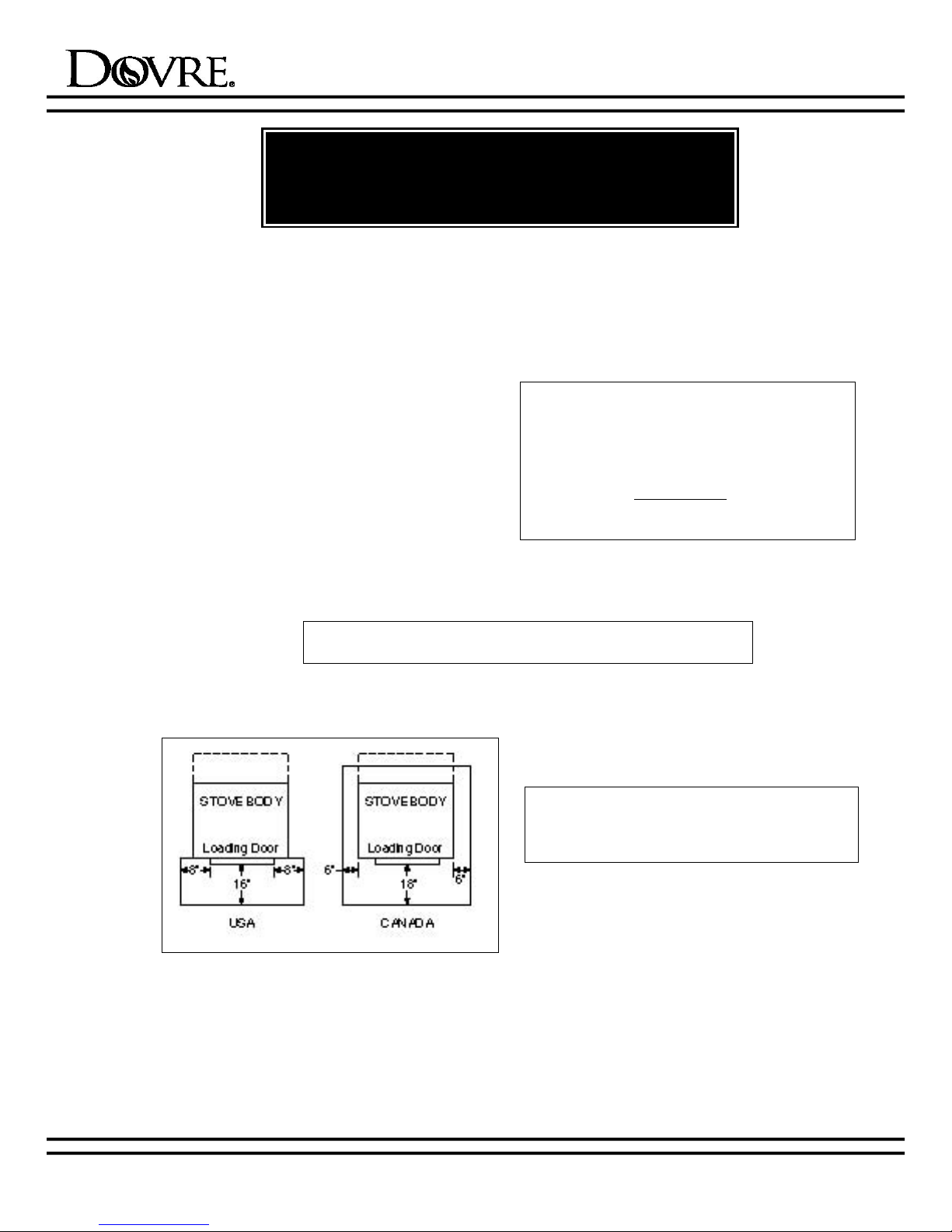

1. MINIMUM CLEARANCES TO COMBUSTIBLES.

The clearances listed in Table I are the minimum distances that must be maintained, as demonstrated in Figures

1 and 2. It is important to note that simply covering a combustible material with a non-combustible material does

not offer sufficient heat protection. For example, drywall conducts the radiant heat directly to the wood, and the

effect is the same as if the wood was unprotected.

Clearances to a combustible backwall may be reduced to 8” by using Dovre Backshield, part #400HSB, and listed

double wall connector pipe.

The following table and diagrams show the minimum clearance requirements between your Dovre, chimney connectors and unprotected combustible walls and materials. If further reduced clearances are needed, obtain

requirements for construction of a protected wall from your local building code authorities and their allowable

reductions of the listed clearances.

5-98 4 72308B

Page 5

5-98 5 72308B

MODEL 400 WOODSTOVE

Table I

Minimum Clearances to Combustibles

FLUE TOP (WITH REAR HEATSHIELD) 8” 15” 18”

CLEARANCES FROM UNIT TO COMBUSTIBLES

BACKWALL SIDEWALL CEILING

FLUE TOP 15” 15” 18”

FLUE REAR 24” 15” - -

Figure 1

Flue Top Clearances

Figure 3a

Figure 2

Flue Rear Clearances

Figure 3b

Page 6

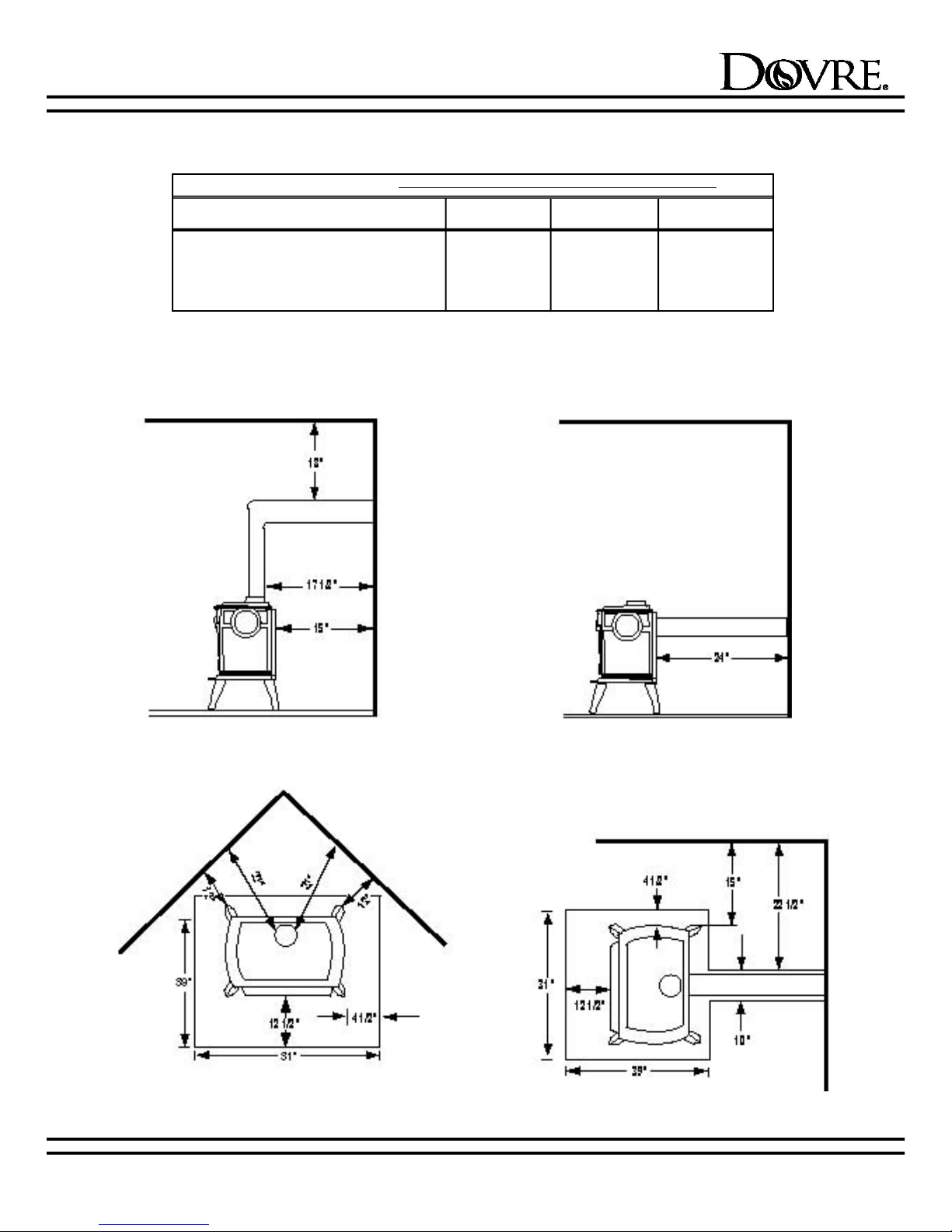

2. FLOOR PROTECTION.

Acombustible floor must be protected from the radiant heat given off by the unit and from the inevitable

spark or falling ember. This includes almost any floor

surface. Only a solid masonry or concrete floor adequately covering the distance around the unit is

acceptable. Alayer of thin brick or ceramic tile over a

combustible floor is insufficient. To protect your floor,

it is necessary to install a floor protector of one layer

of 3/8” non-combustible millboard having a thermal

conductivity of K = 0.84 BTU IN/FTHr F, or an equally

thick UL listed floor protector. The required dimensions of floor protector vary according to the length of

chimney connector as shown. If you construct your

own floor protector with the one layer of millboard, we

suggest that it be covered by one sheet of 24-gauge,

or heavier, galvanized sheet metal. It can then be

covered with ceramic tile, or thin brick, and framed to

protect the millboard and give it a finished look.

NOTE: The minimum Floor Protector Size for the Model 400

Woodstove is 31” wide x 39” deep.

Any horizontal length of chimney connector pipe must

also have the floor protector beneath it and extending

2” on each side of the pipe. The required floor protector size for Model 400 is 31” x 39”. Refer to

Figures 3a and 3b.

WARNING!

COMPLIANCE WITH ALL MINIMUM CLEARANCES SHOWN IN

THIS MANUAL IS NECESSARY FOR YOUR SAFETY.

MODEL 400 WOODSTOVE

NOTE: In calculating equivalent thickness

of alternate materials, the following formula

should be used:

One layer of 3/8” (0.375 inch) thick mill-

board has a K factor of

(BTU) (INCH)

0.31 (HR) ( FT

2)

(F) at 75 F

NOTE: Dotted line indicates additional floor

protection required on through-the-wall

chimney installation. Floor protection must

extend behind the stove to the rear wall.

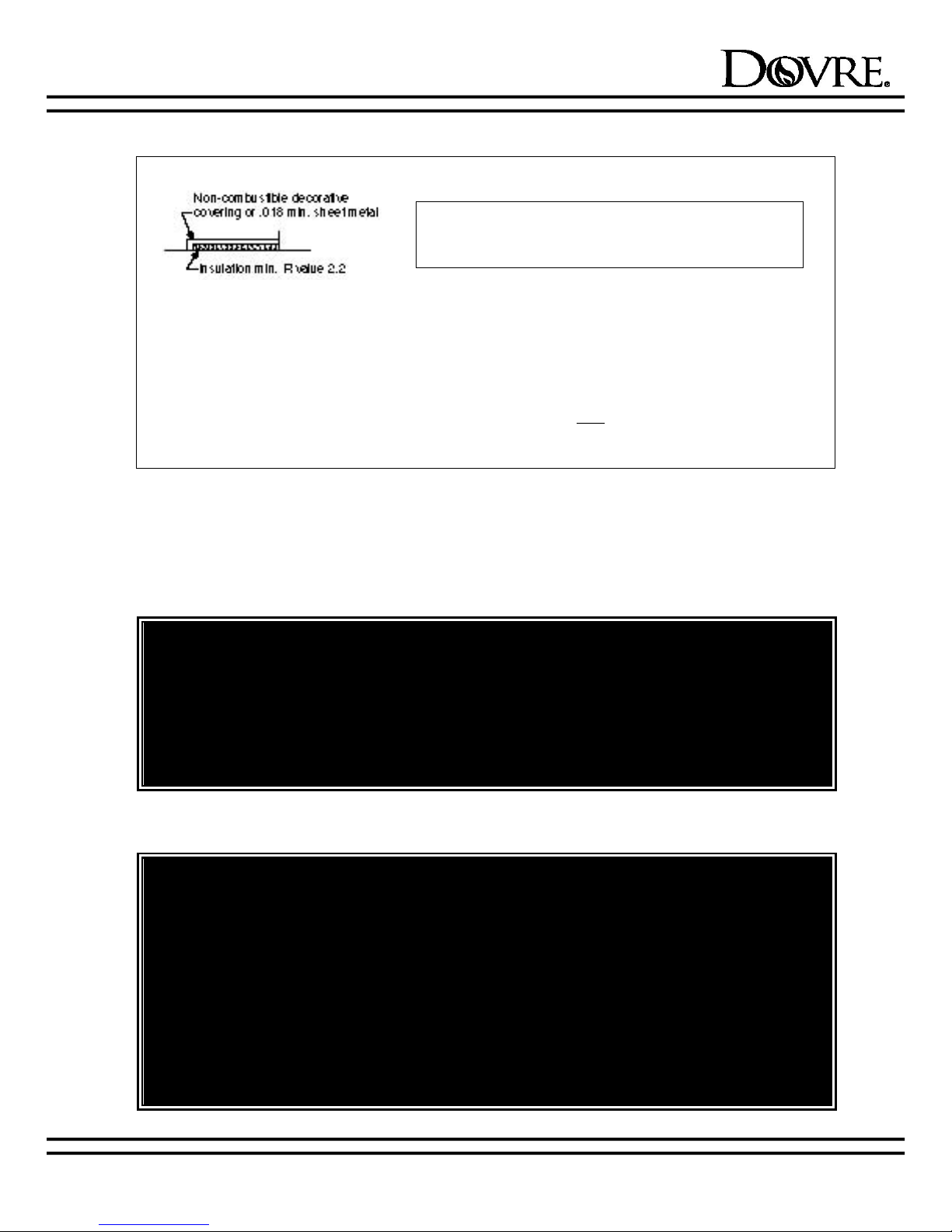

Figure 4

Floor Protection

5-98 6 72308B

Page 7

5-98 7 72308B

MODEL 400 WOODSTOVE

Figure 5

(Thermal Conductivity) “K” = BTU in./hr. ft2F (based on 1” thickness)

To substitute alternate insulation material, you need to know the “K” factor for that material. To calculate the

required thickness for the alternate material use the following formula:

EXAMPLES OF INSULATION

Required

Thickness “K” Value

MICORE 300 1" .45

“K” Alt.

x 1 = Thickness of alternate mat. (inches)

.45

“K” of brick = 5

5

x .50 = 5.5 In. of brick.

.45

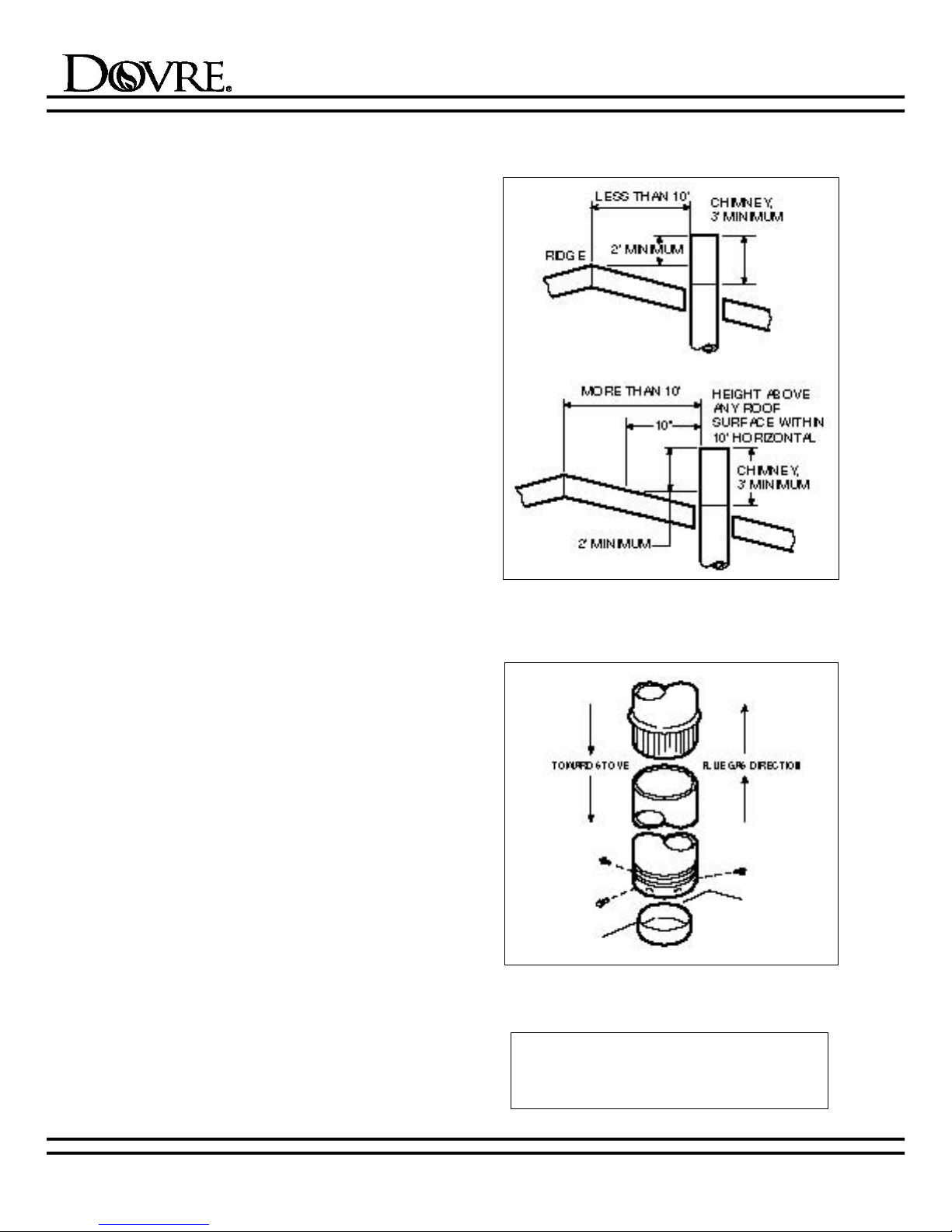

3. CHIMNEY HEIGHT REQUIREMENTS.

WARNING!

ALWAYS FOLLOW CHIMNEY CONNECTOR MANUFACTURER’S INSTRUCTIONS FOR

PROPER INSTALLATION.

CHIMNEY CONNECTOR IS TO BE USED ONLY WITHIN THE ROOM, BETWEEN THE

STOVE AND CEILING WALL, NEVER PASSING THROUGH A COMBUSTIBLE CEILING

OR WALL. ALWAYS KEEP MINIMUM CLEARANCES TO COMBUSTIBLES AS SHOWN

IN TABLE 1.

WARNING!

IF INSTALLING THIS MODELTO AMASONRY CHIMNEY, ALWAYS BE SURE THE

CHIMNEY IS IN GOOD CONDITION AND THAT IT MEETS THE MINIMUM STANDARDS

OF THE NATIONAL FIRE PROTECTION ASSOCIATION (NFPA) STANDARD 211.

THIS APPLIANCE IS MADE WITH A6 INCH/152 MM. DIAMETER CHIMNEY CONNECTOR (IF YOU ARE USING A FACTORY-BUILT CHIMNEY SYSTEM, AS RECOMMENDED) AS THE FLUE COLLAR ON THE UNIT.

CHANGING THE DIAMETER OF THE CHIMNEY CAN AFFECT DRAFT AND CAUSE

POOR PERFORMANCE. IT IS NOT RECOMMENDED TO USE OFFSETS OR ELBOWS

AT ALTITUDES ABOVE 4000 FEET ABOVE SEA LEVEL OR WHEN THERE ARE

OTHER FACTORS THAT AFFECT FLUE DRAFT.

Page 8

Amasonry chimney or a factory-built chimney must

Figure 7

Chimney Connector

be the required height above the roof and any other

nearby obstructions. The chimney must be at least 3

feet higher than the highest point where it passes

through the roof and at least 2 feet higher than the

highest part of the roof or structure that is within 10

feet of the chimney, measured horizontally. See

Figure 6.

These are safety requirements and are not meant to

assure proper flue draft.

We recommend using a minimum total system height

of 12 feet/3657 mm when using single wall connector, not including the chimney cap, measured from

the stove flue collar to the top of the chimney. For a

listed connector pipe, use a minimum total system

height of 9 feet/2743 mm.

MODEL 400 WOODSTOVE

4. FLUE SYSTEMS.

There are two separate and different parts to a flue

system: the chimney connector and the chimney

itself.

Chimney Connector.

The chimney connector connects the stove to the

chimney. The connector must be the same size as

the flue outlet of the stove. There are two types of

chimney connectors.

A. Single wall connector or stovepipe. This must be

at least 24 gauge mild steel or 26 gauge blue

steel. The sections must be attached to the stove

and to each other with the crimped (male) end

pointing toward the stove. See Figure 7. All

joints, including the connection at the stove collar,

should be secured with three sheet metal screws.

Make sure to follow the minimum clearances in

Table 1, page 5.

B. Factory-built listed chimney connector (vented).

The listed connectors must be the same brand at

the listed chimney.

Figure 6

Chimney Height

5-98 8 72308B

NOTE: The chimney connector must be

attached to either an approved masonry

chimney or any safety listed factory-built

chimney.

Page 9

5-98 9 72308B

MODEL 400 WOODSTOVE

5. MASONRY CHIMNEY.

Be sure a masonry chimney meets the minimum standards of the National Fire Protection Association (NFPA)

Standard 211. It must have at least a 5/8 inch/16 mm fire clay liner or a listed chimney liner system. Make sure there

are no cracks, loose mortar or other signs of deterioration and blockage. It is best to have the chimney inspected by

a professional and be sure to have the chimney cleaned before the stove is installed and operated.

The flue should be checked to determine that it is not too large for the stove. NFPA211 allows the cross-sectional

area of the flue to be no more than 3 times the cross-sectional area of the flue collar of the stove (28 x 3 = 84). It is

recommended that a chimney with a larger diameter be relined, since the oversized flue can cause poor performance

and contribute to the accumulation of creosote. (See page 16 for more information about draft.)

When connecting the stove through a combustible wall to a masonry chimney, special methods are needed. There

are several ways to make this connection, including the construction of a masonry thimble. Check with your local

building authorities or consult the National Fire Protection Association (NFPA211). Refer to Figure 8.

NOTE: Never install more than one appliance to any Chimney.

Figure 8

Masonry Thimble

Page 10

MODEL 400 WOODSTOVE

5-98 10 72308B

EIGHT INCH SOLID PACK CHIMNEY

WITH METALSUPPORTS AS A

THIMBLE.

For the method of installation to a masonry chimney

shown in Figures 10 & 11, it will be necessary to purchase a 8 inch inside diameter 12 inch long section of

prefabricated listed solid pack chimney to use as a

thimble. Purchase a wall spacer, trim collar and a

ware manufactured to fit the chimney section you

purchase.

The safety features of this system are: 2 inch air

space between the chimney section and combustible

wall, and the 1 inch air space around the chimney

connector as it passes through the chimney section

to the chimney.

The location of the opening through the wall to the

chimney must leave a minimum 18 inch vertical clearance between the connector pipe and the ceiling to

prevent the ceiling from catching fire.

Cut out an opening in the wall large enough to

accommodate the outside dimension of the chimney

section plus the minimum air space specified by its

manufacturer. It may be necessary to cut the wall

studs and install a header and a sill frame to maintain

the wall support. The hole in the chimney must have

at least an 8 inch diameter fire clay liner or equivalent

secured with refractory mortar. If it is necessary to

cut a hole in the chimney liner, use extreme care to

keep it from shattering.

First, make the frame for the thimble, being sure it is

no smaller than 14 inches square, to maintain a 2

inch air space around the chimney section. Attach

the wall spacer to the chimney side of the frame.

Then insert the frame into the opening, toe nailing it

to the wall studs. Install the wall band in the framing

to secure the chimney section in place. Insert a single section of chimney connector into the chimney

through the wall band, being sure it does not protrude

into the chimney beyond the edge of the chimney flue

lining. Apply high temperature furnace cement to the

end of the chimney section and install it over the connector, through the wall spacer. Tighten the wall

band to hold the chimney section firmly in place and

against the chimney. Install the trim collar on the outside of the opening. Check to assure there is a 1

inch air space between the connector and the chimney section. Also, during installation, always check to

assure that a 2 inch air space is being maintained to

the wood framing. Do not fill this space with insulation. Insulation in this air space will cause a heat

buildup which may ignite the wood framing.

Page 11

MODEL 400 WOODSTOVE

Figure 10

Installation to a Masonry Chimney

5-98 11 72308B

Figure 11

Installation to a Masonry Chimney

Page 12

MODEL 400 WOODSTOVE

5-98 12 72308B

CONNECTION TO AMASONRY FIREPLACE.

There are several kits available to connect the stove to a mason-

ry fireplace. Look for a listed kit. The kit is an adapter which is

installed at the location of the fireplace damper. The existing

damper may have to be removed to allow installation of the kit.

The key points of this type of stove connection are that the connector pipe must extend up the chimney above where the fire

clay liner starts, and the areas of the kit installation and penetra-

tion should fit tightly and be sealed with high temperature furnace cement unless the kit’s instructions state otherwise.

See Figure12. The tight fitting installation aids the proper draw

of the chimney.

6. CONNECTION TO A METAL

PREFABRICATED CHIMNEY.

When a metal prefabricated chimney is used, the

manufacturer’s installation instructions must be

followed precisely. You must also purchase

(from the same manufacturer) and install the

ceiling support package or wall pass through and

“T” section package, firestops (when needed),

insulation shield, roof flashing, chimney cap, etc.

Maintain the proper clearance to the structure as

recommended by the manufacturer. This clearance is usually a minimum of 2 inches, although

it may vary by manufacturer or for certain com-

ponents.

There are basically two methods of metal chimney installation. One method is to install the

chimney inside the residence through the ceiling

and the roof. See Figures 13 and 14.

The other method is to install an exterior chim-

ney that runs up the outside of the residence.

See Figures 15 and 16. The components illustrated may not look exactly like the system you

purchase, but they demonstrate the basic components you will need for a proper and safe

installation.

The chimney must be the required height above

the roof or other obstruction for safety and for

proper draft operation. The requirement is that

the chimney must be at least 3 feet higher than

the highest point where it passes through the

roof and at least 2 feet higher than the highest

part of the roof or structure that is within 10 feet

of the chimney, measured horizontally.

Install an attic insulation shield to maintain the

specified clearance to insulation. Insulation in

this air space will cause a heat buildup which

may ignite the ceiling joists.

This method of installation requires, at minimum,

a ceiling support package, an insulation shield

and roof flashing.

Figure 12

Connection to a Masonry Fireplace

LISTED FACTORY-BUILT CHIMNEY.

Your Dovre unit requires a 6” diameter pipe.

Follow the installation instructions provided by the

chimney manufacturer and maintain the specified

clearances to combustibles.

When using a factory-built chimney, make sure it

is safety listed, Type HTor conforming to

CAN/ULC-S692M, STANDARD FOR 650°C FACTORY-BUILT CHIMNEYS.

IMPORTANT

FOLLOW THE MANUFACTURER’S INSTALLA-

TION INSTRUCTIONS AND MAINTAIN THE

MANUFACTURER’S CLEARANCE DIS-

TANCES.

Page 13

MODEL 400 WOODSTOVE

Figure 14

Figure 13

Installation of an Interior

Chimney

5-98 13 72308B

Page 14

MODEL 400 WOODSTOVE

5-98 14 72308B

Figure 15

Installation of an Exterior Chimney

Figure 16

Page 15

MODEL 400 WOODSTOVE

D. STEP BY STEP INSTALLATION OF THE WOODSTOVE

1. ASSEMBLY.

Before assembly, place the unit near the final

position, then follow the procedures below.

a. Open the stove and remove all the parts and arti-

cles packed inside. Inspect all the parts and the

cast iron body for shipping damage. Contact your

dealer if any irregularities are noticed.

b. Install floor protection if the heater is being placed

on a combustible floor. Refer to the section on

floor protectors for required materials and sizes on

page 6.

c. Lift the unit upright and place it into position on the

floor protector. DO NOT TILT THE UNIT ON THE

ON THE CAST IRON LEGS.

d. The Flue Collar is located inside the Model 400.

For a top flue exit, attach the Collar to the top of

the heater with the bolts and nuts provided. Furnace cement may be used to seal under the

Collar. See Figure 17.

Should a rear flue exit be necessary, you will

need to remove the center section from the back

shield to allow for rear exit. The Flue Collar is

then fastened to the back of the unit with the

bolts and nuts provided, as shown in Figure 17.

Install the cast iron Cover Plate on the top of the

heater in the unused Flue Opening by placing a

bead of furnace cement around the edge and

place the Cover in position so it sits firmly

against the cast iron. Attaching the Cover Plate

to the rear of the stove, you will also need to

attach the Fixing Bar to the Cover Plate with the

washers provided. See Figure 17 for Top and

Rear Cover Plate installation.

5-98 15 72308B

Figure 17

Top and Rear Cover Plate Installation

Page 16

2. FIREBRICK PLACEMENT.

Make sure the firebricks are in position and not broken

before operating the unit. Also make sure the baffle insulation is positioned all the way against the rear of the unit.

✔ PRE-USE CHECK LIST

Use the following checklist as a guide to be sure your installation is correct and complete.

All of the safety warnings have been read and

followed.

Floor protection requirements have been followed.

Chimney connector is properly installed.

The proper clearances from the stove and chimney

to combustible material have been met.

The masonry chimney is inspected and clean or

the factory built metal chimney is installed

according to the manufacturer’s instructions and

clearances.

The chimney meets the required minimum height.

5-98 16 72308B

CAUTION:

IF THE OPTIONAL BLOWER KIT IS

USED, THE CORD SHOULD BE

ROUTED AWAY FROM THE UNIT.

WARNING!

NEVER DRAW COMBUSTION AIR

FROM A WALL, FLOOR OR CEIL-

ING CAVITYOR FROM ANY

ENCLOSED SPACE SUCH AS AN

ATTIC OR GARAGE.

MODEL 400 WOODSTOVE

Page 17

MODEL 400 WOODSTOVE

DO NOT ATTEMPT TO OPERATE THIS WOODSTOVE WITHOUT READING A N D

U N D E R S TANDING THESE OPERATING INSTRUCTIONS THOROUGHLY. FA I L U R E

TO OPERATE THIS APPLIANCE PROPERLY M AY CAUSE A SERIOUS HOUSE FIRE.

E. OPERATING INSTRUCTIONS

WA R N I N G !

GENERAL INFORMATION.

The D O V R E®Model 400 woodstove is an efficient

woodstove designed to burn natural, seasoned

wood. Do not burn artificial logs or driftwood.

The Air Inlet Control is located at the upper right

corner of the stove. Move the lever to the left to

open and to the right to close. See Figure 18a. In

addition, when starting a fire in the Model 400 also

open the Spin Draft Control located in the center of

the Lower Door. To open this Control, turn counter

clockwise and clockwise to close. See Figure 18b.

The more combustion air allowed into the

Firebox, the hotter and faster the fire will burn.

Closing the Air Intake slows the rate of

combustion resulting in a slower burning fire.

Experience with your stove, the quality of your

firewood, and local conditions will determine

the proper setting for maintaining the heat

output that best suits your needs.

BREAK-IN PERIOD.

Build your first few fires small to allow the high temperature paint on your stove to cure. During this

period excessive temperatures may damage the

paint. Allow adequate ventilation to dissipate smoke

and odor that may come from the paint during curing.

Figure 18a

Air Inlet Control

5-98 17 72308B

Figure 18b

Spin Draft Control

Page 18

WARNING!

ALWAYS OPERATE THIS APPLIANCE

WITH THE DOOR CLOSED AND

LATCHED EXCEPT DURING START-

UPAND RE-FUELING.

WA R N I N G !

DO NOT USE A R T I F I C I A LLOGS THAT

C O N TAIN WAX, PARAFFIN, OR OTHER

INGREDIENTS THAT CAN RELEASE

V O L ATILE GASES WHICH MAY C O N-

DENSE ON THE INSIDE OF THE

FIREBOX AND CHIMNEY. SOME

A R T I F I C I A LLOGS CONTAIN FLAM-

MABLE LIQUIDS THAT MAY C A U S E

AN UNCONTROLLABLE FIRE.

3. Move the Air Intake control lever all the way to

the left (High) to open the air intake. Also, open

the Spin Draft by rotating it counter clockwise

4. Light the newspaper in several places, starting at

the back of the firebox and working towards the

front.

5-98 18 72308B

WARNING!

NEVER USE GASOLINE, GASOLINE-

TYPE LANTERN FUEL, KEROSENE,

CHARCOAL LIGHTER FLUID, OR

SIMILAR LIQUIDS TO START OR

‘FRESHEN-UP’A FIRE IN THIS

HEATER. KEEPALL SUCH LIQUIDS

WELL AWAY FROM THE HEATER.

WARNING!

BUILD THE FIRE DIRECTLYON THE

FIREBRICK FLOOR. DO NOT USE A

GRATE OR OTHERWISE ELEVATE

THE FIRE WHEN BURNING WOOD.

WA R N I N G !

FAILURE TO FOLLOW INSTRUC-

TIONS LISTED MAYAFFECT THE

PERFORMANCE OF THE A P P L I A N C E .

DURING STA R T- U PAND RE-FUELING

IT IS NECESSARY T H AT THE A P P L I-

ANCE REACH OPERATING TEMPER-

ATURE FOR PROPER PERFOR-

M A N C E .

STARTING THE FIRE.

1. Place several crumpled newspaper pages on the

firebox floor.

2. Cover the paper with several pieces of kindling.

The kindling should be less than 1" in diameter,

well seasoned, dry, split firewood.

5. Close the door to prevent smoke spillage but do

not latch. This allows extra air into the firebox

for start-up while preheating the glass to help

keep it cleaner.

6. Once the kindling is burning, place three or four

small pieces of firewood, two or three inches in

diameter on the fire, close the door and latch.

NOTE: If the chimney flue is cold due to low

outside temperatures, several pieces of crumpled paper on top of the fuel may help establish

a draft in the flue.

MODEL 400 WOODSTOVE

Page 19

MODEL 400 WOODSTOVE

7. Maintain the fire by adding small pieces of firewood periodically until a uniform fire bed has

been established.

8. After establishing the fire bed, and the small firewood is burning briskly, add a minimum of three

average sized pieces of split firewood, place the

wood in such a manner to allow combustion air

and flames between them.

DO NOT LEAVE THE FIRE UNAT-

TENDED WHEN THE DOOR IS

UNLATCHED. CARELESSLY

PLACED FIREWOOD COULD FALL

OUT OF THE FIREBOX CREATING A

9. After about 45 minutes to 1 hour the stove will

have reached operating temperature. You may

slow down the burn rate by pulling the air intake

control lever out to the desired setting.

10. If equipped with optional blower, turn it on at this

time.

ALWAYS OPEN THE DOOR SLOWLY

WHILE THE FIRE IS BURNING TO

AVOID SMOKE AND FLAME

SPILLAGE. IT IS BEST TO UNLATCH

THE DOOR, WAIT AFEW SECONDS,

THEN OPEN THE DOOR SLOWLY.

TO INSURE GOOD, RAPID RE-IGNI-

TION, CREATE AVALLEY IN THE

COAL BED FROM THE FRONT TO

ABOUT ITS CENTER, WHICH WILL

ALLOW COMBUSTION AIR UNDER-

NEATH THE FRONT PIECE OF FUEL.

WARNING!

FIRE HAZARD.

WARNING!

RE-FUELING.

When adding fresh wood to an existing fire:

1. Open the air intake by moving the control lever

all the way to the left.

2. Wait a few seconds, then open the door slowly.

If the fire has been allowed to die down between refueling, it may be necessary to use smaller pieces of

wood to re-kindle it. Leave the control lever on HI

after re-fueling for 10 to 20 minutes to re-establish a

moderately high firing rate and bring the stove back

up to operating temperature.

OPERATING EFFICIENCY.

Rather than burning the stove hot and not running

the blower, it is more efficient to adjust the damper

down and operate the blower on low to move air

across firebox surfaces. This method of operation

will conserve fuel and gain a maximum amount of

heat from the stove. Model 400 woodburning stove

is designed to be an exceptional value in heating effi-

ciency when installed, operated and maintained in

accordance with the information in this manual.

However, factors unique to your location, installation,

or firewood can affect or alter the performance of this

appliance. If you experience difficulty lighting the fire

or sporadic burning refer to Flue Draft section on

page 23 of this manual.

WARNING!

DO NOT STORE FUEL WITHIN THE

CLEARANCES TO COMBUSTIBLES

MENTIONED ON PAGE 5, OR IN THE

SPACE REQUIRED FOR REFUELING

AND ASH REMOVAL.

WARNING!

DO NOT OVER FIRE THIS HEATER.

ATTEMPTS TO ACHIEVE HEAT OUT-

PUT RATES THAT EXCEED HEATER

DESIGN SPECIFICATIONS CAN

RESULT IN PERMANENT DAMAGE

TO THE HEATER. IF ANY PART OF

THE UNIT OR FLUE SYSTEM IS

GLOWING, THE STOVE IS BEING

OVER FIRED.

5-98 19 72308B

WARNING!

BURNING WET UNSEASONED

WOOD CAN CAUSE EXCESSIVE

CREOSOTE A C C U M U L ATION. WHEN

IGNITED IT CAN CAUSE A C H I M N E Y

FIRE THAT MAY R E S U LT IN AS E R I-

OUS HOUSE FIRE.

Page 20

MODEL 400 WOODSTOVE

The following guideline will ensure properly seasoned wood:

1. Stack the wood to allow air to circulate freely

around and through the woodpile.

2. Elevate the woodpile off the ground to allow

air circulation underneath.

3. The smaller the pieces, the faster the drying

process. Any piece over six inches in diameter should be split.

4. Cover the top of the woodpile for protection

from rain and snow. Avoid covering the sides

and ends completely. Doing so may trap

moisture from the ground and impede air circulation.

The problems with burning wet, unseasoned wood

are twofold. First, you will receive less heat output

from wet wood because it requires energy in the form

of heat to evaporate the water trapped inside. This is

wasted energy that should be used for heating your

home. Secondly, this moisture evaporates in the

form of steam which has a cooling effect in your firebox and chimney system. When combined with tar

and other organic vapors from burning wood it will

form creosote which condenses in the relatively cool

firebox and chimney. See the maintenance section

of this manual for more information regarding creosote formation and need for removal.

5-98 20 72308B

WOOD FUEL.

Hardwood vs. Softwood

Your woodstove’s performance depends a great deal

on the quality of the firewood you use. Contrary to

popular belief, one species of wood varies very little

to the other in terms of energy content. All seasoned

wood, regardless of species, contains about 8,000

BTU’s per pound. The important factor is that hardwoods have a greater density than softwoods.

Therefore, a piece of hardwood will contain about

60% more BTU’s than an equal size piece of softwood. Since firewood is commonly sold by the cord

(128 cu. ft.), a volume measurement, a cord of seasoned oak (hardwood) would contain about 60%

more potential energy than a cord of seasoned pine

(softwood).

There are many definitions of hardwood and softwood. Although not true in every case, one of the

most reliable is to classify them as coniferous or

deciduous.

Softwoods are considered coniferous. These are

trees with needle-like leaves that stay green all year

and carry their seeds exposed in a cone. Examples

of softwood trees are Douglas fir, pine, spruce and

cedar.

Softwoods, being more porous, require less time to

dry, burn faster and are easier to ignite than hardwoods.

Deciduous trees are broadleaf trees that lose their

leaves in the fall. Their seeds are usually found within a protective pod or enclosure. Hardwoods fall into

this category. Some examples of deciduous trees

are oak, maple, apple, and birch. However it should

be noted that there are some deciduous trees that

are definitely not considered hardwoods such as

poplar, aspen and alder. Hardwoods require more

time to season, burn slower and are usually harder to

ignite than softwoods.

Obviously, you will use the type of wood that is most

readily available in your area. However, if at all possible the best arrangement is to have a mix of softwood and hardwood. This way you can use the softwood for starting the fire giving off quick heat to bring

the appliance up to operating temperature. Then add

the hardwood for slow, even heat and longer burn

time.

SEASONING.

Seasoned firewood is nothing more than wood that is

cut to size, split and air dried to a moisture content of

around 20%. The time it takes to season wood

varies from around nine months for softwoods to as

long as eighteen months for hardwoods. The key to

seasoning wood is to be sure it has been split,

exposing the wet interior and increasing the surface

area of each piece. Atree that was cut down a year

ago and not split, is likely to have almost as high a

moisture content now as it did when it was cut.

MOISTURE CONTENT.

Regardless of which species of wood you burn, the

single most important factor that effects the way your

stove operates is the amount of moisture in the wood.

The majority of the problems woodstove and fireplace

insert owners experience are caused by trying to

burn wet, unseasoned wood.

Freshly cut wood can be as much water as it is wood,

having a moisture content of around 50%. Imagine a

wooden bucket that weighs about 8 pounds. Fill it

with a gallon of water, put it in the firebox and try to

burn it. This sounds ridiculous but that is exactly

what you are doing if you burn unseasoned wood.

Page 21

MODEL 400 WOODSTOVE

ASH HANDLING.

Open the ash grate by sliding the upper grate to the

left. See Figure 19. Use a fireplace tool to work the

desired amount of ash through the grate into the ash

pan. Some ash on the grate is desirable to help keep

an active bed of coals for refueling. We recommend

emptying the ash pan at least once a day when the

stove is in constant operation. The amount of ash is

dependent on the type of wood being burned. DO

NOT LET ASHES BUILD UP IN THE ASH PAN

UNTIL THEY REACH THE GRATE AS THIS WILL

LEAD TO PREMATURE DETERIORATION OF THE

GRATE AND MAKE IT DIFFICULT TO EMPTY THE

ASH PAN. See Figure 20 for ash pan diagram.

F. MAINTENANCE INSTRUCTIONS

Figure 20

Ash Pan

Figure 19

Ash Grate

ASH DISPOSAL.

Ashes must be disposed of carefully. The National

Fire Protection Association (NFPA) suggests that all

ashes be placed in a metal container with a tight fitting lid. The closed container of ashes should be

placed on a non-combustible floor or on the ground,

well away from all combustible materials, pending

final disposal. If the ashes are disposed of by burial

in soil or otherwise locally disbursed, they should be

retained in the closed container until all cinders have

thoroughly cooled.

It is critical to remember that while you may not see

any red coals in the ashes being removed, it is most

likely there still is some residual burning occurring

unless the fire has been cold for at least 48 hours.

5-98 21 72308B

Page 22

MODEL 400 WOODSTOVE

WARNING!

NEVER ATTEMPT TO CLEAN THE

GLASS WHILE IT IS HOT.

WARNING!

DO NOT OPERATE THIS INSERT IF

THE DOOR GASKET IS MISSING OR

DAMAGED. DANGEROUS OVERFIR-

ING MAYOCCUR WHICH CAN DAM-

AGE THE APPLIANCE OR IGNITE

CREOSOTE IN THE CHIMNEY, POSSI-

BLYCAUSING A HOUSE FIRE.

Replace the gasket when necessary with 3/4" diameter woodstove gasket material available from your

local woodstove retailer or order Part #18589 Fire

door Gasket Kit from your nearest D O V R E®dealer.

The Fire door Gasket Kit comes complete with gasket material, high temperature adhesive and instructions.

WARNING!

ASHES SHOULD NEVER BE PLACED

IN WOODEN OR PLASTIC CONTAIN-

ERS, OR IN PAPER OR PLASTIC

BAGS, REGARDLESS OF HOW

LONG THE FIRE HAS BEEN OUT.

COALS HAVE BEEN FOUND TO STAY

HOT FOR SEVERAL DAYS WHEN

EMBEDDED IN ASHES.

CREOSOTE & SOOT.

Formation and need for removal.

When wood is burned slowly, it produces tar and

other organic vapors which combine with expelled

moisture to form creosote. The creosote vapors condense in the relatively cool chimney flue of a newly

started fire or from a slowly burning fire. As a result,

creosote residue accumulates on the flue lining.

When ignited, this creosote makes an extremely hot

fire which may damage the chimney or even destroy

the house.

The chimney should be inspected at least twice

monthly during the heating season to determine if a

creosote or soot build-up has occurred. If so, it

should be removed to reduce the risk of a chimney

fire.

To help prevent creosote build-up, always burn dry,

well seasoned firewood. When re-fueling after an

extended low burn rate, allow the appliance to burn

with the combustion air intake fully open (temperature setting on HI) for ten to twenty minutes to burn

off creosote deposits that accumulate during the low

burn.

Inspect the system at the insert connection and at

the chimney top. Cooler surfaces tend to build creosote deposits quicker, so it is important to check the

chimney from the top as well as the bottom.

The creosote and soot should be removed with a

brush specifically designed for the type of chimney in

use. Achimney sweep can perform this service. It is

also recommended that before each heating season

the entire system be professionally inspected, and

cleaned and repaired if necessary. This insert should

be removed for periodic inspection and cleaning of

chimney.

WARNING!

FAILURE TO INSPECT AND CLEAN

YOUR CHIMNEY REGULARLY CAN

RESULT IN A SERIOUS FIRE WHICH

MAYDAMAGE THE CHIMNEY OR

CAUSE A HOUSE FIRE.

DOOR GASKET.

Check the door gasket periodically for proper seal.

As the door gasket compresses or “seats” during use

it will be necessary to adjust or tighten the door latch.

Wear or damage to the gasket material can cause air

leakage into the firebox resulting in overfiring and

loss of efficiency.

5-98 22 72308B

Page 23

MODEL 400 WOODSTOVE

DOOR GLASS.

Do not strike or slam the door shut.

Inspect the glass regularly for cracks or breaks. If you

detect a crack or break, extinguish the fire immediately

and contact your D O V R E®dealer for replacement.

Aportion of the combustion air entering the firebox is

deflected down over the inside of the door glass. This air

flow “washes” the glass helping to keep smoke from

adhering to it’s surface.

When operated at a low burn rate less air will be flowing

over the glass and the smoky, relatively cool condition of

a low fire will cause the glass to become coated. If the

deposits on the glass are not very heavy, normal glass

cleaners work well. Heavier deposits may be removed

by using a damp cloth dipped in wood ashes or by using

a commercially available oven cleaner. After using

an oven cleaner, it is advisable to remove any

residue with a glass cleaner, or soap and water.

Oven cleaner left on during the next firing can permanently stain the glass and damage the finish on plated metal surfaces.

Do not clean the glass with materials that may

scratch or otherwise damage the glass. Scratches

on the glass can develop into cracks or breaks.

Never attempt to clean the glass while a fire is in the

unit.

The best way to keep the glass clean is to operate

the stove efficiently by using dry well seasoned wood

and burning moderate to hot fires.

GOLD PLATED DOOR TRIM.

NOTE: All prints and smudges must be wiped clean from the gold door trim prior to

initial burn. If this is not done, these prints will be cured into the gold finish

and set for the life of the stove.

To keep the finish looking its best, gently wipe with a soft cloth. If desired, use a nonabrasive cleaner such as soap and water, window cleaner, or vinegar and water.

Never use any solvent, thinner, or abrasive cleaner since these will damage the finish.

G. FLUE DRAFT

Like all modern woodburning appliances, The Model

400 woodstove requires the proper amount of flue

draft to assure safe and efficient operation. Flue

draft is measured as negative pressure in the chim-

ney. The amount of negative pressure determines

how strong the draft is. The draft is important

because it draws the combustion air into the firebox

and pulls the smoke out of the chimney.

There are three basic criteria essential in establishing

and maintaining flue draft:

1. Availability of combustion air

2. Heat generated from the fire

3. Diameter and height of the flue system

These three factors work together as a system to create the flue draft. Increasing or decreasing any one of

them will effect the other two and thus change the

amount of draft in the entire system. See Figure 21.

Figure 21

5-98 23 72308B

Page 24

MODEL 400 WOODSTOVE

1. Availability of combustion air. Asource of air

(oxygen) is required in order for combustion to

take place. The air enters the firebox through an

opening in the insert body. The amount of air

allowed in is regulated by the draft slide control.

The important thing is to realize that whatever air

is consumed by the fire must be replaced. If you

are using room air, the air is replaced through

cracks around windows, under doors, etc.

However, most newly constructed houses or

existing homes fitted with tightly sealed doors and

windows are relatively air tight. In this case, an

outside air source must be made available to feed

combustion air from outside the home into the

stove.

2. Heat generated from the fire. Most of the heat

produced from the fire is transferred into the heat

exchanger of the insert, then into the room.

However, part of this heat escapes up the chimney taking smoke and other combustion gases

with it. Most modern woodburning appliances,

including the Model 400, extract heat so efficiently

that the amount that goes up the flue can be minimal. This is one reason why it is important to

burn well seasoned wood. The heat generated

from the fire should be warming your home and

establishing the flue draft. It should not be wasted by evaporating moisture out of wet, unseasoned wood.

3. Diameter and height of flue system. Aspecific

volume of air, determined by the diameter and

height of the chimney connector and chimney, is

contained within the flue system. As heat from

the fire enters the flue, it warms this air causing it

to rise. The air moving up the flue draws smoke

and more heated air from the fire with it, thus

establishing draft. The amount of draft depends

on the temperature of the heated air and the volume of air that is contained in the flue system.

DRAFT PROBLEMS.

For the Model 400 woodstove, the minimum flue draft

requirement is 0.06 inches of water column as measured with a draft meter. Most woodstove dealers

have draft meters available to measure your flue

draft if you suspect a problem.

If the fire is hard to start and smoke spills out of the

door, or you find it difficult to establish and maintain a

moderately high burn rate, then the flue draft is too

low and corrective measures must be taken.

5-98 24 72308B

Be sure you have air available for combustion and

that your firewood is dry and well seasoned. Build

your fires properly and according to the instructions

given on page 18. Be sure your flue system is

installed correctly and that it is the proper diameter

and height. In addition, check for the following:

• All chimney connector sections are properly

installed and the joints are sealed tightly.

• The chimney and chimney connectors are clean;

free of creosote build-up.

• If utilizing an existing chimney that has been left

unused over a period of time, be sure it is not

obstructed with debris from animals or nesting

birds.

• Make sure overhanging trees and branches are cut

back within 10 feet of the top of the chimney.

• If the chimney cap is equipped with a spark arrestor

screen, be sure it is clean and free of any build-up

of soot or creosote.

If you still suspect you have a low draft problem it

may be necessary to increase the volume of air in

your flue system. Since the diameter of your flue system is matched with the size of the flue collar and

should not be changed, then the height of the system

will need to be increased. Add chimney a little at a

time until the draft improves.

In some cases, regardless of what you do, it can still

be difficult to establish the proper flue draft. This is

especially evident when using an exterior factory-built

chimney or exterior masonry chimney which is likely

to have too large of a flue. Try placing several sheets

of crumpled paper on top of your kindling as close to

the flue outlet of the stove as possible. Light this

paper first then the paper under the kindling. The

heat generated from the rapidly burning paper on top

of the kindling should help get the draft established.

Still other factors can effect how well your flue system

performs. Neighboring structures, high winds, tall

trees, even hillsides can effect air currents around the

chimney. Well designed chimney caps, wind directional caps, even draft inducing caps are available

that can help. Your woodstove dealer is the local

expert in your area. He can usually make suggestions or discover problems that can be easily corrected allowing your woodstove and flue systems to operate correctly as it has been designed, providing safe

and economical heat for your home.

Page 25

MODEL 400 WOODSTOVE

H. INSTALLATION OF REPLACEMENT GLASS

DO NOT OPERATE THE WOOD-

STOVE IF THE DOOR GLASS IS BRO-

KEN OR MISSING. DANGEROUS

OVERFIRING CAN OCCUR WHICH

CAN DAMAGE THE APPLIANCE OR

IGNITE CREOSOTE IN THE CHIMNEY,

POSSIBLYCAUSING A HOUSE FIRE.

1. Make certain the fire is out and the appliance is

cool to the touch.

2. Remove door from the appliance.

3. Lay door face down on a table or counter with

the door handle hanging off the edge of the table

so the door lays flat. Protect the table so neither

the table nor door will be scratched.

WARNING!

4. Remove the screws from each glass retainer.

5. Remove the glass.

6. Use only 5mm Ceramic Glass, Part No. 20912.

7. Position the glass with its edges evenly overlapping the opening in the front door.

8. Replace the glass retainers. Be careful not to

cross thread the screws.

9. Tighten each retainer just a few turns until each

is secured. Then continue to tighten alternately

each retainer a few turns at a time until the glass

panel is tightened snugly.

10. Replace the door on the appliance.

5-98 25 72308B

Page 26

MODEL 400 WOODSTOVE

5-98 26 72308B

THIS PAGE LEFT

BLANK INTENTIONALLY

Page 27

MODEL 400 WOODSTOVE

Aladdin Hearth Products warrants their wood heating appliances to the original purchaser for the

lifetime of the appliance, to be free from defects in material and workmanship. This warranty gives

you specific legal rights; you may have other rights which may vary from state to state.

This limited Lifetime Warranty covers items such as but not limited to steel and cast iron components, combustion chambers, doors, gold plating and glass damaged by thermal breakage.

All parts to be replaced must be returned to an authorized Aladdin Hearth Products dealer at purchaser’s expense for inspection and approval by Aladdin Hearth Products prior to repair or

replacement. No repair or replacement costs will be honored without approval of Aladdin Hearth

Products.

This new Dovre product must be installed by a competent, authorized, service contractor. It must

be installed and operated at all times in accordance with the Installation and Operating Instructions

furnished with this product, as well as any applicable local and national codes. Any alteration,

willful abuse accident, or misuse of the product shall void this warranty.

Any installation, construction, transportation or other related costs or expenses arising from defective part(s), repair, replacement, etc., will not be covered by this warranty, nor will Aladdin Hearth

Products assume responsibility for them. Further, Aladdin Hearth Products will not be responsible

for any incidental, indirect, or consequential damages, except as provided by law.

WARRANTY

All electrical components such as but not limited to the blower assembly and speed control switch

are covered by Aladdin’s one-year warranty program.

Aladdin Hearth Products will not be responsible for any alteration to the unit which causes sooting

that results in damage to the interior or exterior of the building in which this appliance is installed.

This warranty is void if the stove has been operated in atmospheres contaminated by chlorine, fluorine, or other damaging chemicals, the stove is subjected to prolonged periods of dampness or

condensation, or there is any damage to the stove or other components due to water or weather

damage which is the result of, but not limited to, improper chimney or venting installation.

This limited Lifetime Warranty does not extend to or include surface finish of the stove, door seal or

firebrick. It does not cover installation or operational-related problems such as overfiring, use of

corrosive driftwood, downdrafts or spillage caused by environmental conditions, nearby trees, buildings, hilltops, mountains, inadequate venting or ventilation, excessive offsets, or negative air pressures caused by mechanical systems such as furnaces, fans, clothes dryers, etc.

This limited Lifetime Warranty does not apply to venting components, hearth components orother

accessories used in conjunction with the installation of this product not manufactured by Aladdin

Hearth Products.

This limited Lifetime Warranty is effective on all wood stoves sold at point of retail after July 1,

1998, and supersedes any and all warranties currently in existence.

5-98 27 72308B

Page 28

Attention

WOODSTOVE

INSTALLER

Please return these

Operating & Installation

Instructions to the

Firebox

for Consumer Use

Aladdin Hearth Products

401 N. Wynne

ADivision of Hearth Technologies Inc.

5-98 28 72308 Rev B

Colville, WA99114

Loading...

Loading...