Dovre 2900GL, 2900GDC, 2900RGD, 2900RGC, 2900GD Installation Instructions And Operating Manual

Page 1

2900 1 03.27896.100

INSTALLATIEVOORSCHRIFTEN EN GEBRUIKSAANWIJZING

INSTALLATION ET MODE D’EMPLOI

INSTALLATION INSTRUCTIONS AND OPERATING MANUAL

EINBAUANLEITUNG UND GEBRAUCHSANWEISUNG

INBOUWHAARD / FOYER

FIREPLACE / KAMINEINSATZ

2900-serie

2900GL 2900GD(C) 2900RGD(C)

Page 2

2900 2 03.27896.100

Foreword

The Installation Manual and Operators Instructions must accompany this appliance.

As well as instructions for installation and information about use, you will also find

advice concerning safety and maintenance.

Please read this booklet carefull y before installation and before firing the unit.

Save this booklet and pass to any subsequent user who can also profit by it.

1. Introduction

Your DOVRE purchase has made you the owner of a high quality product that symbolizes a new generation of energy-saving and ecologically safe heaters, producing

convection heat as well as radiant heat with optimum efficiency. Through the application of a revolutionary combustion concept DOVRE heaters achieve astonishing

results in full compliance with strict environmental and safety norms. Also, you will

be enjoying the lovely sight of the fire blazing in the stove.

Our heaters are produced in accordance with ISO 9002, using state-of-the-art production means.

In the unlikely event of a malfunction, you can always rely on DOVRE’s after-sales

service.

This heater is designed to be installed in a living room and to be hermetically connected to a flue (chimney).

If the stove is professionally installed, connected to a well-functioning chimney and

sufficiently ventilated, you can take the long -term and trouble -free functioning of

your heater for granted.

Please consult an expert when installing and connecting the heater. The manufacturer cannot be held liable for problems caused by faulty installation.

2. Safety

The heating unit is best installed, commissioned, and checked by a competent installer who is aware of national and local legislation.

The heater is designed to heat a room, which means that all surfaces, including the

front glass, can get very hot (> 100 °C).

Please do not place any curtains, clothes, laundry, furniture or other combustible

materials on or near the heater.

It is advised to make a fire in the stove with the highest possible intensity right after

it is installed, so as to cure the heat-resistant paint finish. This may involve some

odour production, which will however disappear after a while.

It is necessary to maintain and regularly clean the stove and the chimney for the

stove to function safely and for a long period of time. Please follow the cleaning instructions in the chapter concerned.

In case of a chimney fire, immediately close all air intake vents of the appliance and

alert the fireman.

Broken glass should be replaced before using the heater again.

The stove is specifically designed for burning ce rtain kinds of fuels. In the technical

specifications under cover you can find detailed information concerning this topic. It

is absolutely prohibited to burn fuels other than these, as this may damage your

heater. Moreover, it is ecologically harmful.

Page 3

2900 3 03.27896.100

3. Installation guideline

3.1. Preparatory measures

The fireplace should be hermetically connected to a well-functioning chimney, sufficiently enclosed to keep combustible materials (floor and walls) at a distance, and

should be installed in a room with sufficient ventilation.

Please inform about national or local norms and regulations concerning this subject.

Your distributor will give you the necessary advice.

You can also consult the fire department and/or an insurance company about specific demands or regulations.

Please read the technical specifications under cover in this manual before installing

the appliance.

3.1.1. The chimney

The chimney (the flue) has a double function:

• It draws air, that is necessary for good combustion, into the stove.

• It functions as an exhaust pipe for combustion gases via thermal or natural

draught. Thermal draught is caused by the difference in heat between the air in and outside the flue. The heated air in the flue is lighter than the colder air ou tside the flue and consequently rises up, along with the combustion gases. Natural draught is caused by environmental phenomena, such as wind.

It is prohibited to connect several heaters to one chimney (for instance the central

heating boiler), unless local or national regulations allow this.

Please check which chimney is to be used for the stove you purchased and whether

your chimney is appropriate for this specific usage. You should consider an expert's

opinion on this matter.

The chimney should meet the following conditions:

• The flue should be made of fireproof material. Ceramic or stainless steel is re-

commended.

• The chimney should be airtight and thoroughly cleaned and should guarantee a

sufficient draught (a draught or negative pressure of 15 to 20 Pa is ideal under

normal circumstances).

• It should run as vertically as possible. Changes in direction or horizontal seg-

ments will disrupt the smoke flow and may cause soot to cumulate inside the

flue (and clog the flue!).

• The chimney's inside dimensions must not be too large in order to prevent the

smoke from cooling off too much. For recommended chimney dimensions, see

the technical specification under cover. Larger dimensions can be used if the flue

is well insulated.

• The flue's diameter should be the same throughout its whole length. Wider, or

especially narrower segments will disrupt the smoke flow and are best avoided.

Page 4

2900 4 03.27896.100

The same is true for a cover plate or exhaust hood on top of the chimney. The

exhaust hood must not narrow the chimney's outlet and should be designed in a

way that wind will not hinder, but promote the smoke flow.

• Especially if the flue runs through unheated rooms or outside the house, further

insulation is necessary. Metal chimneys, or parts of the chimney outside heated

rooms should always have double-walled, insulated flues. The part of the chimney outside the roof should always be insulated.

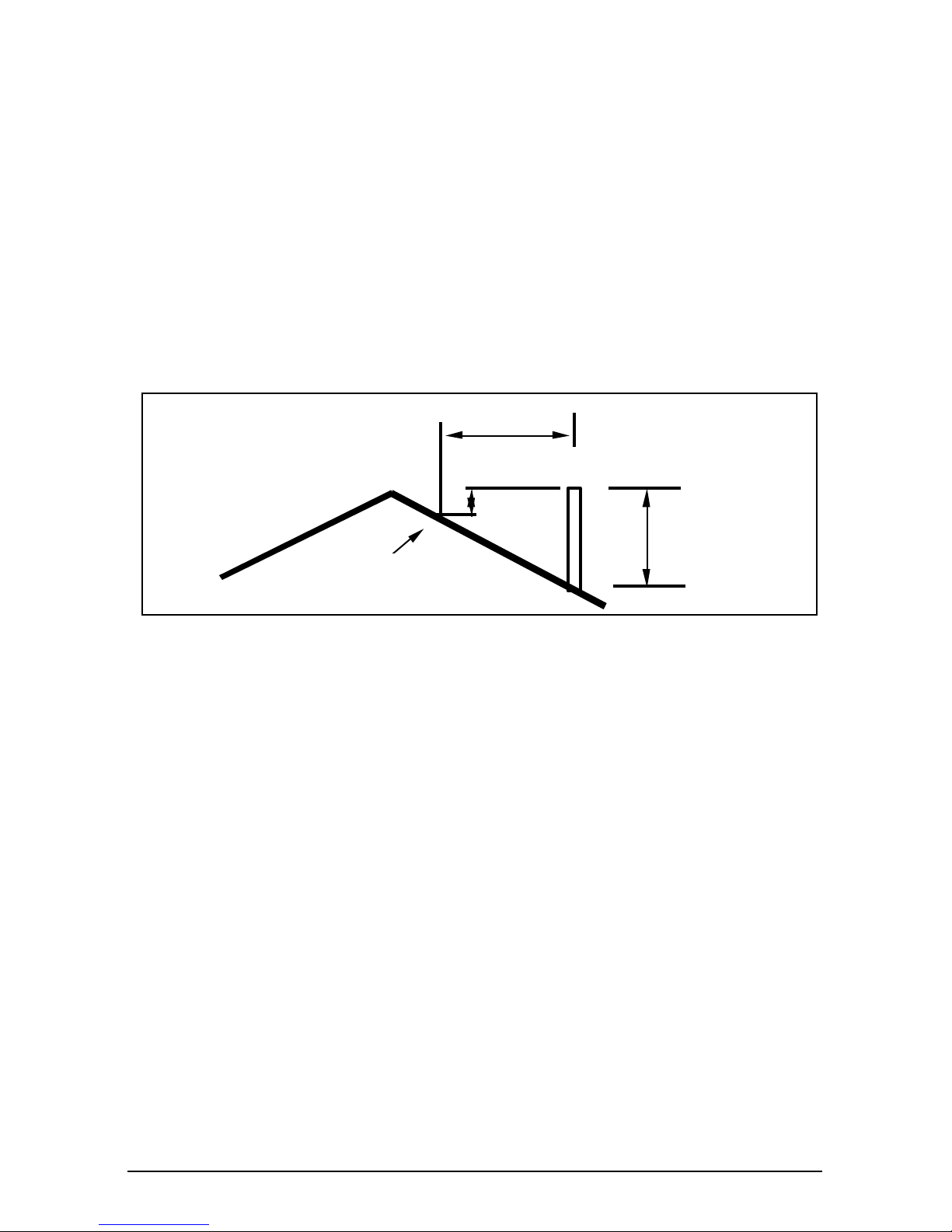

• The chimney should be high enough (at least four metres) and should end in a

zone that is clear of nearby buildings, trees or other obstacles. The rule of

thumb here is: 60 cm above the ridge of the roof. If the distance between the

ridge and the chimney measures more than three metres, see the dimensions

stipulated in the illustration below. Depending on the presence of nearby buildings or trees, the chimney should be higher.

3.1.2. Ventilation

The burning of wood, charcoal or gas involves oxygen consumption. It is of the utmost importance that the room in which the stove is installed should be sufficiently

ventilated.

Insufficient ventilation may disrupt the combustion process and cause the smoke

flow through the chimney to be interrupted, which may lead to smoke emissions

into the room. Mainly in case of a fireplace, together with the combustion gases, lots

of room air will be extracted through the chimney; that makes supply of sufficient

fresh air and ventilation extremely important.

If necessary, you can install a ventilation grille to provide a constant flow of fresh air

in the room. This precaution is particularly necessary in well-insulated rooms with

mechanical ventilation.

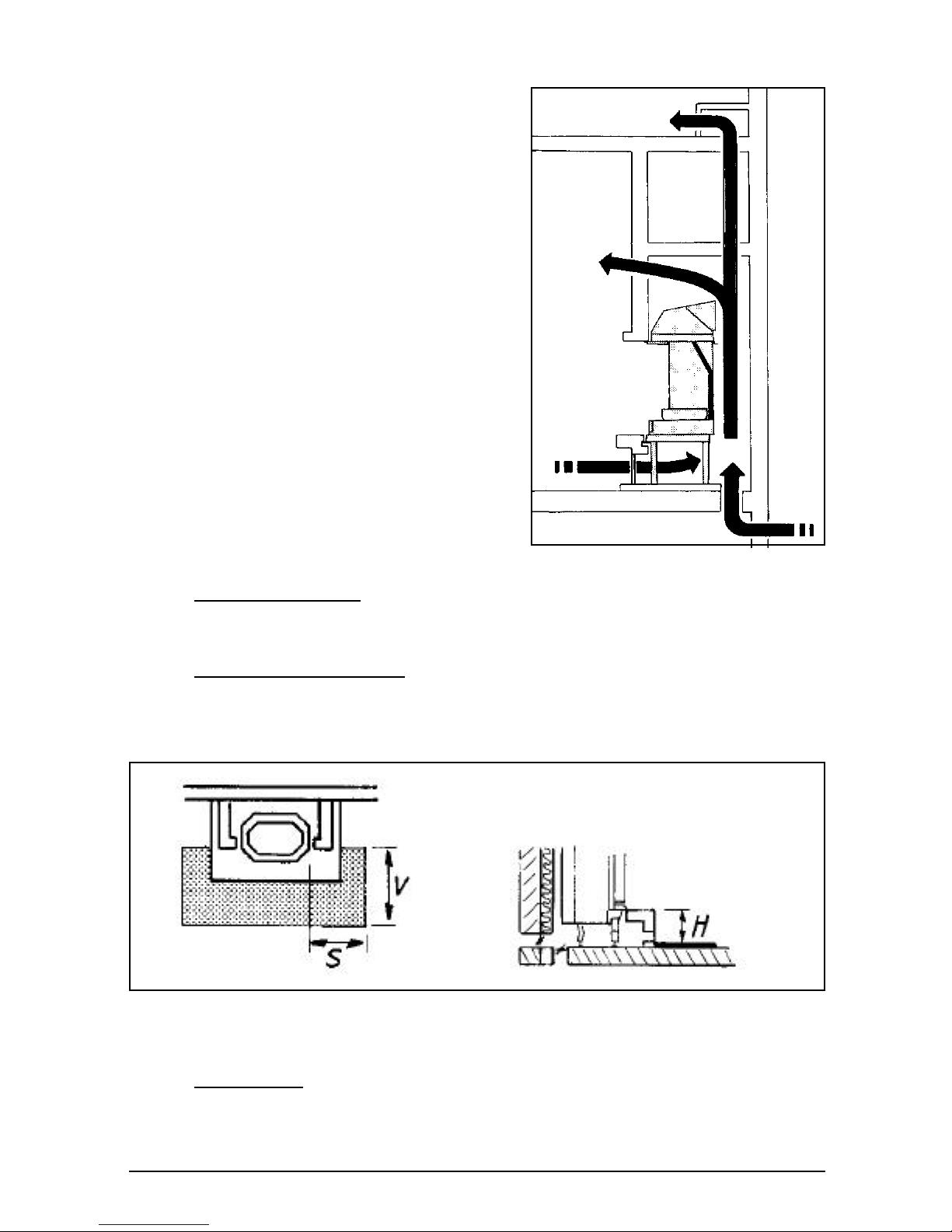

The DOVRE fireplace has been designed to produce most heat by means of convection. Heat is mainly transmitted through the back panel, the lateral panels, and the

smoke dome. Both the material (cast iron) and shape (increased heating surface by

means of corrugation) improve heat transmission to the surrounding air. As this air

is heated, it will rise and a natural hot air flow, i.e. convection, will develop. Up to

your choice, that hot air may be led to the same room or to another room.

For optimal heating and leading the convection air, the airflow must not encounter

any obstacles. Hence, it is important that there is enough space between the fireplace and the surrounding material, and that the inlet and outlet area of convection

air are sufficiently large.

min 0.5 m

3 m

min 1 m

highest point of the roof

within a distance of 3 m.

3 m

min 0.5 m

Page 5

2900 5 03.27896.100

Convection air may be led to arrive from both

the room and outside (other room, cellar, exterior) to the bottom side of the fireplace. In case

convection air is supplied (directly or indirectly)

from outside, it may also be useful as a supply

of fresh air for combustion.

At any rate, assure proper home air management and sufficient air supply into the room.

Ensure not to use other air-consuming appliances, such as heaters, cooking hoods, bathroom ventilators, in the same room or in the

house while the stove is burning; or make sure

to have an extra ventilation grille installed for

these appliances.

3.1.3. Floor, walls

Combustible material must be sufficiently protected. The floor under the fireplace and the

walls around it must not contain elec tric wires.

The appliance shall be installed on floors with

an adequate load-bearing capacity.

Under the appliance

Under the appliance, any combustible material must be removed or specially

shielded by means of a 6 cm concrete slab and 10 cm insulation.

Floor round the appliance

A floor made of combustible material must be properly shielded in the following

areas:

Front: height of the lower part of the fire chamber + 30 cm, but 60 cm at least.

Sides: height of the lower part of the fire chamber + 20 cm, but 40 cm at least.

Walls, ceiling

Combustible walls behind, next to, or above the fireplace must be shielded with at

least a 10 cm stone or brick wall and 10 cm insulation. Fireproof materials should be

covered with at least 6 cm insulation.

V > H + 30 > 60

S > H + 20 > 40

Page 6

2900 6 03.27896.100

3.2. Preparation

Please inspect the fireplace for damage caused during transport immediately after

delivery and notify your distributor in case there are any defects. Do not put the appliance into operation in the meantime.

In order to avoid damaging the fireplace during installation and to make its handling

easier, it is recommended to remove previously all loose parts (fire-resistant bricks,

grille, ashtray, ...) from the stove. Note the location of those parts while removing

them, so that you have no difficulties in re-assembling the parts later on.

See picture 1 for how to handle the aplliance for transport.

See picture 2 for loosing the screws for tansport-securty.

3.2.1. Assembly of the legs (see picture 3)

Fix the adjustment bolts under the legs. These will allow to adjust the fireplace

level.

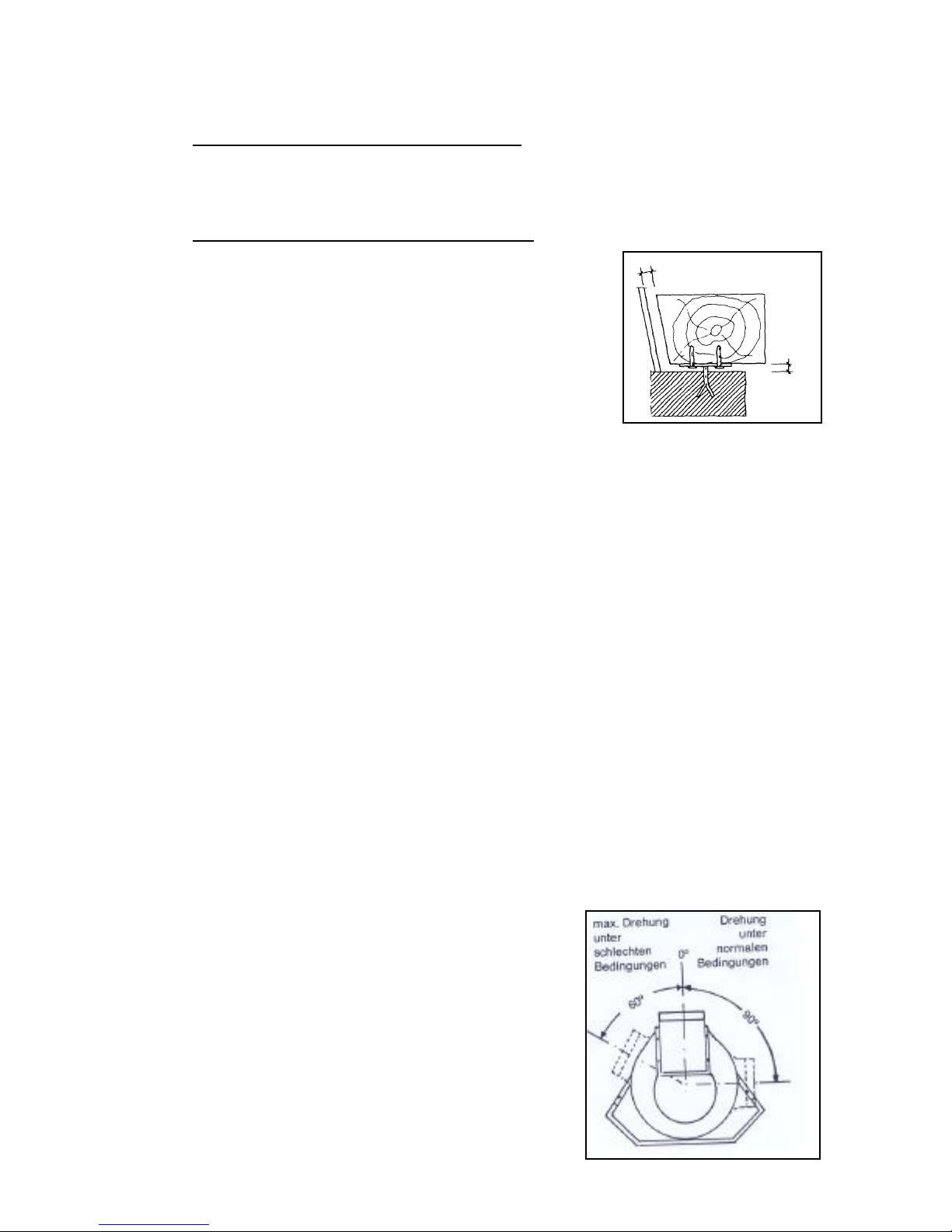

3.2.2. Assembly of the smoke dome and of the flue collar

The smoke dome must be fixed to the top of the device and attached by means of the clamps supplied.

Assure proper sealing by means of the kit or paste supplied.

It is recommended to install the smoke dome with its

exhaust backwards. In case of proper draft, it may be

turned up to 90° to the left or to the right if required

for installation. In case of lower draft, an angle of

maximum 60° is recommended.

The flue collar can be installed either horizontally or

vertically. Fix the flue collar on the smoke dome. Assure proper sealing with kit or paste.

3.1.4. Combustible material round the fireplace

Within the radiation area of the fireplace

Assure a distance of at least 80 cm between the opening of the fireplace and combustible material. That distance may be reduced to 40 cm if the combustible material is sufficiently shielded and well ventilated.

Outside the radiation area of the fireplace

Assure a distance of at least 5 cm between the mantle built

around the fireplace and combustible material. A small surface contact between combustible material and the mantle

(e.g. wall cladding) is allowed if the mantle of the fireplace

is sufficiently insulated.

A wooden ornamental rafter must not be installed within

the radiation area of the fire. Outside the radiation area,

there must always be a ventilation gap of 1 cm all around

to prevent heat from building up (see picture).

No combustible material must be present within 50 cm from the convection outlet

areas.

min 1 cm

min 1 cm

Page 7

2900 7 03.27896.100

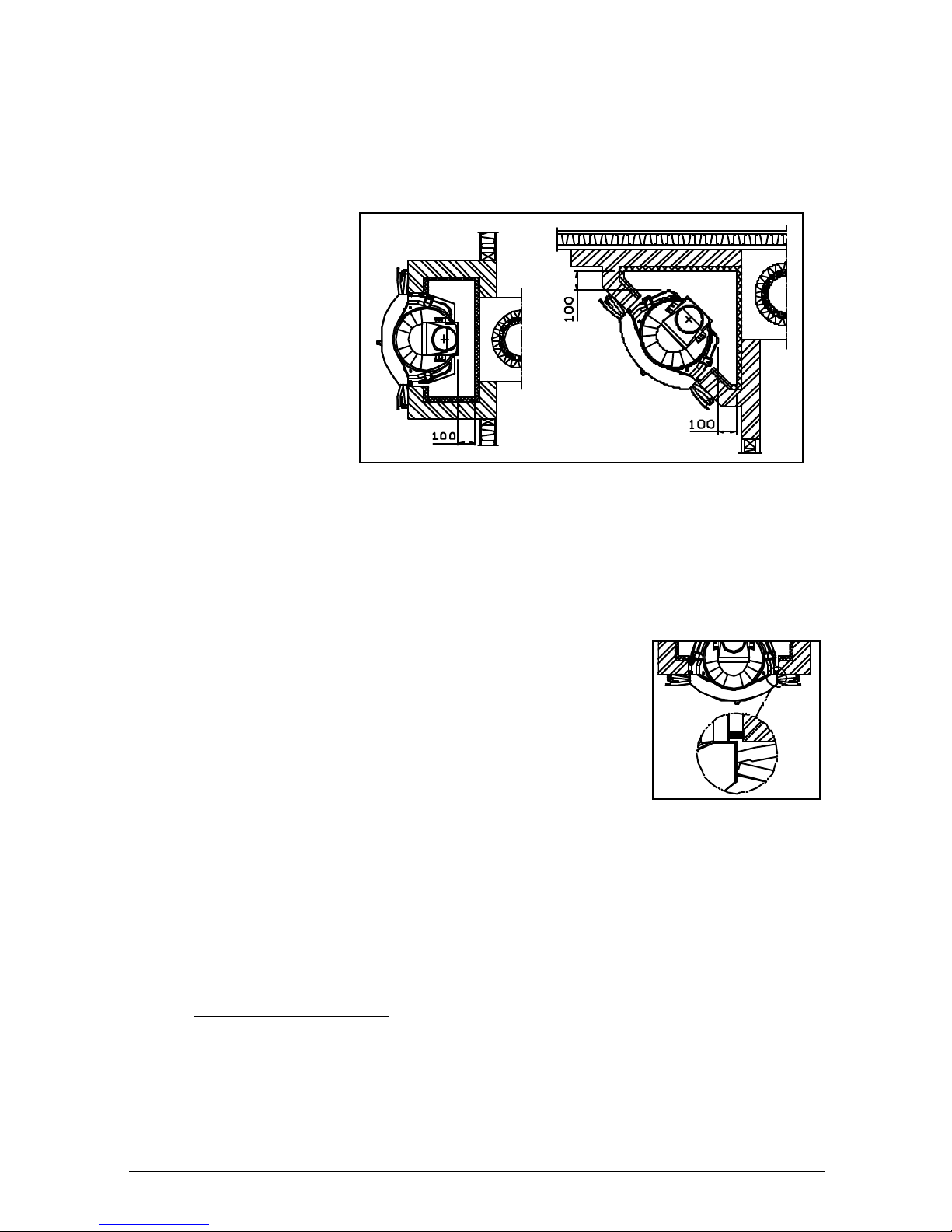

3.3. Installation of the fireplace

3.3.1. Positioning and connection

Put the fireplace at proper height. Make sure that it is stable and level and that the

side panels are perpendic ular to the bottom

plate. Put the fireplace far

enough from the walls, so

that minimum 5 cm of free

air passage remains between the back of the fireplace and the wall after

adding the necessary insulation.

Make an airtight connection between fireplace and

chimney, according to

good pra ctice.

Before further installation of the fireplace, check for sufficient draft in the chimney

and for proper connection between the smoke duct and the appliance.

For that purpose, you can light a small intense fire with paper and small dry kindle.

In case of a brick smoke duct, wait until the duct is dry enough.

3.3.2. Mounting

Start with the masonry round the base of the fireplace. In that

masonry, the air supply grids (optional) will be installed. Minimum air supply opening is 250 cm². The grids may be installed

on all sides.

It is important that air flows freely into the convection chamber. If you use an air vent (to convey outside air into the convection chamber), remember to build in the adjustment knob.

It is recommended to cover the inner side of the convection

chamber with extra reflecting insulation material. That prevents loss of heat radiation to outside walls or adjacent rooms, as well as deterioration of any inside wall insulation.

Make sure that the doors of the hearth move freely over the plate in front of the fireplace.

Continue building the chimney up to the smoke dome. Assure a gap of at least 2

mm between the fireplace and the masonry to allow for dilatation of the fireplace. If

necessary, use heat-resistant strips.

Upper structure support

The masonry over the fireplace must not rest on the fireplace. That is why a support

is used. Between the steel support and the smoke dome, you must leave a free

space of at least 3 mm. That will prevent tensions in the material that might tear the

upper structure. The steel support may rest on the side structure or be attached to

the wall by means of threaded rods.

Page 8

2900 8 03.27896.100

Convection chamber:

The convection chamber topside must be airtight. For that purpose, you can use a

cover of steel, concrete, or any other fire-resistant material, and put extra insulation

on top of it. Make sure that the cover is well horizontally placed.

The cover must be installed at 30 cm at least above the smoke dome. The outlet

grids must be installed straight under that cover. Make sure that convection outlet

area is big enough: minimum 500 cm².

In the convection chamber no combustible material must be used. Make sure that,

when using other auxiliary material such as steel, it will not function as a heat

bridge.

The picture on the next page shows an example of fireplace installation within

combustible

3.4. Finishing

When the appliance is installed in the right place, its connection with the chimney

made airtight, and the masonry mantle completely mounted, all loose parts are installed in the appliance.

Your fireplace is now ready to be used.

Depending on the materials used for mounting, it is recommended to wait for some

time until all masonry is dry before lighting a fire.

Attention: never light a fire with the inner plates or refractory stones removed.

3.5. Packaging materials

Packaging materials should be disposed of in a responsible way and in accordance

with governmental regulations.

Page 9

2900 9 03.27896.100

Example of fireplace installation within combustible material

Chimney

Refractory cement or special

conncetor

Insulation

(min 10 cm)

Fireproof wall

(min 10 cm )

Combustible

wall

Convection air

Fresh air inlet

Fireproof floor Combustible

floor

Convection air

inlet

Insulation (if

necessary))

Convection air

outlet

Opening

against eventu-

al pressure

builup

Stainless steel

pipe

IInsulati-

Combustible

ceiling

Fireproof ceiling

Cover plate

Min 1.5 cm

Page 10

2900 10 03.27896.100

4. Instructions for use

4.1. Fuel

The only suitable fuel for this stove is wood. No other fuels are allowed to be burnt,

as they can inflict serious damage to your stove.

Do not burn any treated wood either, such as scrap wood, dyed wood, impregnated

or preserved wood, plywood or chipboard. The fumes of these, as of synthetic materials, old papers and household waste, are highly polluting for both your stove and

your chimney, and for the environment. They also could cause chimney fires.

Wood

Hard woods, such as oak, birch- and fruit-trees, are the ideal fuels for your stove.

The wood must have dried for at least two years in a covered and well-ventilated

place. Split logs will dry faster. Dry wood should contain no more than twenty percent moisture.

Wet logs are unsuitable for burning, as they do not produce enough heat and all of

the energy is lost in the proc ess of evaporation. Moreover, the burning of wet wood

causes badly smelling gases to be released and a thick layer of tar will deposit on

the stove panels and in the chimney.

4.2. Burning wood

In order to create sufficient draught and to prevent smoke from emanating into your

living room, the chimney should be warm enough before lighting a fire. A cold chimney can be heated up by lighting a ball of paper above the fire plate.

To kindle the fire in the stove you can use paper and/or firelighters and small pieces

of wood.

Slightly open the door and pull the air slides wide open. See the illustration opposite

on how to use the air slides.

It is important that the kindled fire should burn intensely. You can then throw larger

pieces of wood onto the fire, and close the doors. When the fire has eventually stabilized and is glowing enough, you can put the logs.

Add extra fuel when necessary. Never add too much fuel. It is best to fill the stove

for one third and to top it up on a regular basis.

Always open the filling door slowly. Before filling up, the charcoal bed should be

carefully spread open. Check whether the coals are glowing enough just behind the

log retainer, so that the added fuel will immediately catch fire. If necessary you can

open the lower air slide for a while.

Open stacking will make the logs burn very intensely, as the oxygen can easily reach

every part of the fire. This method of stacking is applied when burning wood for a

short while. Compact stacking will make the fire burn slower, as the air can only

reach the outer parts of the fire. This stacking method is best used when burning for

a longer while.

Page 11

2900 11 03.27896.100

Low intensity fires cause tar and

creosote to deposit in the chimney after a long period of time.

Tar and creosote are highly combustible substances. Thicker

layers of these su bstances might

catch fire when the temperature

in the chimney increases suddenly and steeply. Therefore it is

necessary for the fire to regularly burn very intensely, so that

thin layers of tar and creosote

immediately disa ppear.

Low intensity fires also cause tar to deposit on the stove panels and doors.

When it is not too cold outside it is better to let the stove burn intensely for just a

few hours a day.

The fireplace can burn with either open or closed doors. When the doors are left

open, it is recommended to use a spark screen.

4.3. Ash removal

The ashtray must be emptied before the ashes reach the lower edge of the combustion grid. With the cold handle supplied, you can tilt the grid upwards and remove

the ashtray from the device. (See picture 6-8.)

Relatively speaking, burning wood produces little ash and it will not be necessary to

remove it each time daily. Moreover, wood burns better on a bed of ash.

4.4.. Extinguishing the fire

Stop fuelling the fire and let it burn out.

Damping a fire by closing the air slides involves the release of noxious gases. You

should let the fire burn out and keep an eye on it as long as it is still glowing.

4.5. Weather conditions

Attention!

Mist and heavy fog will block the chimney's smoke outlet and may lead to smoke

emissions into the living room.

It is best not to use the fireplace under these weather conditions.

open stacking compact stacking

Page 12

2900 12 03.27896.100

5. Maintenance

It takes only little effort to keep your appliance in good condition.

Regularly check whether the sealing cord still closes the doors tightly enough.

Minor paint damage can be touched up with a can of spray paint. Your dealer can

supply yo u with the correct spray product.

During the first use after repainting your unit might give off some slight odour.

However, this will disappear quickly.

The glass can be cleaned with a number of glass cleaning products available on the

market. Your installer can also supply you with appropriate products. However,

never use abrasive or corrosive cleaning products.

At the end of the heating season, seal off the chimney with a ball of paper. You can

then thoroughly clean the stove on the inside.

If necessary, replace the sealing ropes and use fire cement to fill up possible leaks.

Remove the fireplate for better and more thorough cleaning.

To remove the doors, disassemble the hinges as shown.

You should have your chimney swept by an expert before the heating season begins.

It is useful to check the chimney for soot during the heating season as well. Checking and maintaining the chimney is a statutory requirement.

Desambly of the guidance-system

See pictures 12-16.

When all of the above advice is heeded, you will be able to fully enjoy your stove.

Installation of damper in 2900GL

Insert the damper between the smoke chamber and the connecting flange (see Illustration 1 for how to insert the damper through the smoke chamber). Insert the

damper first at the top between the smoke bell and the connection flange (A), by

holding the damper at the bottom to the right (Illustration 17), and then insert the

damper at the bottom in the seating (B).

Insert the rod through the air spoiler and connect it to the damper (Illustration 20)

The damper ca n still be adjusted with the screw at the end of the rod; when you turn

the screw inwards, the damper does not close completely when the door is closed

(Illustration 22).

Page 13

2900 13 03.27896.100

Installation of damper in 2900(R)GD(C)

Insert the damper between the smoke chamber and the connecting flange (see Illustration 1 for how to insert the damper through the smoke chamber). Insert the

damper first at the top between the smoke bell and the connection flange (A), by

holding the damper at the bottom to the right (Illustration 2), and then insert the

damper at the bottom in the seating (B).

Connect the rod to the damper (Illustration 17).

Then install the flame shield with the rod going through the hole of the flame shield

(Illustration 20).

The connecting piece (C on Illustration 24) is inserted over the rod and everything is

hooked over the bolt on the tumbler (E in Illustration 24).

The adjustment of the damper is carried out with the nut (D on Illustration 24) on the

rod; if you turn the nut down towards the connecting piece then the damper closes

more completely. (The adjustments are best made before the flame shield is installed).

Page 14

2900 14 03.27896.100

Bijlage 1: technische gegevens / Annexe 1: données techniques /

Annex1: technical data sheet / Anlage 1: technischen Daten

Model / Modèle / Modell 2900(R)GD(C) 2900GL

Nominaal vermogen

Puissance nominale

Nominal heat output

Nominalleistung

11 kW

11 kW

Aanbevolen brandstoffen

Combustibles conseillés

Advised combustibles

Empfohlene Brennstoffe

Hout

Bois

Wood

Holz

Bruinkool

lignite

Browncoal

Braunkohl

Hout

Bois

Wood

Holz

Hout

Bois

Wood

Holz

Bruinkool

lignite

Browncoal

Braunkohl

Hout

Bois

Wood

Holz

Deuren

Portes

Doors

Feuerraum

Gesloten

Fermé

Closed

Geschlossen

Gesloten

Fermé

Closed

Geschlossen

Open

Ouvert

Open

Geöffnet

Gesloten

Fermé

Closed

Geschlossen

Gesloten

Fermé

Closed

Geschlossen

Open

Ouvert

Open

Geöffnet

Schoorsteenaansluiting

Raccordement cheminée

Flue connection

Schornsteinanschluss

200 mm

200 mm

Massadebiet van rookgassen

Débit des fumées

Flue gas mass flow

Abgasmassenstrom)

14.5 g/s

15.4 g/s

46.2 g/s

9.5 g/s

9.2 g/s

37.2 g/s

Rookgastemperatuur

Température des fumées

Flue gas temperature

Abgasstutzentemperatuur

410 °C

405 °C

220 °C

313 °C

314 °C

167 °C

Minimum trek

Dépression minimal

Minimum draught

Mindesförderdruck

0.12 mbar

0.12 mbar

0.08 mbar

0.13 mbar

0.13 mbar

0.08 mbar

Gewicht / Poids / Weight

130 kg

75kg

Page 15

2900 15 03.27896.100

1 2

3 4

5 6

Page 16

2900 16 03.27896.100

7 8

9 10

11 12

Page 17

2900 17 03.27896.100

13

13

14 15

17 18

Û

A

Ý

B

14

15 16

Page 18

2900 18 03.27896.100

D —

/

C

\

E

Ù A

Ù B

19 20

21 22

23 24

Page 19

2900 19 03.27896.100

Annex 2 : dimensions

Anlage 2 : Abmessungen

Bijlage 2 : afmetingen

Annexe 2 : dimensions

2900GL

Page 20

2900 20 03.27896.100

2900GD

2900GDC

Page 21

2900 21 03.27896.100

2900RGDC

2900RGDC

Page 22

2900 22 03.27896.100

DOVRE N.V. Tel : +32 (0) 14 65 91 91

Nijverheidsstraat 18 Fax : +32 (0) 14 65 90 09

B-2381 Weelde E-mail : info@dovre.be

___________________________________________________________

03.27896.100 0545

In het kader van een continue productverbetering, kunnen specificaties van het geleverde toestel afwijken

van de beschrijving in deze brochure, zonder voorafgaande kennisgeving.

Dans le cadre d’une amélioration constante des produits, les spécifications du produit livré peuvent différer

du contenu de ce document, sans avis préalable.

Due to continuous product improvement, specifications of the delivered product may differ from the content of this booklet, without further notice.

Im Rahmen kontinuerlicher Produktverbesserung, können Specifikationen des geliefertes Produktes von

den Beschreibungen in dieser Broschure abweichen.

CE-conformiteitsverklaring

Declaration de conformité CE

EC Declaration of conformity

Konformitätserklärung CE

Notified body: 1641

Wij,

Nous,

We,

Wir,

Dovre nv Nijverheidsstraat 18 B2381 Weelde

verklaren bij deze dat de inbouwhaard 2900-serie conform is volgens de EN

13229.

déclarons que le foyer 2900-serie est conforme au norme EN 13229.

declare that the fireplace 2900-serie is in conformity with the EN 13229.

Erklären daß das Produkt 2900-serie entspricht EN 13229.

Weelde, 17.11.2005

Loading...

Loading...