November 15, 2019

Lit. No. 74033, Rev. 01

29049, 29051, 29053, 29400-7

HARNESS KIT

3-PORT ISOLATION MODULE

LIGHT SYSTEM

w/2-PLUG SYSTEM HARNESSES

Parts List and Installation Instructions

CAUTION

Read this document before installing the

snowplow.

CAUTION

See your sales outlet/website for specifi c

vehicle application recommendations before

installation. The online selection system has

specifi c vehicle and snowplow requirements.

A DIVISION OF DOUGL AS DYNAMICS, LLC

29049, 29051, 29053, 29400-7

PARTS LIST

Plug-In Harness Kit and Plug-In Harness Extension

Qty

Part Description

28986 Plug-In Harness, H13 1

28464 Plug-In Harness, 2B or 2D or HB-2 1

29058 Plug-In Harness, 5-Pin Connector 1

29499 -1 Plug-In Harness, HB-3 & H11 1

26357 Vehicle Lighting Harness – 11-Pin 1 1

40284 Isolated Stud Block 1

21563 Battery Cable – 90" 1

29861-4

29071 8" Cable Assembly 1

95837 Fuse Holder 1

90729 200A Fuse 1

Vehicle Lighting Harness – 11-Pin w/Relay

Assembly

– Reclosable Fasteners 4 4 4 4

– Splices 1111

– Heatshrink Tubing 1111

29049

29051

29053

11

LED Plow Light Kit

Part Description Qty

72565 Headlamp Control Module (HCM) 1

72554 Harness Assembly – HCM to Isolation Module 1

72546 Vehicle Harness Assembly – HCM to Grille 1

72548 Harness Assembly – Plow Lighting 1

72550 Cable Assembly – HCM 1

72552 Wire Assembly – EdgeView™ Lights 1

– Reclosable Fasteners 4

29400-7

90730

Lit. No. 74033, Rev. 01 2 November 15, 2019

29049, 29051, 29053, 29400-7

SAFETY DEFINITIONS

WARNING

Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

NOTE: Indicates a situation or action that can lead

to damage to your snowplow and vehicle or other

property. Other useful information can also be

described.

FUSES

The snowplow electrical and hydraulic systems

contain several automotive-style fuses. If a problem

should occur and fuse replacement is necessary,

the replacement fuse must be of the same type and

amperage rating as the original. Installing a fuse with

a higher rating can damage the system and could start

a fi re. Fuse Replacement, including fuse ratings and

locations, is located in the Maintenance section of the

Owner's Manual.

BATTERY SAFETY

CAUTION

Batteries normally produce explosive gases,

which can cause personal injury. Therefore,

do not allow fl ames, sparks, or lit tobacco

to come near the battery. When charging or

working near a battery, always cover your

face and protect your eyes, and also provide

ventilation.

• Batteries contain sulfuric acid, which burns

skin, eyes, and clothing.

• Disconnect the battery before removing or

replacing any electrical components.

TORQUE CHART

CAUTION

Read instructions before assembling.

Fasteners should be fi nger tight until

instructed to tighten according to the torque

chart. Use standard methods and practices

when attaching snowplow, including proper

personal protective safety equipment.

Recommended Fastener Torque Chart

Inch Fasteners Grade 5 and Grade 8

Size Size

1/4-20 148 209

1/4-28 164 232

5/16-18 203 287

5/16-24 230 325

3/8-16 365 510

3/8-24

7/16 -14

7/16 -20

1/2-13

1/2-20

Tor qu e ( N·m)

Grade

5

11. 4

13.1

23.6

26.0

41.8

47.5

67.0

74. 8

102.1

115 .2

Grade

16.2

18.5

33.3

36.9

59.1

67.0

94.6

105.6

144.3

162.7

8

9/16-12

9/16-18

5/8-11

5/8-18

3/4-10

3/4-16

7/8 -9

7/8 -14 643 907

1-12 954 1349

Metric Fasteners Class 8.8 and 10.9

Size Size

M6 x 1.00

M8 x 1.25

M10 x 1.50

M12 x 1.75

M14 x 2.00

M16 x 2.00

M18 x 2.50 431301

Tor qu e ( N·m)

Class

8.8

10.4

26.4

52.2

91

145

226

These torque values apply to fasteners

except those noted in the instructions.

36.5

72.2

126

200

313

Class

10.9

M20 x 2.5015.0

M22 x 2.50

M24 x 3.00

M27 x 3.00

M30 x 3.50

M33 x 3.50

M36 x 4.00

Tor qu e ( N·m)

Grade

5

403 569

582 822

873 12321-8

Tor qu e ( N·m)

Class

8.8

441

580

762

1079

1515

1990

2647

Grade

8

Class

10.9

610

831

1055

154 4

2095

2849

3662

Lit. No. 74033, Rev. 01 3 November 15, 2019

29049, 29051, 29053, 29400-7

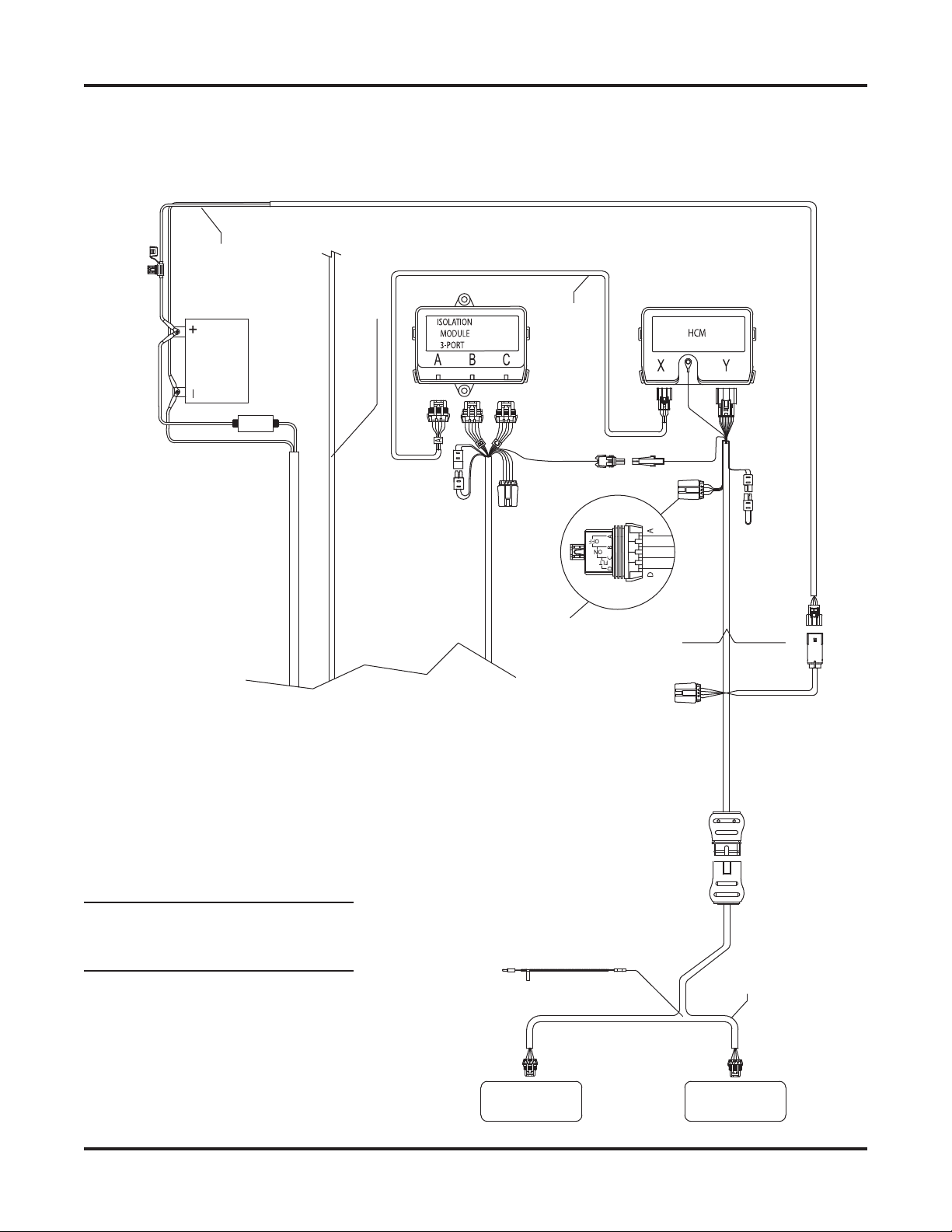

TYPICAL 2-PLUG, 3-PORT MODULE SYSTEM DIAGRAM

NOTE: On 2-plug electrical systems, plug covers

shall be used whenever snowplow is disconnected.

To Switched

Accessory

To Snowplow Control

RED

200A Fuse

and Holder**

Fire Wall

8" Cable**

RED

Battery*

* See the Battery Connections section

for more information.

** Included in 200A Fuse Kit (PN 90730).

BLK

Vehicle Control Harness

3-Port Module

10A Fuses

snowplow control)

(snowplow park/turn &

Turn Signal

Configuration Plug

BAT

(11-pin)

Vehicle Lighting

Harness

Typical Plug-In Harness

Factory Vehicle Harness

Vehicle Battery Cable

Factory Vehicle Harness

Park/Turn

Park/Turn

Lamps

Vehicle

Vehicle

Headlamps

Lit. No. 74033, Rev. 01 4 November 15, 2019

Headlamps

Lamps

29049, 29051, 29053, 29400-7

INSTALLATION INSTRUCTIONS

Isolation Module Mounting

CAUTION

Before installing self-drilling screws or

drilling mounting holes, check the selected

mounting area for any wires, hoses, or other

obstructions.

Isolation modules are sold separately. Check the

online selection system for the correct module for your

vehicle.

Locate a fl at surface within the engine compartment of

the vehicle for mounting the isolation module (on the

driver's side, if possible). The fi re wall, fender well,

or radiator shroud are possible mounting locations. If

a suitable fl at surface is not accessible, cable tie the

isolation module to existing brackets or harnessing.

Reclosable fastener strips and/or cable ties are

supplied for mounting the isolation module, but

self-drilling screws can also be used. When using

reclosable fastener strips, the mounting surface must

be free of dirt and grease.

Isolation Module

(bottom view)

Reclosable

Fastener

Strips

Screws (2)

Cable

Ties (4)

(if supplied)

Vehicle Battery Cable Installation

CAUTION

Batteries normally produce explosive gases,

which can cause personal injury. Therefore,

do not allow fl ames, sparks, or lit tobacco

to come near the battery. When charging or

working near a battery, always cover your

face and protect your eyes, and also provide

ventilation.

• Batteries contain sulfuric acid, which burns

skin, eyes, and clothing.

• Disconnect the battery before removing or

replacing any electrical components.

NOTE: Fuse holder and fuse are to be installed

between the POSITIVE (+) vehicle battery terminal

and the end of the supplied snowplow vehicle

battery cable assembly.

NOTE: When instructed, make all snowplow

battery cable connections to the auxiliary battery,

if vehicle is so equipped.

NOTE: Use dielectric grease on all electrical

connections to prevent corrosion. Fill receptacles

and lightly coat ring terminals before assembly.

NOTE: For vehicles equipped with a tilt cab

or tilt hood, a service loop will be necessary

when making harness or cable transitions from

the cab/hood to the frame. Check the cable

installation for interference by raising and

lowering the cab/hood a number of times. Add

anti-chafi ng material (installer-supplied) as

needed.

1. Turn OFF the vehicle ignition.

2. Disconnect both the NEGATIVE (–) and the

POSITIVE (+) battery cables from the vehicle

battery.

Lit. No. 74033, Rev. 01 5 November 15, 2019

29049, 29051, 29053, 29400-7

3. Route the supplied vehicle battery cable from

the grille or bumper to the battery, avoiding any

sharp edges and hot or moving parts. Cable tie

only the end section closest to the grille. The

vehicle battery cable may need to be lengthened

on vehicles with batteries located under or behind

the cab.

If lengthening cables is necessary, use the

supplied isolated stud junction block. Mount the

block to a fl at surface within reach of the vehicle

battery cable, and connect both the vehicle

battery cable and the supplied 90" battery cable to

the junction block.

Vehicle

Battery Cable

90" Battery Cable

Isolated Stud

Junction Block

4. Remove the fuse holder cover, loosen and remove

the fuse holder nuts and lock washers. Install a

200A fuse into the fuse holder.

5. Attach one end of the supplied 8" cable to the

fuse holder so that the ring terminal is on top of

the fuse. Replace the lock washer and nut on this

terminal and hand tighten the nut.

6. Attach the red lead from the vehicle battery cable

(or 90" battery cable) to the second fuse holder

terminal, placing the cable ring terminal on top of

the fuse lead. Replace the lock washer and nut on

this terminal and hand tighten the nut.

7. Torque the fuse holder nuts to 106–159 in-lb and

snap the fuse holder cover into place.

8. Route the 8" cable from the fuse holder to the

POSITIVE (+) battery terminal. Do not connect at

this time.

9. Route the black wire from the vehicle battery cable

to the NEGATIVE (–) battery connection point.

Do not connect at this time. On vehicles with the

batteries located under or behind the cab, connect

the black wire from the vehicle battery cable to

the frame using an existing hole or ground bolt.

Prior to attaching, clean away any paint or dirt to

ensure a good ground connection. The 4-position

connector from the vehicle battery cable will

connect to the mating connector (labeled "BAT")

on the end of the vehicle control harness.

* For installations requiring an adapter, follow the instructions included with the adapter.

Lit. No. 74033, Rev. 01 6 November 15, 2019

29049, 29051, 29053, 29400-7

Vehicle Lighting and Vehicle Control

Harness Installation

For Halogen plow light installation, proceed with

the following instructions.

For LED plow light installation, install the vehicle

control harness as instructed, but DO NOT install

the supplied vehicle lighting harness. Instead,

refer to the LED Installation Instructions on

page 10.

NOTE: For vehicles equipped with a tilt cab

or tilt hood, a service loop will be necessary

when making harness or cable transitions from

the cab/hood to the frame. Check the cable

installation for interference by raising and

lowering the cab/hood a number of times. Add

anti-chafi ng material (installer-supplied) as

needed.

1. Route both harnesses around or through the

radiator bulkhead to the isolation module.

2. Connect the vehicle lighting harness to

position "A" on the 3-port isolation module.

3. Route the end of the vehicle control harness with

the white 4-pin connector to the fi re wall.

4. Connect the black 4-position connector (labeled

"BAT") from the end of the vehicle control harness

to the 4-position connector from the vehicle

battery cable. Do not cable tie the harness at

this time.

CAUTION

Before installing self-drilling screws or

drilling mounting holes, check the selected

mounting area for any wires, hoses, or other

obstructions.

5. On the driver's side, locate an existing hole

through the fi re wall for the vehicle control

harness. If access through the fi re wall does not

exist, drill a 5/8" hole through the fi re wall of the

vehicle in a convenient location away from sharp

edges and hot or moving parts.

6. Push the braided harness breakout with the cab

control connector through the fi re wall hole into the

cab. Use a grommet, existing plug cover, or proper

chafi ng material to protect the harness where it

passes through the fi re wall. Route the harness to

the selected control mounting location.

To mount the control, follow the instructions

supplied with the control.

7. Locate an accessory wire controlled by the ignition

switch. Acceptable accessory wires show +12V

when the ignition switch is ON, and 0V when it

is OFF.

8. Route the red "ACC" wire from the vehicle control

harness to this location and trim away excess

length.

9. Following the instructions in the Recommended

Splicing Procedure section, splice the red

"ACC" wire into the switched accessory wire using

the supplied parallel splices and heatshrink tubing.

NOTE: Cable tie the control harness and

accessory tap away from the brake, clutch, gas,

or parking brake pedals, and any hot, sharp, or

moving parts.

Lit. No. 74033, Rev. 01 7 November 15, 2019

29049, 29051, 29053, 29400-7

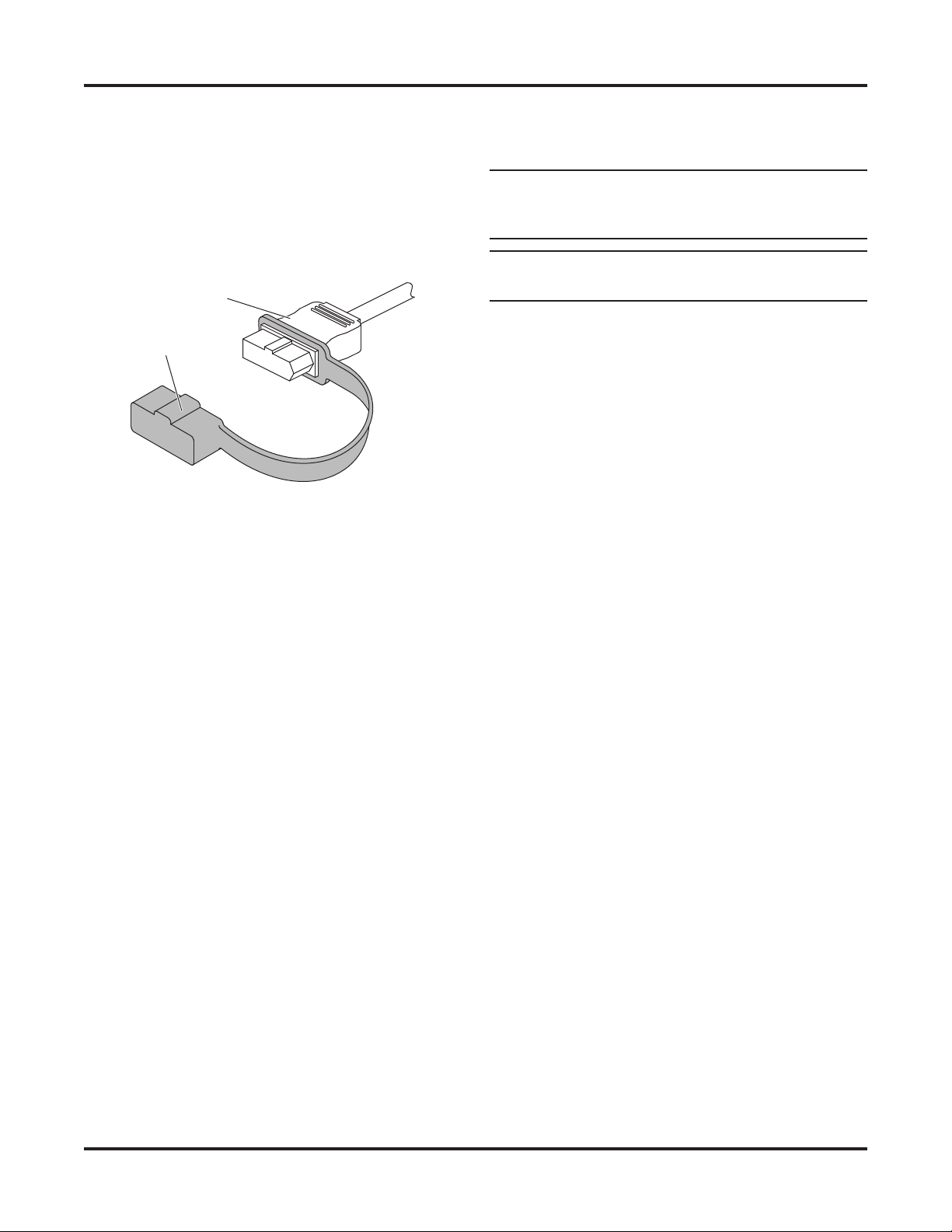

PLUG COVER INSTALLATION

Stretch the rectangular opening of the plug cover

strap over the end of the vehicle battery cable. Place

the plug cover over the molded plug whenever the

snowplow is not in use.

Molded Plug

Plug Cover

PLUG-IN HARNESS INSTALLATION:

VEHICLES USING THE 29053 HARNESS

KIT

1. Locate the passenger-side OEM vehicle headlamp

connector located near the tilt-hood hinge below

the headlamp housing.

2. Remove the small, light gray connector lock by

carefully sliding it back away from the connector.

Save the connector lock. Separate the connectors

by pushing down on the locking tab and pulling

them apart.

3. Connect the plug-in harness female connector

to the male OEM vehicle headlamp connector.

Reinstall the small, light gray connector lock.

4. Connect the plug-in harness male connector to

the female OEM vehicle headlamp connector.

5. Route the remaining half of the plug-in harness to

the driver-side OEM vehicle headlamp connector,

and repeat Steps 2–4.

6. Route the plug-in harness to the 3-port isolation

module by running the harness along the existing

cables underneath the engine and radiator area.

Connect the plug-in harness to the module by

matching harness connector B with module port B

and harness connector C with module port C.

7. Connect the black 4-position connector from

the middle of the vehicle control harness to the

4-position connector from the plug-in harness.

8. Cable tie the vehicle control harness, vehicle

lighting harness, and plug-in harness away from

any sharp, hot, or moving parts.

9. Skip ahead to the Turn Signal Confi guration Plug

section.

Lit. No. 74033, Rev. 01 8 November 15, 2019

29049, 29051, 29053, 29400-7

PLUG-IN HARNESS INSTALLATION:

ALL OTHER APPLICATIONS

NOTE: For vehicles equipped with a tilt cab or

tilt hood, a service loop will be necessary when

making harness or cable transitions from the

cab/hood to the frame. Check the cable installation

for interference by raising and lowering the

cab/hood a number of times. Add anti-chafi ng

material (installer-supplied) as needed.

1. For vehicles using the 29400-7 harness kit:

The plug-in harness contains four reversible

2-position connectors. One set of connectors

connects to the HB-3 bulbs and one set connects

with the H11 bulbs.

NOTE: To properly install reversible 2-position

connectors, it is necessary to know which pin of

the OEM headlamp connectors is common.* When

mating the OEM headlamp connectors with the

plug-in harness, be sure to orient the connectors

as shown below.

A (Common)

B

OEM Headlamp Connector**

A

B (Common)

OEM Headlamp Connector** Plug-In Harness Connector**

** Connector appearance will vary.

NOTE: DO NOT PROBE OR DAMAGE THE WIRE

INSULATION. When the common wire is located

the test lamp will illuminate.

Plug-In Harness Connector**

2. Remove the headlamp or headlamp housing

connectors. Connect the plug-in harness to the

mating connectors removed from the headlamps

or headlamp housings.* Connect the plug-in

harness to the mating connections at the

headlamps or headlamp housings. Route the

plug-in harness to the 3-port isolation module.

Connect the plug-in harness to the module by

matching harness connector B with module port B

and harness connector C with module port C.

For vehicles with dedicated Daytime Running

Light (DRL) bulbs: Connect the DRL wire from

the plug-in harness to the vehicle DRL bulb

POSITIVE (+) wire.

For vehicles with headlamp bulb or turn signal

DRLs: The DRL wire from the plug-in harness will

not be used. Coil and cable tie the DRL wire.

For vehicles requiring the 69826, 69826-1, or

69826-2 relay adapter kit, refer to the Installation

Instructions packed with the kit.

3. Connect the black 4-position connector from

the middle of the vehicle control harness to the

4-position connector from the plug-in harness.

4. If not already done during adapter installation,

locate the turn signal wire on each side of

the vehicle. Splice the "TURN" wire from the

plug-in harness into the signal wire on the

corresponding side following the instructions in the

Recommended Splicing Procedure section.

5. If not already done during adapter installation,

splice the "PARK" wire from the plug-in harness

into the parking light wire following the instructions

in the Recommended Splicing Procedure section.

6. Cable tie the vehicle control harness, vehicle

lighting harness, and plug-in harness away from

any sharp, hot, or moving parts.

7. For vehicles using the 29400-7 harness kit:

To complete the installation, secure the relay

assemblies to an existing assembly using cable

ties. Mount the relay connectors wire side down.

* See A & B markings on the OEM headlamp connector for pin identifi cation when testing for common.

Lit. No. 74033, Rev. 01 9 November 15, 2019

29049, 29051, 29053, 29400-7

TURN SIGNAL CONFIGURATION PLUG

WARNING

If the turn signal confi guration plug is mated

incorrectly, the turn signals will be reversed

between the vehicle and the snowplow.

1. Mate the turn signal confi guration plug located

on the plug-in harness. If the isolation module is

installed on the driver's side, mate the plug so that

the wire colors match (green to green and blue to

blue). If the module is installed on the passenger's

side, mate the plug so that the wire colors are

opposite (green to blue).

Turn Signal Configuration Plug

LED INSTALLATION INSTRUCTIONS

Headlamp Control Module (HCM)

Mounting

Locate a fl at surface within the engine compartment

of the vehicle near the isolation module. If a suitable

fl at surface is not accessible, cable tie the HCM to

existing brackets or harnessing.

Mount the HCM so that the harness connections are

wire side down.

NOTE: If possible, mount the HCM in an area that

is protected from road splash.

Reclosable fastener strips and/or cable ties are

supplied for mounting the HCM. When using

reclosable fastener strips, the mounting surface must

be free of dirt and grease.

Headlamp Control Module

(bottom view)

B – Green & Red Wires C – Blue & Red Wires

Driver-Side Module Passenger-Side Module

GRN GRN

BLU BLU

2. Connect the single-wire connector from the

vehicle lighting harness to the single-wire

connector from the plug-in harness.

BLU GRN

GRN BLU

Reclosable

Fastener

Strips

Cable

Ties (4)

Lit. No. 74033, Rev. 01 10 November 15, 2019

29049, 29051, 29053, 29400-7

HCM Vehicle Battery Cable Installation

CAUTION

Batteries normally produce explosive gases,

which can cause personal injury. Therefore,

do not allow fl ames, sparks, or lit tobacco

to come near the battery. When charging or

working near a battery, always cover your

face and protect your eyes, and also provide

ventilation.

• Batteries contain sulfuric acid, which burns

skin, eyes, and clothing.

• Disconnect the battery before removing or

replacing any electrical components.

NOTE: When instructed, make all snowplow

battery cable connections to the auxiliary battery,

if vehicle is so equipped.

NOTE: Use dielectric grease on all electrical

connections to prevent corrosion. Fill receptacles

and lightly coat ring terminals before assembly.

1. Turn OFF the vehicle ignition.

HCM Vehicle Lighting Harness Installation

1. Route harnesses around or through the radiator

bulkhead to the HCM.

2. Make the following connections:

• 2-position connector from the vehicle lighting

harness to the matching 2-position connector from

the vehicle cable assembly

• Vehicle lighting harness to position "Y" on the

HCM

• Single-pin connector from the plug-in harness

assembly to the single-pin connector on the

vehicle lighting harness.

3. Route the red wire from the vehicle lighting

harness to the stud on the HCM.

4. Remove the protective plastic domed nut and the

top brass nut from the HCM stud. Install the red

wire ring terminal on stud and remaining brass

nut. Reinstall the top brass nut and tighten to

25.9 in-lb. Reinstall the protective plastic domed

nut. (See illustration below.)

2. Disconnect both the NEGATIVE (–) and the

POSITIVE (+) battery cables from the vehicle

battery.

3. Route the supplied HCM vehicle battery cable

from the battery to the 2-position mating connector

on the HCM vehicle lighting harness, avoiding any

sharp edges and hot or moving parts.

Brass Nuts

Domed Nut

Headlamp Control Module (HCM)

Red Wire Ring Terminal

(from vehicle lighting harness)

Lit. No. 74033, Rev. 01 11 November 15, 2019

29049, 29051, 29053, 29400-7

TYPICAL LED PLOW LIGHT, HEADLAMP CONTROL MODULE (HCM),

AND HARNESS DIAGRAM

To Snowplow Control

25A Fuse

Vehicle

Cable

Assembly

Battery

200A Fuse

and Holder*

Vehicle Control Harness

Vehicle Battery Cable

* Included in 200A Fuse Kit (PN 90730).

Accessory

To Switched

HCM to

Isolation Module

Harness Assembly

Plug

Turn Signal

Configuration

10A Fuses

EdgeView

Enable Jumper

Install with

wires down.

RED

EdgeView

Wire

15A Fuses

Ford SD Quad Light

Relay Enable Plug & Cover

RAM Enable

Wire (7-wire

system only)

ORN YEL

Vehicle

Lighting

Harness

NOTE: On 2-plug electrical systems,

plug covers shall be used whenever

EdgeView™

snowplow is disconnected.

Lit. No. 74033, Rev. 01 12 November 15, 2019

Wire Assembly

Plow

YEL

Plow Lights

Lighting Harness

29049, 29051, 29053, 29400-7

PLUG COVER INSTALLATION

Stretch the rectangular opening of the plug cover strap

over the end of the HCM vehicle lighting harness.

Place the plug cover over the molded plug whenever

the snowplow is not in use.

Molded Plug

Plug Cover

HCM TO ISOLATION MODULE HARNESS

INSTALLATION

1. Make the following connections:

• 10-pin connector to port A of the isolation module

• 8-position connector to port X of the HCM.

BATTERY CONNECTIONS

NOTE: Use cable ties to secure cable assemblies

and control and lighting harnesses away from any

sharp edges and hot or moving parts.

NOTE: Follow OEM battery cable connection

recommendations when attaching to the battery.

1. Make the following attachments to the

POSITIVE (+) battery terminal:

• POSITIVE (+) OEM cable assembly

• Red 8" cable from fuse holder

• Red cable from headlamp control module power

cable.

2. Make the following attachments to the

NEGATIVE (–) battery terminal:

• NEGATIVE (–) OEM cable assembly

• Black vehicle battery cable

• Black cable from headlamp control module power

cable.

2. Cable tie harnesses as needed, away from any

sharp, hot, or moving parts.

Lit. No. 74033, Rev. 01 13 November 15, 2019

29049, 29051, 29053, 29400-7

BATTERY CABLE CONNECTIONS

Top Post Batteries w/Lead Cable Ends

1. Attach the POSITIVE (+) OEM cable to the battery

post. Attach the red battery cable to the bolt in the

OEM terminal with original fastener.

2. Attach the NEGATIVE (–) OEM cable to the battery

post. Attach the black wire from the vehicle battery

cable to the OEM terminal bolt with original fastener.

Top Post Batteries w/Stamped Steel

Battery Terminals

Top Post Batteries, Style One

These terminals are secured with a 6 mm washer-head

cap screw and nut. If the cap screw is already long

enough for the added thickness of the cable terminal,

washer, and nut, it will not need to be replaced, and

Step 1 may be skipped.

1. Carefully lift retainer tabs (if present) and remove the

short cap screw. Insert the supplied longer cap screw

through a 3/16" washer and into the hole in the clamp.

Carefully bend the retainer tabs back into place.

Red Battery Cable

Top Post Batteries, Style Two

These terminals are secured with a 6 mm tapered nut

and cam.

1. Make the connections to the POSITIVE (+)

terminal as follows:

a. Remove the cable assembly from the battery

post by loosening the nut. Trim the plastic

terminal cover as shown.

Trim ma rked are as.

Nut

Cam

Tab

Washer

(See Step 3.)

Battery

Clamp

2. Attach the POSITIVE (+) OEM battery clamp to

the battery post, and secure the clamp.

3. Place the red battery cable over the end of the

battery terminal screw. If the added terminal has

large contact area with the battery clamp, retain

with washer and nut. If the terminal contact area

is small (terminal hole almost passes over a 6 mm

nut), add a washer on both sides of the cable and

secure with a nut.

4. Connect the black wire from the vehicle battery

cable and the OEM NEGATIVE (–) cable to the

NEGATIVE (–) battery terminal following the same

procedure used in Steps 1–3.

Vehicle Cable

Cap Screws

(See Step 1.)

b. Carefully bend the tab securing the cam

upward so that the cam can be lifted off the

stamped terminal after the nut has been

removed.

c. Place the red battery cable over the battery

terminal screw.

d. Slide the cam over the terminal screw and tab.

Reinstall the nut.

e. Place the cable assembly on the battery post,

align the red battery cable with the opening

in the cover, and tighten the nut. Close the

plastic terminal cover.

Lit. No. 74033, Rev. 01 14 November 15, 2019

29049, 29051, 29053, 29400-7

2. Make the connections to the NEGATIVE (–)

terminal as follows:

a. Remove the cable assembly from the battery

post by loosening the nut.

b. Carefully bend the tab securing the cam

upward so that the cam can be lifted off the

stamped terminal after the nut has been

removed.

c. Place the black wire from the vehicle battery

cable over the battery terminal screw.

d. Slide the cam over the terminal screw and tab.

Reinstall the nut.

e. Place the cable assembly on the battery post,

and tighten the nut.

Top Post Batteries, Style Three

These terminals are similar to Style Two, but do not

have a visible cam or tab.

2. Make the connections to the NEGATIVE (–)

terminal as follows:

a. Remove the cable assembly from the battery

post by removing the nut.

b. Place the black wire from the vehicle battery

cable over the battery terminal screw and

reinstall the nut.

c. Place the cable assembly on the battery post,

and tighten the nut.

Side Terminal Batteries

1. Use the furnished battery cable adapter to attach

the red battery cable to the POSITIVE (+) terminal

of the battery. Position the cable, and tighten the

adapter to 124–178 in-lb.

2. Connect the OEM POSITIVE (+) cable to the

adapter on the battery. Position the cable and,

while holding the adapter, tighten the battery cable

bolt to 124–178 in-lb.

1. Make the connections to the POSITIVE (+)

terminal as follows:

a. Remove the cable assembly from the battery

post by removing the nut. Trim the plastic

terminal cover as necessary to accommodate

the red snowplow battery cable.

b. Place the red battery cable over the battery

terminal screw and reinstall the nut.

c. Place the cable assembly on the battery post,

align the red battery cable with the opening

in the cover, and tighten the nut. Close the

plastic terminal cover.

3. Connect the black wire from the vehicle battery

cable and the OEM NEGATIVE (–) cable to the

NEGATIVE (–) battery terminal following the same

procedure used in Steps 1 and 2.

Lit. No. 74033, Rev. 01 15 November 15, 2019

29049, 29051, 29053, 29400-7

CHANGING BLADE-EDGE

ILLUMINATION MODE

On snowplows equipped with LED headlamps, the

EdgeView™ technology feature off ers three modes for

blade-edge illumination. The factory default setting is

ON.

To change the blade-edge illumination mode, remove

the cover from the fuse holder located near the

"Y" port of the headlamp control module installed in

the vehicle engine compartment.

HEADLAMP

CONTROL MODULE

Fuse Holder

and Cover

Headlamp

Control Module

Remove the jumper fuse from the fuse holder and

re-insert it in the desired mode position as shown

below. Replace the fuse holder cover.

Jumper

Fuse

Default – ON:

Blade edge lights

illuminate when

plow has power.

FLT: Blade edge

lights illuminate

when blade is in

FLOAT mode.

PLOW-SIDE EdgeView LIGHTING

CONNECTIONS

The EdgeView Float (FLT) mode activation function

will require a second plow-side electrical connection.

1. On the plow-side LED lighting harness, locate the

yellow wire cable tied to the body of the harness

near the "Y" section.

2. Strip the end of the yellow wire and insert

stripped wire end into the pre-installed insulated

butt connector on the supplied EdgeView wire

assembly.

3. Crimp the connection and heat seal the insulated

splice.

4. Remove the snowplow hydraulic unit cover. Route

the EdgeView wire assembly along the snowplow

structure to the snowplow hydraulic unit, and cable

tie wires as needed.

5. Locate the solenoid on the snowplow hydraulic

unit that is activated during the snowplow

Lower/Float function. Refer to the Mechanic's

Guide or snowplow manufacturer's website for

further information.

6. Plug the bullet terminal on the end of the supplied

EdgeView wire assembly into the receptacle on

the corresponding solenoid wire. If a receptacle is

not found on the correct solenoid wire, remove the

bullet terminal from the EdgeView wire assembly

and splice the end of the EdgeView wire into the

correct solenoid wire.

7. Cable tie extra wire length to the snowplow

assembly and reinstall the hydraulic unit covers.

NOTE: EdgeView light will turn ON or OFF

approximately 5 seconds after EdgeView Mode is

activated or canceled.

OFF: Blade edge

lights disabled.

Lit. No. 74033, Rev. 01 16 November 15, 2019

29049, 29051, 29053, 29400-7

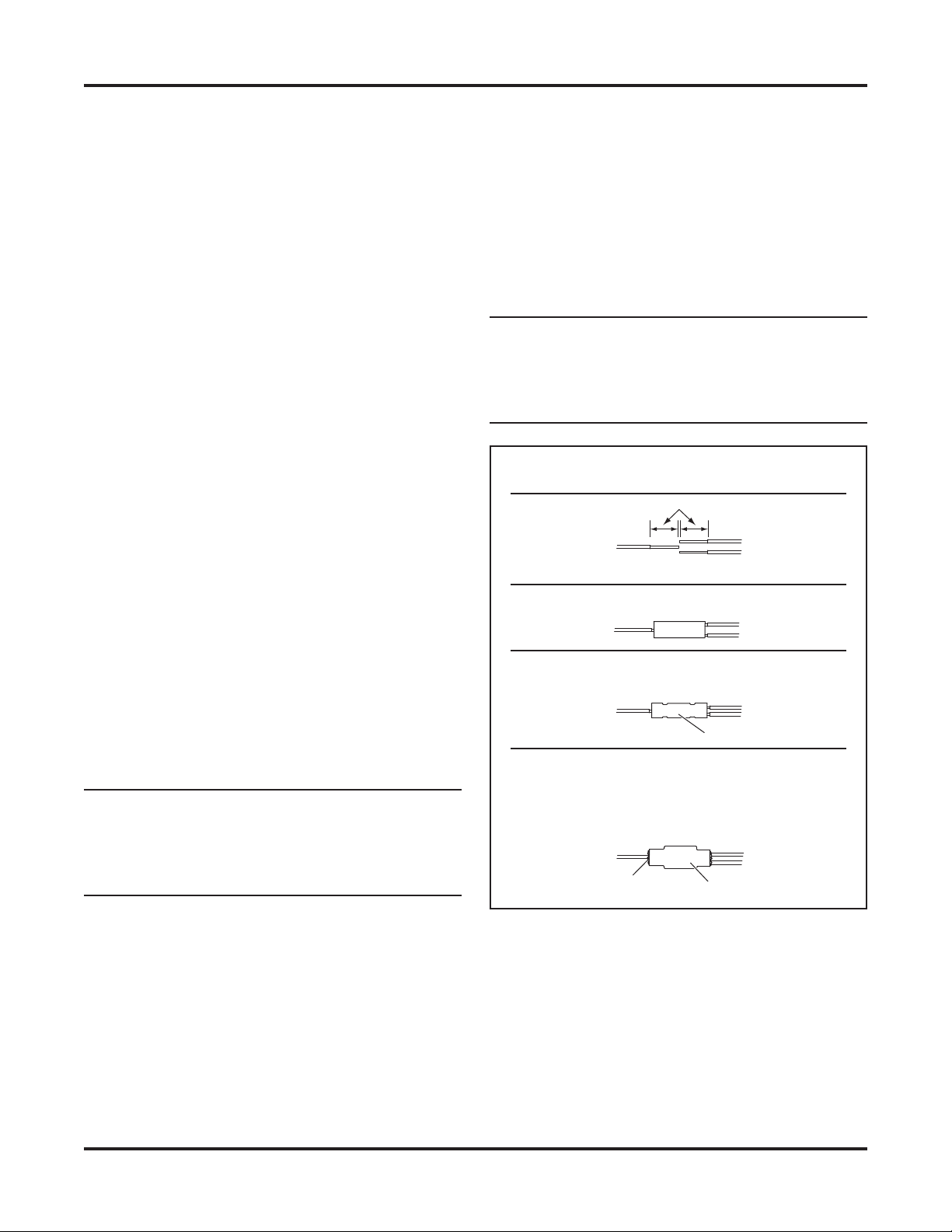

RECOMMENDED SPLICING

PROCEDURE

1. Locate the wire to be spliced into.

2. Cut the wire at least 1-1/2" from any other splice,

connector, or terminal. If wires are covered by

tubing or braid, remove enough of it to achieve the

minimum clearance required.

3. Strip away 5/16" of the insulation from the ends of

the wires to be spliced.

4. Slide two wires into one end of the supplied

parallel splice.

5. Place a piece of heatshrink tubing

(3/16" x 1-1/4" long) over the remaining wire to be

spliced. Cut tubing into 1-1/4" lengths if required.

6. Insert the wire into the open end of the splice and

crimp using an appropriate crimp tool. One or

two crimps may be necessary to ensure a good

connection. No wire strands should be visible

outside of the splice.

9. Check circuits for continuity.

10. Cover the splice with heatshrink tubing. The tubing

should extend beyond the splice on both sides.

11. Using a hot air source, starting in the center and

working to either side, apply heat until the tubing

recovers and glue can be seen around the edges.

Allow the tubing to cool before handling.

NOTE: The splices supplied will accommodate

18-gauge wires as shown. For larger-gauge wires,

cut the wire, strip the ends 3/8" to 1/2", and twist

together. Apply solder to the splice and cover with

heatshrink tubing.

Splicing Procedure

5/16"

From OEM

From park, turn,

or DRL lamp

Insert wires into splice.

vehicle harness

From plug-in

harness

7. Preheat a soldering tool for at least one minute to

help promote even solder fl ow.

8. Apply heat to the splice. Avoid heating too close to

the insulation. Apply solder to the wires, using just

enough solder to produce an even fl ow through

the splice. Use rosin core solder ONLY. Do not

use acid core solder.

NOTE: Avoid using an excessive amount of solder

as it can result in wicking. Wicking occurs when

solder travels up the wire core. This may cause

the wire to become stiff or brittle, which could

lead to a broken or open circuit.

Crimp and solder each splice.

Butt Splice

Cover the splice with heatshrink tubing.

Using a hot air source, apply heat until tubing

recovers and glue can be seen around the

edges. Allow tubing to cool before handling.

Glue

Heatshrink Tubing

Lit. No. 74033, Rev. 01 17 November 15, 2019

29049, 29051, 29053, 29400-7

Copyright © 2019 Douglas Dynamics, LLC. All rights reserved. This material may not be reproduced or copied, in whole or in part, in any

printed, mechanical, electronic, fi lm, or other distribution and storage media, without the written consent of the company. Authorization to

photocopy items for internal or personal use by the company's outlets or snowplow owner is granted.

The company reserves the right under its product improvement policy to change construction or design details and furnish equipment when

so altered without reference to illustrations or specifi cations used. This equipment manufacturer or the vehicle manufacturer may require or

recommend optional equipment for snow removal. Do not exceed vehicle ratings with a snowplow. The company off ers a limited warranty for

all snowplows and accessories. See separately printed page for this impor tant information. The following is an unregistered (™) trademark

of Douglas Dynamics, LLC: EdgeView™.

Printed in U.S.A.

Lit. No. 74033, Rev. 01 18 November 15, 2019

Loading...

Loading...