Doughpro DPO 3.5 Installation Manual

7

(951) 657-0379

(951) 657-4594

(951) 657-0379

For 24 hour assistance please call (951) 236-7092

six

This happens with wood burning ovens.

(951) 657-0379

(951) 657-0379

(951) 657-0379

(951) 657-4594

16

17

19

19

19

20

23

23

23

23

24

25

26

27

28

29

30

31

32

37

18

21

22

32

33/a

34

35

37

,coal or gas or

to be covered in a further

jack

2200 lbs

10 feet

jack

JACK

or shipped in one piece

jack

jack

jack

jack

forklift

jack

jack

jack

jack

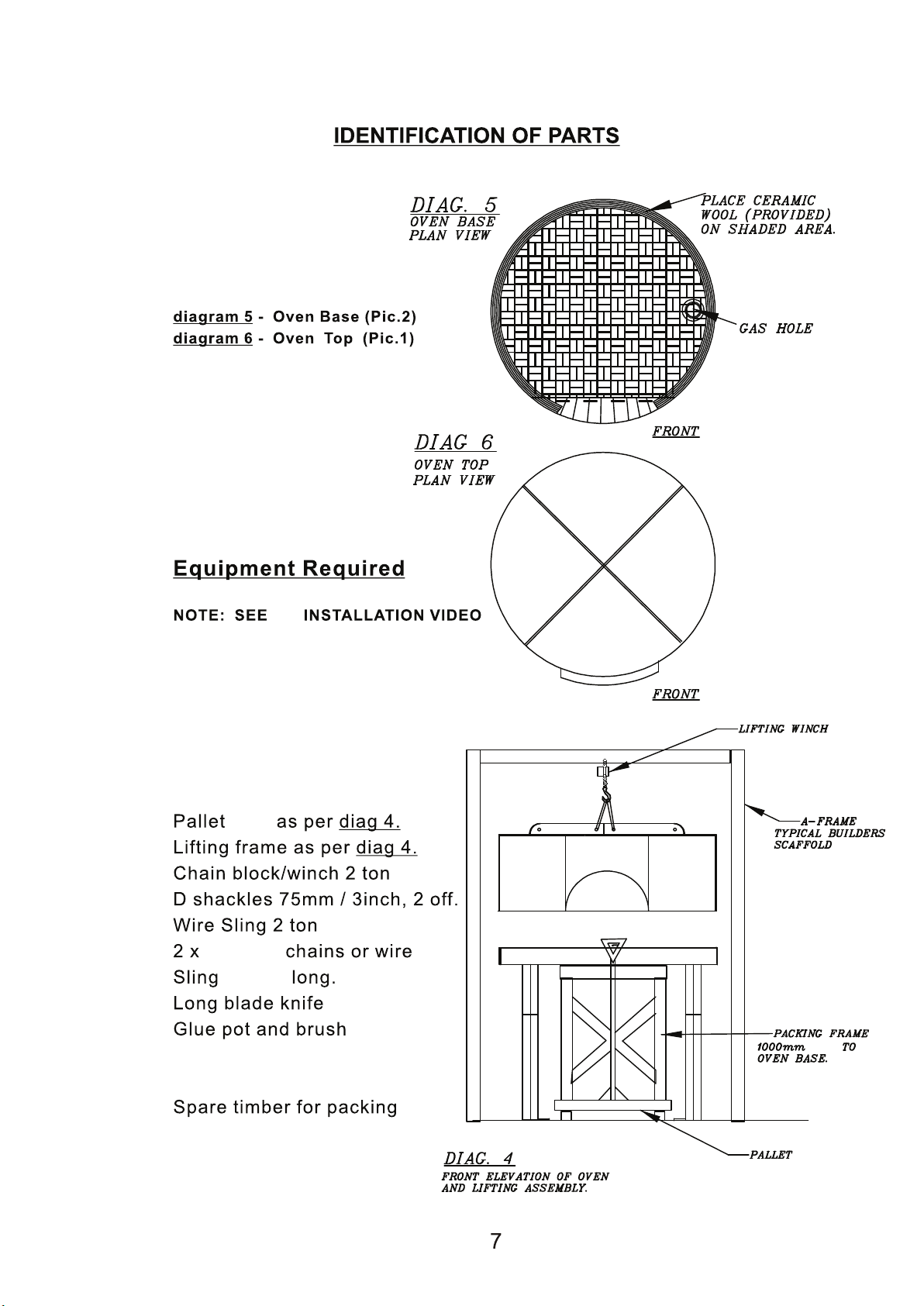

Place strips of ceramic wool (supplied) as per diagram 5

beneath the top of the oven wherever the top touches the base. Position wool

strips so that they remain hidden when t

seam insidethe oven is to be filled later with "moral-cast 35" (supplied).

The oven is then covered externally in ceramic wool (2" (50mm) superwool),

using the wool and glue provided.

.

Installation of the exhaust hood in should be in accordance with the Standard

for Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA

96, or other regulatory body. We recommend "Captive Air...."

National Accounts

Captive-Aire Systems Inc.

4641 Paragon Park

Raleigh NC 27616

919/882-5204 fax#

he two halves of the oven are together. The

800/334-9256

10

Doughpro

RND-REC-RGOManual

Transportation

ke the Oven to the site.

Ta

Lift the Upper section from truck using a

ve the Upper section to kitchen. (Remove

Mo

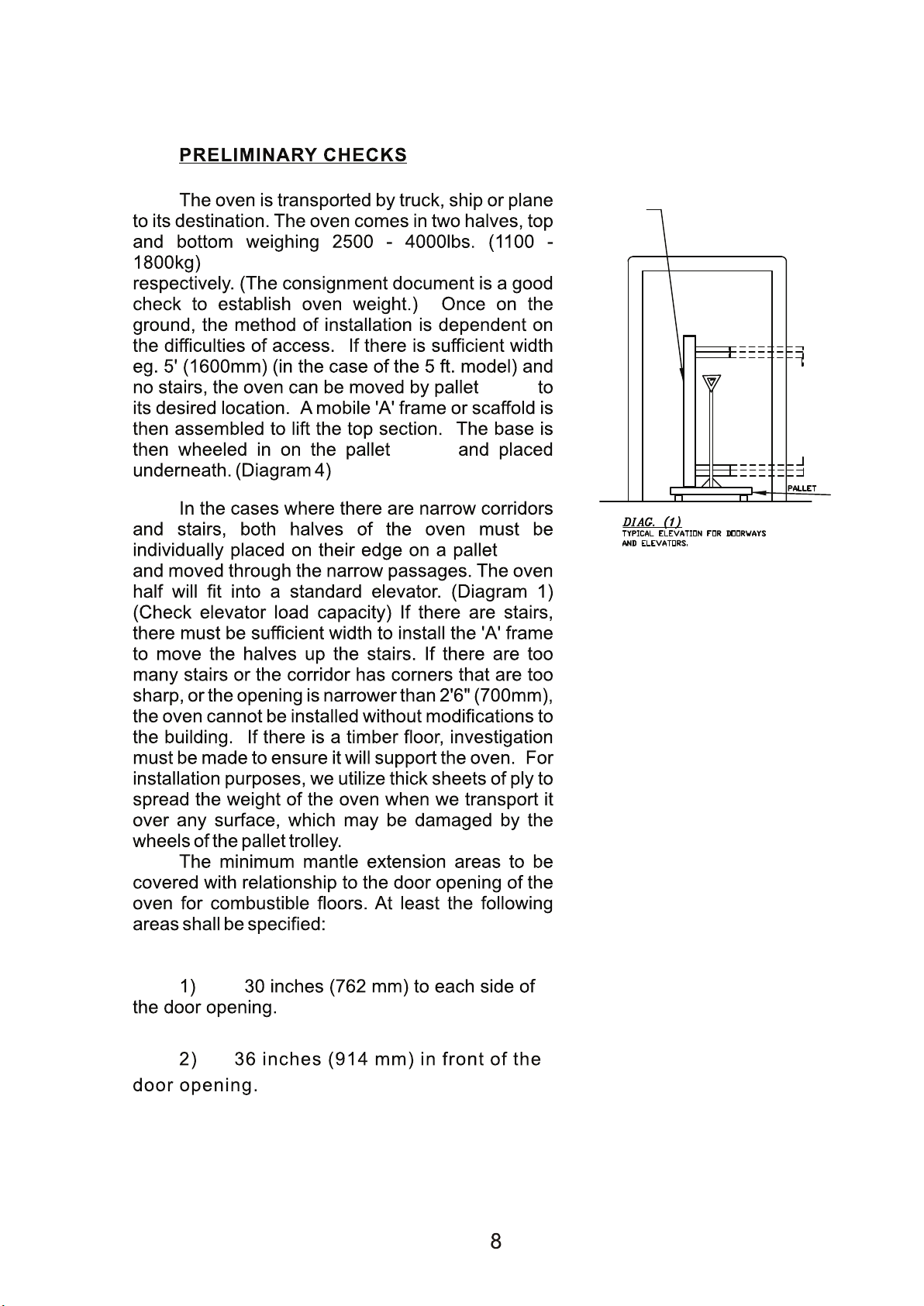

from pallet and place on it’s side on pallet

jack if it must go through narrow doorways See previous section - Lifting Positions )

(Remove from pallet and place on its side on pallet jack if it must go through narrow

doorways - See previous section - Lifting Positions )

Do NOTremove plywood from top of Base.

Now lift the Base onto pallet jack. (On it’s

side if it must go through narrow doorways:

See previous section - Lifting Positions )

Remove leg

width if necessary.

Carefully move this section of oven to

location

bolts if transported on its side).

s from oven base to r

educe its

Carefully remove the equipment stored

beneath the Baseand store in a secure

location (ready for later assembly).

11

Doughpro

RND-REC-RGO Manual

Assembly

The procedure mentioned below uses an “A-Frame” lifting method for assembling the

oven. Other lifting methods may be used e.g. a fork truck or crane, however the

following principals still apply.

Assemble lifting frame in kitchen where space permits.

(The assembled oven must be able to be moved

within the kitchen area without obstruction later on the

pallet jack.)

Utilizing lifting point 3 on previous dia

ree of the pallet and place on the ground, while

top f

moving the base into position.

gram, lift the

Lift the oven top to such a height to leave a

clear space underneath of minimum 46 inches to

top.

(Lift the base of the oven to a horizontal position

Move base under elevated top section using a lifting

frame or a stack of narrow pallets, being careful not to

damage any equipment under the oven; e.g.

burners, sensors, etc.

You may now remove the protective plywood from the

top of the base.

12

Doughpro

RND-REC-RGO Manual

Position wool strips so that they

remain hidden when the two halves

of the oven are assembled together.

Align the top and base using

the positioning tabs welded to

the base, locating the rear tab

Ensure that the oven

mouth aligns with the cutouts in the base.

Place strips of 2 inch x 1/2 inch ceramic

insulation wool (supplied) beneath the top of

the oven where the top section touches the

base.

NOTE: No wool should come between the

steel of the top and base.

With the two halves together the oven is

now ready to have the supplied 2 inch

external surfaces.

The “A-frame” can now be dismantled

and removed.

13

Doughpro

RND-REC-RGO Manual

The external surfaces (sides and top) of the oven are then completely covered with

ceramic insulation wool ( 2 inch Superwool ) using the high temperature Blox Stix glue

provided.

First cut all pieces

required to cover the sides

and top using a sharp knife.

each other with no visible gaps

to allow heat to escape.

When all pieces are cut, place each

apply a generous coat of Blox Stix glue

to the wool as shown using a trowel or

similar application tool.

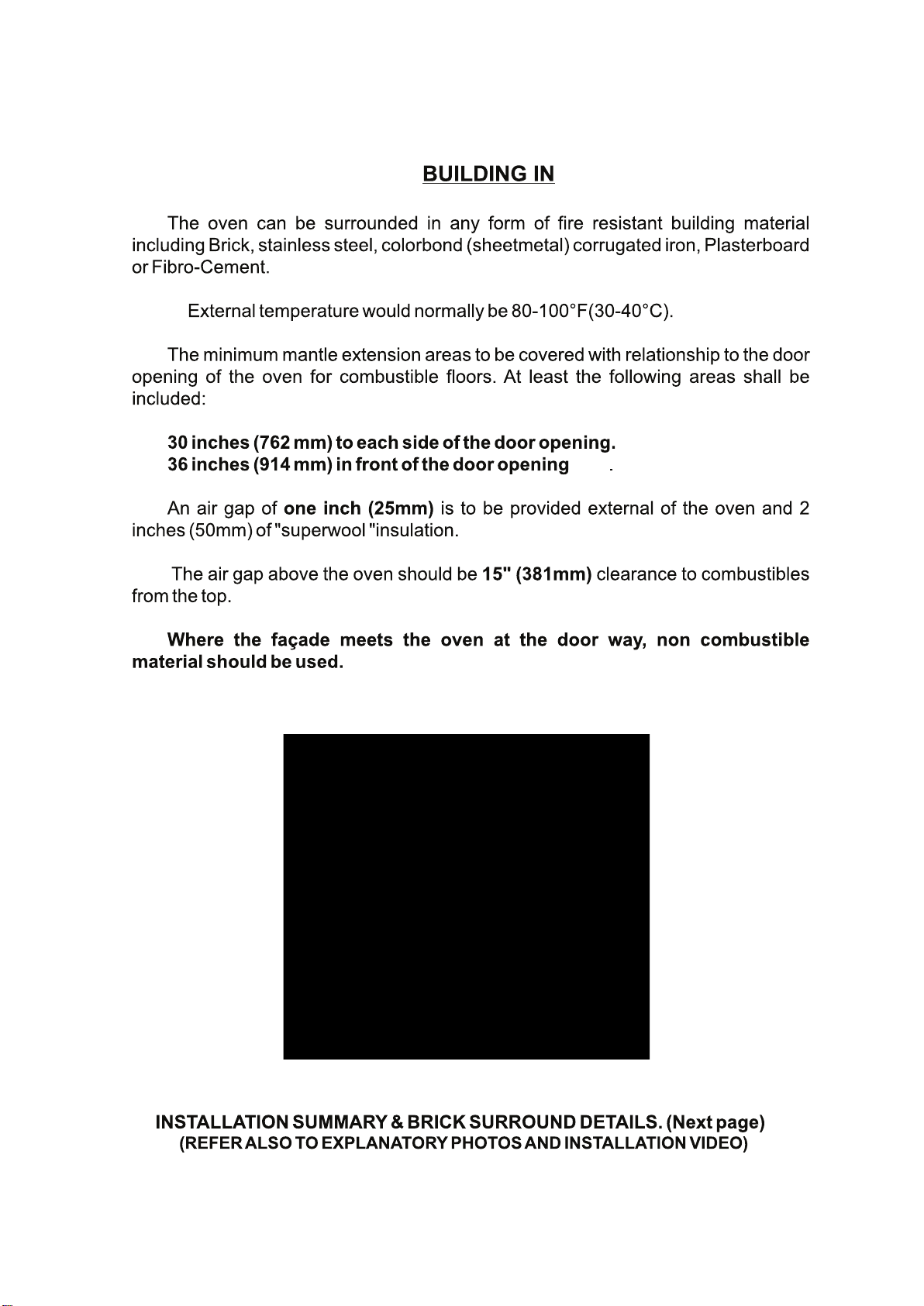

An important area to be aware of is directly in front of the exhaust

spigot of the oven. If the façade protrudes from the spigot there may

be an area between the spigot and the façade which is left uncovered

and vulnerable to soot and grease build up. This area is commonly

sealed creates a .

Exhaust Spigot

Insulation between spigot

and façade face

the area between the exhaust

spigot and the façade with a

not enter the façade cavity

Façade face

14

Doughpro

RND-REC-RGO Manual

place and that all air pockets are removed. The glue will dry in approximately one (1)

hour depending on ambient conditions.

lifting frame and a pallet jack (or similar).

If required, fasten the legs to the

NOTE: Fully assembled the oven can be

1 inch Air Circulation Gap

NOTE: A 1 inch Air Circulation Gap is to be left between the ceramic wool

this air gap will result in above normal temperatures being transferred to

exterior surfaces, causing a

.

15

16

17

(951) 657-0379

18

Loading...

Loading...