Doughpro DP1400C Installation Manual

D

STEARNS PRODUCT DEVELOPMENT CORPORATION

20281 Harvill Ave, Ferris, CA 92570 Tel:

DUDHPRD

624-6717 - Fax: (951) 657-4594

(800)

Operation Manual

DPI300

Automatic Dough Press

Requires remote or s-elf comained air compressor

(D1'141)OC with CA200)

DOUG HPRO

20281 Harvill Ave

Perris, CA 92570

Phone (951) 657-0379

Toll Free (300)624-6717

Fax (951) 657-4594

\Ve bsite: www.doughpro.com

E-Mail: infodoughprocom

Listed:

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

C

USTED

liS

p

Congratulations!

Congratulations!

Your selection of the Doughpro DP1300

Your selection of the Doughpro DP1300

is a sound business decision. Doughpro

is a sound business decision. Doughpro

equipment is a result of the highest

equipment is a result of the highest

quality engineering and time-tested

quality engineering and time-tested

design. Your machine, combined with

design. Your machine, combined with

Doughpro's reputation of innovation in

Doughpro’s reputation of innovation in

dough press equipment manufacturing,

dough press equipment manufacturing,

insures the continuing capability of

insures the continuing capability of

delivering the best-decorated product

delivering the best-decorated product

possible.

possible.

This manual describes installation,

This manual describes installation,

operation, and maintenance procedures

operation, and maintenance procedures

for your new model DP1300.

for your new model DP1300.

Your model DP 1300 machine will have

Your model DP1300 machine will have

a long trouble-free life. Read this

a long trouble-free life. Read this

manual carefully and keep it with your

manual carefully and keep it with your

machine; it's your key to proper

machine; it’s your key to proper

operation and lasting service.

operation and lasting service.

Installation

Installation

DOMESTIC

A

A

Make sure there is a proper electrical

Make sure there is a proper electrical

wall outlet located within reach of the

wall outlet located within reach of the

cord and plug attached to the press.

cord and plug attached to the press.

Then place the press in an area which

Then place the press in an area which

allows for “swing clearance” of the

allows for "swing clearance" of the

lower platen plus vertical and horizontal

lower platen plus vertical and horizontal

clearance of the press itself.

clearance of the press itself.

Limited Machine Warranty

Limited Machine Warranty

Doughpro warrants this dough press

Doughpro warrants this dough press

machine, when operated under normal

machine, when operated under normal

-1- DP1300 2/04

DOMESTIC

Use a separate 15 amp AC

Use a separate 15 amp AC

circuit. Only industrial extension

circuit. Only industrial extension

cords with proper wire size

cords with proper wire size

should be used; size 16/3 wire for

should be used; size 16/3 wire for

distance up to 25 feet, and size

distance up to 25 feet, and size

14/3 for distance up to 50 feet.

14/3 for distance up to 50 feet.

INTERNATIONAL

INTERNATIONAL

Use a designated 16 amp AC

Use a designated 16 amp AC

circuit. Only industrial extension

circuit. Only industrial extension

cords with proper wire size (2.5

cords with proper wire size (2.5

sq. mm) shall be used.

sq. mm) shall be used.

conditions, to be free from

conditions, to be free from

manufacturing defects in material and

manufacturing defects in material and

workmanship for a period of one year on

workmanship for a period of one year on

parts and labor from the invoice date.

parts and labor from the invoice date.

This warranty will be effective only

This warranty will be effective only

when Doughpro authorizes the original

when Doughpro authorizes the original

purchaser to return the product to the

purchaser to return the product to the

factory in South Gate, California freight

factory in South Gate, California freight

prepaid and only when the product, upon

prepaid and only when the product, upon

examination, has proven to be defective.

examination, has proven to be defective.

This warranty does not apply to any

This warranty does not apply to any

machine that has been subjected to

machine that has been subjected to

misuse, negligence or accident.

misuse, negligence or accident.

Doughpro shall not be liable for the

Doughpro shall not be liable for the

injury, loss or damage, direct or

injury, loss or damage, direct or

consequential, arising out of the use or

consequential, arising out of the use or

the inability to use the product.

the inability to use the product.

No claim of any kind shall be greater in

No claim of any kind shall be greater in

amount than the sale price of the product

amount than the sale price of the product

or part to which claim is made.

or part to which claim is made.

This is the sole warranty given by the company, it is in

This is the sole warranty given by the company, it is in

lieu of any other warranties, expressed or implied, in

lieu of any other warranties, expressed or implied, in

law or in fact, including the warranties of

law or in fact, including the warranties of

merchantability andfitness for a particular use, and is

merchantability and fitness for a particular use, and is

accepted such by the purchaser in taking delivery of

accepted such by the purchaser in taking delivery of

this product.

this product.

Specifications

Specifications

Electrical:

Electrical:

i 20V/5 0-60Hz/i 450W/i 2. SAmps/AC

120V/50-60Hz/1450W/12.5Amps/AC

Also available; specify when ordering:

Also available; specify when ordering:

240V/5 0-60Hz/i 45 OW/6.SAmps

240V/50-60Hz/1450W/6.5Amps

Includes 72" cord and NEMA

Includes 72” cord and NEMA

approved plug.

approved plug.

Shipping Weight:

Shipping Weight:

200lbs. (9 1kg.) - DP1300

200lbs. (91kg.) – DP1300

280 lbs. (127 kgs.) - DP1400C

280 lbs. (127 kgs.) – DP1400C

Safety Summary

Safety Summary

WARNING

A

-1- DP1300 2/04

WARNING

In case of power cord damage,

In case of power cord damage,

do not attempt to repair or

do not attempt to repair or

replace the power cord. Contact

replace the power cord. Contact

the manufacturer or the local

the manufacturer or the local

distributor.

distributor.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

WARNING

A

A

CAUTION

A

Operation Timer/Temperature

Operation Timer/Temperature

Control

Control

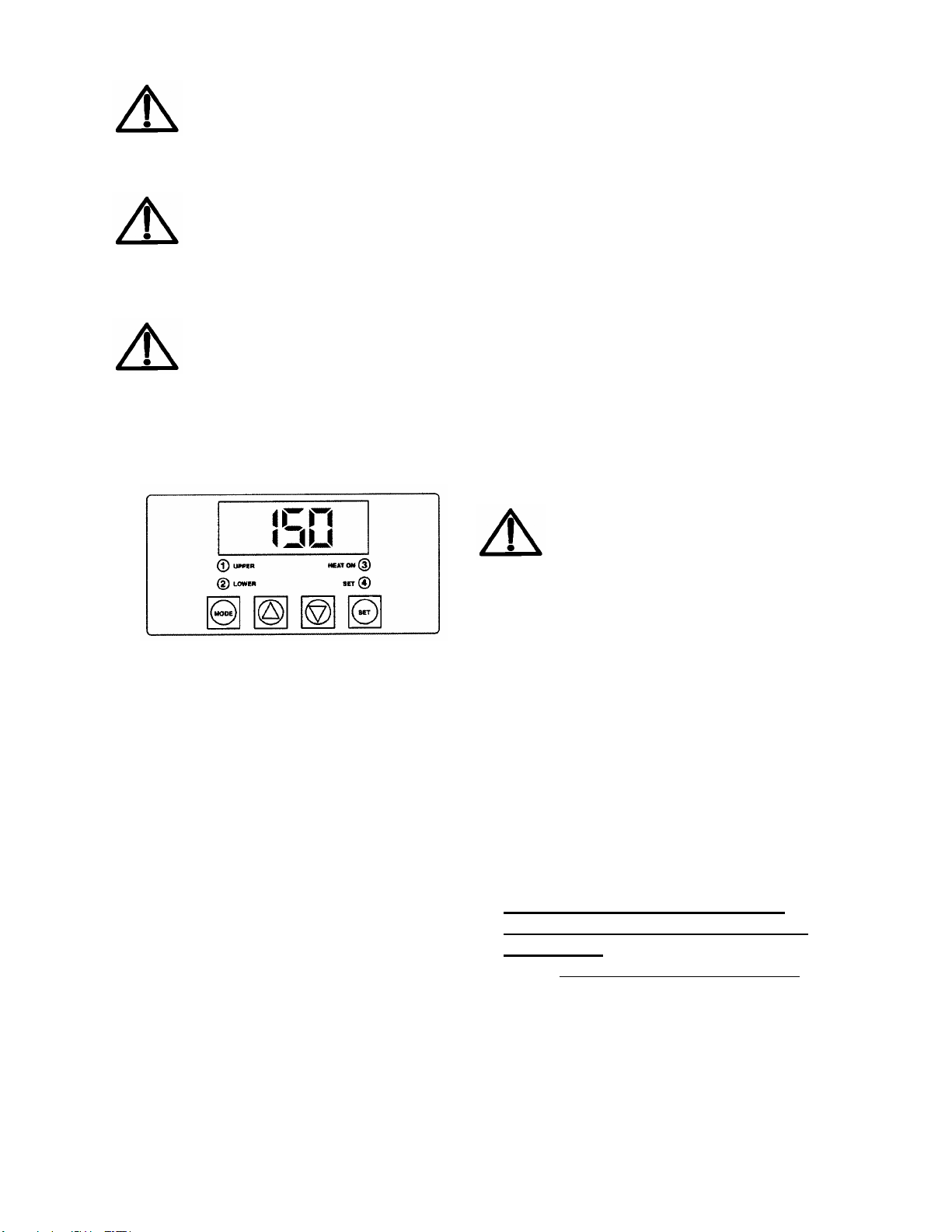

Fig. A

Solid State Controller

Solid State Controller

This controller has three (3) control

This controller has three (3) control

features:

features:

Controller Operation

Controller Operation

-2- DP1300 2/04

WARNING

Avoid touching hot surfaces

Avoid touching hot surfaces

while operating the machine.

while operating the machine.

CAUTION

CAUTION

During normal operation, the

During normal operation, the

base of the machine must be

base of the machine must be

installed or placed above the wall

installed or placed above the wall

socket.

socket.

CAUTION

When servicing or cleaning the

When servicing or cleaning the

machine, make sure that the

machine, make sure that the

power cord is removed from the

power cord is removed from the

wall socket.

wall socket.

UPPER

LOW!

e

©

Fig. A

Temperature - May be set from

1. Temperature – May be set from

100°-425°F (38°-163°C)

100°-425°F (38°-163°C)

2. Time – Time may be set from 1

Time - Time may be set from 1

second to 10 minutes.

second to 10 minutes.

Counter - Cycle counter counts

3. Counter – Cycle counter counts

the number of applications from

the number of applications from

1 to 9999 (see additional Notes -

1 to 9999 (see additional Notes –

Counter).

Counter).

"©Lower" (Fig. A) Refers to

4. “2Lower” (Fig. A) Refers to

models using upper and lower

models using upper and lower

heated surfaces.

heated surfaces.

1. Viewing the Modes of Operation:

1. Viewing the Modes of Operation:

***TOH

©

A

4. Resetting the Counter

PRESSING DOUGH:

PRESSING DOUGH:

For best results, your dough should be

For best results, your dough should be

proofed before pressing, but it will also

proofed before pressing, but it will also

press directly out of your refrigerator.

press directly out of your refrigerator.

Flour is not required to press a crust

Flour is not required to press a crust

and should not be dusted on any part of

and should not be dusted on any part of

the machine.

the machine.

D1400C Cabinet & Compressor

-2-

• To view the set points of

To view the set points of

temperature, timer and counter,

temperature, timer and counter,

press MODE button to view the

press MODE button to view the

desired mode of operation.

desired mode of operation.

2. Changing Temperature:

2. Changing Temperature:

Press MODE button until

• Press MODE button until

temperature is displayed.

temperature is displayed.

Press and hold SET button

• Press and hold SET button

while pressing the UP

while pressing the UP (↑) and

DOWN () arrow buttons to

DOWN (↓) arrow buttons to

desired temperature setting.

desired temperature setting.

3. Changing Time:

3. Changing Time:

Press MODE button until time

• Press MODE button until time

is displayed.

is displayed.

Press and hold SET button

• Press and hold SET button

while pressing the UP

while pressing the UP (↑) and

DOWN () arrow buttons to

DOWN (↓) arrow buttons to

desired timer setting.

desired timer setting.

The DISENGAGE switch may

The DISENGAGE switch may

be pressed anytime during a

be pressed anytime during a

cycle, and the cycle will stop

cycle, and the cycle will stop

immediately, and the timer will

immediately, and the timer will

reset.

reset.

4. Resetting the Counter

Press MODE button until the

• Press MODE button until the

counter is displayed.

counter is displayed.

To Reset the Counter (# of

• To Reset the Counter (# of

Cycles), simultaneously push

Cycles), simultaneously push

UP (↑) or DOWN (↓) arrow

UP(1) orDOWN(.J)arrow

buttons (approx. 5 seconds).

buttons (approx. 5 seconds).

D1400C Cabinet & Compressor

1.

1. After connecting the air hose line

After connecting the air hose line

from the compressor to the press,

from the compressor to the press,

plug it into the properly rated

plug it into the properly rated

electrical outlet for your press

electrical outlet for your press

and air compressor cabinet.

and air compressor cabinet.

Verify the electrical requirements

Verify the electrical requirements

against the nameplate on the

against the nameplate on the

and

(1)

and

(1)

DP1300 2/04

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

lower platen. Doughpro offers

back of the press and air

back of the press and air

compressor cabinet.

compressor cabinet.

Note: The compressor portion of the

Note: The compressor portion of the

machine has a separate on/off switch

machine has a separate on/off switch

located on the rear of the lower cabinet.

located on the rear of the lower cabinet.

2. Switch the DP1300 to the ON

Switch the DP1300 to the ON

position.

position.

Note: Initial temperature setting of

Note: Initial temperature setting of

150°F has been shown to be acceptable

150°F has been shown to be acceptable

for most dough formulations; however,

for most dough formulations, however,

you may have to determine the best

you may have to determine the best

temperature for your own dough by trial

temperature for your own dough by trial

and error testing ofyour product at

and error testing of your product at

different temperature settings.

different temperature settings.

3. Set the timer in accordance with

Set the timer in accordance with

the following information:

the following information:

2-4 seconds For warm dough

2-4 seconds –For warm dough

with moderate yeast content.

with moderate yeast content.

2-6 seconds – For room

2-6 seconds - For room

temperature dough with

temperature dough with

moderate yeast content.

moderate yeast content.

6-8 seconds - For cold dough

6-8 seconds – For cold dough

right out of the refrigerator with

right out of the refrigerator with

low yeast content.

low yeast content.

Remember that the timer does not

Remember that the timer does not

actuate until the upper platen mates

actuate until the upper platen mates

with the lower platen and resistance

with the lower platen and resistance

is felt.

is felt.

4. Set the thickness control lever to

Set the thickness control lever to

"thick" or "thin" or anywhere in

“thick” or “thin” or anywhere in

between these settings as your

between these settings as your

product requires.

product requires.

ADDITIONAL NOTES:

ADDITIONAL NOTES:

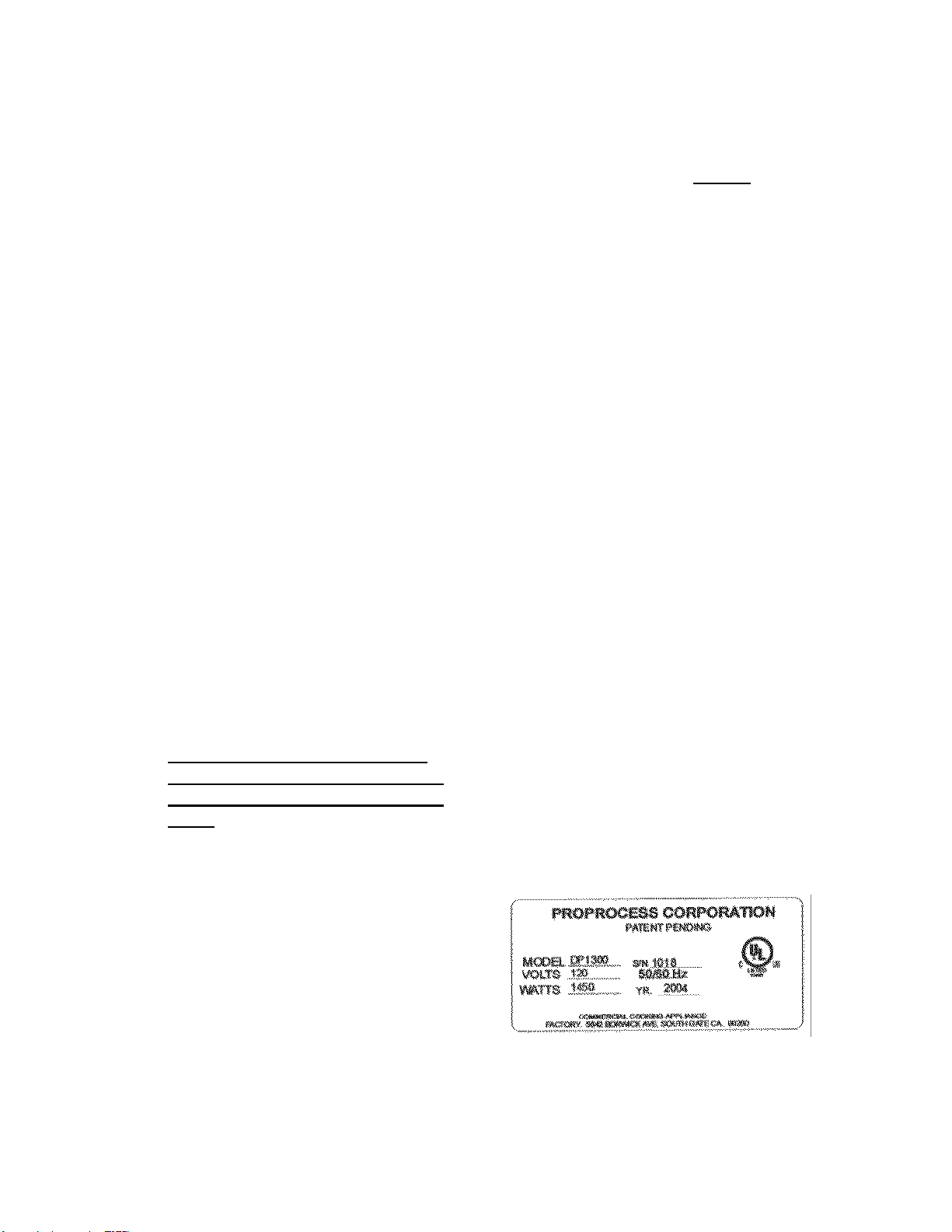

Serial Tags

Serial Tags

f

lower platen. Doughpro offers

its own food release spray

its own food release spray

NATURALLY CLEAR Model

NATURALLY CLEAR Model

No. DPPC1. (See our catalog

No. DPPC1. (See our catalog

and price list for information.)

and price list for information.)

Note: This spray will not affect

Note: This spray will not

the taste ofyour crust in any

the taste of your crust in any

way.

way.

affect

Place your pre-portioned ball of

6. Place your pre-portioned ball of

dough in the approximate center

dough in the approximate center

of the lower platen. Add another

of the lower platen. Add another

dash of spray to the top of the

dash of spray to the top of the

dough ball.

dough ball.

Close the platen and, with both

7. Close the platen and, with both

hands, press the two green

hands, press the two green

buttons on each side of the

buttons on each side of the

machine simultaneously.

machine simultaneously.

8. Hold the buttons in until

Hold the buttons in until

resistance is felt then release at

resistance is felt then release at

once. The timer will actuate and,

once. The timer will actuate and,

when the time cycle is

when the time cycle is

completed, the upper platen will

completed, the upper platen will

rise automatically (timer is preset

rise automatically (timer is preset

at factory for six (6) seconds, but

at factory for six (6) seconds, but

this is easily changed by

this is easily changed by

following the upcoming

following the upcoming

instructions.)

instructions.)

Remove the crust, place on a

9. Remove the crust, place on a

disc, screen, pan or peel, add

disc, screen, pan or peel, add

toppings and bake.

toppings and bake.

PROPROCESS CORPORAÌ1ON

PATENT PENO NC

Note: Diameter and thickness is

Note: Diameter and thickness is

determined through experimenting with

determined through experimenting with

your own dough and is a product of

your own dough and is a product of

dough weight, temperature, pressing

dough weight, temperature, pressing

time, and thickness setting.

time, and thickness setting.

Swing open the lower platen and

5. Swing open the lower platen and

apply a quick spray of a good

apply a quick spray of a good

water based food release on the

water based food release on the

-3- DP1300 2/04

-3-

MOOEL S/N [018

VOLTS 120

WAJTS 1450

FCTÇJRY. 54

50/60117

2004

YR-

ccac1G PJ-1 VNE

UÍUGATFCA

AW

DP1300 2/04

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...