Dosmatic MiniDos 0.4, MiniDos 5, MiniDos 20, MiniDos 2.5, MiniDos 10 Operating Instructions Manual

®

Certified ISO 9001:2000 Quality Management System

MINIDOS

Installation & Operating Instructions

Model No.

MiniDos - 0.4%, 2.5%, 5%, 10%, 20%

1

CONTENTS:

CAUTION:

To reduce risk of injury, user must read and understand the Installation & Operation Instructions

before using this product.

ITEM PAGE

Introduction...........................................................................................................................................3

Safety.....................................................................................................................................................4

Installation..........................................................................................................................................5-7

Operation............................................................................................................................................8-9

Maintenance........................................................................................................................................10

Trouble Shooting.................................................................................................................................11

Repair Parts Motor..............................................................................................................................12

Specications.......................................................................................................................................13

Repair Parts Lower Ends................................................................................................................14-19

Wear Parts Kits...............................................................................................................................20-22

Warranty.........................................................................................................................................23-24

START UP PROCEDURES

SLOWLY turn on main water pressure until water ows between 5 & 12 gpm (11-45 lpm) or 30 psi

(2 bar) maximum to fully prime the suction hose.

SLOWLY open the water supply valve and all valves downstream of injector to release entrapped

air. Carefully open inlet valve allowing water to enter and pressurize the injector. Open outlet valve

and close bypass valve. Water will now ow through the injector, and a continuous sound will be

emitted from the injector as water passes through it. Check for system leaks (see page 5) and correct

if necessary. Adjust the outlet valves downstream from the injector, if necessary.

IMPORTANT:

FOR WARRANTY PURPOSES

VISIT OUR

WEB SITE

WWW.DOSMATIC.COM

TO FILL OUT PRODUCT

REGISTRATION FORM!

Part#013815 Rev E

English:2

QUICK TIPS:

To maintain a long service life for your MiniDos injector

1. Always cover solution container and keep it clean

2. Always use clean water

3. Always lter inlet water

4. Always keep solution lter (#27) 2” from bottom of container

5. Always stock main wear parts for lower end

Trouble-shooting your Dosmatic injector

Injectors should make a gentle clicking noise when in operation

If the unit is not clicking, contact your authorized Dosmatic repair distributor or return the unit to Dosmatic USA,

Inc

If the unit is clicking, but not pulling solution, please inspect the lower end of the injector (see

lower end diagrams) as follows:

Exterior Inspection

1. Inspect and clean lter (#27)

2. Inspect the suction tube (#25) for cracks. Replace suction tube if holes exist

3. If injector still does not pull solution, please proceed to steps 4-7

Cleaning the suction tube tting

4. Remove pin #79 and carefully pull out the inner cylinder (#37)

5. Unscrew the suction tube tting (#11) from the inner cylinder (#37)

6. Clean and rinse suction tube tting assembly (#11). Replace any damaged parts

7. If injector still does not pull solution, please proceed to steps 8-12

How to replace wear parts

8. Unscrew the external cylinder (#7), separating it from the body of the injector

9. Take hold of the shaft (#51) and turn it 90 degrees in any direction to release it.

Pull shaft from its housing

10. If you have the 0.4%, remove the dosage piston (#44) by unscrewing dosage piston support (#52) from

lower shaft assy (#51).

NOTE: Due to the delicate nature of the 0.4%, extra care should be taken to monitor dosage levels, verify

solution is free of debris, and to perform wear maintenance regularly.

If you have the 1% or 2.5%, remove the dosage piston (#44) by turning the lower shaft (#51) one quarter

turn and pull down.

If you have the 5% or 10%, remove the dosage piston (#44) by depressing the two “ears” of the shaft

(#52) simultaneously and removing the piston upwards. Replace dosage piston by sliding a new #44 from

top to bottom of the shaft until you hear a click.

If you have the 20%, remove the dosage piston (#44) by unscrewing the capscrew (#93) and remove the

dosage piston (#44) by pulling down.

Clean and inspect O-ring (#14).

The translucent openings (larger diameter/thinner lips) of the dosage piston should be on top.

11. Clean, dry and inspect inside the inner cylinder (#37 or #7 if 20%) from scratches or cracks. If damaged,

replace inner cylinder.

English:3

44

195008

195012 (2x)

195909

194309

010044

195444

190730

195200

195408

212005

195870

20% 011849

10% 011025

5% 011015

2.5% 010025

1% 010025

5% 011026

10% 011018

25

17

51

44

27

51

44

44

44

55

2.5% 011017

54

195871

195873

0.4% 011023

0.4% 003072

1% 011017

195950 95

93

51

44

2.5%

20%

10%

5%

1%

0.4%

INTRODUCTION:

Please take the time to read this instruction manual thoroughly and follow the procedures. This

will help increase the life of your injector.

Certain precautions, which are marked with this symbol need to be read carefully...

The injector is packaged with the following items: (shown in gure 1)

Dosmatic Injector (not shown)

Dosage Piston

O-ring

Manual (not shown)

Mounting Bracket

Mounting clips

Filter

Suction Tube

English:4

Fig.1

SAFETY:

1.SELECT A LOCATION: that is on the water line that chemical injection is desired and meets all

the following requirements as well as all applicable local codes.

Remove Red Caps Prior to Installation.

NOTE: The entire water line down stream from the injector will have chemical injected into it. If

the chemical injected makes the water unsafe to drink, label the water lines.

WARNING NOT FOR HUMAN CONSUMPTION!

2. AN APPROVED BACK FLOW PREVENTOR MUST BE INSTALLED, in the water

line ahead of the unit to prevent water and chemical mixture from entering the source water supply.

3. AVOID A POTENTIALLY HAZARDOUS CHEMICAL ACCIDENT: An injector loca-

tion should be selected to provide a safe, but accessible, place for the chemical solution container. It

should be kept away from children and/or high usage areas.

4. AVOID SOLUTION CONTAMINATION, use only clean FILTERED water. Do not allow

contaminants to enter the solution container because they will be pumped into the water line, and

can cause the spread of disease and can also cause excessive wear.

5. WATER TEMPERATURE

Max: 100°F or 38°C

Min: 32°F or 0°C

6. MAX WATER PRESSURE

10% & 20% - 65 PSI/4,5 BAR

0.4% - 5% - 140 PSI/9,7 BAR

7. RELEASE WATER PRESSURE, before working on injector

English:5

INSTALLATION:

1.NOTE: Water going through injector must be free of sand, dirt and grit. Installation of 140 mesh

(104 micron) or ner lter will be required.

2. MOUNT INJECTOR: Securely to a solid object such as a wall. Note arrow on injector indicat-

ing water ow. See g. 4.

3. BACKFLOW PREVENTOR: Install one adequately sized that meets your local code require-

ments.

4. BYPASS VALVE: To bypass injector when not in service or to service injector pipe in the three

valve bypass arrangement as shown in Fig. 3

5. CHECK SYSTEM FOR LEAKS: Open the bypass valve (A), close valves (B) and (C) so that

the water will not ow into injector SLOWLY turn on the main water line so that water will

run through the plumbing system. Turn on all of the valves located downstream from your injector

to release trapped air. Slowly turn on the inlet valve (B). Open the outlet valve (C) at injector outlet.

Close (A). As water travels freely through your injector, you will hear a soft “clicking” sound.

6. SOLUTION CONTAINER: Refer to gure 5. You may use any size container but we recom-

mend using one with a lid or cover. To connect your solution container gently push the end of the

suction tube (#25) onto the bottom of the tting assembly (#11). Place the lter into the solution

container at least 2 inches (5cm) from the bottom. Cover the solution lter with at least 2 inches.

(5cm) of chemical solution.

English:6

INSTALLATION DRAWINGS:

50mm

2" Required

Solution Filter

Bypass Valve (Required)

Outlet Valve (Required)

Inlet Valve (Required)

Inlet Filter (Required)

Suction Tube

Covered Container

TYPICAL INSTALLATION

(A)

Fig.3

(B)

(C)

English:7

50mm

2" Required

Covered Container

Inlet Filter (Required)

Inlet Valve (Required)

Bypass Valve (Required)

Outlet Valve (Required)

Suction Tube

Solution Filter

10 Feet (3 Meters)

Minimum Water Level

195008 Bracket

195012 Clip(2)

INSTALLATION DRAWINGS:

TYPICAL WALL MOUNTING

Fig.4

TANK FEED INSTALLATION

English:8

Fig.5

OPERATION:

Run Position

Increase

On/Off Lever

Decrease

Setting Indicator

Mark

SERVICE FLOW: Water drawn down stream from the injector will automatically cause the injec-

tor to “click” and inject the set amount of solution into the water line. The higher the ow rate the

more frequent the clicking, as the injector is designed to inject solution at the same set ratio regardless of water ow.

Water ow and pressure must be within the established specications. See the specication section

on page 10 for your model.

CHANGE FEED RATE: The feed rate on the injector is adjustable EVEN WHILE OPERATING

AND UNDER PRESSURE. Rotate the “Ratio Adjustment Sleeve” (#61) Important: for the 20%

model rotate the #7 Ratio Adjuster, to change the solution injection ratio. See g. 5,. The setting

indicator mark indicates the approximate ratio of injection setting. Check outlet water for chemical

to assure desired feed rate is being delivered.

NOTE: Do not rotate Ratio Adjuster below lowest setting line on decal. This can cause the injector

to lock.

BYPASS OPERATION: Injecting solution into the water line can be TEMPORARILY stopped

with the optional on/off feature. Moving the “On/off Lever” to the “OFF” position allows service

water to pass through the injector without injecting chemical. With the on/off lever set to the “ON”

position the injector will operate as normal and “clicking” will be heard when water is owing. It

is recommended to use the three valve bypass in Fig. 3, for continued bypassing or servicing of the

injector.

Fig.6

Example ratio sleeve

English:9

MAINTENANCE:

RINSE INJECTOR AFTER EACH USE, additive allowed to remain in injector can dry out

and damage lower end at the next start up. Put suction tube into a 1 qt. (4 liters) or more con-

tainer of fresh ltered water. Pull fresh water through the injector by operating until container is

empty. This procedure is not needed for continuous operation.

BYPASS INJECTOR: When not in use put the injector in bypass mode by using the three valve

bypass (preferred) or the optional on/off lever on the injector.

CLEAN SUCTION TUBE FILTER SCREEN: Inspect each time new solution is added. Clean

as frequently as necessary by washing in fresh water. Remove lter screen (#27) from suction tube

(#25) and run water backwards through it. Replace if necessary. Keep lter screen off bottom of

solution container to prevent dirt and precipitate from contaminating solution.

STORAGE: For extended storage, rinse injector as described above and place entire injector

underwater (in 5 gal container). Monthly, apply a small amount (thimble full) of chlorine bleach to

avoid algae growth.

CLEAN SOLUTION CONTAINER: Keep covered to prevent any contaminants from entering

container. Rinse container thoroughly and often. Do not mix chemicals together that might react

and cause a precipitate. Use FILTERED WATER when lling container.

CLEAN INLET FILTER: Clean or replace inlet lter as required to increase the life of the unit

as well as reduce pressure loss.

REPLACE DOSAGE PISTON AND SHAFT SEAL: The injector is shipped with a spare Dos-

age Piston (44) and shaft seal (17), see Fig. 1, as these are normal wear parts, replace both when

solution injection is less than set amount.

English:10

TROUBLE SHOOTING:

NO CLICKING SOUND

1. Water ow rate exceeds rated service ow of injector: Reduce ow rate (See Specications

Pg. 10).

2. Operating pressure exceeds maximum limit: Install a pressure reducer valve (See Specica-

tions Pg. 10).

3. #17 o-ring if leaking: Replace.

4. Main piston assembly #9 worn: Replace #9 and install a 104 micron lter before injector to

remove abrasive particles from water.

5. Cover #1 or main body #40 bores worn or scored: Lightly sand inside diameter of bores to

remove scoring grooves. Install a 104 micron lter to remove abrasive particles from water.

6. Poppets (Upper or Lower) are off poppet arms:

ow and/or pressure.

CLICKING SOUND WITHOUT SUCTION OF SOLUTION

1. Dosage piston #44 and o-ring retainer #15 are installed incorrectly: Be sure #44 dosage

piston is installed thin lips up.

2. Dosage piston #44 worn: Replace as necessary.

3. O-ring seat #14 or dosage piston #44 damaged: Replace as necessary.

4. #7 cylinder is worn or scored: Replace

5. #17 o-ring is worn and/or loose: Replace

6. Suction tube #25 or suction tube tting #11 cracked & leaking: Replace as necessary

7. Clogged suction tube lter: Replace and/or clean as necessary.

Replace all poppet assemblies and reduce

8. Check valve #13 leaking: Clean & replace as necessary.

WATER RE-FILLING SOLUTION TANK

1. Check valve #13 leaking: Check seat area on suction tube tting #11. Check valve and seal

must t loose in the suction tube tting.

2. Washer seal on #13 is swollen: Replace with new check valve assembly.

English:11

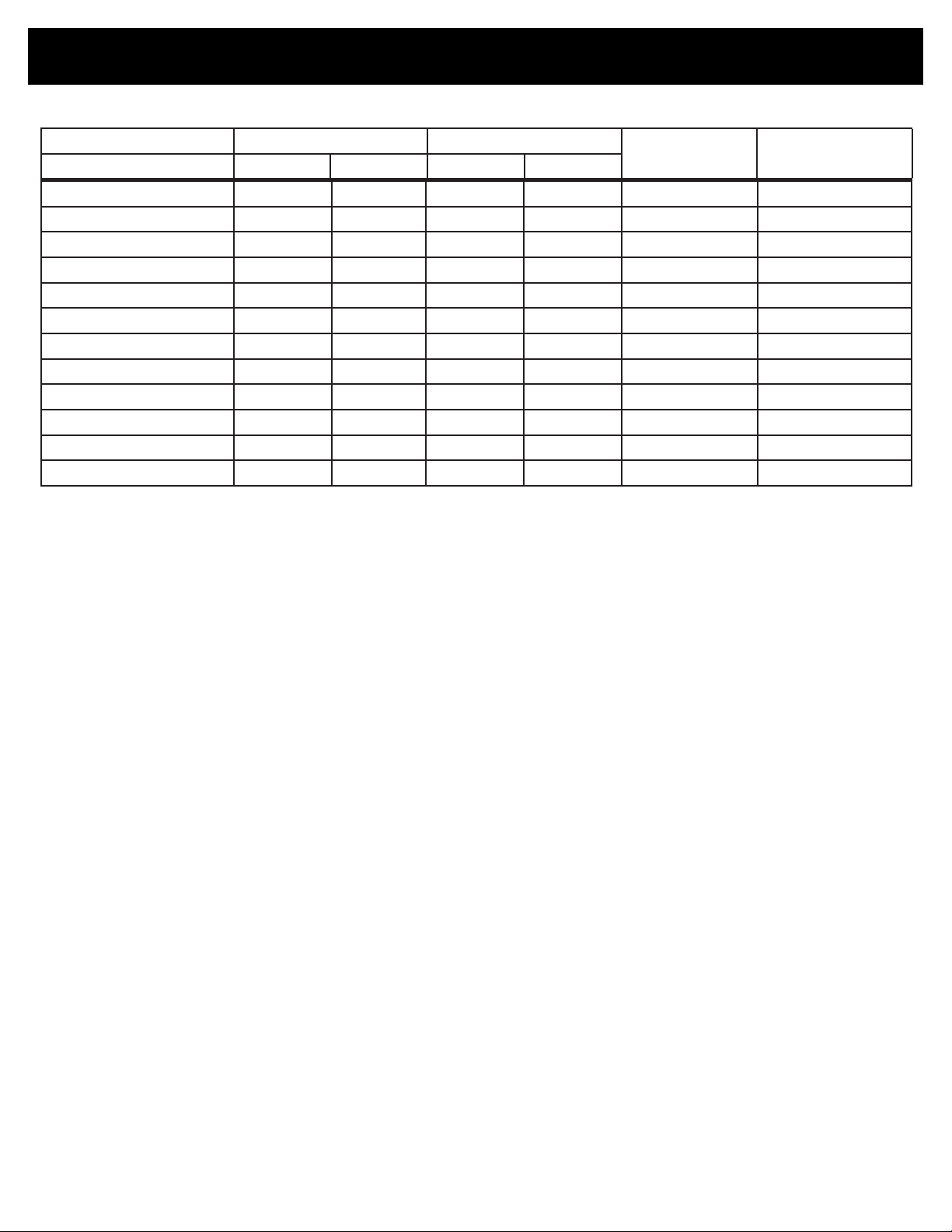

SPECIFICATIONS:

Model Flow Rate Feed Ratio

Minimum Maximum Minimum Maximum

MiniDos 0.4% 0.03 gpm 12 gpm 0.025% 0.40% 6 – 140 psi ¾” npt

0,11 lpm 45,42 lpm 1:4000 1:250 0,41 – 9,7 bar ¾” bsp

MiniDos 1% 0.03 gpm 12 gpm 0.20% 1.00% 6 – 140 psi ¾” npt

0,11 lpm 45,42 lpm 1:500 1:100 0,41 – 9,7 bar ¾” bsp

MiniDos 2.5% 0.03 gpm 12 gpm 0.50% 2.50% 6 – 140 psi ¾” npt

0,11 lpm 45,42 lpm 1:200 1:40 0,41 – 9,7 bar ¾” bsp

MiniDos 5% 0.03 gpm 12 gpm 1.00% 5.00% 6 – 140 psi ¾” npt

0,11 lpm 45,42 lpm 1:100 1:20 0,41 – 9,7 bar ¾” bsp

MiniDos 10% 0.07 gpm 10 gpm 2.0% 10.0% 6 – 65 psi ¾” npt

0.25 lpm 37,85 lpm 1:50 1:10 0,41 – 4,5 bar ¾” bsp

MiniDos 20% 0.07 gpm 7 gpm 4.00% 20.00% 6 - 65 psi ¾” npt

0.25 lpm 27 lpm 1:25 1:5 0,41 - 4,5 bar ¾” bsp

Operating

Pressure

Inlet/Outlet

Pipe Connection

English:12

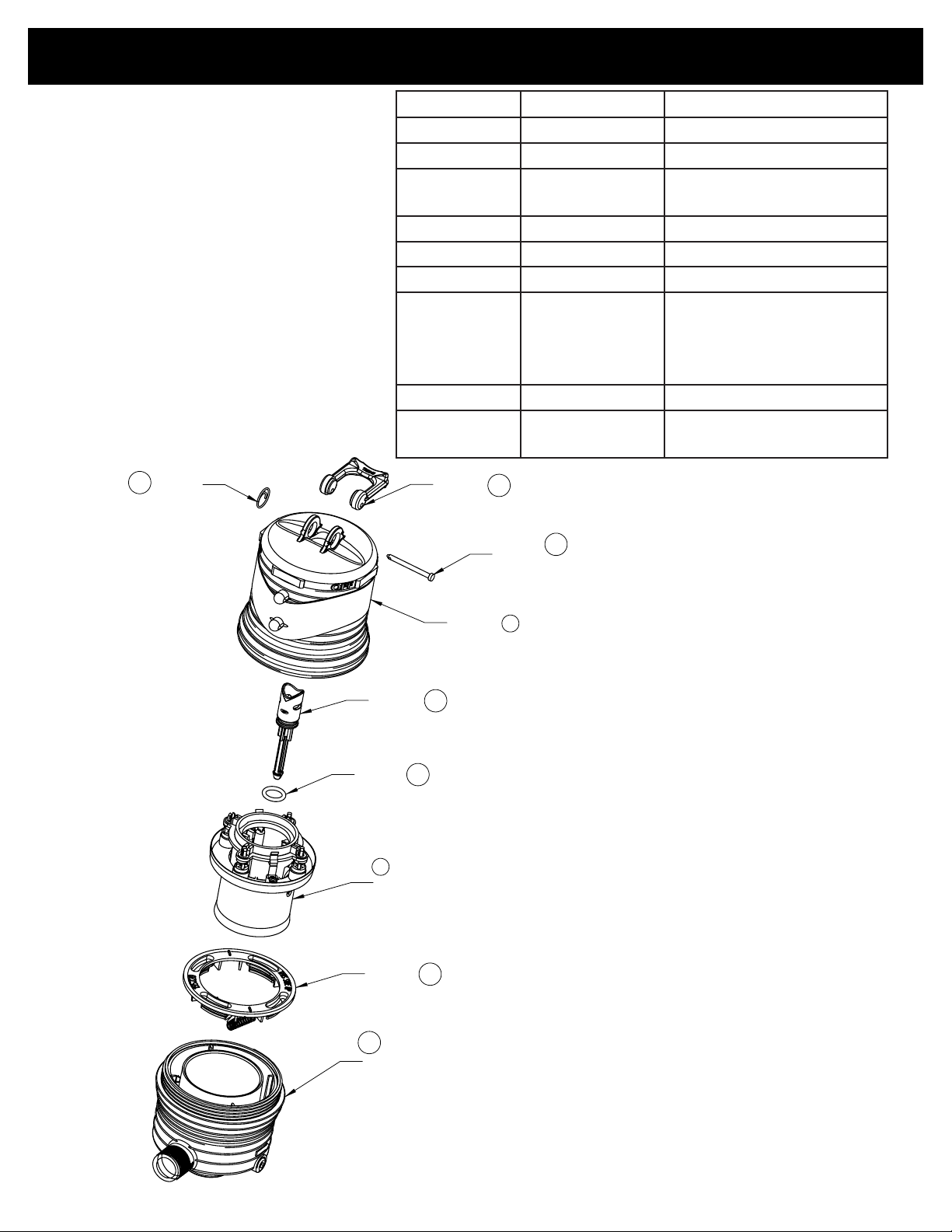

REPAIR PARTS:

87

34

1

9

86

40

20

85

21

195914 (Heavy Duty Pin)

193641

195910

190100

195912

195700

011662UP 20%

011666

195720

011011 20% BSP Threads

Ordering Information

011012 NPT Threads

011013 BSP Threads

011010 20% NPT Threads

212009

(2x for Heavy Duty)

Reference # Part # Description

1 190100 Upper Body

87 195910 On/Off Handle

85

195912

195914

34 193641 Cotter Ring

21 195700 Shaft

20 212009V O-ring

011012

40

011013

011010 20%

011011 20%

86 195720 Mixing Chamber Gasket

9

011666

011662UP 20%

Upper Shaft Pin

Heavy duty upper shaft pin

Lower Body NPT

Lower Body BSP

Piston Assembly

English:13

LOWER END INJECTOR & WEAR PARTS KITS 0.4%:

Kit A - Wear Parts Kit (dosage piston/lower shaft assy,

and oring)

Kit C - Wear Parts Kit (Kit A, inner cylinder and oring) 011110 12, 14, 37, 44, 52

Kit D - Suction Tube Fitting Assy ( poppet, oring, tting,

spring)

Kit E - Wear Parts Kit (Kits C & D, upper shaft, pin) 011112 10, 11, 12, 13, 14, 37, 44, 51, 52,

Kit G - Lower End Kit, complete (Kit E, outer cylinder,

ratio adjuster, orings, clips, pins, retainer, lter, solution

tube)

Kit H - Motor Piston Assy (upper end kit) 011662S 9

Kit Hby - Remote Injection Kit 011762 (Viton) 32

Kit M - Mounting Bracket Kit (mounting bracket, 2 pins) 011732 54, 55

Manual Reference Part # Description of Part

7 190031 MiniDos Outer Cylinder

10 195875 MiniDos 0.4% Spring

11 193201 Suction Tube Fitting

12 212120

*Must specify material

13 011453A Check Poppet

14 212008

*Must specify material

16 195709 Seal

17 212005

*Must specify material

25 011023 Suction Tube 1/8" x 3'

27 003072 Filter for suction tube 1/8"

37 195876 MiniDos 0.4% Inner Cylinder

44 195873 MiniDos 0.4% Dosage Piston

51 011009 MiniDos 0.4% Upper Shaft Assy

52 195871 MiniDos 0.4% Piston Support

60 212517W O-ring

61 195874 MiniDos 0.4% Ratio Adjuster

79 195224 Interlock Pin

82 195740 Shaft seal spacer

91 193054 Seal, check valve

92 193854 Hose Nut 1/8"

Oring

Oring

O-ring

011109 14, 44, 52

011111 10, 11, 13, 91

79, 91

011113 7, 10, 11, 12, 13, 14, 16, 17, 25,

27, 37, 44, 51, 52, 60, 61, 79, 91,

92

011764 (EPDM)

English:14

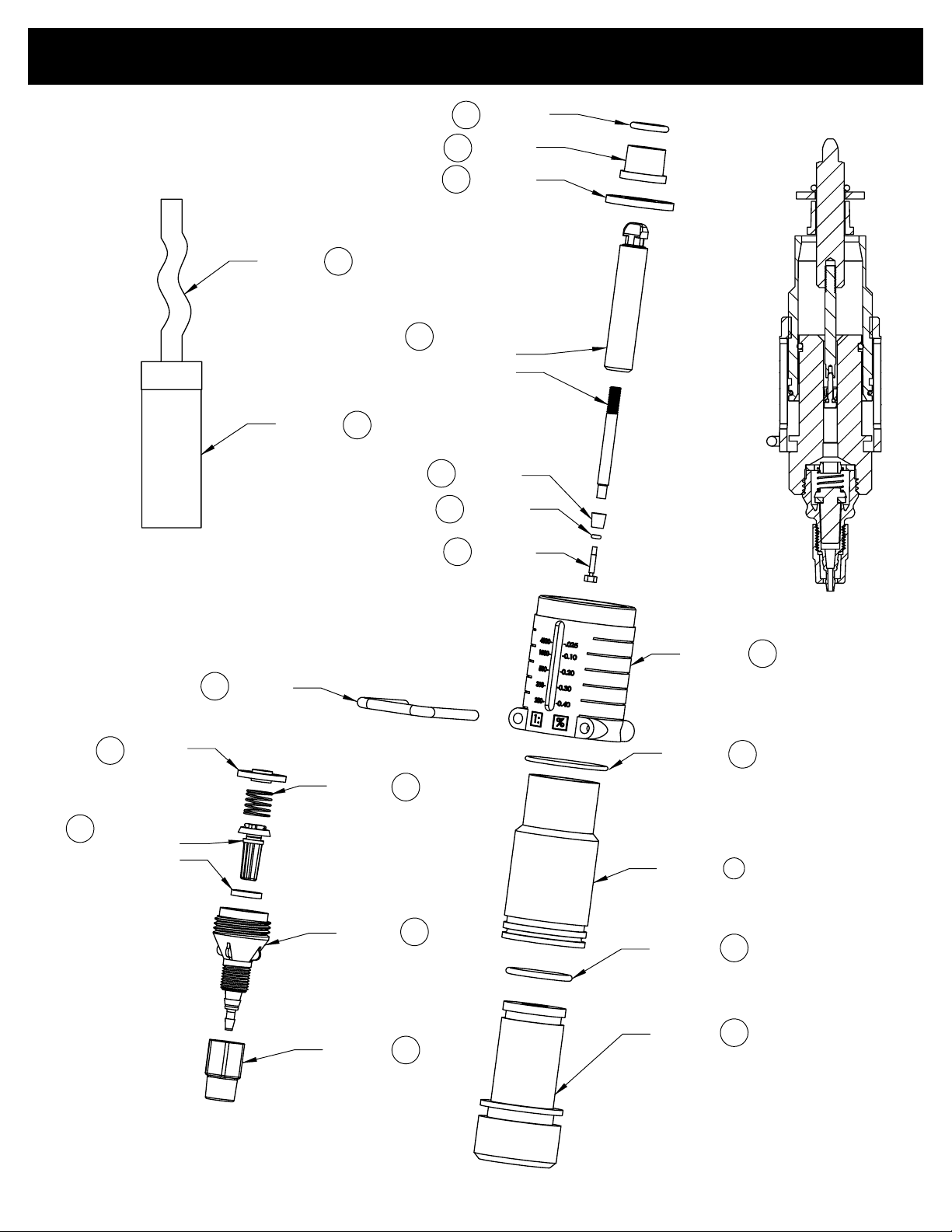

LOWER END INJECTOR PARTS 0.4%:

17

195709

195873

195871

190031

195876

195224

212517

212120

212008

195874

25

190727

195870

011009

212005

19574082

91

011453

27

79

10

11

13

16

52

51

44

14

61

60

12

37

92

194413

193054

195875

194416

193201

193854

003072

011023

7

English:15

LOWER END INJECTOR & WEAR PARTS KITS 1%:

Description of Kit Part # Manual Reference

Kit A – Wear Parts Kit (dosage piston, oring) 011071 14, 44, 51

Kit C – Wear Parts Kit (Kit A, inner cylinder, oring) 011072 12, 14, 44, 51, 63, 68

Kit D – Suction Tube Fitting Assy (poppet, nut, washer,

oring, spring, tting)

Kit E – Wear Parts Kit (Kits C & D, upper shaft, pin) 011073 10, 11, 12, 13, 14, 44, 51, 52,

Kit G – Lower End Cylinder Kit (Kit E, outer cylinder,

ratio adjuster, oring, clip, pin, retainer, lter, solution tube)

Kit H – Motor Piston Assy (upper end kit) 011662S 9

Kit Hby - Remote Injection Kit 011762 (Viton)

Kit M – Mounting Bracket Kit (mounting bracket, 4 hex

caps & nuts)

Manual Reference Part # Description of Part

7 190011 Cylinder,outer

10 194418H Spring

11 194417 Fitting, suction tube, ¼”

12 212120

*Must specify material

13 011453A Poppet, check w/washer

14 212022

*Must specify material

16 195709 Gasket

17 212005

*Must specify material

25 010025 Suction tube, ¼” x 5’

26 195761 Anti Lock Gasket

27 011017 Filter for suction tube, ¼” ID

37 195405 Inner Cylinder

44 195200 Dosage Piston

51 190730 Shaft, lower

52 190030 Shaft, upper

60 212517W O-ring

61 195426 Ratio adjustment sleeve

63 212516

*Must specify material

68 190750 Cylinder, inner for #7

71 194414 Nut, suction tube tting

79 195224 Pin, narrow interlock

80 194415 Twistlock

82 195740 Shaft seal spacer

011046 10, 11, 12, 13, 71, 80

63, 68, 71, 80, 79

011068 7, 10, 11, 12, 13, 14, 16, 17, 25,

26, 27, 37, 44, 51, 52, 60, 61,

63, 68, 71, 79, 80, 82

32

011764 (EPDM)

011732 54, 55

O-ring

O-ring

O-ring

O-ring, inner cylinder

English:16

LOWER END INJECTOR PARTS 1%:

68

011453

79

13

17

82

16

52

44

14

51

60

7

12

26

37

61

010025

011017

71

195740

195709

190030

195200

190730

195426

190011

195761

195405

190750

195224

212005

212022

212517

212120

25

27

12

80

10

11

21251663

194418

194415

194413

194417

194416

194414

212120

English:17

LOWER END INJECTOR & WEAR PARTS KITS 2.5%:

Description of Kit Part # Manual Reference

Kit A – Wear Parts Kit (dosage piston, oring) 011055 17, 44

Kit B – Wear Parts Kit (Kit A, lower shaft, oring) 011044 14, 17, 44, 51

Kit C – Wear Parts Kit (Kit A, inner cylinder, oring) 011045 12, 17, 37, 44

Kit D – Suction Tube Fitting Assy (poppet, nut, washer, oring, spring,

tting)

Kit G - Lower End Kit, complete (Kit D, outer cylinder, ratio adjuster,

oring, retainer clip, pin, retainer, lter, solution tube)

Kit H – Motor Piston Assy (upper end kit) 011662S 9

Kit Hby - Remote Injection Kit 011762 (Viton)

Kit M – Mounting Bracket Kit (mounting bracket, 4 hex caps & nuts) 011732 54, 55

Manual Reference Part # Description of Part

7 190011 Cylinder, outer

10 194418H Spring

11 194417 Fitting, suction tube, ¼”

12 212120

*Must specify material

13 011453A Poppet, check w/washer

14 212501

*Must specify material

16 195709 Gasket

17 212005

*Must specify material

25 010025 Suction tube, ¼” x 5’

O-ring

O-ring

O-ring

26 195760 Anti Lock Gasket

27 011017 Filter and foot valve, suction tube, ¼” ID

37 195404 Inner Cylinder

44 195444P Dosage Piston

51 195408 Shaft, lower

52 195727 Shaft, upper

60 212517W O-ring

61 195430 Ratio adjustment sleeve

71 194414 Nut, suction tube tting

79 195224 Pin, narrow interlock

80 194415 Twistlock

82 195740 Shaft seal spacer

011057 10, 11, 12, 13, 71, 80

011047 7, 10, 11, 12, 13, 14,

16, 17, 25, 26, 27,

37, 44, 51, 52, 60,

61, 71, 79, 80, 82

32

011764 (EPDM)

English:18

LOWER END INJECTOR PARTS 2.5%:

010025

011017

194418

194415

194413

194417

194414

194416

212120

80

27

79

17

82

16

52

44

14

51

61

7

60

12

26

37

11

71

13

10

12

195709

195740

195727

195444

195408

195224

195430

190011

195404

195760

212005

212501

212517

212120

25

011453

English:19

LOWER END INJECTOR & WEAR PARTS KITS 5%:

Description of Kit Part # Manual Reference

Kit A – Wear Parts Kit (dosage piston, oring)

Kit B – Wear Parts Kit (Kit A, shaft)

Kit C – Wear Parts Kit (Kit A, inner cylinder, oring)

Kit D – Suction Tube Fitting Assy (poppet, nut, washer, oring, spring, t-

ting)

Kit E – Wear Parts Kit (Kits C & D, inner cylinder (2nd inner cylinder),

shaft, pin, gasket)

Kit G - Lower End Kit, complete (Kit E, outer cylinder, ratio adjuster, oring,

retainer clip, pin, retainer, lter, solution tube)

Kit H – Motor Piston Assy (upper end kit)

Kit Hby – Remote Injection Kit 011762 (Viton)

Kit M – Mounting Bracket Kit (mounting bracket, 4 hex caps & nuts) 011732 54, 55

Manual Reference Part # Description of Part

7 190031 Cylinder, outer

10 194418H Spring

11 194412 Fitting, suction tube, 3/8”

12 212120

*Must specify material

13 011453A Poppet, check w/washer

14 212005

*Must specify material

16 195709 Gasket

17 212005

*Must specify material

25 011015 Suction tube, 3/8” x 5’

O-ring

O-ring

O-ring

26 195761 Anti Lock Gasket

27 011026 Filter and foot valve, suction tube, 3/8” ID

37 195405 Inner Cylinder

44 010044P Dosage Piston

52 195726 Shaft, upper

60 212517W O-ring

61 195428 Ratio adjustment sleeve

71 194414 Nut, suction tube tting

79 195224 Pin, narrow interlock

80 194415 Twistlock

82 195740 Shaft seal spacer

011076 17, 44

011077 17, 44, 52

011074 12, 17, 37, 44

011079 10, 11, 12, 13, 71,

80

011080 10, 11, 12, 13, 17,

37, 44, 52, 71,

79, 80

011081 7, 10, 11, 12, 13,

14, 16, 17, 25, 26,

27, 37, 44, 52, 60,

61, 71, 79, 80, 82

011662S 9

32

011764 (EPDM)

English:20

LOWER END INJECTOR PARTS 5%:

011015

011026

79

011453

17

82

16

44

14

52

61

26

7

60

12

37

13

194413

194415

194418

194412

194414

194416

212120

11

195740

195709

010044

195726

195428

195761

190031

195405

195224

212005

212005

212517

25

27

12

80

10

212120

71

English:21

LOWER END INJECTOR & WEAR PARTS KITS 10%:

Description of Kit Part # Manual Reference

Kit A – Wear Parts Kit (dosage piston/shaft assy, oring)

Kit B – Wear Parts Kit (Kit A, shaft)

Kit C – Wear Parts Kit (Kit A, inner cylinder, oring)

Kit D – Suction Tube Fitting Assy (poppet, nut, washer, oring, spring, tting)

Kit E – Wear Parts Kit (Kits C & D, inner cylinder (2nd inner cylinder), shaft,

pin, gasket)

Kit G - Lower End Kit, complete (Kit E, outer cylinder, ratio adjuster, oring,

retainer clip, pin, retainer, lter, solution tube)

Kit H – Motor Piston Assy (upper end kit)

Kit Hby – Remote Injection Kit 011762 (Viton)

Kit M – Mounting Bracket Kit (mounting bracket, 4 hex caps & nuts) 011732 54, 55

Manual Reference Part # Description of Part

7 195790 Outer cylinder

10 194418H Spring

11 011452 Fitting, suction tube

12 212120

*Must specify material

13 011453A Poppet, check w/washer

14 212005

*Must specify material

15 194004 Seal retainer, o-ring

16 010016S Gasket, inlet/outlet and cylinder

17 212005

*Must specify material

25 011025 Suction tube, 1/2” x 5’

27 011018 Filter and foot valve, suction tube, 1/2” ID

37 194405P Inner Cylinder

44 194309 Dosage Piston

52 195729 Shaft

61 194406P Ratio adjustment sleeve

64 212017

*Must specify material

65 194310D Pin, upper interlock

66 212025

*Must specify material

71 194414 Nut, suction tube tting

77 003039 Hose Barb 1/2" x 3/8"

79 194410SS Pin, narrow interlock

80 194415 Twistlock

83 190741 Shaft seal spacer

O-ring

O-ring

O-ring

O-ring, inner cylinder, lower end

O-ring, outer cylinder, lower end

English:22

011082 17, 44

011083 17, 44, 52

011084 17, 37, 44, 64

011085 10, 11, 12, 13, 71,

77, 80

011087 10, 11, 13, 17, 37,

44, 52, 64, 65, 71,

77, 79, 80

011088 7, 10, 11, 12, 13,

14, 15, 16, 17, 25,

27, 37, 44, 52, 61,

64, 65, 66, 71, 77,

79, 80, 83

011662S 9

32

011764 (EPDM)

LOWER END INJECTOR PARTS 10%:

212017

194004

190741

010016

194309

195729

195790

194406

194405

194410

25

194310

27

212005

212005

212025

71

011453

17

83

14

52

7

64

61

66

37

65

79

12

80

13

10

11

77

194418

194415

194413

194416

194414

003039

011452

212120

011025

011018

15

16

44

English:23

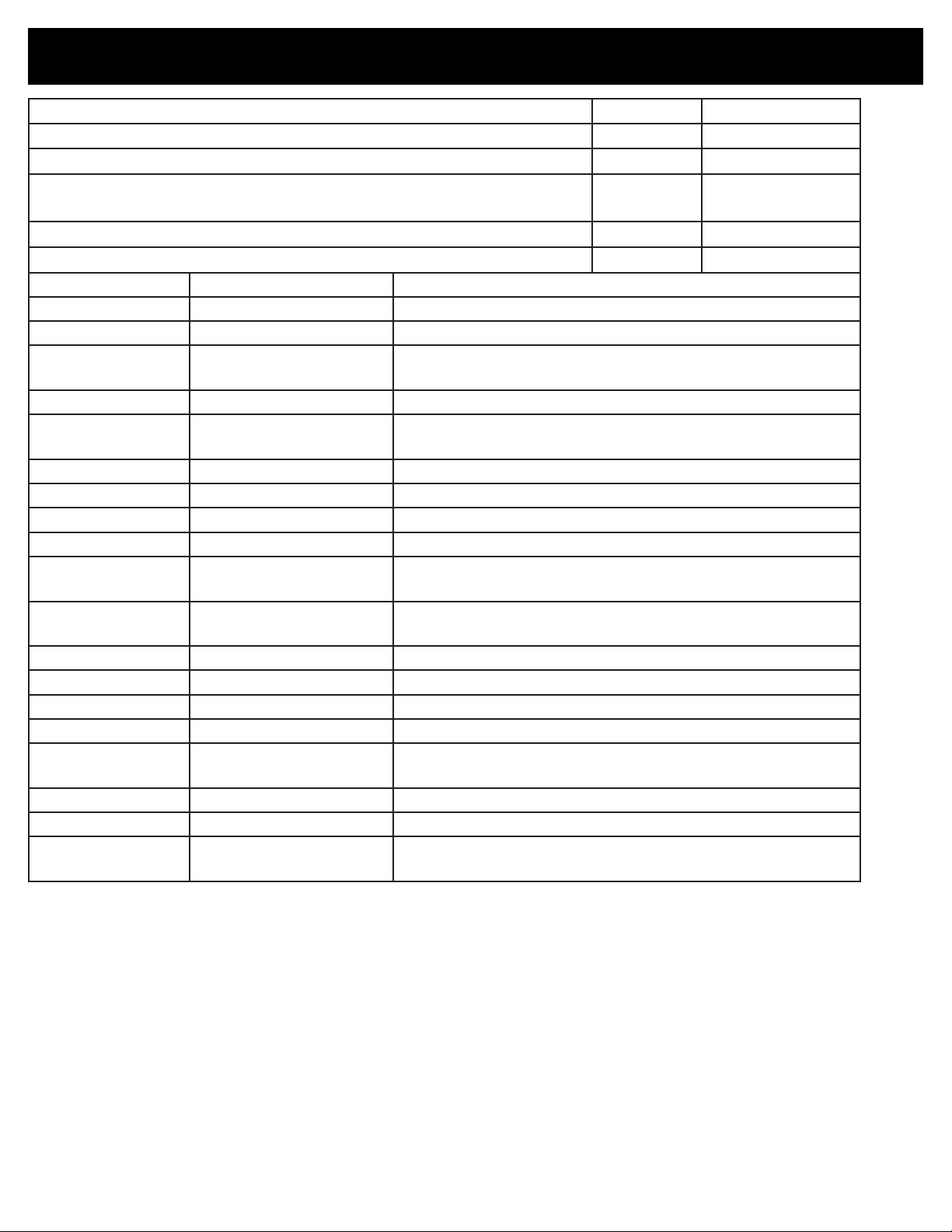

LOWER END INJECTOR & WEAR PARTS KITS 20%:

Description of Kit Part # Manual Reference

Kit A – Wear Parts Kit (dosage piston, o-rings)

Kit B – Hose Kit

Kit C – Wear Parts Kit (Kit A, o-rings)

Kit H – Motor Piston Assy (upper end kit, excluding knob & shaft)

Kit M – Mounting Bracket Kit (mounting bracket, 4 hex caps & nuts)

Manual Reference Part # Description of Part

7 011913P Ratio adjuster

15 194004 Seal retainer, o-ring

17 212005

*Must specify material

44 195909 Dosage Piston

45 212006

*Must specify material

51 011904 Shaft, upper

53 194344 Klipring

60 011849M Hose Kit

61 195851 Outer Cylinder

66 212228

*Must specify material

68 212002

*Must specify material

72 195850 Adapter

73 195855 Dosage Piston Guide

79 195911 Ratio Locking Pin

83 190741 Shaft seal spacer

91 212518

*Must specify material

92 195861 Shaft Cap

93 193003 Capscrew 10-32 x 1/2" SS Hex Head

94 212004

*Must specify material

O-ring

Oring, Adapter, Dosage Piston Guide

O-ring, outer cylinder, lower end

O-ring, Adapter, Lower Housing

Oring, Dosage Piston Guide

Oring, Ratio Adjuster

011105 17, 44, 45

011849M 60

011106 7, 17, 44, 45, 66,

68, 94

011662UPS 9

011732 54, 55

English:24

LOWER END INJECTOR PARTS 20%:

61

60

51

17

53

83

15

68

72

44

45

73

91

92

93

7

94

66

79

011849M (Kit)

212004

194344

194343

194342

195860

190741

194004

195850

195855

195861

193003

011913P

195911

195851

195909

011904

212010

212005

212002

212006

212518

212228

English:25

WARRANTY:

The Dosmatic Warranty

We believe that we make the best and most reliable water-driven injectors available. Therefore, our war-

ranty reects our condence. We will back our units with the best guarantee available.

Dosmatic will provide for replacement of all parts proven to be defective in material or workmanship from

the date of purchase for the following time periods:

3 years - The cover and body are warranted to be free from defects in materials and workmanship for

THREE YEARS from date of purchase, or we’ll replace them free of charge.

2 years - The water motor is warranted to be free from defects in materials and workmanship for

TWO YEARS from date of purchase, or we’ll replace it free of charge.

1 year - The lower end (chemical pump) is guaranteed for ONE YEAR, or we’ll replace it free of charge.

Your only responsibility is ordinary maintenance.

*Note: (Your only responsibility is ordinary maintenance - ltering incoming water and solution and replacing the o-ring and dosage piston when worn).

Return the unit to the distributor or to Dosmatic’s manufacturing facility, freight prepaid. Upon inspection,

the unit will be repaired or replaced at Dosmatic’s option free of charge, if found to be defective in material

or workmanship and will be returned freight prepaid.

This warranty only covers circumstances where the part has failed due to defects caused by the manufac-

turing process. This warranty is not valid if the defects are found to be due to the product’s misuse, lack of

maintenance, defective installation, freezing, water hammer, misuse or abuse or unwanted side effects due

to the chemicals you choose to inject. Possible warranty issues may arise if injector body is disassembled.

If you suspect you are having a problem in the motor piston assembly or inside the body please contact

Dosmatic or any accredited warranty station to arrange to send the injector in to be evaluated and/or repaired. Before using any aggressive chemicals, please visit www.dosmatic.com to conrm chemical com-

patibility or contact your nearest distributor.

There is no warranty expressed or implied relating in any way to products used in conjunction with Dosmatic USA/International, Inc. products.

Dosmatic or authorized distributor shall no be liable for incidental or consequential damage, such as any

economic loss, resulting from breach of this written warranty or implied warranty. There are no warranties,

expressed or implied, which extend beyond those described above.

English:26

WARRANTY & LOCATIONS:

Dosmatic Europe S.A.R.L.

20 Route de Taillefer

33450 Montussan

(Bordeaux) France

Tel: +33 (0) 5 57 97 13 13

Fax: +33 (0) 5 57 97 10 19

Email: info@dosmatic-europe.com

Dosmatic Australia~New Zealand

P.O. Box 9074

Wyoming, NSW 2250 Australia

Tel: +61 (0) 2 43 29 09 05

Fax: +61 (0) 2 43 29 09 04

Mb: (61) 418 607 156

Email: doug.rowe@dosmatic-anz.com.au

Dosmatic Japan

Kakamigahara City,504 Japan

Tel: +81 (0) 583 83 0505

--

Fax: +81 (0) 583 83 1230

Email: hytem@mx2.ne.jp

Dosmatic Asia Co., Ltd.

861/8 T.I.T. Tower Rm. 1703

Satupradit Rd.

Bangkok, Thailand 10120

Tel: +66 (0) 26 74 97 58

Fax: +66 (0) 26 74 97 59

Email: infor@dosmaticasia.com

Lerenveld 14

Lint 2547 Belgium

Tel: +32 3 488 7371

Fax: +32 3 488 0227

Email: jozef.stolck@dosmatic-benelux.be

Dosmatic Latin America

Tel: +54 11 4115 1235

Fax: +54 11 4115 1481

Email: gpadin@dosmaticla.com.ar

Dosmatic Benelux

Loria 398 , 4º Piso Of. 16

Lomas De Zamora

CP B1832 IXH

Provincia de Buenos Aires , Argentina

2-10 Techno Plaza

Dosmatic U.S.A./International, Inc.

1230 Crowley Circle

Carrollton, TX USA 75006

Tel: (972) 245-9765

+1 (800) 344-6767 (USA & Canada)

Email: info@dosmatic.com

Fax: (972) 245-9000

www.dosmatic.com

To return a unit for repair:

1. Thoroughly rinse all chemical solution from the lower end of the unit.

2. Drain the water from the upper end of the injector, leaving a small amount so that the seals do not dry out.

3. If possible, identify the chemical solution injected and include a copy of the chemical manufacturer’s Material

Safety Data Sheet for each chemical injected.

4. All claims for warranty repair must include a copy of the original invoice listing the serial number of the injector

to be repaired.

5. With each injector returned, please ll out the return form in this manual.

6. If returning to Dosmatic, ship to:

Dosmatic U.S.A.

1230 Crowley Circle

Carrollton, TX 75006

7. For the name of your nearest Service Center, call us toll free at (800) 344-6767 or at (972) 245-9765.

8. There are no warranties which extend beyond those described above.

English:27

Loading...

Loading...