Page 1

2100, 2200 & 6200 Series

Center Mount Drive Package

for Standard Load 60 Hz

Parallel Shaft Gearmotors

Setup, Operation & Maintenance Manual

DORNER MFG. CORP. INSIDE THE USA OUTSIDE THE USA

P.O. Box 20 • 975 Cottonwood Ave. TEL: 1-800-397-8664 TEL: 262-367-7600

Hartland, WI 53029-0020 USA FAX: 1-800-369-2440 FAX: 262-367-5827

For other service manuals visit our website at:

www.dorner.com/service_manuals.asp

851-424 Rev. D

Page 2

Table of Contents

IMPORTANT

Introduction ......................................................................... 2

Warnings − General Safety ................................................. 3

Product Description ............................................................. 4

Specifications ...................................................................... 5

Installation ........................................................................... 7

Required Tools................................................................. 7

Mounting.......................................................................... 7

Preventive Maintenance and Adjustment............................ 9

Required Tools................................................................. 9

Introduction

Some illustrations may show guards

removed. Do NOT operate equipment without

guards.

Upon receipt of shipment:

• Compare shipment with packing slip. Contact factory

regarding discrepancies.

• Inspect packages for shipping damage. Contact carrier

regarding damage.

• Accessories may be shipped loose. See accessory instructions for installation.

Timing Belt Tensioning.................................................... 9

Timing Belt Replacement............................................... 10

Drive or Driven Pulley Replacement ............................. 11

Gear Motor Replacement ............................................... 11

Service Parts....................................................................... 14

Notes .................................................................................. 15

Return Policy...................................................................... 16

Dorner 2100 and 2200 Series conveyors are covered by the

following patent numbers: 5131529, 5174435, and

corresponding patents and patent applications in other

countries.

Dorner 6200 Series conveyors are covered by patent number

5174435 and corresponding patents and patent applications

in other countries.

Dorner’s Limited Warranty applies.

Dorner reserves the right to make changes at any time

without notice or obligation.

Dorner has convenient, pre−configured kits of Key Service

Parts for all conveyor products. These time saving kits are

easy to order, designed for fast installation, and guarantee

you will have what you need when you need it. Key Parts

and Kits are marked in the Service Parts section of this

manual with the Performance Parts Kits logo .

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

Dorner Mfg. Corp. 2 851-424 Rev. D

Page 3

Warnings − General Safety

A

A

A

A

A

A

A

WARNING

The safety alert symbol, black triangle with

white exclamation, is used to alert you to

potential personal injury hazards.

DANGER

Climbing, sitting, walking or riding on

conveyor will cause severe injury.

KEEP OFF CONVEYORS.

DANGER

Do NOT OPERATE CONVEYORS IN AN

EXPLOSIVE ENVIRONMENT.

WARNING

WARNING

Exposed moving parts can cause severe

injury.

REPLACE ALL GUARDS BEFORE RUNNING

CONVEYOR.

WARNING

Dorner cannot control the physical

installation and application of conveyors.

Taking protective measures is the

responsibility of the user.

When conveyors are used in conjunction

with other equipment or as part of a multiple

conveyor system, CHECK FOR POTENTIAL

PINCH POINTS and other mechanical

hazards before system start-up.

Exposed moving parts can cause severe

injury.

LOCK OUT POWER before removing guards

or performing maintenance.

WARNING

Gearmotors may be HOT.

DO NOT TOUCH Gearmotors.

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

851-424 Rev. D 3 Dorner Mfg. Corp.

Page 4

Product Description

Refer to Figure 1 for typical components. Figure 1

AConveyor

B Mounting Bracket

C Gearmotor

D Timing Belt Tensioner

ECover

F Timing Belt

GDrive Pulley

H Driven Pulley

E

A

H

B

F

D

C

G

Figure 1

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

Dorner Mfg. Corp. 4 851-424 Rev. D

Page 5

Gearmotor Mounting Package Models:

Example:

2 M 1 P S WW A 32 32

Driven Pulley (see Tables 2 & 3)

Drive Pulley (see Tables 2 & 3)

Mount Position = A or D

(see detail to the right)

Conveyor Width Reference*

Gearmotor Type: S = Standard Load, H = Heavy Load

Output Shaft Type = Parallel

Mount Style: 1 = Type 1, Veritical Mount;

2 = Type 2, Bottom Mount

Language Code = US English

2 = 2100 & 2200 Series Conveyor

6 = 6200 Series Conveyor

Specifications

A

D

* See “Ordering and Specifications” Catalog for details.

Table 1: Gearmotor Specifications

Single Phase Three Phase DC Variable Speed

Output Power 0.17 hp (0.13 kw) 0.25 hp (0.19 kw)

Input Voltage 115 Volts A.C. 230 Volts A.C. 130 Volts D.C.

Input Frequency 60 Hz N/A

Input Current 1.9 Amperes 1.2 Amperes 1.8 Amperes

Motor RPM 1725 2500

Gearmotor Ratios 5:1, 10:1, 20:1, 30:1, 60:1, 180:1

Frame Size NEMA 42 CZ

Motor Type Totally enclosed, Fan-cooled Totally enclosed, Non−ventilated

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

851-424 Rev. D 5 Dorner Mfg. Corp.

Page 6

Specifications

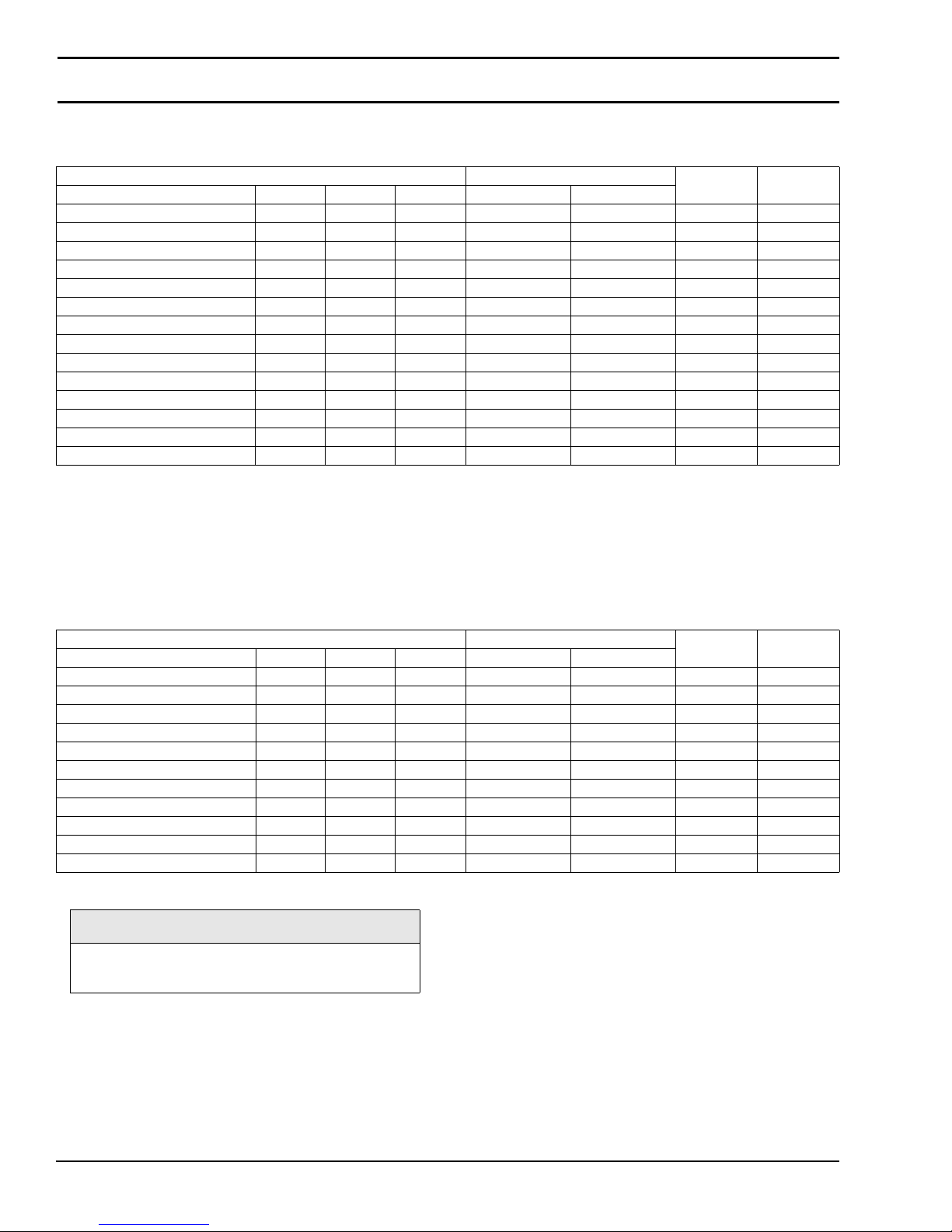

Table 2: Belt Speeds for Standard Load Fixed Speed Parallel Shaft 60 Hz

Gearmotors

Standard Load Gearmotors Top and Bottom Mount Package

Part Number RPM In-lb N-m Ft/min M/min

62M180PS411F(n) 10 341 38.5 2 0.6 22 32

62M180PS411F(n) 10 341 38.5 3 0.9 32 32

62M060PS4(vp)F(n) 29 270 30.5 6 1.8 19 32

62M060PS4(vp)F(n) 29 270 30.5 10 3.0 32 32

62M030PS4(vp)F(n) 58 135 15.3 20 6.1 32 32

62M020PS411F(n) 86 90 10.2 30 9.1 32 32

62M020PS411F(n) 86 90 10.2 45 13.7 48 32

62M010PS4(vp)F(n) 173 45 5.1 61 18.6 32 32

62M010PS4(vp)F(n) 173 45 5.1 91 27.7 48 32

62M005PS411F(n) 345 25 2.8 121 36.9 32 32

62M005PS411F(n) 345 25 2.8 154 46.9 28 22

62M005PS411F(n) 345 25 2.8 181 55.2 48 28

62M005PS411F(n) 345 25 2.8 208 63.4 48 28

62M005PS411F(n) 345 25 2.8 264 80.5 48 22

(vp) = voltage and phase

11 = 115 V, 1-phase

23 = 208 – 230/460 V, 3-phase

(n) = Reversing Capability

N = No reversing switch

R = With reversing switch (115V, 1 phase only)

Drive

Pulley

Driven

Pulley

Table 3: Belt Speeds for Standard Load Variable Speed Parallel Shaft DC

Gearmotors

Standard Load Gearmotors Belt Speed

Part Number RPM In-lb N-m Ft/min M/min

62M180PSD3DEN 14 341 38.5 0.4 − 3.4 0.1 − 1.0 22 32

62M180PSD3DEN 14 341 38.5 0.6 − 4.9 0.2 − 1.5 32 32

62M060PSD3DEN 42 270 30.5 1.0 – 9 0.3 − 2.6 19 32

62M060PSD3DEN 42 270 30.5 1.8 – 15 0.5 – 4.5 32 32

62M030PSD3DEN 83 135 15.3 3.5 − 29 1.1 − 93232

62M020PSD3DEN 125 90 10.2 5.3 – 44 1.6 – 13 32 32

62M010PSD3DEN 250 72 8.1 10 – 88 3.2 – 27 32 32

62M010PSD3DEN 250 72 8.1 18 – 150 5.5 – 46 48 28

62M005PSD3DEN 500 25 2.8 21 – 76 6.4 – 54 32 32

62M005PSD3DEN 500 25 2.8 27 – 224 7.3 – 61 28 22

62M005PSD3DEN 500 25 2.8 31 – 255 9.3 – 78 32 22

Drive

Pulley

Driven

Pulley

NOTE

For belt speed other than those listed, contact

factory for details.

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

Dorner Mfg. Corp. 6 851-424 Rev. D

Page 7

Installation

A

Required Tools

• Hex key wrenches:

2 mm, 2.5 mm, 3 mm, 5 mm

• Straight edge

• Torque wrench

Mounting

WARNING

Exposed moving parts can cause severe

injury.

LOCK OUT POWER before removing guards

or performing maintenance.

NOTE

Type 1 mounting package shown below left

(Figure 2). Type 2 mounting package shown

below right (Figure 2).

Figure 2

1. Gather components (Figure 3)

Figure 3

I

L

J

M

O

N

K

P

Figure 3

NOTE

Type 1 mounting package shown (Figure 3),

Type 2 mounting package similar.

2. Locate drive output shaft (Figure 4, item S) and remove

two (2) screws (R).

Figure 4

Typ e 1

Figure 2

Installation Component List:

I Mount Assembly

J Drive Pulley

K Cover

L M4 Socket Head Screws (4x)

M Driven Pulley

NKey

O M6 Socket Head Screws (2x)

P Timing Belt

S

R

Typ e 2

Figure 4

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

851-424 Rev. D 7 Dorner Mfg. Corp.

Page 8

Installation

A

3. Attach mount assembly (Figure 5, item I) with screws

(O). Install long screws on bottom. Tighten screws to 80

in-lb (9 Nm.).

Figure 5

I

Figure 7

M

U

O

O

Figure 5

WARNING

Drive shaft keyway may be sharp.

HANDLE WITH CARE.

4. Install key (Figure 6, item N).

Figure 6

T

J

Figure 7

7. Depending on direction of conveyor belt travel (1 or 2

of Figure 8), position belt tensioner (V) as shown.

Tension belt to obtain .125” (3 mm) deflection for 1.0 lb

(456 grams) of force at belt mid-point (W). Tighten

tensioner screw to 103 in-lb (12 Nm).

Figure 8

2

V

W

1

W

N

M

P

J

Figure 6

5. Wrap timing belt (P) around driven pulley (M) and drive

pulley (J). Install driven pulley (M) onto conveyor shaft.

6. Using a straight edge (Figure 7, item T), align driven

pulley (M) with drive pulley (J). Tighten driven pulley

set screws (U).

Figure 8

8. Install cover (Figure 9, item K) with four (4) screws (L).

Tighten screws to 35 in-lb (4 Nm).

Figure 9

L

L

K

Figure 9

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

Dorner Mfg. Corp. 8 851-424 Rev. D

Page 9

Preventive Maintenance and Adjustment

A

Required Tools

• Hex key wrenches:

2 mm, 2.5 mm, 3 mm, 5 mm

• Adjustable wrench (for hexagon head screws)

• Straight edge

• Torque wrench

Timing Belt Tensioning

WARNING

Exposed moving parts can cause severe

injury.

LOCK OUT POWER before removing guards

or performing maintenance.

1. Remove four (4) screws (Figure 10, item L) and remove

cover (K).

Figure 10

3. Depending on direction of conveyor belt travel (1 or 2

of Figure 12), position belt tensioner (V) as shown.

Tension belt to obtain .125” (3 mm) deflection for 1.0 lb

(456 grams) of force at belt mid-point (W). Tighten

tensioner screw to 103 in-lb (12 Nm).

Figure 12

2

V

W

1

W

Figure 12

4. Install cover (Figure 10, item K) with four (4) screws

(L). Tighten screws to 35 in-lb (4 Nm).

L

L

K

Figure 10

2. Loosen tensioner (Figure 11, item V).

Figure 11

V

Figure 11

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

851-424 Rev. D 9 Dorner Mfg. Corp.

Page 10

Preventive Maintenance and Adjustment

A

Timing Belt Replacement

Figure 14

2

1

WARNING

Exposed moving parts can cause severe

injury.

LOCK OUT POWER before removing guards

or performing maintenance.

1. Remove four (4) screws (Figure 10, item L) and remove

cover (K).

2. Loosen tensioner (Figure 11, item V).

3. Remove timing belt (Figure 13, item P).

NOTE

If timing belt does not slide over pulley flange,

loosen driven pulley set screws (Figure

13, item U) and remove pulley (M) with belt

(P). For re-installation, see steps 5 and 6 on

page 8.

Figure 13

U

V

W

W

Figure 14

6. Install cover (Figure 15, item K) with four (4) screws

(L). Tighten screws to 35 in-lb (4 Nm).

Figure 15

L

L

M

P

Figure 13

4. Install new timing belt.

5. Depending on direction of conveyor belt travel (1 or 2

of Figure 14), position belt tensioner (V) as shown.

Tension belt to obtain .125” (3 mm) deflection for 1.0 lb

(456 grams) of force at belt mid-point (W). Tighten

tensioner screw to 103 in-lb (12 Nm).

K

Figure 15

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

Dorner Mfg. Corp. 10 851-424 Rev. D

Page 11

Preventive Maintenance and Adjustment

A

A

A

Drive or Driven Pulley Replacement

WARNING

Exposed moving parts can cause severe

injury.

LOCK OUT POWER before removing guards

or performing maintenance.

1. Complete steps 1 through 3 of “Timing Belt

Replacement” section on page 10.

2. Loosen set screws and remove drive or driven pulley.

NOTE

If drive pulley (Figure 20, item J) is replaced,

wrap timing belt around drive pulley and

complete step 3.

3. Complete steps 5 through 8 of “Installation” section on

page 8.

Gear Motor Replacement

WARNING

2. For three phase motor:

a. Loosen terminal box screws (Figure 16, item AF)

and remove cover (AG).

Figure 16

AF

AF

b. Record incoming wire colors on red, black and blue

leads. Loosen wire nuts and remove incoming

wires.

c. Loosen cord grip and remove cord.

3. For DC variable speed motor, unplug motor cord at

disconnect (Figure 17, item AH).

Figure 17

AG

Figure 16

AH

Exposed moving parts can cause severe

injury.

LOCK OUT POWER before removing guards

or performing maintenance.

DANGER

Hazardous voltage will cause severe injury or

death.

LOCKOUT POWER BEFORE before wiring.

1. For single phase motor, unplug power cord from outlet.

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

851-424 Rev. D 11 Dorner Mfg. Corp.

Figure 17

4. Remove four (4) screws (Figure 18, item L) and remove

cover (K).

Figure 18

L

L

K

Figure 18

Page 12

Preventive Maintenance and Adjustment

5. Loosen tensioner (Figure 19, item V).

Figure 19

V

Figure 19

6. Loosen drive pulley set screws (Figure 20, item X).

Remove drive pulley (J) and timing belt (P).

Figure 20

P

8. Remove four (4) adapter plate screws (Figure

22, item AI). Remove adapter plate (AJ).

Figure 22

AJ

AI

AI

Figure 22

9. Install new gearmotor to adapter plate (AJ) and

mounting bracket (Figure 23, item I). Tighten screws

(Figure 21, item Q) to 103 in-lb (12 Nm).

10. Wrap timing belt (Figure 23, item P) around drive

pulley (J) and driven pulley (M). Attach drive pulley (J)

to drive shaft.

Figure 23

J

X

Figure 20

7. Remove four (4) gearmotor mounting screws (Figure

21, item Q). Remove gearmotor with adapter plate.

Figure 21

I

Q

M

I

P

J

X

Figure 23

Q

Figure 21

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

Dorner Mfg. Corp. 12 851-424 Rev. D

Page 13

Preventive Maintenance and Adjustment

11. Using a straight edge (Figure 24, item T), align drive

pulley (J) with driven pulley (M). Tighten drive pulley

set screws (X).

Figure 24

M

T

X

J

Figure 26

L

L

K

Figure 24

12. Depending on direction of conveyor belt travel (1 or 2

of Figure 25), position belt tensioner (V) as shown.

Tension belt to obtain .125” (3 mm) deflection for 1.0 lb

(456 grams) of force at belt mid-point (W). Tighten

tensioner screw to 103 in-lb (12 Nm).

Figure 25

2

V

W

1

W

Figure 25

13. Install cover (Figure 26, item K) with four (4) screws

(L). Tighten screws to 35 in-lb (4 Nm).

Figure 26

14. Replace wiring:

• For a single phase motor, reverse step 1 on page 11.

• For a three phase motor, reverse step 2, on page 11.

• For a DC variable speed motor, reverse step 3 on page 11.

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

851-424 Rev. D 13 Dorner Mfg. Corp.

Page 14

Service Parts

NOTE

For replacement parts other than those shown in this section, contact an authorized Dorner Service Center

or the factory. Key Service Parts and Kits are identified by the Performance Parts Kits logo . Dorner

recommends keeping these parts on hand.

Item Part Number Part Description

1 62M180PS411FN Motor, 0.08hp (0.06Kw), 10

RPM, 115VAC, 60Hz, 1-Phase

62M180PS411FR Motor, 0.08hp (0.06Kw), 10

RPM, 115VAC, 60Hz, 1-Phase

with reversing switch

62M060PS411FN Motor, 0.17hp (0.13Kw), 29

RPM, 115VAC, 60Hz, 1-Phase

62M060PS411FR Motor, 0.17hp (0.13Kw), 29

RPM, 115VAC, 60Hz, 1-Phase

with reversing switch

62M060PS423FN Motor, 0.25hp (0.19Kw), 29

RPM, 230VAC, 60Hz, 3-Phase

62M030PS411FN Motor, 0.17hp (0.13Kw), 58

RPM, 115VAC, 60Hz, 1-Phase

62M030PS411FR Motor, 0.17hp (0.13Kw), 58

RPM, 115VAC, 60Hz, 1-Phase

with reversing switch

62M030PS423FN Motor, 0.25hp (0.19Kw), 58

RPM, 230VAC, 60Hz, 3-Phase

62M020PS411FN Motor, 0.17hp (0.13Kw), 86

RPM, 230VAC, 60Hz, 1-Phase

62M020PS411FR Motor, 0.17hp (0.13Kw), 86

RPM, 115VAC, 60Hz, 1-Phase

with reversing switch

62M010PS411FN Motor, 0.17hp (0.13Kw), 173

RPM, 115VAC, 60Hz, 1-Phase

62M010PS411FR Motor, 0.17hp (0.13Kw), 173

RPM, 115VAC, 60Hz, 1-Phase

with reversing switch

62M010PS423FN Motor, 0.25hp (0.19Kw), 173

RPM, 230VAC, 60Hz, 3-Phase

62M005PS411FN Motor, 0.17hp (0.13Kw), 345

RPM, 230VAC, 60Hz, 1-Phase

62M005PS411FR Motor, 0.17hp (0.13Kw), 345

RPM, 115VAC, 60Hz, 1-Phase

with reversing switch

62M180PSD3DEN Motor, 0.12hp (0.09Kw), 14

RPM, 130VDC

62M060PSD3DEN Motor, 0.25hp (0.19Kw), 42

RPM, 130VDC

62M030PSD3DEN Motor, 0.25hp (0.19Kw), 83

RPM, 130VDC

62M020PSD3DEN Motor, 0.25hp (0.19Kw), 125

RPM, 130VDC

62M010PSD3DEN Motor, 0.25hp (0.19Kw), 250

RPM, 130VDC

62M005PSD3DEN Motor, 0.25hp (0.19Kw), 500

RPM, 130VDC

Item Part Number Part Description

2 814-103 Timing Belt, 15mm W x

385mm L

814-100 Timing Belt, 15mm W x

400mm L

814-096 Timing Belt, 15mm W x

814-105 Timing Belt, 15mm W x

3 802-046 Tensioner Bearing

4 450365MP Driven Pulley, 19 Tooth

450366MP Driven Pulley, 22 Tooth

450367MP Driven Pulley, 28 Tooth

450368MP Driven Pulley, 32 Tooth

5 980422M Square Key, 4 mm x 22 mm

6 450434 Drive Pulley, 22 Tooth

450435 Drive Pulley, 28 Tooth

450436 Drive Pulley, 32 Tooth

450437 Drive Pulley, 44 Tooth

450438 Drive Pulley, 48 Tooth

450439 Drive Pulley, 60 Tooth

7 912−078 Square Key, .188” x .75” Lg

Figure 27

5

4

425mm L

460mm L

(2x)

2

3

1

6

7

Figure 27

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

Dorner Mfg. Corp. 14 851-424 Rev. D

Page 15

Notes

2100, 2200 & 6200 Series Center Mount Drive Package for Standard Load 60 Hz Parallel Shaft Gearmotors

851-424 Rev. D 15 Dorner Mfg. Corp.

Page 16

Return Policy

Returns must have prior written factory authorization or they will not be accepted. Items that are returned to Dorner without

authorization will not be credited nor returned to the original sender. When calling for authorization, please have the

following information ready for the Dorner factory representative or your local distributor:

1. Name and address of customer.

2. Dorner part number(s) of item(s) being returned.

3. Reason for return.

4. Customer's original order number used when ordering the item(s).

5. Dorner or distributor invoice number.

A representative will discuss action to be taken on the returned items and provide a Returned Goods Authorization number

for reference.

There will be a return charge on all new undamaged items returned for credit where Dorner was not at fault. Dorner is not

responsible for return freight on such items.

Conveyors and conveyor accessories

Standard catalog conveyors 30%

MPB Series, cleated and specialty belt conveyors 50%

7400 & 7600 Series conveyors non-returnable items

Engineered special products case by case

Drives and accessories 30%

Sanitary stand supports non-returnable items

Par ts

Standard stock parts 30%

MPB, cleated and specialty belts non-returnable items

Returns will not be accepted after 60 days from original invoice date.

The return charge covers inspection, cleaning, disassembly, disposal and reissuing of components to inventory.

If a replacement is needed prior to evaluation of returned item, a purchase order must be issued. Credit (if any) is issued

only after return and evaluation is complete.

Dorner has representatives throughout the world. Contact Dorner for the name of your local representative. Our Technical

Sales, Catalog Sales and Service Teams will gladly help with your questions on Dorner products.

For a copy of Dorner's Warranty, contact factory, distributor, service center or visit our website at www.dorner.com.

For replacement parts, contact an authorized Dorner Service Center or the factory.

Dorner Mfg. Corp. reserves the right to change

or discontinue products without notice. All

products and services are covered in

accordance with our standard warranty. All

rights reserved. © Dorner Mfg. Corp. 2006

851-424 Rev. D Printed in U.S.A.

DORNER MFG. CORP.

975 Cottonwood Ave., PO Box 20

Hartland, WI 53029-0020 USA

USA

TEL 1-800-397-8664 (USA)

FAX 1-800-369-2440 (USA)

Internet: www.dorner.com

Outside the USA:

TEL 1-262-367-7600

FAX 1-262-367-5827

Loading...

Loading...