1

Thank you for purchasing and using the DORNA DLM1 series inverters. Please read the operation

manual carefully before putting the inverter to use so as to correctly install and operate the inverter

and ensure safety. Please keep the operation manual handy for future reference, maintenance,

inspection and repair.

The inverter must be installed, tested and commissoned by specialized personnels. The marks of

and other symbols in the manual remind you of the safety precautions

during the handling, installation, running and inspection. Please follow

these instructions to make sure the safe use of the inverter. In case of any doubt please contact our

local agent for consultation. Our professional persons are willing and ready to serve you.

The manual is subject to change without notice.

Danger indicates wrong use may kill or injure people.

!Caution indicates wrong use may damage the inverter or mechanical system.

Danger

!Caution

2

Danger

● Be sure to turn off the input power supply before wiring.

● Do not touch any internal electrical circuit or component when the charging lamp is still on

after the AC power supply is disconnected, which means the inverter still has high voltage inside and

it is very dangerous.

● Do not check components and signals on the circuit boards during operations.

● Do not dissemble or modify any internal connecting cord, wiring or component of the inverter

by yourself.

● Be sure to make correct grounding connection of the earth terminal of the inverter.

● Never remodel or replace control boards and components by yourself. It may expose you to an

electrical shock or explosion, etc.

! Caution

● Do not make any voltage-withstanding test with any component inside the inverter. These

semi-conductor parts are subject to the damage of high voltage.

● Never connect the AC main circuit power supply to the output terminals U.V W of the inverter.

●The main electric circuit boards of CMOS and IC of the inverter are subject to the effect and

damage of static electricity. Don’ t touch the main circuit boards.

● Installation, testing and maintenance must be performed by qualifed professional personnel.

● The inverter should be discarded as industrial waste. It is forbidden to burn it

3

Contents

Ⅰ.Safety Precautions ............................................................................................................................ 4

1.1 Introduction ........................................................................................................................... 4

1.2 Before Power-up .................................................................................................................... 4

1.3 During Power-up ................................................................................................................... 6

1.4 JOG operation ....................................................................................................................... 6

1.5 During Operation .................................................................................................................. 6

Ⅱ Product Introduction and installation .............................................................................................. 8

2.1 DLM1 Series model description ........................................................................................... 8

2.2 Particular Specifcations ........................................................................................................ 9

2.3 General Specifications .......................................................................................................... 9

2.4 Storage and Installation ..................................................................................................... 11

2.5 Installation Site and Environment ..................................................................................... 11

2.6 Installation and Direction ................................................................................................... 12

Ⅲ Wiring ........................................................................................................................................... 13

3.1 Main Circuit Wiring Schematic Diagram ......................................................................... 13

3.2 Descriptions of Terminal Blocks ........................................................................................ 14

3.3 Basic Connection Diagram ................................................................................................. 15

3.4 Precautions on Wiring ........................................................................................................ 16

3.5 Optional parts...................................................................................................................... 18

Ⅳ Maintenance and Troubleshooting ................................................................................................ 19

4.1 Maintenance check Notes ................................................................................................... 19

4.2 Regular inspection program ............................................................................................... 19

4.3 Fault information and troubleshooting ............................................................................. 20

Ⅴ Instruction of the Digital Operator ................................................................................................ 23

5.1 Description of the Digital Operator ................................................................................... 23

5.2 Description of Indicator Lamp Status ............................................................................... 23

5.3 Operation Examples ........................................................................................................... 24

Ⅵ Parameter Overview...................................................................................................................... 25

Appendix 1: Function List .................................................................................................................. 53

Appendix 2: Installation Dimensions .................................................................................................. 59

Appendix 3: MODBUS Communication Protocol ............................................................................. 60

4

Ⅰ.Safety Precautions

1.1 Introduction

The inverter has been strictly and well packed before ex-work. In consideration of various

factors during the transportation special attention should be paid to the following points before

the assembly and installation. If there is anything abnormal please notify the dealer or the

relevant people of our company.

● Check if the inverter has got any damage or deformation during the transportation and handling.

● Check if there is one piece of DLM1series inverter and one user manual when unpacking it.

●Check the information on the nameplate to see if the specifications meet your order (Operating

voltage and KVA value).

● Check if there is something wrong with the innerparts, wiring and circuit board.

● Check if each terminal is tightly locked and if there is any foreign article inside the inverter.

● Check if the operator buttons are all right.

1.2 Before Power-up

!Caution

Check to be sure that the voltage of the main circuit AC power supply matches the input

voltage of the inverter.

E terminals are grounding terminals. Be sure to make correct grounding connection of the

earth terminals of the motor and the inverter for safety.

No contactor should be installed between the power supply and the inverter to be used for

starting or stopping of the inverter. Otherwise it will affect the service life of the inverter.

Danger

●R(L),S,T(N) terminals are power input terminals, never mixed with U.V.W terminals. Be sure

that the wiring of the main circuit is correct. Otherwise it will cause damages of the inverter when

the power is applied to it.

5

! Caution

Do not carry the front cover of the inverter directly when handling. It should be handled with

the base to prevent the fall-off of the front cover and avoid the dropping of the inverter, which

may possibly cause the injuries to people and the damages to the inverter.

Mount the inverter on a metal or other noncombustible material to avoid the risk of fire.

Install the inverter in a safe location avoiding high temperature, direct sunlight, humid air or

water.

Keep the inverter from the reach of children or persons not concerned. The inverter can only

be used at the places accredited by our company. Any unauthorized working environment

may have the risks of fire, gas explosion, electric shock and other incidents.

Install a heat sink or other cooling device when installing more than one inverter in the same

enclosure so that the temperature inside the enclosure is kept below 40℃ to avoid overheat

or the risk of fre.

Be sure to turn off the power supply before dissembling or assembling the operation keypanel

and fxing the front cover to avoid bad contact causing faults or non-display of the operator.

● Do not install the inverter in a space with explosive gas to avoid the risk of explosion.

● If the inverter is used at or above 1000m above seal level, the cooling effciency will be

reduced, so please run it by de-rating.

Do not install any switch component like air circuit breaker or contactor at the output of the

inverter. If any of such components must be installed because of the requirements of process

and others, it must be ensured that the inverter has no output when the switch acts. In addition,

it is forbidden to install any capacitor for improvement of power factor or any varistor against

thunder at the output. Otherwise it will cause malfunctions, tripping protection and damages

of components of the inverter. Please remove them as shown in the below diagram.

It will affect the service life of the inverter.If a contact is connected to the front end of input

of the inverter to control its starts and stops. Generally it is required to control it through

Control terminals. Special attention should be paid to its use in the case of frequent starts and

stops.

● Please use an independent power supply for the inverter. Do avoid using the common

power supply with an electrical welder and other equipment with strong disturbance. Otherwise

it will cause the protection or even damage of the inverter.

U

Inverter V

W

M

KM

X

X

6

1.3 During Power-up

Danger

● Do not plug the connectors of the inverter during the power up to avoid any surge into the

main control board due to plugging, which might cause damage to the inverter.

● Always have the protective cover in place before power up to avoid electrical shock.

1.4 JOG operation

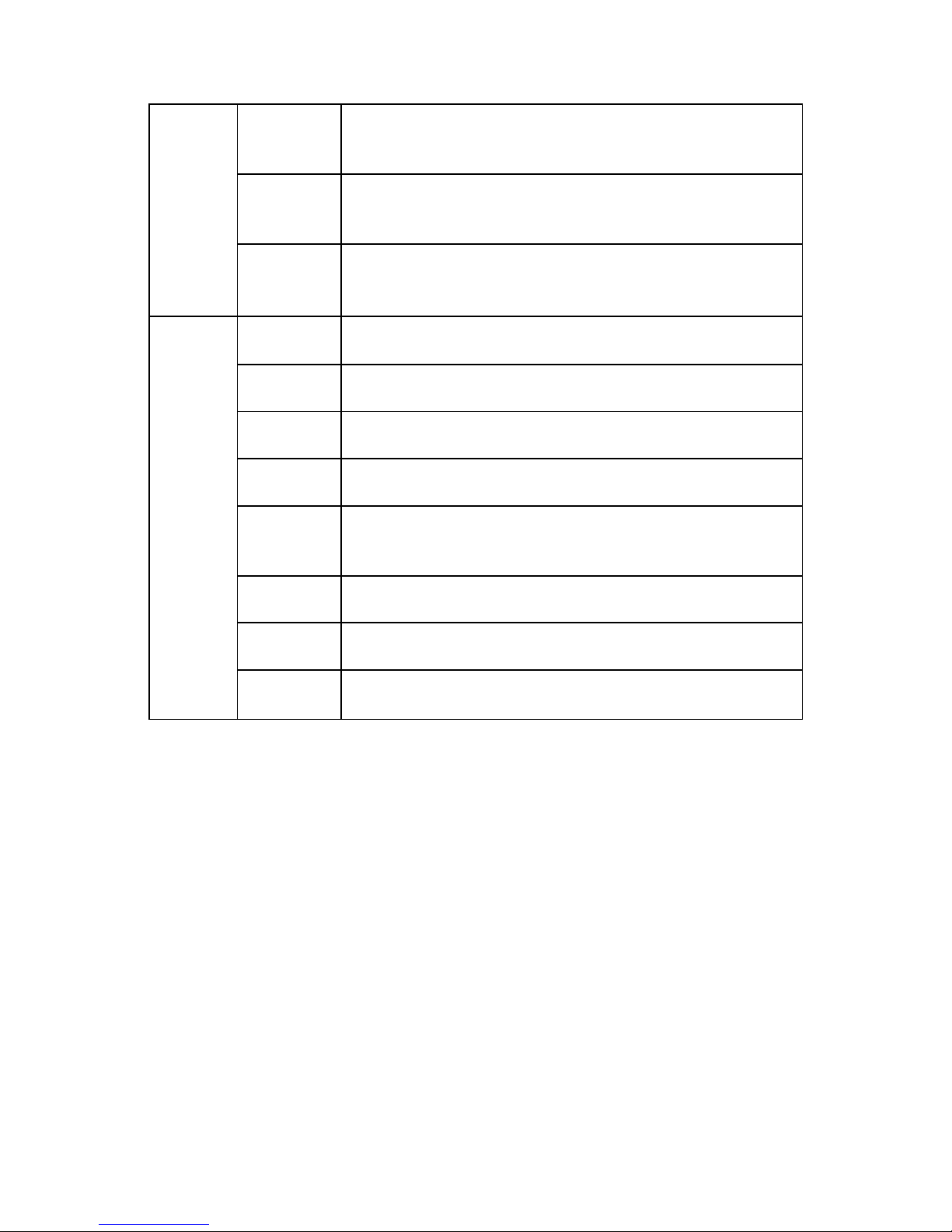

Procedures

Panel display after

operation

Pilot Lamp

Power-up

F000

FWD、STOP light

00.00

FWD、STOP light

05.00

FWD、STOP light

RUN

F05.0

FWD、RUN light and Fans

operation

STOP

F05.0

FWD、RUN light and Fans

operation

1.5 During Operation

Danger

● Never connect or disconnect the motor set while the inverter is in running. Otherwise it will

cause over-current trip and even burn up the main circuit of the inverter.

● Never remove the front cover of the inverter while the inverter is powered up to avoid any

injury of electric shock.

● Do not come close to the machine when the fault restart function is used to avoid anything

unexpected. The motor may automatically restart after its stop.

● The function of STOP Switch is only valid after setting, which is different with the use of

emergent stop switch. Please pay attention to it when using it.

7

!Caution

● Do not touch the heat braking resistor, or other heat elements. These can become very hot.

● Be sure that the motor and machine is within the applicable speed ranges before starting

operation because the inverter is quite easy to run from lower speed to higher speed.

● Do not check the signals on circuit boards while the inverter is running to avoid danger.

● Be careful when changing the inverter settings. The inverter has been adjusted and set before

ex-work. Do not adjust it wantonly. Please make proper adjustments according to the required

functions.

● Do consider the vibration, noise and the speed limit of the motor bearings and the mechanical

devices when the inverter is running at or above the frequency of 50Hz.

8

Ⅱ Product Introduction and installation

2.1 DLM1 Series model description

T:Three phase

S:Single phase

Inverter series

DLM 1-0D75 T 2 G

Inverter capacity

G: general-purpose

P: Light load

Rated input voltage:

2:220V 4:380V

7:660V/690V

Plant code

【1】

【2】

【3】

【6】

【5】

【4】

【1】 Inverter series

【2】 Plant code

【3】 Inverter capacity

Mark

Specification

Mark

Specification

Mark

Specification

DLM

M series

1

General

purpose

0D40

400W

DLB

B series

0D75

750W

DLH

H series

01D5

1.5KW

02D2

2.2KW

【4】Power phase

【5】 Rated input

voltage

【6】Inverter type

Mark

Specification

Mark

Specification

Mark

Specification

S

Single phase

2 220V

G General-purpose

T

Three phase

4 380V

P Light load

9

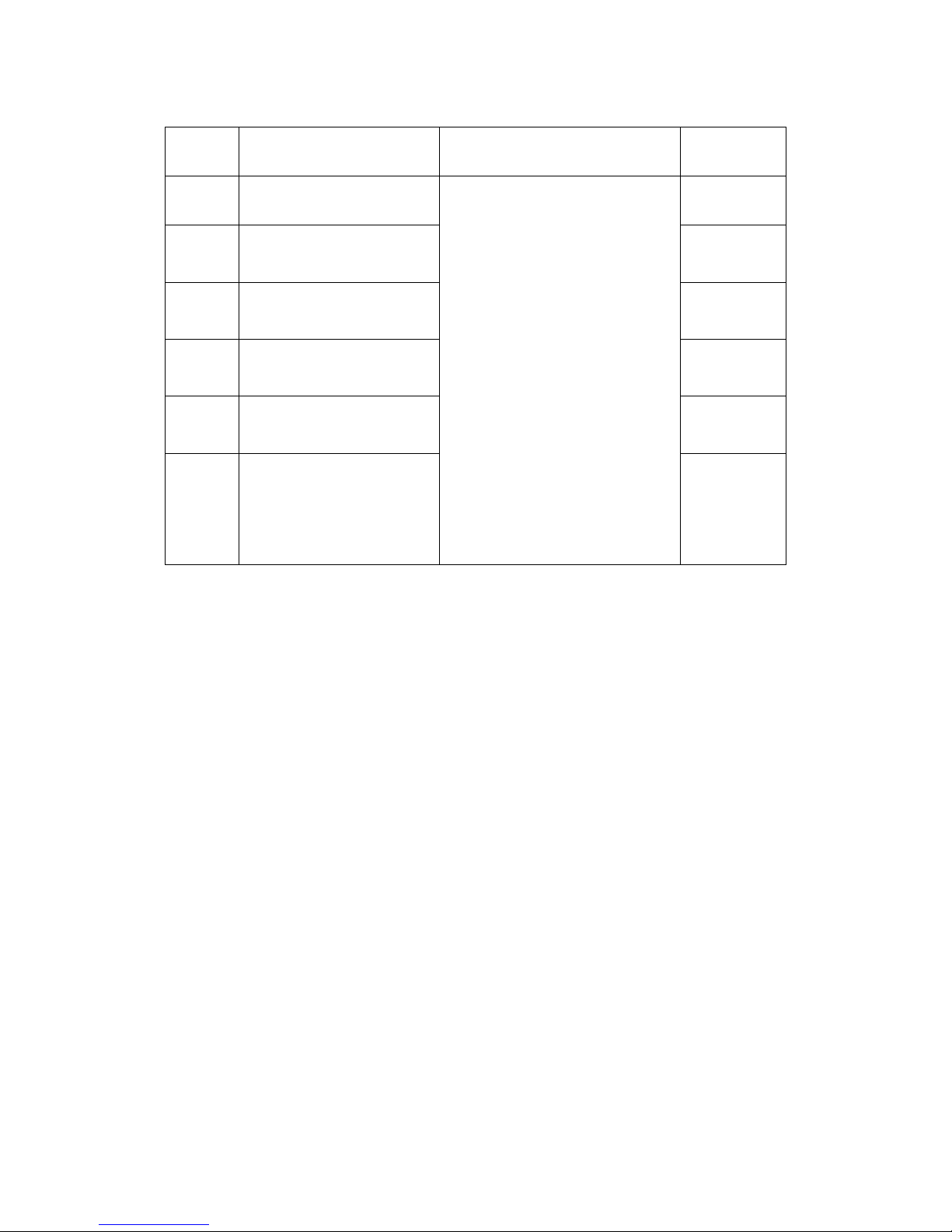

2.2 Particular Specifcations

Model

Input Voltage

Power

(KW)

Inverter

capacity(KV

A)

Output

Current

(A)

Suitable

Motor

(KW)

DLM1-0D40S2G

Single phase 220V

50Hz

0.4

1.0

2.5

0.4

DLM1-0D75S2G

Single phase 220V

50Hz

0.75

2.0

5.0

0.75

DLM1-01D5S2G

Single phase 220V

50Hz

1.5

2.8

7.0

1.5

2.3 General Specifications

Inverter Series

DLM1

Control Mode

SPWM

Input Power

330~440V for 380V power; 170~240V for 220V power

5-Digits Display &

Status Indicator

Lamp

Displaying frequency, current, revolution, voltage, counter, temperature,

forward or reserve running, and fault, etc.

Communication

RS-485

Operation

Temperature

-10~40℃

Humidity

0-95% Relative Humidity(without dew)

Vibration

Below 0.5G

Frequency

Control

Range

0.10~600.00Hz

Accuracy

Digital: 0.01%(-10~40℃), Analog: 0.1% (25±10℃)

Set

Resolution

Digital: 0.01Hz, Analog: 1‰ of Max. Operating Frequency

Output

Resolution

0.01Hz

Operator

Setting

Method

Press directly←∧ ∨ to set (or use potentiometer).

Analog

Setting

Method

External Voltage 0-5V,0-10V,4-20mA,0-20mA.

Other

Functions

Frequency lower limit, starting frequency, stopping frequency & three

skip frequencies can be respectively set.

General

Control

Ramp Control

Selectable 4-speed steps ramp-up and -down time (0.1-6500s).

V/F Curve

Set V/F curve at will

Torque

Control

Torque increase is settable by max. 10.0%. The starting torque can reach

150% at 1.0Hz.

10

Multi-Inputs

6 multi-function input terminals for 8–speed steps control, program

operation, switching of 4-speed Ramp, UP/DOWN function, counter,

external emergency stop and other functions.

Multi-

Outputs

2 multi-function output terminals for displaying of running, zero speed,

counter, external abnormity, program operation and other information

and warnings.

Other

Functions

AVR (auto voltage regulation), Deceleration stop or free-stop, DC brake,

auto reset and restart, frequency track, PLC control, traverse function,

drawing control, auto energy-savings etc.

Protection

Functions

Overload

Protection

Electronic relay protection motor

Drive (150%/1 min for constant torque; 120%/1min for fans/pumps)

FUSE

Protection

FUSE activates and motor stops.

Over-voltage

DC Voltage >400V for 220V class

DC Voltage >800V for 380V class

UnderVoltage

DC Voltage <200V for 220V class

DC Voltage <400V for 380V class

Instant Stop

and

Restart

Restarted by frequency track after instantaneous stop.

Stall

Prevention

Anti-stall during Acc/Dec run

Output End

Shorts

Electronic circuit protecting

Other

Functions

Heat sink over-heat protection, restriction of reverse running, direct start

after power on, fault reset, parameter lock, etc.

11

2.4 Storage and Installation

The inverter must be kept in its original package box before installation. Pay attention to the followings

when keeping it in storage if the inverter is not used for the time being:

● It must be stored in a dry place without rubbish or dust.

● The suitable temperature for storage is between -20℃ and +65℃.

● The relative humidity required is 0-95% without condensation.

● There is no corrosive gas or liquid in the storage ambience.

● It’ s better to lay the inverter on a rack and keep it in a proper package.

● It is better not to store the inverter for long time. Long time storage of the inverter will lead

to the deterioration of electrolytic capacity. If it needs to be stored for a long time make sure

to power it up one time within a year and the power-up time should be at least above five

hours. When powered up the voltage must be increased slowly with a voltage regulator to

the rated voltage value.

2.5 Installation Site and Environment

The inverter should be installed at the following location:

● Ambient temperature -5℃ to 40℃ with good ventilation;

● No water drop and low moisture;

● Free from direct sunshine, high temperature and heavy dust fall;

● Free from corrosive gas or liquid;

● Less dust, oil gas and metallic particles;

● Free from vibration and easy for service and inspection;

● Free from the interference of electromagnetic noise;

Attention: The ambient conditions of the inverter will affect its service life.

12

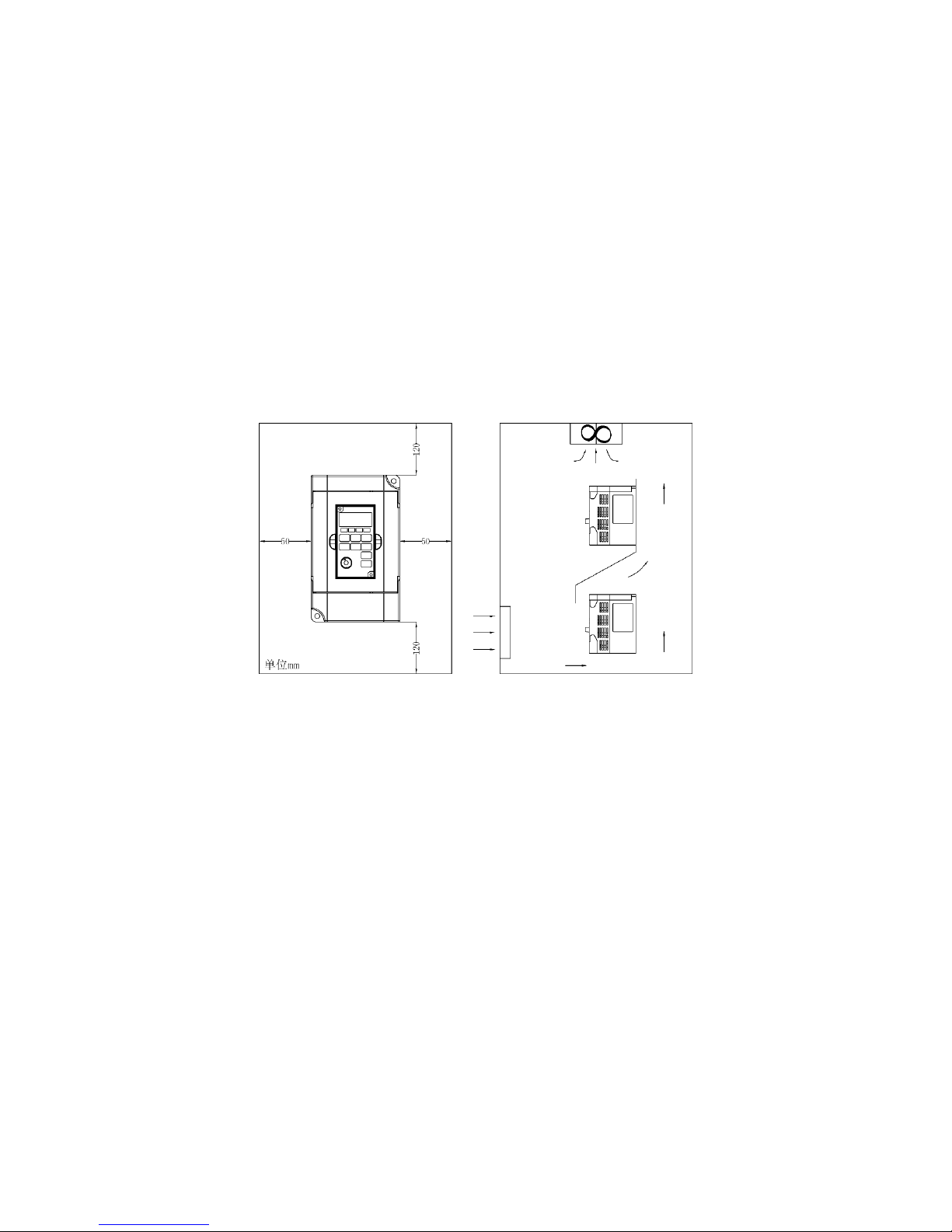

2.6 Installation and Direction

● There must be enough space left around the inverter for easy maintenance and cooling. See

Diagram;

● The inverter must be installed vertically with good ventilation for effective cooling;

● If there is any instability when installing the inverter, please put a flat board under the inverter

bottom base and install it again. If the inverter is installed on a loose surface, stress may cause

damage of parts in the main circuit so as to damage the inverter;

● The inverter should be installed on non-combustible materials, such as iron plate.

● If several inverters are installed, upper and lower, together in one cabinet, please add heat

dissipation plates and leave enough space between the inverters. See Diagram.

13

Ⅲ Wiring

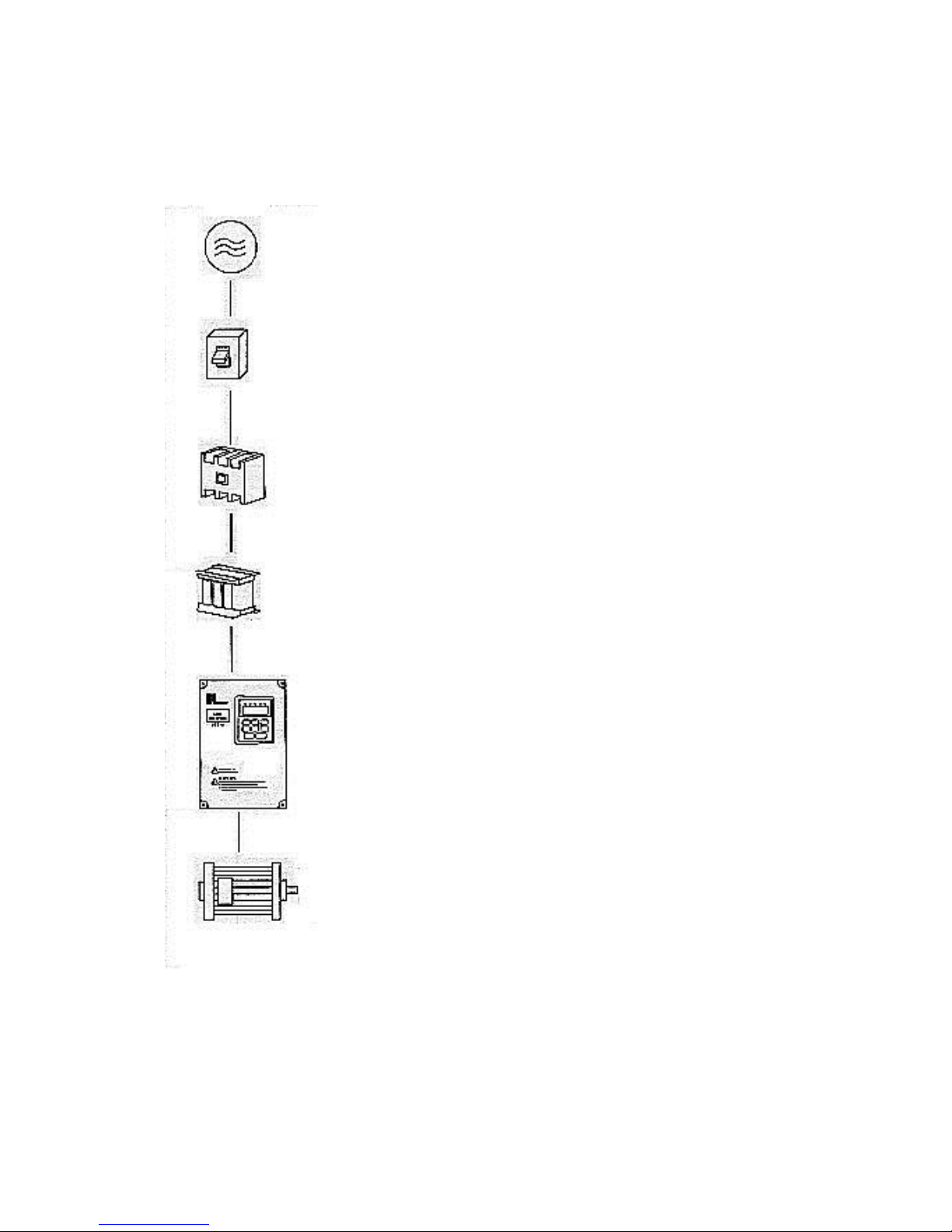

3.1 Main Circuit Wiring Schematic Diagram

Power supply:

● Verify that the inverter’s rated voltage coincides with AC power

supply voltage to avoid a damage of the inverter.

No fuse breaker:

● Refer to the related list.

Ground fault circuit interrupter:

● Use one of anti-high harmonic.

Electromagnetic contactor:

● Note: Do not use the electromagnetic contactor as the on/off

button of power supply for the inverter.

AC reactor:

●It is recommended to install an AC reactor for power factor

improvement if the input capacity is more than 1000KVA

Inverter:

●Be sure to make correct connections of the main circuit wires and

control signal wires of the inverter.

●Be sure to make correct setting of parameters for the inverter.

14

3.2 Descriptions of Terminal Blocks

1、 Arrangement of Main circuit Terminals

T S R

E

U V W R P PR

2、Arrangement of Control Circuit Terminals

FA

FB

FC DRV

FWD

REV

RST

SPL

SPM

SPH

GND

AM

VI

AI

+10

3、Function Description of Main circuit Terminals

Symbol

Function Description

R、S、T

Input terminal of AC line power.

U、V、W

Output terminal of the inverter

P+、PR

Connector for braking resistor (optional). Connector for DC reactor

E

Ground terminal

4、Function Description of Control Circuit Terminals

Symbol

Function Description

Default setting

FWD

Multi- Digital Input 1

Forward

REV

Multi- Digital Input 2

Reverse

RST

Multi- Digital Input 3

Reset

SPH

Multi- Digital Input 4

High-speed

SPM

Multi- Digital Input 5

Medium-speed

SPL

Multi- Digital Input 6

Low-speed

GND

Common & Ground

+10

Power Supply for Analog Setting

+10V

VI

Multi- Analog input

Voltage

AI

Multi- Analog input

0~20mA

DRV

Multi-Digital Output 1 (optical-

coupler)

DC24V/100mA

FA/FB/FC

Multi- Digital Output (Relay)

3A/250V

AM

Multi- Analog Output

0~10V

RS+ 、RS-

RS485 Communication port

15

3.3 Basic Connection Diagram

The wiring of the inverter is divided into two parts, main circuit terminal connections and control

circuit terminal connections. The user can see the main circuit terminals and the control circuit

terminals after removing the cover of enclosure. The terminals must be connected correctly as the

following wiring circuit diagrams.

The following diagram shows the Default setting standard connection of Model DLM1

FWD

Inverter

R

S

T

Single/Three Phase

220V

GND

DRV

W

V

U

E

VI

REV

SPH

SPM

SPL

RST

GND

+10V

GND

E

AI

Ground

terminal

FC

FA

FB

Power input

Multi- Digital Output

(Relay)

3A/250VAC

3A/30V DC

M

24V 100mA

AM

GND

Analog output

RS-485

Communication

port

1、GND

2、+5V

6、GND

5、GND

4、RS-

3、RS+

Multi-

Digital Input

16

3.4 Precautions on Wiring

(1) For the main circuit wiring:

● While wiring the sizes and specifcations of wires should be selected and the wiring should

be executed according to the electrical engineering regulations to ensure the safety.

● It is better to use shielded wire or wire and conduit for power cord and ground the shielded

layer or two ends of wire conduit.

● Be sure to install a Non Fuse Breaker (NFB) between the power supply and the input

terminals (R.S.T). (If using ground fault circuit interrupter, please choose one corresponding

to high frequency)

● Never connect AC power to the output terminal (U.V.W) of the inverter.

● Output wires mustn’t be in touch of the metal part of the inverter enclosure, or it will result

in earth short-circuit.

● Phase-shifting capacitors, LC, RC noise filters, etc, can never be connected to the output

terminals of the inverter.

● The main circuit wire must be enough far away from other control equipments.

● When the wiring between the inverter and the motor exceeds 15 meters (shielded wire) or 50

meters (No shielded wire), much higher dV/dT will be produced inside the coil of the motor,

which will cause the destruction to the interlay or insulation of the motor. Please use a

dedicated AC motor for the inverter or add a reactor at the inverter.

● Please lower the carrier frequency when there is a longer distance between the inverter and

the motor. Because the higher the carrier frequency is the bigger the leakage current of highorder harmonics in the cables will be. The leakage current will have unfavorable effect on

the inverter and other equipment.

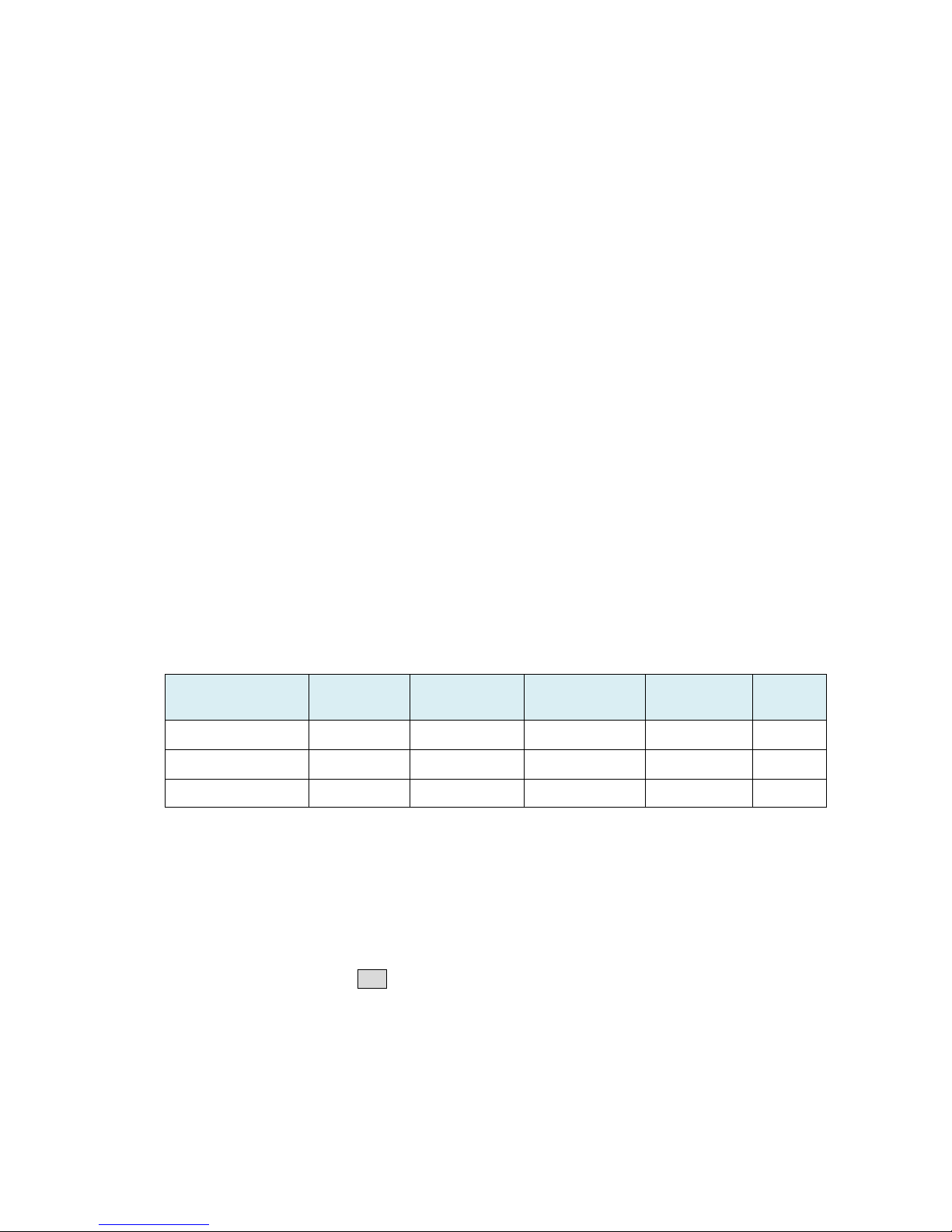

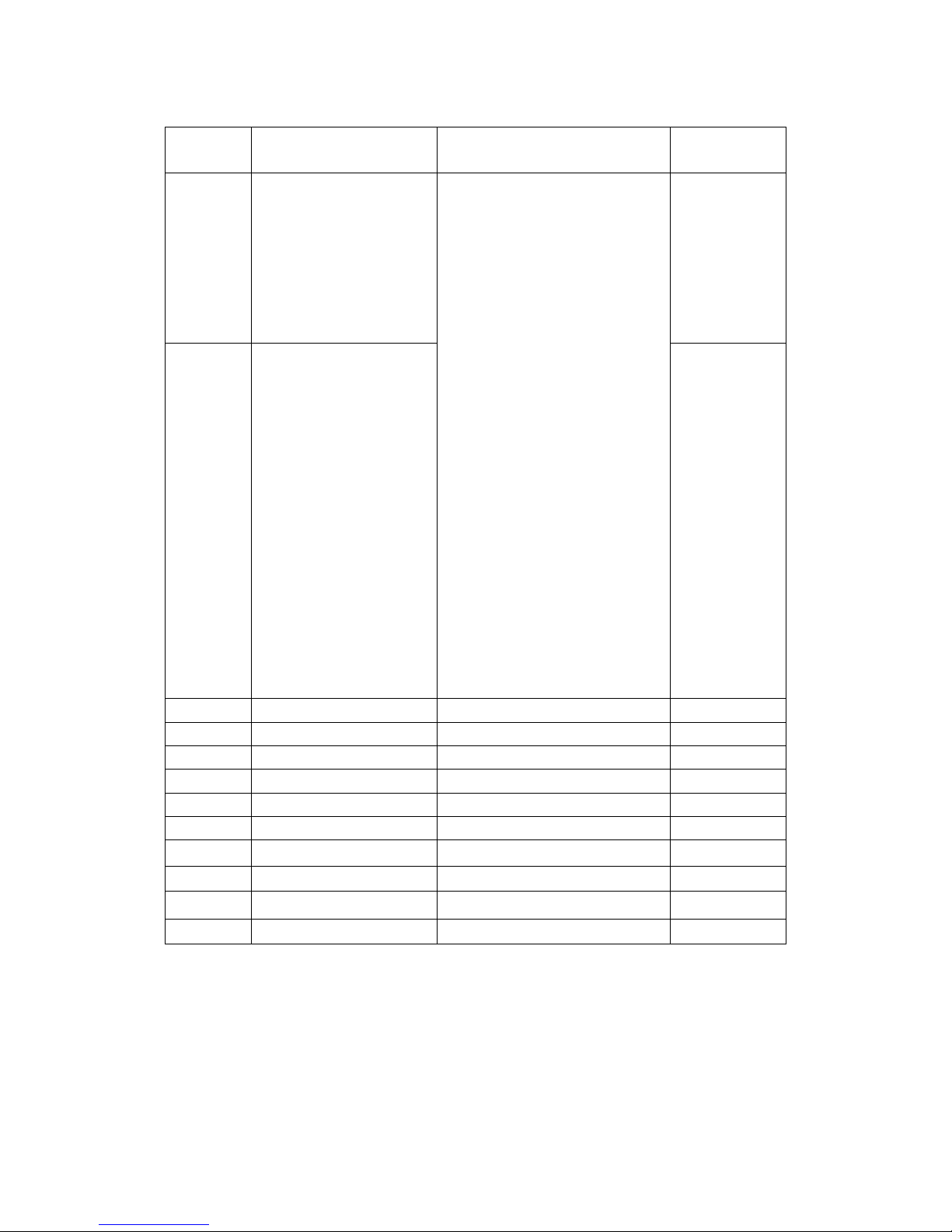

Specifcations of Non Fuse Breaker and Wire

Model

NFB

(A)

Input wire

(mm2)

Output wire

(mm2)

Control wire

(mm2)

Screw

DLM1-0D40S2G

16

2.5

2.5

1

M4

DLM1-0D75S2G

16

2.5

2.5

1

M4

DLM1-01D5S2G

16

2.5

2.5

1

M4

Attention: The parameters in the list are only for reference and should not be regarded as standard.

(2) For control circuit wiring (signal line)

● The signal line should be separately laid in a different conduit with the main circuit wire to

avoid any possible interference.

● Please use the shielded cable with the size of 0.5-2mm2 for signal lines.

● Use the control terminals on the control panel correctly according to our needs.

(3) Grounding

● Grounding terminal E Be sure to make correct grounding 220V class: The third

grounding method (Grounding resistance should be 100Ω or lower.)

380V class: The special third grounding method (Grounding resistance should be 10Ω or

lower.)

● Choose grounding wires according to the basic length and size of the technical requirements

of the electric equipment.

● Do avoid sharing grounding wire with other large power equipment such as electric welder,

17

power machine, etc. The grounding wire should be kept away from the power supply wires

for large power equipment.

● The grounding method for several inverters together should be done as the frst and second

diagrams below. Avoid the third.

(a) Good

(b) Good

(c) Not Good

18

3.5 Optional parts

Optional parts

Function

Circuit breaker and CFCI

Wiring protected of the drive should be sure to set the circuit breaker in

the power supply side. Please use a GFCI with anti higher harmonics.

Electromagnetic contactor

In order to avoid burning the brake resistor, please set the

electromagnetic contactor used on the coil to ground surge absorber.

Surge absorbers

Absorption of electromagnetic contactor and control relays switch

inrush current.

Isolation transformer

Output and input of the isolation transformer can reduce interference.

The braking resistor

Renewable energy consumption of the motor and shorten the

deceleration time.

(1)CFCI

Within the inverte, within the motor and the input and output leads all have the capacitance of

the ground. Due to the higher carrier frequency used, the inverter earth leakage current is large,

especially the high-capacity models. When using the GFCI, sometimes our malfunction can lead

to protection circuit. So when you use of GFCI should pay attention to the GFCI selection, while

appropriate to reduce the carrier frequency, shorten lead and so on.

(2)Braking resistor

Model

Braking resistor’ s Metering

Brake torque 10% ED

Special motor

KW

W

Ω

DLM1-0D40S2G

80

200

125

0.4

DLM1-0D75S2G

100

200

125

0.75

DLM1-01D5S2G

300

100

125

1.5

Attention:

① Please select the company developed resistance value and using frequency;

② If you use not our company provided the braking resistor and braking module, which led

to the drive or other equipment damage, our ompany does not bear any responsibility;

③ When you install the braking resistor, you should consider the safety of the environment,

the flammable, and the distance is greater than 100mm converter;

④ If you want to change the resistance and power numbers, please contactwith us;

⑤ If you need a braking resistor or braking resistor,you need order separately;

⑥ Such as large mechanical inertia, please increase the capacity of the braking resistor.

19

Ⅳ Maintenance and Troubleshooting

4.1 Maintenance checks Notes

● Before maintenance check, please be sure to cut off the inverter input (RST) power;

● Make sure the power of inverter is cut off, the display disappears, and until the internal high-

voltage light is off, then you can start the implementation of maintenance, inspection;

● During the inspection, the internal power, cables and cable roots must be not pull up and

mismatch, otherwise it will lead to inverters not work;

● Do not leave any parts inside the inverter, when mounting screws and other accessories;

● After installing should keep the inverter clean, avoid dust, oil mist and moisture。

4.2 Regular inspection program

● Please make sure the voltage of supply power conforms to the required voltage of inverter;

(Especially attention to the power cable and the motor if there is damaged.)

● Please check wiring terminals and connectors, if there are loose; (Please make sure power

line terminals are not off shares.)

● Please pay attention to dust inside the inverter, iron and corrosive liquids;

● Please do not measure the insulation resistance of the inverter;

● Please check the inverter output voltage, output current, output frequency; (That can not be

much difference between the results and the rated.)

● Please check the surrounding temperature, if there is between -5 ℃ ~ 40 ℃ and the

installation environment is well ventilated;

● Humidity: maintained at 90% or less; (Can not bear water droplets.)

● Please pay attention to abnormal sound and vibration in operation; (The drive can not be

placed where vibration.)

● Please clean the vent regularly.

20

4.3 Fault information and troubleshooting

DLM series inverters have relatively complete protections including overload, phase short circuit,

to-ground short circuit, undervoltage, over temperature and overcurrent protection. When the inverter

protection triggers, please follow the information in the table below to identify the reasons.

Fault Display

Fault content and description

Approach

Acceleration-Overcurrent

1. Please check the motor for short circuit,

especially output lines;

2. Prolong acceleration time;

3. The capacity of inverter is too small, please

increase the capacity;

4. Reduce the torque increase set value.

Constant speed Overcurrent

1. Please check the motor for short circuit, and

output line insulation;

2. Check whether the motor jis jammed or

mechanical load is abruptly changed;

3. The capacity of inverter is too small, please

increase the capacity;

4. Please check if the grid voltage is abruptly

changed.

Deceleration-Overcurrent;

Stop-Overcurrent

1. Please check the motor for short circuit, and

output line insulation;

2. Increase the deceleration time;

3. The capacity of inverter is too small, please

increase the capacity;

4. DC braking is too large, please reduce the

value of DC braking;

5. Inverter failure, contact distributor.

Short circuit to ground

1. Please check the motor for short circuit, and

output line insulation;

2. Inverter failure, contact distributor.

Stop-Overvoltage

Acceleration-Overvoltage

Constant-speed-Overvoltage

Deceleration-Overvoltage

1. Increase the deceleration time, or install

brake resistor;

2. Improve grid voltage.

Blown fuse

Contact distributor

21

Fault Display

Fault content and description

Approach

Under Voltage

1. Please check the input voltage;

2. Please check if the load is abruptly changed;

3. Please make sure if there is a missing phase.

Inverter Overheat

1. Please check if the fansis stalled;

2. Please make sure the temperature is normal;

3. Please keep air convection.

Inverter overload 150%

1 minute

1. The capacity of inverter is too small, please

increase the capacity;

2. Please check the mechanical load, if there is

stuck;

3. Reset the V/F curve.

Motor overload 150%

1 minute

1. Please check the mechanical load, if there is

a sudden change;

2. The motor doesn’t match with the inverter;

3. Motor thermal insulation deterioration;

4. Voltage fluctuations;

5. Please make sure if there is a missing phase.

6. Mechanical load increases.

Motor Over-torque

1. Please check the mechanical load, if there is

sudden change;

2. The motor doesn’t match inverter;

Auxiliary coil of

electromagnetic contactor

feedback

Contact distributor

Braking transistor damage

Contact distributor

CPU fault

Contact distributor

E2Prom fault

Contact distributor

22

Er

External interference

Isolate the source of interference

Es

Emergency Stop

Emergency Stop status

20

4~20mAz

Connect break

Pr

Parameter setting error

Set parameter correctly

DCb

DC braking

DC braking status

E XX Y

Code Table:

A B C D E F G H O S N L T P R U 2

Fettle

Alarm information

Fault

S:Stop

Y A:Accelerate

N:Constant

D:Deceleration

23

Ⅴ Instruction of the Digital Operator

5.1 Description of the Digital Operator

Value

change

key

LED Display Zone

indicating For.,

Rev., frequency,

current,

revolution, etc.

Enter

key

Main Display Zone:

Indicating frequency,

current, AC V, DC V,

Forward, reverse

temperature, etc.

Run

key

Function

key

Value

change

key

Stop/

Reset

key

Potentiometer

5.2 Description of Indicator Lamp Status

1、Description of Indicator Lamp Status

Indicator lamp

Status

Description

FWD

on

The motor is in forward rotation.

REV

on

The motor is in reverse rotation.

RUN

on

Run

STOP

on

Stop

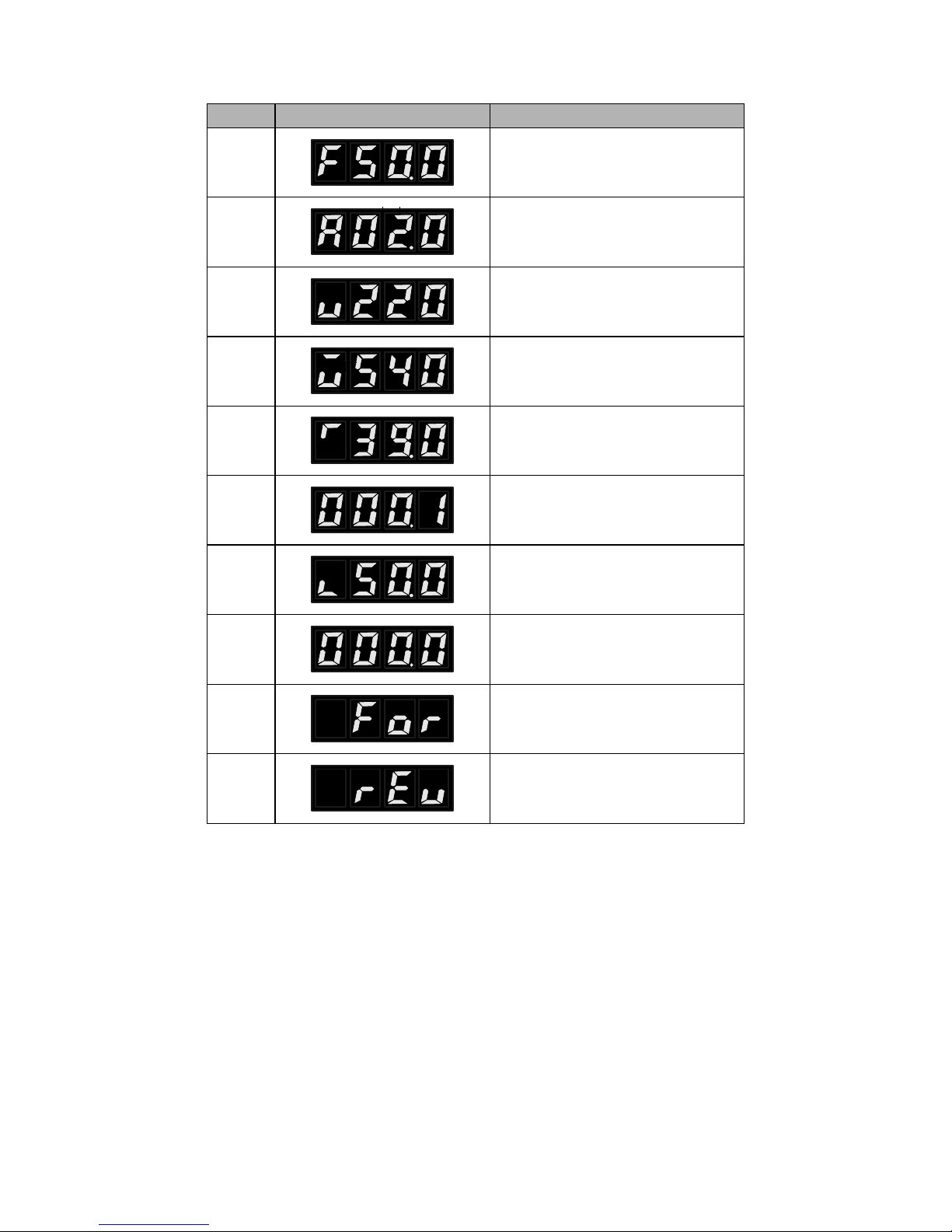

2、Description of Display Items

No.

Display

Meaning

1

Present output frequency is 50.00HZ

24

No.

Display

Meaning

2

Present set frequency is 50.00HZ

3

Present output current is 2.0A

4

Present output voltage is 220V

5

Present DC voltage is 540V

6

Present inverter’ s temperature is

39.0℃

7

Present counter’ s value

8

I Present feedback value of PID is 50%

9

Speed

10

Forward

11

Reverse

5.3 Operation Examples

1、DC voltage, temperature, counter, PID feedback value, and the speed can only be displayed after

setting specific parameter.

2、When under FWD, REV, PXXX and parameter content state, after a few seconds the display can

be automatically restored to the frequency, voltage, current, etc. interface.

3、When in running and stopping status, original interface is still shown, but the corresponding content

will vary depending on the operating conditions. Meanwhile the indicator status will change

accordingly.

4、"Confirm / left": short-press to move left; long-press to confirm.

25

Ⅵ Parameter Overview

P000 Main Frequency **

Set Range: 0.00—600.00 HZ Unit: 0.01Hz Factory Setting: 0.00

When using digital operator, the inverter will run at the setting value of P000. During running,

the running frequency can be changed by pressing the ▲ or ▼ key. During multi-speed running, the

main frequency is the first speed frequency.

When using external terminals, if P013 is set to 1, i.e. the running frequency is given by external

terminals, the first speed step is given by the potentiometer or external analog commands.

The setting of main frequency is limited by the max operation frequency.

P001 Acceleration Time

Set Range: 0.1—6500.0 Unit: 0.1s Factory Setting: 5.0

P002 Deceleration Time

Set Range: 0.1—6500.0S Unit: 0.1s Factory Setting: 5.0

Accelerat ing Time means the time needed for the inverter frequency from 0Hz to 50Hz.

Decelerating Time means time needed for inverter frequency from maximum frequency to 0Hz.

DLM1 Series inverters have 4 Accel/Decel Times. For Accel/Decel Time 2.3.4 the different

accelerating and decelerating time can be selected through the external terminals and by switching of

Accel/Decel Time according to actual needs. In the internal control multi-speed, different

Accel/Decel time can be selected through simple PLC.

P003 V/F Curve

Set Range: 0—16 Unit: 1 Factory Setting: 0

0: Wanton curve

1~16: 16 curves are wanton and available.

26

27

P004 Max. Output Voltage

Set Range: 0.1—255/510V Unit: 0.1V Factory Setting: 220/380V

P005 Base Frequency

Set Range: 0.01—600.00 Hz Unit: 0.01Hz Factory Setting: 50/60

P006 Intermediate Voltage

Set Range: 0.1—500.0V Unit: 0.1V Factory Setting: *

P007 Intermediate Frequency

Set Range: 0.01—600.00 Hz Unit: 0.01Hz Factory Setting: 2.50

P007 can set any intermediate voltage in the V/F curve. If it is set improperly, it will cause motor

over current or under torque, or even an inverter tripping.

P007 set value is limited by P005.

P008 Min. Voltage

Set Range: 0.1—50.0V Unit: 0.1V Factory Setting: * (undefined)

This parameter can set the lowest starting voltage in the V/F curve.

This setting value is limited by the voltage at the highest operating frequency.

P009 Min. Frequency

Set Range: 0.1—20.00 Hz Unit: 0.01Hz Factory Setting: *

This parameter sets the lowest starting frequency in the V/F curve.

P0010 Max Frequency

Set Range: 50.00—600.00 Hz Unit: 0.01Hz Factory Setting: 50.00

This parameter sets the highest operating frequency of the inverter

28

P011 Frequency Lower Limit

Set Range: 0.00—600.00 Unit: 0.01Hz Factory Setting: 0.00

This is set for preventing workers from false operation, avoiding overheat or some other

mechanical faults, which might be caused due to too low running frequency. When the setup frequency

is below the lower limit the inverter is running at frequency lower limit.

This set value is limited by frequency upper limit.

P012 Operation Command Source

Set Range: 0—2 Unit: 1 Factory Setting: 0

0: Digital operator;

1: External terminals or potentiometer.

IMPORTANT: CN1 JUMPER (shown at right hand side after opening inverter upper cover).

Pin 1 & 2 for panel potentiometer & Pin 2 & 3 for external terminals.

2: Communication ports, such as RS485.

P013 Operation Frequency Source

Set Range: 0—2 Unit: 1 Factory Setting: 0

0: Digital operator.

1: External terminals or potentiometer.

IMPORTANT: CN1 JUMPER (shown at right hand side after opening inverter upper cover).

Pin 1 & 2 for panel potentiometer & Pin 2 & 3 for external terminals.

2: Communication ports, such as RS485.

P014 Starting Mode

Set Range: 0—1 Unit: 1 Factory Setting: 0

Two starting modes are available for different equipment.

0: Start from the starting frequency. When P092 is set as 0, i.e. DC brake is invalid at start, it starts

running from its starting frequency. When P092 is set to any non zero value, i.e. DC brake is valid

when starting, it will first have a DC braking at start, and then start from the starting frequency. Refer

to P091 and P092.

1: Starting by Frequency track. This function can be used in the starting of large inertia load. When

starting, the inverter will trace the former speed from the set frequency downward. In case of large

inertia equipment, when restarting, it can implement the running command right away withourt

waiting for the complete stop of the equipment by tracking the former frequency to save time.

Note: When the inverter is restarted by frequency track, it will start tracking the frequency from its

set frequency downward, and search it at the highest speed. When starting, the current will be high,

and over current or stall may occur. Be sure to pay attention to the adjustment of current standard

position of frequency track. Generally, P095 should be set around 100%. The exact value should be

set according to the characteristics of mechanical load.

29

P015 Stopping Mode

Set Range: 0—1 Unit: 1 Factory Setting: 0

Two stopping modes are available for the requirements of different equipment.

0: Decelerate to stop.

When P093 is set as 0, DC braking is invalid. When DC braking is invalid, the inverter will

decelerate to the stopping frequency, and then stop output, and the motor will coast to stop. When

P093 is set for any non-zero value 0, the DC braking is valid, and the inverter will frst decelerate to

the stopping frequency, and then stop fnally by DC braking. When stopping, the DC braking is usually

used in high position stopping or for position control. Be sure to notice that frequent uses of DC

braking will cause the motor overheat.

Related parameters: P091 and P093.

1: Free-running Stop

When the inverter receives a STOP command, it will immediately stop output and the motor will

have a free running till a stop. When the free-running stopping mode is selected for the motor, DC

braking is invalid.

P016 Reverse Rotation Selection

Set Range: 0—1 Unit: 1 Factory Setting: 0

0: Reverse Run is forbidden.

1: Reverse Run is allowed.

This function is suitable when the motor cannot have reverse rotation, and to prevent workers

from false operation. When the reverse rotation is forbidden, the motor can only rotate forward, and

cannot have reverse rotation.

When the reverse rotation is forbidden, if switching between For/Rev rotation on the panel, the

panel will show Rev Run, but the motor is actually making forward rotation with the indicator lamp

indicating For Run.

P017 STOP key selection

Set Range: 0—1 Unit: 1 Factory Setting: 0

0: STOP is invalid.

1: STOP is valid.

This parameter set is only valid when P012 is set as l or 2.

When P012 is set for external terminals or communications, the STOP key on the panel can be

chosen to be valid or not. When choosing it as valid, the STOP key can stop the inverter in running.

When it needs restarting, the former running signal should be released first and then restarting is

allowable.

P018 S-Curve Time

Set Range: 0~6500S Unit: 1 Factory Setting: 0

This parameter can be set for no-impact slow start or slow stop of the inverter when starting or

stopping. When starting S-curve the inverter will make accel or decel curve of different speed rates

according to Accel/Decel Time.

When P018 is set to 0, S-curve is invalid, i.e. accelorate or decelorate in straight line.

30

Without consideration of stall, the actual Accel/Decel Time is equal to the set Acel/Decel Time

plus S-curve Time.

P019 Carrier frequency (Note: 0 ~ 15 corresponding to 0 ~ 16K Hz)

Set Range: 0~15 Unit: 1 Factory Setting: 10

The carrier frequency has some affect on the electromagnetic noise of the motor, and meanwhile

the level of the carrier frequency has certain relation with the heating capacity of the inverter and the

interference to the environment.

See the following table:

Carrier

Frequency

Electromagnetic

Noise

Heating

Capacity

Interference to the

Environment

Low

High

High

Low

Small

Large

Little

Great

Carrier frequency corresponding table:

Set Value

0 1 2 3 4 5 6 7 8 9 10

11

12

13

14

15

Carrier

Frequency

KHz

1.5 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

As shown in the table above, with a higher carrier frequency, the electromagnetic noise will be

lower, but the interference to othersystems must be prevented. With a lower carrier frequency, the

electromagnetic noise will be a little higher, but the heating capacity will be small. So the carrier

frequency should be set as low as possible, especially with large power machines, if the noice demand

is not so high.

P020 Starting Frequency

Set Range: 0.1—10.0 Hz Unit: 0.1Hz Factory Setting: 0.5

Starting frequency is the initial frequency when the inverter is started. If the starting frequency is

set to 4.0Hz, the inverter will begin to run at 4.0Hz .

P021 Stopping Frequency

Set Range: 0.1—10.0 Hz Unit: 0.1Hz Factory Setting: 0.5

When the inverter receives a stop command, it will immediately decelerate to the stopping

frequency, stop output or start DC brake to a final stop.

If P093 is set to 0, DC brake is invalid when stopping and the inverter will stop output.

If P093 is set to any other parameter except “0”, DC brake is valid; the inverter will stop by DC

braking.

P022 Jog Frequency

Set Range 0.00—600.00 Unit: 0.01Hz Factory Setting: 5.00

This parameter can realize the jogging function when the inverter is tested. The jog operation can

be achieved only through the external terminals, which can be set by multi-function input terminals.

Jog frequency is limited by frequency lower/upper limit. While the jog function is implemented, other

31

commands are invalid. The acceleration time of jog frequency is set by P023. When using jog function,

set external terminals to 07 or 08.

This function is only valid at stop condition. It is invalid at running. When P012 is set to 1, it is

valid.

P023 Jog Accel/Decel Time

Set Range: 0.1—25.0 Unit: 0.1S Factory Setting: 1.0

P023 corresponds to Accel/Decel Time of 0~50Hz.

P024 PLC Operation

Set Range: 0—5 Unit: 1 Factory Setting: 0

0: Normal;

1: External 4 –speed control (refer to P050~P055);

2: External multi-speed control;

Multi-function Terminals

Results

Multi-speed 1

Multi-speed 2

Multi-speed 3

OFF

OFF

OFF

Main frequency & set by P000

ON

OFF

OFF

Multi-speed 1 & set by P035.

OFF

ON

OFF

Multi-speed 2 & set by P036.

ON

ON

OFF

Multi-speed 3 & set by P0375.

OFF

OFF

ON

Multi-speed 4 & set by P038.

ON

OFF

ON

Multi-speed 5 & set by P039.

OFF

ON

ON

Multi-speed 6 & set by P040.

ON

ON

ON

Multi-speed 7 & set by P041.

Note:

(1) To realize excternal 8-speed control, it is only valid when Multi-input is set for Multi-speed 1, 2,

3 and P024 is set to 2.

(2) Multi-speed 1, 2, 3 can make up to 7 speeds. Adding the main frequency it will have 8 speeds.

(3) The frequencies of Speed 1 ~ Speed 7 are determined by P035~P41.

(4) Each Acel/Decel Time is determined by the external multi-function terminal.

(5)The directions of each program running are determined by the external multi-function terminals.

(6) The main frequency can be set by P000 or the potentiometer.

Multi-speed1

Multi-speed2

Multi-speed3

FWD

Main

T

F

32

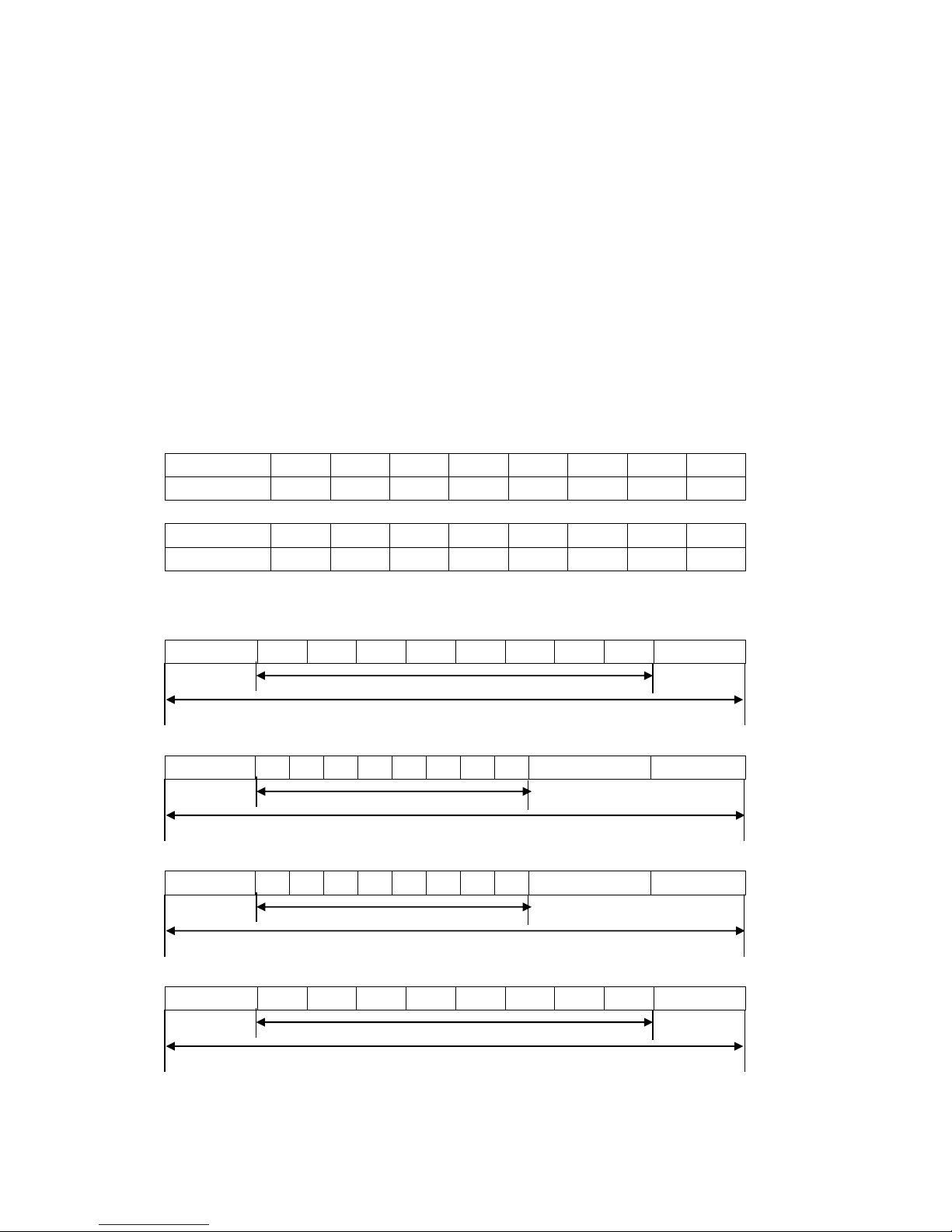

3: Transverse movement

This is a special parameter in the chemical fiber and printing and dying industries to realize transverse

movement. Except the commands of stop, external faults and emergency stop all other commands will

not be accepted at running.

F

P000 P041

P043

P042

P035 P041

T

Note:

(1) The frequency at each inflection point is determinded by P000 and P035.

(2)Skip Frequency is determined by P041.

(3)Running Time is determined by Timer P042 and P043.

(4)Restart after power off. The running status of frequency will not be memorized.

4: Internal Multi-speed control

F

P042 P043 P044 P045 P046 P047 P048 P049 T

Note:

(1) Main speed and 7-speeds compose 8-speeds.

(2) Acel/Decel Time of each speed is set by PLC Acel/Decel Time P027 and P028.

(3) Running Time is set by Timer P042~P049. Set timer to 0 if not used.

(4) Running direction of each speed is determined by P026.

(5 Restart after power off from the main speed. Status before power off will not be memorized.

5: Drawing

This is a special parameter for the constant speed of unwinding and rewinding. By using this function

the linear speed can maintain constant at certain accuracy levels.

T

P035

P036

P000

Mult-input

Multi-output

33

Note:

(1) Triggered by external multi-function terminals and the drawing actions begin to be implemented.

(2) Actual running time is T=P042×10;

(3) When the drawing is finished the inverter will output at a constant speed set by P036 and the

corresponding multi-ouput terminals will activate. Until receiving the Stop command the inverter will

stop running and the multi-ouput terminals will reset.

(4) In case of P133=1, it has the memory function at power off. When it restarts after the power off

the prior status will be memorized.

(5) The output frequency for drawing can be either up or down.

P025 Auto PLC Operation (internal multi-speed)

Set Range: 0~3 Unit: 1 Factory Setting: 0

Note:

This parameter is only valid when P024 is set to 4. For relevant parameters, refer to P000, P024,

P035~P049.

0: Stop after the program runs for one cycle and restart only when another running cammand is given.

1: Loop Run. When the running command is given, the inverter starts to operate in sequence with the

speeds and times set by each internal parameter for infinite loops. During the loop run, except the

commands of stop, external faults and emergency stop, all other commands will not be accepted.

F P036

P037 P040

P000 P041

P038

P039

P035 T

P042 P043 P044 P045 P046 P047 P048 P049

2: Stop after the program runs automatically for one cycle & stop at intermediate intervals beween

different speeds.

(1) When the command of automatic program running is given the inverter will operate according to

each parameter, but it will stop frst and then restart at the change of each stage. It will stop

automatically after running for one cycle. Only with another running cammand is given the inverter

can restart.

(2) The frequencies of each speed are set by P000, P035~P041.

(3) The running times of each speed step are set by P042~P049.

(4) The running direction is set by P026.

3: Loop run & stop at intermediate intervals beween different speeds.

(1) After the auto run command is given the inverter will run according to the parameters, but at every

change of speed it will stop frst and then start again. It will continue and stop until the OFF command

for auto run is given.

34

(2) When each speed is fnished the corresponding multi-function output will act.

(3) When each pattern run is fnished the corresponding multi-function output will act.

(4) The width of output pulse is 20 ms.

(5) When running again after power off all the actions will be started from the beginning and the

previous states will not be memorized.

P026 PLC Rotation Direction

Set Range: 0~255 Unit: 1 Factory Setting: 0

This parameter is only valid when P024 is set to 4.

This parameter determines the rotation directions of each frequency step of P035~P041 and P000

in the pattern run. The setting method is as follows:

The rotation direction is set frst in the binary bit mode, and then converted to a decimal value

for the setting of this parameter.

For instance:

bit 0-7

7 6 5 4 3 2 1

0

0 1 0 0 1 0 1

0

0: For 1: Rev

Main Speed (P000) For

Step 1(P035) Rev

Step 2(P036) For

Step 3(P037) Rev

Step 4(P038) For

Step 5(P039) For

Step 6(P040) Rev

Step 7(P041) For

The parameter value 01001010 is converted to a decimal value:

1×26+1×23+1×21=64+8+2=74

Then P026=74

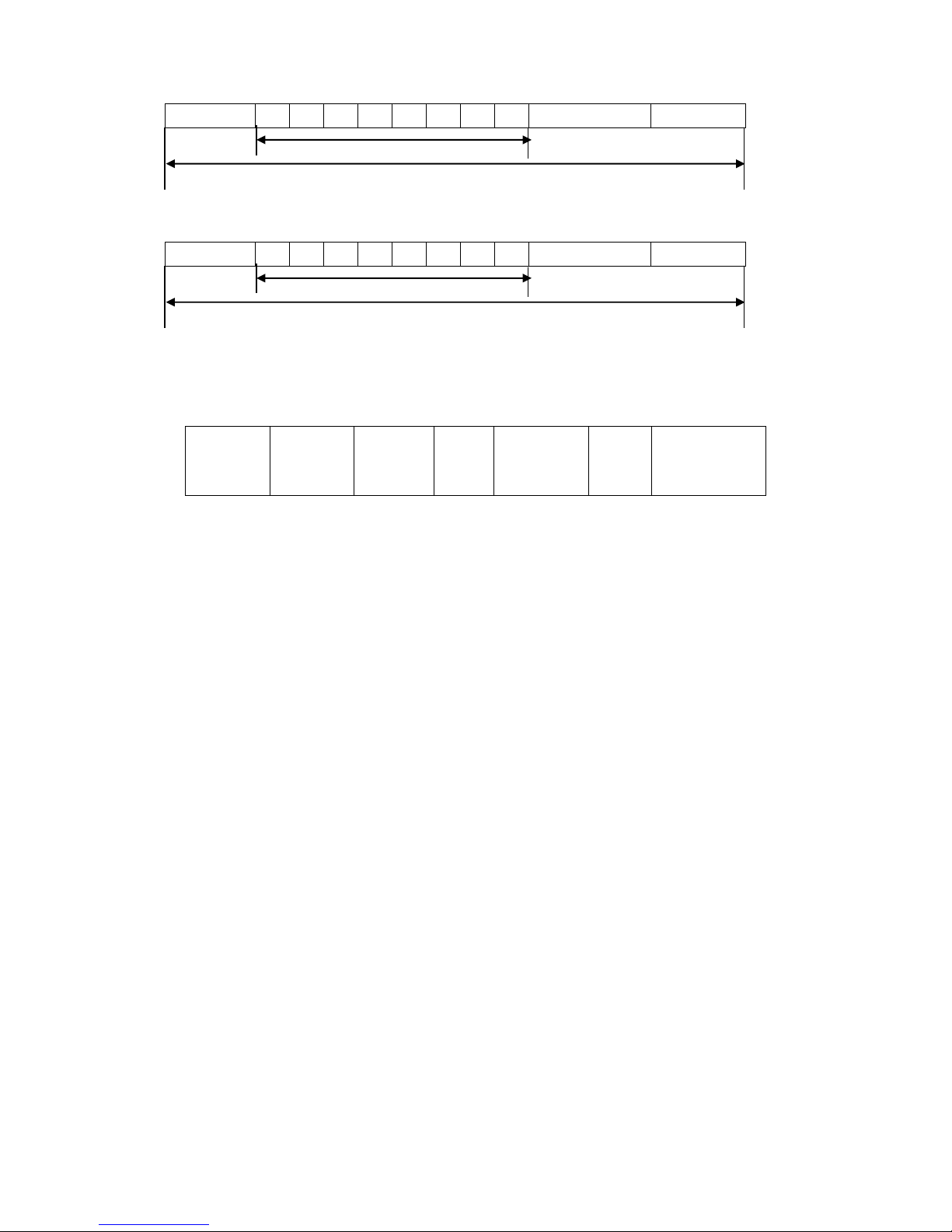

P027 PLC Accel. / Decel. Time 1

Set Range: 0~65535 Unit: 1s Factory Setting: 0

P028 PLC Accel. / Decel. Time 2

Set Range: 0~65535 Unit: 1s Factory Setting: 0

This parameter is only valid when P024 is set to 4.

This parameter is to determine the accel/decel time values of Step 1~4 of the internally controlled

multi-speed. Its setting method is as follows:

(1) Determine each accel/decel time in in the binary 2 bit mode

Bit1

Bit0

Accel/Decel Time

0

0

Accel/Decel Time 1: P001、P002

0

1

Accel/Decel Time 2: P029、P030

1

0

Accel/Decel Time 3: P031、P032

1

1

Accel/Decel Time 4: P033、P034

35

(2) Determine the accel/decel time of each speed step in the binary 8 bit mode

Speed No. 4

Speed No. 3

Speed No. 2

Speed No. 1

t4

t3

t2

t1

0 1 1 0 0 0 1

1

t1 select Accel. Time 4 t3 select Accel. Time 3

t2 select Accel. Time 1 t4 select Accel. Time 2

1×20+1×21+1×25+1×26=99

Then P027=99

P028 is set in the same way as P027.

P029 Accel. Time 2

Set Range: 0.1~6500S Unit: 0.1S Factory Setting: 10.0

P030 Decel. Time 2

Set Range: 0.1~6500S Unit: 0.1S Factory Setting: 10.0

P031 Accel. Time 3

Set Range: 0.1~6500S Unit: 0.1S Factory Setting: 50.0

P032 Decel. Time 3

Set Range: 0.1~6500S Unit: 0.1S Factory Setting: 50.0

P033 Accel. Time 4

Set Range: 0.1~6500S Unit: 0.1S Factory Setting: 100.0

P034 Decel. Time 4

Set Range: 0.1~6500S Unit: 0.1S Factory Setting: 100.0

P035 Frequency 2 Factory Setting: 15.0

P036 Frequency 3 Factory Setting: 20.0

P037 Frequency 4 Factory Setting: 25.0

P038 Frequency 5 Factory Setting: 30.0

P039 Frequency 6 Factory Setting: 35.0

P040 Frequency 7 Factory Setting: 40.0

P041 Frequency 8 Factory Setting: 0.50

Set Range: 0.0~600.0Hz Unit: 0.1Hz

P042 PLC Timer 1 Set Factory Setting: 10.0

P043 PLC Timer 2 Set Factory Setting: 10.0

P044 PLC Timer 3 Set Factory Setting: 0.0

P045 PLC Timer 4 Set Factory Setting: 0.0

P046 PLC Timer 5 Set Factory Setting: 0.0

P047 PLC Timer 6 Set Factory Setting: 0.0

P048 PLC Timer 7 Set Factory Setting: 0.0

P049 PLC Timer 8 Set Factory Setting: 0.0

Set Range: 0.0~6500S Unit: 0.1S

36

P050 Multi-Input FOR Factory Setting: 02

P051 Multi-Input REV Factory Setting: 03

P052 Multi-Input RST Factory Setting: 10

P053 Multi-Input SPH Factory Setting: 17

P054 Multi-Input SPM Factory Setting: 18

P055 Multi-Input SPL Factory Setting: 19

Set Range: 00~32 Unit: no

00: Invalid: When the terminal is set for null, it can avoid faulse operation.

01: Run: It can be combined with other terminals to combine various control methods.

02: FWD Forward rotation

03: REV Reverse rotation

04: STOP

05: FWD/REV

06: JOG

07: Jog Forward rotation

08: Jog Reverse rotation

09: Emergency Stop: It can receive external emergency stop or other fault signals.

10: RST This terminal can be used to reset after the fault is removed.

12: Overheat of radiator or motor: This contact can be used to detect overheat of the radiator or

motor to protect the motor and inverter.

13: Externally Controlled Timer 1 start: When the contact is closed, the timer will start and begin to

count time. When the timer reaches the point the responding multi-outputs will act.

14: Externally Controlled Timer 2 start

17: High Speed: High, middle and low speed can compose three kinds of different operation patterns.

18: Middle Speed: In the three terminals the high-end signal has priority.

19: Low Speed: Determined by Frequency 3, 4.

20: Multi-speed 1 Multi-speed 1, 2, 3 can compose 7-Steps.

21: Multi-speed 2

22: Multi-speed 3

23: Acel/Decel Select 1: This terminal can be used to selcect the acel/decel time of the inverter.

24: Acel/Decel Select 2:

25: UP function: When this terminal switch acts the frequency will increase by one unit.

26: DOWN function: When this terminal switch acts the frequency will decrease by one unit.

27: Counter: When the terminal is set for the counter it can receive the pulse signal of ≤250HZ

and count the number.

28: Counter reset: the action of this contact can clear the present counting value.

29: Drawing start: When the contact is triggered the action of drawing will start.

31: Auto PLC reset suspend: This contact can be used to realize the function of suspending clearup of Auto PLC.

32: PID valid: PID becomes valid and working.

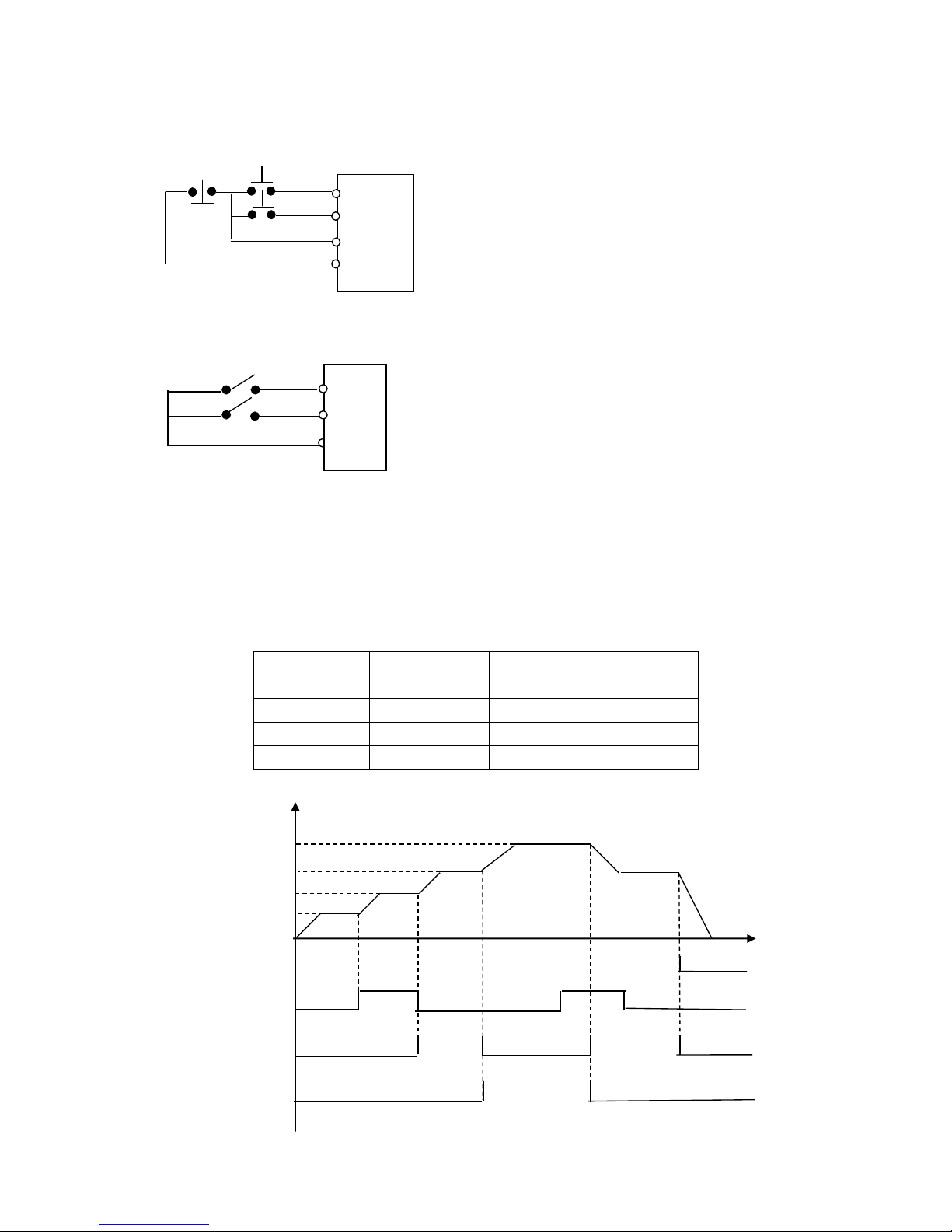

A. Using the three multi-function terminals to form the connection method of three-wire system for

the realization of switching FWD/REV, which is extentively applied in the case of switching

37

FWD/REV of photoelectric switches.

B. Use RUN, GND, FWD/REV to combine for Starting, Stopping and For/Rev:

C. Description of Accel/Decel Time 1 and 2 Select

It is only valid when P024 is set to 0, 1, 2.

Any two multi-function input terminals can be combined to 4 kinds of Accel/Decel for selection.

The related multi-function input terminals are set to Accel/Decel Select 1,2.Take the terminals of

SPH and SPM as example, when the terminals of SPH P053 is set to 23 and the terminals of SPM

to 24, then the terminals of SPH and SPM should be Accel/Decel Time 1, 2 Select.

SPH Terminal

SPM Terminal

Result

OFF

OFF

Accel/Decel Time 1

ON

OFF

Accel/Decel Time 2

OFF

ON

Accel/Decel Time 3

ON

ON

Accel/Decel Time 4

D. Function description of High, middle and low terminals:

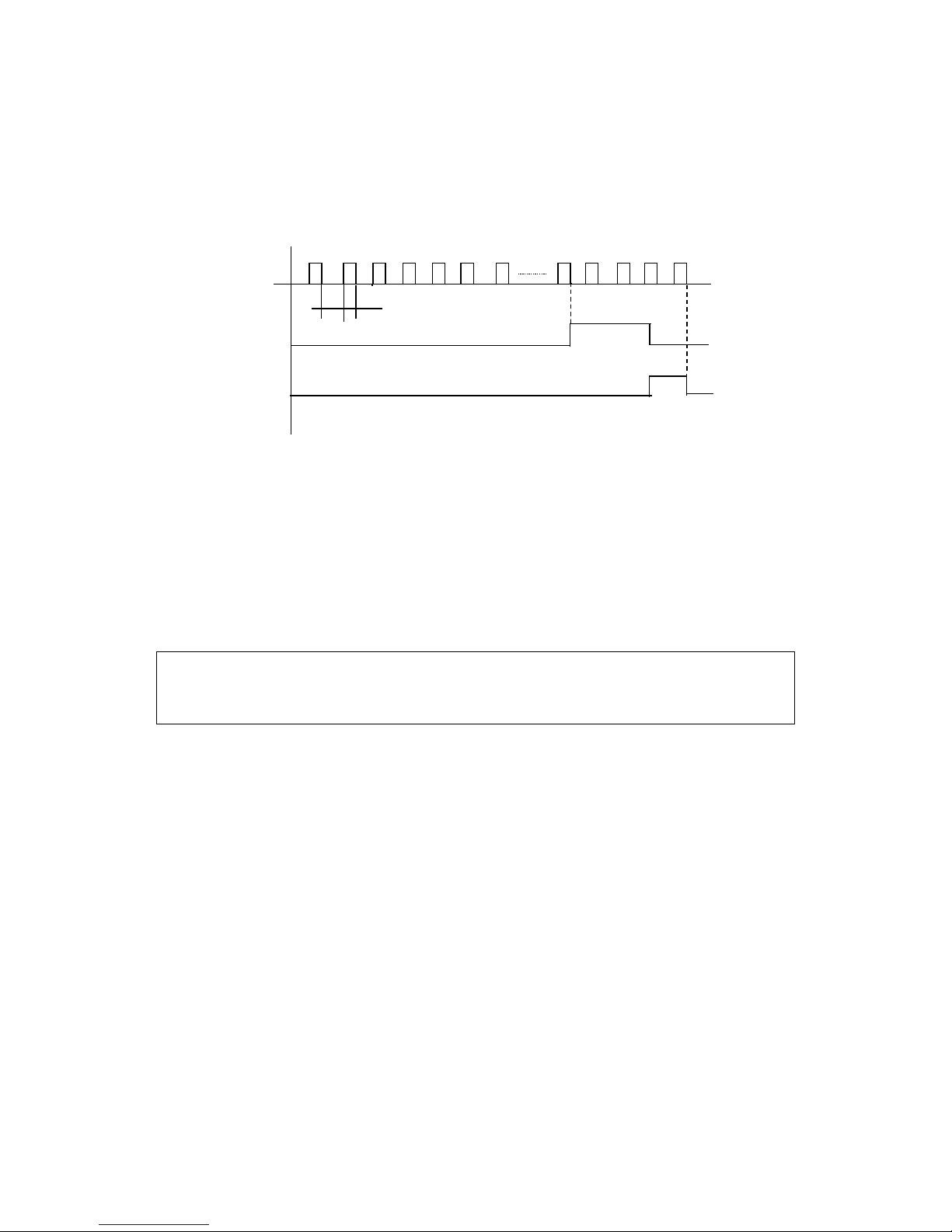

F

H.S

.M.S

.

L.S.

M.F.

RUN COMMAND

L.S.

M.S.

FWD

REV

RST

GND

STOP

RUN

P012=1; P050=02

P051=03; P052=04

When triggering FWD, the inverter will rotate forward

(starting);

When triggering REV, the inverter will rotate reversely;

When pressing STOP, the inverter will stop.

FWD

REV

GND

K1

K2

Select the terminals of FWD and REV

Parameter setting: P012=1 to set the exterminal control.

P050=01 to set RUN

P051=05 to set F/R

When K2 is open it rotates forward, while K2 is closed it

rotates

H.S.

38

RUN

SPL

Terminal

SPM

Terminal

SPH

Terminal

Result

ON

OFF

OFF

OFF

Main frequency and frequency run with the

set value of P000.

ON

ON

OFF

OFF

Low speed and frequency run with the set

value of P035.

ON

ON/OFF

ON

OFF

Intermediate speed and frequency run with

theset value of P036.

ON

ON/OFF

ON/OFF

ON

High speed and frequency run with the set

value of P037.

E. Description of UP and DOWN Function

Max. Ope. Frequency

Set Frequency

F. lower limit

Up Command

Down Command

UP

DOWN

Result

ON

OFF

Frequency up

OFF

ON

Frequency down

ON

ON

No up, no down

Note:

⑴ The function of UP and DOWN is only valid when the operation of Operator is delected

for the source of the running frequency, i.e. P013=0.

⑵ When UP is closed the inverter’ s frequency will increment.

⑶ When DOWN is closed the inverter’ s frequency will decrement.

⑷ When both UP and DOWNare closed at the same time the frequency will neither increase

nor decrease. It is regaded as invalid.

⑸ When the frequency reaches the max. operation frequency it will not increase.

⑹ When the frequency reaches the min. frequency or its lowe limit, it will not decrease.

⑺ It has the function of memory, including the memory for power-off. (Setting P60=1)

⑻ When adopting the function of UP and DOWN, its up and down speed rate is determined

by the present Accel/Decel time.

⑼ When keeping pressing UP or DOWN,the frequency will increase or decrease rapidly.

⑽ The function of UP and DOWN is valid in operation, not during standy by.

39

F. Description of Multi-speed 1, 2 and 3 Functions

They are only valid when P024 is set to 2. Details refer to P024.

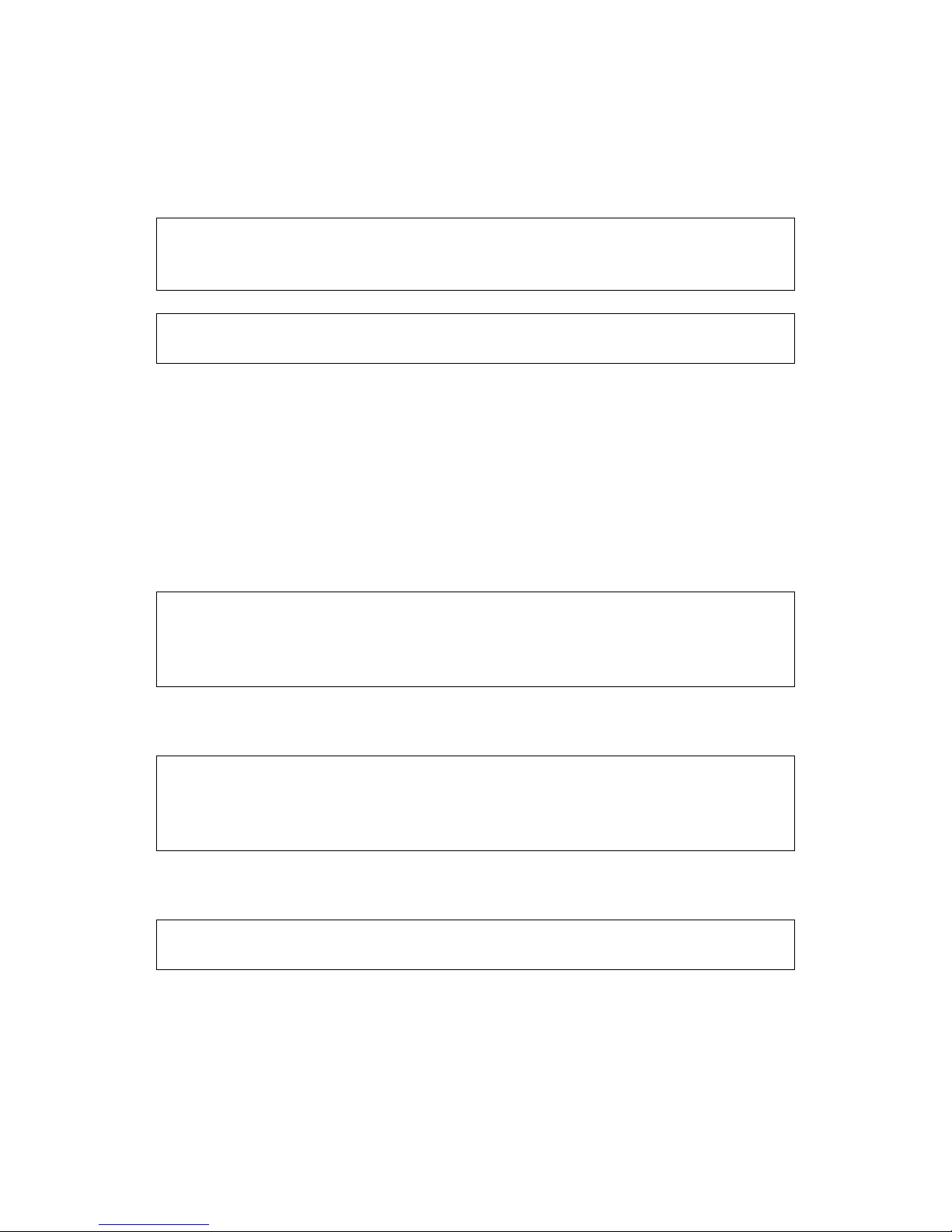

G. Description of Counter Function

cn

t1 S2

Value reach

Value reset

Note:

⑴ The signal width triggered should not be lower than 2msec(t1、S2≥2msec);

⑵ When the counting value is reached the corresponding multi-functionoutput contact will act.

⑶ This counter is reverse counter. When the counter is reset the setting value will be displayed and

then start counting.

⑷ When the counting value is reached the displayed value is 0. It will not count againand only start

counting after it reset.

⑸ It has the function of memory. When P132=1, the counting result can be memorized for power-off.

P056 Multi-Output DRV Factory Setting: 01

P057 Multi-Output FA, FB, FC Factory Setting: 02

Set range: 00—32 Unit: nil

00: Invalid. When the terminal is set for no function it can prevent false action.

01: Running. The contact will act when the inverter is running or receiving running command signals.

02: Fault indication. The contact will act when the inverter detects abnormal condition.

03: Zero Speed: The contact will act when the output frequency is lower than starting frequency.

04: DC Braking indication: The contact will act when the inverter is in DC braking condition.

05: Set Frequency reach: The contact will act when the output frequency reaches the set frequency.

06: Random Frequency 1 Reach: The contact will act when the output frequency reaches the

designated frequency (P070).

07: Random Frequency 2 reach: The contact will act when the output frequency reaches the

designated frequency (P071).

08: In Accel: The contact will act when the inverter is in acceleration status.

09: In Decel: The contact will act when the inverter is in deceleration status.

10: Inverter Overload alarm: The contact will act when the inverter detects overload.

11: Motor Overload alarm: The contact will act when the inverter detects overload of motor.

12: Over-torque detect: The contact will act when the inverter detects over torque.

13: Undervoltage alarm: The contact will act when the inverter detects under voltage.

14: Single Step end: The contact will act and output a pulse when the inverter fnishes a single step.

40

15: Process end: The contact will act and output a pulse when the inverter finishes all the steps in

implementation of pattern operation (i.e. after one cycle).

16: Set Counter reach: The contact will act when the inverterimplements the external counter and

the counting value is equal to the set value (P064).

17: Intermediate Counter reach: The contact will act when the inverter implements the external

counter and the countingvalue is more than or equal to the set value (P065).

18: Externally Controlled Timer 1 reach: The contact will act when the timer reaches the set value.

19: Externally Controlled Timer 1 reach

20: 4∽20mA disconnected. When the AI input signal is opend the contact will act.

27: Drawing Reach: The contact will act when the drawing action is fnished. The contact will

automatically reset when the inverter stops.

28: PID Lower Limit alarm: This contact will act when the PID feedback quantity is lower than the

lower limit (P108).

29: PID Upper Limit alarm: This contact will act when the PID feedback quantity is higher than the

upper limit (P107).

30: Fan run: When the inverter is working in high temperature or in running, this contact will act.

31: Electromagnetic Relay act: When the contact pulls in the corresponding multi-function terminal

will act.

32: Braking Resistor act: When the inverter in running and the DC voltage reaches the braking

voltage the contact will act.

P058 Multi output AM

Set Range: 0~7 Unit: 1 Factory Setting: 0

Function: In combination with P059 it can be connected to a frequency meter with the measuring

range of 0~10V for external monitoring.

0: Analog Output: 0~10V corresponds to 0~ Max operation frequency.

1: Analog Output: 0~10V corresponds to 0~ 2 times Rated current.

2: Analog Output: 0~10V corresponds to 0~1000V DC voltage.

3: Analog Output: 0~10V corresponds to 0~510/255V output AC voltage.

4: Pulse Output: 1 Pulse/Hz.

5: Pulse Output: 2 Pulse/Hz.

6: Pulse Output: 3 Pulse/Hz.

7: Pulse Output: 6 Pulse/Hz.

P059 AM Analog Output Gain

Set Range: 0~100% Unit: 1% Factory Setting: 100%

This parameter can be used to adjust the output voltage value of the multi-output AM to suit

frequency meter with different measuring range and also used to adjust a frequency meter. For example,

for an externally connected frequency meter with the measuring range of 0~5V, a multi-function

terminal can be used to display its operation frequency. Then user can set P059=50.

*Note: When selecting a frequency meter please select one with measuring range below 0~10V.

P060 Up-down Mode

Set Range: 0~1 Unit: 1 Factory Setting: 0

41

0: Not memorized

1: Memorized

Through the setting of this parameter whether the value changed by UP-DOWN will be

memorized after stopping can be selected.

When P060 is set to 1, if restart after stopping, the value at stopping will be memorized. If restart

after power off, the values at power off will not be memorized, but the value set by P000 will be

memorized. When P060 is set to 0, if restart after stopping, it will return to the value of P000, the value

changed by up-down will not be memorized.

P062 Timer 1 Time

Set Range: 0.0~10.0 Unit: 0.1S Factory Setting: 0

P063 Timer 2 Time

Set Range: 0~100 Unit: 1S Factory Setting: 0

Timer 1 is a timer of 0.1S~10.0S and Timer 2 is a timer of 1S~100S.

When the timer for multi-input terminal is opened or closed the timer starts to count time. When

the set time is reached the corresponding multi-output contact will act. When the timer is cut off, the

timer for multi-output will reset. During running, if the machine stops due to fault, the timer will count

time normally and not suspend; if the machine stops due to power off, the timer will reset automatically.

P064 Counter

Set Range: 0~9999 Unit: 1 Factory Setting: 0

An external terminal of multi-function can be used as a trigger for the counter. When the counter

reaches set value P064 the corresponding multi-function output contact will act. After the counter is

reset and returns it will start counting again. A proximity switch or optoelectronic switch can be used

for the trigger signals.

P065 Intermediate Counter

Set Range: 0~9999 Unit: 1 Factory Setting: 0

Intermediate Counting Value is one value within counting range. When the counter reaches this

value the corresponding multi-function output contact will act and output one pulse signal. It is valid

when the set value of P065 is smaller than P064.

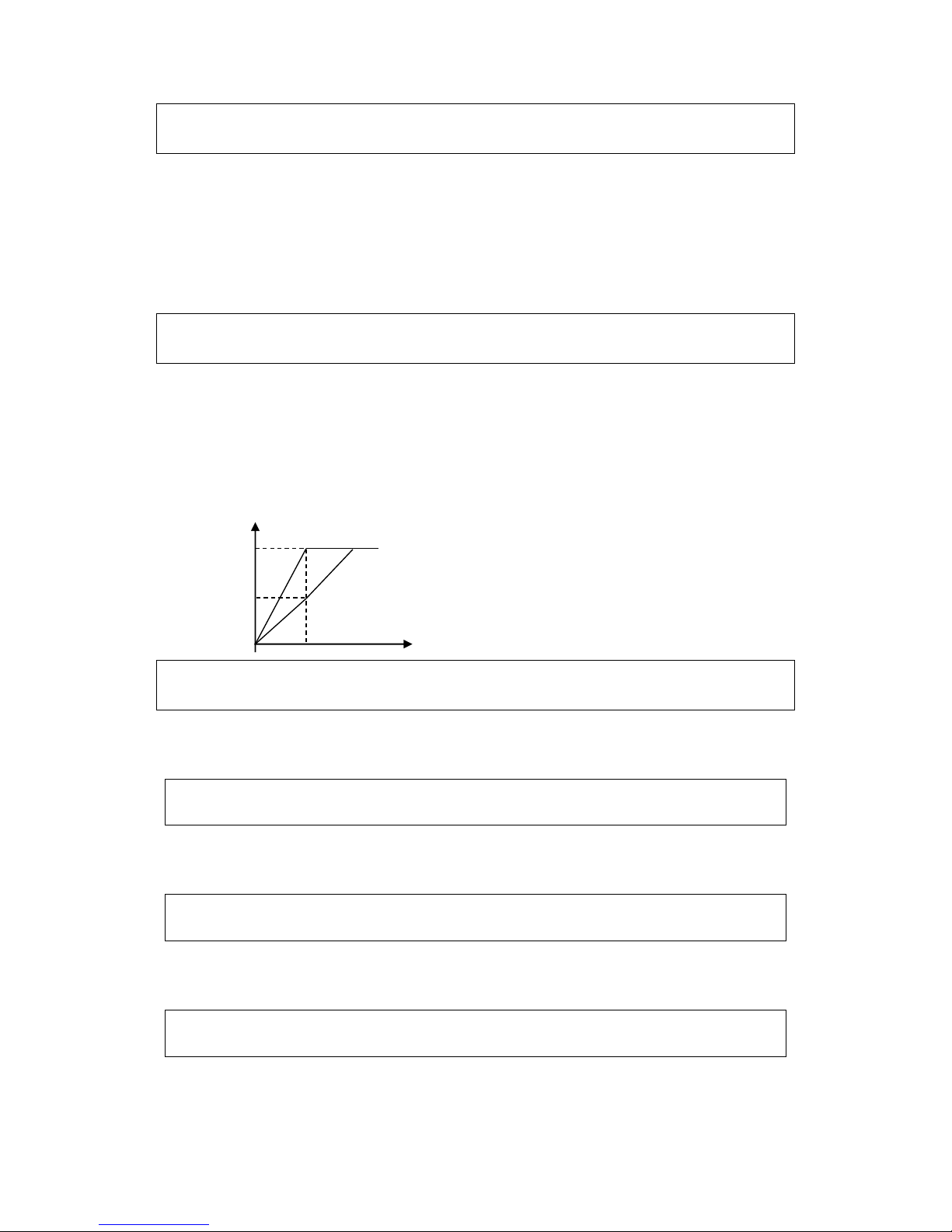

P066 Skip Frequency 1

P067 Skip Frequency 2

P068 Skip Frequency 3

Set Range: 0.00~600.00Hz Unit: 0.1Hz Factory Setting: 0.0

P069 Skip Frequency Range

Set Range: 0.1~10.00Hz Unit: 0.1Hz Factory Setting: 0.5

F

P068 Frequency

P067 P069

P066 P069

42

To avoid a mechanical resonance point three frequency skip points are set. In case of P069=0,

all skipping frequencies are invalid. The actual skipping frequency range is 2 times that of P069, as

shown in the above diagram.

P070 Random Frequency 1

P071 Random Frequency 2

Set Range: 0.00~600 Unit: 0.1Hz Factory Setting: 0.0

P072 Analog Input Select

Set Range: 0~4 Factory Setting: 0

0: 0~10V 1: 0~5V 2: 0~20mA 3: 4~20mA 4: 0~10V and 4~20mA stacked

This parameter can be set to satisfy different analog input signals.

When P072=4, output frequency =(U/Umax + I/Imax)*50Hz/2

Among which: U: Analog Quantity Voltage Quantity; Umax: Maximum Analog Quant ity

Voltage Quant ity; I: Analog Quantity Current Quantity; Imax: Maximum Analog Quantity

Current Quantity.

For example, When +10V and 20mA are respectively entered, the output frequency of the inverter is

50Hz.

(In case the max. operation frequency is set to 50Hz)

P073 Analog Low End Frequency

Set Range: 0.0~600.0Hz Unit: 0.1Hz Factory Setting: 0.0

P074 Bias Direction of Low End Frequency

Set Range: 0~1 Factory Setting: 0

0: Forward dirction

1: Reverse direction

P075 Analog High End Frequency

Set Range: 0.0~600.0Hz Unit: 0.1Hz Factory Setting: 51.0

P076 Bias Direction of High End Frequency

Set Range: 0~1 Factory Setting: 0

0: Forward dirction

1: Reverse direction

P077 Analog Negative bias Reverse

Set Range: 0~1 Factory Setting: 0

0: Negative bias Rev is not allowable.

1: Negative bias Rev is allowable.

The parameter is to measure the range and zero point of the external analog terminals and can be

combined for any kind of curve to control the operation of the motor.

Examples:

43

Rev. Area 50 Hz For. Area

0 5V 10V

4mA 12mA 20mA

F

50

0 10V

4mA 20mA

F

40

0V 2V 10V

4 20mA

10

40

F

0V 2V 10V

4mA 4.8mA 20mA

10

P078 Analog Filtering Constant

Set Range: 0~50 Unit: 1 Factory Setting: 20

The setting of this parameter is related to the responding speed of analog commands. The higher

the value of P078 is set, the slower the responding speed of analog commands. Too low setting of

P078 may cause the instability of frequency with fluctuation.

P079 Overvoltage Stall Prevention

Set Range: 0~1 Unit: 1 Factory Setting: 1

0: Overvoltage stall prevention function is invalid.

1: Overvoltage stall prevention function is valid.

Setting: P073=50

P074=1

P075=50

P076=0

P077=1

P073=50

P074=0

P075=0

P076=0

P073=10

P074=1

P075=40

P076=0

P077=1

P073=10

P074=1

P075=40

P076=0

P077=0

44

When the inverter is in decelerating, due to the effect of load inertia, the motor will produce a

return energy to the inverter and cause the DC voltage of the inverter to increase. So when the function

of overvoltage stall prevention is set valid and the DC voltage of the inverter becomes too high, the

inverter will stop decelerating till the DC side voltage decreases to its rated value, then the inverter

will go on to execute deceleration and the deceleration time will be extended automatically.

* Note: When the output voltage is higher the inverter will become abnormal or turn to

protection. In such case P079 can be set to 0 (Invalid), which is easy to cause overvoltage protection.

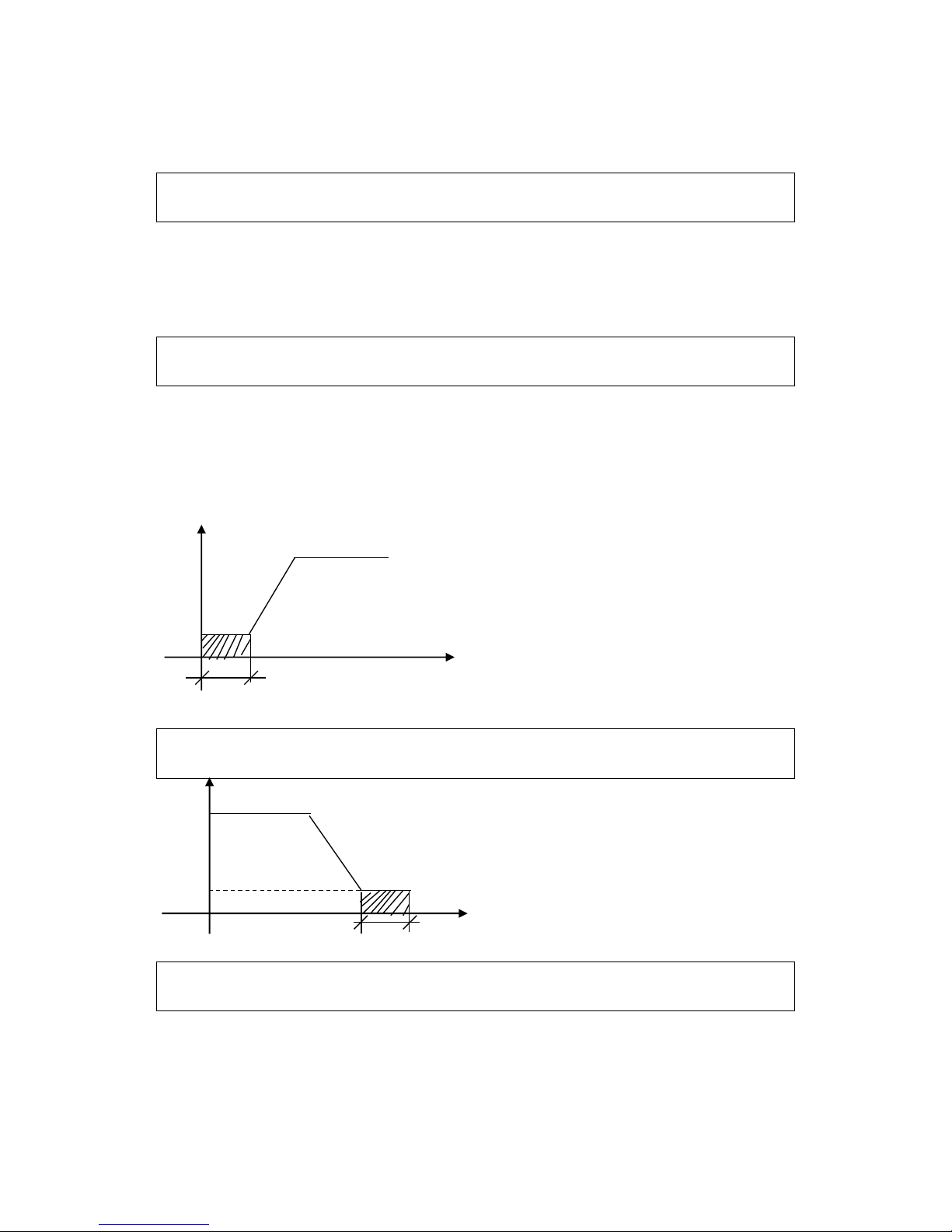

P080 Stall Prevention Level during Acceleration

Set Range: 0~200% Unit: 1% Factory Setting: 150

When the inverter is in accelerating, due to over load or too short acceleration time, the output

current of the inverter will go up quickly and exceed the rated standard level. When this happens, the

inverter will stop accelerating until the current returns under its rated value, will the inverter go on to

accelerate. When using the frequency track function the value of P080 should be lowered properly.

The greater the load initia quantity is, the smaller the value of P080 should be set. Otherwise it is

extremely easy to cause overcurrent protection.

I

Stall Prev. Level

Output frequency

T

100% current is the rated current of the motor. When this parameter is set to 0, the stall prevention

function is invalid.

P081 Stall Prevention Level at Constant Speed

Set Range: 0~200% Unit: 1 Factory Setting: 0

When the inverter is in constant running, due to load fuctuation and other reasons, the current

will go up. When the current exceeds its rated value, the inverter will lower the output frequency.

When the output current returns to its normal range the inverter will accelerate again to its set

frequency.

Stall prevention level

during running

Output frequency

T

100% current is the rated current of the motor. When this parameter is set to 0, the stall prevention

function is invalid.

45

P082 Stall Prevention Level during Deceleration

Set Range: 0~200% Unit: 1 Factory Setting: 180

When this parameter is set to 0, the stall prevention function is invalid.

P083 Overtorque Detect Level

Set Range: 0~200% Unit: 1% Factory Setting: 0

When the output current exceeds the over torque detection level and also exceeds half of the set

over torque detection time (factory setting: 1.0s), the over torque detection will begin to indicate, and

the corresponding multi-function contact will act. When it exceeds the set time value, the inverter will

turn into self-protection. But when this parameter is set to 0, the over torque detection will be invalid.

P084 Overtorque Detect Time

Set Range: 0.1~20.0S Unit: 0.1S Factory Setting: 1.0

When the inverter detects that the output current has exceeded the motor current set value, the

inverter begins to calculate the over torque time. When the over torque time has exceeded half of the

over torque detection time, the corresponding multi-function output contact will act, the over torque

alarm will be produced, while the inverter will continue running. When the over torque time has

exceeded the set detection time (set by P083), the inverter will turn into self-protection, display the

fault signal and stop output.

P085 Rated Motor Voltage

It is set according to the rated voltage value of the namplate. For 230V class inverters the default is

220, while for 400 V class inverters the default is 380V.

P086 Rated Motor Current

It is set according to the rated value of the namplate. This parameter can be used to restrict output

current of the inverter to prevent overcurrent and protect the motor. If the current of the motor has

exceeded this value the inverter of AC motor will turn into self-protection.

P087 Motor Poles

Set Range: 02~10 Unit: 1 Factory Setting: 04

This parameter is set for the pole number of the motor according to the namplate of the motor.

P088 Rated Motor Revolution

Set Range: 0~9999 Unit: rpm Factory Setting: 1440

This should be set according to the actual revolution of the motor. The displayed value is the

same as this parameter. It can be used as monitoring parameter, which is convenient to the user. This

parameter set value corresponds to the revolution speed at 50Hz.

P089 Motor No-load Current

Set Range: 0~100 Unit: 1 Factory Setting: 40

The setting of Motor no-load current will affect the quantity of slip compensation. 100% current

is the rated current of the motor.

P090 Slip Compensation

Set Range: 0~1.0 Unit: 1 Factory Setting: 0.0

When the inverter drives the motor, the slip will become bigger due to the increase of load. This

46

parameter can be set for slip compensation to decrease the slip and make the running speed of the

motor closer to synchronous speed of revolution.

P091 DC Braking Voltage

Set Range: 0.0~20.0% Unit: 0.1% Factory Setting: 2.0

This parameter is set for the DC brake voltage to of the motor at starting and stopping. It can be