DORNA TECHNOLOGY DLA1 Series, DLA1-0D75S2G, DLA1-0D40S2G, DLA1-01D5T4G, DLA1-0D75T4G User Manual

...

DORNA TECHNOLOGY CO., LTD

DLA1 Series Inverter

User Manual (V2.0)

2

Table of Contents

1 Summary ....................................................................................................... 4

1.1 Name plate .......................................................................................................... 4

1.2 Product series ...................................................................................................... 5

1.3 Technical standards ............................................................................................. 6

1.4 Peripheral Electrical Devices and System Configuration ..................................... 8

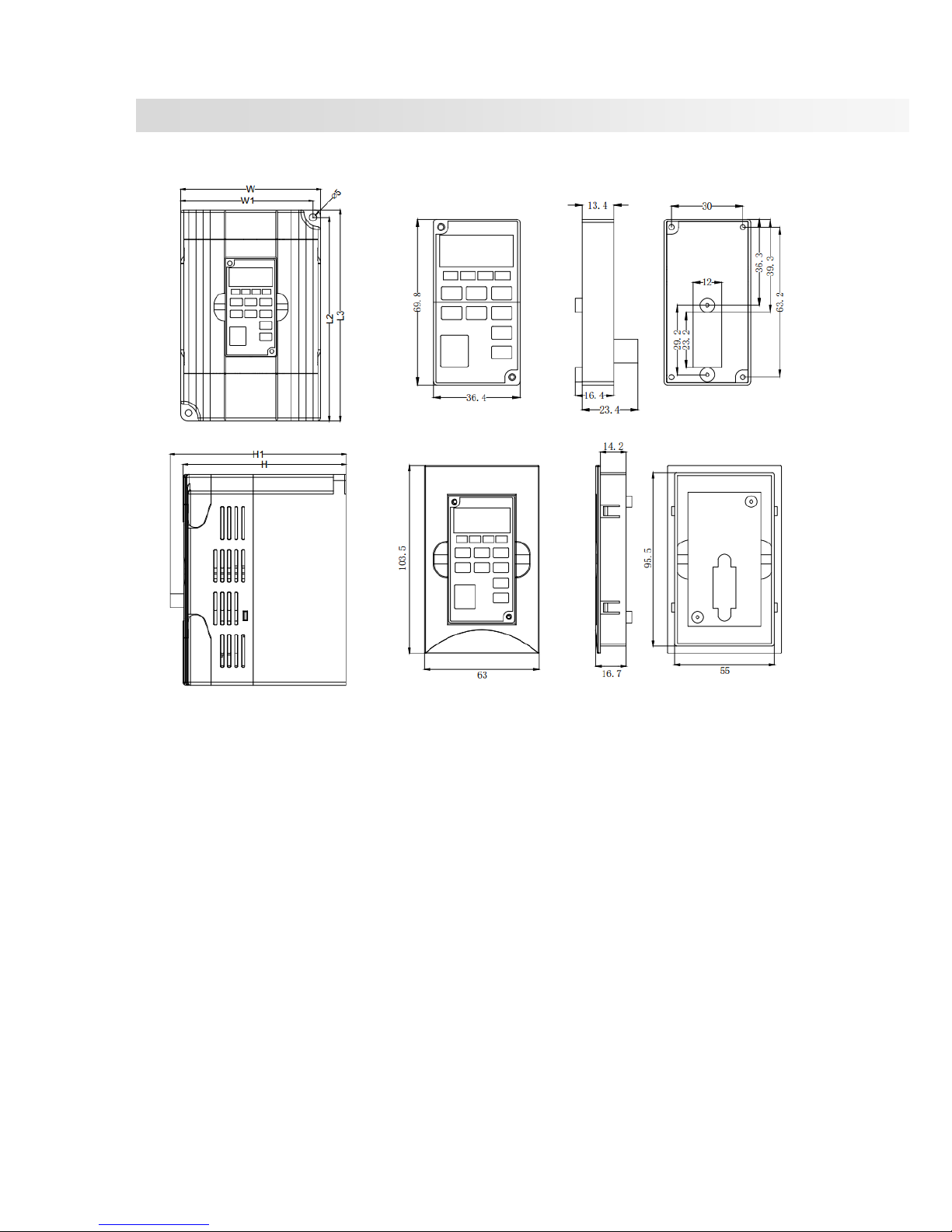

1.5 Product outline and installation dimensions ....................................................... 9

1.5.1 Product outlines (unit: mm) ................................................................................... 9

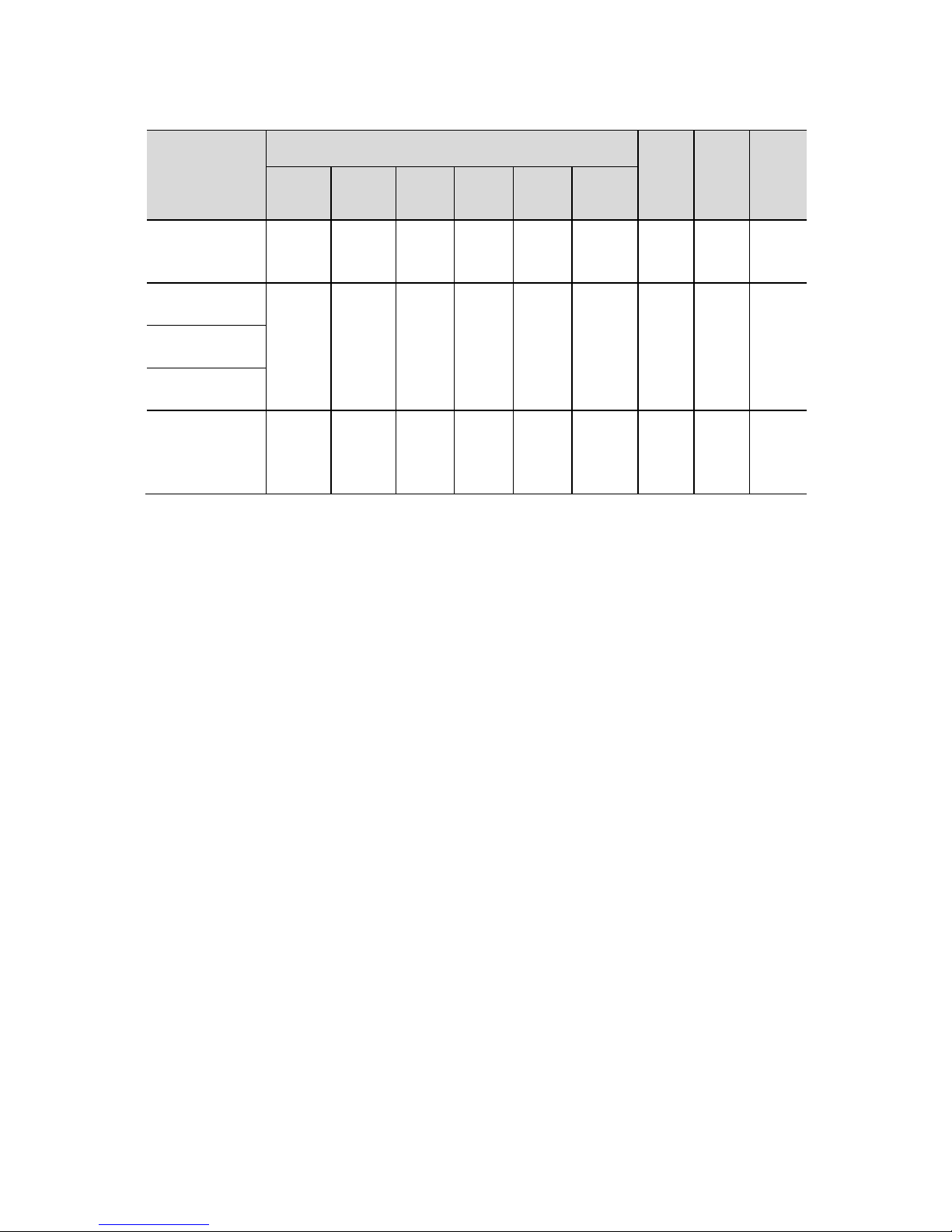

1.5.2 Production dimension table ................................................................................. 10

2 Wirings ........................................................................................................ 11

2.1 Standard wiring diagrams .................................................................................. 11

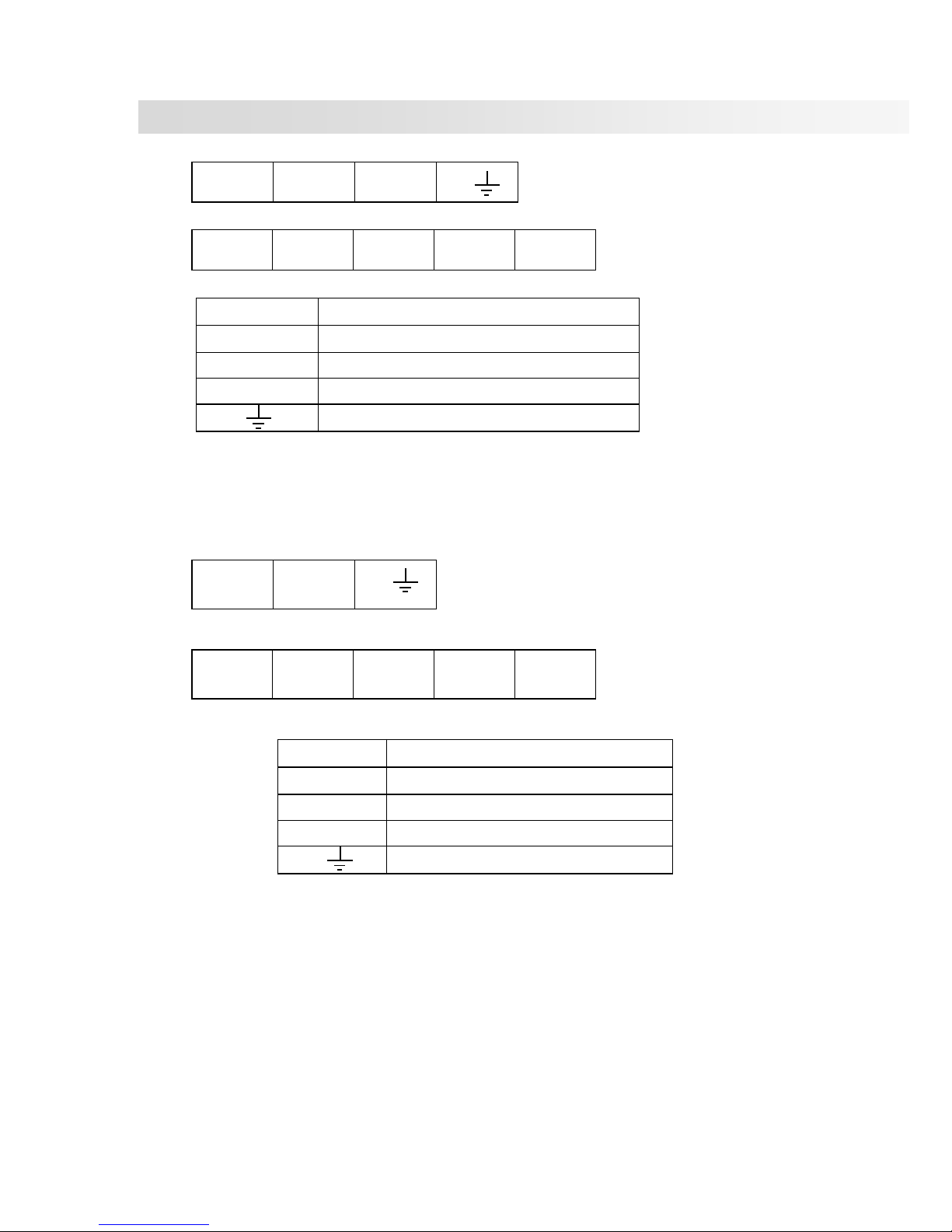

2.2 Main circuit wirings ........................................................................................... 12

2.3 Control circuit wirings ........................................................................................ 13

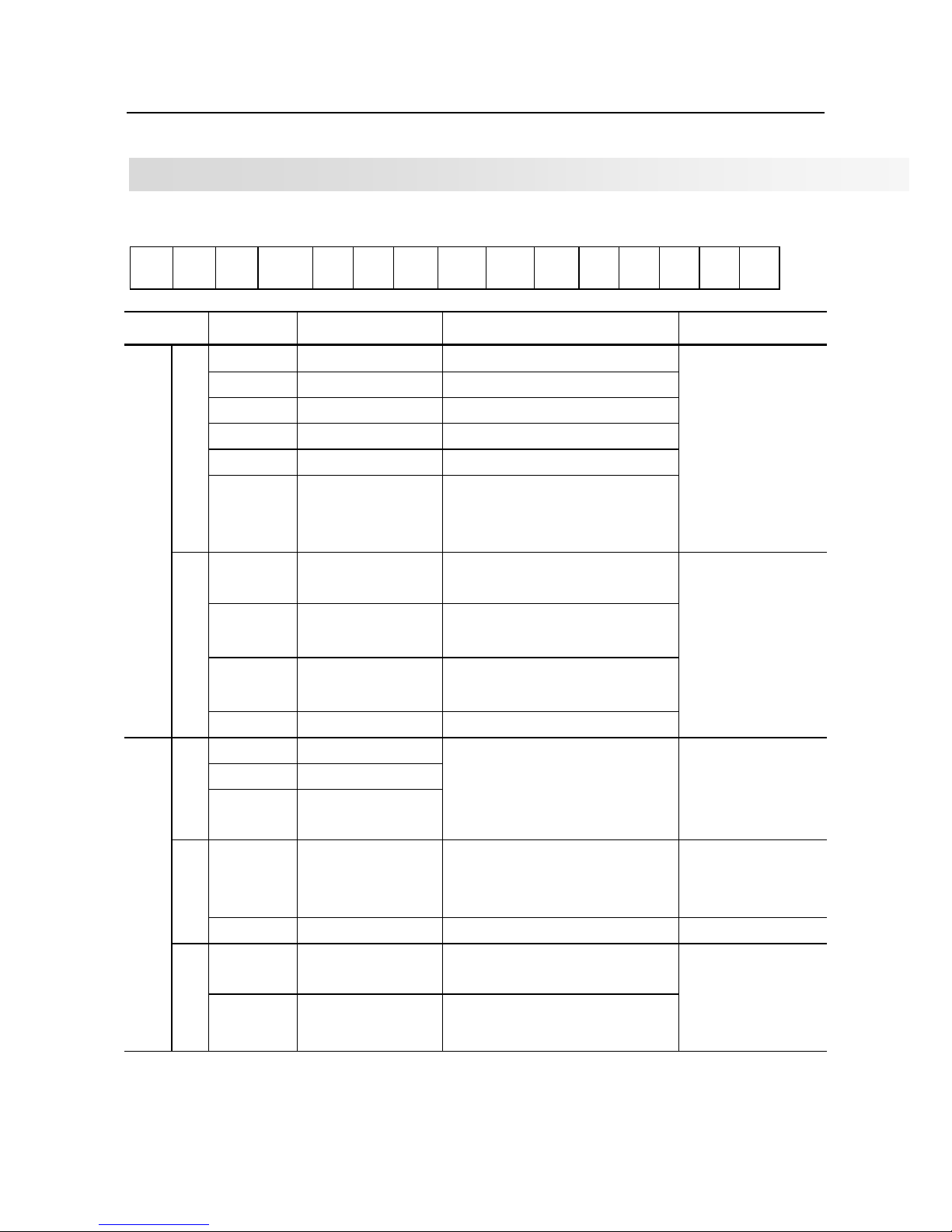

2.3.1 Control circuit signals ........................................................................................... 13

2.3.2 Control circuit wiring notes .................................................................................. 14

2.3.3 Control circuit jumpers ......................................................................................... 15

3 Panel operations ...................................................................................... 16

3.1 Keyboard interface ............................................................................................ 16

3.2 Parameter setting example ............................................................................... 17

3.3 Motor parameter auto-tuning ........................................................................... 17

3.4 JOG run .............................................................................................................. 18

4 Function codes (Parameters) .................................................................... 19

4.1 Monitoring parameters: d0.00-d0.65 ................................................................ 19

4.2 Basic functions group: P0.00-P0.28 ................................................................... 22

4.3 First motor parameters: P1.00-P1.37 ................................................................ 29

4.4 Vector control parameters: P3.00-P3.22 ........................................................... 31

4.5 V/F control parameters: P2.00-P2.27 ................................................................ 31

4.6 Input terminals: P4.00-P4.39 ............................................................................. 37

4.7 Output terminals: P5.00-P5.22 .......................................................................... 46

4.8 Start/stop control: P6.00-P6.15 ......................................................................... 50

4.9 Keyboard and display: P7.00-P7.14 ................................................................... 54

4.10 Auxiliary functions: P8.00-P8.54 ...................................................................... 57

4.11 Fault and protection: P9.00-P9.73 ................................................................... 64

4.12 PID functions: PA.00-PA.28 .............................................................................. 74

4.13 Swing Frequency, Fixed Length and Count: PB.00-PB.09 ................................ 78

4.14 Multi-speed and simple PLC: PC.00-PC.51 ....................................................... 80

4.15 Communication parameters: PD.00-PD.06 ...................................................... 84

4.16 Function code management: PP.00-PP.04....................................................... 85

4.17 Torque control parameters: B0.00-B0.08 ........................................................ 86

4.18 Control optimization parameters: B5.00-B5.09 ............................................... 87

5 Fault and solutions ...................................................................................... 89

5.1 Alarms and solutions ......................................................................................... 89

3

5.2 Other fault and solutions ................................................................................... 94

6 Repair and maintenance ............................................................................. 96

6.1 Routine maintenance ........................................................................................ 96

6.2 Replacement of vulnerable components ........................................................... 96

7 MODBUS communication protocol .............................................................. 97

7.1 Communication protocol ................................................................................... 97

7.2 Verification mode ............................................................................................ 100

7.3 Communication addresses .............................................................................. 101

Appendix I: Brake accessories ...................................................................... 105

Safety Precautions

Please pay close attention to all safety-related information in this user manual; otherwise there may be

fatal consequences. Please note the manufacturer shall bear no liabilities to damages of any sorts

resulting from false operations which is not following this user manual.

Warning ---- potential risks. Fatality may be caused if not avoided.

Attentions – please follow these instructions when using the inverter.

Do not do wiring operations at power on;

Only qualified electrical engineers can install & maintain the inverter;

Power on the inverter only after the covers have been put back on. Do not remove the cover during

power on;

Please wait at least 10 minutes after power of to remove the cover; so as to let DC bus capacitors to

fully discharge;

Please make sure the rated input voltage is compatible with the power supply voltage. Otherwise, there

may be risks of fire;

Please do not operate the inverter with wet hands. The inverter has many semiconductor components

inside;

The inverter is not designed for voltage-withstanding tests;

Do not alter the inverter;

Do not install or use any inverter which is already broken or with faulty parts.

Attentions – when scrapping the inverter.

Electrolytic capacitors on the PCBs of the inverters may explode if incinerated;

Poisonous gas may emit if incinerated;

Please dispose scrapped inverters as industrial waste.

WARNING

Risk of electric shock!

Wait at least 10 minutes after power off to remove the cover.

Read the user manual and follow the safety instructions before use.

A

-2-

Quick installation guide

Flowchart for installation & maintenance:

Tasks

Main circuit wiring.

Control circuit wiring.

Inverter JOG run.

Chapter 5

Chapter 3.3

Chapter 2.6

Chapter 2.5

References

Get familiar with panel

operations.

Chapter 3

Check installations

Chapter 2.4

Remove the packaging and

check inverter model.

Check environment and input/

output cables.

Confirm inverter capacity is

compatible with motor.

Fault & solutions

Chapter 1

B

-3-

Attention: please follow inverter installation location requirements strictly.

Environmental requirements for installation of inverters:

Temperature

-10°C to +40°C (derate 1% for every °C if the ambient temperature is between

40°C and 50°C)

Altitude

Less than 1000m (derate 10% for every 1000m if the altitude is above 1000m)

Other

requirements

Please install the inverter in a place which is not inclining to fierce shocks

or vibrations. Maximum vibration is 5.8m/s

2

(0.6g);

Please install the inverter in a place which is far from electromagnetic

radiations;

Please install the inverter in a place where metal dust, normal dust, oil, or

water is hard to enter inside the inverter;

Please do not install the inverter in a place which is exposed to direct

sunlight, with combustible gas, oil smoke, vapor, drip or salt;

Humidity should be Less than 90%RH, without condensing.

Spacing for inverter installations:

-4-

1 Summary

1.1 Name plate

Model

Power

Input power

Output

MODEL: DLA1-02D2T4G

POWER : 2.2kW

INPUT: AC3PH 380V 50Hz/60Hz 6A

OUTPUT: AC3PH 0~380V 0~30 0Hz 5A

S/N:

Dorna Technology CO.,ltd

Barcode

T:Three phase

S:Single phase

Inverter series

DLA 1-0D75 T 4 G

Inverter capacity

G: general-purpose

P: Light load

Rated input voltage:

2:220V 4:380V

7:660V/690V

Plant code

【1】

【2】

【3】

【6】

【5】

【4】

-5-

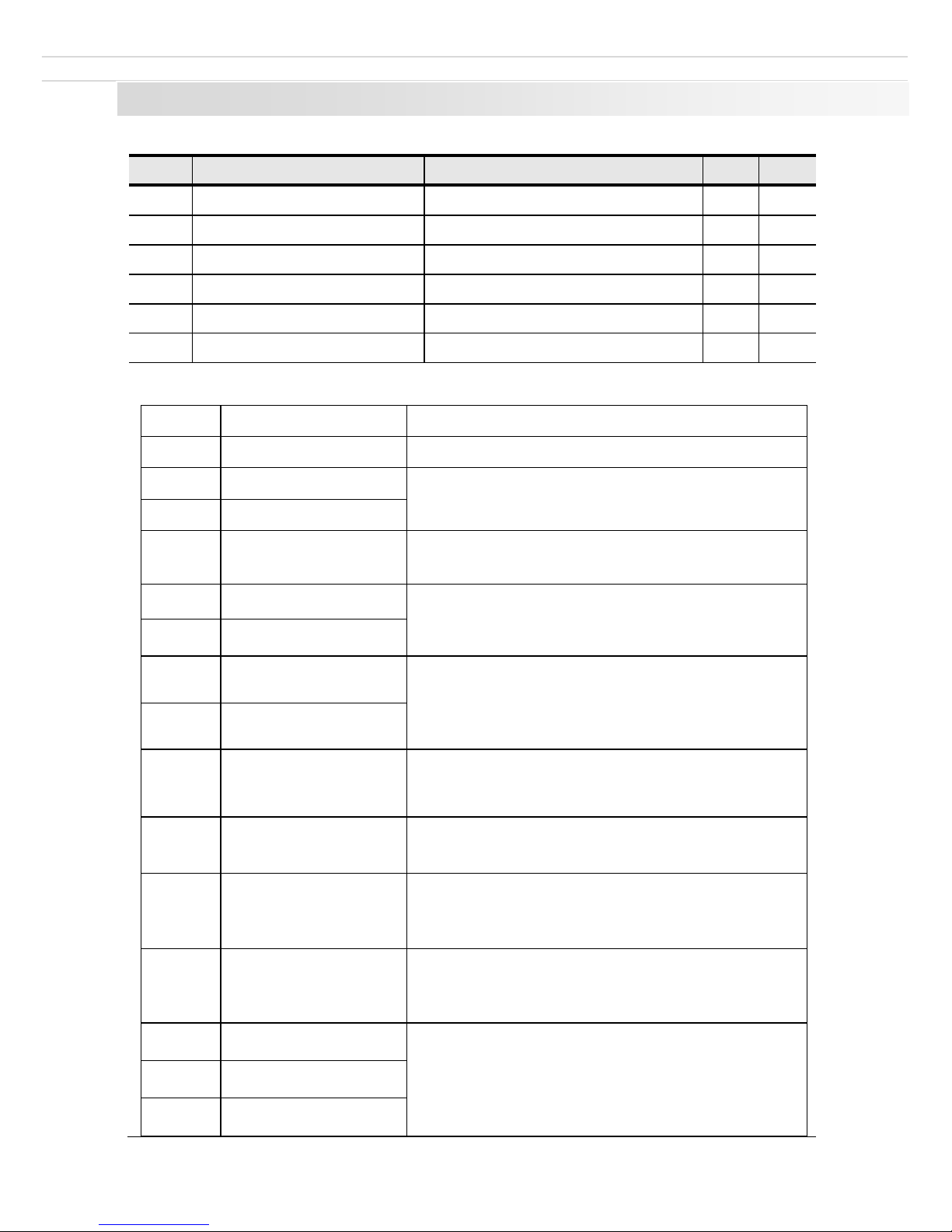

1.2 Product series

Inverter model

Rated output

power (kW)

Rated input current

(A)

Rated output

current (A)

Single Phase input: AC 220V -15%~+10%, 50/60Hz

DLA1-0D40S2G

0.4

5.9

2.5

DLA1-0D75S2G

0.75

8.3

4

DLA1-01D5S2G

1.5

14.1

7

DLA1-02D2S2G

2.2

11.8

10

Three phase input: AC 380V -15%~+10%, 50/60Hz

DLA1-0D75T4G

0.75

4.3

2.5

DLA1-01D5T4G

1.5

5.2

3.7

DLA1-02D2T4G

2.2

6.0

5

DLA1-0004T4G

4.0

10.5

8.5

DLA1-05D5T4G

5.5

15.5

13

-6-

1.3 Technical standards

Item

Specifications

Basic functions

Control system

Current Vector General Purpose Inverter.

Compatible motor

Induction motors.

Maximum

frequency

Vector control: 0~500Hz;

V/F control: 0~500Hz.

Carrier frequency

0.8kHz~12kHz; Depending on load, can automatically adjust.

Input resolution

Digital: 0.01Hz;

Analog: maximum frequency×0.025%.

Control modes

Open vector control (SVC);

V/F (scalar) control.

Starting torque

G type: 0.5Hz/150% (SVC); 0Hz/180% (FVC).

P type: 0.5Hz/100%.

Speed range

1: 100 (SVC)

1: 1000 (FVC)

Speed accuracy

±0.5% (SVC)

±0.02% (FVC)

Torque accuracy

±5% (FVC)

Overload capacity

G type: 150% rated current 60s; 180% rated current 3s;

P type: 120% rated current 60s; 150% rated current 3s.

Torque boost

Automatic

Manual 0.1%~30.0%

V/F curve

Straight-line V/F curve

Multi-point V/F curve

N-power V/F curve (2-power, 1.4-power, 1.6-power, 1.8-

power, 2-power square)

V/F separation

Two types: complete separation; half separation. AVR output.

Ramp mode

Straight-line ramp

S-curve ramp

Four groups of acceleration/deceleration time: 0.0–6500.0s

DC braking

DC braking frequency: 0.00 Hz to maximum frequency

Braking time: 0.0–36.0s

Braking action current value: 0.0%–100.0%

JOG control

JOG frequency range: 0.00–50.00 Hz

JOG acceleration/deceleration time: 0.0–6500.0s

Simple PLC

Up to 16 speeds via the simple PLC function or DI terminals

Onboard PID

Process-controlled closed loop control system

Auto voltage

regulation (VR)

Keep constant output voltage automatically when grid voltage

fluctuates.

Overvoltage/

Overcurrent stall

control

The current and voltage are limited automatically during the running

process so as to avoid frequent tripping due to

overvoltage/overcurrent.

Fast current limit

function

Protect inverter from overcurrent malfunctions.

Torque limit and

control

It can limit the torque automatically and prevent frequent over

current tripping during the running process. Torque control can be

implemented in the FVC mode.

Power dip ride

through

The regenerative energy from load compensates the voltage

reduction so that the inverter can continue to run for a short time.

Timing control

Time range: 0.0–6500.0 minutes

-7-

Two-motor

switchover

Two motors can be switched over via two groups of motor

parameters.

Fieldbuses

RS485

Operations

Command source

Keyboard

Control terminals

Serial communication port

You can perform switchover between these sources in various ways.

Frequency source

10 frequency sources, such as digital setting, analog voltage setting,

analog current setting, pulse setting and serial communication port

setting. You can perform switchover between these sources in

various ways.

Auxiliary

frequency source

10 auxiliary frequency sources. It can implement fine tuning of

auxiliary frequency and frequency synthesis.

Input terminal

5 digital input (DI) terminals;

2 analog input (AI) terminals which support 0–10V voltage input or

0–20mA current input.

Output terminal

1 digital output (DO) terminal;

1 relay output terminal;

1 analog output (AO) terminals which support 0–20mA current

output or 0–10V voltage.

Display and

Key lock

It can lock the keys partially or completely and define the function

range of some keys so as to prevent misconducts.

Protection

functions

Motor short-circuit detection at power-on, input/output phase loss

protection, overcurrent protection, overvoltage protection, under

voltage protection, overheat protection and overload protection

Environment

Location

Indoor, free from direct sunlight, dust, corrosive gas, combustible

gas, oil smoke, vapor, drip or salt.

Altitude

Less than 1000m.

Ambient

temperature

-10°C to +40°C (de-rated if the ambient temperature is between

40°C and 50°C)

Humidity

Less than 90%RH, without condensing

Vibration

Less than 5.8m/s

2

(0.6g).

Storage

temperature

-20℃~+60℃.

-8-

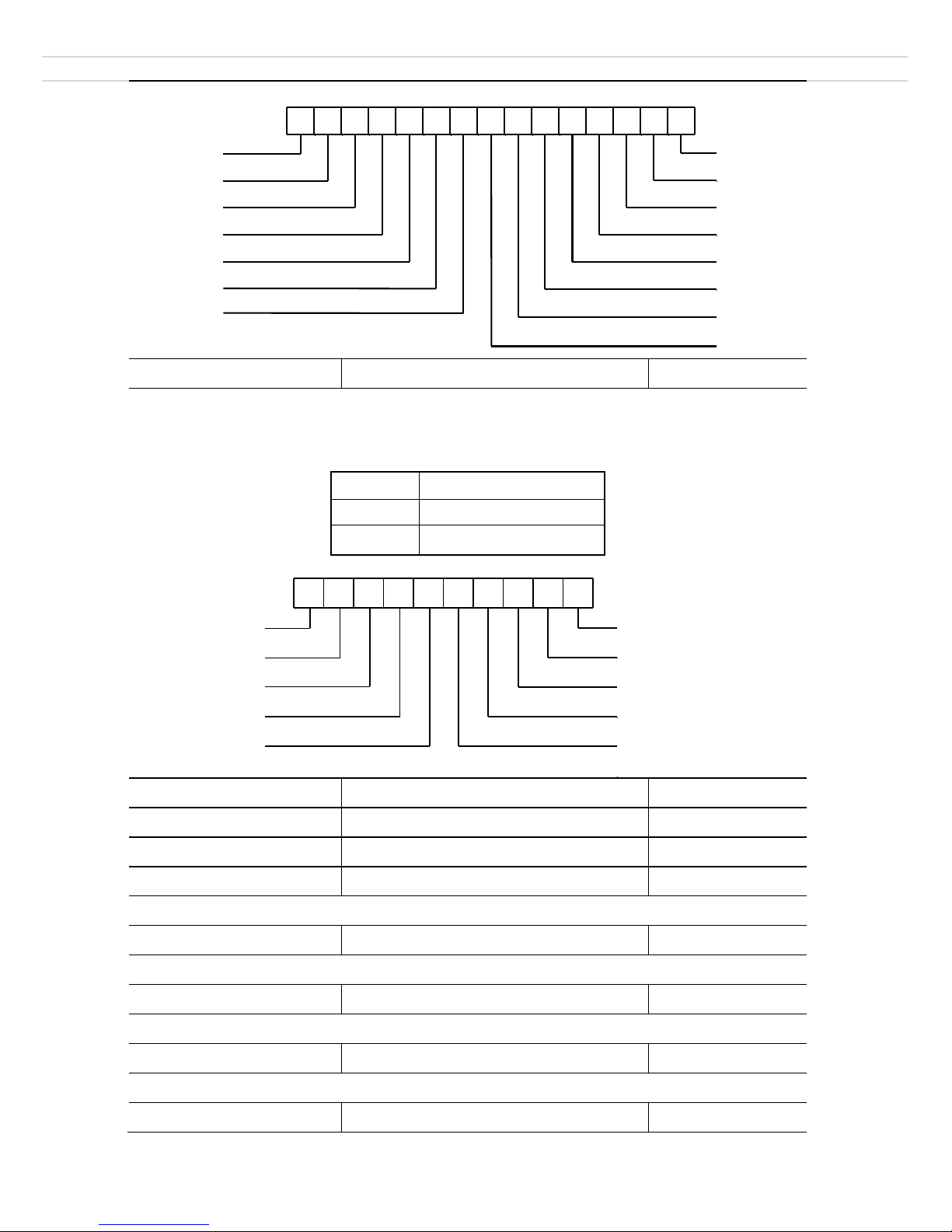

1.4 Peripheral Electrical Devices and System Configuration

Grounding

Circuit

braker

Motor

DC reactor

EMC

filter

Grounding

AC

reactor

Inverter

EMC

filter

Contactor

AC reactor

Power

Brake

resistor

Brake

unit

-9-

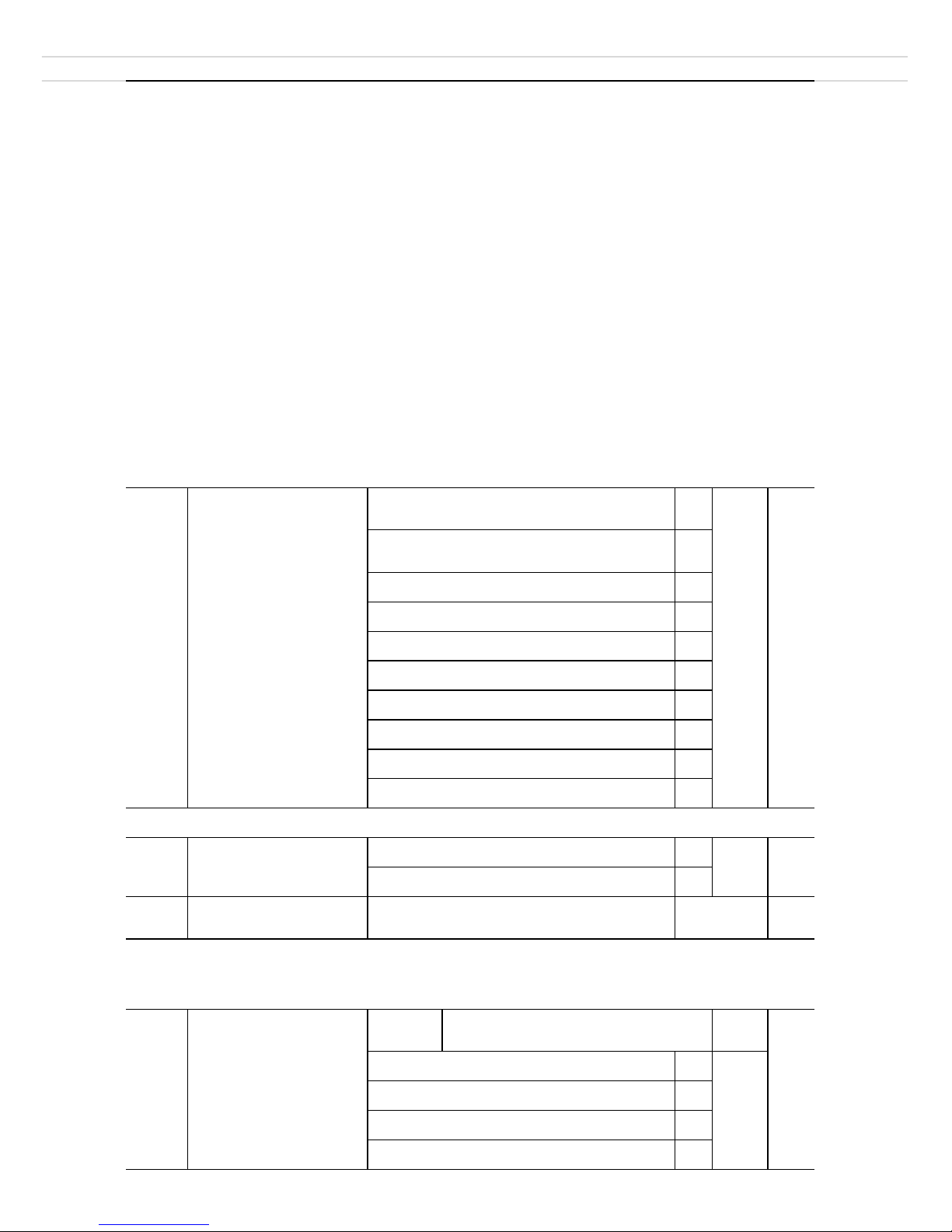

1.5 Product outline and installation dimensions

1.5.1 Product outlines (unit: mm)

-10-

1.5.2 Production dimension table

Model

Dimensions

Holes

(mm)

Net

(Kg)

Gross

(Kg)

L2

(mm)

L3

(mm)

W

(mm)

W1

(mm)

H

(mm)

H1

(mm)

DLA1-0D40S2G

DLA1-0D75S2G

DLA1-01D5S2G

136.5

142

85

79.5

112.5

122.5

M5

DLA1-0D75T4G

DLA1-01D5T4P

145.5

151

100

94.5

116.5

126.5

M5

DLA1-01D5T4G

DLA1-02D2T4P

DLA1-02D2T4G

DLA1-03D7T4P

DLA1-03D7T4G

DLA1-05D5T4P

DLA1-05D5T4G

DLA1-07D5T4P

-11-

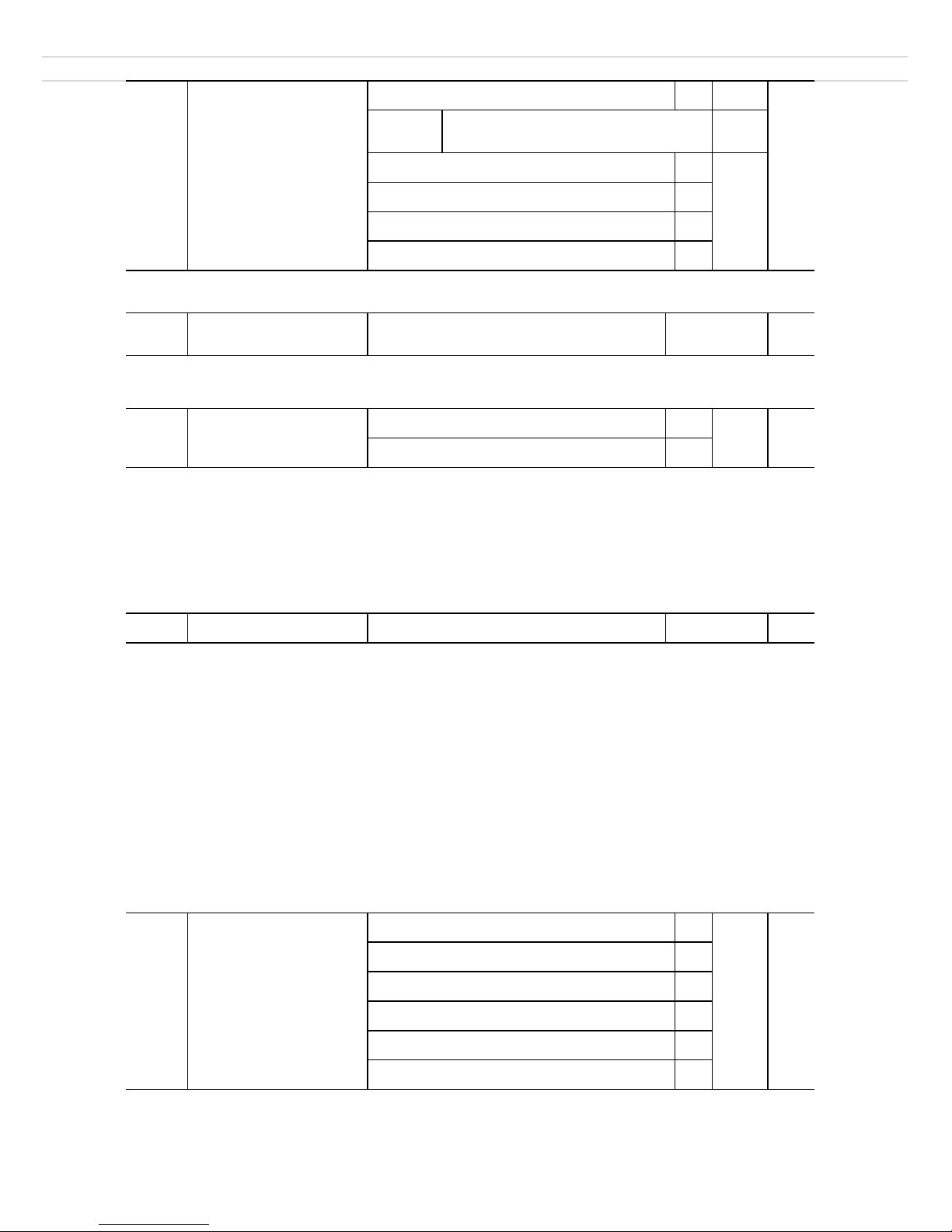

2 Wirings

2.1 Standard wiring diagrams

M

3~

U

W

V

P+P-

R

S

T

Input power

PB

Brake resistor

TA1

TB1

TC1

+24

V

DI1

DI2

DI3

DI4

DI6

COM

P4.00=1 FWD

P4.01=4 FJOG

P4.02=9 RESET

P4.03=12 Speed 1

P4.05=2 REV

NPN (default)

GND

AI1

+10V

PE

VR

1K

2W

Default: 0-10V input

GND

AI2

+10V

PE

VR

1K

2W

GND

Motor

Main circuit

Control circuit

DO1

COM

AO

1

GND

P

E

P5.07=0

0-10V Max load current: 5mA

0-20mA Max load resistance: 250Ω

Circuit

breaker

RS485

GND

P

E

RS+

RS-

Shielding

DLA1

-12-

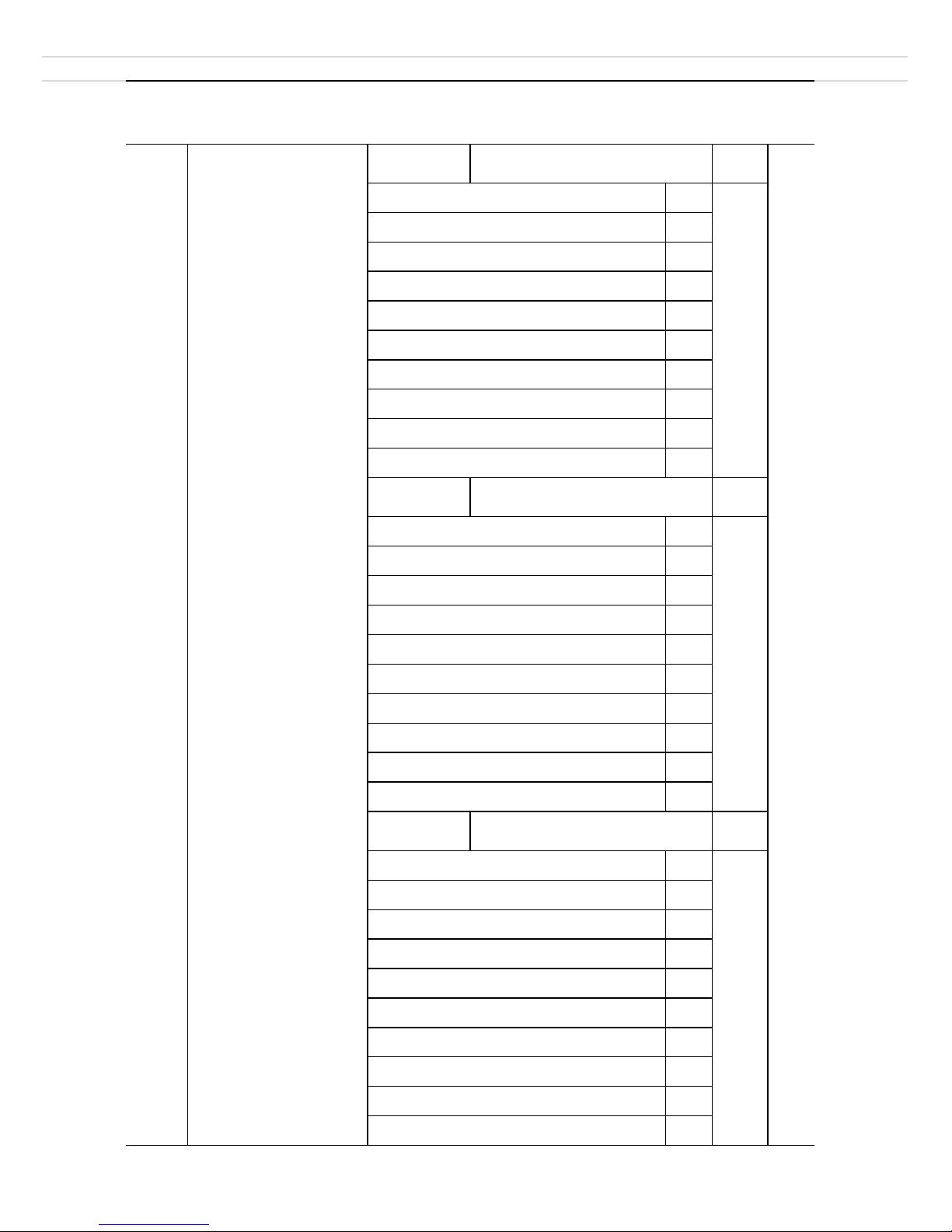

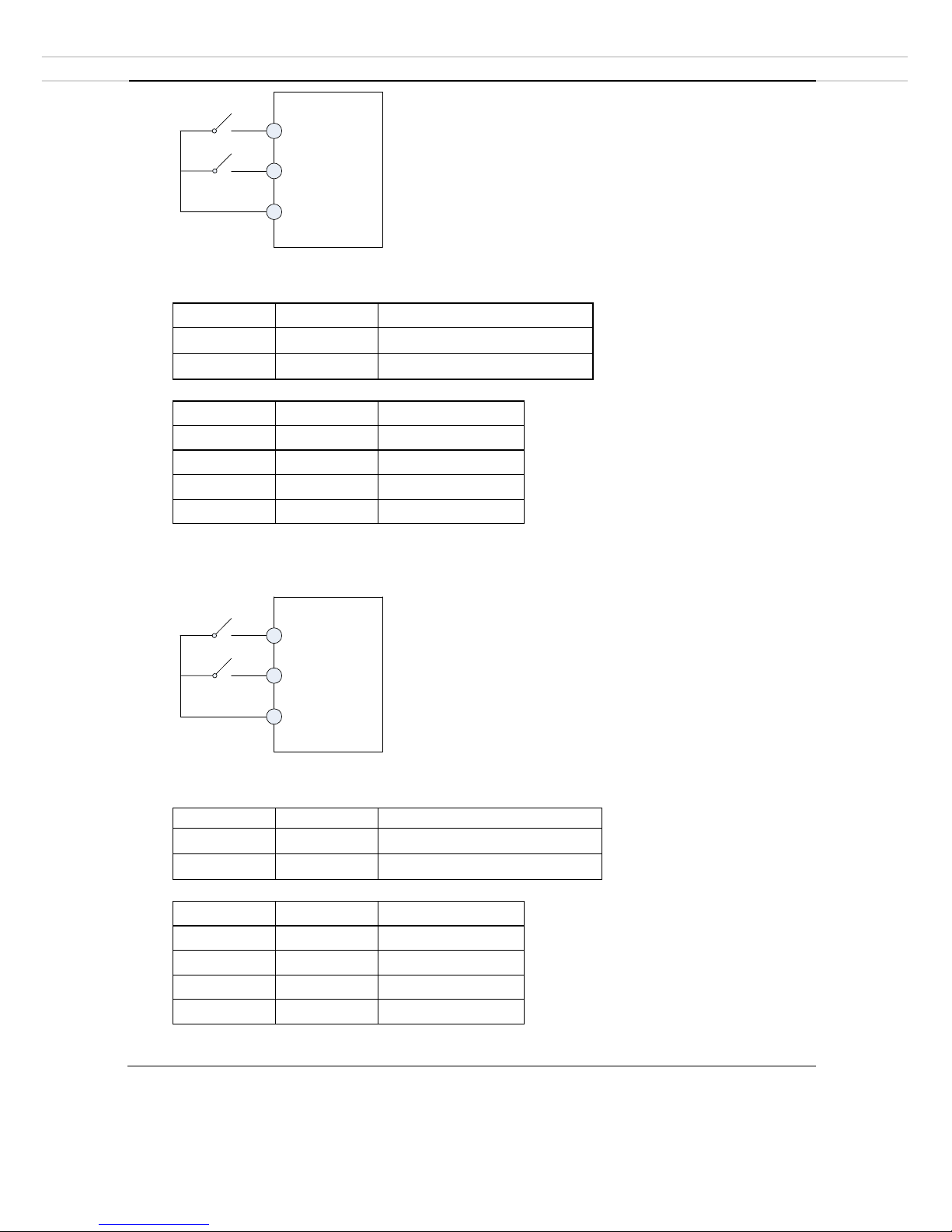

2.2 Main circuit wirings

380V class:

R S T

U V W

P+

PB

Terminals

Functions

R、S、T

Input power

P+、PB

External brake resistor

U、V、W

Output power

GND

220V class

L1

L2

PB

P+ U V

W

Terminals

Functions

L1、L2

Input power

P+、PB

External brake resistor

U、V、W

Output power

GND

-13-

2.3 Control circuit wirings

2.3.1 Control circuit signals

TC1

TB1

TA1

AGND

AI1

AI2

AO1

+10V

COM

DO1

DI1

DI2

DI3

DI4

DI6

Type

Terminal

Name

Function

Specifications

Input

Digital

DI1

Input terminal X1

Default: Forward run (FWD)

Opti-coupler

insulation

DC24V/8mA

External power

voltage range: 9~

30V. DI5 pulse

input range: 0~

100kHz.

DI2

Input terminal X2

Default: Forward JOG (FJOG)

DI3

Input terminal X3

Default: Fault reset (RESET)

DI4

Input terminal X4

Default: Multi-speed terminal 1

DI6

Input terminal X6

Default: Reverse run (REV)

SP

Input terminal

common

Default: +24V short-circuit

with SP by Jumper J9

Analog

10V

Analog 10V

Power

Output capacity: 10mA or

below, 1kΩ~5kΩ

0~20mA input:

input impedance is

500 ohms.

0~10V input:

input impedance is

20K ohms.

AI1

Analog setting 1

Default: 0~10V

(resolution1/1000)

AI2

Analog setting 2

Default: 0~20mA

(resolution1/1000)

AGND

Analog common

0V

Output

Relay

TA1

A node output

Default setting: stop fault

during operation

TA1—TC1: normally open

TB1—TC1: normally close

Node capacity:

AC250V, 3A.

TB1

B node output

TC1

Node output

common terminal

Digital

DO1

Open collector

output 1

Default: inverter in operation

Below DC24V,

50mA.

COM

Digital common

Analog

AO1

Analog monitor

output 1

Voltage or current output;

Default: output frequency

Output voltage

range: 0~10V;

Output current

range: 0~20mA.

AGND

Analog common

0V

-14-

2.3.2 Control circuit wiring notes

Analog input wirings

As analog signals can be easily affected by external interference, shielded cables shall be used. Cables

shall be as short as possible and not exceeding 20 meters. As shown in graphs below, in some severe

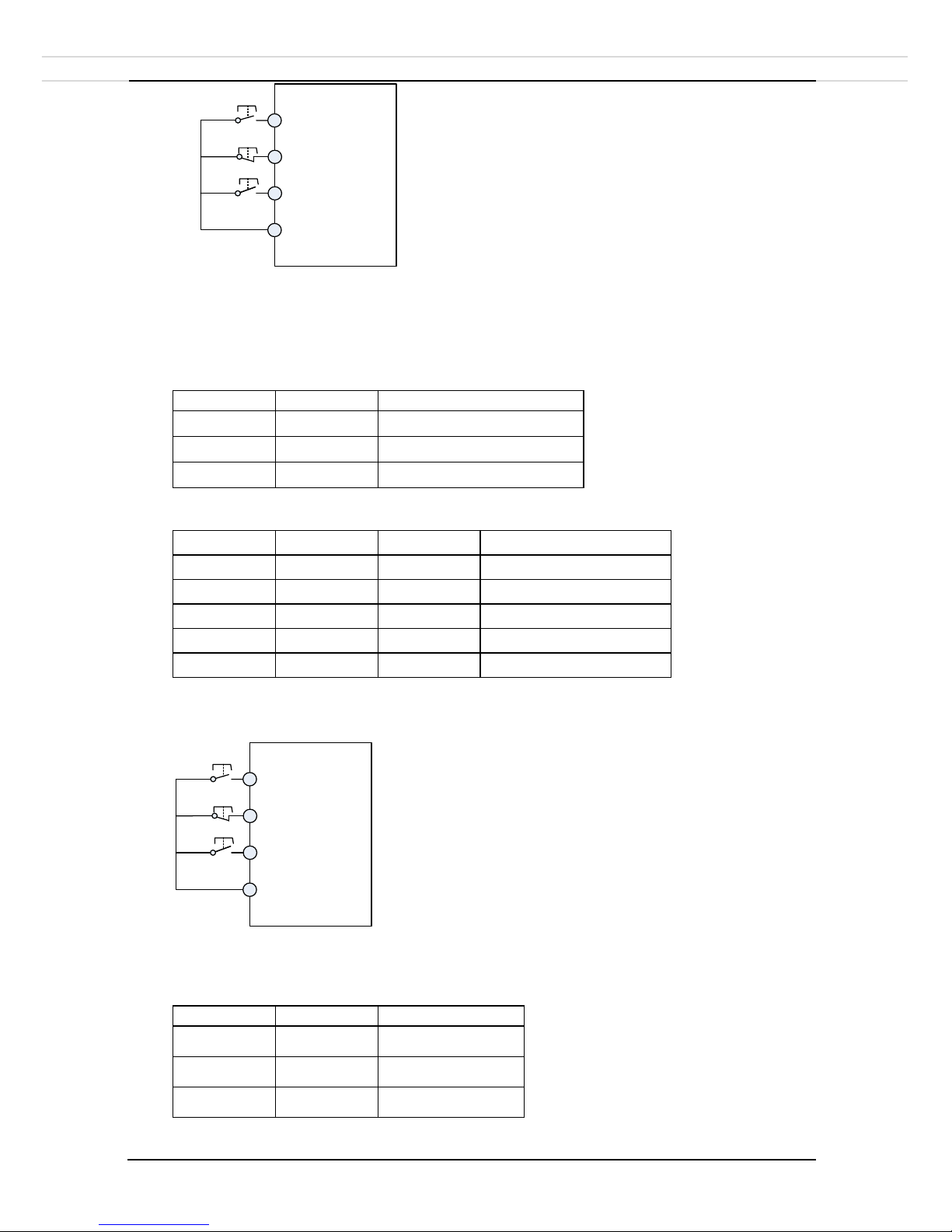

circumstances, filter capacitor or ferrite bread shall be used in analog signal side.

Digital input wirings

Shielded cables shall be used. Cables shall be as short as possible and not exceeding 20 meters. When

using active drive mode, user shall take necessary filter measures to counter power interference. It is

recommended to use node control mode. Digital inputs can be NPN or PNP.

NPN input: Most common. Use

internal 24V power; +24V terminal shortcircuit with SP terminal; COM terminal

is common; J9 is 23 jumped; also known

as drain wiring mode.

PE

+10V

GND

AI1

DLA1

Potentiometer

Less than 20m

DLA1

AI1

GND

0.022uF

50V

Ferrite bread

External

analog

source

NPN

信号

COM

4.7K

4.7K

D15

D11

SP

+24V

0V

+24V

+VCC

3.3Ω

External

controller

Inverter

-15-

PNP input: Use external 24V power;

external power negative node is

connected with SP terminal; external

terminal positive node is common;

external power voltage range is 9~30V;

J9 is 12 jumped; also known as source

wiring mode.

Output wirings

Digital output is open collector output. When using external power, please connect external power

negative node to COM terminal. Maximum current is 50mA for open collector output. If external load is

relay, please install fly-wheel diode to both ends of the relay.

Note: please install fly-wheel diode

polar correctly, otherwise internal

components will be damaged.

2.3.3 Control circuit jumpers

J5: RS485 matching resistor selection J1: AO1 output selection

Not use

Use 120

resistor

1

2

3

1

2

3

0-10V

0-20mA

1

2

3

1

2

3

PNP

信号

COM

4.7K

4.7K

D15

D11

SP

+24V

0V

+24V

+VCC

3.3Ω

External

controller

Inverter

9-30V

Relay

Fly-wheel

diode

+24V

DO1

DO2

CME

Max current: 50mA

Inverter

COM

-16-

3 Panel operations

3.1 Keyboard interface

Keyboard outline is as below:

Keys/Lights

Function

Descriptions

DIR (light)

Rotating direction

status

ON: FWD

OFF: REV

RUN (light)

Operation status

ON: RUN

OFF: STOP

LOCAL (light)

Command source

status

ON: terminal control

OFF: keyboard control

BLINK: remote (communicational) control

TUNE/TC (light)

Tune/fault

ON: in torque control mode

SLOW BLINK: in tuning status

FAST BLINK: in fault status

Hz A V

RPM (Hz+A)

% (A+V)

(lights)

Unit indications

* Hz: frequency unit

*A: current unit

*V: voltage unit

*RPM (Hz+A): speed unit

*% (A+V): percentage

Digital display area

Display settings, output frequency, monitor data, fault etc.

MON/ESC

Program key: Enter level 1 menu or escape

>>

Shit key: Select parameter or select place for editing.

DATA/ENTER

Confirm key: Confirm parameters

▲

Increase key

▼

Decrease key

DIR/JOG

Multi-function selection key: Function switching set by P7.01.

RUN

Operation key: Start operation in keyboard operation mode.

STOP/RESET

STOP/RESET key: Set by P7.02

-17-

3.2 Parameter setting example

DLA1 inverter panel has a three-level structure: function code group (level 1menu) → function code

(level 2 menu) → function code setting (level 3 menu).

Example: Change P2.02 from 10.00Hz to15.00Hz, as shown in graph below:

Parameter monitoring: please refer to P7.03, P7.04, P7.05 for parameter monitoring settings.

Password setting: when PP.00 is not 0, inverter is under password protection. The password is as

shown in PP.00. To cancel password protection, user must enter the correct password and set PP.00=0.

3.3 Motor parameter auto-tuning

1) Set P0.02=0 (keyboard as command source channel)

2) Input motor parameters:

Motor selection

Parameters

Motor 1

P1.00: motor type selection; P1.01: rated power

P1.02: rated voltage; P1.03: rated current

P1.04: rated frequency; P1.05: rated speed

3) If (asynchronous) motor can separate from load, set P1.37=2 (asynchronous motor complete

auto-tuning) and press RUN key. The inverter will automatically calculate parameters below:

Motor selection

Parameters

Motor 1

P1.06: asynchronous motor stator resistor

P1.07: asynchronous motor rotor resistor

P1.08: asynchronous motor leakage inductance

P1.09: asynchronous motor mutual inductance

P1.10: asynchronous motor no load current

4) If (asynchronous) motor cannot separate from load, set P1.37=1 and press RUN key.

5) Finish auto-tuning.

-18-

3.4 JOG run

DLA1 series default setting value

Parameter

Default value

P0.01 0 Sensorless vector control (SVC)

P0.02

0

Keyboard command channel (LED OFF)

P0.03

0

Keyboard setting frequency (P0.08, UP/DOWN

can edit, not retentive at power of)

After correctly set motor parameter P1.00-P1.05 and auto-tuning, user can control motor operation

using keyboard DIR/JOG.

- 19 -

4 Function codes (Parameters)

Legends:

“★”: this parameter’s setting value is not editable when inverter is at operation status;

“●”: this parameter’s value is observed value, not editable;

“☆”: this parameter’s setting value is editable when inverter is at stop or operation status;

“▲”: this parameter is “factory parameter” not for editing;

“-”: this parameter is depending on model.

Def: factory default settings

Res: restrictions when editing

4.1 Monitoring parameters: d0.00-d0.65

d0 group is used for monitoring inverter status. User can read by panel display or by remote communications.

d0.00~d0.31 are defined by P7.03 & P7.04.

Function code

Name

Unit

d0.00

Running frequency (Hz)

0.01Hz

Absolute value of theoretical running frequency.

d0.01

Set frequency (Hz)

0.01Hz

Absolute value of theoretical set frequency.

d0.02

DC Bus voltage (V)

0.1V

Detected value of DC bus voltage

d0.03

Output voltage (V)

1V

Actual value of inverter output voltage.

d0.04

Output current (A)

0.01A

Effective value of inverter output current.

d0.05

Output power (kW)

0.1kW

Value of inverter output power.

d0.06

Output torque (%)

0.1%

Value of inverter output torque percentage.

d0.07

DI input status

1

This displays the current state of DI terminals and the value is hexadecimal. Each bit corresponds

to a DI. "1" indicates high level signal, and "0" indicates low level signal. The corresponding

relationship between bits and DIs is described in the following table.

0~14 place

Input terminal status

0

invalid

1

valid

-20-

d0.08

DO output status

1

This displays the current state of DO terminals and the value is hexadecimal. Each bit corresponds

to a DO. "1" indicates high level signal, and "0" indicates low level signal. The corresponding

relationship between bits and DOs is described in the following table.

0~9 place

output terminal status

0

invalid

1

valid

d0.09

AI1 voltage after correction

V/mA

d0.10

AI2 current after correction

V/mA

d0.11

Keyboard command voltage

V/mA

d0.14

Load speed display

1

Motor actual running speed. Please refer to P7.12 for settings.

d0.15

PID setting value

1

PID preset value percentage.

d0.16

PID feedback

1

PID feedback value percentage.

d0.18

HDI (DI5) pulse frequency

0.01kHz

HDI (DI5) input pulse frequency display.

d0.19

Feedback speed

0.1Hz

11

14

13

12

2

11

2 2 2

121314

DI7

DI8

DI10

DI9

7 6

5

4

3

2

1

0

DI1

DI2

10

9

8

DI3

DI4

DI5

DI6

VDI5

VDI4

VDI3

VDI2

VDI1

2 2 2 2 2 2

2

2

0

1

234567

2 2 2

8910

7 6

5

4

3

2

1

0

FMR

TA1-TB1-TC1

9

8

TA2-TB2-TC2

DO1

DO2

VDO1

2 2 2 2 2 2

2

2

0

1

234567

2 2

89

VDO2

VDO3

VDO5

VDO4

-21-

PG feedback speed, accurate to 0.1Hz.

P7.12 determines location of decimal point for value of d0.19 & d0.29.

If P7.12=2, value range is -320.00Hz~320.00Hz;

If P7.12-1, value range is -500.0Hz~500.0Hz.

d0.20

Remaining running time

0.1Min

Used for timer control. Refer to P8.42~P8.44.

d0.21

AI1 voltage/current before correction.

0.001V

If P4.40=0, this displays voltage; if P4.40=1, this displays current.

d0.22

AI2 voltage before correction.

0.001V

If P4.40=0, this displays voltage; if P4.40=1, this displays current.

d0.23

Keyboard voltage before correction.

0.001V

If P4.40=0, this displays voltage; if P4.40=1, this displays current.

d0.28

Communication setting value

0.01%

It displays the data written from the communication address 0x1000.

d0.30

Main frequency X display

0.01Hz

P0.03 main frequency setting value

d0.31

Auxiliary

frequency Y display

0.01Hz

P0.04 auxiliary frequency setting value.

d0.35

Target torque

0.1%

Target torque is current torque upper limit.

d0.37

Power factor angle

-

d0.39

V/F separation target voltage

1V

Target voltage upon V/F separation

d0.40

V/F separation output voltage

1V

Output voltage upon V/F separation

d0.41

DI terminal status display

ON: high electrical level;

OFF: low electrical level.

d0.42

DO terminal status display

ON: high electrical level;

OFF: low electrical level.

d0.43

DI function display 1

-22-

This uses 5 nixie tubes to display whether terminal functions 1~40 are

valid. Each nixie tube can display 8 functions. From right to left: 1~8,

9~16, 17~24, 25~32, 33~40.

d0.44

DI function display 2

Same as d0.43, this uses 3 nixie tubes to display whether terminal functions 41~59 are valid. From

right to left: 41~48, 49~56, 57~59.

d0.59

Setting frequency percentage

%

d0.60

Running frequency percentage

%

d0.61

Inverter running status

d0.61

Bit0

0: Stop; 1: FWD; 2: REV

Bit1

Bit2

0: Constant speed; 1: Accelerate; 2: Decelerate

Bit3

Bit4

0: DC bus normal; 1: under-voltage

d0.62

Current fault code

d0.63

Point-to-point communication value sent

d0.64

Number of slaves

d0.65

Torque upper limit

4.2 Basic functions group: P0.00-P0.28

Code

Description

Setting range

Def

Res

P0.00

Load type

G type

1

-

●

P type

2

This parameter is to display the delivered model and cannot be modified.

1: Applicable to constant torque load with rated parameters specified

2: Applicable to variable torque load (fan and pump) with rated parameters specified.

P0.01

Speed control mode

Sensorless flux vector control (SVC)

0

2

★

V/F control

2

0: Sensorless flux vector control for asynchronous motors (SVC)

This is for high-performance control applications such as machine tool, centrifuge, wire drawing

machine and injection molding machine. One inverter can only drive one motor.

2: Voltage/Frequency control (V/F)

It is applicable to applications with low load requirements or applications where one inverter

operates multiple motors, such as fans and pumps.

Notes:

If vector control is used, motor auto-tuning must be performed because the advantages of vector

control can only be utilized after correct motor parameters are obtained. Better performance can be

achieved by adjusting speed regulator parameters in group P3.

For the permanent magnetic synchronous motor (PMSM), the DLA1 does not support SVC. FVC is

used generally. In some low-power motor applications, you can also use V/F.

-23-

P0.02

Command source

channel selection

Keyboard (LED OFF)

0

0

☆

Terminals (LED ON)

1

Communication (LED blinks)

2

This is to determine the input channel of the control commands, such as run, stop, forward rotation,

reverse rotation and jog operation.

0: Keyboard ("LOCAL" indicator off)

Commands are given by pressing keys on the keyboard (keyboard).

1: Terminals ("LOCAL" indicator on)

Commands are given by means of multi-functional input terminals with functions such as FWD,

REV, FJOG, and RJOG.

2: Communication ("LOCAL" indicator blinking)

Commands are given from communication with upper controllers. If this parameter is set to 2, a

communication card (Modbus RTU, PROFIBUS-DP card, CANlink card or CANopen card) must

be installed. Please refer to PD group function codes for communication settings.

P0.03

Main frequency source

X selection

Keyboard setting (P0.08, UP/DOWN

editable, not retentive at power off)

0

0

★

Keyboard setting (P0.08, UP/DOWN

editable, retentive at power off)

1

AI1 setting

2

AI2 setting

3

AI3 setting

4

Reserved

5

Multi-speed operation setting

6

Simple PLC setting

7

PID control setting

8

Remote communication setting

9

This is used to select the setting channel of the main frequency X.

0: Keyboard setting (P0.08, UP/DOWN editable, not retentive at power off)

The initial value of the set frequency is the value of P0.08 (Preset frequency). You can change the

frequency by pressing the keyboard (or using the UP/DOWN function of input terminals). When the

inverter is powered on again after power off, the frequency reverts to the value of P0.08.

1: Keyboard setting (P0.08, UP/DOWN editable, retentive at power off)

The initial value of the set frequency is the value of P0.08 (Preset frequency). You can change the

set frequency by pressing the keyboard (or using the UP/DOWN function of input terminals). When

the inverter is powered on again after power off, the frequency is the value memorized at the

moment of the last power off.

Note that P0.23 determines whether the set frequency is memorized or cleared when the inverter

stops. It is related to stop rather than power off.

2: AI1

3: AI2

4:

AI3 (keyboard potentiometer)

Jumper J6 determines whether to use AI3 terminal or keyboard potentiometer as command source.

If AI3 terminal is selected, Jumper J5 determines whether to use

0-10V voltage input or 0-20 mA

current input

-24-

6:

Multi-speed operation setting

In

multi-speed operation setting

mode, combinations of different DI terminal states correspond to

different set frequencies. The DLA1 supports maximum 16 speeds implemented by 16 state

combinations of four DI terminals in Group PC. The

multi-speed operation setting

indicates

percentages of the value of P0.10 (Maximum output frequency).

If a DI terminal is used for the

multi-speed operation setting

, you need to set in group P4.

7: Simple PLC setting

When the simple programmable logic controller (PLC) mode is used as the frequency source, the

running frequency of the inverter can be switched over among the 16 frequency references. You can

set the holding time and acceleration/deceleration time of the 16 frequency references. For details,

refer to the descriptions of Group PC.

8:

PID control setting

The output of PID control is used as the running frequency. PID control is generally used in on-site

closed-loop control, such as constant pressure closed-loop control and constant tension closed-loop

control. When applying PID as the frequency source, you need to set in group PA.

9:

Remote communication setting (RS485)

P0.04

Auxiliary frequency

source Y selection

Keyboard setting (P0.08, UP/DOWN

editable, not retentive at power off)

0

0

★

Keyboard setting (P0.08, UP/DOWN

editable, retentive at power off)

1

AI1 setting

2

AI2 setting

3

AI3 setting

4

Reserved

5

Multi-speed operation setting

6

Simple PLC setting

7

PID control setting

8

Remote communication setting

9

Refer to P0.03.

P0.05

Y reference in X and Y

combination

Relative to P0.10

0

0

☆

Relative to main frequency source X

1

P0.06

Y range in X and Y

combination

0%~150%

100%

☆

If X and Y combination is used, P0.05 and P0.06 are used to set the adjustment range of Y. You can

set Y to be relative to either maximum frequency or main frequency X. If relative to main frequency

X, the setting range of Y varies according to the main frequency X.

P0.07

Frequency source

combination mode

One’s

place

Frequency source selection

00

☆

Main frequency source X

0

Result of “X and Y combination”

1

X and Y switchover

2

X and “X and Y combination” switchover

3

-25-

Y and “X and Y combination” switchover

4

Ten’s

place

X and Y combinations

X+Y

0 X-Y

1

MAX [X, Y]

2

MIN [X, Y]

3

The final output frequency can be simple X setting, or it can be a sophisticated result after Y is

included and/or combined.

P0.08

Preset frequency

setting

0.00Hz~ P0.10 (

valid when frequency

source is digital setting

)

50

.

00Hz

☆

When frequency source selection is “digital setting” or “terminal UP/DOWN”, this value is inverter

frequency digital setting initial value.

P0.09

Operation direction

selection

Same direction

0

0

☆

Reverse direction

1

You can change the rotation direction of the motor just by modifying this parameter without

changing the motor wiring. Modifying this parameter is equivalent to exchanging any two of the

motor's U, V, W wires.

The motor will resume running in the original direction after parameter initialization. Do not use

this function in applications where changing the rotating direction of the motor is prohibited after

system commissioning is complete.

P0.10

Maximum frequency

50.00Hz~320.00Hz

50.00Hz

★

When the frequency source is AI, pulse setting (DI5), or multi-speed, value of this parameter

determines the 100% frequency.

The output frequency of the DLA1 can reach 3200 Hz. To take both frequency reference resolution

and frequency input range into consideration, you can set the number of decimal places for

frequency reference in P0.22.

• If P0.22 is set to 1, the frequency reference resolution is 0.1 Hz. In this case, the setting range of

P0.10 is 50.0 to 3200.0 Hz.

• If P0.22 is set to 2, the frequency reference resolution is 0.01 Hz. In this case, the setting range of

P0.10 is 50.00 to 320.00 Hz.

P0.11

Frequency source

upper limit

P0.12 setting

0

0

★

AI1 1 AI2

2

AI3

3

Reserved

4

Communication setting

5

-26-

It is used to set the source of the frequency upper limit, including digital setting (P0.12), AI, or

communication setting. If the frequency upper limit is set by means of AI1, AI2, AI3, or

communication, the setting is similar to that of the main frequency source X. For details, see the

description of P0.03.

For example, to avoid runaway in torque control mode in winding application, you can set the

frequency upper limit by means of analog input. When the inverter reaches the upper limit, it will

maintain at this speed.

P0.12

Frequency upper limit

Frequency lower limit P0.14 to maximum

frequency

P0.10

50.00Hz

☆

P0.13

Frequency upper limit

offset

0.00Hz~ maximum frequency P0.10

0.00Hz

☆

When frequency is set by analog or pulse, P0.13 is used as setting value offset value, and then

overlap with P0.11 to become final frequency upper limit.

P0.14

Frequency lower limit

0.00Hz~ upper limit frequency P0.12

0.00Hz

☆

If the frequency reference is lower than the value of this parameter, the inverter can stop, run at

the frequency lower limit, or run at zero speed, determined by P8.14.

P0.15

Carrier frequency

0.5kHz~12.0kHz

-

☆

Please refer to table below:

Carrier frequency

Low → High

Motor noise

Big → Small

Output current waveform

Bad → Good

Motor temperature rise

High → Low

Inverter temperature rise

Low → High

Leakage current

Small → Large

External radiation interference

Small → Large

The factory setting of carrier frequency varies with the inverter power. If you need to modify the

carrier frequency, note that if the set carrier frequency is higher than factory setting, it will lead

to an increase in temperature of the inverter's heatsink. In this case, you need to de-rate the

inverter. Otherwise, the inverter may overheat and alarm.

P0.16

Carrier frequency

adjustment based on

temperature

No 0

0

☆

Yes

1

It is used to set whether the carrier frequency is adjusted based on the temperature. The Inverter

automatically reduces the carrier frequency when detecting that the hea tsink temperature is high.

The inverter sets the carrier frequency to the set value when the heatsink temperature becomes

normal. This function reduces the overheat alarms.

P0.17

Acceleration time 1

0.00s~65000s

- ☆ P0.18

Deceleration time 1

0.00s~65000s

-

☆

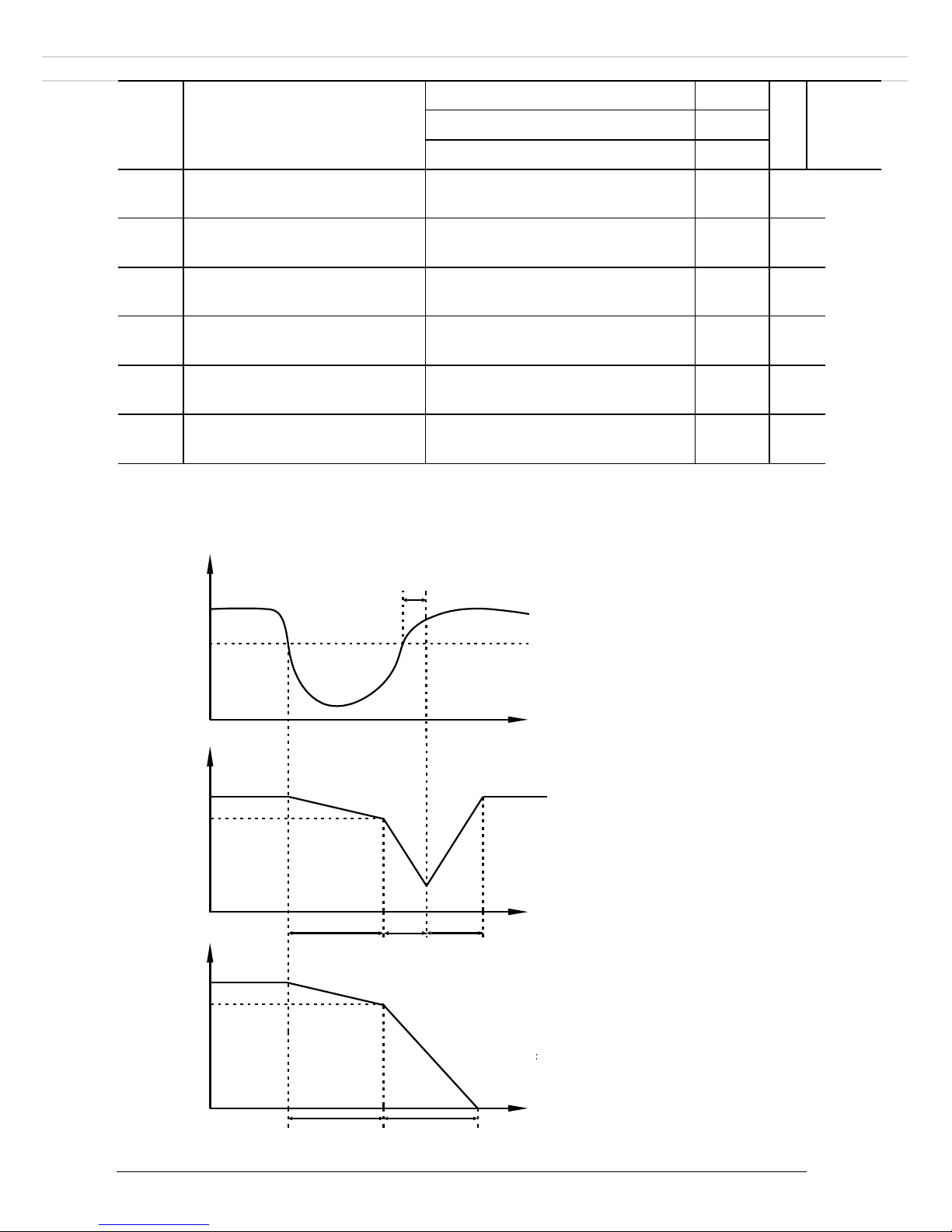

Acceleration time is the time required by the inverter to accelerate from 0 Hz to

"Acceleration/Deceleration base frequency” (P0.25), that is, t1 in figure below.

-27-

Deceleration time is the time required by the Inverter to decelerate from

"Acceleration/Deceleration base frequency” (P0.25) to 0 Hz, that is, t2 in figure below.

The DLA1 provides totally four groups of acceleration/deceleration times. You can perform

switchover by using a DI terminal.

• Group 1: P0.17, P0.18

• Group 2: P8.03, P8.04

• Group 3: P8.05, P8.06

• Group 4: P8.07, P8.08

P0.19

Acceleration/decelerati

on time unit

1s

0

1

★

0.1s

1

0.01s

2

DLA1 provides three acceleration/ deceleration time units, 1s, 0.1s and 0.01s. Modifying this

parameter will make the displayed decimal places change and corresponding

acceleration/deceleration time also change.

P0.21

Y offset

0.00Hz~ maximum frequency P0.10

0

.

00Hz

☆

This parameter is valid only when the frequency source is set to "X and Y combination".

The final frequency is obtained by adding the frequency offset set in this parameter to the X and Y

combination result.

P0.22

Frequency reference

resolution

0.01Hz

2 2 ★

P0.23

Retentiveness of digital

setting at stop

Not retentive

0

0

☆

Retentive

1

This parameter is valid only when the frequency source is digital setting.

If P0.23 is set to 0, the digital setting value resumes to the value of P0.08 (Preset frequency) after the

inverter stops.

If P0.23 is set to 1, the digital setting value is the set frequency at the moment when the inverter

stops.

P0.25

Acceleration/Decelerati

on time base frequency

Maximum frequency (P0.10)

0

0

★

Set frequency

1

100Hz

2

The acceleration/deceleration time indicates the time for the inverter between 0 Hz and the

frequency set in P0.25.

P0.26

UP/DOWN base

frequency at running

Running frequency

0

0

★

Set frequency

1

-28-

This parameter is valid only when the frequency source is digital setting.

It is used to set the base frequency to be modified by using keys and or the terminal UP/DOWN

function.

P0.27

Binding frequency

source to command

source channels

One’s place

Binding frequency source to

keyboard

000

☆

No binding

0 Digital setting

1

AI1 2 AI2

3

AI3 4 Reserved

5

Multi-speed

6

Simple PLC

7

PID 8 Communication

9

Ten’s place

Binding frequency source to

terminals

No binding

0 Digital setting

1

AI1 2 AI2

3

AI3 4 Reserved

5

Multi-speed

6

Simple PLC

7

PID 8 Communication

9

Hundred’s

place

Binding frequency source to

communication

No binding

0

Digital setting

1

AI1

2

AI2 3 AI3

4

Reserved

5

Multi-speed

6

Simple PLC

7

PID 8 Communication

9

-29-

4.3 First motor parameters: P1.00-P1.37

Code

Description

Setting range

Def

Res

P1.00

Motor type selection

Normal asynchronous motor

0

0

★

Variable frequency asynchronous motor

1

P1.01

Motor rated power

0.1kW~1000.0kW

-

★ P1.02

Motor rated voltage

1V~2000V

-

★

P1.03

Motor rated current

0.01A~655.35A (inverter rated power≦55kW)

0.1A~6553.5A (inverter rated power >55kW)

-

★

P1.04

Motor rated

frequency

0.01Hz~ maximum frequency

-

★

P1.05

Motor rated speed

1rpm~65535rpm

-

★

Set these parameters according to the motor nameplate regardless of V/F control or vector control

is adopted. To achieve better V/F or vector control performance, motor auto-tuning is required,

which depends on the correct setting of motor nameplate parameters.

P1.06

Asynchronous motor

stator resistance

0.001Ω~65.535Ω (inverter rated power

≦

55kW)

0.0001Ω~6.5535Ω (inverter rated power >55kW)

- ★ P1.07

Asynchronous motor

rotor resistance

0.001Ω~65.535Ω (inverter rated power

≦

55kW)

0.0001Ω~6.5535Ω (inverter rated power >55kW)

-

★

P1.08

Asynchronous motor

leakage inductive

reactance

0.01mH~655.35mH (inverter rated power

≦

55kW)

0.001mH~65.535mH (inverter rated

power >55kW)

-

★

P1.09

Asynchronous motor

mutual inductive

reactance

0.1mH~6553.5mH (inverter rated power

≦

55kW)

0.01mH~655.35mH (inverter rated power >55kW)

-

★

P1.10

Asynchronous motor

no load current

0.01A~P1.03 (inverter rated power

≦

55kW)

0.1A~P1.03 (inverter rated power >55kW)

-

★

The parameters in P1.06 to P1.10 are asynchronous motor parameters. These parameters are

unavailable on the motor nameplate and are obtained by motor auto-tuning. Motor static autotuning can only obtain P1.06 to P1.08. Motor complete auto-tuning can obtain all parameters from

P1.06 to P1.10.

Each time "Motor rated power” (P1.01) or “Motor rated voltage" (P1.02) is changed, the inverter

automatically restores values of P1.06 to P1.10 to the parameter setting for the common standard

Y series asynchronous motor.

If it is impossible to perform motor auto-tuning onsite, manually input the values of these

parameters according to data provided by the motor manufacturer.

P1.37

Auto-tuning selection

No auto-tuning

0

0

★

Asynchronous motor static auto-

tuning 1

1

Asynchronous motor complete auto-

tuning

2

Asynchronous motor static auto-

tuning 2

3

1: Asynchronous motor static auto-tuning 1

It is applicable to scenarios where complete auto-tuning cannot be performed because the

asynchronous motor cannot be disconnected from the load.

Before performing static auto-tuning, properly set the motor type and motor nameplate parameters

of P1.00 to P1.05 first. The inverter will obtain parameters of P1.06 to P1.08 by static auto -tuning.

Set this parameter to 1, and press RUN. Then, the inverter starts static auto-tuning 1.

-30-

2: Asynchronous motor complete auto-tuning

To perform this type of auto-tuning, ensure that the motor is disconnected from the load. During

the process of complete auto-tuning, the inverter performs static auto-tuning first and then

accelerates to 80% of the motor rated frequency within the acceleration time set in P0.17. The

inverter keeps running for a certain period and then decelerates to stop within deceleration time set

in P0.18.

Before performing complete auto-tuning, properly set the motor type, motor nameplate parameters

of P1.00 to P1.05, "Encoder type” (P1.28) and "Encoder pulses per revolution” (P1.27) first.

The inverter will obtain motor parameters of P1.06 to P1.10, "A/B phase sequence of ABZ

incremental encoder" (P1.30) and vector control current loop PI parameters of P2.13 to P2.16 by

complete auto-tuning.

Set this parameter to 2, and press RUN. Then, the inverter starts complete auto-tuning.

3: Asynchronous motor static auto-tuning 1

This is applicable for asynchronous motors without encoders. During auto-tuning, the motor might

vibrate slightly. Please pay attention to safety.

Set this parameter to 3, and press RUN. Then, the inverter starts static auto-tuning 2.

-31-

4.4 V/F control parameters: P2.00-P2.27

Group P2 is valid only for V/F control. The V/F control mode is applicable to low load applications (fan

or pump) or applications where one inverter drives multiple motors or there is a large difference

between the inverter power and the motor power.

Code

Description

Setting range

Def

Res

P2.00

V/F curve setting

Linear V/F

0

0

☆

Multi-point V/F

1

Square V/F

2

1.2-time V/F

3

1.4-time V/F

4

1.5-time V/F

5

1.6-time V/F

6

1.7-time V/F

7

1.8-time V/F

8

Reserved

9

VF complete separation mode

10

VF half separation mode

11

0: Linear V/F

It is applicable to common constant torque load.

1: Multi-point V/F

It is applicable to special load such as dehydrator and centrifuge. Any such V/F curve can be

obtained by setting parameters of P2.03 to P2.08.

2: Square V/F

It is applicable to centrifugal loads such as fan and pump.

3 to 8: V/F curve between linear V/F and square V/F

10: V/F complete separation

In this mode, the output frequency and output voltage of the Inverter are independent. The output

frequency is determined by the frequency source, and the output voltage is determined by "Voltage

source for V/F separation" (P2.13).

It is applicable to induction heating, inverse power supply and torque motor control.

11: V/F half separation

In this mode, V and F are proportional and the proportional relationship can be set in P2.13. The

relationship between V and F are also related to the motor rated voltage and motor rated frequency

in Group P1.

Assume that the voltage source input is X (0 to 100%), the relationship between V and F is:

V/F = 2 * X * (motor rated voltage) / (motor rated frequency)

P2.01

Torque boost

0.0%~30%

-

★

P2.02

Torque boost cut-off frequency

0.00Hz~ maximum frequency

(P0.10)

50

.

00Hz

★

-32-

To compensate the low frequency torque characteristics of V/F control, user can boost the output

voltage of the inverter at low frequency by modifying P2.01.

If the torque boost is set to too large, the motor may overheat, and the inverter may suffer

overcurrent.

If the load is large and the motor startup torque is insufficient, increase the value of P2.01. If the

load is small, decrease the value of P2.01. If it is set to 0.0, the inverter performs automatic torque

boost. In this case, the inverter automatically calculates the torque boost value based on motor

parameters including the stator resistance.

P2.02 specifies the frequency under which torque boost is valid. Torque boost becomes invalid

when this frequency is exceeded.

P2.03

Multi-point V/F frequency 1 (F1)

0.00Hz~P2.05

0.00Hz

★

P2.04

Multi-point V/F voltage 1 (V1)

0.0%~100.0%

0.0%

★

P2.05

Multi-point V/F frequency 2 (F2)

P2.03~P2.07

0.00Hz

★

P2.06

Multi-point V/F voltage 2 (V2)

0.0%~100.0%

0.0%

★

P2.07

Multi-point V/F frequency 3 (F3)

P2.05~ motor rated frequency (P1.04)

0.00Hz

★

P2.08

Multi-point V/F voltage 3 (V3)

0.0%~100.0%

0.0%

★

These six parameters are used to define the multi-point V/F curve.

The multi-point V/F curve is set based on the motor's load characteristic. The relationship

between voltages and frequencies is:

V1 < V2 < V3, F1 < F2 < F3

At low frequency, higher voltage may cause overheat or even motor burn-out as well as overcurrent

stall or overcurrent protection of the inverter.

-33-

V1~V3: 1st, 2nd and 3rd voltage percentages of multi-point V/F

F1~F3: 1st, 2nd and 3rd frequency percentages of multi-point V/F

Vb: motor rated voltage

Fb: motor rated running frequency

P2.09

V/F slip compensation gain

0%~200.0%

0.0

%

☆

This parameter is valid only for the asynchronous motor.

It can compensate the rotational speed slip of the asynchronous motor when the load of the motor

increases, stabilizing the motor speed in case of load change.

If this parameter is set to 100%, it indicates that the compensation when the motor bears rated load

is the motor rated slip. The motor rated slip is automatically obtained by the inverter through

calculation based on the motor rated frequency and motor rated rotational speed in group P1.

Generally, if the motor rotational speed is different from the target speed, slightly adjust P2.09.

P2.10

V/F over-excitation gain

0~200

64

☆

During deceleration of the inverter, over-excitation can restrain rise of the DC bus voltage,

preventing the overvoltage fault. The larger the over-excitation is, the better the restraining result is.

Increase the over-excitation gain if the inverter is liable to overvoltage error during deceleration.

However, too large over-excitation gain may lead to an increase in the output current. Set P2.09 to a

proper value in actual applications.

Set the over-excitation gain to 0 in the applications where the inertia is small and the DC bus

voltage will not rise during motor deceleration or where there is a braking resistor.

P2.11

V/F oscillation suppression gain

0~100

-

☆

Set this parameter to a value as small as possible in the prerequisite of efficient oscillation

suppression to avoid influence on V/F control.

Set this parameter to 0 if the motor has no oscillation. Increase the value properly only when the

motor has obvious oscillation. The larger the value is, the better the oscillation suppression result

will be.

When the oscillation suppression function is enabled, the motor rated current and no-load current

must be correct. Otherwise, the V/F oscillation suppression effect will not be satisfactory.

-34-

P2.13

Voltage source for V/F

separation

Digital setting (

P2.14)

0

0

☆

AI1 1 AI2 2 AI3

3

Reserved

4

Multi-speed

5

Simple PLC

6

PID

7

Communication

8

100.0% corresponding to motor rated voltage (P1.02)

P2.14

V/F separation voltage digital

setting

0V~ motor rated voltage

0

V

☆

V/F separation is generally applicable to scenarios such as induction heating, inverse power supply.

If V/F separation is enabled, the output voltage can be set in P2.14 or by means of analog, multispeed, simple PLC, PID or communication. If you set the output voltage by means of non-digital

setting, 100% of the setting corresponds to the motor rated voltage. If a negative percentage is set,

its absolute value is used as the effective value.

0: Digital setting (P2.14)

The output voltage is set directly in P2.14.

1: AI1; 2: AI2; 3: AI3

The output voltage is set by AI terminals.

4: Reserved

5: Multi-speed

If the voltage source is multi-speed, parameters in group P4 and PC must be set to determine the

corresponding relationship between setting signal and setting voltage. 100.0% of the multi-speed

setting in group PC corresponds to the motor rated voltage.

6: Simple PLC

If the voltage source is simple PLC mode, parameters in group PC must be set to determine the

setting output voltage.

7: PID

The output voltage is generated based on PID closed loop. For details, see the description of PID in

group PA.

8: Communication setting

The output voltage is set by the host computer by means of communication.

The voltage source for V/F separation is set in the same way as the frequency source. For details,

see P0.03. 100.0% of the setting in each source corresponds to the motor rated voltage. If the

corresponding value is negative, its absolute value is used.

P2.15

Voltage rise time of V/F

separation

0.0s~1000.0s

0

.

0s

☆

P2.16

Voltage decline time of V/F

separation

0.0s~1000.0s

0

.

0s

☆

-35-

4.5 Vector control parameters: P3.00-P3.22

P3 group is valid for vector control, and invalid for V/F control.

Code

Description

Setting range

Def

Res

P3.00

Speed loop proportional gain G1

1~100

30

☆

P3.01

Speed loop integral time T1

0.01s~10.00s

0

.

50s

☆

P3.02

Switchover frequency 1

0.00~P2.05

5.00Hz

☆

P3.03

Speed loop proportional gain G2

0~100

20

☆

P3.04

Speed loop integral time T2

0.01s~10.00s

1.00s

☆

P3.05

Switchover frequency 2

P2.02~P0.10

10.00Hz

☆

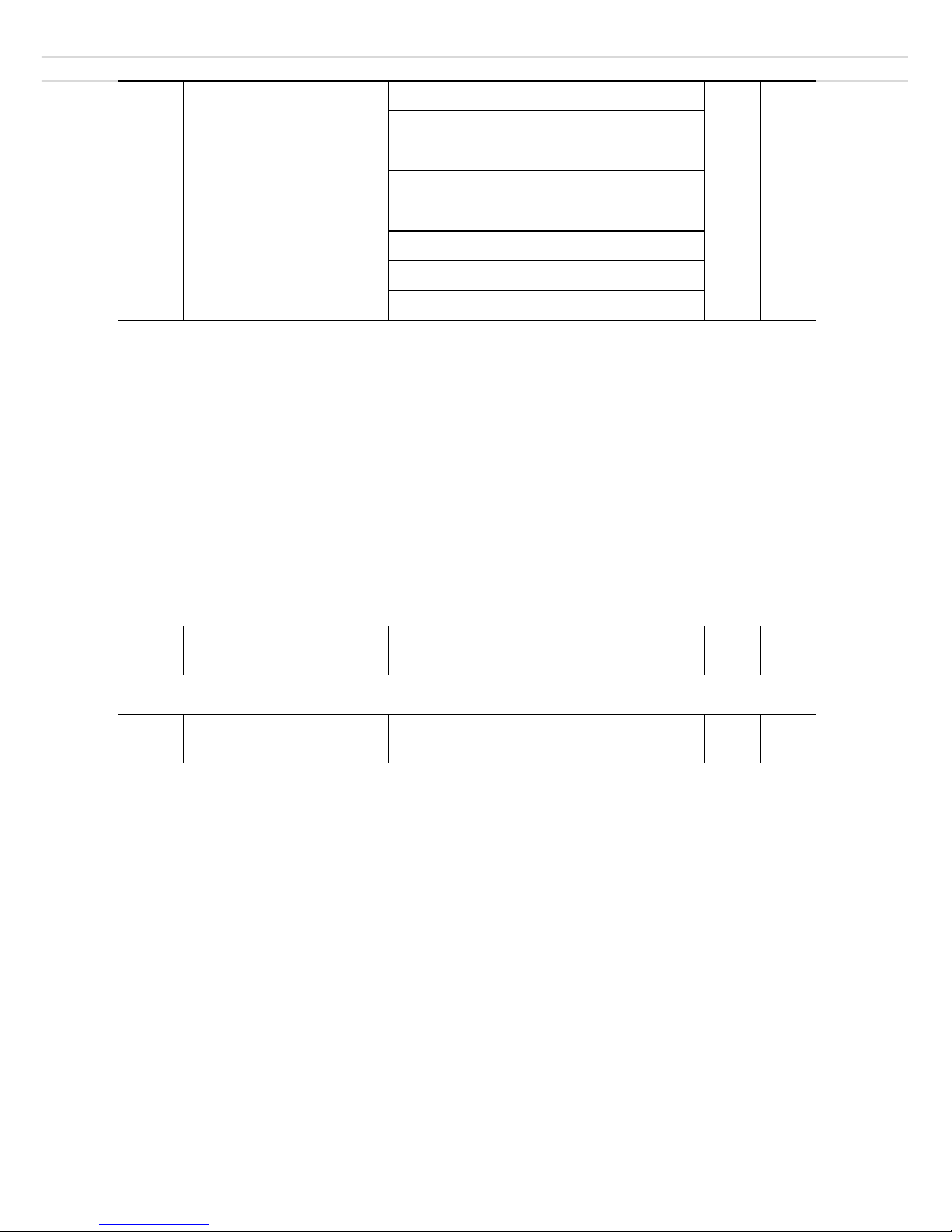

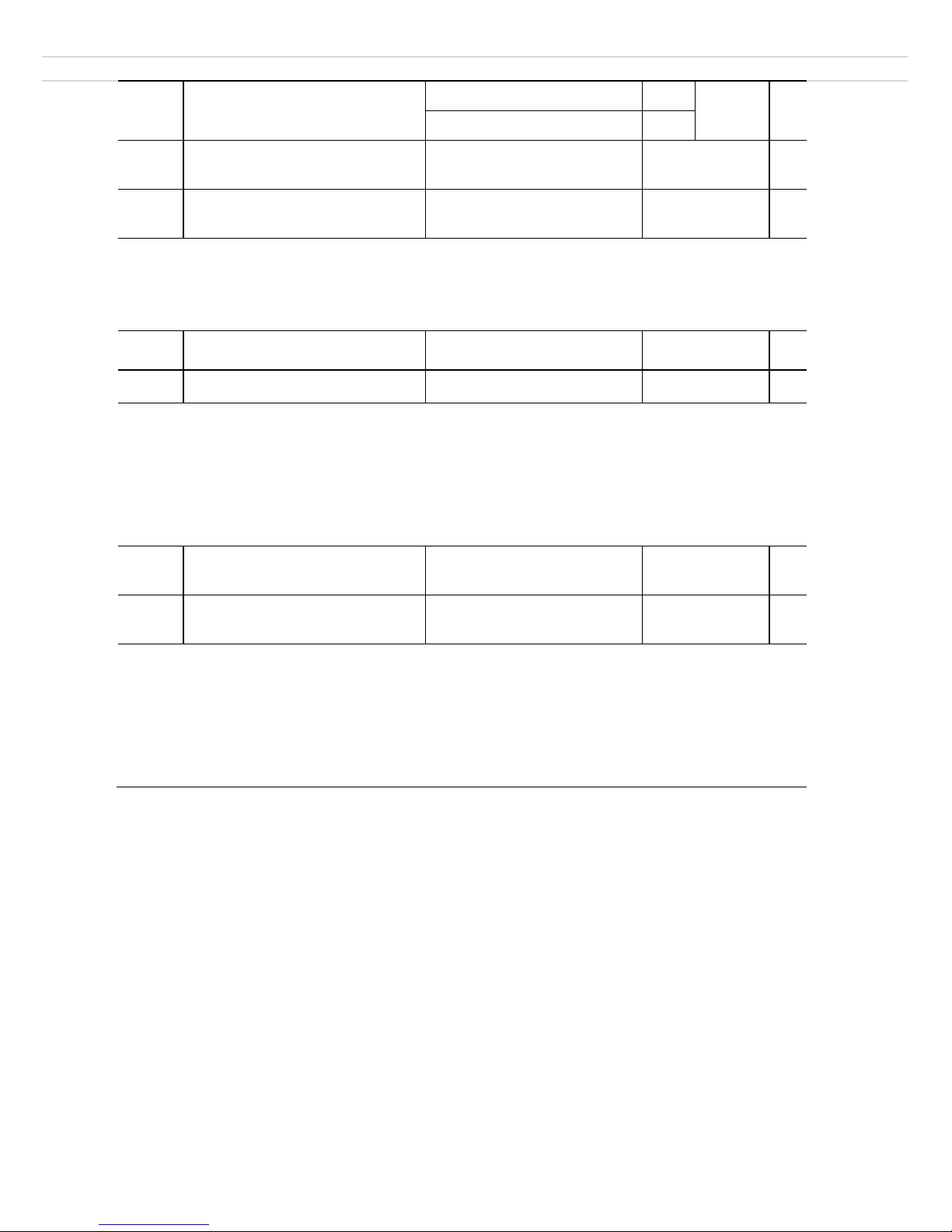

Speed loop PI parameters can vary with running frequencies of the inverter.

• If the running frequency is less than or equal to "Switchover frequency 1" (P3.02), the speed

loop PI parameters are P3.00 and P3.01.

• If the running frequency is equal to or greater than "Switchover frequency 2" (P3.05), the speed

loop PI parameters are P3.03 and P3.04.

• If the running frequency is between P3.02 and P3.05, the speed loop PI parameters are obtained

from the linear switchover between the two groups of PI parameters, as shown in figure below.

PI

Frequency

P2.00

P2.01

P2.03

P2.04

P2.02 P2.05

The speed dynamic response characteristics in vector control can be adjusted by setting the

proportional gain and integral time of the speed regulator.

To achieve a faster system response, increase the proportional gain and reduce the integral time.

Be aware that this may lead to system oscillation.

The recommended adjustment method is as follows:

If the factory setting cannot meet the requirements, fine tune the PI parameters. Increase the

proportional gain first to ensure that the system does not oscillate, and then reduce the integral

time to ensure that the system has quick response and small overshoot.

Improper PI parameter setting may cause serious speed overshoot, and overvoltage fault may even

occur when the overshoot drops.

-36-

P3.06

Vector control slip gain

50%~200%

150%

☆

This is used to adjust speed stability accuracy of the motor. When the motor with load runs at a

very low speed, increase the value of this parameter; when the motor with load runs at a very large

speed, decrease the value of this parameter.

P3.07

SVC torque filter time constant

0.000s~0.100s

0

.

000s

☆

P3.09

Torque upper limit source in speed

control

P3.10

0

0

☆

AI1 1 AI2 2 AI3

3

Pulse (DI5)

4

Communication

5

Min (AI1, AI2)

6

Max (AI1, AI2)

7

P3.10

Torque upper limit in speed control

0.0%~200.0%

150

.

0%

☆

In speed control, the maximum output torque of the inverter is restricted by P3.09. If the torque

upper limit is analog, pulse or communication setting, 100% of the setting corresponds to the

value of P3.10, and 100% of the value of P3.10 corresponds to the inverter rated torque.

P3.13

Excitation adjustment proportional

gain

0~60000

2000

☆

P3.14

Excitation adjustment integral gain

0~60000

1300

☆

P3.15

Torque adjustment proportional

gain

0~60000

2000

☆

P3.16

Torque adjustment integral gain

0~60000

1300

☆

These are current loop PI parameters for vector control. These parameters are automatically

obtained through auto-tuning and need not be modified. The current loop integral regulator here is

integral gain rather than integral time. Note that too large current loop PI gain may lead to

oscillation of the entire control loop. Therefore, when current oscillation or torque fluctuation is

great, manually decrease the proportional gain or integral gain here.

P3.17

Speed loop integration

Invalid

0

0

☆

Valid

1

P3.18

Synchronous field weakening mode

No weakening

0

1

☆

Direct calculation

1

Automatic

2

P3.19

Field weakening depth

50%~500%

100%

☆

P3.20

Field weakening max current

1%~300%

50%

☆

P3.21

Field weakening adjustment gain

10%~500%

100%

☆

P3.22

Field weakening multiplier

2~10

2

☆

-37-

4.6 Input terminals: P4.00-P4.39

DLA1 provides six DI terminals (DI5 can be used for high-speed pulse input) and three analog input

(AI) terminals.

Code

Description

Setting range

Def

Res

P4.00

DI1 function selection

0~59

1

★

P4.01

DI2 function selection

0~59

4

★

P4.02

DI3 function selection

0~59

9

★

P4.03

DI4 function selection

0~59

12

★

P4.04

Reserved

0~59

13

★

P4.05

DI6 function selection

0~59

0

★

The following table lists the functions available for the DI terminals.

Value

Function

Description

0

No function

Set 0 for reserved terminals to avoid malfunction.

1

Forward RUN (FWD)

The terminal is used to control forward or reverse RUN

of the inverter.

2

Reverse RUN (REV)

3

Three-line mode control

The terminal determines three-line mode control of the

inverter. For details, see the description of P4.11.

4

Forward JOG (FJOG)

The JOG frequency, acceleration time and deceleration

time are described respectively in P8.00, P8.01 and

P8.02.

5

Reverse JOG (RJOG)

6

Terminal UP

If the frequency channel terminals, these two are used as

increment and decrement commands for frequency

modification. When the frequency source is digital

setting, they are used to adjust the frequency.

7

Terminal DOWN

8

Coast to stop

The inverter blocks its output, the motor coasts to rest

and is not controlled by the inverter. It is the same as

coast to stop described in P5.10.

9

Fault reset (RESET)

Same as RESET key on the keyboard. Remote fault reset

is implemented by this function.

10

Pause

The inverter decelerates to stop, but the running

parameters are all memorized. After this function is

disabled, the Inverter resumes its status before stop.

11

External fault normally

open (NO) input

If this signal is sent to the inverter, the inverter will

output 15=E.EIOF and performs the fault protection

action. For details please check P9.47.

12

Multi-speed terminal K1

The setting of 16 speeds or 16 other references can be

implemented through combinations of 16 states of these

four terminals.

Please refer to the next table.

13

Multi-speed terminal K2

14

Multi-speed terminal K3

-38-

15

Multi-speed terminal K4

16

Terminal 1 for

acceleration/

deceleration time

selection

Totally four groups of acceleration/deceleration time can

be selected through combinations states of these two

terminals.

17

Terminal 2 for

acceleration/

deceleration time

selection

18

Frequency source

switchover

This terminal is used to perform switchover between two

frequency sources according to the setting in P0.07.

19

UP/DOWN setting

clearance (terminal,

keyboard)

If the frequency source is digital setting, the terminal is

used to clear the modifications by using the UP/

DOWN function or the UP/DOWN key on keyboard,

returning the set frequency to the value of P0.08.

20

Command source

switchover terminal

If the command source is set to terminal control (P0.02

= 1), this terminal is used to perform switchover

between terminal control and keyboard control.

If the command source is set to communication control

(P0.02 = 2), this terminal is used to perform switchover

between communication control and keyboard control.

21

Acceleration/Decelerati

on prohibited

It enables the inverter to maintain the current frequency

output without being affected by external signals (except

the STOP command).

22

PID pause

PID is invalid temporarily. The inverter maintains the

current frequency output without PID adjustment of

frequency source.

23

PLC status reset

The terminal is used to restore the original status of PLC

control for the Inverter when PLC control is started

again after a pause.

24

Swing pause

The inverter outputs the central frequency, and the

swing frequency function pauses.

25

Counter input

This terminal is used to count pulses.

26

Counter reset

This terminal is used to clear the counter status.

27

Length count input

This terminal is used to count the length.

28

Length reset

This terminal is used to clear the length.

29

Torque control

prohibited

The inverter is prohibited from torque control and enters

the speed control mode.

30

Pulse input enabled

(only for DI5)

DI5 is used for pulse input.

31

Reserved

Reserved.

32

Immediate DC braking

The inverter directly switches over to the DC braking

state.

33

External fault normally

closed (NC) input

If this signal is sent to the inverter, the inverter will

output 15=E.EIOF and performs the fault protection

action. For details please check P9.47.

34

Frequency modification

prohibited

The inverter does not respond to any frequency

modification.

-39-

35

PID action direction

negation

The PID action direction is opposite to the direction set

in PA.03.

36

External STOP terminal

1

This terminal can be used to stop the Inverter, equivalent

to the STOP key on the keyboard.

37

Command source

switchover terminal 2

It is used to perform switchover between terminal

control and communication control. If the command

source is terminal control, the system will switch to

communication control after this terminal becomes ON.

38

PID integral pause

After this terminal becomes ON, the integral adjustment

function pauses. However, the proportional and

differentiation adjustment functions are still valid.

39

Switchover between

main frequency source

X and preset frequency

After this terminal becomes ON, the frequency source X

is replaced by the preset frequency set in P0.08.

40

Switchover between

auxiliary frequency source

Y and preset frequency

After this terminal is enabled, the frequency source Y is

replaced by the preset frequency set in P0.08.

41

Reserved

Reserved

42

Reserved

43

PID parameter

switchover

If the PID parameters switchover condition is DI

terminal (PA.18 = 1) and this terminal is invalid, the

valid PID parameters are PA.05 to PA.07; when this

terminal becomes valid, the valid PID parameters are

PA.15 to PA.17.

44

User-defined fault 1

If these two terminals become ON, the inverter reports

27=E.USt1 and 28=E.USt2 respectively, and performs

fault protection actions based on the setting in P9.49.

45

User-defined fault 2

46

Speed control/Torque

control switchover

This terminal enables the inverter to switch between

speed control and torque control. When this terminal

becomes OFF, the inverter runs in the mode set in

B0.00. When this terminal becomes ON, the inverter

switches over to the other control mode.

47

Emergency stop

When this terminal becomes ON, the inverter stops

within the shortest time. During stop, the current

remains at the current upper limit. This function is used

to for stopping the inverter in emergency situations.

48

External STOP terminal

2

In any control mode (keyboard, terminal or

communication), it can be used to make the inverter

decelerate to stop. In this case, the deceleration time is

deceleration time 4.

49

Deceleration DC

braking

When this terminal becomes ON, the inverter

decelerates to frequency set in P6.11 and then switches

to DC braking state.

50

Current running time

clearance

When this terminal becomes ON, the inverter's current

running time is cleared. This function needs to be

supported by P8.42 and P8.53.

51~59

Reserved

Reserved

-40-

Multi-speed control

K

4

K

3

K

2

K

1

Speed setting

Parameter

OFF

OFF

OFF

OFF

Speed 0

PC.

00

OFF

OFF

OFF

ON

Speed 1

PC.

01

OFF

OFF

ON

OFF

Speed 2

PC.

02

OFF

OFF

ON

ON

Speed 3

PC.

03

OFF

ON

OFF

OFF

Speed 4

PC.

04

OFF

ON

OFF

ON

Speed 5

PC.

05

OFF

ON

ON

OFF

Speed 6

PC.

06

OFF

ON

ON

ON

Speed 7

PC.

07

ON

OFF

OFF

OFF

Speed 8

PC.

08

ON

OFF

OFF

ON

Speed 9

PC.

09

ON

OFF

ON

OFF

Speed 10

PC.

10

ON

OFF

ON

ON

Speed 11

PC.

11

ON

ON

OFF

OFF

Speed 12

PC.

12

ON

ON

OFF

ON

Speed 13

PC.

13

ON

ON

ON

OFF

Speed 14

PC.

14

ON

ON

ON

ON

Speed 15

PC.

15

The value 100% of PC-00 to PC-15 corresponds to the value of P0.10 (maximum frequency).

Multi-speed can be also used as the PID setting source or the voltage source for V/F separation.

Acceleration/deceleration time setting

Two terminals for acceleration/deceleration time selection have four state combinations, as listed in

the following table.

Terminal 2

Terminal 1

Acceleration/ deceleration time selection

Parameters

OFF

OFF

Acceleration/Deceleration time 1

P0.17, P0.18

OFF

ON

Acceleration/Deceleration time 2

P8.03, P8.04

ON

OFF

Acceleration/Deceleration time 3

P8.05, P8.06

ON

ON

Acceleration/Deceleration time 4

P8.07, P8.08

P4.10

DI filter time

0.000s~1.000s

0

.

010s

☆

It is used to set the software filter time of DI terminal status. If DI terminals are liable to

interference and may cause malfunction, increase the value of this parameter to enhance the anti-

interference capability. However, increase of DI filter time will reduce the response of DI terminals.

P4.11

Terminal command mode

Two-line mode 1

0

0 ☆

Two-line mode 2

1

Three-line mode 1

2

Three-line mode 2

3

0: Two-line mode 1

-41-

DIx (FOR)

DIy (REV)

COM

K1

K2

It is the most commonly used two-line mode, in which the forward/reverse rotation of the motor is

decided by DI1x and DIy. The parameters are set as below:

Value

Function

Description

D

I

x

1

Forward operation (FWD)

D

I

y

2

Reverse operation (REV)

0: invalid; 1: valid.

K1

K2

Operation

0 0 Stop

0 1 REV

1 0 FWD

1 1 Stop

1: Two-line mode 2

DIx RUN enabled

DIy FWD or REV

COM

K1

K2

In this mode, DIx becomes ‘RUN enabled’ terminal, and DIy terminal decides operation

directions.

Value

Function

Description

D

I

x

1

RUN enabled

D

I

y

2

Directions (FWD or REV)

0: invalid; 1: valid.

K1

K2

Operation

0

0

Stop

0

1

Stop

1

0

FWD

1

1

REV

2: Three-line mode 1

-42-

COM

SB2

SB1

DIx (FWD)

DIy (REV)

DIn RUN enabled

SB3

SB1: Stop button

SB2: FWD button

SB3: REV button

In this mode, DIn is enable terminal, and DIx & DIy terminal decides operation directions.

Value

Function

Description

DIx

1

Forward operation (FWD)

DIy

2

Reverse operation (REV)