Page 1

Always on the mark

Stainless Steel Gas Connectors,

Accessories and Commercial

Plumbing Products

360° Multi-Plane Movement Swivel

Quick-disconnect protection valve

Antimicrobial Coating

Patent Pending

One-handed quick-disconnect

Equipment placement system

Available only from

Dormont

FS 2008

Pricing Effective 01-1-08

REV. 1

Page 2

What is the Dormont®Safety System™?

The Dormont Safety System is the first and only complete gas equipment connection system specifically engineered

for the commercial kitchen. It is a complete system of connection products designed with the safety of your kitchen,

the food you serve, your employees, and your business in mind. The Safety System includes the famous Dormont

Blue Hose

SwivelMAX

connections in your commercial kitchen. Isnʼt the safety, cleanliness, and productivity of your business worth getting

the right connection? All gas connectors are not created equal, demand the Dormont difference.

TM

and our exclusive safety-based fittings - the SnapFastTMQD, the Safety QuikTMQDV, and the

TM

. Safe, unique, and affordable, the Dormont Safety System provides peace of mind for the gas

NEW

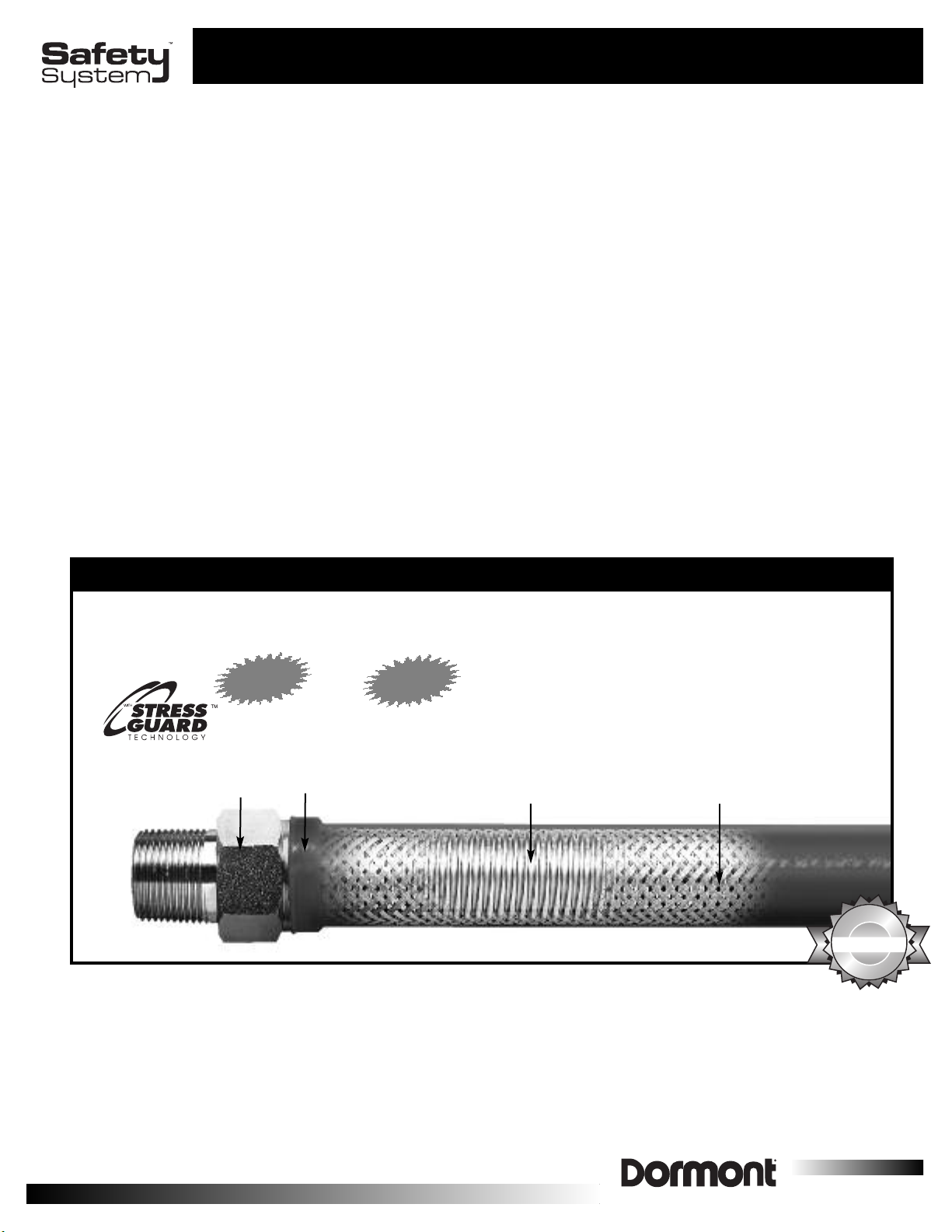

The Dormont Blue Hose

TM

Safety-Set

TM

PRODUCT!

The heart of the Safety System is

the Dormont Blue Hose, specifically

engineered for caster-mounted

commercial cooking equipment.

The Blue Hose includes an

ANTIMICROBIAL PROTECTIVE

PVC COATING, and our

TM

STRESS GUARD

TECHNOLOGY

which makes the hose easier to install and

dramatically reduces stress on the hose at its

most vulnerable points.

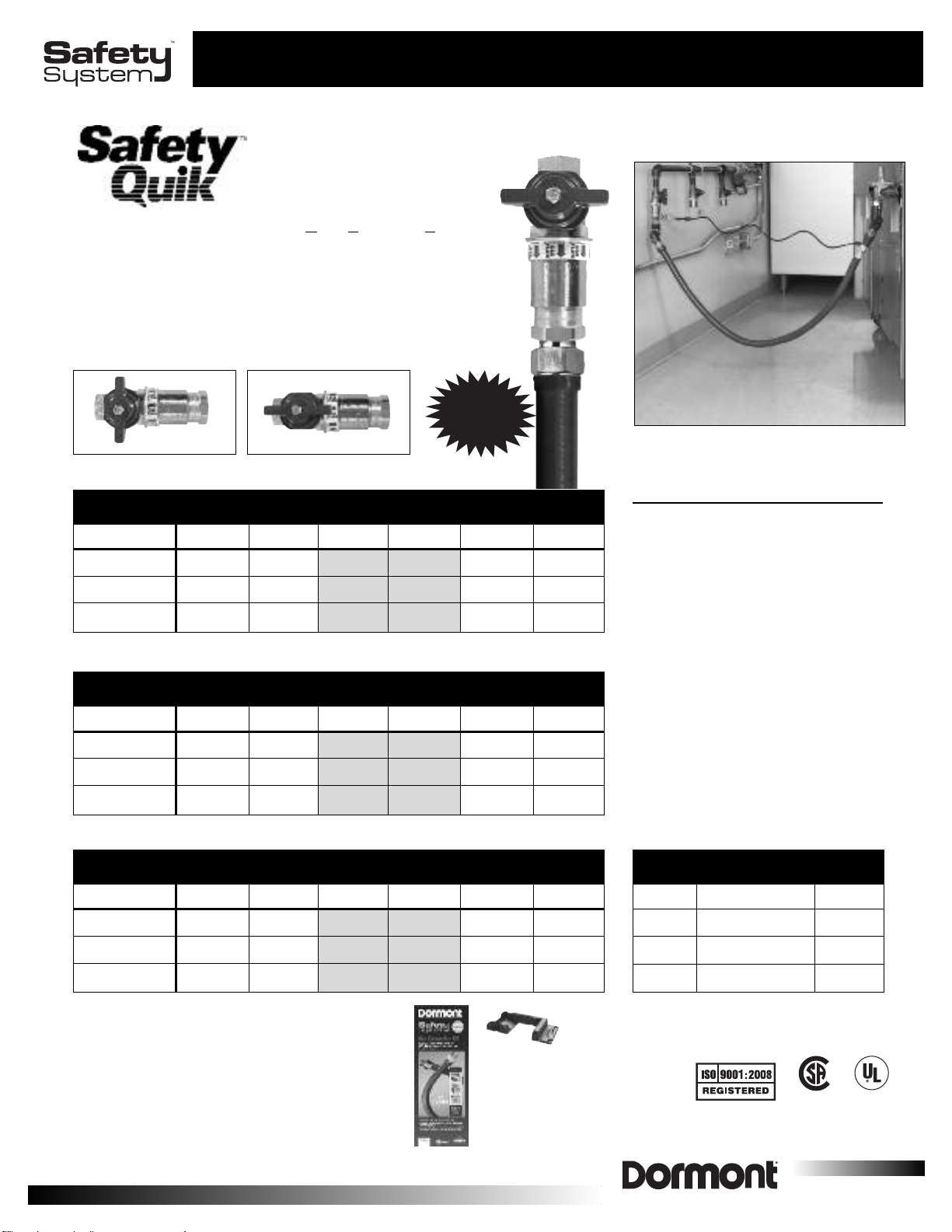

Safety Quik

TM

The Safety Quik is a

quick-disconnect protection

valve that combines the

one-handed QD functionality of the SnapFast, with a

patented safety feature that protects you and your

business from a potential disaster. Safety Quik

prevents users from accidentally turning on the gas

while the appliance is not connected to the supply line.

It also prevents the hose from being disconnected

whenever gas is flowing. Includes thermal shut-off.

Safety-Set is an equipment placement system

designed for all caster-mounted commercial kitchen

equipment. Safety-Set ensures equipment is returned

to its precise design specified location under

the fire suppression and ventilation

systems consistently after removal

for cleaning or maintenance.

SnapFast

®

SnapFast is the only one-handed

quick- disconnect (QD) design-certified

by CSA for commercial gas cooking

equipment.

This makes your equipment easier and less

expensive to service and move for cleaning

purposes by avoiding awkward maneuvering in tight

spaces. Includes thermal shut-off.

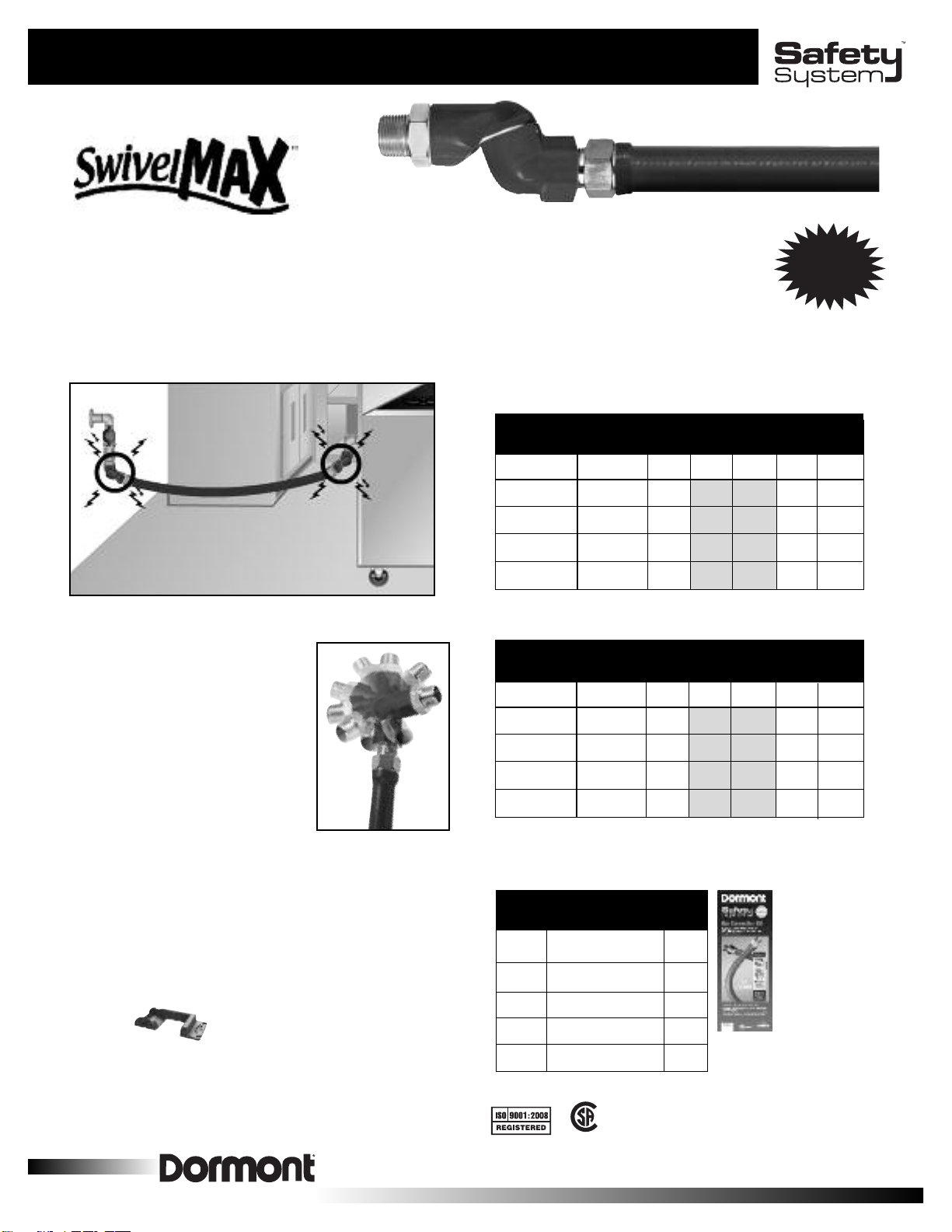

SwivelMAX

TM

SwivelMAX with patented

360° multi-plane movement,

provides maximum movement

and mobility in commercial

gas equipment.

• Maximize space in the production area by

enabling the equipment to be closer to the wall.

• Decreases stress on the connector, thus giving

you a SAFER gas connection for your castermounted equipment.

1-800-DORMONT

www.dormont.com

We guarantee our commercial gas connectors for the

life of the original appliance to which it is connected.

Please see page 18 for complete details.

Setting the standard in gas safety

TM

Page 3

G

A

S

C

O

N

N

E

C

T

O

R

W

A

R

R

A

N

T

Y

Limited

LIFETIME

Table of Contents

The Dormont Safety System™. . . . . . Inside Front Cover

onnector Flow Capacity and Pressure Drop Illustration . . . . . . . . ..1

C

BTU Flow Capacity . . .. . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . . .2

Gas Connector Selection Guide . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .3

Safety Quik™Quick-Disconnect Kits and Assemblies

Safety Quik Deluxe Gas Connector Kits . . . . . . . . . . . . .. . . . . . . . . . .4

Safety Quik Hose Assemblies . . . . . . .. . . . . . . . . .. . . . . . . . . . . . . . .8

SwivelMAX™Kits and Assemblies

SwivelMAX Deluxe Gas Connector Kits . . . . . . . .. . . . . . . . . . . . .. . .5

SwivelMAX Gas Connector Assemblies . . . .. . . . . . . . . . . . .. . . .7-8-9

SnapFast®One-handed Quick-Disconnect Assemblies

SnapFast Deluxe Gas Connector Kits . . . . . . . . . . . . . . . . . . . .. . . . . .6

SnapFast Gas Connector Assemblies . . . . . . . . .. . . . . . . . . .. . . .7-8-9

Basic Gas Connector Kits . . . . .. . . . . . . . . . . . . . . . . . . . . . .. . . . . . . .7

Gas Connector Assemblies . . . . .. . . . . . . . . . . . .. . . . . . . . . . . . . . .8-9

tationary Gas Connector Kits and Hoses . . . . . . . .. . . . . . . . . .. . .10

S

Gas Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. .10

Fittings, Valves, Restraining Cables, and Accessories . . . . . . . . . .. .11

TM

Safety-Set

Equipment Placement System . . . . . . . . . .. . . . . . . . . .12

Hi-PSI®Water Connectors . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . .13

Water and Steam Connectors . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .14

Swirl Hoses and Fittings . . . . . . . . . .. . . . . . . . . .. . . . . . . . . . . . .. .15

Countertop Gas Connector . . .. . . . . . . . . . . . . . . . . . . . . . .. . . . . . .16

Ice Maker Installation Kit . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . . . .16

Grease Interceptors . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .. . . . . .17

OneFlow®Scale Control Products . . . . . . . . . . . . . . . . .. . . . . . . . . . .17

Power ForceTM. . . . .. . . . . . . . . . . . .. . . . . . . . . . . . .. . . . . . . . . . . . .17

Warranty, Codes and Certifications . . . . . . . .. . . . . . . . . . . . . . . . . . .18

Spec sheets for projects and quotations can be downloaded

at www.dormont.com

M

T

The Dormont Blue Hose

E!

• Rotation technology

(patent #6,724,815) reduces

stress at both hose ends

V

I

S

LU

C

EX

Antimicrobial PVC Coating

• Inhibits growth of bacteria,

mold and mildew on the

gas connector (patent pending)

EX

C

LU

E!

V

I

S

Stainless Steel Construction

• Heavy-duty, flexible, corrugated

304 stainless steel tubing

New standards require commercial-grade moveable gas connectors

for foodservice establishments

Fire and health inspectors have long advocated regular cleaning behind commercial-grade fryers, grills, and other gas powered

appliances. The updated standard (ANSI Standard Z21.69/CSA 6.16) requires the use of commercial-grade moveable gas connectors

on all gas appliances (when a flexible connector is used) that are moved for cleaning, sanitation and maintenance. The revised

standard (updated in 2005) will promote safety and hygiene in commercial kitchens. It requires gas connections that make it easier

for operators to quickly and easily move appliances for cleaning or service.

For Commercial Gas Equipment

Stainless Steel Braid

• Tight-weave braid prevents

corrugations from stretching

as equipment is moved

Setting the standard in gas safety

TM

1-800-DORMONT

www.dormont.com

Page 4

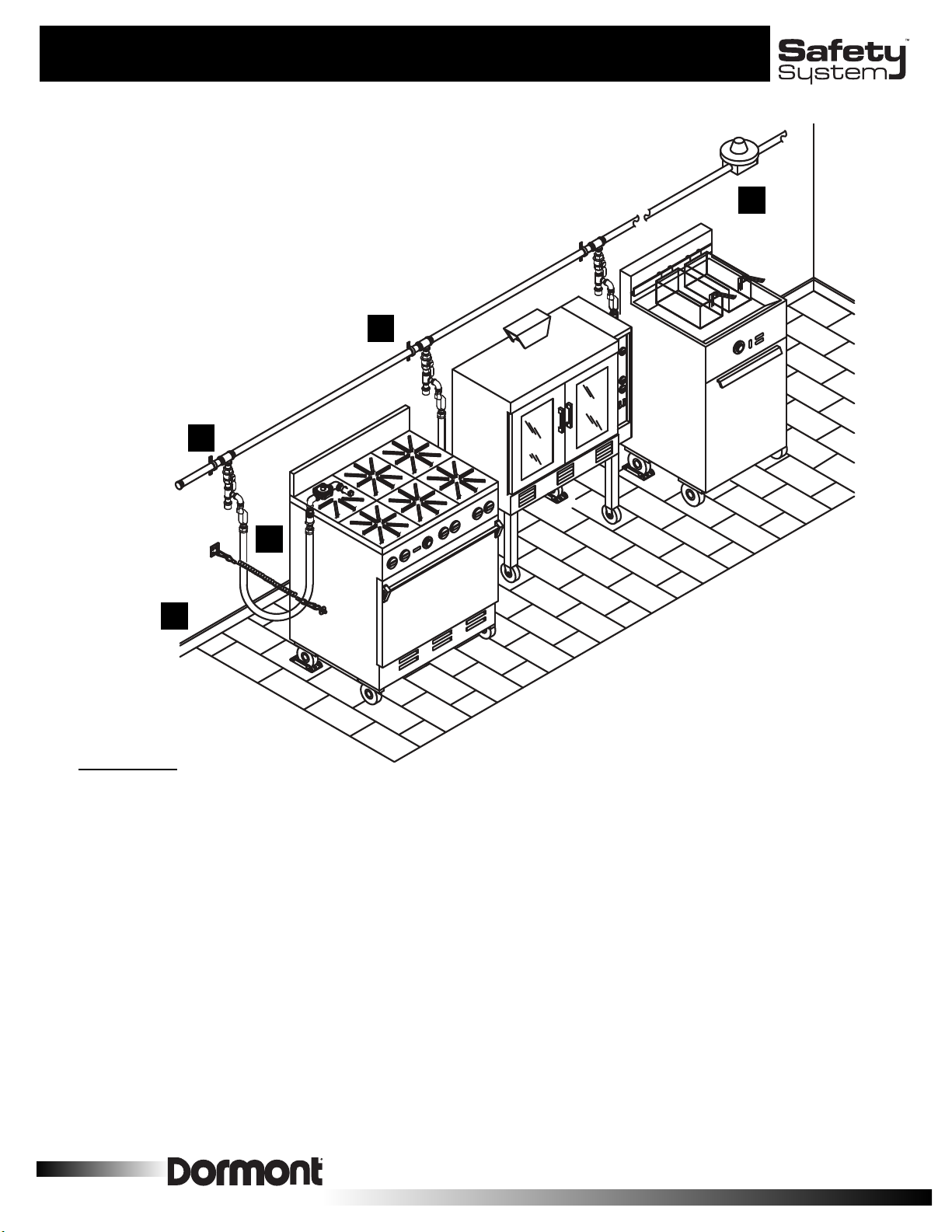

Connector Flow Capacity and Pressure Drop

Gas flow (BTU/hr) and gas line pressure (wc) must be considered

together to understand if a gas appliance will have enough gas

pressure at its inlet to meet its BTU/hr rating.

Below is an illustration of a typical commercial kitchen.

The numbers in the boxes represent examples of

how gas connectors are properly sized for the

gas appliance.

2

3

1

5

4

Explanations

A main-line supply regulator may be located in the kitchen or

1

in a service room which supplies all the gas appliances in the

kitchen. Most National and Local Plumbing codes recommend

that the regulator pressure be set between 6" to 8"wc for natural

gas and 8" to 11"wc for LP gas. Some older metropolitan areas

may have service pressures which are lower than the

recommended minimums. In this example, we will use 7"wc

natural gas.

Some pressure loss due to friction will occur in the main gas line

2

before reaching the gas connector inlet. If the gas pipe diameter

has been sized correctly, this pressure loss will be less than

0.5"wc at the furthest gas appliance from the supply regulator

with all gas appliances on.

The inlet pressure to the gas connector will be less than the

3

supply pressure due to the pressure loss in the gas piping

between the supply regulator (1) and the connector inlet (3).

In our example of a supply pressure of 7"wc with less than

0.5"wc pressure loss, the inlet pressure at point (3) would be

greater than 6.5"wc. (i.e. 7" – .5" = 6.5"wc).

On page 2, our BTU flow capacities are measured at 0.5"wc or

4

less pressure drop between the inlet (3) and outlet (5) at the

maximum BTU/hr demand of the gas appliance. In our example

of a 6.5"wc inlet pressure, the outlet pressure to the gas

appliance would then be 6"wc (i.e. 6.5" – 0.5" = 6"wc).

In cases where upstream piping is undersized or where gas

supply pressures are abnormally low, sizing the gas connector

for at most 0.5"wc of pressure loss helps to insure that the gas

appliance inlet pressure and its BTU/hr rating are met.

Most gas appliances require a minimum of 5"wc inlet pressure

5

for proper operation. Inlet pressure requirements are typically

listed on the gas appliances specifications label along with the

BTU/hr rating. In our example of a commercial kitchen with 7"wc

of natural gas pressure at the main supply regulator, the final

pressure at the inlet to the gas appliance would be 6"wc

(i.e., 7" - 0.5" – 0.5" = 6"wc).

1-800-DORMONT

1

www.dormont.com

Page 5

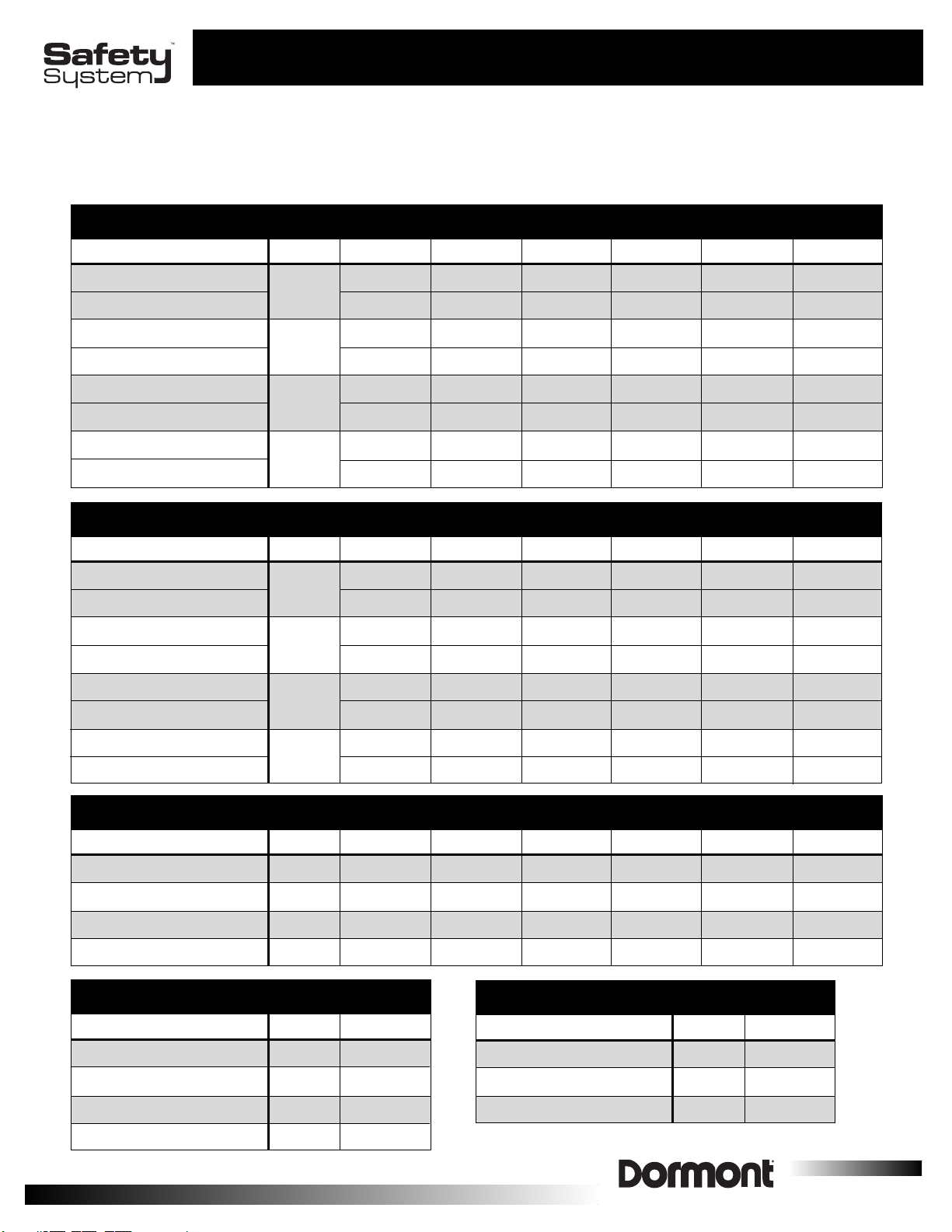

BTU Flow Capacities

Dormont gas connectors are design certified for a maximum operating pressure of 0.5 psig. Minimum required BTU

capacities for gas connectors (B & BP models) are defined by ANSI Z21.69/CSA 6.16. Flow capacities for connector assemblies

exclude manual shut-off valves. BTU capacities decrease when the length of the connector increases.

low rating BTU 0.64 SP.GR @ 0.5 IN. W C Pressure Drop

F

SSaaffeettyy SSyysstteemm MMoovveeaabbllee GGaass CCoonnnneeccttoorrs

PPaarrtt #

#

11665500BB,, 11665500BBP

11665500BBQQ,, BBPPQQ,, BBPPCCF

11667755BB,, 11667755BBP

11667755BBQQ,, BBPPQQ,, BBPPCCF

1166110000BB,, 1166110000BBP

1166110000BBQQ,, BBPPQQ,, BBPPCCF

1166112255BB,, 1166112255BBP

1166112255BBQQ,, BBPPQ

P

F

P

F

P

P

Q

F

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

.

s

1122'''

'

152,000

98,000

326,000

260,000

652,000

425,000

1,204,000

783,000

2244'''

'

150,000

87,000

291,000

232,000

582,000

414,000

1,075,000

699,000

3366'''

'

120,000

77,000

256,000

218,000

512,000

379,000

946,000

615,000

4488'''

'

106,000

68,000

225,000

180,000

451,000

334,000

833,000

541,000

SSaaffeettyy SSyysstteemm MMoovveeaabbllee GGaass CCoonnnneeccttoorrss wwiitthh SSaaffeettyy QQuuiikk aanndd SSwwiivveellMMaaxx FFiittttiinnggs

PPaarrtt #

#

11665500BBPPQQSS,, BBPPCCFFS

11665500BBPPQQ22SS,, BBPPCCFF22S

11667755BBPPQQSS,, BBPPCCFFS

11667755BBPPQQ22SS,, BBPPCCFF22S

S

S

IInnssiiddee DDiiaa.

1/2''

S

3/4''

S

.

1122'''

'

92,000

88,000

242,000

230,000

2244'''

'

81,000

77,000

216,000

205,000

3366'''

'

72,000

69,000

203,000

193,000

4488'''

'

63,000

60,000

167,000

160,000

6600'''

'

93,000

60,000

198,000

158,000

397,000

294,000

733,000

476,000

7722'''

'

87,000

55,000

175,000

139,000

350,000

279,000

645,000

419,000

s

6600'''

'

56,000

54,000

147,000

140,000

7722'''

'

51,000

48,000

130,000

124,000

1166110000BBPPQQSS,, BBPPCCFFS

1166110000BBPPQQ22SS,, BBPPCCFF22S

1166112255BBPPQQS

1166112255BBPPQQ22S

S

S

S

S

SSttaattiioonnaarryy GGaass CCoonnnneeccttoorrs

PPaarrtt #

#

11665500NNPPFFS

11667755NNPPFFS

1166110000NNPPFFS

1166112255NNPPFFS

SSwwiivveellMMaaxx FFiittttiinng

PPaarrtt #

SSMM550

SSMM775

SSMM11000

SSMM11225

S

S

S

S

g

#

0

5

0

5

See Us On AutoQuotes At www.AQNet.com

1''

1-1/4''

s

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

396,000

377,000

556,000

482,000

.

152,000

326,000

652,000

1,204,000

BBTTUU RRaattiinng

.

190,000

229,000

457,000

1,101,000

1122'''

385,000

366,000

535,000

472,000

'

2244'''

'

150,000

291,000

582,000

1,075,000

353,000

336,000

491,000

461,000

3366'''

'

120,000

256,000

512,000

946,000

SSaaffeettyy QQuuiikk QQDDVV FFiittttiinng

g

PPaarrtt #

#

CCFF--550

0

CCFF--775

5

CCFF--11000

0

310,000

295,000

482,000

449,000

4488'''

'

106,000

225,000

451,000

833,000

g

IInnssiiddee DDiiaa.

1-800-DORMONT

1/2''

3/4''

1''

274,000

261,000

463,000

441,000

6600'''

'

93,000

198,000

397,000

733,000

BBTTUU RRaattiinng

.

111,000

237,000

360,000

260,000

247,000

460,000

440,000

7722'''

'

86,000

175,000

350,000

645,000

g

2

www.dormont.com

Page 6

Moveable Gas Connector Selection Guide

SSeelleeccttiinngg aa DDoorrmmoonntt SSaaffeettyy SSyysstteemm

MMoovveeaabbllee GGaass CCoonnnneeccttoorr KKiitt

6 Diameter KIT QD Device SwivelMAX

1

16 KIT

Enter desired

diameter of

connector

Example:

50=1/2'' ID

75=3/4'' ID

100=1'' ID

125=1-1/4'' ID

Enter Dormont

QD fitting

Example:

CF = Safety Quick

(1/2'', 3/4''

& 1'' only)

™

™™

DDeelluuxxee

Enter choice of

swivels

Example:

S = Single swivel

S = Double swivel

2

™

ength (in) Safety-Set

L

Enter length of

connector in inches

Example:

24''

36''

8''

4

60''

72''

Enter PS

o include

t

Safety-Set

Safety System Deluxe Gas Connector

Kits Include:

• Dormont Safety System gas connector with choice of

TM

TM

exclusive Safety System fittings:

Safety Quik™, SnapFast™ and SwivelMAX™

(1) Valve

•

• (2) Street Elbows

• (1) Restraining Cable

NOTE: Safety Quik is a quick-disconnect and

valve combination fitting.

No additional valve will be shipped with a kit where

Safety Quik (CF) has been specified.

For each SwivelMAX (S) selected, one elbow will be

removed from the kit.

Leave blank for

™

SnapFast

Leave blank for

choice of

NO swivel

(Most common

sizes ordered:

36'' & 48'')

IMPORTANT! Leave no spaces between final part number.

Sample part number: 1675KITCF2S48PS

(Deluxe 3/4'' ID Kit with Safety Quik Quick-Disconnect and Double SwivelMAX for a 48'' Connector

with Safety-Set)

Moveable connectors and kits are located on pages 4 – 9.

12'' connectors are available by calling Customer Service.

Leave blank

for choice of

NO Safety-Set

Part Number Explanations

B = Braid

P = PVC Coated (with Antimicrobial Coating)

Q = Quick-Disconnect (SnapFast)

CF= Safety Quik Quick-Disconnect Valve

S = SwivelMAX

NEW

OPTION!

R = Restraining Device & Hardware

PS= Placement system for equipment (Safety-Set)

SSeelleeccttiinngg aa DDoorrmmoonntt SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr AAsssseemmbbllyy

16 Diameter Coated or Uncoated QD Device SwivelMAX™Restraining cable Length (in) Packaging Safety-Set

16

Enter desired

diameter of

connector

Example:

50=1/2'' ID

75=3/4'' ID

100=1'' ID

125=1-1/4'' ID

Enter type of gas

connector

Example:

BP = Braided & PVC coated

B = Braided (uncoated)

Enter Dormont QD

fitting

Example:

CF = Safety Quick

(1/2'', 3/4''

& 1'' only)

Q = SnapFast

™

Enter choice of

swivels

™

Example:

S = Single swivel

2S = Double swivel

Leave blank for

choice of

NO swivel

Enter R to order a

restraining cable.

Leave blank for no

restraining cable

Enter length of

connector

in inches

Example:

24''

36''

48''

60''

72''

(Most common

sizes ordered:

36'' & 48'')

Enter packaging

choice

Example:

BX= Box

(For 36'' & 48''

PVC coated

connector only)

Leave blank

for choice of

polybag

Enter PS

to include

Safety-Set

Can only be

added when

ordering a

restraining cable

Leave blank

for choice of

NO Safety-Set

TM

TM

Sample part number: 1650BPQCF2SR48

(1/2'' ID Braided, Coated (PVC) 48'' Gas Connector with Safety Quik, Double SwivelMAX and a Restraining Cable.

1-800-DORMONT

3

Canadian Orders Put CAN in Front of Part #s

www.dormont.com

Page 7

afety Quik QDV, the first and only

CUS

®

S

u

ick-

DD

sconnect

i

VV

lve

a

QQ

combination fitting designed for the foodservice industry, meets

the safety and operational needs of commercial kitchens. Safety

Quik does the work of both the quick-disconnect and the valve.

The Safety Quik QDV fitting, with its innovative safety-sleeve,

incorporates added safety design features. With Safety Quik, the

gas connector can not be disconnected until the gas valve is shut

off, and can not be opened until the gas connector is attached.

E

xc

lu

siv

P

a

te

n

te

D

e

s

CClloosseed

d

OOppeen

n

ig

Safety Quik™ QDV Kits and Safety Fittings

e

d

n

Deluxe Safety Quik QDV Kits

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr KKiittss wwiitthh SSaaffeettyy QQuuiikk aanndd DDoouubbllee SSwwiivveellMMAAX

PPaarrtt #

#

11665500 KKIITTCCFF22S

11667755 KKIITTCCFF22S

1166110000 KKIITTCCFF22S

Kits Include: 1 Safety System Gas Connector, 1 Safety Quik QDV, 2 SwivelMAX, Restraining Cable & Hardware

Add PS to the end of the part number to include Safety-Set

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr KKiittss wwiitthh SSaaffeettyy QQuuiikk aanndd SSiinnggllee SSwwiivveellMMAAX

PPaarrtt #

#

11665500 KKIITTCCFFS

11667755 KKIITTCCFFS

1166110000 KKIITTCCFFS

Kits Include: 1 Safety System Gas Connector, 1 Safety Quik QDV, 1 SwivelMAX, 1 Elbow, Restraining Cable & Hard

Add PS to the end of the part number to include Safety-Set

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr KKiittss wwiitthh SSaaffeettyy QQuuiik

PPaarrtt #

#

11665500 KKIITTCCF

11667755 KKIITTCCF

1166110000 KKIITTCCF

Kits Include: 1 Safety System Gas Connector, 1 Safety

Quik QDV, 2 Elbows, Restraining Cable & Hardware

• Shaded box areas indicate most commonly purchased sizes.

• Add PS to the end of the part number to include Safety-Set

• 60'' & 72'' kits are packaged in polybags.

NNOOTTEE:: SSaaffeettyy QQuuiikk iiss nnoott ffoorr uussee iinn tteemmppeerraattuurreess lleessss tthhaann 3322°°FF

S

S

F

F

F

IInnssiiddee DDiiaa.

S

S

S

IInnssiiddee DDiiaa.

S

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1/2''

3/4''

1''

1/2''

3/4''

1''

2244'''

.

.

$ 385

464

678

2244'''

$ 328

390

526

'

'

3366'''

'

$ 405

482

704

M

T

(additional list of $74).

3366'''

'

$ 335

408

563

M

T

(additional list of $74).

4488'''

$ 424

510

729

4488'''

$ 356

437

600

'

6600'''

'

$ 459

543

768

'

6600'''

'

$ 375

469

639

7722'''

$ 473

553

812

7722'''

$ 391

497

678

k

2244'''

.

$ 243

309

402

'

3366'''

'

$ 253

327

427

TM

4488'''

$ 274

355

452

'

6600'''

'

$ 300

386

509

To include Safety-SetTM,

add PS to the end of

the kit part number.

Additional list of $74.

See page 12 for details.

7722'''

$ 330

414

568

'

X

'

ware

'

Safety Quik

Product Specifications

X

• US Patent #5,383,492

• Material: Brass body construction,

carbon steel safety-sleeve

• Quick-Disconnect: Flat-face, pushto-connect design

• Thermal Shut-off: Shuts off gas at

temperatures in excess of 350° F

• Valve: Full port brass ball valve,

CSA design certified

• Safety Sleeve: Built-in safetysleeve prevents incorrect use of gas

connector and uncontrolled gas flow

• Safety Quik is always installed at

the gas supply end of the connector

SSaaffeettyy QQuuiikk QQDDVV SSaaffeettyy FFiittttiinng

PPaarrtt ##CCoonnnneeccttoorr SSeerriiees

CCFF--550

0

CCFF--775

5

CCFF--11000

0

Not available in 1-1/4''

1/2''

3/4''

1''

s

g

LLiisstt PPrriicce

$ 104

131

182

e

Setting the standard in gas safety

TM

1-800-DORMONT

4

www.dormont.com

Page 8

SwivelMAX™ Deluxe Gas Connector Kits and Fittings

CUS

®

The Dormont SwivelMAX 360° multi-plane rotation fitting is a patented, innovative device that increases

the functionality and service life of the Dormont Safety System gas connector by increasing its range of

motion. The SwivelMAX enables easier movement of the caster-mounted appliances at angles,

back-and-forth, and from side-to-side, while relieving stress at the ends of the hose. This helps increase

the life of the connector. In addition, it provides more aisle space in a commercial kitchen by allowing

the appliances to be positioned closer to the wall. Other “swivel” fittings, which only rotate in one

plane, cannot match the patented functionality of the Dormont SwivelMAX 360° rotation fitting.

Deluxe SwivelMAX Kits

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr KKiittss

SwivelMAX relieves excess stress on the connector fittings

Unique SwivelMAX

Movement Capabilities

• Allows increased movement at

either end of the gas connector

• Provides full 360° multi-plane range

of motion, greatly reducing the

stress on the connector

• Increased movement at either end

of the equipment

• Replaces rigid street elbows,

common in most installations

• Results in safer connection with

longer connector life

SwivelMAX can be added at anytime, to either end of the hose.

For maximum equipment mobility, add a

SwivelMAX to both ends of the connector.

To include Safety-SetTM,

add PS to the end of the

kit part number.

Additional list of $74.

See page 12 for details.

Patents:

US – 5,178,422 & 4,615,547

Canada – 2,079,825

wwiitthh DDoouubbllee SSwwiivveellMMAAX

PPaarrtt #

#

11665500KKIITT22S

11667755KKIITT22S

1166110000KKIITT22S

1166112255KKIITT22S

Kits include: Safety System gas connector with 2 SwivelMAX swivels, 1 SnapFast QD,

1 full port valve, a restraining cable & hardware.

dd PS to the end of the part number to include Safety-Set

A

S

S

S

S

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

Safety System Gas Connector Kits

with Single SwivelMAX

PPaarrtt #

#

11665500KKIITTS

11667755KKIITTS

1166110000KKIITTS

1166112255KKIITTS

Kits include: Safety System gas connector with 1 SwivelMAX, 1 SnapFast QD, 1 elbow, 1 full

port valve a restraining cable & hardware.

Add PS to the end of the part number to include Safety-Set

60'' & 72'' kits are packaged in polybags.

S

S

S

S

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

SwivelMAX 360° Multi-plane

Rotation Fitting

PPaarrtt #

SSMM550

SSMM775

SSMM11000

SSMM11225

NNOOTTEE:: SSwwiivveellMMAAXX iiss nnoott ffoorr uussee iinn tteemmppeerraattuurreess lleessss tthhaann 3322°°FF

CCoonnnneeccttoorr SSeerriiees

#

0

5

0

5

1/2''

(3/4'' SwivelMax with 1/2'' threads)

3/4''

1''

1-1/4''

.

$ 356

.

$ 277

s

X

2244'''

432

604

1038

2244'''

356

469

835

PPrriicce

'

'

$ 89

89

145

259

3366'''

$ 363

445

635

1064

3366'''

$ 282

370

514

868

e

'

TM

'

M

T

$ 380

1133

additional list of $74).

(

4488'''

$ 304

(additional list of $74).

E

xc

lu

sive

P

a

te

n

D

e

si

g

4488''''6600''''7722'''

$ 445

$ 415

532

504

469

760

716

667

1243

1186

'

$ 331

399

532

893

• Shaded box areas

7722'''

6600'''

'

$ 375

459

429

624

590

1016

953

indicate most

commonly

purchased sizes.

te

d

n

'

'

5

1-800-DORMONT

www.dormont.com

Setting the standard in gas safety

TM

Page 9

SnapFast®Quick-Disconnect and Deluxe Kits

DDeelluuxxee SSaaffeettyy SSyysstteemm GGaass

CCoonnnneeccttoorr KKiittss IInncclluuddee:

•

Safety System gas connector

• SnapFast Quick-Disconnect

•

Coiled restraining device with

installation mounting hardware

•

Full port gas ball valve

•

(2) 90ostreet elbows

DDeelluuxxee SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr KKiitts

PPaarrtt #

#

11665500KKIIT

11667755KKIIT

1166110000KKIIT

1166112255KKIIT

60'' & 72'' kits are packaged in polybags.

T

T

T

T

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

SSnnaappFFaasstt QQuuiicckk--DDiissccoonnnneecct

PPaarrtt ##CCoonnnneeccttoorr SSeerriiees

AA550

0

AA775

5

AA11000

AA11225

Includes nipple and coupling

NNOOTTEE:: SSnnaappFFaasstt iiss nnoott ffoorr uussee iinn tteemmppeerraattuurreess lleessss tthhaann 3322°°FF

0

5

1650 (1/2'')

1675 (3/4'')

16100 (1'')

16125 (1-1/4'')

2244'''

.

'

$ 204

274

344

542

3366'''

$ 213

290

350

584

'

t

PPrriicce

s

e

$ 62

86

116

242

:

s

4488'''

'

$ 223

312

383

642

To include Safety-SetTM,

add PS to the end of the

kit part number.

Additional list of $74.

See page 12 for details.

6600'''

$ 255

350

444

708

Exclusive SnapFast

Quick-Disconnect

ormont makes connecting and

D

disconnecting moveable/castered equipment

easier and safer with the SnapFast

quick-disconnect coupling. SnapFast is the

only quick-disconnect coupling designed

specifically for the needs of the

foodservice industry.

To Connect: Because of its pushto-connect design feature, the coupling's

components are joined quickly and easily by

simply pushing them together until they snap

'

7722'''

$ 285

377

468

771

'

into place. Thereʼs no need to hold or slide

the operating ring.

To Disconnect: Push or pull back the operating ring, and the coupling will separate

immediately. Gas flow will shut off as soon

as the components are separated.

Thermal Shutoff Feature

The thermal shut-off is a polymer ring

located inside the nipple (male) end of the

quick-disconnect coupling. In temperatures

higher than 350°F, the ring melts and the

gas supply shuts off as the valve is closed

by the heavy-duty spring in the coupling.

* Quick-disconnect couplings are available

packaged for display. Contact Customer Service.

SSaaffeettyy SSyysstteemm RReeppllaacceemmeenntt CCoonnnneeccttoorrs

PPaarrtt #

11665500 BBP

11667755 BBP

1166110000 BBP

1166112255 BBP

“BP” Series: Stainless steel corrugated hose, encased in stainless steel braid, covered with antimicrobial PVC coating.

• Add “BX” to end of part number to receive 24'', 36'' or 48'' gas connector in a display box.

#

P

P

P

P

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

.

2244'''

$ 113

148

169

231

'

Setting the standard in gas safety

s

3366'''

$ 124

167

187

266

'

TM

4488'''

$ 139

192

220

322

Coupling

'

6600'''

$ 169

220

260

379

1-800-DORMONT

Nipple

'

7722'''

$ 193

248

299

436

'

6

www.dormont.com

Page 10

Basic Gas Connector Installation Kits

BBaassiicc SSaaffeettyy SSyysstteemm GGaass

CCoonnnneeccttoorr KKiittss IInncclluuddee::

• Safety System

gas connector

with SnapFast

quick-disconnect

coupling.

SwivelMAX

as Flow

G

wivelMAX

S

quipmentGas Supply

E

napFast QD

S

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorrss wwiitthh DDoouubbllee SSwwiivveellMMAAXX && RReessttrraaiinniinngg DDeevviicce

PPaarrtt #

#

11665500BBPPQQ22SSR

11667755BBPPQQ22SSR

R

R

1166110000BBPPQQ22SSR

1166112255BBPPQQ22SSR

• “2S” Suffix denotes Safety System gas connector fitted with the SwivelMAX coupling on supply end and equipment end.

Add PS to the end of the part number to include Safety-SetTM(additional list of $74).

SwivelMAX

R

R

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

.

$ 348

Gas Flow

2244'''

409

604

973

'

3366'''

'

$ 353

428

622

1024

4488'''

'

$ 372

460

654

1079

EquipmentGas Supply

SnapFast QD

397

$

1131

6600'''

486

696

'

7722'''

$ 428

507

742

1245

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorrss wwiitthh SSiinnggllee SSwwiivveellMMAAXX && RReessttrraaiinniinngg DDeevviicce

PPaarrtt #

#

11665500BBPPQQSSR

11667755BBPPQQSSR

R

R

1166110000BBPPQQSSR

IInnssiiddee DDiiaa.

1/2''

3/4''

R

1''

2244'''

.

'

$ 273

351

468

3366'''

$ 279

357

478

'

4488'''

$ 295

383

510

'

6600'''

'

$ 317

7722'''

$ 354

414

553

e

'

e

'

456

598

• Coiled restraining

device with

installation

mounting

hardware.

• Shaded box areas indicate most

commonly purchased sizes.

Part Number Explanations

B = Braid

P = PVC Coated (with Antimicrobial Coating)

Q = Quick-Disconnect (SnapFast)

CF = Safety Quik Quick-Disconnect Valve

S = SwivelMAX

R = Restraining Device & Hardware

PS = Placement system for equipment

(Safety-Set

7

TM

)

1-800-DORMONT

www.dormont.com

1166112255BBPPQQSSR

• Ships with elbow.

• “S” Suffix denotes Safety System gas connector fitted with the SwivelMAX coupling on supply end.

Add PS to the end of the part number to include Safety-Set

R

1-1/4''

Gas Flow

754

M

T

(additional list of $74).

790

849

EquipmentGas Supply

SnapFast QD

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorrss wwiitthh RReessttrraaiinniinngg DDeevviicce

4488'''

PPaarrtt #

#

11665500BBPPQQR

11667755BBPPQQR

1166110000BBPPQQR

1166112255BBPPQQR

• Ships with elbow.

AAdddd ““BBXX”” aatt tthhee eenndd ooff ppaarrtt nnuummbbeerr ttoo rreecceeiivvee 2244'''',, 3366 '''',, oorr 4488'''' ggaass ccoonnnneeccttoorr iinn ddiissppll aayy bbooxx..

•

Add PS to the end of the part number to include Safety-SetTM(additional list of $74).

R

R

R

R

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

2244'''

.

$ 197

264

320

490

'

3366'''

'

$ 204

272

337

537

'

$ 219

300

367

594

Setting the standard in gas safety

910

967

e

6600'''

$ 249

338

420

657

TM

'

7722'''

$ 282

369

460

722

'

Page 11

Safety System Gas Appliance Connector Assemblies

as Flow EquipmentGas Supply

G

afety Quik QD

S

wivelMAX

S

SwivelMAX

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr wwiitthh SSaaffeettyy QQuuiikk aanndd DDoouubbllee SSwwiivveellMMAAXX

PPaarrtt #

#

11665500BBPPCCFF22S

11667755BBPPCCFF22S

1166110000BBPPCCFF22S

“2S” suffix denotes Safety System gas connector fitted with the SwivelMAX coupling for both the equipment and gas supply end.

Safety Quik QD

IInnssiiddee DDiiaa.

S

S

S

1/2''

3/4''

1''

wivelMAX

S

366

$

2244'''

'

.

435

648

3366'''

'

386

$

465

685

Gas Flow EquipmentGas Supply

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr wwiitthh SSaaffeettyy QQuuiikkaannddSSwwiivveellMMAAX

PPaarrtt #

#

11665500BBPPCCFFS

11667755BBPPCCFFS

1166110000BBPPCCFFS

“S” suffix denotes Safety System gas connector fitted with the SwivelMAX coupling on gas supply end. Ships with elbow.

S

S

S

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

.

2244'''

$ 302

358

502

'

3366'''

'

$ 313

387

536

Gas Flow EquipmentGas Supply

4488'''

406

$

487

723

X

$ 328

416

573

4488'''

'

'

6600'''

436

$

519

770

6600'''

$ 354

443

611

'

'

7722'''

472

$

551

812

7722'''

$ 383

470

645

'

'

Safety Quik QD

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorr wwiitthh SSaaffeettyy QQuuiikk

PPaarrtt #

#

11665500BBPPCCF

11667755BBPPCCF

1166110000BBPPCCF

“BPCF” Series – Safety System gas connector fitted with Safety Quik QDV. Ships with elbow.

F

F

F

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

.

2244'''

'

$ 229

297

370

SSaaffeettyy SSyysstteemm CCoonnnneeccttoorrss wwiitthh DDoouubbllee SSwwiivveellMMAAXXaanndd SSnnaappFFaasst

PPaarrtt #

#

11665500BBPPQQ22S

11667755BBPPQQ22S

1166110000BBPPQQ22S

1166112255BBPPQQ22S

“2S” suffix denotes Safety System gas connector fitted with the SwivelMAX coupling on both the equipment side and the gas supply end.

AAdddd ““BBXX”” aatt tthhee eenndd ooff ppaarrtt nnuummbbeerr ttoo rreecc eeiivvee 2244'''',, 3366'''',, oorr 4488'''' ggaass ccoonnnneeccttoorr iinn ddiissppllaayy bbooxx..

S

S

S

S

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

.

2244'''

'

$ 322

388

573

967

Setting the standard in gas safety

Gas Flow EquipmentGas Supply

3366'''

$ 242

317

393

3366'''

$ 333

402

597

998

4488'''

'

'

$ 249

347

429

SnapFast QDSwivelMAX SwivelMAX

t

4488'''

'

TM

'

$ 351

433

622

1054

6600'''

'

$ 276

377

466

6600'''

'

$ 378

465

672

1105

1-800-DORMONT

7722'''

$ 304

406

502

7722'''

$409

491

716

1154

'

'

8

www.dormont.com

Page 12

Safety System Gas Appliance Connector Assemblies

Gas Flow EquipmentGas Supply

wivelMAX

S

napFast QD

S

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorrss wwiitthh SSiinnggllee SSwwiivveellMMAAXXaanndd SSnnaappFFaasst

2244'''

$ 245

328

456

714

$ 175

2244'''

$ 113

148

169

231

2244'''

242

297

488

'

3366'''

'

$ 259

334

466

768

napFast QD

S

4488'''

$274

367

486

826

t

'

3366'''

'

$ 180

249

313

515

4488'''

$ 195

277

348

572

s

'

3366'''

'

$ 124

167

187

266

4488'''

$ 139

192

220

322

PPaarrtt #

#

11665500BBPPQQS

11667755BBPPQQS

1166110000BBPPQQS

1166112255BBPPQQS

“S” suffix denotes Safety System gas connector fitted with the SwivelMAX coupling on gas supply end.

S

S

S

S

IInnssiiddee DDiiaa.

1/2''

3/4''

''

1

1-1/4''

.

Gas Flow EquipmentGas Supply

SSaaffeettyy SSyysstteemm GGaass CCoonnnneeccttoorrss wwiitthh SSnnaappFFaasst

PPaarrtt #

#

11665500BBPPQ

11667755BBPPQ

1166110000BBPPQ

1166112255BBPPQ

“BPQ” Series: Safety System gas connector fitted with a SnapFast quick-disconnect coupling and elbow.

Q

Q

Q

Q

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

.

SSaaffeettyy SSyysstteemm RReeppllaacceemmeenntt CCoonnnneeccttoorrs

PPaarrtt #

#

11665500BBP

11667755BBP

1166110000BBP

1166112255BBP

“BP” Series: Safety System gas connector

P

P

P

P

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

.

t

'

6600'''

'

$ 317

394

547

914

Elbow

'

6600'''

'

$ 227

320

397

635

'

6600'''

'

$ 169

220

260

379

7722'''

$ 345

428

588

954

7722'''

$ 253

347

436

702

7722'''

$ 193

248

299

436

'

'

'

UUnnccooaatteedd MMoovveeaabbllee CCoonnnneeccttoorrss wwiitthh SSnnaappFFaasstt QQuuiicckk--DDiissccoonnnneecct

PPaarrtt #

#

11665500BBQ

11667755BBQ

1166110000BBQ

1166112255BBQ

“BQ” Series: Stainless steel corrugated hose, encased in stainless steel braid, and fitted with a SnapFast quick-disconnect coupling. Ships with elbow.

UUnnccooaatteedd RReeppllaacceemmeenntt GGaass CCoonnnneeccttoorrs

PPaarrtt #

#

11665500B

B

11667755B

B

1166110000B

1166112255B

“B” Series: Stainless steel corrugated hose, encased in stainless steel braid.

AAdddd ““BBXX”” aa tt tthhee eenndd ooff ppaarrtt nnuummbbeerr ttoo rreecceeii vvee 2244'''',, 3366'''',, oorr 4488'''' ggaass ccoonnnneecc ttoorr iinn ddiissppllaayy bboo xx..

Q

Q

Q

Q

B

B

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

IInnssiiddee DDiiaa.

1/2''

3/4'

1''

1-1/4''

.

2244'''

'

$ 160

207

273

425

3366'''

$ 176

223

295

474

'

s

.

2244'''

$ 100

120

143

195

'

3366'''

'

$ 114

132

163

224

4488'''

$ 190

245

316

522

4488'''

$128

154

183

270

t

'

'

1-800-DORMONT

9

Setting the standard in gas safety

www.dormont.com

6600'''

$ 207

274

345

573

6600'''

$145

183

210

322

'

7722'''

'

$ 226

302

372

617

'

7722'''

'

$ 159

210

250

359

TM

Page 13

Stationary Connectors and Regulators

CUS

®

ormont Safety System stationary gas connectors are flexible stainless steel connectors with antimicrobial PVC coating designed to safely

D

and cost-effectively install all types of stationary commercial gas cooking equipment. They are safer than brass connectors, which are

susceptible to corrosion from chemicals in household and commercial cleaning products. Finally, they are designed to supply the adequate

gas flow to the cooking equipment, ensuring peak operating performance. With its high-quality construction, and broad range of sizes, the

Safety System stationary gas connector is the ideal connector for fixed-leg, curb-mount, or table-top gas equipment installations.

Stationary Gas Connector Kit

Kit Contains:

• 1 - NPFS Connector

• 1 - Full Port Valve

• 2 - Elbows

SSttaattiioonnaarryy AAnnttiimmiiccrroobbiiaall PPVVCC CCooaatteedd GGaass CCoonnnneeccttoor

IInnssttaallllaattiioonn KKiitts

PPaarrtt #

#

11665500NNPPKKIIT

11667755NNPPKKIIT

1166110000NNPPKKIIT

1166112255NNPPKKIIT

T

T

SSttaattiioonnaarryy AAnnttiimmiiccrroobbiiaall PPVVCC CCooaatteedd GGaass

CCoonnnneeccttoorrss OOnnlly

PPaarrtt #

#

11665500NNPPFFS

11667755NNPPFFS

1166110000NNPPFFS

1166112255NNPPFFS

S

S

S

S

IInnssiiddee DDiiaa.

T

T

1-1/4''

IInnssiiddee DDiiaa.

1-1/4''

1/2''

3/4''

1''

1/2''

3/4''

1''

s

2244'''

'

92

3366'''

$ 69

103

146

194

'

4488'''

$ 76

113

154

213

6600'''

'

$ 84

120

176

229

'

$ 90

133

186

244

.

$ 66

131

178

y

.

2244'''

$ 47

68

92

123

3366'''

'

$ 52

78

109

137

4488'''

'

$ 56

89

116

156

6600'''

'

$ 66

96

134

173

'

7722'''

$ 73

109

150

189

7722'''

Stationary Gas Connector Kit for the

Canadian Marketplace

This kit meets the code for standard 5.21.4 for stationary

equipment in Canada.

it Contains:

K

• 1 - BP Connector

• 1 - Full Port Valve

• 2 - Elbows

• 2 - Threaded couplers

r

'

SSttaattiioonnaarryy KKiitt ffoorr tthhee CCaannaaddiiaann MMaarrkkeettppllaacce

'

PPaarrtt #

#

CCAANN11665500BBPPEEV

CCAANN11667755BBPPEEV

CCAANN1166110000BBPPEEV

CCAANN1166112255BBPPEEV

V

V

V

V

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

1-1/4''

.

2244'''

$126

162

194

269

'

$135

3366'''

179

212

300

e

'

4488'''

$ 150

203

242

352

'

6600''''7722'''

$192

$199

229

278

405

'

254

315

457

CCoonnvveerrttiibbllee RReegguullaattoorrss --

3

2

2

PPiippee SSiizze

3/8''

1/2''

3/4''

PPaarrtt #

#

RRVV4477CCLL--333

RRVV4488CCLL--332

RRVV4488CCLL--442

pprreesseett ttoo ddeelliivveerr oouuttlleett pprreessssuurreess ffoorr bbootthh NNaattuurraall oorr LLPP ggaassees

BBTTUU CCaappaacciitty

e

RReegguullaattoorrss FFoorr NNaattuurraall GGaas

PPaarrtt #

#

RRVV4477LLNNGG--222

RR4488NN3322--00330066--33..5

RR4488NN4422--00330066--33..5

RRVV6611LLNNGG--552

RRVV6611LLNNGG--662

RRVV8811LLNNGG--772

RReegguullaattoorrss FFoorr LLPP GGaas

PPaarrtt #

#

RRVV4477LLLLPP--222

RR4488PP3322--00551122--110

RR4488PP4422--00551122--110

RRVV6611LLLLPP--552

RRVV6611LLLLPP--662

2

2

2

2

2

2

2

PPiippee SSiizze

5

5

PPiippee SSiizze

0

0

3/8''

1/2''

3/4''

1''

1-1/4''

1-1/2''

3/8''

1/2''

3/4''

1''

1-1/4''

e

BBTTUU CCaappaacciitty

2,500,000

2,500,000

4,500,000

s

e

BBTTUU CCaappaacciitty

2,500,000

2,500,000

Setting the standard in gas safety

125,000

250,000

250,000

s

125,000

250,000

250,000

125,000

250,000

250,000

y

IInnlleett PPrreessssuurre

1/2 PSIG

1/2 PSIG

1/2 PSIG

IInnlleett PPrreessssuurre

y

1/2 PSIG

1/2 PSIG

1/2 PSIG

1 PSIG

1 PSIG

1 PSIG

IInnlleett PPrreessssuurre

y

1/2 PSIG

1/2 PSIG

1/2 PSIG

1 PSIG

1 PSIG

OOuuttlleett PPrreessssuurre

e

4.0'' - 10.0'' wc

5.0'' - 10.0'' wc

5.0'' - 10.0'' wc

OOuuttlleett PPrreessssuurre

e

3.0'' - 6.0'' wc

3.0'' - 6.0'' wc

3.0'' - 6.0'' wc

4.0'' - 8.0'' wc

4.0'' - 8.0'' wc

3.0'' - 8.0'' wc

OOuuttlleett PPrreessssuurre

e

8.0'' - 12.0'' wc

5.0'' - 12.0'' wc

5.0'' - 12.0'' wc

5.0'' - 12.0'' wc

5.0'' - 12.0'' wc

s

e

PPrriicce

e

$ 36

38

RV48CL-32

38

e

PPrriicce

e

$ 33

35

35

127

RV61LNG-52

127

270

Dormont Manufacturing offers gas appliance

pressure regulators designed for main burner

and pilot applications where precise control of

e

PPrriicce

$ 33

35

35

127

gas flow is an essential operating requirement.

e

Housings are high strength aluminum castings.

All models have been tested for multi-positional

mounting and may be installed in any plane or

angle without restriction. They are available for

natural, manufactured, mixed LP, or

LP/ gas-air mixture.

127

TM

1-800-DORMONT

10

www.dormont.com

Page 14

Fittings, Valves, Restraining Cables and Accessories

CUS

®

CCooiilleedd RReessttrraaiinniinngg DDeevviicce

n the ANSI Z21.69 Standard section 1.7.4 states: "Each connector shall be accompanied with instructions that state, in effect,

I

hat the connector when used on caster-mounted equipment shall be installed with a restraining device, which prevents

t

ransmission if the strain to the connector."

t

BBuusshhiinnggs

990

0

990

0

s

PPaarrtt #

#

7700--4411332

2

7700--5511442

2

7700--6611552

2

°

°

SSttrreeeett EEllbbooww -- MMaallee xx FFeemmaallee

°

°

EEllbbooww -- FFeemmaallee xx FFeemmaallee

e

DDeessccrriippttiioon

3/4'' M. NPT x 1/2'' F. NPT

1'' M. NPT x 3/4'' F. NPT

1-1/4'' M. NPT x 1'' F. NPT

n

PPaarrtt #

005500SSE

007755SSE

110000SSE

112255SSE

#

E

E

E

E

DDeessccrriippttiioon

1/2''

3/4''

1''

1-1/4''

PPaarrtt #

005500E

E

007755E

E

110000E

E

112255E

E

#

DDeessccrriippttiioon

1/2''

3/4''

1''

1-1/4''

PPaarrtt #

RRDDCC224

RRDDCC336

RRDDCC448

RRDDCC660

n

n

#

4

6

8

0

PPrriicce

$ 6

6

7

PPrriicce

PPrriicce

e

$ 5

$ 4

DDeessccrriippttiioon

For 12'' and 24'' Connectors

For 36'' Connectors

For 48'' Connectors

For 60'' & 72'' Connectors

TThhrreeaaddeedd CCoouupplleer

TThhrreeaaddeedd NNiipppplle

e

5

6

8

GGaarrddeenn HHoossee AAddaapptteer

e

4

6

7

n

r

#

C

C

C

DDeessccrriippttiioon

1/2'' NPS

3/4'' NPS

1'' NPS

PPaarrtt #

005500C

007755C

110000C

e

PPaarrtt ##DDeessccrriippttiioon

005500SSN

007755SSN

110000SSN

112255SSN

N

N

N

N

1/2''

3/4''

1''

1-1/4''

r

#

H

DDeessccrriippttiioon

3/4'' Hose BIB

PPaarrtt #

9900--44114422GGH

n

n

n

PPrriicce

$ 22

PPrriicce

$ 5

PPrriicce

$ 4

4

4

4

PPrriicce

$ 8

e

24

26

27

e

6

7

e

e

11

SSttrraaiigghhtt VVaallvveess -- FFIIPP xx FFIIPP ((FFuullll PPoorrtt)

PPaarrtt #

003388FFV

005500FFV

007755FFV

110000FFV

112255FFV

115500FFV

#

V

V

V

V

V

V

DDeessccrriippttiioon

3/8'' FIP x 3/8'' FIP

1/2'' FIP x 1/2'' FIP

3/4'' FIP x 3/4'' FIP

1'' FIP x 1'' FIP

1-1/4'' FIP x 1-1/4'' FIP

1-1/2'' FIP x 1-1/2'' FIP

1-800-DORMONT

www.dormont.com

n

Dormont brings you a full line of certified brass gas ball

valves designed for superior reliability and outstanding

durability. All valves supplied by Dormont are CSA

Design-Certified.

)

PPrriicce

e

$ 16

16

20

31

47

66

Setting the standard in gas safety

SSaaffeettyy QQuuiikk QQDDVV FFiittttiinng

PPaarrtt #

#

CCFF--550

0

CCFF--775

5

CCFF--11000

0

Not available in 1-1/4''

g

IInnssiiddee DDiiaa.

1/2''

3/4''

1''

TM

PPrriicce

.

e

$ 104

131

182

Page 15

Always on the mark

M

Safety-Set

T

Equipment Placement System

Positioning System for Commercial Kitchen Equipment.

Safety-Set™ by Dormont is the newest advancement in placement systems delivering

maximum functionality to ensure your equipment is always on the mark!™ Designed for

use with commercial kitchen caster-mounted equipment, Safety-Set allows equipment to

be consistently returned to its desired or design specified location after every cleaning or

maintenance.

How important is safety?

Every commercial kitchen is designed to meet specific codes and standards to ensure the

highest level of safety. One area of code that is receiving stricter enforcement by

inspectors is cooking equipment placement in relation to the fire suppression and

ventilation systems.

CODE

ALERT

be present to ensure cooking equipment is always positioned in

its design specified location in relation to the fire suppression

and ventilation systems during cooking operations.

Safety-Set Equipment Placement System

NFPA Codes 17A (5.6.4) and 96 (12.1.2.3) require that a means

Part # Description Price

2 Safety-Set Units with Adhesive Foam Tape, Pre-applied

PS

Safety-Set may also be purchased with any BPQR or KIT Series Hose. To include Safety-Set, add PS to the end of the part number and

add $74 to the list price. (Example: 1675KIT48PS = List Price + $74.00)

Benefits:

• Can be used with all caster-mounted equipment

• Open floor design allows all casters to rest level on the floor

to ensure even cooking

• Satisfies NFPA codes 17A (5.6.4) and 96 (12.1.2.3)

• Fast, easy installation with choice of adhesive foam tape or

thumb screw hardware pack (both included)

2 Isopropyl Alcohol Wipes

1 Thumb screw Hardware Pack

Installation Instructions

$74

Recommended Applications:

• Gas & Electric Cooking Equipment

• Holding & Warming Carts

• Food Transportation Carts

• Salad Bars

• Mobile Refrigerators & Freezers

• Banquet Carts

Features:

• Compatible with 4'', 5'' and 6'' casters

• Ideal for new and existing applications

• Certified to NSF/ANSI Standard 169-Special Purpose Food

Equipment & Devices

• Composed of a flame retardant PC/ABS injection molded blend

• Able to withstand 1,000 lbs. of crush force

Setting the standard in gas safety

TM

1-800-DORMONT

12

www.dormont.com

Page 16

Hi-PSI®Stainless Steel Hoses for Water

Flexible Stainless Steel Connectors for Water and Steam Service

Dormont Hi-PSI®Flex connectors provide long, trouble-free

service life and permit quick, safe connection of hot and

old water service lines and steam lines to all types of

c

moveable/castered and stationary foodservice equipment.

Applications include utility distribution systems, steam kettles, steam

tables, combi-ovens and other foodservice equipment. Antimicrobial

PVC coated Hi-PSI Flex water lines are gray and include both a

blue (cold) and red (hot) label.

CCooaatteedd WWaatteerr CCoonnnneeccttoorrss wwiitthh QQuuiicckk--DDiissccoonnnneecct

PPaarrtt #

#

WW2255BBPP22QQ((CC//HH)

WW3377BBPP22QQ((CC//HH)

WW5500BBPP22QQ((CC//HH)

WW7755BBPP22QQ((CC//HH)

WW110000BBPP22QQ((CC//HH)

CCooaatteedd WWaatteerr CCoonnnneeccttoorrs

PPaarrtt #

#

((CC//HH)

WW2255BBP

P

((CC//HH)

WW3377BBP

P

((CC//HH)

WW5500BBP

P

((CC//HH)

WW7755BBP

P

WW110000BBP

P

((CC//HH)

)

)

)

)

)

)

)

)

)

)

IInnssiiddee DDiiaa.

1/4''

3/8''

1/2''

3/4''

1''

IInnssiiddee DDiiaa.

1/4''

3/8''

1/2''

3/4''

1''

2244'''

.

$ 155

182

199

283

377

'

3366'''

$ 173

193

216

297

399

'

s

2244'''

.

'

$ 102

113

125

158

214

3366'''

$ 119

128

138

183

244

'

4488'''

$ 192

217

240

329

438

4488'''

$ 142

151

163

213

284

t

'

'

UUnnccooaatteedd WWaatteerr CCoonnnneeccttoorrss wwiitthh QQuuiicckk--DDiissccoonnnneecct

PPaarrtt #

#

IInnssiiddee DDiiaa.

2244'''

.

'

3366'''

'

4488'''

'

t

6600'''

$ 214

242

266

363

478

6600'''

$ 160

178

190

248

324

6600'''

'

'

7722'''

'

$ 236

269

295

399

519

7722'''

$ 184

202

218

284

363

'

7722'''

“BP2Q”: Stainless steel corrugated hose with

braid and a permanent antimicrobial PVC

coating, fitted with a solid brass, two-way

quick-disconnect coupling.

'

“BP” Series: Stainless steel corrugated hose

with braid and a smooth permanent

antimicrobial PVC coating.

'

WW2255BB22Q

Q

WW3377BB22Q

Q

WW5500BB22Q

Q

WW7755BB22Q

Q

WW110000BB22Q

Q

UUnnccooaatteedd WWaatteerr CCoonnnneeccttoorrs

“B” Series: stainless steel corrugated hose

with braid, and brass fittings on both ends.

• 150 PSI max.

• Hot water temperatures up to 225°.

13

1/4''

3/8''

1/2''

3/4''

1''

1-800-DORMONT

$ 133

155

178

254

342

$ 142

163

188

264

357

$ 153

180

205

287

388

$ 162

192

223

308

420

$ 177

207

238

331

450

“B2Q” Series: Stainless steel corrugated hose

with braid, fitted with a solid brass, two-way

quick-disconnect coupling.

s

2244'''

PPaarrtt ##IInnssiiddee DDiiaa.

WW2255B

B

WW3377B

B

WW5500B

B

WW7755B

B

WW110000B

B

1/4''

3/8''

1/2''

3/4''

1''

$ 80

89

98

132

180

'

3366'''

$ 89

97

111

149

202

'

.

4488'''

$ 98

112

128

170

232

'

6600'''

$111

127

146

192

264

'

7722'''

$123

142

160

216

295

'

www.dormont.com

Page 17

Water and Steam Connector Assemblies

G

AS

W

A

T

E

R

CCoommbbii--OOvveenn CCoonnnneeccttoorrs

arden Hose Adapter

G

SStteeaamm CCoonnnneeccttoorrss wwiitthh QQuuiicckk--DDiissccoonnnneecct

“BIP2Q” Series: Stainless steel corrugated

hose with braid, covered with orange insulating

sleeve/heat shield and fitted with a solid brass

two-way quick disconnect coupling.

Steam connectors: 125 PSI max.

500° max temperature

SStteeaamm CCoonnnneeccttoorrs

“BIP” Series: Stainless steel corrugated hose with

braid, and brass fittings on both ends, covered

with orange insulating sleeve/heat shield.

Steam connectors: 125 PSI max.

500° max temperature

If you have a requirement that is not listed, please request a special quotation at 1-800-DORMONT.

s

PPaarrtt #

#

CCMMBB3377BBP

P

CCMMBB3377BBPP22Q

9900--44114422GGH

H

IID

D

33//88'''

33//88'''

Q

33//44'''

DDeessccrriippttiioon

'

3/4'' Hose BIB x 3/8'' MIP

'

3/4'' Hose BIB x 3/8'' QD

'

3/4''Hose BIB

n

t

PPaarrtt #

#

HH5500BBIIPP22Q

HH7755BBIIPP22Q

Q

Q

HH110000BBIIPP22Q

IID

D

11//22'''

33//44'''

11'''

Q

'

2244'''

'

'

$ 218

'

319

$ 238

416

s

PPaarrtt #

#

HH5500BBIIP

P

HH7755BBIIP

P

HH110000BBIIP

P

IID

D

11//22'''

33//44'''

11'''

2244'''

'

'

$ 133

'

'

202

259

3366'''

345

457

3366'''

$ 160

229

299

4488'''

$ 258

354

6600'''

'

'

$ 275

373

$ 8

6600'''

$ 292

428

573

6600'''

$ 216

313

417

'

'

'

4488'''

'

$ 265

386

515

'

4488'''

'

$ 189

271

358

7722'''

$ 320

469

616

7722'''

$ 242

352

460

'

'

WWaatteerr QQuuiicckk--DDiissccoonnnneecctt 22--WWaayy CCoouupplliinngg -- SSoolliidd BBrraasss

PPaarrtt #

#

WW2255QQD

D

WW3377QQD

D

WW5500QQD

D

WW7755QQD

D

WW110000QQD

D

Includes coupling and nipple

SSiizze

1/4''

3/8''

1/2''

3/4''

1''

PPrriicce

e

e

Coupling

Nipple

$ 57

73

88

136

2-way coupling shuts off water at

equipment and supply.

179

s

Water connector and gas connector applications

1-800-DORMONT

14

www.dormont.com

Page 18

Swirl™Hoses – Water Supply Line

Dormont provides the highest quality

products to the foodservice industry

ncluding the Dormont SWIRL Hose.

i

This durable, retractable NSF-certified

polyurethane hose, connects water-fed

appliances and liquid dispensing equipment to water supply lines. The unique

design makes equipment installation

quick and easy and provides many

advantages over traditional coiled

copper tubing water supply lines.

aximum allowable temperature rating: 160°

M

Maximum allowable operating pressure: 100 PSIG

tandard fitting combination:

S

Fixed Male x Female Swivel.

ll hose assemblies include a brass elbow fitting.

A

SSwwiirrll IInnssttaallllaattiioonn –– IIccee MMaacchhiinnee

SSwwiirrll IInnssttaallllaattiioonn –– CCooffffeeee MMaacchhiinnee

1. 71 & 72 Series come with a Male Adapter x Female Elbow

. 73 Series comes with a Male Adapter x Male Elbow

2

3. Coffee Machine Kits include Male NPT Adapter x Female Flare Fitting

SSwwiirrllHHoossee AAsssseemmbblliieess -- MMaallee xx FFeemmaalle

PPaarrtt #

#

7711--1111114

7722--2211224

7733--3311334

4

4

4

IID

D

11//44'''

33//88'''

11//22'''

'

'

'

e

4488'''

'

$ 48

65

107

SSwwiirrllHHoossee AAsssseemmbblliieess -- MMaallee xx QQuuiicckk DDiissccoonnnneecct

7711--1111115

5

7722--2211225

5

7733--3311335

5

CCooffffeeee MMaacchhiinnee KKiitt -- MMaallee xx FFeemmaallee ((11//44'''' IIDD)

7711--1111118

8

1/4'' M. NPT x 1/4'' F. Flare

7711--1111228

8

1/4'' M. NPT x 3/8'' F. Flare

BBrraassss QQuuiicckk--DDiissccoonnnneecctt 22--WWaay

11//44'''

'

33//88'''

'

11//22'''

'

y

Dormont 2-Way Brass QuickDisconnect prevents backflow

from the equipment.

$ 108

138

199

)

$ 53

53

1

LLeennggtthh ((WWhheenn oorrddeerriinngg,, aadddd lleennggtthh aafftteerr ppaarrtt nnuummbbeerr)

7722'''

'

$ 53

74

123

2

9966'''

$ 57

80

132

'

3

t

$ 111

99885500--1122112

99885500--2222222

99885500--3322332

147

212

$ 57

57

2

2

2

$ 115

156

225

$ 62

62

1/4''

3/8''

1/2''

)

114444'''

'

$ 65

98

157

$ 127

174

250

$ 69

69

$ 60

73

89

15

BBrraassss FFiittttiinnggss

PPaarrtt #

Flare

Fitting

9900--1111112

9900--1111222

9900--44114422GGH

#

2

1/4'' M. NPT x 1/4'' F. Flare

2

1/4'' M. NPT x 3/8'' F. Flare

H

3/4'' Garden Hose BIB

1-800-DORMONT

www.dormont.com

SSiizze

EEllbboowws

s

PPrriicce

PPrriicce

$ 7

e

7

8

M x F

Elbow

e

PPaarrtt #

9955--1111112

9955--2211222

9955--3311331

#

1/4'' M. NPT x 1/4'' F. NPT

2

3/8'' M. NPT x 3/8'' F. NPT

2

1

1/2'' M. NPT x 1/2'' M. NPT

SSiizze

e

e

$ 6

7

14

Page 19

Countertop Gas Connector and Ice Maker Installation Kit

COUNTERTOP

Gas Appliance Connector

• Flexible corrugated stainless steel construction

• Tight weave stainless steel braid for reinforcement

• Smooth easy to clean antimicrobial PVC coating

• Available in 1/2'' ID, 24'' and 36'' lengths.

Countertop Connectors and Kits

Part # Description I.D. 24'' 36''

CT1650 Includes 1/2'' F x F elbow and 1/2'' $63 $72

1/2'' F x 3/4'' F reducing elbow

CT1650KIT Includes elbows and 1/2'' full port 1/2'' $ 70 $78

ball valve

Commercial Ice Maker Installation Kit

• Fast, easy installation for professional or do-it-yourself installers

• For all major commercial ice makers

• Rated at 4.3 gal/min at 50 psi

Ice Maker Kit Includes

Part # Description Price

IMIKFS-01D 3/8'' x 60'' braided water connector $81

3/4'' PVC adapters, elbows and Ts

1/2'' Brass check valve

1-800-DORMONT

www.dormont.com

16

Page 20

Grease Interceptors, OneFlowTMand PowerForce

TM

Got Grease?

Grease Interceptors for:

• Cooking/prep sinks

• Pot, pan and scullery sinks

• Dishwasher applications

• PDI Certified

• Full line of “point of use” sizes available

• Epoxy coated steel construction

All stainless steel available upon request

TM

OneFlow®Scale Control Systems

• Protect equipment from the negative effects of scale

• Require no salt, phosphate chemicals, electricity,

backwashing

• Hot and cold water units available up to 8 GPM

INDUSTRY BEST 2 YEAR WARRANTY!

PowerforceTMCommercial Faucets

• Interchangeable with other leading brands

• Chrome plated solid brass construction

• NSF/ANSI 61 Section 9 Certified

17

1-800-DORMONT

www.dormont.com

Page 21

Terms and Conditions

TERMS:

et 30 Days. Minimum order $75 net.

N

rders below minimum and broken cartons

O

re subject to a $25.00 handling fee.

a

1. ACCEPTANCE. If this writing differs in

ny way from the terms and conditions of

a

mmediate Buyer’s (“Buyer”) order or if this

I

riting is construed as an acceptance or as

w

a confirmation acting as an acceptance,

then Dormont’s (“Seller”) acceptance is

XPRESSLY MADE CONDITIONAL ON

E

UYER’S ASSENT TO ANY TERMS AND

B

CONDITIONS CONTAINED HEREIN THAT

ARE DIFFERENT FROM OR ADDITIONAL TO

HOSE CONTAINED IN BUYER’S WRITING.

T

urther, this writing shall be deemed notice

F

of objection to such terms and conditions

of Buyer. If this writing is construed as the

offer, acceptance hereof is EXPRESSLY

LIMITED TO THE TERMS AND CONDITIONS

ONTAINED HEREIN. In any event, Buyer’s

C

acceptance of the goods shall manifest

Buyer’s assent to Seller’s terms and

conditions. No addition to or modification of

hese items will be effective unless set forth

t

n writing and agreed to by Seller.

i

2. WARRANTIES AND REMEDIES.

a. Warranty.

Seller warrants to Buyer that it holds and

will pass marketable title to the goods sold

ereunder. If buyer is not the end user of

h

the goods sold hereunder, Buyer agrees to

provide to any immediate buyer ("Remote

Purchaser") the Limited Warranty and

Disclaimer to End-Use (Remote) Purchasers

issued by Seller. This warranty excludes

coverage for any product that is moved to a

new location. Seller’s products should

never be reused.

b. Exclusions and Conditions.

Seller’s obligations with respect to the

express warranties and remedies contained

herein are conditioned on the following: (i)

Buyer’s return of the nonconforming goods,

if authorized by Seller; and (ii) be installed

by individuals trained and certified as a

professional with respect to such

installations, and be installed, used,

repaired and maintained by Buyer and

Remote Purchaser in accordance with

National, regional and local codes or

regulations (i.e. National Fuel Code

(ANSI Z 223.1/NFPA 54); International Fuel

Gas Code; Uniform Plumbing Code),

standards set by American National

Standard Institute, Inc. (ANSI) and/or

Canadian Standards Association

(CSA) Standards.

3. DISCLAIMER OF IMPLIED WARRANTIES.

SELLER GIVES NO WARRANTIES TO BUYER

EXCEPT THOSE EXPRESSLY CONTAINED

HEREIN. SELLER DISCLAIMS ALL OTHER

WARRANTIES IMPLIED BY LAW, USAGE OF

THE TRADE, COURSE OF DEALING OR

COURSE OF PERFORMANCE INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

4. LIMITATIONS OF LIABILITY.

The following limitations of Seller’s liability

are acknowledged by the parties to be fair

and reasonable and shall apply to any act or

omission hereunder, and to any breach of

this contract of which these terms and

conditions form a part:

a. Disclaimer of Damages.

IN NO EVENT SHALL SELLER BE LIABLE

FOR SPECIAL, INDIRECT, CONSEQUENTIAL

OR INCIDENTAL DAMAGES WHETHER

ARISING UNDER CONTRACT, WARRANTY,

TORT, NEGLIGENCE, STRICT LIABILITY OR

NY OTHER THEORY OF LIABILITY.

A

uch damages include but are not limited to

S

oss of profits, loss of use of the goods,

l

amage to property, and claims of

d

third parties.

. Replacement of Fittings.

b

uyer acknowledges that if Buyer replaces

B

the adapter fittings supplied by Seller with

fittings produced by another manufacturer,

hen all of Seller ’s warranties to Buyer and

t

o Remote Purchaser will be voided and

t

Buyer will assume all liability for any

damage, injury or loss suffered by Remote

urchaser arising out of this unauthorized

P

odification.

m

c. Notice and Time of Claims.

(i) Buyer agrees to inspect all products

against shipping papers and for damage or

hortage upon receipt of goods at

s

destination; (ii) Every claim for loss,

damage in transit, or other cause visible

upon inspection shall be made with carrier.

laims for shortage must be made within

C

ive (5) days of receipt.

f

5. TERMS. Net 30 Days – minimum order

of $75. Interest on accounts overdue more

than thirty (30) days will be charged at 2%

per month or the highest rate permitted by

aw, whichever is lower. Orders below

l

minimum and broken cartons are subject to

a $25.00 handling fee. Prices subject to

change. Buyer shall be liable for any

collection costs or attorneys’ fees incurred

as a result of Buyer’s failure to pay its

account on time.

6. SHIPPING TERMS. Prepaid and allowed

on $1250 net and over. Under $1250 net,

shipments shall be F.O.B. Factory. Buyer is

responsible for all freight charges.

The above shall apply only to shipments

within the continental United States of

America unless otherwise indicated by

Seller. The method of shipment and carrier

shall be selected by Seller.

7. RETURNS. No returns are to be made to

Seller without first obtaining a return

authorization number. Absolutely no

returns will be accepted or credited without

this prior approval. Returns are subject to

25% restocking charge plus any

transportation charges incurred by Seller.

8. TAXES. The Buyer will pay, or reimburse

Seller if it pays, any and all taxes or tariffs

or any other similar charges imposed upon

this contract, the goods covered hereby or

the delivery or use or resale thereof.

9. APPLICABLE LAW.

All questions arising hereunder shall be

interpreted and resolved in accordance with

the Commercial Code of the Commonwealth

of Pennsylvania without regard to its

conflict of law provisions and excluding the

United Nations Convention on the

International Sale of Goods.

10. INDEMNIFICATION

Buyer agrees to indemnify, hold harmless,

and defend Seller from and against all

claims and lawsuits, including attorney's

fees, to the extent that Buyer's negligent

acts or omissions to act cause injury,

damage or loss to customers of

Seller’s products.

Warranty can be viewed at

www.Dormont.com

Safety System Global

Design Certifications

n many international markets, design certifi-

I

ation to the ANSI Standard is accepted for

c

as connector installations. However, in some

g

arkets, other national requirements exist. In

m

hese areas, Dormont works to earn the

t

equired certifications.

r

ormont has worked with international stan-

D

ards boards to help author gas connector

d

tandards. We assist government agencies

s

nd utilities to under-stand the properties of

a

atural and LP gas and requirements of gas

n

ppliances.

a

USA

CR-92-009 Swivel Connectors for use with

ANSI Z21.15/CGA 9.1 Manually Operated Gas Valve for

ANSI Z21.69/CSA 6.16 Metal Connectors for Moveable

ANSI Z21.41/CSA 6.9 Quick Disconnect devices for use

Approved by the Commonwealth of Massachusetts

Board of State Examiners of Plumbers & Gas Fitters.