Page 1

For Residential and Commercial Applications

ES-D-LVBlackCoated

Job Name ________________________________________

Job Location ______________________________________

Engineer _________________________________________

Approval ___________________________________

LV Black Coated

Gas Connectors

Specifically engineered for high-temperature applications such as gas

logs, fireplace inserts, and freestanding fireplaces

Features a low-visibility coating that hides the connector from view

Features and Specifications

• Tubing Annealed, 304 stainless steel (ASTM A240)

• Black coating. Maximum temperature rating: 350°F

• Flare Nuts: Steel with black plating

• Flare Adapters: Steel with Black Plating

• Approved for indoor/outdoor use with stationary

gas appliances/equipment.

• 100% factory leak tested

• When installing a new appliance or when an existing appliance is

moved to a new location a NEW gas connector must be used per

manufacturer's installation instructions and product standards.

• Designed for occasional movement after installation. Repeated

bending, flexing or extreme vibration must be avoided. Normal

operation of a clothes dryer, rooftop HVAC unit or SIMILAR

OUTDOOR APPLIANCE DOES NOT constitute extreme

vibration or movement.

Certifications and Approvals

• ANSI Z21.24/CSA 6.10 – Connectors for Gas Appliances

• ANSI Z21.75/CSA 6.27 – Connectors for Outdoor Appliances

and Manufactured Homes

• City of New York – MEA #376-92-M

• Approved by the Commonwealth of Massachusetts Board of State

Examiners of Plumbers and Gas Fitters – connector length may not

exceed 48"

Contractor ________________________________________

Approval _________________________________________

Contractor's P.O. No. _______________________________

Representative ____________________________________

SKU _____________________________________________

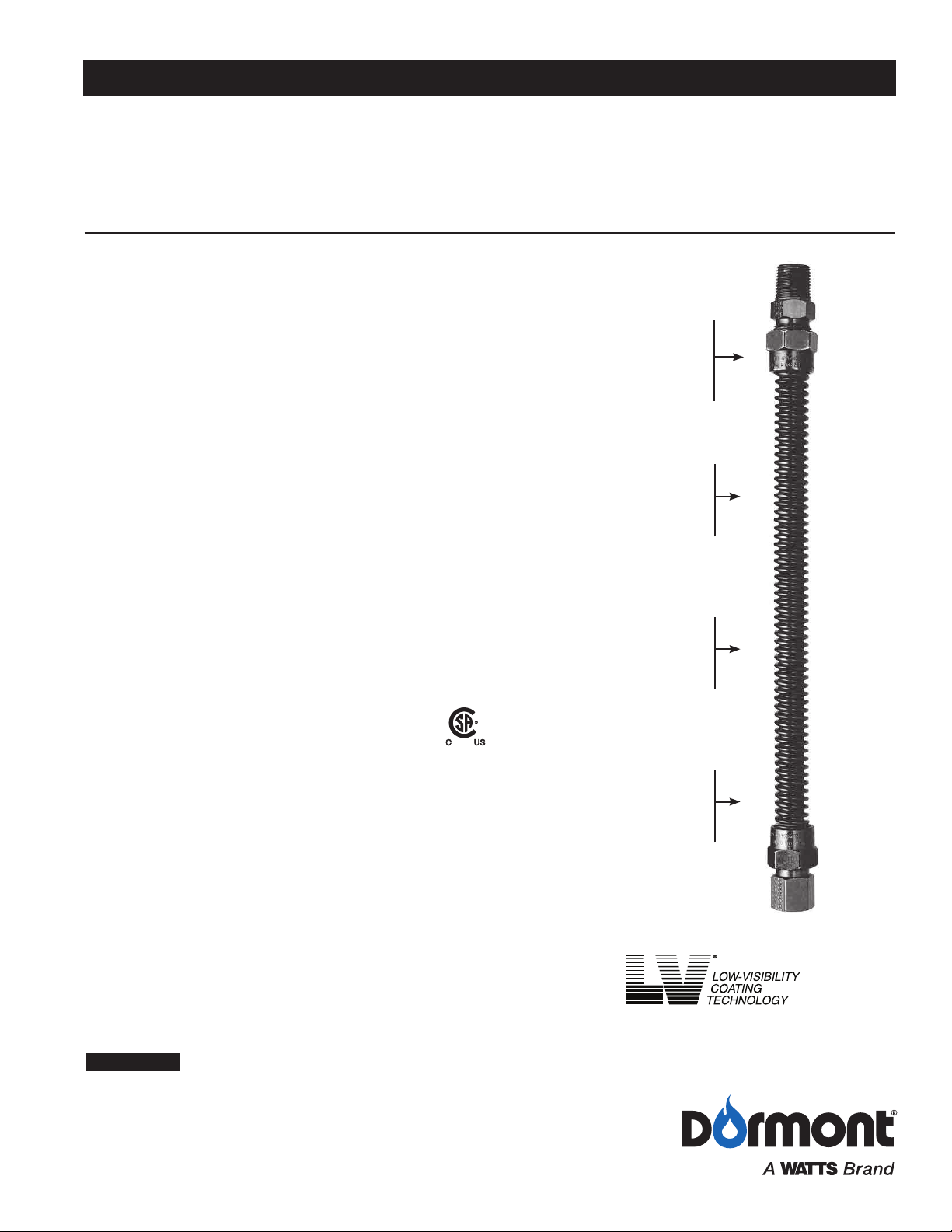

Black adapters and

flare nuts further

reduce visibility of

connector

Durable connector is

made of heavy-duty

304 stainless steel

Hi-temperature black

polymer coating

hides the connector

from view while withstanding up to 350° F

Exclusive No-Neck

Design: Increase

Tubing Flexibility

Applications

• Gas logs

• Fireplace inserts

• Free-standing fireplace

• Wall heaters

WARNING

All installations must completely comply with all Dormont manufacturing company warnings

and instructions, national, state and local codes and all applicable ansi standards.

Dormont product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise

measurements, please contact Dormont Technical Service. Dormont reserves the right to change or modify product design, construction,

specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Dormont

products previously or subsequently sold. Refer to the owner's manual for warranty information.

10A and 20A Series

Page 2

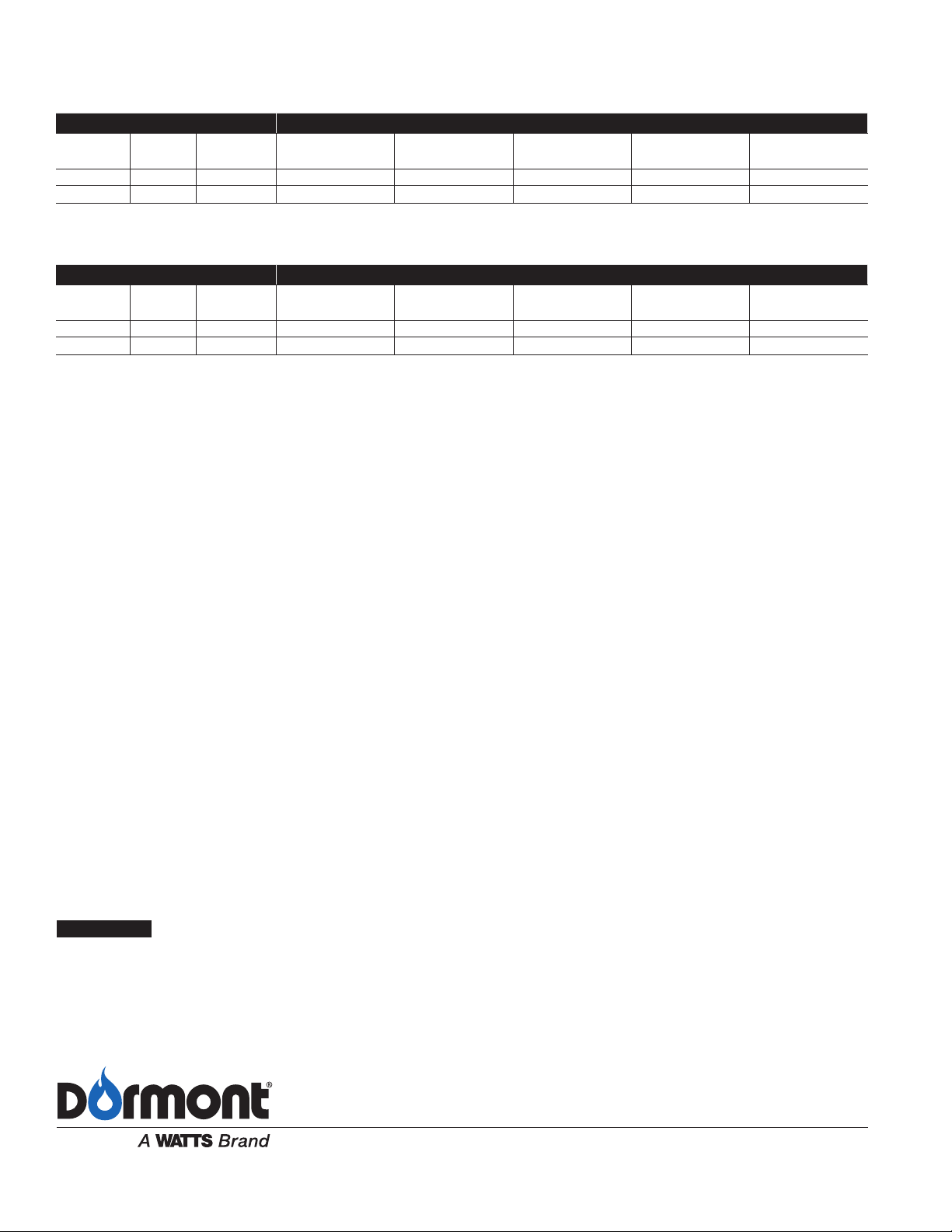

Minimum Flow Capacity

(Connector Minimum Flow Capacity – For Natural Gas (per ANSI Z21.24/CSA 6.10 & ANSI Z21.75/CSA 6.27)

Straight Length Capacity – BTU per Hr 0.64 SG., 1000 BTU per Cu. Ft. at 0.5 inch Water Column Pressure Drop)

Configuration ConnECtor LEngtH [inCHES]

SERIES

10A 3⁄8 1⁄4 48,000 43,800 40,000 36,400 33,400

20A 1⁄2 3⁄8 102,000 93,100 85,000 77,100 71,100

(Connector Minimum Flow Capacity – For LP Gas (per ANSI Z21.24/CSA 6.10 & ANSI Z21.75/CSA 6.27)

Straight Length Capacity – BTU per Hr 1.55 SG., 2500 BTU per Cu. Ft. at 0.5 inch Water Column Pressure Drop

SERIES

10A 3⁄8 1⁄4 76,800 76,080 64,000 58,240 53,440

20A 1⁄2 3⁄8 163,200 148,960 136,000 123,360 113,760

Nominal OD Nominal ID 12 18 24 30 36

in in

Configuration ConnECtor LEngtH [inCHES]

Nominal OD Nominal ID 12 18 24 30 36

in in

in in in in in

in in in in in

NOTICE

The minimum flow capacity values in the charts are at 0.5" w.c. pressure drop (inlet pressure

minus outlet pressure). If your gas system has more available pressure drop then a general

rule of thumb approximate calculation is as follows:

Minimum Flow Capacity @ your pressure drop = Square Root (your pressure drop/0.5) x value

from chart

Example: What is the approximate minimum flow capacity (natural gas) of the Dormont 10A

Series x 24" @ 1" wc pressure drop?

Answer: Square Root (1/0.5) x 40,000 = 56,568 BTU/hr

USA: Tel: (800) 367-6668 • Fax: (724) 733-4808 • Dormont.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • Dormont.ca

Latin America: Tel: (52) 81-1001-8600 • Fax: (52) 81-8000-7091 • Dormont.com

ES-D-LVBlackCoated 1610 © 2016 Dormont

Loading...

Loading...