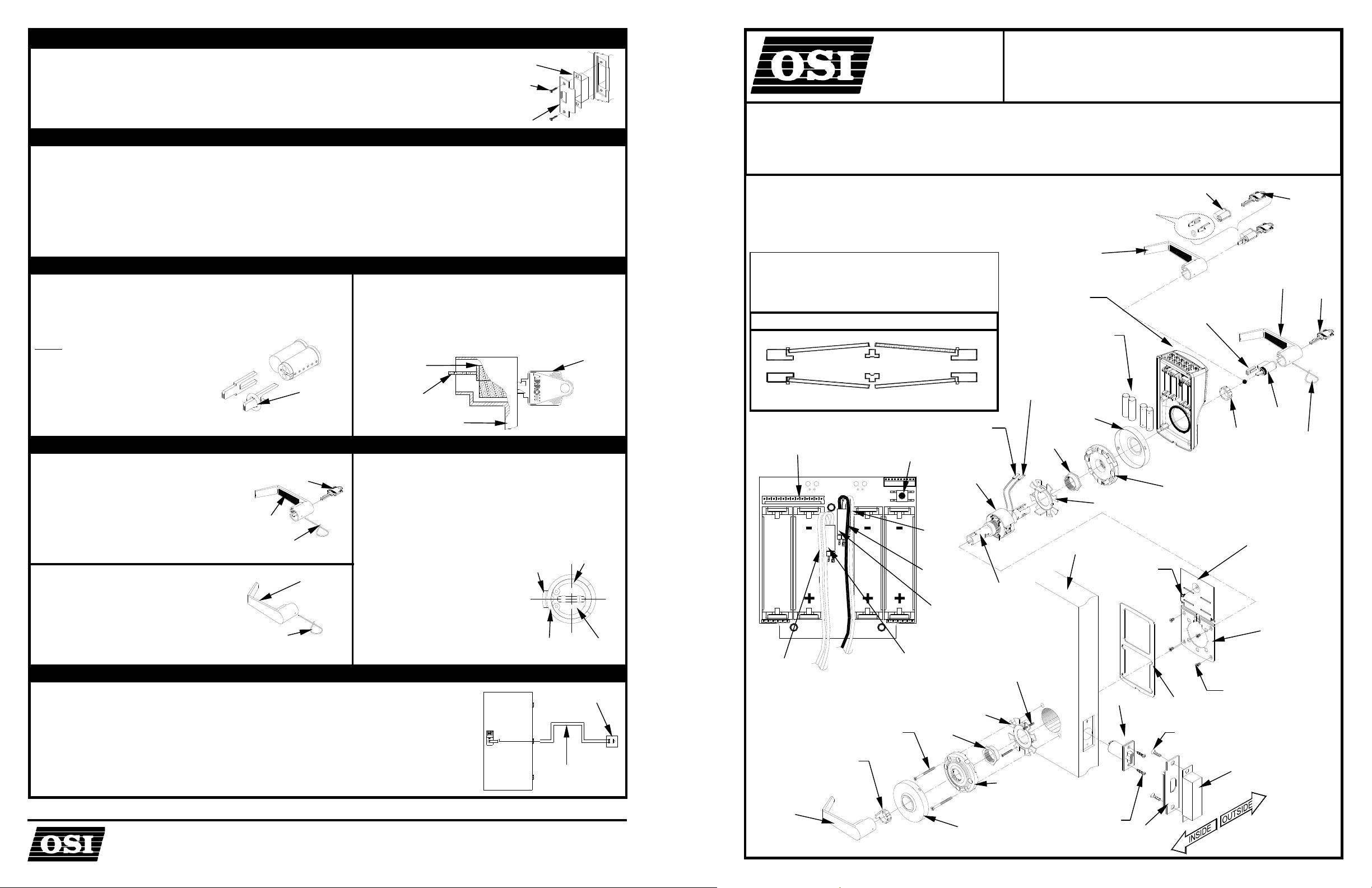

PAIR

SECTION 6: INSTALL THE STRIKE

PAGE 4 OF 4

BOX

SCREW

#12 X 3/4"

(2 REQ’D)

pins if the pins will completely enter the

Insert the applicable I.C. Tailpiece into the I.C. Core. Insert

ey 15° counterclockwise to lock the Core

CONTROL

KEY

SIDE

LEVER

(UNEQUAL LENGTH PINS)

END VI

EW

PLATE

GASKET

OUTSIDE

ALKALINE

BATTERY, 1.5V, 3VOLT

USE APPLICABLE

TAILPIECE

SEMS,

PAN HEAD,

40 X 1/4LG

SCREW, FLAT HEAD,

NUT

SCREW, FLAT HEAD,

#8 X 3/4” LG

(2 REQ’D)

SCREW, PAN HEAD,

(2 REQ’D)

SCREW, FLAT HEAD,

CONTROL

DOOR

SPINDLE

LATCH

NUT

INSIDE

WARNING:

NOT WARRANTED

APPROVED BY OSI SECURITY DEVICES COULD VOID THE

KEY DETECTION

CONNECTOR

(OPTION 1)

I.C. OUTSIDE

LEVER

RETAINER

RIGHT HAND SHOWN

LEFT HAND

REVERSE

LEFT

HAND

HAND

INSIDE

OUTSIDE

DOOR HANDLING

a. Mark the location of the Latch Bolt on the Door Frame.

b. Center the Strike over the Latch Bolt Mark and, using the Strike as a template, mark

the Frame.

c. Using the Strike Box as a template, mark the Frame.

d. Mortise the Frame to accept the Strike and Strike Box.

e. Install the Strike Box and the Strike and secure with the Screws.

STRIKE

STRIKE

®

SECURITY

DEVICES

OMNILOCK

ACCESS CONTROL SYSTEMS

INSTALLATION INSTRUCTIONS FOR OPW2000 SERIES

SECTION 7: PROGRAM THE LOCKSET

IMPORTANT:

Refer to the OMNILOCK Administrator’s Guide for programming instructions. If the System has been installed on a door before the

required programming information is available, and your system has a keypad, the access Level may be set to Unlocked as follows:

a. Enter the Default Manager ID 2222, at the keypad, the green light will flash.

b. Press 2, the green light will flash.

c. Press and hold the CL key until the green light flashes four times. (The light will flash once when the CL key is pressed,

continue to hold the key until the light flashes three more times.)

d. The System will remain in the Unlocked mode.

To avoid unauthorized access, it is important to program a new Programmer ID

.

SECTION 8: INTERCHANGEABLE CORE

8-1

INTERCHANGEABLE (I.C.) CORE AND TAILPIECE

8-2

INTERCHANGEABLE (I.C.) CORE INSTALLATION

INSTRUCTIONS FOR ARROW I.C. CORES

Be certain to use the correct Tailpiece with the Core. Six-Pin

Cores use only the “L6” Tailpiece and Seven-Pin Cores use

only the “L7” Tailpiece.

NOTE:

There are two styles of Tailpieces, one

style has equal length pins and the

other style has unequal length pins.

Use the Tailpiece with equal length

holes in the Core. Otherwise use the

Tailpiece with unequal length pins and

install the O-ring onto the Tailpiece tab.

TAILPIECE

(EQUAL

LENGTH PINS)

O-RING

TAILPIECE

I.C.

CORE

the Control Key into the I.C. Core and turn it 15°

clockwise. Insert the Core into the I.C. Outside Lever and

turn the Control K

in the Lever. Remove the Control Key.

I.C. CORE

I.C. TAILPIECE

I.C OUT

SECTION 9: REMOVAL OF LEVERS

9-1

REMOVING OUTSIDE LEVER WITH STANDARD CYLINDER

a. Insert the Key into the Cylinder and turn 45°

clockwise.

b. Depress the Lever Catch through the

hole in the Outside Lever by using the

Push Pin provided or another suitable

tool.

c. Slide the Outside Lever from the Spindle.

9-3

REMOVING THE INSIDE LEVER

OUTSIDE

LEVER

PUSH PIN

(PROVIDED)

a. Depress the Lever Catch through the

hole in the Inside Lever by using the

Push Pin provided or another suitable

tool.

b. Slide the Inside Lever from the

Spindle.

PUSH PIN

(PROVIDED)

KEY

INTSIDE

LEVER

9-2

REMOVING OUTSIDE LEVER WITH INTERCHAN-

GEABLE (I.C.) CORE

a. Insert the control Key into the I.C. Core and rotate it

15° clockwise. Pull on the Key to remove the I.C.

Core. Be sure that the I.C. Tailpiece is removed with

the Core.

b. Ensure that the Retaining

Ring and the Anti-Pick Plate

are aligned with the Lever

Catch as shown.

OUTSIDE SPINDLE

LEVER

RETAINING

RING

c. Insert an awl or a small

screwdriver through the I.C.

Outside Lever and into the slot in

the Anti-Pick Plate. Depress the

Lever Catch toward the Door

Hinge and slide the I.C. Outside

Lever from the Spindle.

OUTSIDE

SPINDLE

ANTI-PICK

PLATE

SECTION 10: REMOTE SWITCH

a. Remote operation of the System may be accomplished by a momentary Switch closure. This

may be desirable for someone monitoring a protected entrance, such as a receptionist.

Momentarily pressing the Switch will cause the System to go through a normal unlock and

lock sequence. If the Switch is held closed, the open time will be extended.

OMNILOCK

b. Connect a twisted pair of wires from the Terminal Block on the PC Board to a normally open

momentary contact Switch. Plan the route for your wire and the access route through the

door to the PC Board in the OMNILOCK Module. Plan for disconnecting the wires in the Lock

area so that the System can be removed from the door to change the Batteries as required.

Copyright 2003 OSI Security Devices Inc. All Rights Reserved.

OMNILOCK is a Registered Trademark of OSI Security Devices Inc. Arrow is a Trademark of Arrow Lock Co. 12831 Rev.A

SECURITY

(Website: WWW.OMNILOCK.COM)

DEVICES

1580 JAYKEN WAY

CHULA VISTA, CALIFORNIA 91911

(619) 628-1000 FAX (619) 628-1001

SWITCH

TWISTED

NON-WEATHERIZED, CYLINDRICAL LOCKSET USING

ARROW™ Q-SERIES LOCK (LEVER)

WARNING: CHANGES OR MODIFICATIONS NOT EXPRESSLY

USER’S AUTHORITY TO OPERATE THE EQUIPMENT.

NOTE: A DOOR-CLOSER IS HIGHLY RECOMMENDED FOR

USE WITH THIS PRODUCT.

THIS PRODUCT IS NORMALLY FACTORY-PACKED

DO NOT USE ON DOORS THICKER THAN 1-3/4”.

CONNECTOR

-

+

2 YELLOW

WIRES NO

POLARITY

(OPTION 1 ONLY)

LEVER

READ COMPLETE INSTRUCTION BEFORE PROCEEDING.

THIS PRODUCT IS

FOR RIGHT-HAND 1-3/4” THICK DOORS.

TO CHANGE HAND OF LOCK SEE

INSTRUCTION SECTION 3

RIGHT

OUTSIDE

RIGHT HAND

DOOR HANDS DETERMINED FROM OUTSIDE

RESET BUTTON

KEY

DETECTION

CONNECTOR

SCREW, FLAT HEAD,

#10-32 X 2-1/4”LG

(2 REQ’D)

FLEXIBLE

ADAPTER

REVERSE

LOCK

BODY

RED

WIRE

BLACK

WIRE

MOTOR

CONNECTOR

PLATE

ROSE

FOR OUTDOOR USE!

HOUSING

ASSEMBLY

AA

MOTOR

CONNECTOR

#6 X 3/4”LG

OUTSIDE ROSE

INSERT ASSEMBLY

(4 REQ’D)

ROSE

PLATE

#4-

UNIT

-

-

+

+

STRIKE

I.C.CORE

CYLINDER

FLEXIBLE

ADAPTER

OUTSIDE ROSE

INSERT ASSEMBLY

BATTERY

COVER

#8-32 X 3/8” LG

(4 REQ’D)

#12 X 3/4” LG

(2 REQ’D)

STRIKE BOX

KEY

LEVER

KEY

PUSH PIN

(PROVIDED)

BACK

PAGE 1 OF 4

2 YELLOW WIRES

NO POLARITY

BOARD ASSY

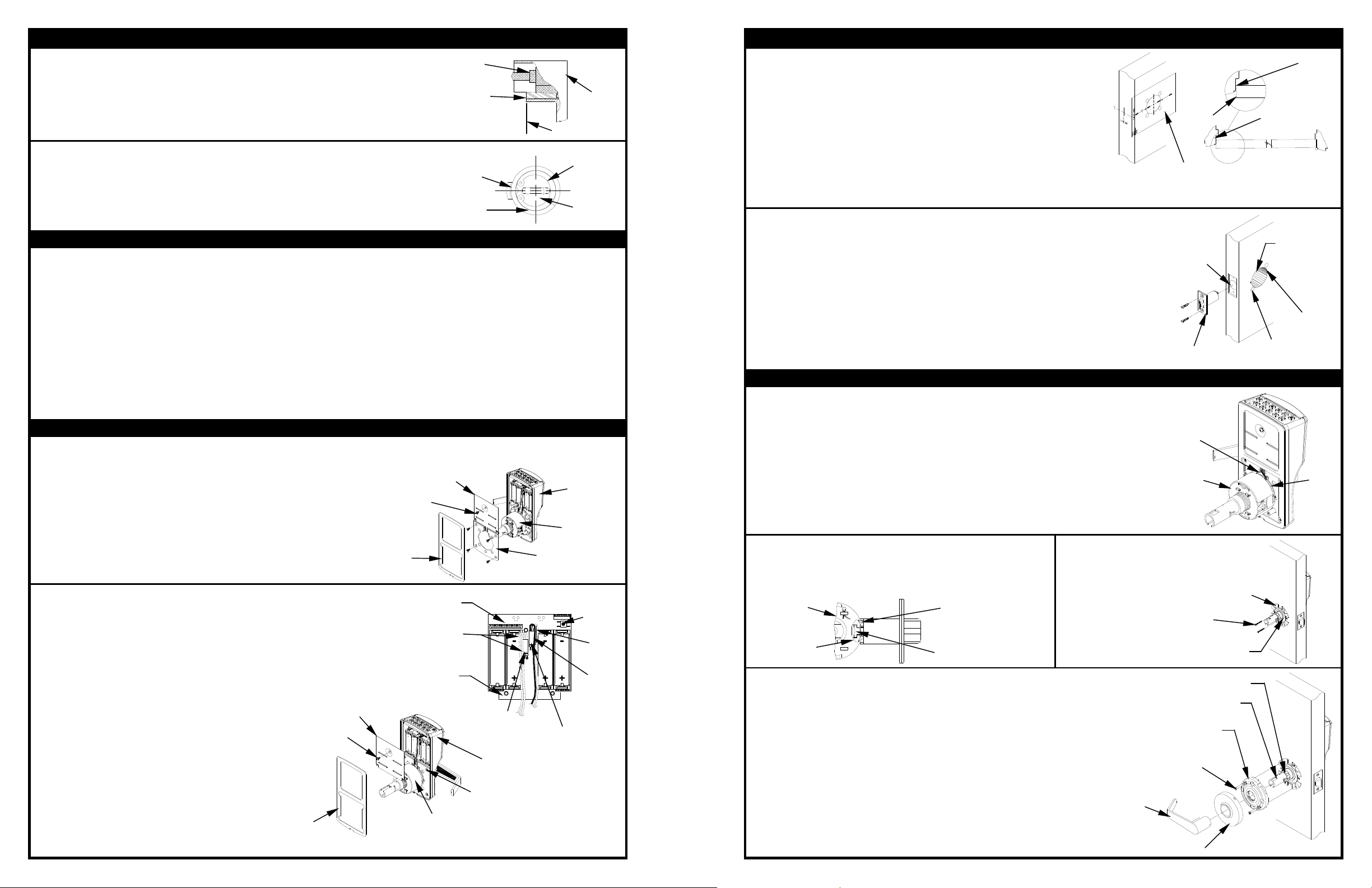

SECTION 1: INSTALL THE KEY CYLINDER AND OUTSIDE LEVER

LEVER

ANTI

PLATE

RING

SPINDLE

END VIEW

PAGE 2 OF 4

GASKET

COVER

ASSEMBLY

ASSEMBLY

Install the Plate and Nut on the inside,

LOCK BODY

RETRACTOR

NUT

SCREW PAN

HEAD #6 X 3/4"

(2 REQ’D)

PLATE

PAGE 3 OF 4

LATCH UNIT

(REQ’D)

SCREW,

FLAT HEAD

1/4”

(2 REQ’D)

FLEXIBLE ADAPTER

INSIDE

ROSE

INSIDE

SPINDLE

1-1

If the Lever requires a standard Key cylinder, proceed as follows:

a. Using standard Pliers, pull out the Outside Retainer.

CYLINDER

b. Insert the Cylinder into the Outside Lever.

c. Secure the Cylinder by pressing the retainer until it is flush with the shelf.

RETAINER

d. Slide the Outside Lever onto the Outside Spindle as far as possible. Insert the

Key and turn ot 45° clockwise. Push the Lever again , until the Lever Catch is

engaged, securing the Lever.

1-2

If the Lever requires an Interchangeable core (I.C.), proceed as follows:

a. Ensure that the retaining Ring and Anti-pick Plate are oriented as shown.

b. Push the I.C. Lever onto the Outside Spindle until the Lever Catch is engaged.

c. Install the Interchangeable Core per Section 8.

OUTSIDE SPINDLE

LEVER

CATCH

OUTSIDE

SHELF

RETAINING

SECTION 2: CHECK OPERATION

a. Verify proper operation of the System using the Default Programmer ID Proximity card. Momentarily place the center of the

Proximity Card (Included in the OMNILOCK Administrator’s Kit) over the recess in the front of the OP2000. The OP2000

will flash green once and unlock, then, during the Open Delay Time, it will flash green five times. The OP2000 will flash

red and lock. While unlocked, check for proper operation of the lock.

b. If your System has a Keypad Proceed as follows, otherwise go to Step c: Verify proper operation of the System using the

Keypad. Enter the Default Programmer ID, 1 2 3 4 , at the Keypad. The Lights will flash as in the previous step.

c. If Key Detection is installed, proceed as follows, otherwise go to step d: Verify proper operation of the Key Detection

Indicator by inserting the Key into the Key Cylinder and rotating clockwise. The green light will flash.

d. If the System malfunctions remove the Battery Cover and check for proper orientation and seating of the Batteries, Motor

Connector and Key Detection Connector. Ensure that the wires are not pinched. Reset the electronics by pressing and

holding the Reset Button on the circuit board until the light flashes green, approximately three seconds. The System will go

through a self-test and flash green 5 times. Any red flash indicates an electronics or motor problem. Repeat the verification

process if all flashes are green.

SECTION 3: ADJUST THE LOCK HAND

3-1

This section is only required if the lock hand does not meet your requirements. The Lockset is normally preset for a right

hand door. Verify the handing of the Lock and, if required, change the hand of the Lock as follows after checking per

Section 2.

a. Carefully release the Gasket from the edge of the Housing Assembly

using your fingers, and remove the Gasket. Remove the Screw from

the Battery Cover and remove the Cover. Disconnect the Motor

Connector and Key Detection connector, if Key Detection is installed,

from the CPU Board.

b. Remove four Flat Head Screws from the Back Plate and remove the

Back Plate.

SEM

#4-40 X .25

BATTERY

-

-

-

+

+

+

HOUSING

LOCKSET

BACK PLATE

3-2

a. Rotate the lockset to left-hand orientation.

b. Route the Wires close to the center of the Lockset and to the upper

center of the Outside Rose.

c. Align Wires into the notch of the Back Plate under the Translucent Label.

Install the Back Plate and four Screws into the Housing Assembly.

WARNING: Ensure that the Wires are not pinched

before and after tightening the Screws.

d. Install the Motor Connector with the Black Wire to

the left (see label on CPU Board). Install the Key

Detection Connector (if available). Arrange the

excess wire between the Battery Holders.

e. Install the Battery Cover and secure it with the

Screw.

f. Install the Gasket so that it seats inside the edge

of the Housing.

#4-40 X .25

PAN HEAD

GASKET

BATTERY

COVER

SEMS

CONNECTOR

CPU PC

LOCKSET

ASSEMBLY

-

+

KEY DETECTION

CONNECTOR

HOUSING

ASSEMBLY

SCREW

PAN HEAD

#8-32 X .375

(4 REQ’D)

MOTOR

CONNECTOR

LEFT HAND

ORIENTATION

SHOWN

OUTSIDE

-PICK

RESET

BUTTON

RED

WIRE

BLACK

WIRE

SECTION 4: PREPARE THE DOOR

4-1

MARK HOLE LOCATIONS

a. Mark a height line on the door faces and edge (suggested height

is 38" from the floor).

b. Line up the Template at the correct marking for the Door Bevel

(high or low bevel, or flat). Position the centerline of the Template

on the height line. Note whether the holes should be marked on

the inside, outside, or both sides of the door. Mark the centers as

required for the holes.

c. Mark the center of the Door thickness on the height line.

4-2

DRILL HOLES

a. Bore the 2-1/8" hole and the 7/16" holes half way through the door from both sides to

avoid splintering.

b. Add the notches to both sides of the door.

c. Bore a 1" hole into the door edge center on the height line. Use the Latch Unit

Faceplate as a pattern and mark the door edge. Mortise the door edge so that the front

of the faceplate will be flush with the door edge. Insert the Latch Unit into the 1" hole,

making certain that the Latch Bolt Bevel faces the direction of the closing Door.

d. Secure the Latch Unit with the Screws supplied.

SECTION 5: INSTALL THE SYSTEM ON THE DOOR

5-1

NOTE: DO NOT USE ON A DOOR THICKER THAN 1-3/4" UNLESS

THE SYSTEM IS SPECIFICALLY DESIGNED FOR A THICKER

DOOR

a. The Lockset is preset for a 1-3/4" Door. For 1-3/4" Door the "short mark” on

the Lockset Plate is aligned with the edge on the Lock Body.

b. For a 1-3/4" door with a Push Plate (.050" max.) turn the Nut counter clock-

wise until the short mark is the thickness of the Push Plate from the edge of

the Lock Body. Adjust the Outside Nut with a pair of narrow jaw Pliers, a

small Screwdriver, a Scribe, or your Fingers.

c. If a Remote Switch is to be used to operate the System, see Section 10.

5-2

Install the System on the outside of the door. The Lock Body

must engage the Latch Unit Prongs as shown. The Lock Body

Retractor must engage the Latch Unit Tailpiece.

LOCK

BODY

5-3

and secure the Plate with the Screws.

LATCH UNIT

PRONGS

LATCH UNIT

TIALPIECE

5-4

a. Align the Tab of the Flexible Adapter opposite to the Lever Catch.

b. Slide the Rose Insert onto the Inside Spindle so that the projections of the

Flexible Adapter line up with matching depressions of the Rose Insert

Assembly and secure the Rose Insert with the Screws.

c. Place the Inside Rose onto the Rose Insert aligning the dimples with the

recesses in the Rose Insert and turn clockwise to secure it. Slide the Inside

Lever on the Inside Spindle. Make certain that the Lever Catch on the

Spindle is engaged with the Lever.

d. Repeat Section 2 to verify proper operation.

Binding or rough operation is an indication of improper installation.

#10-24 X 2-

LEVER

HIGH

BEVEL

TEMPLATEATE

1” HOLE

SHORT MARK

LOCATED ON

PLATE

LOCK BODY

INSERT

INSIDE ROSE

LOW

BEVEL

DOOR

DOOR STOP

DOOR

2-1/8” HOLE

NOTCH

(4 REQ’D)

7/16” HOLE

NUT

Loading...

Loading...