Kaba Remote Reader 91 25-AM (US/CAN)

Technical Manual

04045708 - 04/2016

EN

Kaba AG

Access & Workforce Management

Hofwisenstrasse 24

8153 Rümlang

Switzerland

Kaba AG

Access & Workforce Management

Mühlebühlstrasse 23

8620 Wetzikon

Switzerland

Kaba GmbH

Access & Workforce Management

Albertistraße 3

78056 Villingen-Schwenningen

Germany

Phone +41 44 818 93 11

www.kaba.com

Phone +41 44 931 61 11

www.kaba.com

Phone +49 7720 603 0

www.kaba.com

This document must not be reproduced in any way or otherwise further used without the written consent of Kaba AG.

All product names are trademarks of the respective companies.

Copyright 2016 Kaba AG. All rights reserved.

04045708 - 04/2016

Technical Manual Contents

Contents

1 About this Document ............................................................................................................................. 7

1.1 Validity............................................................................................................................................................................... 7

1.2 Target group ...................................................................................................................................................................7

1.3 Contents and purpose.................................................................................................................................................7

1.4 Supplementary Documents ......................................................................................................................................8

1.5 Change Log ..................................................................................................................................................................... 8

1.6 Orientation in the Document.................................................................................................................................... 8

1.7 Abbreviations/Term Definitions .............................................................................................................................. 9

1.8 Warnings.........................................................................................................................................................................10

1.8.1 Hazard Categories........................................................................................................................................10

1.8.2 Symbols............................................................................................................................................................10

1.9 Notes................................................................................................................................................................................10

2 Grouped safety messages.................................................................................................................... 11

2.1 Use as directed .............................................................................................................................................................11

2.2 Mounting and Installation........................................................................................................................................11

2.3 Service and Maintenance .........................................................................................................................................11

2.4 Accessories and spare parts ....................................................................................................................................11

2.5 ESD (electrostatic discharge) protective measures.........................................................................................12

3 Product Description ............................................................................................................................. 13

3.1 Overview.........................................................................................................................................................................13

3.2 Registration Unit Compatibility .............................................................................................................................14

3.3 Operating modes ........................................................................................................................................................15

3.4 Supported RFID Standards with Possible Media Definitions.......................................................................16

3.4.1 MIFARE .............................................................................................................................................................16

3.4.2 LEGIC.................................................................................................................................................................16

3.5 Interface for Extension Modules ............................................................................................................................18

3.5.1 Number of Supported Extension Modules .........................................................................................18

3.6 Technical Data ..............................................................................................................................................................19

3.6.1 Overview of Technical Data......................................................................................................................19

3.6.2 Dimensions.....................................................................................................................................................21

3.7 Conformity.....................................................................................................................................................................22

3.8 Labeling ..........................................................................................................................................................................24

4 Design and function .............................................................................................................................25

4.1 Device structure........................................................................................................................................................... 25

4.2 Firmware.........................................................................................................................................................................26

4.3 System Requirements................................................................................................................................................26

4.4 Behavior with two Registration Units ..................................................................................................................27

4.5 Behavior with Several Media in the Field (Anti-Collision).............................................................................27

4.6 Functions........................................................................................................................................................................28

4.7 LED Display....................................................................................................................................................................30

4.8 Operating Types ..........................................................................................................................................................31

4.8.1 Overview of Operating Types ..................................................................................................................31

Kaba Remote Reader 91 25-AM (US/

CAN)

304045708 - 04/2016

Contents Technical Manual

4.8.2 Online operation...........................................................................................................................................32

4.8.3 Offline Operation..........................................................................................................................................32

4.9 Operating modes ........................................................................................................................................................34

4.9.1 'Electric strike' operating mode...............................................................................................................35

4.9.2 'Motor Bolt' Operating Mode ...................................................................................................................36

4.9.3 'Automatic door' operating mode .........................................................................................................37

4.9.4 'Turnstile' operating mode........................................................................................................................38

4.9.5 'Night lock' operating mode.....................................................................................................................39

4.9.6 'Motor bolt with panic function' operating mode............................................................................41

4.9.7 'Motor bolt type II with panic function' operating mode (2 outputs) .......................................42

4.9.8 'Motor bolt type III with panic function' operating mode (1 output)........................................44

4.9.9 'Electric lock with panic function' operating mode .........................................................................46

4.9.10 'Automatic door with night lock' operating mode ..........................................................................48

4.9.11 'Online Operation' Operating Mode......................................................................................................49

5 Installation ............................................................................................................................................50

5.1 Installation process.....................................................................................................................................................50

5.2 Installation conditions...............................................................................................................................................51

5.2.1 General.............................................................................................................................................................51

5.2.2 Installation site ..............................................................................................................................................51

5.2.3 Connections ...................................................................................................................................................51

5.3 Installation layout (example)...................................................................................................................................52

5.4 Installation lines...........................................................................................................................................................53

5.4.1 Power supply line.........................................................................................................................................53

5.4.2 Data line RS-485............................................................................................................................................55

5.4.3 Line to the door opener and door contacts........................................................................................57

5.4.4 Coaxial Cable to the Registration Units................................................................................................58

5.4.5 RS-232 Connection ......................................................................................................................................58

5.4.6 Grounding Concept.....................................................................................................................................59

5.5 Mounting the device and extension modules..................................................................................................60

5.6 Connections ..................................................................................................................................................................62

5.6.1 Connections, General..................................................................................................................................63

5.6.2 Power Supply.................................................................................................................................................63

5.6.3 RS-485 interface ............................................................................................................................................63

5.6.4 'Ant. A' and 'Ant. B' Connections.............................................................................................................63

5.6.5 RS-232 A and RS-232 B Interfaces...........................................................................................................64

5.6.6 Programming Interface..............................................................................................................................64

5.6.7 Interface for Extension Modules .............................................................................................................64

5.6.8 Inputs IN1 – IN4, tamper and input 5 ...................................................................................................65

5.6.9 Output OUT1 – OUT3..................................................................................................................................67

5.7 Configuring....................................................................................................................................................................68

5.7.1 Configuration process ................................................................................................................................68

5.7.2 Change Settings............................................................................................................................................68

5.7.3 Set RS-485 termination resistances .......................................................................................................69

5.7.4 Set peripheral addresses............................................................................................................................71

5.7.5 Set Operating Mode ....................................................................................................................................71

5.7.6 Set functions ..................................................................................................................................................72

6 Start-up ................................................................................................................................................. 80

6.1 Putting into operation process ..............................................................................................................................80

6.2 "Standalone Access Control without Host System" Commissioning .......................................................80

6.2.1 Using LEGIC ....................................................................................................................................................80

6.2.2 Using MIFARE.................................................................................................................................................81

4 Kaba Remote Reader 91 25-AM (US/

04045708 - 04/2016

CAN)

Technical Manual Contents

6.3 Functional Test (RS-232 A/B)...................................................................................................................................83

6.4 Issue Write/Read Authorization (Launch)...........................................................................................................84

6.5 Cancel Write/Read Authorization..........................................................................................................................85

6.5.1 Cancel all writing rights granted by a write authorization............................................................85

6.5.2 Cancel a particular writing right granted by a write authorization:...........................................85

7 Servicing................................................................................................................................................ 86

7.1 Programming interface.............................................................................................................................................86

7.2 Restart..............................................................................................................................................................................86

7.3 Service mode ................................................................................................................................................................87

7.3.1 Enable service mode ...................................................................................................................................87

7.3.2 Disable service mode..................................................................................................................................87

7.4 Factory Reset/Reset Device to the Basic Status................................................................................................88

7.5 Firmware Update/LEGIC OS Update.....................................................................................................................90

7.5.1 Firmware update/LEGIC OS update via access manager...............................................................90

7.5.2 Firmware Update / LEGIC OS Update with programmer 1460....................................................90

7.6 Crossgrade .....................................................................................................................................................................92

7.6.1 Device with Bxxx firmware (MRD) ..........................................................................................................92

8 Troubleshooting...................................................................................................................................93

8.1 LED Displays on the Remote Reader ....................................................................................................................93

8.2 During Installation ......................................................................................................................................................93

8.3 During operation.........................................................................................................................................................94

9 Packaging/Return................................................................................................................................. 96

9.1 Complete Devices .......................................................................................................................................................96

9.2 Electronic Assemblies ................................................................................................................................................96

9.3 Marking ...........................................................................................................................................................................96

10 Disposal.................................................................................................................................................98

10.1 Decommissioning .......................................................................................................................................................98

10.2 Dismantling ...................................................................................................................................................................98

10.3 Disposal...........................................................................................................................................................................98

Index....................................................................................................................................................100

Kaba Remote Reader 91 25-AM (US/

CAN)

504045708 - 04/2016

Contents Technical Manual

6 Kaba Remote Reader 91 25-AM (US/

04045708 - 04/2016

CAN)

Technical Manual About this Document

1 About this Document

1.1 Validity

This document describes all device versions and optional equipment and functions.

Options need to be paid for and are therefore only available if they have been purchased. Additional equipment and functions may not yet be available at the time of

issuing the document and, possibly, can only be purchased at a later stage.

Product name: Kaba remote reader 91 25 (US / CAN)

Article number: 04044475

Functional type: AM (access manager)

Serial number:

Date of manufacture:

Firmware version from BREB03.05.RD_

Display in Kabaexos: BREB03.05.RD

1.2 Target group

This document is exclusively intended for specialist personnel.

The descriptions require specialist personnel trained by the manufacturer. The descriptions do not replace product training.

For reasons of device safety, the installation and maintenance operations described

in this document must be carried out only by service persons according to EN

60950-1 (Information technology equipment - Safety).

Service persons are persons having adequate technical training and sufficient experience to be aware of and to minimize the possible risks for themselves or other persons, which may occur when carrying out these operations. The service persons are

responsible for adhering to the instructions given by the manufacturer and to the applicable standards and regulations during execution of their work.

This document is also used as information for persons with the following tasks:

• project planning and implementation

• Commissioning the product within the network

• Connecting the product to the user software by programming customer applica-

• Customer-specific adjustment by setting the parameters of the product

1.3 Contents and purpose

The contents is limited to the assembly, installation, start-up, and basic operation of

the hardware.

tions

CAN)

704045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

About this Document Technical Manual

1.4 Supplementary Documents

Supplementary documentation is available on the Kaba website. The technical manuals are located in a secured area of the website.

• Access is only possible after logging in.

• An account will need to be created before logging in for the first time.

Access and login:

1. In the browser, access the Kaba page http://www.kaba.com.

2. Select the language in the top right.

3. Under "Products", select the "Access Management" or "Workforce Management"

product division.

4. In the top right section of the screen, click on the following symbol:

.

5. Enter your e-mail address and password and login or create an account (see below).

ð The technical manuals can be found under "Downloads".

Create account:

1. Click "Create account".

2. Complete the data fields and confirm.

ð A confirmation link will be sent to your e-mail address.

3. To activate your account, click on the confirmation link in your e-mail.

1.5 Change Log

The most important changes to the last issue of this manual are listed below:

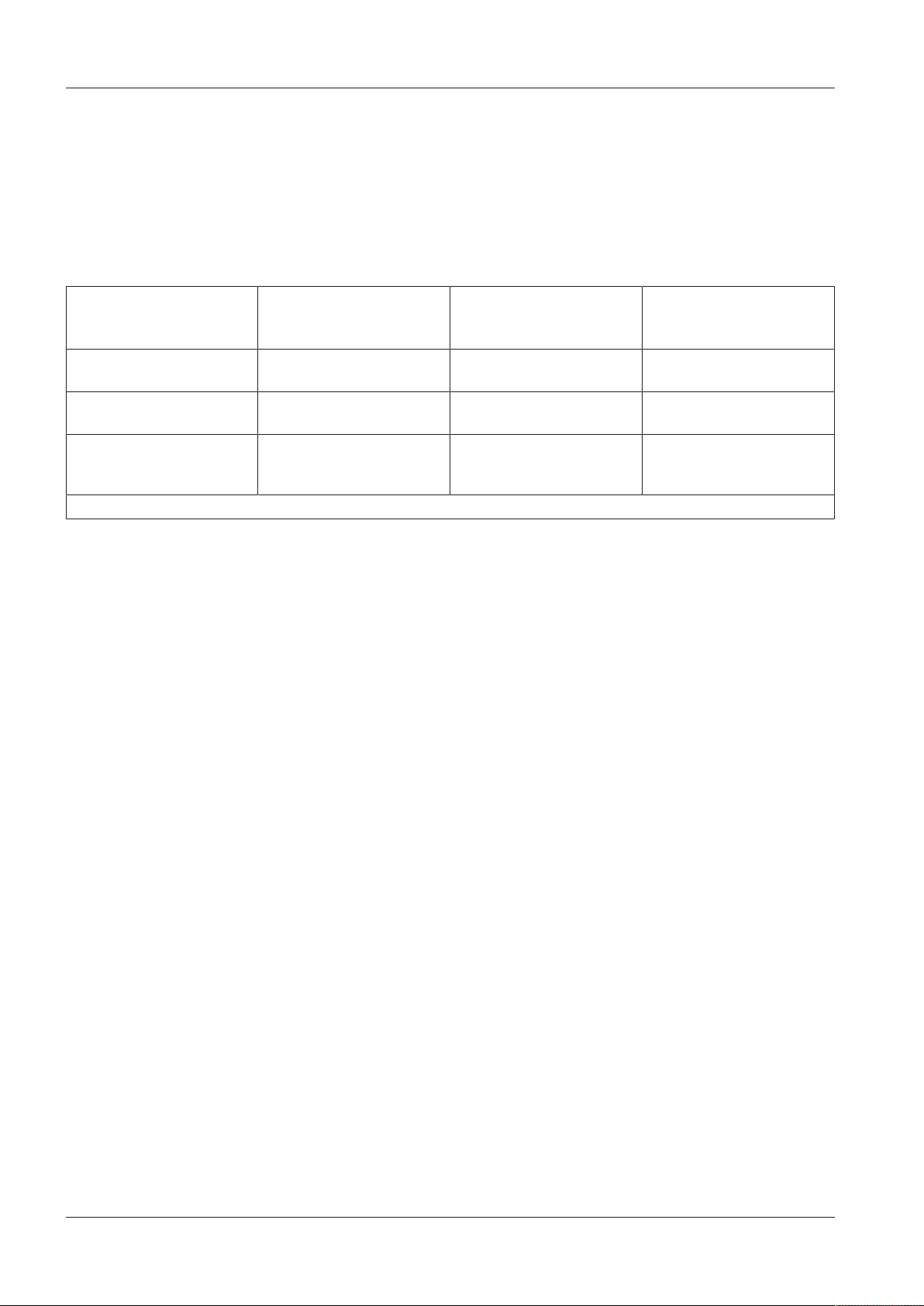

Version number Edition Brief description

TM_RemoteReader9125-AM-USCAN_201603

1.6 Orientation in the Document

This document contains the following orientation aids to facilitate finding of specific

topics:

• An index in the alphabetical order is given at the end of the manual.

• The table of contents at the beginning of the manual gives an overview of all

topics.

• The header always contains the respective main chapter.

03/2016 First edition (US /

CAN)

• This step-by-step guide goes through the installation and commissioning.

• Cross references always indicate the number of the chapter in which the supplementary information can be found. Example [ 5.7].

8 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual About this Document

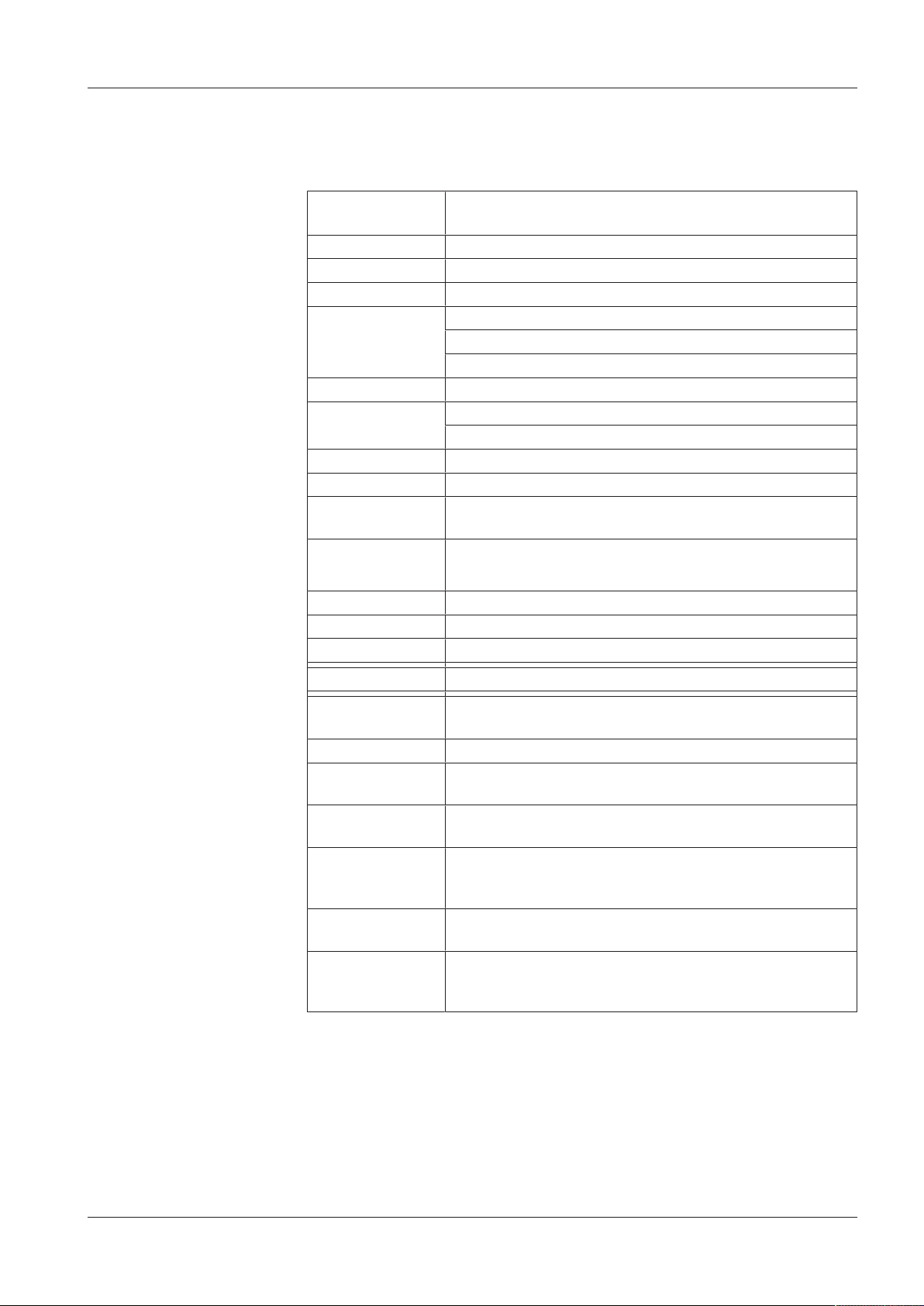

1.7 Abbreviations/Term Definitions

Abbreviations and terms used in this document:

Abbreviation/

term

Remotereader Kaba remote reader 91 25

Device Kaba remote reader 91 25

Door manager Kaba remote reader 91 25

Registration unit Kaba registration unit 90 01

Antenna Registration unit

Extension module Kaba extension module 90 31

Host Host system

KCP Kaba Communication Protocol (RS-485)

BPA/9 subset Protocol for subterminal communication via RS-485 BPA =

Control unit • Access manager or

KMM Kaba Media Manager

Access Manager Kaba access manager 92 00

KabaexosAMC Kabaexos AMCII

Term definition from 07/01/14

Kaba registration unit 90 02

Kaba registration unit 90 00

Kaba extension module 90 30

Benzing Protocol Asynchronous

• B-web terminal

Programmer Kaba Programmer 1460

Authorized access Is active until the door is closed again or the alert duration has

expired

Door opener key Key which triggers single, authorized door opening

Door handle contact

Frame contact Contact in the door frame with which the door status open or

Blocking contact Contact with which the access point can be blocked. In this

Alarm buzzer/alarm

relay

Hold-open mode In the event of authorized access, the door remains activated

Contact in the door handle with which authorized door opening is reported to the system

closed is reported

case, any identification on the registration unit is rejected as

access not authorized and signaled accordingly.

This signal is used to control the relay output if the door is

forced open or in the event of 'Door open too long'

(opened) until the user medium is within the range (field) of

the antenna.

CAN)

904045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

About this Document Technical Manual

1.8 Warnings

Warnings containing information/instructions and prohibitions to prevent injury to

persons and damage to property are specially labeled.

Please pay attention to warnings. They are intended to help prevent accidents and

avoid damage.

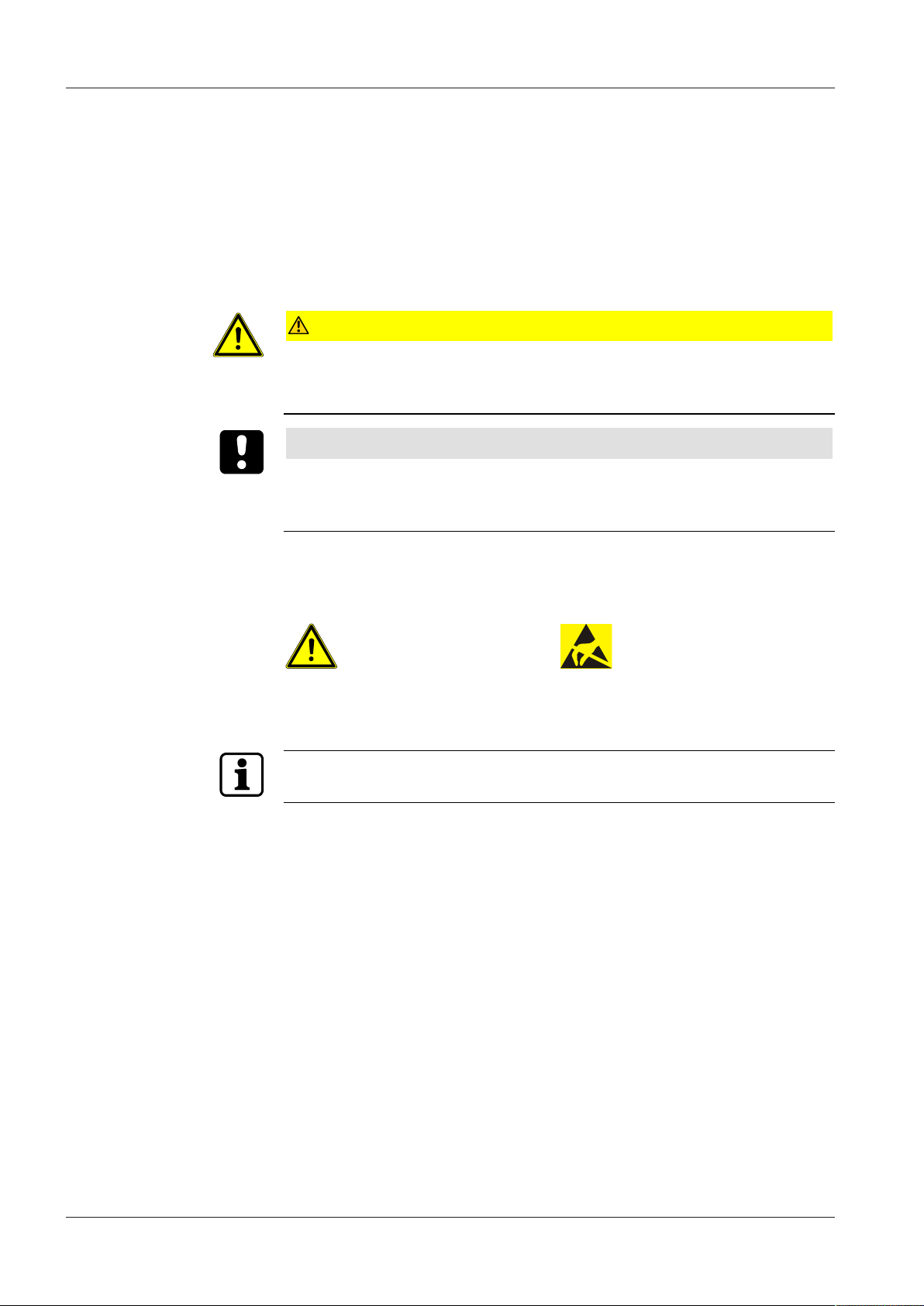

1.8.1 Hazard Categories

Warnings are split into the following categories:

CAUTION

Slight Risk

Describes a potentially hazardous situation that could result in minor physical injuries.

NOTICE

Information on how to handle the product correctly.

Failure to comply with these warnings may result in malfunctions. The product or

something in its vicinity could be damaged.

1.8.2 Symbols

1.9 Notes

Depending on the source of the hazard, symbols are used for the warnings, and

these have the following meanings:

General danger Danger for electronic compo-

nents from electrostatic discharge

Notes are labeled with an info symbol.

Tips and useful information.

These help you to make best use of the product and its functions.

10 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Grouped safety messages

2 Grouped safety messages

This product has been built in accordance with state-of-the-art standards and the

recognized safety rules. Nevertheless, its use may constitute a risk to persons and

cause damage to material property.

Read and observe the following safety instructions before using the product.

2.1 Use as directed

The product is only intended for use as described in chapter “Product description”.

Any use beyond that is considered contrary to its designated use. The manufacturer

cannot be held liable for damage resulting from such use. Such use is at the sole risk

of the user/operator.

2.2 Mounting and Installation

Mounting and installation may only be carried out by service persons (see chapter 1

“Target group”).

Installation may only be carried out in places that fulfill the climatic and technical

conditions stated by the manufacturer.

The manufacturer is not liable for damages resulting from improper handling or incorrect installation.

2.3 Service and Maintenance

Maintenance work / troubleshooting

Only the service person (see chapter 1 “Target group”) is entitled to remove faults

and carry out maintenance work.

Reconstruction and modification

Any alteration or modification to the device may only be performed by the service

person (see chapter 1 “Target group”). Any alteration or modification performed by

unauthorized persons shall render void any liability.

2.4 Accessories and spare parts

Accessories and spare parts must comply with the technical requirements specified

by the manufacturer. This is guaranteed when using original accessories and spare

parts from Kaba.

CAN)

1104045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Grouped safety messages Technical Manual

2.5 ESD (electrostatic discharge) protective measures

NOTICE

Danger for electronic components due to electrostatic discharge.

Improper handling of printed circuit boards or components can cause damages that

lead to complete failures or sporadic errors.

• During installation and repair of the product, the ESD protective measures must

be considered.

• Wear an ESD wristband when handling electronic components. Connect the end

of the wristband to a discharge socket or an unvarnished grounded metal component. This way, static charges are discharged from your body securely and effectively.

• Touch only the edges of circuit boards. Do not touch the circuit board nor the

connector.

• Place all dismantled components on an antistatic surface or in an antistatic container.

• Avoid contact between circuit boards and clothing. The wristband only protects

the printed circuit boards against electrostatic discharge from your body, but

there is still a risk of damage through electrostatic discharge from your clothing.

• Transport and dispatch dismantled modules only in electrostatically shielded

protective bags.

12 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Product Description

90 00

Access manager

90 02

91 15

90 01

1 2 3

4 5 6

7 8 9

1 0 E

90 31

Ethernet

92 00 exos Client

1)

Coaxial cable

RS-485

Access Management System

Kaba exos 9300

(US / CAN)

Registration units

Reader

Communication

Hub

Database

Web- and Application Service

CardLink

USB

92 00

1)

90 30

91 25

91 08

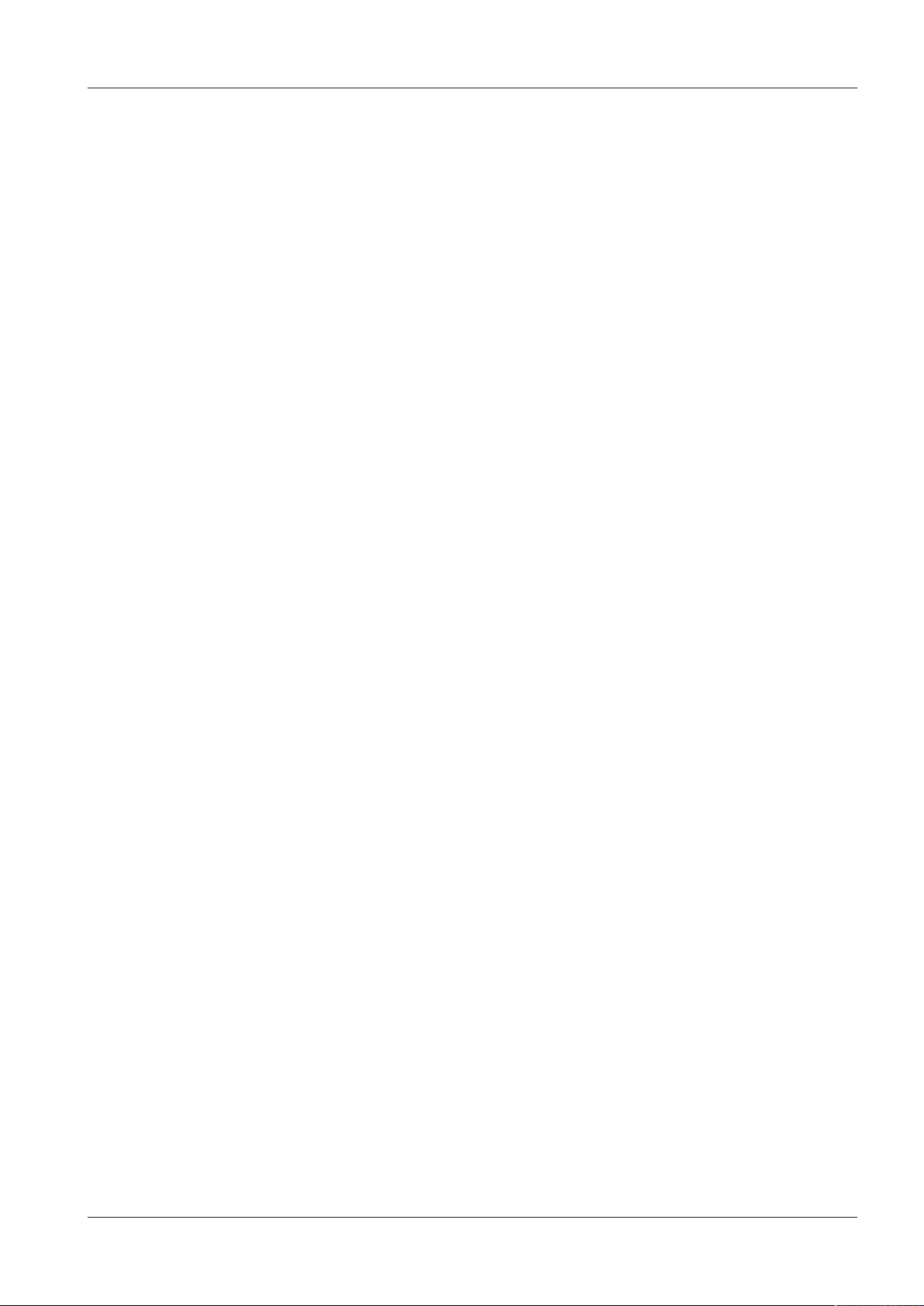

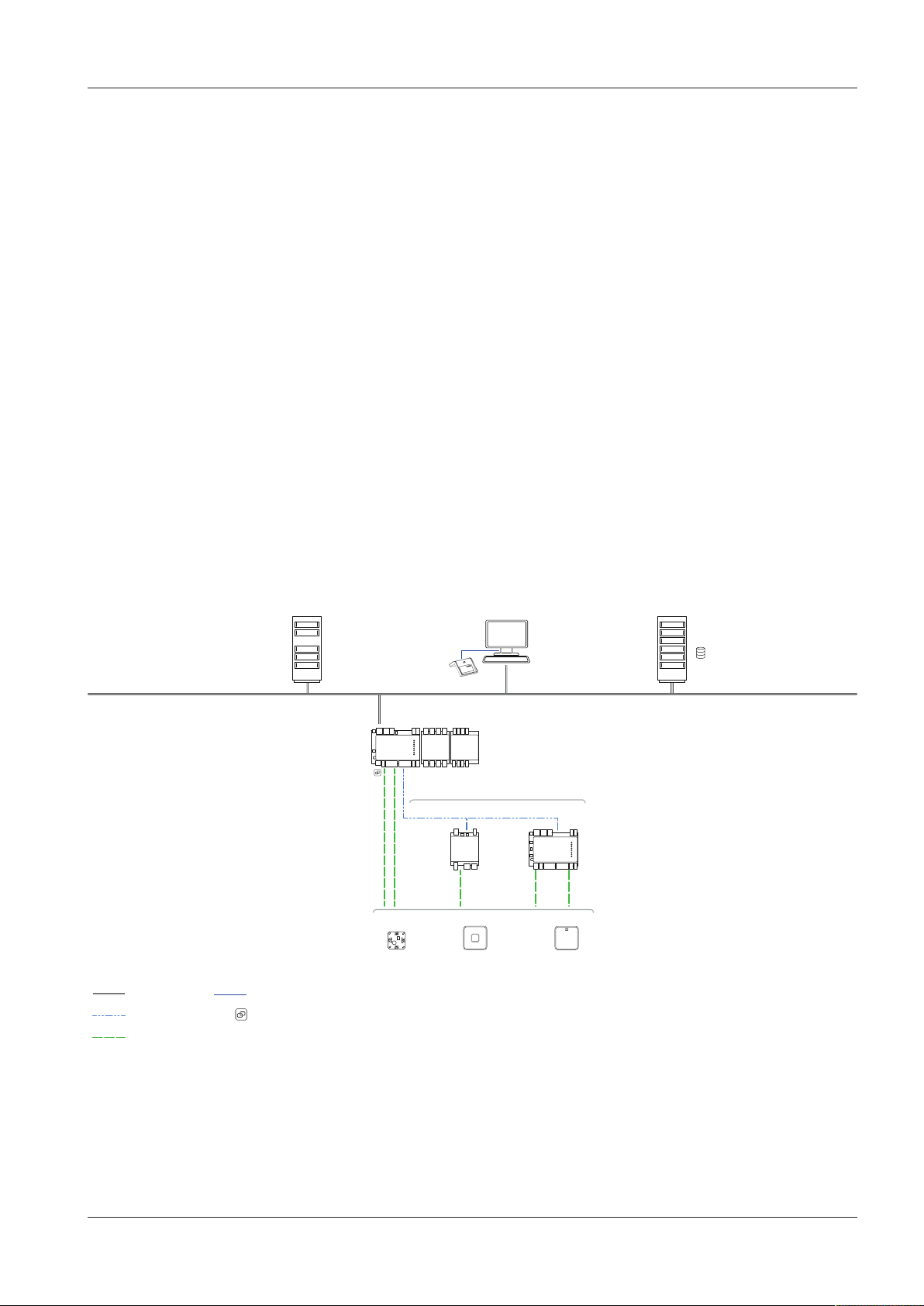

3 Product Description

3.1 Overview

The Kaba remote reader 91 25 with functional type AM can either control and monitor access control at access points or register coming/leaving bookings for time registration.

Two registration units can be connected to the Kaba remote reader 91 25. The remote reader has two RS-232 interfaces (e.g. for keypads, Hyper X or system-dependent functions) and can be integrated into the Kaba exos access control system. The

remote reader is installed on a DIN rail. Thanks to the separation of the remote reader

and registration units, the remote reader can be installed in a tamper-proof area and

the registration units can be installed in an area that is not tamper-proof.

The door components (locking elements, monitoring contacts) are directly connected to the remote reader. This controls the electric strikes as well as the optical

and acoustic signal transmitters of the registration units. As two registration units can

be connected, one Kaba remote reader 91 25 is sufficient for implementing an on/off

configuration (e.g. turnstile). The remote reader communicates with the host system

via the RS-485 interface. The host system checks the company codes and the user

medium numbers, and activates the access points.

If the communication between the remote reader and the host system is interrupted,

then, with the relevant programming of its offline behavior, the remote reader automatically takes on the tasks of the host system; i.e. authorization checks and door

functions are retained.

CAN)

1304045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Product Description Technical Manual

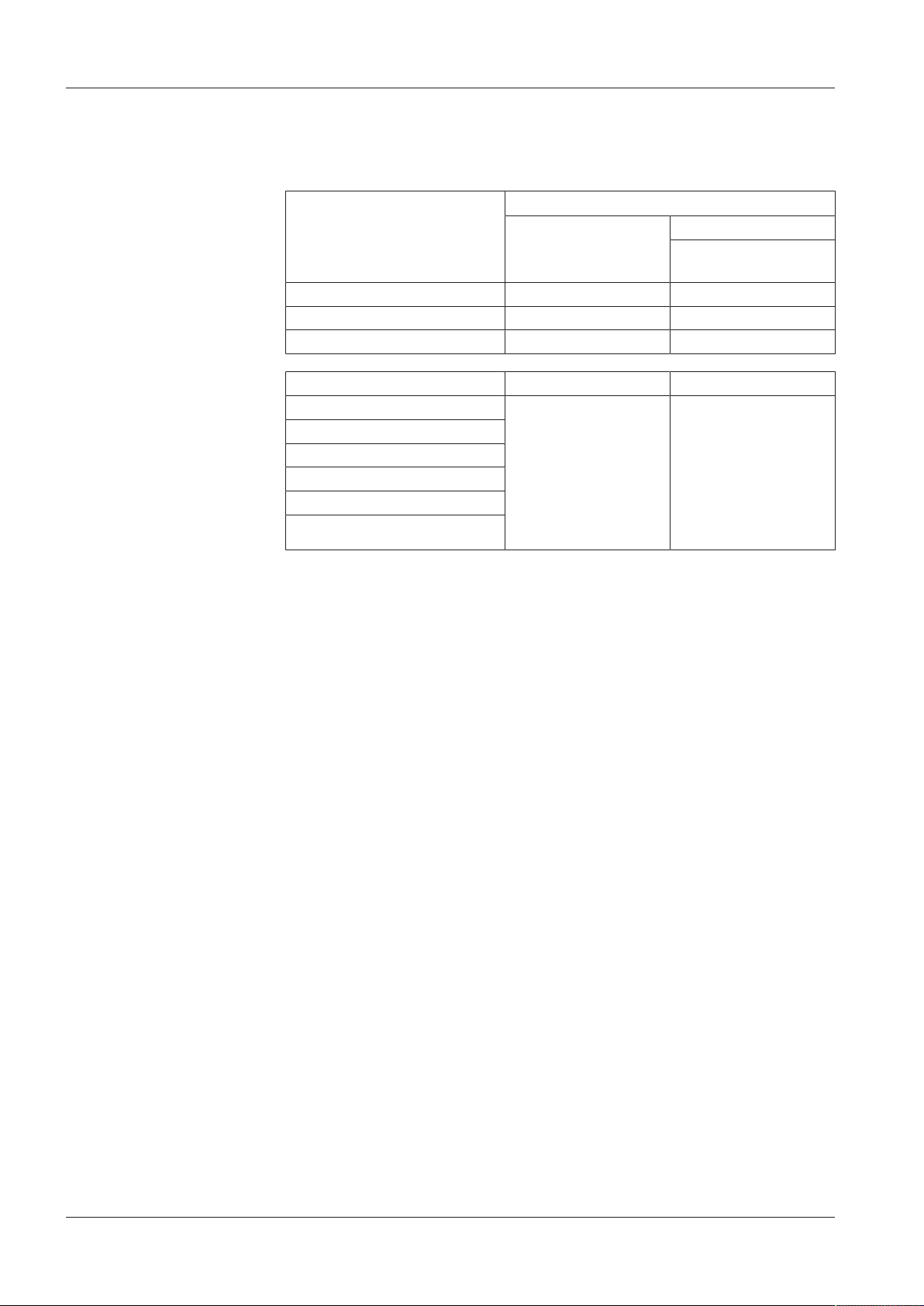

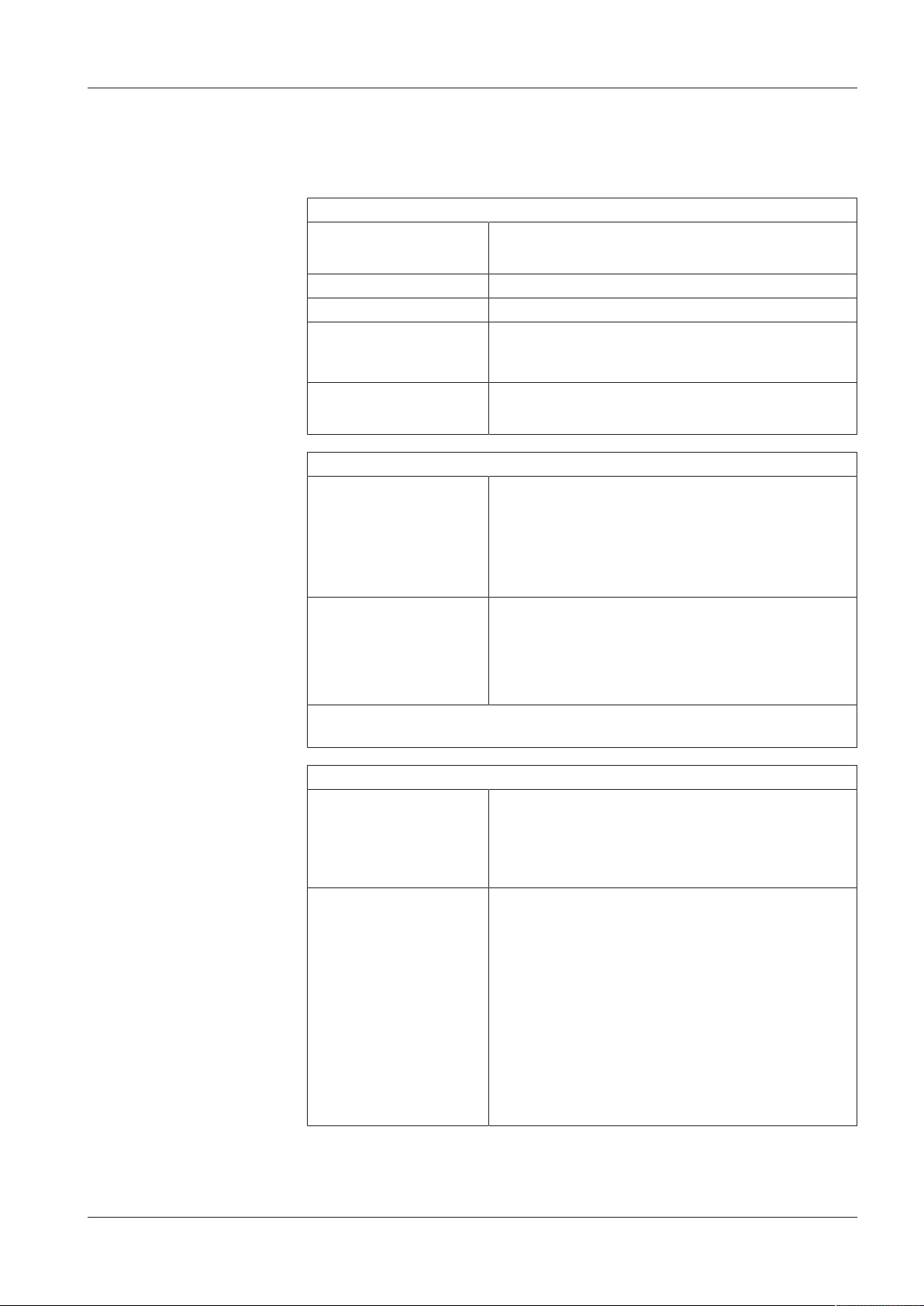

3.2 Registration Unit Compatibility

The following registration units are supported.

Registration unit Control unit

Access Manager Remotereader

Functional type

Access manager

Kaba registration unit 90 00 ✔ ✔

Kaba registration unit 90 01 ✔ ✔

Kaba registration unit 90 02 ✔ ✔

Registration unit FCC IC

Kaba registration unit 9000 Tested Standard: FCC

Kone registration unit PCB

Kaba registration unit 9001

Kone registration unit 9001

Kaba registration unit 9002

Kone registration unit 9002

Code of Federal Regula-

tions, CFR 47, Part 15,

Sections 15.205, 15.207,

15.215 and 15.225

Tested Standard: Indus-

try Canada Radio Stan-

dards Specifications

RSS-GEN Issue 4, Sections 8.8, 8.9 and 8.10

and RSS-210 Issue 8,

Section A2.6 (Category I

Equipment)

14 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Product Description

3.3 Operating modes

The door configuration determines the operating mode of the Remotereader. A detailed description of the door configurations and their operating modes can be

found in the chapter Operating Types and Modes.

CAN)

1504045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Product Description Technical Manual

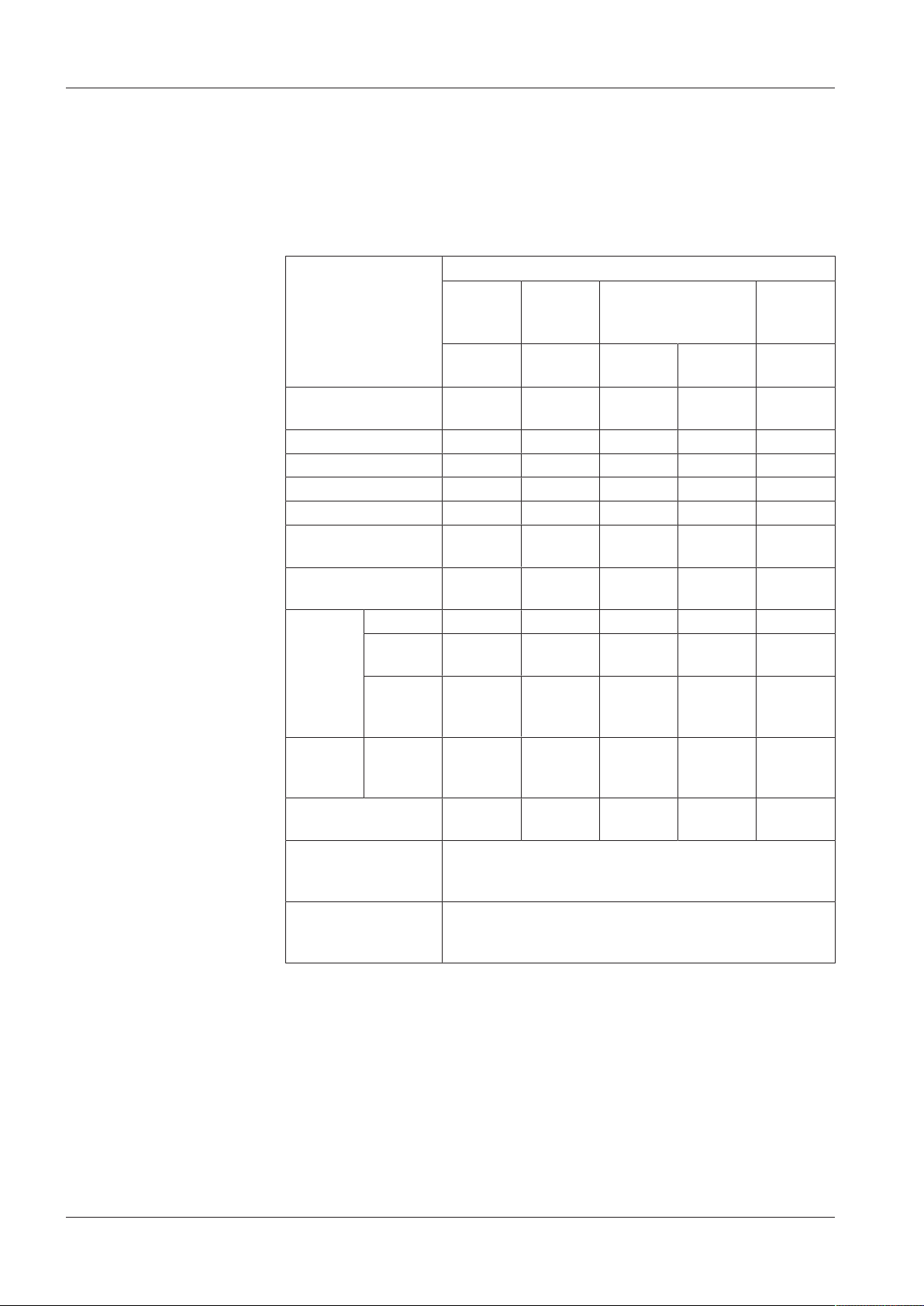

3.4 Supported RFID Standards with Possible Media Definitions

The following table shows the RFID standards and media definitions supported by

the device.

The Kaba remote reader 91 25 recognizes up to eight different media definitions at

the same time.

Media definitions Supported RFID technologies

MIFARE

DESFire

ISO

14443A

Unique number (UID)

*1

Safe UID - - - - ✔

Card ID ✔ ✔ ✔ ✔ -

Kaba group header - - ✔ ✔ ✔

Kaba advant ID - - ✔ ✔ -

LEGIC access™

(advant)

LEGIC access™ pool

(prime)

CardLink

1.1

CardLink1.0Data incl.

Additional media

numbers

Data ✔ ✔ ✔ ✔ -

Actuator

status

Media

traceback

*2

actuator

status

*1 The LEGIC chip set does not use the safe UID command set

*2 Media traceback information can only be read out directly

✔ ✔ ✔ ✔ -

✔ ✔ ✔ ✔ -

✔ - ✔ - -

✔ ✔ ✔ ✔ ✔

so that UID from other media, such as MIFARE, can also be

read.

on the access manager and no media traceback information is written.

MIFAREClassic

ISO

14443A

- - ✔ ✔ -

- - - - ✔

- - - - ✔

LEGICadvant LEGICpri

me

ISO

14443A

ISO

15693

LEGICRF

3.4.1 MIFARE

The system can evaluate everything that can be defined in Kaba media manager. MIFARE DESFire or MIFARE Classic media can be read and described on the same Kaba

remote reader 91 25 MIFARE using various media applications.

3.4.2 LEGIC

LEGIC prime or LEGIC advant media can be read and described on the same Kaba remote reader 91 25 LEGIC using various media applications (LEGIC advant media can

only be described using LEGIC advant components).

16 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Product Description

Dual chip card

A dual chip card with LEGIC advant (14443 A) and CardLink LEGIC prime (LEGIC RF) is

supported.

CAN)

1704045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Product Description Technical Manual

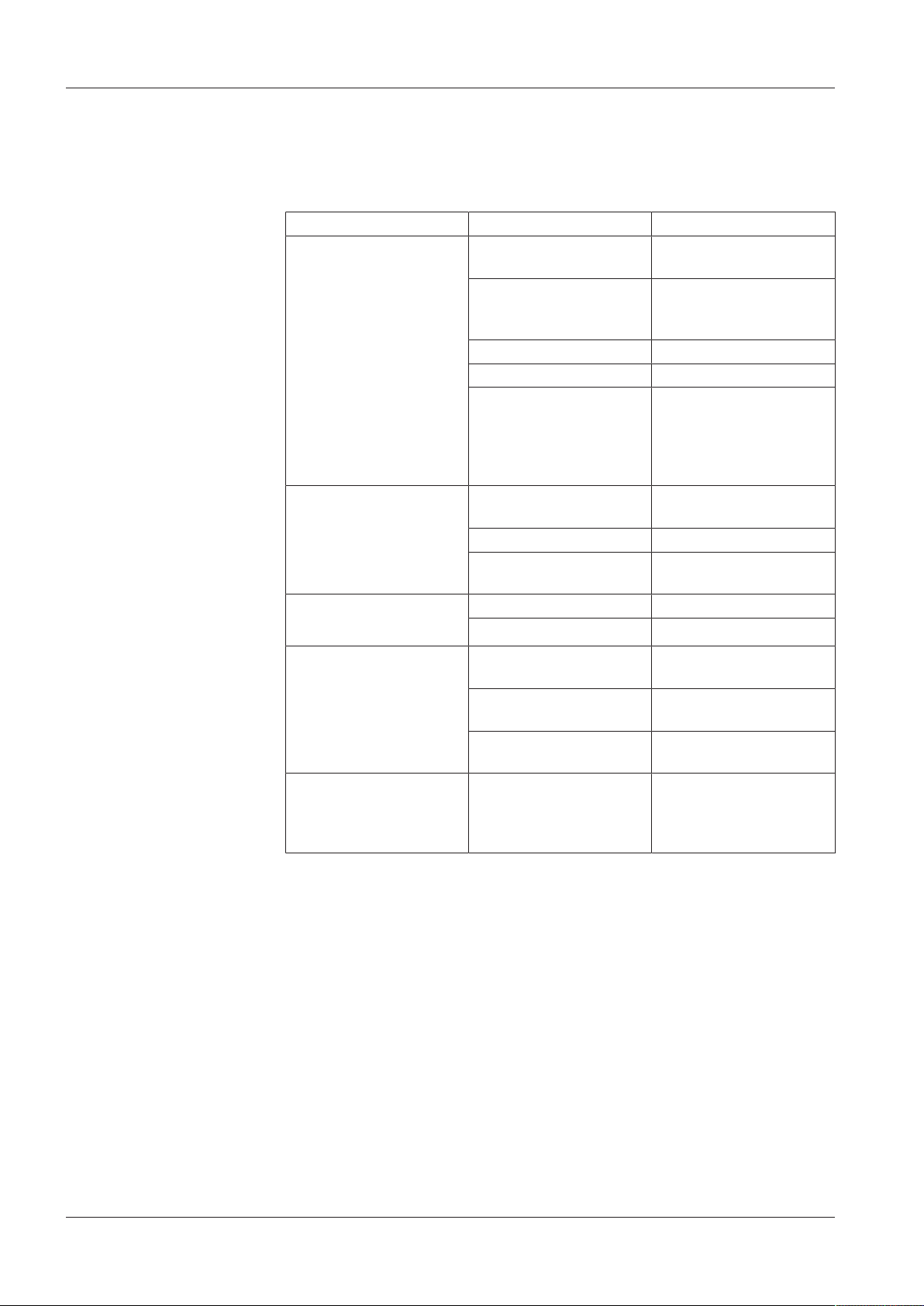

3.5 Interface for Extension Modules

3.5.1 Number of Supported Extension Modules

The extension modules are connected to the system bus of the Kaba remote reader

91 25. There is a limit to the maximum number of supported extension modules.

The host system determines the maximum number of connectible extension modules.

Configuration of the Kaba

remote reader 91 25

Only extension module

9030

Only extension modules

9031

Mixed operation (extension

modules9030 and extension modules 9031)

*non-standard

Max. connectible

extension modules 9030

9 0 20VDC*

0 5 As specified in the technical

2 2 As specified in the technical

Max. connectible

extension modules 9131

Minimum supply voltage

of the Kaba remote reader

91 25

data: 10VDC

data: 10VDC

18 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Product Description

3.6 Technical Data

3.6.1 Overview of Technical Data

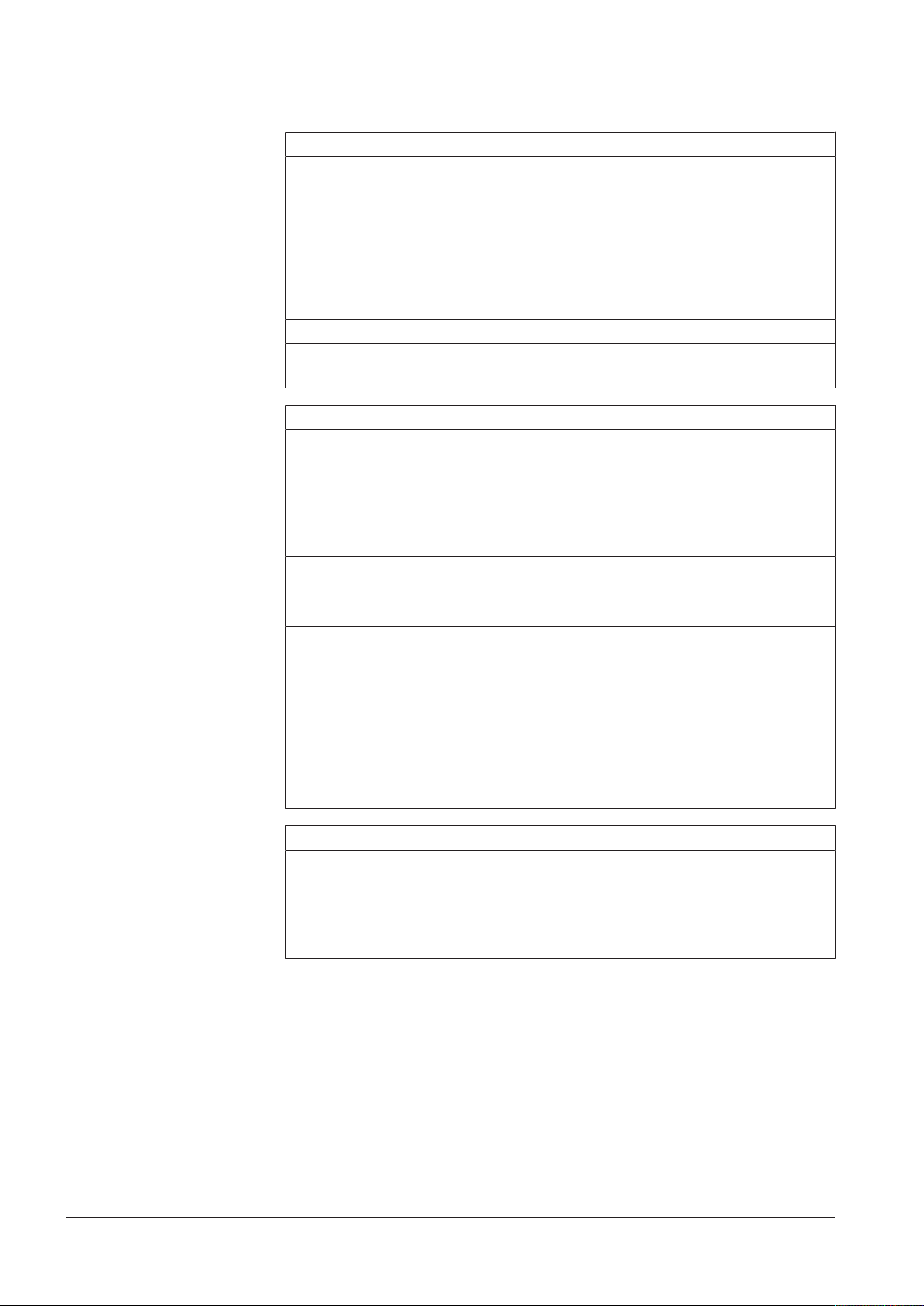

Mechanics

Mounting • Indoors

• On DIN rail in accordance with EN 50022

Housing • ABS black, with imprinted connection diagram

Combustion category • HB (UL94)

Dimensions • 125 x 102 x 45mm (L x W x H) or seven space units

17.5mm width measurement includes screw/plug

terminals

Connections • All connections are screw/plug terminals

• Max. terminal load: 5A

Power supply

Input voltage, without external wiring

• 10–34VDC (50/60Hz), current consumption max.

330mA, max.4.5W

• Power consumption/heat capacity:

– at 12VDC typically 2W

– at 24VDC typically 2.7W

The Remotereader supplies connected devices

with power via the RS-232

connection.

Notice: The device may only be supplied with SELV (Safety Extra Low Voltage) and

LPS (Limited Power Source), according to IEC/UL/CSA 60950-1.

Interfaces

HF RFID • Two registration units with or without keypads

Two RS-232 (A/B)

Basic setting (can be parameterized)

• 5VDC

• max.* 1A (at 25°C)

* Total of all connected devices

(ant. A/B)

• Coaxial cable, impedance 50Ohm

• Encrypted data transfer

Connection with following (default) properties:

• Connection for registration units (keypads, wide

area access solution, as well as system-dependent

functions)

CAN)

• Baud rate max. 115 200baud (Kaba exos AM:

9600baud)

• 8 data bits, no (None) parity, 1 stop bit

• Output voltage 5VDC, max. 500mA each

• Via Kaba exos AM can be parameterized up to

9600baud

1904045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Product Description Technical Manual

Interfaces

RS-485 • For the connection to access hub

• KCP protocol; galvanically separated, 2-wire

• Baud rate 19200baud (fixed)

• 8 data bits, even (Even) parity, 1 stop bit

• Termination resistance for bus or star wiring

• Addressing 1–8

Programmer interface • For firmware update or programmer connection

Extension modules • Maximum number of supported extension mod-

ules, see chapter 3.5

Inputs and outputs

• With internal power supply and common ground,

5 binary inputs

one of which can be used

as a tamper switch (usually IN5).

for connection of insulated switches

• Maximum 5VDC

• Line monitoring (can be disabled)

• LED status indicator

2 internal inputs • In operating mode Kaba exos lock for the door han-

dle contact

• Status indicator (LED OUT1 and OUT2)

3 relay outputs • Switchover contact, max. voltage 34VDC max. cur-

rent 2A at 30VAC/DC

• Switching cycles at 30VDC/1A

typical 500,000 (VdS 2358 requirement is 200,000)

• Switching cycles at 30V DC/2A

typical 100,000

• Status indicator

Ambient conditions

Ambient conditions • Operating temperature: 0°C to +50°C

• Storage temperature: -20°C to +65°C

• Relative humidity: 0% to 95%, non-condensing

• Protection type: IP20

20 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Product Description

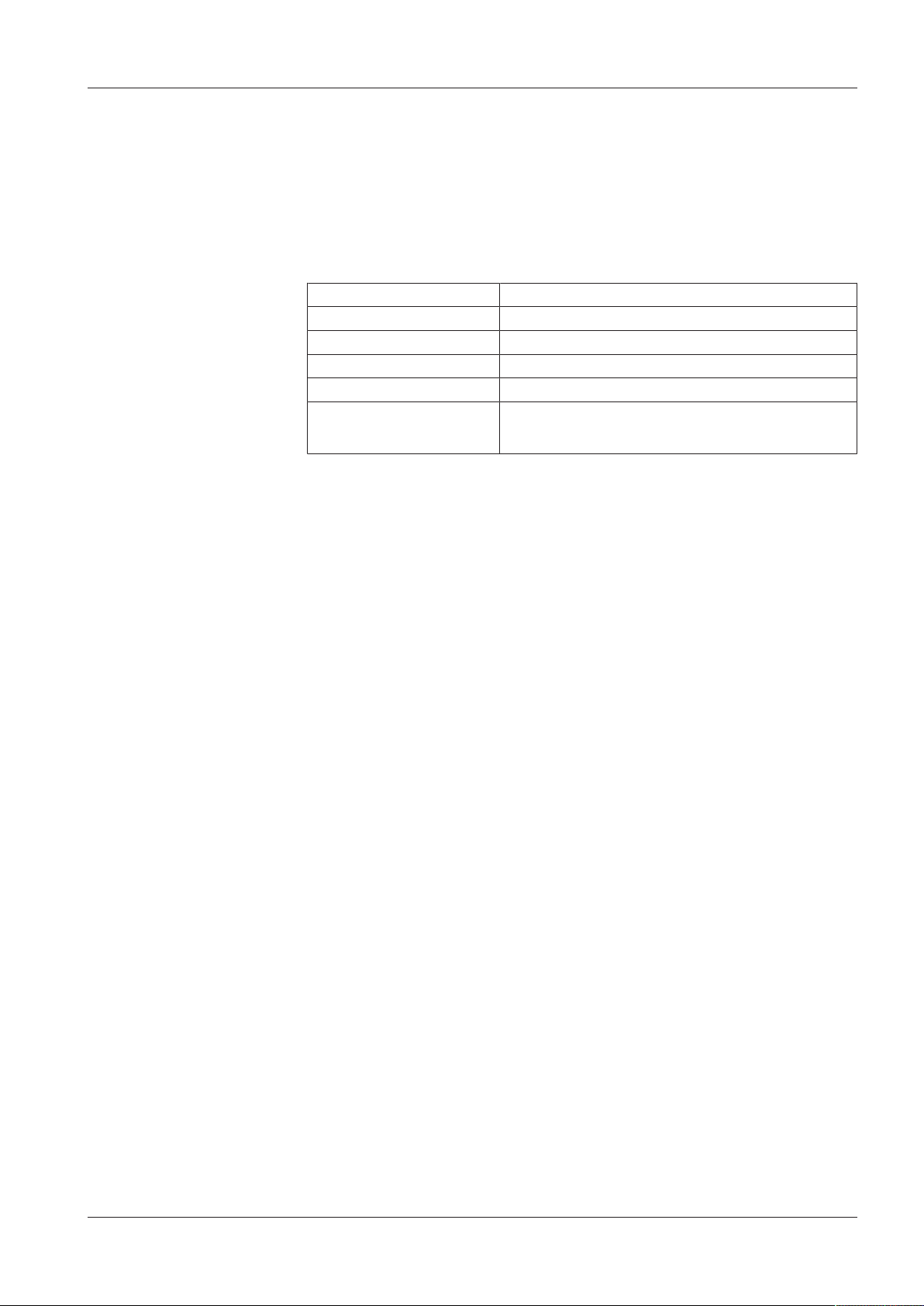

125

84

102

45

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Mode

7

1

8 Service

ON OFF

GND

GND

GND

GND

GND

State

IN1

IN2

IN3

IN4

OUT1

OUT2

OUT3

5VRxTx

RxTx0V

IN5/TP

IN1

IN2

IN3

IN4

Vs-

Vs-

Vs+

Vs+

Function

OUT1

OUT2

OUT3

ABC

Supply 10-34VDCOutput max. 34VDC/27VAC/2AInput max. 5VDCRS-485

5V

0V

RS-232 B RS-232 A

Ant. B

Ant. A

ASA+AS

A+

:

Address

Prog.

Relay Output Class II

91 25

2.

1.

Push

Click

DIN-Rail

91 25

0 - F

0 - F

3.6.2 Dimensions

CAN)

2104045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Product Description Technical Manual

3.7 Conformity

This product conforms to the following standards:

EN 60950-1 : 2014-08

EN 60950-1:2006/A2:2013

UL 60950-1:2007/R:2014-10

CAN/CSA-C22.2 No. 60950-1:2007/A2:2014-10

EN 301 489-1 V1.9.2 : 2011-09

EN 301 489-3 V1.6.1 : 2013-08

EN 300 330-1 V1.8.1 : 2014-12

EN 300 330-2 V1.6.1 : 2014-12

in accordance with the provisions of the EC directives

2014/53/EC: R&TTE Directive

RoHS This device complies with the regulations of the Directive 2011/65/EU of the Euro-

pean Parliament and of the Council of June 8, 2011, on the restriction of the use of

certain hazardous substances in electrical and electronic equipment.

The original Declaration of Conformity can be downloaded from

www.kaba.com/conformity in PDF format.

Tested Standard:

FCC Code of Federal Regulations, CFR 47, Part 15, Sections 15.205, 15.207, 15.215 and

15.225

FCC ID NVI-KRR9125-K5

FCC § 15.19

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause

undesired operation.

FCC § 15.21 (Warning Statement)

[Any] changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

FCC § 15.105

Note: This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

Tested Standard:

Industry Canada Radio Standards Specifications RSS-GEN Issue 4, Sections 8.8, 8.9

and 8.10 and RSS-210 Issue 8, Section A2.6 (Category I Equipment)

IC:11038A-KRR9125-K5

ICES-003

This Class A digital apparatus complies with Canadian ICES-003. Cet appareil

numérique de la classe A est conforme à la norme NMB-003 du Canada.

22 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Product Description

Canada RSS-GEN 8.4

This device complies with Industry Canada’s licence-exempt RSSs. Operation is subject to the following two conditions: (1) This device may not cause interference; and

(2) This device must accept any interference, including interference that may cause

undesired operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux conditions

suivantes : 1) l’appareil ne doit pas produire de brouillage; 2) l’utilisateur de l’appareil

doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.

CAN)

2304045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Product Description Technical Manual

3.8 Labeling

The identification plate is located on the side of the device.

The following information can be found on the identification plate:

• Device designation

• Article number

• Serial number

• Function type

• Connection data (power supply)

• CE mark

• WEEE mark as per DIN EN 50419

24 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Mode

7

1

8 Service

ON OFF

GND

GND

GND

GND

GND

State

IN1

IN2

IN3

IN4

OUT1

OUT2

OUT3

5VRxTx

Rx

Tx

0V

IN5/TP

IN1

IN2

IN3

IN4

Vs-

Vs-

Vs+

Vs+

Function

OUT1

OUT2

OUT3

ABC

Supply 10-34VDCOutput max. 34VDC/27VAC/2AInput max. 5VDCRS-485

5V

0V

RS-232 B RS-232 A

Ant. B

Ant. A

ASA+AS

A+

:

Address

Prog.

Relay Output Class II

91 25

2.

1.

Push

Click

DIN-Rail

91 25

0 - F

0 - F

8 7

5

6

13

14

15

16

17

1 2 3 4

9101112

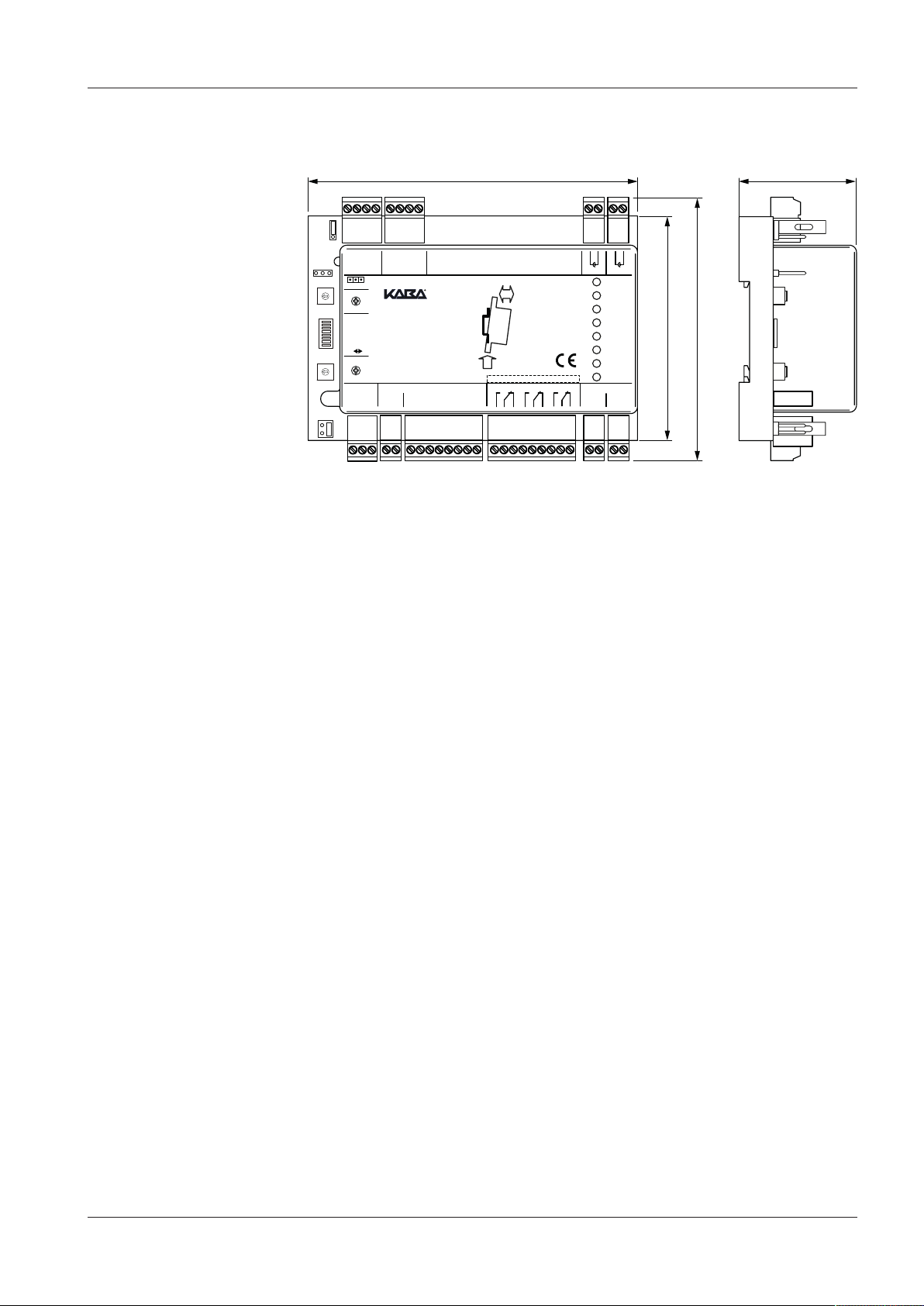

4 Design and function

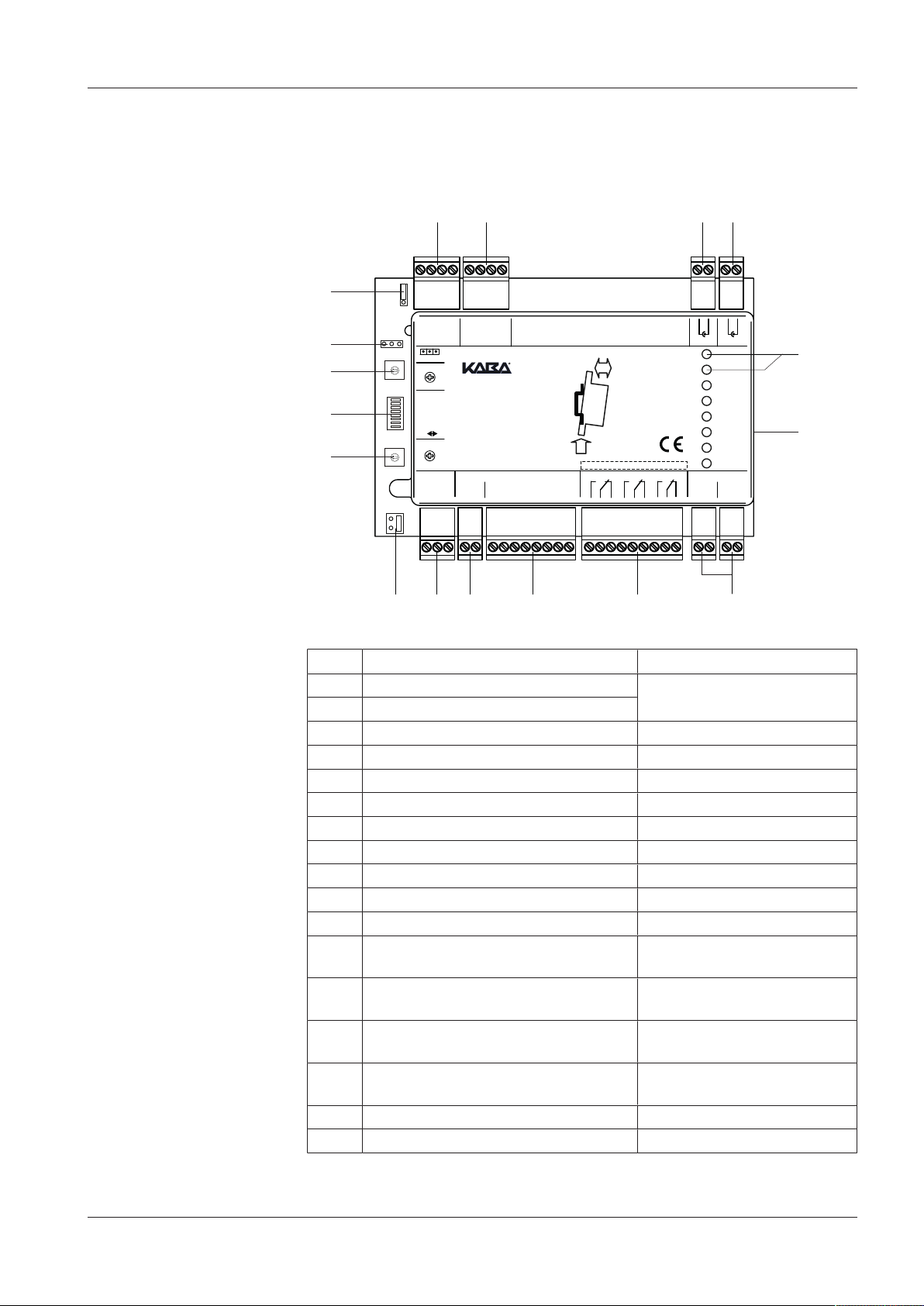

4.1 Device structure

Item Connection/switch Remark

1 RS-232 interface B Connection of peripherals

2 RS-232 interface A

3 Antenna B Registration unit B (antenna B)

4 Antenna A Registration unit A (antenna A)

5 LED Displays

6 Interface for Extension Modules e.g. 90 30/90 31

7 Power supply 10–34 VDC

8 Relay outputs OUT1–OUT3

9 Inputs IN1–IN4

10 Tamper switch

11 RS-485 interfaces A, B and C Connection to the host system

12 Bus termination RS-485 Jumper for adjustment of the

13 Addressing RS-485, 1–8 Rotary switch for selecting the

14 Function DIP switch for selecting the

15 Operating modes 'Mode' rotary switch for select-

16 Interface for Kaba programmer PD 1460

17 Not used

termination resistance

address

function

ing the operating mode

CAN)

2504045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

The functions and connections of the interfaces, inputs, relay outputs, rotary and DIP

switches are described in the chapterDesign and function [}4].

4.2 Firmware

The hardware of this product is used in various Kaba system solutions. The functions

and possible uses of the product are determined by the firmware used.

This manual solely describes the Kaba remote reader 91 25 functional type access

manager (AM).

Firmware designation

Reader type

Device type

Functional type

Version number

Addition 1

Addition 2

Addition 3

Example

Designation of firmware for Kaba remote reader 91 25 with functional type access

manager:

M

A

B

RC

RR

RE

A

B

C

E

xx.xx

R

A

_

MIFARE

LEGIC

LEGIC or MIFARE

(determined during commissioning)

MRD (multi RFID device)

Compactreader

Remotereader 91 15

Remotereader 91 25

E300 V4 or N300/T300/U300 V3

Access Manager

Subterminal

AMC/II (cDML)

Version

Final, approved version

Subversion

Reserve

• BREB03.xxRxx (MRD)

Firmware mark on the product

Devices with firmware with the functional type access manager bear a mark reading

"Type: Access manager" on the identification plate.

4.3 System Requirements

• Kabaexos9300 release 4.0.1 and higher

• Kaba access manager 92 00 AM firmware version 3.00 and higher

Further details can be found in the Release Overviews and Release Notes.

26 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

4.4 Behavior with two Registration Units

The Remote reader 91 25 communicates alternately via the connections 'Ant. A' and

'Ant. B' (toggling) with the connected registration units. This means that the Remote

reader 91 25 cannot communicate with both registration units at the same time. This

results in the following behavior:

• During a longer reading process, the other registration unit is blocked.

• The fields of the two connected registration units do not influence each other.

This means that the two registration units can be installed close together.

• In the case of registration units installed close together, it may be the case that

the medium is read by the two registration units one after the other.

4.5 Behavior with Several Media in the Field (Anti-Collision)

The Remote reader 91 25 can recognize several LEGIC advant user media (ISO 14443

A) in the field simultaneously. The Remote reader 91 25 only considers the first user

medium, which corresponds to the search criteria defined in the system. The remaining user media are ignored.

CAN)

2704045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

4.6 Functions

All data for access decisions are saved in the host control device. The authorization

check of a badge and access control are undertaken by the control device.

Functions available before the remote reader is connected to the host system

Standalone access control (without host system); see chapter "Standalone Access

Control without Host System" Commissioning [}6.2]

Access control functions

• Authorization check using badges and temporal authorization incl. verification

• Connection of two separate registration units

• Control of optical and acoustic signal transmitters of the registration units

• Control of electric strikes (doors with electrical blocking elements)

• Support for door opener keys or door handle contacts

• Monitoring of the door status with frame contact, bolt monitoring and door handle contact

• CardLink support: Validation and UID additional recording (only LEGIC)

• Inspection of the functionality even without host system

• Two RS-232 serial interfaces, e.g., for keypads, Hyper X or system-dependent

functions, such as input or issue (only online) of user media numbers

• Hold-open mode, so that, when access is authorized, the door remains open for

as long as the badge remains within range of the antenna (field)

• Monitoring of a tamper switch by integrating the Remotereader into housing

• Signal for authorized access, e.g., for alarm bypass

Restrictions with interrupted connection (offline)

MIFARE

Reduced authorization check using site keys.

Door function is retained depending on the offline parameter setting.

• Authorization check using site keys. A maximum of eight site keys can be saved.

• Not taken into consideration: Time zones and PIN code

• Logbook for 2000 events

• No room monitoring/balancing and no CardLink functionality

• No change in fabrication key

LEGIC

Reduced authorization check using segment search keys. Door function is retained

depending on the offline parameter setting.

• Authorization check using segment search keys. A maximum of eight segment

search keys can be saved.

28 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

• Not taken into consideration: Time zones and PIN code

• Logbook for 2000 events

• No room monitoring/balancing and no CardLink functionality

Restored connection

Automatic forwarding of saved bookings as well as status and alarm messages when

connection is restored.

CAN)

2904045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

4.7 LED Display

The LED display shows operating statuses and errors. Troubleshooting tips are listed

in Chapter [}8].

LED Designation LED Behavior Meaning

State green permanent Device in operation (off-

line)

flashes green RS-485 interface in the re-

ceive or send mode (online)

orange permanent Service mode

red permanent or off Device defective

flashes green and orange After an interruption in

communication, until the

device is queried for the

first time by the host system

IN1–IN4 green permanent LED lights once the corre-

sponding input is enabled

orange flashing Service mode

orange permanent or off Update via programmer

1460

IN1–IN4

Monitoring enabled

OUT1–OUT3 green permanent the relevant output is ac-

OUT1 red permanent Input 5 (only in Kaba exos

orange permanent Short circuit

red permanent interruption

tive

flashes green Undervoltage (Vs) or relay

defective

red permanent Write/read authorization

(launch data) is deleted

lock operating mode)

As soon as the door handle contact is active

30 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

4.8 Operating Types

4.8.1 Overview of Operating Types

An operating type of the Remotereader is always made up of the operating mode

(door configuration) with the associated extended functions and of the communication with the host system (access hub). The Remotereader supports the online and

offline operating types.

Online operation:

Offline operation:

For the online and offline operation of the device, a minimum of the following hardware settings must be carried out before putting into operation:

System used Minimum hardware settings

Kabaexos9300

The Remotereader communicates with the system.

If a Remotereader connected with the system is disconnected from the system, then the Remotereader switches

to the offline mode.

Online operation:

• Address

Offline operation:

• DIP and rotary switch

CAN)

3104045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

4.8.2 Online operation

In online operation, the Remotereader communicates with the host system. The system makes the access decision on the basis of badges, time-dependent authorization

and verification. The system controls the access points. If communication between

Remotereader and system is interrupted, then the Remotereader independently

switches into offline operation. If the Remotereader is queried by the system again,

then the Remotereader switches back into online operation.

4.8.3 Offline Operation

Even in offline operation, i.e. without communication with the host system, an access

point is monitored and controlled by the Remotereader. For access decisions,

site keys are used under MIFARE and

segment search keys are used under LEGIC.

The Remotereader controls access points in accordance with the operating mode,

door configuration and the corresponding 'extended functions' (offline configuration).

In order to ensure fault-free offline operation, the Remotereader should be operated

with a secure power supply (e.g. UPS).

Offline operation can be turned off in the system and/or using the 'Mode' rotary

switch (F = off). This means that the offline behavior defined in the hardware settings

is deactivated and the access point remains blocked if there is an interruption in

communication.

Behavior in the event of an interruption to communication

• The access point goes to the basic status (possibly alarm if the access point is not

closed)

• Relays which are not involved in a door process (according to DIP switch) deacti-

4.8.3.1 Offline Access Decision

The customer determines the nature of the offline access decision which is parameterized in the system. We differentiate the following offline access decisions:

Parameter settings in the system: no offline access decision

The Remotereader rejects all bookings in offline operation.

Parameter settings in the system:

Checking site key (MIFARE)/segment search key (LEGIC)

In the online mode, the site key (MIFARE)/segment search key (LEGIC) is sent to the

Remotereader by the system and saved in the Remotereader. During the offline

mode, the Remotereader only checks the site key (MIFARE)/segment search key

(LEGIC). The time zone is not considered for this kind of access decision.

Logbook

The logbook records and saves a maximum of 2000 events during the offline operation. Once the Remotereader is online again, the saved data is sent to the host system and deleted from the memory of the Remotereader.

The following events are logged:

• Authorized accesses (incl. type of authorization)

• Tampering, door forced open, door opener key

vate; the same is true for the connected Kaba extension module 9030.

If there are more than 2000 entries, the oldest will be overwritten (ring memory).

Service mode

See chapter Service mode [}7.3]

32 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

Also see about this

2 7.3Service mode [}87]

CAN)

3304045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

4.9 Operating modes

The operating mode of the Remotereader must be selected on the basis of the door

configuration.

The operating mode is set using the rotary switch, see Chapter Set Operating Mode.

The extended functions of a selected operating mode are set using the DIP switch

Extended functions of the operating modes [}5.7.6.1].

Possible operating modes:

• Electric strike; for doors with electrical blocking elements

• Motor bolt; for doors with electrical blocking elements

• Automatic doors; for doors with their own electronic control system (control with

enable pulse; e.g. sliding door)

• Turnstile; for turnstiles/tripod turnstiles with their own electronic control system

(control with direction-dependent enable pulses)

• Night lock; for doors with the two elements electronic strike and motor bolt

• Kaba exos lock; for doors with self-locking Kaba panic locks;

• Cylinder interface LI-EL; for doors with mechatronic Kaba elolegic cylinders

• Motor bolt with panic function; for doors with electrical blocking elements and

additional mechanical panic opening

• Motor bolt type II with panic function (two outputs); for doors with electrical

blocking elements and additional mechanical panic opening. 1 output each for

the pulses 'unlock' and 'lock'.

• Motor bolt type III with panic function (1 output); for doors with electrical blocking elements and additional mechanical panic opening. 1 output for the pulses

'unlock' and 'lock'.

• Electric lock with panic function; for doors with electrical blocking elements and

additional mechanical panic opening

• Automatic door with night lock for doors with their own electronic control system and additional night lock

Also see about this

2 4.9.1'Electric strike' operating mode [}35]

34 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

Access allowed

Intrusion

detection

system

Frame contact

Electric strike

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Alarm RS-232 A/B

Buzzer / LED

Door opener key

Access manager /

Door manager

Authorised booking,

door opener key or

door handle trigger

a door opening

Frame contact

Access allowed

Pre-alarm time

Alarm time

Access control

Door open

Access control

Door closed

Electric strike (not used

with a door handle)

Relais operation time

4.9.1 'Electric strike' operating mode

The 'Electric strike' operating mode is mainly used to operate doors with electric locking elements (strike, magnet).

The access authorised signal is triggered by authorised booking, the door opener key

or the door handle. So that subsequent door opening does not trigger an alarm, the

'Access authorised' signal activates the alarm bypass.

Then the electric strike is triggered. The door is now released for opening and the set

relay operating time starts to run. When the door is opened the pre-alarm and alarm

time start to run ('Door open too long').

CAN)

3504045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

(locked)

RS-232 A/B

Buzzer / LED

Motor bolt

Bolt monitoring

Access allowed

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Door opener key

Intrusion

detection

system

Alarm

Access manager /

Door manager

Authorised booking

or door opener key

trigger a door

opening

Frame contact

Access allowed

Pre-alarm time

Alarm time

Access control

Door open

Access control

Door closed

Motor bolt

Bold monitoring

Relay operation time

Access control

Door unlocked

Access control

Door locked

4.9.2 'Motor Bolt' Operating Mode

The 'motor bolt' operating mode mainly operates doors with electrical locking elements.

The 'authorized access' signal is generated through being triggered by an authorized

booking or the door opener key. So that subsequent door opening does not generate an alarm, the 'authorized access' signal activates the alarm bypass.

Then the motor bolt is activated. The door is now released for opening and the set relay operation time starts to run. When opening the door, the pre-alarm and alarm

time start to run ('Door open too long').

The motor bolt is activated until the frame contact signals that the door is closed

again. Only then will the lock of the motor bolt be extended again. If the motor bolt

is not extended (e.g. in the event of a defect or tampering), then an alarm ('Bolt position incorrect') is triggered.

36 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

Release pulse

RS-232 A/B

Buzzer / LED

Access allowed

Intrusion

detection

system

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Alarm

Door opener key

Access manager /

Door manager

Authorised booking,

door opener key or

door handle trigger

a door opening

Frame contact

Access allowed

Pre-alarm time

Alarm time

Access control

Door open

Access control

Door closed

Release pulse (not used

with a door handle)

Relais operation time

1s

4.9.3 'Automatic door' operating mode

CAN)

The 'Automatic doors' operating mode is mainly used to operate doors with their

own control electronics (e.g. sliding doors). The control is carried out using a release

pulse.

The 'Access authorised' signal is generated triggered by an authorised booking or the

door opener key. So that subsequent door opening does not trigger an alarm, the

'Access authorised' signal activates the alarm bypass.

The release pulse (approx. 1s) is then sent to the control electronics. The set relay operation time starts to run. If the door is opened within the relay operation time, then

the pre-alarm and alarm time start to run ('Door open too long').

If the door is opened outside of the relay operation time, then unauthorised door

opening is present.

3704045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

Release pulse

RS-232 A/B

Buzzer / LED

Buzzer / LED

Release pulse

Outside

Inside

Frame contact

(direction-dependent)

(direction-dependent)

Access allowed

Intrusion

detection

system

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Alarm

Door opener key

Access manager /

Door manager

Authorised booking,

door opener key

trigger a door

opening

Access allowed

Direction-dependent

release puls

Relais operation time

1s

4.9.4 'Turnstile' operating mode

The 'Turnstile' operating mode is mainly used to operate turnstiles/tripod barriers

with their own control electronics (triggered with direction-dependent release

pulses). The turnstile is an access point in which the access point sides (outside/inside) are released in a direction-dependent manner. Therefore two opposite directions of rotation are possible.

The 'access authorised' signal is triggered by authorised booking or the door opener

key. So that subsequent door opening does not trigger an alarm, the 'Access authorised' signal activates the alarm bypass.

Then the direction-dependent release pulse (approx. 1s) is sent to the control electronics and the set relay operation time starts to run. If the door is opened outside of

the relay operation time, then unauthorised door opening is present.

38 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

RS-232 A/B

Buzzer / LED

Motor bolt

Access allowed

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Door opener key

Intrusion

detection

system

Alarm

Bolt monitoring

(locked)

Electric strike

Access manager /

Door manager

4.9.5 'Night lock' operating mode

The 'Night lock' operating mode is mainly used to operate doors with the two elements electric strike and motor bolt. Therefore during the day only the door opener

relay needs to be enabled, and the door can be additionally locked at night (e.g. XLock motor lock with control unit; but without bolt monitoring).

The 'access authorised' signal is triggered by authorised booking or the door opener

key. So that subsequent door opening does not trigger an alarm, the Access authorised signal activates the alarm bypass.

Then the motor bolt is triggered. As soon as the motor bolt is retracted (motor bolt

monitoring), the electric strike is triggered and the door is released for opening. The

set relay operation time starts to run. When the door is opened the pre-alarm and

alarm time start to run ('Door open too long').

• The time profile saved for the night lock only works in online mode.

• Offline mode always corresponds to the night setting. Motor bolt and door

opener relay are controlled.

CAN)

3904045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

Authorised booking,

door opener key or

door handle trigger

a door opening

Frame contact

Access allowed

Pre-alarm time

Alarm time

Access control

Door open

Access control

Door closed

Motor bolt (not used

with a door handle)

Bolt monitoring (not used

with a door handle)

Relais operation time

Electric strike (not used

with a door handle)

Access control

Door unlocked

Access control

Door locked

40 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

(locked)

RS-232 A/B

Buzzer / LED

Motor bolt

Bolt monitoring

Access allowed

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Door handle contact

Intrusion

detection

system

Alarm

Access manager /

Door manager

Authorised booking

or door handle

trigger a door

opening

Frame contact

Access allowed

Pre-alarm time

Alarm time

Access control

Door open

Access control

Door closed

Motor bolt (not used

with a door handle)

Bolt monitoring (not used

with a door handle)

Relay operation time

Access control

Door unlocked

Access control

Door locked

4.9.6 'Motor bolt with panic function' operating mode

The 'Motor bolt with panic function' operating mode is implemented in the same

way as the 'Motor bolt' operating mode. Instead of the door opener key, the door

handle contact is assessed for mechanical panic opening.

The 'access authorised' signal is triggered by an authorised booking or the door handle. So that subsequent door opening does not trigger an alarm, the 'Access authorised' signal activates the alarm bypass.

The door is now released for opening and the set relay operating time starts to run.

When the door is opened the pre-alarm and alarm time start to run ('Door open too

long').

The motor bolt is controlled until the frame contact signals that the door is closed

again. Only then will the bolt of the motor lock be extended again. If the motor bolt

is not extended (e.g. in the event of a defect or tampering), then an alarm ('Bolt position incorrect') is triggered.

CAN)

4104045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

(locked)

RS-232 A/B

Buzzer / LED

Lock motor bolt

Bolt monitoring

Access allowed

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Door handle contact

Intrusion

detection

system

Alarm

Unlock motor bolt

Access manager /

Door manager

4.9.7 'Motor bolt type II with panic function' operating mode (2 outputs)

The 'Motor bolt type II' operating mode is implemented in the same way as the 'Motor bolt with panic function' operating mode. In place of the static 'Motor bolt' signal,

there is one line each for 'Motor bolt unlocking' and 'Motor bolt locking' connected

to the lock (e.g. MIWA AL-02/AL-3M).

The 'access authorised' signal is triggered by an authorised booking or the door handle. So that subsequent door opening does not trigger an alarm, the 'Access authorised' signal activates the alarm bypass.

Then the motor bolt is retracted with the 'unlock' pulse. The door is now released for

opening. When the door is opened the pre-alarm and alarm time start to run ('Door

open too long').

If the frame contact signals that the door is closed again, then the bolt of the motor

lock is extended again via the 'lock' pulse. If the motor bolt is not extended (e.g. in

the event of a defect or tampering), then an alarm ('Bolt position incorrect') is triggered. If the unlocked door (bolt monitoring) is opened again, no alarm will be generated.

42 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

No alarm!

Unlock motor bolt (not

used with a door handle)

Lock motor bolt (not used

with a door handle)

Authorised booking

or door handle

trigger a door

opening

Frame contact

Access allowed

Access control

Door open

Access control

Door unlocked

Bolt monitoring (not used

with a door handle)

Access control

Door closed

Access control

Door locked

Pre-alarm time

Alarm time

Depending on the door used, it may be the case that a door opener key is parameterised as the door component in Kabaexos instead of a door handle.

CAN)

4304045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

(locked)

RS-232 A/B

Buzzer / LED

Lock motor bolt

Bolt monitoring

Access allowed

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Door handle contact

Intrusion

detection

system

Alarm

Unlock motor bolt

Access manager /

Door manager

Unlock motor bolt

Lock motor bolt

(not used with a door handle)

Authorised booking or

door handle trigger a

door opening

Frame contact

Access allowed

Pre-alarm time

Alarm time

Access control

Door open

Access control

Door closed

Access control

Door unlocked

Access control

Door locked

Bolt monitoring (not used

with a door handle)

4.9.8 'Motor bolt type III with panic function' operating mode (1 output)

The 'Motor bolt type III' operating mode is implemented in the same way as the 'Motor bolt with panic function' operating mode. Instead of the static 'Motor bolt' signals, the 'Motor bolt unlocking' pulse is generated on one output and the 'Motor bolt

locking' pulse is generated on the other output.

The 'access authorised' signal is triggered by an authorised booking or the door handle. So that subsequent door opening does not trigger an alarm, the 'Access authorised' signal activates the alarm bypass.

Then the motor bolt is retracted with the 'unlock' pulse. Now the door is released for

opening. When the door is opened the pre-alarm and alarm time start to run ('Door

open too long').

If the frame contact signals that the door is closed again, then the bolt of the motor

lock is extended again via the 'lock' pulse. If the motor bolt is not extended (e.g. in

the event of a defect or tampering), then an alarm ('Bolt position incorrect') is triggered.

44 04045708 - 04/2016 Kaba Remote Reader 91 25-AM (US/

CAN)

Technical Manual Design and function

Depending on the door used, it may be the case that a door opener key is parameterised as the door component in Kabaexos instead of a door handle.

CAN)

4504045708 - 04/2016Kaba Remote Reader 91 25-AM (US/

Design and function Technical Manual

(locked)

RS-232 A/B

Buzzer / LED

Electric lock

Bolt monitoring

Access allowed

Frame contact

(Alarm bypass)

(Access control)

Registration unit A

Blocking contact

Registration unit B

Door handle contact

Intrusion

detection

system

Alarm

Access manager /

Door manager

4.9.9 'Electric lock with panic function' operating mode

The 'Electric lock with panic function' operating mode is implemented in the same