Registration units

(US/CAN)

Technical Manual

04/2016

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

EN

Kaba AG

Access & Workforce Management

Hofwisenstrasse 24

8153 Rümlang

Switzerland

Phone +41 44 818 93 11

www.kaba.com

Kaba AG

Access & Workforce Management

Mühlebühlstrasse 23

8620 Wetzikon

Switzerland

Phone +41 44 931 61 11

www.kaba.com

Kaba GmbH

Access & Workforce Management

Albertistrasse 3

78056 Villingen-Schwenningen

Germany

Phone +49 7720 603 0

www.kaba.com

This document must not be reproduced in any way or otherwise further used without the written consent of Kaba AG.

All product names are trademarks of the respective companies.

Copyright 2016 Kaba AG. All rights reserved.

Publication: 04/2016

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

1 About this Document ............................................................................... 5

1.1 Validity ........................................................................................................ 5

1.2 Target Group .............................................................................................. 5

1.3 Supplementary Documents ........................................................................ 6

1.4 Change Protocol ........................................................................................ 6

1.5 Abbreviations.............................................................................................. 7

1.6 Danger categories ...................................................................................... 7

2 Basic safety information .......................................................................... 8

2.1 Intended usage .......................................................................................... 8

2.2 Service and maintenance ........................................................................... 8

2.2.1 ESD protective measures .......................................................................... 8

2.2.2 Environmental Hazards .............................................................................. 8

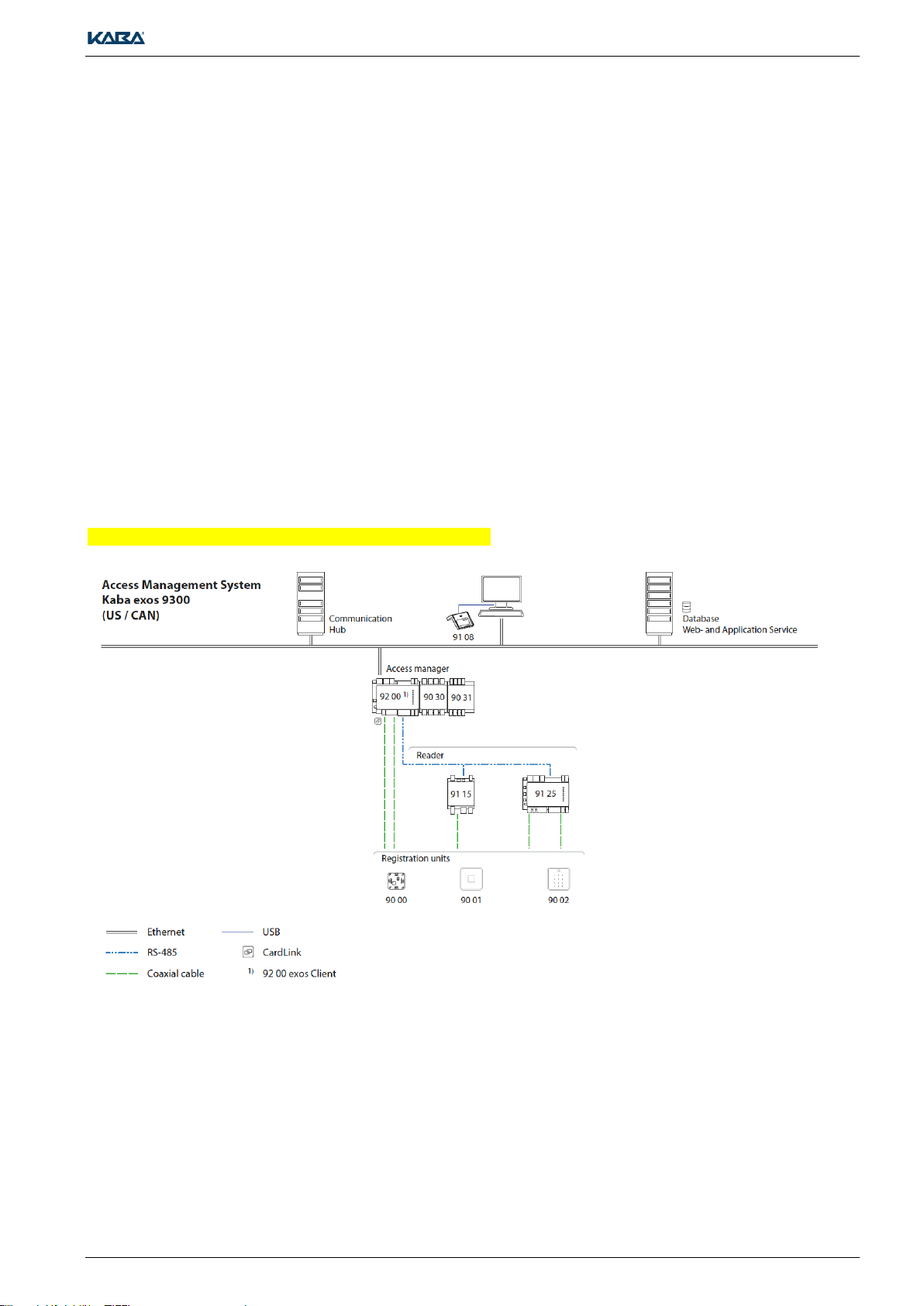

3 General Rules and Information ................................................................ 9

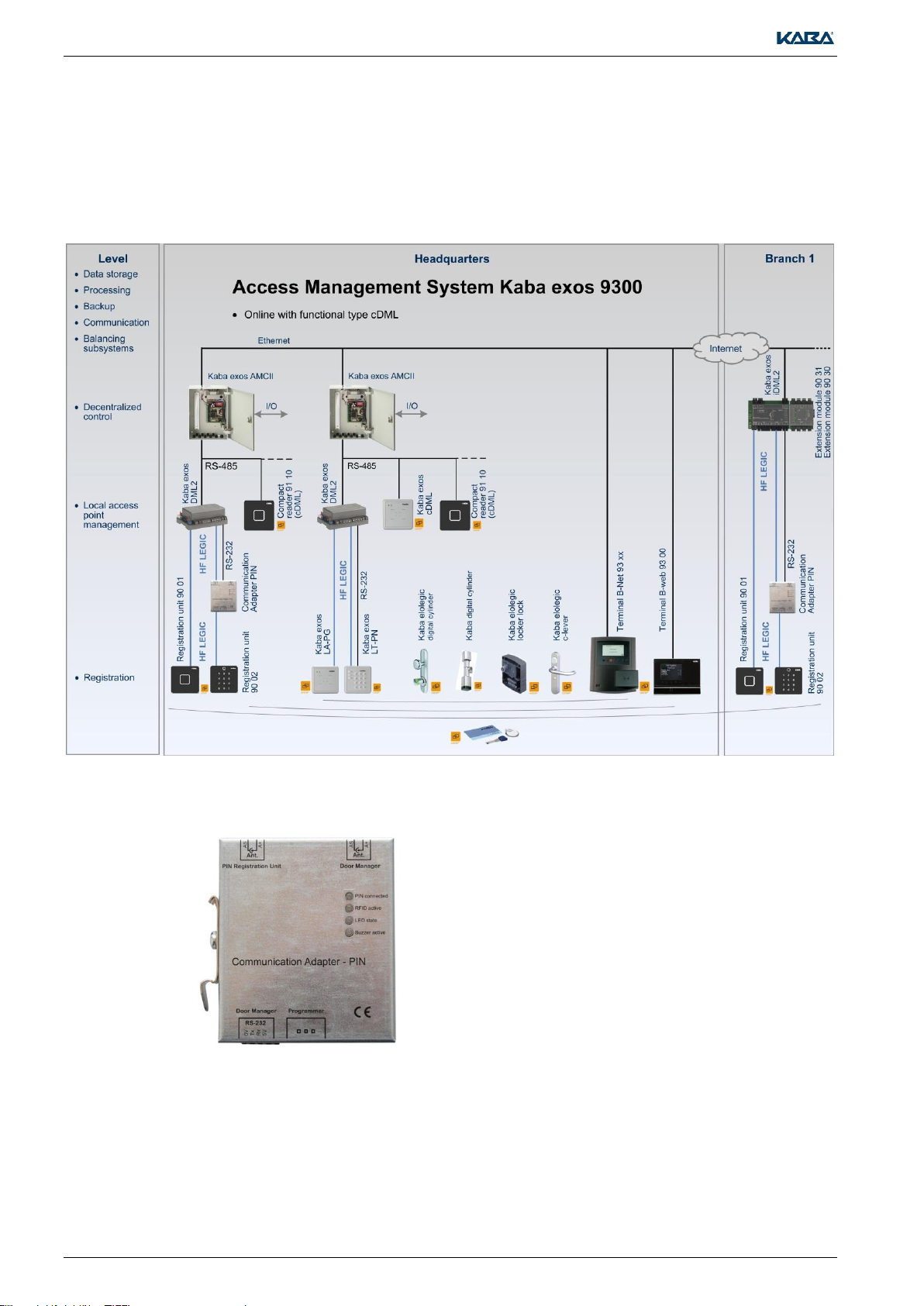

3.1 Topologies .................................................................................................. 9

3.1.1 Access Management System MIFARE / LEGIC ........................................ 9

3.1.2 Replacing Kaba exos LT-PN with Registration Unit 90 02 ...................... 10

3.1.3 B-COMM .................................................................................................. 11

3.1.4 Standalone Mode ..................................................................................... 11

3.2 Hardware Compatibility ............................................................................ 12

3.2.1 Registration Unit Compatibility ................................................................. 12

3.3 Supported RFID Standards ...................................................................... 12

3.4 Reading and Writing Properties ............................................................... 13

3.4.1 Basic Technical Relationships ................................................................. 13

3.4.2 Reading and Writing Distances ................................................................ 13

3.5 Mounting and Installation Information ...................................................... 14

3.5.1 Concealed Cable Mounting ...................................................................... 14

3.5.2 Antenna Cable to the Registration Units .................................................. 14

3.5.3 Coaxial Cable Terminal ............................................................................ 14

3.5.4 Distance between Antennae .................................................................... 14

3.5.5 Antenna Distance - Metal Bodies ............................................................. 15

3.6 Display and Signal Elements ................................................................... 15

4 Kaba registration unit 90 01 / Kone registration unit 90 01 ............... 16

4.1 Product description .................................................................................. 16

4.2 Dimension drawing ................................................................................... 16

4.3 Installation ................................................................................................ 17

4.3.1 Preparation ............................................................................................... 17

4.4 Connection ............................................................................................... 18

4.4.1 Connection with quickwireTM Technology ................................................. 18

4.4.2 Connecting the Coaxial Cable .................................................................. 18

4.5 Typical Maximum Reading Distance ........................................................ 18

4.5.1 Reading and Writing Distance with Direct Mounting on Metal ................. 18

4.6 Technical Data ......................................................................................... 19

4.7 Dismantling ............................................................................................... 20

4.7.1 Accessories .............................................................................................. 20

4.8 Conformity ................................................................................................ 20

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 3

5 Kaba Registration 90 02 / Kone Registration 90 02 .............................. 21

5.1 Product description ...................................................................................21

5.2 Dimensions ...............................................................................................21

5.3 Installation ................................................................................................21

5.3.1 Preparation ...............................................................................................21

5.4 Connection ...............................................................................................22

5.4.1 Connection with quickwireTM Technology .................................................22

5.4.2 Connecting the Coaxial Cable ..................................................................22

5.4.3 Operation of the keypad ...........................................................................24

5.5 Typical Maximum Reading Distance ........................................................24

5.5.1 Reading and Writing Distance with Direct Mounting on Metal .................24

5.6 Technical Data .........................................................................................25

5.7 Dismantling ...............................................................................................26

5.7.1 Accessories ..............................................................................................26

5.8 Conformity ................................................................................................26

6 Kaba Registration 90 00 / Kone registration unit PCB .......................... 27

6.1 Product description ...................................................................................27

6.2 Mounting and Connection ........................................................................27

6.2.1 Mounting and Connection ........................................................................27

Connecting the Coaxial Cable .................................................................................27

6.2.2 LED...........................................................................................................27

6.3 Typical Maximum Reading Distance ........................................................28

6.3.1 Reading and Writing Distance with Direct Mounting on Metal .................28

6.4 Technical Data .........................................................................................28

6.4.1 Accessories ..............................................................................................28

6.5 Conformity ................................................................................................28

7 Dismantling and disposal ....................................................................... 29

7.1 Dismantling / Put out of operation ............................................................29

7.2 Disposal ....................................................................................................29

7.2.1 Disposing of packaging ............................................................................29

7.2.2 Disposing of the device ............................................................................29

8 Conformity ............................................................................................... 30

8.1 FCC- and IC- tested registration units ......................................................30

8.2 Conformity Kone Registration Unit PCB ..................................................30

8.3 Conformity Kaba Registration Unit 90 00 .................................................31

8.4 Conformity Kaba Registration Unit 90 01 / Kone Registration Unit 90 0132

8.5 Conformity Kaba Registration Unit 90 02 / Kone Registration Unit 90 0233

8.6 Declaration of conformity .........................................................................35

8.7 Device mark .............................................................................................35

8.8 Manufacturer ............................................................................................35

4 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

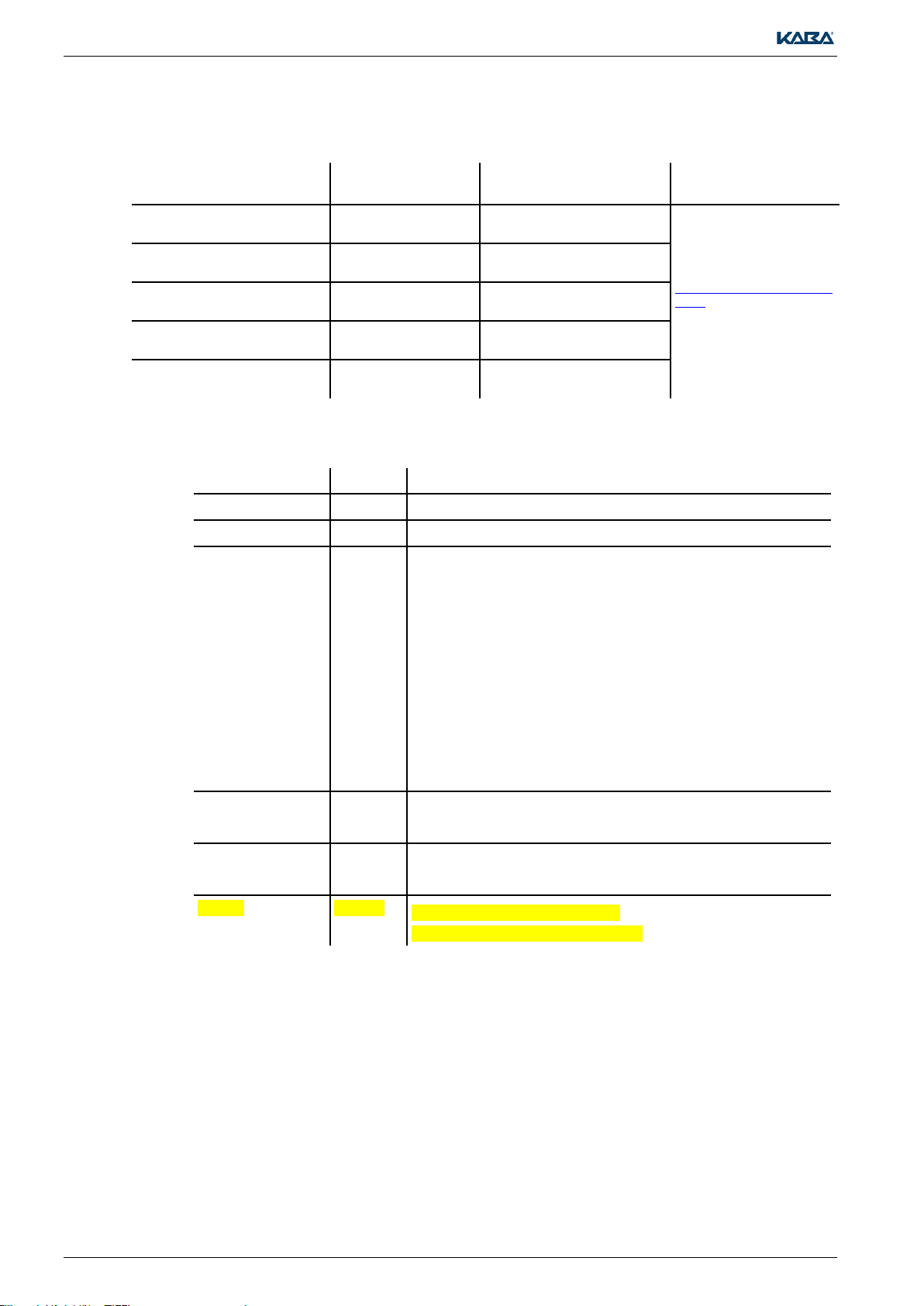

Product name until 2014/06/30

Product from 2014/07/01

Registration unit RFID

Registration unit RFID PIN

Registration unit Print RFID

Kaba registration unit 90 01

Kone registration unit 90 01

Kaba registration unit 90 02

Kone registration unit 90 02

Kaba registration unit 90 00

Kone registration unit PCB

Compatibility between registration units and control units (reading devices) is described in Chapter

3.2.1 on page 12.

NOTICE

For reasons of device safety, the actions described in this document for installation, maintenance and

servicing may only be carried out by a service person in accordance with EN 60950-1 (Information

Technology Equipment – Safety).

1 About this Document

The following registration units can be used in a range of Kaba system solutions (Kaba exos,

B-COMM, KEM):

This document describes the mounting and installation of registration units. The instructions should be

followed consistently to ensure fault-free and safe application.

All drawing dimensions in millimeters (mm).

1.1 Validity

1.2 Target Group

This manual is only intended for specialist personnel.

The descriptions require personnel trained by the manufacturer.

The descriptions do not replace product training.

A service person is a person who has appropriate technical training and experience, which is required

in order to be aware of the risks which they or other people are exposed to when carrying out this work

as well as to keep the risks for themselves and other people as low as possible. It is the responsibility

of the service person to ensure compliance with the conditions stated by the manufacturer, as well as

applicable regulations and standards, when conducting this work.

This document is also used for information for people undertaking the following work:

Project planning and project implementation

Commissioning of the product within the network

Connection of the product to the user software by programming customer applications

Customer specific adjustment via parameterization of the product

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 5

About this Document

Document name until

2014/06/30

Document name

from 2014/07/01

Contents

Availability

TM_AccessManagerMIFARE_V0x

TM_AccessManager9200

Kaba Access Manager 92 00 Technical Manual

http://ftp.kaba.com/ExosDow

nload

partly on Kaba Portal AC

TM_RemoteReaderMIFARE_V0x

TM_ RemoteReader9115

Remote Reader 91 15 Technical Manual

PGL_Thema Kaba exos 9300

PGL_Thema

Kaba exos 9300

Planning Guidelines, according

to subject, e.g., hardware

Kaba exos iDML2 Technical

Documentation

Kaba exos DML2 Technical

Documentation

Version Number

Edition

Brief Description

V01

12/2010

First edition

V02

01/2011

Various adjustments

V03

12/2011

Abbreviations chapter

Topologies chapter supplement with Replacing

Kaba exos LT-PN with Registration Unit RFID PIN and

B-COMM

Hardware Compatibility chapter

Supported RFID Standards chapter

New chapter: Distance between Antennae

Text and graphics: Typical Maximum Reading Distances with

registration units

New chapter: egistration unit LA-PP

New chapter: Bolt Handle for IT Cabinets

Registration Units – Conformity chapter

V04

01/2014

Integration of registration unit 90 04

Various adjustments and additions

201406

06/2014

New product names

New file names

201604

04/2016

Additional FCC / IC sentences

List of supported registration units

1.3 Supplementary Documents

1.4 Change Protocol

The most important changes to the last edition of this manual are listed below:

6 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

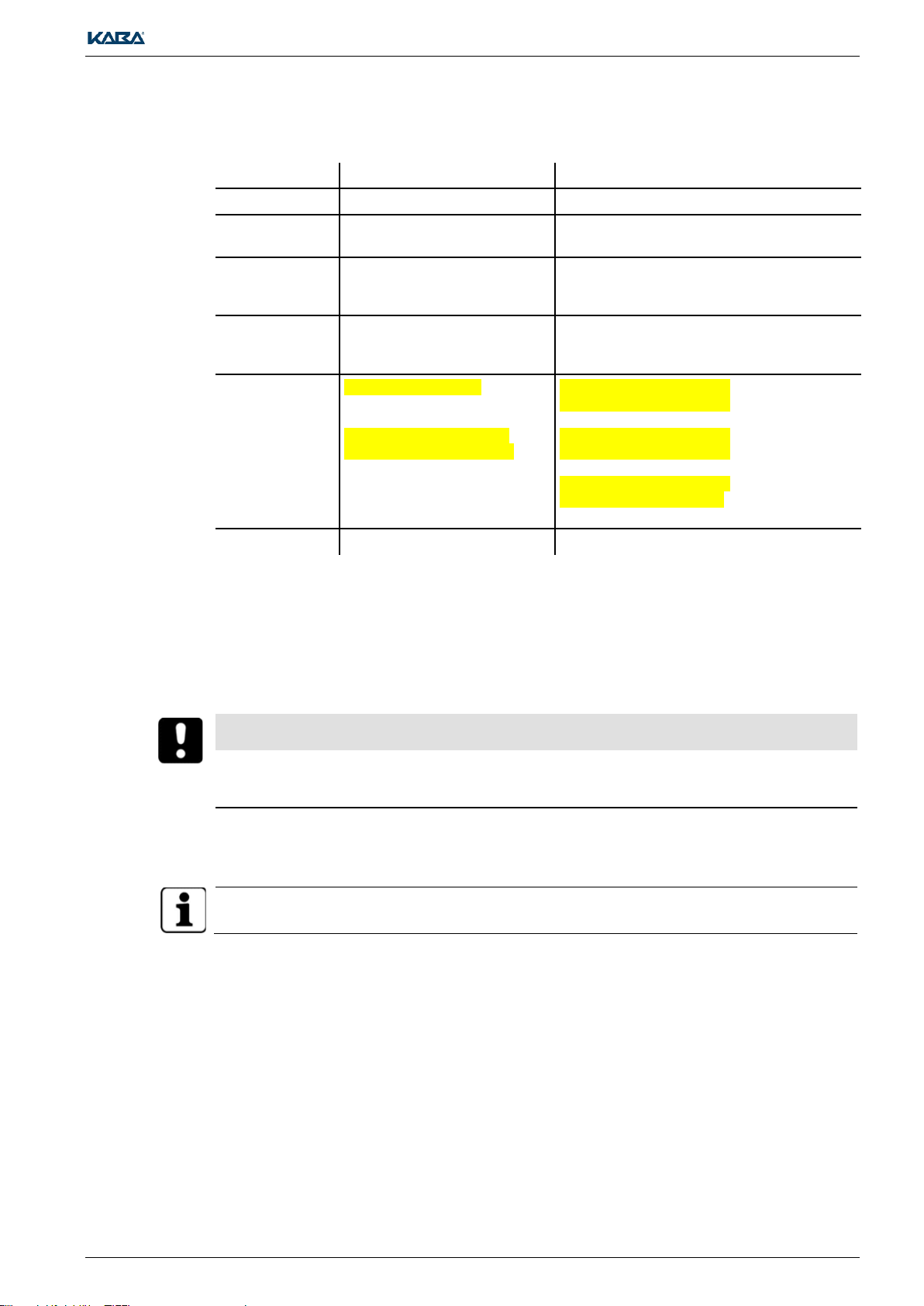

About this Document

Abbreviation

Term name until 2014/06/30

Term from 2014/07/01

Host

Host system

Host system

Control unit

Fehler! Keine gültige

Verknüpfung.

Access manager, terminal or

Kaba exos AMC/-II

Remote Reader

Remote Reader MIFARE (RR-M)

or

Remote Reader LEGIC (RR-L)

Kaba remote reader 91 15

Access Manager

Access Manager MIFARE (AMM), or Access Manager LEGIC

(AM-L)

Kaba access manager 92 00

Registration unit

Registration unit RFID

Registration unit RFID PIN

Registration unit Print RFID

Kaba registration unit 90 01

Kone registration unit 90 01

Kaba registration unit 90 02

Kone registration unit 90 02

Kaba registration unit 90 00

Kone registration unit PCB

Antennas

Registration units

Registration units

NOTICE

Important information regarding proper handling of the product.

Failure to observe this information may lead to malfunctions and may cause the device or other items

in its vicinity to be damaged.

User tips and useful information which help to utilize the product and its functions to their full potential.

1.5 Abbreviations

1.6 Danger categories

Notes containing information, requirements, and prohibitions are clearly marked to help prevent injury

to personnel and damage to equipment.

Observe these danger warnings. They are intended to help prevent accidents and avoid damage.

Danger warnings are categorized as follows:

Notes

Please pay particular attention to the warnings marked with symbols.

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 7

Basic safety information

NOTICE

Danger to electronic components due to electrostatic discharge.

Improper handling of electronic PCBs or components may lead to damage that causes total failure or

sporadic errors.

General ESD protective measures must be observed when installing and repairing the device

2 Basic safety information

The devices are constructed in accordance with the state of the art and recognized safety rules.

Despite this, handling this product may present sources of danger for persons and valuables.

Read and observe the following safety information before you use the product.

2.1 Intended usage

The devices and system are only intended to be used as outlined in the chapter Product description.

Any type of usage beyond the scope of this is not considered to be intended usage. The manufacturer

shall accept no liability for damage resulting from this unintended usage. The user/operator alone shall

bear the associated risk.

Only service persons may carry out the mounting and installation of a device; see Chapter 1.2, page 5.

Installation may only be carried out at locations that fulfill the climatic and technical conditions specified

by the manufacturer.

Kaba GmbH shall not accept liability for any damage that occurs as a result of improper handling or

incorrect installation.

2.2 Service and maintenance

Maintenance work/Correcting faults

Troubleshooting and maintenance work must only be performed by a service person; see Chapter 1.2,

page 5.

Modifications and alterations

Conversions and modifications of the device must only be performed by a service person; see

Chapter 1.2, page 5. Any conversions and modifications performed by other persons will result in a

complete exclusion of liability. Any modifications and alterations carried out by other persons will lead

to total exclusion of liability.

2.2.1 ESD protective measures

The following rules must be observed:

Wear an ESD grounding armband when handling electronic components

Connect the end of the armband to a discharge socket or an unpainted, grounded metal

component. This will discharge static loads safely and effectively from your body

Only handle PCBs by their edges. Do not touch PCBs or connectors

Place any removed components on an antistatic surface or in an antistatic shielded container

Avoid contact between PCBs and articles of clothing. The armband only protects the PCBs against

electrostatic discharge voltage on the body; damage may still result from electrostatic discharge on

clothing

Only use electrostatically shielding and conductive protective bags to transport and ship modules

that have been removed

2.2.2 Environmental Hazards

See Chapter 7.2, page 29

8 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

General Rules and Information

3 General Rules and Information

The registration units can be used in a wide range of Kaba system solutions (Kaba exos, B-COMM,

KEM).

3.1 Topologies

The separation of the registration units from the control unit facilitates various antenna designs. With

the help of suitable housing, the antennae can be adjusted to the spatial and security-related

requirements of a building.

The registration units 90 02 is used for entering the personal PIN code. It is therefore particularly

suitable for external access or installations with increased security requirements. It can be retro-fitted at

any time with no or minimal wiring changes.

The different antenna variants allow different RFID reading-writing distances to be achieved. The

properties also result from local events and the identification medium used.

Tampering Security

The registration units are separate from the hardware (reading devices). Regardless of the mounting

location, the associated control unit can be installed in a tamper-proof room.

Manipulation Security

The communication between registration unit and associated control unit is encrypted and therefore

offers optimal security.

3.1.1 Access Management System MIFARE / LEGIC

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 9

General Rules and Information

3.1.2 Replacing Kaba exos LT-PN with Registration Unit 90 02

The Communication Adapter PIN allows the registration units 90 02 to be integrated into existing or

new LEGIC customer sites. The communication adapter PIN enables connection of the

registration units 90 02 to the door managers Kaba exos DML2 and Kaba exos LS-110 and to the

Access Manager Kaba exos iDML2.

Illustration of Communication Adapter PIN

Detailed information on the mounting and connection of the Communication Adapter PIN can be found

in the supplementary sheet.

10 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

General Rules and Information

3.1.3 B-COMM

The remote reader works as a subterminal on a B-web series terminal. The data exchange between

remote reader and terminal is performed in half-duplex mode via the RS-485 interface (subpartyline).

Communication is performed via the transfer protocol BPA/9 subset.

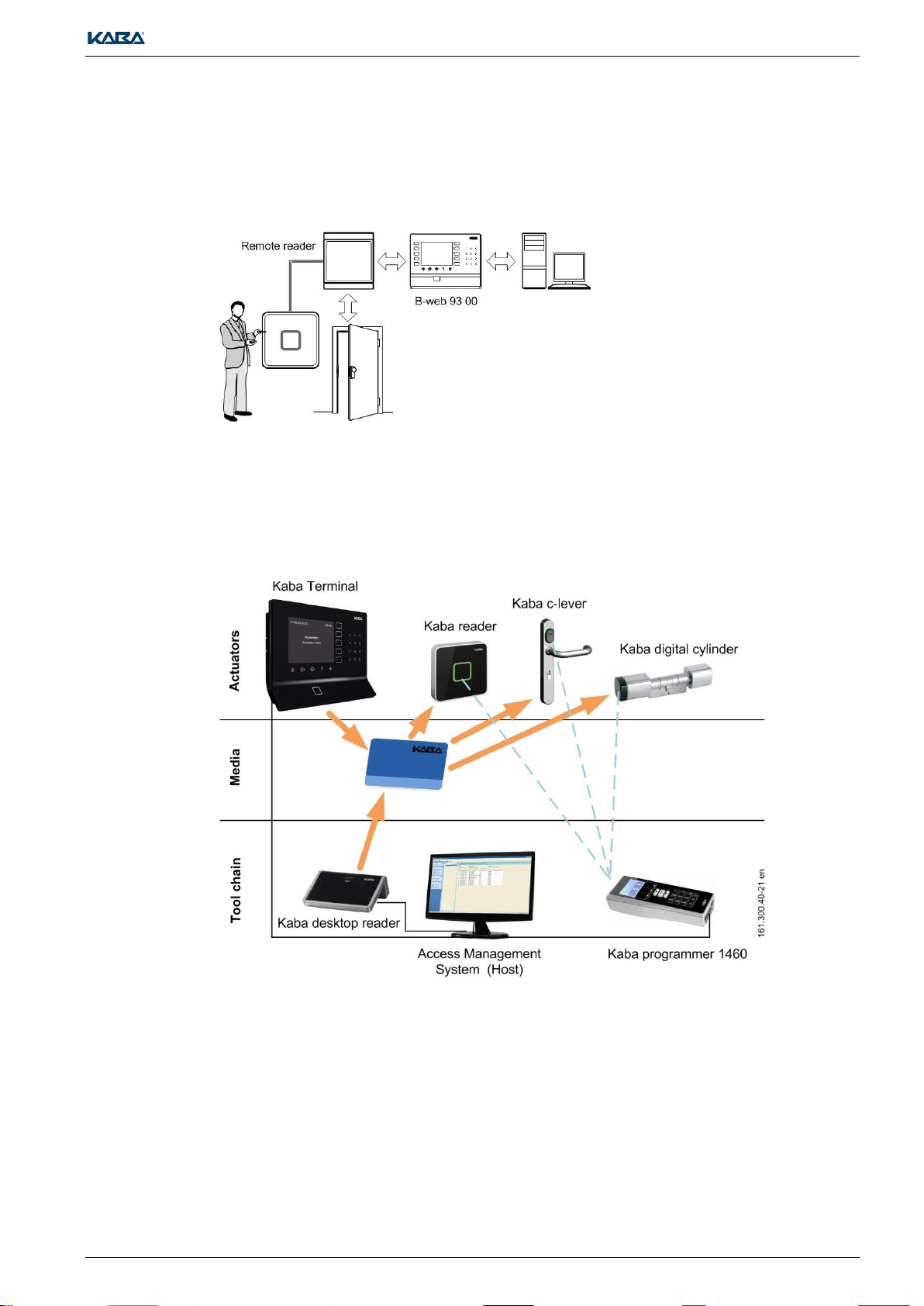

3.1.4 Standalone Mode

The required data for the whitelist or CardLink are saved in the remote reader via the

programmer 1460. The authorization check and access control are therefore sensed by the remote

reader.

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 11

General Rules and Information

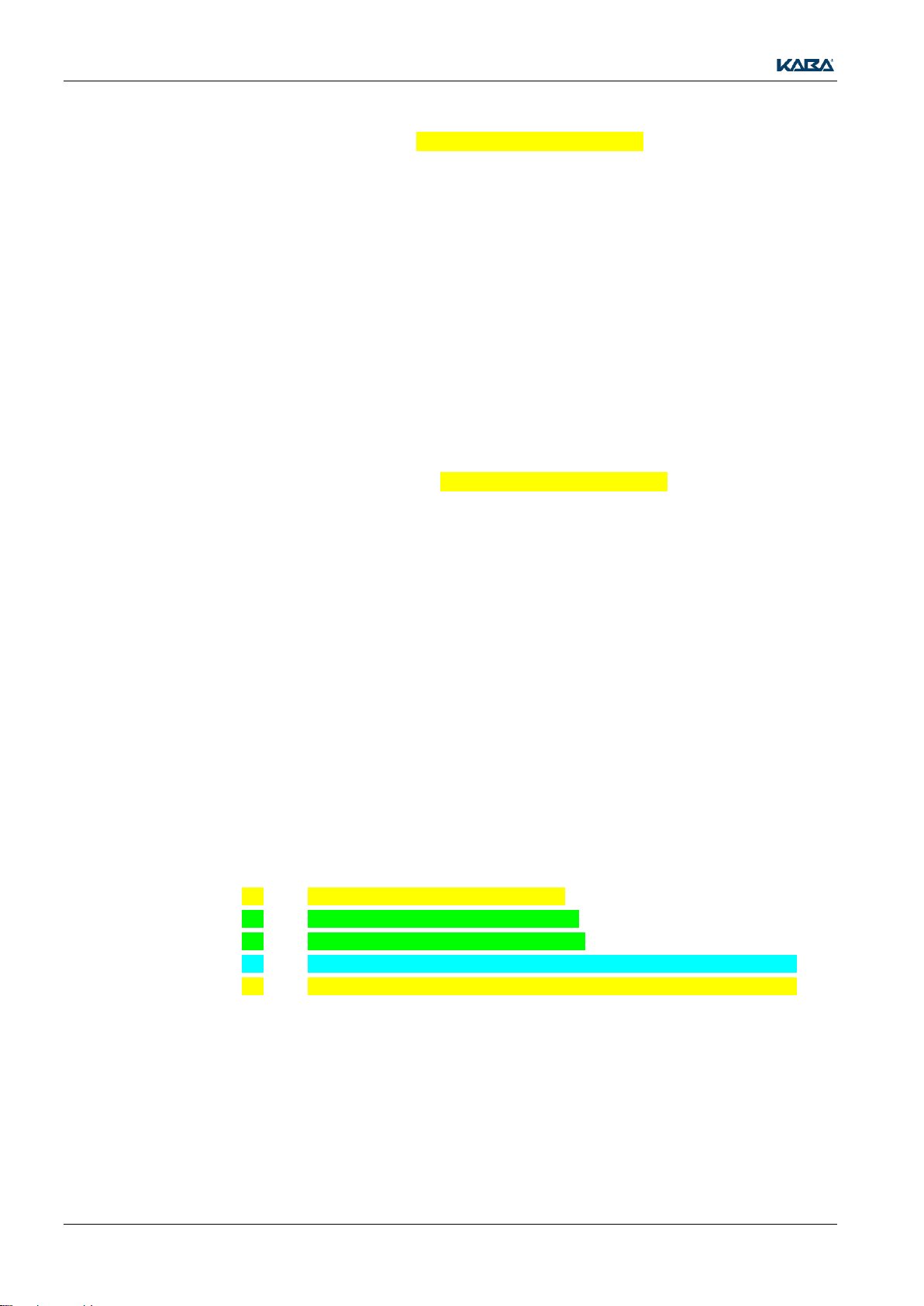

Control Unit

Registration unit

Access Manager

Kaba exos iDML2

Remote Reader

Functional type Access Manager

Remote Reader

Functional type Subterminal

Remote Reader

Functional type E300 V4

Kaba exos DML2

Kaba exos LS-110

Kaba elolegic Remote Reader

Registration unit 90 01

Registration unit 90 02

1

--

1

1

--

Registration unit 90 00

3.2 Hardware Compatibility

3.2.1 Registration Unit Compatibility

1

= only compatible with use of Communication Adapter PIN

3.3 Supported RFID Standards

Depending on the access manager to which the registration unit is connected to, the following

RFID standards are supported:

ISO 14443A MIFARE/LEGIC

LEGIC RF

ISO 15693

12 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

General Rules and Information

The following planning guidelines (PGL) will help you to select suitable media/compact reader

combinations:

PGL_Media_LEGIC

PGL_Media_MIFARE_ARIOS

PGL_Migration_RFID_Technology_Kabaexos9300

The reading distances in the diagram for the

respective registration units RFID are calculated

average values from:

Metal - non-metal

Cable lengths 1 m to 30 m

(registration unit 90 02: 3 - 30 m)

3.4 Reading and Writing Properties

The typical maximum reading distance of a registration units is detailed in the corresponding chapters.

3.4.1 Basic Technical Relationships

The read and write distance fundamentally depends on the size of the registration unit's antenna, the

size of the medium, and the media technology

LEGIC prime, MIFARE classic and ISO15693:

Cards: The read and write distance tends to be slightly greater than the diameter of the registration

unit's antenna

Key fobs and smart keys: The read and write distance tends to be slightly smaller than the diameter

of the registration unit's antenna

LEGIC advant, MIFARE DESFire

The read and write distance is approx. 3/4 of the size of the figures given above.

Influence of a Metallic Environment and the Cable Length

A metallic environment reduces the reading and writing distance The read and write properties of

registration unit 90 04 are not impaired by metallic objects in its surroundings.

The shorter the coaxial cable, the better the reading and writing distance

See Chapter 3.5.4,page Seite 14

3.4.2 Reading and Writing Distances

Information on writing and reading distances can be found on the Kaba Portal Access Management

portal.kaba.biz in the Mechatronics/Kaba evolo/Kaba Media/Instructions tab.

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 13

General Rules and Information

Cable Type RG 174/U

Coaxial cable 50 Ohm

Recommended: RG 174/U, 50 Ohm, Supplier: Huber + Suhner

Recommended Cable Length

< 10 m

Max. Cable Length

30 m

WARNING

To avoid external interference, the antenna cable must not be laid parallel to power lines or other

sources subject to disturbance

Unnecessary antenna cables should be stored in a figure eight

Placing registration units and compact readers close together may reduce the read and write

distances*.

Install registration units and compact readers at a sufficient distance

*

Exception: registration units which are connected to the same reader (e.g. remoter reader 91 15)

1

2

Reader

e.g. remote reader 91 15

Registration unit

e.g. registration unit

3.5 Mounting and Installation Information

The mounting and installation of the device may only be carried out by a service person as per DIN EN

60950-1:2006 + A11:2009.

The device must only be installed in locations that fulfill the climatic and technical conditions specified

by the manufacturer.

3.5.1 Concealed Cable Mounting

The registration unit PCB RFID and registration unit LA-PP are screwed onto the switch box for

concealed mounting. The following must be observed when doing so:

There must be sufficient cable in reserve so that no tension is created at the terminal connections. The

reserve cable should not be too long (max. 25 cm) and, where necessary, should be laid in a figure

eight.

3.5.2 Antenna Cable to the Registration Units

The signals of the antenna, LED, buzzer and PIN code keypad are conducted via the coaxial cable.

3.5.3 Coaxial Cable Terminal

The inner conductor and shield of the coaxial cable must not be connected to ground.

The coaxial cable terminal of the registration units is described in the corresponding chapters.

3.5.4 Distance between Antennae

14 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

General Rules and Information

WARNING

To maximize the antenna when mounting, we recommend surface cable mounting with a spacer

frame

The read/write quality of the antenna should be checked in all cases

Often an air gap in the conductive body is sufficient to weaken the magnetic sufficiently so that the

antenna is no longer materially influenced

The detailed signaling of all registration units during the different booking processes is described in

the documentation Operation of Registration Units RFID.

3.5.5 Antenna Distance - Metal Bodies

Influence of the magnetic field in the vicinity of the antenna by a metal body results in shorter reading

distances and can even cause failure of reading functionality. The electro-magnetic field is shortcircuited in the metallic environment.

3.6 Display and Signal Elements

The registration units are equipped with a two-color, red/green illuminating symbol and a buzzer.

The buzzers provide acoustic signaling of the access decision

The red/green illuminating symbol indicates the operating state and access decision

The keypad lights up brightly when a PIN code input is required

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 15

Kaba registration unit 90 01 / Kone registration unit 90 01

The registration unit 90 01 with integrated

antenna, together with a control unit, represents a

fully-integrated solution for access control with

simultaneous convenient identification of the user.

This registration unit is suitable for both internal

and external applications.

Height incl. rear panel: 19,4 mm

Height spacer frame: 26,4 mm

External dimensions

Dimensions of rear panel/spacer frame

4 Kaba registration unit 90 01 / Kone registration unit 90 01

4.1 Product description

4.2 Dimension drawing

16 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Kaba registration unit 90 01 / Kone registration unit 90 01

Surface cable mounting:

Use the spacer frame (only indoors).

Break open the cable inlet on the spacer frame.

Lead the cable away at the bottom or at the side in a siphon shape.

NOTICE

Only connect the wires when the power is switched off.

Procedure

1.

Pull the cable through the rear panel or the spacer frame.

Screw the rear panel or the spacer frame to an even surface.

The rear panel or spacer frame must not lose its shape.

Small bumps can be balanced out using the sealing pad.

Lead the cable away in a siphon shape to prevent the ingress of water.

2.

Connect the cable strands to the connection terminal.

An overview showing the assignment of connection terminals can be found in Chapter 4.4.2

NOTICE

The pin strip can be damaged. Observe the following instructions.

3.

Slide the registration unit in a parallel position over the rear panel or the

spacer frame.

4.

Press the registration unit against the rear panel or the spacer frame until it clicks into position at

both the top and the bottom.

4.3 Installation

4.3.1 Preparation

If necessary, drill holes for the frame bracket.

A dimension drawing of the frame can be found above.

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 17

Kaba registration unit 90 01 / Kone registration unit 90 01

NOTICE

Notice:

The device may only be supplied with SELV (Safety Extra Low Voltage) and LPS (Limited Power Source),

according to IEC/UL/CSA 60950-1.

Terminal Number

Meaning

Control Unit

6

Antenna cable shield wire

AS

7

Antenna cable inner conductor

A+

1 = Badge, ISO 14443A

2 = Key fob, ISO 14443A

3 = Badge, LEGIC RF

4 = Badge, ISO 15693

5 = Kaba elolegic smart key, LEGIC RF

4.4 Connection

4.4.1 Connection with quickwireTM Technology

With the innovative quickwire technology, the wiring is performed completely separately from the

electronics on the mounting plate (rear panel or spacer frame). The electronics are mounted as a unit

during commissioning. The practical click connection makes mounting simpler and means the

registration unit is quickly changed in case of repair.

In addition, it is possible to upgrade from a registration unit without a PIN to a registration unit with PIN

with no or minimal changes to wiring.

4.4.2 Connecting the Coaxial Cable

4.5 Typical Maximum Reading Distance

4.5.1 Reading and Writing Distance with Direct Mounting on Metal

If the registration unit is mounted directly on a metallic surface, the reading and writing distance is

approx. 10% smaller than an RFID neutral environment (wood, masonry).

18 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Kaba registration unit 90 01 / Kone registration unit 90 01

Spacer Frame / Rear Panel:

Material

PC-ABS

Frame:

Material

PC-ABS

Front:

Material

PMMA back-printed

Dimensions:

With rear panel (concealed cable mounting)

88.5 x 88.5 x 19.4 mm (length x width x height)

With spacer frame (surface cable mounting)

88.5 x 88.5 x 26.4mm (length x width x height)

Protection Type IEC 60529

IP54;

Only with concealed cable mounting and sealing

pad

Temperature Range

- 25° - +70°C (operation)

- 40° - +85°C (storage)

Ambient Conditions

Relative humidity

0% - 95% non condensing

Application

Concealed cable mounting with real panel

Surface cable mounting with spacer frame

Mounting possible directly on metal or neutral

subsurface

Coaxial cable

Recommended: RG 174/U, 50 Ohm

Supplier: Huber + Suhner

max. lenght 30 m

Power supply

The registration unit is powerd by the host

control device

Notice:

The device may only be supplied with SELV (Safety

Extra Low Voltage) and LPS (Limited Power Source),

according to IEC/UL/CSA 60950-1.

4.6 Technical Data

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 19

Kaba registration unit 90 01 / Kone registration unit 90 01

1. Insert a screwdriver (no. 1) into the bottom of the opening and press it

upwards.

The quick-release lock opens up.

NOTICE

The pin strip can be damaged.

Observe the following instructions.

2. Slightly raise the bottom of the registration unit (max. 10º).

3. Pull the registration unit forwards in a parallel position.

4.7 Dismantling

4.7.1 Accessories

Rear panel SL for concealed cable mounting

Spacer frame SL for surface cable mounting

Sealing pad

4.8 Conformity

See Chapter 8.

20 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Kaba Registration 90 02 / Kone Registration 90 02

The registration unit 90 02 with integrated

antenna and keypad, together with the control

unit, represents a fully-integrated solution for

access control with simultaneous convenient

identification of the user.

In addition, for identification in the event of

increased security requirements, it is also

possible to demand verification of the user via

entry of his/her personal PIN code.

This registration unit is suitable for both internal

and external applications.

Additional Product descriptions:

Door code entry for access without a badge

(Code lock function)

Control of alarm systems

Height incl. rear panel: 19,4 mm

Height spacer frame: 26,4 mm

External dimensions

Dimensions of rear panel/spacer frame

Surface cable mounting:

Use the spacer frame (only indoors).

Break open the cable inlet on the spacer frame.

Lead the cable away at the bottom or at the side in a siphon shape.

NOTICE

Only connect the wires when the power is switched off.

5 Kaba Registration 90 02 / Kone Registration 90 02

5.1 Product description

5.2 Dimensions

5.3 Installation

5.3.1 Preparation

If necessary, drill holes for the frame bracket.

A dimension drawing of the frame can be found above.

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 21

Kaba Registration 90 02 / Kone Registration 90 02

Procedure

1.

Pull the cable through the rear panel or the spacer frame.

Screw the rear panel or the spacer frame to an even surface.

The rear panel or spacer frame must not lose its shape.

Small bumps can be balanced out using the sealing pad.

Lead the cable away in a siphon shape to prevent the ingress of water.

2.

Connect the cable strands to the connection terminal.

An overview showing the assignment of connection terminals can be found in Chapter 5.4.2

NOTICE

The pin strip can be damaged. Observe the following instructions

3.

Slide the PIN keypad in a parallel position over the rear panel or the spacer

frame.

4.

Press the PIN keypad against the rear panel or the spacer frame until it clicks into position at both

the top and the bottom.

NOTICE

Notice:

The device may only be supplied with SELV (Safety Extra Low Voltage) and LPS (Limited Power Source),

according to IEC/UL/CSA 60950-1.

Terminal Number

Meaning

Control Unit

6

Antenna cable shield wire

AS

5.4 Connection

5.4.1 Connection with quickwireTM Technology

With the innovative quickwire technology, the wiring is performed completely separately from the

electronics on the mounting plate (rear panel or spacer frame). The electronics are mounted as a unit

during commissioning. The practical click connection makes mounting simpler and means the

registration unit is quickly changed in case of repair.

In addition, it is possible to upgrade from a registration unit without a PIN to a registration unit with PIN

with no or minimal changes to wiring.

5.4.2 Connecting the Coaxial Cable

22 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Kaba Registration 90 02 / Kone Registration 90 02

7

Antenna cable inner conductor

A+

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 23

Kaba Registration 90 02 / Kone Registration 90 02

1 = Badge, ISO 14443A

2 = Key fob, ISO 14443A

3 = Badge, LEGIC RF

4 = Badge, ISO 15693

5 = Kaba elolegic smart key, LEGIC RF

The Kaba elolegic smart key can only be used to a limited extent.

5.4.3 Operation of the keypad

When operating the keypad, please observe the following:

Press your finger (covering as large an area as possible) gently in the center of the relevant key

field

The keypad does not react to fingernails, gloves or just fingertips

5.5 Typical Maximum Reading Distance

5.5.1 Reading and Writing Distance with Direct Mounting on Metal

If the registration unit is mounted directly on a metallic surface, the reading and writing distance is

approx. 10% smaller than an RFID neutral environment (wood, masonry).

24 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Kaba Registration 90 02 / Kone Registration 90 02

Rear Panel / Spacer Frame:

Material

PC-ABS GF10

Frame:

Material

PC-ABS

Front:

Material

ESG float glass

Dimensions:

With rear panel (concealed cable mounting)

88.5 x 88.5 x 19.4 mm (length x width x height)

With spacer frame (surface cable mounting)

88.5 x 88.5 x 26.4mm (length x width x height)

Protection Type IEC 60529

IP54;

Only with concealed cable mounting and sealing

pad

Temperature Range

- 25° - +70°C (operation)

- 40° - +85°C (storage)

Ambient Conditions

Relative humidity

0% - 95% non condensing

Application

Concealed cable mounting with real panel

Surface cable mounting with spacer frame

Mounting possible directly on metal or neutral

subsurface

Coaxial cable

Recommended: RG 174/U, 50 Ohm

Supplier: Huber + Suhner

max. lenght 30 m

Power supply

The registration unit is powerd by the host

control device

Notice:

The device may only be supplied with SELV (Safety

Extra Low Voltage) and LPS (Limited Power Source),

according to IEC/UL/CSA 60950-1.

5.6 Technical Data

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 25

Kaba Registration 90 02 / Kone Registration 90 02

1. Insert a screwdriver (no. 1) into the bottom of the opening and press it

upwards.The quick-release lock opens up.

NOTICE

The pin strip can be damaged. Observe the following instructions.

2. Slightly raise the bottom of the PIN keypad (max. 10º).

3. Pull the PIN keypad forwards in a parallel position.

5.7 Dismantling

5.7.1 Accessories

Rear panel SL for concealed cable mounting

Spacer frame SL for surface cable mounting

Sealing pad, black

5.8 Conformity

See Chapter 8.

26 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Kaba Registration 90 00 / Kone registration unit PCB

The registration unit 9, together with the control

unit, represents a fully-integrated solution for

access control with simultaneous convenient

identification of the user. The registration unit is

suitable for mounting in on-site assortment of

switches or sockets or in customer-specific

solutions. The new antenna design observes

sufficient distance to the environment and is

therefore also suitable for mounting in a metallic

environment. Owing to the simple cabling,

installation costs are very low.

This registration unit can be simply integrated in

current European standard installation sockets

(size I). The thread insert with thread M3 is

suitable for the mounting of various European

covers.

Suitable Housing / Covers

See Accessories

To ensure the visibility of the LED, the cover in

the area of the LED must have a drill hole of

Ø 5.2 mm.

NOTICE

Notice:

The device may only be supplied with SELV (Safety Extra Low Voltage) and LPS (Limited Power Source),

according to IEC/UL/CSA 60950-1.

Terminal

Meaning

Control Unit

S

Antenna cable shield wire

AS

+

Antenna cable inner

conductor

A+

6 Kaba Registration 90 00 / Kone registration unit PCB

6.1 Product description

6.2 Mounting and Connection

6.2.1 Mounting and Connection

Connecting the Coaxial Cable

6.2.2 LED

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 27

The registration unit 90 00 is equipped with a 2-color, red/green LED. To ensure the visibility of the

LED, the cover in the area of the LED must have a drill hole of Ø 5.2 mm, where you would like visual

as well as acoustic signaling.

The LED is mechanically compatible with registration unit LA-PB solutions

Kaba Registration 90 00 / Kone registration unit PCB

1 = Badge, ISO 14443A

2 = Key fob, ISO 14443A

3 = Badge, LEGIC RF

4 = Badge, ISO 15693

5 = Kaba elolegic smart key, LEGIC RF

Dimensions

70 x 70 x ~13 mm (length x width x height)

Temperature Range

- 25° - +70°C (operation)

- 40° - +85°C (storage)

Ambient Conditions

Relative humidity

0% - 95%, non condensing

Application

On-site assortment of switches or sockets

Coaxial cable

Recommended: RG 174/U, 50 Ohm

Supplier: Huber + Suhner

max. lenght 30 m

Power supply

The registration unit is powerd

by the host control device

Notice:

The device may only be supplied with SELV

(Safety Extra Low Voltage) and LPS (Limited

Power Source), according to IEC/UL/CSA 60950-

1.

Supplier

Type

Amacher

Basico

Domino

Busch-Jäger

Feller

EDIZIOdue, pluggable

NUP

Gira

E2

Event

Surface

S-Color

Standard

Jung

CD500

CD Play

ST 550

Legrand

Diplomat

Merten

6.3 Typical Maximum Reading Distance

6.3.1 Reading and Writing Distance with Direct Mounting on Metal

If the registration unit is mounted in metal facades or a metal frame, the reading and writing distance

will be approx. 10% smaller than in an RFID neutral environment (wood, masonry).

6.4 Technical Data

6.4.1 Accessories

6.5 Conformity

See Chapter 8.

28 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Dismantling and disposal

Dispose of packaging in an environmentally responsible manner.

The packaging materials are recyclable. Do not throw the packaging away with domestic waste;

instead, send it for recycling.

NOTICE

Before disposal, the system/device must be put out of operation by the sales partner (see Chapter 7.1,

page 29).

This product meets the requirements of the WEEE Directive and, in accordance with DIN standard

EN 50419, is labeled with the WEEE crossed-out trash can symbol (see Chapter 12.1.6, page 106).

This symbol indicates the separate disposal of electrical and electronic equipment in EU countries.

Do not dispose of electrical devices with general waste

Used devices contain valuable recyclable materials which must be recycled. Used devices should

therefore be disposed of via the collection system used in your country.

Disposal in Germany:

After use, Kaba GmbH undertakes to carry out the proper disposal of the supplied goods in line with

legal requirements (the ElektroG law in Germany). All costs incurred for the transport of goods to the

manufacturer's plant will be paid by the owner of the used electronic equipment.

Disposal in Switzerland:

Send the device to an electronic equipment collection facility. Contact the local authorities for further

information.

Disposal in Austria:

Do not throw the device out with household waste. Dispose of the device and used batteries in

accordance with the Act on Disposal of Waste Electrical and Electronic Equipment (Verordnung über

Entsorgung von Elektro- und Elektronik-Altgeräten – VREG/WEEE) at a local collection point for

waste electronic equipment.

RoHS

This device fulfills the requirements of Guideline 2011/65/EU of the European Parliament and

Council of June 8, 2011, to limit the use of certain hazardous materials in electrical and electronic

equipment.

7 Dismantling and disposal

7.1 Dismantling / Put out of operation

To dismantle the device in an access control system, proceed as follows:

1. During online operation: Check the configuration of the host system

2. Dismantle the device, see chapters Dismantling

7.2 Disposal

7.2.1 Disposing of packaging

7.2.2 Disposing of the device

Old devices contain valuable recyclable materials which should be recovered.

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 29

Conformity

FCC- and IC- tested

registration units

FCC

IC

Kone regsitration unit PCB

Tested Standard:

FCC Code of Federal

Regulations, CFR 47, Part

15, Sections 15.205, 15.207,

15.215 and 15.225

Tested Standard:

Industry Canada Radio Standards

Specifications

RSS-GEN Issue 4, Sections 8.8,

8.9 and 8.10 and

RSS-210 Issue 8, Section A2.6

(Category I Equipment)

Kaba registration unit 90 00

Kaba registration unit 90 01 /

Kone registration unit 90 01

Kaba registration unit 90 02 /

Kone registration unit 90 02

The registration unit conforms to the following standards:

EN 60950-1:2006/A2:2013

Notice:

The device may only be supplied with SELV (Safety Extra Low

Voltage) and LPS (Limited Power Source), according to IEC/UL/CSA

60950-1.

UL 60950-1:2007/R:2014-10

CAN/CSA-C22.2 No. 609501:2007/A2:2014-10

EN 300 330-1 V1.7.1

EN 300 330-2 V1.5.1

In accordance with the provisions of EC directive:

1999/5/EG

Radio and Telecommunications Terminal Equipment

Directive (R&TTE).

FCC

Tested Standard:

FCC Code of Federal Regulations, CFR 47, Part 15, Sections 15.205, 15.207, 15.215 and 15.225

FCC § 15.19

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

.

FCC § 15.21 (Warning Statement)

[Any] changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

FCC § 15.105

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense..

IC

(Industry

Canada)

Tested Standard:

Industry Canada Radio Standards Specifications

RSS-GEN Issue 4, Sections 8.8, 8.9 and 8.10 and

RSS-210 Issue 8, Section A2.6 (Category I Equipment)

8 Conformity

8.1 FCC- and IC- tested registration units

8.2 Conformity Kone Registration Unit PCB

30 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Conformity

ICES-003

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Canada RSS-GEN 8.4

This device complies with Industry Canada’s licence-exempt RSSs. Operation is subject to the following two

conditions:

(1) This device may not cause interference; and

(2) This device must accept any interference, including interference that may cause undesired operation of the

device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux conditions suivantes :

1) l’appareil ne doit pas produire de brouillage;

2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

RoHS

This device fulfills the requirements of Guideline 2011/65/EU of the European Parliament and

Council of June 8, 2011, to limit the use of certain hazardous materials in electrical and electronic

equipment.

The registration unit conforms to the following standards:

EN 60950-1:2006/A2:2013

Notice:

The device may only be supplied with SELV (Safety Extra Low

Voltage) and LPS (Limited Power Source), according to IEC/UL/CSA

60950-1.

UL 60950-1:2007/R:2014-10

CAN/CSA-C22.2 No. 609501:2007/A2:2014-10

EN 300 330-1 V1.7.1

EN 300 330-2 V1.5.1

In accordance with the provisions of EC directive:

1999/5/EG

Radio and Telecommunications Terminal Equipment

Directive (R&TTE).

FCC

Tested Standard:

FCC Code of Federal Regulations, CFR 47, Part 15, Sections 15.205, 15.207, 15.215 and 15.225

FCC § 15.19

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

FCC § 15.21 (Warning Statement)

[Any] changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

FCC § 15.105

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

8.3 Conformity Kaba Registration Unit 90 00

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 31

Conformity

IC

(Industry

Canada)

Tested Standard:

Industry Canada Radio Standards Specifications

RSS-GEN Issue 4, Sections 8.8, 8.9 and 8.10 and

RSS-210 Issue 8, Section A2.6 (Category I Equipment)

ICES-003

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Canada RSS-GEN 8.4

This device complies with Industry Canada’s licence-exempt RSSs. Operation is subject to the following two

conditions:

(1) This device may not cause interference; and

(2) This device must accept any interference, including interference that may cause undesired operation of the

device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux conditions suivantes :

1) l’appareil ne doit pas produire de brouillage;

2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

RoHS

This device fulfills the requirements of Guideline 2011/65/EU of the European Parliament and

Council of June 8, 2011, to limit the use of certain hazardous materials in electrical and electronic

equipment.

The registration unit conforms to the following standards:

EN 60950-1:2006/A2:2013

Notice:

The device may only be supplied with SELV (Safety Extra Low

Voltage) and LPS (Limited Power Source), according to IEC/UL/CSA

60950-1.

UL 60950-1:2007/R:2014-10

CAN/CSA-C22.2 No. 609501:2007/A2:2014-10

EN 300 330-1 V1.7.1

EN 300 330-2 V1.5.1

In accordance with the provisions of EC directive:

1999/5/EG

Radio and Telecommunications Terminal Equipment

Directive (R&TTE).

FCC

Tested Standard:

FCC Code of Federal Regulations, CFR 47, Part 15, Sections 15.205, 15.207, 15.215 and 15.225

FCC § 15.19

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

FCC § 15.21 (Warning Statement)

[Any] changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

FCC § 15.105

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference

8.4 Conformity Kaba Registration Unit 90 01 / Kone Registration Unit 90 01

32 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Conformity

to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

IC

(Industry

Canada)

Tested Standard:

Industry Canada Radio Standards Specifications

RSS-GEN Issue 4, Sections 8.8, 8.9 and 8.10 and

RSS-210 Issue 8, Section A2.6 (Category I Equipment)

ICES-003

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Canada RSS-GEN 8.4

This device complies with Industry Canada’s licence-exempt RSSs. Operation is subject to the following two

conditions:

(1) This device may not cause interference; and

(2) This device must accept any interference, including interference that may cause undesired operation of the

device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux conditions suivantes :

1) l’appareil ne doit pas produire de brouillage;

2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

RoHS

This device fulfills the requirements of Guideline 2011/65/EU of the European Parliament and

Council of June 8, 2011, to limit the use of certain hazardous materials in electrical and electronic

equipment.

The registration unit conforms to the following standards:

EN 60950-1:2006/A2:2013

Notice:

The device may only be supplied with SELV (Safety Extra Low

Voltage) and LPS (Limited Power Source), according to IEC/UL/CSA

60950-1.

UL 60950-1:2007/R:2014-10

CAN/CSA-C22.2 No. 609501:2007/A2:2014-10

EN 300 330-1 V1.7.1

EN 300 330-2 V1.5.1

In accordance with the provisions of EC directive:

1999/5/EG

Radio and Telecommunications Terminal Equipment

Directive (R&TTE).

FCC

Tested Standard:

FCC Code of Federal Regulations, CFR 47, Part 15, Sections 15.205, 15.207, 15.215 and 15.225

FCC § 15.19

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

FCC § 15.21 (Warning Statement)

Any] changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

FCC § 15.105

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference

8.5 Conformity Kaba Registration Unit 90 02 / Kone Registration Unit 90 02

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 33

Conformity

to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

IC

(Industry

Canada)

Tested Standard:

Industry Canada Radio Standards Specifications

RSS-GEN Issue 4, Sections 8.8, 8.9 and 8.10 and

RSS-210 Issue 8, Section A2.6 (Category I Equipment)

ICES-003

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada..

Canada RSS-GEN 8.4

This device complies with Industry Canada’s licence-exempt RSSs. Operation is subject to the following two

conditions:

(1) This device may not cause interference; and

(2) This device must accept any interference, including interference that may cause undesired operation of the

device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux conditions suivantes :

1) l’appareil ne doit pas produire de brouillage;

2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

RoHS

This device fulfills the requirements of Guideline 2011/65/EU of the European Parliament and

Council of June 8, 2011, to limit the use of certain hazardous materials in electrical and electronic

equipment.

34 TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx

Conformity

8.6 Declaration of conformity

Kaba GmbH, Access & Workforce Management, Albertistrasse 3, D-78056 Villingen-Schwenningen

hereby declares as the manufacturer of the device that the Compact Readers conform to the

fundamental requirements and other relevant stipulations of Directive 1999/5/EC (R&TTE).

The original declaration of conformity is available at

http://www.kaba.com/access-control/de/Sales-Support/81668/downloads.html?cat=355024

and can be downloaded in PDF format at any time.

8.7 Device mark

The following information can be found on the label:

Device designation

Article number

Serial number

Manufacturer

CE mark

WEEE labeling in accordance with DIN EN 50419

8.8 Manufacturer

Kaba GmbH

Access & Workforce Management

Albertistrasse 3

78056 Villingen-Schwenningen

Germany

Phone +49 7720 603 0

E-mail: awm.info@kaba.com

http://www.kaba.com

TM_ RegistrationUnits_201604_en KONE US CAN IN ARBEIT.docx 35

Loading...

Loading...