B-Net® 91 04

Manual

12/2008

© Copyright by

Kaba GmbH

Albertistraße 3

D-78056 Villingen-Schwenningen

Phone +49 7720/603-0

Fax +49 7720/603-102

info@kbs.kaba.com

www.kaba.com/workforce-management

All rights reserved. The document and its parts are copyrighted. Only Kaba GmbH has the right to

commercialize, market and distribute this document. This document, or any part of it, may not be copied

or reproduced, adapted, arranged, reworked or modified without the prior consent of Kaba GmbH.

All company, trademark or product names are trademarks or registered trademarks of their respective

owners and are protected.

Subject to technical changes without notice!

Order no. 04038521

1 About this Manual...................................................................................................................5

2 Safety Regulations..................................................................................................................6

2.1 Use as directed...............................................................................................................6

2.2 General Remarks............................................................................................................6

2.3 Installation Instructions...................................................................................................6

2.4 ESD (Electro Static Discharge) Protective Measures ....................................................7

3 Product Description................................................................................................................8

3.1 Technical data ................................................................................................................9

3.2 Conformity ....................................................................................................................10

3.3 Labeling ........................................................................................................................10

4 Design and Function ............................................................................................................11

4.1 Models / Delivery volume..............................................................................................11

4.2 Input possibilities ..........................................................................................................12

4.3 Hardware equipment ....................................................................................................12

4.3.1 LED...................................................................................................................12

4.3.2 Acoustic signal generator.................................................................................12

4.3.3 Digital outputs...................................................................................................12

4.4 Operating Modes..........................................................................................................13

4.4.1 Online mode.....................................................................................................13

4.4.2 Stand-alone operation......................................................................................13

5 Mounting and Installation ....................................................................................................14

5.1 Installation Conditions...................................................................................................14

5.2 Installation Diagram......................................................................................................16

5.3 Installation Lines...........................................................................................................18

5.4 Mounting.......................................................................................................................19

5.5 Installation of devices with connecting cable................................................................20

5.6 Installation of devices with connecting panel................................................................20

5.7 Pin assignment.............................................................................................................21

5.8 Description of connections............................................................................................22

5.8.1 Power Supply...................................................................................................22

5.8.2 Relay output.....................................................................................................22

5.8.3 Data interface to access control unit (subpartyline).........................................22

5.9 DIP-Switch....................................................................................................................23

5.9.1 Required DIP switch settings in different operating modes .............................24

5.10 Final assembly..............................................................................................................25

6 Start-Up..................................................................................................................................26

6.1 Online mode .................................................................................................................27

6.1 Stand-alone operation ..................................................................................................28

6.2 Cold start.......................................................................................................................29

6.3 Status LED....................................................................................................................29

6.4 Adjusting the reader......................................................................................................30

7 System mode.........................................................................................................................31

7.1 Commands ...................................................................................................................32

7.1.1 SETHWC..........................................................................................................33

7.1.2 GETHWC .........................................................................................................36

7.1.3 GETPRG..........................................................................................................37

7.1.4 LOWPAR..........................................................................................................38

7.1.5 RUN..................................................................................................................40

7.1.6 ORIGIN.............................................................................................................40

7.1.7 GETDGN..........................................................................................................41

7.1.8 RSTDGN..........................................................................................................41

8 Description of the Subpartyline...........................................................................................42

8.1 BPA Subset ..................................................................................................................42

8.2 Addressing....................................................................................................................42

8.3 Control Characters and Control Sequences.................................................................43

8.4 Data Records................................................................................................................43

8.5 Data from Subterminal to Control Unit..........................................................................44

8.6 Data from the Control Unit to the Subterminal..............................................................45

8.7 Escape sequences .......................................................................................................46

8.7.1 Controlling LED, relay and beeper...................................................................46

8.7.2 Reset................................................................................................................46

8.7.3 Device configuration.........................................................................................47

8.7.4 Program number ..............................................................................................47

8.7.5 Recorded data..................................................................................................48

8.7.6 Hex Representation of the Recorded Data......................................................48

8.7.7 Acoustic acknowledgement for reading...........................................................48

8.7.8 Customer number list.......................................................................................49

8.7.9 Control stand-alone operation..........................................................................51

8.8 ASCII Table ..................................................................................................................52

9 Packaging / Returns .............................................................................................................53

9.1 Complete Devices.........................................................................................................53

9.2 Electronic Assemblies...................................................................................................53

9.3 Labeling ........................................................................................................................54

10 Disposal.................................................................................................................................55

11 Index.......................................................................................................................................56

Manual B-Net® 91 04 About this Manual

1 About this Manual

Validity

Serial number: 072114- 000100

Creation date: November 2008

Addressees

Contents and

purpose

Orientation in

the manual

This manual describes the Kaba B-Net 91 04 subterminal as of

The manual addresses specialists for mounting, installation, set-up, servi ce, and

maintenance of the device.

The descriptions in this manual are intended for trained personnel. The information

in this manual cannot substitute a product training.

The contents are limited to the assembly, installation, set-up, and basic operation of

the hardware.

This manual contains the following orientation guide to find specific topics more

easily:

Remarks with

symbols

• The table of contents at the beginning of the manual gives an overview of all

topics.

• The header always contains the respective main chapter.

• An index in alphabetical order is at the end of the manual.

Please pay special attention to the remarks that are marked with symbols. The

symbols used in this manual have the following meaning:

NOTICE!

Important information for a proper handling of the product. Ignoring this information

can cause device malfunction.

Remark

Tips and useful information. This information will help you to best use the product

and its functionality.

12/2008 © Kaba GmbH 5

Safety Regulations Manual B-Net® 91 04

Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his own expense.

2 Safety Regulations

2.1 Use as directed

The device or system is only intended for usage as described in chapter ”Product

Description”.

Any use beyond the designated use is not according to rules. The manufacturer is

not responsible for damages resulting from improper use. The user/operator is

2.2 General Remarks

2.3 Installation Instructions

responsible for any risks associated with non-duly use.

Removal of malfunctions and maintenance may only be performed by skilled

technical specialists.

Only specialists authorized by the manufacturer may carry out reconstruction and

modification.

All reconstructions and modifications carried out by unauthorized personnel shall

render void any liability.

Only trained personnel may carry out mounting and installation.

Kaba GmbH is not liable for damages resulting from improper handling or incorrect

installation.

NOTICE!

The relay is designed for 30 V AC / DC and 1 A maximum.

For device safety reasons 120 / 230 V may not be switched with this relay.

Installation may only be carried out in places that fulfill climatic and technical

conditions stated by the manufacturer.

6 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Safety Regulations

2.4 ESD (Electro Static Discharge) Protective Measures

CAUTION

Danger for electronic components due to electrostatic discharge.

Improper handling of printed circuit boards or components can cause damages that

lead to complete failures or sporadic errors.

During installation and repair of the device, the ESD protective measures must be

considered.

Please consider the following guidelines before the installation or maintenance of

the device:

• Always carry an ESD antistatic wristband when dealing with electronic

components. Connect one part of the wristband with a discharge socket or

an unvarnished grounded metal component. This way, static charges are

discharged from your body securely and effectively.

• Only touch the printed circuit boards at the edges. Do not touch the printed

circuit board itself or the connector.

• Place all dismantled components on an anti-static surface or in an anti-static

container.

• Avoid contact between printed circuit boards and your clothing. The

wristband only protects the printed circuit boards against electrostatic

discharge from the body, but there is still a risk of damage through

electrostatic discharge from your clothing.

• Only transport and dispatch dismantled modules in protective bags.

12/2008 © Kaba GmbH 7

Product Description Manual B-Net® 91 04

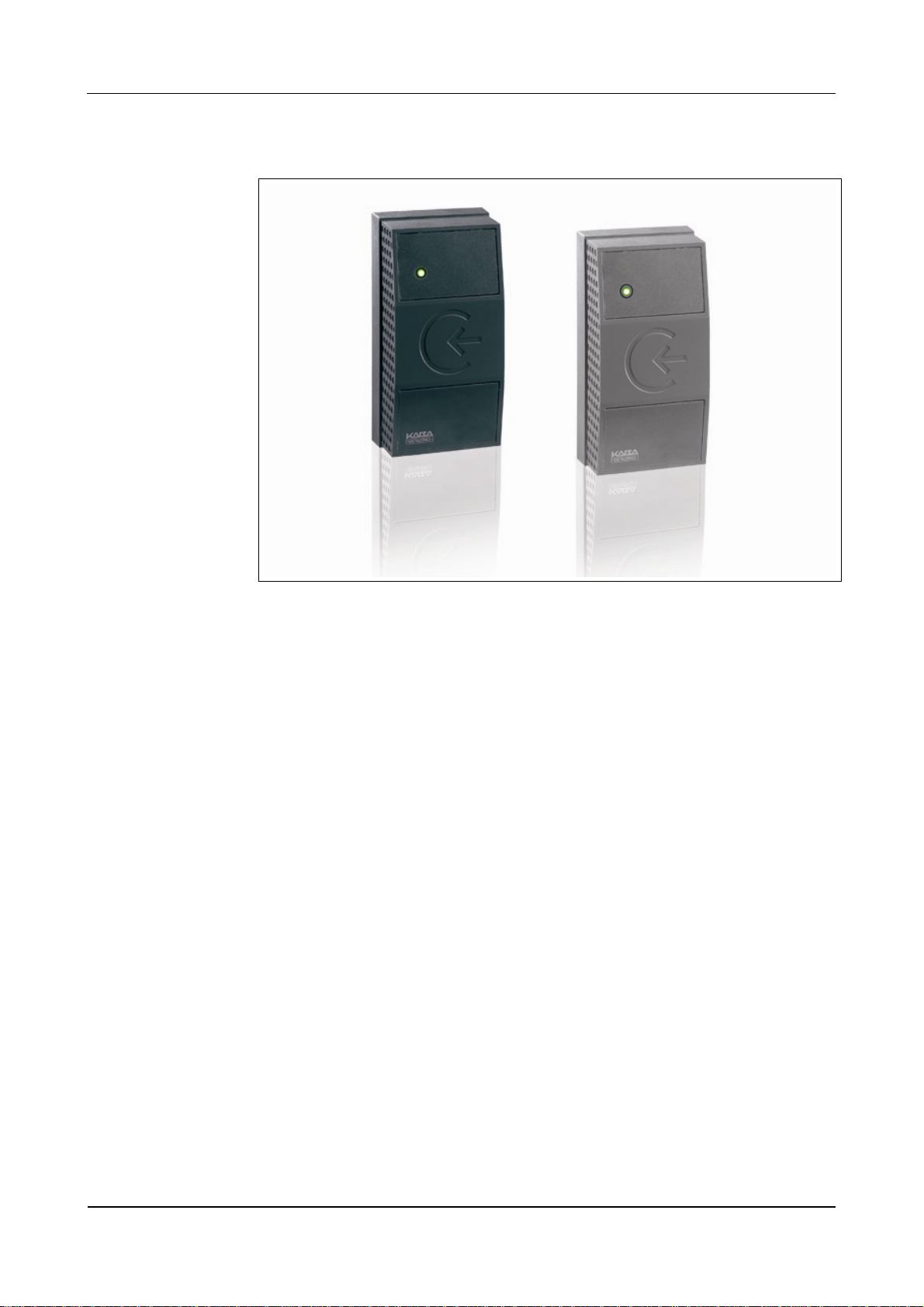

3 Product Description

Fig. 1: Subterminal B-Net 91 04, colors anthracite and grey aluminum

B-Net 91 04 is a subterminal to be used for access control. It is compatible with the

terminal series Bedas / Bedanet 90 00.

The reader is in a sealed plastic housing and also designed for use under rough

environmental conditions. Its compact design allows for installation on door frames

or similar surfaces.

The following operating modes are possible:

• Online mode

The B-Net 91 04 is connected to a higher-level control system, for example

an access manager or a terminal of the B-Net series, by means of the RS485 sub-party line.

• Stand-alone operation without control

The B-Net 91 04 subterminal includes the LEGIC® contact-free identification

medium. The reader is equipped with LEGIC® advant-RFID technology. LEGIC®

data carriers can be read. Writing data on the LEGIC® medium also is possible.

B-Net 91 04 has a relay which can be used for door opening in secured areas.

The subterminal has a multi-color LED and a beeper for optical and acou stic user

guidance.

8 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Product Description

3.1 Technical data Power supply

• Operating voltage: 12 – 32 V DC / 16 – 27 V AC

Interface

Output

Readers

Data retention in

case of power failure

Environmental

conditions

• Current

max. 150 mA at 24 V

consumption:

• RS-485 2-wire subpartyline

Protocol: BPA9; transmission parameters: 9600/19200 baud, 7 data bits, parity

even, 1 stop bit

Other settings via system mode are possible.

• 1 relay output, contact load 30 V AC/DC, max. 1 A

• LEGIC® reader

Reading and writing of LEGIC® media.

• Modified parameters, list of badges, etc. are stored in non-volatile memory

(EEPROM) and are retained when a power failure occurs.

• Protection class according

to IEC 60529:

IP66 with connecting cable

IP54 with terminal board

• Environmental temperature: - 25° C - + 55° C

Environmental class: 4

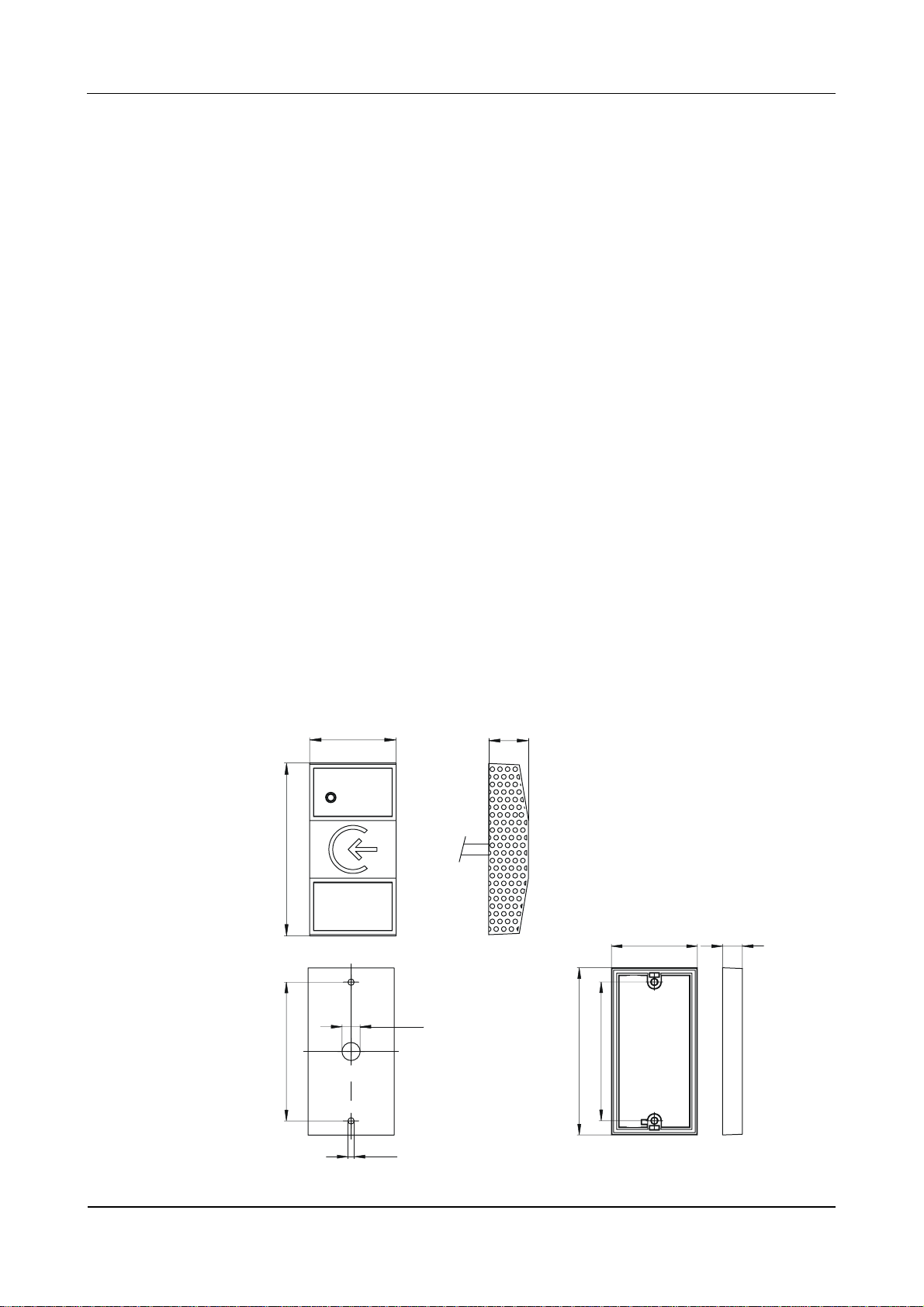

Dimensions

Dimensions in mm

• National Electrical Manufacturers Association (NEMA) 4

45

21

90

Ø10

77

93

77

48 11

Ø3,5

12/2008 © Kaba GmbH 9

Product Description Manual B-Net® 91 04

3.2 Conformity

This device complies with the standards

EN 60950-1 2003

EN 301 489-3 V1.4.1

EN 300 330-2 V1.1.1

according to the regulations of the EU Directives

1999/5/EC

R&TTE Directive

To the best of our knowledge, this device does not contain any substances in

concentration or application, whose introduction in products is permitted according

to the requirements of the 2002/95/EC directive released by the European Union

("RoHS" = Restriction of Hazardous Substances).

3.3 Labeling

The identification plate is located on the rear of the device.

Specified on the identification plate:

• Device name

• Product number

• Serial number

• Power data

• CE identification

• WEEE specification according to DIN EN 50419, please refer to chapter

10

10 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Design and Function

4 Design and Function

4.1 Models / Delivery volume

The device can be delivered in two versions:

• With 3.5 mm connecting cable (standard)

• With terminal board without connecting cable (optional)

The connecting frame provides additional room for cable storage, if needed, and

possesses a predefined location of rupture for cable outlet for surface mounting.

The connecting frame is always part of the delivery.

In addition, the delivery comprises a bag with installation accessories, consisting of

a 6 cm insulating tube and 9 butt connectors for extending the connecting cable.

Upper and lower front panel (cover) are attached unpacked.

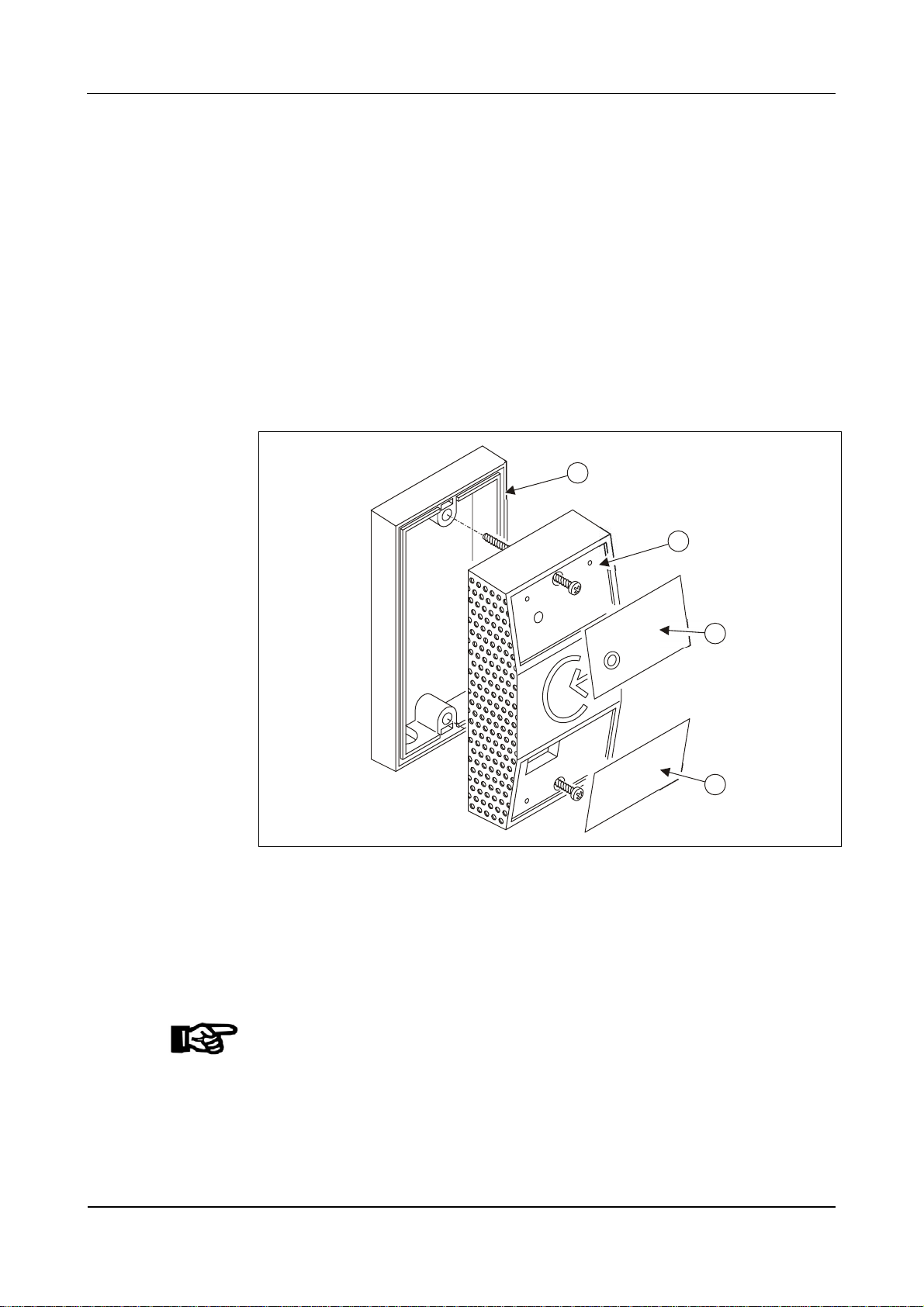

1

2

3

4

Fig. 2: Parts view

1 Terminal frame

2 B-Net 91 04

3 Upper front panel

4 Lower front panel

NOTICE!

Please stick on front plates after setting into operation and test of function.

12/2008 © Kaba GmbH 11

Design and Function Manual B-Net® 91 04

4.2 Input possibilities

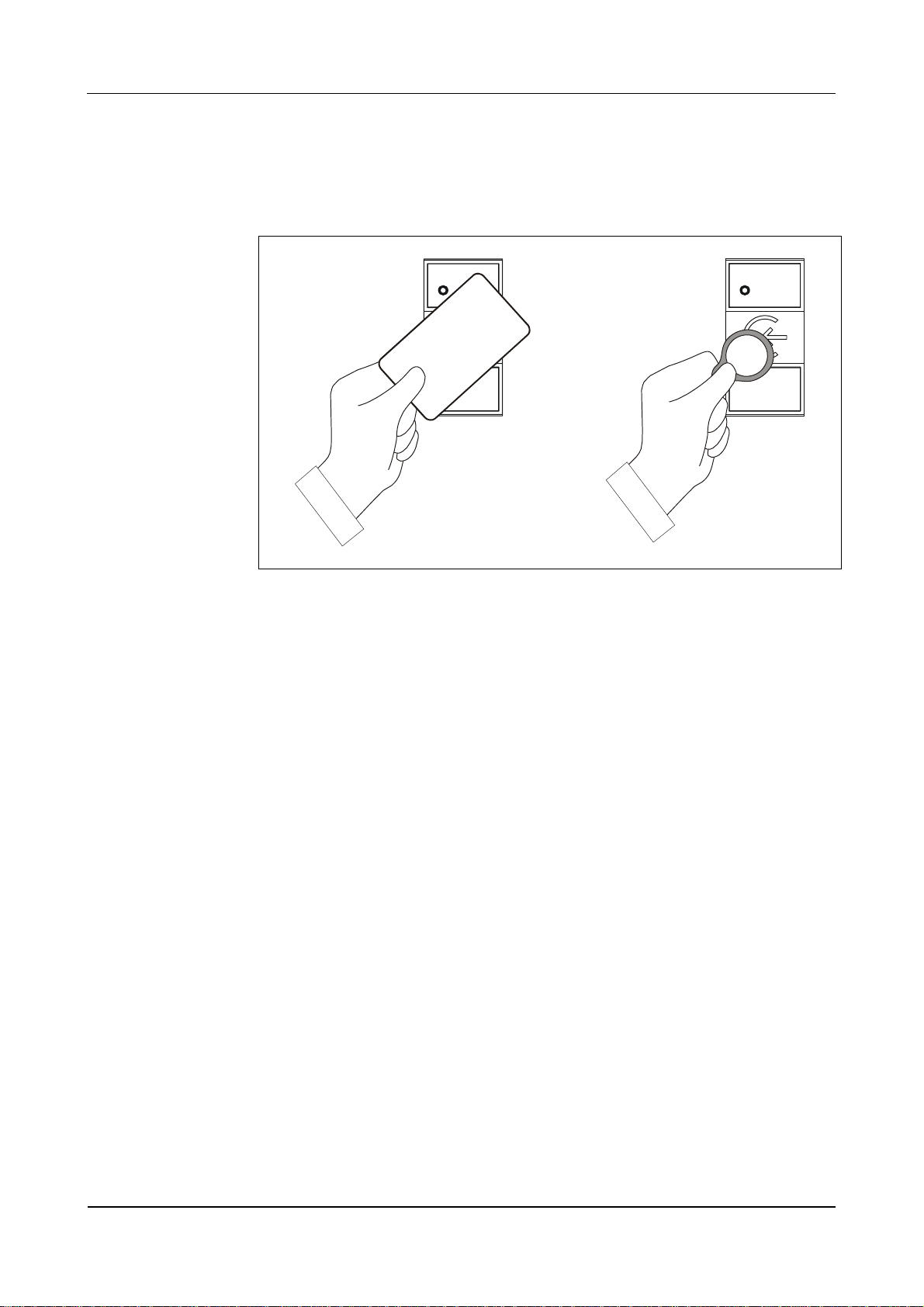

LEGIC® media, such as badges, key tags, smartkeys, etc., can be read. The

LEGIC® medium is positioned in front of the subterminal.

Fig. 3: Entry of LEGIC® media

The reading distance depends on the environmental conditions and the type of

LEGIC®.

• The range of a LEGIC® badge is 5 cm.

• The range of a LEGIC® key tag is approx. 2.5 cm.

4.3 Hardware equipment

4.3.1 LED

For optical user guidance, the subterminal is equipped with a two-color LED (red

and green).

The LED is directly activated by B-Net 91 04 depending on the operating mode or

by corresponding commands from the control unit.

4.3.2 Acoustic signal generato r

The subterminal has a beeper for acoustically signalizing certain states. The

beeper is directly activated by B-Net 91 04 depending on the operating mode or by

corresponding commands from the control unit.

4.3.3 Digital outputs

The B-Net 91 04 has one relay. The name of the relay is R1.

In stand-alone mode, this relay is used for the door opener.

In online operation, the relay may be activated by the corresponding commands

from the access control unit, e.g. door opening in secured areas.

12 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Design and Function

4.4 Operating Modes

4.4.1 Online mode

In online operation, the device works as subterminal of an access control.

The device can be connected to access control units of the device families Bedas,

Bedanet and B-Net, such as B-Net 92 50, Bedanet 92 90, or a time recording

terminal of the B-Net series.

One or several subterminals are connected to the control unit by means of the

RS-485 subpartyline. The subterminal is operated in the polling mode. The control

unit polls the connected subterminals one after the other in order to send or receive

data.

If a badge is presented, the badge data is sent to the control unit. The control unit

decides whether a badge is authorized or not and sends the respective commands

for LED, beeper and relay back to the subterminal. The internal relay should only be

used in secure areas for opening a door. Therefore, the control unit generally

controls and opens the door.

Remark

On delivery, online operation is preset in the subterminal.

4.4.2 Stand-alone operation NOTICE!

Stand-alone operation may only be used together with LEGIC® prime media (media

with existing data structure).

In stand-alone operation, the device works independently without connected

control unit. A customer number list stored in the device allows for the verification

check of every booking. LED, beeper and relay are activated accordingly.

A service PC and a parameter setting tool are required for set-up. The customer

number list is transmitted via the RS-485 subpartyline. After activating the standalone operation, the service PC is removed again.

A customer number list can contain up to 5 entries. One individual entry may be a

customer number or a complete badge number. If, for examples, the authorization

is given to all employees of a company, the customer number must be stored. If

the authorization is given to individual employees, the complete badge number

(customer number + ID) must be stored.

The green LED is lighted during operation. When a badge is presented, the badge

data is read and checked. If the verification is positive, the relay is activated for 3

seconds (default). A successful booking is confirmed by means of a 1-second

acoustic signal. After an invalid booking, the red LED and the beeper are activated

alternately for 3 seconds.

12/2008 © Kaba GmbH 13

Mounting and Installation Manual B-Net® 91 04

m

5 Mounting and Installation

5.1 Installation Conditions

Installation site

Connectors

General

Grounding

An accurate installation of all components is a basic requirement for proper

functioning. The following installation instructions must be adhered to.

The device can be mounted either directly on the wall or on a door frame.

For cable outlet, a drilling of approx. 10 mm diameter is required. An edge which

might be produced must be trimmed.

A screw guide is positioned in the middle of the housing’s top and bottom. Use only

the screws included in the delivery for fastening the device.

The following connectors must be prearranged at the installation site of the device.

• Power supply

• Data line for access control unit (online operation only)

• Cables to the door opener (if required)

The terminal must

be grounded!

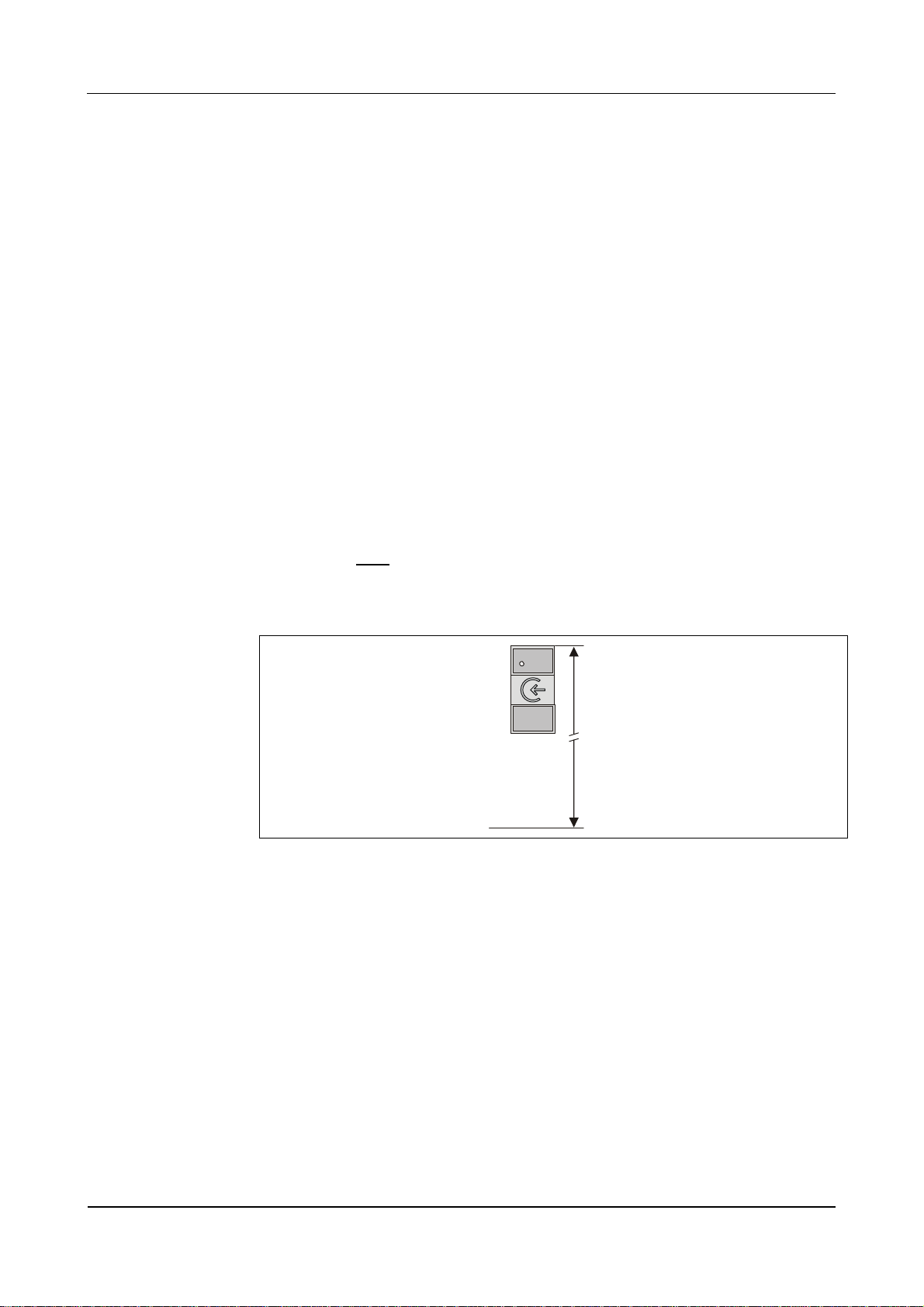

Mounting height

Electromagnetic

fields

To guarantee the highest possible noise immunity according to EMC, the ground

wire must be led to the terminal and connected.

140 c

Fig. 4: Recommended mounting height 140 cm to top edge of terminal.

The terminal must not be installed in the area of strong electromagnetic fields,

caused by e.g. switching power supply, power lines, phase controllers, etc.!

Electromagnetic fields can affect the reading power or cause failures, in particular

with contact-free readers (LEGIC, Mifare).

14 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Mounting and Installation

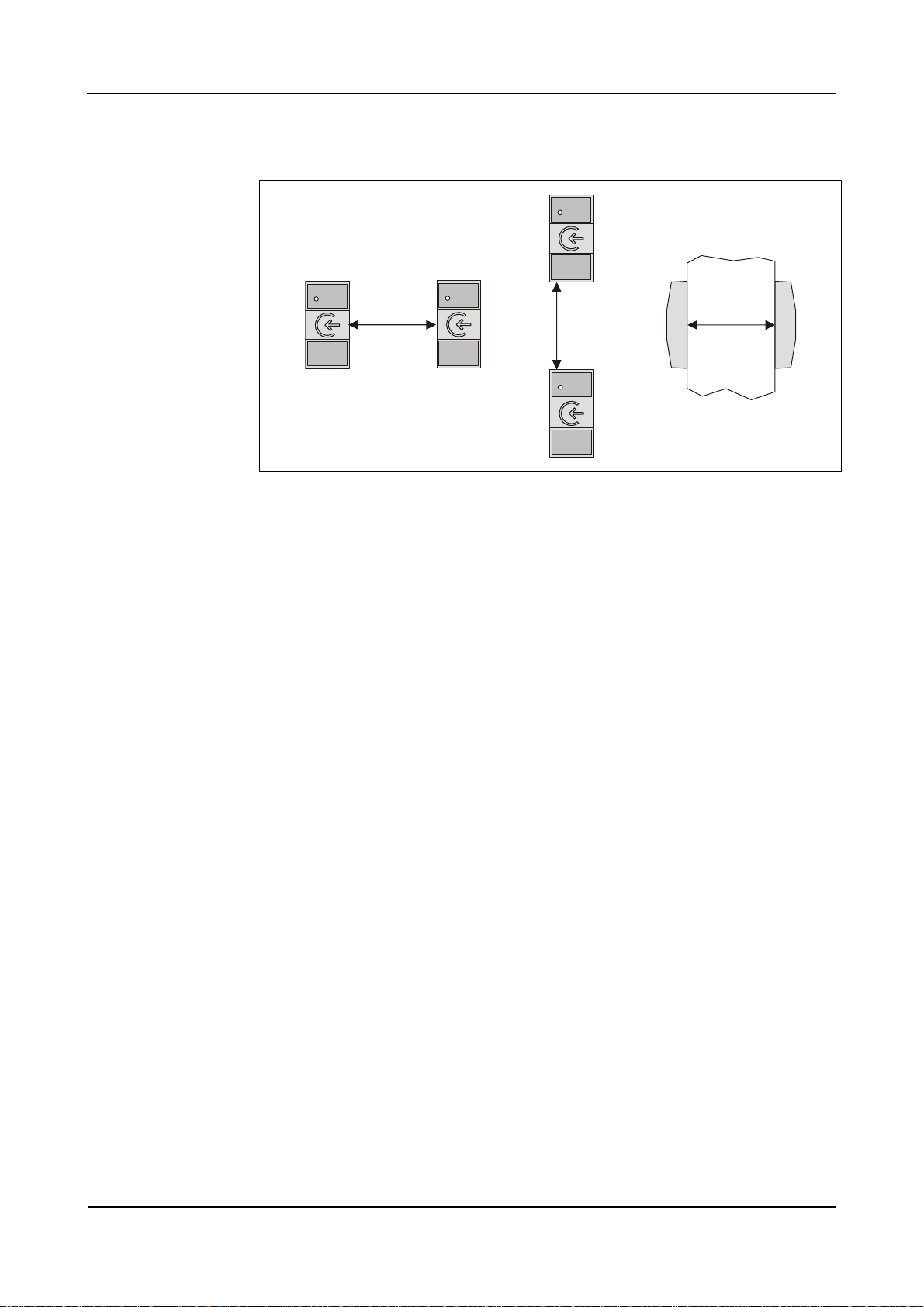

Clearances

Between two B-Net 91 04 devices, a distance of 20 cm must be observed on all

sides.

min. 20 cm

min. 20 cm

min. 20 cm

Fig. 5: Minimum distance between devices with LEGIC® readers.

To steel parts, a distance of 10 cm must be observed on all sides. If this distance is

not observed, the reading quality is impaired. Then, the maximum reading distance

is not achieved. Problems may appear with different LEGIC® media.

The terminals frame included in the delivery must be used for mounting the device

on metal surfaces.

The terminal frame increases the distance between reader and metal surface thus

reducing damping by the metal.

12/2008 © Kaba GmbH 15

Mounting and Installation Manual B-Net® 91 04

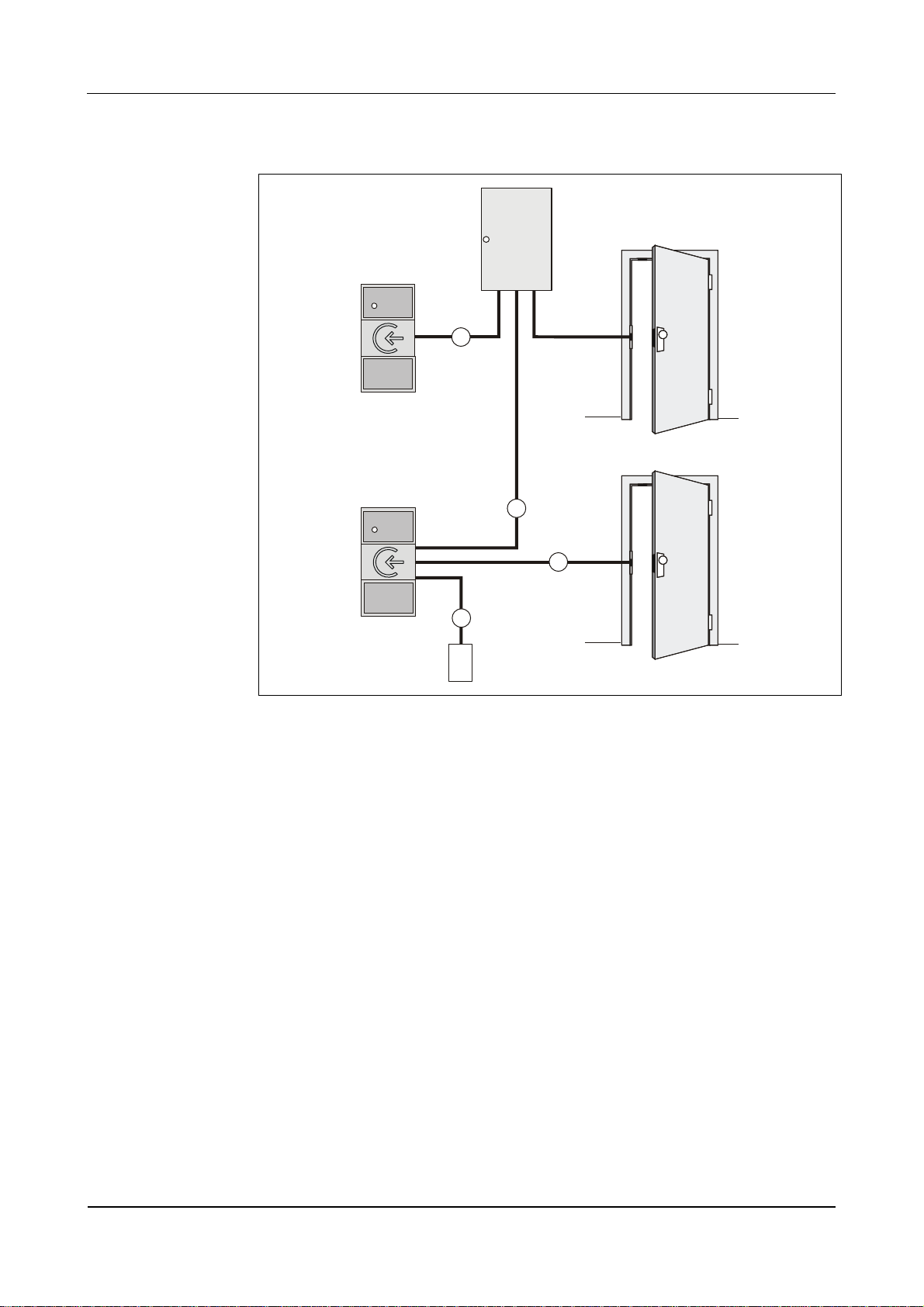

5.2 Installation Diagram

1

2

A

3

A

B

C

4

Fig. 6: B-Net 91 04 installation in online operation

1 Access Control Unit

2 B-Net 91 04

5

5

Power is supplied via the access control unit. The power supply is also led

through the data line (A). This is permitted for cable lengths up to 20 m.

The door opener is led to the access control unit.

3 Subterminal B-Net 91 04 with separate power supply (4).

The door opener is connected to the subterminal. This is only recommended,

however, in secure areas.

4 Power supply SV 100, SV 900 or SV 905 with supply for door opener

5 Door opener

Installation Lines

A Data line (subpartyline)

B Line to door opener

C Power supply and grounding

16 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Mounting and Installation

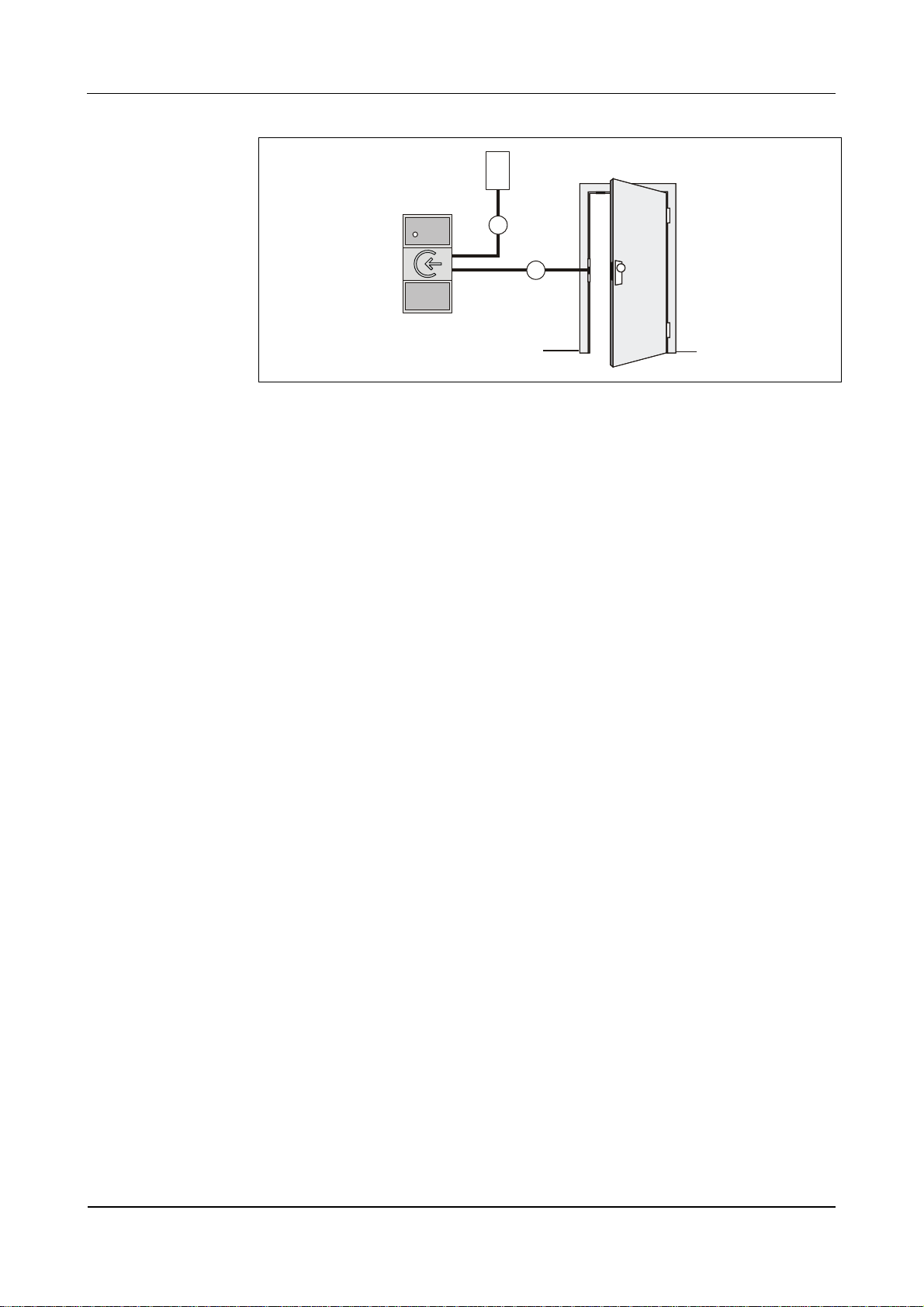

2

1

C

B

3

Fig. 7: B-Net 91 04 installation in stand-alone operation

1 Subterminal B-Net 91 04

2 Power supply SV 100, SV 900 or SV 905 with supply for door opener

3 Door opener

Installation Lines

B Line to door opener

C Power supply and grounding

12/2008 © Kaba GmbH 17

Mounting and Installation Manual B-Net® 91 04

5.3 Installation Lines (A) Data line to subterminal

The subterminals are connected to the control unit via a 2-wire subpartyline. It can

be designed in star-shape or as partyline.

NOTICE!

The shielding of the data line is generally connected on both sides.

The complete bus connection (master lines and branch lines) may be up to 2,000

meters long. One branch line may not exceed 100 m.

For short distances (up to 20 meters max.), it is permitted to have the operating

voltage for the subterminal and the data line in one single cable. In this case, the

subterminal is grounded via the shield of the data line.

For line lengths over 20 m, a separate power supply cable (C) must be provided for

the subterminal.

Line requirements:

Shielded line with twisted wire pairs,

cable diameter 0.4 mm to 0.6 mm

for instance standard telephone cable J-Y (St) Y 2 x 2 x 0.6 mm.

Recommended cable:

CAT.5 S-UTP 4 x 2 AWG 24 or AWG 22 (according to EIA/TIA568).

(B) Line to the door opener

Line requirements:

Cables with a cable diameter from 0.5 mm to 0.8 mm can be used.

Recommended cable:

CAT.5 S-UTP 4 x 2 AWG 24 or AWG 22 (according to EIA/TIA568) or higher.

(C) Power supply and grounding

In online operation, power is supplied by the superior control unit and can be tapped

easily from there.

If the device is used without control unit or if power cannot be supplied by the

control unit, a separate supply unit, e.g. SV 100, SV 900, SV 905, must be used.

In case of long lines, the voltage drop - caused by the line resistance - must be

considered.

The ground wire must be led from the power supply to the terminal.

Cables with a cable diameter from 0.5 mm to 0.8 mm can be used.

Three wires are required for power supply + ground (SV 100 / SV 900).

If door-opener voltage is required, two further wires are needed (SV905).

18 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Mounting and Installation

5.4 Mounting

The device can be mounted either directly on the wall or on a door frame. The

terminal frame included in the delivery must be used for mounting the device on

metal surfaces.

For cable outlet, a drilling of approx. 10 mm diameter is required. A possible edge

must be trimmed.

A screw guide is positioned in the middle of the housing’s top and bottom.

In order to avoid danger of concealed or hidden cracks and tightness problem s at

the screw head, this device may only be mounted with the original screws included

in delivery.

77

Ø

3,5

Fig. 8: Hole pattern for B-Net 91 04; dimensions in mm

Ø 10

12/2008 © Kaba GmbH 19

Mounting and Installation Manual B-Net® 91 04

A

+

5.5 Installation of devices with connecting cable

For the prolongation of the cable tail or for the link to an already mounted data

cable, appropriate butt connectors are attached.

Possible wire and/or stranded wire dimensions are AWG 26-22 (D:0,4-0,65,

A:0,13-0,36) The butt connectors must be fastened offset on the cable to allow

introducing the connecting position into an empty tube or through a bore hole into

the door frame. In case the butt connectors cannot be used, the attached

connecting frame can be used as place for cable joint and/or cable storage room.

The different stranded wires in the cable tail have different colors.

The butt connectors can be joined with the stranded wires with a standard crimpin g

plier.

5.6 Installation of devices with connecting panel

As an option, the B-Net 91 04 terminal can be delivered with a connecting panel.

The terminal board is located on the back side of the device.

The connecting clamps can be drawn from the connecting panel in order to render

the connecting procedure easier.

The connecting panel is available as spare part. Owing to its double plug

configuration, it can even be used if the subterminal was delivered with cable tail,

for instance, if the cross section of t he installed cable does not match with the butt

connectors.

The connecting panel is labeled with the corresponding seizure of the clamp s.

During discharge of tensile load, the shield can be directly laid up.

~

~ -

B

C

~+

ACB

~ -

Fig. 9: Terminal board

20 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Mounting and Installation

5.7 Pin assignment

The following table shows designations and assignments of clamps with regard to

wire colors.

Color Description Data

Power Supply

red AC/DC + or +

12-32 V DC or 16-27 V AC

Gray

Ground

Power consumption max. 150 mA at 24 V

blue AC/DC + or +

Relay

yellow Opener (NC)

Contact loading capacity:

green Center contact (COM)

30 V AC/DC; 1 A max.

orange Closer (NO)

Subpartyline

brown A

violet B

black C

NOTICE!

On principle, all connections have to be performed in off-circuit state.

12/2008 © Kaba GmbH 21

Mounting and Installation Manual B-Net® 91 04

5.8 Description of connections

5.8.1 Power Supply

The B-Net 91 04 subterminal can either be operated at 12 V DC or 24 V AC/DC.

The current consumption with 24 V is 150 mA at maximum.

5.8.2 Relay output

The function of the R1 relay is defined by the access control unit in online mode. In

stand-alone mode, the relay is used for the control of the door opener.

For door openers, which are supplied with direct current, a freewheeling diode

must be connected in parallel to suppress interference (in reverse-bias direction). A

varistor must be connected in parallel to AC door openers.

5.8.3 Data interface to access control unit (subpartyline)

The access control unit is connected via a 2-wire subpartyline. The subpartyline is

an RS485 bus operated in 2-wire technology.

The shielding of the data line is generally connected on both sides.

NOTICE!

Please pay attention to the correct pin assignment of the different control units.

B-Net 91 04

A

B

C

A

B-Net 92 50

B

B-Net 93 xx

Bedanet 92 90 Rack BEX105

C

B-Net 91 04

A

B

C

Bedanet 92 20

B

Bedanet 92 90

A

Bedanet 93 60

Bedas 92 90

C

Bedas 93 60

22 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Mounting and Installation

5.9 DIP-Switch

The DIP switch row is located under the lower front panel. Therefore, the switches

must be adjusted before fixing the front panel.

Remark

All switches are set to ON when delivered.

234

5678910

1

OFF

Fig. 10: DIP switch position

GID/DID

The group and device identifications (GID/DID) serve for addressing a subterminal

via the RS-485 interface. This setting is required if the device is used as a

subterminal in an access control unit.

Switch 1 2 3 4 Logical device address (DID)

on on on on 00

off on on on 01

on off on on 01

off off on on 03

on on off on 04

off on off on 05

on off off on 06

off off off on 07

on on on off 08

off on on off 09

on off on off 10

off off on off 11

on on off off 12

off on off off 13

on off off off 14

off off off off 15

Switch 5 6 7 Logical group address (GID)

on on on 00

off on on 01

on off on 01

off off on 03

on on off 04

off on off 05

on off off 06

off off off 07

12/2008 © Kaba GmbH 23

Mounting and Installation Manual B-Net® 91 04

Baud Rate

The baud rate of the RS-485 subpartyline can be set by means of switch 8.

The remaining transmission parameters are fix.

7 data bits, even parity, 1 stop bit, response control 3 seconds, operation

monitoring 3.5 seconds

Switch 8 Baud Rate

on 19200 (standard)

off 9600

BPA/9 protocol

The BPA/9 protocol can be switched off by means of switch 9.

Switch 9 BPA/9 protocol

on BPA/9 protocol (standard)

off no protocol

DIP switch

All DIP switches can be deactivated by means of switch 10. The parameters are set

in the system mode (see chapter

7) by means of the "LOWPAR" command.

Switch 10 DIP switch

on ON (standard)

off Off

5.9.1 Required DIP s witch settings in different ope rating modes

Online mode:

Switch 1 2 3 4 5 6 7 8 9 10

Device address Group address on on on

Stand-alone operation

Switch 1 2 3 4 5 6 7 8 9 10

Device address Group address on on on

24 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Mounting and Installation

5.10 Final assembly

Fasten the front foils for finishing installation.

NOTICE!

Before fixing the front foils, the device must be put into service, see chapter

6.

Fig. 11: Fixing the front foils

NOTICE!

Observe the following to avoid leaks:

• Use only new front foils with undamaged peel-off foil.

• The housing surfaces on which the foil is to be fixed must be dry, fat-free and

clean. For cleaning purposes use solvents free of any oily or greasy

substances such as n-Heptan or isopropyl alcohol.

• Press the foil down to fix it.

• The ambient temperature must be minimum +4°C.

The ambient temperature must be at least + 4°C. If the minimum processing

temperature is not of + 4°C, or if you expect the temperature to drop below

this value within the next 3 hours after bonding, do not mount the

subterminal.

12/2008 © Kaba GmbH 25

Start-Up Manual B-Net® 91 04

6 Start-Up

NOTICE!

The descriptions in chapter Set-up refer to devices with standard configuration

preset in the factory.

By default, the driver "LEGIC® prime read-only" is active. This driver is compatible

to the Bedas/Bedanet series, i.e. media with previous data structure can be read.

The stand-alone mode is only possible with standard configuration.

Other drivers can be configured in system mode, see chapter

7. These include

"LEGIC® prime read and write" or "LEGIC® advant read and write".

In this case, make sure that the access control unit supports these drivers in the

online mode.

Remark

As a standard, only those badges are accepted which have a segment containing

SSC 02 and a fixed structure of the badge data according to Kaba group header.

Non-segmented badges may have an arbitrary SSC, but must also be coded

according to Kaba group header.

It is also possible to allow badges having a different SSC and a different data field

structure if defined so in the "Customer Number List".

The customer number list can be set by the control (see chapter

PC with parameter setting tool (see chapter

6.1).

8.7.8) or a service

26 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Start-Up

6.1 Online mode Requirements

• A connection to the access control unit must exist.

• The DIP switches must have been set in accordance with the description in

chapter

5.9.

Set-up procedure

1. Provide the subterminal with power.

2. Start up the subterminal at the control unit (see the Control Unit Manual).

3. Perform a functional test.

12/2008 © Kaba GmbH 27

Start-Up Manual B-Net® 91 04

6.1 Stand-alone operation Requirements

• The connections to power supply and door opener must exist.

• The DIP switches must have been set in accordance with the description in

chapter

5.9.

• A service PC and the parameter setting tool, order number 04036126, must

be available. In the service PC, the program "List Editor" (listedit.exe) must

have been installed. This program is part of the parameter setting tool.

Set-up procedure

1. Connect the service PC via the parameter setting tool to the B-Net 91 04.

Use the yellow connecting cable for connecting B-Net 91 04 to the

parameter setting tool.

B-Net 91 04

RS-232C

RS-485

Service-PC

Para-Tool

Fig. 12: Connecting the service PC to B-Net 91 04

2. Provide the parameter setting tool with power (B-Net 91 04 is also supplied

with power).

3. Start the "List Editor" on the service PC.

In the Options menu, the COM port must have been selected and the device

address used of the B-Net 91 04 must have been set.

4. Prepare the desired customer number list and load it to the subterminal.

If a list entry contains 14 digits of customer and badge number in

accordance with the Kaba group header, a single badge will be authorized.

If a list entry contains, for example, only an 8-digit customer number in

accordance with the Kaba group header, a badge group will be authorized.

5. Activate the stand-alone operation and enter the relay pull-in time (default 3

seconds).

6. Perform a functional test.

7. Service PC and parameter setting tool are no longer required and can be

removed.

Remark

The operation of the List Editor is described in the manual of the parameter setting

tool.

The description of the customer number list can be found in chapter

8.7.8.

28 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Start-Up

6.2 Cold start

The device can be reset to default settings by means of a cold start.

How to perform a cold start:

• Turn off the device

• Push the cold start button and keep it pressed

• Turn the device on

• Release the cold start button after approx. 3 seconds

After a successful cold start, an acoustic signal can be heard, and the status LED

flashes three times.

1

2

Fig. 13: Cold start button (1) and status LED (2).

Remark

The following applies to parameters being changed in the system mode:

Parameters adapted via LOWPAR are reset to default settings by means of the cold

start.

Configuration parameters set by the SETHWC command and diagnostics data are

maintained.

6.3 Status LED

The device has a red status LED (2) to signalize states or errors.

After switching on, the LED is lighted shortly and switched off immediately if

operation is trouble-free.

The following states are possible:

LED is still lighted after reset Program does not run

LED flashes 6 times after reset First start (basic initialization)

LED flashes 3 times after reset Cold start

LED flashes once System mode becomes active

LED is switched off immediately after reset Program runs error-free

LED flashes continuously Program has detected an error

The error can be stored in the EEPROM memory and displayed directly or via a

command, see system mode).

12/2008 © Kaba GmbH 29

Start-Up Manual B-Net® 91 04

6.4 Adjusting the reader

The reader has been adjusted in the factory to an optimum range. Normally, it

needs not to be readjusted.

The reader range is influenced by the damping of conducting material around the

reading unit (e.g. housing, built-in units, conductive paint, reinforced concrete,

etc.).

If used in critical environment (small distance to metal parts, etc.), the reading

characteristics might be improved by an adjustment. The reader can thus be

adapted to the installation environment to limited extent.

There is a small trimmer on the front of the device. This trimmer can be accessed

after removing the housing frame.

The adjustment should be made using an alignment pin.

An oscilloscope or LEGIC® Powermeter, order number 04032432, can be used for

adjustment.

Adjusting using an oscilloscope

The logic probe is converted into a measuring loop (connect logic probe ground to

test tip) or extend the test tip by a short piece of wire (antenna effect). The logic

probe must be fastened in front of the reader. The pulses are then set to max.

amplitude.

Adjusting using LEGIC® Powermeter

Fasten the powermeter in front of the reader. Adjust the knob on the powermeter

so that the LED field is lighted in yellow/green.

Then select maximum amplitude on the trimmer.

Fig. 14: Trimmer position for reader adjustment

30 © Kaba GmbH 12/2008

Manual B-Net® 91 04 System mode

ara-Too

7 System mode

The system mode allows parameter setting for the device.

Remark

Default parameters can be modified in system mode. However, this is only required

for special applications.

The "online" and "stand-alone" modes described in this manual require factory

settings. Therefore, parameters have not

to be changed in system mode for these

operating modes.

The system mode is an imitation of the operating system. It can be accessed via

the data interface of the device. A service PC is connected by means of the

parameter setting tool, order number 04036126.

Bedanet 91 04

RS-232C

RS-485

Service-PC

P

l

Fig. 15: Connecting the service PC to B-Net 91 04

Connection is established via a standard terminal software, e.g. HyperTerminal. A

protocol is not used. The following communication parameters are valid:

Baud rate: 9600 Baud

Parity: even

Data bits: 7

Stop bits: 1

The system mode is started by:

• continuously pressing the cold start button (see chapter

6.2) for 2 seconds:

or

• executing the command <ESC>[=99x

This method requires connection to a control unit that supports this

command.

Activation of the system mode is confirmed by a flashing status LED and an

acoustic signal.

After starting system mode, the device replies with the prompt

(<CR>, <LF>, '>').

System mode can only be exited via the commands RUN, ORIGIN, a warm start or

a cold start. It is not cancelled via timeout.

12/2008 © Kaba GmbH 31

System mode Manual B-Net® 91 04

7.1 Commands

Commands only contain capital letters and terminate with <CR>.

When entering commands, the characters following the command are ignored, as

parameters might follow if the device is provided with an operating system. A

wrong command is shown as follows:

Command not found

>_

Once a command has been called successfully, it will be processed.

Upon termination of a command, the device terminal displays a prompt.

If the output of a command is too large for the screen, the stopped output can be

continued with <CR> (Enter key).

If an error is detected upon termination of the command, an error message is

displayed before outputting the prompt:

Write Error

>_

After entering <BS> (backspace key) or <DEL> (delete key), the last entered

character is deleted and the cursor is put back one character.

All entered characters are sent back as echo.

It is checked whether the parameters are correct, and only correct parameters are

applied. The parameters are only accepted if the format (length) is strictly adhered

to.

Before entry, a parameter description is displayed. The currently valid parameter

values, surrounded by simple quotation marks ('parameter'), are then transmitted in

the required input format.

Preset parameters can be applied by means of <CR> (Enter key).

The character '_' represents the cursor in the following examples.

32 © Kaba GmbH 12/2008

Manual B-Net® 91 04 System mode

7.1.1 SETHWC

The SETHWC command (Set Hardware Configuration) is used to enter the

parameters defining the hardware of device.

After having changed the hardware parameters, a cold start must be performed so

that the device applies the defined state. The hardware parameters are not

changed by the cold start.

Example:

>SETHWC

Protocol

Type : '01' : 01

AUX 1

Type : '16' : 16

CIR : '00' : 00

Serial Interface

Baudrate : '009600' :

Number of Data Bits: '8' :

Parity : '0' :

Number of Stop Bits: '1' :

Flow Control : '0' :

LEDs

Number : '02' : 02

Outputs

Number : '01' : 01

12/2008 © Kaba GmbH 33

System mode Manual B-Net® 91 04

7.1.1.1 Description of the Parameters Protocol Type:

2-digit protocol to control unit (data interface)

00 no protocol

01 BPA/9 protocol

02 BPA/9 protocol with activatable header

Keyboard type:

2 digits: Keyboard type

00 No keyboard

Driver type for AUX channels:

2-digit type for AUX 1

00 no component

16 Serial driver for LEGIC prime - read-only

(data such as LEGIC MAG reader without protocol)

- serial interface

- CIR: Information from LEGIC SM100-S

- Interface parameter: 9600 baud, 8 data bits, no parity, 1 stop bit

18 Serial driver for LEGIC advant - read-only

(data such as LEGIC MAG reader without protocol)

- serial interface

- CIR: Information from LEGIC advant SM

- Interface parameter: 9600 baud, 8 data bits, no parity, 1 stop bit

32 Serial driver for LEGIC prime - read and write

(protocol corresponding to ISO 7816-4)

- serial interface

- CIR: Information from SM100-S

- Interface parameter: 9600 baud, 8 data bits, no parity, 1 stop bit

34 Serial driver for LEGIC advent - read and write

(protocol corresponding to ISO 7816-4)

- serial interface

- CIR: Information from LEGIC advant SM

- Interface parameter: 9600 baud, 8 data bits, no parity, 1 stop bit

If the serial interface is used for a driver, specify the interface parameters also. For

some drivers, the above-mentioned parameters must be firmly defined, for

transparent drivers, the following parameters are possible:

Baud rate: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 baud

Data bits: 7, 8

Parity: 0 (no), 1 (odd), 2 (even)

Stop bits: 1, 2

34 © Kaba GmbH 12/2008

Manual B-Net® 91 04 System mode

CIR type:

2-digit type for CIR 1+2

00 No CIR

01 CIR exists

Status and generation depend on component for AUX channel

LEDs

2-digit number of LEDs

00 No LEDs

01 1 LED

02 2 LEDs

Outputs

2-digit number of outputs

00 no output

01 1 output

7.1.1.2 Default configuration

Protocol type 01 BPA/9 protocol

AUX 1 16 LEGIC prime – read-only

00 No CIR

Serial interface 9600 Baud, 8 data bits, no parity, 1 stop bit

Number of LEDs 02

No. of outputs 01

12/2008 © Kaba GmbH 35

System mode Manual B-Net® 91 04

7.1.2 GETHWC

The GETHWC command (Get Hardware Configuration) displays the parameters

described under SETHWC.

Example with default values:

>GETHWC

Protocol

Type : '01'

AUX 1

Type : '16'

CIR : '00'

Serial Interface

Baudrate : '009600'

Number of Data Bits: '8'

Parity : '0'

Number of Stop Bits: '1'

Flow Control : '0'

LEDs

Number : '02'

Outputs

Number : '01'

>_

36 © Kaba GmbH 12/2008

Manual B-Net® 91 04 System mode

7.1.3 GETPRG

The GETPRG command (Get Program Number) requests the program number of

the device.

Example:

>GETPRG

Program Number : '844-00-X-K00'

>_

12/2008 © Kaba GmbH 37

System mode Manual B-Net® 91 04

7.1.4 LOWPAR

The LOWPAR command (Low Level Parametrierung) is used to adjust the

parameters of the data interface.

The parameters for a protocol are only requested if a protocol with SETHWC

command has been registered.

These parameters are reset to default values after a cold start.

Low level parameters without protocol (protocol type 00):

>LOWPAR

Serial Interface

Baudrate : '019200' : 009600

Number of Data Bits : '7' : 7

Parity : '2' : 2

Number of Stop Bits : '1' : 1

Flow Control : '0' : 0

>_

Low level parameters with protokol BPA/9 (protokol type 01):

>LOWPAR

Serial Interface

Baudrate : '019200' : 009600

Number of Data Bits : '7' : 7

Parity : '2' : 2

Number of Stop Bits : '1' : 1

Flow Control : '0' : 0

Protocol BPA/9

Group (GID) : '00' : 01

Device (DID) : '00' : 01

Poll / Cont. Mode : '0' : 0

Fast Select : '0' : 0

Add. <CR> : '0' : 0

Response-TO : '003' : 003

Activity-TO : '004' : 004

Output Delay : '000' : 000

38 © Kaba GmbH 12/2008

Manual B-Net® 91 04 System mode

Additional parameters with protocol type 02:

Header Length

Up : '00' : 00

Down : '00' : 00

>_

7.1.4.1 Description of the Parameters

Serial interface:

5 digits: Baud rate (01200 to 76800)

1 digit: Number of data bits (7, 8)

1 digit: Parity (0 or N = no; 1 or O = odd; 2 or E = even)

1 digit: Number of stop bits (1, 2)

BPA/9:

2 digits: Group number (00 to 29)

2 digits: Device number (00 to 59)

1 digit: Polling (0) or contention mode (1)

1 digit: Quick call (0 or 1)

1 digit: Additional end character (0 or 1)

3 digits: Response timeout (001 to 999 = 0.1 – 99.9 sec.)

3 digits: Operating timeout (001 to 999 = 0.1 – 99.9 sec.)

3 digits: Transmit delay (000 to 999 = 0.0 – 99.9 sec.)

Header Up/Down:

2 digits: Header when sending (00 to 05)

2 digits: Header when receiving (00 to 05)

Remark

The parameters for "serial interface" as well as GID and DID can only be changed

using the LOWPAR command if the DIP switch 10 is set to OFF, see chapter

5.9.

12/2008 © Kaba GmbH 39

System mode Manual B-Net® 91 04

7.1.5 RUN

The command RUN (restart of the program) is used to quit the system mode and

perform a warm start.

Example:

>RUN_

or

>RUN,,S_

The warm start is indicated by the following message:

>Restarting …

7.1.6 ORIGIN

The ORIGIN command resets the device to factory settings. This applies to all cold

start parameters, to hardware parameters that can be set using the SETHWC

command and to the diagnostics data.

Example:

>ORIGIN_

The following messages appear:

Resetting device to delivery state

Are you sure?

After acknowledgement with '1' or 'Y', the factory settings are restored, and the

following message is displayed:

>Restarting …

In all other cases, there is no action, and the system mode remains active.

40 © Kaba GmbH 12/2008

Manual B-Net® 91 04 System mode

7.1.7 GETDGN

The GETDGN command is used to query diagnostics data (possible errors).

Query without error messages:

>GETDGN_

No Errors found

>_

Query with error messages:

>GETDGN

Errors found : 01

Code: 010 Meaning: Error while allocating memory

>_

The following error codes are possible:

7.1.8 RSTDGN

1 Unspecific Error

2 Unknown Error

10 Error while initializing Task Manager

11 Error while creating Task

12 Error from Task Manager

20 Error while initializing EEPROM

21 Error while writing to EEPROM

22 Error while reading from EEPROM

30 Error while allocating memory

31 Error while initializing Buffer

40 Error while writing to Display

The RSTDGN command is used to delete all diagnostics data.

Example:

>RSTDGN

>_

12/2008 © Kaba GmbH 41

Description of the Subpartyline Manual B-Net® 91 04

8 Description of the Subpartyline

In online mode, data transfer takes place via the subpartyline. The subpartyline is

an RS485 bus operated in 2-wire technology.

Normally, transmission takes place at 19,200 baud, parity even and one stop bit.

8.1 BPA Subset

8.2 Addressing

Alternatively 9,600 baud are also possible. 7 bit ASCII characters are transmitted.

The BPA (Benzing Protocol Asynchronous) is a master slave protocol with the

subterminal being the slave. The master is always the superior control unit. The

BPA’s overall control is performed by the control unit.

The BPA subset is a protocol with reduced functionality adapted to data exchange

with subterminals.

Because several subterminals can be connected to a control unit, these must be

distinguished by addresses. For this, two addresses exist. The group ID (GID) is a

group address, the device ID (DID) the actual device address. These addresses

are set at the subterminal. The range of values goes from 0 to 7 for the GID and

from 0 to 15 for the DID.

In transmission these addresses are always represented in ASCII characters. For

transmit polling the upper case letters are used. For receive polling for the GID

lower case letters are used:

Address DID

0 @

1 A

2 B

3 C

4 D

5 E

6 F

7 G

8 H

9 I

10 J

11 K

12 L

13 M

14 N

15 O

(hex)

0 @

(40)

1 A

(41)

2 B

(42)

3 C

(43)

4 D

(44)

5 E

(45)

6 F

(46)

7 G

(47)

(48)

(49)

(4A)

(4B)

(4C)

(4D)

(4E)

(4F)

GID

Address

Transmit polling Receive polling

´

(40)

a

(41)

b

(42)

c

(43)

d

(44)

e

(45)

f

(46)

g

(47)

(hex)

(60)

(61)

(62)

(63)

(64)

(65)

(66)

(67)

42 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Description of the Subpartyline

8.3 Control Characters and Control Sequences Remark

Control characters are displayed in angle brackets, e.g. ESC (1B

underline character “_” is used as blank (2Ø

hex).

hex) as <ESC>. An

In the following examples “0” is used as group address (GID) and “1” as device

address (DID).

The following characters and sequences are used as control characters:

Control characters/

Meaning

sequence

<STX>

<ETX>

<EOT>

<NAK>

STX Start of Text Beginning of the text

ETX End of Text End of the text

EOT End of transmission End of the transmission

NAK Negative

Negative feedback

Acknowledgement

<ENQ>

<DLE> 0

<DLE> 1

<DLE> <

ENQ Enquiry Enquiry

ACK0 Acknowledgement 0

Alternating positive feedback

ACK1 Acknowledgement 1

RVI Reverse Interrupt Reverse Interrupt

ACK0, ACK1 and RVI consist of two characters. The second character (0, 1, <)

added to the control character DLE defines which of the three control characte rs is

meant.

8.4 Data Records

The handshake in the BPA is effected via control characters and control

sequences.

The control sequences are:

<EOT> @ @ A A <ENQ>

<EOT> ´ ´ A A <ENQ>

Transmit polling

Receive polling

These control sequences are used to notify the subterminal whether it has to send

existing data records, or if it has to receive a data record. For receive and transmit

polling, the two addresses are sent twice in order to have a verification possibility.

<EOT> GID GID DID DID <ENQ>

Data records are marked up by the control characters STX (beginning) and ETX

(end). The ETX is followed by an LRC - a check character which is calculated by

exclusive OR of the data and the ETX control character. The STX is not considered

in this calculation.

<STX> Data <ETX> <LRC>

12/2008 © Kaba GmbH 43

Description of the Subpartyline Manual B-Net® 91 04

8.5 Data from Subterminal to Control Unit Transmit polling

Control unit Subterminal

The subterminal does not respond if the address is different from its own address,

or if an error has been detected, or if the two address characters are different. The

control unit repeats the transmit poll after an internal time-out.

<EOT> GID GID DID DID <ENQ>

no response

In the case of the same address, the subterminal must respond. If it has no data for

the control unit, an EOT is sent. This completes the entire transmission process.

<EOT> GID GID DID DID <ENQ>

<EOT>

If data exists, these data is sent and the control unit’s acknowledgement is waited

for. If an RVI is received, the data is acknowledged which is confirmed by the

subterminal by an EOT. This completes the transmission.

<EOT> GID GID DID DID <ENQ>

<RVI>

<STX> Text <ETX> <LRC>

<EOT>

If the control unit answers with NAK, the subterminal will repeat the data

transmission. The control unit repeats the NAK up to two times and then terminates

the transmission by EOT. This does not yet acknowledge the data record and

therefore it must not be discarded by the subterminal. The subterminal has to wait

for the next transmit poll to send the data record.

<EOT> GID GID DID DID <ENQ>

<NAK>

<NAK>

<NAK>

<EOT>

<STX> Text <ETX> <LRC>

<STX> Text <ETX> <LRC>

<STX> Text <ETX> <LRC>

<STX> Text <ETX> <LRC>

44 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Description of the Subpartyline

8.6 Data from the Control Unit to the Subterminal Receive polling

Control unit Subterminal

The subterminal does not respond if the address is different from its own address,

or if an error has been detected, or if the two address characters are different. The

control unit repeats the receive poll after an internal time-out.

<EOT> GID GID DID DID <ENQ>

no response

If the address has been detected correctly, the receive poll is acknowledged by the

subterminal by ACK0. After that the control unit sends the data record, which is

acknowledged by ACK1 if correctly received. If the control unit receives a correct

acknowledgement, the control unit terminates the transmission by sending an EOT.

<EOT> GID GID DID DID <ENQ>

<STX> Text <ETX> <LRC>

<EOT>

<ACK0>

<ACK1>

If the control unit’s data record has not been received correctly, the subterminal will

acknowledge by sending an NAK until the record has been understood.

<EOT> GID GID DID DID <ENQ>

<STX> Text <ETX> <LRC>

<STX> Text <ETX> <LRC>

<EOT>

<ACK0>

<NAK>

<ACK1>

If the control receives no correct acknowledgement, it will send an ENQ to request

a retry of the acknowledgement.

<EOT> GID GID DID DID <ENQ>

<STX> Text <ETX> <LRC>

<ENQ>

<EOT>

<ACK0>

no response

<ACK1>

12/2008 © Kaba GmbH 45

Description of the Subpartyline Manual B-Net® 91 04

8.7 Escape sequences

The subterminal functions are controlled by the following escape sequences.

Which ESC sequences are used or supported depends on the particular co ntrol

unit.

8.7.1 Controlling LED, relay and beeper

With the following sequences, the relay and the acoustic signal transmitter

(beeper) in the subterminal are controlled.

Meaning Code

Switching on LED n

Switching on flashing LED n

Switching off LED n

<ESC>[Pnq

<ESC>[?Pnq

<ESC>[=Pnq

Pn: Number of the local LED: 1 to 2

Meaning Code

Switch off relays and beeper

Turn on beeper

Switch on beeper alternatingly

Turn off beeper

Switch on relay

Switch off relay

<ESC>[ q

<ESC>[99q

<ESC>[?99q

<ESC>[=99q

<ESC>[3q

<ESC>[=3q

The acoustic signal transmitter in the subterminal is activated by means of the

control character <BEL> for 0.3 seconds. The acoustic signal transmitter does not

have to be switched off afterwards.

Meaning Code

Activate the beeper dynamically

<BEL>

8.7.2 Reset

The following ESC sequence will reset the subterminal. The same settings as after

a warm start apply for all parameters.

Meaning Code

Perform reset

<ESC>c

After a reset, the subterminal will send the ESC sequence “LOG IN”.

Meaning Code

LOG IN

<ESC>[98~

46 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Description of the Subpartyline

8.7.3 Device configuration

The device configuration of the subterminal is requested by means of the following

ESC sequence. The subterminal sends the ESC sequence “Device configuration”

in response.

Meaning Code

Requesting equipment

configuration

Response from the subterminal

The number of configuration entries may vary depending on the device

configuration. The individual configuration entries are separated from each other by

“;” (semicolon).

Example:

<ESC>[:2;3;?10;?1000;?1116c

Ps:

0 = Keypad present

8.7.4 Program number

<ESC>[c

<ESC>[:2;Ps;Ps;..c

State:

3 = No keyboard available

?10 = Channel AUX 1 present

?13 = Channel AUX 1 not available

Type:

?1000 No keyboard available

?1100 Channel AUX 1 not available

?11xx Component type xx at AUX 1 channel

The program number (version of the terminal software) is requested by means of

the following ESC sequence. The subterminal will send the ESC sequence “Report

program number” in response.

Meaning Code

Request program number

Response from the

subterminal

1 2

1) Space = 20

2) O as in Otto = 4F

Hex

Hex

<ESC> [ ? c

<ESC>[?18 O<ESC>P844-00-X-K00<ESC>\

12/2008 © Kaba GmbH 47

Description of the Subpartyline Manual B-Net® 91 04

8.7.5 Recorded data

After entering a badge, the subterminal will send the following sequence.

Meaning Code

Badge data

1 2

1) Space = 20

2) O as in Otto = 4F

<ESC>[?11 O<ESC>PDATA<ESC>\

Hex

Hex

DATA:

Badge data

After pressing a key, the subterminal will send the following sequence.

Meaning Code

Key (displayable character)

"E" key (Enter)

"C" key (Clear)

8.7.6 Hex Representa tion of the Recorded Data

The Hex representation of the collected data are set by means of the following

ESC sequences.

Meaning Code

Hex representation with letters

Hex representation with special characters

Example:

20

..7E

Hex

Hex

<CR>

<ESC> [ 2N

<ESC>[?14i

<ESC>[?15i

Hex representation with letters:

Hex representation with special characters:*

*Default

8.7.7 Acoustic acknowledgement for reading

As the search through the customer number list can take up to approximately 1

second, the correct reading of a badge can be acknowledged with a short acoustic

signal.

This acoustic acknowledgement can be switched on/off with the following ESC

sequence:

Meaning Code

Acoustic acknowledgement on

Acoustic acknowledgement off *

* Default

0123456789ABCDEF

0123456789:;<=>?

<ESC>[?16i

<ESC>[?17i

48 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Description of the Subpartyline

8.7.8 Customer number list

If no entries are stored in the customer number list (factory setting), only those

badges are accepted which have a segment containing SSC 02 and a fixed

structure of badge data according to Kaba group header. Non-segmented badges

may have an arbitrary SSC, but must also be coded according to Kaba group

header.

The customer number list allows to accept also badges with a different SSC and

another data field structure. Moreover, it can be determined if only the SSC

decides on the identification of the badge or if the whole customer number must

match so that the badge is passed on to the control unit. In the list, up to 5

badge/customer numbers can be stored. This list is retained also in case of power

failure.

As soon as an entry in the customer number list is stored, the SSC 02 default

check is no longer valid. If the customer number list is deleted, the SSC 02 default

check is performed again.

The following ESC sequence allows a customer number to be deposited in the

customer number list of the terminal.

<ESC>[?19_O <ESC>Paabbbbbbbbccccccddeeffgghh<ESC>\

1 2

1) Space = 20

2) O as in Otto = 4F

Hex

Hex

aa Number of relevant bytes which are used for customer number

verification.

00 = Delete list

01 = Byte 1

...

07 = Byte 1-7

b…b Customer number (hex) consisting of SSC/SC/SC/SC (4 bytes); 8 digits

c…c Badge number (hex) 3 bytes 6 digits

dd Start address of data bytes (BCD); 2 digits

ee Number of data bytes (BCD); 2 digits

ff Address of CRC (BCD); 2 digits

gg CRC check; 2 digits

00 = none

01 = CRC8

02 = CRC16

hh Start segment, segment number from search is started (BCD) 2 digits

The parameters a to h have a fixed length of 26 digits.

Remark

If a list entry contains 14 digits of customer and badge number, a single badge will

be authorized.

If a list entry contains, for example, only an 8-digit customer number, a badge group

will be authorized.

12/2008 © Kaba GmbH 49

Description of the Subpartyline Manual B-Net® 91 04

The following example corresponds to the setting according to Kaba group header.

<ESC>[?19_O<ESC>P04020000000000001411250101<ESC>\

The following ESC sequences allow the entries of the customer number list to be

requested.

Meaning Code

1. Request entry

Request another entry

<ESC>[?1c

<ESC>[?2c

As response, the subterminal sends the ESC sequence "Customer number list",

description see above.

<ESC>[?19_O <ESC>Paabbbbbbbbccccccddeeffgghh<ESC>\

50 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Description of the Subpartyline

8.7.9 Control stand-alone operation

The device can also be operated as a stand-alone unit. When a simple badge or

customer number check is sufficient, a simple access control can be implemented.

To do this, the stand-alone mode is activated, and the respective badge or

customer numbers are deposited in the customer number list.

If a list entry contains 14 digits of customer and badge number, a single badge will

be authorized.

If a list entry contains, for example, only an 8-digit customer number, a badge

group will be authorized.

The subterminal will then independently decide if the relay is pulled-in or not. This

allows the subterminal to be operated without the connection to a control unit.

In order to activate the stand-alone feature, the internal relay selection must be

activated by the following ESC sequence. In addition, the relay pull-in time can be

set.

If stand-alone mode is switched on, the relay is only activated by this operating

mode. The ESC sequences "Activate/switch off relay" are then without effect.

The parameter "Control stand-alone mode" is also retained in case of power

failure.

Meaning Code

Stand-alone operation control

<ESC>[a;bbp

a Stand-alone operation

0 = off

1 = on

bb Relay pull-in time 1 or 2 digits

01-99 = pull-in time in seconds

12/2008 © Kaba GmbH 51

Description of the Subpartyline Manual B-Net® 91 04

8.8 ASCII Table

CONTROL

NUMBERS

SYMBOLS

UPPER

CASE

LOWER

CASE

0 1 2 3 4 5 6 7

0 NUL DLE SP 0 @ P ` p

1 SOH DC1 ! 1 A Q a q

2 STX DC2 " 2 B R b r

3 ETX DC3 # 3 C S c s

4 EOT DC4 $ 4 D T d t

5 ENQ NAK % 5 E U e u

6 ACK SYN & 6 F V f v

7 BEL ETB ´ 7 G W g w

8 BS CAN ( 8 H X h x

9 HT EM ) 9 I Y I y

A LF SUB * : J Z j z

B VT ESC + ; K [ k {

C FF FS , < L \ l |

D CR GS - = M ] m }

E SO RS . > N ^ n ~

F SI US / ? O _ o DEL

52 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Packaging / Returns

9 Packaging / Returns

Not properly packaged components and devices can cause costs due to damages

during shipping.

Please note the following when dispatching Kaba products.

Kaba GmbH is not liable for products that have been damaged due to negligent

9.1 Complete Devices

packaging.

The original packaging has been specifically designed to fit the device. It offers

maximum protection against damage in transit.

NOTICE!

When returning an item, please ensure that you always use the original

packaging.

If this is not possible, packaging must be provided which ensures that the device is

not damaged during shipping and handling.

• Use a robust and thick-walled transport box or cardboard box. Approximately

8 to 10 cm of room needs to be allowed on either side of the device.

• Wrap the device with a suitable foil or put it into a bag.

• Place a sufficient quantity of padding, for example foam pads or air

cushions, all around the device. Movements of the device inside the

packaging must be excluded.

• Use only dustless and environmentally friendly padding material.

9.2 Electronic Assemblies

ESD sensitive electronic assemblies such as printed circuit boards, readers, etc.

must be stored, transported, and shipped in appropriate ESD protective bags.

Packing of electronic assemblies may only

• take place at ESD secure workstation s

• be done by persons familiar with general ESD safety standards and who

Returning electronic assemblies in packaging with sufficient ESD protection is a

prerequisite for

• the submission of warranty claims after functional failures of any type.

• replacement of printed circuit boards and electronic components in

exchange.

Electronic components delivered in packaging without sufficient ESD protection are

--in order to maintain a high quality standard-- neither analyzed nor repaired but

directly disposed of.

apply them on a regular basis.

12/2008 © Kaba GmbH 53

Packaging / Returns Manual B-Net® 91 04

9.3 Labeling

Complete return documents and a correct labeling allow for fast proces sing.

Please make sure that each package includes a delivery note. The delivery note

should contain the following information:

• Number of devices or components per package

• Product numbers, serial numbers, specifications

• Name and address of your company / contact person

• Reason for return, e.g. repair exchange

• Meaningful and detailed error description

Returns from countries outside the European Union require a customs invoice

stating the real customs value.

Some countries (e.g. Switzerland) require a preference.

54 © Kaba GmbH 12/2008

Manual B-Net® 91 04 Disposal

10 Disposal

This product complies with the WEEE directive and is, according to DIN EN 50419,

marked with the “Crossed out garbage can” symbol. See chapter

The symbol refers to separated disposal of electric and electronic devices in EU

countries.

Please do not dispose of the device in your regular garbage.

Used devices contain valuable materials that should be recycled. Used devices

should therefore be disposed of via your country’s take back system.

At the end of use of the goods supplied, Kaba GmbH will take them back for a

proper disposal in accordance with the legal regulations (German law on the

disposal of electrical equipment). Charges incurred for transport to the manufacturer

will be at the expense of the owner of the waste electrical equipment.

Please dispose of in an environmentally responsible way

The packaging materials are recyclable. Please do not throw packaging mate rial

into your regular garbage can. Always take it to a recycling center or have it picked

up by your local waste recycler.

3.3 Labeling.

12/2008 © Kaba GmbH 55

Index Manual B-Net® 91 04

11 Index

A

Access Control Unit............................................13

Acoustic acknowledgment..................................48

Acoustic signal generator ...................................12

B

Baud Rate...........................................................24

Beeper ................................................................12

BPA subset.........................................................42

BPA9/Subset ........................................................9

C

CE.......................................................................10

Clearances..........................................................15

Cold start ............................................................29

Conformity ..........................................................10

Connectors .........................................................14

Control stand-alone operation............................51

Controlling relay and beeper ..............................46

ESD (Electro Static Discharge) Protective

Measures......................................................... 7

G

GID..................................................................... 23

Grounding.......................................................... 14

Group address................................................... 23

H

Hex representation of the recorded data........... 48

Hole pattern ....................................................... 19

I

Identification plate.............................................. 10

Installation.......................................................... 14