Page 1

dormakaba digital cylinder

1220013692 - 11/2017

EN

Technical Manual

Page 2

dormakaba Schweiz AG

Mühlebühlstrasse 23

8620 Wetzikon

Switzerland

T: +41 (0)44 931 61 11

www.dormakaba.com

dormakaba Austria GmbH

Ulrich-Bremi-Straße 2

3130 Herzogenburg

Austria

T: +43 (0)2782 808 0

www.dormakaba.com

Copyright © dormakaba 2017

All rights reserved.

No part of this document may be reproduced or used in any form or by any means without prior written permission of dormakaba Schweiz AG.

All names and logos of third-party products and services are the property of their respective owners.

Subject to technical changes.

1220013692 - 11/2017

Page 3

Table of contentsTechnical Manual

31220013692 - 11/2017 dormakaba digital cylinder

Table of contents

1 About this document 5

1.1 Validity 5

1.2 Target group 5

1.3 Contents and purpose 5

1.4 Supplementary documentation 6

1.5 Digital cylinder abbreviations 6

1.6 Hazard categories 6

1.7 Notes 7

1.8 Symbols 7

2 Basic safety instructions 8

2.1 Proper use 8

2.2 Product changes 8

2.3 Use in emergency exit or panic door locks 8

2.4 Areas of use 9

2.5 ESD protective measures 10

2.6 Handling of lithium batteries 10

3 Product description 11

3.1 Overview 11

3.1.1 Structure 11

3.2 Scope of delivery 11

3.2.1 Also for dual digital cylinder 11

3.3 Accessories 11

3.4 Technical data 12

3.4.1 Dimensions 13

3.5 Conformity 16

4 Installation 17

4.1 Requirements 17

4.1.1 Door components 17

4.1.2 Tools required 18

4.2 Installation versions 19

4.2.1 Installation version A 20

4.2.2 Installation version B 22

4.2.3 Function check on anti-panic digital cylinder 24

5 Programming 25

5.1 Initial programming of MRD components 25

5.2 Initial programming of LEGIC® and MIFARE components 25

5.3 Master media 25

5.4 User media 25

5.5 Program structures 26

5.6 A/B and B structures 26

5.7 Programming user media with B masters 27

5.8 Deleting individual user media 28

5.9 Deleting individual B masters 29

5.10 Deleting all user media 30

5.11 INI reset with master media for whitelist and CardLink™ 31

6 Operation 33

6.1 Operating the digital cylinder 33

6.2 Opening with user media 33

Page 4

Table of contents Technical Manual

4 1220013692 - 11/2017dormakaba digital cylinder

7 Maintenance 34

7.1 Maintenance table 34

7.2 Maintenance of escape doors 34

7.3 Cleaning 35

8 Service 36

8.1 Serial numbers 36

8.2 Replacing the battery 36

8.3 Replace e-module 38

8.4 Disassembling the inner door knob 39

8.4.1 'Click' door knob 39

8.4.2 'Small' inner knob 39

8.5 Configuration and traceback 39

8.6 Reset (INI reset) 39

8.6.1 Reset with master media 40

8.6.2 Reset using programmer 1460 40

8.6.3 Reset using tweezers 40

8.7 Emergency power supply 40

9 Troubleshooting 41

9.1 Error analysis 41

9.2 Error analysis for battery life 43

10 Appendix 44

10.1 Summary of various factors influencing the battery operation 44

10.2 Recommendations for battery operation 44

Page 5

About this documentTechnical Manual

51220013692 - 11/2017 dormakaba digital cylinder

1 About this document

This section contains information for the proper use of this document.

1.1 Validity

This document describes the product:

Product designation: dormakaba digital cylinder

Types: 143X dormakaba Digital cylinder with Euro profile (17mm)

153X dormakaba Digital cylinder with round profile (22mm)

Article numbers and variants:

Euro profile cylinder 1435 Standard

1434 Half

1437 Anti-panic

1439 Dual

1431 Asymmetrical

1433 Half with turning range

Round profile cylinder 1535 Standard

1534 Half

1537 Anti-panic

1539 Dual

1531 Asymmetrical

1533 Half with turning range

All versions are available with wireless functionality.

With the exception of the asymmetrical version, all components

are available as ‘protected’ variants (with high anti-drill protection).

1.2 Target group

This document is intended for specialist personnel only.

The descriptions are tailored to specialist personnel trained by the manufacturer. The descrip-

tions are no replacement for product training.

Service personnel are persons who have the appropriate technical training and experience re-

quired for them to be aware of the risks that could arise for themselves or others when carrying out these activities and to minimise these risks for themselves and others. It is the responsibility of the service personnel to ensure that the conditions stated by the manufacturer

and the applicable regulations and standards are complied with when carrying out these

activities.

1.3 Contents and purpose

The contents of these instructions are limited to the installation, operation, maintenance and

servicing of the product.

Page 6

About this document Technical Manual

6 1220013692 - 11/2017dormakaba digital cylinder

1.4 Supplementary documentation

The following documents are available from the sales partners:

• Programmer 1460 technical manual

• Operating manual for programmer 1364

• Wireless operation: Wireless planning guideline

• Documentation for the system software used

1.5 Digital cylinder abbreviations

Short designation Product designation

Digital cylinder dormakaba digital cylinder

Programmer Programmer 1460

1.6 Hazard categories

Instructions with information on what to do and not to do to prevent injury and material

damage are denoted specially.

Please follow all hazard instructions. These are intended to help prevent accidents and prevent damage.

These instructions are divided into the following categories:

DANGER

High risk

Denotes an immediate danger that could lead to serious injury or death.

WARNING

Medium risk

Denotes a potentially dangerous situation that could lead to serious injury or death.

CAUTION

Low risk

Denotes a potentially dangerous situation that could lead to minor injury.

NOTICE

Important information on the correct use of the product.

Failure to comply with these instructions could lead to malfunctions. The product and/or objects in the local vicinity could be damaged.

Page 7

About this documentTechnical Manual

71220013692 - 11/2017 dormakaba digital cylinder

1.7 Notes

Information is denoted by this symbol.

Tips on using the product are useful pieces of information.

They help to make best use of the product and its functions.

1.8 Symbols

Symbols with the following meanings are used for hazards (depending on hazard source.)

General hazard Hazard from electric shock

Risk of explosion Risk to electronic components from

electrostatic discharge

Page 8

Basic safety instructions Technical Manual

8 1220013692 - 11/2017dormakaba digital cylinder

2 Basic safety instructions

This product has been built to state-of-the-art standards and in line with established safety

regulations. However, hazards for persons and property may arise when handling the product.

Read and observe the following safety instructions before using the product.

2.1 Proper use

This product has been designed exclusively for use as set out in the chapter Product Description. Any other use will be deemed improper use. The manufacturer accepts no liability for any

resulting damage. The user/operator bears sole responsibility for the risk.

2.2 Product changes

NOTICE

No changes should be made to the product, unless in accordance with changes described in

the instructions.

2.3 Use in emergency exit or panic door locks

WARNING

Risk of personal injury or death.

• Improper use or incorrectly installed digital cylinders can lead to emergency exit locks or

panic door locks and doors not opening.

• The use of a digital cylinder must be checked carefully before using it in locks with a panic

function.

• Before installing the digital cylinder in an escape door, a check must be carried out to ensure that the function of the lever handle or the panic push bar is not obstructed by the

inside knob.

• The use of a digital cylinder in emergency exit locks in accordance with EN179 or in panic

door locks in accordance with EN1125 is documented in the lock manufacturers' performance declarations. If the digital cylinder is not listed in the performance declarations or

certificates from the lock manufacturer or the lock does not comply with these standards,

an EC conformity inspection of the lock, digital cylinder, fitting and assembly accessories

as one unit must be carried out.

Page 9

Basic safety instructionsTechnical Manual

91220013692 - 11/2017 dormakaba digital cylinder

2.4 Areas of use

IP56

When used outdoors, the cylinder must be protected against sustained rainfall using a

weather guard.

NOTICE

Freezing liquids can disrupt the function, resulting in doors not opening. No water, therefore,

should get into the cylinder. When used externally, the cylinder must be protected against

sustained rainfall using a weather guard.

When used in fire protection doors, escape routes or rescue routes, the locally applicable

guidelines and building regulations must be observed.

NOTICE

Doors at risk of forced entry

• The following points must be observed for certification as per VdS Class B: On doors at

risk of forced entry, the 'Protected' version of the digital cylinder must be protected with

a VdS-recognised burglary-resistant Class B or C doorplate. These doorplates correspond

to DIN 18 257 Class ES 2 or ES 3 and EN1906 Class 3 or 4. The cylinder must protrude no

more than 3 mm beyond the doorplate.

• The user media (keys, badges, etc.) must always be kept safe to ensure only authorised

personnel may gain access. If identification media are lost, the authorisation data must

be blocked and deleted from all cylinders immediately.

NOTICE

Wrong type of lock

The asymmetrical digital cylinder is not permitted to be used in some lock types.

Please refer to the lock manufacturer’s instructions.

Page 10

Basic safety instructions Technical Manual

10 1220013692 - 11/2017dormakaba digital cylinder

2.5 ESD protective measures

NOTICE

Danger of damage to electronic components from electrostatic discharge.

If electronic printed circuit boards and components are handled incorrectly, damage may occur which leads to their complete breakdown or sporadic faults.

• When installing and repairing the product, the general ESD protective measures are to be

observed.

• Before starting service or maintenance work on the product, e.g. changing the battery,

briefly touch the door handle. This will safely and effectively conduct charges away from

your body.

• When handling electronic components, wear the ESD wrist strap. Connect the end of the

strap to an ESD socket or an unpainted, earthed metal component. This will safely and effectively conduct charges away from your body.

• Only handle the edges of printed circuit boards. Do not touch printed circuit boards or

connecting plugs.

• Put removed components on an anti-static surface or in an anti-static shielding container.

• Avoid contact between printed circuit boards and clothing. The wrist strap only protects

the printed circuit boards from static electricity on the body. Damage can still occur due

to static electricity on clothing.

• Only transport and ship removed modules in ESD-shielding, conductive protective containers.

2.6 Handling of lithium batteries

NOTICE

Lithium batteries can explode or burst explosively.

Improper handling of lithium batteries can lead to fires and explosions.

• Only replace lithium batteries with batteries of the same type.

• Do not open, drill through or squash lithium batteries.

• Do not burn lithium batteries or expose them to high temperatures.

• Do not short circuit lithium batteries.

• Do not recharge lithium batteries.

Page 11

Product descriptionTechnical Manual

111220013692 - 11/2017 dormakaba digital cylinder

3 Product description

This section provides an overview of the product and gives information on technical details.

3.1 Overview

The digital cylinder is an electronic locking cylinder with a reader antenna on the rotary knob.

Depending on the version, the reader antenna may be on the outer knob or on both the outer

and inner knob. The security-related electronics are installed behind the anti-drill protection in

the rotor. After identification using authorised media, the lock and door can be opened manually. An acoustic and optical signal denotes access authorisation.

3.1.1 Structure

2

3

6

7

11

12

13

8

9

10

5

4

1

1 Outer knob 8 Securing shackle

2 Cover with light ring 9 LA, length on outer side

3 Door knob module with antenna 10 LB, length on inner side

4 Battery 11 Cylinder housing

5 Contact protection film 12 Cam

6 O-ring, Ø 15 x 1mm 13 Inner knob

7 MC insert

Table1:

Structure – Description of standard version

3.2 Scope of delivery

• 1 digital cylinder

• 1 forend locking stud

• 1 battery, CR2 lithium type

• 1 set of instructions

3.2.1 Also for dual digital cylinder

• 1 battery, CR2 lithium type

3.3 Accessories

• Relevant system software and programming tools

Page 12

Product description Technical Manual

12 1220013692 - 11/2017dormakaba digital cylinder

3.4 Technical data

The digital cylinder is intended for use in building doors that are equipped with a lock.

Technical data

Dimensions

Outer knob Ø x L 36 x 45mm

Inner knob Ø x L 36 x 29mm

Small inner knob Ø x L 30 x 27mm

Dual inner knob Ø x L 36 x 45mm

Backset 35mm Door opens inwards

(all variants)

30mm Door opens outwards

(standard inner knob)

35mm Door opens outwards

(dual inner knob)

25mm Door opens outwards

(small inner knob)

Power supply

Battery 3V, CR2 lithium

Radio interface

Technology IEEE802.15.4

Frequency band 2400 to 2485.5MHz

Transmission power + 8dBm

Receiver sensitivity - 102dBm @ 1% PER

Ambient conditions

Protection type IP56 Outer knob (standard)

Temperature -25°C – +70°C The temperature range de-

pends on the battery manu-

facturers' specifications.

Humidity 0%–95% rH, non-condensing

Climate Not suitable for heavily cor-

rosive atmospheres (chlorine,

ammonia).

Rooms Not to be used in potentially

explosive environments.

Standards

VdS ‘Protected’ version:

class BZ+

Classification according to

EN15684

Place:

Classification:

1 2 3 4 5 6 7 8

1 6 B 4 A F 3 2

Resistance to fire EN 1634-2: 95min Version 1439 and 1539 from

total length 85mm

Durability > 200,000 cycles

EN 1303 class 6

EN 179/EN 1125 class 7

Page 13

Product descriptionTechnical Manual

131220013692 - 11/2017 dormakaba digital cylinder

Technical data

Corrosion DIN EN 1670 class 3

DIN EN ISO 6988, severity

level 3 (SO2 test)

Dimensions DIN18252 Profile cylinder

SN-EN1303 Round profile cylinder

Cycles

Battery life at 20°C Approx. 50,000 cycles Dependent on the configura-

tion used

Battery life at -20°C EXT version:

approx. 40,000 cycles

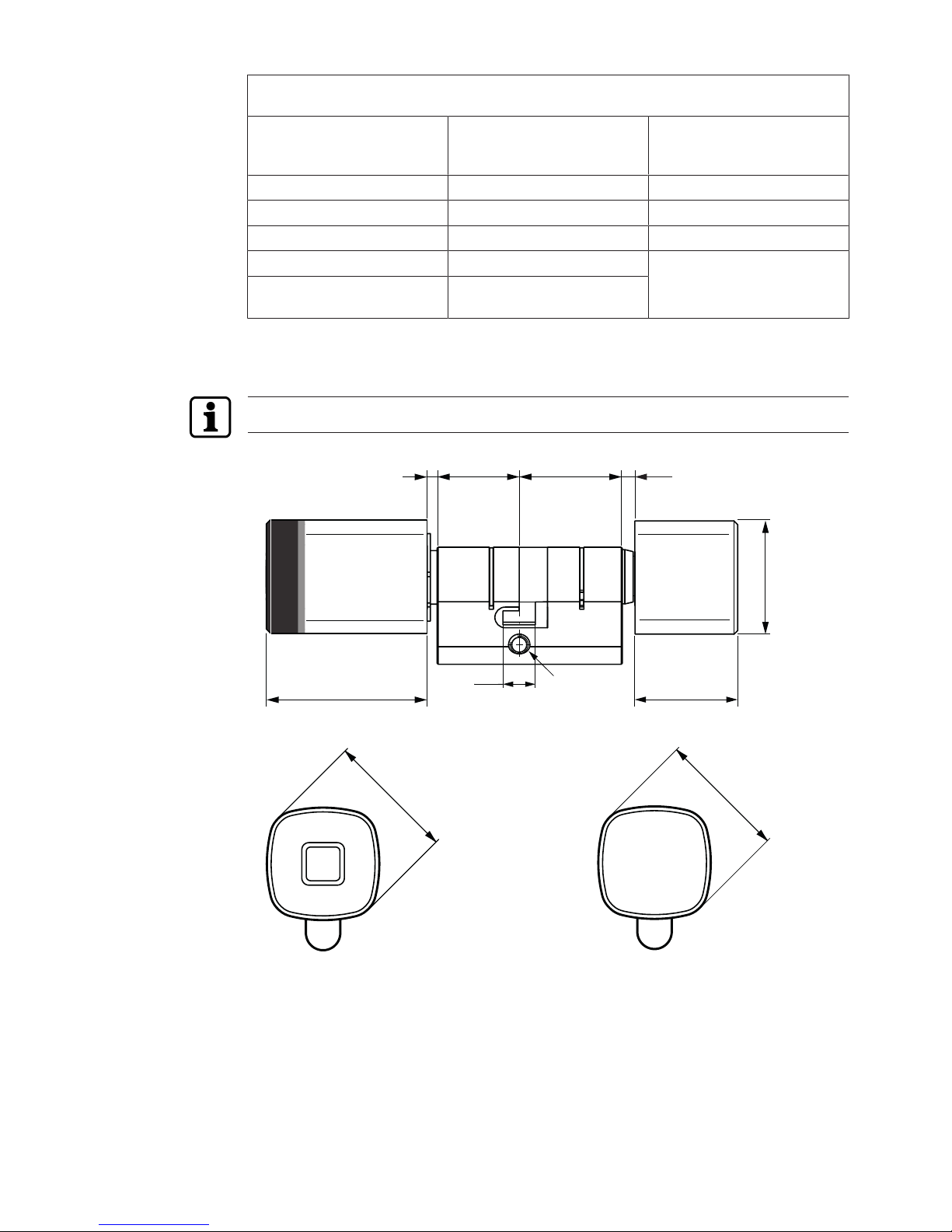

3.4.1 Dimensions

The dimensions stated also apply for the 22mm round profile cylinder.

45

29

32

1431

3 4

36

36

9,2

25 LB

M5

Dimension drawing 1431 Asymmetrical (profile cylinder)

Page 14

Product description Technical Manual

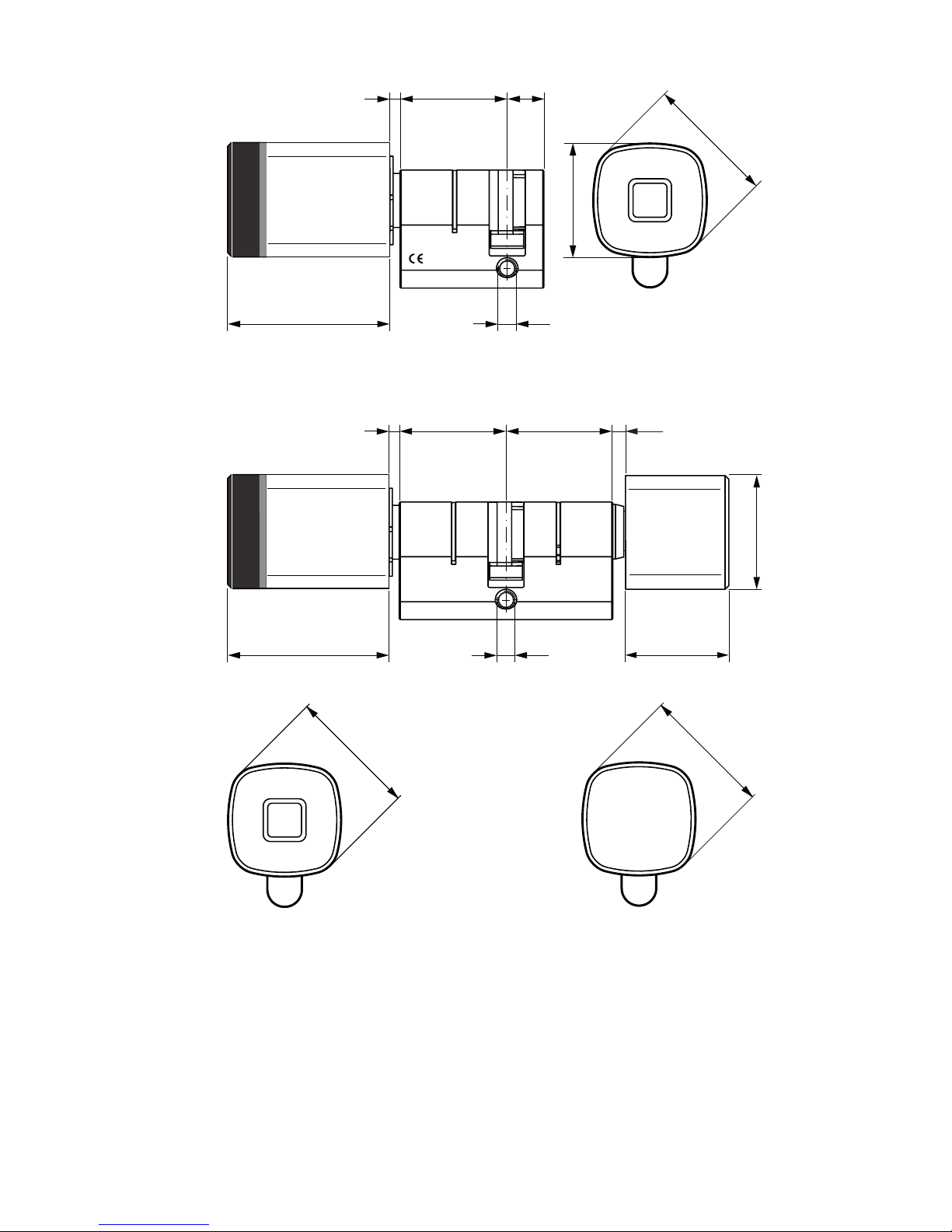

14 1220013692 - 11/2017dormakaba digital cylinder

45

32

M5

LA3 10.5

36

1434

Dimension drawing 1434 Half with outer knob profile (profile cylinder)

45

29

32

M5

LA

1435

3 4LB

36

36

Dimension drawing 1435 Standard (profile cylinder)

Page 15

Product descriptionTechnical Manual

151220013692 - 11/2017 dormakaba digital cylinder

45

27

26

M5

LA3 3.5LB

30

32

36

1437

Dimension drawing 1437 Anti-panic, small inner knob version (profile cylinder)

45

32

M5

LA3 3LB

45

36

1439

Dimension drawing 1439 Dual (profile cylinder)

Page 16

Product description Technical Manual

16 1220013692 - 11/2017dormakaba digital cylinder

3.5 Conformity

This product conforms to the EU directives

2014/53/EU Radio Equipment Directive

2014/35/EU LVD Directive

2011/65/EU RoHS Directive

You can download the original declaration of conformity in PDF format at www.kaba.com/con-

formity.

Page 17

InstallationTechnical Manual

171220013692 - 11/2017 dormakaba digital cylinder

4 Installation

This chapter describes the installation of the product.

4.1 Requirements

4.1.1 Door components

Locking cylinder

The locking cylinder with Euro profile or round profile can be used in any door made from

wood, glass or metal, in accordance with the cylinder perforations.

A notch is required for the locking cylinder with the anti-panic round profile cylinder as this

has a pin going all the way through on the inside (LB).

The locking cylinder with the Euro profile cylinder and dual round profile cylinder, in the protected version (VdS class BZ+) only offers high anti-drill protection on the outside (LA).

WARNING

Risk of personal injury or death.

• Improper use or incorrectly installed digital cylinders can lead to emergency exit locks or

panic door locks and doors not opening.

• The use of a digital cylinder must be checked carefully before using it in locks with a panic

function.

• Before installing the digital cylinder in an escape door, a check must be carried out to ensure that the function of the lever handle or the panic push bar is not obstructed by the

inside knob.

• The use of a digital cylinder in emergency exit locks in accordance with EN179 or in panic

door locks in accordance with EN1125 is documented in the lock manufacturers' performance declarations. If the digital cylinder is not listed in the performance declarations or

certificates from the lock manufacturer or the lock does not comply with these standards,

an EC conformity inspection of the lock, digital cylinder, fitting and assembly accessories

as one unit must be carried out.

NOTICE

Danger of damage to electronic components from electrostatic discharge.

Improper handling can damage or destroy electrostatically sensitive circuit board components.

• Observe and apply general ESD protective measures.

Check the dimensions

The following dimensions are to be checked prior to installation:

Page 18

Installation Technical Manual

18 1220013692 - 11/2017dormakaba digital cylinder

>2 LA LB >2

D

1. Check the door thickness with the fittings (LA and LB)

and the cylinder length.

2. Check the profile cut-out and the backset (D).

• In order for the multitool to be inserted between the knob and the plate, choose cylinder

lengths so as to retain at least a 2mm gap between the plate and the knob.

• In accordance with DIN 18257 for security hardware and security plates, in doors with security hardware (burglary-resistant fitting) the cylinder housing should not protrude more

than 3mm from the external plate.

• Determine the length of the forend screw: Forend screw ≥ backset + 10mm.

4.1.2 Tools required

• Tool – Multitool

• Allen key, small inner knob, 2mm hex

• Flat head and Phillips screwdriver

• Programming cable

• Adaptor/programming pin

Page 19

InstallationTechnical Manual

191220013692 - 11/2017 dormakaba digital cylinder

4.2 Installation versions

NOTICE

When installing the lock, there is a risk of being locking out.

Always install the digital cylinder when the door is open. This prevents you from locking yourself out when using self-locking locks.

The locking cylinder in the digital cylinder version without an inner knob and the dual version

should be programmed before carrying out the function test. After this, hold an authorised

user medium in front of the cylinder and carry out the function test by turning the outer door

knob.

With installation version A, remove the inner door knob and push the cylinder through the fitting and the lock from the outer side of the door.

With installation version B, remove the outer door knob and also the inner door knob if necessary, and push the cylinder housing through the door's lock.

Digital cylinder installation versions

Installation versions

Type A B

1431 Asymmetrical

1435 Standard

recommended optional

1433 Half with turning range

1434 Half

— optional

1437 Anti-panic recommended optional

1439 Dual — recommended

1531 Asymmetrical

1535 Standard

not recommended recommended

1533 Half with turning range

1534 Half

— optional

1537 Anti-panic

1

not recommended optional

1539 Dual — recommended

Key:

1

The fitting needs a recess on the inner side for the cylinder pin.

Page 20

Installation Technical Manual

20 1220013692 - 11/2017dormakaba digital cylinder

4.2.1 Installation version A

1

2

3

1. Remove the outer door knob.

2. Remove the contact protection film.

3. Attach the outer door knob.

4

4. Position the multitool on the outer door knob.

5

5. Turn the multitool to the left and lock it.

The outer door knob and the cylinder housing are now

firmly connected.

6

7

6. Align the cam flush with the cylinder housing.

7. From the outer side of the door, push the digital cylinder

through the fitting and the lock.

8

8. Position the forend locking stud in the lock and tighten it

slightly.

Click!

9

9. Note:

Align the locking spring and the notch with each other!

Place the inner door knob on the cylinder housing.

10

10. Tighten the forend locking stud.

Page 21

InstallationTechnical Manual

211220013692 - 11/2017 dormakaba digital cylinder

11 11

11. Check that the door knobs function correctly.

Both door knobs can be turned without touching the fittings.

12. Check the backset.

The door knobs must not knock against the door frame.

Page 22

Installation Technical Manual

22 1220013692 - 11/2017dormakaba digital cylinder

4.2.2 Installation version B

1

1. Remove the outer door knob.

2

3

4

2. Attach the multitool to the securing shackle from below.

3. Pull out the securing shackle.

4. Remove the knob module.

5

6

5. Align the cam flush with the cylinder housing.

6. Push the cylinder housing through the lock from the inner

side of the door.

7

7. Position the forend locking stud in the lock and tighten it

slightly.

8

8

8. Install the fittings.

9

9. Note:

Align the locking spring and the notch with each other!

Place the inner door knob on the cylinder housing.

Page 23

InstallationTechnical Manual

231220013692 - 11/2017 dormakaba digital cylinder

10

10. Put the inner door knob on to the cylinder housing.

11

11. Push the securing shackle into the knob module from

above until it stops.

The knob module and cylinder housing are then firmly connected.

13

12

12. Remove the contact protection film.

13. Note:

Be careful not to tilt the edge of the knob when installing.

Push the outer door knob over the door knob module.

14

15

14. Position the multitool on the outer door knob.

15. Turn the multitool to the left and lock it.

The outer door knob and the cylinder housing are now

firmly connected.

16

16. Tighten the forend locking stud.

17 17

17. Check that the door knobs function correctly. Both door

knobs can be turned without touching the fittings.

18. Check the backset.

The door knobs must not knock against the door frame.

Page 24

Installation Technical Manual

24 1220013692 - 11/2017dormakaba digital cylinder

4.2.3 Function check on anti-panic digital cylinder

After installing an anti-panic digital cylinder, a function check must be carried out.

WARNING

Risk of personal injury or death.

• After installing the digital cylinder in a panic lock, a function check must be carried out.

It must be possible to open the lock with the lever handle in all cam rest areas.

• For emergency exit or panic door locks, it is vital that the specifications of the lock and fittings manufacturers are observed.

A spring mechanism in the locking cylinder ensures that the cam cannot be positioned in an

area that is not authorised for panic locks.

39

6

12

a) upper authorised rest area

39

6

12

b) lower authorised rest area

Check the reset function as shown:

Check that the lock functions correctly

39

6

12

1. Turn the inner door knob upwards until it cannot be reset.

(Rest area pointing up at 12 o'clock).

Note: If there is no inner door knob, use the outer door

knob.

2. Press the handle.

The lock should unlock.

39

6

12

3.4.Turn the inner knob downwards until it cannot be reset.

(Rest area pointing down at 6o'clock.)

Press the handle.

The lock should unlock.

Check that the locking cylinder is functioning correctly

3

6

12

1. Turn the inner door knob to the 11 o'clock position and release it.

The inner door knob should turn back automatically.

3

6

12

2. Turn the inner door knob to the 1 o'clock position and release it.

The inner door knob should turn back automatically.

Page 25

ProgrammingTechnical Manual

251220013692 - 11/2017 dormakaba digital cylinder

5 Programming

This section describes how to program the components.

Prior to first use, all components must be programmed with the relevant access authorisa-

tions for the user media. Components with a wireless function should be activated in the system.

Manual programming using master media or the programmer 1460 is described in the document

Programming Kaba evolo components

.

The process for setting up the wireless function is described in the handbook for the relevant

system software.

5.1 Initial programming of MRD components

When first used, multi-RFID (MRD) components are set to the technology in which the components are used with a master LEGIC or MIFARE. The components then behave as defined

for the authorisation types LEGIC (LEA) or MIFARE (MID).

Note: After an INI reset using master media, the components must then be re-programmed

using a master LEGIC or MIFARE.

5.2 Initial programming of LEGIC® and MIFARE components

Prior to first use and on request, all components must be programmed with the access authorisation corresponding to their User media. The access authorisations for User media can

be transferred to the components using various types of programming.

5.3 Master media

With the A master and B master media, the components are programmed directly. The B

masters are organised under an A master. The master media do not have any access authorisations.

5.4 User media

All User media are organised under a B master.

NOTICE

Lost User media should be immediately blocked and deleted from all components.

(Delete lost User media in the system software in the whitelist (add CardLink to the blacklist)

or delete all User media with the corresponding master and then re-program all User media).

Page 26

Programming Technical Manual

26 1220013692 - 11/2017dormakaba digital cylinder

5.5 Program structures

All components can be organised manually in an A/B structure or in a B structure.

In the A/B structure, up to 200 B masters can be created with one A master. The User media

cannot be directly programmed in an A structure.

Separate access authorisations to User media can be issued with each B master. User media

can be programmed with different B masters but not with the same components.

Each component can be programmed with up to 4000 User media. These can be distributed

across the various B masters as required. For example, a B1 master only manages 50 users

whilst another master, B2, manages up to 3950 users.

5.6 A/B and B structures

A/B structure

A master

B structure B master

User media

Page 27

ProgrammingTechnical Manual

271220013692 - 11/2017 dormakaba digital cylinder

5.7 Programming user media with B masters

Components confirm the detection of media with acoustic and visual signals.

In this case, the light ring glows green for as long as the medium is located within the antenna

field and is read.

Programming the

User media

Action

1

1 s

Beep

Launch programming mode:

Master B approx. 1 s hold in front

of the antenna.

1 x short

2

1 s

Beep

Program User media:

User media approx. 1 s hold in front

of the antenna.

1 x short

3

1 s

Beep

Additional User media approx. 1 s

hold in front of the antenna.

1 x short

4

Beeeep

1 s

To complete:

Master B approx. 1 shold in front of

the antenna.

Note: If no master medium is held

up within 20 seconds, programming mode ends automatically and

one long acoustic signal sounds.

1 x long

Page 28

Programming Technical Manual

28 1220013692 - 11/2017dormakaba digital cylinder

5.8 Deleting individual user media

In this case, the light ring glows green for as long as the medium is located within the antenna

field and is read.

Deleting

User media

Action

1

1 s

Beep

Launch programming mode:

Master B approx. 1 s hold in front

of the antenna.

1 x short

3 s

2

Beep

Beep

Delete User media:

User media approx. 3 s hold in front

of the antenna.

2 x short

3

Beeeep

1 s

To complete:

Master B approx. 1 shold in front of

the antenna.

Note: If no master medium is held

up within 20 seconds, programming mode ends automatically and

one long acoustic signal sounds.

1 x long

Page 29

ProgrammingTechnical Manual

291220013692 - 11/2017 dormakaba digital cylinder

5.9 Deleting individual B masters

NOTICE

All User media under Master B and the Master B medium under Master A are deleted.

In this case, the light ring glows green for as long as the medium is located within the antenna

field and is read.

Deleting Master Bs Action

1

1 s

Beep

Launch programming mode:

hold in front of the antenna. Mas-

ter A approx. 1 s

1 x short

10 s

2

Beep

Beep

Delete Master B and all user media:

Master B approx. hold in front of

the antenna. 3s

2 x short

3

Beeeep

1 s

To complete:

Master A approx. 1 s hold in front

of the antenna.

Note: If no master medium is held

up within 20 seconds, programming mode ends automatically and

one long acoustic signal sounds.

1 x long

Page 30

Programming Technical Manual

30 1220013692 - 11/2017dormakaba digital cylinder

5.10 Deleting all user media

Components should not be in programming mode.

In this case, the light ring glows green for as long as the medium is located within the antenna

field and is read.

Deleting

user media

Action

10 s

1

Beep

Beep

hold in front of the antenna. Master B approx. 10 s

All User media under the Master B

are deleted.

2 x short

1 x long

1

1 x short

Key:

1

Firmware version 42xx

Page 31

ProgrammingTechnical Manual

311220013692 - 11/2017 dormakaba digital cylinder

5.11 INI reset with master media for whitelist and CardLink™

An INI reset can be used to restore the factory settings for the components.

NOTICE

All User media and master media as well as the traceback are deleted.

Components should not be in programming mode.

INI reset for whitelist

In this case, the light ring glows green for as long as the medium is located within the antenna

field and is read.

INI reset with master Action

15 s

1

Beep

Beep

Master B structure

Master B approx. 15 s hold in front

of the antenna. The INI reset will be

executed after 15 s.

After 10 s,

1 x long,

1 x short,

after 15 s,

2 x short

15 s

1

Beep

Beep

Master A/B structure

Master A approx. 15 s hold in front

of the antenna. The INI reset will be

executed after 15 s.

After 10 s,

1 x long,

1 x short,

after 15 s,

2 x short

Page 32

Programming Technical Manual

32 1220013692 - 11/2017dormakaba digital cylinder

INI reset for CardLink

In this case, the light ring glows green for as long as the medium is located within the antenna

field and is read.

INI reset with master Action

15 s

1

Beep

Beep

B master

Master B approx. 15 s hold in front

of the antenna. The INI reset will be

executed after 15 s.

2 x short

15 s

1

Beep

Beep

Master A

Master A approx. 15 s hold in front

of the antenna. The INI reset will be

executed after 15 s.

2 x short

Page 33

OperationTechnical Manual

331220013692 - 11/2017 dormakaba digital cylinder

6 Operation

This section describes operation of the product.

6.1 Operating the digital cylinder

The digital cylinders are operated with user media. The lock can only be operated if the user

media has an access authorisation. Unauthorised user media are rejected.

6.2 Opening with user media

Before being used for the first time, access authorisations for the relevant system software

must be transmitted to the User media.

1

1. Hold the authorised user medium with the valid access authorisation in front of the knob.

2

2. Access authorisation will be signalled by an acoustic signal1 and a visual display1.

Note: The digital cylinder's opening time is limited; after this time has elapsed, the digital

cylinder closes automatically. Upon delivery, the opening time is approx. 6 s, but this can

be adjusted using the 1460 programmer or the system software.

3

3. Activate the lock by turning the door knob.

ð The door can be opened.

Beep

Beep

Beep

Beep

If there is an attempt to gain access using unauthorised user media, the acoustic1 signal will

sound 4 times and the red1 light will briefly flash 4 times.

Key:

1

If both functions have been activated using the 1460 programmer or the system software.

Page 34

Maintenance Technical Manual

34 1220013692 - 11/2017dormakaba digital cylinder

7 Maintenance

This section describes product maintenance.

7.1 Maintenance table

The component's mechanism and/or electronics do not require any maintenance.

NOTICE

Opening the mechatronic unit.

Opening the mechatronic unit releases the manufacturer from any liability under the guarantee.

Maintenance interval

Components Measures Interval

Digital cylinder

all versions

Function check as specified in the instructions

for the components

12 months

Replacing the batteries ≤ 24 months

Clock (components) Check and set clock time with the system soft-

ware (the clock time is updated with every programming procedure)

12 months

Firmware update For functional modifications as required

7.2 Maintenance of escape doors

WARNING

Risk of personal injury or death.

The service life of the digital anti-panic cylinder is limited by the spring mechanism.

Consequently, they must be replaced by the manufacturer after 10 years.

WARNING

Risk of personal injury or death.

For emergency exit locks in accordance with EN 179 and panic door locks in accordance with

EN 1125, comply with the lock manufacturer's maintenance advice.

Function check on anti-panic digital cylinder

As part of maintenance on a panic lock, also carry out a function check on the anti-panic digital cylinder. (See Chapter Function check on anti-panic digital cylinder [}4.2.3].)

Page 35

MaintenanceTechnical Manual

351220013692 - 11/2017 dormakaba digital cylinder

7.3 Cleaning

Only disinfection agents that are explicitly formulated for cleaning delicate metal surfaces

and plastics may be used. The use of unsuitable cleaning agents or methods can damage the

components' surface.

1. Use a soft, damp cloth to clean the surface.

Page 36

Service Technical Manual

36 1220013692 - 11/2017dormakaba digital cylinder

8 Service

NOTICE

Do not oil the Digital cylinder!

8.1 Serial numbers

The digital cylinder's serial number can be found on the cylinder housing next to the matrix

code. The first 5 digits indicate the manufacturing date.

The manufacturing date can be worked out as follows:

1. Enter the first 5 digits into any cell in an Excel sheet.

2. Right click > Choose Format cells.

3. In the Numbers tab, select the Date category.

4. Select the type 14.03.2001.

Using this procedure, 41038 indicates the manufacturing date of 09/05/2012.

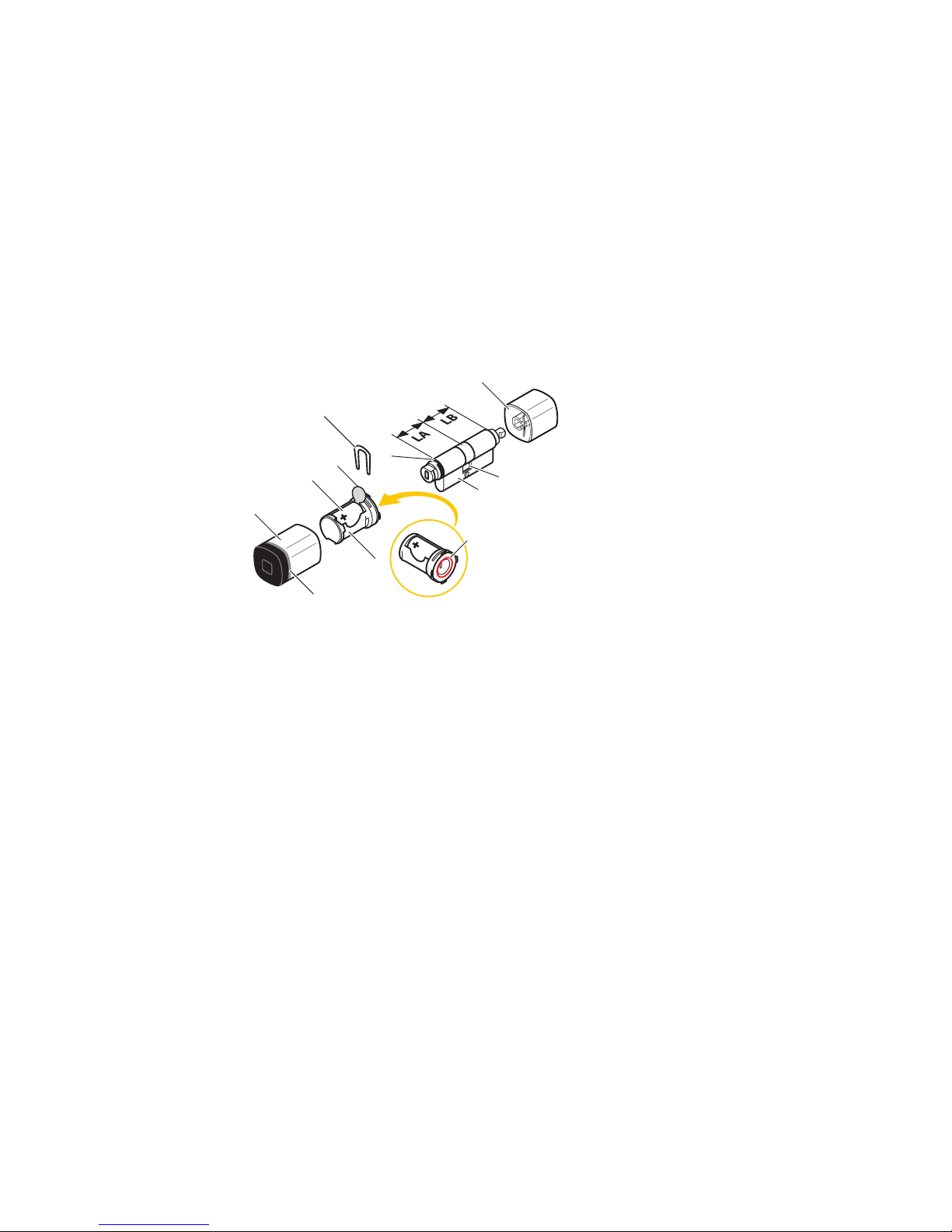

8.2 Replacing the battery

Whilst the battery is being changed, all the data (access authorisations, configurations and

traceback) is retained in the battery-independent memory. The clock settings are lost after 45

seconds.

Requirements:

• New battery available

• Tool – Multitool available

Do not use rechargeable batteries or accumulators.

1

2

1. Position the multitool on the inner side of the outer door

knob.

2. Turn the multitool to the left and unlock the outer door

knob.

3

4

3. Remove the outer door knob.

4. Remove the spent battery.

Page 37

ServiceTechnical Manual

371220013692 - 11/2017 dormakaba digital cylinder

1

2

Note:

If necessary, remove it using the multitool.

5

5. Note:

Make sure you check the polarity of the battery!

Insert the new battery.

Note:

After inserting the battery, the LEDs will briefly flash green

once.

The component is now ready again.

6

6. Push the outer door knob over the door knob module.

7

8

7. Position the multitool on the outer door knob.

8. Turn the multitool to the left and lock it.

The outer door knob and the cylinder are now firmly connected.

9

9. Check that the digital cylinder is functioning correctly.

10. Check theclock time [}8.5] and adjust if required.

Page 38

Service Technical Manual

38 1220013692 - 11/2017dormakaba digital cylinder

8.3 Replace e-module

Prerequisite:

• new e-module available

• tool – multitool available

• knob has been removed.

The different versions of the e-modules are as follows:

MRD e-module and wireless versions

The INI reset contacts are on the round PCB on the front.

LEGIC e-module

The INI reset contacts are on the PCB on the side.

MIFARE e-module

The INI reset contacts are on the PCB on the top.

Procedure for all versions:

1. Remove the battery.

2. Using the multitool, slide [}4.2.2]the securing shackle out of the guide.

3. Carefully remove the e-module.

4. Insert the new e-module.

5. Push the securing shackle into the door knob module from above, to the end stop position.

ð The door knob module and the cylinder housing are now firmly connected.

6. Insert the battery.

ð After it has been inserted, the LEDs will briefly flash green once.

ð The component is now ready again.

7. Attach the door knob.

Page 39

ServiceTechnical Manual

391220013692 - 11/2017 dormakaba digital cylinder

8.4 Disassembling the inner door knob

8.4.1 'Click' door knob

ü Tool – Multitool ready

2

2

1

3

1. Insert the multitool with the narrow pawl between the Knob and the fitting.

2. Press the multitool against the fitting.

ð The locking spring will release.

3. Remove the Thumbturn knob.

8.4.2 'Small' inner knob

ü Allen key, 2mm hex available

2 mm

1. Using the hexagonal key, loosen the screw from the inner door knob.

2. Remove the door knob.

8.5 Configuration and traceback

Correctly set values for date and time ensure time management with the components is upto-date.

Components connected to the system software via the wireless function are updated via the

gateway (e.g. clock time, configurations). The traceback can be read using the system software.

In standalone mode, configurations can be transmitted using the programmer or can be

changed with this (e.g. adjusting the clock time).

A programmer can read the traceback and transmit it to the system software for evaluation.

Further steps are described in the documents

Programmer 1460

and

Programmer 1364

.

8.6 Reset (INI reset)

INI reset of e-module

An INI reset can be used to restore the factory settings for the components.

NOTICE

Loss of data

With an INI reset, all previously saved settings and data on the E-module are deleted.

NOTICE

Before components are returned to Kaba for servicing, always carry out a

reset on the components.

Page 40

Service Technical Manual

40 1220013692 - 11/2017dormakaba digital cylinder

8.6.1 Reset with master media

INI reset can be used to restore the factory settings for the components. (See chapter in operating instructions 'Programming and signals for Kaba evolo components' INI reset with

master media for whitelist and CardLink™ [}5.11].)

8.6.2 Reset using programmer 1460

1. Hold valid master medium in front of the component's antenna.

2. Open Settings menu.

3. Select Actuator.

4. Select INI reset.

5. Select Yes.

ð Successful INI reset is confirmed using an acoustic signal.

Additional steps are described in the

programmer 1460

document.

8.6.3 Reset using tweezers

INI reset with tweezers and valid master media

The components have INI reset contacts on the e-module.

To perform an INI reset, short-circuit these contacts

with electrically conductive tweezers.

Before short-circuiting, present a valid master medium or user medium.

1. Disassemble Knob.

2. Localise both contacts on the e-module. (See Chapter Replace e-module [}8.3].)

3. Using the tweezers, short-circuit the INI reset contacts for approx. 3 s.

ð Successful INI reset is confirmed using an acoustic signal.

8.7 Emergency power supply

If all the alarm signals are ignored until the batteries are completely flat, doors can no longer

be opened from the outside with the digital cylinder. In this case, insert a new battery.

The digital cylinder does not require an emergency power supply using the 1460 programmer.

Page 41

TroubleshootingTechnical Manual

411220013692 - 11/2017 dormakaba digital cylinder

9 Troubleshooting

This chapter provides important information for analysing errors and troubleshooting.

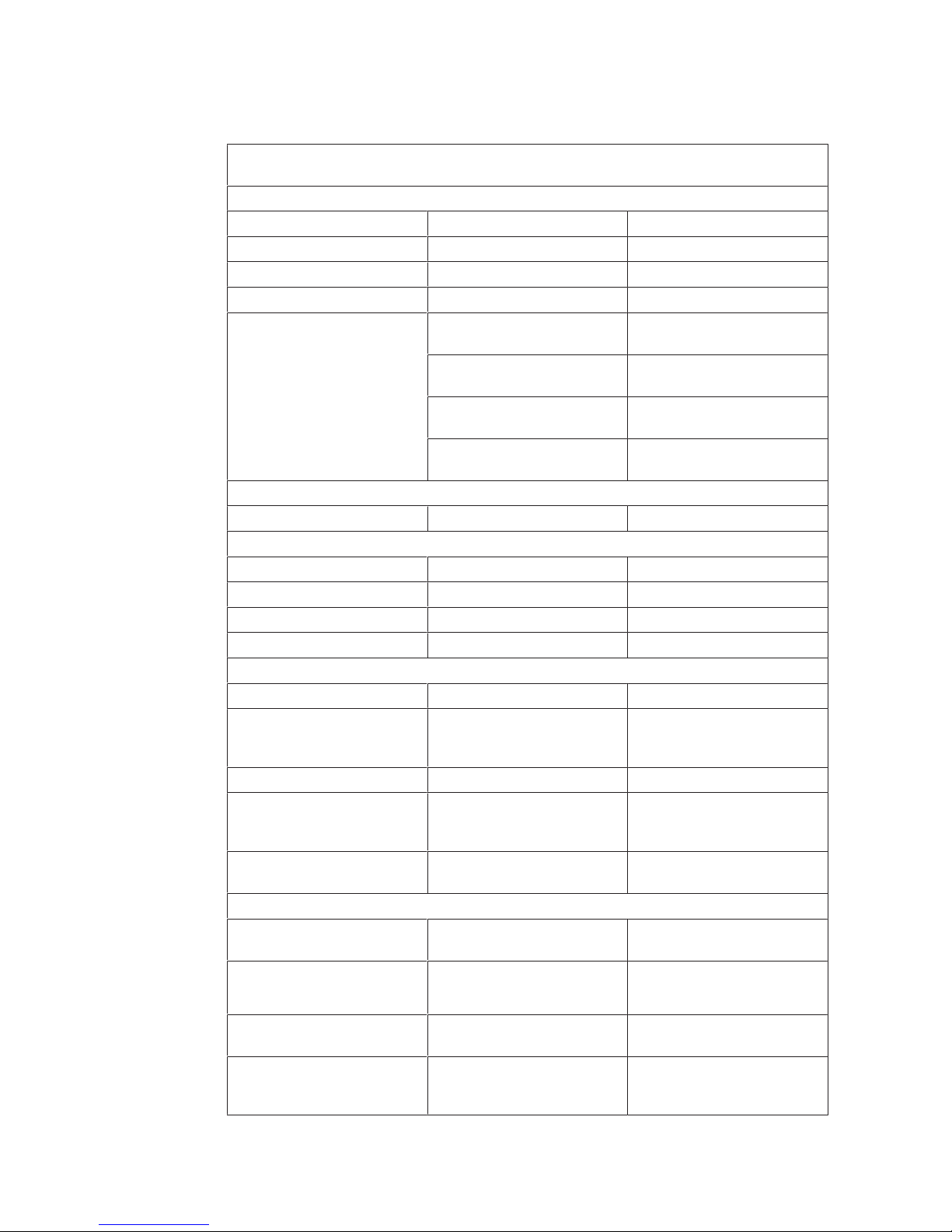

9.1 Error analysis

Symptoms Possible causes Measures

The use of a master or user

medium is confirmed via various acoustic and/or visual

signals by the components

1 x very

short

9 x

flashes

red

5

– Battery 'Low'

(V4 FW 42.XX)

– Replace the batteries

The use of a master or user

medium is confirmed via various acoustic and/or visual

signals by the components

9 x very

short

5

—

2

– Battery 'Low'

(V4 FW 42.XX)

2

– Replace the batteries

The use of a master or user

medium is confirmed via various acoustic and/or visual

signals by the components

2 x

long

after 4

s

1 x

short

green

5

– Battery 'Low'

(V3 FW 31.XX/32.XX)

2

– Replace the batteries

Door does not open: authorisation via an authorised user

medium is confirmed by

acoustic signals

1 x very

long

— – Alarm — Battery "Empty" – Replace the batteries

Door does not open: authorisation by an authorised user

medium is confirmed via

acoustic and visual signals

8 x

short

8 x

short

red

– Self-test could not be completed.

3

– Check or replace the coupling unit

Door does not open: authorisation by an authorised user

medium is confirmed via

acoustic and visual signals

4 x

short

4 x

short

red

– Medium not programmed

– Outside the time window

– Program medium

– Check time profiles

Door does not open: authorisation by an authorised user

medium is confirmed via

acoustic and visual signals

1 x long

1 x

short

1 x long

1 x

short

green

– Internal clock in component

has failed

– Check programming and

clock time

User medium cannot be programmed

— — – 4000 media or groups

already programmed in the

e-module

– Faulty medium

– Not the correct technology

– Contact customer service

Master medium cannot be

programmed

1 x

short

1 x red – E-module already pro-

grammed

– Carry out INI reset

Master medium is not detected

— — – No power supply – Check batteries or power

supply

Incorrect e-module on digital

cylinder

— 3 x red

flash

– E-module knob and MC insert are not compatible

(V4 FW 42.XX)

– Check compatibility

Other errors — 1 x

short

red

– Unintentional re-start —

Page 42

Troubleshooting Technical Manual

42 1220013692 - 11/2017dormakaba digital cylinder

Symptoms Possible causes Measures

1 x

short

green

1 x

short

red

Other errors 1 x

short

1 x long

1 x

short

—

2

– Unintentional re-start —

Key:

2

Components without visual display

3

Function only for c-lever, mechatronic cylinder and digital cylinder

5

The actuator subsequently opens

Page 43

TroubleshootingTechnical Manual

431220013692 - 11/2017 dormakaba digital cylinder

9.2 Error analysis for battery life

Symptoms Possible causes Measures

Battery life deviates significantly

from expectations

– More accesses than anticipated – Read out traceback and check

– Low temperatures

– Firmware version not up-to-date – Carry out update to current firm-

ware version

– Programming/configuration with

non-used functions

– Adjust programming/configura-

tion

– Battery was not new – Insert new, recommended battery

– Batteries that look identical can

contain different amounts of energy

– Insert new, recommended battery

– E-module knob with battery installed was stored separately from

digital cylinder

– Install new battery

– Store e-module knob without

battery

– Defective electronics – Contact customer service

– Activation of digital cylinder

without RFID medium, e.g. by holding your hand in front of it

– Inform user

– Many unauthorised access attempts (unauthorised access requires more energy than authorised

access)

– Clarify causes

– Coupling monitoring often active – Carry out update to current firm-

ware version

Page 44

Appendix Technical Manual

44 1220013692 - 11/2017dormakaba digital cylinder

10 Appendix

This chapter provides additional information about the battery operation.

10.1 Summary of various factors influencing the battery

operation

The digital cylinder operates with a 3V CR2 lithium battery.

The battery life is affected by the following factors:

• Number of accesses and actions (frequency of use)

• Programming/configuration of components

• Battery type

• Battery manufacturer

• Ambient temperature

• Firmware version

• Hardware version (standard INT or extremely low temperature EXT)

10.2 Recommendations for battery operation

• Always use the up-to-date firmware version for the products.

• Always only activate the functions actually required.

• Record the battery replacement date in a maintenance plan.

If the battery life does not meet expectations, determine the cause in accordance with

Chapter [}9.2].

• When the battery is 'low', replace immediately.

• Explain to user the 'low' battery warning signal and urge them to report the 'low' battery

warning to the person responsible immediately.

• Keep a stock of currently recommended batteries:

– Panasonic CR2 Industrial (made in Japan or Indonesia)

– Panasonic CR2 PHOTO Power (made in Japan or Indonesia)

– Duracell Ultra CR2 (made in Japan or Indonesia)

Loading...

Loading...