User Guide

Model : AC Drive (V.F.D)

(3-Phase input)

www.doochpump.com

[SAFETY PRECAUTIONS]

Preface

Thank you for choosing DOOCH’s high performance Q-Drive series.

The Q-Drive is a dedicated pump drive designed for variable Speed pumping system.

The Q-Drive is manufactured with high-quality components and materials and incorporate

the latest microprocessor technology available.

This manual is published for the consumers to easily operate the pump system since the

Q-drive is attached to the pump system.

Before installation and operation please peruse in this manual thoroughly.

※ The information contained in this manual is subjected to change without prior notice.

Safety Precautions

ㆍ Since the safety precautions are actions to allow using this product safely and rightly in

order to prevent possible accident or dangers from occurring, be sure to follow them.

ㆍ This user’s manual contains two kinds of marks such as ‘WARNING,’ and CAUTION.

ㆍ These marks are warning clauses against possibility of faulty use by the users.

ㆍ In order to fully understand the marks for safe procedure, please read the manual

through the end before using the equipment.

ㆍ Please keep this manual where the user of this driver can read it at any time.

Warning:

It indicates a potential dangerous situation that may cause some fault,

serious injury or death if the instruction is not being observed.

Caution:

It shows a potential dangerous situation that may cause some damage

on the product and loss of property if the instruction is not being observed.

DOOCHPUMP

1 |

[SAFETY PRECAUTIONS]

ㆍDo not open cover during powered state or operation.

(Exposed high voltage terminals or charging part of DC voltage may

cause electric shock.)

ㆍDo not open cover even when power is not supplied except for

wiring or inspection work.

(When the power is turned off, charged DC voltage in charging part

of drive may cause electric shock.)

ㆍDuring wiring work or regular inspection, cut off the power and

check with tester if DC voltage is discharged after elapsed

more than 10 minutes.

(It may cause electric shock. Execute work when charging voltage

of DC part is DC 30V or less.)

ㆍDo not operate the switch or drive with wet hands.

(It may cause electric shock.)

ㆍWhen any part of drive input or cable jacket is damaged,

do not apply electricity or operate the equipment.

(It may cause electric shock.)

ㆍDo not put over stress on the input/output power cable or

signal wires of the drive with heavy object.

(It may damage on the cable jacket to cause electric shock.)

ㆍDo not install the equipment near the inflammable materials.

(Installation on or near the inflammable materials may cause fire.)

ㆍWhen drive has any fault, cut off the input power.

(If not, it may cause fire due to consequent accident.)

ㆍDo not touch the drive during powered state or several minutes

after power is turned off.

(Since drive has high temperature after operation, body contact

may cause burn.)

ㆍDo not input power for the drive with damaged product and

part even if installation is completed.

(It may cause electric shock.)

ㆍDo not leave any damageable objects from inside of drive, such

as screw, metal, water, oil, etc.

(It may cause fire.)

DOOCHPUMP

2 |

[SAFETY PRECAUTIONS]

Cautions for Use

A. Transportation and Installation

ㆍ Transport the product with correct method according to its weight.

ㆍ Do not stack the products with more than specified layers.

ㆍ Install the product upon rules described on the User’s Manual.

ㆍ Do not open during transportation of the product.

ㆍ Do not put any heavy object on the product.

ㆍ Installation direction shall follow criteria specified on the User’s Manual.

ㆍ Do not fall or give strong impact on the drive as it is a precise instrument.

ㆍ Draw water completely out of the pump during winter without using for a long time.

ㆍ Use the drive under the environmental conditions as mentioned below .

Installation Location

Temperature/Humidity

Keep out of corrosive gasses, inflammable gasses,

Liquid and dust.

-10 ~ 40℃ / Not more than 90% RH (No dewdrop)

Storage Temperature

Elevation

Vibration

Ambient Atmospheric Pressure

-20 ~ 65℃

Altitude 1,000m or lower

below 5.9m/sec² (=0.6g)

70 ~ 106 kpa

B. Wiring

ㆍ After installing the main body, execute wiring.

ㆍ Wiring or inspection shall be performed by the professional technicians.

DOOCHPUMP

3 |

[SAFETY PRECAUTIONS]

ㆍ Do not install static condenser, radio noise filter, and so on at the output terminals of the

drive.

ㆍ Check if the power input line and motor output line are interchanged.

ㆍ Faulty terminal connection may cause damage on the drive.

ㆍ Use the circuit breaker.

※ Do not install leakage breaker at the power input.

* If you have any problems , please contact our local agent.

C. Checkup on Initial Operation

ㆍ Be sure to check setup parameters of the drive before operating it first. It may require

changing parameters according to states such as type of pump or installed system

environments.

ㆍ For terminal blocks for main power circuit and control circuit, be sure to follow connection

method and electrical specifications specified on this manual. Improper use may damage on

the drive.

ㆍ Be sure to use pressure sensors and low water level sensor specified by Dooch.

D. Operation

ㆍ Since it has automatic restart and recovery functions after power failure in default

and it is automatically restarted in case it is stopped due to fault or system alarm or power is

turned off during operation, be careful when power is applied initially.

ㆍ Do not modify or change inside of the product without approval

ㆍ Do not start or stop the drive with electronic contactor installed at the power input.

ㆍ Install EMC filters to reduce impact from electromagnetic wave in order to protect

electronic equipment being used near the drive.

ㆍ Install input reactor when input voltage is in unbalanced condition. Static condenser or

generator may be overheated and destroyed due to high frequency on power source

generated by drive.

DOOCHPUMP

4 |

[SAFETY PRECAUTIONS]

ㆍ In case of driving 400V class motor with the drive, use the motor with reinforced

insulation or conduct suppress measure against micro-surge voltage. (Motor may

be sometimes destroyed upon deteriorated its insulation performance due to

micro-surge voltage.)

ㆍ In case of initialization of parameters, set up required parameters again before

operation. Parameter initialization changes the parameter values to factory settings.

E. Reaction on Failure and Malfunction

ㆍ In case drive is destroyed to make operation impossible, reliability of pump system

may become deteriorated. It is recommended to install additional auxiliary system in

preparation of such situations.

ㆍ For countermeasure against drive failure, refer to Chapter 7

DOOCHPUMP

5 |

[SAFETY PRECAUTIONS]

6 |

DOOCHPUMP

[CONTENTS]

CONTENTS

[ Chapter 1. Basic Matters ]

1.1 Nameplate information

1.2 Type of product

1.3 Installation

1.4 Wiring

[ Chapter 2. Specification ]

2.1 Specification of Product

[ Chapter 3. External Dimension ]

3.1 NQ-0075T ~ NQ-0220T

3.2 NQ-0400T

3.3 NQ-0550T ~ NQ-0750T

3.4 NQ-1100T ~ NQ-1500T

3.5 NQ-1850T ~ NQ-2200T

[Chapter 4. Installation ]

4.1 Caution on Installation

4.2 Wiring Diagram of Terminals

4.3 Wiring of Main Power Supply Circuit

4.3.1 Description on Main Power Supply Terminals

4.3.2 Caution on Main Power Supply Wiring

4.3.3 Caution on Ground Wiring

4.3.4 Specification of Recommended Wires and Terminal Screw

4.4 Control Circuit Wiring

4.4.1 Arrangement of Control Terminal Block

4.4.2 Functions of Control Terminal Block

4.4.3 Cautions on Control Circuit Wiring

4.4.4 Connection of Pressure Sensor and Low Water Level Sensor

4.4.5 Sink Mode and Source Mode

4.4.6 Communication Line Wiring

1 |

DOOCHPUMP

[CONTENTS]

[ Chapter 5. Operation ]

5.1 FND

5.1.1 Appearance and Description of FND

5.1.2 Functional Description of each Part

5.1.3 How to change Parameter Settings

5.2 Function Setup

5.2.1 Basic Function Setup

5.2.2 Expansion Function Setup

5.3 Basic Operation

5.3.1 Constant Pressure Control Mode

[ Chapter 6. Function Table & Description]

6.1 Display of present status

6.2 Pump Control Group

6.3 Drive Control Group

6.4 Description on Function of Parameter Settings

6.4.1 Pump Control Group

6.4.2 Drive Control Group

[ Chapter 7. Cause of Fault and Reaction ]

7.1 Fault History Table

7.2 Reset of fault and alarm

7.3 Cause of Fault and Reaction

[ Chapter 8. Appendix ]

8.1 RS-485

8.2 Peripherals

8.3 EMC filter

2 |

DOOCHPUMP

[

[CHAPTER 1 BASIC MATTERS]

1. Precautions before Using

1.1 Information Nameplate

After taking drive out of the package box, check up the nameplate at the side of the body

and verify if the type, rated output and so on of the drive are matched with the ordered

product. In addition, check if there is any damage during transportation.

* If you have any question or the product has any abnormal state, please contact the

agent or A/S center of Dooch.

- Nameplate of the Product –

1.2 Type of Product

NQ- 0 7 5 0 T

Type of Drive

Input specification

Output specification

①

T : Three phase

②

It indicates capacity in 00.00kW unit.

0075 : 0.75kW(1HP)

0150 : 1.50kW(2HP)

0220 : 2.20kW(3HP)

0400 : 4.00kW(5.5HP)

0550 : 5.50kW(7.5HP)

0750 : 7.50kW(10HP)

1100 : 11kW(15HP)

1500 : 15kW(20HP)

1850 : 18.5kW(25HP)

2200 : 22kW(30HP)

1-1 |

DOOCHPUMP

[

[CHAPTER 1 BASIC MATTERS]

ㆍ Product model name is indicated as above. Initial four digits indicate driving

capacity of the drive in 00.00kW unit. Decimal point is not indicated.

ㆍ 'T' refers Three phase.

ㆍ ‘D’ means CAN Driver indicating Multi-Drive control system. If it is a single type, D will

be omitted.

1.3 Installation

Install the drive with proper method under specified conditions considering its

life and performance.

1.4 Wiring

Connect power supply and motor to the power supply terminal block and operation and

control signal to the control terminal block. Since improper connection will cause

malfunction or damage, be sure to wire with specified method.

1-2 |

DOOCHPUMP

[CHAPTER 2 SPECIFICATIONS OF PRODUCT]

2. Specifications of Product

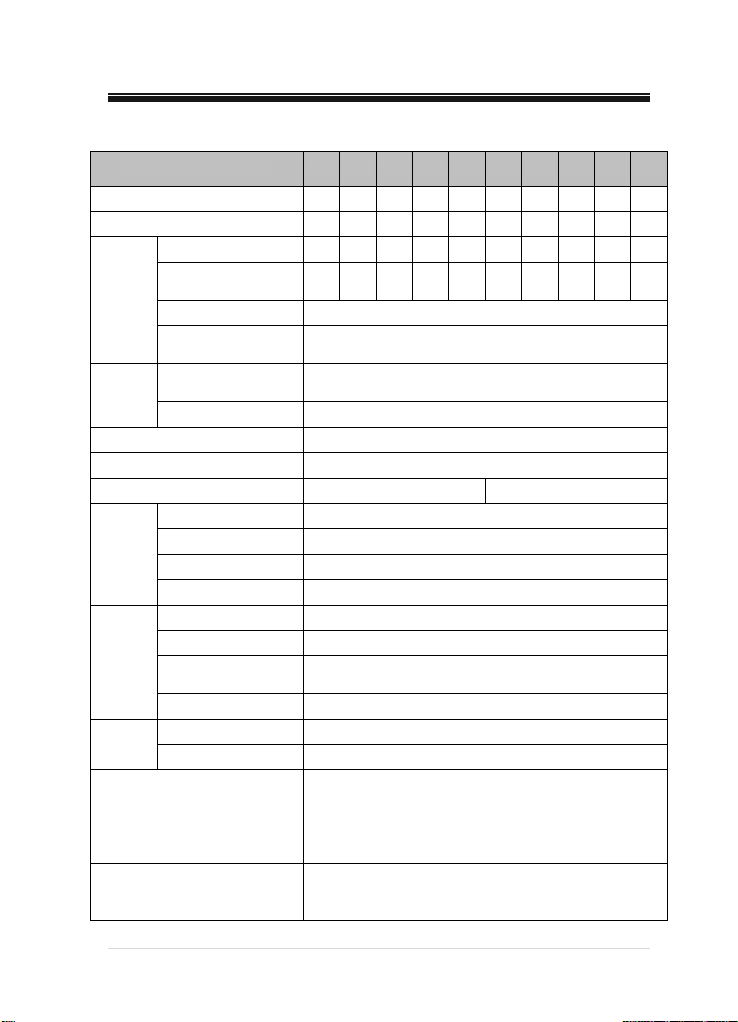

Model NQ-_____S, T( D) 0075 0150 0220 0400 0550 0750 1100 1500 1850 2200

Standard Motor [kW] 0.75 1.5 2.2 4 5.5 7.5 11 15 18.5 22

Standard Motor [HP] 1 2 3 5.5 7.5 10 15 20 25 30

Output Capacity [kVA] 2 2.6 4 5.9 7.9 10.5 15.8

Rated Output Current

Rated

Output

Rated

Input

Protection Class IP55

Switching Frequency [kHz] 1 ~ 15

Control

Operation

Output

Signal

Other Functions

Protection Functions

[A]

Output Voltage [V] 380 ~ 440

Output Frequency

[Hz]

Rated Input Voltage

[V]

Input Frequency [Hz] 50 / 60 (±5%)

Cooling Natural Cooling Forced Fan Cooling

Controlling Method V/F Control, Slip Compensation Control

Frequency Stability 1% of Rated Frequency

Overload Resistance 120%, 1 minute

Torque Boost Manual Torque Boost (0~10%)

Operation Method FND / Term i nal / Communication (CAN) Operation

Frequency Setting FND / Terminal (0~10V or 4~20mA)

Acceleration/

Deceleration Time

Abnormal Reset Automatic Reset upon Automatic Restart Setting

Abnormal Output Output Contact (FLT-AT,CT,BT), LED Output

Operation Status Output Contact (RUN-AT,CT,BT), LED Output

3 4 6 9 12 16 24 30 39 45

0.05 ~ 50 / 60

3φ 380V ~ 440V (-15% ~ +10%)

1 ~ 600 Sec.

Freezing Protection for Pump, Auto Recovery after Power

Fail, High/Low Pressure Alarm, Low Water Level

Detection, Multi-Drive Control, Failure History Storage,

Forced Alternative Operation, PID Control,

Fixed Frequency Operation, Dry running Protection

High Voltage, Low Voltage, Over Current, Surge,

Overload, Inverter Overheating, Output Wire

Disconnection, Communication Error

19.7 25.7 29.6

2-1|

DOOCHPUMP

Display

Code

Use

Condition

[CHAPTER 2 SPECIFICATIONS OF PRODUCT]

Output Frequency, Pump’s Curr ent P re ssur e, Pump’s

Drive Information

Abnormality

Information

Installation

Location

Ambient Temperature

Storage Temperature

Ambient Humidity Under 90% RH (No Due)

Setting Pressure, DC Voltage, Output Current,

Input/Output Pressure (on Differential Pressure Control)

Pressure Sensor Error, High/Low Pressure Alarm, Low

Level Alarm, Drive Error

Altitude 1,000M or lower

Keep out of Corrosive Gases and Liquid, Dust

-10℃ ~40℃

-20℃ ~ 60℃

2-2|

DOOCHPUMP

[CHAPTER 3 EXTERNAL DIMENSION]

3. External Dimension

3-1. NQ-0075T~NQ-0220T

H W D W1 D1 Weight

NQ-0075T 143 151 229 133 217 2.9kg

NQ-0150T 143 151 229 133 217 2.9kg

NQ-0220T 143 151 229 133 217 3kg

3-1|

DOOCHPUMP

3-2. NQ-0400T

[CHAPTER 3 EXTERNAL DIMENSION]

H W D W1 D1 Weight

NQ-0400T 162 151 229 133 217 3.3kg

3-2|

DOOCHPUMP

[CHAPTER 3 EXTERNAL DIMENSION]

3-3. NQ-0550T~NQ-0750T

H W D W1 D1 Weight

NQ-0550T 176 290 290 189 277 5.5kg

NQ-0750T 176 290 290 189 277 5.7kg

3-3|

DOOCHPUMP

[

[CHAPTER 3 EXTERNAL DIMENSION]

3-4. NQ-1100T~NQ-1500T

H W D W1 D1 Weight

NQ-1100T 186 390 290 185 277

NQ-1500T 186 390 290 185 277

3-4| DOOCHPUMP

12.4kg

12.4kg

[

[CHAPTER 3 EXTERNAL DIMENSION]

3-5. NQ-1850T~NQ-2200T

H W D W1 D1 Weight

NQ-1850T 186 440 290 210 277

NQ-2200T 186 440 290 210 277

3-5|

DOOCHPUMP

14kg

14kg

[CHAPTER 3 EXTERNAL DIMENSION]

3-6|

DOO C H P U M P

[CHAPTER 4 INSTALLATION]

4. Installation

4.1 Cautions on Installation

A. Be careful for handling and use.

Since drive consists of sensitive electric/electronic devices, be careful not to damage it

during installation or transportation.

B. Be careful to install the drive on the place with vibration.

In case of installing it on the motor or piping directly, prepare a countermeasure to

reduce vibration.

C. Cautions on Ambient Temperature

Since lifetime and performance of the drive depend on the ambient temperature largely,

maintain the ambient temperature of the place not to exceed allowable temperature

(- 10 ~ 40 ℃). If the ambient temperature is higher than allowable temperature, reduce

output ratings of the drive before use.

D. Install on noninflammable/incombustible materials.

Since the drive becomes high temperature during operation, install it on

noninflammable/incombustible materials.

E. Secure enough space around installation point.

Since the drive is a kind of heating element, be sure to install it toward the direction that

cooling fan flows air from bottom to top and secure enough ambient space not to

interfere the cooling air in order for effective cooling.

F. Install the drive securely in upright position.

Install the drive securely without sway in upright position using fasteners or bolts.

4-1|

DOOCHPUMP

[

[CHAPTER 4 INSTALLATION]

4.2 Wiring Diagram of Terminals

3φ 380V~440

AC Input

50/60 Hz

4-2| DOOCHPUMP

[

[CHAPTER 4 INSTALLATION]

4.3 Wiring of Main Power Supply Circuit

4.3.1 Description on Main Power Supply Terminals

R S T FG FG U V W

Terminal

Sign

R,S,T AC Input To connect commercial AC Input.

FG Ground

U,V,W Drive Output To connect Motor.

4.3.2 Cautions on Main Power Supply Wiring

• Execute wiring work after checking if DC power of drive is discharged (under 30V).

• Be sure to install wiring breaker (MCCB) between AC input power and drive input

power terminals (R,S,T). Use the wiring breaker (MCCB) with 1.5~2 times larger

capacity than rated current of the drive.

• Sometimes EMI occurs due to high speed switching of the drive and it makes radio

interference on electronic devices used around the drive. For that case, install EMC

filters between AC power input and the drive to reduce interference.

• If AC input power is connected to output terminals (U,V,W) of drive, drive will be

damaged. Be sure to connect it to input terminals.

• Even though power input terminals (R,S,T) may be connected regardless to phase

sequence of AC input power, it is required to consider rotation direction of the

motor when connecting input terminals of the motor to output terminals of the

drive (U,V,W). If rotation direction of the motor is reversed, 2 lines from drive output

terminals (U,V,W) should be exchanged each other.

• Do not make short circuit nor ground with drive output terminals (U,V,W). Short

circuit or ground of output terminals may damage on the drive.

• Do not connect static condenser or noise filter at the output of the drive. It may

cause frequent trip on the drive, or static condenser or noise filter may be destroyed

due to overheating.

• Use specified thickness of wires for input/output wiring for the drive. If wires are

Terminal Name Description

It is a ground terminal on drive enclosure. Please ground it.

4-3|

DOOCHPUMP

[CHAPTER 4 INSTALLATION]

thinner than specified thickness, it may cause torque reduced due to voltage

decrease or induce fire accident from overheating.

• Maintain wiring distance between drive and motor within 50m. If it is longer than

50m, be sure to use the motor with reinforced insulation or micro-surge filter.

4.3.3 Cautions on Ground Wiring

• Since a leak current is generated from high speed switching of the drive, it is required to

ground the drive to prevent electric shock.

• Maintain ground resistance within 10Ω during grounding work

• Use thicker wires than specified one for ground wire.

4-4|

DOOCHPUMP

[

[CHAPTER 4 INSTALLATION]

4.3.4 Specifications of Recommended Wires and Terminal Screw

Drive

Capacity

0.75 kW M4 1.2~1.5 2(14) 2(14) 2(14)

1.5 kW M4 1.2~1.5 2(14) 2(14) 2(14)

2.2 kW M4 1.2~1.5 3.5(12) 3.5(12) 2(14)

4 kW M4 1.2~1.5 3.5(12) 3.5(12) 3.5(12)

5.5 kW M5 2.5 5.5(10) 5.5(10) 5.5(10)

7.5 kW M5 2.5 5.5(10) 5.5(10) 5.5(10)

11 kW M6 4~5 8(8) 8(8) 8(8)

15 kW M6 4~5 8(8) 8(8) 8(8)

18.5 kW M6 4~5 14(6) 14(6) 14(6)

22 kW M6 4~5 22(4) 22(4) 14(6)

※ Apply specified torque for fastening the terminal screw.

Size of

Terminal

Screw

Fastening Torque

for Screw (N.m)

Thickness of Wires

mm² (AWG)

R,S,T U,V,W FG

※ Weak fastening may cause malfunction and too strong fastening may destroy terminal

block.

※ Use 600V class wires.

4-5|

DOOCHPUMP

[CHAPTER 4 INSTALLATION]

4.4 Control Circuit Wiring

4.4.1 Arrangement of Control Terminal Block

Power Range : 0.75~4Kw

4-6|

DOOCHPUMP

[CHAPTER 4 INSTALLATION]

Power Range : 5.5~22kW

4-7|

DOOCHPUMP

[CHAPTER 4 INSTALLATION]

4.4.2 Functions of Control Terminal Block

Classification

Pump

Control

Contact

Operation

Input

Signal

Analog

Frequency

Setup

Output

Signal

Signal

Relay

Contact

Com.

RS485

(Option)

CAN

Ter mi nal

Sign

S1P, S1N Pressure Sensor 1 Connection terminal for Pressure Sensor 1

S2P, S2N Pressure Sensor 2

LV1, LV2 Low Level Sensor Connection terminal for low level sensor

P1 Operation Command Operation/Stop Terminal

EST Emergency Stop When EST signal is ON, it turns off drive output.

24V

CG

V1

I1

GND

RUN

(AT,CT,BT)

FAULT

(AT,CT,BT)

CANH,CANL CAN Signal CAN signal line terminal

CG

TX,RX

(AUX1,AUX2)

CG

Terminal Name Description

Contact Operation

Common Terminal

Contact Operation

Common Terminal

Frequency

Setup (Voltage)

Frequency

Setup (Current)

Frequency

Setup

Common Terminal

Abnormal Signal

Output

Multi-function Output

CAN Common

Terminal

RS485 Signal RS485 Signal Terminal

RS485 Common

Terminal

Connection terminal for Pressure Sensor 2

(used for differential pressure control)

Common terminal of input terminal for PNP

contact.

Common terminal of input terminal for NPN

contact.

If entering DC 0~10V, it makes setup frequency.

If entering DC 4~20mA it makes setup

frequency.

Common terminal for Analog frequency setup

terminal

It outputs signal when drive is output. (≤AC250V

5A, ≤ DC30V 5A)

It is output when protection function of system

and drive is activated to cut off output.

(≤AC250V 5A, ≤DC30V 5A)

Common terminal of power ground for CAN

communication

Common terminal of power ground for RS485

communication

4-8|

DOOCHPUMP

[

[CHAPTER 4 INSTALLATION]

4.4.3 Cautions on Control Circuit Wiring

• Maintain wiring distance between pressure sensor and drive within 10m.

• In case of remote control using analog signals, maintain distance between remote

control panel and drive within 50m.

• Set off sensor and analog signal lines enough from power lines.

• Use shield twisted wires for signal lines of control circuit.

• Since GND and CG are insulated each other, do not interconnect or ground them.

4.4.4 Connection of Pressure Sensor and Low Water Level Sensor

• Use the pressure sensor and low water level sensor specified by Dooch.

• General specifications of the pressure sensor and low water level sensor specified by

Dooch are as follows:

• Since terminals on pressure sensor have polarity, be careful about polarity during

installation.

• When using any unspecified pressure sensor and low level sensor, please contact us

before using them.

Category Pressure Sensor Low Water Level Sensor

Excited Voltage DC 12V DC ±15V Pulse

Sensor Output 4~20mA Connection

4-9|

DOOCHPUMP

[

[CHAPTER 4 INSTALLATION]

※

4.4.5 Sink Mode and Source Mode

This product is configured to allow applying both sink mode (NPN: Using CG common

terminal) and source mode (PNP: Using 24V common terminal) to the input terminal logic

of control circuit. It is possible to toggle between sink mode and source mode using

selection switch within the control board.

Wiring methods for sync mode and source mode are shown on figures below.

Sink

Mode(NPN)

Inner power Outer power

Source

Mode(PNP)

4.5.6 Communication Line Wiring

This product basically supports CAN communication that is use for multiple pump control.

When using CAN communication, connect CANH (High of CAN) and CANL (Low of CAN)

on the terminal block and shield wire to CG. Use shield and twisted wire for wiring.

In addition, when using termination resistor for connecting multiple CANs, change the

switch from OPEN to SHORT.

When using RS 485 communication, please contact US.

4-10| DOOCHPUMP

[CHAPTER 5 OPERATION]

5. Operation

5.1. FND

5.1.1 Appearance and Description of FND

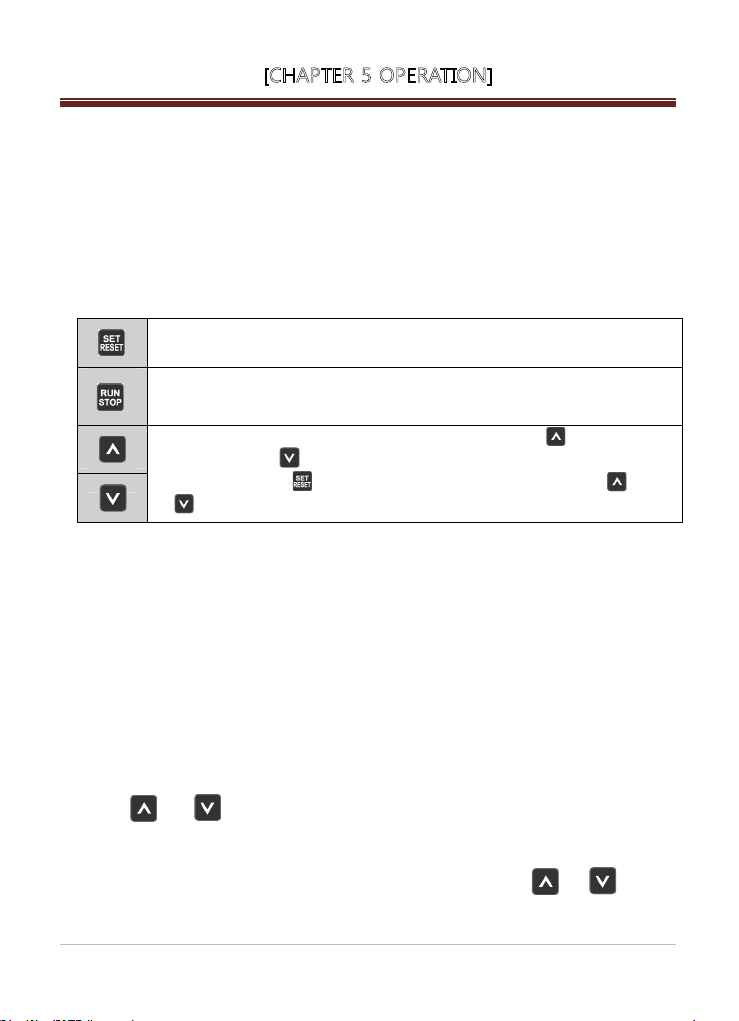

FND has five digits of 7-segment, four LED lamps to display various settings and states and

consists of four buttons to operate drive or enter setting.

5.1.2 Functional Description of each Part

1) LED Lamps

LED lamps consist of Run, Stop, Alarm1 and Alarm2 and functions of them are as follows:

- Functions of each Button

• Run and Stop LEDs indicate status of the drive.

• In case of drive error, Alarm2 lamp will be turned on. In case of alarm for pump system,

Run Turned on for waiting and flickered on operation

Stop Turned on during stop

Alarm1

Turned on for High Pressure/Low Pressure/Sensor Error/Low Level

Alarms

Alarm2 Turned on for drive error

Alarm1 lamp will be turned on.

Lamp Part

Button Part

DOOCHPUMP

5-1 |

[CHAPTER 5 OPERATION]

2) FND Part

FND consists of five digits of 7-segment and displays status value of drive and pump and

parameter settings. FND displays are divided into St group (Status Group), Pr group (Pump

Control Group) and dr group (Drive Group).

3) Button Part

Button part consists of four buttons and it is used for parameter setting or movement.

• Description on Button’s Functions

It is used for setting up pressure settings, various parameters or Alarm Reset.

It operates or stops the drive.

On operation state, RUN lamp will be turned on.

It is used to change parameter items or parameter settings. Key increases

the value, while key decreases the value. After changing the settings,

be sure to press key for saving the final value. If pressing and

for 3 seconds, parameter group is moved.

5.1.3 How to Change Parameter Settings

• Since any change of parameter settings has direct influence on operation, please be careful

about it.

• Before changing any parameter setting, be sure to write it on paper.

• Do not change the parameter setting except for responsible operator or professional

engineer.

• Since there are items with data or parameter unavailable for change during operation, be sure

to confirm. (Refer to Chapter 6. Table of Functions.)

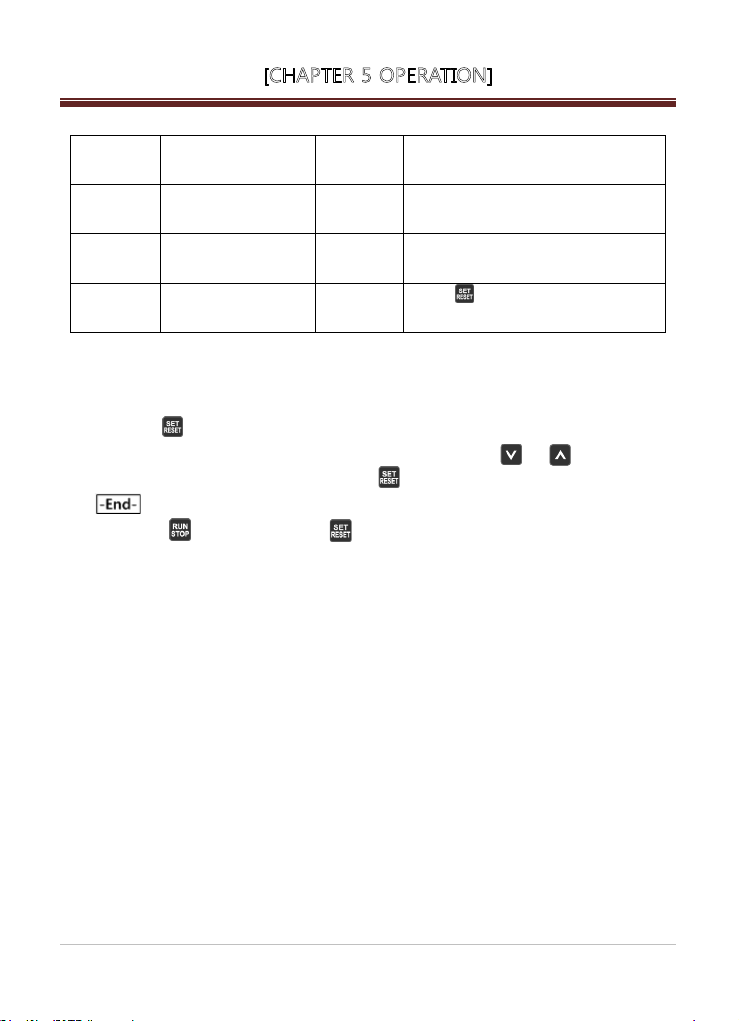

1) Parameter Group Movement

When applying power first, it enters into St group. In order to move to parameter group,

press and buttons for 3 seconds.

2) Parameter Item Movement

ve between parameter items within parameter group, use and buttons

In order to

to move to desired item.

mo

5-2 |

DOO C H P U M P

[CHAPTER 5 OPERATION]

3) How To Change Parameter Settings

In order to change parameter setting, press key at the desired parameter item to enter into

Setting Change Mode. On Setting Change Mode, use and key to change it to desired

setting. Press key again, then message is displayed to apply the setting. If

pressing key on Parameter Edit Mode, setting is not applied and exited from Edit Mode.

5-3 |

DOOCHPUMP

[CHAPTER 5 OPERATION]

5.2 Function Setup

5.2.1 Basic Function Setup

It is a basic parameter setup to operate the drive. Any parameter that is not set by the user,

it is set default value of factory setting.

1) Common Setup

It is a parameter setup to set and confirm commonly when controlling pump using drive

regardless to type of control.

Setup Item

Input Location of Run

Command

Input Method of Target

Frequency

Capacity of Motor dr-10 To set up Capacity of Motor

No. of Poles of Motor dr-11 To set up No. of Poles of Motor

Rated Current of Motor dr-12 To set up Rated Current of Motor

Rated Rotations of Motor dr-13 To set up Rated Rotations of Motor

Rated Voltage of Motor dr-14 To set up Rated Voltage of Motor

No-load Current of Motor dr-15 To set up No-load Current of Motor

Rated Slip Frequency of

Motor

Rated Frequency of

Motor

Efficiency of Motor dr-18 To set up Efficiency of Motor

Rotation Direction

Selection of Motor

Stopping Method of Motor dr-21

Increase/Decrease Time dr-22/dr-23 To set up Increase/Decrease Time of Drive

Parameter

Code

dr-01

dr-02

To select a method to issue Run command

To select a method to control target operation

Description on Function

(FND, Terminal Block)

frequency (Own PID, FND, V1, I1)

dr-16 To set up Rated Slip Frequency of Motor

dr-17 To set up Rated Frequency of Motor

dr-20

To set up Rotation Direction Selection of

Motor Properly

To set up Stopping Method of Motor to stop

the motor

5-4 |

DOOCHPUMP

[CHAPTER 5 OPERATION]

2) Pump Control Function Setup

These parameters are to be set for the pump system when controlling pump using drive.

Setup Item

Pump Capacity Pr-01 To set up Pump Capacity

Pump Control Mode Pr-02 To set up Pump Control Mode

Sensor Capacity and

Correction

To Use Low Water

Level Sensor

3) Drive Control Function upon External Command

These parameters are to be set basically when controlling the drive using external controller.

Setup Item

Frequency Setup upon

V1 Voltage

Frequency Setup upon

I1 Voltage

4) CAN Communication Function Setup

These parameters are to be set basically for CAN communication used on interoperation

or connecting FND/LCD Monitor.

Parameter

Code

Pr-03~06

Pr-76

Parameter

Code

dr-60~63

dr-64~67

Description on Function

To set up capacity of pressure sensor and

correct variation between actual pressure

and pressure sensor

(On constant pressure control, Sensor2 is

not used.)

To decide whether to use low water level

sensor

Description on Function

To set up output frequency range against

voltage when controlling drive using V1

voltage

To set up output frequency range against

current when controlling drive using I1

current

DOOCHPUMP

5-5 |

[CHAPTER 5 OPERATION]

Setup Item

CAN Comm. Mode Pr-50 To set up CAN Comm. Mode

CAN Comm. ID Pr-51

CAN Comm. Speed Pr-52 To set up CAN Comm. Speed

5.2.2 Expansion Function Setup

It is to set up parameters to operate pump system optimally except for those to be set for

operating the drive. Any parameter that is not set by the user, it is set default value of factory

setting.

1) Pump Control Parameters

Setup Item Parameter Code Description on Function

PID Controller Gain

Setup

Control Cycle of PID

Controller

Start Pressure

Variation

Initial Output Ratio on

Starting

Lead Pump

Alternation

Parameter

Code

Pr-07~09

Pr-10

Pr-12

Pr-15

Pr-53~54

Description on Function

To set up CAN Comm. ID

(If ID is ‘0’, CAN Comm. is disabled.)

To set up gain to adjust response

characteristics of PID controller

To set up Control Cycle of PID Controller

Minimum pressure variance to allow drive to

start

To set up initial starting output frequency of PID

controller in order to speed up response against

initial starting

To operate pump alternatively in force during

multi-drive operation

5-6 |

DOOCHPUMP

[CHAPTER 5 OPERATION]

2) Setup Parameters for Pump System Protection

Setup Item

High Pressure Alarm

Low Pressure Alarm

Low Water Level

Alarm

3) Setup Parameter for Fault History Storage

Setup Item

Fault History Storage

and Deletion

Parameter

Code

Pr-70

Pr-72

Pr-71

Pr-73

Pr-74~77

Parameter

Code

Pr-80~86

To set up high pressure alarm level and time

in order to protect discharge pipe from high

pressure

To set up low pressure alarm level and time

in order to protect the pump from damaged

pump

There are two detection methods using low

level sensor or software in order to protect

the pump by detecting existence of water

within suction pipe.

To store or delete fault or alarm generated

from pump system or drive

Description on Function

Description on Function

DOOCHPUMP

5-7 |

[CHAPTER 5 OPERATION]

5.3 Basic Operation

5.3.1 Constant Pressure Control Mode

1) Single Drive Operation

In case of using a single drive to control constant pressure, it is possible to apply it to the

pump system as below.

A. Wiring Diagram

3φ 380V~440V

AC Input

50/60 Hz

• Connect drive wiring so that the power input lines and motor output lines should not be

interchanged.

• Be sure to install wiring breaker at the power input of drive.

5-8 |

DOOCHPUMP

[CHAPTER 5 OPERATION]

• Check the polarity of pressure sensor and connect it properly.

(In case of KELLER 21G series, connect brown line of pressure sensor to SEN1P terminal and

white line to SEN1N terminal respectively.)

• Connect low level sensor (electrode) if necessary.

※ In case of not using low water level sensor (electrode), change setup to use low water level

detection method of software. (To select Para ‘Pr-76’ Low Level Trip Detection Method ‘0’)

B. Setup and Operation Method

• After applying power supply, check if Stop LED on FND is turned on and FND part displays

current press of piping.

※ If is displayed, be sure t

(Connection status or defective pressure sensor, etc.)

※ Caution: Do not surprise even if drive is automatically operate after 10 seconds from

power supply.

This is a normal phenomenon that power fail recovery function operates.

(Refer to power fail recovery function.)

C. Operation Parameters

- Basic Setup Parameters

Setup

Sequence

1

2

3

4

5

Setup Item

Run Command Input

Location Setup

Target Frequency Input

Method Setup

Pump Control Mode

Setup

Sensor1 Capacity

Setup

Sensor1 Pressure

Variation Correction

o check wiring of pressure sensor.

Parameter

Code

Functional Description

dr-01 To set up Run command with FND.

dr-02

Pr-02

Pr-03

To set up Target Frequency Input

Method of drive with own PID.

To set up Pump Control Mode to

Constant Pressure Mode.

To set up rated capacity of pressure

sensor used.

To correct variation between value of

Pr-04

used pressure sensor and real pressure

value.

5-9 |

DOOCHPUMP

[CHAPTER 5 OPERATION]

6 Comm. ID Setup Pr-51

7 Target Pressure Setup St Group

8

Motor Rotation

Direction Selection

dr-20

9 Operation

D. Target Pressure Setup

• If you don’t know about correct pressure setting, contact the specialist.

• If you press key for more than 3 seconds on a mode displaying S of St group, it

changes to pressure setting screen. At the moment, if you use key or key to

change the value to desired setting and press key, the pressure setting is changed with

screen.

※ If you press key without pressing key after changing the setting, the setting will

not be changed and the screen will exit from pressure setting change mode.)

※ If the pressure setting is changed, the high pressure alarm (‘Pr-70’) setting

automatically set to the value 2 bar higher than the pressure setting.

E. Checkup on Rotation Direction of Pump

• It would be correct if the rotation direction is counter clockwise from a viewpoint of fan

cover of the pump. (If the rotation direction is reversed, it cannot generate the normal

pressure.)

• In order change the rotation direction...(Select one of the methods below.)

- Change two from three wires of the motor input.

- Change the value of Parameter ‘dr-20’ to other one. ‘dr-20’.

To set up CAN Comm. ID to ‘0’ in order

to make CAN Comm. Disabled.

To set up target pressure of pump

system.

To make rotation direction of motor

same as pump operation direction

Press

key, them pump operates

with target pressure.

will be

5-10 |

DOO C H P U M P

[

[CHAPTER 5 OPERATION]

2) Multi-Drive Operation of Drives

In case of using several drives linked together to control constant pressure, it is possible to

apply it to the pump system as follows:

A. Wiring Diagram

3φ 380V~440V

AC Input

50/60 Hz

3φ 380V~440V

AC Input

50/60 Hz

3φ 380V~440V

AC Input

50/60 Hz

• Connect drive wiring so that the power input lines and motor output lines should not be

interchanged.

• Be sure to install wiring breaker at the power input of drive.

• Check the polarity of pressure sensor and connect it properly. Connect auxiliary pressure

sensor to each drive depending on the system.

• In order to detect low level of suction pipe connect low level sensor (electrode) if necessary.

In case of not using low level sensor (electrode), change setup to use low level detection ※

method of software

(To select Parameter ‘Pr-76’ Low Level Trip Detection Method ‘0’)

5-11 |

DOOCHPUMP

[CHAPTER 5 OPERATION]

B. Setup and Operation Method

• After applying power supply, check if Stop LED on FND is turned on and FND part displays

P - 0.0

current press

Er - 01

If※ is displayed, be sure to check wiring of pressure sensor.

(Connection status or defective pressure sensor)

Caution: Do not surprise even if drive is automatically operate after 10 seconds from power ※

supply. This is a normal phenomenon that power fail recovery function operates.

(Refer to power fail recovery function.)

C. Operation Parameters

- Basic Setup Parameters

Setup

Sequence

1

2

3

4

5

6

7

8

9

Run Command

Input Location Setup

Target Frequency

Input Method Setup

Sensor1 Capacity

Sensor1 Pressure

Variation Correction

Comm. ID Setup Pr-51

Target Pressure

Direction Selection

Operation

of piping.

Setup Item

Pump Control

Mode Setup

Setup

Setup

Motor Rotation

Parameter

Code

dr-01 To set up Run command with FND.

dr-02

Pr-02

Pr-03

Pr-04

St Group To set up target pressure of pump system.

dr-20

To set up Target Frequency Input Method of

drive with own PID.

To set up Pump Control Mode to Constant

Pressure Mode.

To set up rated capacity of pressure sensor

used.

To correct variation between value of used

pressure sensor and real pressure value.

To set up CAN Comm. ID to 1~6 so that it

should not be duplicated with other drive.

To make rotation direction of motor same as

pump operation direction

Press key, the pump operates with

target pressure.

Functional Description

5-12 |

DOO C H P U M P

[CHAPTER 5 OPERATION]

D. Target Pressure Setup

• If you don’t know about correct pressure setting, contact the specialist.

• In case of linked drive operation, when setting up pressure on one drive, setup pressures are

automatically changed for all drives through CAN communication.

• If you press

to pressure setting screen. At the moment, if you use

to desired setting and press

key for more than 3 seconds on a mode displaying S of ST group, it changes

key or key to change the value

key, the pressure setting is changed with screen.

(If you press

key without pressing key after changing the setting, the setting will not

be changed and the screen will exit from pressure setting change mode.)

If the pressure setting is changed, the high pres※ sure alarm ( ‘Pr-70’) setting will be automatically

set to the value 2 bar higher than the pressure setting.

E. Checkup on Rotation Direction of Pump

• It would be correct if the rotation direction is counter clockwise from a viewpoint of fan cover of

the pump. (If the rotation direction is reversed, it cannot generate the normal pressure.)

• In order change the rotation direction...(Select one of the methods below.)

- Change two from three wires of the motor input.

Change the value of Parameter ‘dr-20’ to other one.

-

5-13 |

DOOCHPUMP

[CHAPTER 5 OPERATION]

5-14 |

DOO C H P U M P

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

6. Function Table of Q Drive

6.1 Status Group

DISPLAY Name Explanation Remark

P

S

Present

pressure

Setting

pressure

H Output Hz

It shows measured present

pressure

It shows setting pressure and

operator can input pressure

value.

It shows present drive output to

HZ

o Output ratio It shows present drive output to%

U Voltage It shows voltage of DC Link

A Current I shows present output current Unit [A]

O

I

Discharge

pressure

Suction

pressure

In case of difference pressure

control, It shows discharge

pressure

In case of difference pressure

control, It shows suction

pressure

In case of difference

pressure,

It shows difference pressure.

If you press setting button

for longer than 2 seconds,

It change to pressure input

mode.

Input voltage *√2=DC Link

voltage[V]

Differential pressure

Differential pressure

6-1 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

6.2 Pump Control Group

DISPLAY Name Range

Pr-00 Jump Code 1~92

Pr-01 Pump Capacity Setup 0.75~25.00[kW] - X O X

Pr-02 Pump Control Mode 0~1 1 O O X

Capacity Setup of

Pr-03

Sensor1

Correction Value of

Pr-04

Sensor1

Capacity Setup of

Pr-05

Sensor2

Correction Value of

Pr-06

Sensor2

P Gain of PID

Pr-07

Controller

Pr-08

Pr-09

Pr-10

Pr-11

Pr-12

Pr-13

Pr-14

Pr-15

Pr-40 485 Comm. Mode

Pr-41 485 Comm. ID

Pr-42 485 Comm. Speed

Pr-43 Comm. Delay time

Pr-50

Pr-51 CAN Comm. ID 0~6 0 X Ο X

I Gain of PID

Controller

D Gain of PID

Controller

Control Cycle of PID

Controller

Selection of Freezing

Prevention

Starting pressure

Variation

Stopping Time after

reaching Setup

Pressure

Ratio of Min Output

Freq. of Stop Mode

after reaching Setup

Pressure

Ratio of Initial Output

on Starting

CAM Comm.

Mode

1.0~25.0[bar] 16.0 X Ο X

-1.0~1.0[bar] 0.0 X Ο O

1.0~25.0[bar] 16.0 Χ Ο X

-1.0~1.0[bar] 0.0 Χ Ο O

0~100[%] 10 Ο Ο O

0~100[sec] 1 Ο Ο O

0~100[ms] 0 Ο Ο O

10~200[ms] 200 Ο Ο X

0~1 0 Ο Ο O

0~2.0[bar] 0.3 Ο Χ O

5~200[sec] 30 Ο Χ O

0~100[%] 100 Ο Χ O

5~100[%] 50

0~1

1~250

1~5

1~9999[ms]

0~1 1 X Ο

Factory

Setting

Para.

Link

51 X O O

X X

0

1

4

5

Diff.

Pressure

Use

ΟΟ Ο X

ΟΟ X

ΟΟ X

ΟΟ X

Change

on

Operation

X

Ref.

Page

6-6

6-7

6-8

6-9

6-10

6-11

6-2 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Name Range

Factory

Setting

Para.

Link

Pr-52 CAN Comm. Speed 1~5 1 X O X

Pr-53 Alteration type 0~1 0

Lead pump

Pr-54

alternation time

Standby Pump wating

Pr-55

time

PID control Type

Pr-61

Setup

0~24(hour) 12 O O O

0~100[sec] 5 Ο Ο O

0~1 0 O O X

Output Ratio of

Pr-64

Starting AllPID

70~100[%] 100 O O O

Increase

High Pressure Alarm

Pr-70

Level

Low Pressure Alarm

Pr-71

Level

High Pressure Alarm

Pr-72

Time

Low Pressure Alarm

Pr-73

Time

Low Level Trip Time

Pr-74

of Pressure Sensor

Low Level Trip

Pr-75

Pressure Level

Low Level Detection

Pr-76

Method Selection

Low Level Trip Time

Pr-77

of Low Level Sensor

0~Sen1 Capacity

[bar]

16.0 Ο Χ O

0~10.0[bar] 0.5 Ο Χ O

0~100[sec] 5 Ο Χ O

0~200[sec] 20 Ο Χ O

0~250[sec] 20 Ο Χ O

0~1.0[bar] 0.3 Ο Χ O

0~1 0 X Χ X

0~250[sec] 2 Ο Χ O

Pr-80 Fault History - - X O X

Pr-81 Fault History 1 - - X O X

Pr-82 Fault History 2 - - X O X

Pr-83 Fault History 3 - - X O X

Pr-84 Fault History 4 - - X O X

Pr-85 Fault History 5 - - X -O X

Pr-86 Delete Fault History 0~1 0 X O O

Pr-87 Sensor percentage 0~200 100 X X O

Pr-90 Initialization Code 0~1 0 X O X

Pr-92 S/W Version - - X O X

Diff.

Pressure

Use

Change

on

Operation

6-3 |

DOOCHPUMP

Ref.

Page

6-11

6-12

6-13

6-14

6-15

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

6.3 Drive Control Group

★To setup initial value according to drive capacity

☆To setup initial value with basis of Dooch induction motor

Change

DISPLAY Name Range Factory Setting

CAN Comm. Speed 1~90 1

dr-00

Command Input Location

dr-01

Setup

Target Freq. Input

dr-02

Method Setup

dr-03 Target Freq. Value Setup

dr-10 Motor Capacity Selection 0.10~75.00[kW]

No. of Motor Poles

dr-11

Selection

dr-12 Rated Current of Motor 1.0~100.0[Arms]

dr-13 Rated Rotations of Motor 1~9999[rpm]

dr-14 Rated Voltage of Motor 200.0~500.0[Vrms]

Non-load Current of Motor

dr-15

Rated Slip Frequency of

dr-16

Motor

Rated Frequency of

dr-17

Motor

dr-18 Efficiency of Motor 50~100[%]

Rotation Direction

dr-20

Selection of Motor

Stopping Method of

dr-21

Motor

dr-22 Increase Time 1.0~600.0 3.0 O

dr-23 Decrease Time 1.0~600.0 6.0 O

Motor Overload Trip

dr-30

Selection

Motor Overload Trip

dr-31

Level

Motor Overload Trip

dr-32

Time

dr-33 Stoll Prevention Setup 0~1 0 X

dr-34 Stoll Prevention Level 100~200[%] 150 X

Motor Overheat

dr-35

Selection

dr-36 Ground Detection 0~1 0 O

dr-37 No. of Restart after Trip 0~50 3 O

0~1 0 X

0~3 0 X

Min Freq. (dr-42)~Max

Freq.

1~2 1 X

0.5~100.0[Arms]

0.10~10.00[Hz]

0~1 1 X

0~1 0 X

0~1 0 X

0~1 0 O

100~200[%] 120 O

5~200[sec] 60 O

0~1 0 O

30.0 O

★

☆

☆

☆

☆

☆

☆

on

Operation

O

X

X

X

X

X

X

X

Ref.

Page

6-15

6-16

6-17

6-18

6-19

6-20

6-4 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

DISPLAY Name Range Factory Setting

Waiting Time of Automatic

dr-38

Restart after Trip

dr-40 Drive Control Mode 0~1 0 X

dr-41 Torque Boost Amount 0~10.0[%] 2.0 X

dr-42 Start Frequency. 0.10~40.00[Hz] 0.50 X

dr-43 Max Operation Freq.

dr-44 Switching Frequency. 1.0~15.0[kHz] 5.0 O

dr-50 Fan Operation Type 0~2 1 O

Power Consumption

dr-51

Correction

dr-52 Output Power Indication 0.0~100.0[kW] -

Indicating Accumulated

dr-53

Mega Wh

Indicating Accumulated

dr-54

Killo Wh

Temp. of Power

dr-55

Semiconductor

dr-56 Ambient Temp. Display

dr-57 Output Power Display 0.0~500.0[V] -

dr-60 V1 Min Input Voltage 0.0~5.0[V] 0.0 O

Corresponding Freq.

dr-61

toV1 Min Input Voltage

dr-62 V1 Max Input Voltage 5.1~10.0[V] 10.0 O

Corresponding Freq. to

dr-63

V1 Max Input Voltage

dr-64 I1 Min Input Current 0~10[mA] 4 O

Corresponding Freq. to I1

dr-65

Min Input Current

dr-66 I1 Max Input Current 11~20[mA] 20 O

Corresponding Freq. to I1

dr-67

Max Input Current

dr-70

dr-71 Month/Date Display 01.01~12.31 dr-72 Hour/Minute Display 00.00~23.59

dr-89 Initializing Integrated Watt 0~1

dr-90 Initialization Code 0~1 0 X

1~250[sec] 10 O

40.0~Rated Freq. of

Motor [Hz]

0.0~1000.0 100.0 O

0~9999[MWh] -

0~9999[kWh] -

0~200℃

0~200℃

0.00~30.00[Hz] 0.00 O

30.01~ Rated Freq. of

Motor [Hz]

0.00~30.00[Hz] 0.00 O

30.01~ Rated Freq. of

Motor [Hz]

60.00 X

-

-

Rated Freq. of

Motor

Rated Freq. of

Motor

0 X

Change

Operation

- 0~9999 Year Display

on

O

O

Ref.

Page

6-20

6-21

6-22

-

6-23

6-5 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

6-4. Description on Functions of Parameter Settings

6-4-1 Pump Control Group

Pr-00 Jump Code

ㆍ It allows moving to desired code number directly.

ㆍ It is also possible to move to other code using key after moving.

Pr-01 Pump Capacity

ㆍTo set up and confirm pump capacity.

ㆍInitial value is automatically set by drive capacity.

Related Functions

dr-10 Capacity of Motor

dr-11 No. of Poles of Motor

dr-12 Rated Current of Motor

dr-13 Rated Rotations of Motor

dr-14 Rated Voltage of Motor

dr-15 No-load Current of Motor

dr-16 Rated Slip Frequency of Motor

dr-17 Rated Frequency of Motor

dr-18 Efficiency of Motor

Pr-02 Pump Control Mode

ㆍ To set up pump control method.

Setup Data Functional Description Related Functions

Pr-03,

Pr-04

Pr-05

Pr-06

Pr-03 Capacity of Sensor 1

Pr-04 Correction of Sensor 1

6-6 |

0

1

DOOCHPUMP

Differential Pressure

Control Method

Constant Pressure

Control Method (Factory

Setting)

Capacity of

Sensor 1

Correction of

Sensor 1

Capacity of

Sensor 2

Correction of

Sensor 2

Discharge

Direction

Suction

Direction

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-03 Sensor 1 Capacity Setup

ㆍ Enter the maximum value that the pressure sensor can measure.

ㆍ By entering capacity of pressure sensor attached to the drive being used, it is possible to display

the currently measured pressure.

Example) In case the using sensor has 10bar, enter 10.0.

If the using sensor has 16bar, enter 16.0.

ㆍ and enter the rated value of the pressure sensor for normal pump operation.

Factory Setting Input Range

]rab[ 0.52 ~ 0.0 ]rab[ 0.61

Pr-04 Sensor 1 Correction Setup

ㆍ It corrects pressure variation between analog or digital pressure meter and the one displayed on

drive FIND.

Factory Setting Input Range

]rab[ 0.1 ~ 0.1- ]rab[ 0.0

Pr-05 Sensor 2 Capacity Setup

ㆍ It is used in case of pressure difference control mode.

ㆍ Setup method is same as described on Pr-03.

Pr-06 Sensor 2 Correction Setup

ㆍ It is used in case of pressure difference control mode.

ㆍ Setup method is same as described on Pr-04.

Pr-07 P Gain of PID Controller

ㆍ It is relevant to ‘P’ (Proportional Constant) out of PID control parameters.

ㆍ If Reference and Feedback is in pressure unit [bar], PID P-Gain 100% means that if PID I-Gain is

0 and 100bar error is maintained, controller output is 1.0[Hz].

Factory Setting Input Range

]%[ 001 ~ 0 ]%[01

6-7 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-08 I Gain of PID Controller

ㆍ It is relevant to ‘I’ (Integral Constant) out of PID control parameters.

ㆍ PID I-Gain 1 second means the time required for the output power to be accumulated to 1.0[Hz]

when 100 bar error is maintained.

Factory Setting Input Range

1[sec]

Pr-09 D Gain of PID Controller

ㆍ It is relevant to ‘D’ (Differential Constant) out of PID control parameters.

ㆍ PID D-Gain means that change rate of error for a specified time will be out on PID control cycle

time.

Factory Setting Input Range

0[ms]

Pr-10 PID Control Cycle

ㆍ It sets up PID control cycle.

ㆍ It outputs values calculated with PID in PID control cycle time unit.

Factory Setting Input Range

0[ms]

Pr-11 Freezing Prevention Function

ㆍ It sets up freezing prevention mode of pump.

ㆍ It is to prevents pump from being broken due to low temperature (below zero) in winter using

ambient temperature sensor information within the drive. The function is operated with a

frequency not generating pressure between 0~10 seconds and maintained as stopped status

between 11~59 seconds based on 1 minute. This function is to prevent the pump from

freeze and burst by generating frictional heat upon rotation within pump casing.

This function is not for preventing freeze and burst of pipe.

0 ~ 100[sec]

0 ~ 100[ms]

0 ~ 200[ms]

6-8 |

Setup Data Functional Description

0(Factory Setting)

1

DOOCHPUMP

OFF

ON

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-12 Start Variation

ㆍ It sets up start variation pressure value. That is, the operation starts when the current pressure

has larger variance than the specified value comparing to setting.

ㆍ In case of alarm occurrence, operation does not start.

Factory Setting Input Range

Pr-13 Stopping Time after Reaching Setup Pressure

ㆍ When the pump pressure reaches to setting and maintained for longer than setup time, it starts to

reduce speed. If there is pressure difference as much as starting variation, the pump starts to

operate again during decrease of speed and if not, it stops.

ㆍ Input Range : 5 ~ 200 [sec]

Factory Setting Input Range

Pr-14 Min Output Frequency Ratio to Stop after Reaching Setup Pressure

ㆍ In order to stop after reaching to specified pressure, the drive is able to stop only if the current

minimum output frequency ratio is less or equal to setup ratio.

Pr-15 Initial Output Ration on Starting

ㆍ It refers to the minimum output ratio on starting of the drive. That is, if it is set to 50% when the

maximum operation frequency is 60 Hz, it can start from 30 Hz.

Factory Setting Input Range

Pr-40 485 Comm. Mode

ㆍ To set up 485.

Setupdata Functional Description

0.0 ~ 2.0[bar]0.3[bar]

5 ~ 200[sec]30[sec]

Input RangeFactory Setting

0 ~ 100[%]100[%]

5 ~ 100[%]50[%]

Not use 485 comm.0(factory setting)

Use 485 comm. 1

6-9 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-41 485 comm.

ㆍIt setsup 485 comm. ID set up

Pr-42 485 comm. speed

ㆍ 485 comm. speed set up

Pr-43 485 comm. delay time

ㆍ485 comm. delay time set up

Pr-50 CAN Communication Mode

ㆍ It set up for multi-drive control, when each drive has different version

* Available for version 1.3x. Please refer version check page

*

When set up for 0(NQ Ver 1.2x), the Pr-53 alteration automatically changed to 0(in order of ID)

Setup Data Functional Description

1~250(Factory Setting)

Setup Data Functional Description

Setup Data Functional Description

1~9999(msec)

Setup Data Functional Description

If the number of data request protocol is

different, data is not transmitted.

1200kbps1

2400kbps2

4800kbps3

9600kbps4(Factory Setting)

19200kbps5

When receive data request protocol, data transmit

after set up delay time(Factory set up : 5[msec]

NQ Ver 1.2x0(Factory Setting)

NQ Ver 1.3x 1

Pr-51 Communication ID Setup

ㆍ It is CAN Communication ID on Multi-Drive control mode.

ㆍ Be sure to not duplicate ID for setup.

6-10 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Setup Data Functional Description

Single Mode0(Factory Setting)

Related Functions

Multi-Drive

1~6

control

Comm. ID

No.

Pr-52 CAN Communication Speed

ㆍ It sets up CAN communication speed. In case of long connection distance, it is better to reduce

the communication speed.

Setup Data Functional Description

Pr-53 Alternation method

ㆍIt determines the order of Q-Driver’s run, stop, alternation on Multi-Drive operation mode.

Setup Data Functional Description

0 In order of low watt-hour

* Setting is available for Ver 1.3x

* When Pr-50 can comm. mode is 0, alternation is set 0.

dr-02 Target Frequency Input Method

Pr-52 CAN Communication Speed

Pr-53 Lead Pump Alternation method

Pr-54 Lead Pump Alternation Time

Pr-55 Stand-by Pump Waiting Time

Pr-61 PID Type on Multi-Drive control

40kbps1(Factory Setting)

50kbps 2

100kbps 3

200kbps 4

250kbps 5

In order if ID1(Factory Setting)

Pr-54 Lead Pump Alternation Time

ㆍ Alternative operation refers to an operation that when it reaches time specified by the user, the

drive with a lot of power consumed is to be stopped and the one with less power consumption is

to be started alternatively at the same time in order to prevent a specific drive(pump) being

operated constantly. If times is set, drives are forcedly shifted.

Setup Data Functional Description

Release of alternation 0

1~24(hour) Alternation time setup. (Factory Setting 12[hour])

6-11 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-55 Stand-by Pump Waiting Time on Multi-Drive Control Mode

ㆍ This is to give some delay to stand-by pump. If the stand-by pump starts operation before

the main drive outputs maximum frequency then the pressure may increase suddenly.

Factory Setting Input Range

0 ~ 100[sec]5[sec]

Pr-61 PID Type Setup on Multi-Drive Control Mode

ㆍ This is to improve energy efficiency on multiple pump operation and selectable for the user.

Master control means acceleration/deceleration operation upon PID by Master for only one drive.

Centralized control is a method that all of drivers participating into operation are allocated with

target value for the output frequency by one PID controller of Master.

This function has an advantage to prevent overload on the drive.

Setup Data Functional Description

Master Control0 (Factory Setting)

1

Centralized

Control

Pr-64

Pr-64 Output Ratio on Starting Increase of AllPID(Preparing)

ㆍ It is an output ratio to start the next drive by applying it centralized control method for multiple

pump operation. That is, if the output ratio of drive in operation is higher than a specified value,

the next drive to be linked starts to be operated.

Factory Setting Input Range

Pr-70 High Pressure Alarm Level

ㆍ It sets standard pressure value to issue the high pressure alarm.

※ When setting the setup pressure, it is automatically set to setup pressure + 2bar.

Factory Setting Input Range Related Function

20.0[bar] 0.0~20.0[bar] Pr-72 High Pressure Trip Time

Pr-71 Low Pressure Alarm Level

ㆍ It sets standard pressure value to issue the low pressure alarm.

Factory Setting Input Range Related Function

0.5[bar] 0.0~10.0[bar] Pr-73 Low Pressure Trip Time

Related Function

Output Ratio on Starting

Increase of All PID

70 ~ 100[%]100[%]

6-12 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-72 High Pressure Alarm Time

ㆍ It sets maintaining time of high pressure alarm level to issue the high pressure alarm. That is, if

the current pressure increases above the high pressure alarm level (Pr-70) and maintains its

state for a specified time, a high pressure alarm is displayed and operation stops.

Factory Setting Input Range Related Function

5[sec] 0~100[sec] Pr-70

Pr-73 Low Pressure Alarm Time

ㆍ It sets maintaining time of low pressure alarm level to issue the low pressure alarm. That is, if the

current pressure decreases under the low pressure alarm level (Pr-71) and maintains its state for

a specified time, a low pressure alarm is displayed and operation stops.

Factory Setting Input Range Related Function

20[sec] 0~200[sec] Pr-71 Low Pressure Alarm Level

Pr-74 Low Water Level Alarm Time of Pressure Sensor

ㆍ It sets maintaining time of alarm level to issue the low water level alarm.

That is, if the current pressure decreases under the low pressure alarm level (Pr-75) and

maintains its state for a specified time, an alarm is displayed and operation stops.

ㆍ It is applied when low water level sensor setup (Pr-76) is released.

Factory Setting I nput Range Related Function

Pr-75 Low Pressure Alarm Level

30[sec] 0~250[sec]

Pr-76

High Pressure Alarm

Level

Low Pressure Alarm

Method Selection

Pr-75 Low Water Level Alarm Pressure Level

ㆍ It is a pressure level to determine low water level when selecting software detection method from

Low Water Level Alarm Detection Method Selection (Pr-76).

Factory Setting Input Range Related Function

Pr-74

0.3[bar] 0.0~1.0[bar]

Pr-76

Low Water Level Alarm

Time of Pressure Sensor

Low Water Level Alarm

Method Selection

6-13 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-76 Low Water Level Alarm Method Selection

ㆍ It is a mode to set up low water level alarm detection method.

ㆍ In case of setting up low water level sensor, it is required to attach electrode outside to determine

existence of water within piping.

ㆍ In case of multi-drive operation, low water level sensor should be linked to the lowest ID Drive.

※ If there is no water on suction part, all of drives (pumps) will stop.

When it is set to Software detection, it detects the alarm on the basis of low water level alarm

pressure level (Pr-75) and low water level alarm time (Pr-74). That is, if the operation is

continued for more than low water level

level alarm pressure level (Pr-75), it is required to display alarm and stop operation as it is

determined that there is no water within the piping.

Setup Data Functional Description Related Function

0

(Factory

Setting)

1 Low water level sensor setup Pr-77

Software detection using

pressure sensor

Pr-77 Low level Sensor Low Level Trip Time

ㆍ It sets maintain time of low level sensor signal to issue low level alarm.

That is, if the low level sensor signal is continued for more than trip time when low level sensor is

selected from low level trip method (Pr-76), it is required to display alarm and stop operation as it

is determined that there is no water within the suction piping.

Setup Data Functional Description

0 Release of low level detection using low level sensor

Pr-80 ~Pr-85 Fault History List

ㆍ Pr-80 displays Error Code value occurred currently.

ㆍ Pr-81 ~ Pr-85 are memorized in reverse order of Error occurrence.

ㆍ It is possible to enter into using

and error content of the fault using key.

FND Display Description

tSF, tOP, tUP, tUL, tASH etc Error Content (Refer to Chapter 8 Fault History Table)

Stdy, StOP, AdOFS, wdOG Operation status with Error

key and to confirm frequency, curren t, operation state

e (Pr-74) with pressure under the low water

alarm tim

Pr-74

Pr-75

Time Setup (Factory Setting 2[sec])1 ~ 250[sec]

Frequency with Error H xx.x

Current with Error A xx.x

No. of Errors coourred t xx

Low Water Level Alarm Time

Of Pressure Sensor

Pressure Level for

Low Water Level Alarm

Low Level Alarm Time of

Low Water Level Sensor

6-14 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

Pr-86 Deletion of Fault History

ㆍ It deletes all of the fault history

Setup Data Functional Description

To maintain error contents(Factory Setting) 0

To delete all of error contents 1

Pr-87 Sensor percentage

ㆍIt corrects sensor by % unit.

ㆍIn order to decrease sensor value, enter smaller value than 100 based on 100% while in order to

increase it, enter larger value than 100.

Pr-90 Initialization Code

ㆍ It carries out initialization with factory settings.

Setup Data Functional Description

0 (Factory Setting) To maintain settings (Factory Setting)

Pr-92 S/W Version

ㆍ It displays program version.

6-4-2 Drive Control Group

dr-00 Jump Code

ㆍ It allows moving to desired code number directly.

ㆍ It is also possible to move to other code using key after moving.

dr-01 Command Input Location Setup

ㆍ It sets operation command location.

When selecting FND key, it is possible to issue operation command using key on main body of

drive. When setting up terminal block, it is possible to issue operation command using external

input(P1)

Setup Data Functional Description

0 (Factory Setting) Operation Command with FND

To initialize with factory settings 1

Operation Command with Terminal Block(P1) 1

6-15 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

dr-02 Target Frequency Input Method Setup

ㆍIt sets up target frequency input method of drive.

Setup Data Functional Description

0 (Factory Setting) Setup with own PID operation

1

dr-03 Target Frequency Value Setup

ㆍWhen using as a fixed frequency, it is possible to set up target frequency value.

Target Frequency Input Method (dr-02) should be set with FND.

Factory Setting Input Range

30.0[Hz] Start Freq. (dr-42) ~Max Freq (dr-43)[Hz]

dr-10 Motor Capacity

ㆍ It sets motor capacity.

ㆍ It is set when pump drive is released from the factory. Setting value is for displaying.

It is used when the current pump drive checks the motor capacity being set.

Changing the setting does not have influence other parameters.

Factory Setting Input Range

Initial value is set upon drive capacity 0.10~ 75.00 [kW]

Setup when using fixed freq.

on the main body of FND

drive

Setup with external voltage V1(0~10V)2

Setup with external current I1(4~20mA)3

Related Function

dr-03

Target Freq. Value

Setup

dr-11 Motor Pole Selection

ㆍ It sets No. of motor poles.

ㆍ It is set when pump drive is released from the factory.

Setup Data Functional Description

2 Pole Motor 1

4 Pole Motor 2

dr-12 Motor Rated Current

ㆍ It sets up rated current (RMS) of the motor. It is based on the rated current indicated on the

nameplate of the motor.

ㆍ It is applied to Stall Prevention Level, Slip Compensation Control and Overload Trip Level

Factory Setting Input Range

Initial value is set upon drive capacity 1.00 ~ 100.0 [Arms]

6-16 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

dr-13 No. of Rated Rotations of Motor

ㆍ It sets No. of rated rotations of motor. It is based on data indicated on the nameplate of the motor.

Factory Setting Input Range

Initial value is set upon drive capacity 1 ~ 9999 [rpm]

dr-14 Rated Voltage of Motor

ㆍ It sets rated voltage of motor. It is based on data indicated on the nameplate of the motor.

Factory Setting Input Range

dr-15 Non-load Current of Motor

ㆍ It sets non-load current of motor.

dr-16 Rated Slip Freq. of Motor

ㆍ It displays slip freq. of motor.

dr-17 Rated Frequency of Motor

ㆍ It sets rated frequency of motor.

dr-18 Efficiency of Motor

ㆍ It is set when pump drive is released from the factory.

※ Motor related constants (dr-10~dr-18) set upon drive capacity may not match with motor data of

Initial value is set upon drive capacity 200.0 ~ 500.0 [Vrms]

Factory Setting Input Range

Initial value is set upon drive capacity 0.5 ~ 100.0 [Arms]

Settings are automatically set upon No. of motor poles, rated No. of rotations, and rated

frequency.

Factory

Setting

Automatic

Setup

Setup Data Functional Description Related Function

1 (Factory Setting) 60[Hz]

Initial value is set upon drive capacity 70 ~ 100 [%]

the user. Be sure to check data on the nameplate.

Input Range

0.10~10.00[Hz]

50[Hz] 0

Factory Setting Input Range

Related Function

dr-11 No. of motor poles

dr-13 Rated No. of Rotations of Motor

dr-17 Rated Frequency of Motor

dr-43

Max Operation

Freq.

6-17 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

dr-20 Motor Rotation Direction Selection

ㆍ It sets up rotation direction of the pump.

ㆍ Be sure to check the rotation direction of the pump for normal operation.

As the rotation direction may change according to wiring, be sure to check it.

Setup Data Functional Description

0 (Factory Setting) Forward Direction– CW(Clockwise)

Reverse - CCW(Counterclockwise)1

dr-21 Motor Stopping Method

ㆍ It sets motor stopping method

Setup Data Functional Description

0 (Factory Setting) Decelerated Stop

To cut off drive output voltage 1

dr-22 Rising Time

ㆍ It is time to reach max frequency from 0[Hz].

ㆍ If rising time is too short, over- current fault may be occurred during motor operation.

Factory Setting Input Range

1.0~600.0[sec] 3.0[sec]

dr-23 Falling Time

ㆍ It is time to decelerate to 0[Hz] from max frequency.

ㆍ If falling time is too short, over- voltage fault may be occurred during motor operation

Factory Setting Input Range

1.0~600.0[sec]6.0[sec]

dr-30 Overload Trip Selection

ㆍ It sets up whether it will generate trip upon overload of the motor.

ㆍ It is used for protecting the motor.

Setup Data Functional Description

Release 0

1 (Factory Setting) Setting

dr-12 Rated Current of Motor

dr-31 Overload Trip Level

dr-32 Overload Trip Time

Related Function

dr-23 Falling Time

Related Function

6-18 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

dr-31 Overload Trip Level

ㆍ It refers to trip current level against rated current of the motor.

That is, if the rated current of the motor is 10[A] and the overload trip level is 120%, the overload

trip will be generated above 12[A].

ㆍ It is used for protecting the motor upon overload.

Factory Setting Input Range Related Function

120[%] 100~200[%]

dr-32 Overload Trip Time

ㆍ It sets maintaining time of overload trip level to generate overload trip.

That is, if it reaches to overload trip level (dr-31) and the specified time elapsed, it indicates

overload trip alarm and stops the operation.

Factory Setting Input Range

dr-33 Stall Prevention Selection

ㆍ It selects whether it uses Stall Protection.

ㆍ On occurrence of Stall, it decelerates the speed.

Setup Data Functional Description

1 Setup

dr-34 Stall Prevention Level

ㆍ It refers Stall protection current level against the rated current of motor.

That is, if the rated current of the motor is 10[A] and Stall protection level is 150%, Stall protection

will be applied above 15[A].

Factory Setting Input Range Related Function

150[%] 100~200[%] dr-12 Rated Current of Motor

dr-12 Motor Rated Current

dr-32 Overload Trip Time

]ces[002~5 ]ces[06

esaeleR)gnitteS yrotcaF( 0

Related Function

dr-12 Rated Current of Motor

dr-34 Stall Prevention Level

6-19|

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

dr-35 Motor Overheat Selection

ㆍ It sets motor overheat protection function.

The drive calculates load current of motor by itself and determines overheat by expecting

increase of temperature.

Setup Data Functional Description

esaeleR )gnitteS yrotcaF( 0

dr-36 Ground Detection

ㆍ It sets ground protection function.

Setup Data Functional Description

dr-37 No. of Auto Restart after Trip

ㆍ It refers to No. of automatic operations for drive after occurrence of trip.

If the trip occurs more than specified number, it can not restart.

ㆍ If there is no trip during certain time, No of trip might be deleted.

ㆍ It may not be restarted according to error code. Refer to Chapter 7 Fault History Table.

Factory Setting Input Range

dr-38 Automatic Restart Waiting Time after Trip

ㆍ When a specified time elapsed after trip, it restarts.

Factory Setting Input Range

dr-40 Drive Control Mode

ㆍ It selects V/F control or slip compensation control.

V/F control refers to a control to make ratio of output voltage and output frequency constant,

while slip compensation control makes motor speed regular with slip compensation function.

Setup Data

0 (Factory Setting) V/F control dr-41 Torque boost amount

1

Functional

Description

Slip Compensation

Control

dr-10 Motor capacity

dr-12 Rated current of motor

dr-15

dr-16 Rated slip of motor

dr-18 Efficiency of motor

puteS 1

esaeleR )gnitteS yrotcaF( 0

puteS 1

0~50[times]3[times]

0~250[sec]10[sec]

Related Function

Non-load current of

motor

6-20 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

dr-41 Torque Boost Amount

ㆍ It is a boost amount to be applied on initial operation of drive.

ㆍ If starting torque is not enough under overload operation, torque can be increased by rising this

value.

Factory Setting Input Range

dr-42 Start Frequency

ㆍ It refers to frequency that drive starts to output.

Factory Setting Input Range

dr-43 Max Operation Frequency

ㆍ It can limit max operation frequency of drive.

ㆍ It cannot exceed range of rated frequency (dr-17) of motor.

Factory Setting Input Range

dr-44 Switching Frequency Setup

ㆍ In case of high noise or temperature, it is required to decrease the frequency for use.

dr-50 Fan Operation Method

ㆍ It sets cooling fan operation method.

dr-51 Power Consumption Correction

ㆍ It corrects a consumed power upon operation of drive.

60.00[Hz] 40.00 ~ rated frequency of motor [Hz]

As the switching frequency becomes lower, noise of motor is increased while noise or leak

current is decreased.

Factory Setting Input Range

Setup Data Functional Description

To operate upon application of drive power0

1 (Factory Setting) To operate upon output of drive frequency

2 To operate upon abnormal state of internal setup temperature

dr-52 Indication of Power Consumption

ㆍ It displays a consumed power upon operation of drive.

Range 0.0~100.0[kW]

0.0~10.0[%]2.0[%]

0.1~40.00[Hz]0.50[Hz]

1.0~1.5[kHz]5.0[kHz]

6-21 |

DOOCHPUMP

[CHAPTER 6 FUNCTION TABLE & DESCRIPTION]

dr-53~dr-54 Indication of Accumulated Power

ㆍ It displays accumulated power of drive in Mega, kilo Wh unit.

Displayed accumulated power may have error comparing to actual value.

Parameter Functional Description

To display in Mega Wh unitdr-53

dr-55 Power Semiconductor Temperature

ㆍ It displays temperatures of core module devices in the drive.

If temperature is more than 100℃, It display alarm and stop.

ㆍ

Range

dr-56 Ambient Temperature Display

ㆍ It displays ambient temperature of the drive.

Range