DOMUSA TEKNIK LIGNUM NG Series, LIGNUM NG 20, LIGNUM NG 40, LIGNUM NG 30 Installation And Operating Instructions Manual

INSTALLATION AND OPERATING INSTRUCTIONS

LIGNUM NG

Thank you for choosing a DOMUSA TEKNIK heating boiler. From the range

of DOMUSA TEKNIK products you have chosen the Lignum NG model.

With a suitable hydraulic installation and with firewood for fuel, this highefficiency wood boiler will provide the ideal level of comfort for your

home.

This manual forms an essential part of the product and it must be given to

the user. We recommend you read the warnings and recommendations in

the manual carefully, as they contain important information on the safety,

use and maintenance of the installation.

These boilers must be installed by qualified personnel only, in accordance

with the legislation in force and following the manufacturer's instructions.

Incorrect installation of these boilers could result in damage to people,

animals or property, and the manufacturer will hold no liability in such

cases.

CONTENTS Page

1 LIST OF COMPONENTS ..................................................................................................................................................... 2

2 CONTROL COMPONENTS ................................................................................................................................................ 3

3 INSTALLATION INSTRUCTIONS ..................................................................................................................................... 4

LOCATION ............................................................................................................................................................................................. 4

3.1

HYDRAULIC INSTALLATION .................................................................................................................................................................. 4

3.2

FUEL: PREPARING THE FIREWOOD ....................................................................................................................................................... 5

3.3

IGNITION AND POSITIONING OF THE FIREWOOD ................................................................................................................................ 7

3.4

IGNITION TUNNEL .............................................................................................................................................................................. 7

3.4.1

3.4.2

PAPER, CARDBOARD AND KINDLING ................................................................................................................................................ 7

SAWN WOOD (PLANKS) .................................................................................................................................................................... 8

3.4.3

THICK WOOD OR STUMPS ................................................................................................................................................................. 8

3.4.4

THICK KINDLING AND WOODWORKING WASTE ............................................................................................................................... 8

3.4.5

UNSUITABLE FUEL ................................................................................................................................................................................ 8

3.5

COMBUSTION PRODUCT REMOVAL ..................................................................................................................................................... 8

3.6

3.7

ELECTRICAL CONNECTION ................................................................................................................................................................... 9

DHW TANK ELECTRICAL CONNECTION (OPTIONAL). ..................................................................................................................... 9

3.7.1

EXAMPLE OF AN INSTALLATION WITH A BUFFER TANK .................................................................................................................... 10

3.8

EXAMPLE OF AN INSTALLATION WITH A BUFFER TANK AND DHW TANK....................................................................................... 11

3.9

4 ADJUSTING THE COMBUSTION AIR .......................................................................................................................... 12

5 TEMPERATURE RELIEF SAFETY VALVE ..................................................................................................................... 13

5.1

OPERATING PRINCIPLE ....................................................................................................................................................................... 13

VALVE ASSEMBLY ................................................................................................................................................................................ 13

5.2

6 STARTING UP THE BOILER ............................................................................................................................................ 14

6.1

PRIOR WARNINGS ............................................................................................................................................................................... 14

6.2

FILLING THE INSTALLATION ................................................................................................................................................................ 14

START-UP ............................................................................................................................................................................................ 14

6.3

INSTALLATION HAND OVER ................................................................................................................................................................ 15

6.4

7 DIGITAL DISPLAY AND SELECTING PARAMETERS ............................................................................................... 16

8 BOILER MAINTENANCE AND CLEANING ................................................................................................................. 18

8.1

CLEANING THE BOILER ....................................................................................................................................................................... 18

8.1.1

ASHES .............................................................................................................................................................................................. 18

TAR ................................................................................................................................................................................................... 18

8.1.2

BOILER MAINTENANCE: ...................................................................................................................................................................... 19

8.2

DRAINING THE CONDENSATION WATER ........................................................................................................................................ 19

8.2.1

BOILER WATER CHARACTERISTICS .................................................................................................................................................. 19

8.2.2

8.3

SAFETY WARNINGS: ............................................................................................................................................................................ 20

SAFE HANDLING OF ASHES ............................................................................................................................................................. 20

8.3.1

HAZARDS RELATED TO THE DOOR OF THE FUEL LOADING CHAMBER. ........................................................................................ 20

8.3.2

9 SHUTTING DOWN THE BOILER ................................................................................................................................... 21

9.1

DETECTION OF LACK OF FUEL ............................................................................................................................................................ 21

10 TECHNICAL CHARACTERISTICS ................................................................................................................................ 22

11 DIAGRAMS AND MEASUREMENTS ......................................................................................................................... 23

12 ELECTRICAL DIAGRAM ................................................................................................................................................ 24

13 SENSOR VALUES ............................................................................................................................................................ 25

14 SPARES LIST .................................................................................................................................................................... 26

15 ALARM CODES ............................................................................................................................................................... 38

16 GUARANTEE CONDITIONS ........................................................................................................................................ 39

1

Lignum NG

1 LIST OF COMPONENTS

1. Water inlet/outlet

2. Top cover

3. Safety heat exchanger

4. Pipe cleaning mechanism

5. Fume pipes

6. Top refractory element

7. Bottom refractory element

8. Control panel

2

9. Heat exchanger

10. Wood housing

11. Peep-hole

12. Base

13. Top door

14. Bottom door

15. Extractor fan

16. Fume chamber

2 CONTROL COMPONENTS

1. Button for changing Menu settings:

Used for selecting the adjustable Menu settings.

2. STOP button (and reduce value):

Used to stop the fan and, as a result, the

combustion adjustment. Also used to reduce

the values of the selected Menu settings.

3. START button (and increase value):

Activates the fan and the combustion

adjustment. Also used to increase the values of

the selected Menu settings.

4. Main switch:

Turn on the controller.

5. Fuse carrier:

It protects the controller and the elements

dependent on the controller. It is recommended

that a porcelain, slow-blow, 5x20mm, 3.15A

nominal current fuse be used.

3

Lignum NG

3 INSTALLATION INSTRUCTIONS

The boiler must be installed by personnel authorised by the Ministry of Industry, in compliance with

the applicable laws and regulations.

This boiler is suitable for heating water to a temperature below boiling point at atmospheric pressure.

It must be connected to a heating buffer tank, which must always be compatible with its performance

and power.

This appliance must only be used for the purpose for which it has been expressly designed. Any other

use is considered unsuitable and therefore hazardous. The manufacturer shall not be considered liable

under any circumstances for damage caused by unsuitable, erroneous or irrational use.

Remove all the packaging and check the contents are complete. In case of doubt, do not use the

boiler. Contact your supplier. Keep the packaging elements out of reach of children, as they can be

dangerous.

When you no longer wish to use the boiler, disable the parts that could represent a potential hazard.

3.1 Location

The boiler must be installed in a sufficiently ventilated site, away from humidity. It must be located

so that the air grilles on the premises are not obstructed and normal boiler maintenance is possible.

It must be kept a minimum distance of 1 m from the fuel tank or install a radiation protection plate.

The boilers must not operate on flammable surfaces. The boiler must have an external combustion

air supply (minimum opening 300 cm2).

Generally, it is not recommended to install boilers of up to 50 kW in stairways, living areas, corridors

or garages. Similarly, installing boilers in locations with ventilation, fans, extractor fans, air

extraction systems, etc. should be avoided (e.g. tumble dryer extraction). It must be kept a

minimum distance of 0.4 m from flammable building materials so as to not reach surfaces

temperatures above 85°C.

3.2 Hydraulic installation

The hydraulic installation must be made by qualified personnel. The applicable installation

legislation (RITE) must be complied with, and the following recommendations should also be taken

into account:

- It is obligatory and essential to install a heating water buffer tank (see “

installation with buffer tank”).

based on Standard EN 303-5.

- It is obligatory and essential to install a device for raising the return temperature, to prevent

any water condensation in the heat exchanger. If this requirement is not complied with,

DOMUSA TEKNIK's guarantee of the appliance will automatically be null and void.

The minimum volume of the buffer tank must be calculated

Example of

- It is obligatory and essential to install the temperature relief valve supplied with the boiler.

To correctly install the boiler, carefully follow the instructions given in the section "Installing

the temperature relief valve" . If this requirement is not complied with, DOMUSA TEKNIK's

guarantee of the appliance will automatically be null and void.

- The inside of the installation piping should be thoroughly cleaned before switching on the

boiler.

- We recommend inserting cut-off valves between the installation piping and the boiler to

simplify maintenance tasks.

4

- Leave a free space around the boiler for carrying out any maintenance and repair operations.

- Drain valves and suitable devices for correctly bleeding the air from the circuit during the boiler

filling stage should be fitted.

- Install all the necessary safety elements (expansion vessel , safety valve, etc.) to comply with the

applicable regulations for the installation.

3.3 Fuel: preparing the firewood

Firewood is the fuel which must be used for the Lignum NG boiler. If this requirement is not

complied with, DOMUSA TEKNIK's guarantee of the appliance will automatically be null and void.

The quality of the fuel plays an important part in the performance and useful life of the boiler. The

firewood must have less than 20% water content (humidity). If the percentage of water is too high,

the corrosion inside the boiler increases and the boiler performance is drastically reduced.

"Green" wood (recently cut) may contain over 50% humidity. Its caloric power is approximately half

of that of "seasoned" wood with 15% humidity. The greater the humidity of the wood, the slower

the combustion and the lower the flame temperature. This abruptly increases the amount of soot

and tar in the fumes.

To reach dry levels in the air (<20%), the following drying times are recommended:

- Oak: 2.5 years

- Beech, ash, fruit trees: 2 years

- Linden, alder, birch: 1.5 years

- Pine, poplar, spruce: 1 year

If the wood is not cut (round wood), a minimum of 2 extra months are required.

In addition to the cutting, another important factor is the physical size of the firewood. In relation

to its mass, smaller firewood has a greater surface than larger pieces of wood. It is easier to ignite

and its combustion is quicker. Large firewood may slow down combustion due to an unfavourable

volume/surface area ratio. This, unavoidably, implies a lower flame temperature and greater

contaminant emissions.

The following sizes of firewood are those recommended for a perfect and homogeneous service in

the combustion chamber:

For Lignum NG 20, Lignum NG 30 and Lignum NG 40 boilers, the recommended log length is 50

cm. If the logs are short, it is recommended that they be placed lengthwise in the back part and

that the free space at the front be filled with logs placed obliquely.

5

Lignum NG

Make sure the logs in the fuel loading compartment do not get stuck (avoid logs which are too

long). If the logs are too long, they do not fall properly and can cause gaps, causing a drop in the

boiler power. In order to avoid this, it may be necessary to cut the total length in half.

Place the rounded part of the logs facing down, to avoid any wedging effect.

If using briquettes, they must have a diameter of 6 to 10 cm. Their use is only recommended in

combination with firewood.

Pay special attention to the energy density of the firewood, as a full load of pine wood is equivalent

to 2/3 of a load of beech wood and to ½ a load of briquettes.

6

3.4 Ignition and positioning of the firewood

How the firewood is loaded into the housing is very important for an optimised combustion

process. It is recommended that the firewood be inserted into the loading compartment as follows:

Insert thick pieces of wood or stumps in the top area

only

4th Layer: Medium firewood

- Load the necessary amount in the compartment

3rd Layer: Ignition material

- Thick chippings, small chippings

2nd Layer: Paper, cardboar d

Chippi

- Ignite evenly throughout the compartment

Ignition

tunnel

Grill

opening

1st Layer: Small firewood

- Do not place im me diately on top of the grill opening

- Place the chippings crosswi s e o n top of the first l aye r

IMPORTANT: If there is no charcoal from a previous firewood load, put the first layer (at the bottom

of the fireplace) with abundant wood, as dry as possible, to obtain the proper amount of charcoal

(approximately 10 zm).

3.4.1 Ignition tunnel

The ignition tunnel allows the combustion air to flow during ignition. Therefore, do not place any

combustion material on top of the opening of the grill during the ignition, leaving the ignition

tunnel free of obstacles.

3.4.2 Paper, cardboard and kindling

The fire should be lit with paper, cardboard and/or kindling. The cardboard should be placed

evenly on top of the ignition tunnel, across the entire surface of the first layer of small logs. If the

cardboard used is small, distribute it in paper ball shapes. The kindling must be placed crossways

under the cardboard.

The ignition process is manual and must be performed as follows:

- Partially load the combustion chamber with small dry logs and paper, cardboard or wood

chips.

- Turn the boiler on and press START to start up the induced draught fan.

- Light a paper ball using a match or a lighter.

- The lit paper is placed with the paper/cardboard on top of the ignition tunnel. The door can

be kept slightly open to ease ignition.

7

Lignum NG

- Once the fire has spread and embers have formed, distribute them evenly, add the rest of

the load on top and fully close the doors.

- The control automatically regulates the combustion process.

3.4.3 Sawn wood (planks)

Sawn wood can be used in a similar way to kindling to ease ignition above the tunnel. The

planks should not be placed too close to each other, so that air circulates during ignition. It is

recommended that at least 1 cm be left between planks.

3.4.4 Thick wood or stumps

Thick wood or tree stumps (part of the trunk joined to the root) can be placed on the top layer,

on top of several layers of firewood. Do not use more than one oversized piece of firewood or

stump in the same load.

3.4.5 Thick kindling and woodworking waste

Thick kindling (G100, > 100mm), small material, woodworking waste, etc. must only be placed in

the loading compartment on top of at least three layers of firewood (approximately half of the

combustion chamber).

3.5 Unsuitable fuel

- Wood with >20% humidity.

- Waste, plastics

- Paper and cardboard (only for ignition).

- Sawdust, wood shavings.

- Small kindling.

- Coal.

- Material generally forbidden by legislation regarding atmospheric contamination and air

quality, such as treated wood, beams, etc.

3.6 Combustion product removal

The Lignum NG boiler is a biomass boiler and it is essential for it to be connected to a flue, i.e. a

smoke duct able to create a pressure drop (which in this case should be between 0.10 and 0.20

mbar), in compliance with the applicable laws in this regard.

The combustion product exhaustion ducts must be installed by qualified personnel and must

comply with the regulations in force. For the flue to create a pressure drop, the following

recommendations should be taken into account:

- It should be suitably insulated.

- It should be independently located, with a separate flue for each boiler.

- It should be vertical, avoiding any angles greater than 45º.

8

- It should always have the same diameter. It is recommended that it be circular, and never any

narrower than the boiler outlet.

- It is obligatory to install a fume inspection plate with condensation collection, to remove

the condensation generated in the flue. Otherwise, the condensation may reach the inside of

the boiler and cause irreparable damage, which would not be covered by DOMUSA TEKNIK's

guarantee. The condensation pipe should lead to a drain outlet, as a large amount of water

may be generated. This connection must be made in compliance with the regulations for

draining off condensation water to the drain system.

- It is recommended that a draught stabiliser be installed to prevent any pressure drop

variations in the flue due to atmospheric conditions, which could affect correct boiler

combustion. This draught stabiliser must be installed below the fume inspection plate to

prevent any leakage of combustion gases.

3.7 Electrical Connection

The Lignum NG boiler must be connected to 230 V~ ac 50 Hz by the connector labelled “220V AC”

on the back of the boiler. The socket should have an appropriate earth connection.

The circulating pump must be connected to the 3-pin connector “

” on the back of the boiler,

on the side opposite the connection to the mains electrical supply.

3.7.1 DHW tank electrical connection (optional).

If there is an optional DHW tank, connect the DHW 3-way diverter valve in the 3-pin connector

“

Diagram"

”. Connect the DHW temperature sensor in the controller, as indicated in the

.

The hydraulic installation for the 3-way DHW diverter valve should be made so that the heating

circuit (buffer tank) can flow through the valve when it is idle (not powered):

BOILER

HEATING

NA / NO

NC

V3V

"Electrical

DHW

9

Lignum NG

IMPORTANT: Before carrying out any work on the boiler's electrical installation, always ensure

it is disconnected from the mains.

IMPORTANT: Make sure that none of the mains cables come into contact with a hot surface

(e.g. flue).

3.8 Example of an installation with a buffer tank

The Lignum NG boiler is equipped with an electronic control that can govern a circuit with buffer

tank, with an external circulation kit to prevent condensation in the heat exchanger. The heating

circuit must be regulated and controlled with an external regulator (not included in the boiler

control).

The figure below shows an example of a hydraulic diagram of a buffer tank heating installation:

VS: Heating safety valve

VR: Anti-condensation thermostatic valve

VA: Drain valve

BC: Heating pump

IMPORTANT: It is obligatory and essential to install a heating water buffer tank.

10

BT: Buffer tank VDT: Temperature relief

valve

VC: Heating expansion vessel

BCD: Direct circuit pump

BCM: Mixed circuit pump

P: Automatic air bleed valve

3.9 Example of an installation with a buffer tank and DHW tank

The Lignum NG boiler is equipped with an electronic control that can govern a buffer tank circuit,

with an external circulation kit to prevent condensation in the heat exchanger and, optionally, a

DHW tank loading circuit.

To control a DHW circuit, connect a DHW sensor from the hot water tank to the boiler (optionally

supplied by DOMUSA TEKNIK) and a 3-way diverter valve (see

"Electrical Diagram

”).

The figure below shows an example of a hydraulic diagram for a heating installation with radiators

and a DHW tank:

VS: Heating safety valve

VR: Anti-condensation thermostatic valve

VA: Drain valve

BC: Heating pump

BT: Buffer tank

V3V: 3-way valve

VC: Heating expansion vessel

BCD: Direct circuit pump

BCM: Mixed circuit pump

P: Automatic air bleed valve

IMPORTANT: It is obligatory and essential to install a heating water buffer tank.

11

Lignum NG

4 ADJUSTING THE COMBUSTION AIR

The various stages of combustion (drying, pyrolysis, gasification and combustion) of the Lignum NG

wood boiler take place in a controlled manner in different parts of the boiler.

The wood dries and decomposes in the loading compartment via the technique known as "inverted

draught", generating a combustible gas. The heat required for the decomposition reactions (pyrolysis

and gasification) is provided by the partial combustion of the firewood. The air necessary for the

gasification is called primary air.

The gas produced in the housing is mixed with the preheated secondary air and generates an

extremely high temperature combustion in the refractory chamber, reducing emissions and

increasing the boiler efficiency.

The induced draught fan supplies the primary and secondary air to the boiler by suction.

The air regulators or the boilers are set by default to optimal conditions for obtaining suitable fume

temperatures and emissions. Therefore, the initial air setting of the boiler should not be modified.

12

5 TEMPERATURE RELIEF SAFETY VALVE

In order to avoid the temperature inside the boiler reaching damaging levels, this valve opens and lets

the mains water supply pass into the interior coil, thereby dispelling the heat in a fully reliable manner.

This occurs when, for hydraulic reasons or due to lack of electric current, the boiler cannot dispel the

heat it is generating. This valve is obligatory in Lignum NG boiler installations.

5.1 Operating principle

The valve is regulated by the hot water from the boiler. If the water temperature is greater than

95ºC, the valve opens and lets the mains water through. This water moving in the coil absorbs the

boiler temperature and this prevents overheating and any damage to the boiler. The boiler

protection system corresponds with Standard EN 303-5.

5.2 Valve assembly

The temperature relief valve must be connected with free discharge to the safety heat exchanger

(in accordance with Standard EN 12828). The connection must not be blocked manually.

Furthermore, access must be granted to the heat protection mechanism and to the cleaning

inspection, once assembled. The minimum connection pressure for the safety heat exchanger is 2

bars. The nominal pressure of the valve is 5 bars.

The temperature relief valve is installed up-current of the coil (placed respecting the flow direction

according to the arrow on the coil). The mains water supply must be connected directly to the

temperature relief valve. The connection is threaded, type Rp 3/4" (DIN EN 10226).

IMPORTANT: It should not be possible to close the supply pipe so as to avoid any accidental

blockage.

IMPORTANT: The cold water pressure should not depend on the electricity supply.

IMPORTANT: The pipe must be thoroughly washed before installation.

13

Lignum NG

6 STARTING UP THE BOILER

6.1 Prior warnings

Repair and maintenance of the boiler must be carried out by a qualified professional, authorised by

DOMUSA TEKNIK. For optimum functioning and conservation of the boiler, it should be serviced

annually.

Carefully read this instruction manual and keep it in a safe, easily-accessible place. DOMUSA

TEKNIK will not be liable for any damages caused by failure to follow these instructions.

During some of the operating phases, a forced noise may be heard for a few minutes. This is normal

and does not affect the boiler's integrity in any way.

Before any servicing, disconnect the boiler from the mains.

6.2 Filling the installation

The hydraulic installation must include a fill valve, a manometer, a safety valve, drain valves and the

necessary hydraulic components for correctly filling the installation.

To fill the installation, open the fill valve until the installation manometer shows a pressure of 1 - 1.5

bars. The installation must be filled slowly, bleeding the air from the water circuit using the drain

valves provided for this purpose. Close the fill valve after filling.

IMPORTANT: Switching on the boiler with no water inside could result in serious damage.

6.3 Start-up

Before beginning the start-up process, the following must be complied with:

- The boiler must be connected to the mains.

- The installation must be filled with water (the pressure must be between 1 and 1.5 bar).

The following steps are obligatory in the start-up sequence:

- Remove the cleaning brush and the rake supplied with the boiler.

- Check the flue is correctly installed using the condensation inspection plate and a draught

stabiliser

- Check the external hydraulic anti-condensation kit is correctly installed.

- Check that the temperature relief valve is properly installed.

- If the installation has flow and return valves, check they are open.

- Set the installation type parameter (see “

The value is 04 if there is a buffer tank without a DHW tank.

The value is 02 if there is a buffer tank and a DHW tank.

- Set the boiler adjustment mode parameter (see “

The recommended value is 02.

14

Digital display and selecting parameters"

):

Digital display and selecting parameters"

):

6.4 Installation hand over

After the initial start-up, the installation engineer will explain to the user how the boiler works,

making any observations they consider relevant.

The installer is responsible for clearly explaining to the user the functioning of any control or

regulation device forming part of the installation but not supplied with the boiler.

15

Lignum NG

7 DIGITAL DISPLAY AND SELECTING PARAMETERS

The Lignum NG boiler is equipped with a digital touch display for viewing and adjusting the different

boiler settings. The various parameters displayed on the main screen are described below.

The various parameters displayed on the screen are described in the table below. You can browse

through the parameters by pressing the "F" button:

Selecting the boiler set-point temperature, T1.

Default value (recommended): 80ºC

If the DHW sensor is connected and the hydraulic installation type selected

includes a DHW tank, after selecting the boiler temperature and pressing the F

button, the DHW set-point temperature must be selected, T2 (only valid for

installation with DHW tank ).

Default value: 55ºC

After pressing the F button again, select the fume set-point temperature, T3 (only

valid for Adjustment Mode 03).

Recommended value: 180ºC

Ventilation time during periods with no heat demand.

Default value (recommended): 10 s

Ventilation interval during periods with no heat demand.

Default value (recommended): 5 min

Maximum fan speed.

Default value (recommended): 99%

16

Minimum fan speed.

Recommended value: 50%

Settings for hydraulic installation type.

When the Lignum NG boiler is installed with a buffer tank (see

installation with buffer tank

), the value of this parameter must be 04.

Example of

If there is a buffer tank and a DHW tank (see

tank and DHW tank

tank, a domestic hot water temperature sensor (see

way valve must be connected in the "

IMPORTANT: Hydraulic installation types 01 and 03 are not operational in

Lignum NG boilers.

Boiler adjustment mode. There are 3 options:

To select the parameters, press "F". Use the “+” and “-“ buttons to increase or reduce the value of the

selected parameter (the value will be flashing). Check that the value shown on the boiler temperature

set-point indicator is the one desired.

- Classic Adjustment. 01

- PID adjustment based on the boiler temperature adjustment. 02

- PID adjustment based on the fume temperature adjustment. 03.

Recommended parameter: 02 (PID adjustment based on boiler temperature)

Service menu symbol.

), the selected parameter is 02. In order to work with a DHW

Example of installation with buffer

Electrical Diagram

" connector (see

Electrical Connection

) and a 3-

).

IMPORTANT: If the fume temperature is selected as an adjustment parameter, it must be taken into

account that the real value is 10 times greater than that selected. For example 20ºC

means 200ºC.

17

Lignum NG

8 BOILER MAINTENANCE AND CLEANING

8.1 Cleaning the boiler

8.1.1 Ashes

The ashes must be cleaned out regularly and properly after every 3 or 5 loads of firewood,

depending on the type of wood. The ashes accumulate in both the loading compartment and

the refractory combustion chamber and in the flue. The ash could be deposited in the ash box.

To clean the boiler, follow these steps:

- The boiler must be cold before cleaning. Wait 2-3 hours after all the fuel has been finished.

- Open the top loading door, clean the ashes through the hole in the refractory burner using the

cleaning rake provided with the boiler. We recommend that you save part of the ashes and

carbonised wood to make it easier to light the next time. Avoid scraping the rake on the

middle refractory part in order to avoid abrasion of the part.

- Close the top loading door and open the bottom front door. Remove the ashes that have built

up inside the combustion chamber and surrounding areas.

- Clean the flue by moving the lever towards the boiler approximately 10 times. Perform full 90º

cycles.

NOTE: The flue cleaning lever can be placed on the opposite side of the boiler. To do so,

remove the sides, the back part of the roof and the flue lid, loosen the lever and the arm of

the cleaning axle, remove the axle and place it in the reverse position.

8.1.2 Tar

Clean the tar from the metal surface of the fuel loading chamber using the scraper. The

gasification process produces tar and the amount will depend on the type of wood, its humidity

and the water inlet and outlet temperatures. It is recommended that it be cleaned once a month,

although the frequency may vary depending on the type of wood used.

18

8.2 Boiler maintenance:

Various maintenance operations should be carried out at different intervals to keep the boiler in

perfect working order.

The most important aspects to be checked are as follows:

No. Operation Frequency

Clean ashes from the loading compartment, combustion chamber and

1.

flue.

2. Check the boiler visually. weekly

3. Clean tar from the loading compartment monthly

4. Clean the windows of the peep-holes with alcohol visual control

Clean all exchange surfaces: flue, fume chamber, etc. You can use the

5.

cleaning brush for scraping and descaling any embedded tar or ashes.

Check and clean the flue. The flue must be free of any obstacles and have

6.

no leaks.

7. Check the expansion vessel. It must be full, according to its reference plate. yearly

8. Check the air-tightness of the housing doors. yearly

Check the water pressure in the heating installation. In cool mode, it

9.

should be between 1 - 1.5 bars.

8.2.1 Draining the condensation water

3-5 loads of

firewood

yearly

yearly

yearly

Draining of condensation water from the flue should not be altered in any way and it must be

kept free of obstructions.

8.2.2 Boiler water characteristics

In areas with water hardness exceeding 25-30ºfH, treated water must be used in the heating

installation to avoid any scale deposits on the boiler. It should be noted that even a few

millimetres of lime-scale will greatly reduce the boiler's heat conductivity, causing a significant

decrease in its performance.

Treated water must be used in the heating circuit in the following cases:

- Very large circuits (containing a large amount of water).

- Frequent filling of the installation.

If repeated partial or total draining of the installation is necessary, we recommend filling it with

treated water.

19

Lignum NG

8.3 Safety warnings:

8.3.1 Safe handling of ashes

For safe handling of the ashes, you should take the necessary safety precautions and wear

suitable clothing to protect against possible injury. The following advice should be particularly

taken into account:

- Shut down the boiler operation before removing the ashes.

- It is recommended to wear heatproof "thermal gloves" to protect your hands from any burns

from hot parts of the drawer.

- It is recommended you wear a "protective mask" to avoid breathing in any ash particles,

particularly in the case of people with allergies or any type of respiratory trouble, who should

always wear a mask when carrying out ashes.

- As the ash to be removed may be burning or glowing, special precautions should be taken with

regard to the type of container it is emptied into. A metal container is recommended, or the

ash should be totally put out at the time of handling, using water or another extinguishing

agent.

DOMUSA TEKNIK shall not be liable for any damage caused to people, animals or property as a

result of incorrect handling of the ash drawer or the ash itself.

IMPORTANT: The ash clearance must only be undertaken when the boiler is switched off.

8.3.2 Hazards related to the door of the fuel loading chamber.

To avoid hazards related to the door of the fuel loading chamber, take the following advice into

account:

- If opening the fuel load ing door when there is combustion in the housi ng, do so carefully. First

open very slightly. Keep your body and face away from the fuel loading door.

- Close the door of the fuel loading chamber immediately after performing the control of the

fuel load amounts or after having reloaded fuel.

- The danger of deflagration increases after uncontrolled conditions in the installation (power

cut).

- Let the installation cool down before opening it.

- Do not open the door of the combustion chamber during/after a power cut.

- The flames can cause damage to the control unit.

- Inspect the doors and joints of the installation in search of possible leaks.

20

9 SHUTTING DOWN THE BOILER

To stop the boiler, press the "STOP" button. In shut-down mode, the fan stops working. To shut down

boiler operation completely, unplug it from the mains.

9.1 Detection of lack of fuel

The controller automatically detects the lack of fuel. When the fuel runs out, the message AL1

appears on the screen.

After detecting the lack of fuel, the circulating pump and the fan are deactivated so as to avoid any

heat loss in the buffer tank. In this case, if no additional load of wood is desired, the controller can

be turned off. The “AL1” alarm can be cancelled by pressing the “START” button or after turning the

controller on and off.

NOTE: If the lack of fuel is detected too quickly or too slowly, call the Technical Support Service

to check and modify the controller values.

21

Lignum NG

10 TECHNICAL CHARACTERISTICS

MODEL

Lignum NG

20

Lignum NG

30

Lignum

NG 40

Maximum output power kW 20 30 40

Performance (indirect method) % 88,8 89,4 91,2

Fuel load volume lt 89 113 137

3

CO at maximum power (10% of O2)

NOx at maximum power (10% of O2)

mg/m

mg/m3

317 238 231

161 141 199

Classification (as per EN 303-5) - Class 5 Class 5 Class 5

Maximum operating pressure bar 3

Fume temperature ºC 150 - 200

Control temperature range ºC 65 - 80

Minimum return temperature ºC 55

Safety thermostat temperature ºC 97

Boiler water volume litres 90 104 114

Water pressure drop (∆T=10ºC) mbar 39 22 44

Water pressure drop (∆T=20ºC) mbar 11 6 11

mbar 0.01

Minimum flue draught

Pa 10

Electrical supply - 230 V~, 50 Hz

Average electrical consumption in nominal

power

W 57 64 70

Average electrical consumption in Standby W 3

Fume outlet diameter mm 125 -130 146-150

Weight (net)

Kg 385 425 450

22

11 DIAGRAMS AND MEASUREMENTS

Lignum NG

MODEL

Boiler height (A) mm 1060 1210 1310

Total height (B) mm 1165 1315 1415

Feeder connection height (C) mm 1137 1287 1387

Fumes outlet connection (D) mm 125-130 146-150

Chimney connection height (E) mm 715 865 955

Height of the Safety Heat Exchanger (F) mm 975 1125 1225

Lignum NG

20

Lignum NG

30

Lignum NG

40

23

Lignum NG

12 ELECTRICAL DIAGRAM

yellow-green

yellow-green

yellow-green

yellow-green

brown

Red

Lamp

DS

NO

C

blue

STB

NC

yellow-green

9 1011121314151617181920

ecoSTER200

D+

ecoMAX 200

1

2

C

blue

blue

blue

brown

Mains

STB

230 V~

230 V~

AN AL BN BL CN CL

LN12345678

yellow-green

yellow-green

blue

Male

L1

N

Female

blue

brown

FemaleMale

N

Black Socket

blue

MaleFemale

L1

N

Black Socket

brown

L

White Socket

°C

D-

+5V

red

T3 T2

GND

red

blue

MaleFemale

N

T1

2,7 μF

Capacitor

brown

L

White Socket

Central

blue

black

brown

M

Heating Pum p

Fan

LN

Mains

230 V~

clockwise seen from

the rotor side

L: Phase.

N: Neutral.

C: Common.

GND: Earth.

T1: Boiler sensor.

T2: DHW sensor.

T3: Fume temperature sensor.

: Room thermostat (not operative in the Lignum NG boilers).

STB: Safety thermostat (100ºC).

DS: Door switch.

NO: Normally open port.

NC: Normally closed port.

DHW Tank

Pump

24

13 SENSOR VALUES

The table below shows the electrical resistance values for each temperature on the sensors connected

to the boiler. To correctly measure these values, the sensors must be electrically disconnected from

their corresponding terminal block:

DHW/BOILER SENSOR PTC (1 kΩ at 25ºC)

R (ohms) Temp. (ºC) R (ohms) Temp. (ºC)

815 0 1209 50

886 10 1299 60

961 20 1392 70

1000 25 1490 80

1040 30 1591 90

1122 40

FUMES SENSOR PT1000 (1 kΩ at 0ºC)

R (ohms) Temp. (ºC) R (ohms) Temp. (ºC)

1000 0 1385 100

1097 25 1479 125

1194 50 1573 150

If there are significant differences with regard to the values in the table, the sensor must be changed.

25

Lignum NG

14 SPARES LIST

Boiler

No. Code Description

1

2

3

4

5

6

7

8

9

CLIG000163

10

CLIG000111

Top door

Bottom door

LIGNUM NG coil

Gas flue cleaning system

Fan

Controller

Bottom back part

Outside

Refractory parts

Air adjustment LIGNUM NG 20/30

Air adjustment LIGNUM NG 40

26

Top door

No. Code Description

LIGNUM NG 20 top door seal

LIGNUM NG 30 top door seal

LIGNUM NG 40 top door seal

LIGNUM NG door hinge

LIGNUM NG door handle assembly

LIGNUM NG Bakelite arm

LIGNUM NG door fixing

LIGNUM NG handle shaft

LIGNUM NG Door lock

LIGNUM NG door lock pin

LIGNUM NG upper front door with refractory LIGNUM NG 20

LIGNUM NG upper front door with refractory LIGNUM NG 30

LIGNUM NG upper front door with refractory LIGNUM NG 40

1.1

1.2

1.3

1.4

1.5

1.6

1,7

1,8

1,9

CLIG000116

CLIG000117

CLIG000118

CLIG000003

CLIG000004

CLIG000005

CLIG000006

CLIG000113

CLIG000119

CLIG000120

CLIG000121

CLIG000122

CLIG000123

27

Lignum NG

Bottom door

No. Code Description

2.1

2.5

2.6

2.7

2.8

2,9

CLIG000126

CLIG000127

CLIG000011

CLIG000012

CLIG000013

CLIG000128

CLIG000129

CLIG000130

LIGNUM NG 20 bottom door seal

LIGNUM NG 30/40 bottom door seal

LIGNUM NG peep-hole

LIGNUM NG peep-hole casing

LIGNUM NG rake

LIGNUM NG ash box

LIGNUM NG 20 bottom front door with refractory

LIGNUM NG 30/40 bottom front door with refractory

28

Coil

No. Code Description

3.1

3.2

3.6

3.8

CLIG000016

CLIG000017

CLIG000019

CLIG000131

LIGNUM NG cooling heat exchanger

LIGNUM NG Temperature relief valve

LIGNUM NG Temperature relief valve casing

LIGNUM NG Temperature relief valve seal

29

Lignum NG

Gas flue cleaning system

No. Code Description

CLIG000132

4.1

CLIG000133

CLIG000134

4.2

CLIG000026

4.3

CLIG000135

4.4

CLIG000030

4.5

CLIG000031

LIGNUM NG 20 turbulator

LIGNUM NG 30 turbulator

LIGNUM NG 40 turbulator

LIGNUM NG turbulator axle

LIGNUM NG cleaning axle

LIGNUM NG cleaning arm

LIGNUM NG cleaning handle

No. Code Description

4.8

4.9

4.11

4.14

4.15

CLIG000032

CLIG000034

CLIG000136

CLIG000137

CLIG000042

LIGNUM NG cleaning axle arm

LIGNUM NG cleaning axle support

LIGNUM NG flue lid

LIGNUM NG flue lid insulation

LIGNUM NG cleaning brush

30

Fan

No. Code Description

5.1

5.4

RLIG000113

RLIG000114

CLIG000046

LIGNUM NG fan

LIGNUM NG fan cover box

LIGNUM NG fan gasket

31

Lignum NG

Controller

No. Code Description

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.11

6.12

6.13

CLIG000048

CLIG000049

CLIG000050

CLIG000051

CLIG000052

CLIG000053

CLIG000138

CFOV000151

CLIG000114

LIGNUM NG controller

LIGNUM NG safety thermostat

LIGNUM NG fumes sensor

LIGNUM NG boiler sensor

LIGNUM NG DHW sensor

LIGNUM NG controller light

LIGNUM NG controller housing

LIGNUM NG capacitor

LIGNUM NG capacitor terminal

LIGNUM NG door switch

32

Bottom back part

No. Code Description

7.1

CLIG000139

7.2

CLIG000140

LIGNUM NG back part

LIGNUM NG back door insulation

33

Lignum NG

Outside

34

No. Code Description

8.1

8.2

8.3-a

8.4

8.5

8.6

8.7

8.9

8.13

8.14

CLIG000141

CLIG000142

CLIG000143

CLIG000144

CLIG000145

CLIG000146

CLIG000147

CLIG000148

CLIG000149

CLIG000150

CLIG000151

CLIG000152

CLIG000153

CLIG000154

CLIG000155

CLIG000156

CLIG000157

CLIG000090

CLIG000091

LIGNUM NG front roof

LIGNUM NG back roof

LIGNUM NG 20 left side

LIGNUM NG 30 left side

LIGNUM NG 40 left side

LIGNUM NG right side

LIGNUM NG right side

LIGNUM NG right side

LIGNUM NG top door

LIGNUM NG top door

LIGNUM NG top door

LIGNUM NG 20 bottom door

LIGNUM NG 30/40 bottom door

LIGNUM NG 20 bottom back

LIGNUM NG 30 bottom back

LIGNUM NG 40 bottom back

LIGNUM NG coil cover

3-pin socket connector LIGNUM NG

3-pin plug connector LIGNUM NG

35

Lignum NG

Refractory parts

No. Code Description

9.1

9.3

9.4

9.5

9.6

9.8

CLIG000158

CLIG000159

CLIG000160

CLIG000161

CLIG000108

CLIG000109

RLIG000124

LIGNUM NG top refractory element

LIGNUM NG top fibre seal

LIGNUM NG middle refractory element

LIGNUM NG bottom fibre seal

LIGNUM NG 20 bottom refractory element

LIGNUM NG 30/40 bottom refractory element

LIGNUM NG primary air duct

36

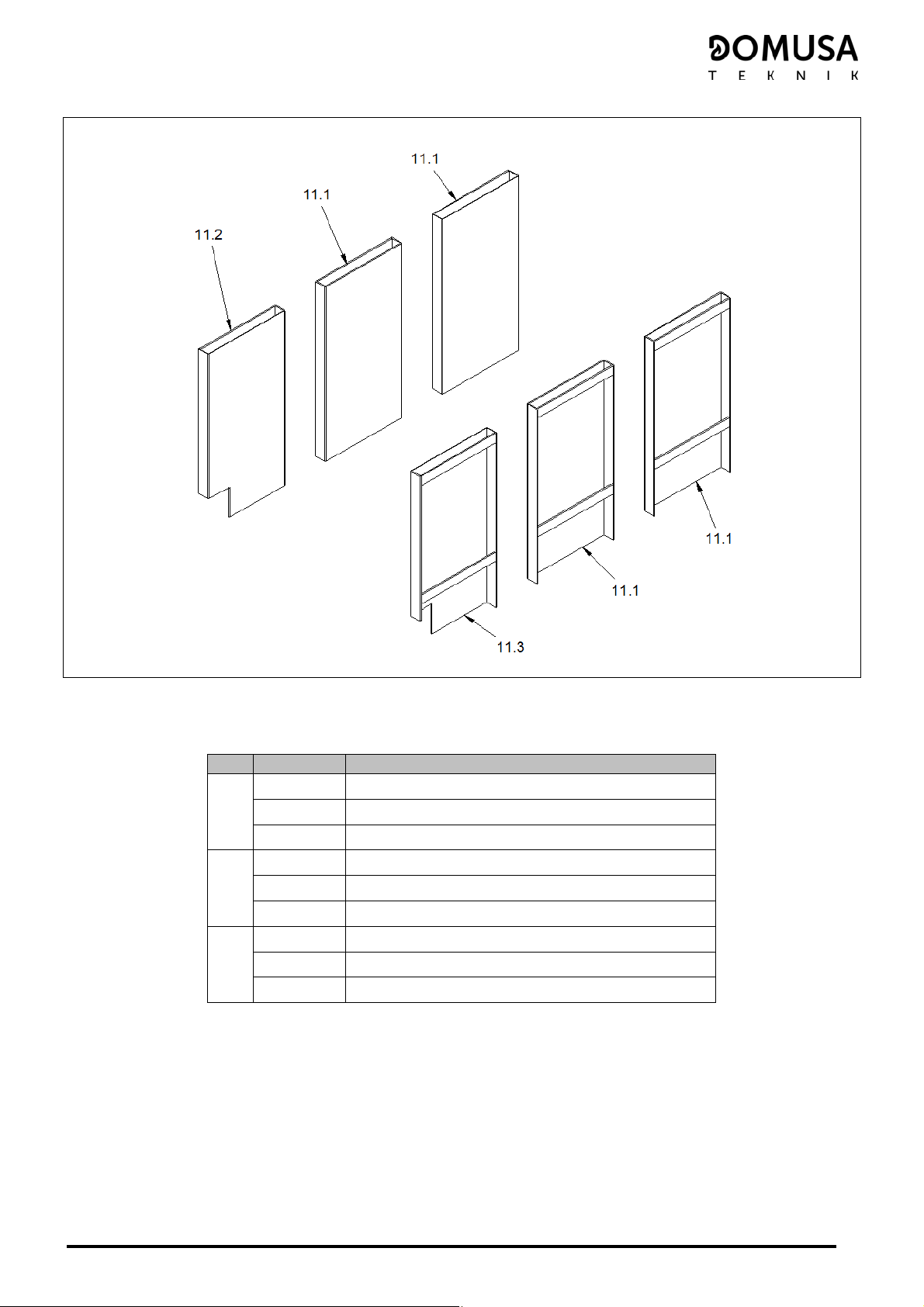

Anti-condensates

No. Code Description

11.1

11.2

11.3

RLIG000118

RLIG000121

RLIG000115

RLIG000119

RLIG000122

RLIG000116

RLIG000120

RLIG000123

RLIG000117

Rear anti-condensates sheet LIGNUM NG 20

Rear anti-condensates sheet LIGNUM NG 30

Rear anti-condensates sheet LIGNUM NG 40

Front left anti-condensates sheet LIGNUM NG 20

Front left anti-condensates sheet LIGNUM NG 30

Front left anti-condensates sheet LIGNUM NG 40

Front right anti-condensates sheet LIGNUM NG 20

Front right anti-condensates sheet LIGNUM NG 30

Front right anti-condensates sheet LIGNUM NG 40

37

Lignum NG

15 ALARM CODES

The Lignum NG boiler has an electronic control able to detect overheating or lack of fuel in the boiler.

When the electronic control detects an operating error, this is indicated by an alarm code on the

display. The table below shows a list of the alarm codes that may appear:

CODE ALARM CAUSE / ACTION

AL1

AL2

AL3

AL4

Lack of fuel alarm

Damage to the boiler

sensor alarm

Boiler overheating

alarm

Fume temperature

sensor alarm

Maximum fume

temperature overrun

Safety thermostat

alarm

When the fuel runs out, this message appears on the screen.

It does not emit an acoustic signal.

This alarm occurs when the boiler temperature sensor does not function

properly or after it has exceeded its measuring range. The alarm activates

the heating pump and an acoustic signal.

The alarm is deactivated once the temperature returns to its measurement

range and after the general switch on the controller is turned off and on.

The Technical Support Service must be called to check and replace the

sensor.

This alarm occurs when the boiler temperature exceeds 90ºC. If this

happens, the fan switches off and the pumps are activated. In addition, an

acoustic signal is emitted.

When the boiler temperature drops, the regulator which controls the boiler

will operate normally.

This alarm occurs when the electronic control detects a failure in the fume

temperature sensor.

The regulator warns the user that the fume temperature is too high when it

exceeds 450ºC. This temperature can be reached if the housing door is left

open or due to a malfunction of the fume temperature sensor.

The alarm is displayed visually and emits a short, acoustic signal.

When the boiler temperature exceeds 100ºC, the safety thermostat (manual

reset) deactivates the fan and the red light on the control panel turns on.

38

16 GUARANTEE CONDITIONS

DOMUSA TEKNIK's commercial guarantee covers normal operation of the products manufactured by

DOMUSA TEKNIK Calefacción S.Coop., in accordance with the following conditions and time periods:

1. This commercial guarantee is valid for the following periods, as from the start-up date:

2 Years for electric and hydraulic elements, pumps, valves, etc.

5 Years for heat exchangers.

During the 2-year period following the date of first start-up, DOMUSA TEKNIK will carry out any

repairs of original flaws or defects totally free of charge.

After these 2 years have elapsed and until the end of the guarantee period, labour costs and callout charges will be payable by the user.

2. The annual service is not included in the terms of this guarantee.

3. The commissioning and annual service are to be carried out by personnel authorised by DOMUSA

TEKNIK.

4. The commercial guarantee will be null and void in the following cases:

- If the annual service has not been carried out by personnel authorised by DOMUSA TEKNIK.

- If the boiler has not been installed in accordance with the applicable laws and regulations for this

type of appliance.

- If the boiler has not been commissioned immediately after its installation, by personnel authorised

by DOMUSA TEKNIK.

Failures due to misuse or incorrect installation, use of non-suitable power or fuel, water supply with

physical or chemical properties causing lime-scale or corrosion, incorrect handling of the appliance

and, in general, for any reason beyond DOMUSA TEKNIK's control, are excluded from this guarantee.

This guarantee does not affect the consumer's rights as stipulated by law.

39

Lignum NG

NOTES:

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

40

NOTES:

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

41

POSTAL ADDRESS FACTORY & OFFICES

Apartado 95 Bº San Esteban s/n

20730 AZPEITIA 20737 ERREZIL (Gipuzkoa)

Tel: (+34) 943 813 899

www.domusateknik.com

DOMUSA TEKNIK reserves the right to make modifications of any kind to its

product characteristics without prior notice.

*CDOC001642*

CDOC001642 10/19

Loading...

Loading...