OPERATION USER GUIDE

AVANTTIA

ER-0170/1996

CGM-04/392

Thank you for choosing a DOMUSA TEKNIK heating boiler. From the

range of DOMUSA TEKNIK products you have chosen the Avanttia

model. With a suitable hydraulic installation, this boiler is capable of

providing you with the temperature comfort suitable for your home, as

well as balanced and economical Domestic Hot Water (DHW)

production.

This manual forms an essential part of the product and it must be

given to the user. Read the warnings and recommendations in the

manual carefully, as they contain important information on the safety,

use and maintenance of the installation.

These boilers are to be installed by skilled personnel only, in

accordance with the legislation in force and following the

manufacturer’s instructions.

The start-up of these boilers and any maintenance operations must

only be carried out by DOMUSA TEKNIK’s Authorised Technical

Assistance Services.

The instructions shall include the substance of the following: This

appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall not be made by

children without supervision.

Incorrect installation of these boilers could result in damage to people,

animals or property, and the manufacturer will hold no liability in such

cases.

DOMUSA TEKNIK informs all parties concerned that, in compliance

with section 1 of the first additional provision of Law 11/1997, the

responsibility for delivering packaging waste or used packaging for its

proper environmental management will be that of the final owner of

the product (Article 18.1 Royal Decree 782/1998). At the end of its

useful life, the product must be taken to a selected collection point for

electrical and electronic equipment or must be returned to the

distributor at the time of purchasing a new equivalent appliance. For

more detailed information on the collection schemes available, contact

either the collection facilities of the local authority or the distributor

where the purchase was made.

1

ÍNDICE Pág.

1 COMPONENTS DIAGRAM................................................................................................................................................2

2 CONTROL ELEMENTS........................................................................................................................................................4

3 DIGITAL DISPLAY................................................................................................................................................................5

3.1 OPERATION IN “STANDARD” DISPLAY MODE.....................................................................................................................................5

3.2 CHANGING THE SETTINGS....................................................................................................................................................................7

4 OPERATION...........................................................................................................................................................................8

4.1 SELECTING THE BOILER SETPONT TEMPERATURE ...............................................................................................................................9

4.2 SELECTING THE DHW SETPOINT TEMPERATURE................................................................................................................................9

4.3 SELECTING THE SETPOINT TEMPERATURE OF HEATING CIRCUIT 1..................................................................................................10

4.4 SELECTING THE SETPOINT TEMPERATURE OF HEATING CIRCUIT 2..................................................................................................10

5 ADDITIONAL FUNCTIONS............................................................................................................................................ 11

5.1 ANTILEGIONELLA FUNCTION .............................................................................................................................................................11

5.2 PUMPS ANTI-BLOCK FUNCTION.........................................................................................................................................................11

5.3 ANTI-FROST FUNCTION......................................................................................................................................................................11

5.4 BOILER PRESSURE SENSOR FUNCTION...............................................................................................................................................11

5.5 RESETTING TO FACTORY DEFAULT VALUES.......................................................................................................................................11

5.6 CONNECTING THE LAGO FB OT+ REMOTE CONTROL...................................................................................................................11

5.7 ROOM THERMOSTAT CONNECTION...................................................................................................................................................11

6 FUNCTIONING OF HEATING CIRCUIT 2 (OPTIONAL).......................................................................................... 12

7 LAGO FB OT+ REMOTE CONTROL (OPTIONAL).................................................................................................... 13

7.1 FUNCTIONING WITHOUT AN OUTDOOR SENSOR..............................................................................................................................13

7.2 FUNCTIONING WITH AN EXTERNAL SENSOR (OPTIONAL)................................................................................................................14

7.3 DHW FUNCTION................................................................................................................................................................................14

8 COMMISSIONING OF THE BOILER............................................................................................................................. 15

9 BOILER DELIVERY............................................................................................................................................................. 15

10 SHUTTING DOWN THE BOILER.................................................................................................................................15

11 DRAINING THE BOILER................................................................................................................................................15

12 SAFETY CUT-OUTS........................................................................................................................................................ 16

12.1 TEMPERATURE SAFETY CUT-OUT....................................................................................................................................................16

12.2 BURNER CUT-OUT............................................................................................................................................................................16

12.3 LOW PRESSURE CUT-OUT ................................................................................................................................................................16

13 BOILER MAINTENANCE...............................................................................................................................................17

14 ALARM CODES............................................................................................................................................................... 19

15 DIAGRAMS AND MEASUREMENTS.........................................................................................................................20

15.1 AVANTTIA HDX...............................................................................................................................................................................20

15.2 AVANTTIA HDXM...........................................................................................................................................................................21

16 TECHNICAL CHARACTERISTICS................................................................................................................................ 22

16.1 PRODUCT DATA (ACCORDING TO EC/125/2009 DIRECTIVE).....................................................................................................22

16.2 TECHNICAL DATA ............................................................................................................................................................................22

17 ELECTRICAL CONNECTION DIAGRAM...................................................................................................................24

17.1 AVANTTIA HDX...............................................................................................................................................................................24

17.2 AVANTTIA HDXM...........................................................................................................................................................................25

18 COMMERCIAL GUARANTEE.......................................................................................................................................26

Avanttia

2

1 COMPONENTS DIAGRAM

1

Avanttia HDX

9

11

3

7

8

6

2

10

4

5

1. Heat exchanger.

2. DHW expansion vessel.

3. Main primary circuit drain.

4. Heating expansion vessel.

5. DHW storage tank Inox.

6. Disconnect fill.

7. Siphon safety group.

8. Safety group.

9. Automatic boiler drain valve.

10. Main heating circuit drain.

11. Heating circuit circulation pump.

3

1

Avanttia HDXM

9

11

3

7

8

6

2

10

4

5

13

14

12

1. Heat exchanger.

2. DHW expansion vessel.

3. Main primary circuit drain.

4. Heating expansion vessel.

5. DHW storage tank Inox.

6. Disconnect fill.

7. Siphon safety group.

8. Safety group.

9. Automatic boiler drain valve.

10. Main heating circuit drain.

11. Heating circuit circulation pump.

12. Motorized 3 way valve.

13. Automatic air vent.

14. Heating mixed circuit circulation pump.

Avanttia

4

2 CONTROL ELEMENTS

16 19 2018

15

17

15. Digital display:

This is the main boiler functioning display, on

which all the operating information, settings

and values appear. This display is also used to

access the appliance’s user and service settings.

In standard operating mode (default display),

the actual boiler temperature is shown. If

malfunction occurs, an alarm code will appear

on the digital display instead of the

temperature.

16. Boiler temperature touch button:

This is used to select the boiler setpoint

temperature. It is also used to disable the hot

water function.

17. DHW temperature touch button:

This is used to select the setpoint temperature

for domestic hot water. It is also used to disable

the DHW function.

18. MODE touch button:

This button is used to access and browse the

different menus.

19. ON touch button:

This button switches the boiler on and off.

20. RESET touch button:

When the boiler is in lock-out mode, the RESET

button is pressed to reset the lock-out and

restore “Standard” functioning. If you are

modifying any of the settings or browsing the

menus, you may press the RESET button to exit

the menu WITHOUT SAVING and return to the

previous menu level.

5

3 DIGITAL DISPLAY

The Avanttia boilers are electronic and have a display

(15)

for viewing the different boiler settings. The

display has various zones where different icons and numbers appear to indicate the different statuses.

3.1 Operation in “standard” display mode

AB CFD E

A Indication of boiler status: Heating function enabled.

DHW production enabled.

B Indication of burner status: Burner functioning.

Boiler lock-out.

C Numerical display.

D Special operating icons.

Anti-frost function: This flashes when the boiler’s anti-frost function is enabled.

Servicing spanner: Steady: When any of the boiler’s technical settings on the

“Service

menu"

are being browsed or modified.

Flashing: When manual functioning of any of the outlets is forced.

E Auxiliary icons.

Steadily lit when the digits show a temperature.

bar Steadily lit when a value or setting connected with the boiler water pressure is shown.

EXT Steadily lit when a value or setting connected with the outside temperature is shown.

INT Steadily lit when a value or setting connected with the temperature inside the home or

settings connected with the LAGO FB OT+ are shown.

F Operating mode icons (see next page).

cd1 radiator: This appears on the display when the circulating pump of direct circuit 1 is

switched on (BC1 on and Sr1 not connected) or when a value or setting

connected with direct circuit 1 is shown.

Avanttia

6

cd2 radiator: This appears on the display when the circulating pump of direct circuit 2 is

switched on (BC2 on and Sr2 not connected) or when a value or setting

connected with direct circuit 2 is shown.

cm1 radiator: This appears on the display when the circulating pump of mixed circuit

1 is switched on (BC1 on and Sr1 connected) or when a value or setting

connected with mixed circuit 1 is shown. The arrows appear according

to the mixed circuit 1 mixer valve control. The upper arrow indicates

that the hot channel of the valve is open, and the lower arrow shows

that the hot channel of the valve is closed.

cm2 radiator: This appears on the display when the circulating pump of mixed circuit

1 is switched on (BC1 on and Sr1 connected) or when a value or setting

connected with mixed circuit 2 is shown. The arrows appear according

to the mixed circuit 2 mixer valve control. The upper arrow indicates

that the hot channel of the valve is open, and the lower arrow shows

that the hot channel of the valve is closed.

House: Steadily lit when a value or setting connected with the temperature inside or

outside the home or settings connected with the room thermostat or remote

controls are shown.

K curves: Steadily lit when a value or setting connected with operating in accordance

with outside weather conditions or K curves is shown.

Recirculation: Steadily: When any value or parameter related to the recirculation of DHW

is displayed or when it's ON the recirculation of DHW function (the

auxiliary input of the controller is closed.

Flashes: When the DHW recirculation pump is ON (Auxiliary boiler relay

activated).

Boiler: Steadily when viewing any value or parameter related to the gas boiler.

Hot water tank: Steadily lit when a value or setting connected with the DHW hot water

tank temperature or functioning is shown.

Browser: Steadily lit when any of the

“User Menus"

or

"Service menus”

are being

browsed.

SET Flashes when access is made to modify any of the settings.

7

3.2 Changing the settings

The boiler adjustment settings are located in the

“User Menu"

and the

“Service menu"

. To access the

“User Menu"

, press . Then press repeatedly to progress sequentially through the user settings. If

the setting shown can be modified, SET will flash on the display and the setting can be changed by

pressing the “” and “▬” symbols for DHW

(17)

and heating

(16)

.

These settings are listed in the table below:

Nº. Setting Type Range Display

1 DHW setpoint temperature Modificable

Off, 15 – 65 ºC

By default: Off

2 Actual DHW temperature Visual

3 Boiler setpoint temperature Modificable

Off, 25 – P.08

By default: Off

4 Actual boiler temperature Visual

5 Water pressure Visual

6 Boiler setpoint temperature enabled Visual

7 Setpoint flow temperature of mixed circuit 1 Modificable

Off, 10 – 45 ºC

By default: Off

8 Actual flow temperature of mixed circuit 1 Visual

9 Setpoint flow temperature of mixed circuit 2 Modificable

Off, 10 – 45 ºC

By default: Off

10 Actual flow temperature of mixed circuit 2 Visual

11 Actual outdoor temperature Visual

12 Heating demand Visual

13 Display contrast Modificable

1 – 5

By default: 3

Avanttia

8

4 OPERATION

The Avanttia boiler is designed to heat a heating installation and provide domestic hot water,

instantly and/or by collection.

Standaring functioning:

The boiler provides both heating and DHW in this mode. The burner and the circulating pump

will switch on and the diverter valve will switch to DHW mode. When the DHW storage tank

reaches the DHW setpoint temperature selected, it was ready to warm the heating installation, by

putting the diverter valve in heating mode. The burner will shut down when the boiler reaches its

selected setpoint temperature. The circulation pump will stop when the room temperature reaches

or exceeds the temperature set on the installation’s room thermostat (if it has one).

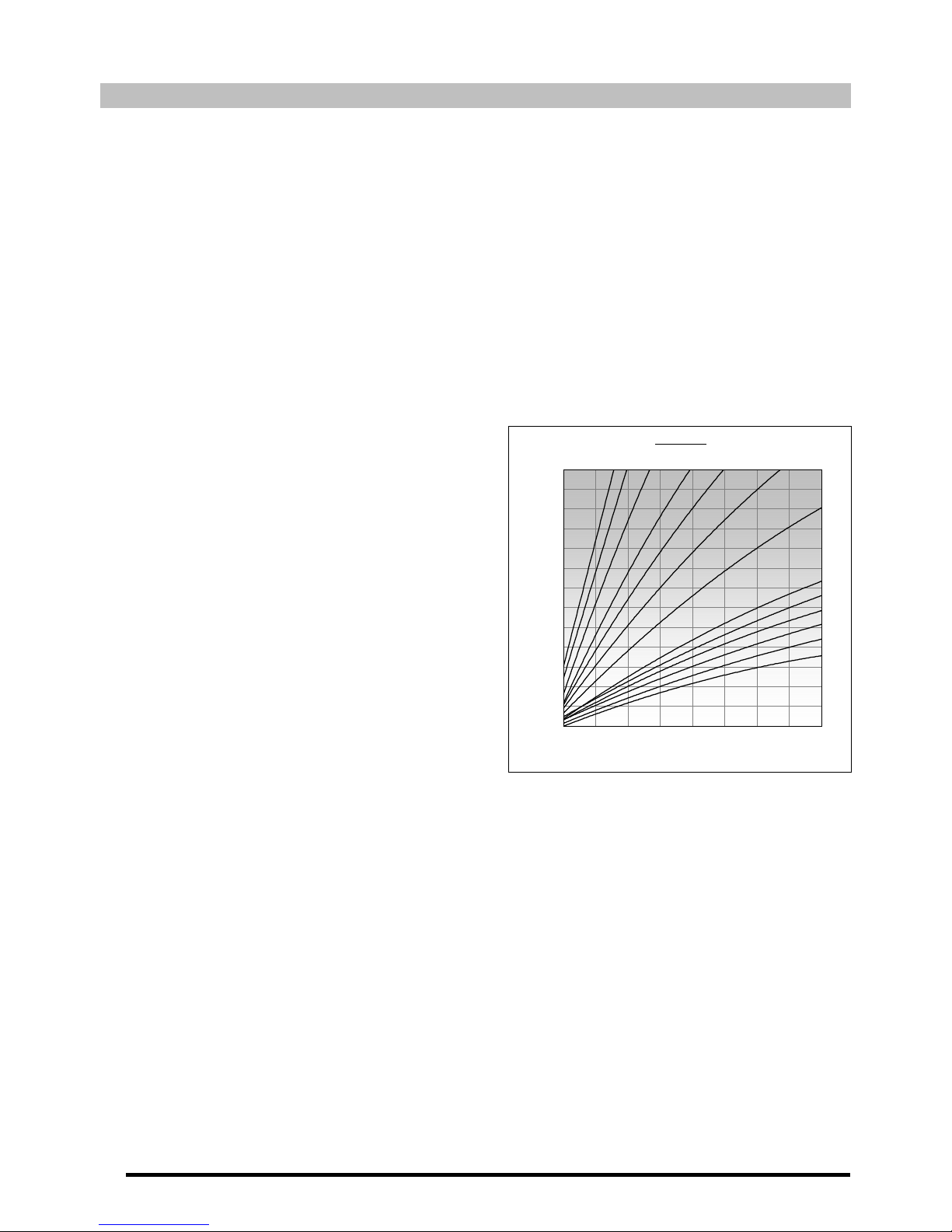

Functioning according to outdoor temperature conditions

When the boiler is connected to an outdoor temperature sensor (supplied with the boiler),

functioning may be activated according to the

outdoor temperature conditions, using parameter

P.10 on the

"Technical Menu".

When this operating mode is activated, the boiler

and/or heating output temperature are

determined in accordance with the K curve set (for

parameter P.11 of the

"Technical Menu"

for circuit

1 and P.31 for circuit 2) and the outdoor

temperature measured. If the installation is

correctly dimensioned, the boiler temperature

and/or output temperature calculated will ensure

the room temperature is in accordance with the

set point programmed.

The K curve relates the outdoor temperature

reading on the sensor installed outside the home

to the boiler temperature setpoint. The graph

shows the temperature ratio for each point on the

K curve.

IMPORTANT: To connect the outdoor temperature sensor to the boiler, carefully follow the

connection instructions provided in the

"Electrical Connections"

section.

Disabling the heating function (Summer Mode):

In this mode, the boiler provides DHW but not heating. To disable the heating function, press the

heating “▬” symbol

(16)

until “oFF” appears on the display.

Disabling the DHW function:

In this mode the boiler provides heating but not DHW. To disable the DHW function, press the

DHW “▬” symbol

(17)

until “oFF” appears on the display. The burner, the circulation pump and the

diverter valve are in heating mode. The burner will shut down when the boiler reaches its selected

setpoint temperature. The circulation pump will stop when the room temperature reaches or

exceeds the temperature set on the installation’s room thermostat (if it has one).

K - factor

0,5

0,6

0,7

0,8

0,9

1

1,5

22,53

4

5

6

20

25

30

35

40

45

50

55

60

65

70

75

80

85

-20-15-10-505101520

Outdoor Temperature (ºC)

Boiler Temperature (ºC)

9

4.1 Selecting the boiler setpont temperature

Depending on the boiler configuration, the Heating “” and “▬” symbols

(14)

may be used to

select the desired boiler functioning temperature, as well as enabling and/or disabling the heating

function.

Providing there is a direct circuit that is not functioning according to the outside weather

conditions (P.11 = oFF and/or P.31 = oFF), or when no second heating circuit is installed, the

Heating “” and “▬” symbols

(16)

can be used to selected the desired boiler functioning

temperature, in addition to enabling and/or disabling the heating function.

The boiler setpoint temperature can also be selected by pressing until the icon appears on

the display, with the word SET flashing. The setting can be changed by pressing the Heating “”

and “▬” symbols

(16)

.

In all other cases, pressing the Heating “” and “▬” symbols

(16)

will only enable and/or disable

the heating function.

The permitted boiler setpoint temperature range is 25 - 85 ºC. Model Avanttia boilers are

condensing boilers. In order to obtain maximum boiler performance and energy savings, it is

recommended to select a setpoint temperature of 60 - 70 ºC, providing this is permitted by the

heating system installed and the insulation conditions of your home.

4.2 Selecting the DHW setpoint temperature

The desired DHW temperature can be selected by pressing the DHW “” and “▬” symbols

(17)

. If

they are not pressed for 2 seconds, the display will return to “standard” mode.

The DHW setpoint temperature can also be selected by pressing

until the icon appears on the

display, with the word SET flashing. The setting can be changed by pressing the DHW “” and “▬”

symbols

(17)

.

Avanttia

10

4.3 Selecting the setpoint temperature of heating circuit 1

The flow temperature of the circuit may be selected, providing heating circuit 1 is a mixed circuit

(heating pump of circuit 1 (BC1) and the mixer valve (M1) and sensor (Sr1)) and it is not functioning

in accordance with outside weather conditions (P.11 = oFF). To select it, press to browse until

the icon

appears on the display with the SET symbol flashing. The temperature can be

changed by pressing the Heating “” and “▬” symbols

(16).

However, if the boiler is functioning according to outside weather conditions (external EVT sensor

connected and P.10 = oN and P.11 not oFF), the circuit flow temperature cannot be selected; only

the K curve can be selected with the P.11 setting.

4.4 Selecting the setpoint temperature of heating circuit 2

The flow temperature of the circuit may be selected, providing heating circuit 2 is a mixed circuit

(heating pump of circuit 1 (BC

2

) and the mixer valve (M2) and sensor (Sr2)) and it is not functioning

in accordance with outside weather conditions (P.31 = oFF). To select it, press to browse until

the icon

appears on the display with the SET symbol flashing. The temperature can be

changed by pressing the Heating “” and “▬” symbols

(16).

However, if the boiler is functioning according to outside weather conditions (external EVT sensor

connected and P.10 = oN and P.11 not oFF), the circuit flow temperature cannot be selected; only

the K curve can be selected with the P.31 setting.

When both the boiler’s circuits are functioning with an external sensor, the Heating “” and

“▬” symbols

(16)

can only be used to enable or disable the heating function.

11

5 ADDITIONAL FUNCTIONS

The Avanttia boiler has the following additional control functions:

5.1 Antilegionella function

Using the P.17 parameter, it is possible to activate the function of protection against Legionella

bacterium. With the feature enabled, every 7 days, DHW tank temperature rises up to 65 ºC.

5.2 Pumps anti-block function

This feature prevents the boiler circulation pumps from seizing up if they have been out of use for a

long period. This system remains enabled while the boiler is plugged into the mains.

5.3 Anti-frost function

This function protects the boiler from freezing up during cold weather. If the boiler temperature

drops to below 6 ºC, the heating circulation pump will start up. If the boiler temperature continues

to drop and reaches 4 ºC, the burner will start up, heating the installation. When this function has

been activated, it will continue working until the boiler reaches 8 ºC. This system remains on

standby while the boiler is plugged into the mains.

5.4 Boiler pressure sensor function

This function prevents boiler failure caused by a low water level and excess pressure in the boiler.

The pressure is detected by a pressure sensor, and its value appears on the control panel display

(on the

“User Menu”

). If the pressure drops below 0.05 MPa (0.5 bar), the electronic control switches

off the boiler and triggers an alarm on the display ("E02"). When the boiler pressure exceeds 0.25

MPa (2.5 bar), an alarm is triggered on the display ("HI") to warn of the excess pressure. If this should

occur, we recommend calling the nearest Technical Assistance Service, and draining the boiler

until the pressure is between 0.1 and 0.15 MPa (1 and 1.5 bar).

5.5 Resetting to factory default values

If these settings are wrongly adjusted or if the boiler functions incorrectly, all the original settings of

all the parameters can be restored by selecting oH in parameter P.26.

5.6 Connecting the LAGO FB OT+ remote control

The boiler has a terminal strip, J5, for connecting the LAGO FB OT+ remote control (see

"Connection Diagram”

). This allows the heating mode for circuit 1 to be switched off, according to

the room temperature.

Installing the LAFO FB OT+ remote control enables the heating and DHW system to adapt to the

scheduled times for use of the installation. It also optimises the installation’s functioning, adapting

the heating setpoint temperature to the room temperature and improving comfort.

5.7 Room thermostat connection

The boiler has two terminal strips, J4 and J6, for connecting room thermostats or room

chronothermostats (TA1 and TA2, see "Electrical Connection Diagram”). This allows the heating

mode for each circuit installed to be switched off according to the room temperature. To connect it,

remove the bridge joining the terminals of each terminal strip, J4 and J6, and connect room

thermostat Nº 1 or Nº 2 for circuits 1 or 2 respectively.

Installing a room thermostat will optimise the performance of the installation, adapting the heating

to your home’s requirements and obtaining enhanced comfort. Also, if the thermostat allows the

hours of functioning to be programmed (chronothermostat), it can adapt the heating system to the

hours of use of the installation.

Avanttia

12

6 FUNCTIONING OF HEATING CIRCUIT 2 (OPTIONAL)

All the boiler models in the Avanttia range may optionally control a second heating circuit. For this

second circuit to be controlled, a second circulating pump (BC2) needs to be installed on the boiler if a

direct circuit is required, or a pump (BC2) and a mixer valve (M2) if a mixed circuit is required. For

correct installation, carefully follow the instructions given in the

“Installation with two heating circuits”

section of this manual.

Direct circuit functioning

Heating circuit 2 will work with the selected boiler setpoint temperature and the temperature of

room thermostat 2 (TA2) (if the boiler has one). When circuit 2 is functioning with an external

sensor (P.10 = ON and P.31 not OFF), the boiler temperature will depend on the outside

temperature and the curve selected in setting P.31.

Mixed circuit functioning

Heating circuit 2 will work with the selected setpoint flow temperature for mixed circuit 2 and the

temperature of room thermostat 2 (TA2) (if the boiler has one). When circuit 2 is functioning with

an external sensor (P.10 = ON and P.31 not OFF), the setpoint flow temperature will depend on the

outside temperature and the curve selected in setting P.31.

In both cases, the burner, the heating pump of circuit 2 (BC2) and the mixer valve (M2) (if the

installation has one) will begin to function until the selected temperature is reached in the installation

or on room thermostat 2 (if the installation has one). When the temperature of the installation drops

below the selected boiler temperature, the burner will start up again, running the heating cycle.

13

7 LAGO FB OT+ REMOTE CONTROL (OPTIONAL)

A remote control (LAGO FB OT+) can optionally be supplied together with the Avanttia boiler. This

remote control can be used to fully operate the boiler from anywhere in the room in which it is

installed. The LAGO FB OT+ remote control governs the parameters of heating circuit Nº 1 and the

installation’s domestic hot water production.

This remote control allows the hours of home comfort to be programmed for heating circuit Nº 1,

adjusting the installation to the particular requirements of the home by measuring the room

temperature and consequently adapting the installation temperature. The remote control can also be

used to adjust the hot water and heating set point temperatures at any time, and for viewing the

different boiler operation parameters. It also warns of any functioning anomalies affecting the boiler.

The LAGO FB OT+ remote control may optionally be connected to an external sensor, for measuring

the outside temperature. With this option installed, the remote control can adjust the home comfort

level (circuit Nº 1) according to the weather conditions at each particular time, optimising fuel

consumption and heating comfort in the home.

The LAGO FB OT+ remote control takes over the control of the boiler when it is connected to it. The

different selectable boiler temperatures must be modified using the remote control. It is easy to install,

only requiring 2 wires for communication between the boiler and the LAGO FB OT+ control. It is

connected to the boiler by connecting the two wires on terminal strip J6 (see “Electrical Connection

Diagram”). For correct installation and functioning, carefully read the instructions enclosed with the

remote control.

The following sections contain a general explanation of the different operating modes and options of

the LAGO FB OT+ remote control.

NOTE: The "AF outdoor temperature sensor" indicated in the instructions manual of remote

controller is not compatible with the boiler, so it is compulsory the use of "EVT outdoor

sensor" (provided within the boiler) to measure the outdoor temperature.

7.1 Functioning without an outdoor sensor

Conventional heating installation (direct circuit)

The maximum temperature for heating circuit Nº 1, the heating times and the desired room

temperatures can be selected on the remote control. The LAGO FB OT+ remote control will

calculate the boiler temperature required at each particular time, depending on the temperature

of the room, and it will activate or disable the heating mode of circuit Nº 1 depending on the

heating times and room temperatures programmed.

Instalation of heating circuit Nº 2 (optional)

If the boiler is supplied with an second heating circuit, this circuit is adjusted and controlled via

the boiler control panel (see

"Functioning of heating circuit Nº 2 (optional)"

).

Avanttia

14

7.2 Functioning with an external sensor (Optional)

If the LAGO FB OT+ remote control is fitted with an outdoor temperature sensor, it can calculate the

heating temperature of heating installation Nº 1 according with the outside weather conditions at

each particular time, with optimum adjustment of the heating installation conditions for improved

heating comfort in the home and energy savings.

The maximum temperature and an operating curve for heating circuit Nº 1, the heating times and

the room temperatures desired can all be selected on the remote control (see instructions enclosed

with the LAGO FB OT+ remote control). The LAGO FB OT+ remote control calculates the required

boiler temperature at each particular time, depending on the temperature inside the home and the

outside weather conditions, in accordance with the operating curve selected (parameter 01 on the

“User Menu"

of the LAGO FB OT+), switching the heating on and off in accordance with the heating

times and the room temperatures programmed.

Depending on the type of heating circuit, the following adjustments should be made:

Conventional heating installation (direct circuit)

In setting 01 of the LAGO FB OT+

“User Menu"

, select a curve of at least 1. The maximum boiler

temperature can also be selected on the LAGO FB OT+ remote control.

Installing low temperature heating (mixed circuit)

In setting 01 of the LAGO FB OT+

“User Menu”

, select a curve of less than 0.8. We also

recommend selecting a maximum flow temperature NO HIGHER THAN 85ºC, to protect the

underfloor heating installation from overheating. To do this, select the maximum flow

temperature of heating circuit 1 in setting 07 of the LAGO FB OT+

“Service Menu”

.

0,2

0,4

0,6

0,8

1

1,2

1,5

20

25

30

35

40

45

50

55

60

65

70

75

80

85

20161284 0-4-8-12-16

Outdoor Tempera ture (ºC)

Boiler Temperature (ºC)

K Curves

NOTE: The "AF outdoor temperature sensor" indicated in the instructions manual of remote

controller is not compatible with the boiler, so it is compulsory the use of "EVT outdoor

sensor" (provided within the boiler) to measure the outdoor temperature.

7.3 DHW function

When the remote control is connected to an Avanttia boiler, the desired DHW temperature and the

desired hours for DHW use can be selected on the LAGO FB OT+ remote control. The LAGO FB OT+

remote control regulates the DHW tank temperature at each particular time, and enables or

disables the DHW function according to the times scheduled.

15

8 COMMISSIONING OF THE BOILER

The start-up of the boiler, for the validity of warranty to be in force, is to be carried out by an

authorised Technical Assistance Service. Prior to proceeding to such a start-up, the following steps

will be performed:

- Check that the boiler is properly connected to the electric power supply.

- Check that the installation is filled with water (the pressure gauge must indicate a pressure

between 0.1 and 0.15 MPa (1 and 1.5 bar)).

- Check for the proper chimney installation.

- Check that the gas supply connection is properly installed.

- Drain the air off the boiler gas circuit by opening the shutoff valve of the gas line and loosening

lightly the valve gas intake pressure tapping for a moment as, otherwise, the air would be forced

to come out slowly through the pilot burner injector.

- Check that the heating circuits outlet and return flow valves are opened, if any.

- Turn the chronothermostat or LAGO FB OT+ remote control (if these are fitted) to the desired

setting.

- It is compulsory to do a combustion analysis in the boiler, using a proper tester. The combustion

test will be done through the hole for this purpose, placed in the plastic pipe of combustion

products exhaustion inside the boiler. If test is out of margins described in the section

"Combustion adjustment", it will be necessary to adjust the combustion.

To start up the boiler, hold down the button, select the desired setpoint temperatures and turn

the chronothermostat or LAGO FB OT+ remote control (if these are fitted) to the desired setting.

9 BOILER DELIVERY

The Technical Assistance Service, once the commissioning of the boiler has been carried out, will

explain the boiler operation to the users by informing them about the most necessary remarks.

The installer will be responsible for explaining to the users the operation of any control or regulation

device that is a part of the installation and it is not supplied with the boiler.

10 SHUTTING DOWN THE BOILER

To switch off the boiler, hold down the button. In Off mode, while the boiler is plugged into the

mains and connected to the fuel installation, its heating and hot water functions will be switched off

but the anti-frost protection and pump anti-block functions will remain activated.

To shut down the boiler functioning completely, unplug it from the mains and cut off the fuel supply.

11 DRAINING THE BOILER

The water is drained from the boiler by opening the air drain valve

(10)

, located inside the boiler on

the lower left hand side of the heat exchanger. Connect a flexible tube to this valve and run it to a

drain. After draining the boiler, close the valve again and remove the flexible tube.

Avanttia

16

12 SAFETY CUT-OUTS

The boiler’s electronic control system may activate the following safety cut-outs to stop the boiler

functioning. When one of these safety cut-outs occurs, the boiler will stop functioning, a cut-out code

will flash on the display and the red alarm warning pilot light will flash on the control panel.

If any of the safety cut-outs described below should occur repeatedly, switch off the boiler and

call your nearest official technical assistance service.

12.1 Temperature safety cut-out

When this cut-out occurs, the "E30" code (temperature alarm) will begin to flash on the digital

display and the alarm warning pilot light will flash on the control panel. The burner will switch off

and stop heating the installation.

This occurs when the boiler exceeds a temperature of 110 ºC. To unblock it, wait until the boiler

drops to below 100 ºC and press the button .

12.2 Burner cut-out

When this cut-out occurs, the code “E09” will begin to flash on the digital display and the flame

failure symbol. The burner will switch off and stop heating the installation.

This occurs as a result of an anomaly in the burner or in the fuel installation. To unblock it, press the

button

.

12.3 Low pressure cut-out

When this cut-out occurs, the code “E02” will begin to flash on the digital display and the flame

failure symbol. The burner amd the boiler circulation pumps will switch off, cutting off the heating

and water flow to the installation.

This occurs when the boiler pressure drops to below 0.05 MPa (0.5 bar), preventing the boiler from

functioning when the water is drained from the installation, due to either leakage or maintenance

operations. To unlock it, press the button

.

17

13 BOILER MAINTENANCE

To maintain the boiler in perfect working order, a yearly overhaul is to be performed by DOMUSA

TEKNIK’s authorised personnel.

Boiler and flue maintenance

The most important aspects to be checked are as follows:

- The water pressure in the heating installation, when the water is cold, must be between 0.1

and 0.15 MPa (1 and 1.5 bar). If it is not between these values, it must be filled until they are

reached.

- The control and safety devices (thermostats, gas valve, etc.) must function correctly.

- The burner and the inside of the boiler chamber must be clean. Soft brushes or compressed air

are recommended for cleaning the boiler, to prevent damage. Do not use chemical products.

- The expansion vessel must be full, in accordance with the specifications on the vessel plate.

- Check the gas and water installations are completely sealed.

- The flues must be free of any obstacles and have no leaks.

- The gas flow must remain between the values indicated on the

Specifications Sheet

.

- The circulating pumps and mixer valves (if the boiler is equipped with these) must not be

blocked.

Cleaning the boiler

The boiler does not require any special maintenance. Yearly cleaning at the end of the heating

season will be sufficient. The boiler chamber and burner should not be cleaned using chemical

products or steel brushes. After any cleaning operation has been carried out, it is important to

ensure that several ignition cycles are performed to check all the elements are functioning

correctly.

After checking the boiler is functioning correctly, ensure there are no leaks.

Draining the condensation water

The boiler condensation water drain outlet should not be altered in any way and it must be kept

free of obstructions. Yearly cleaning of the condensation collection siphon is recommended.

If a neutralisation system is installed at the condensation drain outlet, it should undergo periodical

maintenance, in accordance with the manufacturer’s instructions.

Cleaning products

Never use chemical products to clean the boiler. A plastic brush is sufficient, if the cleaning is

carried out annually.

The cleaning of the boiler and hydraulic circuit will have lasting effects if water with a hardness of

over 25ºF is treated previously. For softer water no treatment is required. In any case, a descaling

pump should be used to carry out the descaling process.

Avanttia

18

Anti-frost precautions

The Avanttia boiler, have a function to prevent the installation from freezing, ensuring that the

boiler is connected to the electrical power supply. In any case, and mainly in geographical zones

where very low temperatures are usual, it is advisable to add anti-freezing liquid to heating circuit.

When a very long period the boiler is not going to work, it is advisable to empty the boiler totally.

Boiler water characteristics

In case of water hardness of over 25-30ºF, we recommend using treated water in the heating

installation to avoid any scale deposits on the boiler.

Bear in mind that a scale deposit of even a few millimetres will cause a major reduction in boiler

performance, as scale is a poor thermal conductor.

It is essential to treat the water used in the heating circuit in the following cases:

- Very long circuits (containing a large amount of water).

- Frequent filling of the installation.

If repeated partial or total draining of the installation is necessary, we recommend filling it with

treated water.

19

14 ALARM CODES

The Avanttia boiler has an electronic circuit which performs continuous self-testing to detect any

malfunctioning in the boiler. When the electronic control detects malfunctioning, this is indicated by

an alarm code flashing on the display. The following list describes the alarm codes that may appear:

Cod. Cause Action required

E02 Low water pressure If it occurs repeatedly, call the TAS.

E03 Ignition failure Reset the boiler.

E04 Flame simulation Call the TAS.

E05 Boiler temperature sensor: open Call the TAS.

E06 Boiler temperature sensor: shorted Call the TAS.

E07 N/A: Wrong boiler model selected Call the TAS.

E08 N/A: Wrong boiler model selected Call the TAS.

E09 Fan anomaly Reset the boiler.

E10 Air pressure anomaly Reset the boiler.

E11 Water pressure sensor failure Call the TAS.

E12 Flame extinguished Reset the boiler.

E15 BMC anomaly Reset the boiler.

E16 Heat exchanger overheating Reset the boiler.

E17 Switch selection error Reset the boiler.

E18 Return temperature sensor: open Call the TAS.

E19 Return temperature sensor: shorted Call the TAS.

E21 DHW tank temperature sensor: open Call the TAS.

E22 DHW tank temperature sensor: shorted Call the TAS.

E27 Air pressure sensor anomaly Reset the boiler.

E28 Water leak Call the TAS.

E30 Fume outlet overheating Reset the boiler.

E40 Outdoor temperature sensor: shorted Call the TAS.

E41 Outdoor temperature sensor: open Call the TAS.

E62 External safety system Call the TAS.

E64 Safety valve anomaly Call the TAS.

E65 External pump anomaly Reset the boiler.

E82 Boiler communication failure Call the TAS.

E93 Abnormal functioning of panel buttons Call the TAS.

A01 Sr1 sensor: open circuit or shorted Call the TAS.

A02 Sr2 sensor: open circuit or shorted Call the TAS.

A03 Si sensor: open circuit or shorted Call the TAS.

A05 Wrong button held down on control panel Call the TAS.

A06 Boiler model configuration error Call the TAS.

A07 NCN control communication error Call the TAS.

CnF Wrong micro switch configuration Call the TAS.

NOTA: It will be very useful for the technical assistance service if you can inform them of the

alarm code that has appeared on call-out.

Avanttia

20

15 DIAGRAMS AND MEASUREMENTS

15.1 Avanttia HDX

1690

1667

1008866

PR

ES

VSES

EG

RC

IC

SS

VC

VSC

VD

B

A

C

920

910

E

D120

559

286436

720

1690

1667

1008866

PR

ES

VSES

EG

RC

IC

SS

VC

VSC

VD

B

A

C

920

910

E

D120

559

286436

720

EA

Connection

Avanttia

25 HDX

Avanttia

37 HDX

IC: Heating output.

3/4" M

A

665 765

RC: Heating return.

3/4" M

B

780 880

EG: Gas inlet.

3/4" M

C

850 950

ES: DCW inlet.

3/4" M

D

560 660

SS: DHW outlet.

3/4" M

E

730 830

PR: Recirculation outlet.

1/2" M

VSES: DHW safety valve.

-

VD: Disconnect exit.

-

VSC: Heating safety valve.

-

VC: Condensate drain.

-

EA: Gas removal / Air intake.

Ø60-100

21

15.2 Avanttia HDXM

286436

720

1690

1667

C

7165

86

PR

ES

VSES

EG

IC

SS

VC

VSC

VD

RC

ICM

RCM

A

B

910

1090

1150

1210

E

120

D

910 180

EA

Connection

Avanttia 25

HDXM

Avanttia 37

HDXM

ICO: Heating output optional circuit.

3/4" M

A

665 765

RCO: Heating return optional circuit.

3/4" M

B

780 880

ICM: Heating output mixed circuit

3/4" M

C

850 950

RCM: Heating return mixed circuit.

3/4" M

D

560 660

EG: Gas inlet.

3/4" M

E

730 830

ES: DCW inlet.

3/4" M

SS: DHW outlet.

3/4" M

PR: Recirculation outlet.

1/2" M

VSES: DHW safety valve.

-

VD: Disconnect exit.

-

VSC: Heating safety valve.

-

VC: Condensate drain.

-

EA: Gas removal / Air intake.

Ø60-100

Avanttia

22

16 TECHNICAL CHARACTERISTICS

16.1 Product data (according to EC/125/2009 Directive)

AVANTTIA

25 HDX

25 HDXM

37 HDX

37 HDXM

-

Condensation

Boiler type

-

Heating and instantaneous hot

water production

Rated heat output P

rated

kW 24 35

Useful heat output P4 kW 23,1 34,2

Useful heat output (30%) P1 kW 5,2 7,5

Seasonal space heating energy efficiency

Ƞ

S

% 91 92

% (PCI) 98 98

Useful efficiency

Ƞ

4

% (PCS) 88,3 88,3

% (PCI) 108,3 108,2

Useful efficiency (30%)

Ƞ

1

% (PCS) 97,6 97,5

Auxiliary electricity consumption at full load el

max

kW 0,110 0,110

Auxiliary electricity consumption at part load el

min

kW 0,042 0,042

Auxiliary electricity consumption in standby mode PSB kW 0,043 0,043

Standby heat loss P

stby

kW 0,043 0,043

Emissions of nitrogen oxides NOx mg/kWh 37 41

Declared load profile - XL XL

Water heating energy efficiency

Ƞ

wh

% 81 80

Daily electricity consumption Q

elec

kWh 0,220 0,210

Daily fuel consumption Q

fuel

kWh 25,102 25,899

16.2 Technical Data

AVANTTIA

Specifications

25

HDX / HDXM

37

HDX / HDXM

Heating consumption (Max/Min) kW 23,5 / 4,9 34,9 / 7,0

DHW heat consumption (Max/Min) kW 23,5 / 4,9 34,9 / 7,0

Heating output (Max/Min) at 80/60 ºC kW 23,1 / 4,8 34,2 / 6,8

DHW output (Max/Min) kW 23,1 / 4,8 34,2 / 6,8

Condensing heating output (Max/Min) at 50/30 ºC kW 25,2 / 5,2 37,6 / 7,5

Full load efficiency at Max/Min output, at 80/60 ºC % 98,1 / 97,4 98,0 / 97,6

Full load efficiency at Max/Min output, at 50/30ºC (condensation) % 107,2 / 106,9 107,7 / 106,9

Partial load (30%) efficiency, with 47 ºC return temperature % 101,6 101,9

Partial load (30%) efficiency, with 30 ºC return temperature % 108,4 108,3

Heat Loss through the case with burner switched on % 0,1 0,1

Heat Loss through the chimney with burner switched on % 1,8 1,9

Seasonal efficiency rate (SEDBUK rating) - A

NOx class - 5

Category - II2H3P

Heating output adjustment -

Adjustable over entire Max/Min output

range

Type of heating installation - Close circuit

Maximum heating pressure MPa 0,3 (3 bar)

23

AVANTTIA

Specifications

25

HDX / HDXM

37

HDX / HDXM

Maximum heating temperature ºC 110

Adjustable heating temperature range ºC 25 - 85

Expansion heating vessel volume l 7,5 12

Expansion heating vessel pre-load MPa 0,1 (1 bar)

Expansion DHW vessel volume l 8

Expansion DHW vessel pre-load MPa 0,3 (3 bar)

Minimum DHW pressure MPa 0,7 (7 bar)

Adjustable tank DHW temperature range ºC 15 – 65

Capacity of storage tank L 100 130

D.H.W. production in 10 min. ∆T = 30 ºC

L 245 359

D.H.W. production in 1 hour. ∆T = 30 ºC

L 830 1240

Electrical supply - 230 V~ / 50 Hz

Electrical maximum consumption (HDX/HDXM) W 315 / 415

Electrical protection - IP X5D

Boiler mounting system type - Standing

Flue exhaust/Air intake system types - B23-B33-B53-C13-C33-C43-C53-C63-C83

Flue exhaust/Air intake system diameters mm

Coaxial Ø60/100 and Ø80/125 – Dual duct

Ø80/80

Maximum gas pipe pressure drop Pa 167 167

Flue gas temperature ºC 63 63

Maximum flow of fumes g/s 10,2 10,2

Max. horizontal coaxial length Ø60/100 m 20

Max. vertical coaxial length Ø60/100 m 21

Equivalent elbow length at 90º Ø60/100 m 1,3

Equivalent elbow length at 45º Ø60/100 m 1

Max. horizontal coaxial length Ø80/125 m 68

Max. vertical coaxial length Ø80/125 m 70

Equivalent elbow length at 90º Ø80/125 m 2,2

Equivalent elbow length at 45º Ø80/125 m 1

Equivalent length of adapter Ø60/100 => Ø80/125 m 0,5

Max. dual duct length Ø80-Ø80 m 110

Equivalent elbow length at 90º Ø80 m 2,2

Equivalent elbow length at 45º Ø80 m 1,4

Heating

3/4 3/4

DHW

1/2 1/2

Hydraulic connection

diameter

Gas inlet

3/4 3/4

Dimensions (Width x Depth x Height) mm 559 x 720 x 1690 559 x 720x 1690

Weight Kg 180 / 191 195 / 202

Avanttia

24

17 ELECTRICAL CONNECTION DIAGRAM

There are a series of removable terminal strips located on the rear of the control panel, for connecting

the various options and components of this model. To connect them correctly, carefully follow the

indications shown below:

17.1 Avanttia HDX

1

976

5

NNN

N

8

J1

J2

16

151413

J3

NF

J4

TA1

2

230 V~

J6

TA

2

10 11

43

17 18 19

Rr

1

Rr

2

R

12

J5

Lago FB

7

6

5

4

3

2

1

J7

NC

NO

C

T

aux

S

ext

BC

1

M

1

BC

2

M

2

+

-

+

-

F: Phase.

N: Neutral.

BC1: Heating circuit N. 1 circulating pump.

BC2: Heating circuit N. 2 circulating pump.

M1: Underfloor 3 way valve motor circuit 1.

M2: Underfloor 3 way valve motor circuit 2.

TA1: Heating circuit N. 1 room thermostat.

TA2: Heating circuit N. 2 room thermostat.

Rr1: Underfloor circuit N.1 option resitance.

Rr

2

: Underfloor circuit N.2 option resitance.

Raux: Auxiliary relay.

R: Phone relay.

C: Common of auxiliary relay.

NO: Normaly open of auxiliary relay.

NC: Normaly closed of auxiliary relay.

Sext: Exterior room sensor.

Taux: Auxiliary entrance.

J1: Power supply connector

J2: Components connector.

J3: Sensor connector.

J4: Room thermostat N. 1 connector.

J5: Remote control connector.

J6: Room thermostat N. 2 connector.

J7: Principal connector (Orange).

25

17.2 Avanttia HDXM

1

976

5

NNN

N

8

J1

J2

16

151413

J3

NF

J4

TA1

2

230 V~

J6

TA

2

10 11

43

17 18 19

S

r

1

12

J5

Lago FB

Rr

2

R

7

6

5

4

3

2

1

J7

NC

NO

C

T

aux

S

ext

M

1

M

2

+

-

+

-

F: Phase.

N: Neutral.

BC1: Heating circuit N. 1 circulating pump.

BC2: Heating circuit N. 2 circulating pump.

M1: Underfloor 3 way valve motor circuit 1.

M2: Underfloor 3 way valve motor circuit 2.

TA1: Heating circuit N. 1 room thermostat.

TA2: Heating circuit N. 2 room thermostat.

Sr1: Heating circuit mixed 1 sensor.

Rr2: Underfloor circuit N.2 option resitance.

Raux: Auxiliary relay.

R: Phone relay.

C: Common of auxiliary relay.

NO: Normaly open of auxiliary relay.

NC: Normaly closed of auxiliary relay.

Sext: Exterior room sensor.

Taux: Auxiliary entrance.

J1: Power supply connector.

J2: Components connector.

J3: Sensor connector.

J4: Room thermostat N. 1 connector.

J5: Remote control connector.

J6: Room thermostat N. 2 connector.

J7: Principal connector (Orange).

Avanttia

26

18 COMMERCIAL GUARANTEE

DOMUSA TEKNIK’s commercial guarantee(*) covers the standard functioning of the products

manufactured by DOMUSA TEKNIK Calefacción S.Coop., in accordance with the following conditions

and time periods:

1. This commercial guarantee is valid for the following periods, as from the start-up date:

2 Years for electric and hydraulic elements: pumps, valves, etc.

5 Years for heat exchangers.

5 Years for domestic hot water tanks.

During the 2-year period following the start-up date, DOMUSA TEKNIK will carry out any repairs of

original flaws or defects totally free of charge.

After these 2 years have elapsed and until the end of the guarantee period, labour costs and callout charges will be payable by the user.

2. The annual overhaul is not included in the terms of this guarantee.

3. The start-up and annual overhaul are to be carried out by personnel authorised by DOMUSA

TEKNIK.

4. The commercial guarantee will be null and void in the following cases:

- If the annual overhaul by personnel authorised by DOMUSA TEKNIK has not been carried out.

- La caldera no haya sido instalada respetando las leyes y reglamentos vigentes en la materia.

- If the boiler has not been installed in accordance with the applicable laws and regulations for this

type of appliance.

- If the boiler has not been started up immediately after its installation, by personnel authorised by

DOMUSA TEKNIK.

Failures due to misuse or incorrect installation, use of non-suitable electrical power or fuel, supply with

water with physical or chemical properties causing incrustation or corrosion, incorrect handling of the

appliance and, in general, for any reason beyond DOMUSA TEKNIK’s control, are excluded from this

guarantee.

This guarantee does not affect the consumer’s rights as stipulated by law.

Note: Start-up is included in the price of the boiler. The call-out charge is not included.

27

NOTES:

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

Avanttia

28

NOTES:

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

29

NOTES:

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

UK ADDRESS HEADQUARTERS & FACTORY

Unit D4 Stanlaw Abbey Business Centre, Bº San Esteban s/n

Ellesmere Port, CH65 9BF

20737 RÉGIL (Guipúzcoa)

Tel: 0151 909 6222 Tel: (+34) 943 813 899

www.domusateknik.com

DOMUSA TEKNIK reserves the right to make modifications of any kind to its product

characteristics without prior notice.

*CDOC001264*

CDOC001264 06/16

Loading...

Loading...