For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Do-more T1H Series

PLC

The T1H Series PLC takes the modular

and space-saving package of our

Terminator I/O line and converts it into

a stand-alone control system. Using

Do-more Designer as a foundation,

the T1H Series PLC system provides a

powerful, flexible instruction set, inside a

user friendly programming environment.

Do-more T1H PLC System with T1H-DM1E CPU Module

T1H-DM1

CPU modules

The Do-more T1H Series PLC offers two

CPU modules, T1H-DM1 and T1H-DM1E,

both of which must be programmed using

the Do-more Designer programming software version 1.2 or later.

T1H-DM1E

(with Ethernet)

Base units

The Do-more T1H Series PLC supports

all of the base units available for the

Terminator I/O line.

www.automationdirect.com/do-more-plcs

Do-more T1H PLCs

tDMT-1

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Discrete I/O modules

The Do-more T1H Series PLC supports all

of the discrete I/O modules available in

the Terminator I/O product line.

Analog I/O modules

The Do-more T1H Series PLC supports all

of the analog I/O modules available in

the Terminator I/O product line.

Specialty module

The Do-more T1H Series PLC supports

the T1H-CTRIO High-Speed Counter I/O

module that is available in the Terminator

I/O product line.

Programming Software

The Do-more T1H Series PLC can only

be programmed by Do-more Designer

version 1.2 or later.

T1H-CTRIO

1.2

tDMT-2

Do-more T1H PLCs

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

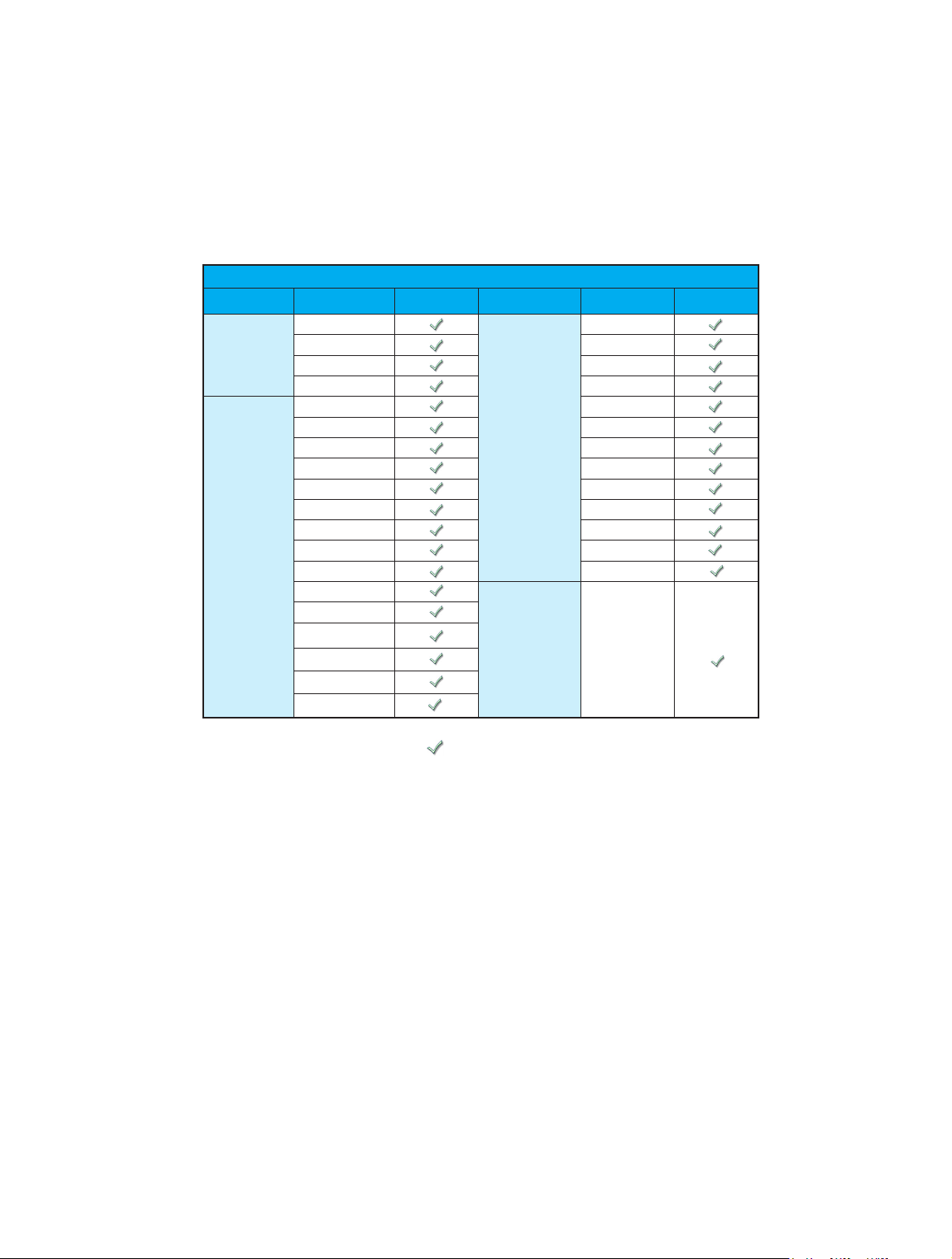

Module Compatibility

The following table shows which Terminator I/O product line components are supported

by the T1H-DM1 and T1H-DM1E Do-more CPUs.

Module Compatibility Table

Module Part Number

T1K-08B

Base Units

Discrete I/O

Modules

T1K-08B-1 T1F-08AD-2

T1K-16B T1F-16AD-1

T1K-16B-1 T1F-16AD-2

T1K-08ND3 T1F-16RTD

T1K-16ND3 T1F-16TMST

T1K-08NA-1 T1F-14THM

T1K-16NA-1 T1F-08DA-1

T1K-08TD1 T1F-08DA-2

T1K-16TD1 T1F-16DA-1

T1K-08TD2-1 T1F-16DA-2

T1K-16TD2-1 T1F-8AD4DA-1

T1H-08TDS T1F-8AD4DA-2

T1K-08TA

T1K-16TA

T1K-08TAS

T1K-08TR

T1K-16TR

T1K-08TRS

Status Module Part Number Status

T1F-08AD-1

Analog I/O

Modules

Specialty

Module

T1H-CTRIO

= Supported

www.automationdirect.com/do-more-plcs

Do-more T1H PLCs

tDMT-3

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Communications

The Do-more T1H Series PLC supports many communication protocols. The following table shows which CPU module

communications port supports each protocol.

CPU Modules

T1H-DM1 / T1H-DM1E T1H-DM1E

Protocols

Do-more Designer Programming

USB Port

Yes Yes Yes

RS-232

Serial Port

Ethernet

Port

Modbus/RTU Client (Master)

Modbus/RTU Server (Slave)

Modbus/TCP Client (Master)

Modbus/TCP Server (Slave)

DirectLOGIC RX/WX Client (Master)

DirectLOGIC RX/WX Server (Slave)

K-Sequence Server (Slave)

DirectNET Server (Slave)

HEI Ethernet I/O Master

SMTP (EMail) Client w/Authentication

Simple Network Time Protocol (SNTP) Client

Do-more/PEERLINK

Do-more Time Synchronization Protocol (Client, Server,

Alternate Client)

Do-more Logger/UDP

Serial ad-hoc ASCII/Binary Programatic Control

UDP ad-hoc Programmatic Control

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

tDMT-4

TCP Client Programmatic Control

TCP Server Programmatic Control

Do-more T1H PLCs

Yes

Yes

Blank = Not Supported

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Do-more T1H Series PLC Hardware User Manual (T1H-DM-M)

Do-more T1H Series PLC Hardware User Manual is available as a free download from Automationdirect.

com. A hard copy is also available for purchase.

Do-more Designer (Part No. DM-PGMSW)

Do-more Designer is the full-featured programming software for the

Do-more PLC series. Do-more Designer is a free download from

Automationdirect.com. A CD-ROM version is also available for

purchase for $11.00.

Start Page

When the software is started, the Start Page is

displayed. This page contains a Launchpad with

Projects, Applications and Links windows. It also

contains shortcuts to important help file topics, and

you can start the Do-more Simulator from this page.

1.2

Project

Toolbar

Project

Browser

Ladder

View

Launchpad

Do-more

Simulator

Help File

Shortcuts

Main Programming Window

The Main Programming Window is displayed

when a new project is started or an existing

project is opened. It is divided into Menus,

Toolbars, and Windows that work together to

make project development simple.

Ladder

Palette

Bar

www.automationdirect.com/do-more-plcs

Do-more T1H PLCs

tDMT-5

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Do-more Designer Features

Do-more Designer has the following main features:

• Supports the Do-more PLC instruction set

• Project Browser (Window to organize the user project)

• Data View (Interface to monitor and edit PLC data in a list)

• Trend View (Interface to monitor PLC data with trend graphs)

• PID View (Interface to monitor and tune the individual PID control loop)

• PID Overview (Interface to monitor multiple PID control loops)

• Debug View (Interface to debug the ladder programs)

When Do-more Designer is installed on your PC, the following tools are also installed:

• Do-more Simulator (Offline simulator of ladder program execution and PID control)

• Do-more Logger (Software tool to log PLC data)

• ERM Workbench (Configuration tool for the ERM modules)

• NetEdit 3 (Configuration tool for the ECOM/EBC Ethernet modules)

PC Requirements

The Do-more Designer Windows-based programming software works with Windows®

XP (Home or Professional, 32-bit), Vista (Home, Basic, Premium, 32 or 64-bit),

Windows 7 (Home, Professional, Ultimate, 32 or 64-bit) or Windows 8 (Home,

Professional, Enterprise 32 or 64-bit; Windows 8 RT edition is NOT supported).

Please check the following requirements when choosing your PC configuration:

• Minimum PC to PLC Connectivity, at least one of the following:

- USB Port: connects to the CPU with USB-A connector (USB-A to USB-B cable)

- RS-232 Serial Port: connects to the CPU with RJ-12 connector (RJ-12 to DB9 or RJ-12 to USB-B

serial converter cable)

- Ethernet Port: connects to the CPU (T1H-DM1E) with RJ-45 10Base-T or 100Base-T

(Cat5 Patch Cable)

• Hard Disk: 100MB free disk space

• Video Display: 1024x768, 256 colors resolution (1280x720, true color recommended)

• Windows XP, 32-bit:

- 800MHz, single core CPU (2GHz, multi-core or hyperthreaded recommended)

- 512MB RAM (2GB recommended)

• Vista or Windows 7 or Windows 8, 32 or 64-bit:

- 1GHz, single core CPU (2GHz, multi-core recommended)

- 1GB RAM (3GB recommended)

Programming Cables

The Do-more T1H Series CPU module T1H-DM1 has two communication ports (USB

and RS-232 Serial) and the T1H-DM1E has three communication ports (USB, RS-232

Serial and Ethernet). You can use any of those ports for programming and monitoring.

Cables for these ports are listed below and can be purchased at Automationdirect.com.

USB Cables (USB 2.0, Type A-B connectors):

• USB-CBL-AB3 (3 ft.)

• USB-CBL-AB6 (6 ft.)

• USB-CBL-AB10 (10 ft.)

• USB-CBL-AB15 (15 ft.)

RS232 Serial Cable

• D2-DSCBL (12 ft. 9-pin D-sub to RJ12 connector)

Ethernet Cables (Cat5e)

Automationdirect.com sells many Ethernet patch cables in various colors and lengths. Please check

the Cables section in this catalog for further details.

tDMT-6

Do-more T1H PLCs

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Do-more PLC Instruction Set

This Instruction Set was developed specifically for the new Do-more PLC series; the

‘Instruction Palette’ displays all available

instructions.

You may see some similarities to the

DirectLOGIC PLC instruction set. However,

the instruction set for the Do-more PLC is

more advanced and intuitive. A good example

is the MATH instruction. Now, just one MATH

instruction covers all math operations and

also allows you to mix different data types in

one expression.

There are over 60 operators and functions

available with the MATH instruction.

Note: To learn more about the MATH instruction, please refer to the Do-more Designer

help topic ‘MATH – Calculate Expression’.

Operators

+, -, *, /, %, **, <, <=, ==, !=, >=, >, &&, ||, &, |, ^, <<, >>, >>>, -, ~, !

Funcons

ABS, ACOS, ASIN, ATAN, AVGR, COS, COUNTIFEQ, COUNTIFNE,

COUNTIFGE, COUNTIFGT, COUNTIFLE, COUNTIFLT, DEG, E, FRAC, IF,

LN, LOG, MAXR, MAX, MINR, MIN, NOW PI, ,

REF, ROUND, SIN, SQRT, STDEVR, STDEVPR, SUMIFEQ, SUMIFNE,

SUMIFGE, SUMIFGT, SUMIFLE, SUMIFLT, SUMR, TAN, TICKms,

TICKus, TOINT, TOREAL, TRUNC

RAD, RANDINT, RANDREAL,

www.automationdirect.com/do-more-plcs

Do-more T1H PLCs

tDMT-7

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Data Types

The Do-more PLC supports the following seven primary data types:

• Bit (0 or 1)

• Unsigned Byte (0 to 255)

• Signed Byte (-128 to 127)

• Unsigned Word (0 to 65,535)

• Signed Word (-32,768 to 32,767)

• Signed DWord (-2,147,483,648 to 2,147,483,647)

• Real (-3.4028235E+038 to 3.4028235E+038)

Data Structures

The Do-more PLC supports data structures as additional data types. Structures use the

familiar PC programming organization of “dot notation”. All available elements of a

structure are shown in this format. The following data structures are currently available:

• Timer Structure

• Counter Structure

• String Structure

• PID Structure

• Date/Time Structure

• Task Structure

• Rampsoak Structure

• Program Structure

• DeviceRef Structure

• Drum Structure

The data structure is a set of data. For instance, a Timer structure (Timer Struct) has the

following set of data:

• Acc (Accumulated Time, Signed DWord)

• Done (Bit)

• Zero (Bit)

• Timing (Bit)

• Reset (Bit)

When you use a timer instruction (TMR), a Timer structure is assigned to the instruction. If

you select ‘T0’, you can access the above data with dot notation. For instance, to access

the accumulated time (Acc), enter ‘T0.Acc’. To access the Done bit, enter ‘T0.Done’.

• Stream Structure

• SIM_Process Structure

• Server Structure

• Peerlink Structure

• I/O_Master Structure

• Eth_IO_Master Structure

• GS Drive Structure

• Packet Structure

Memory Addressing

With the Do-more PLC, each memory address type has its own specific data type. Here

are some examples:

• V (Unsigned Word)

• N (Signed Word)

• D (Signed DWord)

• R (Real)

If you see address ‘V123’ in the ladder program, the memory address always stores an

Unsigned Word value. With this memory addressing method, it becomes easier to read

and write the ladder programs.

Although most of the memory addressing is decimal, the memory addresses DLX, DLY,

DLC and DLV use octal. These four memory address types can be used to exchange data

with DirectLOGIC PLCs, which use octal memory addressing.

tDMT-8

Do-more T1H PLCs

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Do-more T1H Series PLC Overview

Array Addressing

The Do-more PLC supports one-dimensional array addressing with all memory

addresses. A V-memory address must be used as the index for an array. With the

Do-more PLC, the following ladder program is valid.

Note: In this example, V0, V100, V101, V102 and V200 are indices.

Code-block, Program and Task

One Do-more project can consist of more than one ladder program. Each ladder

program is called a ‘Code-block’. The Do-more PLC supports two types of code-blocks,

Program and Task:

Program

Programs are code-blocks that run based on an event using the RUN instruction. They

can be self-terminating or never terminate. Stage programming is only supported inside

Program code-blocks.

Task

Tasks are code-blocks that are enabled and disabled using the ENTASK instruction. The

ENTASK instruction allows you to specify an interval to execute the task’s logic with a

millisecond resolution or to execute a single time on a leading edge input.

Stages

The Do-more PLC supports Stages. You can use Stages only in the Program code-blocks.

(They are not available in the Task code-blocks.) The Do-more PLC supports the following

instructions for Stage Programming1:

• SG (Stage)

• JMP (Jump To Stage)2

• JMPI (Index Jump)

• SGSET (Enable Stage)

• SGRST (Disable Stage)

• SGRSTR (Disable Range of Stages)

• SGCONVRG (Converge Multiple Stages to SG)

• SGDIVRG (Jump to Multiple Stages)

1 There is no ISG (Initial Stage) instruction for the Do-more PLC; the first stage in the Program code-

block becomes the initial stage automatically.

2 Many asynchronous instructions can directly initiate a Jump to Stage.

www.automationdirect.com/do-more-plcs

Do-more T1H PLCs

tDMT-9

Loading...

Loading...