Chapter

Chapter

SpecificationS:

Chapter

Specialty ModuleS

7

7

1

In This Chapter...

Specialty Modules Overview ..................................................................................... 7-2

Specialty Modules .................................................................................................... 7-2

H2-CTRIO(2) .............................................................................................................. 7-4

H2-CTRIO(2) Overview ............................................................................................. 7-4

H2-CTRIO(2) Specifications ...................................................................................... 7-6

H2-CTRIO(2) LED Indicators ..................................................................................... 7-7

H2-CTRIO(2) Jumper Setup ...................................................................................... 7-8

Wiring Information ................................................................................................... 7-9

PNP Field Device (source) ......................................................................................... 7-9

NPN Field Device (sink) ............................................................................................ 7-9

H2-CTRIO(2) Input Wiring Examples ...................................................................... 7-10

TTL Quadrature Encoder Field Wiring ..................................................................... 7-10

TTL Input Wiring Example ...................................................................................... 7-10

Quadrature Encoder Wiring Example .................................................................... 7-11

NPN Open Collector Device ................................................................................... 7-11

PNP Open Collector Device .................................................................................... 7-11

H2-CTRIO(2) Output Wiring Examples ................................................................... 7-12

H2-ECOM100 .......................................................................................................... 7-13

H2-ECOM100 Overview ......................................................................................... 7-13

H2-ECOM100 Specifications ................................................................................... 7-13

H2-ECOM100 LED Indicators ................................................................................. 7-14

H2-ECOM100 Network Identifiers .......................................................................... 7-14

H2-ECOM100 Network Layouts ............................................................................. 7-17

H2-ECOM100 Network Cabling ............................................................................. 7-18

H2-ERM(100)/ H2-EBC100 ....................................................................................... 7-21

H2-ERM(100) Overview .......................................................................................... 7-21

H2-ERM(100) Specifications ................................................................................... 7-21

1

2

3

4

5

6

Table of Contents

H2-ERM(100) LED Indicators .................................................................................. 7-22

H2-EBC100 Overview ............................................................................................. 7-22

H2-EBC100 Specifications ....................................................................................... 7-22

H2-EBC100 LED Indicators ..................................................................................... 7-23

H2-ERM(100)/H2-EBC100 Network Identifiers ........................................................ 7-23

H2-ERM(100)/H2-EBC100 Network Layouts ........................................................... 7-26

H2-ERM(100)/H2-EBC100 Network Cabling ........................................................... 7-27

H2-SERIO(-4) ............................................................................................................ 7-29

H2-SERIO(-4) Overview .......................................................................................... 7-29

H2-SERIO(-4) Specifications .................................................................................... 7-31

H2-SERIO(-4) Wiring: RS-232 .................................................................................. 7-31

H2-SERIO-4 Wiring: RS-422/485 ............................................................................. 7-32

7

8

9

10

11

12

13

14

A

B

C

F2-08SIM, Input Simulator ...................................................................................... 7-33

F2-08SIM Specifications ......................................................................................... 7-33

D

ii

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Specialty Modules Overview

RS232 SERIAL POR

TS

SERIAL PORTS

B

C

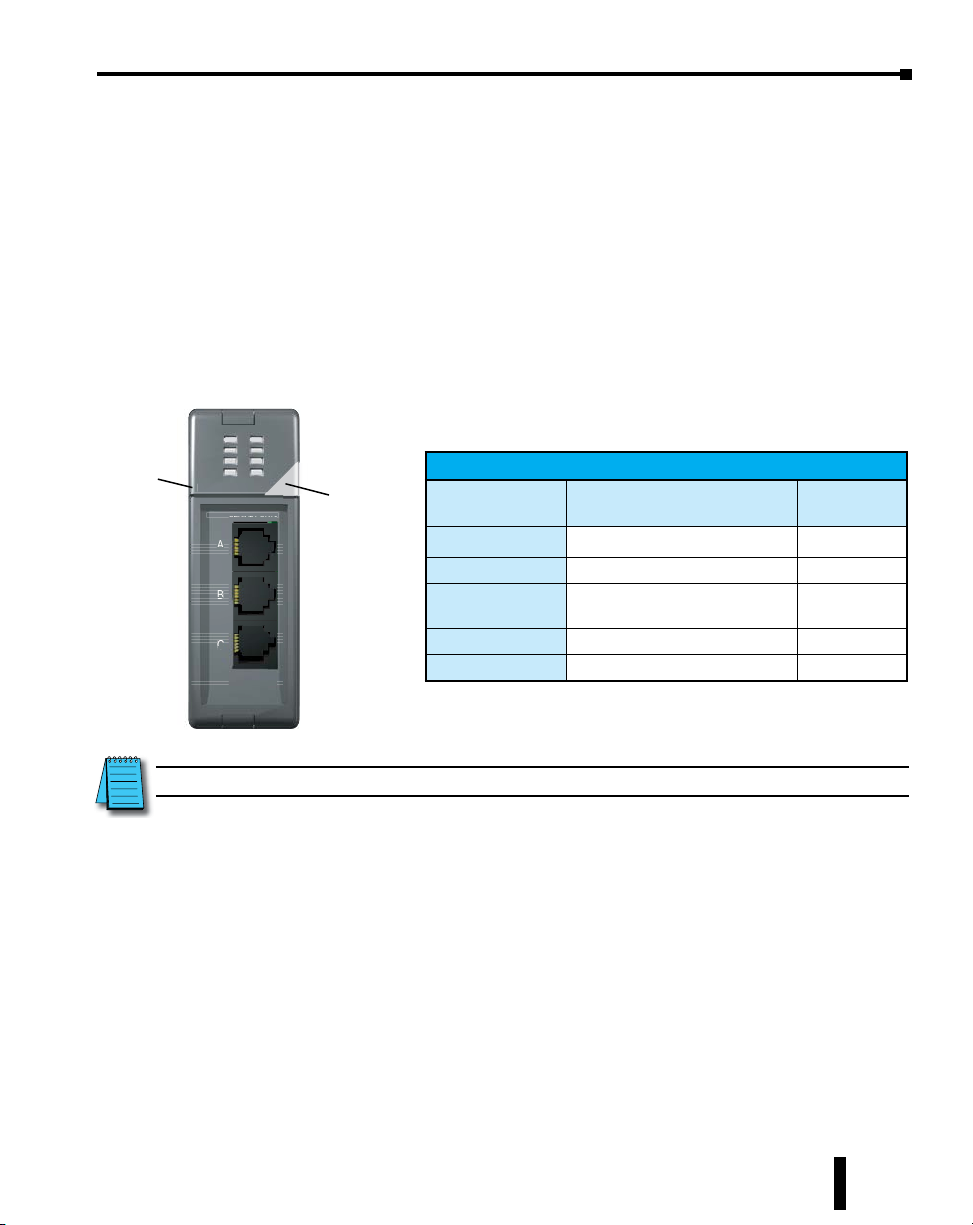

There are several Specialty modules available for use in local and remote I/O bases. These

modules are listed in the tables below and their specifications are found in this chapter. Each

specialty module is identified with a White bar across the front panel as seen below. The

module’s front panel is also equipped with LED status indicators. Depending on the module,

these indicators can show the network health, module health, I/O status or mode of operation

the module is currently in.

Specialty Modules

Chapter 7: Specifications - Specialty Modules

Module

Part Number

RCV A

RCV B

RCV C

H2-SERIO

RS232 SERIAL PORTS

XMT A

XMT B

XMT C

Module Type

(White: Specialty)

A

Part Number Description See Page

H2-CTRIO2*

H2-ECOM100

B

H2-ERM100*

H2-EBC100

C

H2-SERIO(-4)

F2-08SIM

Specialty Modules

High Speed Counter Interface Module 7-5

Ethernet Communications Module 7-14

Ethernet Remote Master Module

Ethernet Base Controller

Serial I/O Module 7-30

8-point Input Simulator Module 7-34

* The H2-CTRIO and H2-ERM modules are discontinued.

NOTE: The H2-CTRIO module has been discontinued. The H2-CTRIO2 is the replacement module.

7-22

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–3

Chapter 7: Specifications - Specialty Modules

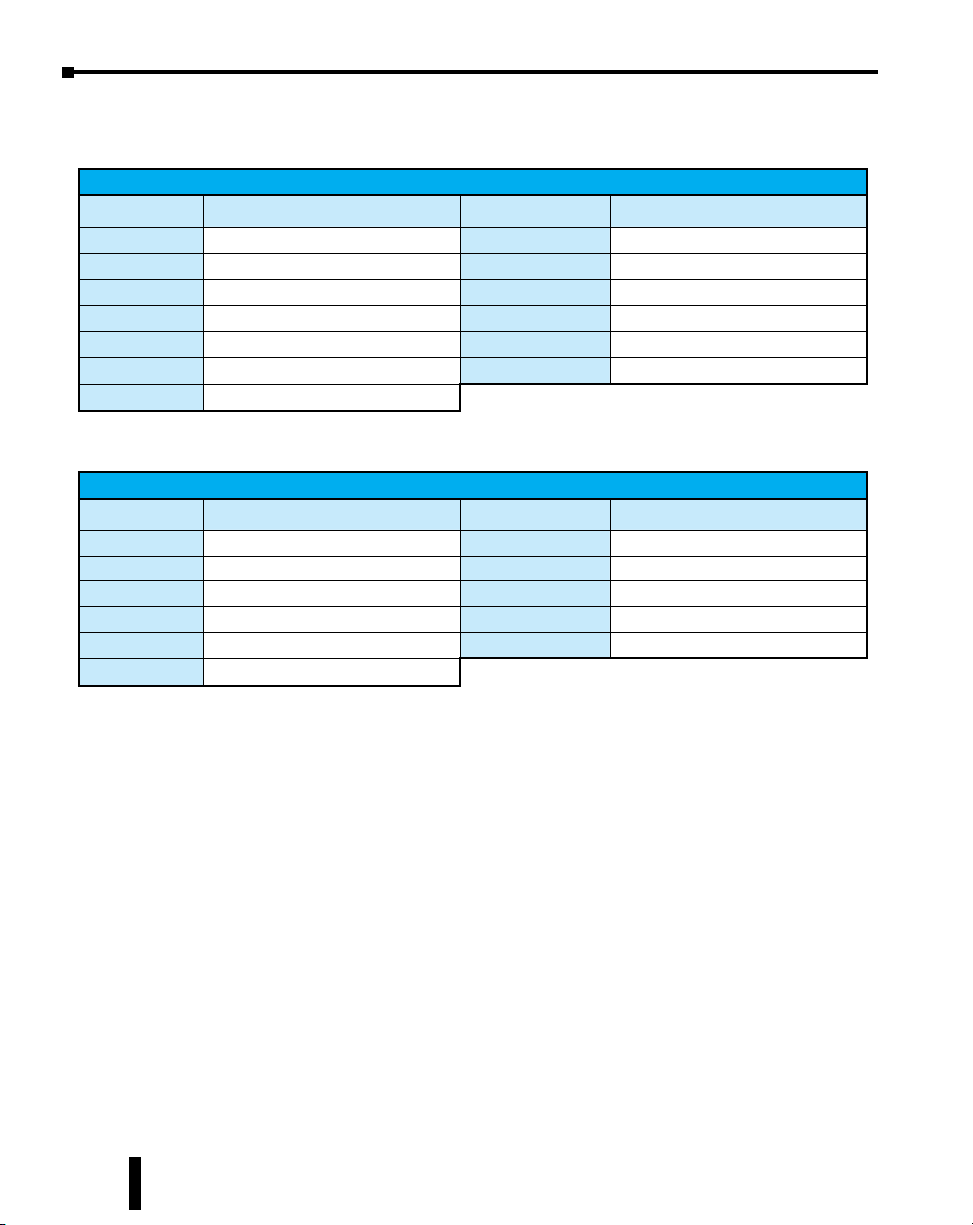

Specialty Modules Overview - continued

Specialty Modules Supported

Part Number Description Part Number Description

H2-CTRIO*

H2-CTRIO2

H2-ECOM*

H2-ECOM100

H2-ECOM-F

H2-ERM(100)

H2-ERM-F

* The H2-CTRIO, H2-ECOM and H2-EBC modules are discontinued but are still compatible with the new Do-more H2 Series

PLC.

High Speed Counter Interface Module

High Speed Counter Interface Module

10 Base-T Ethernet Communication Module

100 Base-T Ethernet Communication Module

10 Base-FL Ethernet Communication Module

10/100 Base-T Ethernet Remote Master Module

10 Base-FL Ethernet Remote Master Module

Specialty Modules NOT Supported

H2-EBC*

H2-EBC100

H2-EBC-F

H2-SERIO

H2-SERIO-4

F2-08SIM

Part Number Description Part Number Description

D2-CTRINT

D2-DCM

D2-RMSM*

D2-CM

F2-CP128

D2-HPP

* The D2-RMSM and H2-PBC modules are discontinued.

Counter Interface Module

Data Communication Module

Remote I/O Master Module

Expansion Base Controller

CoProcessor Module

Handheld Programmer

D2-EM

H2-PBC*

F2-DEVNETS-1

F2-SDS-1

DV-1000

10 Base-T Ethernet Base Controller

100 Base-T Ethernet Base Controller

10 Base-FL Ethernet Base Controller

Serial I/O Module

Serial I/O Module

8-point Input Simulator Module

Expansion Base I/F Module

Profibus Base Controller

DeviceNet Base Controller

Smart Distributed System Base Controller

DirectVIEW 1000 Timer/Counter access unit

7–4

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

H2-CTRIO(2)

H2-CTRIO(2) Overview

The H2-CTRIO(2) Counter I/O (CTRIO) module is designed to accept high-speed pulse

input signals for counting or timing applications. This module also provides high-speed

pulse output signals for servo/stepper motor control, monitoring and alarming as well as other

discrete control functions.

The H2-CTRIO(2) module offers greater flexibility for applications which call for precise

counting or timing based on input events or for high-speed control output applications. They

can also be used for applications that call for a combination of both high-speed input and highspeed output control functions.

The H2-CTRIO(2) module has its own internal microprocessor and operates asynchronously

with respect to the CPU. Therefore, the response time of the on-board outputs is based on

the module scan time, not the CPU’s scan time (unless the CPU is controlling the outputs

directly).

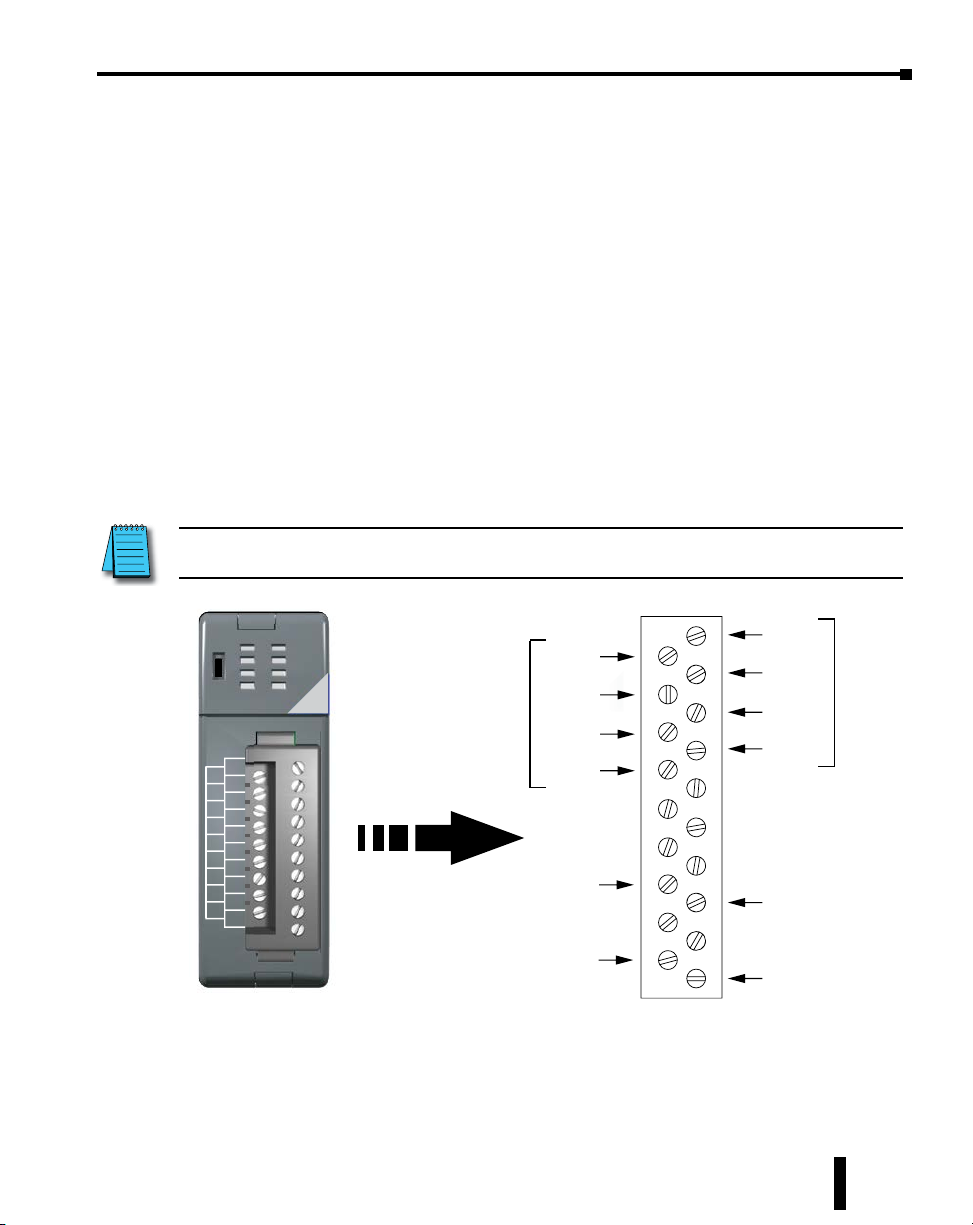

H2-CTRIO2 Terminal Block Layout

NOTE: The H2-CTRIO module has been discontinued. Please use the H2-CTRIO2 modules as the

replacement. H2-CTRIO and H2-CTRIO modules have the same terminal block layout.

Chapter 7: Specifications - Specialty Modules

CTR

IN

H2-CTRIO2

IN 9-30 VDC 5-12 mA

OUT 5-36 VDC

1.0Amax

per point

2A

2B

2C

2D

2M

C2

Y2

C3

Y3

+24 VDC

OUTPUTS

OK

ER

0

1

1A

2

2A

3

Input A

Input B

Channel 2

Input C

1A

1B

1C

1D

1M

NC

C0

Y0

C1

Y1

Input D

Output 2

Output 3

1A

2A

1

B

2B

2C

2D

2

C

1

1D

1

M

M

N

2C

2Y

3C

3Y

C

0

C

0

Y

C

1

Y1

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Input A

Input B

Channel 1

Input C

Input D

Output 0

Output 1

7–5

Chapter 7: Specifications - Specialty Modules

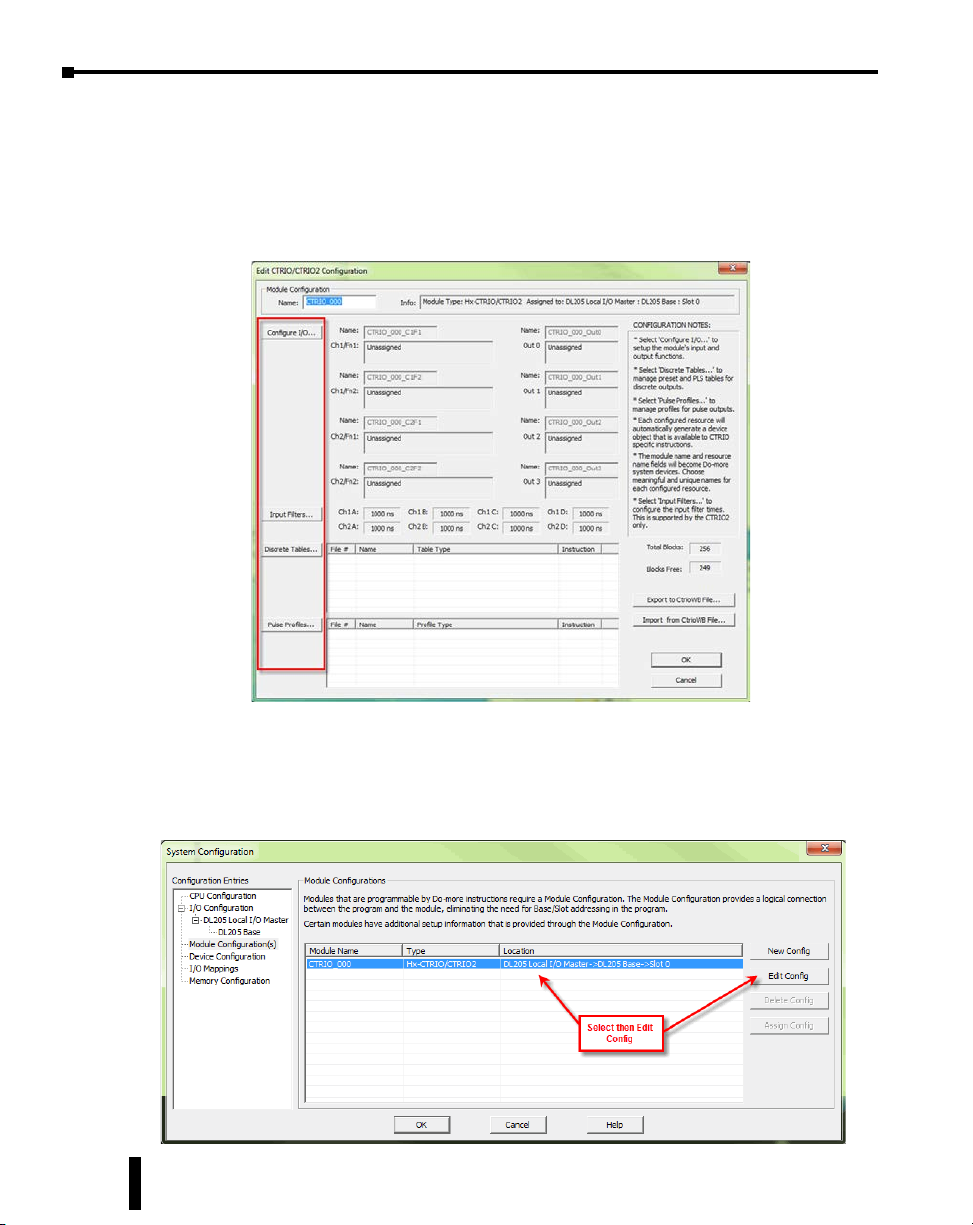

H2-CTRIO(2) Configuration

The module configuration of the H2-CTRIO2 is done from within the Edit

CTRIO/CTRIO2 Configuration window seen below. The Configure I/O..., Input Filters...,

Discrete Tables... and Pulse Profiles... buttons in the left hand column will allow you to

configure the input and output functions of the selected module. Refer to the Do-more

Designer Help File for more information on configuration options.

7–6

The above window can be accessed once the H2-CTRIO2 module is added to the I/O

configuration either manually or automatically. See the Verify Hardware Configuration

section of the Getting Started chapter for more information on setting up the I/O

configuration. With the module added, select the Module Configuration(s) entry from the

System Configuration page. Then choose the desired module and select Edit Config.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

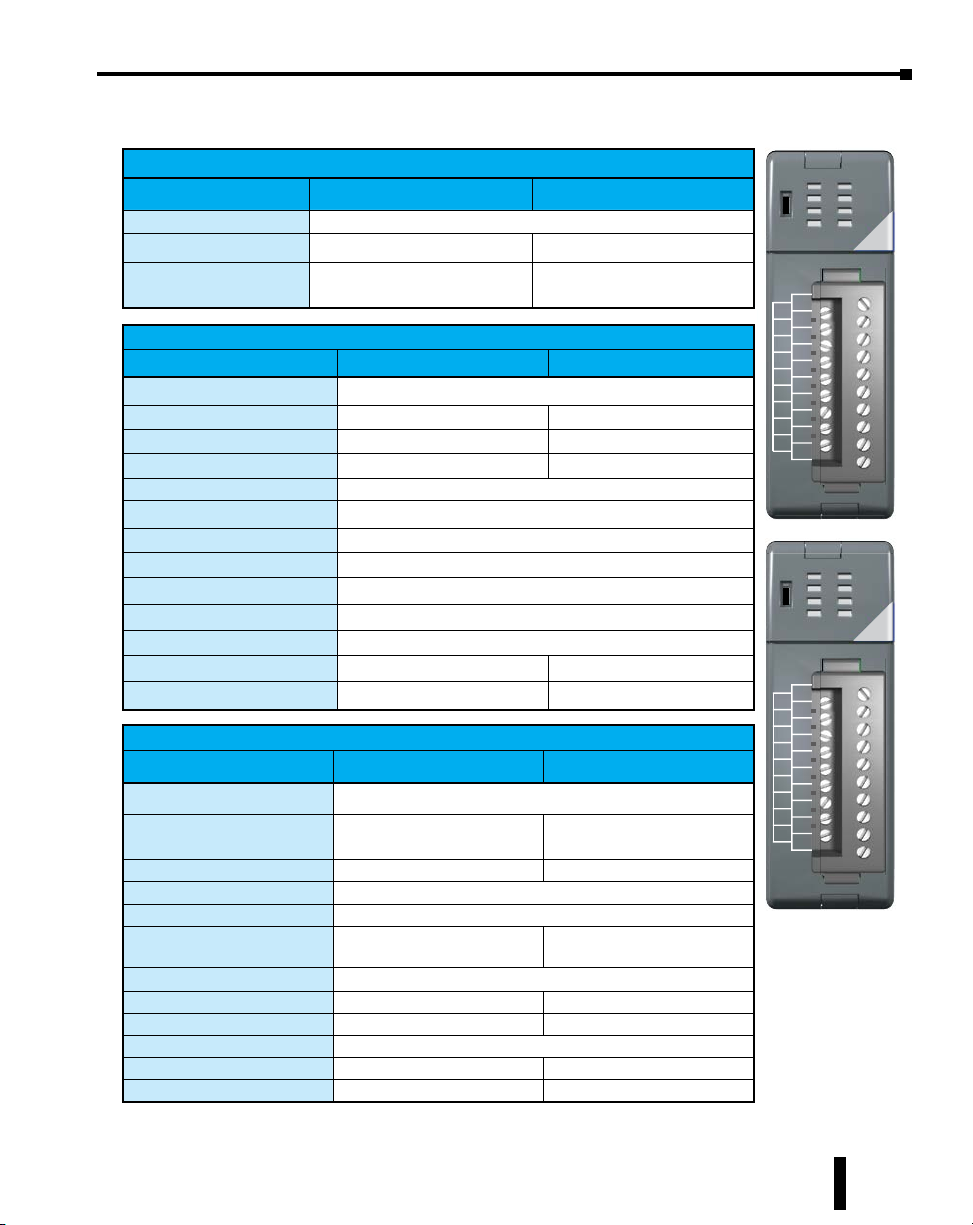

H2-CTRIO(2) Specifications

Chapter 7: Specifications - Specialty Modules

General Specifications

Specifications H2-CTRIO* H2-CTRIO2

Discrete I/O Points Used

Base Power Required

Isolation

2500V I/O to Logic, 1000V among Input

None (I/O map directly in H2-DM1/E data structure)

400mA Max 275mA Max

Channels and All Outputs

1500V I/O to Logic, 1000V among Input

Channels and All Outputs

Input Specifications

Specifications H2-CTRIO* H2-CTRIO2

Inputs

Maximum Input Frequency

Minimum Pulse Width

Input Voltage Range

Maximum Voltage

Input Voltage Protection

Rated Input Current

Minimum ON Voltage

Maximum OFF Voltage

Minimum ON Current

Maximum OFF Current

OFF to ON Response

ON to OFF Response

100kHz 250kHz

5µsec 0.5 µs

9–30 VDC 9–30 VDC

less than 3µs less than 0.5 µs

less than 3µs less than 0.5 µs

8 pts sink/source

30VDC

Zener Clamped at 33VDC

8mA typical 12mA maximum

9.0 VDC

2.0 VDC

5.0 mA

2.0 mA

Output Specifications

Specifications H2-CTRIO* H2-CTRIO2

Outputs

Pulse Outputs

2 channels, 20Hz to 25kHz Pulse/

Minimum Pulse Width

Output Voltage Range

Maximum Output Voltage

Maximum Load Current

Maximum Leakage Current

Inrush Current

ON State V Drop

Overcurrent Protection

OFF to ON Response

ON to OFF Response

* The H2-CTRIO module has been discontinued. The H2-CTRIO2 is the replacement.

4 pts (sink/source), independently isolated

2 channels, 20Hz to 250kHz Pulse/

Direction or CW/CCW

Direction or CW/CCW

5µs 0.5 µs

5–36 VDC

36VDC

1.0 A

1.0 A at 23°C

0.5 A at 60°C

100µA

5.0 A for 20ms 2.0 A for 10ms

0.3 VDC or less 0.45 VDC or less

Yes

less than 3µs less than 1µs

less than 3µs less than 1µs

CTR

IN

OK

ER

1A

2A

H2-CTRIO

IN 9-30 VDC 5-12 mA

OUT 5-36 VDC

1.0Amax

per point

1A

2A

1B

2B

1C

2C

1D

2D

1M

2M

NC

C2

C0

Y2

Y0

C3

C1

Y3

Y1

CTR

IN

OK

ER

1A

2A

H2-CTRIO2

IN 9-30 VDC 5-12 mA

OUT 5-36 VDC

1.0Amax

per point

1A

2A

1B

2B

1C

2C

1D

2D

1M

2M

NC

C2

C0

Y2

Y0

C3

C1

Y3

Y1

+24 VDC

OUTPUTS

0

1

2

3

+24 VDC

OUTPUTS

0

1

2

3

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–7

Chapter 7: Specifications - Specialty Modules

H2-CTRIO(2) LED Indicators

H2-CTRIO(2) LED Descriptions

Module OK

OK

User Program Error

ER

Channel 1 Status

1A

Channel 2 Status

2A

Output Status

0–3

CTR

IN

OK

ER

1A

2A

H2-CTRIO

+24 VDC

OUTPUTS

0

1

2

3

H2-CTRIO(2) LED Diagnostic Definitions

LED OK LED ER Description

Blinking Blinking Boot Mode - Used for Field OS Upgrades

Blinking OFF Program Mode

OFF Blinking

OFF ON Module Error Due to Watchdog Timeout

OFF OFF No Power to Module

ON OFF All is well - RUN Mode

ON ON

Module Self-Diagnostic Failure

(Blinks may be coded by counts)

Hardware Failure (H2-CTRIO)

Not Used (H2-CTRIO2)

H2-CTRIO(2) LED Diagnostic Definition

1A/2A

Blinking 7 times per second Input is configured as Counter and is changing

Following state of input Input is not configured as counter

0-3

Follow actual output state: ON = output is passing current

CTR

IN

OK

ER

1A

2A

H2-CTRIO2

+24 VDC

OUTPUTS

0

1

2

3

7–8

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Chapter 7: Specifications - Specialty Modules

Y3M2Y00

Y0Y0

1

M

C3C3

C3C3

C3C3

Y0

C0C0

C2C2

C1C1

Y0Y0

H

H

Y0Y0

C0C

0

2M

Y1Y1

YY2

Y3Y

3

C1C1

CC2

C3C

3

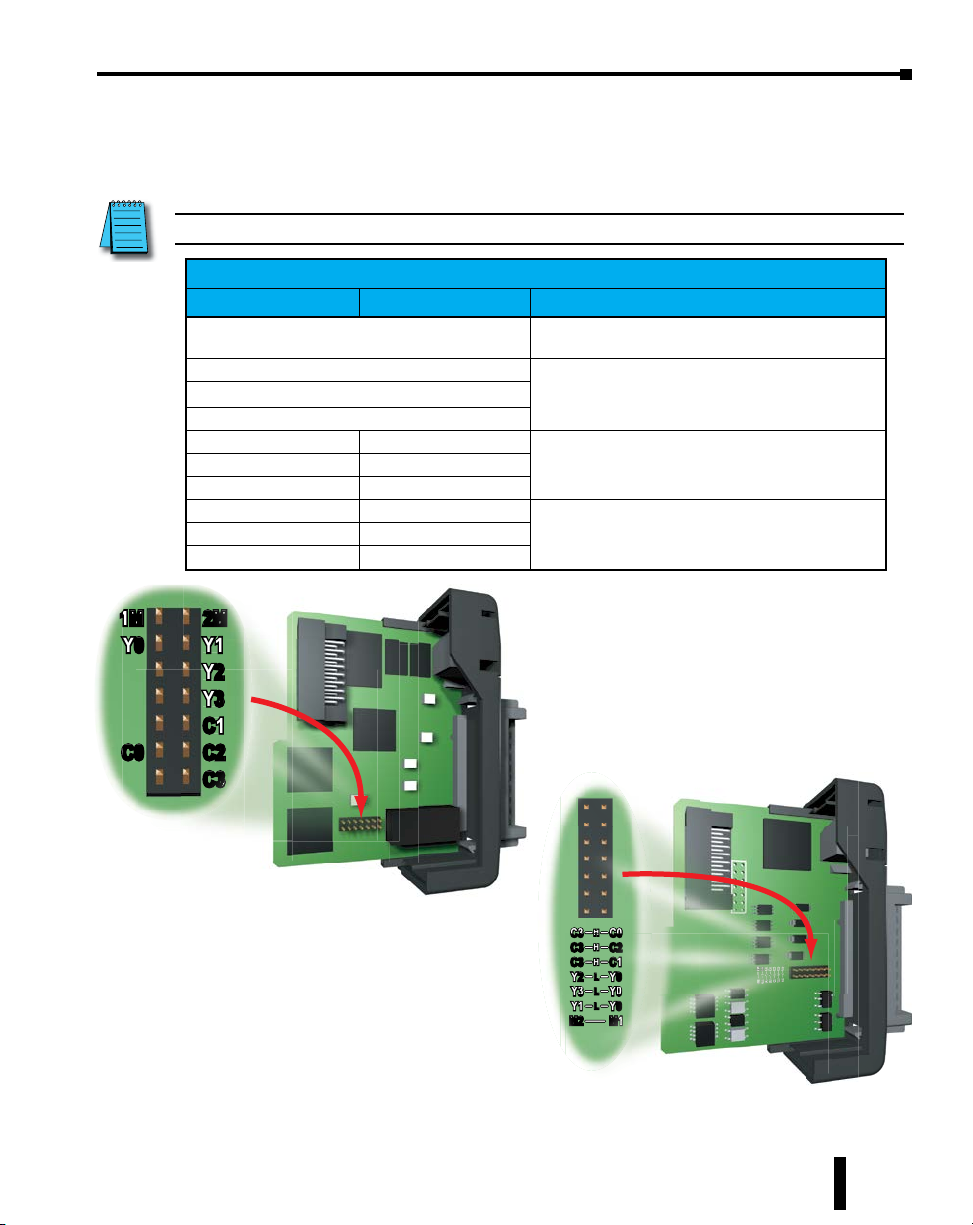

H2-CTRIO(2) Jumper Setup

Jumpers are provided to connect input commons or outputs/output commons. Use of these

jumpers is not necessary to set up the CTRIO(2) module. The jumpers are provided solely for

convenience in wiring.

NOTE: The location of the jumper board and pin assignments are different between the CTRIO and CTRIO2.

H2-CTRIO(2) Jumper Functions

H2-CTRIO H2-CTRIO2 Function

1M-2M

Y0-Y1

Y0-Y2

Y0-Y3

C0-C1

C0-C2

C0-C3

C3-C0

C3-C1

C3-C2

Install jumper to internally connect the input commons 1M and 2M in

order to reduce wiring if appropriate.

Install jumper(s) to internally connect Y0 to other Y terminals in order

to reduce wiring if appropriate. Connect wire at Y0.

Install jumper(s) to internally connect C0 to other C terminals in order

to reduce wiring if appropriate. Connect wire at C0.

Install jumper(s) to internally connect C3 to other C terminals in order

to reduce wiring if appropriate. Connect wire at C3.

1M

1M

Y0

Y0

C0

C0

H2-CTRIO

2M

2M

Y1

Y1

Y2

Y2

Y3

Y3

C1

C1

C2

C2

C3

C3

H

C3

C0

H

C3

C2

H

C3

C1

L

Y2

Y0

L

Y3

Y0

L

Y1

Y0

M2

M1

H2-CTRIO2

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–9

Chapter 7: Specifications - Specialty Modules

– +

Wiring Information

The H2-CTRIO(2) module has two

independent input channels, each consisting of

four optically isolated input points (pts. 1A-1D

on common 1M and pts. 2A-2D on common

2M). The inputs can be wired to either sink or

source current.

The module has four optically isolated output

points (Y0-Y3 with isolated commons C0-C3,

respectively) that can be wired to either sink

or source current. Remember that the internal

jumpers can be used to connect the input

commons or output commons together.

NOTE: Field device wiring must be compatible with the module configuration configured in Do-more

Designer

DC type field devices are configured to either sink or source current. This affects the wiring of

the device to the CTRIO module as seen below.

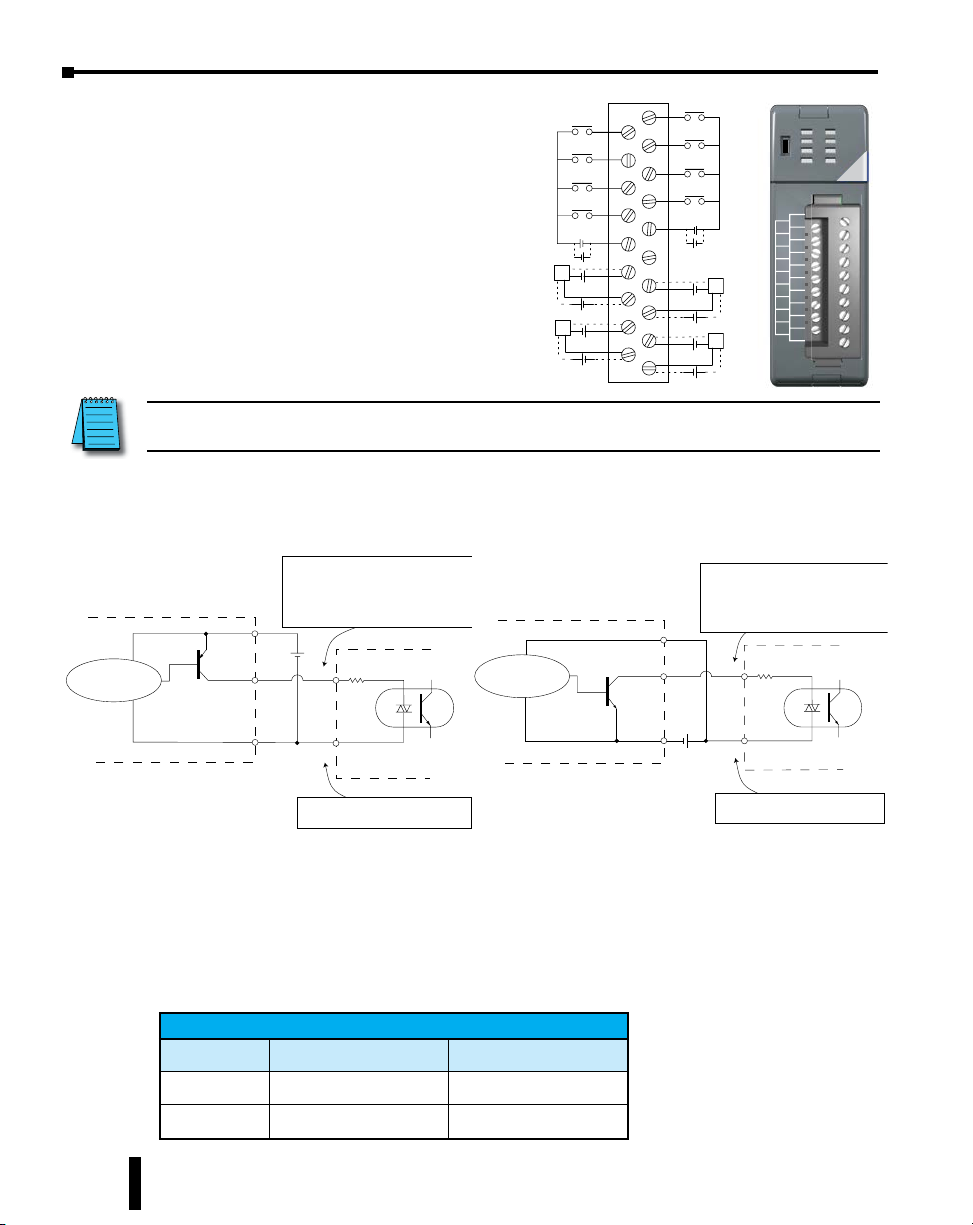

PNP Field Device (source)

Sensing Circuit

This drawing illustrates wiring that is

typical for Channel 1 terminals 1A, 1B,

1C, and 1D. The same circuitry is also

present at the corresponding

Channel 2 terminals.

+

-

24VDC

1A

2A

2B

2C

2D

M

2

+-

+-

2C

L

– +

2Y

– +

3C

L

– +

3Y

– +

NPN Field Device (sink)

Sensing Circuit

1A

1

B

C

1

1D

1

M

+-

+-

N

C

0

C

L

– +

0

Y

– +

C

1

L

– +

Y1

This drawing illustrates wiring that is

typical for Channel 1 terminals 1A, 1B,

1C, and 1D. The same circuitry is also

present at the corresponding

Channel 2 terminals.

1A

CTR

IN

OK

ER

1A

2A

H2-CTRIO

IN 9-30 VDC 5-12 mA

OUT 5-36 VDC

1.0Amax

per point

1A

2A

1B

2B

1C

2C

1D

2D

1M

2M

NC

C2

C0

Y2

Y0

C3

C1

Y3

Y1

+24 VDC

OUTPUTS

0

1

2

3

H2-CTRIO(2) Wiring Considerations

When wiring CTRIO(2) modules, please consider the following:

• Keep encoder input wiring as short as possible

• Route wiring to avoid any runs parallel to noisy cables.

• Route wiring to avoid the proximity of noisy devices.

• Use shielded, twisted pair cables, such as:

Type of Cable Supplier/Part Number Supplier/Part Number

3 pair, twisted,

overall shield

1 pair, twisted,

overall shield

7–10

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

1M

The same circuitry is present at the

corresponding Channel 2 terminal.

Suggested Cabling

AutomationDirect/L19853-XXXX Belden/8103

AutomationDirect/L19827-XXXX Belden/9841

24VDC

+-

1M

The same circuitry is present at the

corresponding Channel 2 terminal.

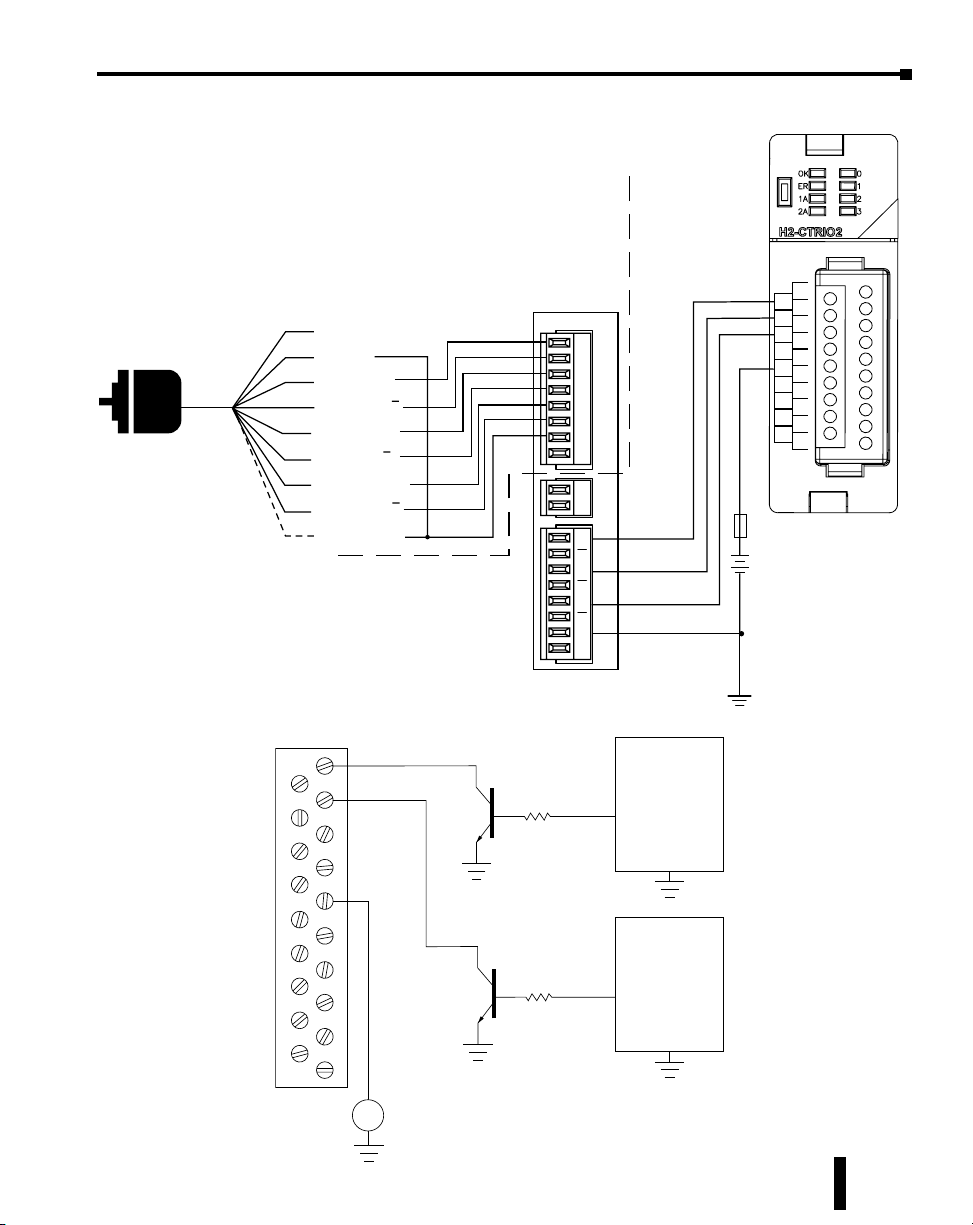

H2-CTRIO(2) Input Wiring Examples

NPN

TTL Quadrature Encoder Field Wiring

Brown: Power source*

ENCODER

Differential Line

Driver Encoder

* Use separate power supply to maintain isolation

Blue: 0 V

Black: OUT A

Purple: OUT A

White: OUT B

Gray: OUT B

Orange: OUT Z

Yellow: OUT Z

Shield: Ground

Chapter 7: Specifications - Specialty Modules

FC-ISO-C

+Ai

-Ai

+Bi

-Bi

+Zi

-Zi

COM

COM

V+

0V

Ao

Ao

Bo

Bo

Zo

Zo

0V

0V

ISOLATION

BARRIER

CTR

IN

IN 9-30 VDC 5-12 mA

OUT 5-36 VDC

1.0 max

per point

2A

2B

2C

2D

2M

C2

Y2

C3

Y3

PLC High Speed Counter

Interface Module

+

24VDC

-

+24 VDC

OUTPUTS

1A

1B

1C

1D

1M

NC

C0

Y0

C1

Y1

TTL Input Wiring Example

1A

2A

1

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

B

2B

C

1

2C

1D

2D

1

M

M

2

N

C

2C

0

C

2Y

0

Y

3C

C1

3Y

Y1

+

-

9 - 30VDC

General Purpose Transistor

C

HFE > 100

B

E

C

B

E

HFE > 100

10K

0.1W

10%

10K

0.1W

10%

TTL Device

TTL Device

7–11

Chapter 7: Specifications - Specialty Modules

PNP Open Collector Device

CITRIO2

NPN Open Collector Device

Quadrature Encoder Wiring Example

2A

A

B

Z

Power

Gnd

PNP Open

Collector or

Totem Pole

+

-

2B

2C

2D

M

2

9-30VDC

2C

2Y

3C

3Y

NPN Open Collector Device

1A

Power

9-30VDC

+

-

A

B

Z

Gnd

NPN Open

Collector

1

B

C

1

1D

1

M

N

C

0

C

0

Y

C1

Y1

7–12

Encoder

Shield twisted

pair

1A

+

_

Ground shield this

end only

1M

PNP Open Collector Device

Encoder

Shield twisted

+

pair

_

Ground shield this

end only

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

1A

1M

CITRIO2

Chapter 7: Specifications - Specialty Modules

+5 to 36VDC

H2-CTRIO(2) Output Wiring Examples

The four outputs are individually isolated so each output can be used

to break the high or the low side of a DC load seperately

+

_

Step Amplifier

Direction (or CCW)

Cn (where n=0, 1, 2, 3)

CTRIO

Output

Yn (where n=0, 1, 2, 3)

+

Load

-

OPTO Power

Pulse (or CW)

5-36VDC

+-

+5 to 36VDC

2A

2B

2C

2D

M

2

2C

2Y

3C

3Y

+

Load

-

+

_

Cn (where n=0, 1, 2, 3)

CTRIO

Output

Yn (where n=0, 1, 2, 3)

1A

1

B

C

1

1D

1

M

5-36VDC

N

C

0

C

0

Y

C1

Y1

+

-

Step Amplifier

OPTO Power

Pulse (or CW)

Direction (or CCW)

WARNING: The above example assumes that the Step Amplifier interface is made up of optocoupler

LEDs (common anodes at the “OPTO Power” terminal) with internal current limiting resistors. This is

a standard method, but you must consult your step amplifier documentation to ensure that this method

is applicable.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–13

Chapter 7: Specifications - Specialty Modules

10/100 BASE

0/00S

T

ETHERNET POR POR

T

H2-ECOM100

H2-ECOM100 Overview

The H2-ECOM100 Ethernet Communication (ECOM) module provides high-speed

Ethernet connections for the Do-more PLC. These modules are easy to set up and install on

10/100BaseT (twisted pair, copper wire) Ethernet networks.

LEDs on the face of each module give vital information about the status of the module and

the communications link. The 10/100BaseT modules use standard RJ45 modular connectors.

You can use the ECOM modules to share data between two or more Do-more PLCs or between

Do-more PLCs and personal computers. The H2- ECOM100 additionally allows client/

server communications with other Ethernet devices using the MODBUS TCP/IP protocol.

Communication between PLCs and MODBUS TCP/IP devices is accomplished by using the

MRX/MWX instructions.

You can use a personal computer equipped with a 10/100BaseT network adapter card and

NetEdit3 software to configure the ECOM module over the network. Once configured, the

H2-ECOM100 module allows you to program your Do-more PLC over the Ethernet network

using the Do-more Designer programming software. The NetEdit3 utility installs with the

Do-more Designer software and can be very useful for troubleshooting certain communication

problems.

NOTE: We recommend using a dedicated network for your PLC control applications.

7–14

H2-ECOM100 Specifications

H2-ECOM100 Ethernet Communications Module

Specifications H2-ECOM100

Communications

Data Transfer Rate

Link Distance

Ethernet Port

Ethernet Protocols

Power Consumption

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

10/100Base-T Ethernet

100 Mbps max.

100m (328ft)

RJ45

TCP/IP, IPX, Modbus TCP,

DHCP, HTML configuration

300mA @ 5VDC

STATUS

LINKGD

ACTIVE

ERROR

H2-ECOM100

10/100 BASE-T

ETHERNET PORT

100MBIT

Chapter 7: Specifications - Specialty Modules

H2-ECOM100

H2-ECOM100 LED Indicators

H2-ECOM100 LED Descriptions

Indicator Status Description

STATUS

LINKGD

ACTIVE

ERROR

100MBIT

ON (Green) Module is powered up and functional

OFF Module powerup failed

ON (Green) Properly connected to network

OFF Not connected to network or incorrect configuration

ON or FLASHING (Red) Active Network Data

OFF Network Idle

ON or FLASHING (Red) A fatal error has occurred

OFF No error present

ON 100Base T Frequency detected

OFF (With ACTIVE LED ON) - 10Base T Frequency detected

STATUS

LINKGD

ACTIVE

ERROR

H2-ECOM100 Network Identifiers

Each module must be assigned at least one unique identifier to make it possible for other devices

to recognize it on the network. There are four identifiers possible with the ECOM modules:

• Module ID

• Name

• IP (Internet Protocol) Address

• Ethernet (MAC) Address

The first three are user selectable but the MAC address is set at the factory. The type of identifier

chosen depends on the requirements of your particular application. PC-to-PLC communication

typically uses one type of identifier while PLC-to-PLC communication may require another. The

following table summarizes Network Identifiers and their uses:

100MBIT

Network Identifiers

Identifier How to Set Format Communication Notes

DIP Switch Number 1–63 PLC-to-PLC or PC-to-PLC Disables Module ID in NetEdit3

Module ID

Name

IP Address

Ethernet (MAC) Address

NetEdit3 Number 1–90 PLC-to-PLC or PC-to-PLC DIP Switch must be set to “0”

NetEdit3 Number 1–999,999,999 PC-to-PLC only >90 (Not for PLC-to-PLC)

NetEdit3 32 Alphanumeric Characters PC-to-PLC only HMI software may have restrictions

NetEdit3

Set at Factory 12 Hex digits PC-to-PLC only Factory assigned for IPX

4 sets of numbers, up to three

digits each (192.168.76.3)

PC-to-PLC, (PLC-to-PLC

Client/Server using TCP/IP or

Modbus TCP protocols)

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

See your Network Administrator for

IP addresses

7–15

Chapter 7: Specifications - Specialty Modules

000

3

22212

0

e

Module ID

A Module ID is required for PLC-to-PLC communication and it can be set in two ways:

• Using the DIP switches on the module

• Using the configuration tools in

NetEdit3

• HTML configuration (after IP address is

assigned to module using NetEdit3)

Use the DIP switches if you want the

ON

Binary Value

(32) (16) (8)(4) (2)(1)

Not

52423222120

Used

2

7 6 5 4 3 2 1 0

2 1

ability to install or change modules

without having to use a PC to set the

Module ID. Set the module’s DIP

switches, install the module in the base

and apply power. The Module ID will be

accepted on powerup and your ECOM

will be ready to communicate.

Name

A Name makes it easy to recognize the PLC by its function. An example of a Name is

“PumpStationOne”, as seen in the diagram below. The Name can be up to 32 alphanumeric

characters in length.

NOTE: Some HMI software products will not accept Names with numbers as the first character, spaces or

certain other non-alphanumeric ASCII characters. Also, your HMI product may not accept Names longer

than 16 characters. Consult your HMI product documentation about its naming conventions.

7–16

IP Address

An IP Address can be

Do-more

PLC

assigned to the ECOM

module if your network

requires one. Usually, the IP

Address is required in cases

where PLCs are sharing the

Pump Station One

same network with PCs, and

some of the PCs are carrying

out functions unrelated to

PLC control. Normally, a

network administrator will

assign an IP Address to each

device on the network. Use

NetEdit3 to configure the

assigned IP address to the

ECOM.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

ECOM

Module

H2-DM1E

Pump Station One

ERM

Module

GS-EDRV100

AC

Drive

n

Chapter 7: Specifications - Specialty Modules

H

to. Prod

s

060

D

00.E0.62.20.1B.95

5VDC

6

LIS

33ZL

NOTE: You must use an IP address if you are using the UDP/IP or Modbus TCP protocol.

The module ships from the factory with an IP Address of 0.0.0.0. This is not a usable IP

Address for normal communication. It only serves as a default setting which can be changed

using NetEdit3. The valid setting for each field is 1 through 254. You do not have to change

the default IP Address unless you are using the IP Address to link to your ECOM module. The

default setting does not cause conflicts with other network communications. If you change the

default IP Address for linking to other network devices, you must change all four “0” fields.

Example IP Addresses - If the Client (PC/ECOM) Subnet Mask is 255.255.0.0 and the Client

has an IP Address of 192.168.50.2, then the following are valid Server IP Addresses:

• 192.168.55.5 - Valid Server ECOM IP Address

• 192.168.70.15 - Valid Server ECOM IP Address

The subnet mask determines which fields must match by assigning a 255 to that field. In the example

above, the first two fields are masked with a 255, therefore valid Server IP Addresses must match the first

two fields of the Client IP or 192.168. The last two fields are allowed to vary because they are masked

with a “0”.

WARNING: It is extremely important not to have duplicate IP Addresses on your network. If you are

using the IP Address to link the ECOM to any network devices (PCs or PLCs), the ECOM must have a

unique number.

Ethernet (MAC) Address

A unique Ethernet (MAC) Address is assigned to each module at the factory and will not

change. It is printed on a label attached to each ECOM module. The Ethernet (MAC)

Address is recognized by NetEdit3. The Ethernet (MAC) Address is a twelve digit number

with no deliberate relationship to your network or functional areas of your plant. Typically, the

MAC address is not a convenient and easily remembered identifier for your ECOM module.

Host Auto. Products

ost Au

H2-ECOM

H2-ECOM

MFG:IES 0602 4D

MFG:IES

00.E0.62.20.1B.95

2 4

uct

5VDC

60DegC

0DegC

LISTED

TED

33ZL

Using Multiple Network Identifiers

You can use IP Addresses to satisfy network requirements, the Name identifier for PCs running

HMI software and Module IDs for PLCs to share data among themselves. Using one type of

identifier does not limit your use of the other identifier types.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–17

Chapter 7: Specifications - Specialty Modules

Point-to-Point

H2-ECOM100 Network Layouts

The ECOM Ethernet network is a peer-to-peer network. Using Read (RX) or Write (WX)

instructions, any PLC on the network can initiate communications with any other PLC on the

network. A PC running our KEPDirect software can also initiate communications with any

ECOM that is on the same network, but a PLC cannot initiate communication with the PC.

An ECOM can sequence through communication connections with each PLC on the network,

one at a time.

The ECOM products inherently support two network layouts:

point-to-point and star. The point-to-point layout can be

used to link together two PLCs or a PC and a PLC. A switch

connects multiple networkable devices into a star topology.

Multiple switches are used to modify the star topology so that

it becomes a star-bus-star topology. See the figures below

H2-DM1E

TERM

RUN

STOP

USB

PGM

PORT

RS-232

SERIAL

E

1

T

0

H

/

E

1

R

0

N

0

E

T

7–18

Switches can connect together to make it possible to connect more devices to the network or

to extend the range of the network.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Chapter 7: Specifications - Specialty Modules

H2-ECOM100 Network Cabling

The H2-ECOM100 module supports 10/100BaseT standard cabling consisting of copper wire

twisted pairs.

10/100BaseT

Unshielded TwistedPair cable with RJ45

STATUS

LINKGD

ACTIVE

ERROR

H2-ECOM100

100MBIT

connectors

10/100 BASE-T

ETHERNET PORT

10/100 BaseT Networks

The cable used to connect a PLC (or PC) to an Ethernet switch is called a patch (straightthrough) cable. The cable used to connect together two PLCs, a PC and a PLC, or two

switches is a crossover cable. We recommend that you purchase cables pre-assembled with

connectors for convenient and reliable networking.

NOTE: The above diagram illustrates the standard wire positions in the RJ45 connector. We recommend

all ECOM 10/100BaseT cables to be Category 5, UTP cable.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–19

Chapter 7: Specifications - Specialty Modules

Cable Lengths

The maximum distance per 10/100BaseT cable segment is 100 meters or 328 feet. Switches

allow multiple 100 meter cable segments to be joined together increasing the allowable distance.

For example, two switches connected together adds an additional 200 meters to the system, for

a total range of 300 meters.

7–20

Maximum Number of ECOM Modules on the Network

The maximum number of nodes that can be connected to a 10/100BaseT network is a function

of the topology used in constructing the network. Therefore, it is not possible to state an

absolute maximum number of nodes that would apply in all cases.

The IEEE 802.3 specification defines the maximum node limit for an Ethernet segment in

terms of the ability to detect and avoid data collisions. A “legal” network can have any number

of devices provided that they can:

• Detect all data collisions that may occur during the communication process and

• Respond to these collisions appropriately.

You must take into consideration the network limitations imposed by all cabling and network

devices. Consider the limitations imposed on your network if your network uses:

• A combination of cabling standards, such as 10/100 BaseT and 10Base2, or

• Intermediate devices, such as switches or routers.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Chapter 7: Specifications - Specialty Modules

Each ECOM module can be assigned a Module ID ranging from 1 to 999,999,999.

Theoretically, you could have this many Ethernet modules coexisting on a single network.

Other network limitations would restrict the network size before reaching this limit. For the

majority of network PLC applications there is practically no limit to the number of ECOM

modules you can access from the NetEdit3 or Do-more Designer software. There is a node

limit for PLC-to-PLC communications. The network Read and Write instructions performed

by the initiating (master) PLC are only capable of accessing PLCs with Module IDs of 1

through 90. This effectively sets the maximum number of nodes available for PLC-to-PLC

communications at 90.

WARNING: We recommend against connecting Ethernet modules to the same network that serves as

your primary office network. While Ethernet networks can handle a very large number of data

transmissions, and normally handle them very quickly, heavy Ethernet traffic can adversely affect the

reliability and speed of the network.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–21

Chapter 7: Specifications - Specialty Modules

H2-ERM(100)/ H2-EBC100*

NOTE: The H2-ERM module has been discontinued. The H2-ERM100 is the replacement module.

H2-ERM(100) Overview

Expanding I/O beyond the local chassis is useful for a system which has a sufficient number of

sensors and other field devices located a relatively long distance from the CPU. The Ethernet

Remote Master H2-ERM(100) connects Do-more CPU systems to slave I/O over a highspeed Ethernet link.

Each ERM module can support up to 16 H2-EBC systems, 16 Terminator I/O EBC systems,

or 16 fully expanded H4-EBC systems. Of course, combinations are fine, too.

NOTE: Applications requiring an extremely large number of T1H-EBC analog I/O or H4-EBC 16-channel

analog I/O, could exceed the buffer capacity of a single H2-ERM(100) module. In these cases, an

additional H2-ERM(100) may be required.

The ERM connects to your control network using Category 5 UTP cables for cable runs up

to 100 meters (328ft). Use Ethernet switches to extend distances and expand the number of

nodes.

The PLC, ERM and EBC slave modules work together to update the remote I/O points.

These three scan cycles are occurring at the same time, but asynchronously. Critical I/O

points that must be monitored every scan are best placed in the CPU base.

It is highly recommended that a dedicated Ethernet remote I/O network be used for the ERM

and its slaves. While Ethernet networks can handle a large number of data transactions, and

normally handle them very quickly, heavy Ethernet traffic can adversely affect the reliability

of the slave I/O and the speed of the I/O network. Ensure ERM networks, multiple ERM

networks and ECOM/office networks are isolated from one another.

7–22

H2-ERM(100) Specifications

H2-ERM(100) Ethernet Remote I/O Master Module

Specifications H2-ERM H2-ERM100

Module Type

Slaves per ERM

Communications

Data Transfer Rate

Ethernet Port

Power Consumption

Operating Environment

Link Distance

Ethernet Protocols

Ethernet Communications Master Module

16 Max

10BaseT Ethernet 10/100BaseT Ethernet

10Mbps 100Mbps

RJ45

320mA @5VDC 300mA @5VDC

0ºC to 60ºC (32ºF to 140ºF), 35% to 95% humidity (non-

TCP/IP, IPX

condensing)

100m (328ft)

TCP/IP, IPX

Modbus TCP/IP, DHCP, HTML

configuration

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

LINKGD

ACTIVE

ERROR

H2-ERM

10BASE-T

ETHERNET PORT

LINKGD

ACTIVE

ERROR

H2-ERM100

10/100BASE-T

ETHERNET PORT

Chapter 7: Specifications - Specialty Modules

H2-ERM100

RS 232

SERIAL PORT PORT

H2-ERM(100) LED Indicators

H2-ERM(100) LED Descriptions

Indicator Status Description

LINKGD

ACTIVE

ERROR

ON Communications Link OK

ON Network Active

OFF Network Idle

ON or Flashing Fatal Error Detected

LINKGD

ACTIVE

ERROR

H2-EBC100 Overview

The Ethernet Base Controller (EBC) serves as an interface between the master control system

and remote I/O modules. The control function is performed by the master controller, not

the EBC slave. The EBC occupies the CPU slot in the base and communicates across the

backplane to input and output modules. The function of the EBC is to:

• Process analog and digital input signals

• Format the I/O signals to conform to the Ethernet standard

• Transmit input signals to the network master

• Receive and translate output signals from the network master

• Distribute the output signals to the appropriate output module in the base

The H2-EBC100 module supports industry standard 10/100BaseT Ethernet and Ethernet/IP

communications.

NOTE: The RS-232 serial port on the EBC module cannot be used when the EBC module is part of the

Do-more controller system.

H2-EBC100 Specifications

Specifications H2-EBC100

Communications

Data Transfer Rate

Link Distance

Ethernet Port

Ethernet Protocols

Serial Port*

Serial Protocols

Power Consumption

* The serial port on the EBC modules cannot be used when the H2-DM1/E is the

network master.

10/100BaseT Ethernet

100Mbps max.

100 meters (328ft)

RJ45

Ethernet/IP, TCP/IP, IPX/Modbus TCP/IP,

DHCP, HTML configuration

RJ12

K-Sequence, ASCII IN/OUT, Modbus RTU

300mA @ 5VDC

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

STATUS

LINKGD

ACTIVE

ERROR

H2-EBC100

SERIAL PORT

10/100 BASE-T

ETHERNET PORT

RS-232

-

100MBIT

TXD

RXD

7–23

Chapter 7: Specifications - Specialty Modules

H2-EBC100 LED Indicators

H2-EBC100 LED Descriptions

Indicator Status Description

STATUS

LINKGD

ACTIVE

ERROR

100MBIT

TXD

RXD

ON (Green) Module is powered up and functional

OFF Module powerup failed

ON (Green) Properly connected to network

OFF Not connected to network or incorrect configuration

ON or FLASHING (Red) Active Network Data

OFF Network Idle

ON or FLASHING (Red) A fatal error has occurred

OFF No error present

ON 100Base T Frequency detected

OFF (With ACTIVE LED ON) - 10Base T Frequency detected

FLASHING (green) Serial port is transmitting data

FLASHING (green) Serial port is receiving data

H2-ERM(100)/H2-EBC100 Network Identifiers

Each module must be assigned at least one unique identifier to make it possible for other

devices to recognize it on the network. There are three identifiers possible with the

ERM/EBC modules:

• Module ID

• IP (Internet Protocol) Address

• Ethernet (MAC) Address

The first two are user selectable but the MAC address is set at the factory. The identifiers are

used to link the ERM module to its remote EBC slaves. The type of identifier chosen depends

on the protocol requirements of your particular application. The following table summarizes

Network Identifiers and their uses:

STATUS

LINKGD

ACTIVE

ERROR

H2-EBC100

100MBIT

TXD

RXD

Identifier Protocol How to Set Format Notes

Module ID

IP Address

Ethernet (MAC) Address

7–24

Network Identifiers

IPX

UDP/IP NetEdit3

IPX Set at Factory 12 Hex digits Factory assigned for IPX

DIP Switch Slave Number 1-63, Set ERM to 0

NetEdit3 Slave Number 1-65535, Set ERM to 0 DIP Switch must be set to “0”

4 sets of numbers, up to three digits

each (192.168.76.3)

Module ID can be changed without

NetEdit3. When set, disables Module

ID selection in NetEdit3

See your Network Administrator for

IP addresses

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Chapter 7: Specifications - Specialty Modules

000

3

2

1

0

Module ID

Always set the ERM module ID to 0. A slave EBC Module ID can be set in one of two ways:

• Use the DIP switches on the module (1-63).

• Use the configuration tools in NetEdit3 (1-65535).

Set the Module ID using the DIP switches if you wish to be able to install and change slave

modules without using a PC. The Module ID equals the sum of the binary values of the slide

switches set in the ON position. For example, if slide switches 1, 2 and 3 are set to the ON

position, the Module ID will be 14. This is found by adding 8+4+2=14. The maximum value

which can be set on the DIP switch is 32+16+8+4+2=63. This is achieved by setting switches

0 through 5 to the ON position. The 6 and 7 switch positions are inactive.

Binary Value

(32) (16) (8)(4) (2)(1)

Not

52423222120

Used

2

7 6 5 4 3 2 1 0

ON

2 1

H2-ERM(100)/H2-EBC Module

H2-ERM(100)/H2-EBC Module DIP Switch Location

Set the module’s DIP switch, insert the module in the base, and connect the network cable.

The Module ID is set on powerup, and it is ready to communicate on the network.

The Module IDs can also be set or changed on the network from a single PC by using the tools

in NetEdit3.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–25

Chapter 7: Specifications - Specialty Modules

Host Auto. Products

H2-ECOM

MFG:IES 0602 4D

00.E0.62.20.1B.95

5VDC

60DegC

LISTED

33ZL

H

ost Au

to. Prod

uct

s

H2-ECOM

MFG:IES

060

2 4

D

00.E0.62.20.1B.95

5VDC

6

0DegC

LIS

TED

33ZL

Factory-assigned Ethernet (MAC) Address

IP Address

An IP Address can be assigned to the ERM module or its slaves if your network requires one.

Normally, a network administrator will assign an IP Address to each device on the network.

Since it is recommended to use a separate dedicated network for your ERM , you do not have

to use the IP Address, unless you are using the UDP/IP protocol. Use the Module ID or

Ethernet Address for each module when using the IPX protocol. You can use NetEdit3 within

the ERM Workbench utility to give the ERM or its slave modules an IP Address. Each ERM

and slave must have a unique IP Address.

The module ships from the factory with an IP Address of 255.255.255.255. This is not a

usable IP Address for normal communications. It only serves as a default setting which can be

changed using NetEdit3. The valid settings are 0 through 254. You do not have to change

the default IP Address unless you are using IP Address protocol. The default setting does not

cause conflicts with other network communications. If you change the default IP Address for

linking to other network devices, you must change all four “255” fields. If any field contains

the number 255 and other fields have been changed, the module will not be recognized on the

network.

Example IP Addresses

• 192.168.55.5 - Valid IP Address

• 255.168.55.5 - Not Valid

WARNING: It is extremely important not to have duplicate IP Addresses on your network. If you are

using the IP Address, all modules must have a unique number.

7–26

Ethernet (MAC) Address

A unique Ethernet (MAC) Address is assigned to each module at the factory and will not

change. It is printed on a label attached to each ERM/EBC module. The Ethernet (MAC)

Address is recognized by NetEdit3. The Ethernet (MAC) Address is a twelve digit number

with no deliberate relationship to your network or functional areas of your plant. Typically,

the MAC address is not a convenient and easily remembered identifier for your ERM/EBC

module.

Host Auto. Products

H2-EBC

MFG:IES 0903 9B

00.E0.62.00.21.6A

Using Multiple Network Identifiers

You can use IP Addresses to satisfy network requirements and Module IDs for PLCs to share

data among themselves. Using one type of identifier does not limit your use of the other

identifier types.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

5VDC

LISTED

33ZL

Host Auto. Products

H2-ERM

MFG:IES 0802 4D

00.E0.62.20.1C.5C

5VDC

60DegC

LISTED

33ZL

Chapter 7: Specifications - Specialty Modules

H2-ERM(100)/H2-EBC100 Network Layouts

Each ERM module can support up to 16 remote slaves. The slaves supported are the

H4–EBC, H2–EBC, T1H–EBC, GS–EDRV100 and HA–EDRV2. Use a PC equipped with

a 10/100BaseT network adapter card and the Ethernet Remote Master (ERM) Workbench

software configuration utility to configure the ERM module and its slaves over the Ethernet

remote I/O network. Once the ERM I/O network is configured and running, the PC can be

removed from the network.

AC

Drive

GS-EDRV100

Stride

Ethernet

Switch

Stride

Ethernet

Switch

Terminator I/O

with EBC Module

Do-more PLC

H4-EBC 110/220VAC

LINK GOOD

POWER

ACTIVITY

ERROR

405EBC

BATT LOW

RELAY

Do-more PLC

ERM

Module

H2-DM1E

DirectLogic

DL405 I/O with

EBC Module

ERM

Module

H2-DM1E

DirectLogic

DL205 I/O with

EBC Module

DirectLogic

DL205 I/O with

EBC Module

H4-EBC 110/220VAC

POWER

LINK GOOD

ERROR

ACTIVITY

405EBC

RELAY

BATT LOW

AC

Drive

GS-EDRV100

Terminator I/O

with EBC Module

DirectLogic

DL405 I/O with

EBC Module

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–27

Chapter 7: Specifications - Specialty Modules

H2-ERM(100)/H2-EBC100 Network Cabling

The ERM/EBC modules support 10/100BaseT standard cabling consisting of copper wire

twisted pairs.

10/100BaseT

Unshielded Twisted-

LINKGD

ACTIVE

ERROR

H2-ERM

Pair cable with RJ45

connectors

10/100 BASE-T

ETHERNET PORT

10/100 BaseT Networks

The cable used to connect a PLC (or PC) to an Ethernet switch is called a patch (straightthrough) cable. The cable used to connect together two PLCs, a PC and a PLC, or two

switches is a crossover cable. We recommend that you purchase cables pre-assembled with

connectors for convenient and reliable networking.

7–28

NOTE: The above diagram illustrates the standard wire positions in the RJ45 connector. We recommend

all ECOM 10/100BaseT cables to be Category 5, UTP cable.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Chapter 7: Specifications - Specialty Modules

Cable Lengths

The maximum distance per 10/100BaseT cable segment is 100 meters or 328 feet. Switches

allow multiple 100 meter cable segments to be joined together increasing the allowable distance.

For example, two switches connected together adds an additional 200 meters to the system, for

a total range of 300 meters.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–29

Chapter 7: Specifications - Specialty Modules

H2-SERIO(-4)

H2-SERIO(-4) Overview

With the H2-SERIO, three additional RS-232 ports can be added to your Do-more system. On

the other hand, the H2-SERIO-4 can give you two additional RS-232 ports and one RS-485 or

RS-422 port. As many as eight of these modules may be added to the local base, adding up to

24 serial ports (there is no means of using these modules in Ethernet remote bases).

The serial ports of the H2-SERIO(-4) support the following functions which can be selected

in the Module Configuration of the Do-more software (as seen below):

• Do-more Programming - Select this option to setup the port to work with the Do-more Designer

programming software.

• K Sequence - Select this option to have the port respond to client devices running K Sequence

protocol.

• Modbus RTU Server - Select this option to have the port respond to client devices running

Modbus/RTU protocol.

• Modbus RTU Client - Select this option to make the port available for use by the Do-more

controller’s Modbus Network Read (MRX) and Modbus Network Write (MWX) instructions.

• General Purpose - Select this option to make the port available for use by the Do-more controller’s

Input String from Device (STREAMIN) and Output String to Device (STREAMOUT)

instructions.

7–30

Baud rates, parity and communication bit settings are accessible by selecting the Device

Settings... button located below the General Purpose selection or through the Device

Configuration section of the System Configuration window. Baud rates up to 115,200 are

supported.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Chapter 7: Specifications - Specialty Modules

These parameters can also be set programmatically using the SETUPSER instruction seen here.

See the Do-more Help file for more information on communication instructions.

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

7–31

Chapter 7: Specifications - Specialty Modules

RS232 SERIAL POR

TS

SERIAL PORTS

B

C

Type Jack – both ports

SERIAL PORTS

SERIAL PORTS

B

H2-SERIO(-4) Specifications

H2-SERIO / H2-SERIO-4 Serial Communications Module

Specifications H2-SERIO H2-SERIO-4

Module Type

Approvals

Number of Serial Ports

per Module

Signals

Number of Modules

Supported per Do-more

PLC

Recommended Cables

Protocols Supported

Power Consumption

Baud Rates

Parity

Start and Stop Bits

Operating Environment

Storage Temperature

Intelligent

cUL Listed, file number E185989

3 ports: all RS-232 (RJ12 jack)

3 ports: 2 RS-232 ports (RJ12 jack) and 1

RS-422/485 (5 position terminal strip)

RS-232: CTS, RXD, TXD RTS, GND

RS-232: CTS, RXD, TXD RTS, GND

RTS transmission delay times: 5, 50, 250 and

500ms

RTS transmission delay times: 5, 50, 250 and

500ms

RS-422 (4 wire) : TX+, TX-, RX-, RX+, GND

RS-485 (2 wire): Data+, Data-, GND

8

RS-232: ZL-RJ12CBL-2

RS-232: ZL-RJ12CBL-2

RS-422: ADC L19853-x (Belden 8103)

RS-485: ADC L19954-x (Belden 9842)

Serial ASCII (full-duplex), K Sequence, Modbus/RTU and Do-more programming

80mA @ 5VDC

1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

None, odd, even

1, 2

0 to 60°C (32°F to 140°F), 5% to 95% RH (non-condensing); No corrosive gases, Pollution level

2; Vibration: MIL STD 810C 514.2; Shock: MIL STD 810C 516.2

-20 to 70°C (-4°F to 158°F)

RCV A

RCV B

RCV C

H2-SERIO

RS232 SERIAL PORTS

A

B

C

RCV A

RCV B

RCV C

H2-SERIO-4

SERIAL PORTS

RS232

XMT A

XMT B

XMT C

XMT A

XMT B

XMT C

A

B

H2-SERIO(-4) Wiring: RS-232

7–32

RS-232

6 pin RJ12 Phone

H2-SERIO(-4) RS-232 Pin

Descriptions

1 0V Power (-) connection (GND)

2 CTS Clear to Send

6

3 RXD Receive data (RS-232)

4 TXD Transmit data (RS-232)

1

5 RTS Request to Send

6 0V Signal Ground (GND)

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

TXD+

TXD-

(D-) RXD-

(D+) RXD+

GND

RS422/485

n

Set DIP switch S2 on the H2-SERIO-4 to:

n

(H2-SERIO-4 contains an optional 120Ω termination resistor between

receiver while maintaining EIA/TIA-485 compatibility.)

H2-SERIO-4 Wiring: RS-422/485

1. Activate or deactivate the internal 120Ω termination resistor.

2. Select RS-422 or RS-485 operation.

TXD+

TXD-

(D-) RXD-

(D+) RXD+

GND

(H2-SERIO-4 contains an optional 120Ω

termination resistor between RX+ and RX-; use

DIP switch S2 to activate or deactivate resistor.)

Chapter 7: Specifications - Specialty Modules

NOTE: Set DIP Switch for

desired configuration

OFF

NO TERM

RS422

SERIO-4

Slave 1 Last Slave

RX+

RX-

TX-

TX+

GND

ON

120 OHM

RS485

RS-422

Slave 2

RX+

RX-

TX-

TX+

GND

RX+

RXTX-

TX+

GND

User Supplied

120Ω Terminatio

Resistor

TXD+

TXD-

(D-) RXD-

(D+) RXD+

GND

RX+ and RX-; use DIP switch S2 to activate or deactivate resistor.

H2-SERIO-4 also contains internal biasing to be a true failsafe

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

SERIO-4

RS-485

Slave 1

D-

D+

GND

Slave 2

D-

D+

GND

Last Slave

D-

D+

GND

User Supplied

120Ω Terminatio

Resistor

7–33

Chapter 7: Specifications - Specialty Modules

F2-08SIM, Input Simulator

F2-08SIM Specifications

F2-08SIM Input Simulator

Inputs per Module

Base Power Required 5VDC

Terminal Type

Status Indicator

Weight

8

50mA

None

Switch side

2.65 oz. (75g)

IN

0

1

2

3

F2-08SIM

0

1

2

3

4

5

6

7

SIM

4

5

6

7

ON

7–34

Do-more H2 Series PLC User Manual, 1st Edition, Rev. I - H2-DM-M

Loading...

Loading...