Page 1

V100, V200 & V400

Operation and

Maintenance Manual

Page 2

Amendment Rec

ord

Issue 1 January 2008

2) 27864 Issue 1 January 2008

(

Page 3

CONTENTS

PART 1 : HEALTH & SAFETY........................................................................5

PART 2 : INSTALLATION..................................................................

PART 3 : OPERATION ......................................................................

PART 4 : MAINTENANCE & FAULT FINDING ..................................

APPENDIX A :TECHNICAL REFERENCE ........................................

...........15

...........71

......... 163

......... 251

APPENDIX B : EASYDESIGN MANUAL .................................................... 257

27864 Issue 1 January 2008 (

3)

Page 4

THIS PAGE INTENTIONALLY LEFT BLANK

4) 27864 Issue 1 January 2008

(

Page 5

PART 1 : HEALTH & SAFETY

CONTENTS

Page

EC DECLARATION OF CONFORMITY ........................................

GENERAL SAFETY.......................................................................

HAZARD INFORMATION..............................................................

Warning Notices .....................................................................................11

Caution Notices ......................................................................................13

............. 7

............. 9

........... 11

27864 Issue 1January 2008 (5)

Page 6

HEALTH & SAFETY

THIS PAGE INTENTIONALLY LEFT BLANK

6) 27864 Issue 1 January 2008

(

Page 7

HEALTH & SAFETY

EC DECLARATION OF CONFORMITY

(In accordance with ISO/IEC 17050-1)

Issuer’s Name: Domino UK Ltd

Issuer’s Address: Bar Hill Cambridge CB23 8TU

Objects of the Declaration: V100, V200, V400 Printers. Standard and FHE V-

Series Controllers

The Objects of the declaration described above are in conformity with the

requirements of the following D

irectives:

• 89/392/EEC : Machinery Directive as amended by 91/

368/EEC, 93/44/EEC,

93/68/EEC and 98/37/EEC

• 73/23/EEC : Low Voltage Directive as amended by 93/68/EEC

• 89/336/EEC : EMC Directive as amended by

92/31/EEC and 93/68/EEC

The

Following Standards have been used to show compliance:

• EN 61000

industrial environments.

• EN 61000-6-2, 1997: Generic standards section 2: Immunity for industrial enviro

• EN 61000-6-4, 2001: Generic standards section 4: Emission standard for indust

environments.

• FCC part 15 subpart B

• EN 55011, 1998+A1+A2: Limits and methods

characteristics of industrial, scientific and me

• EN 61000-3-2: 1995+A1+A2, Limits for harmonic

current up to and including 16 A per phase)

• EN 61000-3-3: 1995, Limits, limitation of voltage fluctuations and flicker

supply systems for equipment with rated current ≤ 16 A

• EN 61000-4-2, Electrostatic discharge requirements

• EN 61000-4-3, Radiated electromagnetic field requirements

• EN 61000-4-4, Electri

• EN 61000-4-5, Surge immunity requirements

• En 61000-4-6, Immunity to conducted disturbances, induced by radio frequency fields.

• ENV 50204, 1995 Radiated electromagnetic field from digital radio telephones.

-6-1, 1997: Generi

c standards section 1: Immunity for residential, commercial and light

of measurement of electromagnetic disturbance

dical (ISM) radio frequency equipment.

current emissions (equipment input

in low voltage

cal fast transient/burst immunity test; Basic EMC publication

nments.

rial

Signed for and on behalf of

Domino UK Limited, Bar Hill, Cambridge (December 2007)

27864 Issue 1January 2008 (7)

Page 8

HEALTH & SAFETY

THIS PAGE INTENTIONALLY LEFT BLANK

8) 27864 Issue 1 January 2008

(

Page 9

HEALTH & SAFETY

GENERAL SAFETY

p hine Safety Regulations.

The roduct is designed to conform to all current Mac

Note: Please read through this section before operating the machine.

This printer is designed for use with the following supply systems that conform to IEC

664 light industrial / domestic installation category II mains supply:

• ‘TN’ (any of following - TN-C, TN-S or TN-C-S) for example;

having one or mo

exposed conductive parts of the installation being connected to tha

protective conductors.

• ‘TT’ for example; a system having one point of the source of energy directly

earthed, the exposed conductive parts of the installation being co

earth electrodes electrically independent of the earth electrodes o

It is not suitable for connection to an ‘IT’ system for example; a system hav

direct connection between live parts and earth, the exposed conductive pa

installation being earthed. This therefore excludes any ‘phase to phase’ conn

supplies such as may be available in some factories and / or countries. If eit

fuse (located on the rear of the Controller, below the supply connector) is

must be replaced by a fuse 3.15/6.3AT - 230/115V – 50/60Hz - 300VA. Installation

must only be performed by qualified Domino personnel. For customer installa

authorisation must be obtained from Domino UK Ltd. All relevant Safety P

must be followed.

The printer and its component parts must onl

were sold, and for which they are designe

other functions.

Do not touch the printer or the controller with wet or damp hands.

Failure to do so may invalidate warranty.

re points of the source of energy directly earthed, the

y be used for the purpose for which they

d and constructed. No parts may be used for

a system

t point by

nnected to

f the source.

ing no

rts of the

ected

her supply

replaced it

tions

rocedures

Do not expose the printer or controller to rain.

Do not run the printer without ribbon material, as this may damage the

ALWAYS disconnect the power to the machine before removing any covers. You

must remove the plug from the mains power supply.

DO NOT insert body parts into the print head opening whilst the printer

as there is a danger that the mechanism will move without warning an

crushing h

DO NOT operate the machine with any covers removed. ALL covers must

place using the appropriate number of fasteners. It is essential that electrical a

electrical connector dust covers (provided with the machine) are fitte

connectors to protect against dust and dirt and possible static damage to internal

components.

Ensure all reasonable safety precautions have been undertaken. However, please ensure

that when working with / or around the machine, every care is taken to avoid

potential hazards. ALWAYS take great care around the machine not to slip, trip or fall;

especially if the machine is used in areas where the floor may be wet or greasy.

27864 Issue 1January 2008 (9)

azard.

print head.

is powered

d present a

be in

nd non

d to all unused

Page 10

HEALTH & SAFETY

If non Domino ribbon is used, it is recommended that anti static propert

considered. Domino U

K Limited cannot guarantee the safety and / or suitability of

ies are

non Domino print ribbon.

Take care, in the unlikely event of an e

lectronic fault causing an unexpected start up of

printer drive motors, to avoid possible injury.

If a verification scanner is used on this machine, please follow the manufac

procedures. When fitting and / or operating the scanner, follow th

e specifications as

turer’s safety

stated in the appropriate Laser Safety Standards (IEC825).

Please read the Manufacturers Safety Data Sheet (MSDS) for Isopropanol before using

the cleaning kit with any Domino product.

There is a danger of electrical shocks from the electrical outlet. All electro

nic checks

must be performed by qualified personnel.

There is a non replaceable lithium battery mounted on the Industrial PC. Under no

circumstances should thi

failure, please return the whole control board assembly to

s be replaced (it should last for several years). In the event of

Domino for repair. Please

note the following:

There is a danger of explosion if the battery is incorrectly replaced

.

Only Domino recommended replacements must be used.

Used batteries should be disposed of according to the battery manufacturer

’s

instructions.

The information above is correct to the best of our knowledge, information

at the date of this publication. The information given is d

esigned only as guidance for

and belief

safe handling use, processing, storage, transportation, disposal and release and is not

considered a warranty or quality specification. The information relates only to the

specific material designated and may not be valid for such material used in combination

with any other materials or in any process unless specified in text.

10) 27864 Issue 1 January 2008

(

Page 11

HEALTH & SAFETY

HAZARD INFORMATION

This section contains important notices. You must read these notices b

printe

r. The hazard information is prioritised into warning and caution notices as

follows:

Warning Notices

Warnin

notices clearly state th

avoided.

Handlin

Airborne particles

g notices denote a potential hazard to the health and safety of users. These

e nature of respective hazard and the means by which it can be

g the V200

The Cassette handle is for removing the cassette only.

be used as a means of carrying or holding the printer as this may

result in the printer becoming detached from the cassette causing

a crushi

Airborne particles and substances are a health hazard. Do not use

high-

ng hazard.

pressure compressed air for cleaning purposes.

It must not

efore using the

Heating element

The heating element and surrounding area become very hot

during

head, never touch the heating element area of the print head with

your fingers.

use. To avoid the risk of burns or damage to the print

Organic solvents

Cleaning fluid contains organic solvents, it is recommended to

wear suitable goggles and clothes to avoid contact with the eyes

and skin. Avoid inhalation of the vapour. Do not smoke in the

presence of the vapour.

27864 Issue 1January 2008 (11)

Page 12

Lethal voltages

Lethal voltages are present within this equipment w

connected to the mains supply. Only

personnel may carry out maintenance work.

HEALTH & SAFETY

hen it is

trained and authorised

Observe all statutory electrical safety codes and practi

is necessary to run the printer, disconnect the print

mains electrical supply service before removing the cover or

attempting any service or repair activity, otherwise death or

personal injury may result.

Compre

ssed air supply

To avoid the risk of injury to personnel or damage to the

equipment, do not exceed the flow and pressure specification.

Battery replacement

Replaceable batteries should only be replaced using

the same type and ra

explosion hazard.

Used b

manufactures instructions.

atteries should be disposed of according to the battery

ces. Unless it

er from the

batteries of

ting. Failure to do so may result in an

Fuses fire hazard

To ensure continued protection against the risk of fire, replace

fuses with the specified type and rating only.

12) 27864 Issue 1 January 2008

(

Page 13

Caution Notices

HEALTH & SAFETY

Cautionary notices denote a potential hazard to the physical integrity of

software but not a danger to personal. Thes

hazard and the means by which it can be avoided.

e notices clearly state the nature of the

equipment /

Damag e to Print Head

Changing the print head without setting the new resistance value

may cause severe damage to the print head.

Loss o

The counter values are not retained when the control box is switched off.

f Counter Data

The counter values are not retained when the control box is

switched off.

Equip ment Damage

To avoid the possibility of electric shock hazard and damage to

equipment. Do not fit or remove any connector on the printer

wh

ile the printer is switched on.

Cable Routing

To avoid damage to the cables or equipment, ensure that the

uted clear from any moving parts. cables are ro

Mains Supply Voltage

To avoid damage to the equipment, do not exceed the supply

voltage stated in the manual.

27864 Issue 1January 2008 (13)

Page 14

HEALTH & SAFETY

Cleaning Materials for Print Head

To avoid damage to the printer components, use only

brushes a

nd lint-free cloths. For cleaning we recommend using

cleaning kit.

Do not use high pressure air, cotton waste, abrasiv

metal

lic objects or degreasing cleaning fluids (e.g., Benzene,

acetone).

Spare Parts and Consumables

To avoid the risk of damage to the print head use only Domino

spares, parts and consumables.

Contact your supplier for

les and Service contact:

For sa

Domino UK Ltd.

details.

soft

e materials,

Bar Hill

Cambridge CB23 8TU

Tel: (01954) 782551

Fax: (01954) 782874

© DOMINO UK LTD 2007

14) 27864 Issue 1 January 2008

(

Page 15

PART 2 : INSTALLATION

CONTENTS

UNPACKING ............................................................................................

FHE Controller Main Parts ..........................................................

STD Controller Main Parts ..........................................................

V200 Printer Main Parts ..............................................................

V100 Printer Main Parts ..............................................................

V400 Printer main parts...............................................................

V200 Printer - Optional Bracket...................................................

V100 Printer - Optional Bracket...................................................

V400 - Optional Manual Bracket.............................................................

V400 - Optional Automatic Bracket .............................................

MECHANICAL INSTALLATION.....................................................

Installation Requirements............................................................

Installation ...................................................................................

Electrical FHE controller I/O Connection to a host machine........

...........20

...........21

...........22

...........23

...........24

...........26

...........26

...........29

........... 30

...........30

...........31

...........32

Page

17

28

Electrical FHE controller I/O Connection to a host machine........

STD controller I/O Connection to a host machine .......................

SETTING UP THE FIRMWARE ...............................................................

Saved in Design ..........................................................................

Print Counter ...............................................................................

System ........................................................................................

Time / Date..................................................................................

Error / Warning............................................................................

System Variables ........................................................................

International ...........................................................................................43

Hardware................................................................................................44

Diagnostics.............................................................................................45

I/O Test ..................................................................................................46

...........33

...........34

...........35

...........36

...........37

...........38

...........39

...........42

35

27864 Issue 1January 2008 (15)

Page 16

Sensor Test............................................................................................47

Interface ......................................................................................

Serial Communication .................................................................

I/O Settings .................................................................................

Network .......................................................................................

Network IP Address.....................................................................

Network Host Name ....................................................................

Network ODBC Service...............................................................

...........49

...........50

...........51

...........53

...........54

...........55

...........56

Printer Type............................................................................................

Admin ..........................................................................................

Users and Passwords .................................................................

Users and Passwords, Advanced................................................

...........59

...........60

...........64

Signing Setup.........................................................................................65

Logging ..................................................................................................67

57

(

16) 27864 Issue 1 January 2008

Page 17

INSTALLATION

UNPACKING

The printer can be delivered with tw

• FHE (For Harsh Enviro

• STD (Standard) Controller.

Before installation, it is importa

damaged during shipment, and that all parts needed for the installation and

operation of the printer are present.

o different controllers:

nment), or

nt to check that the printer has not been

Ensure that the following i

STD Controll

Contents Part No.

1 x STD Controller VEP4065E

1 x Cable Printer Power and signal Y1196 VE

1 x Cable for Main Power supply Area Specific) VEYxxxx (

1 x Cable for I/O 15 pin connection VEY0168

er Inventory

tems are present.

1 x Cable Serial VEY1191

1 x V Series Manual 27864 (English)

1 x 128 Mb Compact Flash memory card VEY0527

27864 Issue 1January 2008 (17)

Page 18

INSTALLATION

FHE Controller Inventory

Contents Part No.

1 x FHE Controller VEP4063E

1 x Cable Printer Power and signal 96 VEY11

1 x Cable for Main Power supply Area

VEYxxxx (

cific)

Spe

1 x Cable for I/O 16 pin connection Y0195 VE

1 x Cable Serial VEY1193

1 x Encoder Adapter VEY1197

1 x V Series Manual 27864 (English)

1 x 128 Mb Compact Flash memory card VEY0527

FHE Optional Accessories Inventory

Contents Part No.

Network Adapter Type VEY1185N

Keyboard Adapter Type VEY1185K

Network/Keyboard Adapter Type VEY1185NK

(

18) 27864 Issue 1 January 2008

Page 19

INSTALLATION

Printer Unit Inventory

Contents Part No.

1 x Printer unit s on type Depend

1 x Cleaning kit Type VPR0222

1 x Air pressure regulator

1 x 3 meter 6mm air tube Type VEY0786

1

AS1001 Type V

1

Not for V200 printer unit, as this model has a built in air regulator.

27864 Issue 1January 2008 (19)

Page 20

FHE Controller Main Parts

CONTROL BOX (front view)

Touch screen

Power supply

230/115 V a.c.

INSTALLATION

Optional Network and /

Keyboard connection

or

I/O Connection

Printer Connection

Serial Communication

RS232

Control box with touch screen, slots for the flash memory card, and all connectors for

external input.

Encoder

CONTROL BOX (right side)

Power Supply

On/Off

Compact Flash Card

Slot <512Mb

(

20) 27864 Issue 1 January 2008

Page 21

INSTALLATION

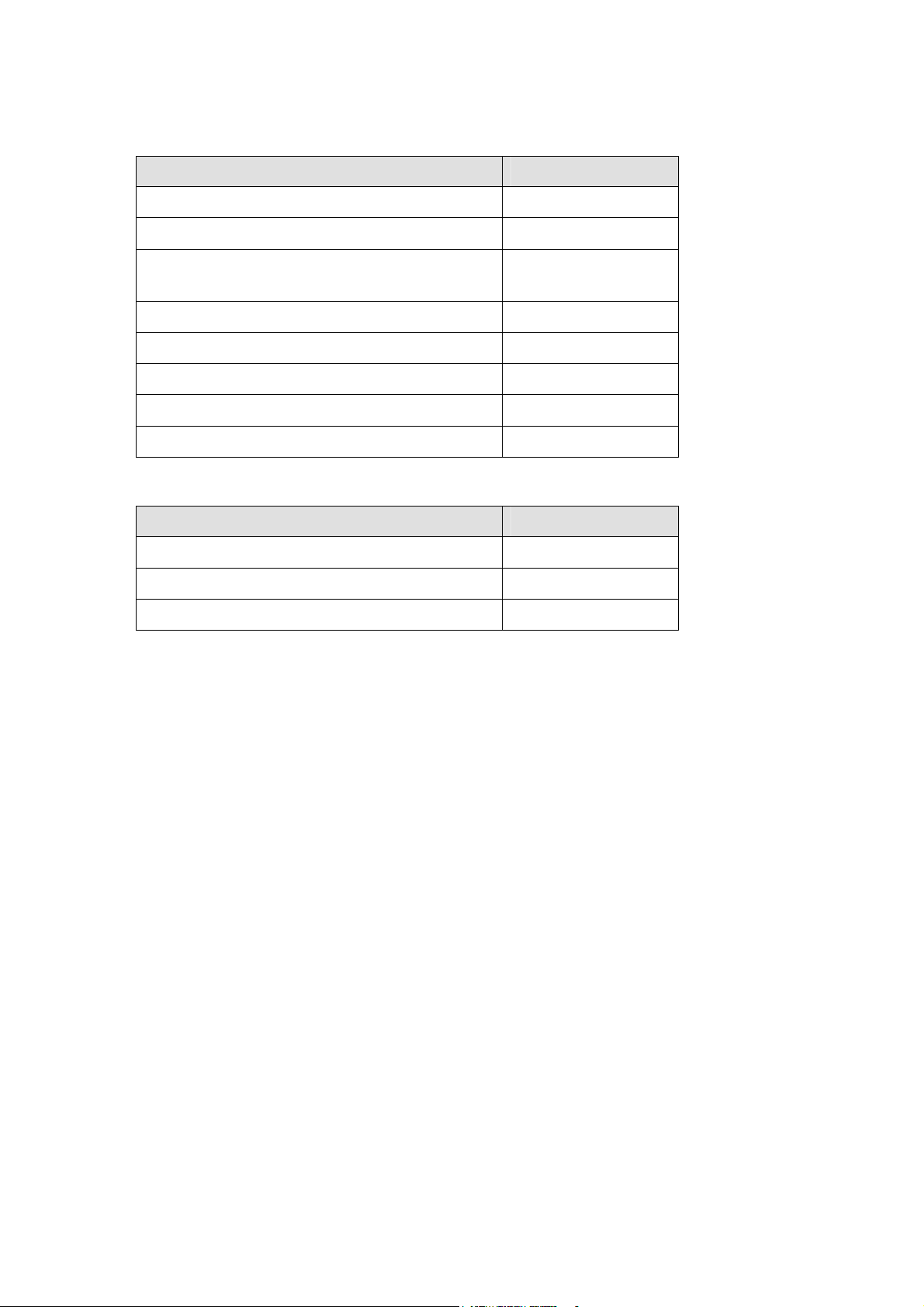

STD Controller Main Parts

Allows the creation of labels, programming and electronically control machine

handling and receive all internal service instru

Com 2 Serial

RS232

cessible) (Not ac

Com 1 Serial

RS232 Input

Control Box with the LCD touch screen display (IP20 Protec

ctions in text and pictures. Label design

iewed b g, without ha ed.

efore printin

PC Screen VGA

Connection

ving a printer connectcan be prev

Keyboard Connection

tion)

LAN

Compact

Flash

Card Slot

Power Supply

230V a.c./115V a.c.

2786

V100 and V200 model

4 Issue 1January 2008 (21)

Encoder

only

I/O Input

(Packaging Machine)

Printer Connection

LAN

Page 22

INSTALLATION

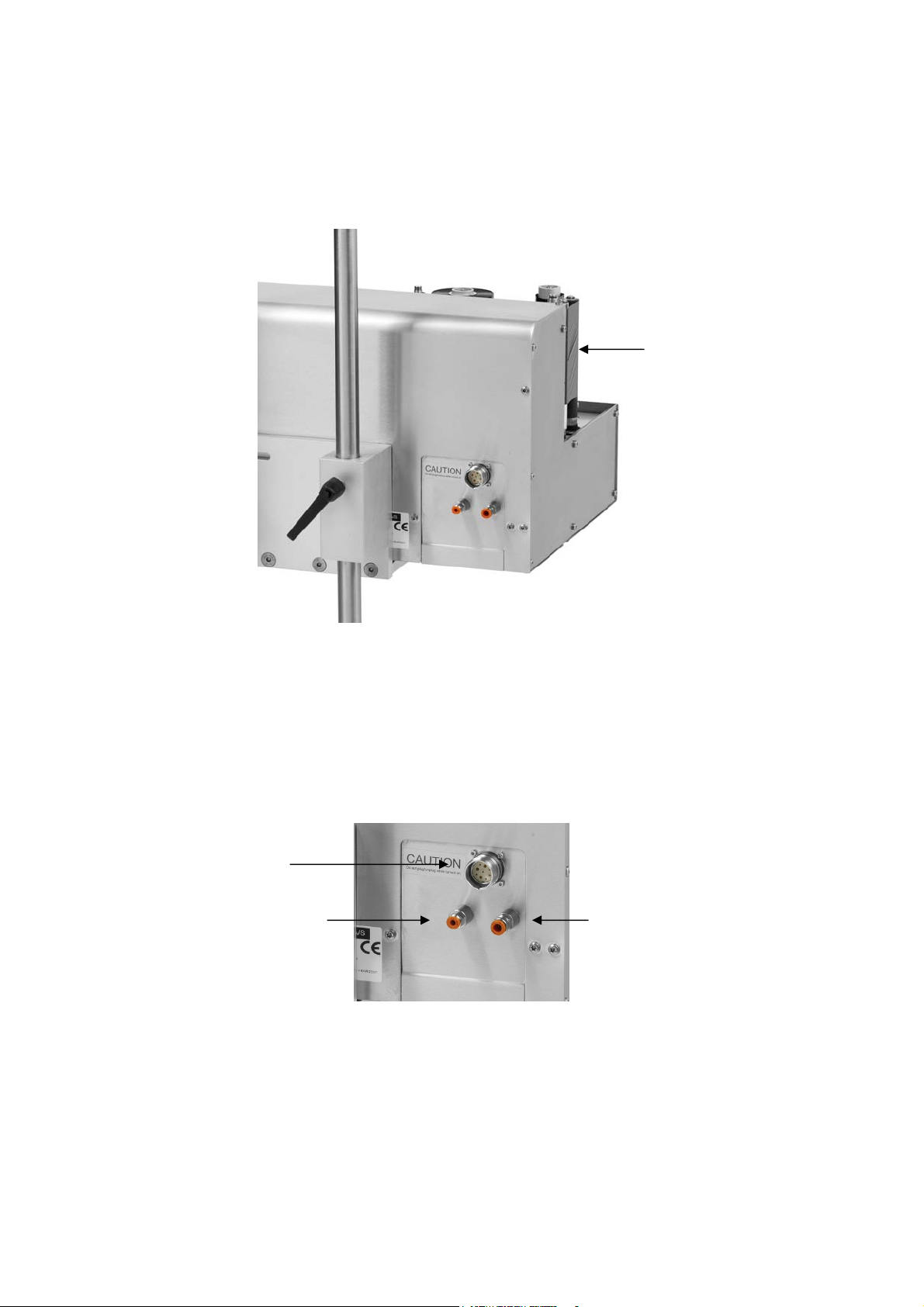

rts V200 Printer Main Pa

Air pressure inlet port

(clean dr

Connection to

controller

y air)

V200 Printer Unit

tions (rear view) Printer Connec

(

22) 27864 Issue 1 January 2008

Page 23

INSTALLATION

V100 Printer Main Parts

V100 Printer Unit

Printer Connector Plate (rear view)

Pressure air inlet port

(clean dry air)

Connection to

controller

4 Issue 1January 2008 (23)

2786

Page 24

INSTALLATION

V400 Printer main parts

The system offers a wide range of printing options.

V400 Printer Unit

V400 Printer front view with cover removed

Ribbon

Web

Platen

(

) 27864 Issue 1 January 2008

24

Page 25

V400 (rear view)

INSTALLATION

Ribbon

Web

V400 Connections (rear view)

Connection to

Controll er

Open exhaust from

the solenoid valve.

Ø 4 mm

(for special GMP

regulation)

Air pressure input

max 6 bars. Ø 6

4 Issue 1January 2008 (25)

2786

Page 26

INSTALLATION

V200 Printer - Optional Bracket

Standard Bracket System

The Standard Bracket System ensures a safe

machine, and makes it eas

Type: VEP 56XXXX (where XXXX range

Standard Intervals are 100mm

y to set up and adjust the printer according to requirements.

mounting of the printer on the packaging

s from 400 to 1300mm).

V100 Printer - Optional Bracket

Standard Bracket System

The Standard Bracket System ensures a safe mounting of the printer on the packaging

machine, and makes it easy to set up and adjust the printer according to requirements.

Type: VEP 51XXXX: (where XXXX ranges from 400 to 1300mm.

Standard intervals are 100mm.

(

26) 27864 Issue 1 January 2008

Page 27

INSTALLATION

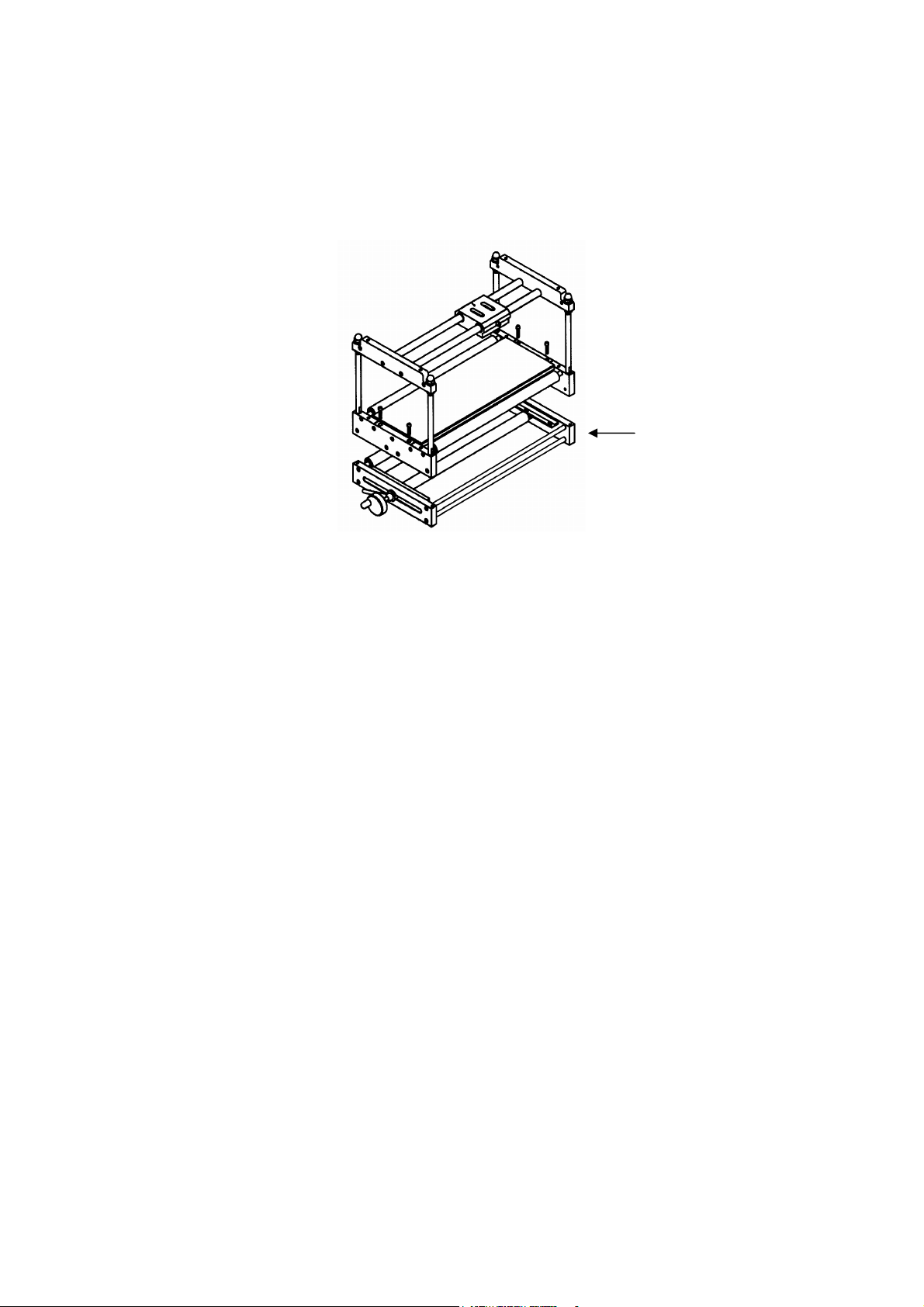

Bracket System with Optional Web Positioning S

ystem

The Web positioning system (shown here below the bracket) can be used i

intermittent applications to vary

the position of the web relative to the print position.

n

It fits to the standard bracket system.

Web positioning

System

Web positioning system: Type: VASWP – XXXX (where X ranges from 400 to

1300mm).

Standard Intervals are 100mm

4 Issue 1January 2008 (27)

2786

Page 28

INSTALLATION

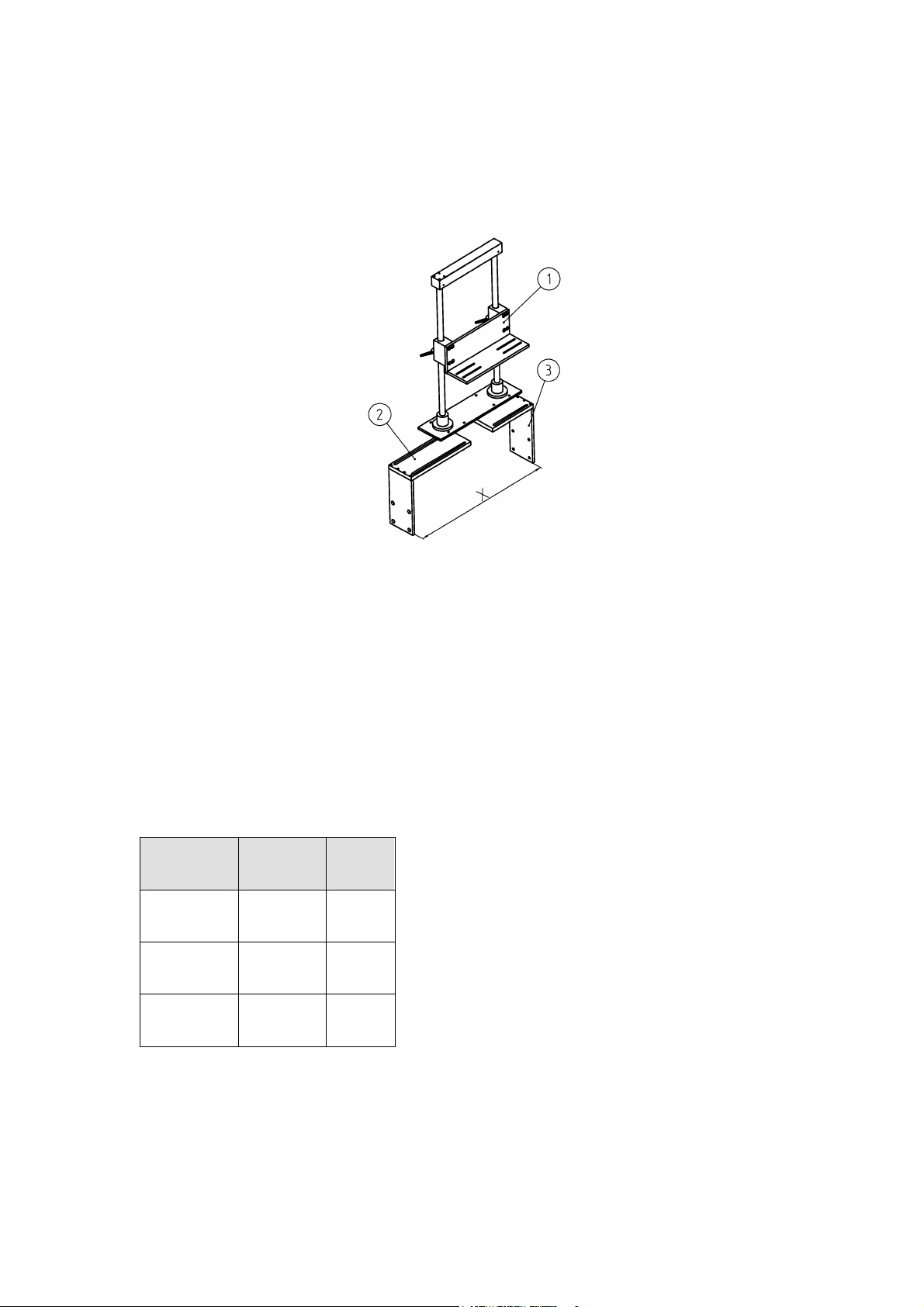

V400 - Optional Manual Bracket

Manual Bracket System

Bracket parts.

1. Mounting plate for the V400 printer

2. Packaging machine large mounting angle

3. Packaging machine small mounting angle

The Manual Bracket System ensures a safe mounting of the printer on the packaging

ma ne, a akes to set up and adjust the printer according to requirements.

chi nd m

Bracket Sy

stem for V400:

it easy

Type: VASHBTM100X (where X determines the width)

X Min. Max.

Width Width Width

4 750

610 mm

mm

5 490 mm 630

mm

6 730 mm 870

mm

(

28) 27864 Issue 1 January 2008

Page 29

INSTALLATION

V400 - Optional Automatic Bracket

Automatic Bracket System

Automatic

Bracket

V400 Printer

The automatic bracket system allows the V400 printer to print over a larger area

during each printing cycle (whilst the material to be printed remains station

The automatic bracket moves the printer vertically in steps after each horizontal stroke

of the printer.

The bracket uses a stepper moto

a dedicated control module which uses signals from the V Series cont

packag

The automatic bracket comprises of unguarded moving parts and must be installed to

ensure a safe operating environment.

The automatic bracket is supplied with installation guidelines and an operations

manual.

ing machine.

r to drive the vertical movement and is controlled via

ary)

roller and

4 Issue 1January 2008 (29)

2786

Page 30

INSTALLATION

MECHANICAL INSTALLATION

Installation Requirements

Ensure that the following services and control sig

(1) Power - 115/230 Vac (+10%, -15%) 50/60Hz

(2) Compressed Air - 6 Bar (max.), dry, uncontaminated.

(3) A print start signal - this has to be a vo

printing is required.

(4) Sufficient space for installation and operation.

(5) If using a V200 an encoder to monitor the substrate speed is required.

nals are available:

.

lt free contact which closes when

(

30) 27864 Issue 1 January 2008

Page 31

INSTALLATION

In ts allation

(1

) Mount the printer in the bracket system.

Note:

If mounting is a V200 ensure the print head is mounted on the top point of the

rubber roller.

(2) Adjust the nuts on the 4 shafts of the brac

rubber plate / rubber roller and the print head.

On the V100 printer the distance should be between 1 and 1.5mm

•

• On the V200 the distance should be between 0.2 to 1.0mm.

V100

1.0 - 1.2 mm

ket to the correct distance between the

V200

0 - 1 mm

0.2 - 1 mm

27864 Issue 1January 2008 (31)

Page 32

INSTALLATION

(4) Connect cables.

• Connect the main cable from the controller to the main supply

• Connect the printer cable between the printer and the controller

• Conn

ect the air pressure to the printer and adjust to 2.5 Bar (5 inch printer:

3.5 Bar)

• If a V200, con

nect the encoder.

(5) Turn on the controller.

(6) Put ribbon on the cassette. Follow the instruction inside the c

Load the test design from the design library

(7)

assette.

(8) Carry out a test print as described below.

• V100 only - when printing with the V100 printer push the

test print on

the touch screen

• V200 only - when printing with an CM or V200 run the web on the

packaging machine with 300 mm / s. (note: the start signal must be in

continuous mode)

• Only V200 - If the quality of the print is equal to the print

ou

with the printer then reduce the contrast until the quality is redu

(approximate 10% reduction)

• Only V200 - Fine adjust the print head position according to th

point on the rubber roller. Do the adjustment in steps of a half tu

screw, adjust, run and check again. The adjustment has to be tr

directions depen

may need to be reduced several times in this procedure. Con

adjustmen

t until the best result has been found. The mechanical adjustment

ding on the quality of the packaging material; the contrast

tinue with this

of the printer has now been found and further adjustment of the printer is

not needed anymore

• Only V200 - Increase the contrast until an acceptable quality has been

achieved.

t received

ced

e top

rns on the

ied in both

Head position

screw

(

32) 27864 Issue 1 January 2008

Locking screw

Page 33

INSTALLATION

Electrical FHE controller I/O Connection to

machin

Use Cable VEY0195

Vcc

Vcc

Vcc

Vcc

e

Start Signal

Ribbon Tension

Print Ready Signal

Printer Error Signal

Ribbon Warning Signal

Park out Signal

Max voltage: 30V DC

Max current: 100mA

Input Signals

Signal length min 50ms

Input

Start Signal

24V+

1 Red +

2 Grey 2

_

24V+

5 Black + 5

6 Yellow 6

_

Output

+

15 Blue + 15 Ready

_

16 Green 16 Closed when ready

13 White / Yellow + 13 Error

+

14 Yellow / Brown 14 Closed when no error

_

11 Pink + 11 Ribbon Warning

+

12 Violet 12 Open when low ribbon

_

9 Park (V400 only)

9 White / Green Signal is closed when

+

10 Brown printer is in park osition

_

10 Auto bracket output

To use this output (10), the automatic bracket must

be enabled

K1

Ribbon Tension

K2

K1 and K2 wire length

Output Signals

a host

NPN

or

NPN

or

p

4 Issue 1January 2008 (33)

2786

Page 34

INSTALLATION

STD controller I/O Connection to a host machine

Use Cable VEY0168

Start Signal

Ribbon

Tension

Vcc

Vcc

Vcc

Vcc

Print Ready Signal

Printer Error Signal

Ribbon Warning Signal

Park out Signal

Max voltage: 30V DC

Max current: 100mA

+

_

Input Signals

Signal length min 50ms

Input

Start Signal

24V+

5 Yellow +

13 Black / White 13

_

24V+

7 Blue + 7

15 Red White 15

_

Output

4 Orange + 4 Ready

12 Light Green 12 Closed when ready

3 Red + 3 Error

+

11 Pink 11 Closed when no error

_

2 Brown + 2 Ribbon Warning

+

10 White 10 Open when low ribbon

_

1 Park (V400 only)

1 Black Signal is closed when

+

9 Grey printer is in park posit

_

9 Auto bracket output

To use this output (9) the automatic bracket must be

enabled

K1

Ribbon Tension

K2

K1 and K2 wire length

Output Signals

NPN

or

NPN

or

(

34) 27864 Issue 1 January 2008

Page 35

INSTALLATION

SETTING UP THE FIRMW

ARE

Saved in Design

Find "Save in design" in the "Settings / Run" menu.

This menu allows you to defi

is examined in detail below:

It can sometimes be useful to store some of the settings directly in the design

A scenario could be that design1 uses a low contrast setting but a high start

while design2 requires a high contrast but a low

both contrast and start pulse offset every time the specific design is loaded, t

values for these settings can be stored with the design.

Use the menu below to define which setting you wish to be stored in the design files.

ne the settings you wish to save in the design. The menu

files.

pulse offset,

start pulse offset. Instead of changing

he optimal

1

(1) Settings

This shows the user a complete list of all the settings in the printer that can b

with the individual design. Pressing on the desired settin

"CONTRAST”) will select that item. By pressing the "Toggle” button (in the bottom

right-hand corner), and then "Save”, the selected setting will be saved with each

individual design.

If "CONTRAST” is subsequently altered in a design and the design is then loaded, the

CONTRAST value will update the global CONTRAST value.

g (in the example above:

e saved

4 Issue 1January 2008 (35)

2786

Page 36

Print Counter

INSTALLATION

The system supports t

defined amount of prints.

he use of a print counter. That means it can be used to print a

1

3

(1) Enable prompting of print coun

If this check box is selected, the system will prompt the operator (when a j

manually started) for the number of prints to do. The prin

manually ended (or the print is otherwise interrupted).

ter

ting will continue until

2

ob is

Please note that this setting only applies to a print job started on the printer itself. If a

design is transferred, the sender determines the "number of prints”.

) Action when done

(2

Use this field to define what should happen when the required number of prints has

been printed.

The options are:

• Quit print: Unlo

• Restart print: Restart

selected)

• b, when the last

Ask: The operator is asked whether to restart or unload the jo

print has been printed.

ads the print job when the last print is printed.

s the print job (a new number of desired prints must be

(3) Protect print memory

If enabled, a print in the print memory cannot be overwritten by an

external source. To load another print job, the current job must be

(manually) unloaded first.

(

36) 27864 Issue 1 January 2008

Page 37

INSTALLATION

System

The “System” menu is a configuration menu where the user must s

information needed by the printer to function optimally. These in

language, keyboard layout, all of which should be configured in this men

This menu will normally only be used upon installation of the printer, an

recommended to go through this menu before starting the printer for the first time.

et up some of the

clude; date,

u.

d users are

1

2

3

4

(1) T

Here the user can set

menu is the time used

page 38.

ime/Date

the time and date in the printer’s system. The time set in this

by the printer when calculating the various types of RTC. See

(2) Error/Warning

The menu allows the user

”Error”, e.g., when the printer should display a message when the ribbon

close to being used up. See page 39.

(3) System va

This menu is used to define the printer’s ID. If the printer is required to p

ACHINE ID), this ID must be set before it can be inserted as a variable. See page

(M

42.

riables

to define when the printer should send a ”Warning” or an

is getting

rint its ID

(4) International

This menu allows the user to define keyboard set-up and printer language. See page

43.

4 Issue 1January 2008 (37)

2786

Page 38

INSTALLATION

Time / Date

The time and date in the printer can be set here.

1

2

(1) Set Time

Define the printer’s time here.

local time.

Pressing “Set Time” will allow the user to key in the

(2) Set Date

Set the date in the printer system here. Pressing “Set Date” will allow the user to alter

the date.

(

38) 27864 Issue 1 January 2008

Page 39

Error / Warning

INSTALLATION

This menu allows users to determine when the printer should send a

message. The difference between “Warning” and “Error” is that in th

“Warnin

operating.

In the case o

operating.

To switch from “Error” to “Warning” simply press the button.

g” the user will be informed on the screen but the printer will carry on

f “Error” the printer will display an error message on screen and stop

4

warning or error

e case of

1

2

3

(1) T

The “Error/Warning” menu contains two screens that the user can scroll between. By

pressing the right-han

pressing the left-hand arrow key, the user will be returned to the previou

disp

he arrow keys

d arrow key the user will come to the next screen display. By

s screen

lay.

(2) Ribbon Alarm

When the ribbon is broken, the system has tw

fault.

• A dancer arm act

• The ribbon roll has not r

though a certain amount of ribbon was used.

(3) Ribbon Warnin

When the ribbon roll is almost empty the ribbon-warning feature is activated (the

ribbon warning output is activated).

By setting this feature to “Error” the printer will stop when the diameter of the

ribbon roll is equal to the value set in the "Activate ribbon warning when

diameter is below:" field.

ivates the ribbon alarm sensor

otated (measured by the ribbon warning sensor) even

g

o independent ways of detecting the

4 Issue 1January 2008 (39)

2786

Page 40

INSTALLATION

3

5 4

This item is described below. If ”Ribbon Warning” has been set to ”Warn

warning will be displayed on screen when the ribbon has reached the d

"Activate ribbon warning when diameter i

Activate ribbon warning when diameter is below

This menu is used to set the minimum diamete

together with “Ribbon Warning” (described above).

When ribbon diameter reaches the set value, the “Ribbon Warning” function is

activated. The most suitable diameter is based on the printer’s speed and the size of the

print.

s below:" (see next paragraph):

r of ribbon roll. The menu is used

ing”, a

iameter set in:

(4) Default

The default button allows you to r

To do this, press the “default” button once.

Notice that the button is now reversed

When the default button is reversed, press the setting you wish to reset.

If you have accidentally pressed the default button, press it again to deselect it.

eset a single setting to the factory default.

1

2

6

(1) The arrow keys

The “Error/Warning” menu contains two screens that the user can scrol

pressing the right-hand arrow k

pressing the left-hand arrow the user will be returned to the previous screen

ey the user will come to the next screen display. By

(2) Print pulse when not ready

If the packing or labeling machine sends a signal whilst the printer is calculating, an

error/warning as follows can be set:

l between. By

display.

Error: If the printer is interrupted by a signal during printing, retraction, or calculating

the next label, pause or not ready, it will stop.

(

40) 27864 Issue 1 January 2008

Page 41

INSTALLATION

Note: if the printer is interrupted by a signal during printing, retraction or calculating

label, pause, not ready, it will ignore the signal. The system will first accept the

it has finished calculating. Thus producti

exceeded (but some products may miss a print).

(3) Spe

(CM-Types)

If the web speed is below 50 mm/s, a warning or error signal will be displayed on the

screen, in accordance to the settings.

ed too low

on will not halt if the printer’s maximum speed is

the next

next signal when

(4) Abort print when speed too low

(CM-Types)

By selecting the field, the printer will abort the current print

the setting is unselected t

web is started again, the r

he printer remains in its current print position and when the

emains of the current print is finished.

if the speed is too low. If

(5) Y-offset too short

If the distance between the label start and the first line are too short, a warn

al will be displayed on the screen. If the Y-offset is too short the print head cannot

sign

print the firs

standards. Th

print.

t pixels and hence the print may not comply with the desired quality

e minimum Y-offset depends on the print speed and the actual design to

ing or error

(6) Default

The default button allows the user to reset a single setting to the factory default. To

do this press the “default” button once.

Notice that the button is now reversed. When the default button is reversed, press the

setting you wish to reset.

If the default button was accidentally pressed, press it again to deselect it.

27864 Issue 1January 2008 (41)

Page 42

INSTALLATION

System Variables

1

2

(1) Machine ID

Use this setting to assign a name to the printer. It is this name that the machine id

(identity) vari

able (page 133) refers to.

Please do not confuse the machine id w

ith the host name (see page 55).

(2) Hotstart

The system has limited hot start functionality.

When ever a design is loaded, the name of the design and all entries for pro

variables are stored on the internal system drive. W

the information is purged from the internal system drive.

If the system is switched on, th

any design being printed. If such information is found, the design in question is loaded

and any prompted variables will automatically be filled in.

Please note that any counters and real time variables in the design is initialised as it

would be during a normal job load.

e internal system drive is searched for information about

hen the design is unloaded again,

mpted

(

42) 27864 Issue 1 January 2008

Page 43

INSTALLATION

International

The screen below shows the ”International” menu

1

2

(1) Printer language

Defines the language the V Series Controller User Interface should use. By pressing on

the “English” fi

which the user may select the desired language.

eld in the above illustration, a dropdown list will be displayed from

(2) Keyboard

The user can set the keyboard appropriate to

“English (UK)” field in the above illustration, a dropdown list will be displ

which the user can select the appropriate keyboard layout.

The keyboard is used when designing your print and it is therefore important that this

setting is defined before beginning to design prints.

It is possible to temporarily change the keyboard layout when the keyboard is

displayed.

the printer language here. By pressing the

ayed from

4 Issue 1January 2008 (43)

2786

Page 44

INSTALLATION

3

Hardware

The next tab is the "Hardware” menu.

1

2

(1) Diagnostics

Should problem

the testing of some of the functions necessary for operation of the printer.

s arise in connection with the printer, the ”Diagnostics” item allows

(2) Interface

All connections to

must be defined under “INTER

the surrounding environment (be it a packaging machine or a PC)

FACE”.

(3) Printer Type

Select the printer model connected.

(

44) 27864 Issue 1 January 2008

Page 45

Diagnostics

INSTALLATION

1

2

3

(1) I/O test

Use this menu to verify the interface to the pa

(2) Sensor test

Use this menu to verify the sensors on the

(3) Speed

Use this menu to measure the speed of the web.

The menu will further display information about the voltage to the print head and

stepper motors.

Finally, the menu will show the current temperature of the print head.

/ Voltages / Temperatures

ckaging machine.

print unit.

4 Issue 1January 2008 (45)

2786

Page 46

I/O Test

1

INSTALLATION

2

3

(1) Input

The input co

open or closed.

lumn shows the status of the four inputs to the system. Possible values are

(2) Output

Use the buttons to force the output to either open or closed (simply press the output

you wish to change).

(3) Loop test

The loop test requires the use of a special cable (loop cable) that will test the unit’s

input/output signals.

(

46) 27864 Issue 1 January 2008

Page 47

INSTALLATION

Sensor Test

The menu display reflects the actual printer attached (the screen below is for a V200

printer)

Ribbon Alarm

The ribbon alarm is acti

manually activate th

verify that the sensor is activated.

vated if the dancer arm reached this reflective sensor. To

e sensor, place something reflective in front of the sensor and

Ribbon Warning

The ribbon-warning sensor monitors the rotation of the roll with unused ribbon. Use

a piece of pape

On some models, the ribbon warning is a reflective senso

turn the roll of unused ribbon and verify that the sensor is activated.

r to block the fork sensor and verify that the sensor is activated.

r. On these models, simply

Printer Open

Open and close the cassette and verify

that the sensor is activated.

Encoder

Activate the enc

pulse from the encoder (12 pulses per mm).

The speed test can be used to verify the function of the encoder.

oder and verify that the screen changes. The screen changes for each

Start Winder

(V200 printer only)

Printer has a reflective sensor that monitors the second dancer arm’s position. Place

something reflective in front of the sensor and verify the sensor is activated.

27864 Issue 1January 2008 (47)

Page 48

Stop Winder

(V200 Printer only)

INSTALLATION

Printer has a reflective sensor that monitors the second dancer arm

’s position. Place

something reflective in front of the sensor and verify the sensor is activated.

(

48) 27864 Issue 1 January 2008

Page 49

Interface

3

INSTALLATION

All connections to

must be defined here.

the surrounding environment (be it a packaging machine or a PC)

(1) Serial Communication

Use the serial com

system. The serial port can be used to connect a PC, scale or other de

munication menu to define the behavior of the serial port of the

1

2

4

vice.

(2) I/O Set

Use the I/O settings menu to set up the in

(3) Netw

Ethernet LAN Set-up, u

Ethernet can be used to transfer designs and to remotely control th

(See page 53)

tings

terface with the packaging machine.

ork

sed to set-up IP address.

e printer.

(4) Screen Calibrate

Make a manual update with a pointing device for the touch screen settings.

4 Issue 1January 2008 (49)

2786

Page 50

Serial Communication

2

INSTALLATION

1

3

(1) Com1 Settings

Use this menu to modify the baud rate, number of data and stop bits and also to

modify the parity chec

Note: Hardware handshake is always enabled on this system.

k.

(2) Com2 Settings

The Com2 port of the system is reserved for future use and this me

nu is disabled.

(3) Require user logon

If this setting is enabled, no serial data is accepted before the sender has been

authorised (user name and password of a user known to the system).

(

50) 27864 Issue 1 January 2008

Page 51

I/O Settings

2

This menu display is as follows:

I/O Settings (All printers)

I/O Settings (V100 & V400 printers)

INSTALLATION

1

3

4

I/O Settings (V200 printers)

(1) Start signal

The signal can be set-up in three ways

• Front edge: After the start contact has been closed the printer mak

and

waits for a new start signal. Open and close the start contact again for a new

print cycle.

•

Level – triggered: After the start contact has been closed, the printer prints

until the start s

cycle.

• Continuous: Used for test purposes. Internal start signal whose interval is

defined by the actual

ignal has been removed, and will then stop at the end of a print

label length.

es 1 cycle,

(2) RS while print

Defines whether the system should report back ready (or not ready) while printing.

(3) RS while returning

(V100 and V400 printers)

4 Issue 1January 2008 (51)

2786

Page 52

INSTALLATION

Defines whether the system should report ready (or not ready) while the print head is

returning to its home position.

(4) Encod

er Divide

(V200 printers)

If set to zero, the encoder must give 12 pulses per mm.

If set to another value, the encoder must give 12 times that val

setting the value to 4 requires and encoder tha

t gives 48 pulses per mm.

(The value zero and one requires the same encoder).

ue pulses per mm. E.g.

(

52) 27864 Issue 1 January 2008

Page 53

INSTALLATION

Network

The settings related to network is also divided into several screens.

1

(1) Network Adapter

A list of available network adapters is shown. Press one of the available adapters to set

it up.

4 Issue 1January 2008 (53)

2786

Page 54

INSTALLATION

2

6

Network IP Address

The settings related to network is also divided into several screens.

Please contact your l

use a local area network.

(1) Name Serve

Reserved for future use.

ocal network administrator for guidelines on how to set up and

rs

1

3

4

5

(2) Adap

Shows the name of the adapter currently being edited.

(3) DHCP

Specifies whether the system should automatically fetch an IP address fro

if an IP address should be manually assigned to the printer.

(4) IP Address

The IP address currently assigned to the system is shown here if DHCP i

manual IP assigning is active, use this entry area to type in the printers IP address.

(5) Subnet Mas

The subnet in use is shown here if DHCP is active. If manual IP assigning is active,

use this entry area to type in the printers subnet mask.

(6) Default Gateway

Reserved for future use.

ter Name

m a server, or

s active. If

k

(

54) 27864 Issue 1 January 2008

Page 55

Network Host Name

3

INSTALLATION

1

2

(1) Hostname

This is the printer’s networking name. The printer can be found on the local area

network using th

Note: Two pr

e hostname.

inters cannot have the same name.

(2) Listen Port

Set this to 700.

(3) Require user logon

If this setting is enabled, no serial data is accepted before the sender has been

authorised (user name and password of a user known to the system).

4 Issue 1January 2008 (55)

2786

Page 56

INSTALLATION

2 3

Network ODBC Service

1

(1) IP Address

Type in

running. Yo

the IP address of the computer where the ODBC server application is

u can type in the computers name instead of the IP address.

(2) Port

Set this to 701.

(3) ODBC Active

Specifies whether the printer will allow connections to the ODBC server application.

(

56) 27864 Issue 1 January 2008

Page 57

Printer Type

6 5

INSTALLATION

V400

1

2

3

4

(1) Printer Type

Select the printer type the controller is connected to.

(2) Head Resistance

The resistance of the print head varies from head to head. Eac

changed, the user must remember to key in the resistance of the print head. Print head

resistance consists of 4

Caution: Sett

ing an incorrect value may decrease the lifetime of the print head.

digits and is indicated on the bottom of the print head.

h time the print head is

(3) Printer Length

(V400 printers)

This setting refers to the travel distance for the print head carrier, f

to the machine frame (minus 1 mm).

avoid damage toCaution: To

print head carrier can move, before entering

collide at high speed, with the printer frame and could potentially damage the print

the printer, please take time to measure the correct distance the

a value. If the setting is too high, the carrier will

rom the start point

er.

(4) Automatic bracket

(V400 printers)

Note: If you want to use the V400 Automatic bracket system

When the printer has ended the last label print, the bracket system will start moving in

accordance with the RDY signal.

, mark the field.

(5) Printing statistic

Shows statistical information about print head and electronics.

4 Issue 1January 2008 (57)

2786

Page 58

INSTALLATION

Print head temperature

Use this menu to set a warm up temperature for the print head (requires a heating

element in the print head).

The current temperature can be monitored here as well.

For applications where the ambient temperature is cold (l

ess than 10 degrees Celsius)

the print quality can sometimes improve if the heater is activated.

If no heater is installed (or you do not wish to use it) set the requested temperature to

zero.

(6) Park

(V400 printers)

Moves the print head carrier to/from park position.

(

58) 27864 Issue 1 January 2008

Page 59

Admin

INSTALLATION

The last tab under “Settings” is “Admin”. T

to be set up as well as other administrative options.

his menu allows a variety of user profiles

(1) Users and Passwords

This menu is normally on

printer. This menu allows

can be linked to various user groups. See page 60

ly for use by the person responsible for the running of the

different printer users to be set up in the system, and these

1

2

3

4

(2) Data Management

This menu allows the user to access a list of all the printer’s internal and external files.

It is also possible to copy,

This menu is also used to backup/restore data a

See page 174

(3) Settings Upgra

Used when up

Press the field “Settings Upgrade” and select “Allow Upgrade During ne

followed by “Save”. The menu also gives you the option of re-setting the p

factory defaults. See page 208

grading or changing the V200 software.

rename, move, etc. all of these files.

nd to migrate data from the controller.

de

xt boot”

rinter to

(4) Logging

This menu allows the user to set the parameters to be saved in the printer’s log file.

These are parameters that, for example, can tell the administrator when the printer was

last used and who used it. (See page 67).

4 Issue 1January 2008 (59)

2786

Page 60

INSTALLATION

1 3

Users and Passwords

This menu is used to set up individual users and user types.

Users

The menu is used to manage users.

2

(1) Username/Fu

The list shows the currently defined users that have access to the printer.

Username is the name that should be used when logging in, and “Full Name” is the

actual name of the person.

(2) Log in (defa

Use the drop-down menu to select if the system should automatically log

user in, or i

companies, it will not be relevant for system users always having to log o

Username and Password.

If “LOG IN (default)” is selected, it will not be necessary to log on using username

and passw

If this option is se

users in the system. Use this drop down menu to specify which user should be logged

in automatic

f it is required that the operator always types in a password. In some

ord.

ally at start up.

ll name

ult)

a specific

n using

lected, another drop down appears to the right, containing all the

(3) New

Creates a new user.

Properties

Edits an existing user.

(

60) 27864 Issue 1 January 2008

Page 61

INSTALLATION

6 2

Delete

Deletes the selected user.

Note: You cannot delete the user that is currently logged in.

It is STRONGLY recommended to set up two

administrators. If all administrat

ors forget their password

the unit must be returned for repair.

User Properties

When creating a new user (or editing an existing user) the menu below is displayed.

1

3

4

5

(1) Username

Type in the username. The username is used when logging in to the printer

(2) Full Name

The actual name of the user. Only used for descr

(3) Type

Use the drop down menu to select the user type (group) that the user is a pa

age 62 for information about managing user types.

See p

(4) Password

Type in the new user’s password. The first time the password is used, the user is forced

to type in another password. When editing a user the actual password is replaced with

8 stars.

Note: If a user enters an incorrect password three times in a row the user is suspended. The

administrator can issue a new password to a suspended user to reactivate the user again.

iptive purposes.

rt of.

4 Issue 1January 2008 (61)

2786

Page 62

INSTALLATION

(5) Password Expir

If the password should expire after

set to zero, the password never expires.

If a user’s password expires they are forced to change the password before a real login is

Note:

accepted.

es

a certain number of days, you can define it here. If

(6) Status

The status of the user (new user, Active user or suspended).

User Types

The menu used to manage user types.

1

2

(1) User Type List

The list shows the currently available user types.

The first

The second column i

The last colu

(2) New

Create

Properties

Edits an existing user type.

The user type “Administrator” and “Guest” is read-only and cannot be modified or

deleted.

column (User Type) shows the name of the user type.

s an optional description of the user type.

mn indicates how many users is a part of the group.

s a new user type.

(

) 27864 Issue 1 January 2008

62

Page 63

Delete

Deletes the selected user type.

INSTALLATION

Note: You cannot delete a user type that still has users assigned to that group. If yo

delete a user type you must first modif

another group (or delete the users if desired).

User Type (Properties)

When creating a new user type (or editing an existing user type) the menu below is

shown.

y all the users that are a part of that group to be a part of

u wish to

1

2

3

4

(1) Name

Type in the name of the user type.

(2) Description

Type in an optional description. It is rec

(3) Allo

This is a list of all security items that a

those th

(4) Save

Saves the changes.

Toggle

Inserts (or removes) a checkmark on the security item that is selected.

wed to

at the user type should have access to.

ommended that this is used.

user can have access to. Insert a check mark on

4 Issue 1January 2008 (63)

2786

Page 64

INSTALLATION

2 3

Users and Passwords, Advanced

1

(1) Lock screen automatically

Specifies whether the screen should automatically lock (If a screen is locked, a valid

username and password ne

eds to be entered).

If a user is not authorised to the current screen, the screen will lock im

(2) Lock w

Specifies the number of minutes (of no operator action) before the scr

hen idle for

mediately.

een locks.

(3) Signing

The principle of signing is that whenever a critical operation is to take place, an

authorised user must approve (sign) this.

The button “Signing…” allows the administrator to define which actions require a

signature to execute.

(

64) 27864 Issue 1 January 2008

Page 65

INSTALLATION

1 2

Signing Setup

The screen below shows the menu used to modify which actions require a signature.

(1) List of signing operations

The list s

a signature is required.

(2) Edit

Edits the selected operation (see page 65).

The following screen is used to modify one signing operation

hows all operations that are viable for a signature. A check mark indicates that

1

2

3

4

(1) Default Name

The default name of the operation - all operations have a unique default name.

4 Issue 1January 2008 (65)

2786

Page 66

INSTALLATION

(2) Current Name

Use this edit field to give the operation another name that better suits your needs.

(3) Enable use of this signature

Indicates whether a signature is required to perform this operation.

Only an authorised user can sign for the operation (see pages

how to authorise a user).

60 and 62 for info on

(4) Use default name

Resets the current name of the operation to the default name.

Examples on Signing Setup in resp

The process of design approval uses the fo

(1) Draft (the designer can modify the design).

(2) Locked (the designer has locked the design)

(3) Reviewed (a reviewer has roughly approved the desi

(4) Approved (the person responsible for the designs have approved th

can now be printed by the normal o

alled (T ped an b

Once the approved state is reached the design cannot go back to the earlier states.

llowing states:

perator).

d can no longer (5) Rec he design is scrap e used).

ect to design approval.

gn)

e design, and it

Signing

operation

Lock Design for 9

Review

Review Desig 9 n

Lock and

Review

Approve Design 9 9

Lock, Review

and Approve

States used:

Draft & Approved

9

9

States used States used

Draft, Reviewed Draft, Locked,

& Approved: Reviewed &

Approved

(

66) 27864 Issue 1 January 2008

Page 67

Logging

3

The system has two logs.

INSTALLATION

• System

disabled)

• User log: Used for user related data.

log: Used by the system (for CFR21 Part 11, the system log cannot be

System Log

Basically anything that happens is logged (i.e. an error is acknowledged, a design is

being approved, a print job is started, user prompted information, modifying users etc.)

1

2

(1) LAN

Use the drop down to select the media to store the log file.

• LAN: The log file will be stored

below)

• Internal: The log file will be

location

• Disabled: No log file will be generated.

on a network share (using the path specified

stored on the internal memory card on a fixed

(2) Directory to store log file

(Only visible

The user may select the loc

by browsing the printer’s file system or simply by w

the file is to be saved.

if LAN is selected)

ation where the file is to be saved. This can either be done

riting the name of directory where

(3) Browse

(Only visible if LAN is selected)

Allows a search for the desired location to store the log file.

4 Issue 1January 2008 (67)

2786

Page 68

INSTALLATION

User Lo

The user log is an optional log (meaning that the user is free to decide whe

activate this log or not). Also the user has a choice of selecting which it

which to ignore. At the tim

printed information in a design.

g

ems to log and

e of writing, the user selectable items are all related to

1

3

ther to

2

4

(1) LAN

Use the drop down to select the media to store the log file.

• LAN:

• Internal: The log file will b

• Disabled: No log file will be generated.

The log file will be stored on a network share (using the path specified

below)

e stored on the internal memory card on a fixed

location

(2) Directory to store log file

(Only visible if LAN is selected)

The user may select the loc

by browsing the printer’s file system or

the file is to be saved.

ation where the file is to be saved. This can either be done

simply by writing the name of directory where

(3) Browse

(Only visible if LAN is selected)

Allows a search for the desired location to store the log file.

(4) Optional Events

Use the menu to select which of the optional events you wish to be logged.

(

68) 27864 Issue 1 January 2008

Page 69

INSTALLATION

2

User Optional Log Events

The User log has the option of logging

which of the optional events should be used.

some optional events. Use this menu to define

1

(1) Optio

The list shows the events that the user can choose to log.

nal Events to Log

(2) Toggle

Use the toggle button to set/remove a checkmark on the selected event.

In the example above, six different events are selected.

Please note that the log itself must also be activated for any log file to be generated.

4 Issue 1January 2008 (69)

2786

Page 70

THIS PAGE INTENTIONALLY LEFT BLANK

(

70) 27864 Issue 1 January 2008

Page 71

PART 3 : OPERAT

ION

CONTENTS

SOFTWARE ..................................................................................

User Interface..............................................................................

Components on the screen .........................................................

FIRMWARE VERSION ..................................................................

TOUCH SCREEN KEYBOARD .....................................................

Using the Keyboard.....................................................................

Single Line Edit ...........................................................................

Multi Line Edit.........................................................................................

Page

........... 73

...........73

...........73

........... 75

........... 76

...........76

...........77

78

Symbol Keyboard ........................................................................

USING THE EXPLORER...............................................................

Basic Principle.............................................................................

File Options .................................................................................

MAIN MENU ..................................................................................

PRINTING .....................................................................................

Locating the design .....................................................................

View Design ...........................................................................................

Print Screen.................................................................................

DESIGNING ..................................................................................

Getting Started ............................................................................

Edit Existing Design ....................................................................

The Design Screen......................................................................

Design Attributes .........................................................................

Fields......................................................................................................93

...........79

........... 80

...........80

...........82

........... 83

........... 84

...........84

...........86

........... 88

...........88

...........89

...........90

...........92

85

Inserting Fields .......................................................................................93

Editing Label Field..................................................................................94

Line ........................................................................................................95

27864 Issue 1January 2008 (71)

Page 72

Box .........................................................................................................96

Barcode.......................................................................................

Graphic........................................................................................

Text .............................................................................................

Variables .....................................................................................

Inserting variables .......................................................................

Edit a Variable.............................................................................

Sequential Variable .....................................................................

Real Time Clo ) ........................................................................ck (RTC

Shift Code ...................................................................................

Prompted Variable.......................................................................

Machine ID ..................................................................................

User ID ........................................................................................

Serial Variable.............................................................................

Macro Variable ............................................................................

Macro Output Variable ...............................................................

...........98

.........104

.........107

.........112

.........112

.........113

.........114

118

.........129

.........131

.........133

.........134

.........135

.........138

..........144

Database Variable................................................................................

Database Extract Variable...........................................................

SETTINGS.....................................................................................

Run..............................................................................................

.........149

......... 150

.........151

Run Settings Economy.........................................................................154

Run Settings Position ...........................................................................158

Run Settings Technical ........................................................................161

145

(

72) 27864 Issue 1 January 2008

Page 73

OPERATION

4

SOFTWA

RE

User Interface

This section describes the user interface of the printer.

Components on the screen

1

2

3

5

(1) System Menu

All screens (except pop up windows) have a System Menu butto

Menu button opens up the

Menu button once more.

The content of the System Menu depends on the actual context.

In this example the user can lock the sc

page 75) and change passwords.

(2) Help Button/Status in

The question mark is a built in help function. Pressing the question mark inverts the

question mark to indicate that the help function has been activated. Then press the

item for which you would like help.

If the screen has been locked, the question mark is replaced by a lock symbol to

indicate that the screen has been locked.

System Menu. To close the menu again, pres the System

reen, check firmware versions (see

dicator

n. Pressing the System

4 Issue 1January 2008 (73)

2786

Page 74

OPERATION

(3) Title Bar

Displays the name of the current screen. Sometimes the title bar contains in

about the current “operation (i.e

., in the file explorer the title will change to “Copy”

when a copy operation is in progress).

(4) Main area

This is where the actual screen information is placed.

formation

The main area us

ually contains pictures, combo boxes, buttons and text.

(5) Menu Row

ies of buttons that change to reflect the current situation.

A ser

A Cancel button will discard any unsaved i

screen.

A Save button will save any unsaved information.

An Ok button will save any unsaved information and revert to the previous screen.

nformation or take you to the previous

(

74) 27864 Issue 1 January 2008

Page 75

OPERATION

FIRMWARE VERSION

Example screen shot taken from firmware 2.12.

To check the actual firmware version on your controller, press the System menu (see

page 73)) followed by “Version”.

This will display the software version to which the V200 has been configur

We recommend that the user make a note

If the user should require assistance from the supplier, they will be asked to

some of the information contained in this menu. Moreover, the user should be aware

of possible updates to the printer software.

If the supplier has not automatically provided information about possible updates, it is

recommended that the user contact the supplier for updates to the printer software at

regular intervals.

of this information before using the printer.

ed.

provide

27864 Issue 1January 2008 (75)

Page 76

OPERATION

The syst

is pressed.

em has a built-in keyboard. The keyboard is activated when a string edit field

TOUCH SCREEN KEYBO

ARD

Using the Keyboard

The menu row of the keyboard can have the following option (depending on the

context).

Keyboard

Use this button to change the keyboard layout temporarily, or to hide th

for bette

The default keyboard can be configured according to the nationality of the country

involved.

To set up th yboard, refer to the following menu:

SETTINGS | System | International (Page 43)

r view of the text.

e ke

e keyboard

Clip board

Allows user to import text from a text file, cut, copy and paste.

Only available in a multi-line edit field (see page 78)

(

76)

27864 Issue 1 January 2008

Page 77

OPERATION

Single Line Edit

Used for inputting a single line of text; in this example a filename.

1

2

(1) Edit are

Used for inputting a single line of text. In this example a filename.

(2) Key

Use this button to change the keyboard layout temporarily, or to hide the keyboard

for better view of the text.

See page 76.

a

board

4 Issue 1January 2008 (77)

2786

Page 78

Multi Line Edit

OPERATION

Used for inputting text. Used for example when creating desi

Pressing the enter key on the keyboard inserts a line break in the text.

(1) Edit area

Used for inputting multiple lines of text. In this example a text fiel

gns.

d for a design.

1

2

(2) Clip

Allows user to import text from a text file, cut, copy and paste. See page 76

board

.

Variable

Allows the insertion of a variable a

t the current cursor position. Used when designing.

Keyboard

Use this button to change the keyboard layout temporarily, or to hide the keyboard

for better view of the text. See page 76.

(