Page 1

Domino Macrojet 2

Product Manual

Page 2

THIS PAGE INTENTIONALLY LEFT BLANK

(2) 20509 Issue 7 Jan 2018

Page 3

DOMINO MACROJET 2 PRINTER

PRODUCT MANUAL

This manual, Domino Part No. 20509, is for use in the operation and repair

of the Domino Macrojet 2 printer.

This manual is for use with all Macrojet printers manufactured on or after

1st Feb 2018 (from Serial Number L-21826 onwards).

For Pocket Terminal operating instructions, refer to Type 64 Terminal User's

Pocket Book, Part No 20524.

Users of this printer are warned that it is essential to read, understand and

act according to the information given in Part 1 : Health and Safety.

All rights reserved. No part of this publication may be reproduced, stored

on a retrieval system, or transmitted in any form, or by any means,

electronic, mechanical, photocopying, recording or otherwise, without the

prior permission of Domino Printing Sciences plc.

Domino Printing Sciences plc. has a policy of continuous product

improvement, the Company therefore reserves the right to modify the

specification contained in this manual without notice.

© Domino Printing Sciences plc. 2018.

For sales, service and inks please contact:

Domino UK Ltd. Domino North America

Bar Hill 1290 Lakeside Drive

Cambridge CB23 8TU Gurnee IL.60031

England U.S.A.

Tel: 01954 782551 Tel: 847 244 2501

Fax: 01954 782874 Fax: 847 244 1421

20509 Issue 7 Jan 2018 (3)

Page 4

CONTENTS of

EU DECLARATION OF CONFORMITY

No. Doc-0009847_R02

Manufacturers name: Domino UK Ltd.

Manufacturers Address: Bar Hill, Cambridge CB23 8TU

This declaration of conformity is issued under the sole responsibility

of the manufacturer.

Object of the declaration: Domino Macrojet, from serial number

L21548

The object of the declaration described above is in conformity with

the relevant Union harmonisation legislation:

2014/35/EU : Low Voltage Directive.

2014/30/EU : EMC Directive.

EN 60950-1:2006/A2:2013 Information technology equipment -

Safety - Part 1:General requirements.

EN 61000-6-2:2005 Electromagnetic compatibility (EMC).

Part 6-2 Generic standards -

Immunity for industrial environments.

EN 61000-6-4:2007/A1:2011 Electromagnetic compatibility (EMC).

Part 6-2 Generic standards -

Emission standard for industrial

environments.

(4) 20509 Issue 7 Jan 2018

Page 5

20509 Issue 7 Jan 2018 (5)

Page 6

FCC Notice

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own

expense.

Any changes or modifications not expressly approved by the manufacturer

could void the user's authority to operate the equipment.

(6) 20509 Issue 7 Jan 2018

Page 7

CONTENTS

PART 1 HEALTH AND SAFETY

PART 2 DESCRIPTION

PART 3 MAINTENANCE PROCEDURES

PART 4 FAULT FINDING AND REPAIR

PART A INSTALLATION

20509 Issue 7 Jan 2018 (7)

Page 8

AMENDMENT RECORD

Amendment Date

All Parts at Issue 1 Feb 91

Following pages amended to Issue 2.0: July 91

Preface-7, 1-4, 1-5, 3-32, 4-11, 4-13, 4-17, 5-17, A2, A20.

All pages at Issue 3 April 92

All pages at Issue 4 July 95

All pages at Issue 5 April 99

All pages at Issue 6 July 2011

All pages at Issue 7- Changes to voltage regulator Jan 2018

(8) 20509 Issue 7 Jan 2018

Page 9

PART 1 : HEALTH AND SAFETY

CONTENTS

Page

Introduction .......................................................................................... 1-3

Basic Requirements ......................................................................... 1-3

Storage ............................................................................................ 1-4

Fire Risk ........................................................................................... 1-4

Spillages and Disposal ..................................................................... 1-5

20509 Issue 7 Jan 2018 1-1

Page 10

HEALTH AND SAFETY

THIS PAGE INTENTIONALLY LEFT BLANK

1-2 20509 Issue 7 Jan 2018

Page 11

HEALTH AND SAFETY

INTRODUCTION

Domino supplies Safety Data Sheets (SDS) giving specific safety

information with each of its ink, make-up and wash fluids. There are also

warnings on each container. The following notes are for general guidance

only.

Basic Requirements

When used correctly, printing inks do not cause problems. However,

everybody using them should be familiar with the appropriate safety

standards and be aware of the precautions that should be taken. The

following are basic requirements:

• Proper standards of industrial practice relating to cleanliness and

tidiness must be maintained.

• Inks and their containers must be stored and handled with care.

• Do not smoke or allow naked flames (or other sources of ignition) in the

vicinity of any inks or solvents as this is highly dangerous.

• All who come into contact with inks must be properly instructed in their

use.

Directions for safe working practices vary according to the environment.

The following are broad principles so that necessary precautions may be

taken:

• Contact with the mouth must be avoided. Therefore eating, drinking or

smoking, or any personal habits or actions which may transfer ink to

the mouth, must be avoided.

• Contact with the eyes must be avoided. Suitable eye protection must

always be worn whenever there is any risk of splashing or misting. If

ink does get into the eyes, first aid treatment is to flood the affected

eye for 15 minutes with saline solution, (or clean water if saline solution

is not available), taking care not to allow the water to run into an

unaffected eye. Medical aid must be obtained immediately.

• Most inks contain solvents which may injure the skin. Good working

practice must always be employed and risk assessments carried out.

Safety Data Sheets are available that give advice on personal

protective equipment. Most gloves only offer limited and short term

exposure protection and must be changed after any splashing and on

a frequent basis.

• Many inks contain materials which vaporise easily and can be inhaled.

Good ventilation and extraction is necessary.

• Any used cleaning materials, e.g. rags, paper wipes, are a potential fire

hazard. They must be collected for safe disposal after use.

• After exposure to ink, all possible traces must be washed off as soon

as possible at the nearest washing facility.

20509 Issue 7 Jan 2018 1-3

Page 12

HEALTH AND SAFETY

Certain inks are allowed for use where they can be in indirect contact with

food. In these cases, the following precautions must be observed in

addition to those appropriate to hygiene:

• The inks must only be used in printers supplied from new for use with

these inks. Any repairs and replacements must use genuine, new and

unused spare parts.

• The inks must not be used in printers which have previously been

used, at any time, for any other purpose.

Storage

Printing inks must be stored in well-ventilated buildings, in areas set aside

for the purpose, chosen for safety in case of fire. Materials based on

volatile, flammable solvents must be stored in accordance with local

regulations.

Fire Risk

For an electrical fire, do not use water. If water must be used, such as in

the case of a Nitro-cellulose ink fire (see below) the power MUST BE

REMOVED first.

Many inks contain Nitro-cellulose as the binder and remain highly

flammable when dry. Observe all warnings given on the machine and the

following safety instructions:

• If there has been an accumulation of dried ink, do not use metal

scrapers to remove it, as they can produce sparks.

• If dry Nitro-cellulose based ink ignites, it will generate its own oxygen

and can only be extinguished by lowering the temperature with water.

• If a Nitro-cellulose fire occurs, ENSURE THAT THE ELECTRICAL

POWER IS IMMEDIATELY REMOVED FROM THE PRINTER BEFORE

water is used to extinguish the fire.

Fire risk is a most important consideration where printing inks are stored

and used. The degree of fire hazard will vary considerably from one type of

ink or wash to another.

Water-based inks will not burn, although inks based on water-alcohol

mixtures may burn if there is sufficient alcohol present. Prolonged exposure

of water-based systems to high temperatures may evaporate the water to

give a flammable residue.

Solvent-based inks offer a greater degree of hazard depending on the

particular solvent or solvent combination. When there is a particular hazard

the appropriate information is given on the SDS.

During maintenance, print drops may be collected in a container, such as a

beaker. It is essential that this container is made of conducting material and

is securely connected to ground/earth.

If there is a fire, there is a likelihood that dangerous fumes will arise from

printing inks. For this reason ink must be stored where it can be reached

1-4 20509 Issue 7 Jan 2018

Page 13

HEALTH AND SAFETY

quickly by the fire fighting service, and where it will not spread beyond the

store.

Spillages and Disposal

WARNING: Some dried inks are highly flammable. Clean up

all ink spillages immediately. Do not allow the

ink to dry or allow any build-up of dried ink spills.

Spillages must be cleaned up as soon as possible with the appropriate

solvent materials and with regard to the safety of personnel. Care must be

taken to prevent spillages or residue from cleaning up entering drains or

sewage systems.

Inks and associated fluids are materials which conduct electricity.

Therefore, power to the printer must be switched off while spillages inside

the printer cabinet are being cleaned up.

Printing inks and associated fluids must not be treated as ordinary waste.

They must be disposed of using approved methods according to local

regulations.

20509 Issue 7 Jan 2018 1-5

Page 14

HEALTH AND SAFETY

THIS PAGE INTENTIONALLY LEFT BLANK

1-6 20509 Issue 7 Jan 2018

Page 15

DESCRIPTION

PART 2 : DESCRIPTION

CONTENTS

Introduction .......................................................................................... 2-4

Printer Specification ............................................................................. 2-5

Print Heads ...................................................................................... 2-5

Print Characteristics: ........................................................................ 2-5

Cabinet ............................................................................................ 2-5

Print Heads ...................................................................................... 2-5

Environment ..................................................................................... 2-6

Electrical Requirements ................................................................... 2-6

Supply Fuse Rating .......................................................................... 2-6

Inputs ............................................................................................... 2-6

External Alarms ................................................................................ 2-6

Print Head ............................................................................................. 2-7

Control Cabinet .................................................................................... 2-11

Ink System ............................................................................................ 2-12

General ............................................................................................. 2-12

Ink System ............................................................................................ 2-14

Electronic System ................................................................................. 2-16

General ............................................................................................. 2-16

Controls and Indicators ................................................................... 2-17

Universal Serial Interface PCB ......................................................... 2-18

Solenoid Driver PCB ........................................................................ 2-18

Low Voltage Power Supply PCB ..................................................... 2-18

Motherboard .................................................................................... 2-20

Product Detector ............................................................................. 2-20

Shaft Encoder (Optional) .................................................................. 2-20

External Connections .......................................................................... 2-22

Product Detector and Shaft Encoder Connectors (5-pin AXR) ........ 2-22

Power Connector ............................................................................ 2-22

Pocket Terminal Connector (Data Entry 25-way D Connector) ....... 2-23

External Alarms ............................................................................... 2-23

Page

20509 Issue 7 Jan 2018 2-1

Page 16

DESCRIPTION

This page intentionally left blank

2-2 20509 Issue 7 Jan 2018

Page 17

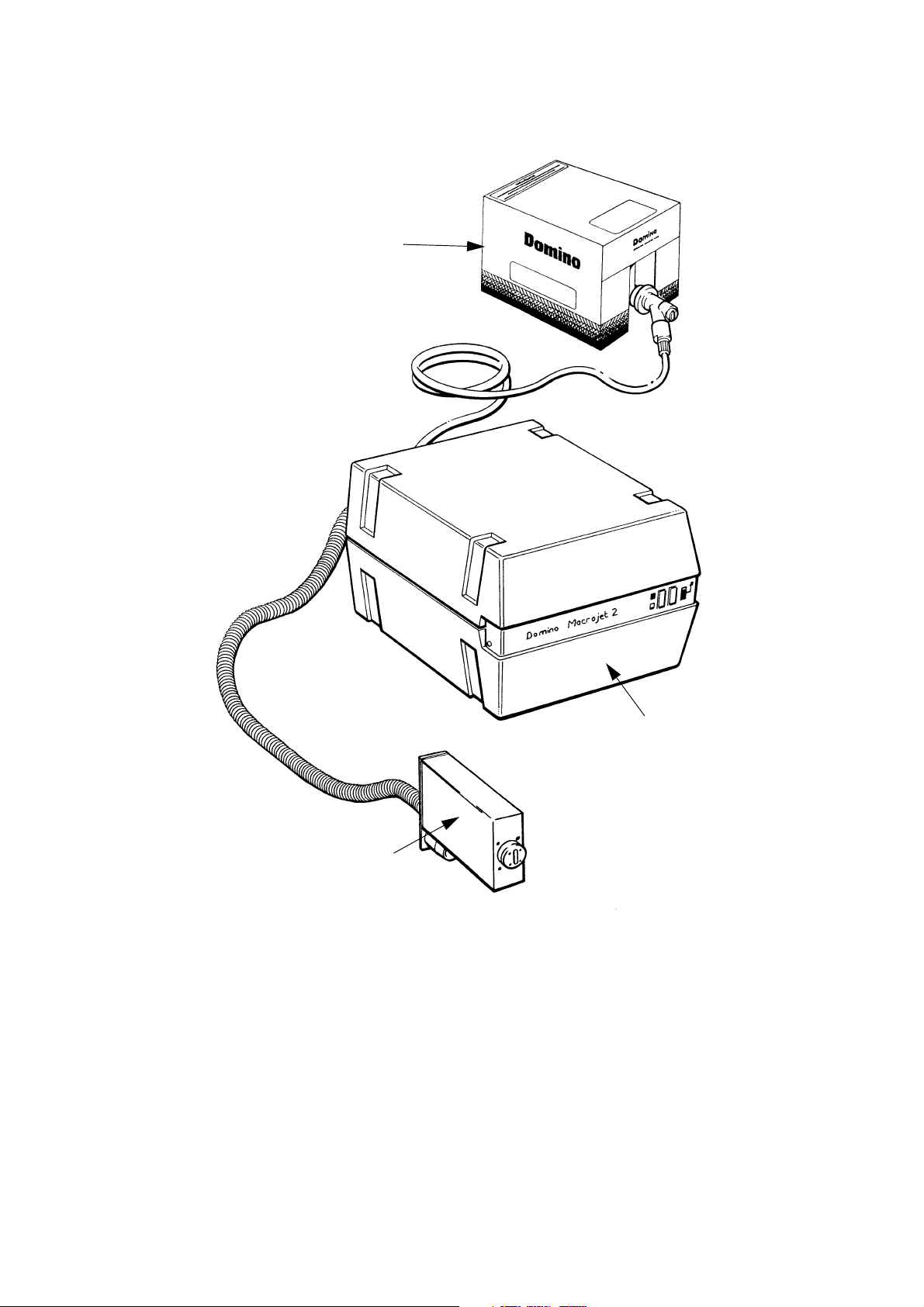

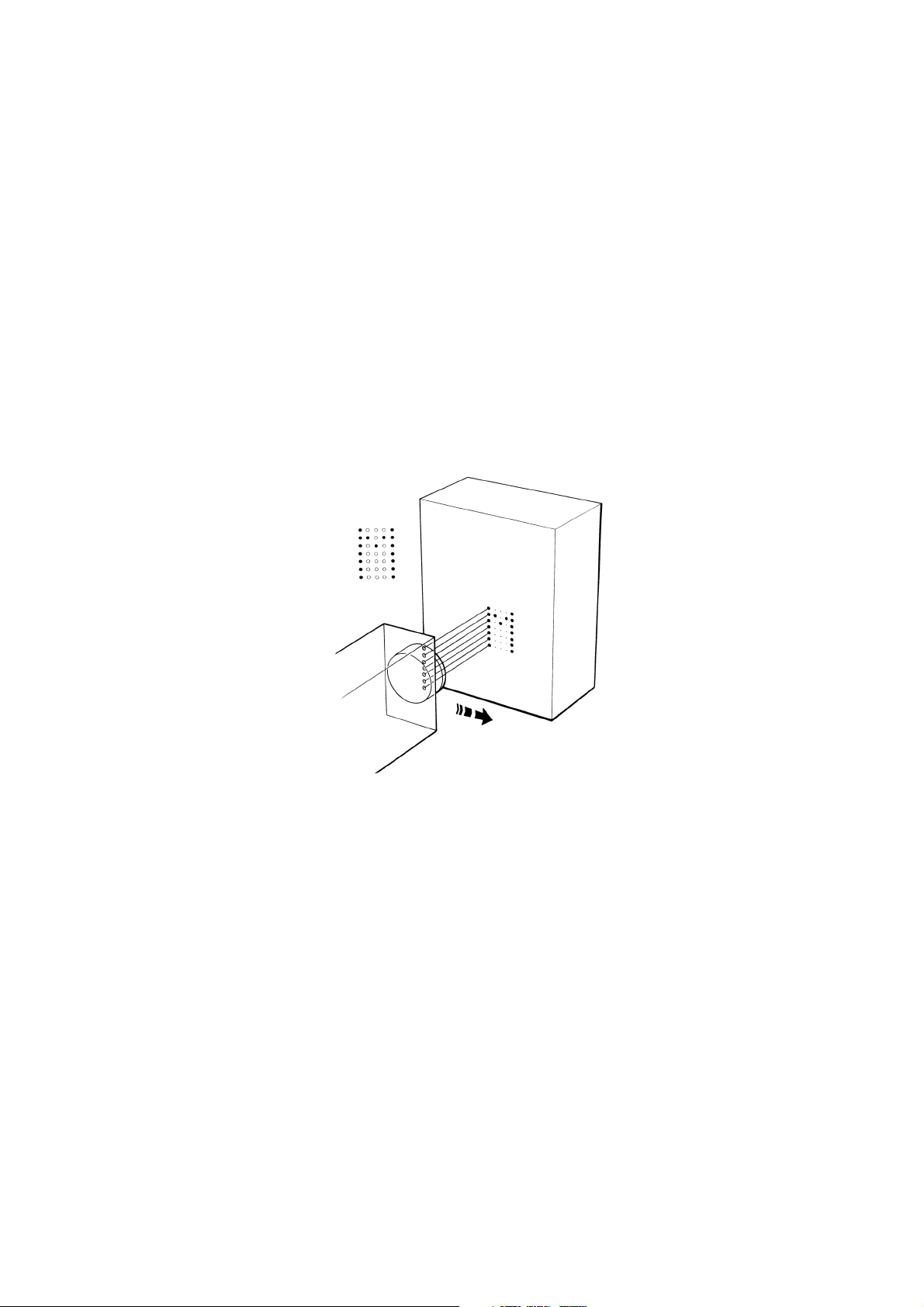

Macrojet 2 Large Character Printer

TP1006_1

Ink Box

Control Cabinet

Print Head

DESCRIPTION

20509 Issue 7 Jan 2018 2-3

Page 18

DESCRIPTION

INTRODUCTION

The Macrojet 2 large character printer consists of:

• The print head (up to four can be fitted to one cabinet)

• The control cabinet

• The product detector (one or two can be fitted)

• The disposable ink supply container.

Print messages are normally entered using a Domino Pocket Terminal.

Print heads can be supplied to print with either 7 or 16 ink drops and in a

range of character heights (see

assembly connected to the cabinet by a flexible conduit and will work in

any position. Print heads can be added or changed without difficulty.

The control cabinet contains an ink system supplying ink to the print

head(s) and an electronics control system. Controls and external

connections are grouped on a panel at the rear.

The product detector is mounted on the line and senses the product as it

approaches the print head. There are three optional types: two are infra-red

beams and a third works by metal detection.

page 2-7). Each is a separate stainless steel

Ink is supplied in a disposable 5 litre bag-in-box ink container, connected to

the printer by a Quick Connect/Disconnect (QCD) connector.

Messages to be printed are normally entered as serial digital data from a

Domino Pocket Terminal, but it is also possible to control the printer from a

separate computer system (details from Domino).

The printer contains a set of separate auxiliary alarm contacts which can be

connected to external indicators or other equipment. An optional alarm

beacon is also available to show the printer status.

Another option is a shaft encoder which allows the printer to follow line

speed variations. This includes the slowing down and speeding up

involved in line stop and start.

2-4 20509 Issue 7 Jan 2018

Page 19

DESCRIPTION

PRINTER SPECIFICATION

Print Heads

7 or 16 drop nozzle heads. Multiple heads in combinations of:

• Up to 4 heads each of 7 nozzle size, or

• Up to 2 heads each of 16 nozzle size, or

• 1 head of 16 nozzle size and 1 head of 7 nozzle size, or

• 1 head of 16 nozzle size and 2 heads of 7 nozzle size.

Print Characteristics:

Character set: 96 ASCII, printed as 7x5 or 16x10 matrix.

Character height: 8mm (5x5 matrix 12 and 32 only)

12, 16, 20, (7 x 5 matrix).

12mm Tray Coder

32mm (16 x 10 matrix)

or 2 lines 12mm (7x5 matrix).

50mm (16 x 10 matrix)

or 2 lines 20mm (7x5 matrix).

Maximum print speed: 100 metres/second at 12.5mm Character width ch

Messages: Up to 40 messages of up to 200 characters length

Cabinet

Dimensions: Width: 394mm (15.51")

Depth: 443mm (17.44")

Height: 282mm (11.1")

Weight: 24.5kg (54lb)

Print Heads

Spacing from print surface: 25mm max.

Conduit Length: 4m, 8m.

7 Nozzle Head:

Height: 85mm

Width: 70mm

Depth: 223mm (12, 16 and 20)

Depth: 278mm (low level 12mm)

16 Nozzle Head:

Height: 111mm

Width: 70mm

Depth: 269mm

20509 Issue 7 Jan 2018 2-5

Page 20

DESCRIPTION

Environment

Temperature Range

+5º to +40ºC (42ºF to 104ºF)

(Operating):

Humidity: 10 - 90% RH (non-condensing)

Electrical Requirements

Supply Voltage: 110V, 130V, 150V, 220V, 240V, 260V, single

phase with ground.

Power: 300VA

Supply frequency: 50/60Hz

Supply Fuse Rating

Power switch: 2A (220-260V)

4A (110 - 150V)

Inputs

Product Detector: 12V, 100mA dc supply to sensor, 5 pin AXR

connector.

Shaft Encoder (print rate

control):

Data Interface: RS232 or 20mA current loop

suitable for open collectors or TTL encoders.

Encoder power supply link selectable, +5V

or +12V. 5 pin AXR connector.

75-19,200 Baud, selectable.

External Alarms

One output via changeover

relay contacts:

2.5A at 260V max. Non inductive.

2-6 20509 Issue 7 Jan 2018

Page 21

DESCRIPTION

TP1290_1

PRINT HEAD

Ink jet printing does not require contact with the print surface. It is therefore

particularly suitable for printing on rough, irregular, soft or other "difficult"

surfaces.

Macrojet 2 is a valve jet printer. Ink is maintained under pressure behind a

closed nozzle or valve. When the valve is opened for a short time, ink

emerges as a drop and is propelled by the pressure towards the print

surface or substrate. Drops are, therefore, only produced as required in

what is known as Drop-on-Demand printing.

Macrojet 2 print heads have either 7 or 16 nozzles producing a line of drops

called a stroke on the print surface. As the print surface moves past the

head, successive strokes containing different combinations of ink drops

build up the character in the form of a dot matrix. This is best understood

by studying the illustration below.

A dot matrix is specified by the number of dots in a stroke and the number

of strokes making up a single character (for example, the illustration shows

a 7x5 matrix).

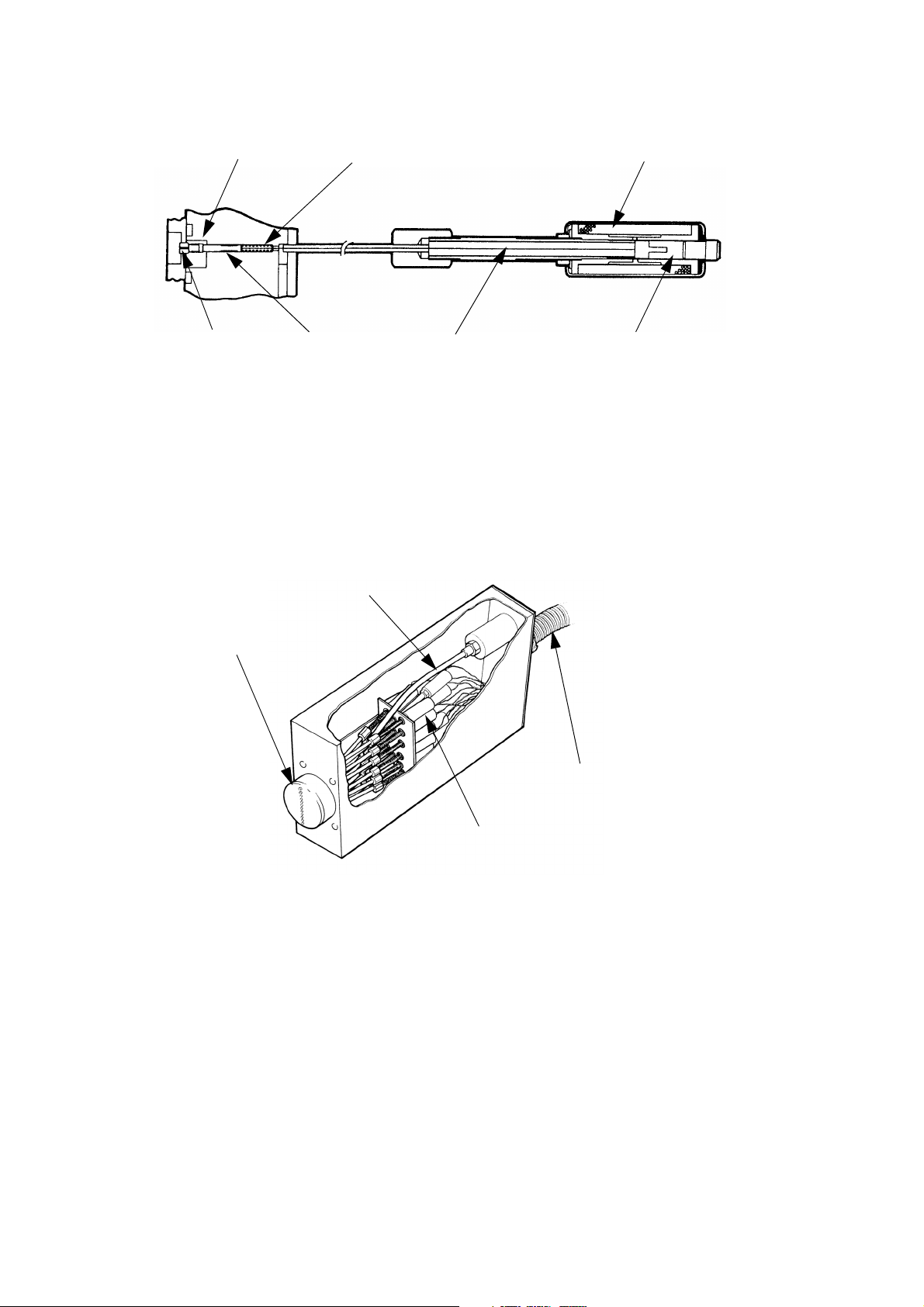

The Macrojet print head has, at the front, a nozzle plate with either 7 or 16

nozzles. Ink is supplied under pressure to a manifold behind the nozzle

plate. A plunger, fitted with a rubber slug on its tip, is held against each

nozzle by a spring. The plunger is connected by a wire to a metal slug

sitting part of the way into a solenoid. When the solenoid is energised, the

slug is pulled into the centre of the solenoid. This pulls back the plunger,

opening the nozzle. When the solenoid is de-energised, the spring pushes

the plunger back to close the nozzle.

20509 Issue 7 Jan 2018 2-7

Page 22

DESCRIPTION

TP1291_1

Plunger Slug Slug Return Spring Solenoid

Nozzle Plunger Control Wire Solenoid Slug

TP1380_1

Nozzle Plate

Feed Pipe

Solenoids

Conduit

The Print Head

The ink that emerges from the nozzle forms a drop, ejected onto the print

surface by the ink pressure. Drop size, density and quality of the print is

controlled by three factors:

• The time for which the solenoid is energized

• The position of the slug when the solenoid is de-energized

• The ink pressure.

Ink flow into the head can be shut off with the print head valve. A purge

switch operates all the nozzles to remove any air (see

The print head is mounted at right angles to the print surface, at a distance

of 3 to 5mm for best print quality. At distances outside these limits, print

quality will be reduced.

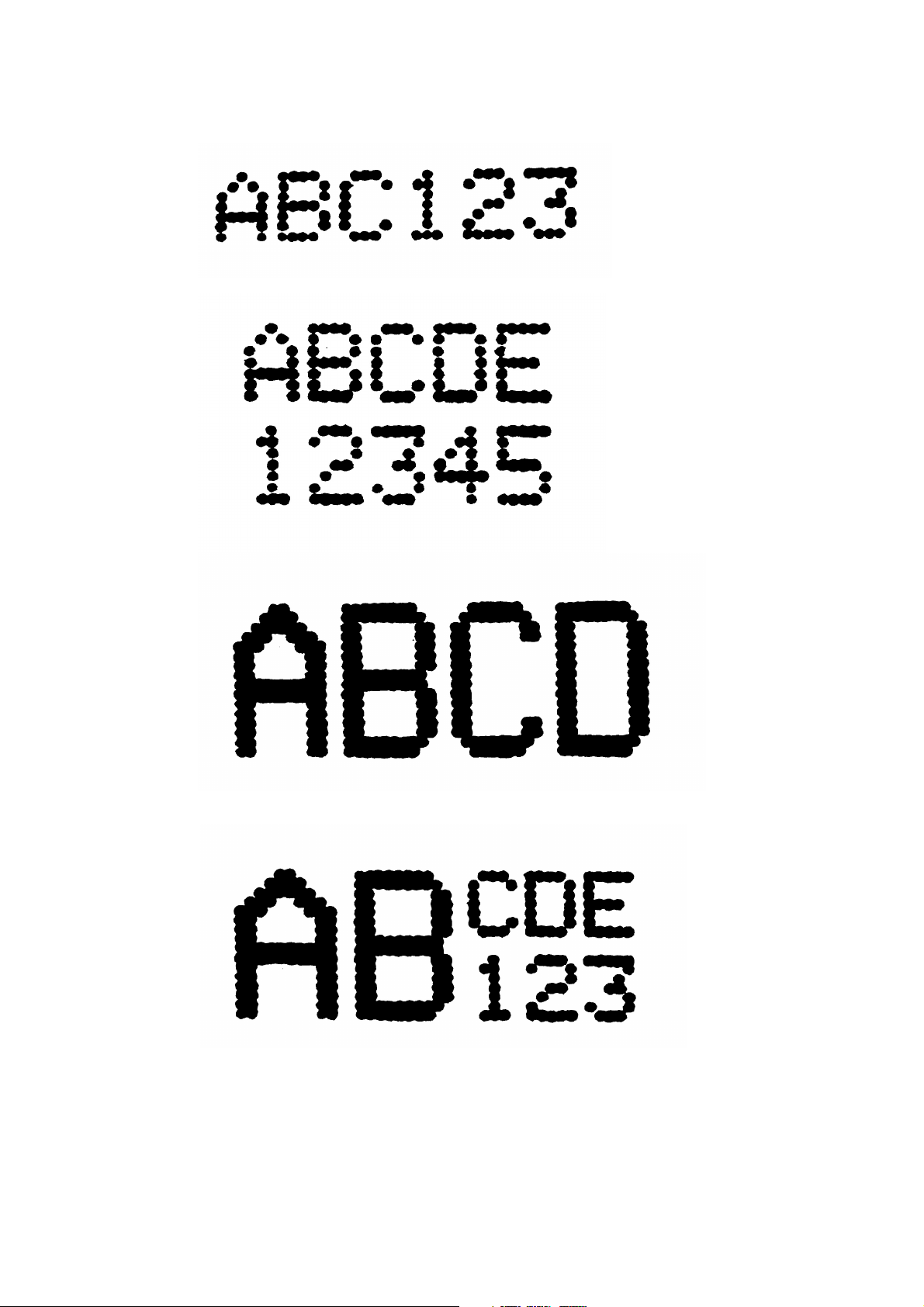

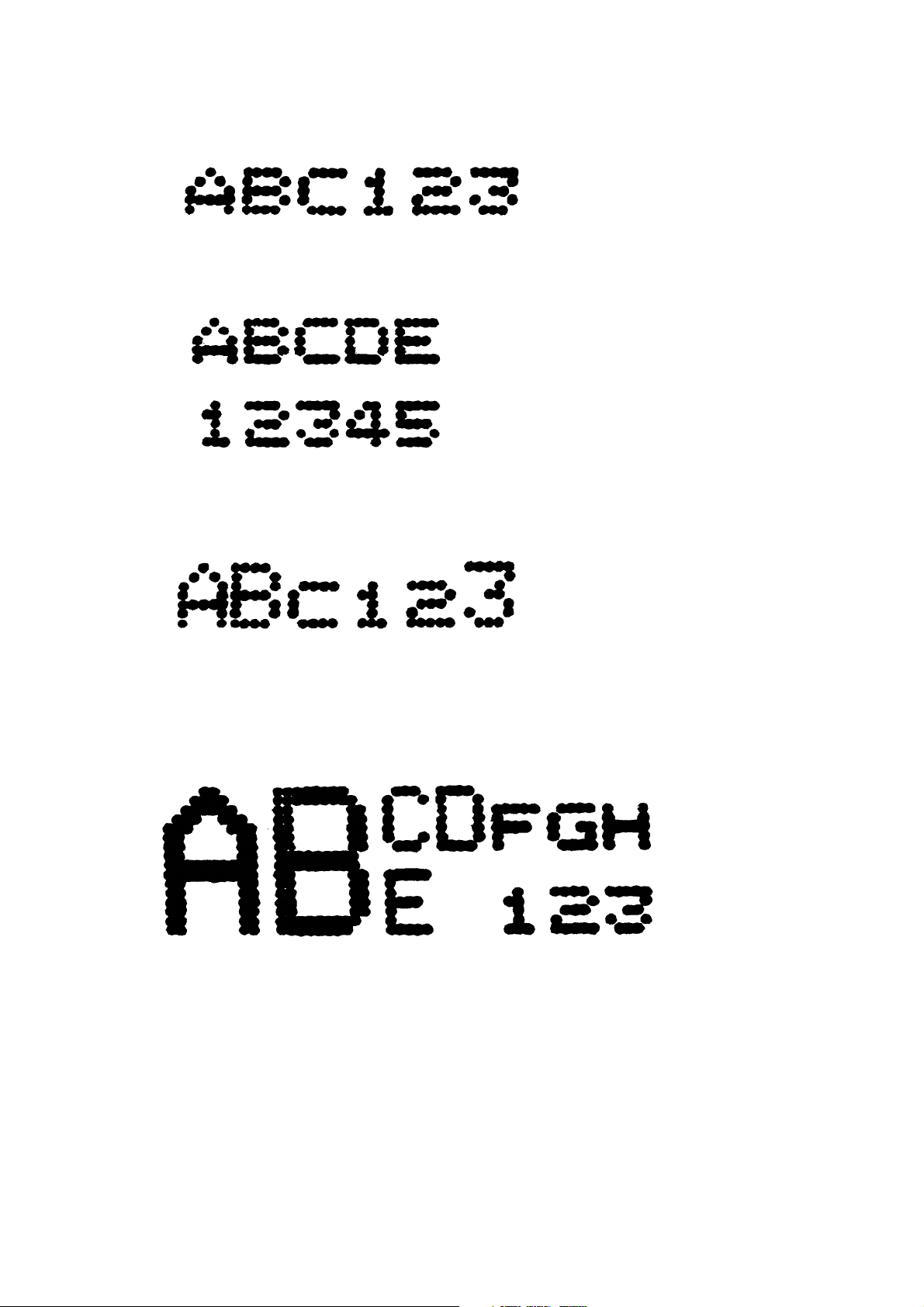

Macrojet 2 has a number of print head and print options. The print options

are shown in the diagrams (see

will print only the single line options. A 16 drop head is required to print the

page 2-9 and page 2-10). A 7 drop head

twinline and large options. Up to four lines of print (7x5), by way of four 7

drop heads or two 16 drop heads, can be supplied from a single control

cabinet

page 3-4).

2-8 20509 Issue 7 Jan 2018

Page 23

TP1410_1

Single line 7 x 5 matrix.

Standard Character Printing Styles

TP1412_1

TP1413_1

TP1414_1

Twin line 7 x 5 matrix.

Single line

16 x 10

matrix.

Single line 16 x

10 and 7 x 5

matrix (top or

bottom line).

DESCRIPTION

20509 Issue 7 Jan 2018 2-9

Page 24

TP1415_1

Single line 5 x 5 matrix.

Optional Character Printing Styles

TP1417_1

TP1418_1

TP1419_1

Twin line 5 x 5 matrix.

Single line 5

x 5 and 7 x 5

matrix.

Single line 16 x 10 with single

line 7 x 5 and single line 5 x 5

(top or bottom line)

DESCRIPTION

2-10 20509 Issue 7 Jan 2018

Page 25

DESCRIPTION

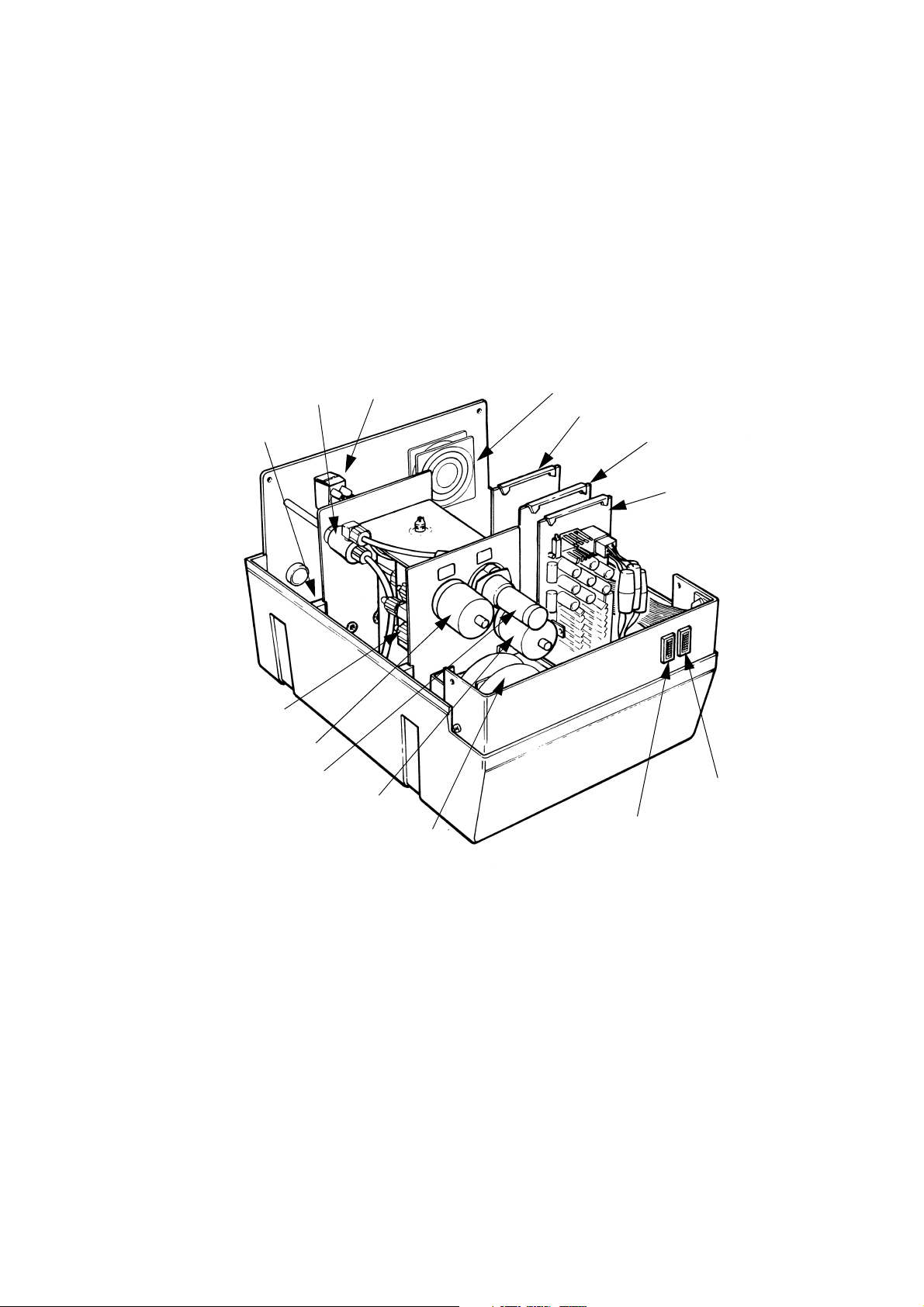

Control Cabinet

TP1039_3

Accumulator

Bleed

Valve

Pump

Switch

Inhibit

Fan

Solenoid Driver

Serial Interface

Board

Low Voltage

PSU

Power On

Indicator

Ink Container

Empty Indicator

Power Transformer

Vacuum Switch

Pump

Pressure Switch

Manifold

CONTROL CABINET

The control cabinet is moulded in a structural foam material which is

extremely strong, light and easy to clean. It is sprayed internally and

externally with epoxy paint. A special coating providing RF shielding is also

applied to the internal surfaces.

The cabinet consists of a base, holding the ink and electronics systems,

and a cover fitted over the top. A panel carrying the controls and

connectors is fitted into the rear of the cabinet. The panel is also fitted with

a fan that prevents an accumulation of fumes in the cabinet. The air is

exhausted out of holes in the base under the transformer.

The ink and electronics systems occupy separate halves of the base and a

bulkhead formed in the cover drops between them. Removing four screws

and lifting the cover provides access to the whole cabinet.

20509 Issue 7 Jan 2018 2-11

Page 26

DESCRIPTION

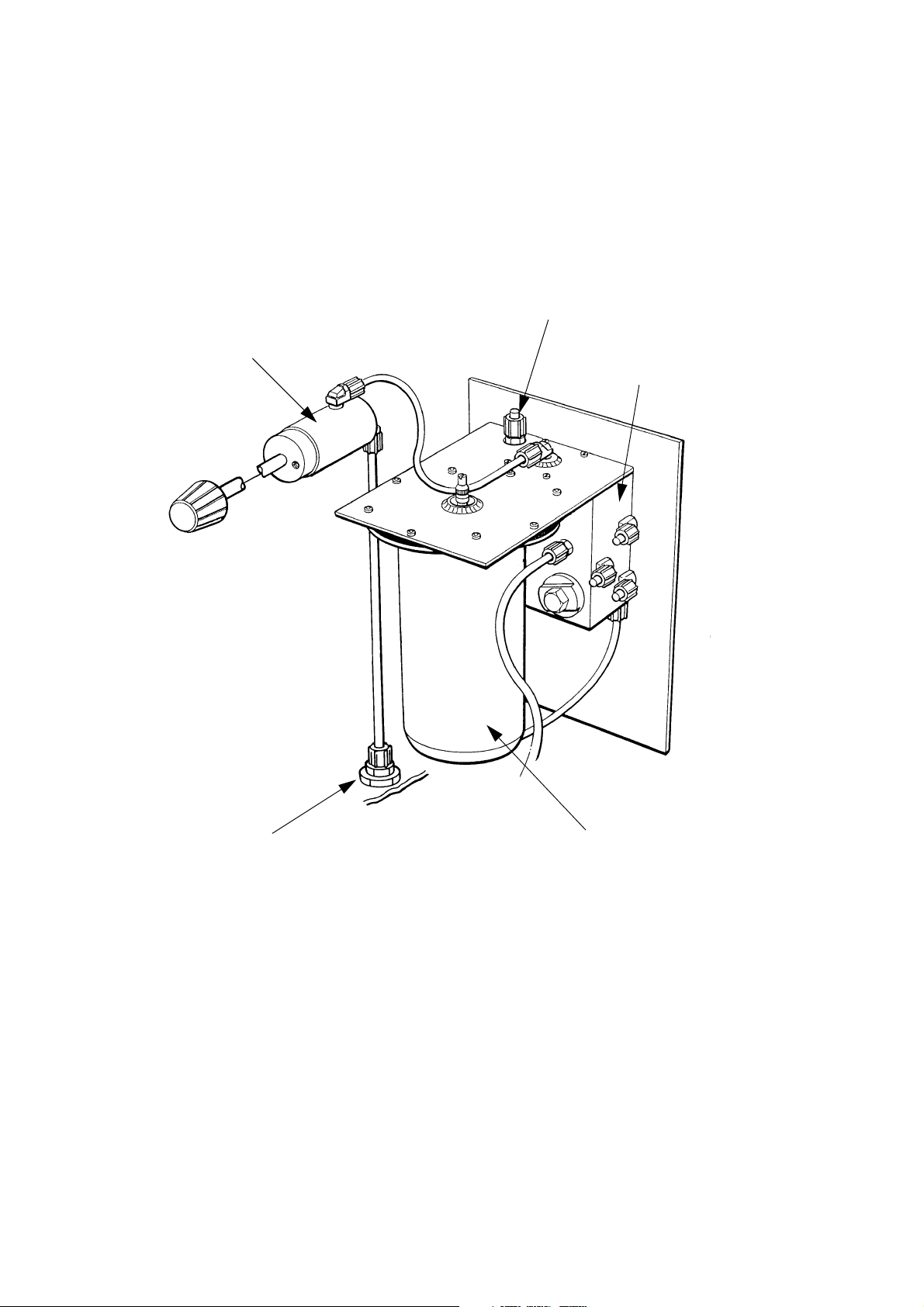

Ink System Components

TP1385_2

Vent

Bleed Valve

Priming Port

Ink Manifold

Accumulator

INK SYSTEM

General

The ink system draws in ink from the ink supply container and supplies it

under pressure to the print head. The system is governed by switches

which control the ink pressure and detect when the ink container is empty.

2-12 20509 Issue 7 Jan 2018

Page 27

Ink System Diagram

M

Accumulator

Bleed

Valve

Vent

Print Head

Valve

Print Head

Main Cabinet

Ink

Container

QCD

Connector

Vacuum Switch

Filter

Spring

NRV

Print Head

Manifold

Solenoids

Pressure Switch

Choke

Bleed

Reservoir

NRV

DESCRIPTION

20509 Issue 7 Jan 2018 2-13

Page 28

DESCRIPTION

INK SYSTEM

The ink system is shown schematically in the diagram opposite. Fresh ink

is contained in a 5 litre disposable ink container, which consists of a flexible

bag protected by a robust cardboard box. The ink container is connected

using a special quick QCD connector.

A gear pump draws ink into the system through a 20 micron filter and spring

Non-Return Valve (NRV) and pumps it into the bleed reservoir. Residual air

collects in the reservoir and opening the bleed valve allows this air to

escape through the vent in the cabinet floor. A by-pass loop, containing a

choke to reduce the flow rate, is connected from the bleed reservoir to the

inlet side of the gear pump. This ensures that the pump remains primed if

air is drawn in through the ink feed pipe.

Ink from the bleed reservoir is forced through a plain NRV into the

accumulator which holds the working reservoir of ink for the print heads.

The accumulator has a flexible diaphragm clamped between the

accumulator body and the mounting flange on the steel frame. The

diaphragm is shaped to contain a volume of air. The mounting flange is

sealed and the only access into the diaphragm is an air valve provided for

maintenance purposes.

As ink is pumped into the accumulator it compresses the air sealed inside

the diaphragm. When the ink is pressurised to 7psi (0.48 Bar) the pressure

switch trips and switches the pump off. The plain NRV closes to maintain

the pressure in the accumulator and re-opens only when the pump next

runs. As ink from the accumulator is used up in printing, the pressure

drops. At approximately 5psi (0.35 Bar) the pressure switch resets,

switching on the pump. The accumulator has a capacity of approximately

70ml, provided by compressing the air behind the diaphragm.

Pressurised ink is fed from the accumulator, through the print head hand

valve and the conduit feed pipe, to the print head manifold behind the

nozzle plate.

When the pump is running and the ink supply container becomes empty, a

vacuum is generated in the feed line. At 8 - 10 inches of mercury (2.76 -

3.45 kilogrammes per sq cm) the vacuum switch trips, switching off the

pump and lighting the Ink Container Empty indicator. The spring NRV shuts

off, and maintains the vacuum.

2-14 20509 Issue 7 Jan 2018

Page 29

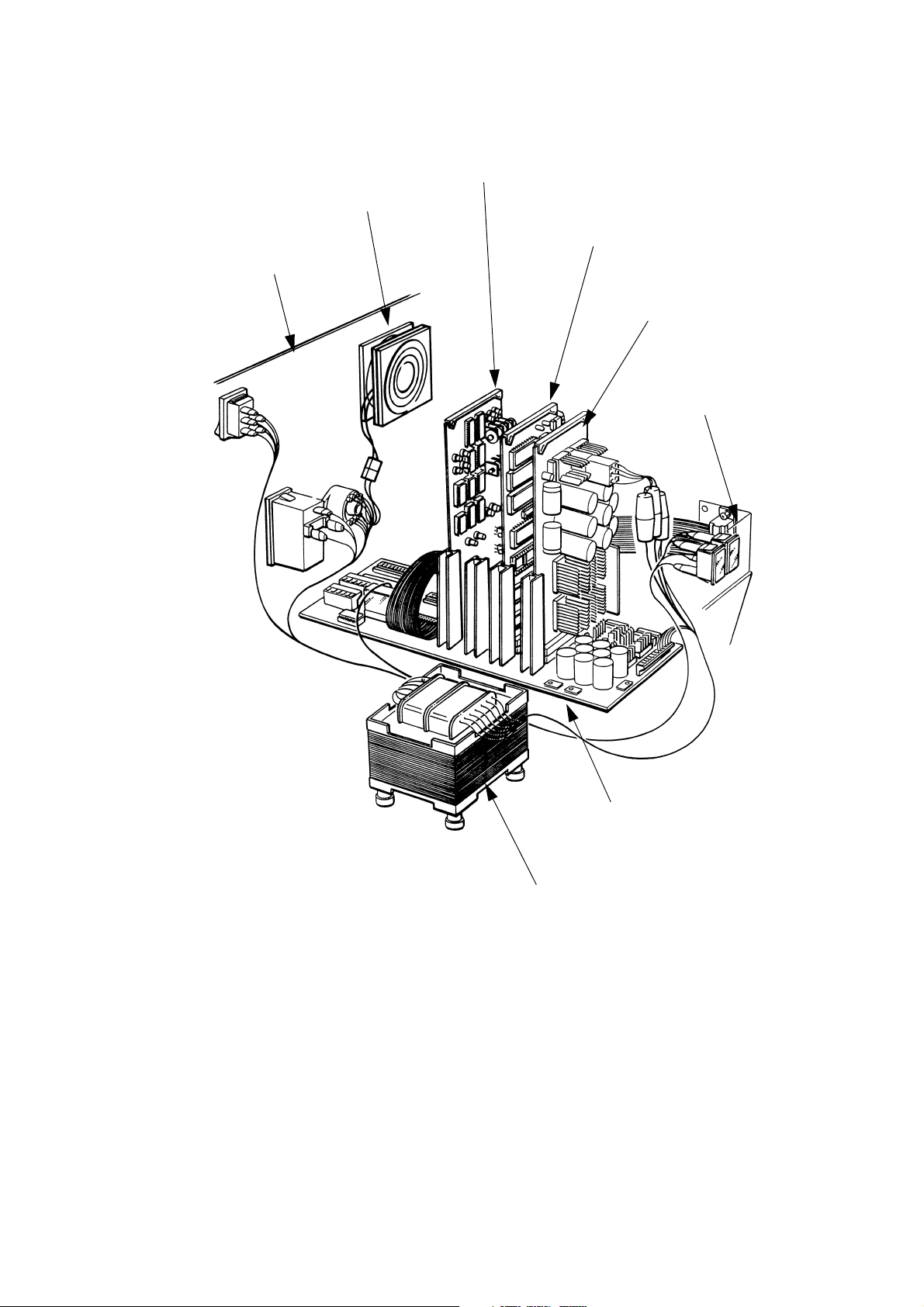

Electronics Components

TP1390_2

Power Transformer

Motherboard

Front Panel

Assembly

Low Voltage

Power Supply

PCB

Universal Serial

Interface PCB

Solenoid Driver

PCB

Fan

Rear Panel

Assembly

DESCRIPTION

20509 Issue 7 Jan 2018 2-15

Page 30

DESCRIPTION

ELECTRONIC SYSTEM

General

The electronic system contains a microprocessor, which controls the

message data input, processing and printing. It also contains circuits to

drive the solenoids in the print head and to generate d.c. power supplies.

The system consists of the following Printed Circuit Boards (PCBs):

• Universal Serial Interface

• Solenoid Driver (one or two depending on the number of print heads)

•Low Voltage Power Supply

• Motherboard.

The motherboard lies flat in the base moulding. The PCBs are plugged

vertically into it and are held in place by a foam strip in the top cover. A

single power transformer provides the low voltages required by the power

supply circuits.

The product detector is part of the electronics system. It detects the

product as it approaches the print head and provides a Print Go signal to

the printer. Macrojet 2 is able to use two detectors, with assignment of

print heads to detectors being set up with the Pocket Terminal. For details

see Pocket Terminal User's Guide, Part Number 20524.

Having been detected, the product still needs time to pass under the head

and reach the correct position for printing. The electronics system allows

for this with the Print Go delay, which is also set up using the Pocket

Term in al .

A shaft encoder is an option which enables the printer to follow line speed

variations. It has been explained how characters are printed by strokes, as

the product passes the head. If the stroke rate is fixed and the product

speed changes, the strokes will become closer or further apart. The result

is a change in the character shape. The Print Go delay is also measured in

strokes and a fixed stroke rate gives a fixed delay. Changes in the product

speed will, result in a change in the position of the printed message.

A shaft encoder is attached to the line and follows the line speed. Using it

to control the stroke rate eliminates the variations in character shape and

message position.

2-16 20509 Issue 7 Jan 2018

Page 31

DESCRIPTION

Controls and Indicators

TP0150_1

Power On

Indicator

Ink Container

Empty Indicator

Character Width

Control

Fan

Intensity

Control

External

Connection

Cable Glands

Pump Inhibi t

Switch

Ink System

Bleed Valve

Product

Detector

Inputs

Shaft

Encoder

Input

Voltage

Selector

Power On/

Off Switch

Print Head

Conduit

Holes

TP0151_1

2A (220 - 260V)

4A (110 - 150V)

2A

4A

Controls and Indicators

Controls and indicators are shown in the diagram below. The supply power

on/off switch also contains a fuse (see

the printer together with any equipment connected to the Auxiliary Power

connector block. The voltage selector switch must be set to the nearest

value to the input supply.

page 4-30) which is rated to support

The pump maintaining ink pressure is controlled by the ink pressure switch.

The pump therefore only operates intermittently. It may be necessary to

ensure that the pump does not operate at all (for example, during

maintenance). The rear panel therefore carries a Pump Inhibit switch,

containing an indicator which goes out when the switch is inhibiting the

pump and the printer is not completely ready for use.

20509 Issue 7 Jan 2018 2-17

Page 32

DESCRIPTION

Universal Serial Interface PCB

The Universal Serial Interface PCB contains a microprocessor which

controls both data input and printing routines. It receives input data in the

form of serial characters and control codes, and converts it into dot matrix

patterns for output to the Solenoid Driver PCB. Characters to be printed

are converted into dot matrix form by character set look up tables

contained in Electronically Programmable Read Only Memories (EPROMs).

Print commands such as bold or reversed are stored in the Random Access

Memories (RAM) along with the dot matrix for that character.

The Universal Serial Interface PCB contains circuits for the RS232 interface,

real time clock, stroke generator, product detector inputs and printed stroke

output. When Macrojet 2 is powered down, a battery backup automatically

maintains the RAM and clock in standby.

This PCB has links and switches that need to be set up to match the printer

system and application (see

page 4-31 and page A-8).

Solenoid Driver PCB

This PCB accepts parallel dot matrix information and amplifies it into

signals suitable to drive the print head solenoids. Each solenoid driver PCB

can drive up to sixteen solenoids. The PCB is arranged as two identical

channels of eight lines. The channels can run independently and drive one

or two 7 drop heads. Alternatively, the two channels can drive one 16 drop

head. Selector links allow one intensity control to govern all sixteen

nozzles. Data is input to the board in 8-bit patterns. With a 16 drop head,

the first 8- bit pattern controls the upper eight nozzles.

Low Voltage Power Supply PCB

This PCB assembly provides the +5V, +12V regulated and +10V

unregulated supplies to the electronics system. The +5V supply powers all

the logic and microprocessor circuits. The +12V supply is used to power

the RS232 circuits, the stroke generator, product detector and the shaft

encoder. The +10V unregulated supply is used to charge the Universal

Serial Interface PCB battery. It is also used to power the power fail detect

circuit which detects the onset of a power failure.

2-18 20509 Issue 7 Jan 2018

Page 33

The Electronic Control System

Universal Serial Interface PCB

Character

Width

Control

Shaft

Encoder

(Optional)

Product

Detector

Pocket

Termi na l

Stroke

Generator

Micro

Processor

Memory

Battery

Backup

Real Time

Clock

Input/

Output

Latch

Solenoid

Driver Pulse

Generator

Store

Gate

Gate

Solenoid

Solenoid

Solenoids

Solenoids

Low Voltage Power Supply PCB

+5V

+12V

+10V

External

Alarms

Intensity

Control

DESCRIPTION

20509 Issue 7 Jan 2018 2-19

Page 34

DESCRIPTION

Motherboard

The motherboard provides the interconnections between the PCBs in the

control system. It also carries all the input/output connections for the print

heads, data input, product detector, vacuum switch and external alarm

relay. The connections for one print head are all contained in a single "D"

connector. There are, therefore, four of these connectors on the

motherboard. Associated with each connector is a dual-in-line (DIL) switch

controlling the aspect ratio of the characters printed by the head.

Four rectifier/capacitor circuits on the motherboard, supplied from windings

on the power transformer, provide the 24V power supplies for the solenoid

drivers.

The motherboard has connections and switches that need to be set up to

match the printer system and application (see

page 4-38 and page A-8).

Product Detector

With a fixed product speed past the print head, the Macrojet 2 may be set

up to use a fixed print speed and operate with one of the following types of

detector:

• Photocell Detector (Reflective)

• Photocell Detector (Proximity)

• Inductive Proximity Detector.

Photocell detector (Reflective) uses a reflector mounted on the opposite

side of the product line. A light beam from the detector is returned by the

reflector to the photocell in the detector. The control circuits detect when

the reflected beam is broken (or restored after interruption) and generates

the print go signal. A time delay will normally still exist between detection

of the product and its arrival in the exact position required for printing. A

compensating delay is, therefore, entered as part of the input print data.

Photocell Detector (Proximity) does not use a reflector. Product detection

depends on reflection from the body of the product or when the edges of

light or dark markings on the product are detected.

The proximity detector senses metal products when they come within

range. This detector normally requires to be very close to the product. The

exact distance is usually dependent upon the material from which the

product is made.

The product detector must be positioned "up-stream" from the print head.

A time delay is necessary to allow the product to reach the print head and

the printing to be placed correctly. This is set up in the printer as the print

go delay (part of the Pocket Terminal input data).

Shaft Encoder (Optional)

With a fixed print speed, if the line speeds up, the printing will be spaced

further apart. If the line slows down, the printing will close up. This

problem is avoided by fitting a shaft encoder.

2-20 20509 Issue 7 Jan 2018

Page 35

DESCRIPTION

The shaft encoder is attached to the product line and produces electrical

pulses as it revolves. There are a fixed number of pulses to each revolution.

The printer is set up so that character stroke rate or print speed is

controlled by these pulses instead of by the internal character width control

(see LK6 on

page 4-35). As the line speeds up or slows down, the shaft

encoder pulses change speed and change the speed of printing.

The exact type of shaft encoder depends upon the installation and more

details of the factors to be considered are given in Appendix A.

20509 Issue 7 Jan 2018 2-21

Page 36

DESCRIPTION

EXTERNAL CONNECTIONS

Product Detector and Shaft Encoder Connectors

(5-pin AXR)

There are three connectors SK1, SK2 and SK3. Connectors SK1 and SK3

are wired with the same connections so that a product detector can be

connected into either connector and a shaft encoder connected into the

other. Alternatively, SK1 and SK3 can be used to loop a single product

detector to another Macrojet 2 in an extended system. Where a second

product detector is used this must be connected into SK2. Pin connections

are given below:

SK1 SK2 SK3 Signal

1 1 1 0V

2 2 2 Shaft Encoder

3 - 3 Print Go 1

- 3 - Print Go 2

4 4 4 +5V

5 5 5 +12V

Product Detector and Shaft Encoder Connections

Power Connector

Euroconnector with moulded lead:

•Line - brown

• Neutral - blue

• Ground - yellow/green.

Macrojet 2 must be connected to earth (ground).

2-22 20509 Issue 7 Jan 2018

Page 37

DESCRIPTION

Pocket Terminal Connector (Data Entry 25-way

D Connector)

PIN SIGNAL PIN SIGNAL

1 0V 12 Tx +ve

2 RS232 Data In 13 Rx +ve

3 RS232 Data Out 18 -12V

4 CTS (Input) 21 20mA ENABLE

5 RTS (Output) 22 +12V

7 0V 24 Tx -ve

9 +5V 25 Rx -ve

11 20mA Source

Data Input Pin Connections

For RS232 operation, pins 13 and 24 are linked to disable the 20mA loop.

Pins 4 and 9 may also be linked to set CTS. For 20mA loop operation, pins

21 and 22 are linked. The terminal as supplied has the connections set for

RS232 operation.

Data must be fed from the external source while the machine is being set

up or during non-print periods.

External Alarms

The printer has a set of changeover relay contacts which are operated at

the same time as the printer fault lamp. However, they are completely

separate from the printer circuits and are provided for external use. Wiring

to the contacts enters the cabinet through one of the cable glands and

goes to the motherboard.

The connections are:

• PL5/1 and PL5/2 (printer internal contacts normally open)

• PL5/1 and PL5/3 (printer internal contacts normally closed).

20509 Issue 7 Jan 2018 2-23

Page 38

DESCRIPTION

THIS PAGE INTENTIONALLY LEFT BLANK

2-24 20509 Issue 7 Jan 2018

Page 39

MAINTENANCE PROCEDURES

PART 3 : MAINTENANCE

PROCEDURES

CONTENTS

Routine Maintenance ............................................................................ 3-3

Cleaning the Nozzle Plate ................................................................ 3-3

Purging the Print Head ..................................................................... 3-4

Bleeding the Ink System .................................................................. 3-5

2000HR Maintenance ........................................................................... 3-6

Access to the Cabinet and Print Heads ........................................... 3-6

Ink Filter Replacement ..................................................................... 3-6

Checking Drop Size ......................................................................... 3-9

Adjusting Drop Size ......................................................................... 3-9

Fan and Filter Check ........................................................................ 3-10

Changing Inks ....................................................................................... 3-11

Changing to New Ink with same Solvent Base ................................ 3-11

Changing to New Ink with different Solvent Base ........................... 3-13

Page

20509 Issue 7 Jan 2018 3-1

Page 40

MAINTENANCE PROCEDURES

THIS PAGE INTENTIONALLY LEFT BLANK

3-2 20509 Issue 7 Jan 2018

Page 41

MAINTENANCE PROCEDURES

ROUTINE MAINTENANCE

WARNINGS: (1) When working on or near the ink system,

protective clothing (especially safety glasses)

must be worn.

(2) Power to the printer must be removed before

carrying out any maintenance.

The main requirement is cleanliness. Keep Macrojet 2 clean and it will give

little trouble. The following procedures will make sure that print quality

does not deteriorate.

CAUTION: The ink system vent is on the underside of the

printer cabinet. Clean away any ink deposits which

may occur under the cabinet.

Cleaning the Nozzle Plate

CAUTION: Some wash solutions can damage the electronic

components inside the print head. The following

methods must be used to avoid any damage.

The nozzles must be washed and dried carefully before start-up and after

shut-down. Make sure the correct wash solution is used and always wipe

with lint-free tissue.

If only light cleaning is necessary, or the print head cannot be dismounted,

clean the nozzle plate with tissue moistened with wash solution.

For thorough cleaning:

(1) Remove the print head from its mounting.

(2) Hold the print head vertically with the nozzle plate at the bottom,

facing downwards.

(3) Using a wash bottle, flush the nozzle plate with wash solution. Pay

particular attention to the nozzles and minimise spraying solution

where it can penetrate into the head.

(4) Wipe away all wash solution while the print head is still vertical.

(5) Inspect the nozzle plate. If it is not entirely clean repeat the cleaning

process (steps (2) - (4)) with the nozzle plate facing downwards as

before.

(6) Refit the print head into its operation position.

Note: If a nozzle becomes blocked, partially or completely, purge the

print head (see

page 3-4).

20509 Issue 7 Jan 2018 3-3

Page 42

MAINTENANCE PROCEDURES

Purge

Switch

TP2105-1

Purging the Print Head

The purge switch on the print head operates all solenoids continuously, to

sweep out traces of air and dirt.

Move a piece of card across the nozzle plate, at the same time operate the

purge switch.

Check the dots printed on the card. They must show that all nozzles are

producing drops of ink correctly.

If purging does not clear all nozzles, the nozzle assembly must be removed

and cleaned in an ultrasonic bath (see

page 4-9).

3-4 20509 Issue 7 Jan 2018

Page 43

MAINTENANCE PROCEDURES

Pump Inhibit

Switch

Bleed Valve

Bleeding the Ink System

At regular intervals, normally once a day, the ink system must be bled to

prevent the build up of air in the system.

(1) Set the Pump Inhibit switch on the rear panel to position 0.

Note: The light in the switch will extinguish.

(2) Slowly open the bleed valve on the rear panel by turning the knob

counter-clockwise. Use a piece of tissue to catch any ink escaping

from the vent in the underside of the printer cabinet.

(3) Wait for 10 seconds and close the valve.

(4) Set the Pump Inhibit switch to position 1.

20509 Issue 7 Jan 2018 3-5

Page 44

MAINTENANCE PROCEDURES

Securing

Screws

TP2105-1

2000HR MAINTENANCE

Access to the Cabinet and Print Heads

The cabinet cover is lifted off after removing the four securing screws.

Note: The cover has a ground wire connected by a snap connector.

Make sure this wire is connected whenever replacing the cover.

The cover on the print head is removed by sliding forward over the nozzle

plate after removing the four securing screws at the front and rear of the

print head. When replacing the cover, make sure that the "O" ring round

the nozzle plate is correctly fitted.

Ink Filter Replacement

The ink filter is fitted into the manifold block. It must be replaced every

2000 hours or every six months, whichever comes first.

The printer must be switched off at the power switch and the cabinet cover

removed. Pull out the electronic circuit PCBs and lay safely to one side,

then proceed as follows:

(1) Disconnect the QCD from the ink supply container.

(2) Close the valve on the print head by turning the knob fully clockwise.

(3) Place a container under the print head and carefully release the

screws fixing the nozzle plate just sufficiently for ink to escape.

(4) Slowly open the print head valve and allow ink to escape into the

container.

3-6 20509 Issue 7 Jan 2018

Page 45

Gasket

TP2104-1

Cover

Securing

Screws

Connector

O-Ring

Spring

Diaphragm

End Cap

O-Rings

TP3395-2

MAINTENANCE PROCEDURES

20509 Issue 7 Jan 2018 3-7

Page 46

MAINTENANCE PROCEDURES

(5) Continue to allow ink to escape until the ink system pressure has

fallen to zero. Leave the print head valve fully open.

(6) Place tissue in the cabinet base to catch any escaping ink.

(7) Unscrew the filter end cap.

(8) Remove the outer and inner O-Rings and the filter.

(9) Discard the O-Rings and filter. Wash out the filter recess and clean

the filter end plug.

To fit the new filter:

(10) Fit a new filter disc into the manifold block with the sharp edge of the

disc facing inward.

(11) Fit a new inner O-Ring onto the end cap.

(12) Fit a new outer O-Ring into the groove in the manifold block.

(13) Refit the filter end cap and tighten.

(14) Carefully refit the PCBs into their correct positions.

(15) Reconnect the QCD to the ink supply container

(16) Switch on the printer.

(17) Check the system for leaks. If everything is satisfactory, switch off

the printer and replace the print head and cabinet covers.

3-8 20509 Issue 7 Jan 2018

Page 47

MAINTENANCE PROCEDURES

Dot

Diameter

TP2103-1

Purge

Switch

Checking Drop Size

All dots printed by a print head must be the same diameter. The diameter

must be 2.5 to 3.0mm for 12, 16, 20, 32 & 50mm heads.

(1) Remove, clean and replace the nozzle plate (see page 4-9).

(2) Switch on the printer and turn the intensity control to maximum (fully

clockwise).

(3) Move a piece of card at a constant speed across the front of the print

head at a distance of 8 - 10mm. At the same time operate the purge

switch.

(4) With a little practice it will be possible to print a series of separate

strokes on the card.

(5) Inspect the strokes printed on the card. All strokes must be made up

of dots of the same diameter. The dot diameter must be within the

dimensions given above.

Note: If the dots are not uniform and the correct diameter, it will be

necessary to adjust the solenoids to change the size of the ink

drops (see below).

Adjusting Drop Size

All nozzles must produce drops of the same size. They are made to do so

by adjusting the solenoids.

The printer must be switched on and working correctly in all other respects.

It will be necessary to work inside the print head and to print on a moving

test surface at the correct distance. If necessary, fit the print head onto a

test mounting to do this.

20509 Issue 7 Jan 2018 3-9

Page 48

MAINTENANCE PROCEDURES

Filter Cover

TP2050-2

Filter

Air

Flow

Air Flow Check

(1) Remove the print head cover.

(2) Turn the intensity control to maximum (fully clockwise). Perform a

drop size check to obtain a print sample.

(3) Check the printed dots and identify the solenoids that need adjusting.

(4) Loosen the locknuts which secure these solenoids.

(5) Adjust the solenoids counter-clockwise to increase dot size or

clockwise to reduce dot size.

(6) Check and adjust until the dots are correct.

(7) Re-tighten the locknuts and replace the print head cover.

(8) Set the intensity control to mid-position and repeat the drop size test

procedure. Check that the drops all remain uniform in size.

Fan and Filter Check

Switch on the printer and check that the fan starts and runs freely.

Switch off the printer, unclip the filter cover and remove the filter. Clean the

filter using warm, soapy water and dry thoroughly. Replace the filter if it is

badly clogged or damaged. If the filter is very dirty after 2000 hours, reduce

the interval between checks.

3-10 20509 Issue 7 Jan 2018

Page 49

MAINTENANCE PROCEDURES

TP2098-1

CHANGING INKS

Changing to New Ink with same Solvent Base

The procedure is to flush the printer with solvent appropriate to the ink type

in use, then to connect an ink supply container with the new ink and bleed

all the heads until the new ink flows through.

20509 Issue 7 Jan 2018 3-11

Page 50

MAINTENANCE PROCEDURES

Note: This procedure assumes the printer has more than one print

head. If only one head is fitted, the basic procedure is the same.

Flushing Procedure.

(1) Disconnect the QCD from the ink supply container.

(2) Make sure that the Pump Inhibit switch is set to 0 (Inhibit).

(3) Close the valve on each print head and remove the heads from their

mountings.

(4) Place all the print heads with their nozzles over a suitable container.

(5) Loosen each nozzle plate sufficiently for ink to escape.

(6) Open the valve on one print head and allow the contents of the ink

system to drain into the beaker.

(7) Close the valve.

(8) Remove the QCD from the feed pipe. Immerse the free end of the

pipe in a container containing several litres of the solvent appropriate

to the ink type currently used in the machine. Do not allow this

container to run dry.

(9) Set the Pump Inhibit switch to position 1 to allow the pump to

pressurise the ink system. When the pump stops, set the switch to

position 0. The ink system will now be full of solvent.

(10) Open the valve in the first print head and allow the solvent in the

system to drain from the nozzle plate.

(11) Close the valve.

(12) Repeat steps (9) to (11), draining the ink out through the next print

head. Repeat this until the ink system has been flushed five times

and each head at least three times.

(13) Refit the QCD to the feed pipe and connect a new colour ink

container.

(14) Bleed all the heads (see page 4-8) until the new ink emerges.

(15) Make sure the nozzle plates are secure. The printer can now be used

to print the new colour.

3-12 20509 Issue 7 Jan 2018

Page 51

MAINTENANCE PROCEDURES

Changing to New Ink with different Solvent Base

CAUTIONS: (1) If MEK base ink is to be changed to water base ink,

the ink system must be meticulously flushed to

prevent ink contamination. Extreme care must be

taken to remove all traces of the old ink. In older

printers it may be necessary to replace some pipes

to thoroughly remove the ink.

(2) Changing from water base ink to MEK base ink is

not possible without extensive replacement of ink

system components.

To change inks from one solvent base to another, flush first with the solvent

for the ink in the printer, then flush with the solvent for the replacement ink.

If the change is from MEK base to water base, ethanol solvent must be

used as an intermediate step. The ink base changes and the solvents used

in the flushing sequence are given in the table.

(1) Flush the ink system following steps (1) to (12) in the procedure given

above (page 3-12), using solvent with the same base as the ink in the

printer (First Flushing Sequence - see table below).

(2) Clean the container - see step (8) - and change the solvent to the

type given in the Second Flushing Sequence column in the table

below.

(3) Repeat steps (9) to (15) of the procedure given above.

Change

From

Change To

1st Flush

Sequence

2nd Flush

Sequence

6000 1100 6000 1100

1100 6000 1100 6000

1100 1000 1100 1000

1000 1100 1000 1100

KEY: 6000 Wash, Water (Old No: Type F)

1100 Wash, Alcohol (Old No: Type K)

1000 Wash, MEK (Old No: Type A)

Flushing Procedures

20509 Issue 7 Jan 2018 3-13

Page 52

MAINTENANCE PROCEDURES

THIS PAGE INTENTIONALLY LEFT BLANK

3-14 20509 Issue 7 Jan 2018

Page 53

FAULT FINDING AND REPAIR

PART 4 : FAULT FINDING AND REPAIR

CONTENTS

Introduction .......................................................................................... 4-2

Faults Related to the Ink System .......................................................... 4-2

Faults Related to the Print Head .......................................................... 4-4

Faults Related to the Electronic System .............................................. 4-5

User Related Faults .............................................................................. 4-5

Print Quality Faults ............................................................................... 4-6

Print Head ............................................................................................. 4-8

Bleeding the Print Head ................................................................... 4-8

Removing the Nozzle Plate .............................................................. 4-9

Testing a Solenoid ........................................................................... 4-10

Replacing a Solenoid ....................................................................... 4-11

Print Head Plunger Slug Replacement ............................................ 4-11

Replacing a Print Head .................................................................... 4-15

Ink System ............................................................................................ 4-16

Depressurising the Ink System ........................................................ 4-16

Pressurising the Ink System ............................................................ 4-17

Priming the Ink System .................................................................... 4-17

Filter and NRV Leaks ....................................................................... 4-19

Refurbishing a Spring NRV .............................................................. 4-19

Refurbishing a Plain NRV ................................................................. 4-20

Pressure Switch Replacement ......................................................... 4-21

Vacuum Switch Check ..................................................................... 4-23

Vacuum Switch Replacement .......................................................... 4-24

Pump Replacement ......................................................................... 4-25

Accumulator Check ......................................................................... 4-26

Reinflating the Accumulator Diaphragm .......................................... 4-26

Refurbishing the Accumulator ......................................................... 4-28

Removing the Ink System ................................................................ 4-29

Electronic System ................................................................................. 4-30

Fuse Replacement ........................................................................... 4-30

PCB Replacement ........................................................................... 4-30

Replacing the Universal Serial Interface PCB .................................. 4-31

Minimum Width Adjustment ............................................................. 4-36

Replacing a Solenoid Driver PCB .................................................... 4-37

Replacing the Low Voltage Power Supply PCB .............................. 4-37

Replacing the Motherboard ............................................................. 4-38

Fan or Filter Replacement ................................................................ 4-39

Cabinet Wiring Component Replacement ....................................... 4-40

Page

20509 Issue 7 Jan 2018 4-1

Page 54

FAULT FINDING AND REPAIR

INTRODUCTION

WARNING: Protective clothing, especially eye protection,

should be worn at all times when working on the

ink circuit.

This part of the manual provides help in identifying the causes of problems

and gives repair procedures. Certain repairs should only be carried out by

trained personnel, and it is recommended that the printer or sub-assembly

is returned to Domino or a distributor.

FAULTS RELATED TO THE INK SYSTEM

Indication Possible Cause Remedy

Ink pressure

reduced

(* See Note)

Pressure drops

when bleed valve

opened

Pump runs

intermittently

during normal

pressurisation

Back leakage through

NRVs

Pressure switch leak Check connections and

Air leak at manifold Tighten all external

Air leak at accumulator

valve, elbow fitting,

flange or valve boss

weld

Back leakage through

accumulator NRV

Restriction in inlet pipe

from ink container

Ink filter blocked Replace ink filter. (see

Check NRVs and clean

as necessary. (see page

4-19)

replace if necessary. (see

page 4-21)

elbow fittings and check

piping. If fault persists

replace ink system

Check tightness of

fittings. If fault persists

replace ink system

Check tightness of

fitting. Strip and clean

where necessary. (see

page 4-21)

Check condition of inlet

pipe from ink container

page 3-6)

* Note: Ambient temperature drop will cause an apparent loss in

pressure. This is normal.

4-2 20509 Issue 7 Jan 2018

Page 55

FAULT FINDING AND REPAIR

Indication Possible Cause Remedy

Pump runs

intermittently with

ink container

empty

Pump runs but

does not

pressurise

system

Pump runs

continuously

Air leak in inlet line at ink

container fitting

Check condition of ink

container QCD and feed

line

Air leak at inlet filter Check tightness of

fittings

Back leakage through

spring NRV O-Rings

Check condition of NRV.

Strip and clean where

necessary. (see page -

19)

Excess air in bleed

reservoir

Bleed air from ink

system. (see page 3-5)

Air leak in system Check tightness of all

connections and fittings.

If fault persists replace

ink system

Faulty pump Replace pump. (see

page 4-25)

Back leakage through

NRVs

Strip and clean NRVs

(see page 4-19)

Ink leakage Check tightness of all

fittings

Faulty pressure switch Check pressure switch.

Replace if fault persists,

page 4-21)

(see

Air leak at accumulator Check tightness of all

fittings. If fault persists,

replace ink system.

20509 Issue 7 Jan 2018 4-3

Page 56

FAULT FINDING AND REPAIR

FAULTS RELATED TO THE PRINT HEAD

Indication Possible Cause Remedy

One or more

nozzles not

working (new

head)

One or more

nozzles not

working (head

previously OK)

One or more

drops cannot be

adjusted large

enough

Dirty nozzles Clean nozzles. (see page

3-3)

Stuck plunger Check condition of

plunger and replace slug

if necessary. (see

page

4-11)

Solenoid has weak pull Check condition and

replace if necessary. (see

page 4-11)

Bad electrical

connection

Check wiring in print

head

Air in print head Bleed print head. (see

page 4-8)

Blocked nozzles Clean nozzles. (see page

3-3)

Solenoid adjustment

incorrect

Rubber plunger slug

damaged

Adjust solenoid. (see

page 3-9)

Replace plunger slug.

(see page 4-11)

Partially blocked nozzle Clean nozzles. (see page

3-3)

Solenoid has weak pull Check condition and

replace if necessary. (see

page 4-11)

One or more

drops misaligned

Partially blocked nozzle Clean nozzles. (see page

3-3)

on printed output

Nozzle jewel misaligned Replace nozzle plate.

page 4-9)

(see

Solenoid driver PCB fault Replace Solenoid driver

PCB. (see page 4-37)

Ink pressure too low Check ink pressure. (see

page 4-21, step 8)

Abnormally large

drops

4-4 20509 Issue 7 Jan 2018

Leaks on air side of

accumulator

See page 4-26.

Page 57

FAULT FINDING AND REPAIR

FAULTS RELATED TO THE ELECTRONIC

SYSTEM

Indication Possible Cause Remedy

Fuse blows

repeatedly

Encoder not

working

Machine stops

printing at

maximum width

Cannot enter

data

Incorrect rated fuses

fitted in main switch

Voltage selector setting

incorrect

Link on motherboard in

wrong position

Links on Serial interface

PCB in wrong position

Preset width adjustment

incorrect

Baud rate switches

incorrectly set

Fit correctly rated fuses

(see page 4-30)

Adjust to line voltage

(see page 2-17)

Check links on

motherboard (see page

4-38)

Check links on Serial

interface. (see

31)

Check width adjustment

(see page 4-36)

Adjust baud rate

switches (see page 4-35)

USER RELATED FAULTS

INDICATION PROBABLE CAUSE REMEDY

page 4-

Machine stops

printing at

minimum width

setting

Cannot enter

head on/off data

Two heads of the

same size print

different width

characters

No ink pressure Machine has run with ink

20509 Issue 7 Jan 2018 4-5

Intensity set too high Reset to a lower setting

page 2-17)

(see

Aspect ratio switches

incorrectly set

Aspect ratio switches

incorrectly set

container empty for long

period

Reset aspect ratio

switches. (see

Reset aspect ratio

switches. (see

Replace ink container

page A-8)

page A-8)

Page 58

FAULT FINDING AND REPAIR

TP3040-1

TP3041-1

TP3042-1

Machine will not

print

Data entry sequence not

terminated

See Pocket Terminal

Instructions

Heads are not turned on See Pocket Terminal

Instructions

Heads are not assigned

to product detectors

See Pocket Terminal

Instructions

PRINT QUALITY FAULTS

Before investigating faults further:

• check that the ink pressure is correct (see page 4-21, steps (7) and (8),

• clean nozzle plate (see page 3-3 ),

• bleed the system (see page 4-8),

• check solenoid adjustment (see page 3-9).

(1) Correct print quality

The following are examples of faulty printing:

(2) Head not mounted at 90° to direction of printing (see page A-6).

(3) Head too far from substrate (see page A-6).

4-6 20509 Issue 7 Jan 2018

Page 59

FAULT FINDING AND REPAIR

TP3043-1

TP3044-1

TP3045-1

TP3046-1

TP3047-1

(4) Pressure too low (see page 4-21, steps (7) and (8)) or intensity too low.

(5) Pressure too high (see page 4-21, steps (7) and (8))

(6) Incorrect solenoid adjustment - note varying drop sizes (see page 3-

9).

(7) Air in print head - note drops not properly formed (see page 4-8).

(8) Splashing on substrate - pressure too high (see page 4-21, steps (7)

and (8)).

20509 Issue 7 Jan 2018 4-7

Page 60

FAULT FINDING AND REPAIR

TP3048-1

TP3370-1

(9) Tails forming on printed drops - surface speed too high - reduce

intensity (see

page 2-17).

PRINT HEAD

Bleeding the Print Head

The printer should be switched on, with the Pump Inhibit switch in position

1 and the ink system properly primed.

(1) Close the valve on the print head by turning the knob fully clockwise.

(2) Place a 500 ml beaker under the nozzle plate. A suitable beaker is

supplied in the tool kit.

(3) Carefully loosen the nozzle plate fixing screws just sufficiently for air

and ink to escape.

(4) Slowly open the print head valve by turning the knob counter-

clockwise and allow air and ink to escape into the beaker. Continue

bleeding the print head until approximately 250ml of ink has been

collected.

(5) Close the print head valve and tighten the nozzle plate screws. Wash

surplus ink from the nozzle plate and dry with lintfree tissue.

(6) Open the print head valve. Purge the head (see page 3-4). Check the

print head for leaks.

4-8 20509 Issue 7 Jan 2018

Page 61

FAULT FINDING AND REPAIR

TP3371-1

Removing the Nozzle Plate

It may be necessary to remove the nozzle plate for cleaning if it becomes

blocked. This could occur after a period out of use, such as during repair or

after a long shutdown.

WARNING: The printer must be switched off before

removing the nozzle plate.

(1) Close the valve in the print head by turning the knob fully clockwise.

Place a container under the nozzle plate to catch escaping ink.

(2) Holding the nozzle in place, unscrew and remove the fixing screws.

Lift the nozzle plate off the head (do not slide it off).

(3) Clean the nozzle in an ultrasonic bath for 10 minutes using the

appropriate wash solution.

(4) Wet the O-Ring with wash solution and fit it into the O-Ring groove.

(5) Replace the nozzle plate and retaining screws.

(6) Open the valve at the print head by turning the knob clockwise.

(7) Bleed the head (see page page 4-8).

Note: If a new nozzle plate assembly is fitted, it may be necessary to

adjust the solenoids (see

20509 Issue 7 Jan 2018 4-9

page 3-9).

Page 62

FAULT FINDING AND REPAIR

TP3372-1

Locknut

Mounting Tube

Solenoid

Testing a Solenoid

The solenoids operate the print valves by pulling a slug into their centre.

This pull must therefore be correct as part of producing the correct drop

size.

The printer should be switched on. Arrange a container to catch ink from

the head during step(

(1) Disconnect the solenoid wiring from the connector.

(2) Loosen the locknut sufficiently to release the solenoid.

(3) Unscrew and remove the solenoid from the mounting tube. Leave the

locknut to mark the position of the solenoid.

5)

(4) Reconnect the solenoid wiring to connector.

(5) Insert a small screwdriver into the solenoid and operate the purge

switch on the print head.

(6) The solenoid should now be exerting a magnetic pull on the

screwdriver. No pull indicates either open circuit solenoid or a bad

connection. Check the connections at print head 16

and 37

way "D" type connector in cabinet.

way connector

(7) If the solenoid is faulty, it must be replaced, see below.

(8) When the solenoid is satisfactory, replace it on the mounting tube,

secure it with the locknut and check the drop size (see

4-10 20509 Issue 7 Jan 2018

page 3-9).

Page 63

FAULT FINDING AND REPAIR

TP3380-1

Plunger Slug

Replacing a Solenoid

The printer should be switched off and the print head cover removed.

(1) Disconnect the solenoid wiring from the connector.

(2) Loosen the locknut sufficiently to release the solenoid.

(3) Unscrew the solenoid and pull it off the mounting tube, leaving the

locknut to mark the original solenoid position.

(4) Screw the new solenoid onto the mounting tube up to the locknut.

(5) Tighten the locknut.

(6) Connect the solenoid wiring.

(7) Check and if necessary adjust drop size (see page -9).

Print Head Plunger Slug Replacement

Nozzles can occasionally leak due to worn plunger slugs. However, first

clean the nozzle plate to make sure the leakage is not caused by dirt. While

the nozzle plate is removed, check:

• Condition of plunger slugs

• That the jewels forming the nozzles in the plate are not damaged or

displaced.

Note: An insertion tool, 33574, is required to replace a damaged

plunger slug.

Having identified the faulty plunger slug proceed as follows:

(1) Close the print head valve. Remove the head from its normal

mounting and support it, preferably in the vertical position.

(2) Remove the nozzle plate

(3) Carefully pull the plunger out from the print head manifold block.

(4) Remove the damaged plunger slug. Make sure the recess for the

plunger slug is clean.

Note: The insertion tool consists of a barrel, sleeve and insertion pin.

The sleeve should be prepared by inserting silicone grease

(MS4) and pushing a plunger slug through several times with the

insertion pin. Wipe away excess grease and discard the slug.

20509 Issue 7 Jan 2018 4-11

Page 64

FAULT FINDING AND REPAIR

TP3384-1

Sleeve

Insertion Pin

TP3381-1

Barrel

TP3382-1

(5) Apply a thin film of silicone grease to the new plunger slug and insert

into the top of the insertion tool sleeve. Push down a short way with

the insertion pin.

(6) Fit the barrel of the insertion tool onto the control wire.

(7) Push the plunger down until it is seated in the barrel.

(8) Push the barrel down onto the manifold (keeping the plunger properly

seated) and fit the sleeve over the barrel. Do not allow the barrel to

slip sideways, risking damage to the plunger and control wire.

4-12 20509 Issue 7 Jan 2018

Page 65

FAULT FINDING AND REPAIR

TP3383-1

(9) Fit the insertion pin into the sleeve and push the new slug into the

plunger. Push only until the slug is felt to be fully inserted excessive

force will damage the slug.

(10) Remove the insertion pin and sleeve. Pull out the plunger and control

wire sufficiently to remove the barrel.

(11) Inspect the plunger, plunger slug, and the control wire to make sure

that they are undamaged and slide them back into the manifold.

(12) Check that the plunger, control wire, etc, move freely.

(13) Refit the nozzle plate and open the print head valve.

Note: At first, there may be a small leakage of ink from the nozzles.

This will stop once the seals are bedded in.

20509 Issue 7 Jan 2018 4-13

Page 66

Solenoid Connections

FAULT FINDING AND REPAIR

4-14 20509 Issue 7 Jan 2018

Page 67

FAULT FINDING AND REPAIR

Replacing a Print Head

The printer should be switched off and the print head cover removed.

(1) Close the valve on the print head by turning the knob fully clockwise.

(2) Place a 500 ml beaker under the nozzle plate. A suitable beaker is

supplied in the tool kit.

(3) Carefully loosen the nozzle plate fixing screws just sufficiently for air

and ink to escape.

(4) Slowly open the print head valve by turning the knob counter-

clockwise and allow air and ink to escape into the beaker. Continue

bleeding the print head until the ink system pressure is reduced to

zero, then close the print head valve.

(5) Fully remove the nozzle plate and put carefully to one side.

(6) Retrieve the O-Ring from the manifold block and the gasket from the

print head cover.

(7) Disconnect the solenoid cables from the conduit connector(s).

(8) Disconnect the pipe from the print head valve. Use a tissue to catch

any escaping ink from the pipe.

(9) Remove the two fixing screws that hold the print head to the end

cover, then remove the print head.

(10) Fit a new print head to the end cover using the two fixing screws.

(11) Connect the pipe, attached to the print head manifold, to the valve.

(12) Connect the solenoid cables to the connector(s) as shown in the

diagram (see

for the 16 drop print head is fitted with a black sleeve.

(13) Refit the O-Ring to the print manifold block and fit the nozzle plate.

(14) Refit the print head cover and gasket.

(15) Open the print head valve by turning the knob fully counter clockwise.

(16) Turn on the printer and bleed the print head (see page 4-8).

(17) Check the drop size. (see page 3-9)

(18) Check for leaks. The print head should now be ready for use.

page 4-14). Note that the cableform for solenoids 1 to 8

20509 Issue 7 Jan 2018 4-15

Page 68

FAULT FINDING AND REPAIR

TP3390-1

INK SYSTEM

WARNING: The ink system MUST BE DEPRESSURISED

before any work is done on it. After the work is

completed the ink system must be pressurised

again. Procedures for both of these are included

below.

Whenever an ink pipe is disconnected, clean the pipe and its fittings and

check that they are undamaged. To achieve an ink-tight joint, apply some

Loctite542 to the fitting before it is reassembled.

Depressurising the Ink System

This procedure must be used before commencing work on the ink circuit.

(1) Set the Pump Inhibit switch to position 0.

(2) Switch off the printer at the power switch.

(3) Close the valve on the print head by turning the knob fully clockwise.

(4) Place a container under the print head and carefully release the

screws fixing the nozzle plate just sufficiently for ink to escape.

Alternatively, remove the print head cover, disconnect the pipe at the print

head manifold, and put the end of the pipe into a container.

(5) Slowly open the print head valve and allow ink to escape into the

container.

(6) Continue to allow ink to escape until the pressure has fallen to zero.

4-16 20509 Issue 7 Jan 2018

Page 69

FAULT FINDING AND REPAIR

Pressurising the Ink System

It is assumed that work on the ink system has been completed and all

connections, etc. are tight. Correct working also depends on the

accumulator being fully inflated to its correct shape at zero pressure. If

there is any doubt about this, carry out the inflation procedure (see page

26).

(1) Make sure that the printer is connected to a full ink container.

(2) Tighten the screws fixing the nozzle plate on the print head (or

reconnect the pipe to the print head manifold in the print head).

(3) Reconnect the input supply and switch on the printer.

(4) Set the Pump Inhibit switch to 1 and the pump should start running.

When the pump stops, the pressure should be normal.

(5) Bleed the ink system (see page 3-5).

(6) Purge the head to remove any traces of air. (see page 3-4).

(7) Check the system for leaks.

(8) Refit the print head cover if necessary.

-

Priming the Ink System

After any work on the ink system manifold, the system must be primed.

The pump is not designed to prime the ink system from a dry state or for