Page 1

Page 2

CONTENTS

F-SERIES LASER CODER ................................................................4

CONTENTS OF THE EC DECLARATION OF CONFORMITY ...........5

CONTENTS OF THE EU DECLARATION OF INCORPORATION .....7

CERTIFICATION ................................................................................10

HEALTH AND SAFETY ......................................................................11

GENERAL ..........................................................................................11

SPECIFIC DANGERS ........................................................................12

Electrical Energy ..........................................................................12

Laser Radiation ...........................................................................13

AIMING BEAM / PILOT LASER .........................................................14

HARMFUL DUST AND VAPOURS ....................................................14

TOUCHING THE LENS .....................................................................14

Scan Head Mirrors ......................................................................15

Noise ...........................................................................................15

Crushing ......................................................................................15

Laser Marking Process ................................................................16

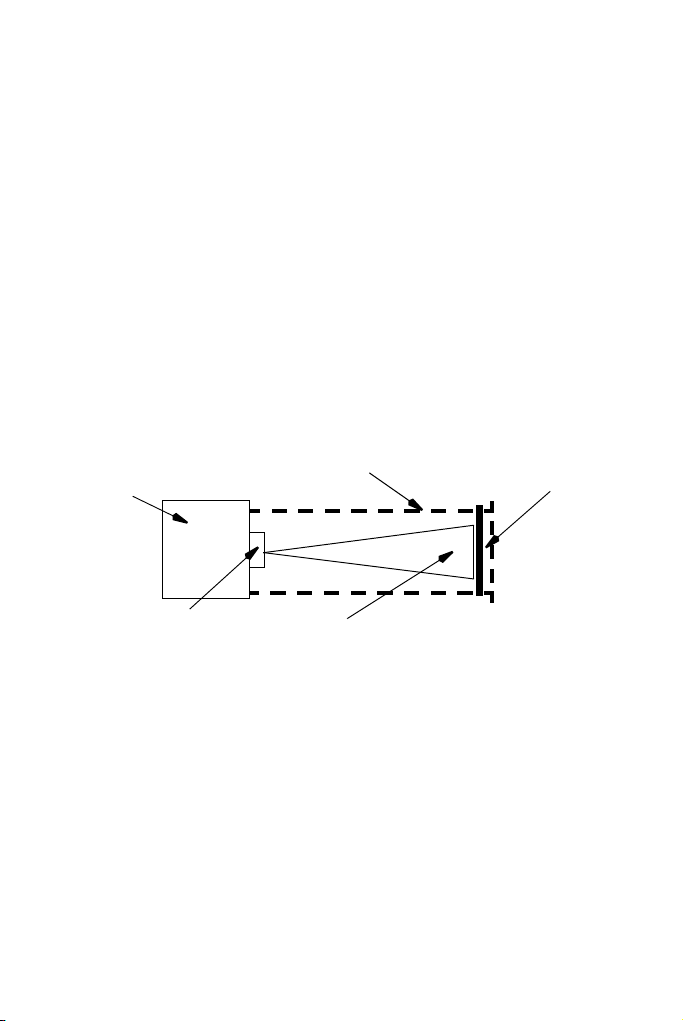

GUARDING .......................................................................................17

ACCESS GUARDS ............................................................................17

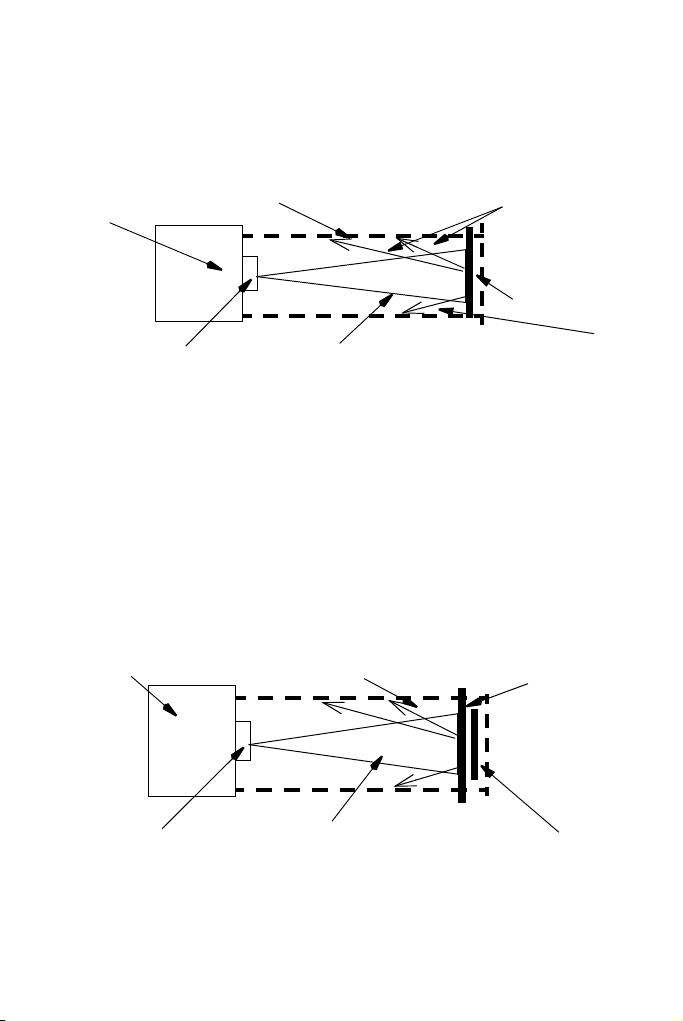

VISOR GUARDS ................................................................................18

BEAM STOP GUARD ........................................................................18

MATERIALS ......................................................................................19

BEAM DELIVERY CABLE (FIBRE) .....................................................20

INTERLOCK SWITCHES ...................................................................21

Emergency Off .............................................................................21

GUARDING LABELS .........................................................................21

OPERATION ......................................................................................22

F-SERIES LASER MARKING SYSTEM .............................................22

CONTROLS AND INDICATORS ........................................................23

TouchPanel and Interface ............................................................23

Controls .......................................................................................23

Indicator lamps ............................................................................24

Additional Indicators Laser Unit F220i ........................................26

SWITCHING ON AND OFF ...............................................................30

Switching On the Control Unit .....................................................30

Switching On the Laser Head .....................................................30

Switching Off the Laser Head .....................................................31

Switching Off the Control Unit ....................................................31

F-SERIES CONNECTIVITY ...............................................................32

WEBSERVER ....................................................................................33

QUICKSTEP INTERFACE ..................................................................34

Home Screen ...............................................................................34

1

Page 3

Status Bar ..............................................................................36

General Functions .......................................................................37

Initial Setup ..................................................................................38

Display Settings .....................................................................38

Setting the Master Clock .......................................................38

Security Management .................................................................39

Creating and Editing a Message .................................................40

Add Text .................................................................................40

Add a New Barcode ..............................................................41

Add an Image ........................................................................41

Add a New Variable .....................................................................42

Add a New Clock ...................................................................43

Add a New Counter ...............................................................43

Add a New Prompted Field ...................................................45

Add a New Link .....................................................................47

Undo / Redo ................................................................................48

File ...............................................................................................48

Edit ..............................................................................................49

Add ..............................................................................................49

Move ............................................................................................50

Zoom ...........................................................................................50

Re-order Visual Items ..................................................................51

Item Selection List .......................................................................51

Resize ..........................................................................................51

MESSAGE STORE AND FILE MANAGEMENT .................................52

Selecting an Existing Message ...................................................52

File Manager ................................................................................52

MAINTENANCE .................................................................................53

CHECKING FANS AND AIR VENTS ..................................................53

CONTROL UNIT ................................................................................53

CLEANING THE LENS ......................................................................53

GENERAL CLEANING .......................................................................54

SERVICE: REPLACEMENT OF COMPONENTS ...............................55

Applications without Shutter .......................................................55

Applications with Shutter ............................................................55

FAULT FINDING ................................................................................56

SYSTEM STATUS MESSAGES ........................................................56

2

Page 4

WARNINGS: (1) As supplied, this coder is a class 4 laser

product. During operation, it will emit up to 40

watts of pulsed invisible laser radiation at a

wavelength between 1030 and 1120

nanometers. Avoid eye or skin exposure to

direct or scattered radiation.

(2) The products contain embedded laser devices

that emit invisible radiation in the region of 900

- 1000 nm with a total output power of up to

120W for the rated output power of the laser

modules: this radiation is not accessible to the

user unless the protective housing is opened.

(3) The laser may emit significantly higher powers

under a single fault condition (<120 W 1030 –

1200 nm; <100 W 900 – 1000 nm).

(4) This coder must be fitted with class 1 laser

safety guarding, to safeguard against

accidental exposure to direct or scattered

radiation before it is operated or made ready

for use.

(5) Guidance on creating and fitting laser

guarding can be found in part 1 of the Product

Manual.

(6) Use of controls or adjustments of

performance or procedures, other than those

specified in this manual, may result in

hazardous radiation exposure.

3

Page 5

F-SERIES LASER CODER

WARNING: This is a Class 4 laser using high power

invisible light. A risk of personal injury or

damage to equipment may result if proper

safety precautions are not observed. Reading

and understanding this manual is required

before operating this laser system.

This manual has been produced for use in the operation of the Domino

F-Series Laser Coder and to reinforce and complement any training

program available with the product. It is not designed to replace any

such training program.

All rights reserved. No part of this publication may be reproduced,

stored on a retrieval system, or transmitted in any form, or by any

means, electronic, mechanical, photocopying, recording or otherwise,

without the prior permission of Domino Printing Sciences plc.

Domino Printing Sciences plc has a policy of continuous product

improvement. The Company, therefore, reserves the right to modify the

specification contained in this manual without notice.

For sales and service assistance please visit the following website and

select “Contact Domino in your country” for local technical support:

http://www.domino-printing.com

Domino Printing Sciences plc

Bar Hill

Cambridge

CB23 8TU

United Kingdom

Tel: +44 1954 782551

Fax: +44 1954 782874

© Domino Printing Sciences plc 2015

4

Page 6

Contents of the

EC DECLARATION OF CONFORMITY

(in accordance with ISO/IEC 17050-1)

No. EPT009665/2

Issuer’s name: Domino Laser GmbH, Germany

Issuer’s Address:

Fangdieckstrasse 75a, 22547 Hamburg / Germany

Object of the declaration:

F-Series laser marking system consisting of: Controller F220i (BCP7),

Laser Unit and optional TouchPanel.

The object of the declaration described above is in conformity with

the requirements of the following documents:

EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2:

Generic standards - Immunity for industrial environments.

EN 60825-1:2014 Safety of Laser Products.

EN 55011:2007 + A2:2007 Industrial scientific and medical (ISM) radiofrequency equipment - Electromagnetic disturbance characteristics Limits and methods of measurement (IEC/CISPR 11:2003 + A1:2004,

modified + A2:2006)

EN 60950-1:2006/A1:2010 Safety of Information Technology

Equipment.

EN 61326-1:2006 Electrical equipment for measurement, control and

laboratory use - EMC requirements - Part 1: General requirements (IEC

61326-1:2005)

EN ISO 13849-1:2008 Safety of machinery - Safety related parts of

control systems - Part 1

5

Page 7

2006/95/EC: Low Voltage Directive

2004/108/EC: EMC Directive

2011/65/EU: RoHS2 Directive

Additional Information

Compliance is dependent upon installation and use in accordance with

the Product Manual supplied.

6

Page 8

Contents of the EU declaration of incorporation

(in accordance to the Directive 2006/42/EC on Machinery

appendix II I.B for partly completed machines)

No.:EPT009665/2

Issuer‘s Name: Domino Laser GmbH

Issuer‘s Address:

Fangdieckstrasse 75a, 22547 Hamburg, Germany

Person authorised to compile the relevant technical

documentation, who must be established in the Community:

Research & Development Department, Domino Laser GmbH

Object of the declaration:

F-Series laser marking system consisting of: Controller F220i (BCP7),

Laser Unit and optional TouchPanel.

The special technical documents corresponding to the machine

have been created according to Appendix VII, part B.

It is expressly stated that the partly completed machine fulfills all

the relevant provisions of the following EC directives

2006/42/EU Directive 2006/42/EC of the European

parliament and of the Council of 17 May 2006

on machinery, and amending Directive 95/16/

EC (recast)

.

2006/95/EU Directive 2006/95/EC of the European

parliament and of the Council of 12 December

2006 on the harmonisation of the laws of

Member States relating to electrical equipment

designed for use within certain voltage limits

7

Page 9

2004/108/EU Directive 2004/108/EC of the European

parliament and of the Council of 15 December

2004 on the approximation of the laws of the

Member States relating to electromagnetic

compatibility

and repealing Directive 89/336/EEC

2011/65/EU Directive 2011/65/EU of the European

parliament and of the Council of 8 June 2011

on the restriction of the use of certain

hazardous substances in electrical and

electronic equipment (recast)

Published applied harmonized standards according to Article 7 (2)

EN 602041:2006-06

EN 61000-62:2005

EN 608251:2014

EN

55011:2007 +

A2:2007

EN 609501:2006/

A1:2010

8

Safety of machinery - Electrical equipment of

machines. Part 1: General requirements.

Electromagnetic compatibility (EMC) - Part 62: Generic standards - Immunity for industrial

environments.

Safety of Laser Products.

Industrial scientific and medical (ISM) radiofrequency equipment - Electromagnetic

disturbance characteristics - Limits and

methods of measurement (IEC/CISPR 11:2003

+ A1:2004, modified + A2:2006)

Safety of Information Technology Equipment.

Page 10

EN 613261:2006

Electrical equipment for measurement, control

and laboratory use - EMC requirements - Part

1: General requirements (IEC 61326-1:2005)

EN ISO

13849-1:2008

Published other applied technical standards and specifications

ÖNORM EN

ISO 11252

2013 -12-01

Safety of machinery - Safety related parts of

control systems - Part 1

Lasers and laser-related equipment Laser device - Minimum requirements for

documentation (ISO 11252:2013);

German version EN ISO 11252:2013

We commit to transmit, in response to a reasoned request by the

surveillance authorities, relevant documents on the partly completed

machinery. Property rights of the manufacturer of the partly completed

machinery remain unaffected.

Important Note

The partly completed machinery must not be put into service until

the final machinery into which it is to be incorporated has been

declared in conformity with the provisions of this Directive, where

appropriate.

9

Page 11

CERTIFICATION

Industrial Laser Unit for Marking:

Controller F220i (BCP7),

Laser Unit F220i.

Approved by Certificate No.: CU72150806 01

10

Page 12

HEALTH AND SAFETY

General

The F-Series laser marking systems are designed and built in

accordance with international standards and other technical

specifications, which are to be observed. The equipment conforms to

current technology and approved safety requirements.

Domino F-Series laser marking systems are produced by Domino

Group company; Domino Laser GmbH Germany. For Sales and

support, contact Domino.

This safety standard, however, can only be achieved if all intended and

required measures have been taken and are constantly observed. It is

part of the equipment operator’s duties to plan these measures and

check their continuing implementation.

The F-Series laser marking systems have been developed and

designed for fully automated marking of packaging materials and

products by use of laser radiation.

The user must ensure that:

• The laser system is only made ready for use after it has been

installed and guarded to Class 1 laser safety standards (EN60825)

• The equipment is only to be used for its intended purpose

• The equipment is only operated in a good, serviceable condition,

and that all safety installations are regularly checked for their

serviceability

• Personal protective goggles for maintenance and repair personnel

are required and made available

• Only suitable and approved tools and equipment are used

• The product manual is complete and in a legible condition at the

equipment location at all times

• The valid rules and laws regarding accident prevention are available

and observed

• Only sufficiently qualified and authorised personnel shall operate,

maintain, and repair the laser marking system

11

Page 13

• These personnel are regularly instructed in all matters concerning

appropriate labour safety and environmental protection, and that

they are familiar with the product manual, particularly the safety

instructions contained therein

• Any safety and warning signs on the laser marking system must not

be removed and must remain in a readable condition.

Specific Dangers

Electrical Energy

In the F-Series laser marking system, the maximum operating voltage is

the connected mains voltage, which can pose a hazard to health. The

mains voltage to be maintained is shown on the name plate.

Work on live components must only be performed by authorised

personnel.

In the case of a defective power supply, operation of the laser marking

system is to be stopped immediately and is only to be repaired by

authorised personnel.

Keep the control unit closed at all times. Only expressly authorised

personnel are permitted to open the control unit.

12

Page 14

Laser Radiation

Laser radiation can pose a risk to eyes and skin. The danger is not only

posed by direct laser radiation, but also by scattered radiation and

reflections from the work piece or the packaging machine. The degree

of injury depends on the duration of the effect, the power and the

wavelength of the laser.

Lasers and their installations are classified into seven laser protection

classes, depending on their potential danger. Class 1 is the safest and

Class 4 is potentially the most harmful. These classes are defined in

detail in EN60825 Part 1 and are summarised below:

Class 1 The accessible laser radiation may be visible or invisible

and is harmless.

Class 1M The accessible laser radiation may be visible or invisible

and is harmless, provided additional optical instruments

are not used.

Class 2 The accessible laser radiation is visible and is harmless

for accidental exposure to eyes for periods of less than

0.25 seconds.

Class 2M The accessible laser radiation is visible and is harmless

for accidental exposure to eyes for periods of less than

0.25 seconds, provided additional optical instruments

are not used.

Class 3R The accessible laser radiation may be visible or invisible.

It is potentially harmful to eyes.

Class 3B The accessible laser radiation may be visible or invisible.

Direct radiation is harmful to the eyes and skin although

diffuse radiation (reflected from a matt surface) is

harmless.

13

Page 15

Class 4

The accessible laser radiation may be visible or invisible.

Direct and diffuse radiation is extremely harmful to eyes

and skin and can pose a fire risk if projected onto

combustible materials.

The F-Series laser marking systems, taken by

themselves, are Class 4 and must not be used until

suitable, interlocked guarding is fitted to achieve a Class

1 laser installation that physically prevents access to the

laser radiation or automatically disables the laser when

access is required to the marking area (for cleaning or

maintenance, etc.).

Aiming Beam / Pilot Laser

The system contains an aiming beam with a wavelength of 630nm to

670nm.

This laser is a class 1 laser.

Harmful Dust and Vapours

When radiating materials by means of a laser, harmful dust and vapours

can be produced. The user is responsible for appropriate measures,

e.g. an exhaust system, to reduce such harmful dust and vapours to a

level that complies with the allowed maximum concentration of

pollutants at the work place.

Touching the Lens

Fused silica lenses are used in the F-Series laser system.

Lenses must not be touched.

If the lens has been soiled, it must be thoroughly cleaned before any

operation.

14

Page 16

Scan Head Mirrors

Never touch the mirrors of the scan head.

The mirrors are inside the scan head and there is a small risk of touching

them when cleaning the lens.

The mirrors for the i-Tech 15 scan head are made of Beryllium.

If the mirrors have been touched accidentally, wash hands thoroughly

with water and soap.

Fumes and dust from Beryllium metal can be hazardous if inhaled.

Noise

All systems emit during operation a noise level lower than 80dB(A). No

personal protective equipment against noise is needed.

Crushing

There is a crushing hazard during installation and operation due to:

• Product moving along the laser head.

• Products moving into and out of protective housing.

• Doors and maintenance openings of protective housings.

15

Page 17

Laser Marking Process

Potential fire risks could result from examples as listed below. This list

is not considered to be complete. Local conditions must be considered

as well.

• Printing on not specified material (e.g. easily inflammable or

explosive materials).

• Invalid parameter settings (e.g. very low mark speed).

• Invalid parameter settings due to corrupted print data.

• Printing constantly on the same product (e.g. no product movement

caused by various reasons).

• Inflammable gases or materials inside the working area.

• In printing mode the laser beam is controlled by software which

must be considered as part of the risk assessment.

• Install a fire detector near the laser to monitor the marking process.

16

Page 18

Guarding

Substrate

Laser Beam Path

Access Guard

Laser Head

Lens

The following type of guarding, using the recommended materials and

construction techniques, is required to achieve a safe installation.

WARNING: Never install a laser in such a way that the lens

points to a door or in the direction of an

operator.

When designing a housing for a fibre laser, always use overlaps where

possible to trap the laser light inside the housing, especially for mark on

the fly applications where a product inlet and outlet to the housing are

needed

Access Guards

Access guards are required to prevent direct human access to the laser

beam. In practice, this requires full guarding of the area between, and

including, the laser output lens and the area to be marked on the

substrate.

Note: Guarding is required behind the substrate to prevent access to

the laser beam when the substrate is removed, or following

accidental burn through of the substrate.

17

Page 19

Visor Guards

Substrate

Laser Beam Path

Access/Visor Guard

Laser Head

Lens

Scattered

Radiation

Scattered

Radiation

Substrate

Laser Beam Path

Access Guard

Laser Head

Lens

Beam Stop

Visor guards are required to prevent the escape of scattered radiation.

Often the access guarding can be designed to perform this function

without the need of an extra guard.

WARNING: Visor guards have to be installed at a

minimum distance of four times the focus

distance to the laser beam.

Beam Stop Guard

A beam stop guard is required for applications where guarding material

is fitted within 100mm of the laser lens focal plane. The beam stop is to

prevent burn through of the guard should the laser be repeatedly

operated without the substrate in position. The beam stop must be

capable of absorbing the full output power of the laser for a period of

eight hours and be large enough to cover the complete laser marking

field area.

18

Page 20

Materials

All guard materials must be opaque to 1040 to 1200 nanometers

wavelength laser light produced by the fibre laser. Guards may be

metallic and non-reflecting, however if a see-through guard is required

a material opaque 1030 to 1200 nanometers wavelength laser light

must be used.

See through guards must be special laser safety windows.

Always use non-reflecting materials.

The thickness of the guard material depends on the mechanical

strength required, and the amount of ‘burn through’ anticipated. For the

purpose of adequate mechanical rigidity, a thickness of at least two

millimetres, and preferably three millimetres of steel plate is

recommended. To ensure laser safety a greater thickness of the guard

material may be required.

In a fault condition, these materials withstand the laser beam for a

limited time before the beam burns through. The laser must therefore be

monitored to avoid a risk of fire.

A ceramic or metal plate may be used as a beam stop. A greater

thickness is required to achieve the “eight hour burn through”

requirement.

Guidance regarding laser guards can be found in EN60825-Part 4.

19

Page 21

Beam Delivery Cable (Fibre)

The beam delivery cable is not Class 1 under a worst case single fault,

no cable break or fibre break detection is offered on this product. The

integrator must either include the beam delivery cable inside the Class

1 enclosure with the Pulsed Laser Aperture or undertake suitable

measures to ensure that under reasonable use, the cable is suitably

positioned to prevent it from becoming damaged or mishandled.

The beam delivery cable has not been designed for robotic

applications. The Laser must not be designed into systems where the

Beam Delivery Cable will be subject to high levels of acceleration,

torsion and twist, or combination thereof. If this is a requirement for the

integration, please contact Domino to discuss the application in more

detail.

The minimum bedding radius (r) for the fibre is 75mm.

20

Page 22

Interlock Switches

Interlock switches must be fitted to all access guards preventing access

to the laser output lens and marking area that can be opened without

the use of access tools.

Interlock switches must be wired into the laser control circuit so that the

laser beam is disabled when the guard is removed.

Emergency Off

Integrate the laser into the emergency off circuit of the machine into

which the laser is integrated. Install an emergency off push button near

the laser marking systems which turns off the laser. Connect the

emergency off push button via the interlock circuit to the controller.

Guarding Labels

Domino recommend that the following information is prominently

displayed on the guard:

WARNING: Class 1 laser product containing an embedded

class 4 laser.

Operation of the product with safety guards

removed may result in hazardous exposure to

laser radiation.

These labels are supplied with the laser system. Additional labels are

available from Domino Printing Sciences plc as part of the Guarding

Labels Kit, Part Number L007628.

21

Page 23

OPERATION

Optional

TouchPanel

Laser key switch

BCP 7

Controller

On/Off Switch

Laser Unit

(Laser Box)

Scanner Head

Laser Lens

Mains

connector

Laser Unit

(Laser Module)

Laser Fibre

Beam Delivery

F-Series laser Marking System

22

Page 24

Controls and Indicators

Key switch

On/Off Button

Indicator Lamps

The User Interface, Indicator Lamps and Software icon functions are

described in the following paragraphs:

TouchPanel and Interface

The software is operated via a PC keyboard, TouchPanel or Web

Browser. An entry is confirmed with the left mouse button if PC or Web

browser are used. The optional TouchPanel if connected, allows entry

by touching the tabs and function keys on the screen. An onboard

keyboard is included in the software.

Note: The Web Browser does not support the message editor.

Controls

ON / OFF BUTTON - Starts and stops the controller and PC unit

KEY SWITCH - Starts and stops the Laser Unit (fans and laser tube)

The key switch has three positions:

• “0” Laser off

• “1” Laser ready

• “*” Laser start.

23

Page 25

Indicator lamps

Interlock 1

Interlock 2

PC Ready

Printer Ready

Printer Busy

Power supply LED

on the rear of the

laser unit.

• Interlock 1 - Illuminates when the interlock 1 is closed.

• Interlock 2 - Illuminates when all the interlocks are closed.

• PC Ready - Illuminates when the internal PC is ready.

• Printer Ready - Illuminates when the Laser is powered up and

marking system is ready to print.

• Printer Busy- Illuminates when the Laser is marking

The activation of the laser power supply is also indicated by two red

(Power) LEDs on the front and one at the rear of the laser module.

24

Page 26

To scanner head

Power supply LED on the

front of the laser unit.

Shutter LEDs on the front of the laser unit

(only with shutter option)

Illuminates when shutter is open

Shutter LED

Power supply LED on the

front of the laser unit.

To scanner head

Laser Module without Shutter Option

Laser Module with Shutter Option

25

Page 27

Additional Indicators Laser Unit F220i

Interlock Indicator 1

Shutter Preparation / Error Indicator

Laser Indicator

Interlock Indicator 2

Shutter State / Error Indicator

Interlock Indicator 1 and 2

Lit GREEN Interlock 1 and 2 respectively

are closed.

Both interlock 1 LED and

interlock 2 LED are alternating

RED flashing

Both interlock 1 LED and

interlock 2 LED parallel RED

flashing

Both Interlock 1 LED and

interlock 2 LED are lit RED:

Within approximately 8 seconds after power up (boot phases of the

safety relay) the display of both interlock LEDs is not valid.

Wrong order was in the

interlock loops e.g. open and

close one loop only. Correct

and restart the process.

The interlock has been

opened while the shutter selftest was running.

An electrical error (cross

connection) was detected.

Debug wiring and restart the

process.

The safety relay is completely

shut down. Inspecting of its

display is suggested. Power

cycling is required.

26

Page 28

Shutter Preparation / Error Indicator

Blinking GREEN Waiting for start command.

Lit GREEN Ready.

Lit RED A shutter malfunction is

present

Blinking RED A shutter malfunction was

detected but no more present.

Blinking ORANGE A shutter malfunction was

detected - waiting for start

command.

Lit ORANGE: No shutter and shutter

controlling is equipped.

27

Page 29

Shutter State / Error Indicator

Lit YELLOW Shutter is open, caution laser

radiation is possible!

Lit RED Shutter temperature display

(after power-up only).

Lit RED (permanent) shutter feedback cross-check

failed.

Flashing RED while the

GREEN Shutter preparation

Shutter is close to over

temperature.

LED is lit or blinking

Blinking RED while GREEN

shutter preparation LED is

blinking

A shutter over temperature, or

sensor fail (<10°C) had

occurred. Therefore the laser

was switched off. Restart is

possible.

Flashing RED while GREEN

shutter preparation LED is off

A shutter temperature sensor

fail (<10°C) is present.

Therefore the laser is switched

off.

Blinking RED while GREEN

shutter preparation LED is off

A shutter over temperature is

present. Therefore the laser is

switched off.

Note: The GREEN shutter preparation LED blinking is suppressed if

one or both interlock is not closed.

28

Page 30

Laser Indicator / Error Indicator

Lit YELLOW Laser source ready for

emission.

Lit RED (error) Laser is not (correctly) started.

1x Flashing YELLOW Laser modulation (print

activity) missed.

2x Flashing YELLOW Laser modulation (print

activity) not permitted.

3x Flashing YELLOW Laser modulation (print

activity) missed AND not

permitted.

LED Test display on Power Up

After power up, the laser unit F220i will start an error test display in the

following sequence:

• Shutter state error; each sec. means 10° Celsius of scanner

temperature. This display shows that the temperature sensor of the

shutter housing is properly connected, and that the LED works.

Then, approximately 8 seconds after power up the 4 LED’s from top to

bottom:

• Extinguish for a moment

• Light up (RED) for 1 second each, top to bottom

• Extinguish for a moment

• Display status as described above

If unauthorised changes are performed, the warranty will be invalidated.

29

Page 31

Switching On and Off

WARNINGS: (1) The laser marking system must only be used

CAUTION: The lens cap must be removed before operation.

Switching On the Control Unit

Turn on the laser unit F220i first by switching the switch from position

“0” to “1”. At the control panel, release the On/Off button by turning it

clockwise. Wait until the SERVER RUNNING indicator has

illuminated.

Switching On the Laser Head

Turn the key switch from position “0” to position “1”. To start the laser

turn the key clockwise to the laser symbol and hold it for at least 1

second. The key automatically turns back to position “1”.

• The laser needs a warm-up phase of 3 seconds.

The PRINTER BUSY indicator will illuminate when the laser

hardware is switched on.

The PRINTER READY indicator illuminates. After initialising the

Dynamark 3 software and starting the lasers, the marking system is

ready.

Laser emission is also displayed by a red LED on the rear of the laser

unit.

for its intended purpose.

(2) The laser marking system may only be

operated by trained personnel.

(3) Operation is only allowed with all required

cables connected and all parts mounted. Do

not disconnect any cables during operation.

30

Page 32

Switching Off the Laser Head

• Turn the key switch from position “1” to position “0”. The laser

hardware is switched off.

Switching Off the Control Unit

• Press the On/Off button at the BCP7 controller. The computer will

immediately switch off.

• Turn off the laser unit F220i by switching the switch from position

“1” to “0”.

31

Page 33

F-Series Connectivity

X59 TouchPanel Connector

The F-Series is operated either via a remote TouchPanel or via a PC

running on Microsoft Windows 7®

QuickStep software.

To connect to one D-Series, the TouchPanel is connected to the X59

TouchPanel connector of the controller.

The TouchPanel then displays the UI relating to that printer.

One TouchPanel can control multiple F-Series in the same network if

required.

Details about the printer being controlled are displayed in the Home

screen which lists: the logged in user, the printer’s name and the printer

model. To connect to another printer in the network, follow the steps

below:

(1) Disconnect from the current printer by pressing the Lock button

and selecting Disconnect From Printer to display the printers’

list screen.

(2) Press the Lock button and select Unlock UI Settings, enter the

password (QS).

(3) Press Settings, select Broadcast (default) as the connection

method.

(4) Go back to the printers’ list screen and press Refresh to view a

list of all printers in the network.

(5) Select the required printer.

or Windows 8® with installed

32

Page 34

A list of favourite remote printers can be created, as follows:

(1) From the printer’s list screen, press the Lock button and select

Unlock UI Settings, enter the password (Domino1).

(2) Press Settings and select Favourite as the connection method.

(3) Press Add Favourite and fill in the required fields manually or get

a favourite printer from broadcast

(4) Select a printer from the Broadcast list.

(5) Press Add to Favourites.

Webserver

One may also connect to the printer’s UI via standard web browser. The

following web browsers are supported:

• Microsoft Internet Explorer from version 9.0 on

• Mozilla Firefox from version 22 on

• Google Chrome from version 27 on

• Apple Safari from version 6 on

Not the complete functionality of the UI is available when connecting to

the printers via a web browser.

Not available is:

• The Message Editor which is accessed via Home Screen > Settings

> Message Editor or via Home Screen > Messages > New Message

/ Edit Printing Message

33

Page 35

Quickstep Interface

Status Icons

Status Bar

Start/Stop Button

Lock

Main Menu

Selection

Buttons

Live Message

Preview

Zoom Toolbar

Printer Name

Home Screen

When starting the printer, the following Home screen is displayed.

34

Page 36

Status Icons: Displays current status of printer, e.g:

• Laser active

(Laser is busy - laser emission!)

• USB device connected

(USB device connected to

controller or TouchPanel)

• Dongle connected

(Pharma or Service dongle

connected)

Status Bar: Displays printer and alert status. If

more than one alert is present, the

highest priority alert is

displayed.

Start/Stop Button: • Enables marking

Note: If the laser unit is switched off,

it must be switched on before

marking can take place.

• Stops marking

• Triggers a print

• Restarts the Printer

Zoom Toolbar: Zooms in and out and to marking field

Live Message Preview: Main working area. Used for settings

and message creation.

Main Menu

Selection Buttons:

Navigate to the four main QuickStep

areas where all functions of the

operational software can be

accessed.

35

Page 37

Lock Button: • Locks the screen to prevent

accidental changes

• Login and logout

• Disconnects from printer

Printer Name: Shows the printer which is being

currently controlled

Status Bar

The status bar displays informal warning and error messages in different

colours:

• Green - the condition is normal, no action is required.

• Blue - the condition requires attention but does not prevent marking

except when the system is in standby mode.

• Yellow - the condition prevents marking, however if marking was

enabled and the reason for this fault has become obsolete it

automatically re-enables marking.

• Red - the condition prevents marking and requires immediate

correction.

Note: Click on the status bar to acknowledge errors.

36

Page 38

General Functions

Status Icons Status Bar

Start/Stop Button

Screen

Title

Tabs

Breadcrumb navigation

Scroll By

Page

Scroll By

Line

The following illustration shows the Global Print Settings screen and the

various screen areas.

Click long on a button to get a description. Click long on a button of the

Settings area to move this button to the Home screen.

Note: The breadcrumb navigation shows the current location inside

the menu structure. One can switch the user interface level by

clicking on the icons; it is also a quick way to return to the home

screen from any page.

37

Page 39

Initial Setup

The initial setup configures the overall look of the interface and also

configures basic settings and presets for printer operation.

Display Settings

Home > Settings > Regional > Language and Keyboard

Set:

• Language.

• Keyboard layout.

•IME Scheme.

• Primary currency.

Setting the Master Clock

Home > Settings > Regional > Date and Time

Set:

• System date.

• System time (24 hour clock).

• Time zone.

• Automatic Daylight Saving Time.

• Setup the Network Time Protocol.

38

Page 40

Security Management

Password protection prevents unauthorised changes to the software,

and unauthorised operation of the laser marking system.

Some functions can only be accessed from higher user levels; the

higher the user level, the more functions are available. The current user

level is displayed in the Title Bar across the top of the user interface

screen.

The functions that can be accessed for each user level are as follows:

User Level Functions Password

Logout View the main functions none

Operator Start / stop marking, select

op

message, acknowledge alerts

Supervisor Create/Edit messages; Change

sv

Marking Parameters; Access to

Editor and Save Editor

Administrator Edit most of the setup Not

published

Service Access everything Daily

changing

Extended system parameter settings can only be changed after

entering the Administrator password. This password is only known by

employees authorised by Domino.

Note: If unauthorised changes are performed, the warranty will be

invalidated.

Changing the passwords after the initial installation is recommended.

39

Page 41

Creating and Editing a Message

Tex t Barcode

(MRC)

Image Arc

Rectangle

Clone Item

Add Text

(1) Select Messages > New Message or Settings > Message Editor

to open the Message Editor.

(2) Press on the screen within a specific area of the Message Editor

where you require the item to appear. A cross hair will appear at

this location.

(3) Select the Add icon.

The Add sub-menu displays.

(4) From the sub-menu select the Text icon.

Note: Change keyboards by selecting the appropriate Alternative

Keyboard icon at the bottom of the text entry screen.

(5) Enter the required text using the keyboard and select the green

tick icon when finished.

(6) To change text, select the text item and then the Keyboard icon

on the Edit sub-menu.

(7) To change text parameters (Object Name, Position, Bold, Width

etc.), use the sub-menu (Font, Alignment) or select More…

(8) To delete an object, select the object and select the delete

icon of the Edit menu

(9) Activate the message for printing by sending it to the printer

via the File menu

40

Page 42

Add a New Barcode

To add a barcode to the message:

(1) Press on the screen within a specific area of the Message Editor

where you require the item to appear. A cross hair will appear at

this location.

(2) Select the Add Barcode icon and select the type and

specification required from the list and editable text boxes.

(3) Use the Text, Variable, Edit Variable and Properties tabs to enter

the barcode data.

(4) Select the green tick icon to insert the code into the message.

(5) Edit the barcode by highlighting the barcode within the

message and using the sub-menu or by selecting More…

(6) Activate the message for printing by sending it to the printer

via the File menu .

Add an Image

To insert an image into the message:

(1) Press on the screen within a specific area of the Message Editor

where you require the item to appear. A cross hair will appear at

this location.

(2) Select the Image icon from the Add menu.

(3) An images folder stored in the printer will open.

(4) Browse for the required image.

(5) Select the green tick icon to insert the image.

Note: Monochrome Bitmap (*.bmp), DXF (*.dxf) (up to Version 12,

information about 3-dimensional objects is discarded, fonts and

labels are not supported) and Hewlett Packard Graphics

Language HPGL (*.plt) black white graphic file formats are

supported.

Supported commands for HPGL import are: Arc Absolute, Arc

Relative, Plot Absolute, Plot Relative, Pen Up, Pen Down

(6) Select the Move icon to move the copied item to the

desired location within the message.

(7) Activate the message for printing by sending it to the printer

(8) Use the File Manager (Home > Settings > File Manager) to copy

via the File menu .

an image from a USB device to the controller.

41

Page 43

Add a New Variable

Message or system variables may be added. Message variables may

only be used in the message in which they have been created. System

variables can be used in all messages.

• Message variables are created via Home > Settings > Message

Editor >

Add > Text > Add Variable .

• System variables are created via Home > Settings > Message Editor

>

File > Add/Edit Variable > Add Variable .

Note: System variables are referenced within message via a link. Insert

a link into a message to use a global variable.

The following variables can be created and added to the message:

• Clock (message & system).

• Counter (message & system).

• Prompted Field (message only).

• Link (message only).

• Script (message only).

• Coding (message only).

• Shift Code (message only).

• Text Insert (message & system).

• Text Variable (message & system).

• Text Link (message only).

Notes: (1) System variables are empted on a power cycle.

(2) All steps below are described for local variables as they

are the same for global variables.

42

Page 44

Add a New Clock

To add a new offset clock to the message:

(1) Press on the screen within a specific area of the Message Editor

where you require the item to appear. A cross hair will appear at

this location.

(2) Select the Add icon.

(3) From the sub-menu select the Add Text icon.

(4) Select +Variable > +Create New > Clock.

(5) The scope cannot be changed - use the File menu to create a

global counter.

(6) Enter a name for the clock or use the default name and use the

drop down lists to select the format.

(7) Select the required offset parameters (Days, Months, Years and/

or Hours, Minutes, Seconds and/or Weeks) and add values

using the keyboard. Select the green tick icon when each

parameter is completed.

(8) Review the entered information and select the green tick icon if

correct or press in the required field to add or change values.

(9) Select the green tick icon to enter the offset clock into the

message.

(10) Activate the message for printing by sending it to the printer

via the File menu .

Add a New Counter

To add a new counter to the message:

(1) Press on the screen within a specific area of the Message Editor

where you require the item to appear. A cross hair will appear at

this location.

(2) Select the Add icon.

(3) From the sub-menu select the Add Text icon.

(4) Select +Variable > +Create New > Counter.

(5) The scope cannot be changed - use the File menu to create a

global counter.

(6) Enter a name for the counter and enter the Format String “N” for

numerical and “A” for alpha characters.

(7) Select a Leading Character Mode from the drop down options:

None, Blank or Custom. If a custom character is selected in the

Leading Character box, enter the character required.

43

Page 45

(8) In the Step Control box, select the option required to activate

the increment:

Print Start

User Input (Rising Edge)- specify the User Input to be used

User Input (Falling Edge)- specify the User Input to be used

(9) In the External Reset box, select None, Mark Enable,

Application Start, Message Load, User input Rising Edge, User

input Falling Edge.

(10) In the Counter Repeat box, enter the number of items to be

marked before the counter increments (default value is ‘1’).

(11) Step Size sets the increment value of the selected counter from

1 to 99999. The default value is ‘1’.

(12) Set the current value in the selected alphanumeric format of the

counter.

(13) Set the start value in the selected alphanumeric format for the

counter. If the start value is larger than the end value the

counter will count backwards.

(14) Set the end value in the selected alphanumeric format of the

counter.

(15) Edit, if required, the Alpha Field String. to be used for the alpha

designators in the counters. All alphanumeric characters are

available for use in this string. The maximum string length is 26

characters. The default string is A to Z (including all characters).

(16) Select an Ending Action: Select None, Disable, User Output or

User output and disable. Select the User Output if activated.

(17) If required, set a Batch Link to another counter when this

counter has it’s end value and select the linked counter from the

drop down list.

(18) Review the entered information and select the green tick icon if

correct or press in the required field to add or change values.

(19) Select the green tick icon to enter the counter into the message.

(20) Activate the message for printing by sending it to the printer

via the File menu .

44

Page 46

Add a New Prompted Field

Prompted text fields may be inserted into messages. The content of

these text fields is entered in QuickStep after sending the message to

the printer.The content format has to be specified when creating these

text fields in a message in the Message Editor.

To add a new prompted field to the message:

(1) Press on the screen within a specific area of the Message Editor

where you require the item to appear. A cross hair will appear at

this location.

(2) Select the Add icon.

(3) From the sub-menu select the Add Text icon.

(4) Select +Variable > +Create New > Prompted Field.

(5) Enter a name or use the default name for the prompted field

object.

(6) Set a default value in the format matching the input mask for the

prompted field.

(7) Enter a prompt which is displayed on screen when the data for

the prompted field should be entered. (After sending the

message to the printer).

(8) Select an input mask for the prompted field which specifies the

type of content for the prompted field.Possible formats:

Mask Description

0 Mandatory numeric character 0-9

9 Optional numeric character 0-9

L Mandatory alpha character A-Z or a-z

? Optional alpha character A-Z or a-z

A Mandatory alphanumeric character

0-9, A-Z or a-z

a Optional alphanumeric character

0-9, A-Z or a-z

45

Page 47

C Mandatory any character

c Optional any character

# Optional currency symbol €, $, £ or ¥

& Mandatory any character or space

(9) Review the entered information and select the green tick icon if

correct or press in the required field to add or change values.

(10) Select the green tick icon to enter the prompted field into the

message.

(11) Activate the message for printing by sending it to the printer

via the File menu .

46

Page 48

Add a New Link

To add a new link to the message:

(1) Press on the screen within a specific area of the Message Editor

where you require the item to appear. A cross hair will appear at

this location.

(2) Select the Add icon.

(3) From the sub-menu select the Add Text icon.

(4) Select +Variable > +Create New > Link.

(5) Enter a name or use the default name for the link object.

(6) Specify the source of the link, e.g. a counter or a clock or

message content element. System variables are entered into a

message via a link.

(7) Select the green tick icon to enter the offset clock into the

message. The link object will have the same content as the

source object.

(8) Activate the message for printing by sending it to the printer

via the File menu .

47

Page 49

Undo / Redo

Undo Redo

New

Message

Save

Save as

Coding

Laser

Parameters

Global

Variables

Message

Properties

Send to

Printer

Undo re redo the last editing steps in the message editor including

change of settings or parameter settings.

Note: Creating a new message clears the undo cache - no undo to the

last message is possible.

File

New Message - Creates a new message.

Save - Saves the current message in a selected message store.

Save as - Saves the current message with a given name in a selected

message store.

Coding - Selects a source for the coding variable.

Laser Parameters - Create, delete and edit laser parameter sets.

Global Variables - Create global variables.

Message Properties - Message settings overwrites system settings of

Fields, Mark on the Fly, Vector Sorting and activate usable fields. Also

enables the user to activate Optical Correction, Tube Distortion and PN

Transformation.

Send to Printer - sends the current message to the printer and

activates it for printing.

48

Page 50

Edit

Edit Text

Select

Font

Alignment

Edit Object

Properties

Delete

Object

Edit menu for a text object.

Tex t Barcode

(MRC)

Image Arc

Rectangle

Clone Item

Edit Text - Opens the keyboard to edit the text content.

Select Font - Opens the list of available fonts to select a font.

Alignment - Sets the alignment of the object.

Edit Object Properties - Allows editing the properties of the object.

Delete Object - Deletes the selected object.

Add

49

Page 51

Move

Zoom in

Zoom out

Fit height

Fit Width

Zoom 100%

Zoom to

Item

Select an object in the editor by clicking on it and move it in the desired

direction by clicking on the arrow icons.

Drag and drop can also be used.Select and hold the item within the

message and move it to the desired location.

Zoom

To view the item(s) in the Message field, or the whole Message field in

a different size, select the item(s) and then select the appropriate button

from the above toolbar:

Incrementally zoom in on the message area.

Incrementally zoom out of the message area.

Fit whole message height to area.

Fit whole message width to area.

Zoom to 100% (actual size) of Message.

Zoom selected item to fit into message area.

50

Page 52

Re-order Visual Items

Sets the order of objects to print.

Select an object of the list and use the arrows to change the order.

Item Selection List

Selects multiple or all objects of a message. Select the items of the list

to be selected. Or click on “Select all” to select all objects. Click on

“Clear Selection” to have no object selected.

Resize

Resize an object by selecting it and dragging the red mark of the object.

51

Page 53

Message Store and File Management

Selecting an Existing Message

Note: Where no message is selected for printing, no live message will

be displayed in the Home screen.

(1) Select the Messages button to open the Message Store.

(2) Select the required message from the list.

(3) Choose to Edit, Preview or Send to Print.

Note: Send to Print will revert to the Home screen. The selected

message will then be displayed.

File Manager

Home > Settings > File Manager

File Manager is a useful way of reviewing and organising stored

messages, images and scripts.

Using File Manager it is easy to edit files, create new folders and copy

content between folders.

New Store: Create a new store for messages, images and

scripts.

Note: A new message store can only be

created in the messages folder.

Edit: • Rename

•Copy

•Cut

•Delete

•Details

Paste: Used with the Copy/Cut commands to add

files into folders.

52

Page 54

MAINTENANCE

Checking Fans and Air Vents

WARNING: Before undertaking any work on the laser

marking system, unplug the mains power.

The fans are located at the sides of the control unit.

A fan defect immediately poses a danger of overheating that may result

in damage to the control unit, therefore the fans must be checked once

a month.

Control Unit

(1) Check the fans for bearing noises. If bearing noise exist, the

respective fan must be replaced.

(2) Check the fan filters of the controller (2 on the left side and 2 on

the right side) for blockages and dirt. If necessary, exchange

them. This may be easily done from the outside without opening

the controller.

Cleaning the Lens

CAUTIONS: (1) Do not use compressed air from the installation

WARNING: Ensure the mains power plug is removed

The lens must be checked monthly for dust, and if necessary be

cleaned with (absolutely clean) compressed air from a can.

For all other dirt, the lens must be cleaned with Isopropyl Alcohol and

lens paper, or cotton swabs (Q-tips), as follows:

(1) Take an unused cotton swab (cotton bud) and soak one end in

Isopropyl Alcohol.

(2) Lightly wipe with ONE PASS ONLY across the surface of the

lens.

for cleaning.

(2) Water must not be used for cleaning, as the

lenses are not water resistant.

(3) Clean carefully as there is a risk of scratch marks

on the lens which will reduce the marking quality

before cleaning the lens.

53

Page 55

Cotton Swab

Lens Assembly

(3) Inspect the cotton swab. If dirt or oil is present, repeat steps (1)

to (3).

(4) Use the dry end of the cotton swab to lightly wipe excess liquid

from the lens.

General Cleaning

WARNING: The laser marking system and the connected

installation must be switched off with the

mains supply to the laser marking system

disconnected.

The outer surfaces may be cleaned with a damp cloth and a mild

cleaning agent only. No humidity must get into the system.

54

Page 56

Service: Replacement of Components

Applications without Shutter

Maximum cycles of E-Stop Relay PNOZ S4

15 Million

(opening of guard door when laser is printing)

Maximum cycles of E-Stop Relay PNOZ S4

100 Million

(opening of guard door when laser is not

printing)

Applications with Shutter

Maximum cycles of Shutter 10 Million

55

Page 57

FAULT FINDING

System Status Messages

Status

Message

11 Encoder/Line

too fast

(overflow).

12 Encoder/Line

too slow

(underflow.)

13 List buffer

repeat count

fail.

14 Maximum print

to print

distance

exceeded.

15 Print start

signal ignored.

16 Maximum laser

on time exceed

(laser disabled

by hardware).

17 Laser warm up. A short warm up

30 Scanhead

power missing.

Cause Suggested Action

The message has

not been completed

in time.

The message has

not been completed

in time.

Internal Fault. Restart the system. Contact

The maximum

distance between

print go signals has

been exceeded and

an expected print go

was not received.

A print go has been

received too soon

after the previous.

The laser has been

firing for longer than

expected.

period is required

before use.

There is no +/-15v at

the scanhead, or no

data returning from

scanhead.

Slow down the conveyor,

reduce the mark time, or

move the text upstream on

the field.

Reduce the mark time or

move the text upstream on

the field.

Domino.

Restart the system. Contact

Domino.

Restart the system. Contact

Domino.

Restart the system. Contact

Domino.

Restart the system. Contact

Domino.

Restart the system. Contact

Domino.

56

Page 58

Status

Message

31 Scanhead

temperature

out of valid

range.

32 Scanhead

warming up please wait.

33 Control unit

over

temperature.

51 Control unit

near over

temperature.

56 Printer ready to

print.

58 No Message

loaded

549 Turn keyswitch

to enable

marking

550 System

disabled

551 Aiming turned onThe aiming beam,

Cause Suggested Action

The scanhead is

cold.

The scanhead is

cold.

The temperature in

the controller is very

cold or too hot.

The controller is

getting quite hot.

Printer will print if a

print go signal

arrives.

There is no valid

message loaded

into the controller.

The safety relay

needs to be set after

an interlock has

been opened.

The keyswitch is at

position 0.

configurable in the

global settings, is

turned on.

Restart the system. Contact

Domino.

Wait for the heaters in the

scanner motors to warm the

scanners, the printer can be

used but you may

experience very minor

position errors.

Check that the fans are

working and that the filters

are not blocked.

Check that the fans are

working and that the filters

are not blocked.

Information Only.

Load a message and send it

to printer.

Turn keyswitch to start

position, or give a remote

start input (the “Play” button

on the UI will not function).

Turn the keyswitch to

position 1.

Information Only.

57

Page 59

Status

Message

552 External

Interlocks

Open

553 External

Interlock 1

Open

554 External

Interlock 2

Open

555 Air Fault Not enough air flow

556 Vacuum Fault The DPX is not

557 Filter not ok The DPX filters are

578 System

Standby

579 Printer

enabling.

580 Inconsistent

Laser On State

Cause Suggested Action

The interlock or

interlocks are open.

The interlock switch

1 is open

The interlock switch

2 is open

to cool the laser.

running.

blocked.

The keyswitch is at

position 1 but not

yet set by turning

the keyswitch or

remote start.

The laser is

switched on but

warming up.

The laser start input

level is being

overridden by a user

interface laser on

selection or by a

fault message.

Close the guards to 'make'

the interlocks.

Close the guards to 'make'

the interlocks.

Close the guards to 'make'

the interlocks.

Check the air regulator filters

and pressure settings.

Make sure the DPX is

serviceable and running.

Change the DPX filters.

Turn the keyswitch to start

position, or give a remote

start input, or press the

“Start” button on the user

interface.

Wait for the printer to be

ready.

Restart the system. Contact

Domino.

58

Page 60

Status

Message

581 Next controller

not ready

582 Controller Idle

(Multi Head

System)

583 External

Interlock has

been opened

594 Safety Relay

Fault

Cause Suggested Action

The next controller

in a “chain” in a

Multihead

configuration is not

ready.

The system is part

of a multi head

“chain” but has

been disabled (see

install options). This

is for information

only.

One or both

interlocks was

opened but is now

closed.

There was a laser

start command

present while one or

both (CAT3/4)

interlocks where not

closed.

Restart the system. Contact

Domino.

Restart the system. Contact

Domino.

Restart the system. Contact

Domino.

Make sure the interlocks are

closed before giving the laser

start input.

Note: For all other errors or messages contact Domino.

59

Page 61

Loading...

Loading...