Domino C6000 plus, C6000i plus, C3000 plus, C3000X plus, C6000MF plus Operation And Maintenance Manual

...Page 1

C-Series plus

Printer

Operation and

Maintenance Manual

Page 2

THIS PAGE INTENTIONALLY BLANK

2 77144 Issue 8 August 2009

Page 3

DOMINO C-SERIES plus PRINTER

OPERATION AND MAINTENANCE

MANUAL

This manual, Part No. 77144, is for use with the Domino C6000, C6000(i,)

C6000MF, C6000v, C3000, C3000X, C1000, C1000X

For further printer maintenance information, call Domino.

For sales, service and inks enquiries, please contact:

Domino Printing Sciences plc Domino Amjet Inc

Bar Hill 1290 Lakeside Drive

Cambridge CB3 8TU Gurnee IL. 60031

Tel: +44 1954 782551 Tel:+1 847 244 2501

Fax: +44 1954 782874 Fax:+1 847 244 1421

All rights reserved. No part of this publication may be reproduced, stored on a

retrieval system, or transmitted in any form, or by any means, electronic,

mechanical, photocopying, recording or otherwise, without the prior permission

of Domino Printing Sciences plc.

Domino Printing Sciences plc has a policy of continuous product improvement,

the Company therefore reserves the right to modify the specification contained in

this manual without notice.

© Domino Printing Sciences plc 2009

plus Printers.

77144 Issue 8 August 2009 3

Page 4

C-SERIES plus

EC DECLARATION OF CONFORMITY

(in accordance with ISO/IEC 17050-1)

No. 77144/1

Issuer’s name: Domino UK Ltd.

Issuer’s Address: Bar Hill, Cambridge CB3 8TU

Object of the declaration: Domino C1000, C1000X, C3000, C3000X,

C6000, C6000(i,) C6000v and C6000MF Printers

The object of the declaration described above is in conformity with the

requirements of the following documents:

EN 61000-6-4:2007 Electromagnetic Compatibility (EMC). Generic

Standards. Emission standard for industrial environments.

EN 61000-6-2:2007 Electromagnetic Compatibility (EMC). Generic

Standards. Immunity Standard for industrial environments.

EN 55022-1 1998 Class A : Electromagnetic Compatibility (Radiated).

EN 60950:2000 Safety of Information Technology Equipment.

2006/95/EC : Low Voltage Directive.

2004/108/EC : EMC Directive.

Signed for and on behalf of:

Domino UK Ltd.

Bar Hill,

Cambridge,

August 2009

Pete Jakes

OCC Technical Manager

4 77144 Issue 8 August 2009

Page 5

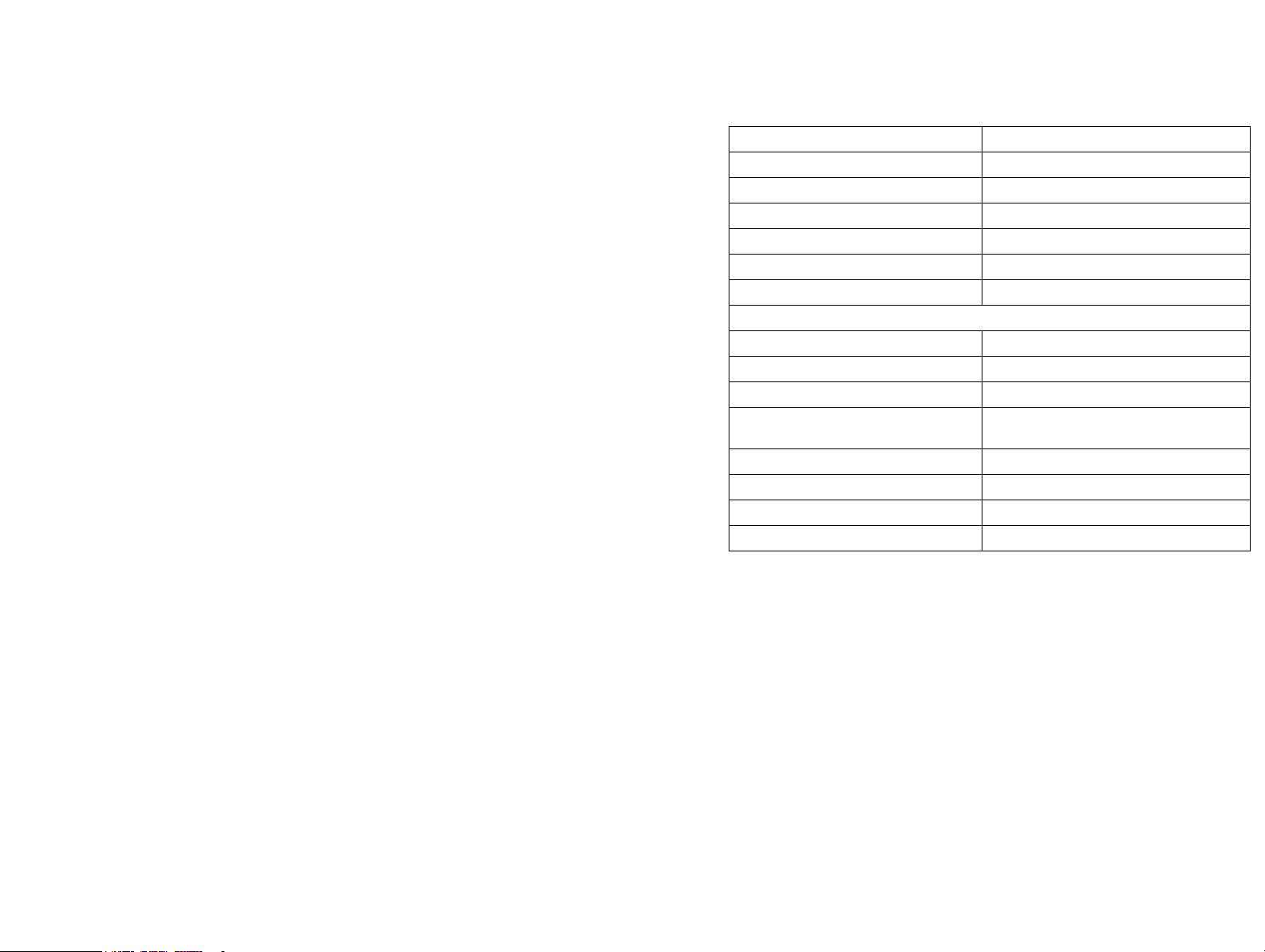

CONTENTS

Page

EC DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fire safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Eye contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Skin contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ingestion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Inhalation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PRINTER SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Print Head (Remote) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Base Unit Connectors (MHB) . . . . . . . . . . . . . . . . . . . . . . . . 15

BASIC OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Base Unit Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dual Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control Unit Head Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Control Unit Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rotating the Remote Head 90° - C3000X and C1000X Only . . . . . . . . . 28

Printing at Angles - C6000I Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PRINT HEAD SETUP – C6000v ONLY . . . . . . . . . . . . . . . . . 32

Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Printing at Angles - C3000X and C1000X Only . . . . . . . . . . . . . . . . . . . 34

Head Mounted Box Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Ship Cap Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Releasing the Air Flow Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

77144 Issue 8 August 2009 5

Page 6

Replacing an Ink Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

200ml Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

2 Litre Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Control Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Priming the Print Head(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

C6000v Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Priming a Rotated Head - C3000X and C1000X only . . . . . . . . . .51

Auto Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Number of Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Timed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Event Driven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Control Unit Keypad Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Basic Interface Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Functions and Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Keypad Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Function Keys - C6000 MF Only . . . . . . . . . . . . . . . . . . . . . .58

LCD Screen Icons - C6000 MF Only . . . . . . . . . . . . . . . . . . . .58

LCD Screen Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Interface Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Setting a Print Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Printing a Default Test Message . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Printing a Saved Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Deleting a Saved Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

PROGRAMMING THE PRINTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Selecting a Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Setting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Rollover Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Enter Number of Shifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Checking Current Box Count . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Erasing the Control Unit Memory . . . . . . . . . . . . . . . . . . . . . . . .79

6 77144 Issue 8 August 2009

Page 7

Print Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Ink Cost Calculator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Prompted Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

External Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

External Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Message Revert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Action Comms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Echo Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Satellite Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Shaft Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Shaft Encoder Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Screen Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Acknowledgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Record Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Bottle Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Extra Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Retrieve Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Auto Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

IP Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

FORMATTING MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Creating a Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Edit Which Message? Sub-Menus . . . . . . . . . . . . . . . . . . . . . . 90

Select Alternative Font . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Entering Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Message Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Adding Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Saving a Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Message Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Entering a Sell By Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

77144 Issue 8 August 2009 7

Page 8

Real Time Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Character Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Bar Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Creating a Bar Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Data Matrix Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

QR Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Logos (Graphics) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

ADJUSTING PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Message Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Changing the Ink Collection Sponge . . . . . . . . . . . . . . . . . . . . . .131

Every 6 Months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Cleaning the Nozzle Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

C6000v Head Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Relocating the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

C1000X & C3000X PRINT HEAD POSITIONING . . . . . . . . . . . . . . . . 137

DIMENSION DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

OPERATOR NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Message Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

8 77144 Issue 8 August 2009

Page 9

SAFETY INFORMATION

SAFETY INFORMATION

SAFETY RECOMMENDATIONS

Before proceeding with installation, using or maintaining the printer, please read

this section of the manual carefully.

Domino UK Ltd. shall not be liable against any damage or problems that arise from

the use of any options or consumable products other than those designated as

original Domino UK Ltd. or Domino UK Ltd. approved products.

Fire safety

The C-Series range of inks are not classed as flammable. In the event of an

electrical fire, combustion of the ink may produce toxic and irritating vapours.

Locating the printer in a well ventilated location is highly recommended. The inks

are also sensitive to ignition by electrostatic discharge, precautions must be taken to

prevent this form of ignition occurring.

Please refer to the Domino Safety Data Sheet (SDS) for further details.

Maintenance

WARNINGS: (1)When performing any maintenance tasks that

involve the disassembly of any part, ensure the

mains power is removed.

(2)Ink contact with the eyes must be avoided,

therefore eye protection must be worn whenever

there is risk of ink splashing or misting.

CAUTION: The printer must always be kept upright, with the keyboard facing

upwards. During transit and in general handling, the printer should

not be tilted by more than 15 degrees. When installed, the underside

of the printer should be as close to horizontal as possible, so that the

printing nozzles are in a vertical line (not applicable to remote

heads). The printer should never be subjected to knocks or vibration.

If damage occurs to the mains plug or cable, replace immediately by contacting

your local Domino office.

77144 Issue 8 August 2009 9

Page 10

SAFETY INFORMATION

INK

The use of ink other than supplied by Domino UK Ltd.will almost certainly result

in the damage of the print head.

When handling ink or cleaning ink spillages, care should be taken to avoid contact

with skin or eyes.

Protective glasses and gloves must be worn. In the event of contact with skin, eyes,

or ingestion, follow the first aid instructions below and refer to the relevant Safety

Data Sheet (SDS).

Eye contact

Flood the affected eye for 15 minutes with saline solution (or clean water if saline

solution is not available), taking care not to allow the water to run into the

unaffected eye. Medical aid must be obtained immediately.

Skin contact

Remove contaminated clothing. Wash skin with water. If symptoms develop,

obtain medical attention.

Ingestion

Wash out mouth with water and give 200-300ml of water to drink. Do not induce

vomiting. Obtain medical advice.

Inhalation

Remove patient from exposure, keep warm and at rest. Obtain medical attention if

ill effects occur.

Storage and Disposal

If storing any ink, containers should be tightly closed. Keep ink away from

oxidising agents and precautionary measures should be taken against contact with

static discharges.

Disposal of any ink containers or ink spillage’s should be in accordance with local,

state or national authority legislation.

10 77144 Issue 8 August 2009

Page 11

INTRODUCTION

INTRODUCTION

The C6000(i), C6000v, C3000(X) and C1000(X)

are the latest in high resolution ink jet case coders,

capable of printing up to 8 lines of text, graphics,

various barcodes, box counts and time/date

functions, all from its stand alone unit. The text

ranges from a maximum character height of:

C6000(i): 70mm to a minimum of 8mm

C3000(X): 35mm to a minimum of 4mm and

C1000(X): 17mm to a minimum of 2mm,

and is editable with various formats.

The (X) designates that the printer has a remote print head (attached to the control

unit via a conduit). The (i) designates a remote inclined print head (also attached

to the control unit via a conduit), this can be used where a conveyor is not

horizontal. Unless otherwise stated in this manual, the information refers to all

variants.

The maximum recommended printing speed is up to 144 metres per minute with

four different font heights available.

77144 Issue 8 August 2009 11

Page 12

INTRODUCTION

THIS PAGE INTENTIONALLY BLANK

12 77144 Issue 8 August 2009

Page 13

PRINTER SPECIFICATION

PRINTER SPECIFICATION

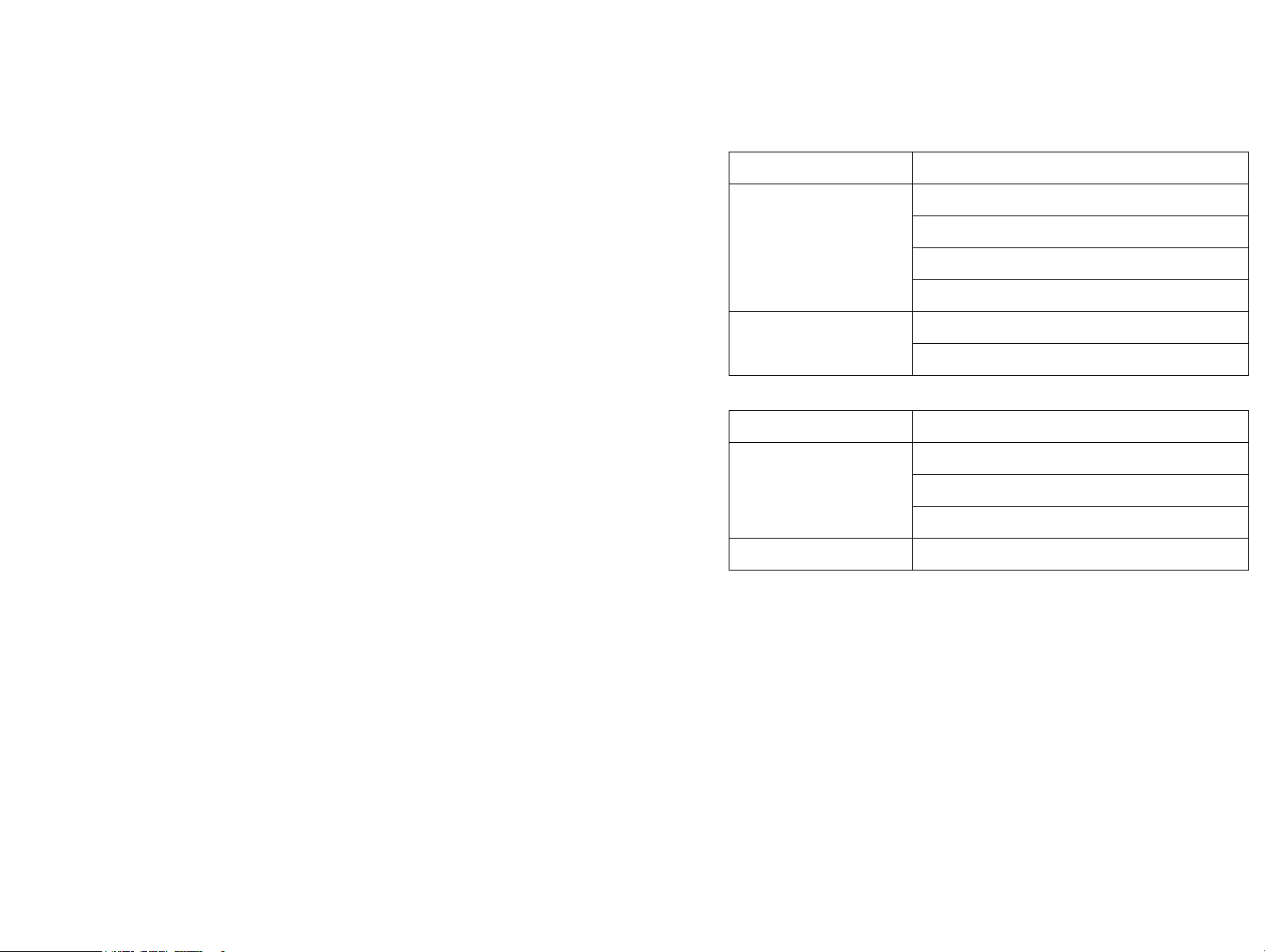

Print Head (Remote)

Standard Finish: Grained 304 Stainless Steel

Dimensions: (width x

height x depth):

Conduit Length: (128 & 256 dot): 1.0m

Control Unit

Standard Finish: Grained 304 Stainless Steel

Dimensions: (width x

length x height):

Control Panel Material: Polyester Membrane Touch Panel

(128 dot): 39.5mm x 71.5mm x 65mm

(256 dot): 59.5mm x 90mm x 90mm

(500 dot inclined): 79mm x 114mm x 187mm

(500 dot): 79mm x 170mm x 114

(500 dot only): 1.5m

(128 dot): 113mm x 295mm x 125mm

(256 dot): 113mm x 295mm x 146mm

(500 dot): 113mm x 370mm x 160mm

77144 Issue 8 August 2009 13

Page 14

PRINTER SPECIFICATION

Base

Standard Finish: (200ml) Grained 304 Stainless Steel

(2 litre) Grained 304 Stainless Steel

Grained 304 Stainless Steel

Dimensions: (width x

(200ml): 152mm x 360mm x 108mm

length x height):

(2 litre): 228mm x 507mm x 139mm

Dimensions (incl. bracket):

289mm x 520mm x 252mm

(width x height x depth):

Weight (no fluids): 16.3kg

Data Input

Interface Rate

RS232: 300 - 115200 Baud Software Configurable

TCP/IP: 10BaseT

Environment

Temperature Range (working):

Humidity: 10 - 90% RH

Electrical Supply: Single Phase, 90-240V @ 50-60 Hz

+10

ºC to +40ºC (50ºF to 104ºF)

14 77144 Issue 8 August 2009

Page 15

PRINTER SPECIFICATION

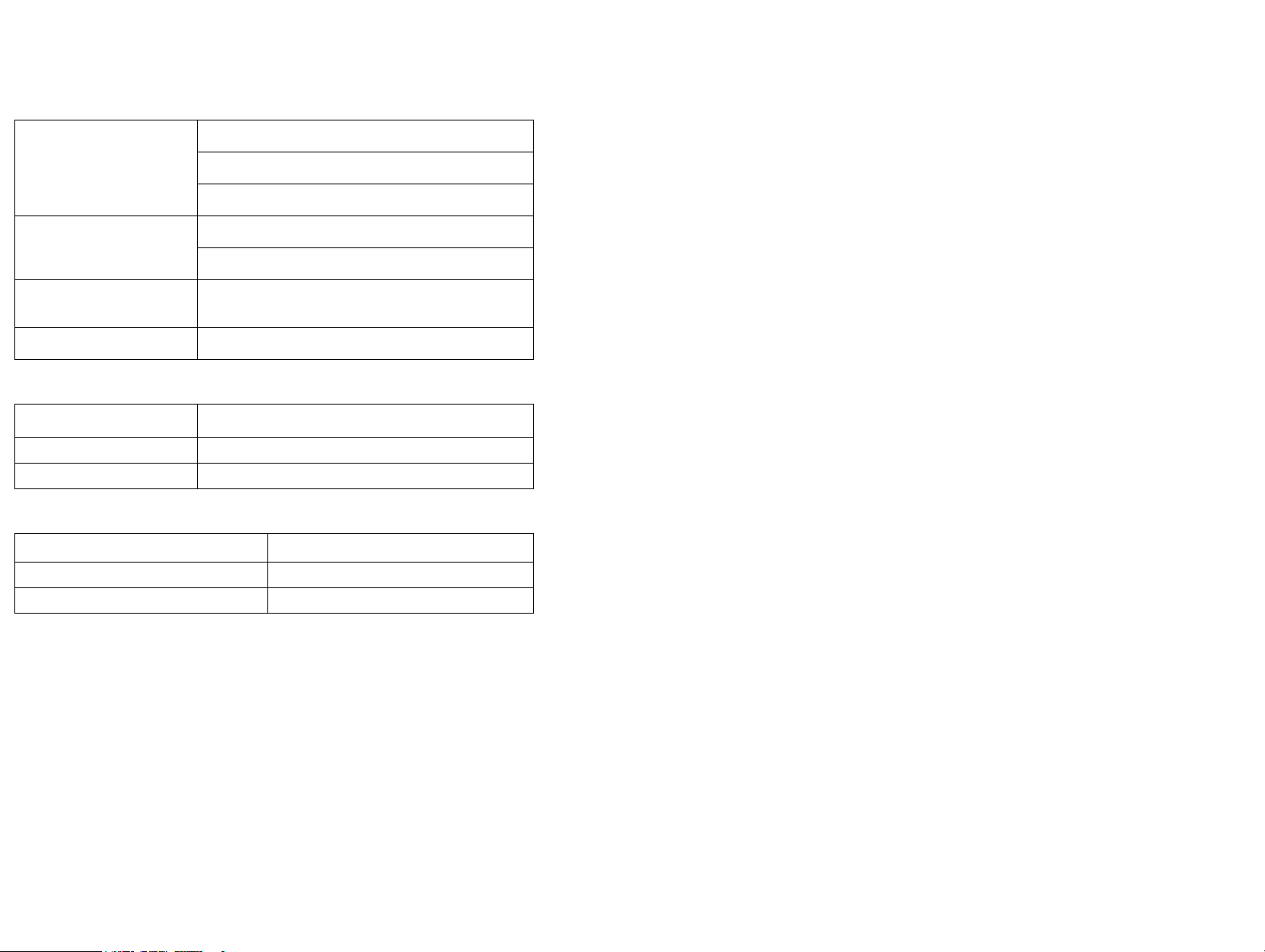

Base Unit Connectors (MHB)

Power Connector: IEC

Product Detector Connector: DIN 5-way 180

Shaft Encoder Connector: DIN 4-way

Shaft Encoder Input: PNP

RS232 Connector: 9-way D

Bottle Empty Alarm Connector: DIN 5-way 240

Ink Out Alarm Connector: DIN 5-way 240

Base and Head Connections

Product Detector Connector: DIN 5-way 180

TCP/IP Connector: RJ45

“Bottle Out” Alarm Connector: DIN 5-way 240 (2 litre base only)

Shaft Encoder Connector (via

Accessory Connection Box (ACB)): DIN 4-way

Shaft Encoder Input: PNP

RS232 Connector (via ACB) 9-way D

Ink Out Alarm Connector (via ACB) DIN 5way 240

Power Connector IEC

77144 Issue 8 August 2009 15

Page 16

BASIC OPERATIONS

Door Latch

Power Switch

Multi-head Base Unit

Ink Bottle (behind door)

Mounting Bracket

BASIC OPERATIONS

16 77144 Issue 8 August 2009

Page 17

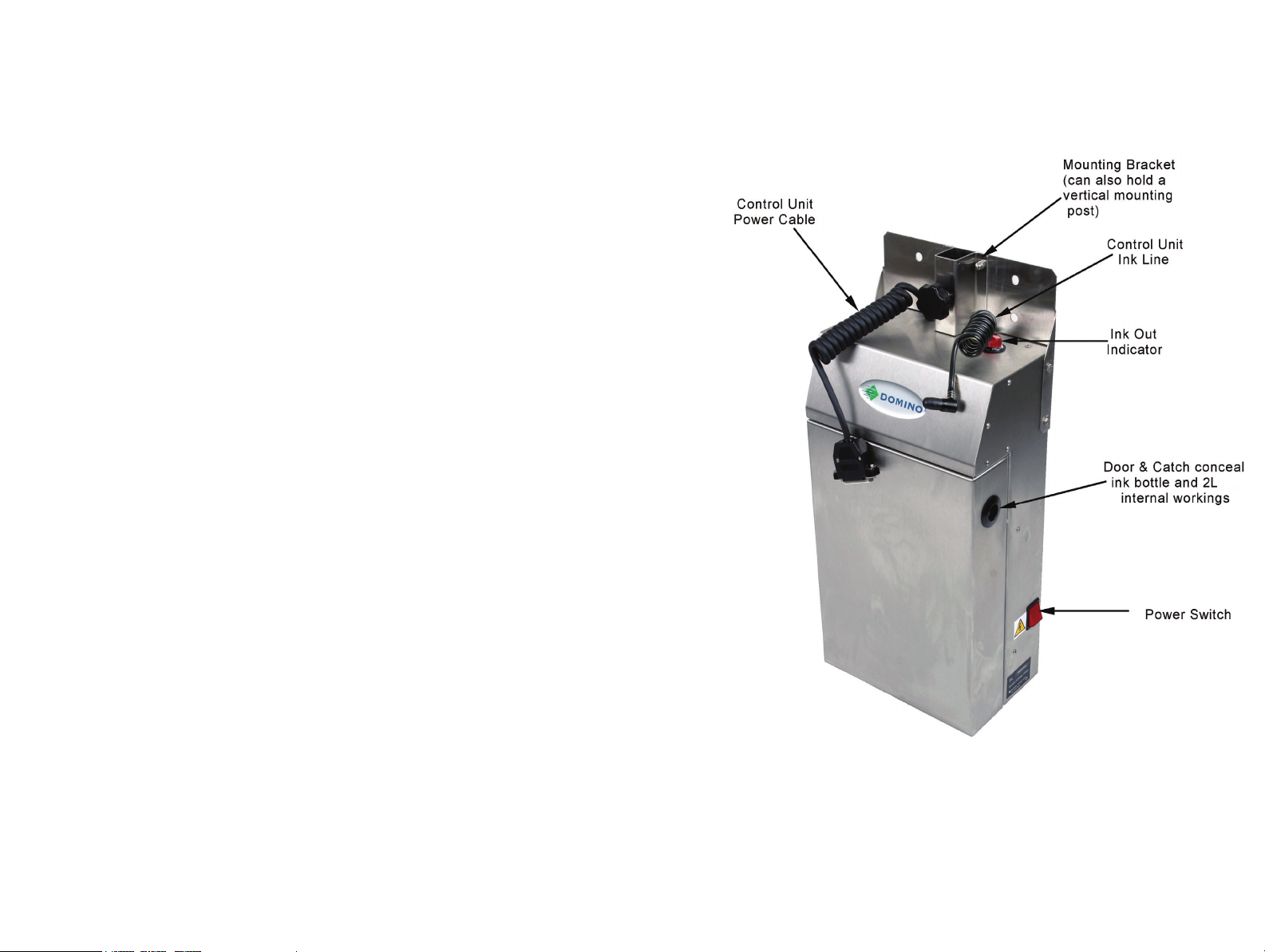

2 Litre Base Unit

BASIC OPERATIONS

77144 Issue 8 August 2009 17

Page 18

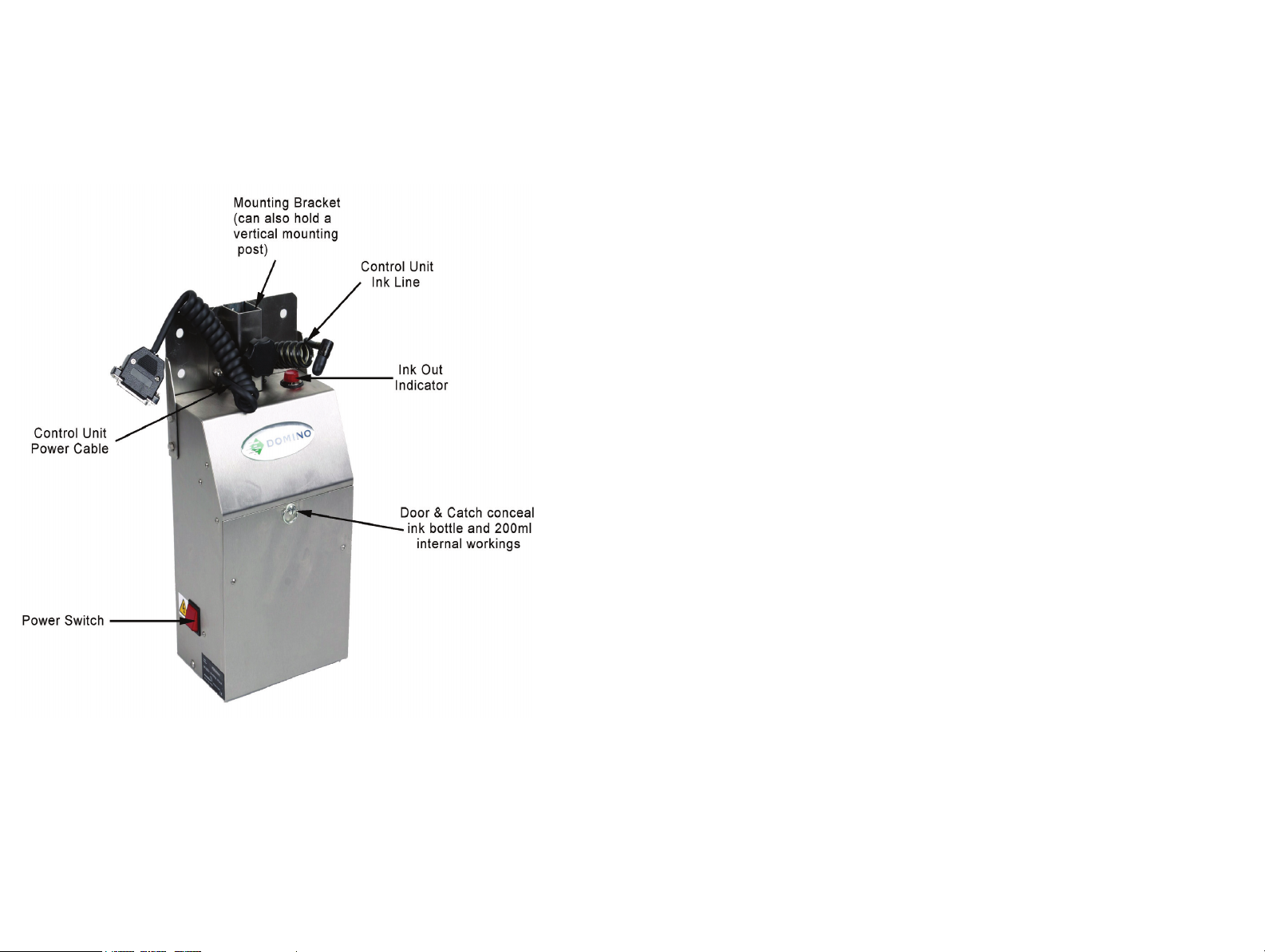

BASIC OPERATIONS

200ml Base Unit

18 77144 Issue 8 August 2009

Page 19

Alphanumeric

keypad

LCD display

Control unit

Control unit

power cable

C6000(i) Control Unit

C6000i Control Unit and Print Head

Conduit

Control unit

Print head

Product

Detector

BASIC OPERATIONS

77144 Issue 8 August 2009 19

Page 20

Keypad

LCD display

Control unit

Control unit

power cable

C6000MF - Control Unit

Product

Detector

BASIC OPERATIONS

20 77144 Issue 8 August 2009

Page 21

LCD display

Control unit

Control unit

power cable

C3000(X) Control Unit

C3000X Control Unit and Print Head

Conduit

Print head

Control unit

Alphanumeric

keypad

BASIC OPERATIONS

77144 Issue 8 August 2009 21

Page 22

Alphanumeric

keypad

LCD display

Control unit

Control unit

power cable

C1000 (X) Control Unit

C1000X Control Unit and Print Head

Conduit

Print Head

Control unit

Product

Detector

BASIC OPERATIONS

22 77144 Issue 8 August 2009

Page 23

Stand

Multi-head Base Stand

BASIC OPERATIONS

BASE UNIT MOUNTING

The base unit and control units must be mounted either on a stand or onto the

conveyor.

77144 Issue 8 August 2009 23

Page 24

BASIC OPERATIONS

Conveyor

24 77144 Issue 8 August 2009

Page 25

BASIC OPERATIONS

Dual Mounting

Bracket

Stand

DUAL MOUNTING BRACKET

Domino can supply a mounting bracket to enable two print heads to be mounted

next to each other on the stand.

77144 Issue 8 August 2009 25

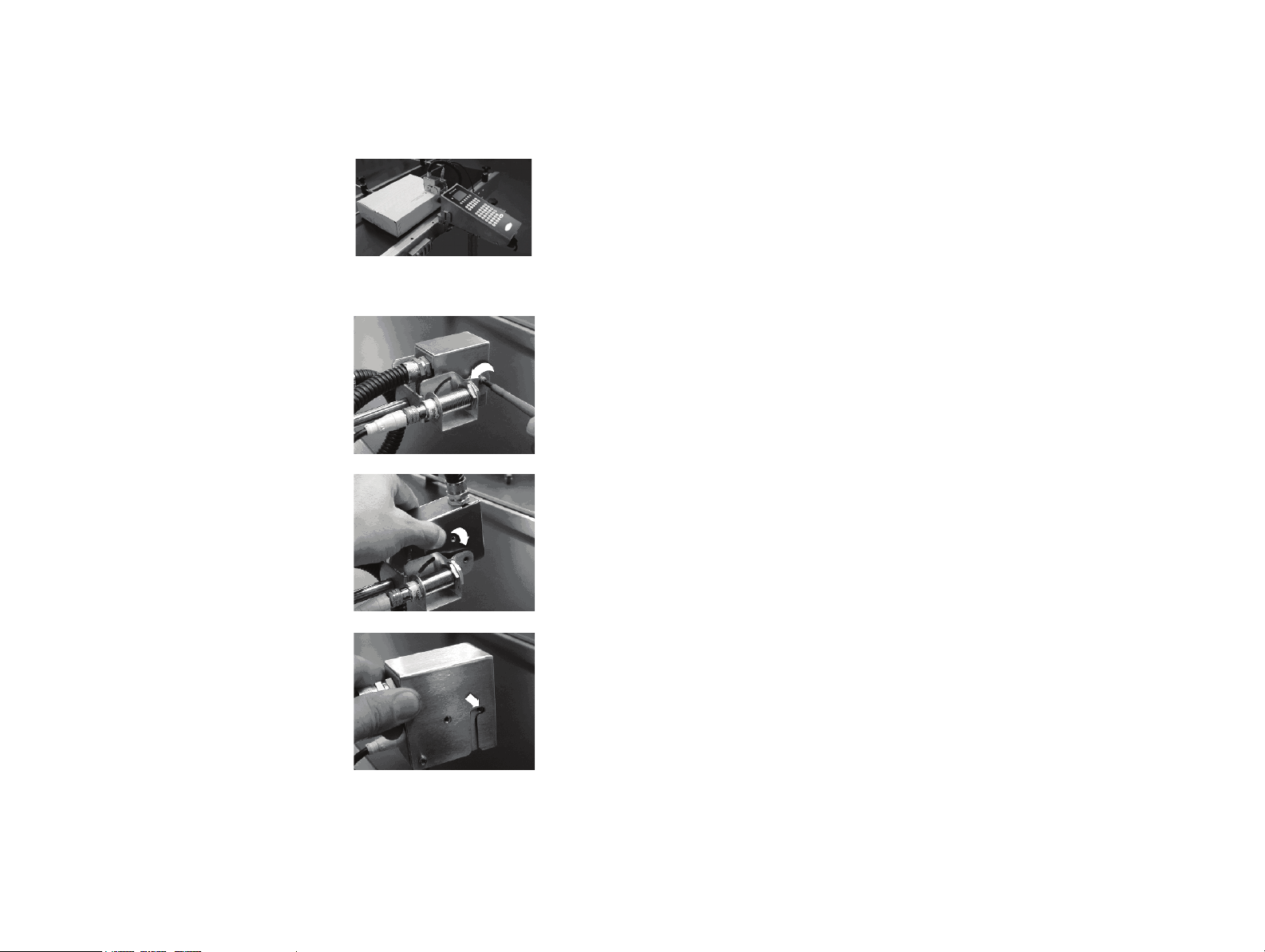

Page 26

BASIC OPERATIONS

Views show C6000

CONTROL UNIT HEAD MOUNTING

Note: It is recommended that control units are mounted on stands.

(1) To mount or dismount the control unit head,

loosen the fixing knob on the top of the

vertical mounting post.

(2) Mount the control unit by gently moving the

unit’s slide bar over the loosened clamping

plate. Ensure that the unit is well supported

during this operation.

(3) Ensure the front of the unit is facing the

conveyor belt as shown. To dismount the

unit, move the slide bar back off the

loosened clamping plate, ensuring that all

connections to the control unit are

unplugged.

(4) When the control unit has been moved to

the required position, tighten the fixing knob

at the top of the vertical mounting post.

26 77144 Issue 8 August 2009

Page 27

BASIC OPERATIONS

Base of Head and Base of

Control Unit must be at

same height when printing

vertically

CONTROL UNIT HEIGHT ADJUSTMENT

(1) The vertical mounting post on the printer

base unit can be adjusted up or down to the

required height. This operation should be

carried out with the control unit in place.

Note: Picture shown with control unit removed for

clarity.

(2) Tighten the fixing knob on the front of the

vertical column so that it is holding the

vertical mounting post securely in place.

CAUTION: The C6000i print head and

control unit must be adjusted to

the same height (bases) and must

be kept in the same environment.

Refer to page 30 for printing at

angles.

(3) To Adjust the C6000i print head, slacken the

fixing knob and adjust to the required

height.

77144 Issue 8 August 2009 27

Page 28

BASIC OPERATIONS

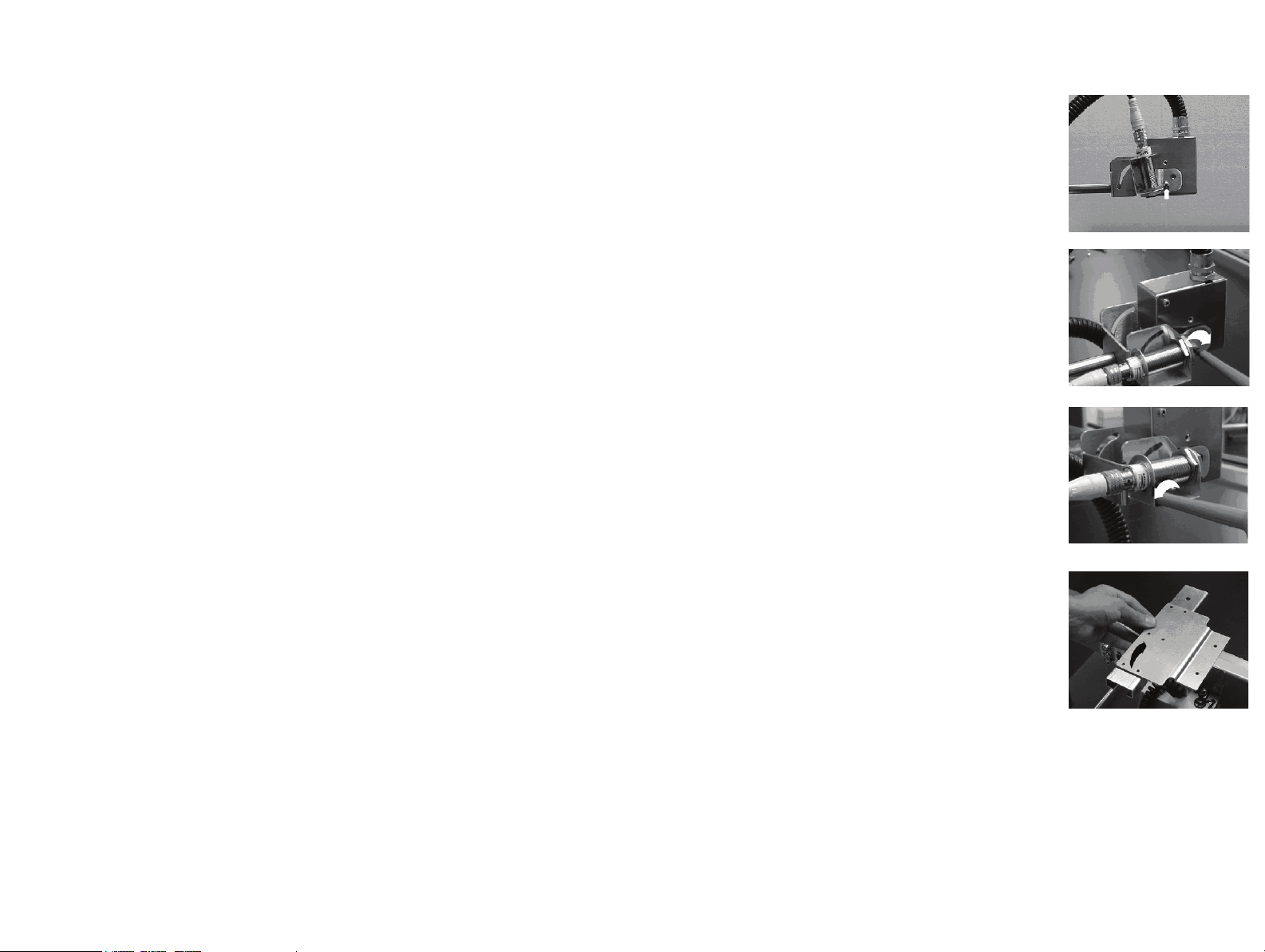

ROTATING THE REMOTE HEAD 90° C3000X AND C1000X ONLY

(1) To set a remote head to print down, the head

must be set to the correct height to provide

adequate tolerance for the print surface to

pass beneath it. By adjusting the length of the

bracket arm, the position of the message can

be placed accurately on the print surface.

(2) Before setting the print the head must be

rotated. The pivot point of the head will

need switching as follows; release the bracket

screws on either side of the head, ensure that

the head is held securely and the ship cap is

attached.

(3) Whilst holding the head, gently rotate it to

the position indicated.

(4) There are two sets of fixings on either side of

the head, use the ones shown.

28 77144 Issue 8 August 2009

Page 29

BASIC OPERATIONS

(5) There are two pivot points on the remote

head bracket. The top right position is for

forward and angled printing. The lower left

pivot point (indicated) is the mounting

position for printing down.

(6) Align the fixing holes and the pivot point on

the mounting bracket and refit the screws

enough to secure the head. Do not over

tighten.

(7) The sensor must also be inverted by

slackening the bottom left screw on the

sensor bracket and pushing the sensor up so

that it is facing down, ensuring that the

sensor is not triggered by the conveyor.

(8) The remote head mounting plate must be

removed and turned over to compensate for

the drop in height due to the new pivot

point. The mounting plate has a bend on

one side that increases the head height by

9mm, see step (3) on page 34. To do this,

dismount the control unit, remove and flip

the plate and remount the unit to the vertical

pillar.

77144 Issue 8 August 2009 29

Page 30

BASIC OPERATIONS

0o TO +25

o

0o TO +25

o

Controller

Print head

PRINTING AT ANGLES - C6000i ONLY

When printing horizontally, the controller

should be mounted so that the bottom

face is level with the bottom face of the

print head.

The print head can print up to a

maximum angle of 25

angle is maintained - i.e. the bottom dot

position should be higher than the bottom

of the controller face. To achieve this, the

print head should be mounted on either

side of the mounting post as follows:

Note: Before repositioning the mounting

brackets, ensure the ship cap has

been fitted and the vent valve is

shut. Ensure that the conduit

does not become twisted whilst the

print head is removed from its

mounting.

(1) Remove the bracket and print head

from the mounting post, then

remove the bracket from the print

head. Take care to retain screws

and nuts.

(2) Mount the bracket on the other

side of the print head and refit to

the mounting post. Adjust the

print head to the required angle (up

to a maximum of 25

º as long as a positive

º).

30 77144 Issue 8 August 2009

Page 31

BASIC OPERATIONS

(3) After the print head has been mounted at the required angle, check the ink

flow from the controller to the print head (for initial start up it may be

useful to place tissue beneath the print head face):

(a) If the print head face is weeping:

(i) Ensure the bottom edge of the print head is the same height as

the bottom face of the controller.

(ii) Ensure that the print head angle has not exceeded 25

(iii) If the print head is still weeping, it is recommended to lower the

controller slightly whilst observing the print, until the weeping

around the lower dot position has stopped.

(b) If any dots are missing from the message (particularly at the top), it

may suggest that the controller is positioned too low in relation to the

print head. In this instance, the controller should be raised slightly

whilst observing the print until the dots re-appear.

º.

77144 Issue 8 August 2009 31

Page 32

BASIC OPERATIONS

PRINT HEAD SETUP – C6000V ONLY

The C6000v is designed only to print vertically down - for this to work there must

be a difference of 40mm ± 5mm between the bottom of the unit and the face of

the print head.

When first putting ink in the unit there are a few procedures that should be

followed to ensure that the printer works as expected and that it removes all the air

from the print head.

Setup Procedure

(1) Place a suitable ink bottle in the base and set the head to the correct height;

this is 40mm ± 5mm between the bottom of the unit and the face of the

print head. Let the unit top up with ink so that it displays ‘ink ok’.

(2) With the ink line disconnected, prime heavily until the unit displays ‘ink

low’. Turn the unit off then lift the head cover to close the AR/03 valve.

(3) Turn the unit back on. It will display ‘ink-low’. Place a container or cloth

under the print face to catch the ink. Then reconnect the ink line. This will

give a continuous ink flow from the print head. Once all the air stops

coming out of the print face, switch off the unit, lift the cover and open the

AR/03 valve.

32 77144 Issue 8 August 2009

Page 33

BASIC OPERATIONS

(4) Turn the head 90 degrees. Prime heavily, catching the ink in a suitable

container or cloth until all air is removed.

(5) Turn the head to its original vertical position.

Clean the head and test (see ‘Head Cleaning’ and ‘Priming’ on the next

page).

After the setup has been completed there are several things to look for. Below are a

few examples:

(a) Weeping: If the head is weeping then ensure that the AR/03 is open

and that all air has been removed by priming the unit. If weeping

continues then raise the print head, remembering that the maximum

height for the face of the print head should be 45mm from the bottom

of the unit.

(b) Missing channels: If a channel is missing on the test print, prime the

unit and if the problem persists lower the print head. No lower than

35mm from the bottom of the unit.

(c) Missing dots: Prime the unit. If this does not fix the problem then

clean the print head face with either WJ-910 or WJ-911.

77144 Issue 8 August 2009 33

Page 34

BASIC OPERATIONS

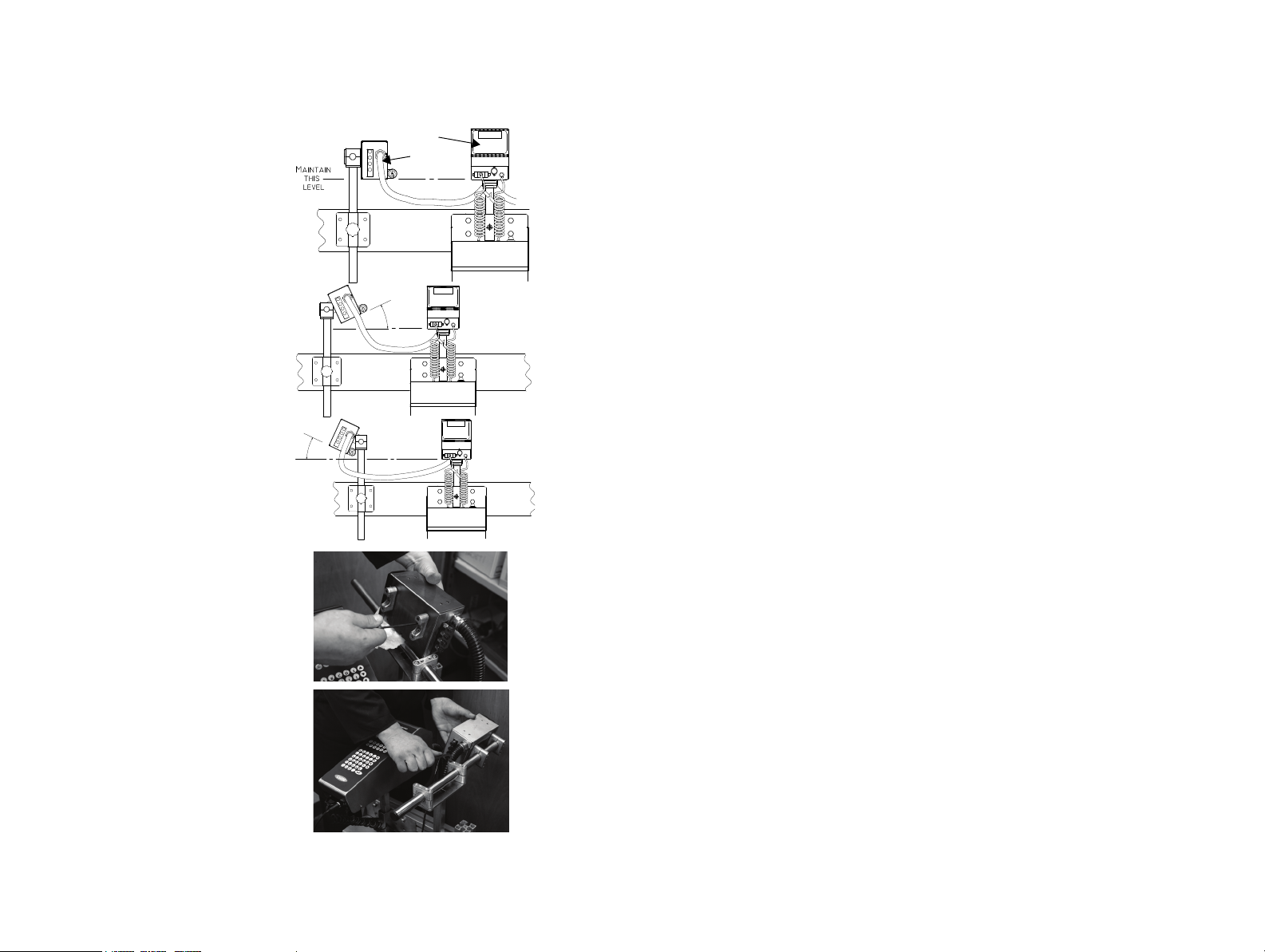

30°

90°

0°

30°

If using the bottom left pivot point the bend

in the bracket plate should be facing up

If using the top right pivot point the bend in

the bracket plate should be facing down.

PRINTING AT ANGLES - C3000X AND C1000X ONLY

(1) The remote head must be tilted in the

bracket arm to the required angle as follows;

slacken the two bracket fastening screws and,

using the top right pivot point, rotate the

head to the required angle. Note the

minimum and maximum angles for the top

pivot.

(2) If a smaller angle is required, the lower pivot

point must be used. When the lower pivot

point is used, the bracket mounting plate

must be turned over to compensate for the

height difference between the two pivot

points. The picture shows the different

bracket orientations.

(3) Turn the mounting plate in the direction

indicated to correspond with one of the

orientations outlined above, this will depend

on the pivot point chosen. Align the holes

then mount the control unit and the remote

head bracket to the sliding bar.

34 77144 Issue 8 August 2009

Page 35

BASIC OPERATIONS

Box

guide

rail

Buffer plateBox Guide

Ink drip tray

and ink

collection

sponge

HEAD MOUNTED BOX GUIDE

Some conveyors require extra guidance rails for the

boxes to travel on the conveyor without twisting or

hitting the control unit. The head mounted box

guide rail controls the distance between box and

print head and also corrects the misalignment of

boxes that have moved out of the correct printing

path. The box guide should only be used in

conjunction with conveyor guide rails. For

installation instructions on this box guide refer to

your local Domino office. Instructions for changing

the ink collection sponge are on page 131.

77144 Issue 8 August 2009 35

Page 36

BASIC OPERATIONS

Ship cap attachment

SHIP CAP ATTACHMENT

The ship cap is the protective cover placed

over the nozzle plate to protect it during transit

and from dust when it is not in use for more

than 24 hours.

Fit the ship cap to the print head as follows:

(1) Align the ship cap screws with the holes

either side of nozzle plate on the front

of the control unit and tighten the

screws.

(2) Screws should be tightened to the

following torque:

C1000 and C1000X - 0.34 N.m

C3000 and C3000X - 0.68 N.m

C6000, C6000MF, C6000v and C6000i - 0.34 N.m

(3) Remove the ship cap before re-starting the unit.

36 77144 Issue 8 August 2009

Page 37

BASIC OPERATIONS

Air Flow

Vent

Air Flow

Release

Locking

Screw

RELEASING THE AIR FLOW VENT

WARNING: If the printer is being run for the first time since

installation or re-mounting, the air flow vents must

be released.

There are two air flow vents in the C6000 and C6000(i), and one in the C3000

and C1000 that require releasing prior to initial power up. There is also a vent in a

2L base that needs to be released.

For the vent(s) on the header tank:

(1) Using a screwdriver, remove the four screws

securing the control unit cover.

(2) Carefully raise the control unit cover and move back

just enough to expose the header tank in the top left

corner of the control unit.

(3) The header tank air flow vent is a small plastic

valve located on the top of the header tank.

77144 Issue 8 August 2009 37

Page 38

BASIC OPERATIONS

C6000(i)

C3000, C1000, C6000v

2xvalves

Remove all securing

screws to remove the

panel cover.

Valve is located on top

of the reservoir.

(4) Using thumb and forefinger, fully undo the metal

locking ring surrounding the grey plastic air flow

release, then fully open the air flow release. When

complete, tighten the locking ring. Carefully slide

the cover back in place and secure. Take care not

to trap any wires or pipes.

For the vent in the 2 litre base unit:

(5) Open the base door and remove the panel cover.

(6) Repeat step (4) for this valve.

38 77144 Issue 8 August 2009

Page 39

BASIC OPERATIONS

REPLACING AN INK BOTTLE

CAUTION: Do not pull on the pipes in the cap, when replacing the ink bottle.

It is possible to fit either a 1 or 2 litre ink bottle.

If fitted, the beacon will flash to indicate that the

ink bottle needs replacing.

(1) If installing the printer for the first time,

there may be a piece of protective tubing

over the ends of the probes. Pull off this

piece of tubing carefully - the probes

are very sharp. Check that both O-ring

seals are present around the supply stems,

otherwise air and ink leaks may occur.

(2) Discard the transit cap from the new ink

bottle and place the bottle into the front of

the unit.

(3) Push the air and ink probes into the correct

holes in the ink bottle, puncturing the

seals.

Note: The probes have different diameters which

must be aligned correctly with the holes in

the bottle, otherwise damage can occur if

the cap is forced.

(4) Press the centre of the probe assembly

firmly to ensure that both probes have

pierced the seals.

(5) Tighten the bottle cap (hand tight only).

Arrange the air and ink tubes so that they

cannot be trapped in the door mechanism.

77144 Issue 8 August 2009 39

Page 40

BASIC OPERATIONS

200ml Base

Note: New printers are shipped with a protective tube over the septum, ensure this is

removed prior to fitting the ink bottle.

When the ink bottle is exhausted, printing will continue for a short while because

of the small reserve of ink in the header tank. When the ink supply to the header

tank runs low, the replenishment indicator on the base unit will flash. If it is empty,

replace as follows:

(1) Open the base door by pushing the catch

toward the door and twisting 90º

anticlockwise. Unscrew to remove the used

ink bottle. Ensure the use by date on the new

ink bottle has not expired and unscrew the

protective cap from the bottle non-leak top.

(2) Gently push the top of the bottle into the housing

containing the steel puncture probe.

(3) When the ink bottle is located, apply a small

downward pressure and twist the bottle in a

clockwise direction until it tightens.

(4) Close the base unit door.

Note: Discard any used or damaged ink bottles in

accordance with local waste disposal legislation. Do

not attempt to reuse used or damaged ink bottles.

40 77144 Issue 8 August 2009

Page 41

BASIC OPERATIONS

2 Litre Base

CAUTION: Do not to pull on the pipes in the cap, when replacing the ink bottle.

A warning light on the top of the base will flash to indicate that the ink bottle

needs replacing. The light will flash slowly as the ink falls below the first level

(bottle empty, up to 8hrs of printing time remaining). When the ink falls below

the second level (ink chamber empty), the warning light will flash rapidly. When

the printer screen shows Ink status out, there are 19 prints remaining before the

printer will stop.

The ink cap is attached to the inside of the base unit by its two feed pipes (air in

and ink out). Two metal probes pierce the seal in the ink bottle allowing an airtight, ink-tight seal to be formed.

(1) If installing the printer for the first time, there may

be a piece of protective tubing placed over the ends

of the probes. Pull off this piece of tubing

carefully - the probes are very sharp. Check

that both “O” ring seals are present around the

supply stems, otherwise air and ink leaks may occur.

(2) Discard the transit cap from the new ink bottle and

push the bottle into its slots in the door of the unit.

(3) Push the air and ink probes into the correct holes

in the ink bottle, puncturing the seals. Notice that

the probes have different diameters which must be

aligned correctly with the holes in the bottle,

otherwise damage will result if the cap is forced.

77144 Issue 8 August 2009 41

Page 42

BASIC OPERATIONS

(4) Press the centre of the probe assembly firmly

with the thumbs to ensure that both probes

have pierced the seals.

(5) Tighten the bottle cap (hand tight only).

Arrange the air and ink tubes so that they

cannot be trapped in the door mechanism.

42 77144 Issue 8 August 2009

Page 43

BASIC OPERATIONS

Control Unit

Connectors

RS232

Product

Detector

Shaft

Encoder

Power

Connector

Ink Out

Beacon

Bottle Out

Beacon

Base Unit

Ink Connectors

Base Unit Connectors

To control Unit

1, 2, 3 and 4

To control Unit 1, 2, 3 and 4

INTERCONNECTIONS

Base Unit

CAUTION: Ensure that Control Unit connector 1 and ink connector 1 are

connected to control unit 1 and so on.

(1) The connections on the back of the control unit are for power, 4 x Control

unit connections, 1 x product sensor, 1 x shaft encoder, 2 x beacons (1 for

bottle out, 1 for ink out) and 1 x RS232 connection, there are also 4 x ink

connections. The control unit and ink connections relate to the 4 control

units that can be connected to the base. All connections should be checked

and maintained to ensure that the unit remains in good working order.

(2) Connect the 25-way connector(s) from the

control unit(s) to the base unit.

(3) Remove the blanking plug from the ink

connectors and connect the ink tube(s)

from the control unit(s) to the base unit.

(4) If required (e.g. for downloading messages),

connect the RS232 connection. This only

communicates to head 1, see “Options” on

page 85 for communication to multiple

heads.

77144 Issue 8 August 2009 43

Page 44

BASIC OPERATIONS

(5) Connect the product sensor and shaft

encoder.

(6) If used, connect the beacon(s).

(7) Power to the base unit is supplied via the

connector on the rear and switched on via

the illuminated switch on the side.

.

44 77144 Issue 8 August 2009

Page 45

BASIC OPERATIONS

C6000(i), C6000v

C3000 & C1000

C6000(i), C6000v

C3000 & C1000

C6000(i), C6000v

C3000 & C1000

Control Units

(1) The four connections on the back of the control unit

are the power, ink, external sensor and ethernet

connections. These connections should always be

checked and maintained to ensure that the unit

remains in good working order.

(2) The black power cable, from the base unit, is connected

to the power connection port and is secured in position

by two fixing screws. To unplug the connector ensure

these screws are unfastened.

(3) To connect the ink line, use the quick release (QR)

connector on the end of the translucent plastic tube,

running from the bottom rear of the base unit. The

QR connector must be pushed into the female

connection port on the back of the control unit head

until it clicks into place.

77144 Issue 8 August 2009 45

Page 46

BASIC OPERATIONS

C6000(i), C6000v

C3000 & C1000

Sensor

Socket

Sensor

Socket

Ethernet

Connection

Ethernet

Connection

(4) To disconnect the ink line, push the locking plate on

the side of the connection port. The connector will

release with ease. The QR plug and connection port

both contain spring loaded valves that automatically

seal to prevent ink loss.

CAUTION:The ink line should always remain connected when

the printers power is on, if disconnecting the ink line ensure the

power is turned off.

(5) The power is supplied via a connection on the

bottom of the base unit. The power cable should

be connected to a mains supply.

(6)The Ethernet connection is required if

communicating using TCP/IP protocol.

(7)The Multi-head Base Unit supplies all control units

fitted, with the print-go and shaft encoder signals.

(8)On 2L and 200ml bases only. The product sensor is

required for the C6000(i), C6000v, C3000X and

C1000X which connects into the sensor 5 pin DIN

socket.

46 77144 Issue 8 August 2009

Page 47

BASIC OPERATIONS

Power

Switch

Power

Switch

2 Litre Base

200ml Base

Powering Up

When the unit is correctly connected, the power can be switched on.

WARNING: If the printer is being run for the first time since

installation or re-mounting, the air flow vents must

be released - see page 37.

Note: If connecting for the first time, it may take a few minutes for the ink to transfer

from the bottle into the chamber.

(1) To power on the printer, press the power

switch on the bottom/top right side of the

unit (as shown). This switch will illuminate

to indicate that power is on.

77144 Issue 8 August 2009 47

Page 48

BASIC OPERATIONS

PLEASE WAIT

PRINTING Name

NORMAL PRINT

INK STATUS OK

ABC

(2) The printer will power up. The LCD screen will

flash twice and the screen will prompt “Please

wait” for a short while followed by

“Initialising”.

(3) After a short wait the screen shown will be

displayed. Where “Name” is seen, the

currently selected message name is displayed.

Before proceeding to the printing stage, it is

recommended that the prime function is

carried out to prime the nozzle plate with

ink, clearing any dust from the print head.

48 77144 Issue 8 August 2009

Page 49

BASIC OPERATIONS

PRINTING TEST

NORMAL PRINT

INK STATUS OK

ABC

ABOUT TO PRIME

PRESS TO

CONFIRM

OR ESC TO RESUME

PRIMING THE PRINT HEAD(S)

It is good practice to prime the control unit(s) at least once a day. It is

recommended that this is carried out as soon as the printer has been powered up at

the beginning of a shift to prevent degradation in the print quality.

Note: To run remote units for the first time: Power up the unit until ink ok is

displayed and then disconnect the ink line. Purge the unit until the head

reports ink low. Close the vent valves in the print head and reconnect the ink

line. The base will now pump ink through the system. Turn the unit off when

a constant stream of ink is coming from the print face. Release the vent valves

and turn unit on.

CAUTION: Do not wipe across the face of the nozzle plate.

Note: Illustrations show C6000.

(1) Hold a cleaning wipe just below the base of the

nozzle plate.

(2) Press the prime key on the LCD screen.

This will purge a small amount of ink through

the nozzle plate so it is primed and ready to

print.

(3) Before any ink is expelled from the nozzle plate,

a screen prompt will appear on the LCD asking

for confirmation of the prime function. Press

enter to confirm the action.

(4) Continue holding the cleaning wipe in position.

The print head will expel a small amount of ink

whilst making a vibrating sound for

approximately five seconds. Only remove the

cleaning wipe when all the ink has been soaked

up. The control unit is now primed and ready to

print. Repeat the procedure if necessary.

77144 Issue 8 August 2009 49

Page 50

BASIC OPERATIONS

Ink

Vent

Note: In the case of persistent air in the ink system, it

is possible to intermittently plug the ink vent on

the bottom of the printer with a finger during the

prime procedure. Put finger over vent hole for

maximum 1 second only. Do not keep finger

over the ink vent for the duration of the prime

procedure.

C6000v Priming

(1) Ensure the print head face is back in its vertical position. Prime as with

other units, catching the ink in a suitable container or cloth.

(2) To remove spots of ink from the print face, use a swab and gently blot to

remove the ink off the print face.

50 77144 Issue 8 August 2009

Page 51

BASIC OPERATIONS

PRINTING TEST

NORMAL PRINT

INK STATUS OK

ABC

ABOUT TO PRIME

PRESS TO

CONFIRM

OR ESC TO RESUME

PRIMING A ROTATED HEAD - C3000X AND C1000X ONLY

When a remote head is in the printing down position, prime as follows:

CAUTION: Do not wipe across the face of the nozzle plate.

(1) Slacken the bracket screws and pull the head

back at a slight angle as shown. Hold a

cleaning wipe just below the base of the nozzle

plate as shown.

(2) Press the prime key on the LCD screen.

This will purge a small amount of ink through

the nozzle plate so it is primed and ready to

print.

(3) Before any ink is expelled from the nozzle

plate, a screen prompt will appear on the LCD

asking for confirmation of the prime function.

Press enter to confirm the action.

(4) Continue holding the cleaning wipe in

position. The print head will expel a small

amount of ink whilst making a vibrating sound

for approximately five seconds. Only remove

the cleaning wipe when all the ink has been

soaked up.

(5) Move the head back to the printing down position and tighten the bracket.

Repeat the procedure if necessary.

77144 Issue 8 August 2009 51

Page 52

BASIC OPERATIONS

AUTO PRIME

WARNING: Ensure that any purged ink is collected using a box

guide with ink drip tray and collection sponge.

Note: The Auto Prime function is controlled using Connect software for the

C6000MF. Please refer to the Connect manual.

Number of Prints

It is possible to set the printer to automatically prime the print head after a set

number of prints. The printer will expel a small amount of ink from the nozzle

plate after the prints.

Set the auto prime function as follows:

Press the Options icon and select auto prime.

Note: This function is password protected.

Enter the number of prints after which the printer will auto prime. This is up to a

maximum of 32,000 prints and 0 is disabled.

The printer will then auto prime the nozzle after this amount of prints.

Duration

It is also possible to set the duration of the purge (the length of time the purge

pump is on), this can be set between 0.08 and 9.99 seconds.

Timed

Instead, or as well as setting the number of prints, it is possible to select the time in

minutes after which the purge occurs, up to a maximum of 32,000 minutes (0 is

disabled).

Event Driven

An external source can also give the printer a signal to auto prime, this is done in

conjunction with the above settings and is set to either Enable or Disable.

52 77144 Issue 8 August 2009

Page 53

BASIC OPERATIONS

Liquid Crystal

Display Screen

(LCD)

Main Menu Bar

Horizontal Scrolling

Scroll Menu Bar

Left

Delete

Alphanumeric

Keypads

Shift Up &

Down

Four

Corresponding

Menu Bar Selection

Keys

Scroll Menu Bar

Right

Escape Current

Menu/selection

Cursor Keys

Enter (Select)

Current Settings

Space

PRINTING TEST

NORMAL PRINT

INK STATUS OK

ABC

Standard Keypad Layout

CONTROL UNIT KEYPAD LAYOUT

77144 Issue 8 August 2009 53

Page 54

Liquid Crystal

Display Screen

(LCD)

Delete

Numeric

Keypad

UpShift

Escape Current

Menu/selection

Function Keys

Enter (Select)

Current Settings

PRINTING TEST

NORMAL PRINT

INK STATUS OK

ABC

Down Shift

Point

Scroll Left/

Right

Scroll Up/

Down

MF Keypad Layout

BASIC OPERATIONS

54 77144 Issue 8 August 2009

Page 55

BASIC OPERATIONS

Menu icons

correspond

with the plain

keys directly

beneath

If there are no

icons left in the

menu bar, the

direction key

will not do

anything if

pressed

This graphic is

part of the next

icon and means

there are

further icons to

the right

Directional

menu keys will

scroll through

the icons in the

menu bar

PRINTING TEST

NORMAL PRINT

INK STATUS OK

ABC

ABC

ABC

New graphic of

partial icon

appears on the

left side of the

LCD, indicating

that menu bar

can scroll left

New Product

direction icon

appears to the

right of the

LCD

PRINTING MESSAGE1

NORMAL PRINT

INK STATUS OK

ABC

Basic Interface Controls

The main menu bar is shown above. There are never more then four icons on

display at one time. These icons correspond directly with the plain keys beneath

them. For example if the plain key on the far right is pressed the prime icon

would be selected.

If the operator presses the left arrow key nothing will happen as there are no icons

in this direction. If the right arrow key is pressed once, the menu bar will scroll

across by one icon. As a result the print which message? icon will disappear

and the product direction icon is displayed.

77144 Issue 8 August 2009 55

Page 56

BASIC OPERATIONS

Functions and Menus

When the basic operation of the control unit is understood, the operator may

commence programming instructions and commands into the printer. It is

recommended to read through the different menus and familiarise with all icons.

Note: When using the directional keys to scroll through the menu bar, if the

directional arrow key is pressed and held, then the menu will continue to scroll

until the operator releases the key or the end of the menu bar is reached.

56 77144 Issue 8 August 2009

Page 57

BASIC OPERATIONS

E

SC

BC

Keypad Functions

The control unit communicates via an array of various keypad and LCD functions.

A brief explanation of these functions is as follows.

CONTROL UNIT,

FUNCTION KEYS

The enter key is used to execute commands like

saving changes to a message or confirming the

selection of certain commands.

The escape key is used when a command or icon

that has been selected is not required or needs to be

cancelled without making further selections.

The delete key is mainly used in the message editor

to erase text, graphics or spaces. It can also be used to

delete characters when entering information into

other menus and functions.

The up shift key can be combined with delete or the

alphanumeric keys, to give greater options for these

keys. For example if used with the alphanumeric keys,

the small green character in the top right corner of the

keys are used.

Name & Description

The down shift key is combined with other keys to

give alternate options with various keys. For example,

when down shift is pressed simultaneously with a

letter key, it will create a lower case character. Rather

than the default upper case.

The cursor keys control the movement of the

flashing cursor block in various option screens, for

example when editing text or setting the clock. They

can also be combined with the shift keys in the

message editor.

The space key is used to add spaces between text and

attributes when editing or creating a new message.

77144 Issue 8 August 2009 57

Page 58

BASIC OPERATIONS

E

SC

BC

2001

Function Keys - C6000 MF Only

CONTROL UNIT,

FUNCTION KEYS

The enter key is used to execute commands like

saving changes to a message or confirming the selection

of certain commands.

The escape key is used when a command or icon that

has been selected is not required or needs to be

cancelled without making further selections.

The delete key is used to delete messages from the

memory, or editing information.

The cursor keys control the movement of the flashing

cursor block in various option screens, for example

when editing the IP address.

LCD Screen Icons - C6000 MF Only

ROOT LEVEL, MENU

BAR ICONS

Name & Description

NAME & DESCRIPTION

It is recommended that the Prime print head is

performed every time the printer is started or

when the nozzle plate requires cleaning.

Enable user password, the operator can restrict

access to the control unit by installing a numeric

user password.

Wipe completely erases the control unit memory,

this icon will delete all saved messages and

downloaded logos. The printer will revert to its

default factory settings.

External Setup, used to setup parameters of

external variables - preamble, postamble &

timeout.

Options, allows the user to enable external

settings, such as IP Address.

58 77144 Issue 8 August 2009

Page 59

BASIC OPERATIONS

Down Shift

FIPTV

C6000MFSpecial Function Keys

UpShift

Point

The following keys are used to perform specific functions, usually in conjunction

with the downshift key.

Downshift + F Fill the ink system. If ink system is already full, will report

Ink system filled

Downshift + I View the IP setting details. To change the IP address, see

below.

Downshift + P Enable/Disable the password.

T To print a test message, hold the T button in and power

the printer on.

V View current software issue details

To change the IP address, use the scroll left/right buttons to locate the Options

icon , select by pressing the button below the icon. Using the Up/Down

scroll buttons, scroll the cursor to IP Settings, press enter to select the IP setting.

Use the delete key to remove the old value and replace using the numeric keys - to

enter a decimal point, use the upshift and Point keys. Once complete, scroll to

OK and press the enter key.

77144 Issue 8 August 2009 59

Page 60

BASIC OPERATIONS

ABC

ABC

LCD Screen Icons

ROOT LEVEL, MENU

BAR ICONS

NAME & DESCRIPTION

Print which message?, select a saved message to

be printed from the control unit’s memory.

Edit or create a message?, to format a new

message, update or edit an old message.

Parameters of the message can be altered, e.g.

print speed, DPI, delay, adjusting the bar codes or

copying current message parameters as the default

settings.

Prime print head, it is recommended the prime

function is performed every time the printer is

started or any time the nozzle plate requires

cleaning.

Product direction, depending on which side of

the conveyor the printer is mounted, will

determine whether the message is printed from left

to right or right to left.

Enter new time, can be adjusted at any point.

Details of time, date, month and day can be

entered for printing.

Rollover time, the default rollover time is set to

midnight. This is when the system clock will

rollover on to a new day. The rollover function can

be changed to suit.

Enter number of shifts, the printer can keep a

track of the shifts during the running time of the

production line, this icon allows the selection of

between 1-4 different shifts.

60 77144 Issue 8 August 2009

Page 61

BASIC OPERATIONS

123

2001

ABC

V

V

ROOT LEVEL, MENU

BAR ICONS

NAME & DESCRIPTION

Box count, this icon allows the operator to record

the number of products passing on the production

line.

Choose language, allows the operator to select

from the list of operating languages.

Options screen, allows the operator to enable

external peripherals, e.g. a shaft encoder or

external photo cell.

Enable user password, the operator can restrict

access to the control unit by installing a user

password so that the settings cannot be changed.

Wipe, to completely erase the control unit

memory, this icon will delete all saved messages

and downloaded logos. The printer will revert to

its default factory settings.

Orientation, to invert and reverse the message.

The print direction is automatically changed.

Ink Cost Calculator, used to calculate the cost

and amount of ink used for a specified message.

Var ia bl es , add either a prompted or external

variable into a message.

External Setup, used to setup parameters of

external variables - preamble, postamble &

timeout.

Shaft Encoder Sensing, measures S/E pulses to

ensure not being overdriven for current DPI.

77144 Issue 8 August 2009 61

Page 62

BASIC OPERATIONS

THIS PAGE INTENTIONALLY BLANK

62 77144 Issue 8 August 2009

Page 63

Interface Map

DPI

A

ABC

A

A

30 31 1

123

Æ

Ç

Ä

â

ABCD

ABCD

ABCD

ABCD

AB

A

D

Y

H

MM

DOW

DOY

W

PRINT

MAGNIFICATION

VARIABLE

EXTERNAL

SETUP

ALTERNATIVE

FONT

ABC

ABC

123

2001

ABC

V

V

ORIENTATION

INK COST

CALCULATOR

WIPE

MEMORY

ENTER

PASSWORD

OPTION

SCREEN

SELECT A

LANGUAGE

CURRENT BOX

COUNT

ENTER NUMBER

OF SHIFTS

ROLLOVER

TIME

ENTER NEW

TIME

DIRECTION

PURGE NOZZLE

PLATE

PARAMETERS

EDIT OR

CREATE NEW

MESSAGE

PRINT WHICH

MESSAGE?

PRINT WHICH

MESSAGE?

> MESSAGE 1

MESSAGE 2

MESSAGE 3

EDIT WHICH

MESSAGE?

>MESSAGE 1

MESSAGE 2

MESSAGE 3

PHASE

ADJUST

COPY

PARAMETERS

AS DEFAULT

PICK MESSAGE

TO ADJUST

PICK CURRENT

MESSAGE

WHICH

MESSAGE?

> MESSAGE 1

MESSAGE 2

MESSAGE 3

SPEED

RESOLUTION

DELAY BAR CODE

SPACING

BAR

WIDTH

V

V

VARIABLE

LOGO LIST

BAR CODE

CHARACTER

MAP

COUNTING

REAL TIME

COMMANDS

SELL BY

DATE

SELECT

FONT SIZE

EDIT

EIGHTH

HEIGHT

QUARTER

HEIGHT

HALF

HEIGHT

FULL

HEIGHT

OPTIONS

MENU

DAY MONTH

YEAR

D

Y

DAY MONTH

YEAR

OPTIONS

MENU

D

Y

DAY MONTH

YEAR

DAY OF

WEEK

DAY OF

YEAR

WEEK

SHAFT ENCODER

SENSING

BASIC OPERATIONS

77144 Issue 8 August 2009 63

Page 64

BASIC OPERATIONS

THIS PAGE INTENTIONALLY BLANK

64 77144 Issue 8 August 2009

Page 65

BASIC OPERATIONS

Bottom

of

nozzle

plate

SETTING A PRINT JOB

When setting a print job, it is good practice to prepare the site - ensuring that the

printer and conveyor are set correctly. The following steps outline this set up

procedure:

A Multi-head Base Unit should be mounted in a suitable position to enable the

control units to be mounted within 3 metres of the base. Each print head can be

set up as follows:

(1) Calculate exactly where the message is to be

printed on the surface of the substrate. For

this example, the message is printed on the

box.

(2) To calculate how high to set the print head,

place the print surface (box) onto the

conveyor next to the control unit, measure

from the lowest point of the intended

message to the conveyor surface. This

measurement will be where the bottom of

the nozzle plate will need to be set.

(3) Measure from the bottom of the nozzle plate

to the conveyor. Ensure this measurement

matches the distance from step (2). If not,

loosen the black plastic fixing knob on the

front of the base unit and adjust to the

desired height.

77144 Issue 8 August 2009 65

Page 66

BASIC OPERATIONS

Fixing knob

(4) When the control unit is at the required

height, tighten the fixing knob.

(5) When the vertical height of the unit is set,

the conveyor mounted guide rails should be

positioned so the box is not too far from the

print head. At this point the distance from

the control unit front to the box can be

approximated. It will be adjusted more

accurately in the next step.

(6) To accurately adjust the horizontal distance

between the box and the unit, loosen the

black plastic fixing knob beneath the control

unit, then move the unit forward until it sits

flush against the surface of the box. Do not

press too hard, the surfaces should be as

close as possible without touching.

(7) When the horizontal distance is set, ensure

there is adequate tolerance for the box to

move past the print head without getting

stuck or misaligned. If not, move the control

unit back very slightly.

(8) Repeat steps (1) to (7) above for all control

units (print heads).

66 77144 Issue 8 August 2009

Page 67

BASIC OPERATIONS

A

(9) When the set up is complete, the printer

should be switched on and tested. Run a test

box on the conveyor, past the print head(s) to

check that the message is printing in the

required location. The vertical and

horizontal adjustments may need to be fine

tuned. If the message is printing too close to

the edge of the box then this must be

adjusted using the delay function . See

Adjusting Parameters for further

information, for the C6000MF printer this is

done via the Connect software, refer to the

Connect manual.

77144 Issue 8 August 2009 67

Page 68

BASIC OPERATIONS

PRINTING A DEFAULT TEST MESSAGE

The printer can print a test message to check print quality, as follows:

(1) Turn off the printer.

(2) Hold down the letter ‘T’ button and switch on the printer.

(3) Keep the ‘T’ button depressed until the screen shows that initialising is

complete. During this time the test message will be loaded.

(4) Print the test message by passing a piece of card in front of the product

detector and printer. Check the test message is clear and complete. If any

nozzles appear blocked, refer to the section “Priming the print head”.

It is also possible to print the test message by selecting the message called “TEST”

from the print which message menu.

68 77144 Issue 8 August 2009

Page 69

BASIC OPERATIONS

ABC

LOAD MESSAGE

LOAD MSG TO MEMORY

DELETE MSG FROM MEMORY

ABC

PRINT WHICH MESSAGE

> ALAN

BEST

DATE

CRISPS

PRINT WHICH MESSAGE

DATE

EXPIRY

s*

> SCREWS

SWAP

TINNED

PRINTING A SAVED MESSAGE

The printer can quickly switch between saved messages.

The message store can be viewed and messages uploaded by selecting the print

which message? icon. To use this function:

(1) Select the print which message?

icon on the main menu bar. The following

sub menu screen is displayed.

(2) The menu options can be selected using

the cursor keys to scroll the selection arrow

up or down and the enter key.

Load Message: The screen will display

the saved messages list in alphanumeric

order. The list can be scrolled up or down

using the cursor keys.

Alternatively, if the list is long, to save

scrolling through all the messages with the

up down cursors, the operator can press the

first letter of a message name. This will

cause the > cursor to move directly to the

first message beginning with that letter or

number (s in this example), this character is

retained so the second character entered

searches on the second character of the

message names,i.e.

SCREWS S would point to SCREWS

SWAP W would point to SWAP.

The search string is cleared if the UP or DOWN arrows are pressed. When

on the correct message, press enter to confirm the upload.

77144 Issue 8 August 2009 69

Page 70

BASIC OPERATIONS

PRINTING SCREW

NORMAL PRINT

INK STATUS OK

ABC

(3) When enter is pressed, the screen will return

to the main menu and the appropriate

message name will appear on the screen

prompt to confirm that it has been uploaded.

The message is now ready to be printed.

Load msg to memory: This also displays the saved messages in

alphanumeric order but, on selection it loads the message into memory to

allow for fast message changeover. It does not affect the currently printing

message. These messages in memory are selected from an external source.

Delete msg from memory: This displays the current list of messages

that are loaded into memory and enables the user to delete messages from

the memory list. This does not delete the message from the printer.

70 77144 Issue 8 August 2009

Page 71

BASIC OPERATIONS

ERASE

YOU ARE ABOUT TO

ERASE MESSAGE

SCREW

PLEASE CONFIRM

BC

DELETING A SAVED MESSAGE

To delete a message, select the edit which

message? menu, scroll the message list as

described in step (2) on page 69 and select a saved

message to erase. When the

appropriate message press the delete key and

the screen prompt opposite is displayed. Press

enter to confirm, or escape to undo, this action.

Note: It is not possible to delete the currently

printing message.

> cursor is on the

77144 Issue 8 August 2009 71

Page 72

PROGRAMMING THE PRINTER

Press the corresponding key to select the function

PRINTING MESSAGE1

NORMAL PRINT

INK STATUS OK

Press right directional key until the menu bar starts to scroll

123

> ENGLISH

FRENCH

ITALIAN

PORTUGUESE

SPANISH

GERMAN

DUTCH

PROGRAMMING THE PRINTER

SELECTING A LANGUAGE

The printer can communicate with the operator in one of several resident

languages. Select a new operating language as follows:

(1) Scroll through the menu bar using the right directional key and select the

global map icon. The arrow key can be pressed continuously to scroll

through the menu quicker.

(2) When selected, a list of languages will appear

on the LCD, use the up and down cursor

keys to scroll through the list.

(3) When the appropriate language has been

selected, press the enter key to complete the

command. All the menus and options will

then operate in the chosen language.

72 77144 Issue 8 August 2009

Page 73

PROGRAMMING THE PRINTER

ENTER NEW TIME....

HR:MI DT/MO/YR D

15 : 28 10/11/00 5

SETTING THE CLOCK

This function determines the clock time used to run some of its real time

functions, e.g. shift codes, sell by dates and date/time prints.

Note: When the current time is set, it continues to operate even when the control unit

has been switched off. The only time the clock will need to be reset is if the

control unit’s memory has been wiped or if adjustments for daylight saving are

made.

The time, date and day are held in the systems

memory in the following format:

The top line is a key for the current format the

bottom contains the time/date/day data.

HR:MI is the current time in hours and minutes,

displayed in 24 hour format. In the example, the

clock reads 15:28 (3:28pm).

DT/MO/YR is the date/month/year. The

example, reads 10/11/00 (10th of November 2000).

D is the day of week. The printer works on 7 day

cycle, as a default, Monday is day 1. So Monday = 1, Tuesday = 2 Wednesday = 3,

etc. Therefore, in the example above day 5 would be Friday.

When inputting the year format, it should be entered as a two unit figure. For

example to enter 2000 as the year, enter 00 as the value. 2001, 2002, 2003 would

be 01, 02, 03, etc.

77144 Issue 8 August 2009 73

Page 74

PROGRAMMING THE PRINTER

Press the corresponding key to select the function

PRINTING MESSAGE1

NORMAL PRINT

INK STATUS OK

Press right directional key until the menu bar starts to scroll

123

CLOCK OPTIONS

> FIRST WOY

TIME

HR:MI DT/MO/YR D

5 : 28 10/12/99 5

Flashing block cursor can scroll

across time/date/day format

enabling operator to edit the

clock time.

Amend the clock function, as follows:

(1) Scroll through the menu bar functions and select the set clock icon.

(2) The Clock Options submenu is displayed.

Select the time option by using the up down

cursor keys and press enter.

(3) A flashing cursor block at the beginning of

the hours format can be moved left or right

by pressing the cursor arrows on the key pad.

(4) To re-adjust any of the values, place the

cursor over the character to be adjusted and

overtype the new value, when all changes are

completed press enter.

Note: Values that are outside the parameters of the 24 hour clock or calendar month,

74 77144 Issue 8 August 2009

are not accepted.

Page 75

PROGRAMMING THE PRINTER

Press the corresponding key to select the function

PRINTING MESSAGE1

NORMAL PRINT

INK STATUS OK

Press right directional key until the menu bar starts to scroll

123

ROLLOVER TIME

0:00

ROLLOVER TIME

The default working day ends and starts at midnight. This is when the control unit

will rollover to the next working day. This value can be adjusted as follows:

(1) Scroll through the main menu bar icons using the directional arrow keys

and select the rollover icon.

(2) When the icon has been selected, the following will be displayed

The flashing cursor block on the first character can

be moved using the left and right cursor arrows.

Move the cursor over the character to be changed

and overtype with the required rollover time, e.g.

06:00 if six AM is the required rollover time. Press

enter to confirm the changes.

77144 Issue 8 August 2009 75

Page 76

PROGRAMMING THE PRINTER

Press the corresponding key to select the function

PRINTING MESSAGE1

NORMAL PRINT

INK STATUS OK

123

ENTER NUMBER OF

SHIFTS 2, 3 OR 4

SHIFT CODES

A 00:00

A 00:00

A 00:00

Default shift code screen

ENTER NUMBER OF SHIFTS

Up to four production shifts can be programmed, and can be given code letters,

for example shifts A, B, C, D.

These shift codes are then split into the working hours of the production line. The

printer can be set to print out the shift automatically. See also formatting messages

on page 88. To enable the print out of different shifts, the times and shift codes

must be programmed. Enter the shift codes and times as follows:

(1) Scroll through the main menu bar on the LCD with the directional arrow

keys and select the shift code icon

(2) A prompt asking how many shifts are

required is displayed, in this case select 3,

press enter.

(3) A flashing cursor block will be seen at the

top left of the screen under the A character.

Decide which code letters are to be

designated to the shifts. For this example there

are 3 shifts

76 77144 Issue 8 August 2009

Page 77

PROGRAMMING THE PRINTER

SHIFT CODES

A 06:00

B 10:00

C 14:00

Newly entered shift codes

(4) Using the four cursor keys, scroll

around the shift code screen over-typing the

default letters. In this example, shift A starts

at 6am and finishes at 10am. Shift B starts at

10am and finishes at 2pm. Shift C, the final

shift, starts at 2pm and finishes at 6am. Press

the enter key to save the shift codes and

times.

77144 Issue 8 August 2009 77