Page 1

C-SERIES PRINTERS

OPERATION AND

MAINTENANCE MANUAL

MODELS

C7, C16 AND C34

Page 2

DECLARATION OF CONFORMITY

We

Domino UK Ltd, Bar Hill, Cambridge, England CB3 8TU

declare under our sole responsibility that the products,

Domino C7, C16 and C34 Printers

to which this declaration relates, are in conformity with the following standards:

BS EN 60204 - 1:1992 Safety of machinery - electrical equipment of machines

73/23/EEC : Low Voltage Directive as amended by 93/68/EEC

Council Directive 89/336/EEC EMC compatibility as amended by directive

92/31/EEC of 28th April 1992

BS EN 50082 - 1:1992 Electromagnetic Compatibility-Generic Immunity

Standard

BS EN 50081 - 1:1992 Electromagnetic Compatibility - Generic Emission

Standard

EN 55022:1987 Limits and measures of measurement of radio interference

characteristics of information technology equipment

EN 55011:1996 Conducted emissions

EN 61000 - 4 - 1:1995 Electromagnetic compatibility (EMC). Part 4. Testing

and measurement techniques

EN 61000 - 4 - 2:1995 Electromagnetic compatibility (EMC). Electrostatic

discharge immunity test

EN 61000 - 4 - 3:1996 Electromagnetic compatibility (EMC). Radiated RF

immunity.

EN 61000 - 4 - 4:1995 Electromagnetic compatibility (EMC). Electrical fast

transient burst immunity test

EN 61000 - 4 - 6:1996 Electromagnetic compatibility (EMC). Direct injection

immunity to RF signals

EN 61000 - 4 - 11:1994 Electromagnetic compatibility (EMC). Part 4. Voltage

dips, short interruptions and voltage variations immunity tests.

L. J. Mason

Technical Director

2 77091 Issue 2 November 2003

Page 3

C-SERIES PRINTERS

OPERATION AND MAINTENANCE

MANUAL

MODELS C7, C16 AND C34

This manual, Domino Part No. 77091, is for use in the maintenance of Domino

C7, C16 and C34 printers.

Users of this equipment are warned that it is essential to read, understand and act

according to the information given in Health and Safety, page 9. This part of the

manual also specifies a set of symbols which are used elsewhere in the manual to

convey special warnings or requirements. It is, therefore, essential that users are

also familiar with these symbols and act accordingly.

All rights reserved. No part of this publication may be reproduced, stored on a

retrieval system, or transmitted in any form, or by any means, electronic,

mechanical, photocopying, recording or otherwise, without the prior permission

of Domino UK Ltd.

Domino UK Ltd has a policy of continuous product improvement, the Company

therefore reserves the right to modify the specification contained in this manual

without notice.

© Domino UK Ltd 2001.

For sales, service and inks please contact:

Domino UK Ltd Domino Amjet Inc

Bar Hill 1290 Lakeside Drive

Cambridge CB3 8TU Gurnee IL.60031

England U.S.A.

Tel:+44 (0)1954 782551 Tel:(001) 847 244 2501

Fax:+44 (0)1954 782874 Fax:(001) 847 244 1421

77091 Issue 2 November 2003 3

Page 4

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the Federal Communication Commission

(FCC) Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communication. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case, the user will be required

to correct the interference at his own expense.

If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

• Re-orientate or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the manufacturer could

void the user's authority to operate the equipment.

TÜV CERTIFICATION

This product has been designed for maximum safety, and has been certified as such

by TÜV Product Services.

Modifications to this machine that are not approved by Domino, or the use of

non-Domino approved spares, will invalidate the CE mark and the TÜV

certification.

4 77091 Issue 2 November 2003

Page 5

AMENDMENT RECORD

Amendment Date

All Parts at Issue 1 October 2001

All Parts at Issue 2 November 2003

77091 Issue 2 November 2003 5

Page 6

6 77091 Issue 2 November 2003

Page 7

CONTENTS

HEALTH AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Basic Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fire Risk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spillages and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How it works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

The Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

One Litre Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Three Litre Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

The Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Where to Site the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Buffer plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Mounting the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Voltage Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

One Litre Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Three Litre Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connecting an Ink Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connecting the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Priming the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Purging the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Two Line LCD Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Four Line LCD Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

PROGRAMMING AND PRINTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Selecting a language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Setting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Creating a Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Printing a Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

77091 Issue 2 November 2003 7

Page 8

CONTENTS

Adjusting the Dot Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjusting the line print density . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Adjusting the Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Adjusting the delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Setting the Print Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Setting the Print Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Product Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Setting Up a Second Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Clearing all Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

FORMATTING MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Formatting Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Slashed and Non-Slashed Zeros . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Bold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Text Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Standard Text Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Box Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Pallet Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Setting Up Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Printing the Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Printing the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Printing a Sell-by-Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Start code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Incremental value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Date code letters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

End code “e” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Printing Shift Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Before Long Holidays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Six Monthly Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

The Ink Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Flushing the Jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Solenoid Valve Tubing Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

8 77091 Issue 2 November 2003

Page 9

HEALTH AND SAFETY

HEALTH AND SAFETY

INTRODUCTION

Domino supplies Safety Data Sheets (SDS's) giving specific safety information with

each of its ink products. There are also warnings on each container. The

following notes are for general guidance only.

Basic Requirements

When used correctly, printing inks do not cause problems. However, everybody

using them should be familiar with the appropriate safety standards and be aware of

the precautions that should be taken. The following are basic requirements.

• Proper standards of industrial practice relating to cleanliness and tidiness must

be maintained

• Inks and their containers must be stored and handled with care

• All who come into contact with inks must be properly instructed in their

use.

Directions for safe working practices vary according to the environment. The

following are broad principles so that necessary precautions may be taken.

• Contact with the mouth must be avoided. Therefore eating, drinking or

smoking, or any personal habits or actions which may transfer ink to the

mouth, must be avoided

• Contact with the eyes must be avoided. Suitable eye protection must always

be worn whenever there is any risk of splashing or misting. If ink does get

into the eyes, first aid treatment is to flood the affected eye for 15 minutes

with saline solution, (or clean water if saline solution is not available), taking

care not to allow the water to run into an unaffected eye. Medical aid must

be obtained immediately

• Most inks contain ingredients which may injure the skin. Warning of this is

given on the SDSs. Barrier creams should be used and protective clothing

worn

• Many inks contain materials which vaporise easily and can be inhaled. Good

ventilation is necessary

• Any used cleaning materials, e.g. rags, paper wipes, are a potential fire hazard.

They must be collected for safe disposal after use

• After exposure to ink, all possible traces must be washed off as soon as

possible at the nearest washing facility.

77091 Issue 2 November 2003 9

Page 10

HEALTH AND SAFETY

Storage

Store in a cool dry place, avoiding direct sunlight. Keep in the original container

and keep the container fully closed.

Fire Risk

For an electrical fire, do not use water. If water must be used, the power MUST

BE REMOVED first.

Water-based inks will not burn, although inks based on water-alcohol mixtures

may burn if there is sufficient alcohol present. Prolonged exposure of water-based

systems to high temperatures may evaporate the water to give a flammable residue.

If there is a fire, there is a likelihood that dangerous fumes will arise from printing

inks. For this reason ink must be stored where it can be reached quickly by the fire

fighting service, and where it will not spread beyond the store.

Spillages and Disposal

WARNING: Some dried inks are highly flammable. Clean up all

ink spillages immediately. Do not allow the ink to

dry or allow any build-up of dried ink spills.

Spillages must be cleaned up as soon as possible with the appropriate solvent

materials and with regard to the safety of personnel. Care must be taken to prevent

spillages or residue from cleaning up entering drains or sewage systems.

Inks and associated fluids are materials which conduct electricity. Therefore,

power to the printer must be switched off while spillages are being cleaned up.

Printing inks and associated fluids must not be treated as ordinary waste. They

must be disposed of using approved methods according to local regulations.

10 77091 Issue 2 November 2003

Page 11

SYSTEM OVERVIEW

INTRODUCTION

The Domino C-Series is a family of high quality ink jet printers enabling printing

at speeds of up to 35 metres per minute. Each C-Series unit is designed to be

compact and efficient, requiring no external connections except power.

The C-Series printers are capable of printing up to four lines of text at once

(depending on the model used), each line containing up to 40 characters. Text

heights range from 10mm to 68mm. Each line (or lines) of text printed at once is

known as a “message”. 50 separate messages can be stored in the printer’s memory.

Once input, these messages can be recalled for printing at the touch of a button

and are entirely unaffected by power loss.

Production dates, sell-by-dates, shift codes and incremental box counting can be

generated automatically. The system is quick and easy to install and operate,

requiring minimal user input and maintenance. All communication with the

printer is made using the combination membrane keypad and LCD panel on the

top of the unit.

Ink is held in a special disposable container inside the printer case. A window in

the case allows an instant check on ink level to be made.

77091 Issue 2 November 2003 11

Page 12

SYSTEM OVERVIEW

The C7, C16 and C34 printers are robust, stand-alone units manufactured from

high quality metal and will give many years of service in even the most demanding

of environments.

HOW IT WORKS

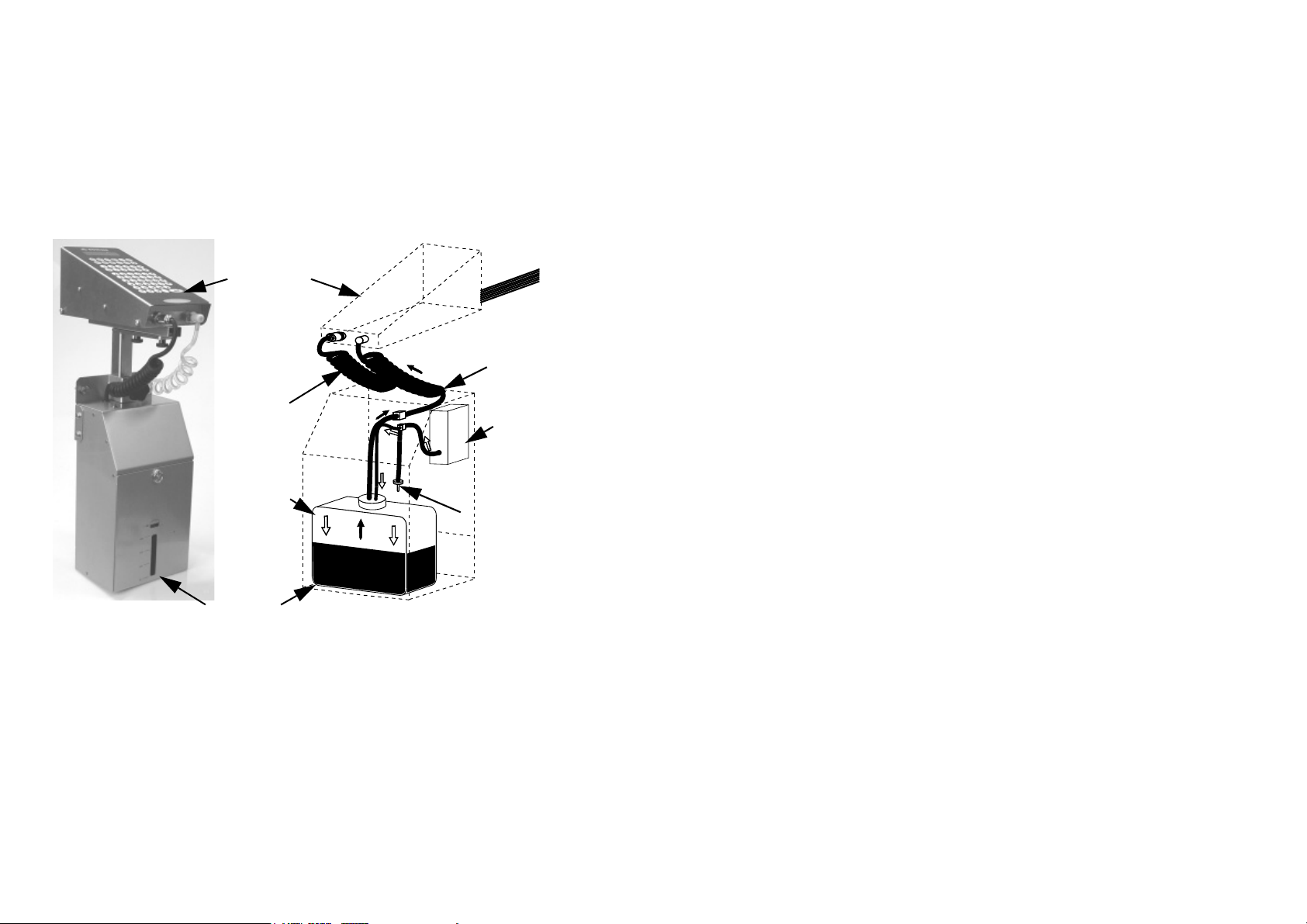

Each printer is manufactured in two main parts. The base unit holds the ink

storage and delivery system, power supply unit and in-built air pump.

Print Head

Print Head

Ink Supply

Print Head

Power Cable

Ink Bottle

Base Unit

Print Head and Base Unit

The print head contains the printer’s processor, memory and ink valve driver

electronics, keypad, LCD screen and photocell (or other product sensor). It also

contains all the electro-mechanical valves, tubing, filters and ink jet system

required to form a matrix of alphanumeric characters.

Air is supplied from an internal air pump mounted in the base unit, which remains

active while power is switched on. Low pressure air is fed into the sealed ink

bottle, forcing ink up into the print head. A manually operated pressure release

Air Pump

Air Pressure

Release

12 77091 Issue 2 November 2003

Page 13

SYSTEM OVERVIEW

e

valve is fitted in order to depressurise an empty ink bottle when changing to a fresh

supply.

Due to the air pump, there is a constant pressure of ink driven up the coiled

supply tube linking the base unit to the print head (a second, separate coiled tube

provides the print head with power). A quick disconnect “QD” plug at the end of

the ink supply tube is fastened into the rear of the print head.

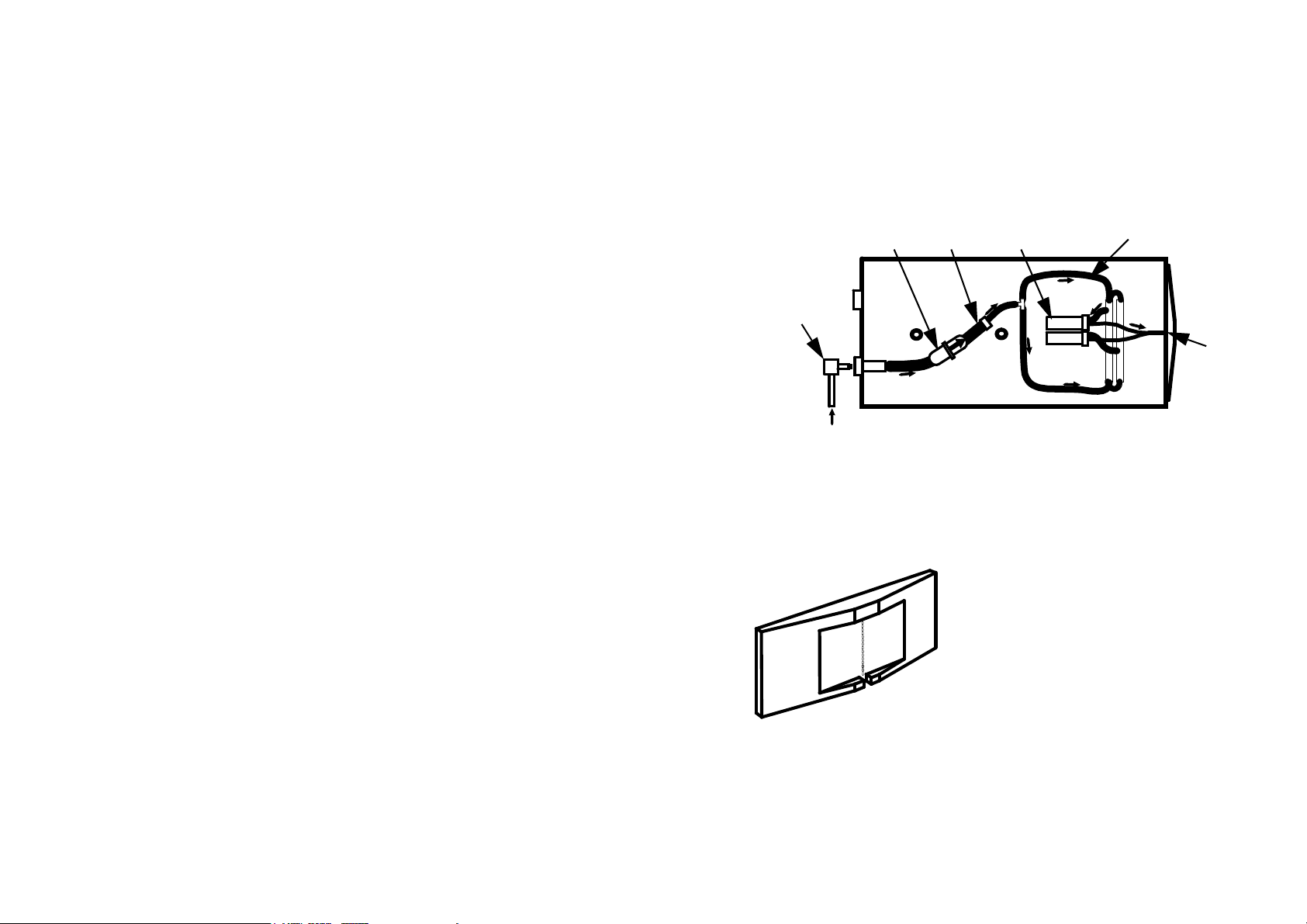

Ink Filter

QD Ink

Connector

Print Head Ink Distribution

Entering the print head, the ink passes through a 25 micron ink filter which traps

any minute particles suspended in it, then an ink reducer. Finally it is distributed

to all the inlets in the solenoid valve array. The diagram above shows the ink path

in a typical print head. For clarity, only two of the valves are shown. The number

of valves and layout of the ink distribution assembly depends on the model used.

Printer Nozzle Plate

Valv esReducer

On activation, each solenoid valve allows a

measured amount of ink (still under air pump

pressure) to move forward into the outlet tube

linking the valve with the nozzle plate. The

nozzle plate consists of a series of openings

arranged vertically. The ink is ejected from

these openings in droplets, driven a few

millimetres onto the surface of whatever is to be

printed. Each time the valve is activated more

ink is released into the relevant outlet tube,

forcing another droplet of ink out of the nozzle

plate.

Ink Distribution

Assembly

Nozzl

Plate

77091 Issue 2 November 2003 13

Page 14

SYSTEM OVERVIEW

The vertical component of text is produced

by the vertical arrangement of openings in

the nozzle plate. Since the printer is fixed in

position, the horizontal component of text is

produced by the movement of product on the

conveyor. It is similar to the action of a

typewriter; the place at which printing takes

place is fixed, and the carriage moves (to the

left) correctly positioning the paper for each

character. In the case of the C-Series

printers, it is not each character which needs

to be positioned but each vertical row of dots.

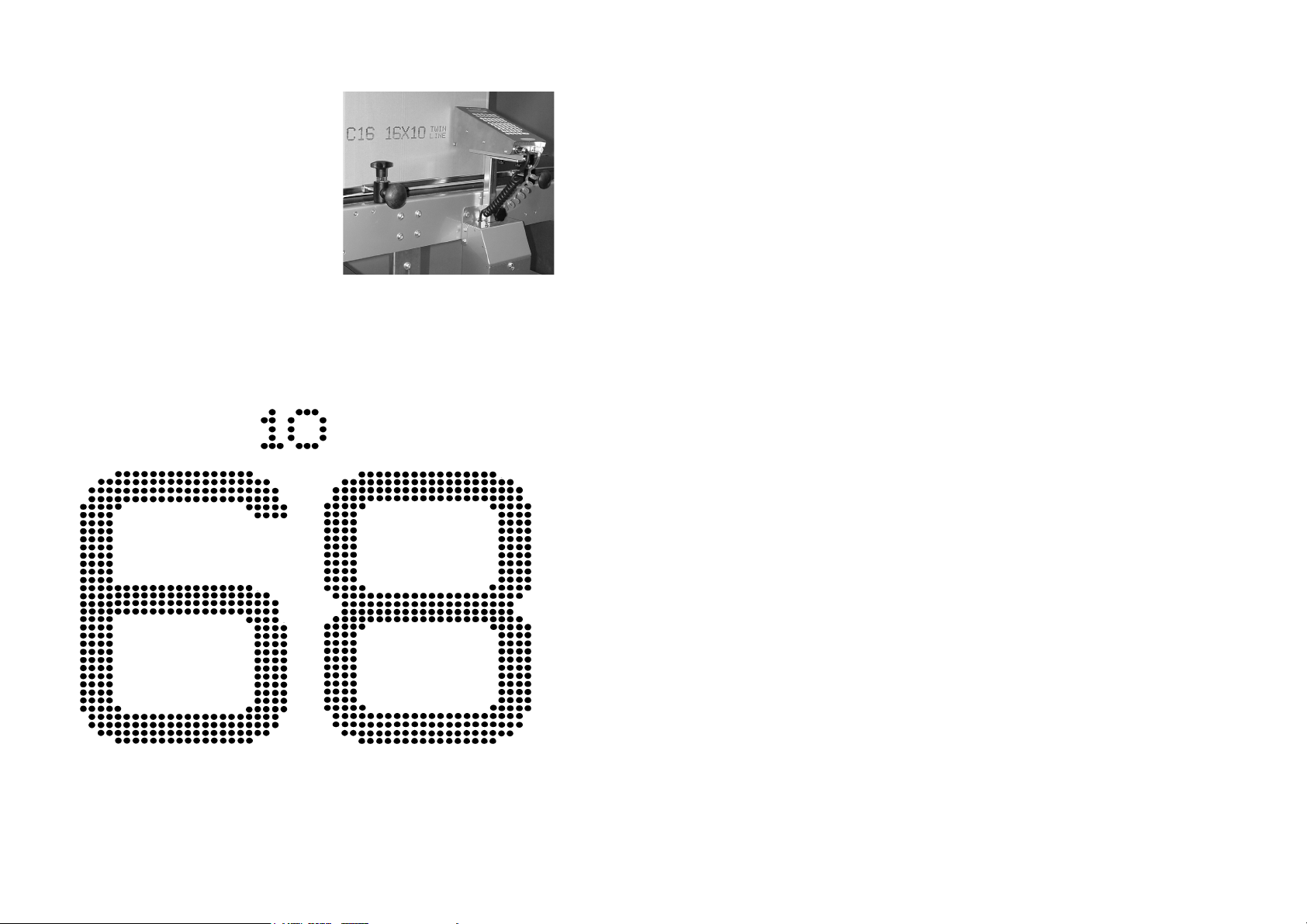

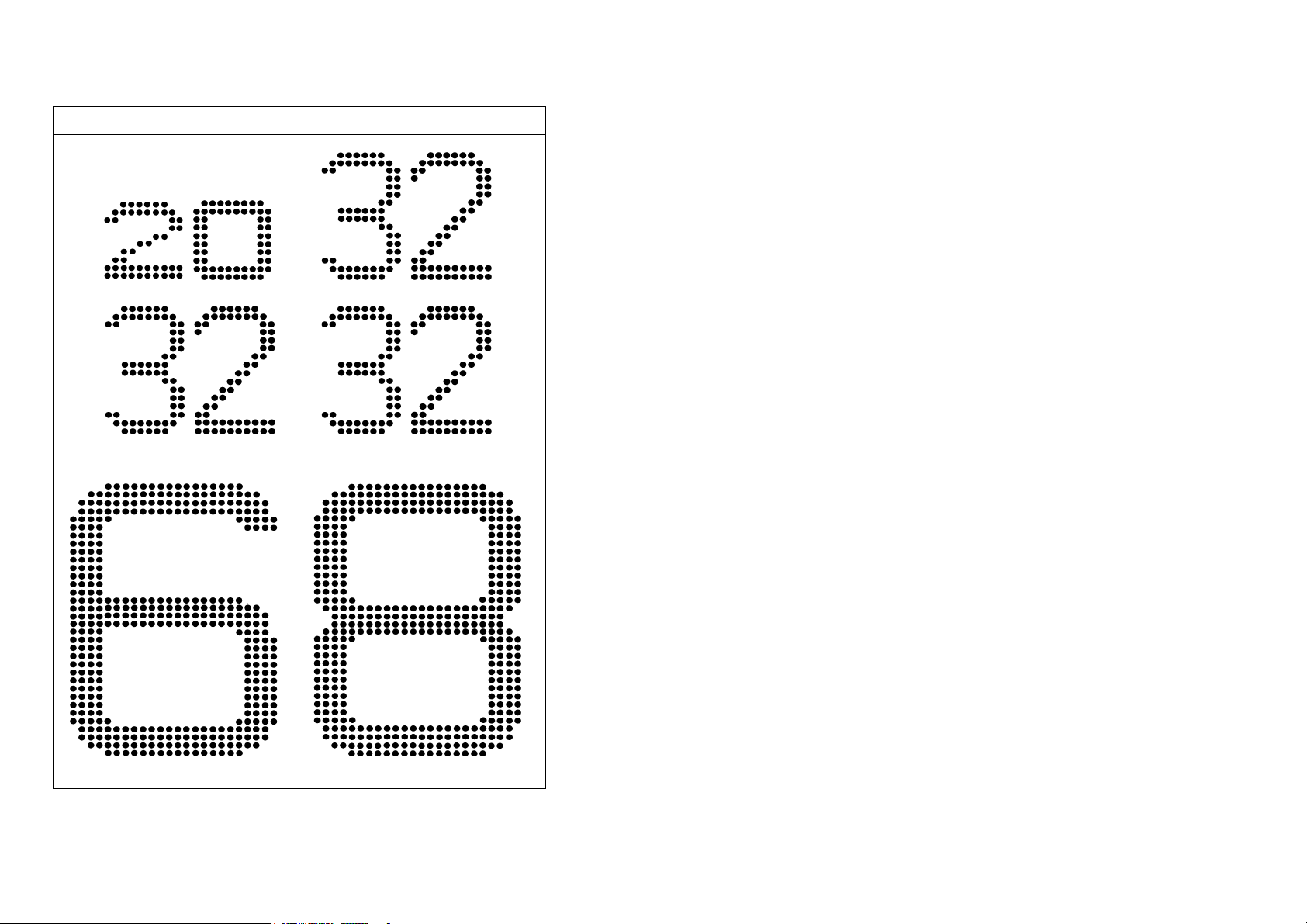

C-Series printers produce text in several

available matrices, depending on the text size

chosen and the capabilities of the model used. These matrices can range from 5 x

5 (five dots high and five dots wide) to 34 x 24.

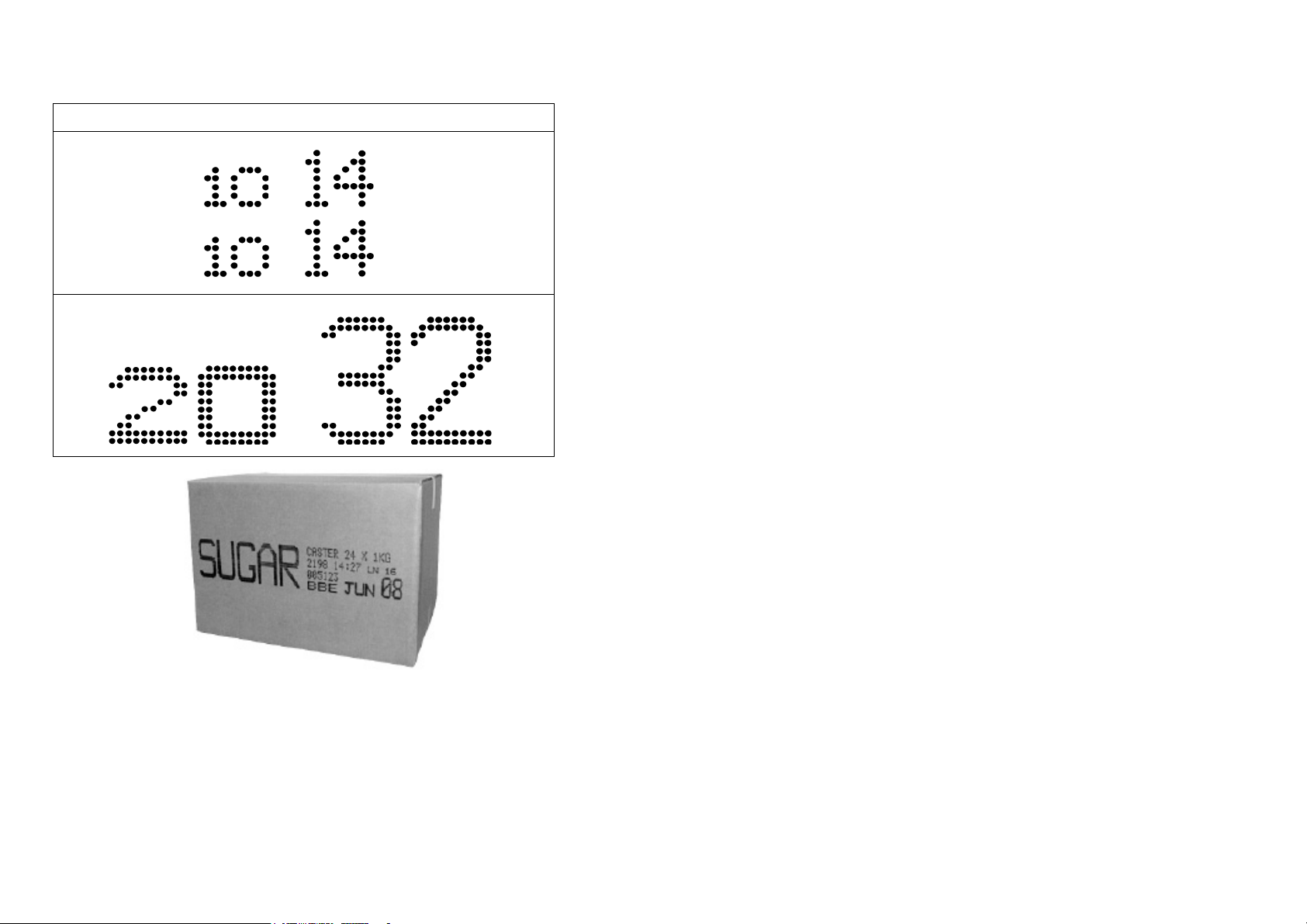

Printing single and

two line text

The previous diagram shows the smallest and largest matrices available in the C7,

C16 and C34 printer range. The text is to scale but not full size; the numbers give

14 77091 Issue 2 November 2003

Page 15

the actual height of the text in millimetres. Each character in the top row is

formed using a 5 x 5 matrix; each character in the bottom row is formed using a

34 x 24 matrix.

The number of jets per nozzle plate, and hence the

largest matrix available, is fixed for each model. Thus,

a C14 has 14 jets arranged in two blocks of seven.

This allows two lines of 7 x 5 matrix text to be

produced. (Note: it cannot produce one line of text

14 jets high - multi-line text requires a C14.)

Heigh

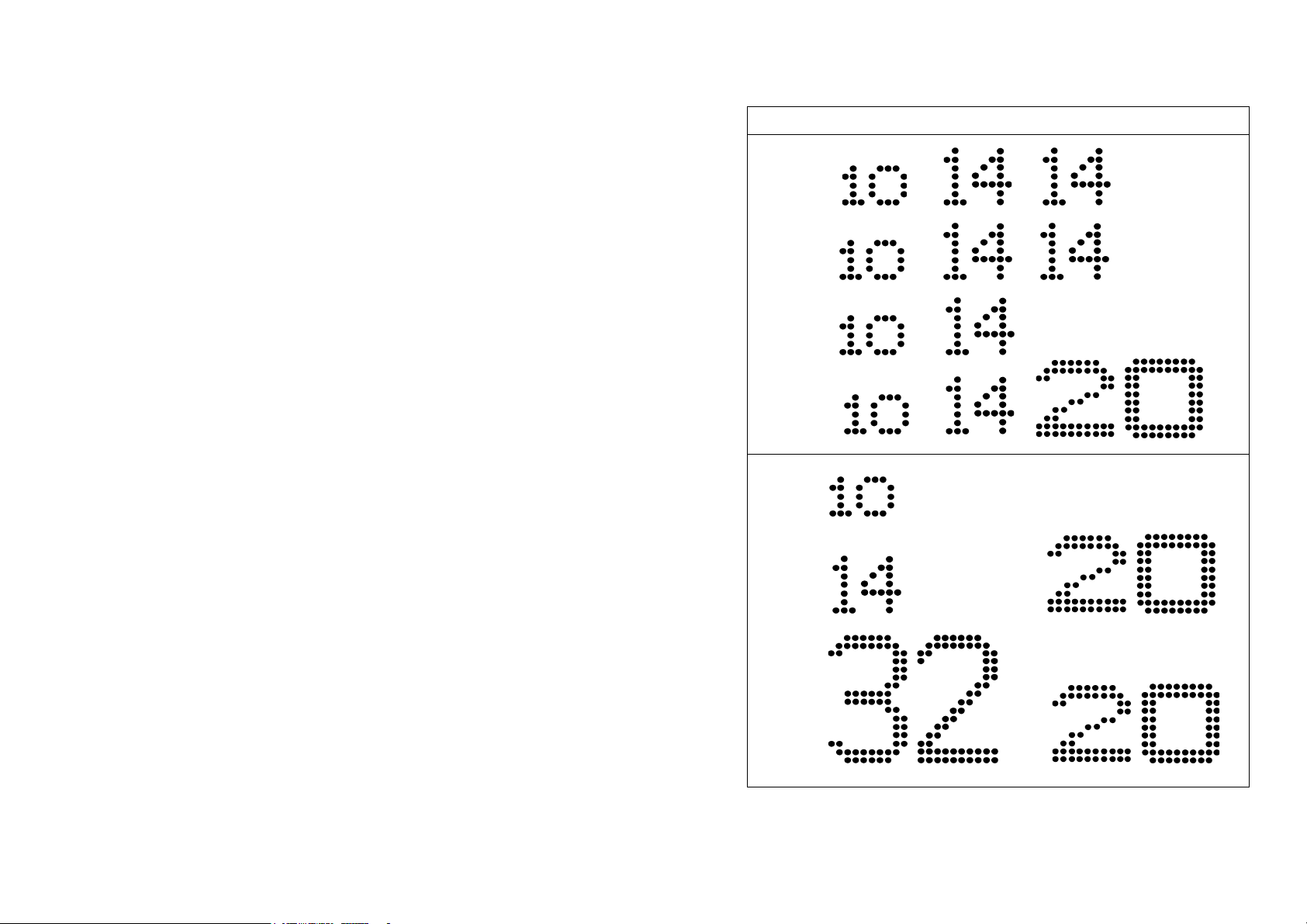

The diagrams below show proportionally the print

capabilities of each of the printers. In each case, the

number is the height of the relevant text in

millimetres.

Nozzle Plate Height

Note: The sizes given are representative only. When

dealing with nozzle plates, the “height” is assumed

to be the measurement between the middle of the top jet and the middle of the

bottom plate in the array.

C7

The print capabilities differ widely between models. The larger model number

printers are capable of a bigger range of text sizes. The models also differ in the

size of LCD screen. Functions and features detailed in this manual are relevant to

all models in the range except where indicated.

77091 Issue 2 November 2003 15

Page 16

SYSTEM OVERVIEW

C14

An Example of a Printed Message

16 77091 Issue 2 November 2003

Page 17

SYSTEM OVERVIEW

C34

77091 Issue 2 November 2003 17

Page 18

SYSTEM OVERVIEW

C34 (continued)

18 77091 Issue 2 November 2003

Page 19

SYSTEM OVERVIEW

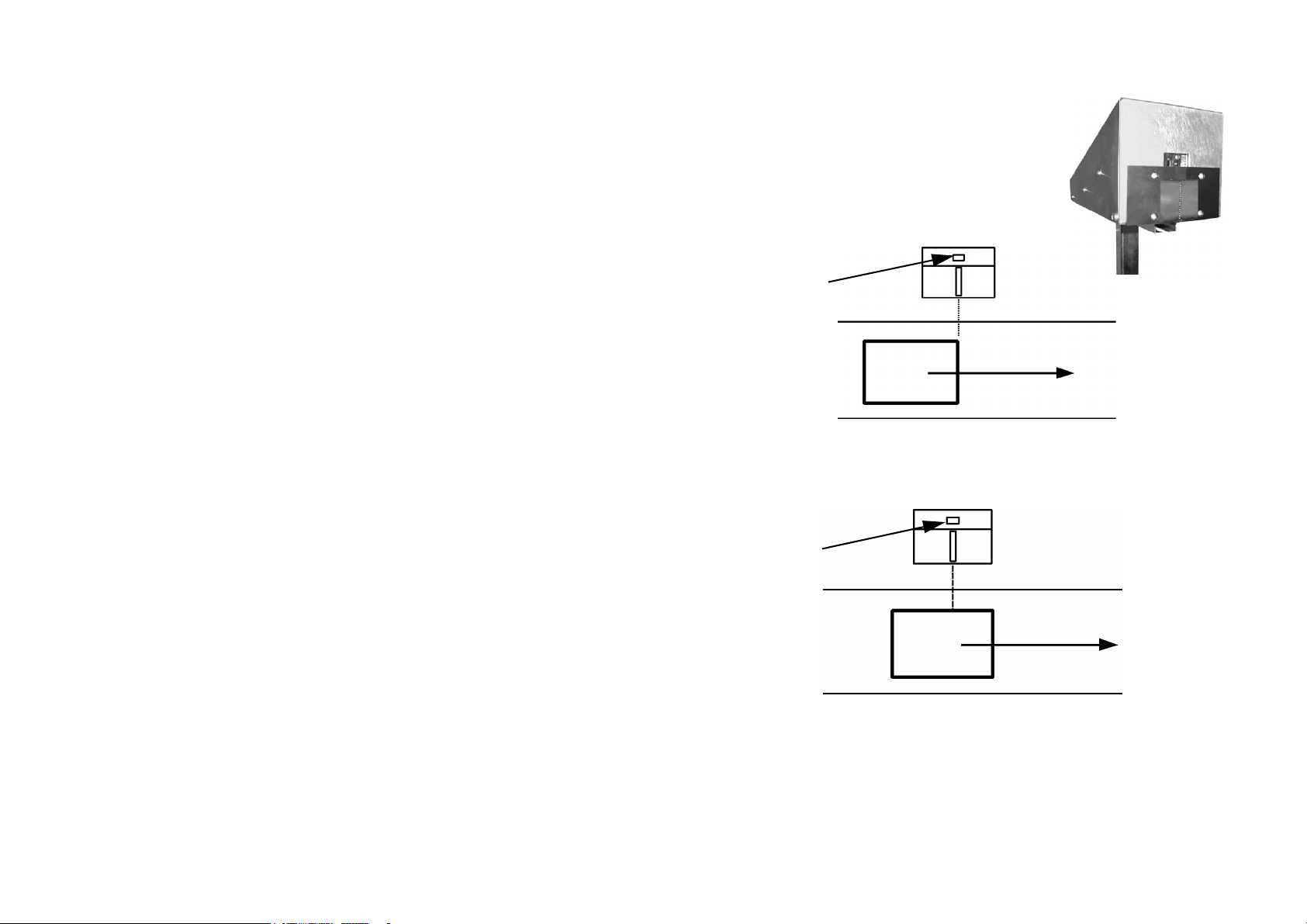

The printer is fixed to the side of a conveyor

along which move the items to be printed.

As an item reaches the print head it is

detected by a built-in photocell mounted just

above the nozzle plate. (The diagram left

shows a C16 print head. The arrangement is

slightly different for some printers, but the

principle remains the same.)

Photocell

Direction of Travel

The system then allows a short time delay to enable the item to be carried on past

the print head. This delay depends on the speed of the conveyor and the length

and position of the message and is set by the operator for each message.

Photocell

Direction of Travel

When the item is at the correct position in respect to the print head, the desired

text is printed by repeated triggering of the solenoid valves.

Meanwhile a second item may be approaching the print head. Items do not need

to be equally spaced along the conveyor since the printer senses each one

individually as it reaches the photocell.

77091 Issue 2 November 2003 19

Page 20

SYSTEM OVERVIEW

As mentioned earlier, it is the steady horizontal motion of the item along the

conveyor which produces the text. On a stationary item only a single vertical band

of ink would be produced.

The printer is capable of high volume printing (at a maximum line speed of 35

metres per minute) dependent on the speed of the conveyor. Software controls

regulate the speed at which the vertical lines of dots are produced in order to

match the speed at which the items pass by the nozzle plate.

It is important that the conveyor runs at a steady, uniform speed. Conveyors

which judder or run at variable speed will produce uneven print. On a suitable

conveyor the ink jet system is capable of good quality text due to its extremely

accurate timing and control of ink drop release.

Ink

CAUTION: Do not use ink or cleaner not supplied by Domino. The use of any

other ink or cleaner can cause serious damage to the printer. Contact

your nearest distributor or Domino Service for advice on ink and

printing applications.

Printer ink comes in a choice of colours and is specially formulated to maintain the

long life of the printer and to provide the optimum performance in a wide variety

of applications. There is no messy mixing or topping up of ink as this is supplied

in easily-changed disposable containers.

Domino’s water-based inks are best suited to porous surfaces such as cardboard,

paper and fibres. The main advantage of using water-based ink is that the ink is

less prone to drying while in the tube and on the jet openings which are exposed

to the atmosphere. Spirit-based inks tend to dry in and on the jets, creating a need

for more maintenance. Domino only use water-based ink in the C7, C16 and

C34 printers.

20 77091 Issue 2 November 2003

Page 21

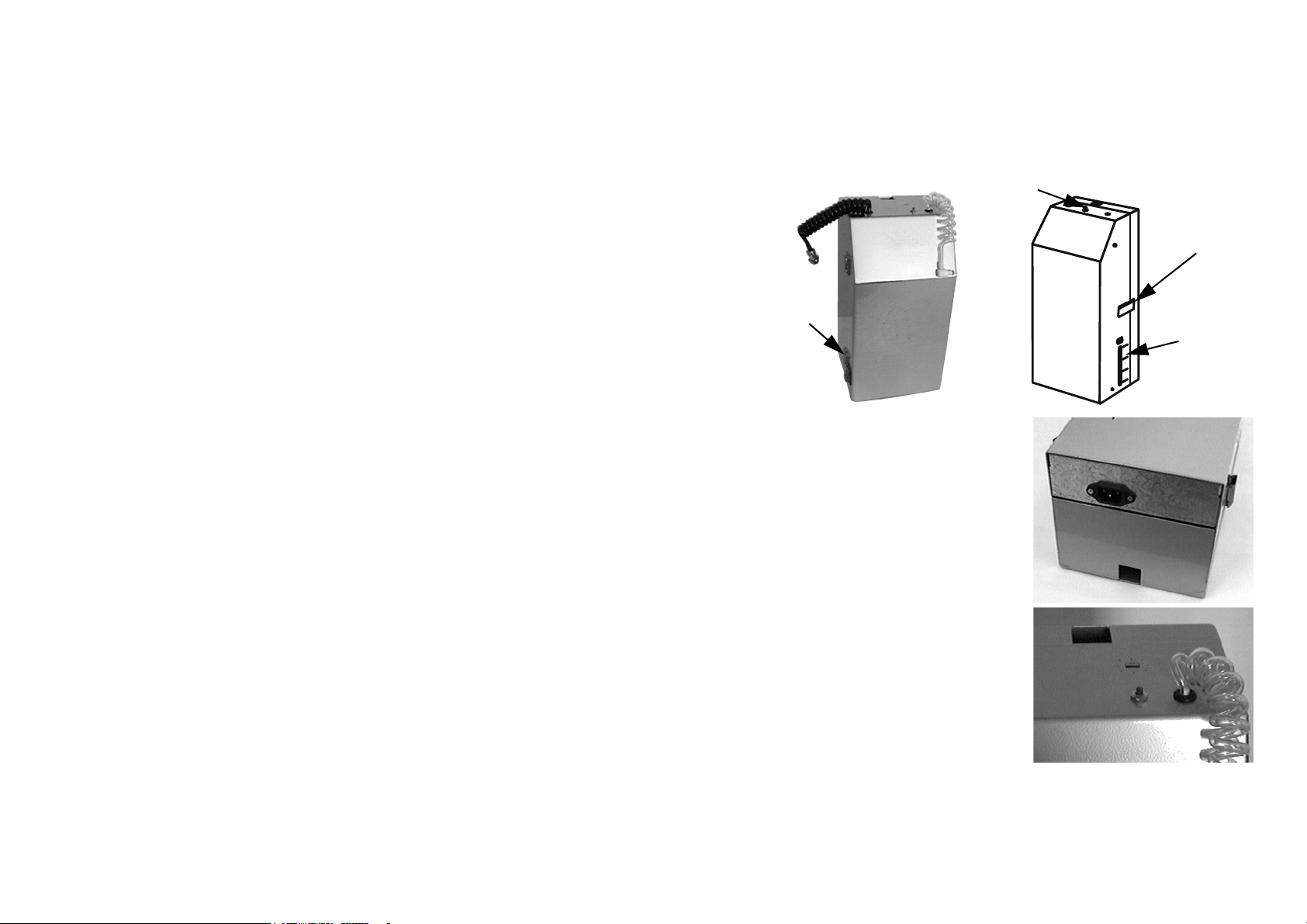

SYSTEM OVERVIEW

The Base Unit

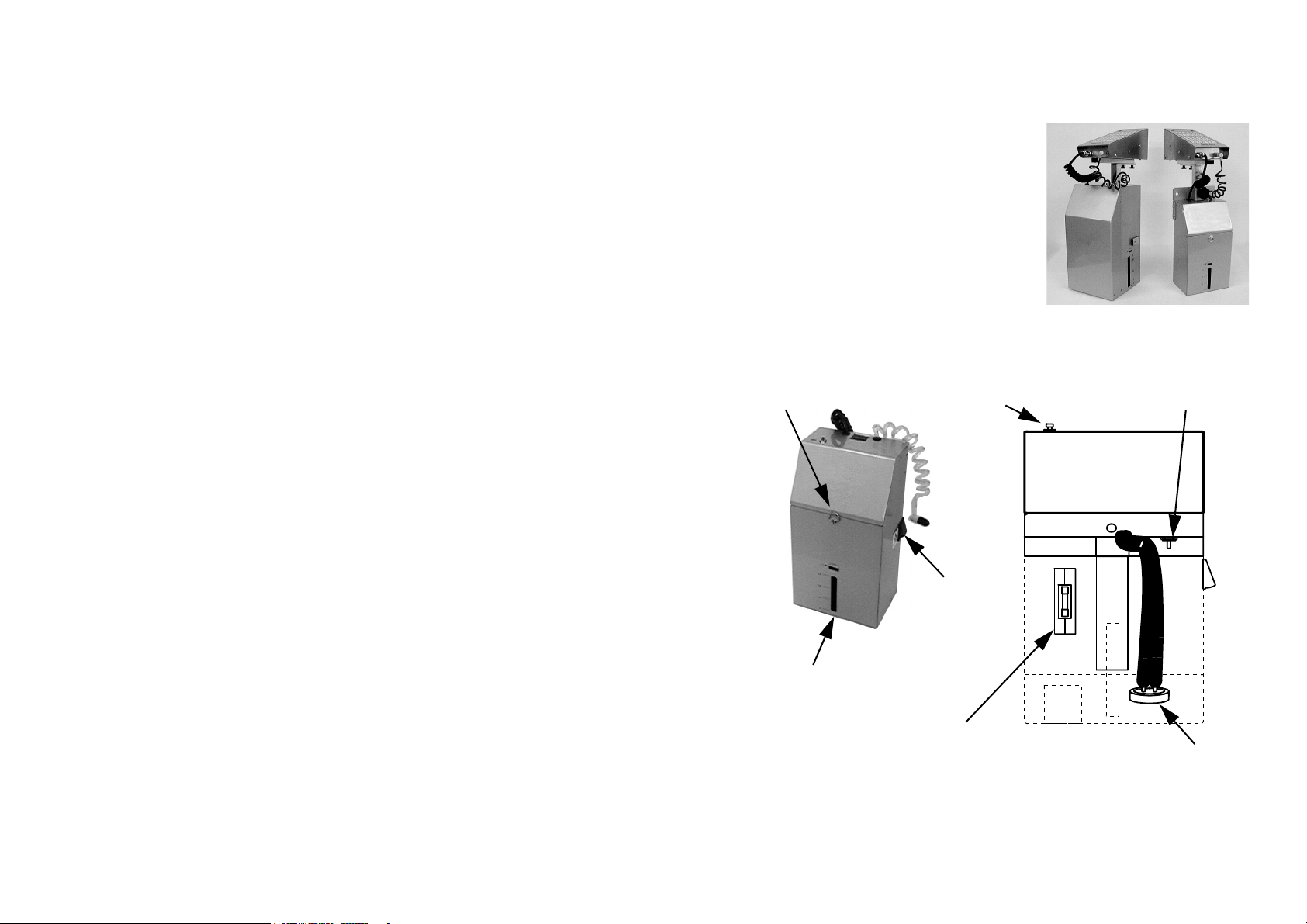

Two different sizes of base unit have ink

containers of different capacities.. The C7

and C16 printers are supplied with a one litre

base as standard. The C34 is supplied with a

three litre base as standard. The larger base

with its larger capacity ink container, allows

extended operation between ink changes.

One Litre Base

In the one litre base the ink bottle is located

inside the base unit, accessed by rotating the

door catch ring on the front of the unit 90°,

allowing the door to swing down. The diagram below shows the layout of the ink

bottle compartment behind the door.

Door

Catch

Ink Level Indicator

Switch

Pressure Release

Valv e

Power

Switch

Ink Level

Window

Ink Level

Indicator Lamp

77091 Issue 2 November 2003 21

Ink Cap

Page 22

SYSTEM OVERVIEW

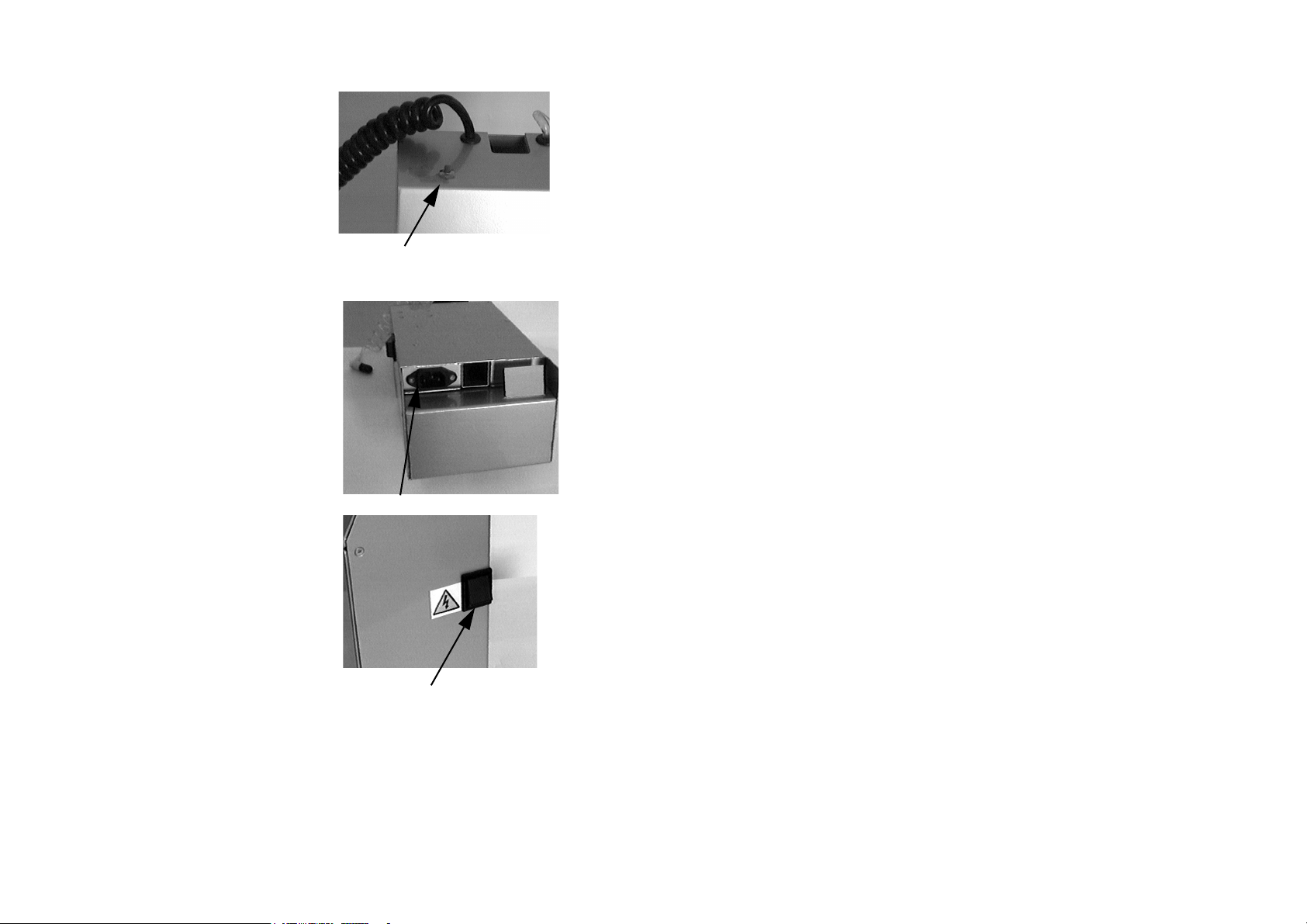

To check the level of ink in the bottle, press

the red push-button on the top of the base

unit. This switches on the ink level indicator

lamp inside the unit. The light from the

lamp shines through the ink bottle. The

remaining ink can be seen through the ink

level window at the front of the base unit. (If

the unit has been moved, allow the ink to

settle before checking the ink level.) It can

then be seen when the ink bottle should be

replaced.

Power is supplied to the printer by the mains

input plug located on the bottom face of the

base unit, just behind the hinged door. This

is the only input that is required for

operation of the printer.

Ink Level Indicator

Switch

Power Input

The power switch is located on the right side

face of the base unit. When power is turned

on, this switch will illuminate. A serial

number label near the switch will indicate

the supply voltage to which the printer unit

is set. Before switching on the printer,

ensure that the supply matches the voltage

stated on this label. If the unit is set to the

wrong voltage, before switching on the

printer, change the voltage settings inside

the base unit as given in the

INSTALLATION chapter of this manual.

22 77091 Issue 2 November 2003

Power Switch

Page 23

SYSTEM OVERVIEW

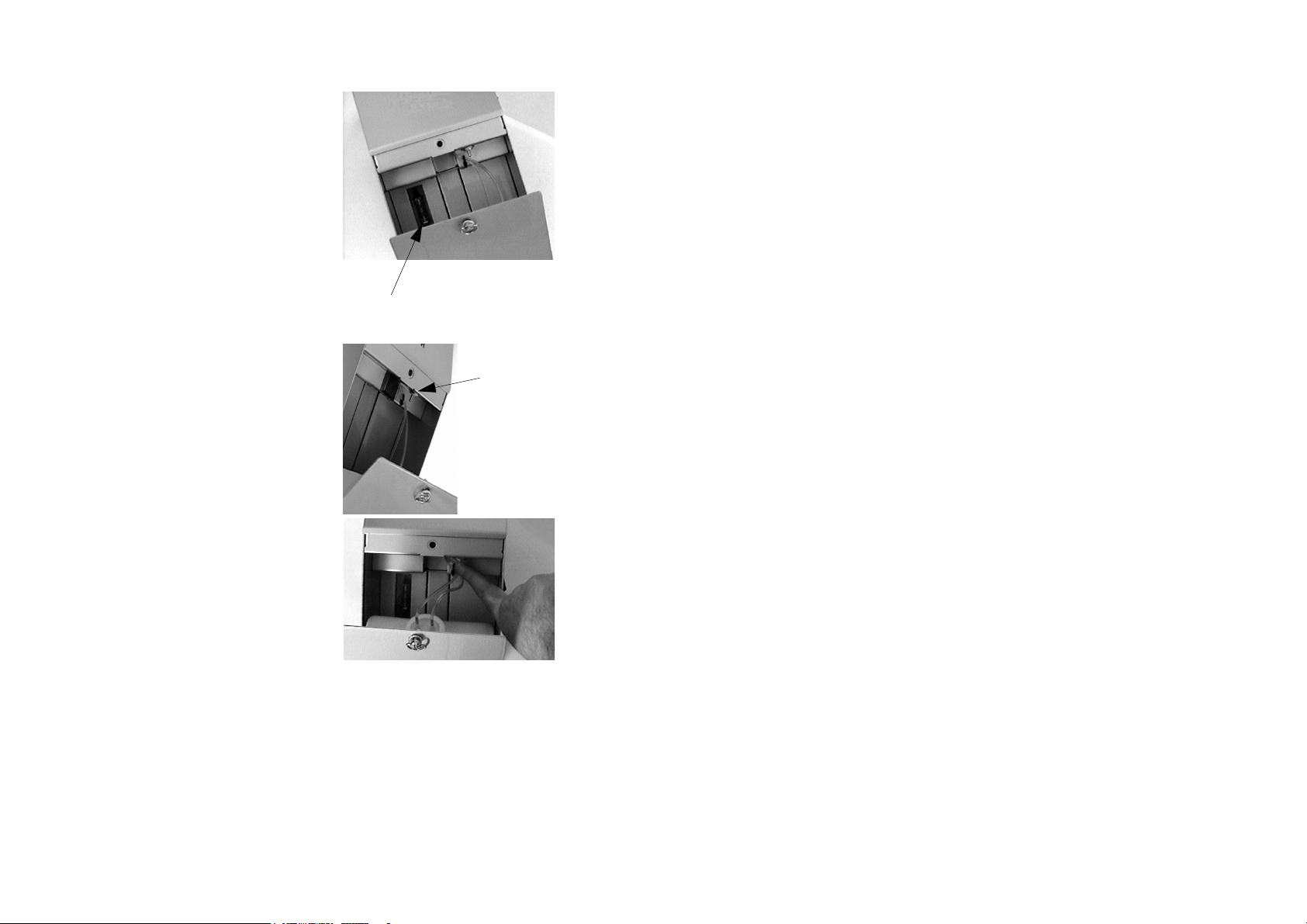

To open the ink compartment door, grasp

the door catch ring and rotate it 90° anticlockwise to disengage the catch. The door

will then fall forward on its hinge allowing

access to the interior. A stopper beneath the

door ensures that it will not trap the mains

cable.

To close the ink compartment door, reverse

this procedure. Push the catch in while

rotating it 90° clockwise until it holds firm.

Take care not to trap the ink and air lines

when closing the door.

77091 Issue 2 November 2003 23

Page 24

SYSTEM OVERVIEW

In this photo the ink level indicator lamp

(which looks like a fuse) is visible on the left

hand side of the back wall.

A pressure release valve is located just inside

the door. This valve safely depressurises the

ink bottle when it is exhausted. Since the

internal air pump keeps the ink bottle

pressurised in order to force ink up into the

print head, it is not advisable to attempt to

remove an exhausted bottle without first

depressurising it.

Ink level

indicator

Pressure

release

valve

Switch the power off (stopping the air pump)

then press the valve stem upwards to release

the pressure from the bottle. The bottle can

then be removed and discarded.

Full instructions on connecting up a new ink

bottle are given in the INSTALLATION

chapter of this manual.

24 77091 Issue 2 November 2003

Page 25

SYSTEM OVERVIEW

Three Litre Base

The three litre base is identical in operation to the one litre base; the differences are

in the location of the various components and, of course, in the size of ink bottle it

uses.

Ink level indicator

switch

Door

catch

Power

switch

The mains input plug is again located on the

bottom of the base unit, this time on the

door itself. The power switch is located on

the left side face of the base unit door and

will illuminate when power is turned on.

Ink level

window

Like the one litre base, an ink level indicator

switch is located on the top of the base unit

in the form of a red push-button. When it is

pressed down the ink level indicator lamp

will illuminate and the level of ink in the

bottle can be seen through the window on

the right side face of the base unit door.

77091 Issue 2 November 2003 25

Page 26

SYSTEM OVERVIEW

To open the ink compartment door, pull

open the door catch so that it disengages

with the rear of the base unit (as shown

right). The door can then be swung open

on its hinge allowing access to the interior.

To close the ink compartment door, reverse

this procedure. Hook the catch around the

fastening on the rear of the base unit and

press it in place. Take care not to trap the ink

and air lines when closing the door.

This photo shows the interior of the three

litre base’s door. The captive ink bottle cap

can be clearly seen hanging from its

connecting air and ink tubes. All the base

unit’s electronics are located behind the panel

in the door.

26 77091 Issue 2 November 2003

Page 27

SYSTEM OVERVIEW

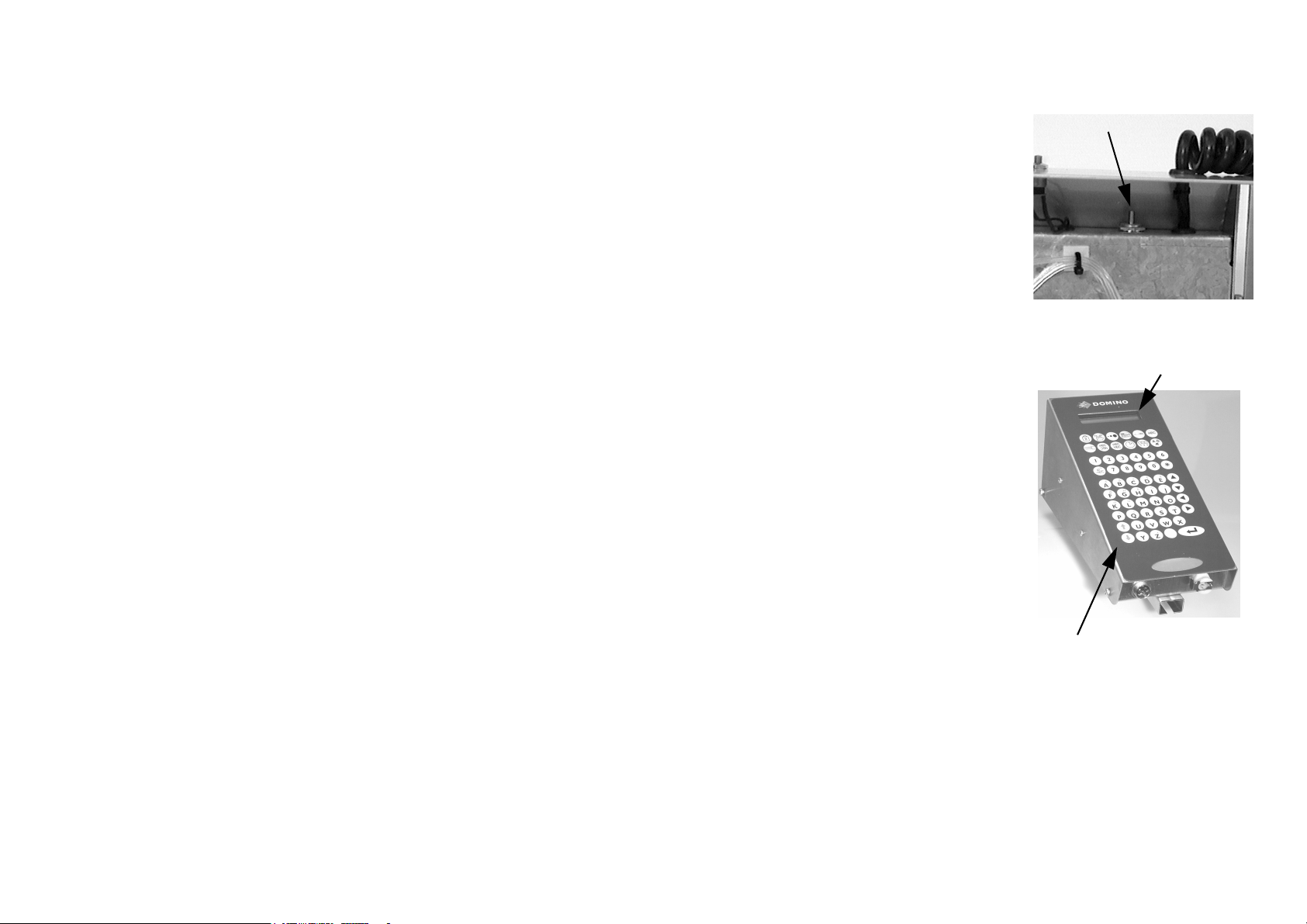

The pressure release valve is located at the

top of the base unit’s door. This valve safely

depressurises the ink bottle when it is

exhausted, enabling the supply to be

renewed.

Full instructions on connecting up a new ink

bottle are given in the INSTALLATION

chapter of this manual.

Pressure Release

Valve

The Print Head

Communication with the printer is achieved

by using the built-in membrane keypad and

LCD display on the top of the print head.

The C34 incorporates a four-line LCD

display. The other models use a two-line

LCD display. This reflects the larger models’

increased print capabilities - all other

functions are exactly the same.

All printers use the same keypad layout and

communicate with the operator in the same

way, with the same keys accessing the same

options and the same prompts requesting the

same information.

Notes: (1) The keys are activated by pressure-

sensitive pads just beneath the

printed surface of the keypad. Press

once firmly in the centre of the

selected key to activate it.

(2) Do not use pens or other sharp

objects to activate the keys as serious

damage could result. The keypad

was designed for fingertip use only.

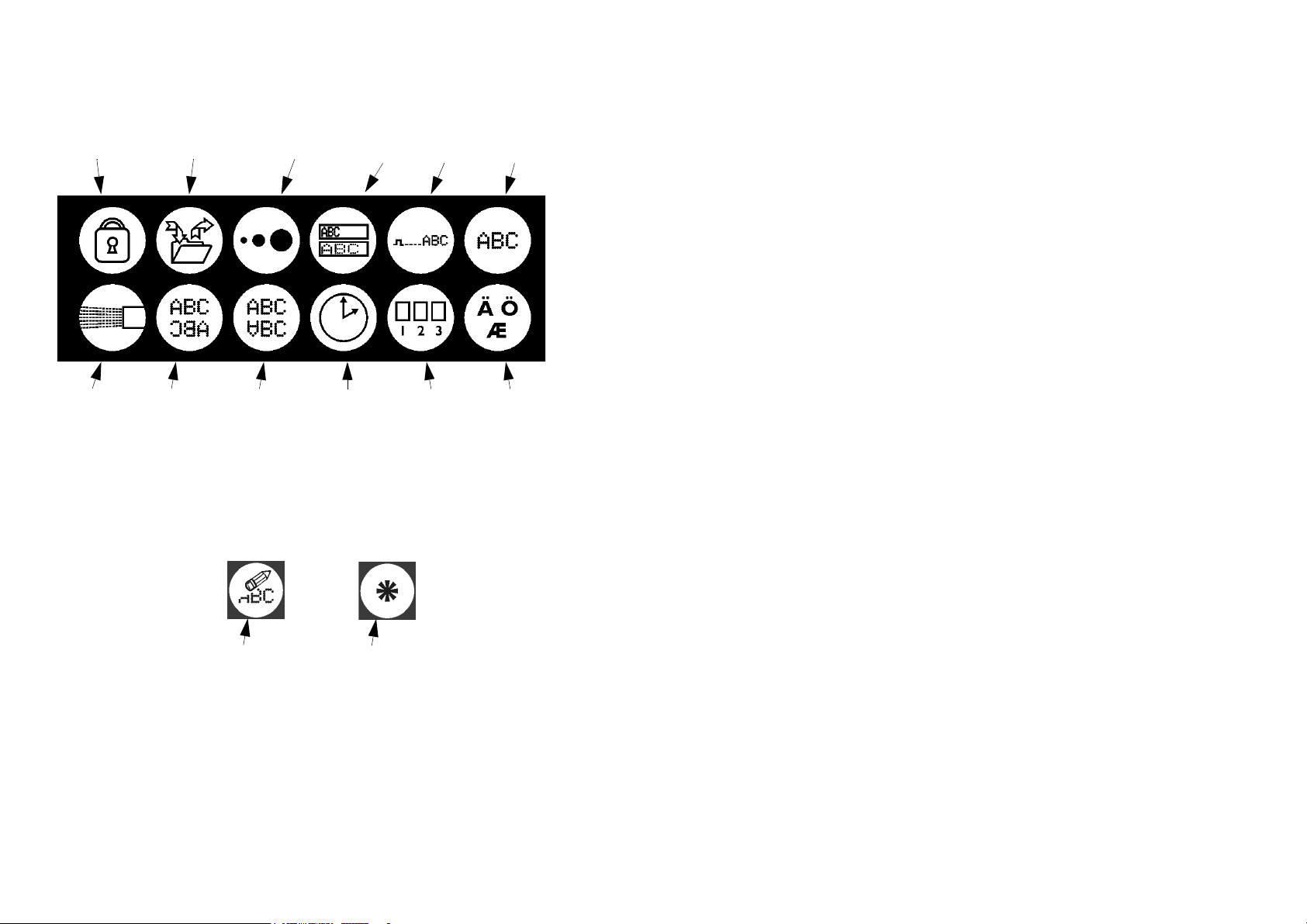

The keypad is in three sections. Pressing any of the special icon keys at the top

accesses the appropriate function as detailed in the Programming and Printing

Keypad

LCD Display

77091 Issue 2 November 2003 27

Page 28

SYSTEM OVERVIEW

section of this manual. When pressed in combination with the SHIFT key (see the

following page) some of these keys access additional functions.

Password

Create and Edit

Messages

Dot Size

Speed

Delay Print

Purge Direction Orientation Set the

Clock

The central section of the keypad contains the number keys and the BACKSPACE

and ALL keys. The BACKSPACE key is used when editing messages to delete the

character to the left of the currently high-lighted character. When pressed in

combination with the SHIFT key (see below), the BACKSPACE key clears the

entire message line while editing messages; when not editing messages this key

combination erases all the messages in the printer's memory.

Backspace key All key

The ALL key is used in many functions to select all the messages in the printer’s

memory.

The bottom section of the keypad contains the letter keys and SPACEBAR. To

the right of the letter keys, the arrow keys (in blue) are used for navigating through

messages and other entered data.

Product

Count

Set the

Language

28 77091 Issue 2 November 2003

Page 29

SYSTEM OVERVIEW

In the bottom left hand corner there are the SHIFT and DOWN SHIFT keys (in

red). The SHIFT key is used in combination with the icon keys to access

additional printer functions. It is also used in combination with the letter and

number keys to enter the special characters and punctuation marks displayed in red

in the top right hand corner of the key.

To access these

characters, use

the downshift

Shift Key

The DOWN SHIFT key is used in combination with the number keys 1 to 6 to

enter the lower case characters displayed in red in the bottom left hand corner of

the key.

The key in the bottom right hand corner of the keypad is the ENTER key. This

key is used to execute a function once data has been entered. Unlike the other

keys, the ENTER key consists of multiple pressure-sensitive pads. Ensure this key

is pressed in the correct place to activate it.

Downshift Key

To access these

characters, use

the shift key

77091 Issue 2 November 2003 29

Page 30

INSTALLATION

INSTALLATION

Where to Site the Printer

WARNINGS: (1)The printer must not be sited where there is a

risk of water splashing onto the machine. The

printer is not water-resistant.

(2)The printer must not be sited near a source of

static or electromagnetic radiation, such as

metal detectors or high current sealing

machines.

(3)The electricity supply to the printer must be of

constant voltage and current and must be free

from transient spikes and interference. Check

the voltage setting before switching on the

machine.

Before installing the system, check the shipment carefully, removing all packaging,

to ensure that all the ordered components have arrived and that there is no obvious

mechanical damage from shipping. Installation is not complicated, and should take

less than half an hour.

The printer is capable of exceptional print quality at high speed. The performance

of the system depends greatly on its proper installation. Contact your local

distributor or service technician for advice on installing the printer.

It is important to prepare the site carefully. Choose a suitable place for the printer

to be mounted to the conveyor frame. A level, straight sextion of conveyor is

required. If printing on both sides of the items, using more than one printer, both

sides of the printer must be easily accessibe for programming and maintenance.

30 77091 Issue 2 November 2003

Page 31

INSTALLATION

Beware of trailing cables. For example, the printer requires a power cable.

Therefore, ducting or some other form of cable management may be required.

The printer is equally suited to right-to-left or left-to-right conveyor travel legibility in the latter case achieved simply by reversing the direction of print using

the operating software. Reversed printing also means that it is possible to print

simultaneously on both sides of items using more than one printer.

Right to Left Conveyor Travel

Normal Printing

Each printer will need individual servicing, for example when replacing ink

bottles. A printer should not be placed in a location where it may be knocked or

jolted. The printer is also sensitive to vibration which may adversely affect print

quality.

For the best quality of print, select a power-driven section of conveyor for

mounting. Guide bars are essential to align the product to pass the print head only

just touching the front face.

Though items do not need to be equally spaced on the conveyor, there must be an

adequate gap - of at least 100mm - between them for the photocell to register the

arrival of each one. Items must not jam up on the conveyor; the photocell will not

recognise multiple products in a jam. This will result in missed products and

incorrect box counting.

Left to Right Conveyor Travel

Reversed Printing

77091 Issue 2 November 2003 31

Page 32

INSTALLATION

Avoid locations where operators or machinery moving close to the printer are

likely to trigger the photocell. Do not place the printer opposite a large reflective

area as this may also trigger the photocell. When printing on both sides of

product, never place the two printers exactly opposite - the photocells will trigger

each other.

Buffer plate

Each printer incorporates a buffer plate to

afford some protection to the nozzle plate, to

provide a degree of print-head-to-product

spacing for correct character generation and

to help prevent smearing before the ink

dries. In the C16, this is built into the nozzle

plate itself.

In all other models, the buffer plate is

separate to the nozzle plate and is bolted in

place. The position of the buffer plate may

need to be changed to correspond with the

direction of product movement on the

conveyor - make sure that the product

reaches the buffer plate before it reaches the

nozzle plate. This involves removing the

print head cover, which is explained in the

MAINTENANCE chapter of this manual.

Combined Buffer and

Nozzle Plate

Separate Buffer Plate

- Position as Required

Mounting the printer

The exploded diagram (below) shows the arrangement of components used in the

mounting of a printer with a one litre base. Items A and B are not required when

installing a three litre base as they are built into the base unit.

32 77091 Issue 2 November 2003

Page 33

INSTALLATION

H

G

F

C

I

C

A

B

B

E

A Mounting Bracket MJ/605

B Base Mounting Bolts M5x10

D

C Mounting Bolts M8x20

Mounting Washers M8

Mounting Nuts M8

D Vertical Mounting

MF006

Bracket

E Height Adjustment

M8x15

Knob

F Slide Bar MF/

005M

G Print Head Fixing

M5x6

Screws

H Clamping Plate MF/008

I Overhang Adjustment

M5x10

Screws

77091 Issue 2 November 2003 33

Page 34

INSTALLATION

(1) (One litre base only.) Using the

mounting bracket (A) as a template,

drill two holes at an appropriate place

on the conveyor.

(2) (One litre base only.) Fix the

mounting bracket to the base unit

using the M5 mounting bolts (B)

provided. These bolts thread into the

holes at the top of the longest edge of

each side of the base unit.

(3) (One litre base only.) Fix the

mounting bracket/base unit assembly

to the conveyor using the two sets of M8 mounting bolts, washers and nuts

provided (C).

(4) (Three litre base only.) Open the base

unit door and locate the fixing holes

at the rear of the cabinet. Use these

as a template to drill into the

conveyor at the appropriate place.

Fix the base unit to the conveyor

using the M8 mounting bolts,

washers and nuts provided (C).

Mounting Bolts

Vertical Mounting Bracket

Fixing Holes

34 77091 Issue 2 November 2003

Page 35

(5) Slot the vertical mounting bracket

(D) into the square section of the

mounting bracket/base unit and

tighten the height adjustment knob

(E). The horizontal arm may point

towards or away from the conveyor

depending on the application.

(6) Turn the print head upside down.

On its base are three slide bar

mounting holes. Two of the holes

(not all three) will be used to fix the

print head to the slide bar (F). Screw

the two print head fixing screws (G)

into two adjacent holes. Which two

are depends on the application - in

other words, how far from the edge of

the conveyor the product will be

moving. Do not tighten these screws

yet.

(7) Slot the slide bar (F) onto the print

head by passing the two fixing screws

through two of the “keyhole” cutouts

in the slide bar. Make sure the slide

bar does not extend beyond the

nozzle plate. Tighten the screws.

Slide Bar

Mounting Holes

77091 Issue 2 November 2003 35

Page 36

INSTALLATION

(8) Thread the slide bar onto the

horizontal arm of the vertical

mounting bracket so that the upper of

the two clamping plates (H) is inside

the slide bar. Use the two overhang

adjustment screws (I) to hold the

print head securely in position.

Print head overhang can be adjusted by

sliding the slide bar in and out, or by moving

the fixing screws to different holes in the

print head or slide bar. The vertical

mounting bracket can also be rotated 180° to

extend or shorten the overhang. The vertical

position of the print head can be adjusted

using the height adjustment knob.

Overhang

Adjustment

Screws

Height

Adjustment

Knob

Voltage Setting

WARNING: DANGER OF ELECTRIC SHOCK. Disconnect the

printer completely from the mains supply before

attempting any internal access or making any

adjustments to the PSU.

Before switching the printer on, ensure that the internal power setting is set to

match the local electricity supply - either 240v, 220v or 110v AC. The printer

will operate at either 50Hz or 60Hz.

36 77091 Issue 2 November 2003

Page 37

INSTALLATION

Normally the printer is correctly set during manufacture to match the supply

voltage in the country of destination. This is marked on the Serial Number label

next to the power switch on the side of the base unit. However, should it become

necessary to change the voltage settings, follow this procedure.

CAUTION: This procedure involves unscrewing the base unit case to expose the

circuitry inside. Do not attempt to remove the base unit case unless

qualified to do so. If unsure about mounting or connecting the

printer, call Domino Service or your local distributor for assistance.

One Litre Base

(1) Disconnect the printer from the power supply.

(2) Remove the two screws indicated below from both sides of the base unit.

(3) Swing the angled top plate of the base

unit up and backwards, taking great

care not to stress any of the cables or

pipes.

77091 Issue 2 November 2003 37

Page 38

INSTALLATION

(4) The printer power supply (PSU) is located in the top left hand corner of

the exposed circuitry. Changing the voltage setting requires moving the

jumper pins on this board. It may also require changing the fuse located

nearby. (Jump to the section “ALL MODELS” to continue.)

Three Litre Base

(1) Disconnect the printer from the power supply.

Base Unit

Screws

(2) Remove all of the visible screws from both sides of the base unit door.

There will be six in total.

(3) Open the base unit door carefully,

and rotate the plate containing the

electronics. Take great care not to

stress any of the cables or pipes.

(4) The printer power supply (PSU) is

located in the middle of the exposed

circuitry. Changing the voltage

setting requires moving the jumper

pins on this board. It may also require

changing the fuse located nearby.

Power

Supply

Unit

(PSU)

38 77091 Issue 2 November 2003

Page 39

INSTALLATION

All Models

(5) Set the jumpers and fuse to match the input voltage as shown below (1L

base) and over the page (3L base)

.

One Litre Base Link Settings and Fuse Ratings

240V

220V

110V

0.25A

0.25A

0.5A

Jumpers

Fuse

Location of Jumpers and Fuse in

One Litre Base

77091 Issue 2 November 2003 39

Page 40

INSTALLATION

Three Litre Base Link Settings and Fuse Ratings

240V

220V

110V

0.25A

0.25A

0.5A

Fuse

Jumpers

Location of Jumpers and Fuse in

Three Litre Base

(6) Carefully reassemble the base unit and tighten all the screws. Complete the

installation process before switching on the machine.

Note: The voltage setting on the serial number label must be changed to correspond to the

PSU setting.

40 77091 Issue 2 November 2003

Page 41

INSTALLATION

Connecting an Ink Bottle

In the photos on this page a one litre base is shown; follow exactly the same

procedure for the three litre base.

The ink cap is attached to the inside of the base unit by its two feed pipes (air in

and ink out). The two metal probes pierce the seal into the ink bottle allowing an

air-tight, ink-tight seal to be formed.

(1) If installing the printer for the first

time, there may be a piece of

protective tubing placed over the ends

of the probes. Pull off this piece of

tubing carefully - the probes are very

sharp. Check that both “O” ring

seals are present around the supply

stems, otherwise air and ink leaks may

occur.

WARNING: If replacing an empty ink bottle, remember to switch

the power off and press the pressure release valve

before unscrewing the old bottle.

(2) Discard the transit cap from the new

ink bottle and push the bottle into

place. In the one litre base it slots

down into the door of the unit. In

the three litre base it sits on the ledge

at the bottom of the unit.

77091 Issue 2 November 2003 41

Page 42

INSTALLATION

(3) Push the air and ink probes into the correct holes in the ink bottle,

puncturing the seals. Notice that the probes have different diameters which

must be aligned correctly with the holes in the bottle, otherwise damage

will result if the cap is forced on.

Note: Ensure that the

large and small

probes go into the

correct holes.

(4) Press the centre of the probe assembly

firmly with the thumbs to make sure

that both probes have pierced the

seals. Then screw the bottle cap in

place.

(5) Tighten the bottle cap firm (hand

tight only). Arrange the air and ink

tubes so that when the door is shut

they cannot be trapped in the door

mechanism. Switch the printer on

(activating the air pump) before

closing the door and check the cap

thoroughly for leaks.

42 77091 Issue 2 November 2003

Page 43

INSTALLATION

Ensure the ink level is checked regularly (by pressing the ink level indicator switch

and looking through the window on the base unit door) since an exhausted ink

bottle will draw large quantities of air into the system. The process of changing

the ink supply will always cause some air bubbles to become lodged in the ink feed

tubes - these must be removed by priming the system.

Note: If the printer is not going to be used for periods of longer than three weeks, it is

recommended that to replace all the ink in the system with Domino flushing fluid for

the idle period.

Connecting the Print Head

There are two connections to the print head:

a black coiled power cable and a translucent

coiled ink supply tube fitted with a quick

disconnect (“QD”) plug.

Connect the power cable to the socket on

the left hand side of the print head (under

the ledge). The pins are arranged to prevent

incorrect insertion. Screw the cable firmly

in place.

Remove the shipping caps from the end of

the ink supply tube and the QD socket on

the right hand side of the print head.

Connect the QD plug by simply lining it up

with the socket and pressing it in place. A

“click” will be heard as the locking plate

secures the plug.

77091 Issue 2 November 2003 43

Page 44

INSTALLATION

To remove the QD plug, push the locking plate to

the right. The plug will then disconnect and can be

easily pulled free.

The tip of the QD plug contains a spring-loaded

valve which will automatically seal when removed

from the socket. A drip of ink might leak out before

the valve closes, but this is normal. Take care not to

press the tip of the plug against any object, as ink will

then escape under pressure.

Priming the System

On initial installation, and whenever the ink bottle is replaced, air will be trapped

in the ink supply tube. In order to remove this air, the system will need to be

primed.

If the ink supply tube is connected to the print head, disconnect it as shown on the

previous page. Turn the printer on - this will activate the air pump. The air pump

remains on whenever there is power to the system.

A large container, not required for any other

purpose, will be required to catch expelled ink.

Press the tip of the QD plug against an internal

surface of the container. Ink and air will escape into

the container. Once all the air has been expelled,

release the plug, sealing the ink line, and connect it

to the print head.

A purge will now need to be performed. This is

explained on the following page.

Note: Discard any expelled ink in accordance with local waste disposal legislation. Do not

attempt to re-use old printer ink.

Purging the Print Head

Priming the system expels trapped air from the ink supply tube. Purging the print

head continues this process, expelling trapped air and particles from the ink feed

system inside the print head itself. A purge may need to be performed whenever

changing ink bottles or when changing from ink to flushing fluid or vice versa.

44 77091 Issue 2 November 2003

Page 45

INSTALLATION

Like priming, a large container will be needed to

catch expelled ink. Hold this container at an

angle in front of the print head.

Purging is an electronic command; it is achieved

by pressing the PURGE key on the printer’s

keypad.

Two Line LCD Models

Press the key labelled:

If a password prompt appears on the LCD panel, type it in. The following screen

will appear:

Cover eye to go

key to stop

Ensure that the waste ink container in place, then briefly cover the photocell

window on the front of the print head to begin purging.

Four Line LCD Models

Press the key labelled:

If a password prompt appears on the LCD panel, type it in. The following screen

will appear:

Purge which line

press 1, 2 or 3

Type in the number of the line that requires purging. (Each line will need to be

purgeed in turn.) The C34 has five.

Purge line 5 for the C34 refers to the two dots between lines 2 and 3 which are

only used when printing 34 x 24 (68mm) text.

77091 Issue 2 November 2003 45

Page 46

INSTALLATION

Ensure that the waste ink container in place, then briefly cover the photocell

window on the front of the print head to begin purging.

All Models

On initial installation there may be a considerable

amount of spluttering while air is driven out of the

print head. Continue to purge until all the jets in

the nozzle plate are firing consistently.

When finished, press the ENTER key to end the

purge. Wipe the nozzle plate clean with a lint-free

cloth). The printer is now ready to begin

programming and printing messages.

If a good clean jet cannot be obtained by purging,

wipe the nozzle plate with a lint-free cloth dipped

in cleaning fluid and repeat the purge cycle. For

further help in obtaining good jet flow, refer to the

TROUBLESHOOTING chapter of this manual.

Types of correct and

incorrect jet flow

Correct

Feathering

Blocked

Drooling

46 77091 Issue 2 November 2003

Page 47

PROGRAMMING AND PRINTING

PROGRAMMING AND PRINTING

Selecting a language

The printer can communicate with the operator in one of several languages (as

listed below). To select which language to use, press the key labelled:

A list of available languages will appear. Use the keys

to move up and down the list until the required language is located. Press the

ENTER key to confirm choice.

Languages include:

English Italian

French Spanish

German Portuguese

Dutch

Password Protection

To prevent unauthorised use, the printer requires a password to be entered every

time it is switched on. Password protection can be enabled while the printer is in

use by pressing the Password key labelled:

77091 Issue 2 November 2003 47

Page 48

PROGRAMMING AND PRINTING

The following screen will appear:

2 line LCD models:

Enable password

again Y or N

4 line LCD models:

Press Y to enable

the password, press

any other key to

leave it disabled

Press

to enable password protection or any other key to leave the option.

Setting the Clock

This option allows the current system time and date to be changed, and to set up

the rollover time (the time at which the date changes as far as each production line

is concerned.)

Note: Do not attempt to set the printer’s clock while printing is taking place.

It is important that the printer is given the correct current date and time before

date stamping or sell-by-dates can be printed. Once entered, the correct time will

remain in the printer even if the power is switched off.

Press the key labelled:

48 77091 Issue 2 November 2003

Page 49

PROGRAMMING AND PRINTING

The following screen will appear:

2 line LCD models:

HR:MI DT/MO/YR D

14:51 28/08/01 2

4 line LCD models:

use > < to move then

replace numbers

HR:MI DT/MO/YR D

14:51 28/04/01 2

The top line gives a key for the current time (in 24 hour format) and date which

are displayed on the bottom line.

HR:MI stands for hours and minutes. In the example above, the current time is

14:51.

DT/MO/YR stands for day, month and year. In the example above, the current

date is 28/08/01, (which is the 28th August 2001.)

D stands for day of the week. In a typical system, Monday = 1, Tuesday = 2 etc.

In the example above, the current day is Tuesday.

The day of the week setting can be amended as required, for instance if the

working week begins on Sunday. The system will calculate the current day of the

week simply by using a seven-day cycle based on whatever value is entered here.

77091 Issue 2 November 2003 49

Page 50

PROGRAMMING AND PRINTING

To amend the date or time, use the arrow keys:

to move the cursor to the part of the display requiring change then overtype this

with the new entry.

By default the rollover time is midnight. To change this value, press the arrow key.

Press the key labelled:

The following screen will appear:

ROLLOVER TIME

00:00

This prompt is the same for both types of LCD screen.

Amend the time by using the left and right arrow keys to move the cursor to the

digit requiring change then over-typing this with the new value.

When complete press the ENTER key.

Note: If the rollover time does not need to be changed, press the ENTER key instead of

the down arrow key.

50 77091 Issue 2 November 2003

Page 51

Creating a Message

A “message” is the line or lines of text that are printed whenever the photocell is

triggered. A total of fifty messages can be stored in the printer, each given a

reference number from 0 to 49. It is this number which must be entered whenever

editing or printing a message.

The number of message lines available depends on the printer:

C7 ONE LINE

C16 TWO LINES

C34 FOUR LINES

All messages are stored in permanent memory, which means that even if the power

to the printer is switched off the messages will be retained. When the power is

switched back on, all the messages can be recalled.

As many or as few messages (up to the maximum of 50) can be stored and each

one can be given whichever reference number required (0 to 49). It is not

necessary to start with message 0.

It may be valuable to make a note of the reference number and contents of each of

the messages in the system. A space is provided at the end of this manual for this

purpose.

Press the key labelled:

the following screen will appear

Edit which

message

This prompt is the same for both types of LCD screen.

Type in the number (0 to 49) of the message to be created (or edited), then press

the ENTER key.

77091 Issue 2 November 2003 51

Page 52

PROGRAMMING AND PRINTING

Note: Each message line can be up to 40 characters in length, including formatting codes -

refer to the FORMATTING MESSAGES chapter of this manual for further

information).

If there is already a message in the chosen location it will be displayed. To leave

the message without making any changes, press the ENTER key a second time. If

there is no existing message in the chosen location, a blank message screen will

appear. Type in the message using the keypad.

At the end of each message line, a marker will appear (a vertical line) indicating the

limit of entered text. To move to the next (or previous) line of a multi-line

message use the keys

These keys also allow the user to move to successive and previous messages (in

reference number order) held in the printer’s memory. As many messages as

required can be edited or created in one editing session. The following message

editing keys can also be used:

Enters a space

at the cursor

position.

Removes the character to

the left of the cursor

position. To delete the

last character in a line,

position the cursor over

the vertical marker.

Moves forward

through the

current message

line.

Moves backward

through the

+

Clears the

contents of

the entire

current line.

current message

line.

52 77091 Issue 2 November 2003

Page 53

PROGRAMMING AND PRINTING

To preview the message on the LCD screen, press together the keys labelled:

+

This displays the message as it will actually print within the limitations of the

screen. Left and right arrow keys will assist to view the whole message.

Formatting codes such as date codes and sell-by-dates will show values correct for

the time at which print preview was accessed. To return to the editing screen,

press the ENTER key.

When the message is complete, press the ENTER key to fix the changes in the

printer’s memory.

Note: Print preview is unable to show bold characters (they will display as normal).

Reverse formatting is included to eliminate the use of added spaces within the

message edit function for print alignment. Therefore print in reverse will come out

the same as in forward as per print preview.

Printing a Message

To print a message, enter the required message reference number (0-49) to be

printed. Once this has been done, the printer will print the selected message

whenever the photocell is triggered.

Press the key labelled:

The following screen will appear:

2 line LCD models:

Print msg no.?

4 line LCD models:

Which message number

do you want to print

Type in number then

press EXE.?

77091 Issue 2 November 2003 53

Page 54

PROGRAMMING AND PRINTING

Type in the number of the message to print then press the ENTER key. The next

time the photocell is triggered the selected message will be printed.

Adjusting the Dot Size

Use this option to set up the optimum print quality for the system. Dot size

adjustment can be applied to one particular message or to all the messages in the

printer’s memory.

Dot size set too low

Dot size set too high

Dot size correct

Press the key labelled:

The following screen will appear:

2 line LCD models:

For which msg

(* for all)

4 line LCD models:

For which message

Enter number or

press * for all...

Enter the number (0-49) of the message to change, or press the key labelled:

to change the setting for all the messages held in the printer. Now press the

ENTER key.

54 77091 Issue 2 November 2003

Page 55

PROGRAMMING AND PRINTING

If a specific message is chosen the screen will change to:

2 line LCD models:

Dotsize =

New value:

4 line LCD models:

Type in a new number

or press EXE to quit

Dot size =

Enter new value:

If all messages are chosen, the screen will change to:

2 line LCD models:

All messages

New value:

4 line LCD models:

Now altering the

settings for all the

messages.

Enter new value:

Type in a value greater than 100 and press the ENTER key to store the changes in

memory and exit the dot size setting routine.

Perform a test print. If the print quality is incorrect, increase or reduce the dot size

value. Higher values increase the dot size and lower numbers reduce it. In some

circumstances the value may need to be reduced to less than 100.

Adjusting the line print density

Use this option to adjust the print density of individual lines in a multi-line

message.

Press together the keys labelled:

+

77091 Issue 2 November 2003 55

Page 56

PROGRAMMING AND PRINTING

The following screen will appear:

2 line LCD models:

Dotsize 1 2

0...3 0 0

Note: This screen presumes a printer capable of two line messages.

4 line LCD models:

Dot size 1 2 3 4

0...3 0 0 0 0

Note: This screen presumes a printer capable of four line messages.

For each of the message lines, enter a number from 0 to 3 where 0 is the least print

density and 3 is the most.

When finished, press the ENTER key to store the changes in memory and exit the

line print density setting routine.

Adjusting the Speed

Use this option to match the speed of printing (the rate at which vertical lines in

the dot matrix are produced) to the speed of the conveyor. The faster the

conveyor, the faster the text must be printed in order to be legible. Speed

adjustment can be applied to one particular message or to all the messages in the

printer’s memory.

Note: The larger the speed value the longer the gap between printing the vertical lines in

the dot matrix.

Speed set too high

56 77091 Issue 2 November 2003

Page 57

PROGRAMMING AND PRINTING

Speed set too low

Correct speed

Press the key labelled:

The following screen will appear:

2 line LCD models:

For which msg

(* for all)

4 line LCD models:

For which message

Enter number or

press * for all...

Enter the number (0-49) of the message to change, or press the key labelled:

to change the setting for all the messages held in the printer. Now press the

ENTER key.

If a specific message is chosen the screen will change to:

2 line LCD models:

Speed =

New value:

77091 Issue 2 November 2003 57

Page 58

PROGRAMMING AND PRINTING

4 line LCD models:

Type in a new number

or press EXE to quit

Speed =

Enter new value:

If you chose all messages the screen will change to:

2 line LCD models:

All messages

new value:

4 line LCD models:

Now altering the

setting for all the

messages.

Enter new value:

Type in a value between 15 and 255. Lower numbers produce a faster print rate,

forming narrower characters; higher numbers produce a slower print rate, forming

broader characters.

The faster the conveyor, the smaller the speed value. This may need to be fine

tuned in order to obtain optimum print quality.

When finished, press the ENTER key to store the changes in memory and exit the

speed setting routine.

58 77091 Issue 2 November 2003

Page 59

PROGRAMMING AND PRINTING

Adjusting the delay

The delay setting determines the time gap between the photocell being triggered

and the nozzle plate beginning to emit ink. Since the photocell is triggered by the

leading edge of the items on the conveyor, the larger the delay setting the further

along the side of the item each message will begin to print.

TEXT TEXT

Small delay setting: message

printed close to the leading edge of

item

Small delay setting: message

printed close to the leading edge of

item

Delay is normally set for each individual message since different messages will be of

different lengths. Long messages may need shorter delay times than brief messages.

The delay value used will also depend on the speed of the conveyor - faster

conveyors may need lower delay times.

Press the key labelled:

The following screen will appear:

2 line LCD models:

For which msg

(* for all)?

4 line LCD models:

For which message

Enter number or

press * for all

77091 Issue 2 November 2003 59

Page 60

PROGRAMMING AND PRINTING

Enter the number (0-49) of the message to change, or press the key labelled:

to change the setting for all the messages held in the printer. Now press the

ENTER key.

If a specific message is chosen, the screen will change to:

2 line LCD models:

Delay =

New value:

4 line LCD models:

Type in a new number

or press EXE to quit

Speed =

Enter new value:

If all messages are chosem, the screen will change to:

2 line LCD models:

All messages

new value:

4 line LCD models:

Now altering the

setting for all the

messages.

Enter new value:

Type in a value between 0 and 255. Higher numbers increase the delay time,

retarding printing along the side of the product. A value of 0 means that there is

no delay - in other words the message will begin printing the moment the

photocell is triggered.

When finished, press the ENTER key to store the changes in memory and exit the

delay setting routine.

60 77091 Issue 2 November 2003

Page 61

PROGRAMMING AND PRINTING

Setting the Print Direction

Use this option to set the print direction for the printer. Messages can be printed

in either forward or reverse direction, enabling products moving in either direction

on conveyors (right to left (forward print) or left to right (reverse print)) with

respect to the print head. It also allows the product to be printed on both sides

(with more than one printer on the line). The system assumes a normal conveyor

movement from right to left.

Printing “forward” for a conveyor

moving right to left

Printing “forward” for a conveyor

moving left to right

Printing “reverse” for a conveyor

moving right to left

Printing “forward” for a conveyor

moving left to right

Forward printing means that the first character of the message is printed first, just

like a typewriter. Reverse printing means that the last character is printed first.

Press the key labelled:

The following screen will appear:

2 line LCD models:

Direction

Press F or R

4 line LCD models:

Set direction

press F for forward,

R for reverse or EXE to

leave

77091 Issue 2 November 2003 61

Page 62

PROGRAMMING AND PRINTING

Press:

or

for forward or reverse printing respectively. Then press the ENTER key to

confirm.

Setting the Print Orientation

Use this option to set the print orientation for the printer. Messages can be

printed in either normal or inverted orientation, enabling the message to be

printed upside down. When printing inverted messages on conveyors moving

right to left, the message direction will also need to be set to reverse.

Printing “normal” for a conveyor

moving right to left

Printing “inverted” and “reverse” for

a conveyor moving right to left

Press the key labelled:

The following screen will appear:

2 line LCD models:

Orientation

Press N or I

Printing “inverted” for a conveyor

moving right to left

Printing “inverted” for a conveyor

moving left to right

62 77091 Issue 2 November 2003

Page 63

PROGRAMMING AND PRINTING

4 line LCD models:

Set orientation

press N for normal,

I for inverse or EXE to

leave

Press:

or

for forward or reverse printing respectively. Then press the ENTER key to

confirm the choice.

When printing inverted, each individual line of the message is inverted, not the

whole message. So a four line message which prints like this in normal

orientation:

will print like this in inverted orientation:

Each line of the message has been inverted, but line 1 is still line 1, line 2 is still line

2, and so on. The layout of the message may need to be amended ensure legibility

in multi-line messages.

77091 Issue 2 November 2003 63

Page 64

PROGRAMMING AND PRINTING

Product Count

This option displays the total number of product triggers registered by the printer

so far - in other words since the last time the value was reset to zero. It is not the

same as the box count automatic attribute.

Press the key labelled:

The following screen will appear:2 line LCD models:

Count

Zero count = Y/N

4 line LCD models:

Box count =

Press Y to zero the

count or any other key

to leave it.

The current product count appears at the top of the screen. This value can be

reset to zero at any time by pressing

64 77091 Issue 2 November 2003

Page 65

PROGRAMMING AND PRINTING

Setting Up a Second Password

The printer allows two passwords to be used. One password is set into the printer

at the factory and cannot be changed. The other can be set to the operator’s own

preference. When using the system, enter either password to access printer

functions (presuming that password protection has been set).

To maintain security, whenever the password is entered in order to access a printer

function, the password characters will not appear on the screen. Instead, a series of

ash marks will appear (e.g. ######).

To set up a second password press together the keys labelled:

+

At the prompt, type in the new password. Printer passwords can be up to six

characters in length using any alphanumeric characters. This new second password

will replace any password previously set.

When finished, press the ENTER key to store the new password in the printer’s

permanent memory.

77091 Issue 2 November 2003 65

Page 66

PROGRAMMING AND PRINTING

Clearing all Messages

This option will clear all the messages and settings from the printer’s memory.

Both password protection and a confirmation prompt are provided to reduce the

risk of accidental erasure.

Note: Do not run this routine unless absolutely certain it is necessary. Once the messages

have been erased, it will not be possible to retireve them.

Press together the keys labelled:

+

The following screen will appear:

2 line LCD models:

Type in password

4 line LCD models:

Type in your

password first...

Enter the password. If password is less than 6 digits press enter key. The screen

will change to:2 line LCD models:

N.B. This will

wipe memory Y/N

4 line LCD models:

N.B. This will erase

our messages. Press

Y to do this or any

other key to quit

Press:

to erase all messages from the printer’s memory or any other key to exit the

routine.

66 77091 Issue 2 November 2003

Page 67

FORMATTING MESSAGES

FORMATTING MESSAGES

Formatting Text

When setting up messages, a wide range of different codes and attributes can be

included which enables the way text is printed to be changed, or to include

variable information in the messages such as production dates or shift indicators.

Non-printing formatting information, included into messages, may include things

such as square or curly brackets or letters in lower case. The non-printing

characters can all be found in the top right and bottom left corners of the number

keys (1 to 6).

Each message line can be up to 40 characters long. This includes any non-printing

formatting codes.

Note: The lower case letters on the keypad do not print. They are used exclusively as

codes.

To include a non-printing bracket in a message, hold down the key labelled:

while pressing the relevant number key. To include one of these lower case letters

in a message, hold down the key labelled:

while pressing the relevant number key.

The letter keys contain a range of international characters and punctuation marks

(in the top right hand corner of each key) which can be included in a message.

Due to the limitations of the LCD screen the international characters will display

using lower case letters - the correct characters will be printed. To include one of

these characters in a message, hold down the key labelled:

while pressing the relevant letter key.

77091 Issue 2 November 2003 67

Page 68

FORMATTING MESSAGES

Slashed and Non-Slashed Zeros

The printer can print zeros either with a slash (Ø) or without (0). This is set for all

messages at once. The slash will appear on the screen during message editing but

will print correctly.

Choose which the printer will use by pressing together the keys labelled:

+