Page 1

DOMINO A--SERIES

INK JET PRINTER

OPERATION AND

MAINTENANCE

MANUAL

Page 2

DECLARATION OF CONFORMITY

We,

Domino UK Ltd, Bar Hill, Cambridge CB3 8TU

declare under our sole responsibility that the products,

Domino A300 and Pinpoint, A200 & A100 Printers

to which this declaration relates, are in conformity with the following

standards:

EN50081--2 1992 Class B : Electromagnetic Compatibility

(Conducted),

EN50082--2 1992 : Electromagnetic Compatibility, General

Immunity Standard

EN55022--1 1987 Class A : Electromagnetic Compatibility

(Radiated)

EN60204 Part 1 : Safety of Machinery -- Electrical Equipment of

Industrial Machines

EN60950 : Safety of Information Technology Equipment, including

Electrical Business Machines

following the provisions of:

73/23/EEC : Low Voltage Directive

89/336/EEC : EMC Directive.

Bar Hill,

Cambridge,

17th July 1998 D.W. Reed

(2) 27080 Issue 1 Sept 98

Page 3

DOMINO A--SERIES

INK JET PRINTER

OPERATION AND MAINTENANCE MANUAL

This manual, Domino Part No. 27080, is for use in the maintenance of

Domino A300 and Pinpoint, A200 and A100 printers.

For instructions on how to operate the printer, refer to the Domino

A--Series Operator’s Pocketbook, Domino Part No. 27090.

Users of this ink jet printer are warned that is is essential to read,

understandandactaccordingtotheinformationgiveninPart1:Health

andSafety. Thispartofthemanualalsospecifiesasetofsymbolswhich

are used elsewhere in the manual to convey special warnings or

requirements. It is,therefore,essentialthat users arealso familiarwith

these symbols and act accordingly.

All rights reserved. No part of this publication may be reproduced,

stored on a retrieval system, or transmitted in any form, or by any

means, electronic, mechanical, photocopying, recording or otherwise,

without the prior permission of Domino UK Ltd.

Domino UK Ltd has a policy of continuous product improvement,the

Company therefore reserves the right to modify the specification

contained in this manual without notice.

E Domino UK Ltd 1998

For sales, service and inks please contact:

Domino UK Ltd Domino Amjet Inc

Bar Hill 1290 Lakeside Drive

Cambridge CB3 8TU Gurnee IL.60031

England U.S.A.

Tel: 01954 782551 Tel: 847 244 2501

Fax: 01954 782874 Fax: 847 244 1421

27080 Issue 1 Sept 98 (3)

Page 4

FCC Notice

Thisequipmenthasbeentestedandfoundtocomplywiththelimitsfor

a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment.

Thisequipmentgenerates,usesandcanradiateradiofrequencyenergy

and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communication.

Operation of this equipment in a residential area is likely to cause

harmfulinterference,in whichcase,the userwillbe requiredtocorrect

the interference at his own expense.

Ifthis equipmentdoes causeharmful interferencetoradioortelevision

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

D Re--orientate or relocate the receiving antenna

D Increase the separation between the equipment and receiver

D Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected

D Consultthedealeroranexperiencedradio/TVtechnicianforhelp.

Any changes or modifications not expressly approved by the

manufacturercouldvoidtheuser’sauthoritytooperatetheequipment.

(4) 27080 Issue 1 Sept 98

Page 5

DOMINO A--SERIES

INK JET PRINTER

OPERATION AND MAINTENANCE MANUAL

CONTENTS

CHAPTER 1 Part 1 Health and Safety

Basic requirements and symbol

explanations.

Part 2 Introduction

Including printer specification, menu map

and use of the front panel.

CHAPTER 2 Part 3 Operation

Start up, shut down, cartridge and

reservoir replacement and how to create a

message.

Part 4 Display Messages and Fault Finding

Message interpretation and basic

fault--finding.

Part 5 Reference

Glossary of terms and screen descriptions

with details of the options.

CHAPTER 3 Part 6 Printer Description

Print head, cabinet, electronics and ink

systems.

Part 7 Maintenance

General and periodic maintenance, jet

alignment and ink changes.

Part 8 Repair

Print head, electronics system and ink

system.

Part 9 Spares and Accessories

Accessories, consumables, tools and

spares.

Part 10 Options

Additional parts for the printer.

Appendix A Installation

Installation and preparation for use.

Index To locate a subject in the manual.

Appendix B Compressor Driven Airdryer

Instructions and maintenance.

Appendix B Air Driven Airdryer

Instructions and maintenance.

27080 Issue 1 Sept 98 (5)

Page 6

(6) 27080 Issue 1 Sept 98

Page 7

DOMINO A--SERIES

INK JET PRINTER

OPERATION AND MAINTENANCE MANUAL

AMENDMENT RECORD

Amendment Date

All Parts at Issue 1 September 98

Appendix B : Compressor Driven Airdryer April 98

Appendix B : Air Driven Airdryer April 98

27080 Issue 1 Sept 98 (7)

Page 8

(8) 27080 Issue 1 Sept 98

Page 9

DOMINO A--SERIES

INK JET PRINTER

OPERATION AND MAINTENANCE MANUAL

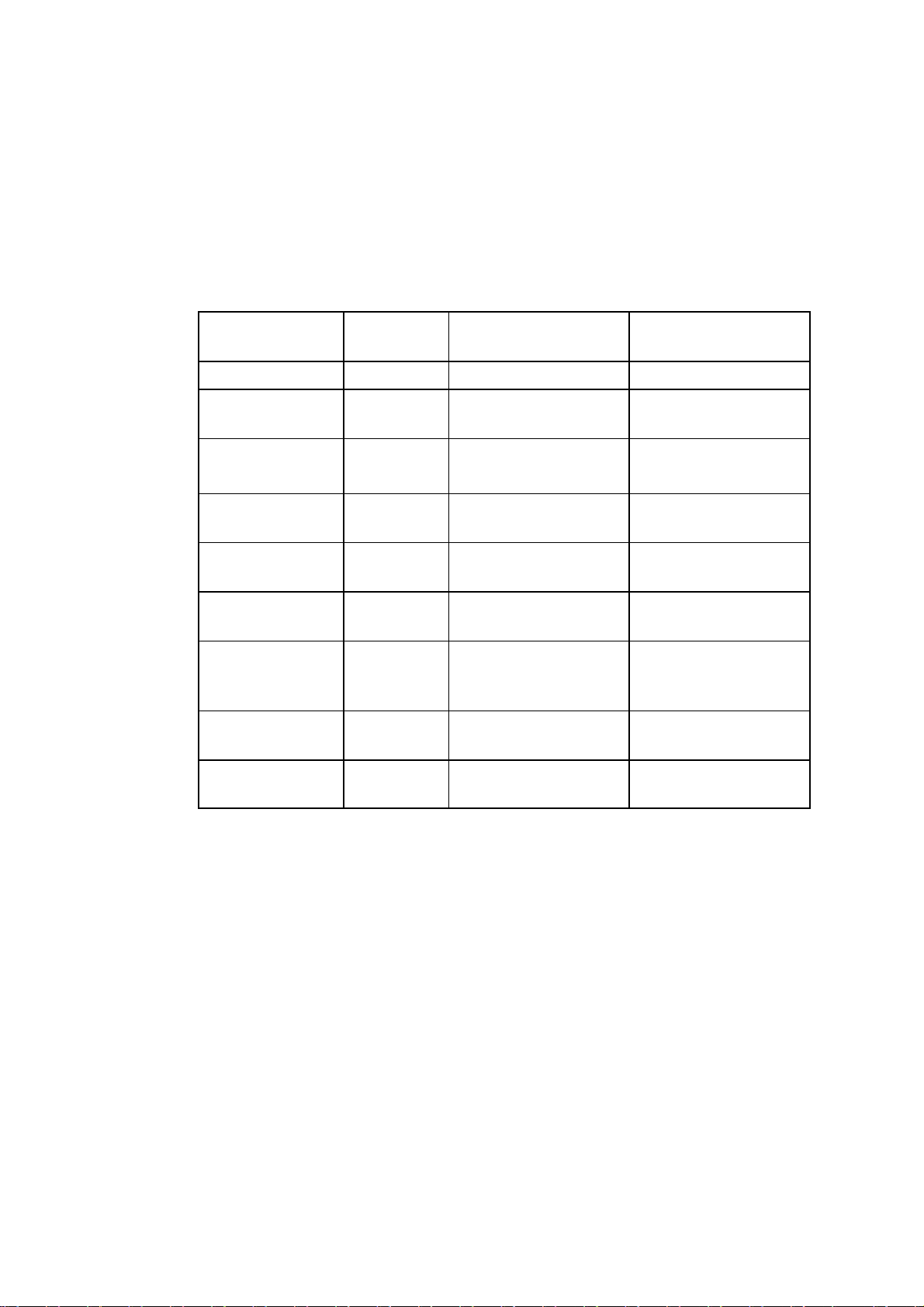

In order that the machine continues to comply with the standards

required by the certification, the following components must not be

altered in any way or replaced by other types.

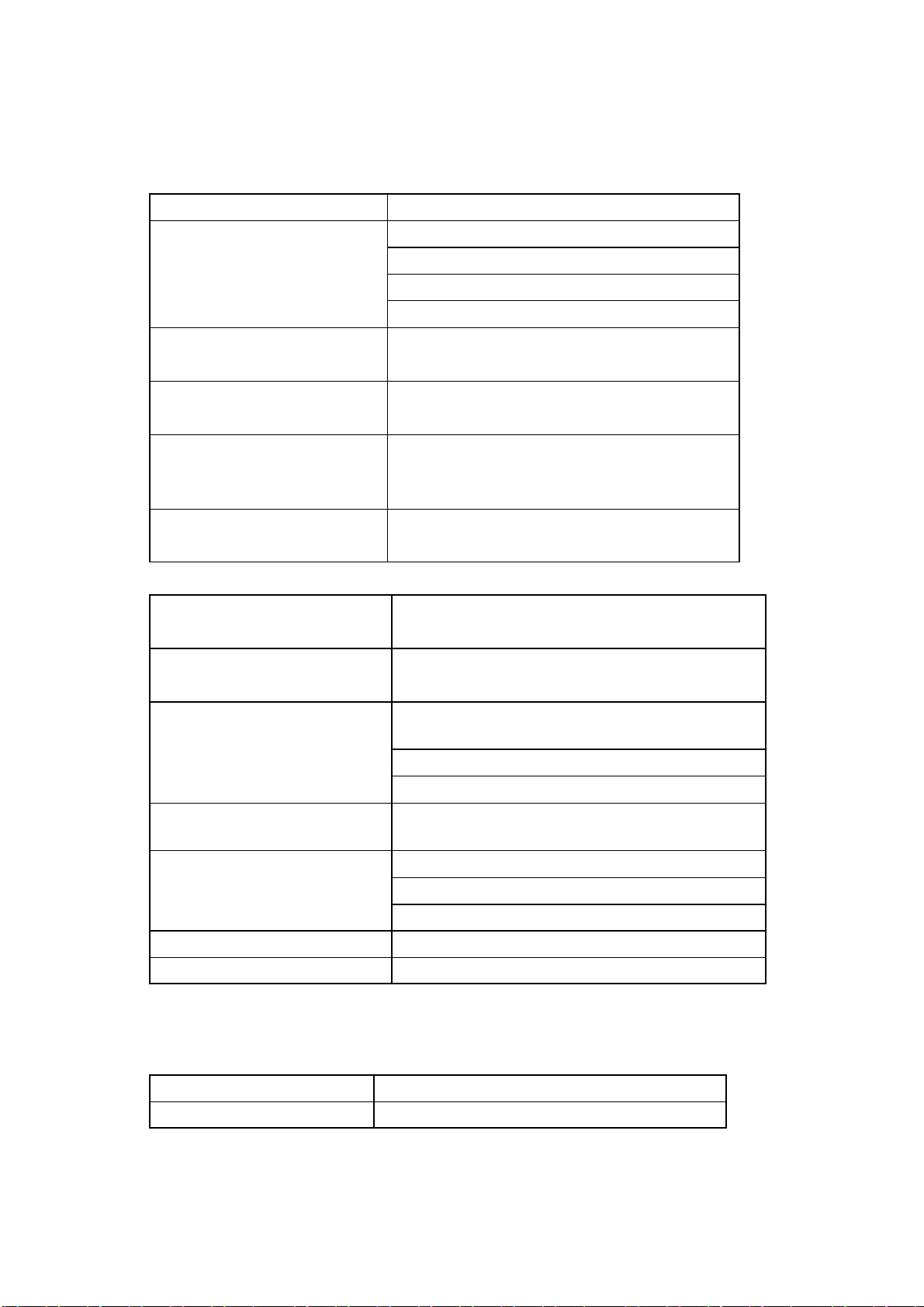

COMPONENT DOMINO

PART NO.

HV PSU 12170 Advance HI Volt GM7--19

PSU Assy 37758 Bulgin Power

Filter

Mains/Power

Switch

Mains/Power

Plug 3 Way

Mains/Power

Socket 7 Way

Mains/Power

PCB Assy

External

Interface

Fuse 20x5 (T)

1A

Fuse 20x5 (T)

4A

13492 Shaffner

37744 EAO 61--8420.12

13496 Bulgin PX0730/P

13498 Bulgin PX0744/S

25109 Domino 25109

01210 Little Fuse 213.001.MA000

01229 Little Fuse 218.004.MA000

MANUFACTURER MANUFACTURER

PART NO.

SAX110--34

Source

FN332--3/05

Bulgin

PS02/A0320/63

27080 Issue 1 Sept 98 (9)

Page 10

(10) 27080 Issue 1 Sept 98

Page 11

PART 1 : HEALTH AND S AFETY

CONTENTS

INTRODUCTION Page 1--3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Requirements 1--3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 1--4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fire Risk 1--4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spillages and Disposal 1--6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYMBOLS 1--7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27080 Issue 1 August 98 1--1

Page 12

HEALTH AND SAFETY

1--2 27080 Issue 1 August 98

Page 13

HEALTH AND SAFETY

HEALTH AND SAFETY

INTRODUCTION

Domino supplies Safety Data Sheets (SDS’s)giving specific safety

information with each of its ink, make--up and wash fluids. There are

also warnings on each container. The following notes are for general

guidance only.

Basic Requ irements

When used correctly, printing inks do not cause problems. However,

everybody using them should be familiar with the appropriate safety

standards and be aware of the precautions that should be taken. The

following are basic requirements.

D Proper standards of industrial practice relating to cleanliness and

tidiness must be maintained

D Inks and their containers must be stored and handled with care

D All who come into contact with inks must be properly instructed

in their use.

Directions for safe working practices vary according to the

environment. The following are broad principles so that necessary

precautions may be taken.

D Contact with the mouth must be avoided. Therefore eating,

drinkingorsmoking, or any personal habits oractionswhichmay

transfer ink to the mouth, must be avoided

D Contact with the eyes must be avoided. Suitable eye protection

must always be worn whenever there is any risk of splashing or

misting. If ink does get into theeyes,firstaid treatment is toflood

theaffectedeyefor15minuteswithsalinesolution,(orcleanwater

ifsalinesolutionisnotavailable),takingcarenottoallowthewater

to run into an unaffected eye. Medical aid must be obtained

immediately

D Most inks contain solvents which may injure the skin. Warning of

this is given on the SDSs. Barrier creams should be used and

protective clothing worn

27080 Issue 1 August 98 1--3

Page 14

HEALTH AND SAFETY

D Many inks contain materials which vaporise easily and can be

inhaled. Good ventilation is necessary

D Any usedcleaning materials,e.g.rags, paperwipes,are apotential

fire hazard. They must be collected for safe disposal after use

D After exposure to ink, all possible traces must be washed off as

soon as possible at the nearest washing facility.

Certain inks are allowed for use where they can be in indirect contact

with food. In these cases, the following precautions must be observed

in addition to those appropriate to hygiene:

D The inks must only be used in printers supplied from new for use

with these inks. Any repairsand replacementsmust use genuine,

new and unused spare parts

D The inks must not be used in printers which have previously been

used, at any time, for any other purpose.

In other words, a printer using ”food grade” ink can be converted for

use with other inks, but a printer which has used other inks must not

be converted for use with food grade ink.

Storage

Printing inks must be stored in well--ventilated buildings, or in areas

set aside for the purpose, chosen for safety in case of fire. Materials

based on volatile, flammable solvents must be stored in accordance

with local regulations.

Fire Risk

For an electrical fire, do not use water. If water must be used, such as

inthe caseof aNitro--cellulose inkfire (seebelow) thepowerMUST BE

REMOVED first.

Manyinks usedin inkjetprintingcontainNitro--celluloseas thebinder

and remain highly flammable when dry. Observe all warnings given

on the machine and the following safety instructions:

D If there has been an accumulation of dried ink, do not use ferrous

metal (iron or steel) scrapers to remove it, as they can produce

sparks

1--4 27080 Issue 1 August 98

Page 15

HEALTH AND SAFETY

D If dry Nitro--cellulose based ink ignites, it will generate its own

oxygenand canonly beextinguished bylowering thetemperature

with water

D If a Nitro--cellulose fire occurs, ENSURE THAT THE

ELECTRICAL POWER IS IMMEDIATELY REMOVED FROM

THE PRINTER BEFORE water is used to extinguish the fire.

Fire risk is a most important consideration where printing inks are

storedandused. Thedegreeoffirehazardwillvaryconsiderablyfrom

one type of ink or wash to another.

Water--based inkswillnot burn, althoughinksbased on water--alcohol

mixtures may burn if there is sufficient alcohol present. Prolonged

exposureof water--based systemstohigh temperatures mayevaporate

the water to give a flammable residue.

Solvent--based inks offer a greater degree of hazard depending on the

particular solvent or solvent combination. When there is a particular

hazard the appropriate information is given on the SDS.

Ink jet printers place small electrostatic charges on the ink drops used

for printing. In most circumstances, such as when they arrive at the

print surface, these electrostatic charges are either conducted away or

cannotaccumulate. However,duringmaintenance,printdropsmaybe

collected in a container, such as a beaker. It is essential that this

container is made of conducting material and is securely connected to

ground/earth. The electrostatic chargeswill then be safely conducted

to ground/earth.

If there is a fire, there is a likelihood that dangerous fumes will arise

from printing inks. For this reason ink must be stored where it can be

reached quickly by the fire fighting service, and where it will not

spread beyond the store.

27080 Issue 1 August 98 1--5

Page 16

HEALTH AND SAFETY

Spillages and Disposal

WARNING: Some dried inks are highly flammable. Clean up

allink spillagesimmediately. Do notallow theink

to dry or allow any build--up of dried ink spills.

Spillages must be cleaned up as soon as possible with the appropriate

solventmaterials andwith regardtothesafetyofpersonnel. Caremust

be taken to prevent spillages or residue from cleaning up entering

drains or sewage systems.

Inks and associated fluids are materials which conduct electricity.

Therefore, power to the printer must be switched off while spillages

inside the printer cabinet are being cleaned up.

Printing inks and associated fluids must not be treated as ordinary

waste. They must be disposed of using approved methods according

to local regulations.

1--6 27080 Issue 1 August 98

Page 17

HEALTH AND SAFETY

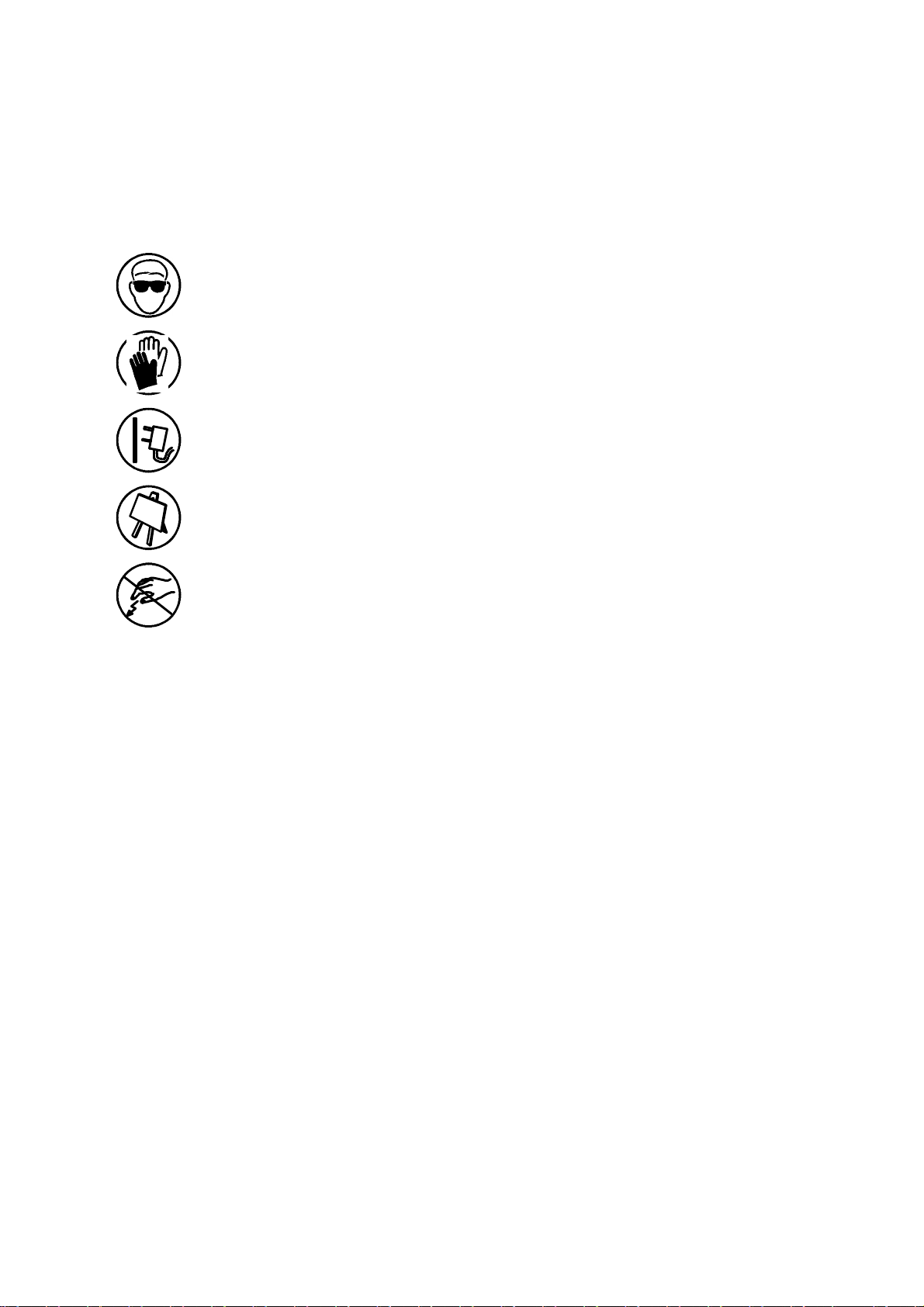

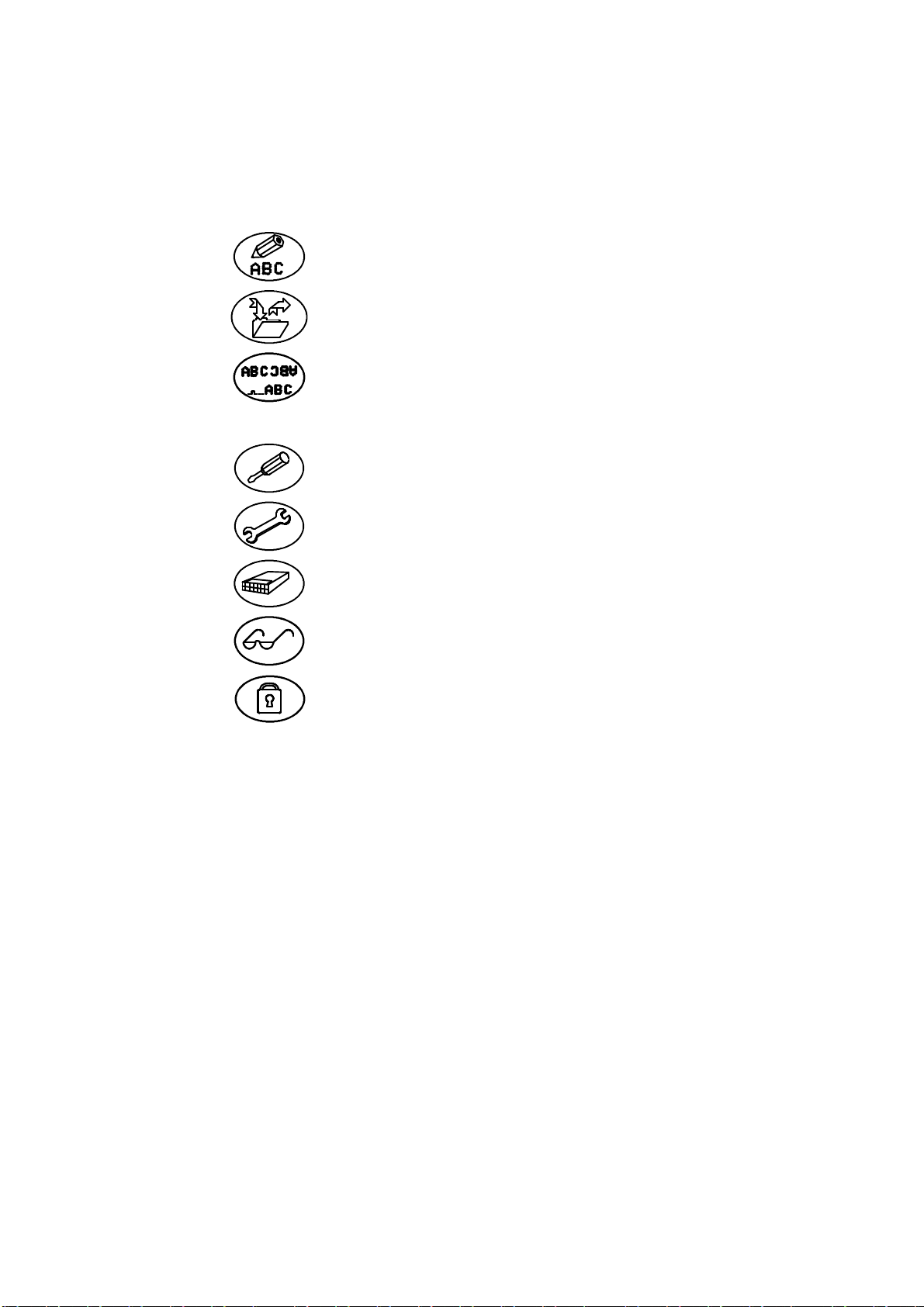

SYMBOLS

The following symbols are used in this manual. Where they appear

next to a procedure or instruction, they have the significance and

importance of written warnings and cautions.

Eye protection must be worn.

Protective clothing must be worn.

The equipment must be switched off and power removed.

Only trained personnel should carry out this procedure.

Beware of Electrostatic Discharge (ESD). Electrostatic precautions

must be used.

D Switch off machine first

D Wear a wristband connected to ground

D Avoid wearing clothing which can build up electrostatic voltages

D Use ESD protective bags to transport PCBs

D Only place PCBs on a mat made from a material which will

dissipate electrostatic voltages and which is connected to ground.

27080 Issue 1 August 98 1--7

Page 18

HEALTH AND SAFETY

1--8 27080 Issue 1 August 98

Page 19

PART 2 : INTRODUCTION

CONTENTS

GENERAL Page 2--5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINTER SPECIFICATION 2--6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Head 2--6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet 2--6.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Input 2--6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ink System 2--7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment 2--7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 2--7.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINTER CONTROL 2--8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Control Panel 2--8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display 2--8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On/Off Switching 2--9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Topic Keys 2--11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Purpose Keys 2--12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help Key 2--13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Currency Key 2--13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Password System 2--13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unicode Character Entry 2--14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Importing and Exporting Data 2--14. . . . . . . . . . . . . . . . . . . . . . . . . .

User Port 2--14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FRONT PANEL TOPIC KEY MENUS 2--15. . . . . . . . . . . . . . . . . . . . . . .

27080 Issue 1 August 98 2--1

Page 20

Page 21

Page 22

Page 23

INTRODUCTION

INTRODUCTION

GENERAL

This manual provides:

D A basic introduction to the printer and how to use the front panel,

with procedures that demonstrate how to manage the printer

D Reference sections describing the functions and messages

presented through the front panel

D A full description of the ink and electronics systems

D Maintenance and repair procedures.

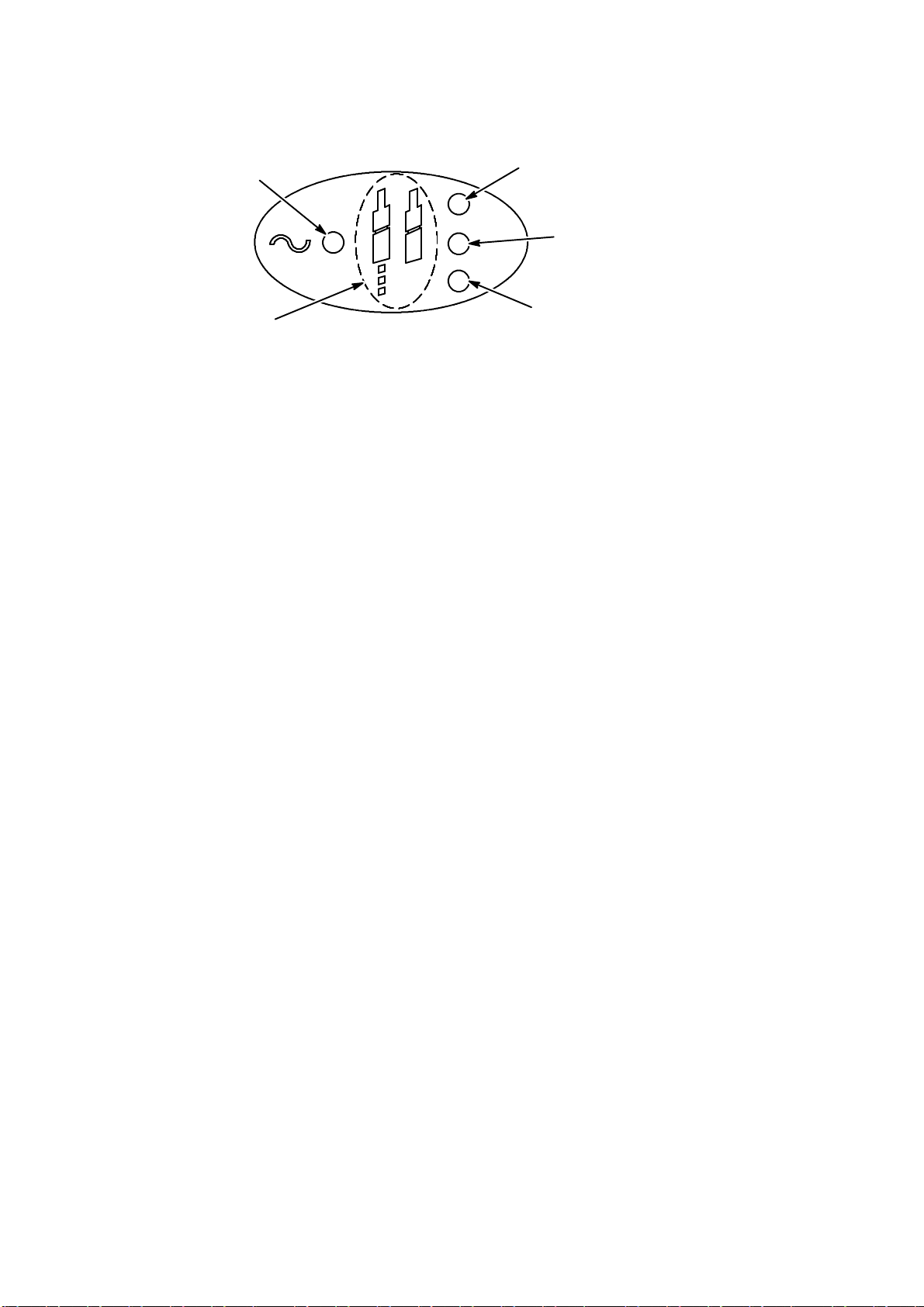

Theprinterconsistsofaprinthead connectedtoastainlesssteelcabinet

by way of a flexible conduit. The cabinet contains an ink system and a

controlling electronic system operated through a panel on the cabinet

upper door. The printers are shown on pages 2--2, 2--3 and 2--4, with

internal views of thecabinetupper(electronic) and lower (inksystem)

compartments shown on pages 6--7 and 6--8.

27080 Issue 1 August 98 2--5

Page 24

INTRODUCTION

PRINTER SPECIFICATION

Print Head

Standard Finish: Aluminium alloy, Tufram coated

Dimensions: Width: 40mm (1.575”)

Depth: 42.5mm (1.673”)

Height: 280.5mm (11.05”)

Weight: 1.0kg (2.2lbs)

Nozzle size:

Pinpoint only:

Spacing from print surface:

Pinpoint only:

Working height relative to

cabinet base:

Conduit Length: 3 or 6 metres (10ft and 20ft)

60 or 75 micron

40 micron

12mm (0.47”) nominal

4mm (+/-- 1mm)

3m conduit: +/--2m (8ft 2ins)

6m conduit: +/--3m (10ft) (A300/A200

only)

A300 Pinpoint and A100: 3m only

Cab inet

Standard Finish: Brushed 316 stainless steel (A300)

Brushed 304 stainless steel (A200 & A100)

IP Rating: A300 is IP65 (1977)

A200/A100 are IP53 (1977)

Dimensions (A300 &

A200):

Width: 475mm (18.7”) --not incl. handles

Depth: 245mm (9.65”) --not incl. front panel

Height: 715mm (28.15) --not incl. feet

Weight (A300 & A200)

(incl. fluids):

Dimensions (A100): Width: 450mm (17.7”) -- not incl. handles

Weight (A100) (incl. fluids): 33kg (72.6lbs)

Control Panel: Polyester, Membrane touch button

For cabinet and print head installation dimensions, see Installation

page A--13.

36kg (79lbs)

Depth: 245mm (9.46”)

Height: 650mm (25.6”)

Data Input (Optional)

Interface: Serial, RS232, RS485

Rate: 110 -- 38.4kBaud software configurable

2--6 27080 Issue 1 August 98

Page 25

INTRODUCTION

Ink System

Ink Capacity (Reservoir): 1.2 litres (0.32 US gall.) -- automatically

metered

Ink Capacity (Cartridge): 825ml (0.218 US gall.)

Make--up Capacity

(Reservoir):

Make--up Capacity

(Cartridge):

Ink Viscosity Control: Automatic Viscometer

Ink Bleed Control: Automatic Start--Up/Shut--Down

Working Pressure:

Pinpoint only:

600 ml (0.16 US gall.) nominal --

automatically metered

825ml (0.218 US gall.)

Automatic, 2900mBar (42 psi) nominal

Automatic, 4000mBar (60psi) nominal

Environment

Temperature Range

(working):

Temperature Range

(Storage):

Humidity: 10 -- 90% RH (non--condensing)

Electrical Supply: 90--132V/180--264V 50/60Hz single phase

+5° to +45°C (42°F to 112°F)

--20° to +60°C (--4°F to +140°F) (machine dry

storage, wet dependent upon fluids)

Auto ranging, 200VA, internal fuse rating 4A

General

Acoustic Noise Level: Not more than 70 dBA

Positive Air Pressure (print

head):

Product detector/Shaft

encoder connectors:

Shaft Encoder Input: Open collector or TTL encoder

Beacon Connector (option): Bulgin ”Buccaneer” 7 way socket

Alarms Connector (option): Bulgin ”Buccaneer” 9 way plug

User Port Connector (option): Bulgin ”Buccaneer” 25 way socket

Communications Port

connector (option):

Power connector: Bulgin ”Buccaneer” 3 way plug,

Internal or external supply. Max

external supply pressure to cabinet

1 bar. (A100 is internal only)

Bulgin ”Buccaneer” 6 way socket.

12V 100mA for photocell or

proximity detector

Bulgin ”Buccaneer” 9 way socket

cable supplied

27080 Issue 1 August 98 2--7

Page 26

INTRODUCTION

PRINTER CONTROL

The printer is switched on by pressing the black button--switch on the

side of the cabinet. This supplies power to the whole printer and after

a short period control of the printer is transfered to the front panel.

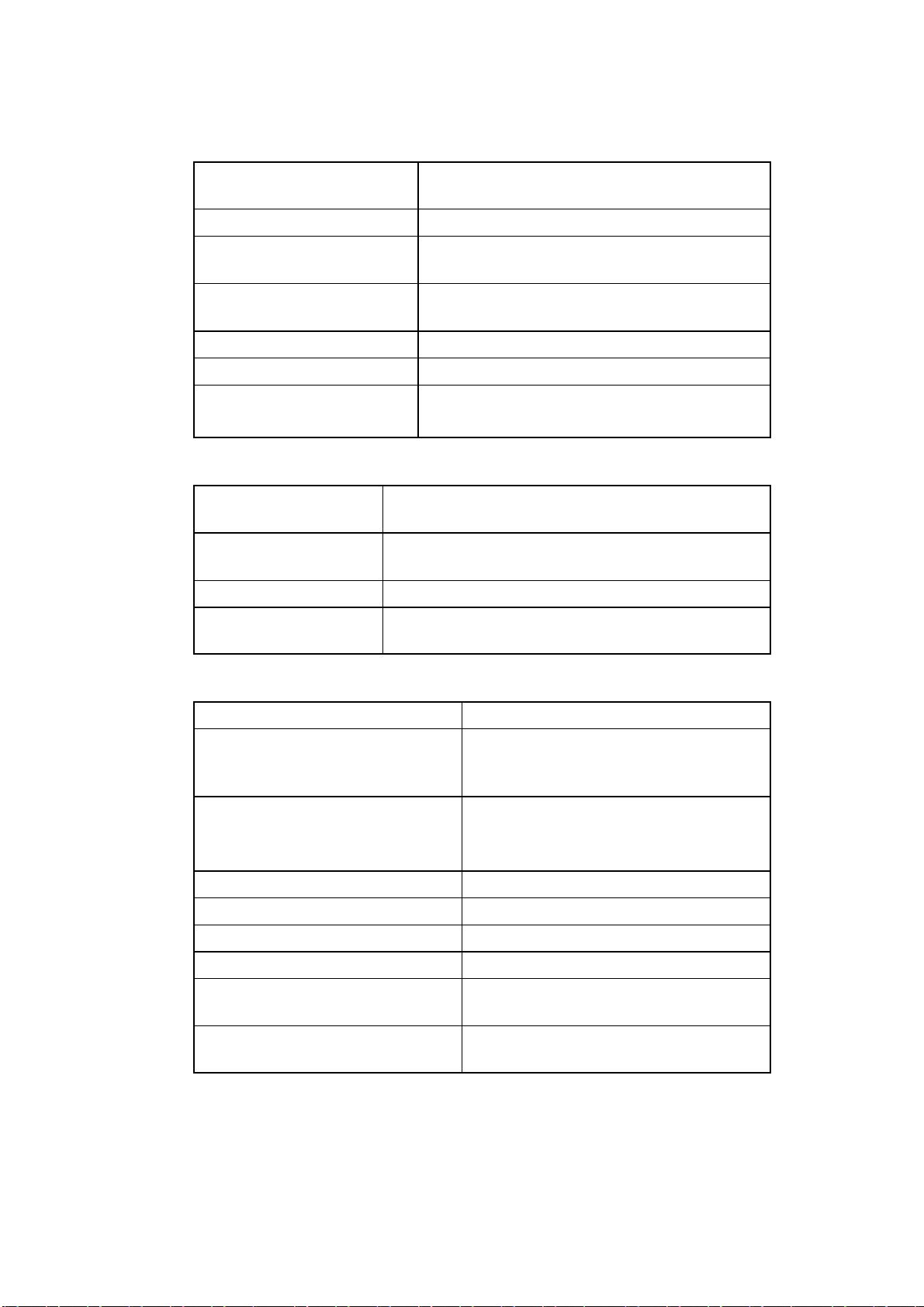

Control Panel

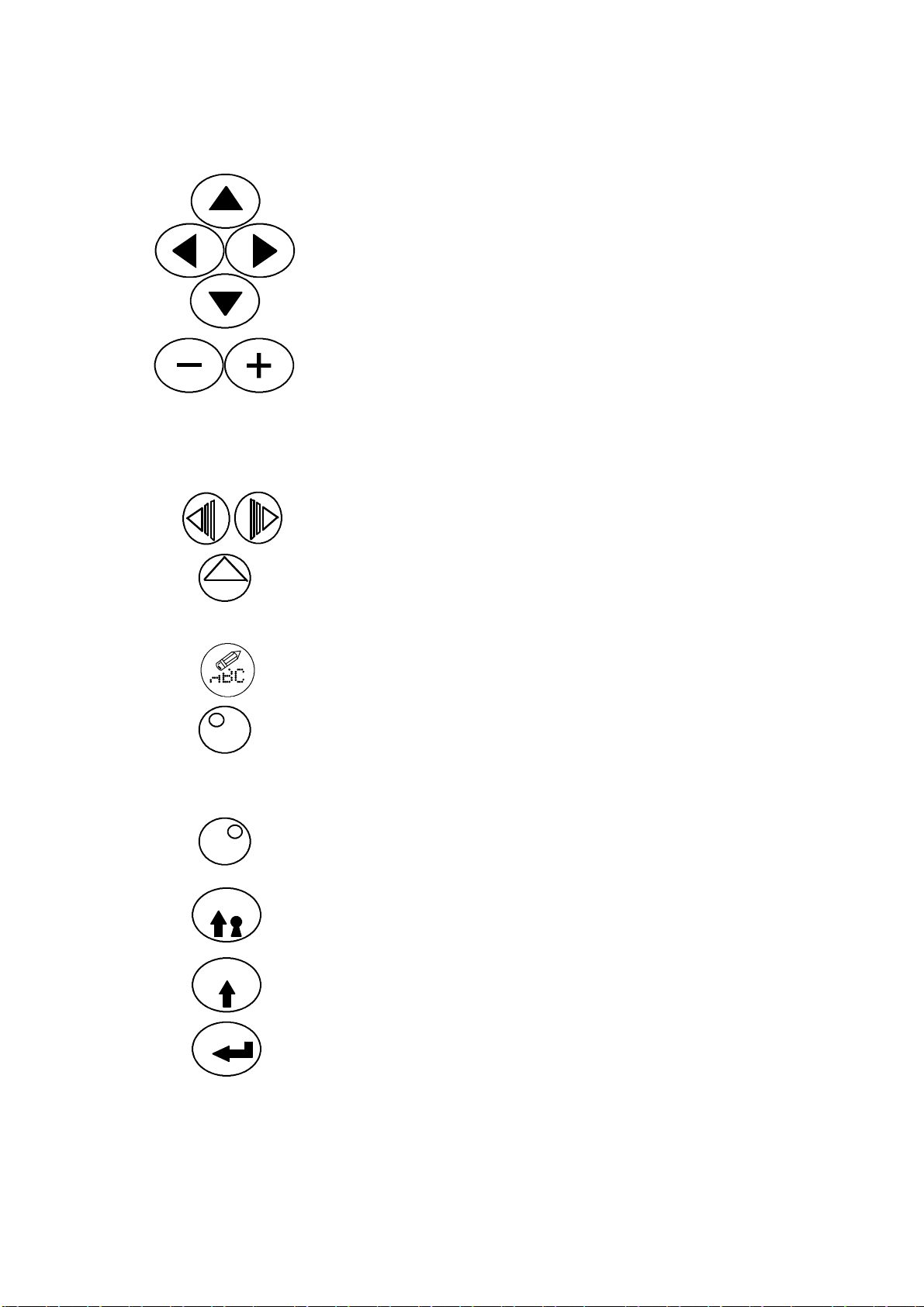

Theprinter iscontrolledexclusivelythroughthefrontpanel. Thereare

two types of keys:

D Permanent keys with fixed functions (these form the majority of

keys)

D Function keys with functions which can change under software

control.

The main areas of the front panel are identified in the diagram below.

Topic Keys

Jet

On/Off

Key

Character

Set Keys

A1006_1

Displa y

Display

Front Panel Keyboard Layout

Cursor Keys

Data Entry Keys

Increment

Keys

Function

Keys

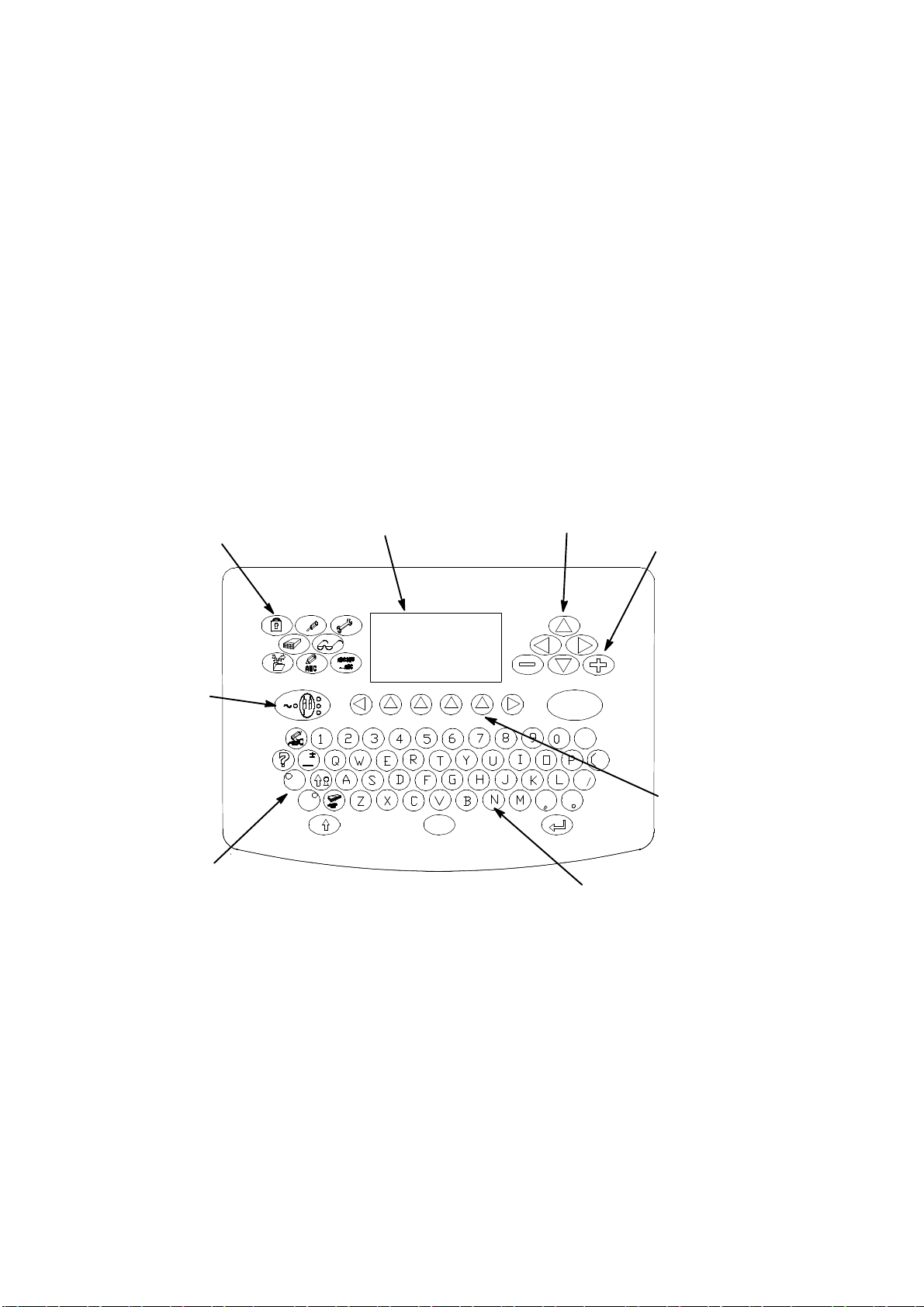

The display presentation has the following basic structure.

Alertbar shows amessagewhen a printeralertis raised. Themessage

flashes until acknowledged bypressingany character key or thespace

key,after whichthe messageis displayedcontinuously. Whenthealert

condition is cleared,themessageis cleared. If two or more alerts exist

2--8 27080 Issue 1 August 98

Page 27

INTRODUCTION

Alert Bar

Status Bar

Working Area

Information Bar

Key Option Bar

Screen Number

Print Symbol

Scroll Arrow

simultaneously, the highest priority alert is displayed. An

unacknowledged alert is always at a higher priority than any other

acknowledged alert. Screen messages are detailed in Part 4.

Status bar shows status and other non--alert information.

Working area provides a general presentation area for the function in

use.

Informationbar usually showswhich levelis currentlyselected, but is

also used for general information.

Key option bar shows up to four key options at any one time,

presentingthemaslabelsforthefour functionkeysimmediatelybelow

the screen. The options are scrolled left and right in groupsof four by

the keys on each side of the function keys, which appear when thereis

morethanfourkeyoptions. Scrollingresultsinthekeylabelschanging,

with the functions of the keys also changing to correspond with the

labelling.

Screen n umber provides a numerical identity for each screen.

Scroll arrow shows that the screen detail extends off the display. The

up-- and down--cursor keys must be used to show the hidden detail.

Print symbol shows printing as each Print Go signal is received. At

very slow print rates the symbol will appear to flash, but typical print

rates will give the appearance of a continuous symbol.

Jet On/Off Switching

TheJetOn/Off switchispressed toswitchon the jetandpressedagain

to switch off the jet. It is necessary to press the switch for two seconds

as a precaution against accidental use. The switch also carries the

following indicators:

Power On Indicator shows when the power is switched on at the

switch on the side of the cabinet.

Red Alert Indicator shows the printer has a fault which prevents

printing. The indicatorflasheswhilethe alert is unacknowledged and

27080 Issue 1 August 98 2--9

Page 28

INTRODUCTION

Power On

Indicator

Jet On/Off

Key

Red Alert

Indicator

Amber Alert

Indicator

Green

Indicator

displays steadily when the alert is acknowledged. It is extinguished

when the fault is cleared.

Amber Alert Indicator shows the printer has a fault that requires

attention. Theindicatorflasheswhilethealertisunacknowledgedand

displays steadily when the alert is acknowledged. It is extinguished

when the fault is cleared.

Green Indicator flashes while the printer is starting up or shutting

down and displays steadily when the printer is printing or ready to

print. It is extinguished by a fault or when the jet is not running.

2--10 27080 Issue 1 August 98

Page 29

INTRODUCTION

Topic Keys

Thetopic keyseach opensets ofscreenoptions. These areshown inthe

diagram on pg. 2--8 and described in detail in Part 5 : Reference.

Message Editor Provides access to the message

creation utilities.

Message Store Provides access to the stored

Messages.

Print Setup Provides access to the utilities

controlling the message being

printed, e.g. message

orientation.

Machine Setup Provides access to adjustments

in setting up the printer.

Service Provides access to the printer for

the Service engineer.

Memory Card Provides access to the PCMCIA

utilities.

Message

Monitor

Shows the message currently

being printed.

Lock--out Switches on password

protection, where used.

27080 Issue 1 August 98 2--11

Page 30

General Purpose Keys

Cursor Keys Four permanent keys used to

Increment Keys Two permanent keys used to

INTRODUCTION

move the cursor around the

screen.

increment and decrement values

shown on the screen and

marked with the highlight bar.

The effect of these keys on

settings and values is

immediate.

Option Key Bar

Scroll Keys

Two keys used to scroll the

functions in the keybar.

Function Keys Keys with functions identified

by the names in the keybar

immediately above.

Delete Key Deletes entries marked by the

highlight bar.

Alternative

Character Set -Left (Blue)

Press this key to select the top

left blue character on each

character key. Also (used with

the + and -- keys) controls screen

contrast.

Alternative

Character Set -Right (Green)

Press this key to select the top

right green character on each

character key.

Shift Lock Key Changes characters to lower case

until pressed again to return to

upper case characters.

Shift Key Hold down to change characters

to lower case.

Enter Key Press this key to put data into

the system to complete an

action.

2--12 27080 Issue 1 August 98

Page 31

INTRODUCTION

Help Key

Help Key Provides access to help

information concerned with the

current menu screen.

Currency Key

Currency Key Provides entry for localised

currency characters. Pressing

this key generates the minor

currency symbol (e.g. p,c) and

pressing it in combination with

the Shift key generates the major

currency symbol (e.g. £, $, etc).

Lockou t

Pressing the Lockout key prevents unauthorised changes through the

front panel or, for example, interference with the printer while it is

unattended. WithLockout selected, control of the printer is restricted

toswitchingon,switchingoffandinspectingthecurrentmessagebeing

printed (by pressing the Label Monitor key). Access to all other

functions requires the use of the appropriate password, provided this

has been set.

The Lockout screen also shows the internal clock, which is replaced in

all other cases by a screen number.

Password System

Entry to the Lockout and Message Monitor areas of printer control is

unrestricted, but all other areas can, if required, be protected by

password.Therearetwolevelsofpasswordprotection:Supervisor,and

Service. Each of these has a progressivelyhigher level of access to the

machine. When accessing a protected area, it is necessary to enter the

appropriatepassword (orthepassword forahigher level). Entry toall

areas with the same or lower protection status will subsequently be

unhindered. Returning to Lockout resets the password access. It is

possible to change the Supervisor password.

27080 Issue 1 August 98 2--13

Page 32

INTRODUCTION

Thefollowingtableshowstheavailablepasswordprotection:

LEVEL PASSWORDREQUIRED

Lockout None

MessageMonitor None

MessageEditor Supervisor

MessageStore Supervisor

PrintSetup Supervisor

MemoryCard Supervisor

MachineSetup Supervisor

Service Service

UnicodeCharacterEntry

Charactersthatarenotrepresentedbyakeycanbeavailablefor

printing.TheycanbeenteredintotheMessageEditororadataentry

dialogusingtheirUnicodeidentity.Thisisdonebyholdingdownboth

alternativecharactersetkeysandtypingtheUnicode4--digit

hexadecimalnumber(0000toFFFF).

ImportingandExportingData

MemoryCard

Thememorycardisablank,formattedPCMCIAcardwhichcanbe

usedtocopyandback--upmessagesandlogos.Thiscanthenbeused

asaback--upforthemessagesandlogos,orusedtocopymessagesand

logostoanotherprinter.

Itispossibletocopytheentiremessage(seepg.5--30)orlogostoreor

individualmessagesorlogos(seepg.5--23and5--25).

Back--up/RestoreCard

TheBack--up/RestorecardisadedicatedPCMCIAcardusedto

back--upandrestorealloftheconfigurationdataofaprinter.Itcanalso

beusedtorestorepartialconfigurationdatatothesameprinterorcopy

ittoanotherprinter(althoughtheprintersmustbethesame,i.e.

machinetype,inktype,etc.andhavethesameversionofmain

program).Thepartialrestorewillcopydatasuchas:nozzlesize,ink

type,conduitlength,etc.butnotdatasuchas:pumpspeed,modulation

voltage,etc.(seepg.5--44).

UserPort

ExternalcontroloftheprinterispossiblethroughtheUserPort.

2--14 27080Issue1August98

Page 33

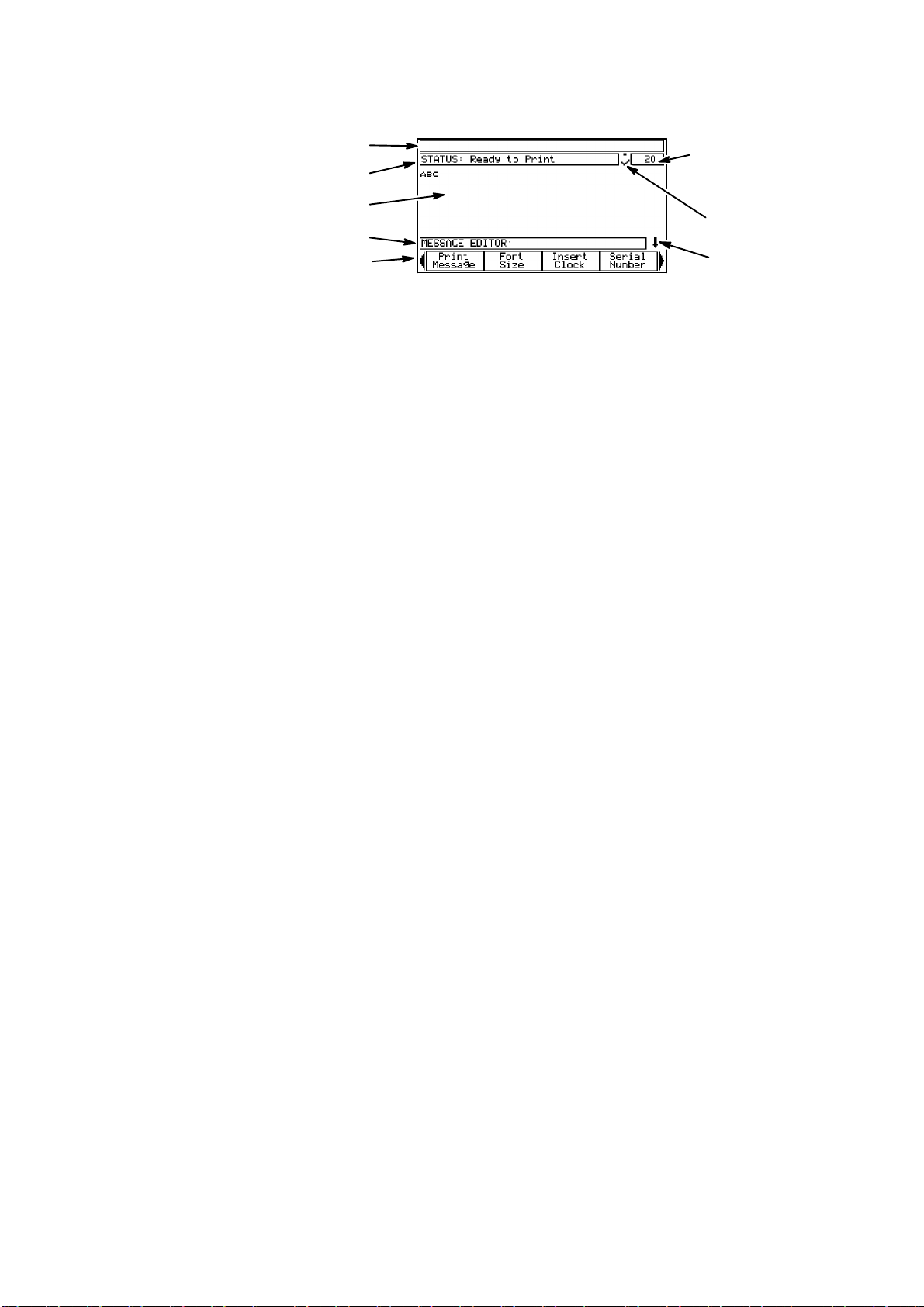

27080 Issue 1 August 98 2--15

MESSAGEEDITOR

Print

Message

(pg.5--8)

Font

Size

(pg.5--8) (pg.5--9) (pg.5--9)

Insert

Clock

Serial

Number

Edit

(pg.5--11)

New

Message

(pg.5--11) (pg.5--11)

Bold

On/Off

Dblspace

On/Off

(pg.5--12) (pg.5--12)(pg.5--12)

Shift

Code

Insert

Logo

Text

Field

(pg.5--13)

Clock

Offsets

(pg.5--13)

MessageEditor(Cont.)

Start

MRC

(pg5--14)

End

MRC

(pg5--14)

MRC

Text

(pg5--15) (pg5--16)

Toggle

MRCs

Special

Setup

(pg.5--16)

INTRODUCTION

SPECIALSETUP

Exit

Message

Bold

(pg.5--16) (pg.5--17)

Reverse

Control

Inverse

Control

(pg.5--18) (pg.5--19)

Repeat

Printing

Message

Offset

(pg.5--19)

Product

Select#

(pg.5--20)

Raster

(pg.5--20)

MESSAGESTORE

Select

Message

(pg.5--21)

Print

Message

(pg.5--21)

StopMsg

Printing

(pg.5--21)

Save

Message

(pg.5--22)

Delete

Message

(pg.5--22)

Storage

Stats

(pg.5--23)

Export

Message

(pg.5--23)

Import

p:\)

(pg.5--23)

Import

r:\)

(pg.5--24

Logo

Store

(pg.5--24)

StopAll

Printing

(pg.5--25)

A300/A200

Only

LOGOSTORE

Cancel

FrontPanelTopicKeyMenus

OK Delete

Logo

(pg.5--24)

Storage

Stats

(pg.5--25) (pg.5--25)

Export

Logo

Import

(p:\)

(pg.5--25)

Import

(r:\)

(pg.5--25)

Page 34

2--16 27080 Issue 1 August 98

PRINTSETUP

Message

Bold

(pg.5--26) (pg.5--26)

Reverse

Control

MACHINESETUP

Master

Clock

(pg.5--31)

Serial

Port

(pg.5--31)

(pg.5--32)

SERVICE

Print

Head

(pg.5--37)

Ink

System

(pg.5--38)

MEMORYCARD

Export

Messages

(Pg.5--30)

Import

Messages

(pg.5--30)

Inverse

Control

(pg.5--26) (pg.5--26)

Ink

Data

Product

Counter

(pg.5--32) (pg.5--32) (pg.5--33)

Repeat

Printing

ViscosityExternal

I/F

(pg.5--39)

(pg.5--41) (pg.5--42) (pg.5--43)

SERVICE:EXTERNALI/F

Export

Logos

(pg.5--30)(pg.5--30)

Import

Logos

Enable

Printing

(Pg.5--27)

Day

Names

Month

Names

Config

Cancel OK

FrontPanelTopicKeyMenus

Print

Delay

(pg.5--27) (pg.5--28)

Reset

Serial#

Alpha

Hours

(pg.5--33)

Event

Log

Product

Sequence

Format

(pg.5--33)

Change

Resvr

(pg.5--43) (pg.5--44)

Start

Product

(Pg.5--44)

PRODUCTSEQUENCESIMULATION

Exit

Time

Change

Height

(pg.5--28) (pg.5--29)

Password

Setup

(pg.5--34) (pg.5--35) (pg.5--35)

Change

Width

Set

Currency

Backup

Printer

End

Product

Start

Sequence

Print

Once

Start

Cont

(pg.5--44)

Beeper

INTRODUCTION

Stop

Page 35

PART 3 : OPERATION

Repl. Resv

Repl. Cart.

Create Msg.

CONTENTS

START--UP Page 3--3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHUT DOWN 3--3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INK RESERVOIR REPLACEMENT 3--4. . . . . . . . . . . . . . . . . . . . . . . . . .

INK AND MAKE--UP CARTRIDGE REPLACEMENT 3--6. . . . . . . . .

CREATING A MESSAGE 3--7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Contrast 3--7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 3--7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Message 3--8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Print the Message 3--8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Save the Message 3--8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Delete the Message from Store 3--8. . . . . . . . . . . . . . . . . . . . . . . . .

To Select an Existing Message 3--9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Enter a Clock Entry 3--9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Enter a Serial Number 3--11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Enter a Shift Code 3--12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Enter a Text Field 3--12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Create a Machine Readable Code 3--13. . . . . . . . . . . . . . . . . . . . .

27080 Issue 1 August 98 3--1

Page 36

OPERATION

3--2 27080 Issue 1 August 98

Page 37

OPERATION

OPERATION

START--UP

Pressthepush--buttonswitchontheleftsideofthecabinet.

(Thefollowingswitch--onandautomaticrun--uptakesabout40

seconds).

DScreendisplays”Pleasewait...”

DGreenindicatorontheJetOn/Offkeybeginstoflash.

DStatusbarshowsmessagePrinterInitialising.Seepgs.2--8and2--9

forscreenandkeydetails.

Note: TheamberalertindicatorontheJetOn/Offkeymayflashanda

messageappearinthealertbaronthedisplay.

DStatusbarmessagechangestoPrinterOffandthegreenindicator

stopsflashingandremainsoff.

DEitherA300,A200,A100(dependingonprintertype)orDomino

Logoisdisplayedonthescreen.

Theprinterisnowreadyforthejettobeswitchedon.

PresstheJetOn/Offkeyfor2--3secondsoruntilanaudible“beep”is

heard(ifactivated--seepg.5--35).

(Turningonthejetisanautomaticproceduretakingabout70seconds).

DStatusbarshowsthemessageSequencingOn,

DGreenindicatorontheJetOn/Offkeybeginstoflash.

DStatusbarmessagechangestoReadytoPrint,greenindicatorshows

steadily.

Theprinterisnowreadytoprintmessages.

SHUTDOWN

CAUTION Donotremovepowertotheprinteruntil’PrinterOff’

isdisplayed.

PresstheJetOn/Offkeyfor2--3secondsoruntilanaudible“beep”is

heard(ifactivated--seepg.5--35).

(Shutdownisanautomaticproceduretakingabout3minutes).

DStatusbarshowsthemessageSequencingOff.

DGreenindicatorontheJetOn/Offkeybeginstoflash.

DStatusbarmessagechangestoPrinterOffandthegreenindicator

stopsflashingandremainsoff.

Pressthepush--buttonswitchontheleftsideofthecabinettoswitchoff

theprinter.

27080Issue1August98 3--3

Page 38

OPERATION

Reservoir Replacement

INK RESERVOIR REPLACEMENT

Themessages Inkchange neededin lessthan24 hoursand,later,Inkchange

needed in less than 2 hours will appear near the end of the reservoir life

(If a long--life system is being used, these warnings will appear at 300

hours and 24 hours before the end of reservoir life). Printing will not

continue beyond the expiry of the reservoir life.

It is necessary to enter the reservoir quality code of the new reservoir

and reset the reservoir replacement alarms, using the following

procedure:

(1) Press the Service key and enter the password if required.

(2) Use the key bar scroll keys to find the Change Resvr option at the

bottom of the screen.

Change

Resvr

OK

(3) Pressthefunction key markedbyChange Resvr andthe screenwill

change to show a prompt requesting input of the Quality Code

printed on the label of the new ink reservoir.

(4) Type in the reservoir quality code.

(5) Press the function key marked OK.

If the correct code is typed in, the reservoir run time will be reset and

the alarms cancelled. Proceed to step (6).

If the number is typed inaccurately, it can be corrected by typing in

again. If an invalid code number is typed, the number will not be

accepted and messages in the information bar will indicate the

problem, e.g. Incorrect ink type, Ink out of date, or Resvr already used (an

old reservoir number). The offending reservoir should be replaced.

(6) Shut down the printer using the proper procedure.

(7) Switch off the printer.

Replace the reservoir as follows.

Notes (1) Tissue will be required for this procedure.

Removetheink cartridge (seediagramon thenextpage). Unscrewthe

manifold locking ring, lift the manifold out of thereservoirand secure

themanifoldintothemanifoldretainerinsidethetopofthe inkcabinet.

Fitacaptothereservoir. Pushthemetalreservoirretainingbarandpull

the reservoir forward to remove.

To fit a new reservoir, reverse the above procedure.

3--4 27080 Issue 1 August 98

(2) The make--up reservoir is non--replaceable.

Page 39

OPERATION

Manifold

Retainer

Reservoir

Retaining Bar

MG188- -1

MG187- -1

Removing the Ink Reservoir

Reservoir

Retaining Bar

MG189- -1

Refitting the Ink Reservoir

27080 Issue 1 August 98 3--5

Page 40

OPERATION

INK AND MAKE--UP CARTRIDGE

REPLACEMENT

Note: If only small amounts of ink are being used by the printer, it may

notbe necessaryto fitan inkcartridge. Leavetheink manifoldseal

inplace andonly fitan inkcartridge whena requestappears onthe

display.

Messages‘AddInkCartridge’or‘AddMake--upCartridge’willappear

on the front panel display when the ink or make--up cartridges need

replacing, and the amber alert will illuminate.

Theinkcartridge is rotated anti--clockwiseandthemake--up is rotated

clockwise to free them before being lifted away. This mechanism

ensures that the cartridges cannot be fitted onto the wrong manifold.

To fit a cartridge, cut off the sealing tab and push on to the correct

manifold.

Rotate and lift

cartridges to

remove.

MG184- -1

Press cartridge down

firmly to fit.

MG186- -2

Cartridge Replacement

MG183- -1

If the make--up cartridge is not replaced, the make--up reservoir will

empty and the ink viscosity will eventually go outside limits. Also,

headflushingwillnotbecarriedoutwhentheprinterisshut downand

ink may be deposited on the print head components. Thus, although

the printer can still be used, head faults may occur.

3--6 27080 Issue 1 August 98

Page 41

OPERATION

Create Message

CREATING A MESSAGE

Thefollowingshowshowtocreateandprintamessage. Thesuggested

entries could be used as a working example. All of the screens

presented on the display are fully described in Part 5 : Reference.

Displa y Contrast

For comfort, the display contrast can be adjusted by pressing the blue

alternative character set key and adjusting the contrast using the

increment (+ and --) keys.

General Information

The following is general advice for using the keyboard. For example,

if a mistake is made, and it is required to delete a character, the cursor

keys (see pg. 2--12) can be used to move a highlight bar over the

character. Pressing the delete key (see pg. 2--12) will then remove the

character. Note that new characters are always inserted immediately

in front of the highlight. Therefore, if a replacement character is

required in the same place as a deleted character, type in the new

character without moving the highlight.

Font (character) size, bold characters and double spacing can be

selected as function key options. Pressing the key activates the option

and allsubsequententrieswill be size/bold/spaced accordingly,until

the key is pressed again.

Valuescanbetypedin,or changedbyusingtheincrementkeys (seepg.

2--12). Values changed with the increment keys are effective

immediately. By contrast, values typed in using the number keys

become effective only when OK or the equivalent is selected using the

function keys, or a +/-- key is pressed.

Font size is indicated by the vertical size of the cursor. If a larger font

size is inserted into a multi--line message, the other characters will be

automatically arranged around the larger characters.

Note: The following attributes/parameters can be set as special setups

into individual messages (through Message Editor) and also set

into the printer as overall global settings (through Print Setup):

Bold

Repeat messages

Reverse/Inverse

Individual message settings take priority over the global settings.

27080 Issue 1 August 98 3--7

Page 42

OPERATION

The key labels along the bottom of the screen may not show the

requiredoptions immediately. Ifnecessary, use the scrollkeys(seepg.

2--12) to move the options acrossthescreen. To select the option, press

the key below the label on the screen.

To Create the Message

(1) Press the Message Editor topic key.

(2) Type in the message (e.g. abc).

Creating a detailed message can include entering clock data, serial

numbers, shift codes or text fields (see below). To continue with a

simple message, proceed as follows.

To Print the Messa ge

(1) With Message Editor selected, press the scroll keys to search the

key options and find Print Message.

Print

Message

Save

Message

OK

(2) Press the key below Print Message the prompt ’Message Ready for

Printing’ is displayed. The message will now be printed at each

Print Go signal if the printer is in the Ready to Print state.

Note: Ifanon--linemessageischangedinanyway,itisnecessarytopress

Print Message again to implement the changes.

To Save the Message

(1) Press the Message Store key. (The screen will change and may

show the name of a previous message -- ignore this!)

(2) Select Save Message from the key options along the bottom of the

screen (by pressing the key under the label).

(3) Type in the name of the message (e.g. ”Example”).

(4) Select OK from the key options (by pressing the key under the

label).

To Delete the Message from Store

Delete

Message

(1) WithMessage Storeselected, pressthe scrollkeys tosearchthekey

options and select Delete Message. The screen will change to show

a list of names of stored messages.

(2) Use anup-- or down--cursorkeyto move thehighlightbar to cover

the name of the required message, e.g. ”Example”. The list of

3--8 27080 Issue 1 August 98

Page 43

OPERATION

message names may extend off the screen -- continuing to use the

cursor key will automatically scroll the list.

Note: Amessagebeing currentlyusedfor printing (marked ”>”)cannot

be deleted.

Delete

Message

OK

Cancel

Select

Message

OK

(3) Select Delete Message fromthekey options. Thescreenwill change

to show Delete message? and the message name.

(4) SelectOKtodeletethemessage andthescreenwill returntothelist

of messages.

The deleted message name will not now be included in the list and

steps (2) to (4) can be repeated to delete any other messages.

(5) Select Cancel from the key options.

To Select an Existing Message

(1) WithMessage Storeselected, pressthe scrollkeys tosearchthekey

options and select Select Message. The screen will change to show

a list of names of stored messages.

(2) Use down-- andup--cursor keys to move the highlightbartoselect

the name of the required message.

(3) Select OK from the key options. The display will change to show

the name of the chosen message only.

Note: To print this message, select Print Message from the key options.

Insert

Clock

(4) Press Message Editor and the display will show the full message.

To Enter a Clock Entry

(1) With Message Editor selected, select Insert Clock from the key

options. The display will change to show the Insert Clock screen

with a highlight bar over Clock Offset Number.

(2) Type in a numerical value, e.g. 2. (This value selects one of four

clocks on A300/A200, or one of two clocks on A100, containing

time offsets entered into the printer by way of the Clock Offsets

option. For example, a continuously updated date four weeks

ahead of the current date can be inserted into the message).

(3) Press the down--cursor key to move the highlight bar down over

Format.

The clock entries consist of names, etc. arranged in a range of formats.

Thenames,codes, available formats,etc. canallbe changedifrequired

(see pgs. 5--33 and 5--34).

27080 Issue 1 August 98 3--9

Page 44

OPERATION

(4) Useanincrementkeytochangethedateformatinthehighlightbar

to a suitable format.

(5) Select OK from the key options. The display will change to show

OK

the message with the clock detail inserted at the cursor position.

Clock entries on the display will not be updated. However, the

printed messages will have clock entries updated fromthemaster

clock and Message Monitor will also display the correct clock

information after each received print go.

3--10 27080 Issue 1 August 98

Page 45

OPERATION

To Enter a Serial Number

(1) With Message Editor selected, press the scroll keys to search the

Select

Message

key options and select Serial Number.

The screen will change to show the parameters controlling the serial

numbering. Theseincludethe startnumber (firstlimit),finish number

(secondlimit) andthe changebetweenmessages (stepsize). If thestart

number is below the finish number the change (step) will be

incremental, i.e. positive. If the start number is above the finish

number, the change (step) will automatically be decremental, i.e.

negative. Also,ifrequired,thesame serial number can be enteredinto

a selected number of messages before it is changed (Repeat Count).

More advanced serial numbers can be set up, to include a letter--type

prefix or suffix and batch linking between two serial numbers (batch

linking on A300/A200 only). In the case of alphanumeric serial

numbers,theorder (precedence)in which thealphaand numericparts

areupdatedcanbeselected.Inthefollowing steps,the exampleentries

willcreatea serialnumberAA0000, AA0001 . ..throughAX0000 . . up

to KK1000, increasing at each step by 1.

(2) Use down-- and up--cursor keys to move the highlight bar and

select the details of the serial number, and type in the required

values. For example:

First Limit: 0. . . . . . . . . . .

Second Limit: 1000. . . . . . . . .

Start Value: 0. . . . . . . . . .

Leading Zeros: Y es(selected with the increment keys). . . . . . . .

Step Size: 1. . . . . . . . . . . .

Repeat Count: 0. . . . . . . .

The serial number is displayed at the bottom of the screen.

(3) If a more complex serial number is required, select Advanced.

(4) Use down-- and up--cursor keys to move the highlight bar and

select the details of the serial number, and enter the required

values. For example:

Alpha: Prefix (selected with the increment keys). . . . . . . . . . . . . . .

Batch Link: No (selected with the increment keys). . . . . . . . . . .

(A300/A200 only)

Precedence: Numeric (selected with the increment keys). . . . . . . . . . .

First Limit: AA. . . . . . . . . . .

Second Limit: KK. . . . . . . . .

27080 Issue 1 August 98 3--11

Page 46

OPERATION

Lower Character: A. . . . . .

Upper Character: X. . . . . .

Start Value: AA. . . . . . . . . .

(5) Select OK from the key options.

OK

To Enter a Shift Code

(1) With Message Editor selected, press the scroll keys to search the

functionkey optionsand selectShift Code. The displaywillchange

Shift

Code

OK

Text

Field

to show the Shift Code screen. Up to 24 shift codes can be entered

inthe formof startand stoptimes (inhours andminutesaccording

to the 24 hour clock system) and a shift code name (in the String

column). Move the highlight bar using the up-- and down--cursor

keys to mark the entry being entered or amended.

(2) Type in a shift code, e.g. Start 08:30, Stop 12:30, String Red.

(3) Select OK from the key options. The display will change to show

the message and, provided the current real time falls within the

specified shift code start and stop times, the shift code name, e.g.

Red, will be inserted at the cursor position. (If the shift code time

isoutsidethetimelimits,theshiftcodepositioninthemessagewill

show as a blank space.)

To Enter a Text Field

A text field is a blank area which can be left within a message, e.g. to

avoid interference with other pre--printed information.

(1) With Message Editor selected, select Text Field from the key

options. The display will change to show the Text Field screen.

Enter a value representing the size of the field (measured in

characters).

(2) Select OK from the key options. The message will re--appear

OK

showing a space sized to the value entered in the previous step at

the position of the cursor.

3--12 27080 Issue 1 August 98

Page 47

OPERATION

To Create a Machine Readable Code (MRC) (A300/A200

only)

The following procedure is carried out in Message Editor, either as a

new message or as part of a message being constructed.

During the following procedures, decisions on the following will be

required:

(a) MRC type

(b) MRC data which is appropriate to the MRC type

(c) Positionofany human--readabletext relatedto theMRC. This

is usually indented into a barcode, but can, if required, be

placed elsewhere.

(d) Type of human readabletext. This is usually thesamedataas

the MRC and, ifsetupaccording to the followingprocedures,

amendmentsorupdatestotheMRCwillthenbeautomatically

Font

Size

Start

MRC

applied to the human--readable text.

During the procedures,key labels along the bottom of the screen may

not show the requiredoptions. It will be necessary to be familiar with

using the scroll keys (see pg. 2--12) to move the key options across the

screen and selecting an option by pressing the key below the label on

the screen.

It will also be necessary to be familiar with using the up-- and

down--cursorkeysto move thehighlightbarto select settings given on

a display screen.

(1) Inspectthecursoronthe displayand pressthe FontSizeoption key

until it is the size of the required MRC.

(2) SelectStartMRCoption keyandnotetheappearanceofthesymbol

”>” at the correct MRC size.

Height

(Lines)

Barcode

Size

(Lines)

123456

Quiet Zone

(Left)

27080 Issue 1 August 98 3--13

Indentation

Width

Quiet Zone

(Right)

Page 48

OPERATION

(3) Type in the MRC message.

End

MRC

OK

(4) Press End MRC option key. The screen will change to show the

MRC Identifier i.e. whether the barcode is the first, second, etc. in

the message, and the MRC type.

(5) If necessary, use the increment keys to change the MRC setting to

the required type.

To Create a Barcode:

(6) If asimplebarcode onlyisrequiredselectOK and the barcodewill

appear. If human--readable information is to be included, select

Advanced as in step (7).

To confirmthebarcode data, usetheToggle MRC’soption key to switch

between the barcode and its human--readable version. (Toggling the

data does not affect printing -- only the barcode is printed.) However,

selecting the human--readable version helps editing, as the cursor can

be moved to the required character and changed in the normal way.

Note the ”<” symbol at the end of the barcode data. Marking this and

selectingEdit returnsthescreentostep (4)allowing thebarcodedetails

tobechanged. Alternatively,togglingtothe barcodeandselectingEdit

also returns the screen in step (4).

Advanced

OK

OK

Font

Size

(7) The barcode data can be printed in human--readable form, either

before or after the barcode, or it can be indented into the barcode

as shown in the diagram. Some barcodes (such as EAN 13) use a

double indentation. Select Advanced.

(8) WithAdvanced selected,setthe indentation width. Foranexact fit,

this width ismeasuredin strokes, butfordemonstrationpurposes

enter any large number (e.g. 1000) to create the largest available

width in the barcode.

(9) Enter the height (in number of lines) of the barcode above the

indentation (see diagram).

(10)If required, values (in strokes) can be entered to give quiet zones

(clear spaces) at the beginning and end of the barcode.

(11) Select OK to return to the barcode screen.

(12)SelectOK to returnto the MessageEditorscreen. The barcodewill

now show the indentation(s).

(13)Inspectthe cursor atthefront ofthedisplay and pressthe Font Size

optionkey untilitisthesize oftherequiredbarcode. Ifthebarcode

3--14 27080 Issue 1 August 98

Page 49

OPERATION

text is to be fitted into the indentation, it is important that this is a

height suitable to fit into the indentation (or the text will be fitted

outside the barcode). Then use the cursor keys tomovethecursor

to the required position.

MRC

Text

OK

MRC

Text

(14)SelectMRC Text or, if thebarcodeuses two indentations,gotostep

(18).

(15)HighlighttheNumberofCharactersandenterthenumberofbarcode

characters.

(16)Select OK.

(17)The barcode will appear including the human--readable text. If

required, this text can be re--positioned by entering character

spaces or thin spaces (shift + space keys).

(18)In a barcode using two indentations, selected human--readable

characters would be placed in the two positions. Select MRC Text.

(19)Select Number of Characters and enter the number of characters to

beput intothefirst indent(thisis usuallyhalf ofthetotal number).

Leave the Offset value at zero.

First indent characters

OK

MRC

Text

OK

123456789123

Offset

Second indent characters

123456 789123

(20)SelectOK and checkthatthe requiredcharacters appearin thefirst

indentation. Ifnecessarymove thecursor tothestart ofthesecond

indentation.

(21)Select MRC Text again.

(22)SelectOffsetandenter the number of characters not required to be

shown. Select Number of Characters and enter the number of

characters (usually half of the total number), beyond the offset, to

be put into the second indent.

(23)SelectOK and checkthatthe requiredcharacters appearin thefirst

and second indentations.

27080 Issue 1 August 98 3--15

Page 50

OPERATION

To Create A Dot Code:

Followsteps under’CreateaMachineReadableBarcode’up tostep(5),

then continue as follows:

(6) Select therequiredcode(Snowflakeor Data Matrix) and press the

Advanced key.

(7) Select the requiredDot Code parameters in this screen. These are

as follows:

Formatwhichdescribesthetypeofdatatobeencoded,optionsare:

SNOWFLAKE DATA MATRIX

1. Numeric only (0..9) 1. Numeric only (0..9)

2. Upper case only (A..Z) 2. Alpha only (A..Z)

3. Lower case only (a..z) 3. Printable ASCII

4. Punctuation (;:’,.?!)

5. Alphanumeric (A..Z a..z 0..9)

Error CorrectionCode (ECC) applied to dotcode. Use the help(?)

to enter the required ECC for Snowflake, values of none and

checksum are not permitted and will be changed to the minimum

supported value of 10%. For Data Matrix, ECC values of 000, 010

and 040 are not supported and are changed to the minimum

supported value of 050. The reason that numbers are entered is to

make the menu generic for all dotcode symbologies (see the

following Help screens).

(8) Select the height and width required and press OK.

3--16 27080 Issue 1 August 98

Page 51

OPERATION

DENSITY

DENSITY

Snowflake Encryption Capacities

10% E rror Code Correction

DENSITY MAXIMUM CHARACTER ENCRYPTION CAPACITY

Numeric

Format 1

Upper

Case

Format

2

Lower

Case

Format

3

Punctuation

Format 4

Alphanumeric

Format 5

7 x 16 4 3 3 4 3

7 x 24 10 8 8 10 7

8 x 8 n/a n/a n/a n/a n/a

9 x 9 2 1 1 2 1

10 x 10 2 2 2 2 1

11 x 11 6 4 4 6 4

11 x 24 23 19 19 23 15

12 x 12 8 7 7 8 5

12 x 24 26 21 21 26 17

13 x 13 12 9 9 12 8

14 x 14 15 12 12 15 10

15 x 15 17 13 13 17 11

16 x 16 21 17 17 21 14

16 x 24 39 31 31 39 26

20% E rror Code Correction

DENSITY MAXIMUM CHARACTER ENCRYPTION CAPACITY

Numeric

Format 1

Upper

Case

Format

2

Lower

Case

Format

3

Punctuation

Format 4

Alphanumeric

Format 5

7 x 16 2 2 2 2 1

7 x 24 6 5 5 6 4

8 x 8 n/a n/a n/a n/a n/a

9 x 9 1 n/a n/a 1 n/a

10 x 10 2 1 1 2 1

11 x 11 3 2 2 3 2

11 x 24 15 12 12 15 10

12 x 12 4 3 3 4 2

12 x 24 16 13 13 16 11

13 x 13 6 5 5 6 4

27080 Issue 1 August 98 3--17

Page 52

OPERATION

DENSITY

14 x 14 8 7 7 8 5

15 x 15 11 9 9 11 7

16 x 16 13 10 10 13 9

16 x 24 25 20 20 25 17

40% E rror Code Correction

DENSITY MAXIMUM CHARACTER ENCRYPTION CAPACITY

Numeric

Format 1

Upper

Case

Format

2

Lower

Case

Format

3

Punctuation

Format 4

Alphanumeric

Format 5

7 x 16 n/a n/a n/a n/a n/a

7 x 24 2 2 2 2 1

8 x 8 n/a n/a n/a n/a n/a

9 x 9 n/a n/a n/a n/a n/a

10 x 10 n/a n/a n/a n/a n/a

11 x 11 1 n/a n/a 1 n/a

11 x 24 6 5 5 6 4

12 x 12 1 1 1 1 1

12 x 24 7 5 5 7 4

13 x 13 2 1 1 2 1

14 x 14 2 2 2 2 1

15 x 15 4 3 3 4 2

16 x 16 5 4 4 5 3

16 x 24 11 9 9 11 7

3--18 27080 Issue 1 August 98

Page 53

OPERATION

DataMatrixSquareEncryptionCapacities

ErrorCodeCorrection50

DENSITY MAXIMUMCHARACTERENCRYPTIONCAPACITYDENSITY

NumericFormat1 Alphanumeric

Format2

11x11 1 1 n/a

13x13 10 6 4

15x15 20 13 9

16x16 20 13 9

ASCIIFormat3

ErrorCodeCorrection80

DENSITY MAXIMUMCHARACTERENCRYPTIONCAPACITYDENSITY

NumericFormat1 Alphanumeric

Format2

13x13 4 3 2

15x15 13 9 6

16x16 13 9 6

ASCIIFormat3

ErrorCodeCorrection100

DENSITY MAXIMUMCHARACTERENCRYPTIONCAPACITYDENSITY

NumericFormat1 Alphanumeric

Format2

13x13 1 1 n/a

15x15 8 5 3

ASCIIFormat3

16x16 8 5 3

ErrorCodeCorrection200

DENSITY MAXIMUMCHARACTERENCRYPTIONCAPACITYDENSITY

NumericFormat1 Alphanumeric

Format2

8x18 10 6 6

8x32 20 13 8

10x10 6 3 3

12x12 10 6 5

12x26 32 22 14

12x36 44 31 20

14x14 16 10 6

16x16 24 16 10

16x36 64 46 30

16x48 98 72 47

ASCIIFormat3

27080Issue1Sept98 3-19

Page 54

PART 4 : DISPLAY MESSAGES AND FAULT

FINDING

CONTENTS

INTRODUCTION Page 4--3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Red alerts 4--3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Amber alerts 4--3.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Acknowledgement 4--4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALERT BAR MESSAGES 4--4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATUS BAR MESSAGES 4--14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INFORMATION BAR MESSAGES 4--16. . . . . . . . . . . . . . . . . . . . . . . . .

PRINTER FAULTS 4--17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Indicators Showing. 4--17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine Does Not Print. 4--17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Position Incorrect. 4--17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Size Too Small. 4--18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gutter Over--flowing Ink. 4--18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINT QUALITY FAULTS 4--19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27080 Issue 1 August 98 4--1

Page 55

DISPLAY MESSAGES AND FAULT FINDING

4--2 27080 Issue 1 August 98

Page 56

DISPLAYMESSAGESANDFAULTFINDING

DISPLAYMESSAGESANDFAULTFINDING

INTRODUCTION

Thereareseparatebarsonthedisplayshowing:

Dalertmessages(seebelow)

Dstatusmessages(seepg.4--14)

DInformationmessages(seepg.4--16).

RedAlerts

RedalertsareshownbyaflashingredLEDindicatoronthejeton/off

switchandamessageflashinginthealertbar(seepg.4--4).Theyshow

thepresenceoffaultsandstoptheprinterprintingorpreventanunsafe

conditionoccurring.Therearetwotypes:

Non--recoverableThejetwillshutoff(withoutfollowingthenormal

sequencing).Ifthefaultconditionisstillpresentwhenacknowledged

(seebelow),theredLEDwillremainonandthealertbarmessagewill

showcontinuously. Ifthefaultconditionhasclearedwhen

acknowledged,theredLEDwillextinguishandthemessagewillbe

removed.

RecoverableThegreenLEDonthejeton/offswitchwillflashasthe

printerattemptstorecover.Thejetremainsswitchedon.Ifrecovery

issuccessful,thegreenLEDwillremainonandtheredLEDwillflash

untilacknowledged. Whenacknowledged,theredLEDwill

extinguishandthealertbarmessagewillberemoved.

AmberAlerts

Amberalertsareusedtoinformtheoperatorthattheprinterisinneed

ofattentionorthattherearemessagehandlingerrors.

Ifthefaultconditionisstillpresentwhenacknowledged(seebelow),

theamberLEDwillremainonandthealertbarmessagewillshow

continuously.Ifthefaultconditionhascleared,theamberLEDand

alertbarmessagewillflashuntilacknowledged,whentheamberLED

willextinguishandthealertbarmessagewillberemoved.

27080Issue1August98 4--3

Page 57

DISPLAY MESSAGES AND FAULT FINDING

Fau lt Acknow ledgement

Alertbarmessagesflashuntilacknowledgedbypressinganycharacter

keyorthespacekey,afterwhichthemessageisdisplayedcontinuously.

Dependingon thealert, somemessages areclearedwhenthe condition

is cleared. In other cases the message is retained until acknowledged.

If two or more alerts exist simultaneously, the highest priority alert is

displayed. An unacknowledged alert is always at a higher priority

than any acknowledged alert.

All reports are recorded in the error log, together with times of

acknowledgement and repair.

ALERT BAR MESSAGE S

Alert Bar

The following warning and alert messages may be displayed:

Abandoned message, product ended

End of product detected before end of message.

Check sensor position, message length.

Abnormal ink pressure

Ink pressure is outside limits for current ink type: pump failed,

pressure transducer failed or connection problem.

Check electrical and ink connections, pump and pressure

transducer.

Ink pressure set too high or too low.

Adjust ink pressure.

Add ink cartridge

The ink level is low.

Fit a new ink cartridge.

4--4 27080 Issue 1 August 98

Page 58

DISPLAY MESSAGES AND FAULT FINDING

Abnormal vacuum level

Flow through jet pump low with low pump speed.

Check for and eliminate any ink leakage.

Flow through jet pump with high pump speed.

Check for and eliminate any partial blockage in feed circuit

or jet pump.

Check for and eliminate any air leakage into feed circuit.

Add make--up cartridge

The make--up level is low.

Fit a new make--up cartridge.

Beware! Ink reservoir change overdue

The ink life has expired.

Fit a new reservoir.

Blank message detected (no drops)

Attempting to print a blank message.

Editmessage orreassignamessagecontaining information.

Cabinet overheated

Cabinet temperature is too high.

Ensure printer is operating within specified temperature

environment.

Check air filter. If fault persists, call Domino Service.

Cabinet temperature sensor input error

Failure at input to sensor.

If fault persists, call Domino Service.

Charge detection has failed

Incorrect modulation, ink or solvent on charge electrode.

Reset modulation, clean/check charge electrode.

Could not convert message to Codenet

Selectedmessage isnot inavalidformatforthecurrentlyselected

font and raster.

If fault persists, call Domino Service.

27080 Issue 1 August 98 4--5

Page 59

DISPLAY MESSAGES AND FAULT FINDING

Could not find message to be printed

Message does not exist.

Select a new message.

Could not find message to be updated

Message to be updated does not exist.

Select a new message.

Could not find message to clear queue

Message queue is already empty.

Send new message.

Could not prepare message for printing

Selectedmessage isnot inavalidformatforthecurrentlyselected

font and raster.

Send new message.

EEPROM write failed

The EEPROM (a hardwaredevice used by the printer to storethe

ink life data) has failed.

If fault persists, call Domino Service.

Excess pump overspeed

Ink pressure is being maintained but pump speed is excessive.

Check ink system for leaks or worn pump.

Excess pump underspeed

Ink pressure is being maintained but pump speed is too low.

Checkinksystemforblockages,kinkedtubes,badlyformed

connections, etc.

Excessive ink pressure

Ink pressure is too high. Blocked jet pump.

Refurbish jet pump.

Failed to write to store file

Message store is full or corrupted.

Delete unused messages or restore the contents from

backup.

4--6 27080 Issue 1 August 98

Page 60

DISPLAY MESSAGES AND FAULT FINDING

Fall--back jet modulation in use

During start--up sequencing, the modulation level is

automatically determined if automatic modulation has been

selected. If the modulation level cannot be determined

automatically, the last successful modulation level is used and

this warning raised. Check and if necessary clean the charge

electrode. Printer can be used, but check print quality.

If fault persists, call Domino Service.

Fault: PEB restarted

Internal error.

If fault persists, call Domino Service.

Fault: PSB restarted

Internal error.

If fault persists, call Domino Service.

Fault: SGB restarted

Internal error.

If fault persists, call Domino Service.

Gunbody temperature high

Gunbody temperature is higher than set value.

If fault persists, call Domino Service.

Gunbody temperature low

Gunbody temperature is lower than set value.

If fault persists, call Domino Service.

Gutter dry

Ink not entering gutter.

Check jet alignment.

Check that nozzle is not blocked.

Head temperature sensor input error

Failure at input to sensor.

Check sensor connections. If fault persists, call Domino

Service.

27080 Issue 1 August 98 4--7

Page 61

DISPLAY MESSAGES AND FAULT FINDING

Ink temperature sensor input error

Failure at input to sensor.

Check sensor connections. If fault persists, call Domino

Service.

Ink change due -- replace ink reservoir

Ink life has expired.

Fit new reservoir before printing can be restarted.

4--8 27080 Issue 1 August 98

Page 62

DISPLAY MESSAGES AND FAULT FINDING

Ink change needed in less than 2hrs (Not given in extended ink life

printers.)

Ink life is within 2 hours ofexpiry. (A firstwarningisgiven at 24

hours before expiry.)

Fit new ink reservoir.

Ink change needed in less than 24hrs

Ink life is within 24 hours of expiry.

Fit a new ink reservoir.

Ink change needed in less than 300hrs (Extended ink life printers only.)

Inklifeiswithin 300 hours of expiry. (A second warning isgiven

at 24 hours before expiry.)

Hold new ink reservoir ready for use at 24 hour warnings.

Ink detected on charge electrode

Ink on charge electrode.

Clean charge electrode (see pg. 7--17), restart printer.

Ink ”hours--to--go” data altered

Ink life setting has been altered due to either ink being changed

or ink life setting value adjustment.

Check authorisation for change.

Ink heating failed

Ink heating system has failed.

Check heater connections and check thermistor.

Ink level sensor input error

Failure at input to sensor.

Check sensor connections. If fault persists, call Domino

Service.

Ink pressure loss

Pressure loss due to leakage, pump failure or transducer failure.

Check for leaks. Check electrical connections, pump and

transducer operation.

Ink temperature high

Ink temperature is outside control system limits.

Ensure printer environment is within specification.

27080 Issue 1 August 98 4--9

Page 63

DISPLAY MESSAGES AND FAULT FINDING

Ink temperature low

Ink temperature is outside control system limits.

Ensure printer environment is within specification.

Invalid or missing Font file

Font file missing or corrupted.

Replace the font file.

Invalid or missing Raster file

Raster file is either missing or corrupted.

Replace the raster file.

Long print, check print quality

Long print generated.

Inspect print quality.

New Store file created

This message is displayed for information only. It indicates that

a new file store (for the display of messages, logos etc.) has been

created. Thismay happenifthe printerhasbeen reconfigured(to

use a different ink type, nozzle size or print format).

No ink

Ink level is below minimum.

Fit a new ink cartridge.

No make--up

Make--up level is below minimum.

Fit a new make--up cartridge.

PEC config. item defaulted

Configuration data not available (during initialisation).

Initialisation will be continued using default values.

Print Engine Standby timed--out

Printer has remained in standby state for longer than the pre--set

time (and sequenced full off).

Start up printer if required.

4--10 27080 Issue 1 August 98

Page 64

DISPLAYMESSAGESANDFAULTFINDING

PECchanged--newbuildinformation

Softwareupgradehasresultedinchangetobuilddatastoredin

printer.

Ifmessagedoesnotcorrespondtoasoftwarechange,call

DominoService.

PECchanged--newconfigurationdata

Configurationchangehasresultedinchangetobuilddatastored

inprinter.

Ifmessagedoesnotcorrespondtoaconfigurationchange,

callDominoService.

Pressuresensorinputerror

Failureatinputtosensor.

Checksensorconnections.Iffaultpersists,callDomino

Service.

Printdatageneratedtoolate

Printratetoofast.

Adjust print delay.

Printfailed--printdelaytooshort

Messagedatawasnotreceivedbeforethenextproductwas

detected.

Increaseprintdelayuntilanacceptablevaluecanbe

entered.Ifnecessary,adjustpositionofproductsensoror

printhead.Iffaultpersists,callDominoService.

PrintGooccurredwhileprinting

Nextproductwasdetectedbeforethecurrentmessagecompleted

printing.

Checksensorposition,messagelength.

Printlate--printdelaytooshort

Messagedatawasreceivedtoolateforthemessagetobe

generatedandprinted.

Iffaultpersists,callDominoService.

27080Issue1August98 4--11

Page 65

DISPLAY MESSAGES AND FAULT FINDING

Print max speed limit in force

Maximum stroke rate has been exceeded.

Reduce print rate.

PSB Battery low or disconnected

Backup battery voltage low and data will be lost when printer is

switched off.

Copy all files to a PCMCIA card before shutting down the

printer. Call Domino for support.

Pump speed outside normal range

Pump system is trying to compensate for excess or loss of

pressure.

Check for blockages or leaks in ink circuit.

Pump pressure could be set too high

Check and adjust if necessary.

Quality code OK -- fit reservoir

Quality code indicates a reservoir of the correct type.

Fit reservoir.

RAM disk has been reformatted

File store has been re--initialised with loss of any changes to

configuration parameters and edited messages. Possible battery

backup failure.

Check battery.

Reset by watchdog

Internal error.

If fault persists, call Domino Service.

Solvent level sensor input error

Failure at input to sensor.